Page 1

Instructions-Parts

WB3000

WB3000 WB3000

60

AA

60 60

AA AA

Air

assisted

Air Air

- --assisted assisted

meet

at

meet meet

For

For For

3000psi(21MPa,210bar)Maximum

FluidWorkingPressure

100psi(0.7MPa,7bar)MaximumAir

WorkingPressure

Seepage3formodelpartnumbersand

approvalinformation.

least

at at

least least

professional

professional professional

Important

Important Important

Readallwarningsandinstructionsinthismanualbeforeusingthe

equipment.Save Save

Isolation

Isolation Isolation

WB

WB WB

spray

spray spray

one

one one

Gun

Gun Gun

system

system system

of

of of

use

use use

Safety

Safety Safety

Save

for

for for

the

conditions

the the

conditions conditions

only.

only. only.

Instructions

Instructions Instructions

these

these these

System

System System

&

Pro

& &

Pro Pro

Xp™

Xp™ Xp™

3A2497H

EN

use

when

use use

instructions.

instructions. instructions.

electrostatically

when when

electrostatically electrostatically

for

non

for for

ammability

non non

- --ammability ammability

spraying

spraying spraying

listed

listed listed

conductive,

conductive, conductive,

on

page

on on

3.

page page

3. 3.

waterborne

waterborne waterborne

uids

that

uids uids

that that

PROVENQUALITY.LEADINGTECHNOLOGY.

Page 2

Contents

Contents Contents

Models...............................................................3

RelatedManuals................................................3

Warnings...........................................................4

GunOverview....................................................7

HowtheElectrostaticAASprayGun

Works............................................7

SprayingWaterborneFluids

Electrostatically..............................7

Controls,Indicators,andComponents...........8

SmartGuns.................................................9

Installation..........................................................14

SystemRequirements..................................14

WarningSign...............................................14

InstalltheSystem.........................................14

VentilatetheSprayBooth.............................14

AirSupplyLine............................................15

GroundtheCabinet......................................15

Grounding...................................................16

ConnecttheWaterborneFluidHose..............18

AgitatorKitAccessory..................................22

GunSetup..........................................................23

GunSetupProcedure...................................23

CheckGunElectricalGrounding...................26

FlushBeforeUsingEquipment......................27

Operation...........................................................28

PressureReliefProcedure............................28

OperatingChecklist......................................29

FluidVoltageDischargeandGrounding

Procedure......................................29

FilltheFluidSupply......................................30

Startup........................................................30

Shutdown....................................................30

Maintenance......................................................31

DailyCareandCleaningChecklist................31

Flushing......................................................31

CleantheGunDaily.....................................33

DailySystemCare.......................................35

ElectricalTests...................................................36

TestGunResistance....................................36

TestPowerSupplyResistance.....................37

TestGunBarrelResistance..........................37

TestGroundStripResistance.......................38

TestCylinderResistance..............................38

Troubleshooting..................................................39

VoltageLossTroubleshooting.......................39

SprayPatternTroubleshooting......................41

GunOperationTroubleshooting....................42

ElectricalTroubleshooting............................43

Repair................................................................44

PreparetheGunforService.........................44

AirCap,SprayTip,andFluidSeatHousing

Replacement..................................44

ElectrodeReplacement................................45

GunBarrelRemoval.....................................46

GunBarrelInstallation..................................46

FluidNeedleReplacement............................47

PowerSupplyRemovaland

Replacement..................................48

AlternatorRemovalandReplacement...........49

FanAirAdjustmentValveRepair..................51

AtomizingAirAdjustmentValve

Repair............................................51

ESOn-OffValveRepair...............................52

AirValveRepair...........................................53

SmartModuleReplacement..........................53

AirSwivelandExhaustValve

Replacement..................................54

Parts..................................................................55

StandardAir-AssistedSprayGun

Assembly.......................................55

SmartAir-AssistedSprayGun

Assembly.......................................57

IsolationEnclosure.......................................59

TubingandWiring.......................................62

AlternatorAssembly.....................................64

ESOn-OffValveAssembly...........................65

FanAirAdjustmentValveAssembly..............66

AirCapAssembly........................................66

SmartModuleAssembly...............................67

SprayTipSelectionChart....................................68

AEMFineFinishSprayTips..........................68

AEFFineFinishPre-OriceSpray

Tips...............................................69

RoundSprayTips........................................69

RepairKitsandAccessories................................70

GunAccessories..........................................70

OperatorAccessories...................................71

SystemAccessories.....................................71

Signs..........................................................71

TestEquipment...........................................71

Hoses.........................................................71

245895AgitatorKit......................................72

IgnitabilityofCoatingMaterials............................73

Dimensions........................................................74

TechnicalSpecications......................................75

CaliforniaProposition65.....................................75

2

3A2497H

Page 3

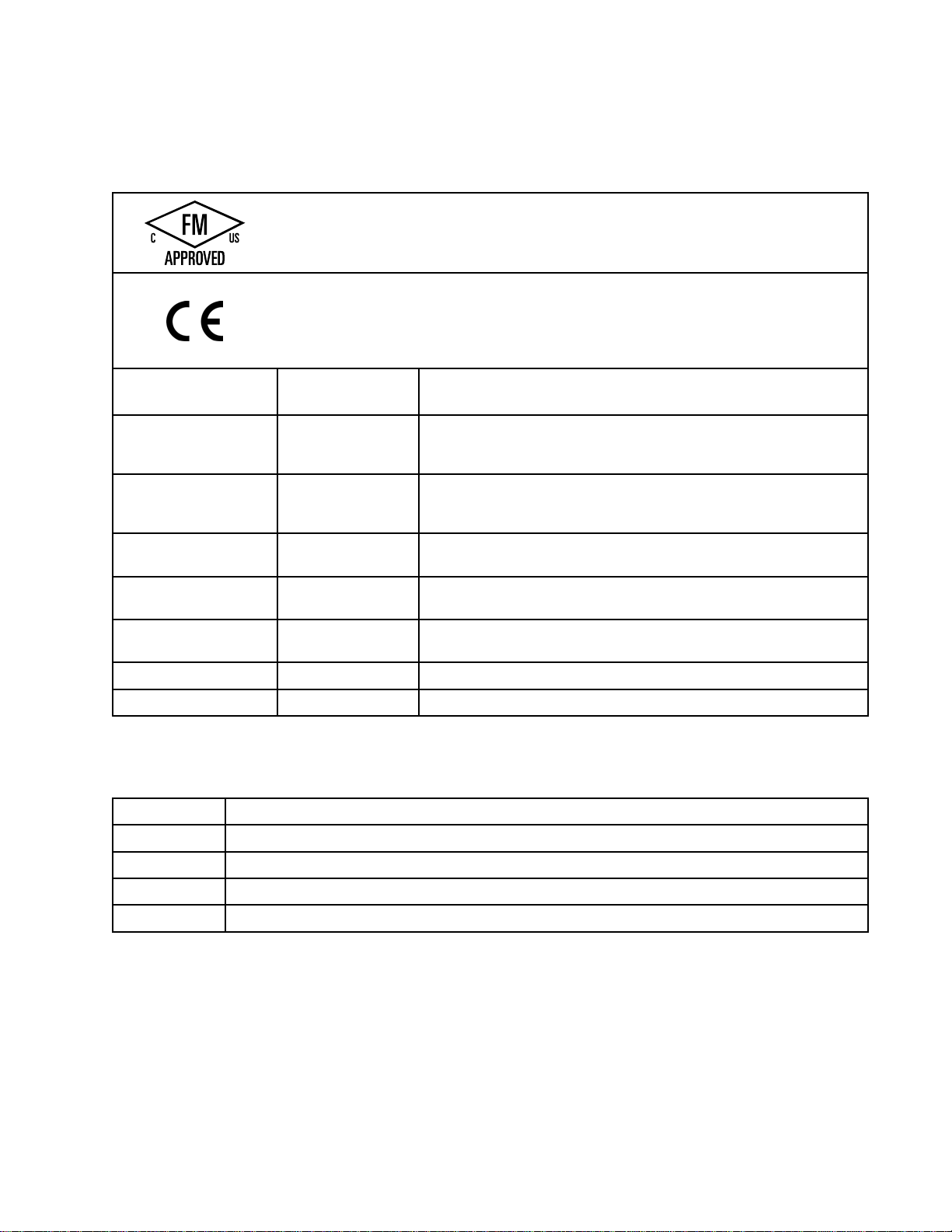

Models

Models

Models Models

Models

Models Models

Part

Part Part

24N551WB3000WaterborneIsolationEnclosure24N550withstandard

24P632WB3000WaterborneIsolationEnclosure24N550withsmartelectrostatic

24N550WB3000

H60T18ProXp60AAWB

which

are

FM

which which

are are

No.

No. No.

Approved

FM FM

Approved Approved

FM

FM FM

• ••Material Material

Models

Models Models

criteria:

criteria: criteria:

• ••Material Material

and

Compliant

and and

Compliant Compliant

approved

approved approved

Material

for

Sustained

for for

Sustained Sustained

Material

For

more

For For

more more

Model

Model Model

for

for for

does

does does

Compliant

Compliant Compliant

classied

is isisclassied classied

information,

information, information,

with

EN50059

with with

EN50059 EN50059

use

with

uids

that

meet

the

use use

with with

uids uids

that that

meet meet

not

sustain

not not

sustain sustain

Burning

Burning Burning

with

with with

Description

Description Description

electrostaticair-assistedspraygunH60T18,groundedairhose

235070,andunshieldedwaterborneuidhose24M508.

air-assistedspraygunH60M18,groundedairhose235070,

andunshieldedwaterborneuidhose24M508.

WaterborneIsolationEnclosureforunshieldedhoses.Doesnot

includehosesandgun.

StandardElectrostaticAir-assistedSprayGun,forwaterborne

coatings.

burning

burning burning

Liquid

of ofofLiquid Liquid

EN

50059

EN EN

50059 50059

as

non

as as

ignitable

non non

- --ignitable ignitable

see

Ignitability

see see

Ignitability Ignitability

accordance

in ininaccordance accordance

Mixtures,

Mixtures, Mixtures,

when

when when

following

the the

following following

ASTM

ASTM ASTM

used

with

used used

with with

as

dened

as as

dened dened

Coating

of ofofCoating Coating

condition:

condition: condition:

with

with with

D4206.

D4206. D4206.

uids

uids uids

by

EN

by by

EN EN

Materials,

Materials, Materials,

the

Standard

the the

Standard Standard

that

meet

that that

meet meet

50059:

50059: 50059:

page

page page

Test

Method

Test Test

Method Method

the

following

the the

following following

2018.

2018. 2018.

73

.

73 73

. .

H60M18ProXp60AAWB

25R012

25R014

Related

Related Related

Manual

Manual Manual

3A2498

307263ProbeandMeter,Instructions

309455TestFixture,HighVoltageProbe,andkVMeter,Instructions

406999

No.

No. No.

Manuals

Manuals Manuals

Description

Description Description

RoundSprayKit,Instructions

VoltageTesterConversionKit,Instructions

-------

-------

SmartElectrostaticAir-assistedSprayGun,forwaterborne

coatings.

WaterborneFluidHoseAssembly,25ft(7.6m)

WaterborneFluidHoseAssembly,50ft(15.2m)

3A2497H3

Page 4

Warnings

Warnings

Warnings Warnings

Thefollowingwarningsareforthesetup,use,grounding,maintenance,andrepairofthisequipment.The

exclamationpointsymbolalertsyoutoageneralwarningandthehazardsymbolsrefertoprocedure-specic

risks.Whenthesesymbolsappearinthebodyofthismanualoronwarninglabels,referbacktothese

Warnings.Product-specichazardsymbolsandwarningsnotcoveredinthissectionmayappearthroughout

thebodyofthismanualwhereapplicable.

WARNING

WARNING WARNING

FIRE

AND

FIRE FIRE

Combustibledustinwork work

•Fluidsusedmustmeetthefollowingammabilityrequirements:

Stop

•Stop Stop

equipmentuntilyouidentifyandcorrecttheproblem.

•Checkgunresistance,hoseresistance,andelectricalgroundingdaily.

•Useandcleanequipmentonlyinwellventilatedarea.

•Interlockthegunairsupplytopreventoperationunlessventilatingfansareon.

•Onlyusenon-ammablesolventswhenushingorcleaningequipment.

•Alwaysturntheelectrostaticsoffwhenushing,cleaningorservicingequipment.

•Eliminateallignitionsources;suchaspilotlights,cigarettes,portableelectriclamps,and

plasticdropcloths(potentialstaticarc).

•Donotplugorunplugpowercordsorturnlightsonoroffwhenammablefumesarepresent.

•Keepsprayareafreeofdebris,includingsolvent,ragsandgasoline.

•Keepaworkingreextinguisherintheworkarea.

EXPLOSION

AND AND

EXPLOSION EXPLOSION

FM,

FMc

•FM, FM,

MaterialdoesnotsustainburninginaccordancewiththeStandardTestMethodfor

SustainedBurningofLiquidMixtures,ASTMD4206.

CE

•CE CE

Materialisclassiedasnon-ignitableasdenedbyEN50059:2018.

operation

operation operation

Approved:

FMc FMc

Approved: Approved:

EN

50059

- --EN EN

50059 50059

immediately

immediately immediately

HAZARD

HAZARD HAZARD

work

area

area area

canigniteorexplode.Tohelppreventreandexplosion:

Compliant:

Compliant: Compliant:

ifstaticsparkingoccursoryoufeelashock.Donotuse

4

3A2497H

Page 5

Warnings

WARNING

WARNING WARNING

ELECTRIC

ELECTRIC ELECTRIC

Impropergrounding,setup,orusageofanisolatedwaterbornesystemcanresultinelectric

shock.Tohelppreventelectricshock:

•Groundallequipment,personnel,objectbeingsprayed,andconductiveobjectsinorclose

tosprayarea.SeeGrounding Grounding

•Connecttheelectrostaticguntoavoltageisolationsystemthatwilldischargethesystem

voltagewhennotinuse.

•Allcomponentsoftheisolationsystemthatarechargedtohighvoltagemustbecontained

withinanisolationenclosurethatpreventspersonnelfrommakingcontactwiththehigh

voltagecomponentsbeforethesystemvoltageisdischarged.

•FollowtheFluid Fluid

thevoltage;beforecleaning,ushing,orservicingthesystem;beforeapproachingthefrontof

thegun;andbeforeopeningtheisolationenclosurefortheisolateduidsupply.

•Donotenterahighvoltageorhazardousareauntilallhighvoltageequipmenthasbeen

discharged.

•Donottouchthegunnozzleorelectrode,orcomewithin4in.(102mm)oftheelectrode

duringgunoperation.FollowtheFluid Fluid

•Interlockthegunairsupplywiththevoltageisolationsystemtoshutofftheairsupplyanytime

theisolationsystemenclosureisopened.

•Onlyusethered-coloredGracoelectricallyconductivegunairhosewiththisgun.Donot

useblackorgray-coloredGracoairhoses.

•Donotsplicehosestogether.InstallonlyonecontinuousGracowaterborneuidhose

betweentheisolateduidsupplyandthespraygun.

SKIN

SKIN SKIN

High-pressureuidfromgun,hoseleaks,orrupturedcomponentswillpierceskin.Thismay

looklikejustacut,butitisaseriousinjurythatcanresultinamputation.Get Get

treatment.

treatment. treatment.

SHOCK

SHOCK SHOCK

Fluid

INJECTION

INJECTION INJECTION

HAZARD

HAZARD HAZARD

Grounding

Voltage

Voltage Voltage

HAZARD

HAZARD HAZARD

instructions.

Discharge

Discharge Discharge

and

Grounding

and and

Grounding Grounding

Fluid

Voltage

Voltage Voltage

Procedure

Procedure Procedure

Discharge

Discharge Discharge

and

and and

wheninstructedtodischarge

Grounding

Grounding Grounding

Procedure

Procedure Procedure

Get

immediate

immediate immediate

.

surgical

surgical surgical

•Donotspraywithouttipguardandtriggerguardinstalled.

•Engagetriggerlockwhennotspraying.

•Donotpointgunatanyoneoratanypartofthebody.

•Donotputyourhandoverthespraytip.

•Donotstopordeectleakswithyourhand,body,glove,orrag.

•FollowthePressure Pressure

orservicingequipment.

•Tightenalluidconnectionsbeforeoperatingtheequipment.

•Checkhosesandcouplingsdaily.Replacewornordamagedpartsimmediately.

Pressure

Relief

Procedure

Relief Relief

Procedure Procedure

whenyoustopsprayingandbeforecleaning,checking,

3A2497H5

Page 6

Warnings

WARNING

WARNING WARNING

EQUIPMENT

EQUIPMENT EQUIPMENT

Misusecancausedeathorseriousinjury.

•Donotoperatetheunitwhenfatiguedorundertheinuenceofdrugsoralcohol.

•Donotexceedthemaximumworkingpressureortemperatureratingofthelowestrated

systemcomponent.SeeTechnical Technical

•Useuidsandsolventsthatarecompatiblewithequipmentwettedparts.SeeTechnical Technical

Specications

Specications Specications

Forcompleteinformationaboutyourmaterial,requestaSafetyDataSheet(SDS)from

yourdistributororretailer.

•Donotleavetheworkareawhileequipmentisenergizedorunderpressure.

•TurnoffallequipmentandfollowthePressure Pressure

•Checkequipmentdaily.Repairorreplacewornordamagedpartsimmediatelywithgenuine

manufacturer’sreplacementpartsonly.

•Donotalterormodifyequipment.Alterationsormodicationsmayvoidagencyapprovals

andcreatesafetyhazards.

•Makesureallequipmentisratedandapprovedfortheenvironmentinwhichyouareusingit.

•Useequipmentonlyforitsintendedpurpose.Callyourdistributorforinformation.

•Routehosesandcablesawayfromtrafcareas,sharpedges,movingparts,andhotsurfaces.

•Donotkinkoroverbendhosesorusehosestopullequipment.

•Keepchildrenandanimalsawayfromworkarea.

•Complywithallapplicablesafetyregulations.

PLASTIC

PLASTIC PLASTIC

Manysolventscandegradeplasticpartsandcausethemtofail,whichcouldcauseserious

injuryorpropertydamage.

MISUSE

MISUSE MISUSE

PARTS

PARTS PARTS

HAZARD

HAZARD HAZARD

Technical

inallequipmentmanuals.Readuidandsolventmanufacturer’swarnings.

CLEANING

CLEANING CLEANING

SOLVENT

SOLVENT SOLVENT

Specications

Specications Specications

Pressure

HAZARD

HAZARD HAZARD

Relief

Relief Relief

inallequipmentmanuals.

Procedure

Procedure Procedure

whenequipmentisnotinuse.

Technical

•Useonlycompatiblewater-basedsolventstocleanplasticstructuralorpressure-containing

parts.

•SeeTechnical Technical

TOXIC

TOXIC TOXIC

Toxicuidsorfumescancauseseriousinjuryordeathifsplashedintheeyesoronskin,

inhaled,orswallowed.

•ReadSafetyDataSheets(SDS)toknowthespecichazardsoftheuidsyouareusing.

•Storehazardousuidinapprovedcontainers,anddisposeofitaccordingtoapplicable

PERSONAL

PERSONAL PERSONAL

Wearappropriateprotectiveequipmentwhenintheworkareatohelppreventseriousinjury,

includingeyeinjury,hearingloss,inhalationoftoxicfumes,andburns.Thisprotective

equipmentincludesbutisnotlimitedto:

•Protectiveeyewear,andhearingprotection.

•Respirators,protectiveclothing,andglovesasrecommendedbytheuidandsolvent

Technical

andsolventmanufacturer’sSafetyDataSheet(SDS)andrecommendations.

FLUID

FLUID FLUID

guidelines.

manufacturer.

Specications

Specications Specications

OR

FUMES

OR OR

FUMES FUMES

PROTECTIVE

PROTECTIVE PROTECTIVE

inthisandallotherequipmentinstructionmanuals.Readuid

EQUIPMENT

EQUIPMENT EQUIPMENT

63A2497H

Page 7

GunOverview

Gun

Gun Gun

How

How How

Works

Works Works

Thisisnotanairspraygun.Tohelpprevent

seriousinjuryfrompressurizeduid,suchasskin

injection,andsplashinguid,readandfollowthe

Skin

Skin Skin

Theair-assistedsprayguncombinesairlessand

airsprayingconcepts.Thespraytipatomizes

andshapestheuidintoafanpattern,asdoes

aconventionalairlessspraytip.Airfromtheair

capfurtheratomizestheuidandcompletesthe

atomizationoftheuidtailstoproduceauniform

pattern.

Asthegunistriggered,partoftheregulatedair

operatesthealternatorturbineandtherestofthe

airhelpsatomizetheuidbeingsprayed.The

alternatorgeneratespower,whichisconvertedby

thepowercartridgetosupplyhighvoltagetothe

gun’selectrode.

Thegun’sinternalpowersupplyprovideshigh

voltage.Theuidiselectrostaticallychargedasit

passestheelectrode.Thechargeduidisattracted

tothegroundedworkpiece,wrappingaroundand

evenlycoatingallsurfaces.

Theregulatedairthatisdirectedtotheaircapcan

befurthercontrolledusingthegun’satomizingair

adjustmentvalve.Thisvalvecanbeusedtorestrict

airowtotheaircapwhilemaintainingsufcientair

owtothealternator.Theatomizingairadjustment

valvedoesnotcontrolpatternwidth.Tochange

patternwidth,useanewtipsize,orusethefan

adjustmenttonarrowthepatternwidth.

Thehighworkinguidpressureofthisgunprovides

thepowerneededtoatomizehighersolidsmaterials.

Overview

Overview Overview

the

Electrostatic

the the

Electrostatic Electrostatic

Injection

Injection Injection

Note

Forairlessatomization,ifdesired,turn

thegun’satomizingairadjustmentvalve

completelyoff.Closingthisvalvedoesnot

affectalternatoroperation.

Hazard

Hazard Hazard

Warnings

Warnings Warnings

AA

AA AA

Spray

Spray Spray

onpage5.

Gun

Gun Gun

Spraying

Spraying Spraying

Electrostatically

Electrostatically Electrostatically

Thiselectrostaticair-assistedspraygunisdesigned

tosprayonly only

followingammabilityrequirements:

FM,

FMc

•FM, FM,

FMc FMc

Materialdoesnotsustainburninginaccordance

withtheStandardTestMethodforSustained

BurningofLiquidMixtures,ASTMD4206.

CE-EN

•CE-EN CE-EN

•Materialisclassiedasnon-ignitableasdenedby

EN50059:2018.

Formoreinformation,see

IgnitabilityofCoatingMaterials,page73.

Whenconnectedtoavoltageisolationsystem,

alloftheuidinthespraygun,uidhose,and

isolateduidsupplyischargedtohighvoltage,

whichmeansthatthesystemhasmoreelectrical

energythanasolvent-basedsystem.Therefore,

onlynon-ammableuids(asdenedunder

Models,page3)canbesprayedwiththesystemor

beusedtoclean,ush,orpurgethesystem.

Precautionsmustbetakenwhenusingelectrostatic

waterborneequipmenttoavoidpotentialshock

hazards.Whenthespraygunchargestheisolated

uidtohighvoltage,itissimilartocharginga

capacitororabattery.Thesystemwillstoresomeof

theenergywhilesprayingandretainsomeofthat

energyafterthespraygunisshutoff.Donottouch

thegunnozzleorcomewithin4in.(102mm)of

theelectrodeuntilthestoredenergyisdischarged.

Theamountoftimeittakestodischargethe

energydependsonthesystemdesign.Followthe

FluidVoltageDischargeandGroundingProcedure,

page29beforeapproachingthefrontofthegun.

TheGracowarrantyandapprovalsarevoidifthe

electrostaticspraygunisconnectedtoanon-Graco

voltageisolationsystemorifthegunisoperated

above60kV.

Waterborne

Waterborne Waterborne

only

waterborneuidswhichmeetthe

Approved:

Approved: Approved:

50059

50059 50059

Compliant:

Compliant: Compliant:

Fluids

Fluids Fluids

3A2497H

7

Page 8

GunOverview

Controls,

Controls, Controls,

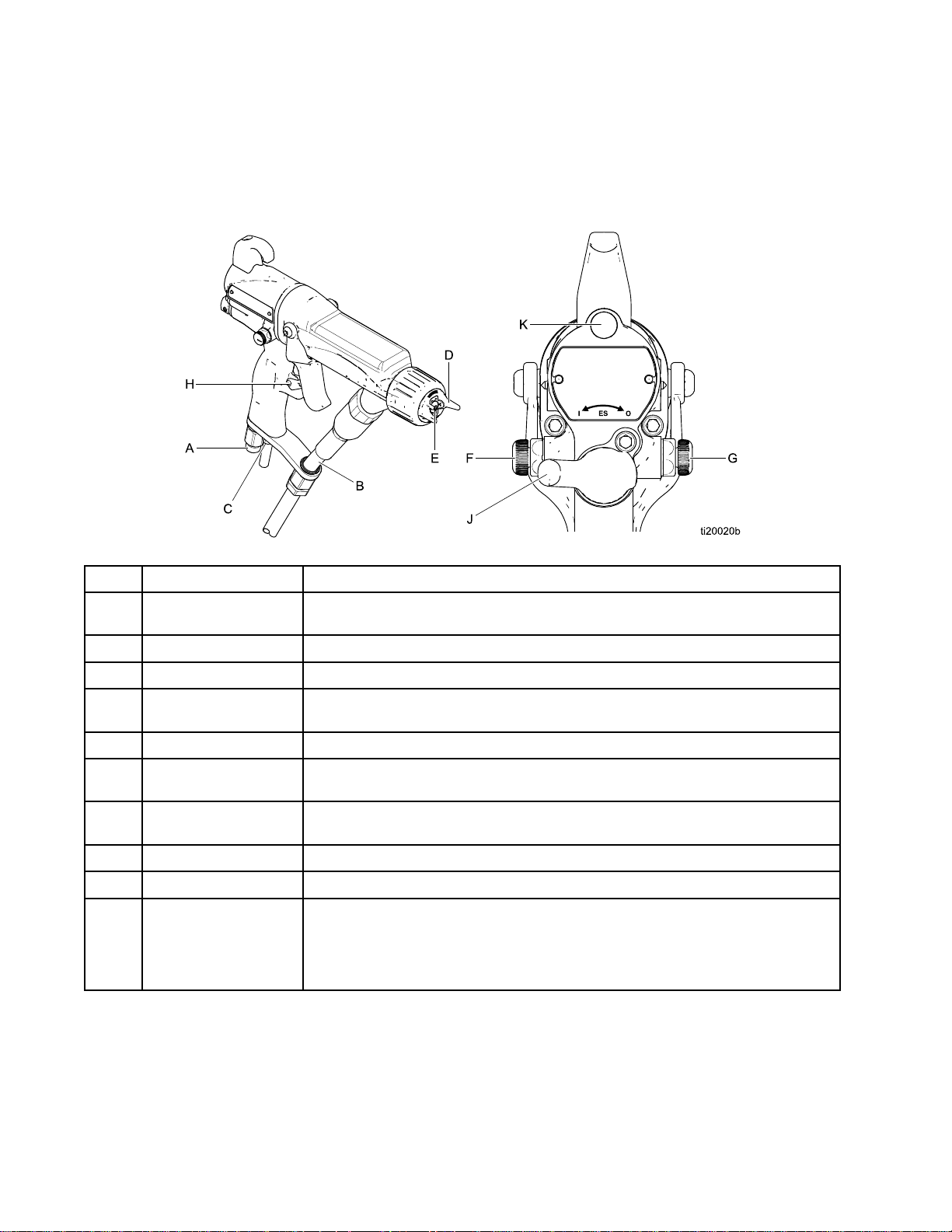

Theelectrostaticgunincludesthefollowing

controls,indicators,andcomponents(seeFig.

1).ForinformationonSmartguns,alsosee

SmartGuns,page9.

Figure1GunOverview

Indicators,

Indicators, Indicators,

and

Components

and and

Components Components

Item

Item Item

A

BFluidHose

C

D

EElectrode

FFanAirAdjustment

G

H

J

K

Description

Description Description

AirSwivelInlet1/4npsm(m)left-handthread,forGracored-coloredgroundedairsupply

TurbineAirExhaust

AirCap/TipGuard

andSprayTip

Valve

AtomizingAir

AdjustmentValve

TriggerSafetyLockLockstriggertopreventgunfromspraying.

ESOn-OffValveTurnselectrostaticsON(I)orOFF(O).

ESIndicator(standardgunonly;for

Smartgunindicator,

seeOperatingMode,

page9)

Purpose

Purpose Purpose

hose.

Gracowaterborneuidhose

Barbedtting,forsuppliedexhausttube.

SeeSprayTipSelectionChart,page68,foravailablesizes.

Supplieselectrostaticchargetotheuid.

Adjustsfansizeandshape.Canbeusedtodecreasepatternwidth.

Adjustsatomizingairow.

LitwhenESisON(I).Colorindicatesalternatorfrequency.SeetheLED

indicatortableinGunSetup,page23.

83A2497H

Page 9

GunOverview

Smart

Smart Smart

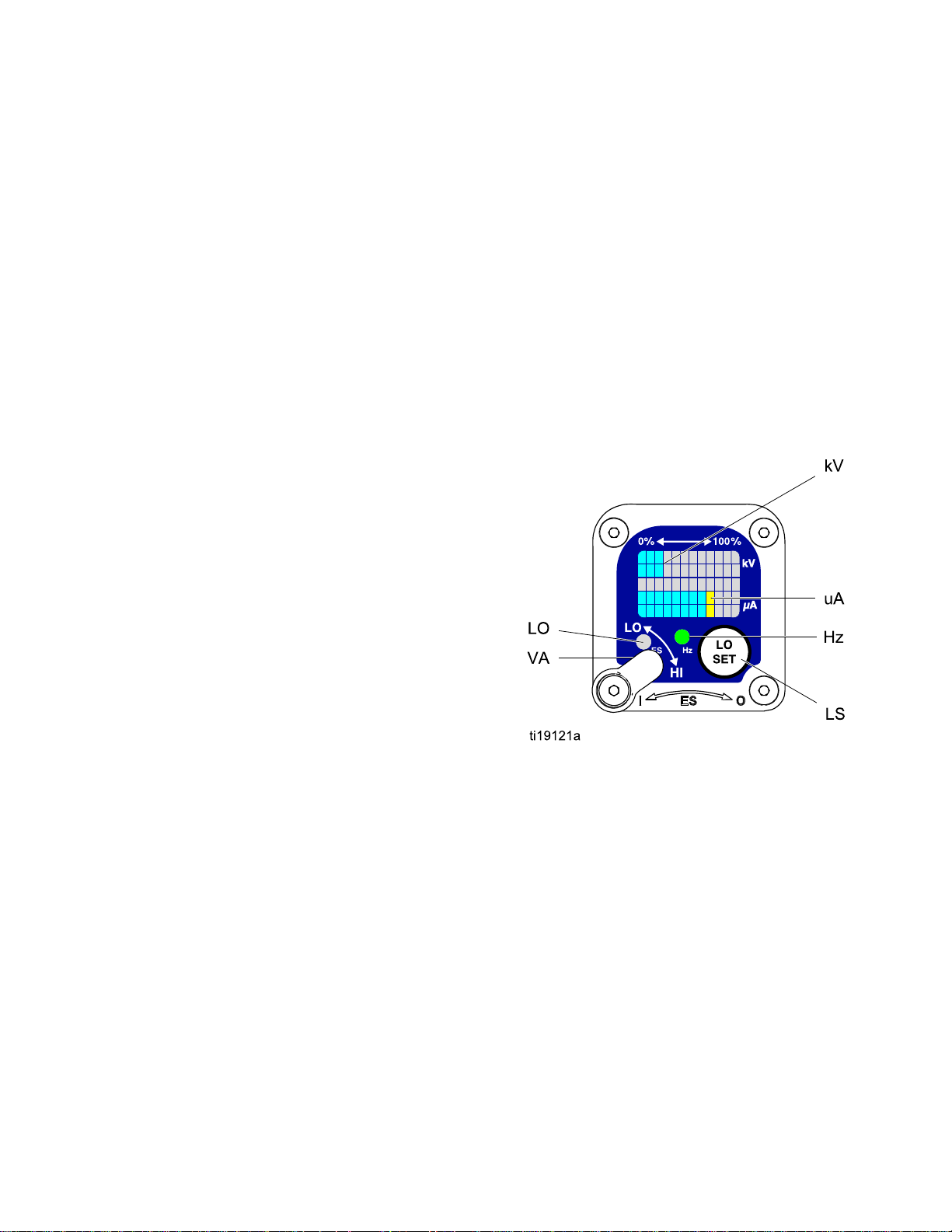

TheSmartGunmoduledisplayssprayingvoltage,

current,alternatorspeed,andthevoltagesetting(low

orhigh).Italsoallowstheusertochangetoalower

sprayingvoltage.Themodulehastwomodes:

•OperatingMode

•DiagnosticMode

Operating

Operating Operating

Bar

Bar Bar

SeeFig.2andSmartGunKey,page11.The

OperatingModedisplaysgundataduringnormal

spraying.Thedisplayusesabargraphtoshowthe

voltagelevelinkiloVolts(kV)andthecurrentlevelin

microAmperes(uA).Thebargraphrangeisfrom0

to100%foreachvalue.

IftheuAbargraphLEDsareblue,thegunisready

tospray.IftheLEDsareyelloworred,thecurrentis

toohigh.SeeElectricalTroubleshooting,page43.

Guns

Guns Guns

Mode

Mode Mode

Graph

Graph Graph

Voltage

Voltage Voltage

Thevoltageadjustmentswitch(VA)allowsthe

operatortochangefromlowtohighvoltage.

•Thehighvoltagesettingisdeterminedbythe

maximumvoltageofthegunandisnotadjustable.

•Thelowvoltageindicator(LO)lights

whentheswitchissettoLO.Thelow

voltagesettingisuseradjustable.See

AdjustingtheLowVoltageSetting,page10.

Adjustment

Adjustment Adjustment

Note

IftheErrordisplayappears,theSmart

modulehaslostcommunicationwiththe

powersupply.SeeErrorDisplay,page10for

furtherinformation.

Switch

Switch Switch

Hz

Indicator

Hz Hz

Indicator Indicator

TheHzindicatorfunctionsthesameastheES

indicatoronstandardguns.Theindicatorlightsto

showthealternatorspeedstatus,andhasthree

colors:

•Greenindicatesthealternatorspeediscorrect.

•Iftheindicatorchangestoamberafteronesecond,

increasetheairpressure.

•Iftheindicatorchangestoredafteronesecond,

reducetheairpressure.Decreaseairpressure

untiltheindicatorisgreen.Tomaintainahigher

airpressure,installESOn/OffValveRestrictorKit

26A294.Then,adjustthepressureasneededto

ensurethattheindicatorremainsgreen.

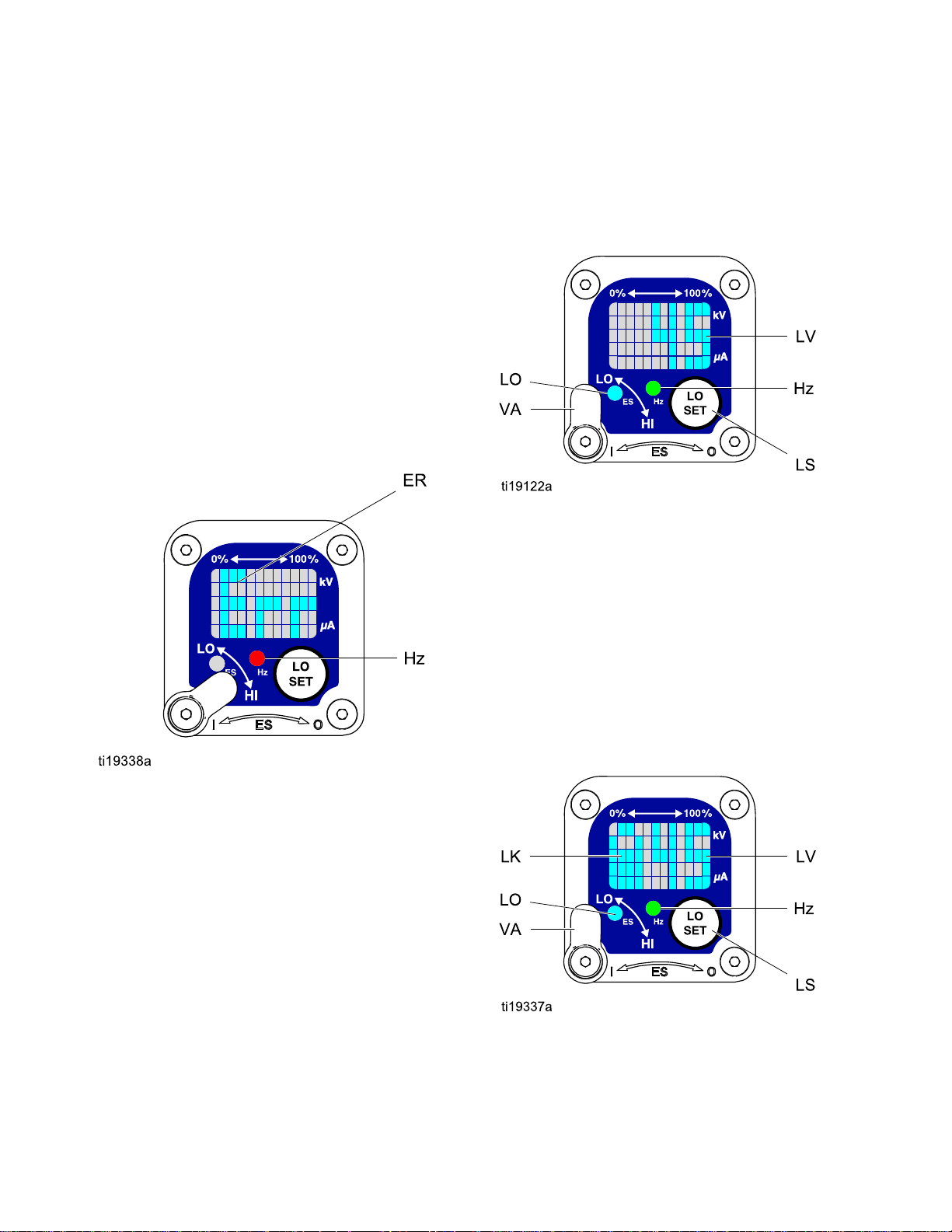

Figure2SmartGunModuleinOperatingMode

3A2497H9

Page 10

GunOverview

Error

Error Error

IftheSmartmodulelosescommunicationwith

thepowersupply,theErrordisplayappears,the

Hzindicatorturnsred,andtheSmartmoduleis

disabled.SeeFig.3andSmartGunKey,page11.

ThiscanoccurinOperatingModeorDiagnostic

Mode.SeeElectricalTroubleshooting,page43.

CommunicationmustberestoredtomaketheSmart

modulefunctional.

Display

Display Display

Note

Ittakes8secondsfortheErrordisplayto

appear.Ifthegunhasbeendisassembled,

wait8secondsbeforesprayingtoensure

thatanErrorconditionhasnotoccurred.

Note

Ifthereisnopowertothegun,theError

displaywillnotappear.

Note

After2secondsofinactivitythedisplaywill

returntotheOperatingScreen.

Note

Thelowvoltagesettingmaybelocked.See

LockSymbol,page10.

Figure4LowVoltageSettingScreen(Unlocked)

Lock

Symbol

Lock Lock

Symbol Symbol

Figure3ErrorDisplay

Adjusting

Adjusting Adjusting

Thelowvoltagesettingisuseradjustable.Toaccess

thelowvoltagesettingscreenwheninOperating

Mode,presstheLOSETbutton(LS)momentarily.

Thescreenwilldisplaythecurrentlowvoltage

setting.SeeFig.4andSmartGunKey,page11.

Therangeis30–60kV.

SettheVoltageAdjustmentswitch(VA)toLO.Press

theLOSETbuttonrepeatedlytoincreasethesetting

inincrementsof5.Whenthedisplayreachesthe

maximumsetting(60kV)itwillreturntotheminimum

setting(30kV).Continuepressingthebuttonuntil

youreachthedesiredsetting.

the

Low

the the

Voltage

Low Low

Voltage Voltage

Setting

Setting Setting

Thelowvoltagesettingmaybelocked.Whenlocked,

animage(LK)appearsonthescreen.SeeFig.5

andSmartGunKey,page11.

•WheninHImode,thelowvoltagesettingisalways always

locked.ThelocksymbolwillappearwhentheLO

SETbuttonispressed.

•WheninLOmode,thelocksymbolwill

only

only only

appearifthelockisenabled.See

LowVoltageLockScreen,page13,tolockor

unlockthelowvoltagesetting.

Figure5LowVoltageSettingScreen(Locked)

always

103A2497H

Page 11

GunOverview

Smart

Smart Smart

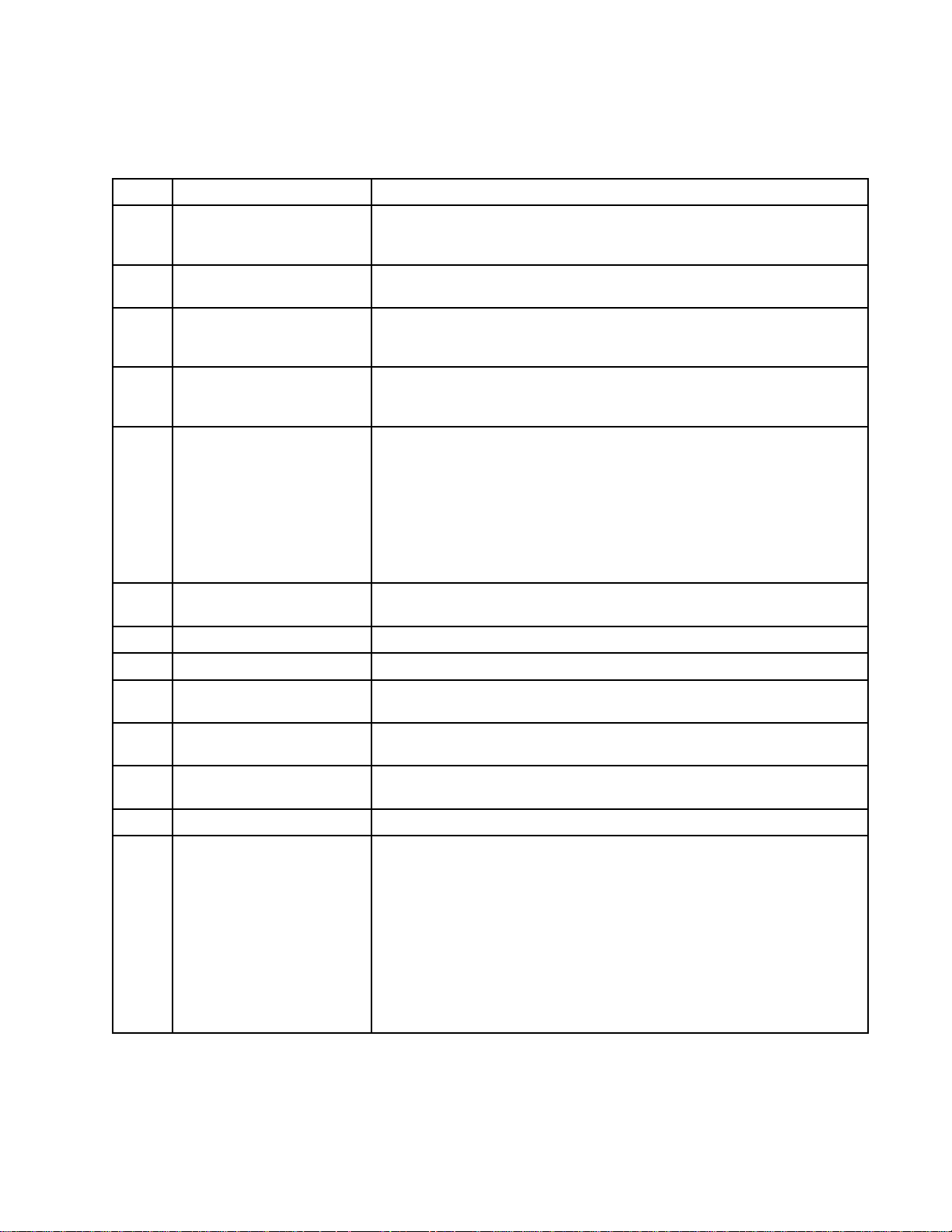

Table

Table Table

Item

Item Item

VA

LO

kV

uA

LSLOSETbuttonPressmomentarilytoentertheLowVoltageSettingscreen.

Gun

Key

Gun Gun

Key Key

Key

for

Figs.

1 11Key Key

for for

Description

Description Description

VoltageAdjustmentSwitchTwo-positionswitchsetsSmartgunvoltagetolowsetting(LO)or

LowVoltageMode

Indicator

Voltage(kV)DisplayDisplaysactualsprayingvoltageofthegun,inkV.InOperatingMode,

Current(uA)DisplayDisplaysactualsprayingcurrentofthegun,inuA.InOperatingMode,

2–9.

Figs. Figs.

2–9. 2–9.

Purpose

Purpose Purpose

highsetting(HI).ThisswitchisfunctionalinOperatingModeandin

DiagnosticMode.

Lights(blue)whentheSmartgunissettoLowVoltage.

displayisabargraph.InDiagnosticMode,voltageisdisplayedas

anumber.

displayisabargraph.InDiagnosticMode,currentisdisplayedas

anumber.

Pressandholdforapproximately5secondstoenterorexitDiagnostic

Mode.

WhileinDiagnosticMode,pressmomentarilytoadvancethrough

screens.

WhileontheLowVoltageLockScreen(inDiagnosticMode),press

andholdtoturnthelockonoroff.

LVLowVoltageDisplayDisplaysthelowvoltagesettingasanumber.Thesettingcanbe

changed.SeeFig.4.

LKLowVoltageLocked

LD

ERErrorDisplay

VIVoltageIndicator

CICurrentIndicatorInDiagnosticMode,thetwobottomrightLEDsofthescreenlight,

ASAlternatorSpeedDisplayInDiagnosticMode,Hzlevelisdisplayedasanumber.SeeFig.8.

Hz

LODisplayAppearsontheLowVoltageLockScreen.SeeFig.9.

AlternatorSpeedIndicatorInOperatingMode,indicatorcolorvariestoshowthealternatorspeed

Appearsifthelowvoltagesettingislocked.SeeFig.5andFig.9.

AppearsiftheSmartmodulelosescommunicationwiththepower

supply.SeeFig.3.

InDiagnosticMode,thetwotoprightLEDsofthescreenlight,

indicatingthatthevaluedisplayedisinkV.SeeFig.6.

indicatingthatthevaluedisplayedisinuA.SeeFig.7.

status:

•Greenindicatesthealternatorspeedisatthecorrectlevel.

•Iftheindicatorchangestoamberafteronesecond,thealternator

speedistoolow.

•Iftheindicatorchangestoredafteronesecond,thealternatorspeed

istoohigh.TheindicatoralsoturnsrediftheErrordisplayappears.

InDiagnosticMode,theindicatorisgreenwhenintheAlternator

Speed(Hertz)screen.

3A2497H

11

Page 12

GunOverview

Diagnostic

Diagnostic Diagnostic

DiagnosticModeincludesfourscreenswhichdisplay

gundata:

•Voltage(kiloVolts)Screen

•Current(microAmperes)Screen

•AlternatorSpeed(Hertz)Screen

•LowVoltageLockScreen

Note

YoumustbeinOperatingModetoadjust

thelowvoltagesetting;thesettingisnot

adjustableinDiagnosticMode.However,the

voltageadjustmentswitch(VA)canbesetto

HIorLOinOperatingModeandDiagnostic

Mode.

ToenterDiagnosticMode,pressandholdtheLOSET

(LS)buttonforapproximately5seconds.Thedisplay

willgototheVoltage(kiloVolts)Screen,page12.

Toadvancetothenextscreen,presstheLOSET

buttonagain.

ToexitDiagnosticMode,pressandholdtheLOSET

buttonforapproximately5seconds.Thescreenwill

returntoOperatingMode.

Note

Iftheguntriggerisreleasedwhilein

DiagnosticMode,thelastscreenviewedwill

bedisplayedwhenthegunistriggeredagain.

Note

DiagnosticModecannotbeexitedfromthe

LowVoltageLockScreen.Fordetails,see

LowVoltageLockScreen,page13.

Mode

Mode Mode

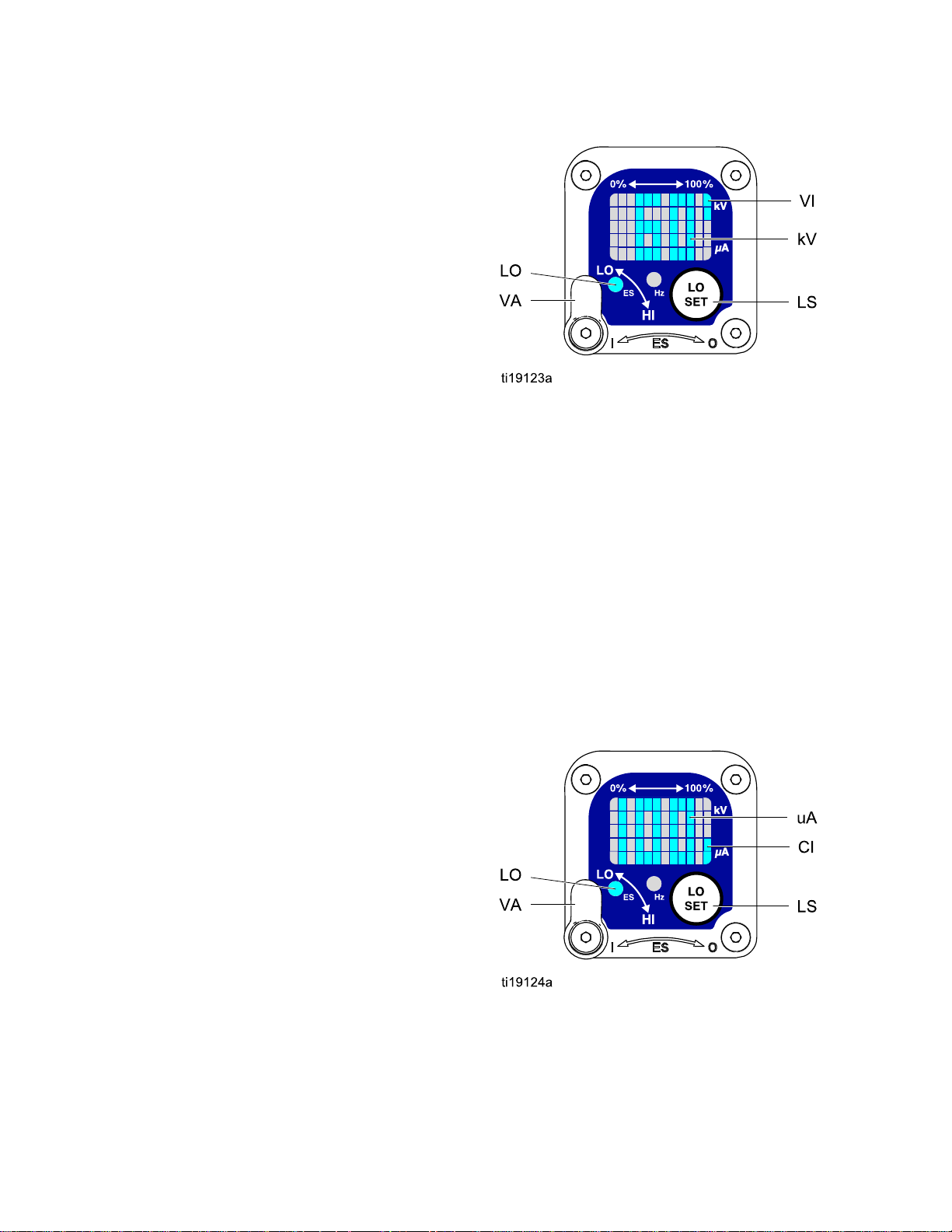

Figure6Voltage(kiloVolts)Screen

Current

Current Current

TheCurrent(microAmperes)Screenisthesecond

screenintheDiagnosticMode.SeeFig.7and

SmartGunKey,page11.Toenterthisscreen,press

theLOSETbuttonwhileintheVoltage(kiloVolts)

Screen.

Thisscreendisplaysthesprayingcurrentofthegun

asanumber(uA),roundedtothenearest5uA.The

twobottomrightLEDs(CI)ofthedisplaypanellight,

indicatingthattheCurrent(microAmperes)Screen

isdisplayed.Thedisplayisareadoutandcannot

bechanged.

PresstheLOSETbuttontoadvancetothe

AlternatorSpeed(Hertz)Screen,page13.Press

andholdforapproximately5secondstoreturnto

OperatingMode.

(microAmperes)

(microAmperes) (microAmperes)

Screen

Screen Screen

Voltage

Voltage Voltage

TheVoltage(kiloVolts)Screenistherstscreento

appearafterenteringDiagnosticMode.SeeFig.6

andSmartGunKey,page11.Toenterthisscreen,

pressandholdtheLOSETbuttonforapproximately

5secondswhileintheOperatingMode.

Thisscreendisplaysthesprayingvoltageofthe

gunasanumber(kV),roundedtothenearest5kV.

ThetwotoprightLEDs(VI)ofthedisplaypanel

light,indicatingthattheVoltage(kiloVolts)Screen

isdisplayed.Thedisplayisareadoutandcannot

bechanged.

PresstheLOSETbuttontoadvancetothe

Current(microAmperes)Screen,page12.Press

andholdforapproximately5secondstoreturnto

OperatingMode.

(kiloVolts)

(kiloVolts) (kiloVolts)

Screen

Screen Screen

12

Figure7Current(microAmperes)Screen

3A2497H

Page 13

GunOverview

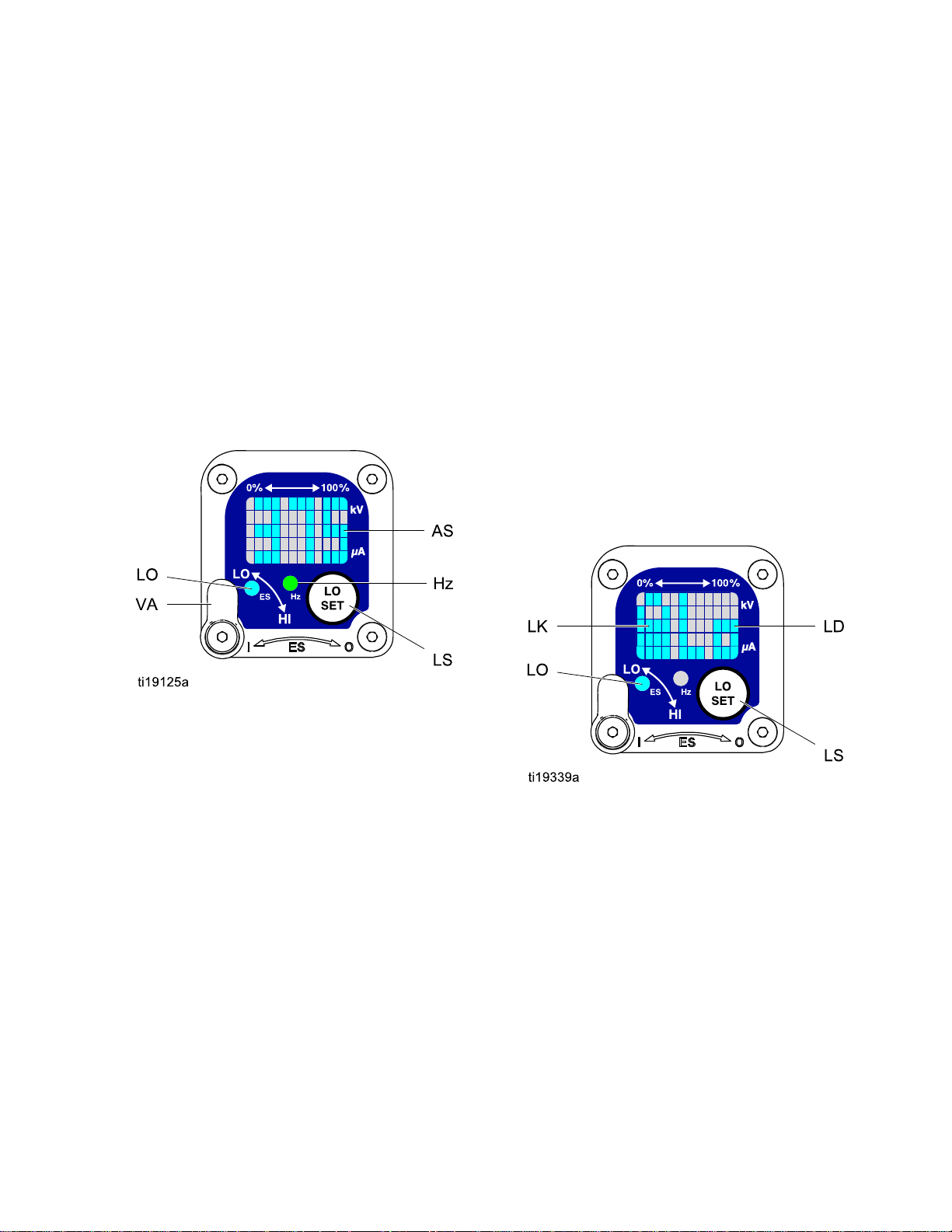

Alternator

Alternator Alternator

TheAlternatorSpeed(Hertz)Screenisthethird

screenintheDiagnosticMode.SeeFig.8and

SmartGunKey,page11.Toenterthisscreen,

presstheLOSETbuttonwhileintheCurrent

(microAmperes)Screen.

Thisscreendisplaysthealternatorspeedasa3

digitnumber(AS),roundedtothenearest5Hz.The

displayisareadoutandcannotbechanged.Ifthe

alternatorspeedisgreaterthan999Hz,thedisplay

willshow999.

TheHzindicatorlightsgreentoshowthatyouare

viewingtheAlternatorSpeed(Hertz)Screen.

PresstheLOSETbuttontoadvancetothe

LowVoltageLockScreen,page13.Pressandhold

forapproximately5secondstoreturntoOperating

Mode.

Speed

Speed Speed

(Hertz)

(Hertz) (Hertz)

Screen

Screen Screen

Low

Voltage

Low Low

Voltage Voltage

TheLowVoltageLockScreenisthefourth

screenintheDiagnosticMode.SeeFig.9and

SmartGunKey,page11.Toenterthisscreen,press

theLOSETbuttonwhileintheAlternatorSpeed

(Hertz)Screen.

ThisscreendisplaysthestatusoftheLowVoltage

Lock.Ifthesettingislocked,thelockimage(LK)

appearstotheleftoftheLodisplay(LD).Ifthesetting

isunlocked,thelockimagedoesnotappear.

Tochangethelockstatus,pressandholdthe

LOSETbuttonuntilthelockimageappearsor

disappears.Ifthelockisset,theimagewillalso

appearontheLowVoltageSettingScreenwhenin

lowvoltagemode(seeFig.4).

Note

DiagnosticModecannotbeexitedfromthis

screen,becausepressingandholdingthe

LOSETbuttonisusedtoturnthelockonor

off.Toexit,pressLOSETmomentarilyto

returntotheVoltage(kiloVolts)Screen,then

exitDiagnosticModefromthere.

Lock

Screen

Lock Lock

Screen Screen

Figure8AlternatorSpeed(Hertz)Screen

Figure9LowVoltageLockScreen

3A2497H13

Page 14

Installation

Installation

Installation Installation

System

System System

Theuseofmultiplegunswithoneisolationcabinet

maycauseelectricshock,re,orexplosion.To

helppreventinjuryorequipmentdamage,useonly

onegunperisolationcabinet.

AGracovoltageisolationsystemmusthavethe

followingfeatures:

•Anisolationenclosurethatpreventspersonsfrom

makingcontactwiththehighvoltagecomponents

beforethesystemvoltageisdischarged.All

componentsoftheisolationsystemthatare

chargedtohighvoltagemustbecontainedwithin

theenclosure.

•Ableedresistortodrainoffthesystemvoltage

whenthespraygunisnotinuse.Ametalpartof

theuidsupplyunitmustbeelectricallyconnected

tothebleedresistor.

•Asafetyinterlockthatautomaticallydischargesthe

systemvoltagewhenanyoneopenstheisolation

enclosure.

Requirements

Requirements Requirements

Install

Install Install

Installingandservicingthisequipmentrequires

accesstopartswhichmaycauseelectricshock

orotherseriousinjuryifworkisnotperformed

properly.

•Donotinstallorservicethisequipmentunless

•Complywithalllocalcodesandregulations.

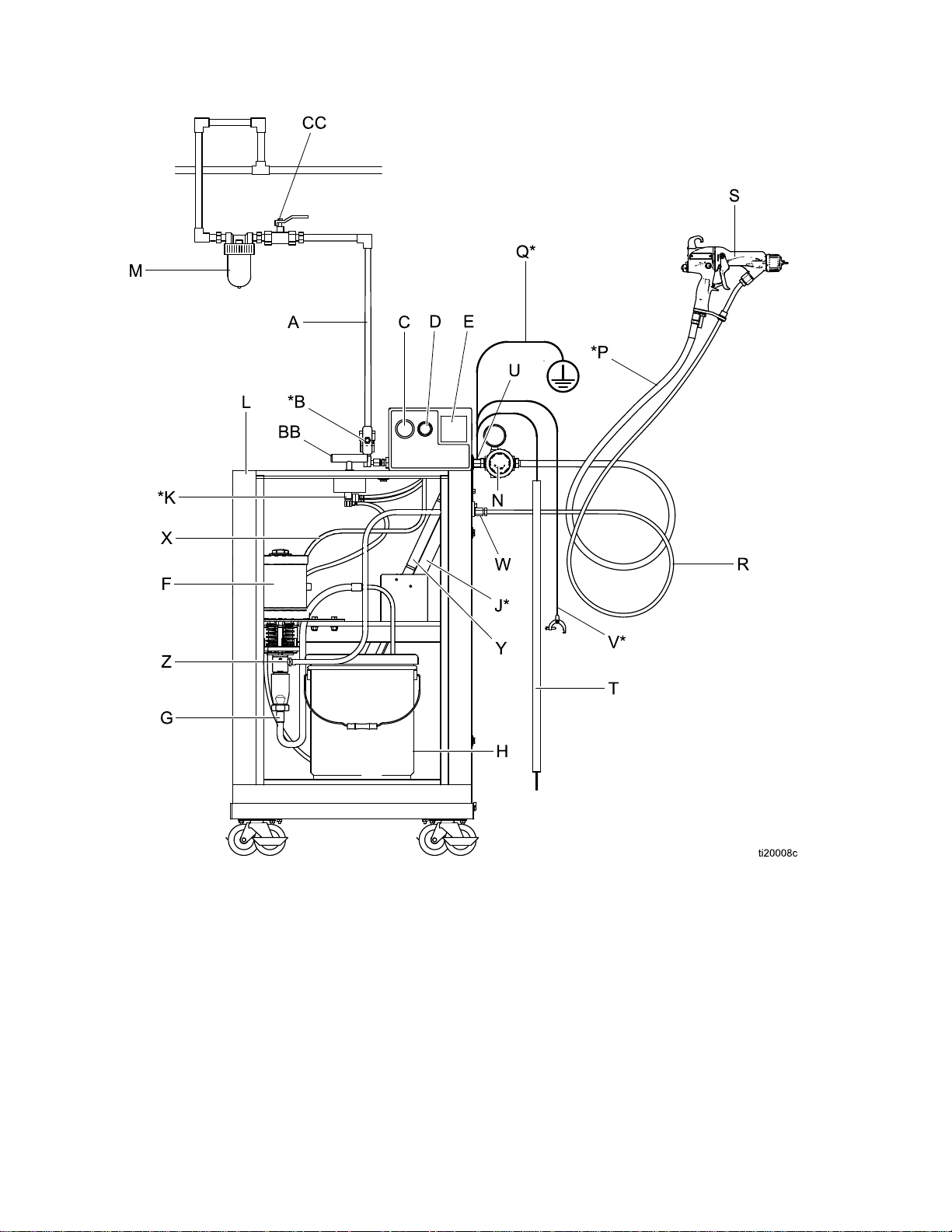

Fig.12(TypicalInstallation)showsatypical

electrostaticair-assistedspraysystem.Itisnotan

actualsystemdesign.Forassistanceindesigning

asystemtosuityourparticularneeds,contactyour

Gracodistributor.

Ventilate

Ventilate Ventilate

the

the the

youaretrainedandqualied.

System

System System

the

Spray

the the

Spray Spray

Booth

Booth Booth

NOTICE

NOTICE NOTICE

Thesystemshouldnothaveanyseverearcing

occurringwhentheisolationmechanismopens

andcloses.Severearcingwillshortenthelifeof

thesystemcomponents.

Note

TheGracowarrantyandapprovalsarevoidif

theelectrostaticspraygunisconnectedtoa

non-Gracovoltageisolationsystemorifthe

gunisoperatedabove60kV.

Warning

Warning Warning

Mountwarningsignsinthesprayareawherethey

caneasilybeseenandreadbyalloperators.An

EnglishWarningSignisprovidedwiththegun.

Sign

Sign Sign

Donotoperatethegununlessventilatingairowis

abovetheminimumrequiredvalue.Providefresh

airventilationtoavoidthebuildupofammableor

toxicvaporswhenspraying,ushing,orcleaning

thegun.Interlockthegunairanduidsupply

topreventoperationunlessventilatingairowis

abovetheminimumrequiredvalue.

Thesprayboothmusthaveaventilationsystem.

Electricallyinterlockthegunairanduidsupplywith

theventilatorstopreventgunoperationanytimethat

theventilationairowfallsbelowminimumvalues.

Checkandfollowalllocalcodesandregulations

regardingairexhaustvelocityrequirements.Verify

theoperationoftheinterlockatleastonceayear.

14

3A2497H

Page 15

Air

Supply

Air Air

Supply Supply

Toreducetheriskofelectricshock,theairsupply

hosemustbeelectricallyconnectedtoatrueearth

ground.Use Use

Hose.

Hose. Hose.

Toreducetheriskofelectricshockorother

seriousinjury,youmustusethered-coloredGraco

ElectricallyConductiveAirHoseforthegunair

supply.Donotusetheblackorgray-coloredGraco

airhoses.

1.SeeFig.12.Installanairlinelter/water

separator(M)onthemainairsupplylineto

ensureadry,cleanairsupplytothegun.Dirtand

moisturecanruintheappearanceofyournished

workpieceandcancausetheguntomalfunction.

2.TheWB3000systemincludesableed-typeair

regulator(N)onthegunairsupplyline(P),to

controlairpressuretothegun.

3.Connectthered-coloredGracoElectrically

ConductiveAirHose(P)betweenthegunair

regulator(N)andthegun’sairinlet.Thegunair

inletttinghasaleft-handthread.Connectthe

airsupplyhosegroundwire(Q)toatrueearth

ground.

Line

Line Line

Use

only

Graco

only only

Graco Graco

Grounded

Grounded Grounded

Air

Supply

Air Air

Supply Supply

Ground

Ground Ground

Connectthemaingroundwire(V)toatrueearth

ground.

the

Cabinet

the the

Cabinet Cabinet

Installation

Trappedaircancausetheuidsupplyunitto

cycleunexpectedly,whichcanresultinserious

injury,includingsplashinguidintheeyesor

ontheskin.Donotoperatetheequipment

withoutthebleed-typeairvalve(B)installed.

4.TheWB3000systemincludesableed-typeair

valve(B).Thebleed-typeairvalveisrequired

toshutoffallairtothesystemandrelieveair

trappedbetweenthevalveandtheuidsupply

unitaftertheairregulatorisshutoff.Connectthe

mainairsupplyline(A)tothebleedvalve.

5.Installanadditionalbleed-typeairvalve(CC)

upstreamoftheairlter(M)toisolatethelter

forservicing.

3A2497H15

Page 16

Installation

Grounding

Grounding Grounding

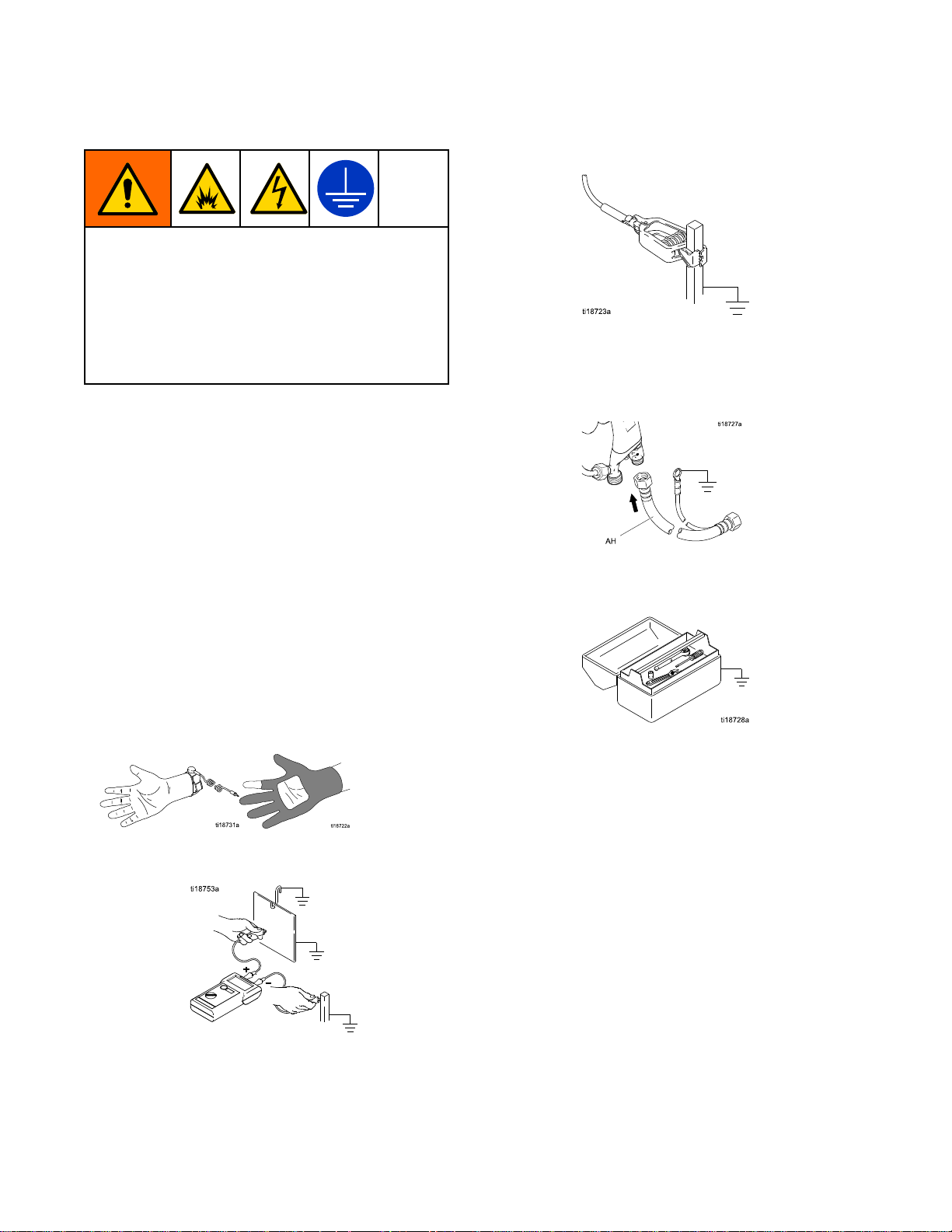

Theequipmentmustbegroundedtoreducethe

riskofstaticsparkingandelectricshock.Electric

orstaticsparkingcancausefumestoigniteor

explode.Impropergroundingcancauseelectric

shock.Groundallequipment,personnel,objects

beingsprayed,andconductiveobjectsinorclose

tothesprayarea.Theresistancemustnotexceed

100ohms.Groundingprovidesanescapewirefor

theelectriccurrent.

Whenoperatingtheelectrostaticgun,any

ungroundedobjects(suchaspeople,containers,and

tools)inthespraylocationcanbecomeelectrically

charged.

Thefollowingareminimumgroundingrequirements

forabasicelectrostaticwaterbornesystem.Your

systemmayincludeotherequipmentorobjects

whichmustbegrounded.Yoursystemmustbe

connectedtoatrueearthground.Checkground

connectionsdaily.Checkyourlocalelectricalcodes

andregulationsfordetailedgroundinginstructions.

Allpersonsenteringthesprayarea:

•

shoeshavingconductivesolessuchasleather,

orwearpersonalgroundingstraps.Donot

wearshoeswithnon-conductivesolessuchas

rubberorplastic.Ifglovesarenecessary,wear

theconductiveglovessuppliedwiththegun.If

non-Gracoglovesareworn,cutoffngersorpalm

areaofglovestoensureyourhandcontactsthe

groundedgunhandle.

•

Objectbeingsprayed:

cleanandgroundedatalltimes.

Keeptheworkpiecehangers

mustwear

•

VoltageIsolationSystem:

voltageisolationsystemtoatrueearthground.

SeeGroundtheCabinet,page15.

•

ElectrostaticAir-AssistedSprayGun:

thegunbyconnectingthered-coloredGraco

GroundedAirHosetothegun,andconnectingthe

airhosegroundwiretoatrueearthground.See

CheckGunElectricalGrounding,page26.

•

Allelectricallyconductiveobjectsordevicesinthe

sprayarea:

•

Fluidandwastecontainers:

wastecontainersinthesprayarea.Donotusepail

linersunlesstheyareconductiveandgrounded.

Whenushingthespraygun,thecontainerused

tocatchtheexcessuidmustbeelectrically

conductiveandgrounded.

Aircompressors:

•

tothemanufacturer'srecommendations.

•

Allairlines

groundedhoseswithamaximumof100feet(30.5

m)combinedhoselengthtoensuregrounding

continuity.

mustbeproperlygrounded.

Groundtheequipmentaccording

mustbeproperlygrounded.Useonly

Electricallyconnectthe

Groundalluidand

Ground

163A2497H

Page 17

•

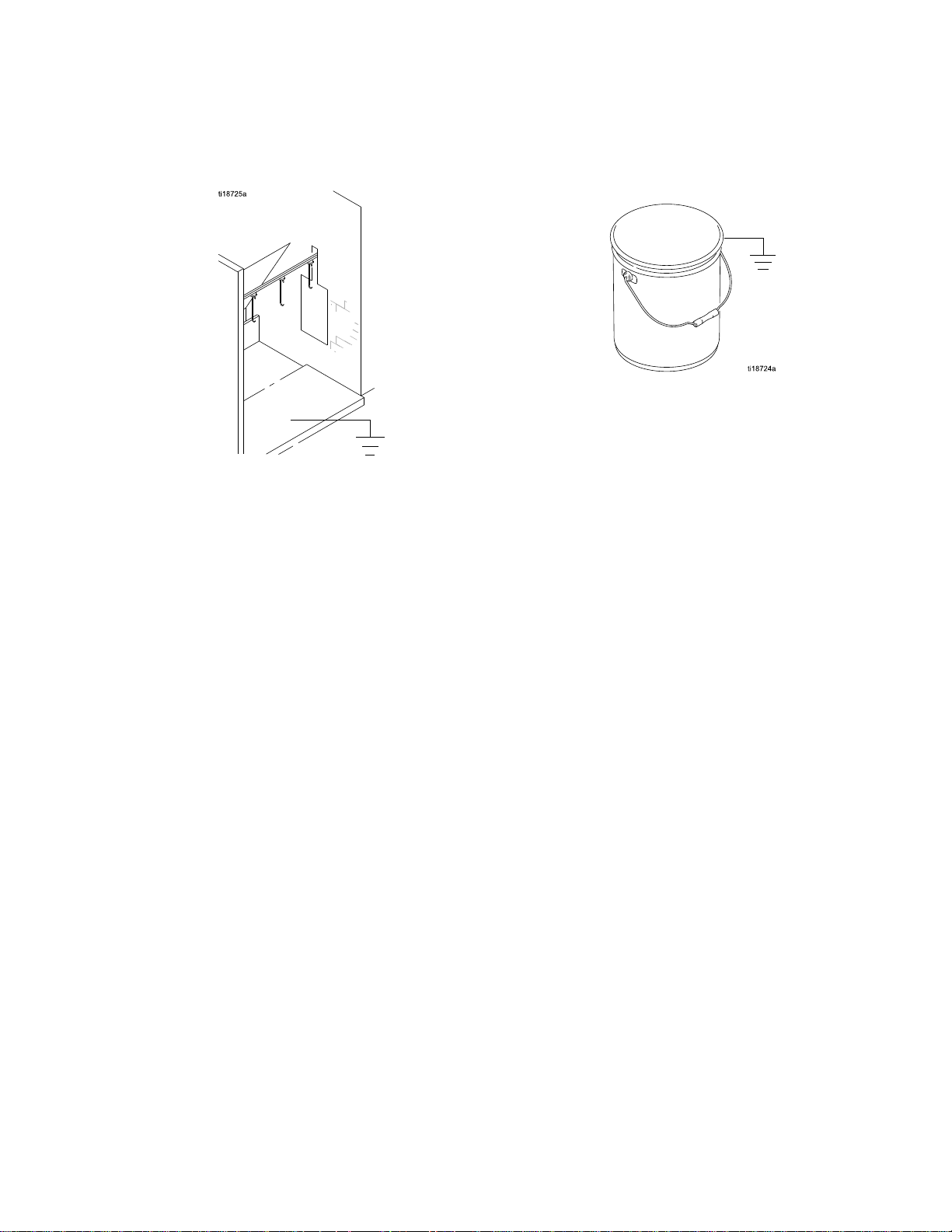

Theoorofthesprayarea:

conductiveandgrounded.Donotcovertheoor

withcardboardoranynon-conductivematerial

whichwouldinterruptgroundingcontinuity.

mustbeelectrically

•

Allsolventpails:

metalcontainers,whichareconductive.Donot

useplasticcontainers.Onlyusenon-ammable

solvents.Donotstoremorethanthequantity

neededforoneshift.

Useonlyapproved,grounded

Installation

3A2497H

17

Page 18

Installation

Connect

Connect Connect

AlwaysuseaGracowaterborneuidhosebetween

thevoltageisolationsystemuidoutletandthegun

uidinlet.

Beforeconnectingthewaterborneuidhosetothe

gun,blowitoutwithairandushwithwaterto

removecontaminants.Flushthegunbeforeusingit.

Toreducetheriskofelectricshock,installonly

onecontinuousGracowaterbornehosebetween

theisolateduidsupplyandthegun.Donotsplice

hosestogether.

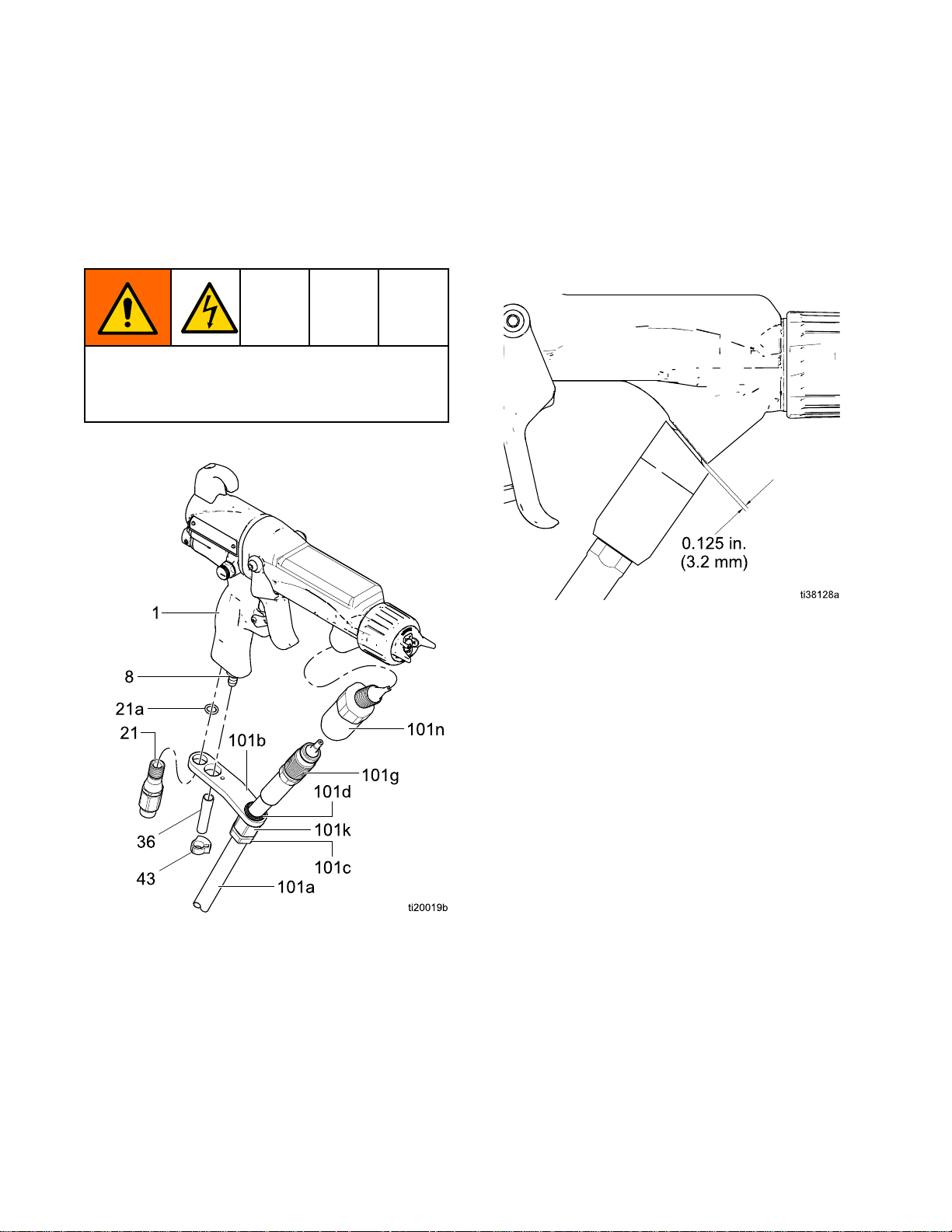

1.Removethegunairinlettting(21).

the

Waterborne

the the

Waterborne Waterborne

Fluid

Fluid Fluid

Hose

Hose Hose

3.Makesurethebarreluidinletiscleananddry.

Applydielectricgreasetothethreadsandfrontof

thebarrelconnector(101a)andscrewitintothe

uidinletjustuntilsnug.Thencontinuetotighten

thettingaminimumof1/2turnandcontinueto

rotateuntilthettingisorientedasshown.The

gapbetweenthettingandthebarrelmustbe

lessthan.125in(3.2mm).

Figure10ConnecttheFluidHose

2.Removetheo-ring(21a)andassembletheinlet

ttingthroughthebracket.Reassemblethe

o-ring.

Figure11OrientationofFittingandBarrel

4.Loosenthestrainreliefnut(101c).

5.Applydielectricgreasetothethreadsofthe

hoseconnector(101g).Pulltheconnectorback

andapplygreasetotheoutsidediameterofthe

hose.Threaditintothebarrelconnector(101n)

untilsnugandthenaminimumof1/2turnmore.

Useawrenchtoholdthebarrelconnectorwhen

tightening.

6.Alignthebracket(101b)holeswiththeairinlet

andexhaustoutlet.Securewiththeairinlettting

(21).

7.Tightenthestrainreliefnut(101c).

8.Presstheexhausttube(36)ontotheexhaust

valve.Securewiththeclamp(43).

Note

Wheneverpossible,keeptheuidhose

assembledtothegunbarrel.Toremove

thebarrel,disconnectthehosebracket

atthegunhandle.

9.Loosenthestrainreliefnutatthehoseinletend.

10.Slidetheotherendofthehosethroughthehole

inthesideoftheisolatedenclosure.Connectthe

swivel(Z)totheuidoutletofthepump.

183A2497H

Page 19

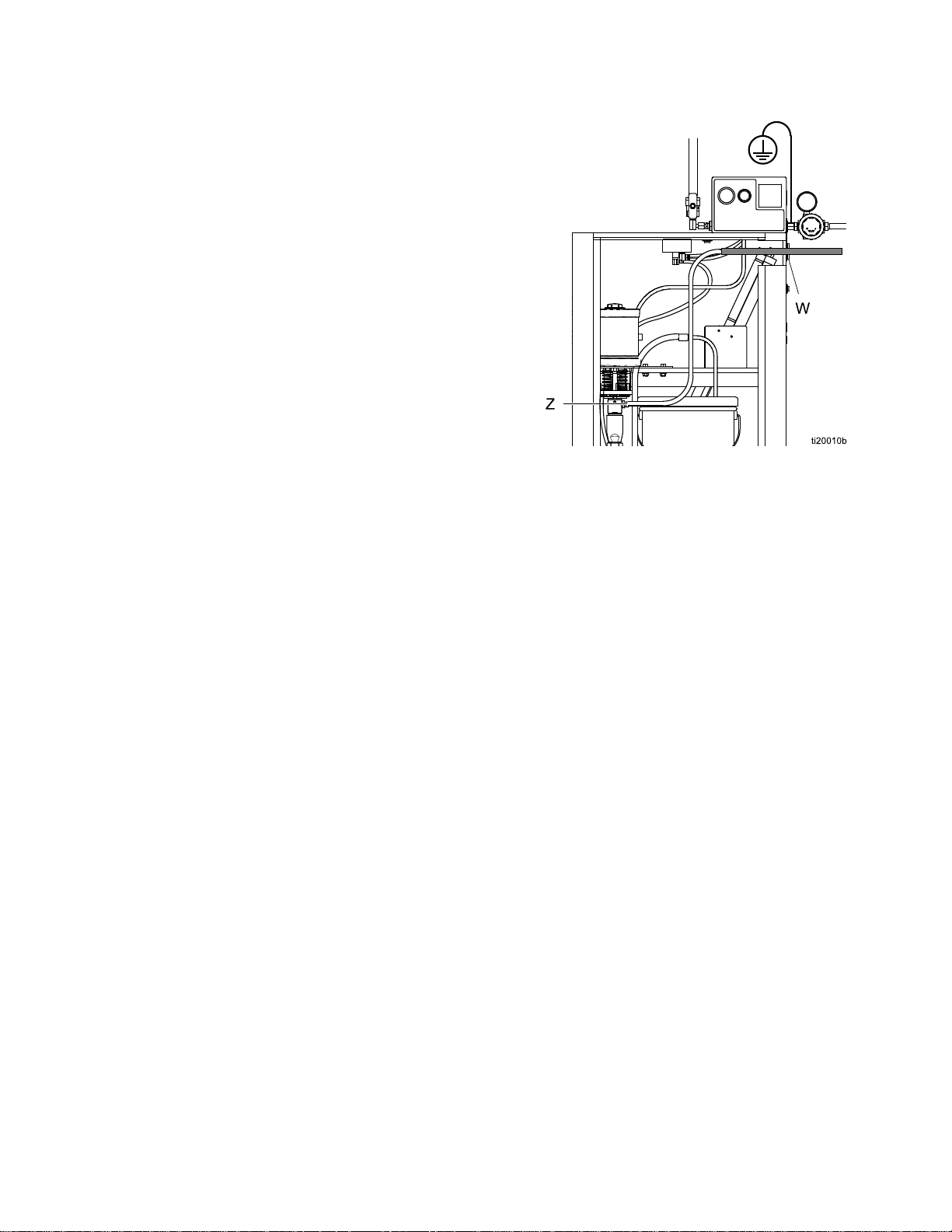

11.Securethehosetothesideoftheenclosurewith

thebracket(W).Aboltassemblesthroughthe

holeinthebracketandscrewsintothesideof

theenclosure.

12.Tightenthestrainreliefnut.

Note

TheGracowarrantyandapprovals

arevoidiftheelectrostaticspraygun

isconnectedtoanon-Gracovoltage

isolationsystemorifthegunisoperated

above60kV.

Installation

Figure12HoseConnectionatWB3000Enclosure

3A2497H19

Page 20

Installation

Figure13TypicalInstallation,ProXpWaterborne

System

203A2497H

Page 21

Installation

Typical

Typical Typical

Item

Item Item

A

B*Bleed-TypeAirShutoffValve

CPumpAirPressureGauge

DPumpAirPressureRegulator

EkVMeter

FPump

GPumpSuctionHose

H

J*

K*EnclosureSafetyInterlock

LIsolatedEnclosure

M

N

P*GracoRedGroundedAirHose(left-hand

Q*GunAirHoseGroundWire

Installation

Installation Installation

Description

Description Description

MainAirSupplyLine

PaintContainer

BleedResistor

GunAirLineFilter

GunAirPressureRegulator

threads)

Key

Key Key

Item

Item Item

S

T

U

V*MainGroundWire

W

X

Y

Z

AA

BB

CCAccessoryBleed-TypeAirShutoffValve

*Theseitemsarerequiredforsafeoperation.They

areincludedwiththeWB3000system.

Description

Description Description

WaterborneElectrostaticAir-Assisted

SprayGun

GroundingRod

GroundTerminal

StrainReliefFitting

PumpAirSupplyLine

GroundingCylinder

PumpFluidOutletFitting

IsolatedEnclosureDoor(notshown,to

illustrateinternalcomponents.Doormust

beclosedandlockedtooperatesystem).

EnclosureT-HandleLockingScrew(part

ofdoorassembly)

R

GracoWaterborneFluidHose

3A2497H

21

Page 22

Installation

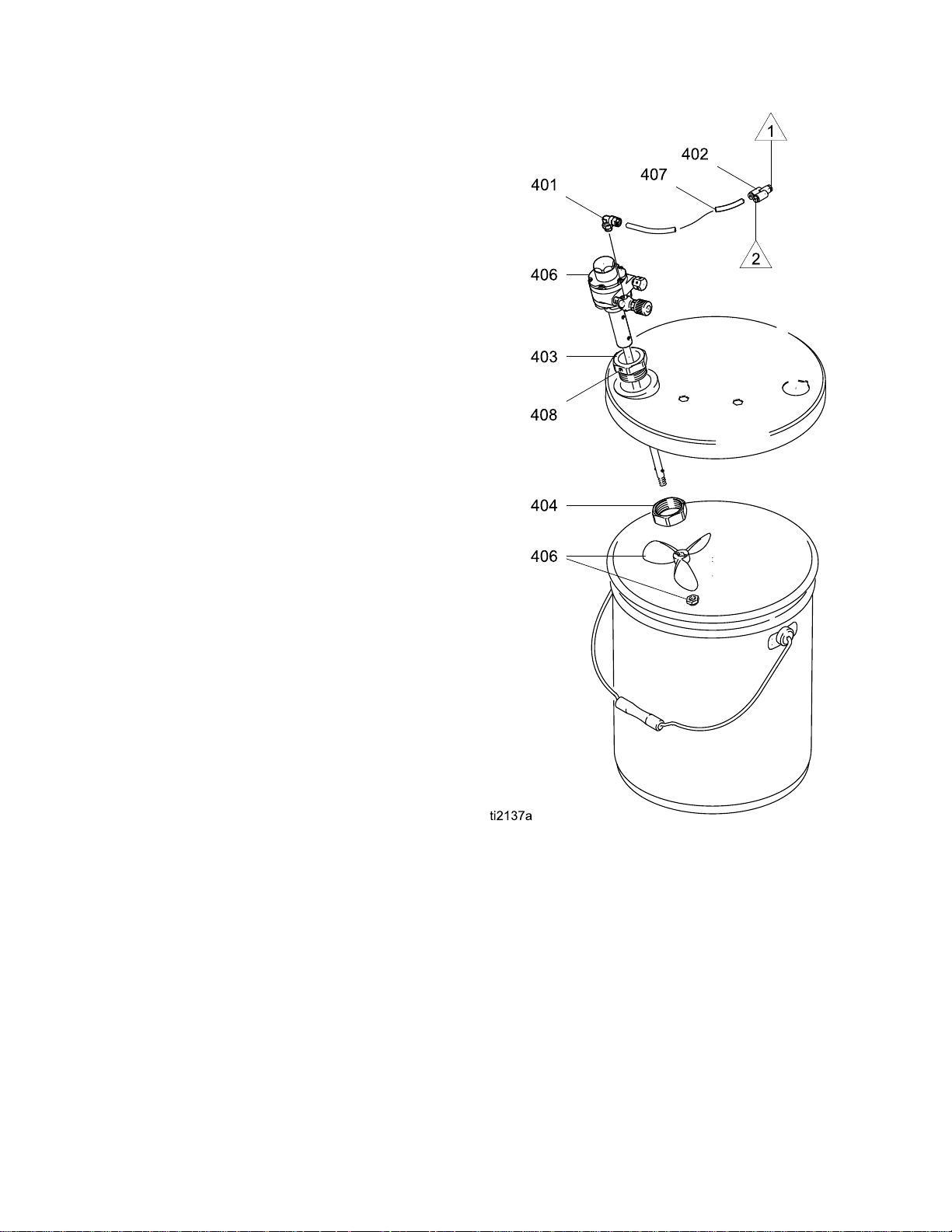

Agitator

Agitator Agitator

ToaddanagitatortotheGracoisolationsystem,order

PartNo.245895.See245895AgitatorKit,page72,

forthekitpartslist.

1.Dischargethesystemvoltage(seeFluidVoltage

DischargeandGroundingProcedure,page29).

2.Relievethepressure(see

PressureReliefProcedure,page28).

3.Opentheisolatedenclosuredoor.

4.Removethebackofthecontrolbox(258).

5.Removetube(A2)fromelbow(282)attheair

manifold;seeTubingandWiring,page62.

InstalltheYtting(402)intotheelbow.Install

tubes(A2)and(407)intotheYtting.Routethe

agitatortube(407)intothecabinet.

6.Replacethebackofthecontrolbox(258).

7.Assembletheotherpartsofthekitasshown.

Securetheagitatorwiththesetscrew(408).

8.Returnthesystemtoservice.

Kit

Accessory

Kit Kit

Accessory Accessory

Figure14245895AgitatorKit

22

3A2497H

Page 23

GunSetup

Gun

Gun Gun

Gun

Gun Gun

Toreducetheriskofreandexplosion,uidsused

mustmeetthefollowingammabilityrequirements:

•FM, FM,

•CE CE

Setup

Setup Setup

Setup

Setup Setup

FM,

FMc

FMc FMc

Materialdoesnotsustainburninginaccordance

withtheStandardTestMethodforSustained

BurningofLiquidMixtures,ASTMD4206.

CE

EN

- --EN EN

Materialisclassiedasnon-ignitableasdened

byEN50059:2018.

Formoreinformation,see

IgnitabilityofCoatingMaterials,page73.

Procedure

Procedure Procedure

Approved:

Approved: Approved:

50059

50059 50059

Compliant:

Compliant: Compliant:

Toreducetheriskofaninjury,followthe

PressureReliefProcedure,page28wheneveryou

areinstructedtorelievethepressure.

Seethegurebelowtolocatetheelectrostaticgun

controls.

Contactwiththechargedcomponentsofthespray

gunwillcauseanelectricshock.Donottouch

thegunnozzleorelectrodeorcomewithin4in.

(102mm)oftheelectrodeduringoperationor

untilperformingtheFluidVoltageDischargeand

GroundingProcedure,page29.

FollowtheFluidVoltageDischargeandGrounding

Procedure,page29whenyoustopsprayingand

wheneveryouareinstructedtodischargethe

voltage.

Toreducetheriskofcomponentrupture,which

cancauseseriousinjury,donotexceedthe

maximumworkingpressureofthelowestrated

systemcomponent.Thisequipmenthasa100psi

(0.7MPa,7bar)maximumairworkingpressure

anda3000psi(21MPa,210bar)maximumuid

workingpressure.

Figure15ElectrostaticGunControls

1.TurnOFF(O)theESOn-Offswitch(J).

2.Shutofftheairbleedvalvetothegun.

3A2497H23

Page 24

GunSetup

3.Checkgunresistance.See

TestGunResistance,page36.

4.FollowallstepsunderGrounding,page16.

5.Followallstepsunder

CheckGunElectricalGrounding,page26.

Readingmustbelessthan100ohms.

6.Connecttheexhausttubeandsecurewiththe

clampprovided.

7.Flushifneeded.SeeFlushing,page31.

Toreducetheriskofaskininjectioninjury,alwaysfollowthe

PressureReliefProcedure,page28,

beforeremovingorinstallingthespraytip,air

cap,ortipguard.

11.Closetheatomizingairadjustmentvalve(G)and

thefanairadjustmentvalve(F).

12.CheckthattheESOn-OffswitchisOFF(O).

13.Startthepump.Settheuidregulatorto400psi

(2.8MPa,28bar).

14.Sprayatestpattern.Examinetheparticlesizein

thecenterofthepattern(tailswillberemoved

instep18).Increasethepressureinsmall

increments.Sprayanotherpattern.Compare

particlesize.Continueincreasingpressureuntil

theparticlesizeremainsconstant.Donotexceed

3000psi(21MPa,210bar).

8.Theuidoutputandpatternwidthdepend

onthesizeofthespraytip,theuid

viscosity,andtheuidpressure.Usethe

SprayTipSelectionChart,page68,asaguide

forselectingtheappropriatespraytipforyour

application.

9.Alignthespraytiptabwiththegrooveintheair

cap.Installthetip.

10.Installtheaircapandretainingring.Orientate

theaircapandtightentheretainingringsecurely.

15.TurnON(I)theESOn-Offswitch.

24

3A2497H

Page 25

GunSetup

16.CheckthattheESindicator(Hzindicatoron

Smartguns)islit,orcheckthatthekVindicator

ontheisolatedenclosurereads30–50kV.

TheactualsprayingvoltageforAAwaterborne

systemsis40–50kV,butbecausethecharging

electrodedoesnotdirectlycontacttheuid,the

voltagemeasuredbytheWB3000kVmeterwill

be5–10kVlower.Seethefollowingtable.

Table

Table Table

Indicator

Indicator Indicator

Amber

LED

2 22. ..LED LED

Color

Color Color

Green

Red

Indicator

Indicator Indicator

Whenspraying,theindicator

shouldremaingreen,indicating

sufcientairpressuretothe

alternatorturbine.

Iftheindicatorturnsamberafter

1second,theairpressureistoo

low.Increaseairpressureuntil

theindicatorisgreen.

Iftheindicatorturnsredafter1

second,theairpressureistoo

high.Decreaseairpressureuntil

theindicatorisgreen.

Colors

Colors Colors

Description

Description Description

18.Turntheatomizingairadjustmentvalve

counterclockwiseuntilanytailsdisappear.

19.Ifdesiredatomizationisnotachieved,change

thetipsize.Thesmallerthetiporice,thener

theatomization.

20.Sprayatestpiece.Examinetheedges

forcoverage.Ifwrapispoor,see

Troubleshooting,page39.

17.Setthegunairregulatortodeliveraminimumof

45psi(0.32MPa,3.2bar)atgunwhentriggered,

toensurefullsprayingvoltage.Seethetable

below.

Table

Table Table

mm]

mm] mm]

Pressure

3 33. ..Pressure Pressure

Air

Hose

Air Air

Hose Hose

Length

Length Length

(using

(using (using

in ininft ftft(m) (m)

5/16

5/16 5/16

diameter

diameter diameter

15(4.6)52(0.36,3.6)

25(7.6)57(0.40,4.0)

50(15.3)68(0.47,4.7)

75(22.9)80(0.56,5.6)

100(30.5)90(0.63,6.3)

Drop

Drop Drop

Air

Air Air

(m)

in.

[8

in. in.

[8 [8

hose)

hose) hose)

Regulator

Regulator Regulator

psi

in ininpsi psi

[with

gun

[with [with

gun gun

Setting

Setting Setting

(MPa,

(MPa, (MPa,

bar)

bar) bar)

triggered]

triggered] triggered]

Note

Ifanarrowerpatternisneededoccasionally,

openthefanairadjustmentvalveslightly.

(Excessivefanairowcancausepaint

buildupontheaircap.)

3A2497H25

Page 26

GunSetup

Check

Check Check

MegohmmeterPartNo.241079(AA-seeFig.

14)isnotapprovedforuseinahazardousarea.

Toreducetheriskofsparking,donotusethe

megohmmetertocheckelectricalgrounding

unless:

•Thegunhasbeenremovedfromthehazardous

•Orallsprayingdevicesinthehazardousarea

Failuretofollowthiswarningcouldcausere,

explosion,andelectricshockandresultinserious

injuryandpropertydamage.

GracoPartNo.241079Megohmmeterisavailable

asanaccessorytocheckthatthegunisproperly

grounded.

1.Haveaqualiedelectricianchecktheelectrical

2.TurnOFF(O)theESOn-Offswitch.

Gun

Gun Gun

area;

areturnedoff,ventilationfansinthehazardous

areaareoperating,andtherearenoammable

vaporsinthearea(suchasopensolvent

containersorfumesfromspraying).

groundingcontinuityofthespraygunandair

hose.

Electrical

Electrical Electrical

Grounding

Grounding Grounding

6.Measuretheresistancebetweenthegunhandle

(BB)andatrueearthground(CC).Usean

appliedvoltageof500minimumto1000volts

maximum.Theresistanceshouldnotexceed

100ohms.SeeFig.14.

Figure16CheckGunElectricalGrounding

7.Iftheresistanceisgreaterthan100ohms,check

thetightnessofthegroundconnectionsandbe

suretheairhosegroundwireisconnectedtoa

trueearthground.Iftheresistanceisstilltoo

high,replacetheairhose.

8.Usinganohmmeter(AA)measuretheresistance

betweenthecabinetgroundlug(214)andatrue

earthground(CC).Theresistancemustbeless

than100ohms.

3.Turnofftheairanduidsupplytothegun.Follow

thePressureReliefProcedure,page28.

4.Disconnecttheuidhose.

5.Makesurethegroundedairhoseisconnected

andthehosegroundwireisconnectedtoatrue

earthground.

Figure17CheckCabinetGrounding

263A2497H

Page 27

GunSetup

Flush

Flush Flush

Theequipmentwastestedinuidatthefactory.To

avoidcontaminatingyouruid,ushtheequipment

withacompatiblesolventbeforeusingtheequipment.

SeeFlushing,page31.

Before

Before Before

Using

Using Using

Equipment

Equipment Equipment

3A2497H

27

Page 28

Operation

Operation

Operation Operation

Pressure

Pressure Pressure

Thisequipmentstayspressurizeduntilpressure

ismanuallyrelieved.Tohelppreventserious

injuryfrompressurizeduid,suchasskininjection,

splashinguidandmovingparts,followthe

PressureReliefProcedurewhenyoustopspraying

andbeforecleaning,checking,orservicingthe

equipment.

1.TurnOFF(O)theESOn/Offswitch.

2.FollowtheFluidVoltageDischargeand

GroundingProcedure,page29.

3.Engagethetriggerlock.

Relief

Relief Relief

Procedure

Procedure Procedure

5.Disengagethetriggerlock.

6.Triggerthegunintoagroundedmetalwaste

containertorelievetheuidpressure.

7.Engagethetriggerlock.

8.Openthepumpdrainvalve,havingawaste

containerreadytocatchthedrainage.Leave

thepumpdrainvalveopenuntilyouareready

tosprayagain.

4.Turnofftheairbleedvalvestotheuidsource

andtothegun.

9.Ifthespraytiporhoseiscompletelycloggedor

pressureisnotfullyrelieved,slowlyloosenthe

hoseendcoupling.Nowclearthespraytipor

hose.

283A2497H

Page 29

Operation

Operating

Operating Operating

Checkthefollowinglistdaily,beforestartingthe

system.

Alloperatorsareproperlytrainedtooperate

anelectrostaticwaterborneair-assistedspray

systemasinstructedinthismanual.

Alloperatorsaretrainedinthe

PressureReliefProcedure,page28.

Theelectrostaticsareturnedoffandsystem

voltageisdischargedaccordingtothe

FluidVoltageDischargeandGrounding

Procedure,page29,beforeanypersonen-

terstheisolationenclosure,beforecleaning,

andbeforeperforminganymaintenanceor

repair.

Thesystemisgroundedaccordingtothe

instructionsinGrounding,page16.

TheGracowaterborneuidhoseisingood

conditionwithnocutsorabrasionsofthe

innerlayer.Replacehoseifdamaged.

Ventilationfansareoperatingproperly.

Alldebris,includingammableuidsand

rags,isremovedfromthesprayarea.

Fluidsusedmustmeetthefollowing

ammabilityrequirements:

Checklist

Checklist Checklist

Fluid

Fluid Fluid

Grounding

Grounding Grounding

Theuidsupplyischargedwithhighvoltageuntil

thevoltageisdischarged.Contactwiththecharged

componentsofthevoltageisolationsystemor

spraygunelectrodewillcauseanelectricshock.

Toavoidanelectricshock,followtheFluid Fluid

Discharge

Discharge Discharge

•wheneveryouareinstructedtodischargethe

•beforecleaning,ushing,orservicingthesystem

•beforeapproachingthefrontofthegun

•orbeforeopeningtheisolationenclosureforthe

1.TurntheESON/OFFvalveOFFandwait30

Voltage

Voltage Voltage

and

and and

voltage

equipment

isolateduidsupply.

seconds,toallowthevoltagetodischarge

throughthebleedresistor.

Discharge

Discharge Discharge

Procedure

Procedure Procedure

Grounding

Grounding Grounding

and

and and

Fluid

Procedure:

Procedure: Procedure:

Voltage

Voltage Voltage

FM,

FMc

•FM, FM,

Materialdoesnotsustainburningin

accordancewiththeStandardTestMethod

forSustainedBurningofLiquidMixtures,

ASTMD4206.

CE

•CE CE

Materialisclassiedasnon-ignitableas

denedbyEN50059:2018.

Formoreinformation,see

IgnitabilityofCoatingMaterials,page73.

Approved:

FMc FMc

Approved: Approved:

EN

50059

- --EN EN

50059 50059

Compliant:

Compliant: Compliant:

2.FullyunscrewthedoorT-handlelockingscrew.

Thiswillshutofftheairtothegunandtriggerthe

groundingcylindertodischargeanyremaining

electricalcharge.

3.Usethegroundingrodtotouchthepump

andsupplypail.Ifyouseeanyarcs,see

ElectricalTroubleshooting,page43.

3A2497H29

Page 30

Operation

Fill

the

Fill Fill

1.FollowtheFluidVoltageDischargeand

2.FollowthePressureReliefProcedure,page28.

3.Opentheisolatedenclosuredoor.

4.Removethepailcoverfromthepail,holdingarag

5.Removethesupplypailfromtheenclosure.

6.Cleanupanyuidspillsintheenclosure,using

7.Fillthesupplypailwithuidandreturnittothe

8.Reinstallthepailcover,holdingaragoverthe

9.Closetheisolatedenclosuredoorandfasten

Startup

Startup Startup

FollowallstepsunderGunSetupProcedure,page23.

Fluid

the the

Fluid Fluid

GroundingProcedure,page29.

overthesuctiontubestrainertopreventanyuid

fromdrippingintotheisolatedenclosure.Place

thecoverandsuctiontubeoutsidetheenclosure.

Besuretowipeupalluidspillsintheisolated

enclosure.Fluidcancreateaconductivepath

andcausethesystemtoshortout.

asoftclothandanon-ammable,compatible

solvent.

enclosure.Cleanupanyspills.

suctiontubestrainertopreventuidspillswhile

youplacethepumpsuctiontubeinthepail.

securelywiththeT-handlelockingscrew.

Supply

Supply Supply

NOTICE

NOTICE NOTICE

•Theconditionofthegun’selectrical

componentshasbeencheckedasinstructedin

ElectricalTests,page36.

•Ventilationfansareoperatingproperly.

•Workpiecehangersarecleanandgrounded.

•Alldebris(includingammableuidsandrags)is

removedfromthesprayarea.

•Allammableuidsinthespraybootharein

approved,groundedcontainers.

•Allconductiveobjectsinthesprayareaare

electricallygroundedandtheoorofthespray

areaiselectricallyconductiveandgrounded.

Shutdown

Shutdown Shutdown

Toreducetheriskofaninjury,followthe

PressureReliefProcedure,page28wheneveryou

areinstructedtorelievethepressure.

1.Dischargethesystemvoltage.SeeFluidVoltage

DischargeandGroundingProcedure,page29.

2.Flushthegun.SeeFlushing,page31.

3.FollowthePressureReliefProcedure,page28.

4.Hangthegunfromitshook,withthenozzle

pointingdown.Besuretokeepthegunfrom

groundingout.

Checkthefollowinglistdaily,beforestartingto

operatethesystem,tohelpensureyouofsafe,

efcientoperation.

•Alloperatorsareproperlytrainedtosafelyoperate

anautomaticelectrostaticairspraysystemas

instructedinthismanual.

•Alloperatorsaretrainedinthe

PressureReliefProcedure,page28.

•Thewarningsignprovidedwiththegunismounted

inthesprayareawhereitcanbeeasilyseenand

readbyalloperators.

•Thesystemisthoroughlygroundedandthe

operatorandallpersonsenteringthesprayarea

areproperlygrounded.SeeGrounding,page16.

303A2497H

Page 31

Maintenance

Maintenance

Maintenance Maintenance

Daily

Daily Daily

Checkthefollowinglistdailyuponcompletionof

equipmentusage.

Care

Care Care

Flushthegun.SeeFlushing,page31.

Cleantheuidandairlinelters.

Cleantheoutsideofthegun.See

CleantheGunDaily,page33.

Cleantheaircapandspraytipdaily,at

aminimum.Someapplicationsrequire

morefrequentcleaning.Replacethespray

tipandaircapiftheyaredamaged.See

CleantheGunDaily,page33.

Checktheelectrodeandreplace

ifbrokenordamaged.See

ElectrodeReplacement,page45.

Checkforuidleakagefromthegunanduid

hoses.Tightenttingsorreplaceequipment

asneeded.

Checkelectricalgrounding.See

CheckGunElectricalGrounding,page26.

and

Cleaning

and and

Cleaning Cleaning

Checklist

Checklist Checklist

Flushing

Flushing Flushing

•Flushbeforechanginguids,beforeuidcandry

intheequipment,attheendoftheday,before

storing,andbeforerepairingequipment.

•Flushatthelowestpressurepossible.Check

connectorsforleaksandtightenasnecessary.

•Flushwithanon-ammablesolventthatis

compatiblewiththeuidbeingdispensedandthe

equipmentwettedparts.

Toreducetheriskofre,explosion,orelectric

shock,turnOFF(O)theESOn-Offswitchbefore

ushingthegun.

FollowtheFluidVoltageDischargeandGrounding

Procedure,page29,beforeushing.

Onlyush,purge,orcleanthegunwithuidsthat

meetthefollowingammabilityrequirements:

FM,

FMc

•FM, FM,

Materialdoesnotsustainburninginaccordance

withtheStandardTestMethodforSustained

BurningofLiquidMixtures,ASTMD4206.

CE

•CE CE

Materialisclassiedasnon-ignitableasdened

byEN50059:2018.

Formoreinformation,see

IgnitabilityofCoatingMaterials,page73.

Approved:

FMc FMc

Approved: Approved:

EN

50059

- --EN EN

50059 50059

Compliant:

Compliant: Compliant:

NOTICE

NOTICE NOTICE

Onlyusenon-ammablesolventswhenushing

orcleaningequipment.

1.TurnOFF(O)theESOn-Offswitch.Wait30

secondsforthevoltagetobleedoff.

2.Dischargethesystemvoltage.SeeFluidVoltage

DischargeandGroundingProcedure,page29.

3.FollowthePressureReliefProcedure,page28.

3A2497H31

Page 32

Maintenance

4.Removeandcleantheaircapandspraytip.

5.Changetheuidsourcetonon-ammable

solvent.

6.Pointthegunintoagroundedmetalpail.Flush

untilcleansolventowsfromthegun.

7.FollowthePressureReliefProcedure,page28.

Engagethetriggerlock.

8.Alignthespraytiptabwiththegrooveintheair

cap.Installthetip.

9.Reinstalltheaircap,tipguard,andretainingring.

10.Opentheisolatedenclosuredoor.Leavethe

ushinguidinthesystemuntilyouareready

tosprayagain.

11.Hangthegunfromitshook,withthenozzle

pointingdown.Besuretokeepthegunfrom

groundingout.

12.Beforeusingthesystemelectrostaticallyagain,

makesurenoammablevaporsarepresent.

323A2497H

Page 33

Maintenance

Clean

Clean Clean

1.TurnOFF(O)theESOn-Offswitch.

2.Dischargethesystemvoltage.SeeFluidVoltage

3.FollowthePressureReliefProcedure,page28.

4.Removetheaircap/tipguardandspraytip.

the

Gun

the the

Gun Gun

DischargeandGroundingProcedure,page29.

Daily

Daily Daily

7.Cleantheoutsideofthegunwithanon-ammable

solvent,asdenedunderFlushing,page31.

Useasoftcloth.Pointthegundowntoprevent

solventfromenteringthegunpassages.Donot

immersethegun.

5.Flushthegun,seeFlushing,page31.

6.FollowthePressureReliefProcedure,page28.

8.Cleantheaircap/tipguardandspraytipwitha

softbrushandnon-ammablesolvent.

3A2497H33

Page 34

Maintenance

9.Ifnecessary,useatoothpickorothersofttoolto

cleantheaircapholes.Donotusemetaltools.

10.Alignthespraytiptabwiththegrooveintheair

cap.Installthetip.

11.Installtheaircapandretainingring.Orientate

theaircapandtightentheretainingringsecurely.

343A2497H

Page 35

Maintenance

Daily

Daily Daily

1.Followtheinstructionsunder

2.Cleantheuidandairlters.

3.Checkforuidleaks.Tightenallttings.

4.Cleanworkpiecehangers.Usenon-sparking

5.Checkthemovementofthetriggerandvalves.

System

System System

CleantheGunDaily,page33.Follow

thePressureReliefProcedure,page28.

tools.

Lubricateifnecessary.

Care

Care Care

7.Hangthegunfromitshook,withthenozzle

pointingdown.

8.Cleanthecabinet:

•Inspectthecabinetandcleanupanyspilled

paint.Conductivepaintresidueallowedto

contactgroundedpartsmayshortoutthe

electrostatics.

•Keeptheinsideofthecabinetclean,forproper

operation.

•InspectthedoorT-handlelockingscrew

regularly,toensurethethreadsarewell

greased.Applysilicone-freegreasetothe

threadswhennecessary.

•Visuallyinspectthegroundstrip(240)

fordamage.Replaceifneeded.

Measuretheresistanceweekly.See

TestGroundStripResistance,page38.

6.CheckGunElectricalGrounding,page26.

3A2497H35

Page 36

ElectricalTests

Electrical

Electrical Electrical

Electricalcomponentsinsidethegunaffect

performanceandsafety.Usethefollowing

procedurestotesttheconditionofthepowersupply

andgunbody,andelectricalcontinuitybetween

components.

Thegunbodyresistorcartridgeispartofthebody

andisnotreplaceable.Toavoiddestroyingthegun

body,donotattempttoremovethebodyresistor.

UsemegohmmeterPartNo.241079(AA)withan

appliedvoltageof500V.Connecttheleadsas

shown.

MegohmmeterPartNo.241079(AA-seeFig.

17)isnotapprovedforuseinahazardousarea.

Toreducetheriskofsparking,donotusethe

megohmmetertocheckelectricalgrounding

unless:

Tests

Tests Tests

NOTICE

NOTICE NOTICE

Test

Test Test

1.Flushanddrytheuidpassage.

2.Measureresistancebetweentheelectrode

Gun

Gun Gun

needletip(25a)andtheairswivel(21).

Theresistanceshouldbe104–150

megohms.Ifoutsidethisrange,goto

TestPowerSupplyResistance,page37.Ifin

range,seeElectricalTroubleshooting,page43for

otherpossiblecausesofpoorperformance,or

contactyourGracodistributor.

Resistance

Resistance Resistance

•Thegunhasbeenremovedfromthehazardous

area;

•Orallsprayingdevicesinthehazardousarea

areturnedoff,ventilationfansinthehazardous

areaareoperating,andtherearenoammable

vaporsinthearea(suchasopensolvent

containersorfumesfromspraying).

Failuretofollowthiswarningcouldcausere,

explosion,andelectricshockandresultinserious

injuryandpropertydamage.

Figure18TestGunResistance

363A2497H

Page 37

ElectricalTests

Test

Test Test

1.Removethepowersupply(11).SeePower

2.Removethealternator(15)

3.Measureresistancefromthepowersupply's

4.Besurethespring(11a)isinplacebefore

Power

Power Power

SupplyRemovalandReplacement,page48.

fromthepowersupply.See

AlternatorRemovalandReplacement,page49.

groundstrips(EE)tothespring(11a).The

resistanceshouldbe90–115megohms.Ifoutside

thisrange,replacethepowersupply.Ifinrange,

gotoTestGunBarrelResistance,page37.

reinstallingthepowersupply.

Supply

Supply Supply

Resistance

Resistance Resistance

3.Iftheresistanceisstilloutsidetherange,

removetheconductivering(9)andmeasurethe

resistancebetweentheconductiverod(B)and

thewireleadatthebottomoftheconductivering

groove.

4.Iftheresistanceisinrange,replacethe

conductivering(9)withanewone.Insertthe

endsoftheconductiveringintotheslots(S)at

thefrontofthebarrel,thenpresstheringrmly

intothegroove(G).

NOTICE

NOTICE NOTICE

Theconductivering(9)isaconductivemetal

contactring,notasealingo-ring.Forbest

performanceandtoavoidpotentialdamageto

thespraygun,donotremovetheconductive

ring(9)excepttoreplaceitandneveroperate

thegunwithouttheconductiveringinplace.

Donotreplacetheconductiveringwith

anythingbutagenuineGracopart.

Figure19TestPowerSupplyResistance

Test

Test Test

1.Insertaconductiverod(B)intothegunbarrel

2.Measuretheresistancebetweentheconductive

Gun

Gun Gun

(whichwasremovedforthepowersupplytest)

andagainstthemetalcontact(C)inthefrontof

thebarrel.

rod(B)andtheconductivering(9).The

resistanceshouldbe10–30megohms.Ifthe

resistanceisincorrect,makesurethemetal

contact(C)inthebarrelandtheconductivering

(9)arecleanandundamaged.

Barrel

Barrel Barrel

Resistance

Resistance Resistance

5.Iftheresistanceisstilloutsidetherange,replace

thegunbarrel.

Figure20TestGunBarrelResistance

3A2497H37

Page 38

ElectricalTests

Test

Test Test

Usinganohmmeter,measuretheresistancebetween

thelatchhousing(206)andthegroundlug(214).

Thegroundstripisgroundedthroughthecartback

tothegroundlug.Resistancemustbelessthan100

ohms.Ifgreaterthan100ohms,replacetheground

strip(240).

Ground

Ground Ground

Strip

Strip Strip

Resistance

Resistance Resistance

Test

Test Test

Removetheenclosuredoor.Usinganohmmeter,

measuretheresistancefromthepump(209)tothe

groundlug(214).Resistancemustbelessthan

100ohms.Ifgreaterthan100ohms,replacethe

groundingcylinder.

Cylinder

Cylinder Cylinder

Resistance

Resistance Resistance

Figure21TestGroundStripResistance

Figure22TestCylinderResistance

383A2497H

Page 39

Troubleshooting

Troubleshooting

Troubleshooting Troubleshooting

•Fluidintheairpassages

Installingandservicingthisequipmentrequires

accesstopartswhichmaycauseanelectricshock

orotherseriousinjuryiftheworkisnotperformed

properly.Donotinstallorservicethisequipment

unlessyouaretrainedandqualied.

FollowtheFluidVoltageDischargeandGrounding

Procedure,page29beforecheckingorservicing

thesystemandwheneveryouareinstructedto

dischargethevoltage.

Toreducetheriskofaskininjectioninjury,always

followthePressureReliefProcedure,page28,

wheneveryouareinstructedtorelievethe

pressure.

CheckallpossibleremediesintheTroubleshooting

Chartbeforedisassemblingthegun.

Voltage

Voltage Voltage

Normalsprayingvoltageforasystemusingthe

waterbornegunis40–50kV.Thesystemvoltageis

lowerduetosprayingcurrentdemandsandvoltage

isolationsystemlosses.

Alossofsprayingvoltagecanbecausedbya

problemwiththespraygun,uidhose,orvoltage

isolationsystem,sinceallofthesystemcomponents

areelectricallyconnectedthroughtheconductive,

waterborneuid.

Beforetroubleshootingorservicingthevoltage

isolationsystemitself,youneedtodeterminewhich

componentinthesystemismostlikelycausinga

problem.Possiblecausesincludethefollowing:

Spray

Spray Spray

•Fluidleakage

•Dielectricbreakdownattheuidhoseconnection

oruidpackings

•Notenoughairpressureforthealternatorturbine

•Faultypowersupply

•Excessiveoversprayongunsurfaces

Loss

Loss Loss

Gun

Gun Gun

Troubleshooting

Troubleshooting Troubleshooting

Waterborne

Waterborne Waterborne

•Dielectricfailureofthehose(pin-holeleakinthe

innerlayer)

•Airgapintheuidcolumnbetweenthegunandthe

isolateduidsupply,causingalowvoltagereading

ontheisolationsystemvoltagemeter.

Voltage

Voltage Voltage

•Fluidleakage

•Dirtyinterior

Visual

Visual Visual

First,checkthesystemforanyvisiblefaultsorerrors

tohelpisolatewhetherthespraygun,uidhoseor

voltageisolationsystemhasfailed.Avoltageprobe

andmeter,partno.245277,ishelpfulfordiagnosing

voltageproblemsandisrequiredforsomeofthe

troubleshootingteststhatfollow.

1.Checkthatalloftheairanduidtubesandhoses

2.Checkthatthevoltageisolationsystemvalves

3.Checkthattheinterioroftheisolatedenclosure

4.Checkthatthespraygunandvoltageisolation

5.CheckthatthegunESON/OFFvalveisinthe

6.Checkthatthevoltageisolationsystem's

7.Makesurethevoltageisolationsystemisin

8.Toeliminateairgapsintheuidcolumn,spray

Checks Checks

areproperlyconnected.

andcontrolsareproperlysetforoperation.

isclean.

systemhavesufcientairpressure.

ONpositionandthatthegunESindicatorlight

ison.IftheESindicatorlightisnoton,remove

thespraygunforserviceandcompletethe

ElectricalTests,page36.

enclosuredoorisclosedandthatanysafety

interlocksareengagedandworkingproperly.

the“isolate”mode,whereitisisolatingtheuid

voltagefromground.

enoughuidtopurgetheairoutbetweenthe

voltageisolationsystemandthespraygun.An

airgapintheuidhosecanbreaktheelectrical

continuitybetweenthespraygunandtheisolated

uidsupplyandcausealowvoltagereadingon

avoltagemeterconnectedtotheisolateduid

supply.

Fluid

Hose

Fluid Fluid

Hose Hose