Page 1

Setup - Parts

HFRS Tandem

3A2264A

Supply System Kit

For use with non-heated bulk supply of medium to high viscosity sealants and adhesive

materials. For professional use only.

Not approved for use in European explosive atmosphere locations.

EN

125 psi (0.9 MPa, 9 bar) Maximum Air Inlet Pressure - S20 3 in. rams

150 psi (1.0 MPa, 10 bar) Maximum Air Inlet Pressure - D200 3 in. rams

Important Safety Instructions

Read all warnings and instructions in manual

3A2175. Save all instructions.

24M226 Assembly Shown

r_24m226_cover

Page 2

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Kit Description . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Pneumatic Crossover System Components . . . . 6

Integrated Air Controls . . . . . . . . . . . . . . . . . . . . 8

Air Line Accessories . . . . . . . . . . . . . . . . . . . . . . 8

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Ram Installation and Setup . . . . . . . . . . . . . . . . . 9

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 10

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Prime . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Ram Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Pump Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Crossover Schematics . . . . . . . . . . . . . . . . . . . 14

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pneumatic Crossover . . . . . . . . . . . . . . . . . . . . 15

D200 Ram Tube Connection Diagram . . . . . . . 16

S20 Ram Tube Connection Diagram . . . . . . . . . 17

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Tandem Supply System - D200 . . . . . . . . . . . . . 18

Tandem Supply System - S20 . . . . . . . . . . . . . . 20

Pneumatic Crossover Kits . . . . . . . . . . . . . . . . . 22

Pump Outlet Check Valve Kits . . . . . . . . . . . . . 25

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 28

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . 28

2 3A2264A

Page 3

Related Manuals

Component Manuals in U.S. English:

Manual Description

313526 Supply Systems Operation

313527 Supply Systems Repair-Parts

312375

312376

312889

312374 Air Controls Instructions-Parts

Check-Mate

Instructions-Parts

Check-Mate

Instruction-Parts

60 cc Check-Mate Displacement Pump

Repair-Parts

®

Displacement Pumps

®

Pump Packages

Related Manuals

3A2264A 3

Page 4

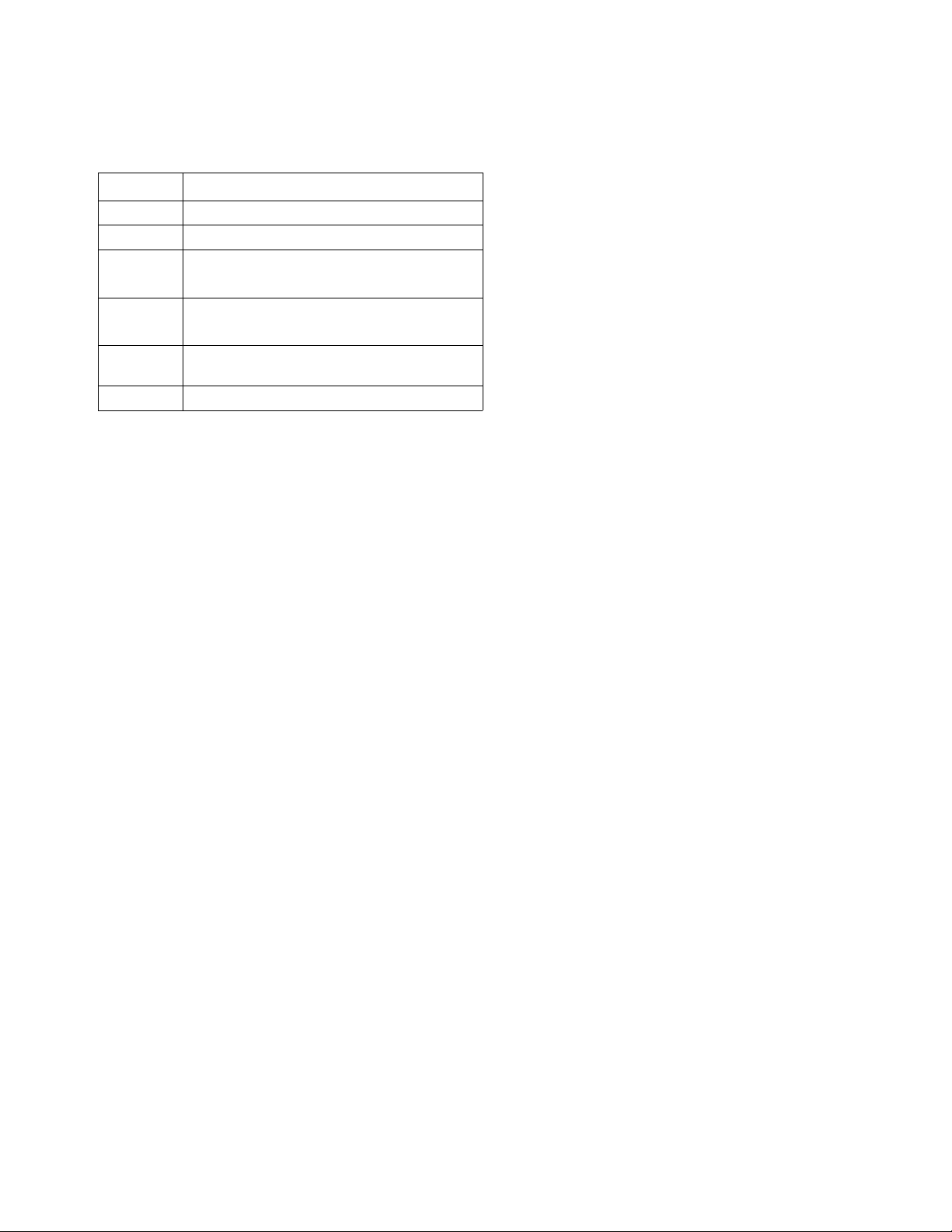

Models

Models

Check the identification plate (ID) for the 6-digit part number of your tandem system.

ID

To order replacement parts, see Parts starting on page 18.

Each tandem supply kit consists of one single air-powered r

components necessary to configure all pneumatic tandem supply system controls. This kit must be added to an identical single ram supply system (identified with the model information) with supply hoses to make up a complete tandem supply unit. This kit is intended only f

manual 3A2175). Attempts to integrate with other systems may not be functional and may require additional parts.

Model Description

24M226 Tandem Crossover Kit, 20:1, 55 gallon, Carbon Steel CM7A59

24M227 Tandem Crossover Kit, 20:1, 55 gallon, Stainless Steel CM7C58

24M228 Tandem Crossover Kit, 20:1, 5 gallon, Carbon Steel CM7A3C

24M229 Tandem Crossover Kit, 20:1, 5 gallon, Stainless Steel CM7C3F

or use with HFRS systems that include a D200 or S20 supply system (See

am supply system and supply hose, as well as all the

o Be Installed with

T

Existing Supply

System

4 3A2264A

Page 5

Overview

Kit Description

Each tandem supply kit consists of one single air-powered ram supply system and supply hose, as well as all

he components necessary to configure all pneumatic

t

tandem supply system controls. This kit must be added

to an identical single ram supply system (identified with

the model information) with supply hoses to make up a

complete tandem supply unit. This kit is intended only

for use with HFRS systems that include a D200 or S20

supply system (See manual 3A2175). Attempts to integrate with other systems may not be functional and may

quire additional parts.

re

Keep clear of the inactive ram, as automatic crossover

may occur unexpectedly. To repair or adjust the ram, first

follow all steps of the Pressure Relief Procedure on

page 10.

Overview

3A2264A 5

Page 6

Overview

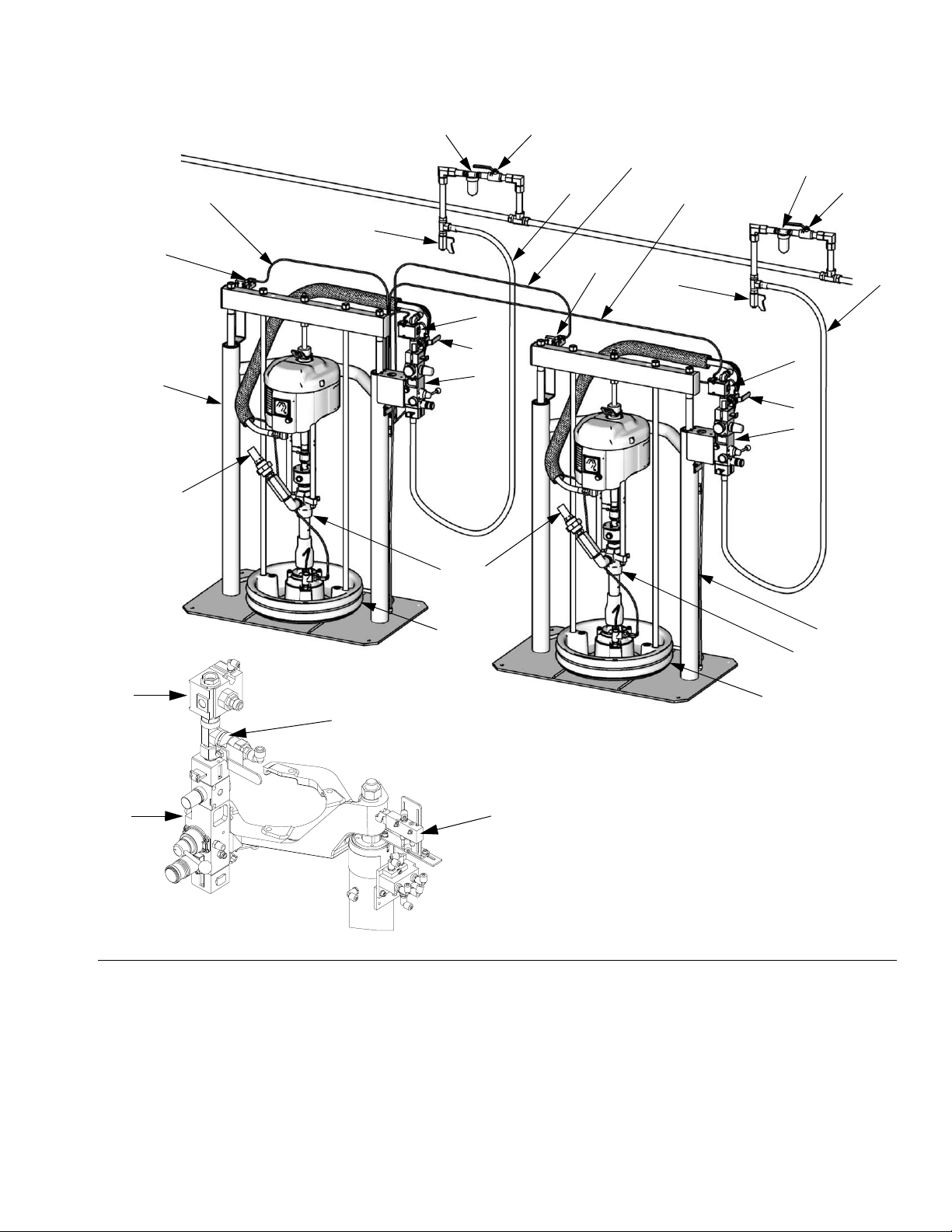

Pneumatic Crossover System Components

NOTE:

D200, and S20 sizes are used in pneumatic crossover systems.

FIG. 1. shows a pneumatic crossover system. Refer to

manual 313526 (supplied) for ram installation and operating instructions. The pneumatic crossover operates as

follows:

During system operation, as the ram approaches the

drum bottom, the top of the ram contacts the limit switch

(E). The limit switch shuts off air to the air motor via a

solenoid valve (Y), which stops air flow to one motor and

starts air flow to the other air motor. This allows continu

ous material flow and changing of material drums.

The position of the limit switch (E) on the ram determines when the air motor is turned off. Start by positioning the limit switch to trip when the ram platen (D) is 1 in.

(25 mm) from the bottom of the drum. During operation

the position may be adjusted as desired.

The bypass valve (L) allows you to prime the inactive

pump after a drum change. Open the valve to prime the

pump. Close the valve when priming is complete, and

during normal operation.

-

6 3A2264A

Page 7

Overview

Typical Crossover System Diagram

AA

E

A

S

V

W

AB

T

AC

V

W

U

E

U

T

Y

L

Y

H

L

H

S

C

D

D200 Rams Shown

Y

L

H

S20 Ram Shown

FIG. 1: Component Identification, Pneumatic Crossover

Key to FIG. 1:

ARam A

BRam B

C Pump (Ram A and B)

D Platen (Ram A and B)

E Limit Switch (Ram A and B)

H Integrated Air Controls (Ram A and B); see page 8

L Bypass Valve (Ram A and B)

S Fluid Line (not supplied)

C

D

E

T Main Air Line (not supplied)

U Air Line Drain Valve (not supplied)

V Air Filter (not supplied)

W Bleed-Type Air Shutoff Valve (not supplied)

Y Solenoid Valve (Ram A and B)

AA Cable from Ram A to Limit Switch A

AB Cable from Ram A to Limit Switch B

AC Main Crossover Cable; from Ram A to Solenoid B

B

TI11160A

3A2264A 7

Page 8

Overview

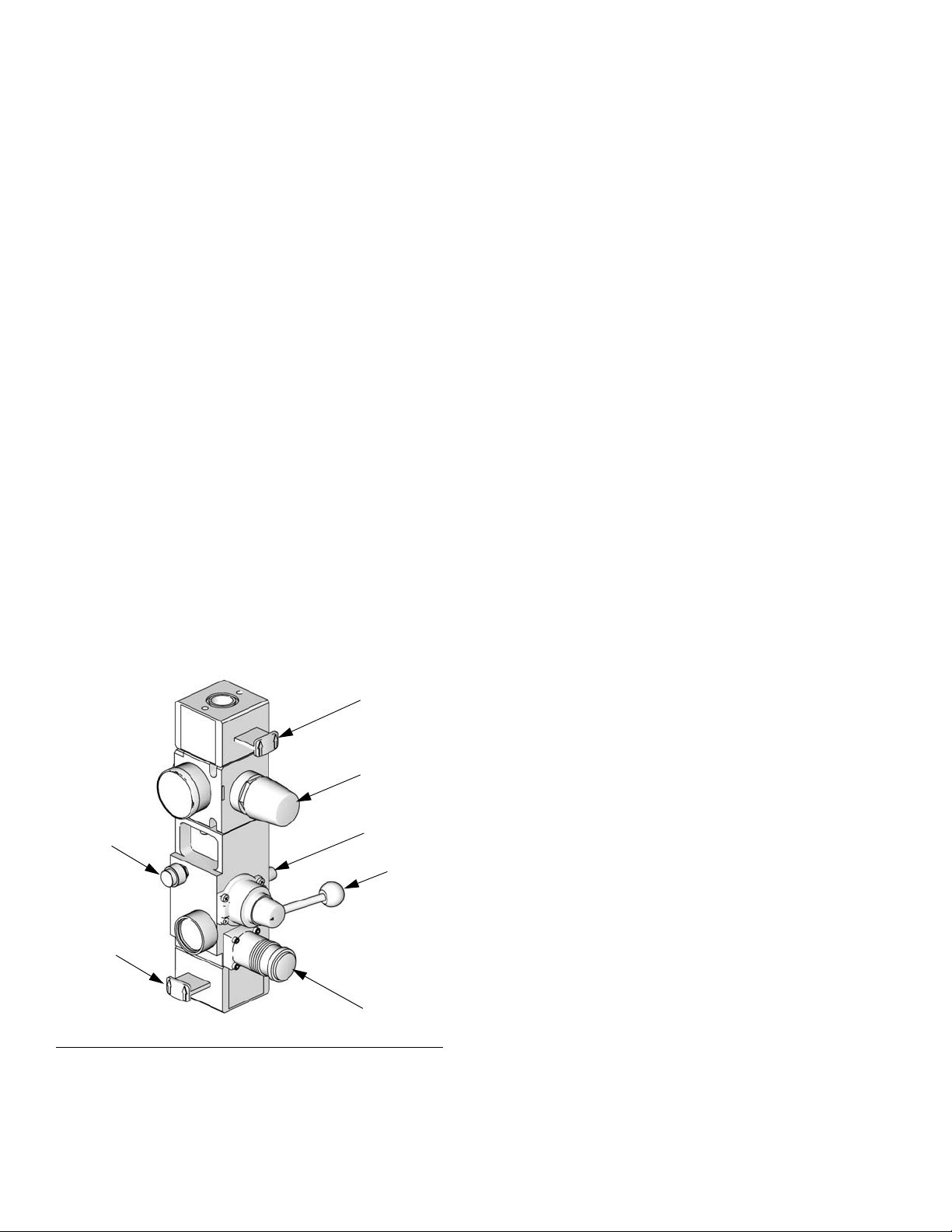

Integrated Air Controls

The integrated air controls include:

• Main air slider valve (BA): tu

the system. When closed, the valve relieves pressure downstream.

• Ram air regulator (BB): cont

pressure and blowoff pressure.

• Ram director

• Exhaust port with muffler (BD)

• Air motor regulator (BE): Cont

motor.

• Air m

otor slider valve (BF): turns air on and off to

the air motor. When closed, the valve relieves air

trapped between it and the air motor. Push the valve

in to shutoff. Remote DataTrak: The air solenoid

IG. 1), the air motor slider valve (BF), and the

(Y, F

main air slider valve (BA) must be open for air to

low. (See Remote DataTrak Setup section in Supply

f

Systems operation manual 313526.)

valve (BC): controls ram direction.

rns air on and off to

rols ram up and down

rols air pressure to

Air Line Accessories

See FIG. 1.

• Air line drain valve (U)

r line filter (V): removes harmful dirt and mois-

• Ai

ture from compress

• Sec

• Ai

ond bleed-type air valve (W): isolates air line

accessories and supply system for servicing. Locate

upstream from all other air line accessories.

r relief valve (attached to ram air regulator, not

visible): automatically relieves excessive pressure.

ed air supply.

• Blo

F

woff button (BG): turns air on and off to push

the platen out of an empty drum.

BG

BA

IG. 2. Integrated Air Controls

TI10438A

BF

BE

BD

BC

BB

8 3A2264A

Page 9

Setup

Setup

Ram Installation and Setup

1. Install and set up individual rams as explained in

manual provided.

2. Install outlet check valve assemblies on each ram.

Refer to page 25.

3. Install pneumatic crossover kits components on

each ram.

a. See pilot valve assembly drawing on page 22.

b. Identify and locate the integrated air control

module.

c. Remove the air hose and air fitting from the top

of the integrated air control module.

NOTE: Leave the hose attached to the air motor on the

other end

d. Install the pilot valve assembly on top of the

integrated air control module as shown on page

22.

k. Tube the system using the appropriate D200 or

S20 tubing drawing.

NOTE: The table on the drawing shows tubing cut

lengths. Using longer tube lengths will require additional

tubing (not provided).

4. When tubing is complete, slowly extend rams to the

full up and full down positions and take note how the

tubing moves.

5. Secure tubing in place with tape or wire ties.

NOTICE

To avoid machine damage and ensure proper operation, verify tubes are not pinched, kinked, or pulled

taught where they are secured when the rams are

raised or lowered.

e. Install removed fitting from step c into port 1 of

the pilot valve assembly.

f. Remove plug located on the integrated air con-

trol moduel and replace it with a tube fitting.

(See item 209 on page 22).

g. Install the crossover valve assembly on the ram

cylinder as shown on page 22. This assembly

will be installed on only one ram.

h. See tubing drawing on page 16 (D200 Ram

Tube Connection Diagram) or page 17 (S20

Ram Tube Connection Diagram) for location

of level switch assembly.

i. Install level switch assembly to the top of the

ram cylinder as shown on page 23.

j. Calibrate the switch to trip when the follower is

about 2 in (51 mm) above the ram base.

3A2264A 9

Page 10

Pressure Relief Procedure

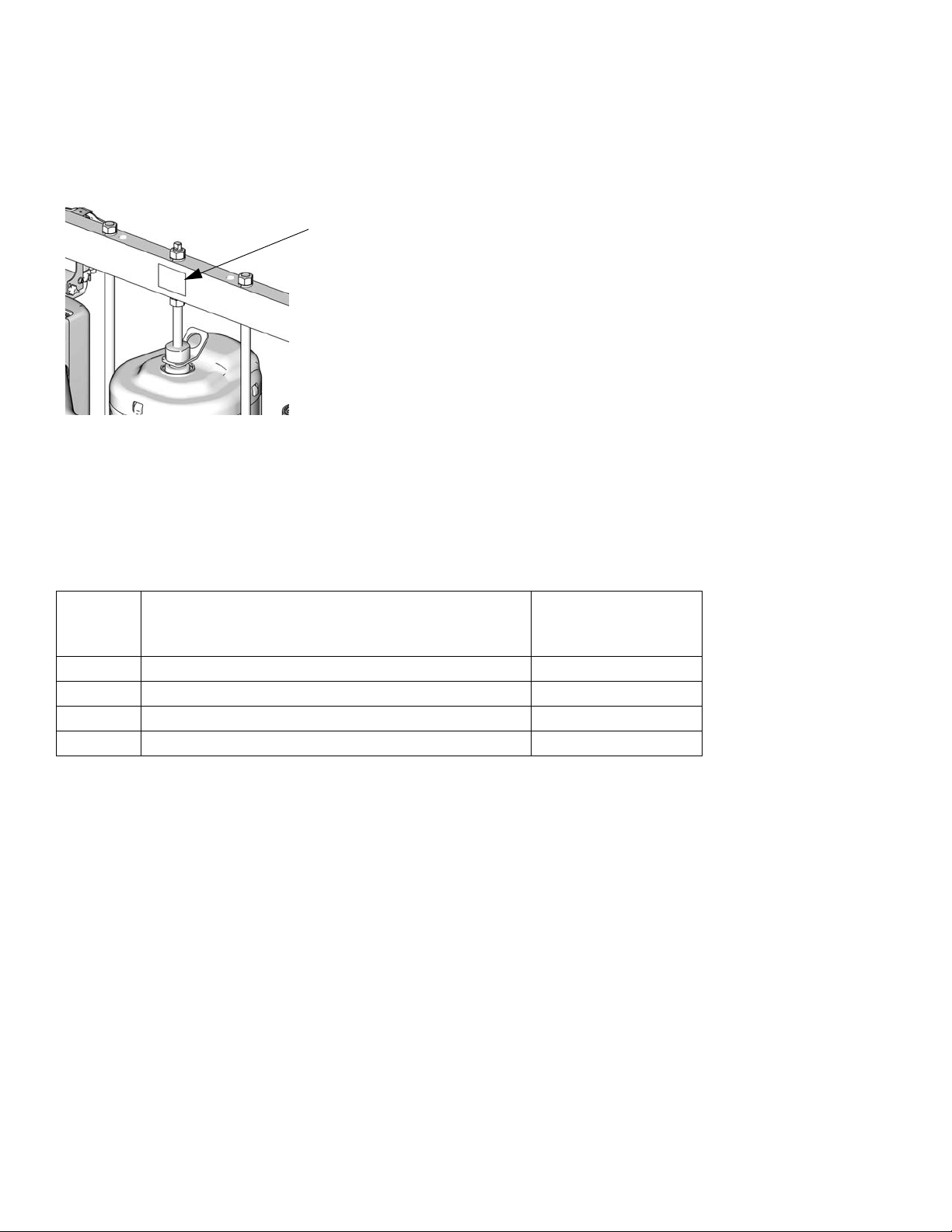

Grounding

The equipment must be grounded. Grounding reduces

the risk of static and electric shock by providing an

escape wire for the electrical current due to static build

up or in the event of a short circuit.

Pump: use g

grounding lug locknut and washer. Insert ground wire

end into lug slot and tighten locknut securely. Connect

ground clamp to a true earth ground.

Air and fluid hoses: use on

hoses with a maximum of 500 ft. (150 m) combined

hose length to ensure grounding continuity. Check electrical resistance of hoses. If to

exceeds 29 megohms, replace hose immediately.

Air compressor:

tions.

round wire and clamp (supplied). Loosen

ly electrically conductive

tal resistance to ground

follow manufacturer’s recommenda-

Pressure Relief

Procedure

NOTE: Refer to FIG. 2 on page 8 for the following proce-

dure.

1. Turn off the air motor slider valve (BF) on both ram A

d B.

an

2. On both ram A and B, turn off the main air slider

valve (BA). Set the ram director valve (BC) to the

down position. The ram will slowly drop.

3. Perform Pressure Relief Procedure of the HFR

system. See manual 3A2175.

4. On both ram A and B, open the drain valve and/or

the pump bleed port. Have a container ready to

catch the drainage.

Dispense valve: g

erly grounded fluid hose and pump.

Fluid supply container: f

Solvent pails used when flushing: f

Use only conductive metal pails, placed on a grounded

surface. Do not place the pail on a nonconductive surface, such as paper or cardboard, which interrupts

rounding continuity.

g

To maintain grounding continuity when flushing or

lieving pressure: hold metal part of the dispense

re

valve firmly to the side of a grounded metal pail, then

trigger the valve.

round through connection to a prop-

ollow local code.

ollow local code.

If you suspect that the spray tip/nozzle or hose is completely clogged, or that pressure has not been fully

ved after following the steps above, very slowly

relie

loosen the tip guard retaining nut or hose end coupling

and relieve pressure gradually, then loosen completely.

Now clear the tip/nozzle or hose.

10 3A2264A

Page 11

Startup

Startup

Flush Before Using Equipment

The pump was tested with lightweight oil, which is left in

the fluid passages to protect parts. To avoid contaminating your fluid with oil, flush the pump with a compatible

ent before use. See your pump manual for flushing

solv

directions.

1. Perform Setup on pa

2. Verify the following:

• That you have equal line air pressure supplied

o both A & B units within 5 psi (35 kPa, 0.3 bar)

t

of each other.

• The Bypass/Prime ball valves (item L in F

page 7) are closed,

• That the air motor regulators are adjusted to

30 psi (210 kPa, 2.1 bar)

To prevent pump seal damage, adjust the pressure

wn if the motor cycles too rapidly during the follow-

do

ing test procedure

ge 9.

IG. 1,

NOTICE

10. Move to the current “Active” ram and lower it to the

bottom.

11. Verify that the cross bar contacts and actuates the

Air Limit Valve when lowered and that the Ram

Crossover occurs.

NOTE: Th

become “Inactive” and the opposite ram motor should

begin to cycle becoming “Active”).

12. Verify that the Bypass/Prime function works on the

13. Close Bypass/Prime ball valve.

14. Lower the “Active” ram to the bottom. Verify that

NOTE: Wh

ram is still lowered, a crossover should not occur. A

crossover in this condition could be caused by an air

leak, unequal supply line pressures, or a problem with

the 4-way Remote Air Valve.

15. Raise the opposit ram.

e motor of the ram lowered should stop and

nactive” ram by opening the Bypass/Prime ball

“I

valve. The “Inactive” ram motor should begin to

cycle (the “Active” ram should continue to cycle).

Ram Crossover does not occur.

en an Active ram is lowered while the Inactive

3. Position both A & B units about half way up, place in

“N

eutral”, and open both motor isolation slider

valves (item BA in F

4. Verify that only one ram unit motor cycles.

5. Go to the “Active” ram with the cycling motor and

lower it to the bottom.

6. Verify that the cross bar contacts and actuates the

Air Limit Valve when lowered and that the Ram

Crossover occurs.

NOTE: T

become “Inactive” and the opposite ram motor should

begin to cycle becoming “Active”).

7. Verify that the Bypass/Prime function works on the

8. Close the Bypass/Prime ball valve.

9. Raise the “Inactive” ram about half way and place in

he motor of the ram lowered should stop and

nactive” ram by opening the Bypass/Prime ball

“I

valve. The “Inactive” ram motor should begin to

cycle (the “Active” ram should continue to cycle).

“Neutral”.

IG. 2 on page 8).

. Verify that crossover occurs when the Air Limit Valve

16

is deactivated. Lower the same ram and verify that

Ram Crossover does NOT occur.

17. Startup Complete.

3A2264A 11

Page 12

Shutdown

Shutdown

Turning the system OFF relieves pressure from the

pump motor. It does not depressurize the fluid pressure. Follow the Pressure Relief Procedure, page

10.

The tandem supply controls do not effect essential system operation.

The tandem controls act to allow only one of the two

mp air motors to run at any given time, unless the

pu

pilot valve is bypassed. To manually activate the air

motor, open the bypass ball valve (F

system functions are not effected by the tandem controls.

1. Follow the procedure defined in the supply system

nual for shutdown.

ma

IG. 1, item L). Other

Prime

If the pump being primed is not the active pump, it will

be necessary to activate the air motor by opening the

bypass ball valve (F

1. Follow the procedure defined in the supply system

nual for priming.

ma

2. After priming, close the bypass ball valve to allow

the level sensors to shutdown the air motor.

IG. 1, item L).

12 3A2264A

Page 13

Troubleshooting

Troubleshooting

NOTE: Refer to the Supply System Repair-Parts

manual for specific ram troubleshooting. Refer to

the Check-Mate Pump Packages manual for pump

troubleshooting.

Problem Cause Verification Solution

Does not crossover. Alternate ram has an empty

sensor activated.

Alternate pump is not

primed.

Level switch not adjusted to

trip properly.

1. Follow Pre

disassembling any part of the supply system.

2. Disconnect power before repairing the supply system.

3. Check all possible problems and causes before disassembling the supply system.

Verify ram has material. Replace empty drum.

Verify alternate ram is

ready to run.

Verify level switches activate at desired low level

point.

ssure Relief Procedure, page 10, before

Prime pump.

Adjust level switch.

3A2264A 13

Page 14

Repair

Repair

Ram Repair

See manual 313527 for ram and platen repair procedures and replacement parts.

Pump Repair

See pump manuals for pump repair procedures and

replacement parts.

See manual 312796 for air motor repair procedures and

replacement parts.

Crossover Schematics

See page 15 for a schematic of pneumatic crossover

systems.

14 3A2264A

Page 15

Schematics

Pneumatic Crossover

P1

LEVEL

RAM B

SWITCH

V2

2

315

Schematics

4

A2

LEVEL

RAM A

SWITCH

A2

RAM B

V1

3(CYL)

PILOT

REMOTE

1(IN)

PILOT

VALV E

2

P2

315

C2C1

2(EX)

VALV E

RAM B

BYPASS

V2

INTEGRATED

AIR CONTROL

4

ESTCODE

PUMP

RAM B

RAM B

AIR

V2

INLET

A1

RAM A

3(CYL)

PILOT

REMOTE

1(IN)

2(EX)

PILOT

VALV E

VALV E

RAM A

BYPASS

INTEGRATED

AIR CONTROL

M1

ESTCODE

PUMP

RAM A

RAM A

AIR

P1

INLET

A

A1

B

A

A2

B

P2

IN

EX

V1

M1

TEE

V1

3A2264A 15

Page 16

Schematics

D200 Ram Tube Connection Diagram

C1

M1

A2

P1

A1C1

V1 P2 C2 C2 P1

V2

A1

P2

V1

A2

V2

M1

Tube Size

Tag

A1 1/4 36 (914) Pilot air to switch on Unit A air motor

A2 1/4 180 (4572) Pilot air to switch on Unit B air motor

C1 3/8 6.5 (165) Bypass air - Unit A

C2 3/8 6.5 (165) Bypass air - Unit B

M1 1/4 20 (508) Main air to 4-way valve

P1 1/4 180 (4572) Pilot air to switch from Unit B to A

P2 1/4 68 (1727) Pilot air to switch from Unit A to B

V1 1/4 68 (1727) Supply air to limit valve - Unit A

V2 1/4 68 (1727) Supply air to limit valve - Unit B

16 3A2264A

(in.)

Length

in (mm) Function

Page 17

S20 Ram Tube Connection Diagram

Schematics

C1

C1

M1

A1

P2

V1

P1

A2

A1

M1

P2

V1

C2

C2

A2

P1

V2

V2

Tube Size

Tag

A1 1/4 61 (1550) Pilot air to switch on Unit A air motor

A2 1/4 180 (4572) Pilot air to switch on Unit B air motor

C1 3/8 6.5 (165) Bypass air - Unit A

C2 3/8 6.5 (165) Bypass air - Unit B

M1 1/4 49 (1245) Main air to 4-way valve

P1 1/4 180 (4572) Pilot air to switch from Unit B to A

P2 1/4 7 (178) Pilot air to switch from Unit A to B

V1 1/4 12 (305) Supply air to limit valve - Unit A

V2 1/4 49 (1245) Supply air to limit valve - Unit B

3A2264A 17

(in.)

Length

in (mm) Function

Page 18

Parts

Parts

Tandem Supply System - D200

003

Supply System A

005,

006

004

002

003

003

Supply System B

003

005,

006

002

007

001

009 (2x)

008 (2x)

006

18 3A2264A

Page 19

Quantity

Ref Part Description

24M226, KIT,

upgrade, 20:1,

pxover, 55 gallon,

carbon

24M227, KIT,

upgrade, 20:1,

pxover, 55 gallon,

stainless

001 CM7A59 SUPPLY UNIT, 20:1, 0 volt, d200 1

CM7C58 SUPPLY UNIT, 20:1, 0 volt, d200 1

002 257377 KIT, pump outlet check 2

255452 KIT, pump outlet, check, carbon steel 2

003 255675 KIT, pneumatic cross-over 1 1

004 24F726 HOSE, assy, 3/4id, female/male, sst 1

24M225 HOSE, coupled, 180l, 3/4id 1

005 C19661 BUSHING, reducing 2

006 124406 FITTING, adapter, 3/4npt x 12jic 3

15M863 FITTING, connector, male 1

007 801787 FITTING, tee, pipe 3\4 1

113833 TEE, pipe, female 1

008 122763 FITTING, elbow, straight, 3/4npt, 90, ss 2

122327 FITTING, elbow, street 2

009 6303-21 ADAPTER, swvl, jic12x3/4npt, feamle/male 2

124433 FITTING, swivel, 3/4nptx12jic, male/female, sst 2

Parts

3A2264A 19

Page 20

Parts

Tandem Supply System - S20

004

005,

006

002

Supply System A

007

003

Supply System B

003

005,

006

002

001

009 (2x)

008 (2x)

006

20 3A2264A

Page 21

Quantity

Parts

Ref Part Description

24M228, KIT,

upgrade, 20:1,

pxover, 5 gallon,

carbon

24M229, KIT,

upgrade, 20:1,

pxover, 5 gallon,

stainless

001 CM7A3C SUPPLY UNIT, 20:1, 0 volt, s20, 20l 1

CM7C3F SUPPLY UNIT, 20:1, 0 volt, s20, 20l 1

002 257377 KIT, pump outlet check 2

255452 KIT, pump outlet, check, carbon steel 2

003 257373 KIT, pneumatic xover 1 1

004 24F726 HOSE, assy, 3/4id, 180l, feamle/male, sst 1

24M225 HOSE, cpld, 180l, 3/4id 1

005 C19661 BUSHING, reducing 2

006 124406 FITTING, adapter, 3/4npt x 12jic 3

15M863 FITTING, connector, male 1

007 801787 FITTING, tee, pipe 3\4 1

113833 TEE, pipe, female 1

008 122763 FITTING, elbow, straight, 3/4npt, 90 2

122327 FITTING, elbow, street 2

009 6303-21 ADAPTER, swivel, jic12x3/4npt, female/male 2

124433 FITTING, swivel, 3/4nptx12jic, male/female 2

3A2264A 21

Page 22

Parts

Pneumatic Crossover Kits

255675, for 3 in. D200 Rams

257373 for S20 Rams

Pilot Valve Assembly 255675

229

202

201

203

206

207

205

204

206

208

209

Pilot Valve Assembly 257373

207

206

229

235

206

203

202

201

233

205

208

204

209

223

221

TI10932A

Typical Crossover Valve

Assembly

222

230

226

229 229

r_257373_313529_2a

229

224

214

225

229

225

TI10941A

22 3A2264A

Page 23

Pneumatic Crossover Kits (continued)

Level Switch Assembly 255675

Parts

218

217

228

216

226

229

226

211

215 214

210

216

219

229

220

228

213

212

214

215

222

221

TI10942A

Level Switch Assembly 257373

229

211

222

213

218

219

217

220

226

229

3A2264A 23

212

221

226

210

214

215

r_257373_313529_1a

Page 24

Parts

Pneumatic Crossover Kits

Ref. Part Description Qty

201 111337 TEE, street; 3/4 npt(m) x 3/4 npt(f) x 3/4 npt(f) 2

202 C20487 NIPPLE, hex; 3/4 npt 2

203 C59752 VALVE, pneumatic, 3-way. 2

204 113218 VALVE, ball, vented; 3/4 npt (m x f) 2

205 C12508 HOSE, nylon; 3/8 in. (10 mm) OD; 6 in. (153 mm);

black

206 C19683 BUSHING, reducing; 3/4 npt(m) x 3/8 npt(f) 4

207 115240 FITTING, tube; 3/8 npt(m) x 3/8 in. (10 mm) OD tube 2

208 115436 ELBOW, tube, 90°; 3/8 npt(m) x 3/8 in. (10 mm) OD

tube

209 116658 FITTING, tube; 1/4 npt(m) x 1/4 in. (6 mm) OD tube 2

210 --- BRACKET, crossover 2

211 --- BRACKET, limit valve; for D200 rams 2

--- BRACKET, limit valve; for S20 rams 2

212 104116 WASHER, plain; #10 4

213 111820 SCREW, cap, socket hd; 10-24 x 3/4 in. (19 mm) 4

214 C19204 WASHER, lock; #10 6

215 100179 NUT, hex mscr; 10-24 4

216 C06182 VALVE, limit, air 2

217 100813 WASHER, flat 4

218 C19965 SCREW, cap, socket-hd; 6-32 x 1-1/4 in. (31 mm) 4

219 100068 WASHER, lock, spring; #6 4

220 100072 NUT, hex mscr; 6-32 4

221 100016 WASHER, lock; 1/4 6

222 101682 SCREW, cap, socket-hd; 1/4-20 x 5/8 in. (16 mm) 6

223 --- PLATE, mounting, 4-way valve 1

224 113338 VALVE, air, remote, 4-way 1

225 123366 SCREW, cap, socket-hd; 10-24 x 1-1/8 in. (29 mm) 2

226 C06061 MUFFLER 5

228 100139 PLUG, pipe; 1/8 npt 2

229 597151 ELBOW, tube; 1/8 npt(m) x 1/4 in. OD tube 12

230 110475 TEE, street; 1/8 npt(m) x 1/8 npt(f) x 1/8 npt(f) 1

231 C12509 TUBE, nylon; 1/4 in. (6 mm) OD; 52 ft (15.9 m); black AR

232★ 114958 STRAP, tie 4

233 104969 BUSHING, reducing; for S20 rams 2

235 100896 BUSING, reducing 2

AR

2

★ Not shown.

--- Not for sale.

24 3A2264A

Page 25

Pump Outlet Check Valve Kits

255452, used on carbon steel Check-Mate 60 and 100 Displacement Pumps (shown)

257377, used on stainless steel Check-Mate 60 and 100 Displacement Pumps

5

Ref. Description 255452 257377

401 UNION, pipe; 1-1/4 in. npt(f) 521975

CONNECTOR; 3/4 npt(m) x 1

in. unf

402 NIPPLE, hex; 1-1/4 in. npt C20490

NIPPLE, hex; 1-1/4 in. npt

NIPPLE, reducing; 1 in. npt x

3/4 npt

403 VALVE, check; 1-1/4 in. npt

(fbe)

VALVE, check; 3/4 npt (fbe) C59546

404 ELBOW, street, 90°; 1 in. npt (m

x f)

ELBOW; 3/4 npt (m x f) 15M864

521850

C38324

15M863

Ref. Description 255452 257377

ELBOW; 1-1/2 in. npt (f x f)

405 BUSHING, reducing; 1 in.

npt(m) x 3/4 npt(f)

NIPPLE, reducing; 1-1/4 in. npt

x 1 in. npt

NIPPLE, reducing; 1 in. npt x

3/4 npt

BUSHING, reducing; 1-1/2 npt

x 1-1/4 npt (fbe)

COUPLING, reducing; 1-1/2 in.

npt x 1 in. npt (fbe)

Parts

C19661

4.

401

402

403

404

405

TI10888A

255455 Shown

401

402

403

402

405

404

r_255455_313529_1f

3A2264A 25

Page 26

Technical Data

Technical Data

Max air input pressure (supply system) psi (MPa, bar) / Air inlet size

S20 - 3 in. single post, 5 gal. (20 L) . . . . . . . . . . . . . . 125 (0.9, 9) / 1/2 npt(f)

D200 - 3 in. dual post, 55 gal. (200 L), 30 gal. (115 L),

16 gal. (60 L), 8 gal. (30 L), 5 gal. (20 L). . . . . . . . . . 150 (1.0, 10) / 3/4 npt(f)

Max fluid, air working pressure, and weigh

(displacement pump) . . . . . . . . . . . . . . . . . . . . . . . . . For Check-Mate pump packages, see manual 312376.

Pump Wetted parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . For Check-Mate displacement pumps, see manual

312375.

Ambient operating temperature range (supply system) 32-120 °F (0- 49°C)

Sound data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See separate air motor manual.

26 3A2264A

Page 27

Technical Data

3A2264A 27

Page 28

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective par ts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Toll Free: 1-800-746-1334 or Fax: 330-966-3006

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2011, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 3A2264

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Loading...

Loading...