Page 1

Repair - Parts

3A2176J

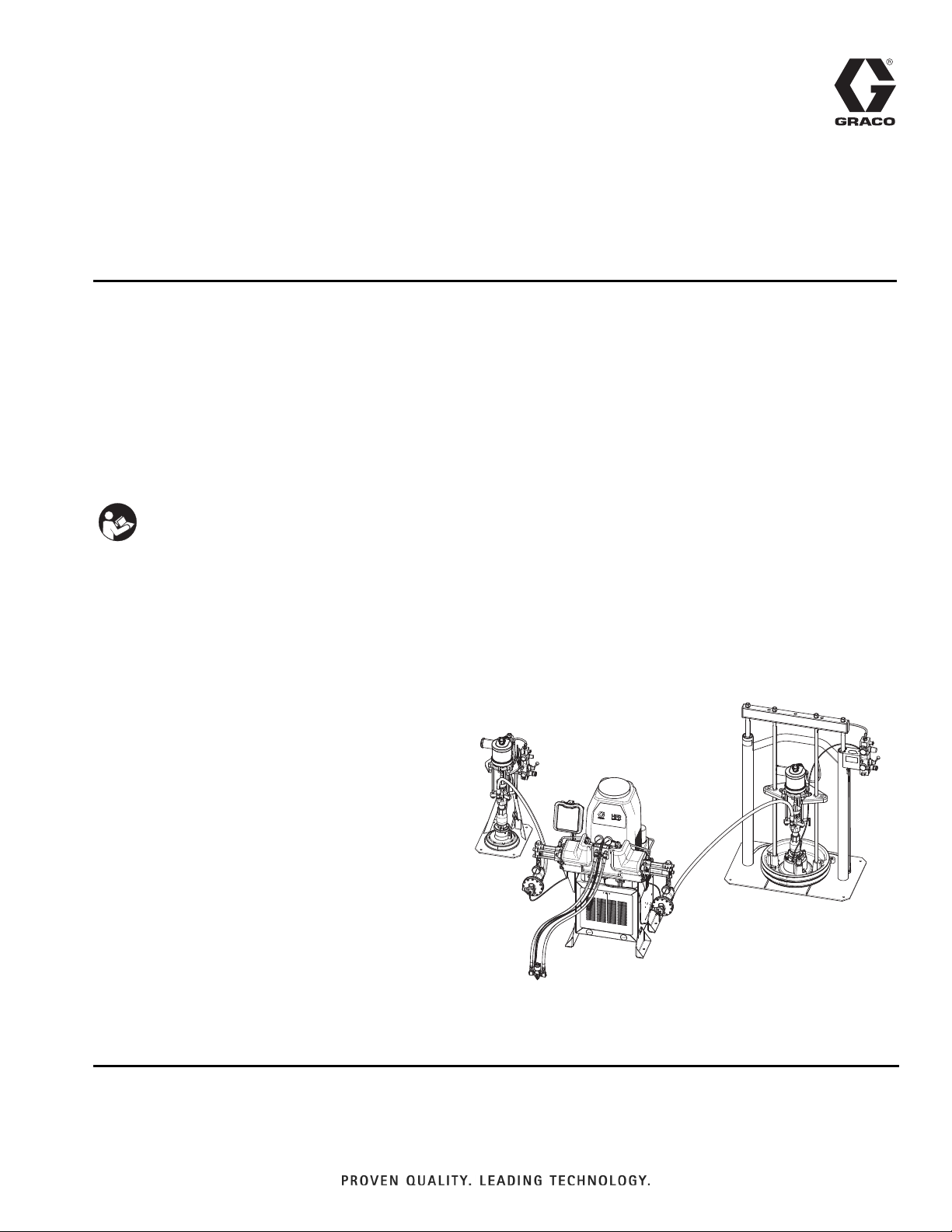

HFRL and HFRS

Hydraulic, Plural-Component, Fixed-Ratio Proportioner.

For pouring and dispensing laminates and silicones.

For professional use only. Not approved for use in explosive atmospheres or hazardous

locations.

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

EN

See page 4 for model information and maximum

working pressure.

ti18208a

Silicone unit shown.

Page 2

Contents

Related Manuals ...........................3

Models ...................................4

HFR-Laminate (HFRL) ....................4

HFR-Silicone (HFRS) .....................6

Warnings ................................10

Important Two-Component Material Information 14

Isocyanate Conditions .................... 14

Material Self-ignition .....................14

Keep Components A (Red) and B (Blue) Separate

14

Moisture Sensitivity of Isocyanates ..........14

Changing Materials ......................15

A (Red) and B (Blue) Components ............ 15

Operation ................................16

Shutdown .............................16

Pressure Relief Procedure ................16

Flushing .............................. 17

Repair ...................................18

Pumpline ..............................18

Hydraulic Power Pack Repair ..............25

Replace Power Supply ...................31

Replace Circuit Breaker ..................31

Parts ....................................32

HFRL Models .......................... 32

HFRS Models ..........................34

Base Module ........................... 40

Power Pack Module ...................... 44

Hydraulic DC Power Pack Module, 257442 .... 46

Power Modules, 24M034 & 24M035 ......... 48

Power Panels, 24M030 & 24M031 .......... 50

Fluid Outlet Modules, 24M167 & 24M168 ..... 52

Fluid Manifolds, 255629 & 289999 ..........54

Fluid Inlet Assembly, 24M129 (HFRL) ........56

Fluid Inlet Assemblies, 24M132 & 24M133 (HFRS)

58

Dispense Hose Assembly Kits ............. 60

Inlet Hose Assembly Kits ................. 62

Lubrication Kit, 24M154 .................. 63

Logic Drawings ...........................64

230V, 1 Phase .........................64

400V, 3 Phase ..........................65

DC Hydraulic Power Pack ................. 66

Motor Control Module (MCM) .............. 67

Accessories ..............................69

Technical Data ............................ 70

Motor Control Module Technical Data ........71

Graco Standard Warranty ...................72

Graco Information .........................72

2 3A2176J

Page 3

Related Manuals

Manuals are available at www.graco.com.

Component manuals in U.S. English:

System Manuals

3A2175 HFRL and HFRS Setup-Operation

Pumpline Manuals

3A0019 Z-Series Chemical Pumps Instructions-Parts

3A0020

Feed System Manuals

3A0235 Feed Supply Kits Instructions-Parts

Dispense Valve Manuals

312185 MD2 Valve, Instructions-Parts

Accessory Manuals

HFR™Hydraulic Actuator Instructions-Parts

Related Manuals

3A1149 HFR Discrete Gateway Module Kits Manual

3A2176J 3

Page 4

Models

Models

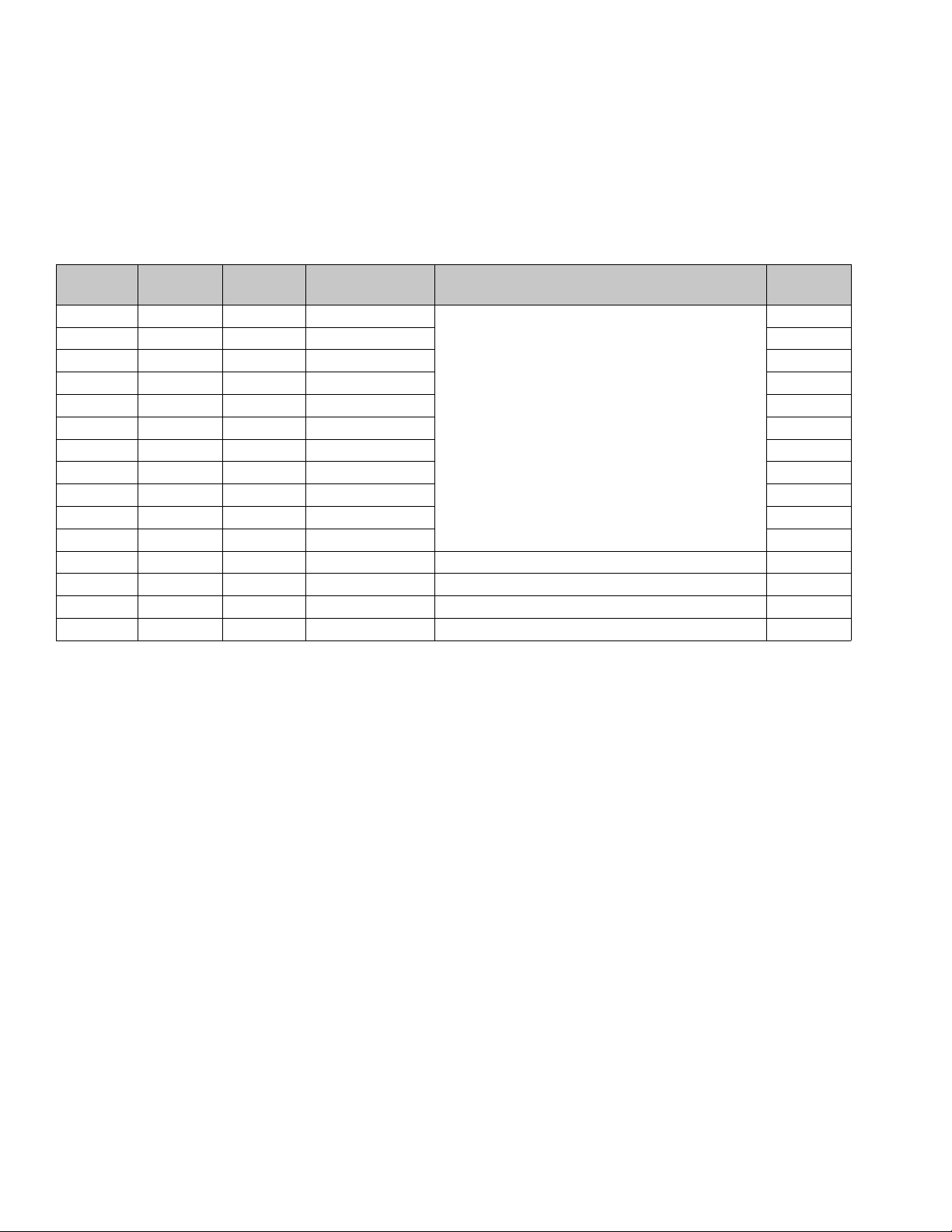

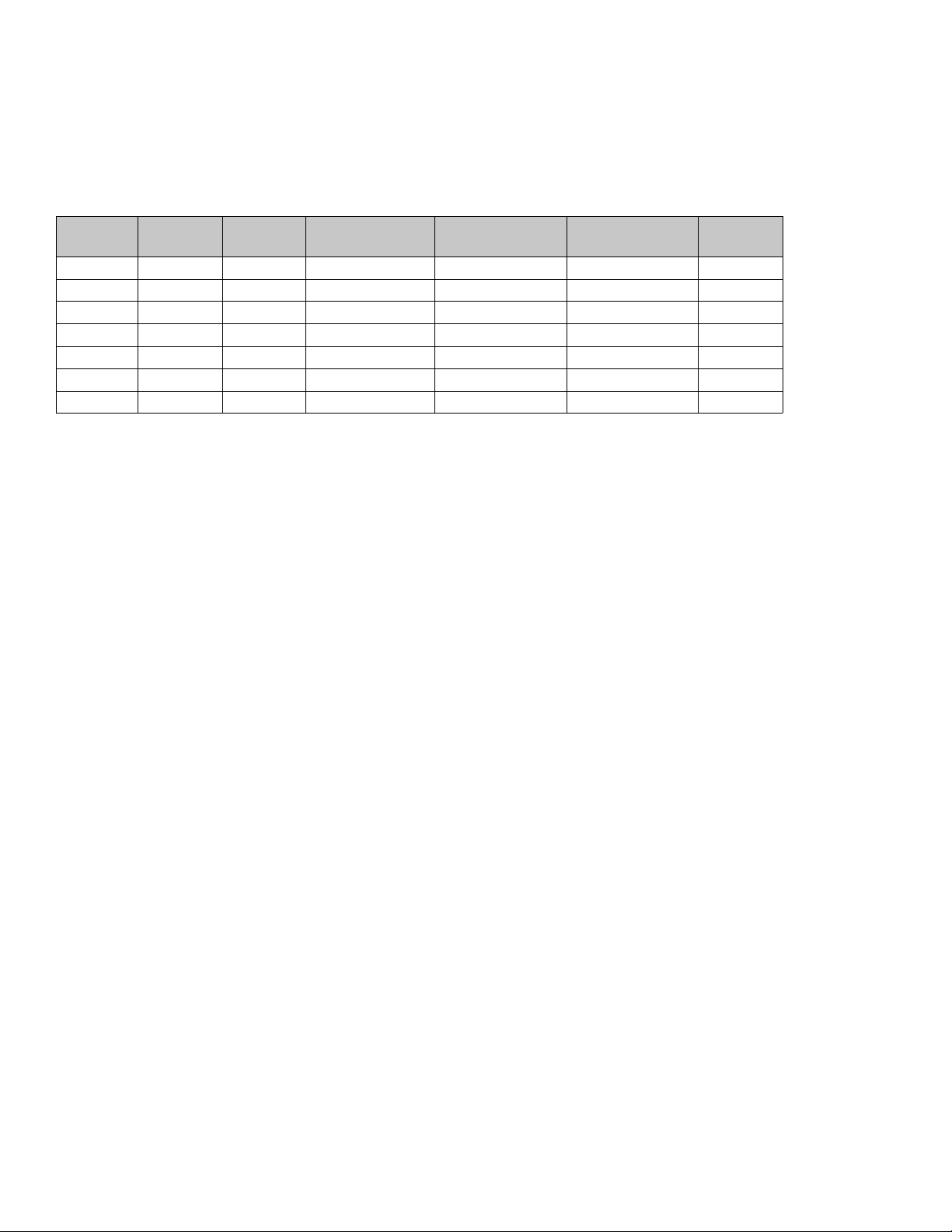

HFR-Laminate (HFRL)

HFRL models are designed for use with low viscosity, unheated urethane laminating adhesives at flow rates of up to

30 cc/sec (4 lb/min) @ 1500 psi (10 MPa, 103 bar).

A Pump

Size

160 86 246 8

100 86 186 10 1.16

86 80 166 11 1.08

80 80 160 12 1.00

80 65 145 13 1.23

80 60 140 13 1.33

80 50 130 14 1.60

86 40 126 15 2.15

60 50 110 17 1.20

65 40 105 18 1.63

60 40 100 19 1.50

60 25 85 20 28 (3.7) 2.40

50 30 80 20 26 (3.5) 1.67

50 25 75 20 25 (3.3) 2.00

50 20 70 20 23 (3.1) 2.50

** Cycle rate should be between 8 and 20 cycles per minute. Max flow rate is determined for continuous service at

120°F (39°C) at stated cpm and pressure. Higher cycle rates are possible at lower temperatures/pressures and

intermittent use. Lower cycle rates may be possible, but should be tested under application conditions.

B Pump

Size cc/cycle

Required cpm@

Flow**

Max Flow †

cc/sec (lb/min) @ 1500 psi (10 MPa, 103 bar) Ratio

1.86

30 (4)

† Dispense rate in excess of max flow and pressure may result in an elevated temperature of the hydraulic system,

resulting in a thermal shutdown (T4H1). Other system models are available for sustained flow rates and pressures

in excess of above.

4 3A2176J

Page 5

Models

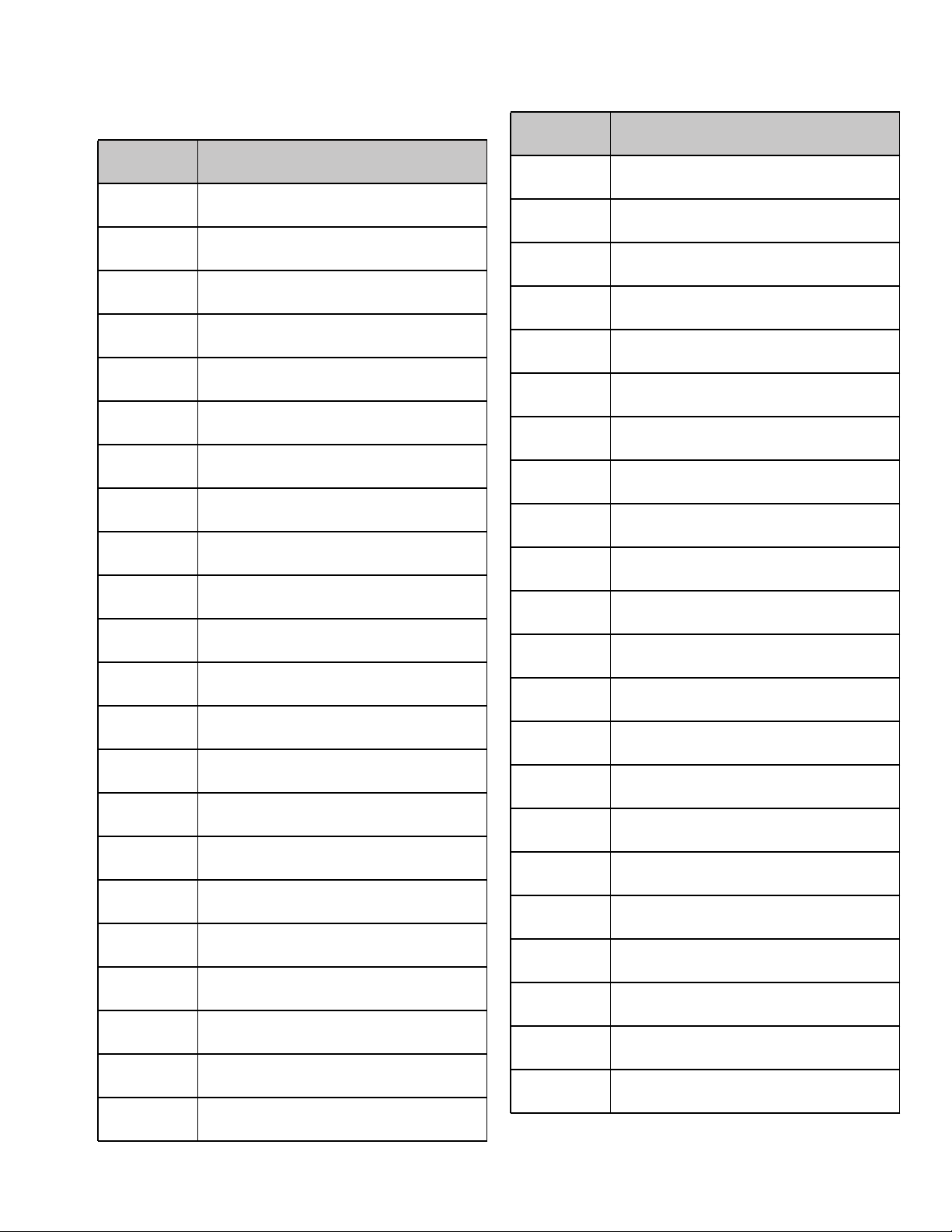

HFRL Models

Part Number Description

HFRL01 HFR for Lamination, 230/1, 1.00:1,

80/80, Carbon Steel

HFRL02 HFR for Lamination, 230/1, 1.08:1,

86/80, Carbon Steel

HFRL03 HFR for Lamination, 230/1, 1.16:1,

100/86, Carbon Steel

HFRL04 HFR for Lamination, 230/1, 1.20:1,

60/50, Carbon Steel

HFRL05 HFR for Lamination, 230/1, 1.23:1,

80/65, Carbon Steel

HFRL06 HFR for Lamination, 230/1, 1.33:1,

80/60, Carbon Steel

HFRL07 HFR for Lamination, 230/1, 1.50:1,

60/40, Carbon Steel

HFRL08 HFR for Lamination, 230/1, 1.60:1,

80/50, Carbon Steel

HFRL09 HFR for Lamination, 230/1, 1.63:1,

65/40, Carbon Steel

HFRL10 HFR for Lamination, 230/1, 1.67:1,

50/30, Carbon Steel

HFRL11 HFR for Lamination, 230/1, 1.86:1,

160/86, Carbon Steel

HFRL12 HFR for Lamination, 230/1, 2.00:1,

50/25, Carbon Steel

HFRL13 HFR for Lamination, 230/1, 2.15:1,

86/40, Carbon Steel

HFRL14 HFR for Lamination, 230/1, 2.40:1,

60/25, Carbon Steel

HFRL15 HFR for Lamination, 230/1, 2.5:1,

50/20, Carbon Steel

HFRL16

★✖

HFRL17

★✖

HFRL18

★✖

HFRL19

★✖

HFRL20

★✖

HFRL21

★✖

HFRL22

★✖

HFR for Lamination, 400/3, 1.00:1,

80/80, Carbon Steel

HFR for Lamination, 400/3, 1.08:1,

86/80, Carbon Steel

HFR for Lamination, 400/3, 1.16:1,

100/86, Carbon Steel

HFR for Lamination, 400/3, 1.20:1,

60/50, Carbon Steel

HFR for Lamination, 400/3, 1.23:1,

80/65, Carbon Steel

HFR for Lamination, 400/3, 1.33:1,

80/60, Carbon Steel

HFR for Lamination, 400/3, 1.50:1,

60/40, Carbon Steel

Part Number

HFRL23

★✖

HFRL24

★✖

HFRL25

★✖

HFRL26

★✖

HFRL27

★✖

HFRL28

★✖

HFRL29

★✖

HFRL30

★✖

★ approved.

✖ See 400 V Power Requirements.

Description

HFR for Lamination, 400/3, 1.60:1,

80/50, Carbon Steel

HFR for Lamination, 400/3, 1.63:1,

65/40, Carbon Steel

HFR for Lamination, 400/3, 1.67:1,

50/30, Carbon Steel

HFR for Lamination, 400/3, 1.86:1,

160/86, Carbon Steel

HFR for Lamination, 400/3, 2.00:1,

50/25, Carbon Steel

HFR for Lamination, 400/3, 2.15:1,

86/40, Carbon Steel

HFR for Lamination, 400/3, 2.40:1,

60/25, Carbon Steel

HFR for Lamination, 400/3, 2.5:1,

50/20, Carbon Steel

400 V Power Requirements

• 400 V systems are intended for International voltage

requirements. Not for voltage requirements in North

America.

• If a 400 volt configuration is operated in North America, a special transformer rated for 400 V (“Y” configuration (4 wire)) may be required.

• North America mostly employs a 3 wire or Delta

configuration. The two configurations are not interchangeable.

3A2176J 5

Page 6

Models

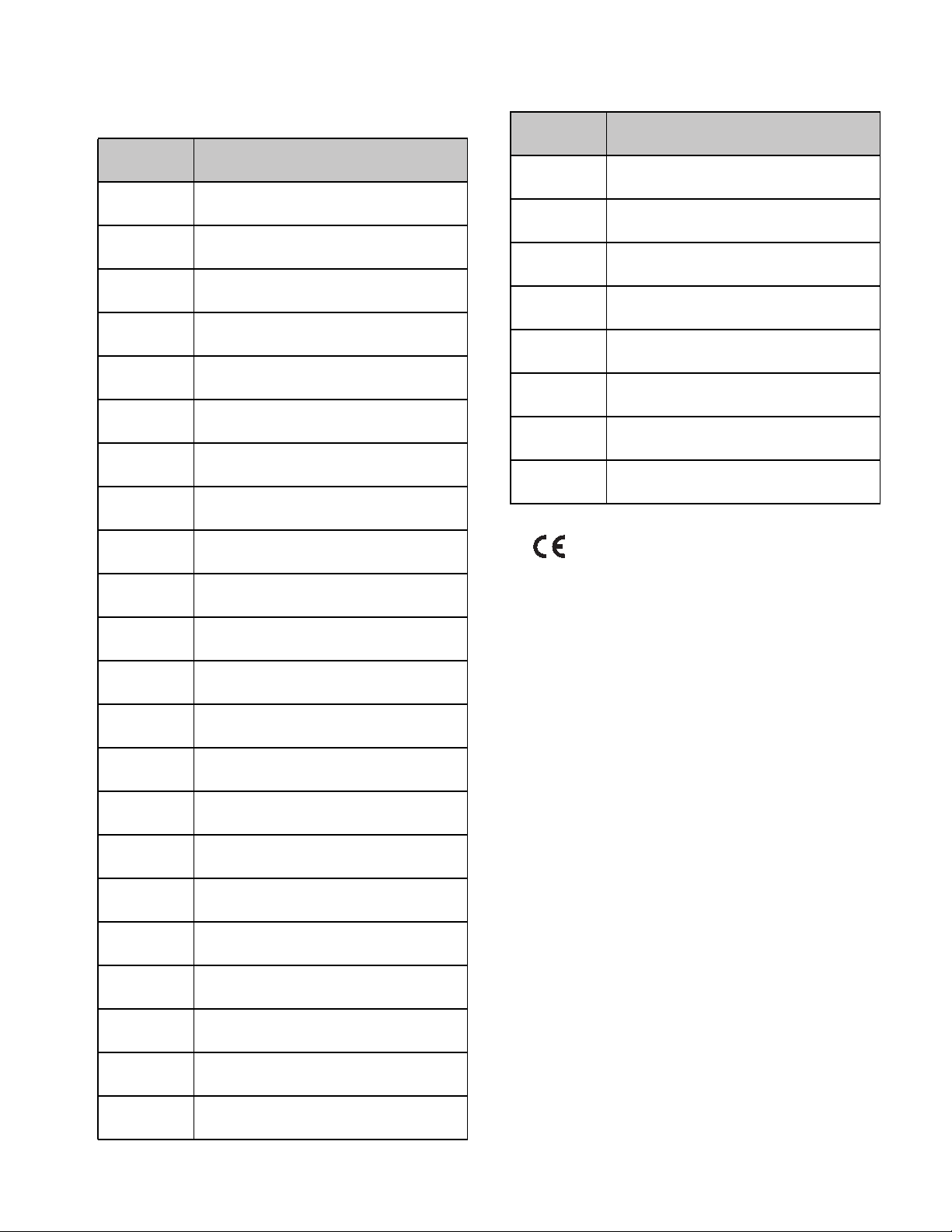

HFR-Silicone (HFRS)

HFRS models are designed for use with high viscosity, unheated silicone adhesives at flow rates of up to

20 cc/sec (3 lb/min) @ 2500 psi (17 MPa, 172 bar). The equipment can be run at up to 20 cycles per minute

continuous duty.

A Pump

Size

10 100 110 11 5.6 20 10.00

15 80 95 12.5 4.8 20 5.33

40 40 80 15 4 20 1.00

10 60 70 17 3.6 20 6.00

20 40 60 20 3 20 2.00

10 40 50 20 2.5 16.7 4.00

10 10 20 12 1 4 1.00

** Cycle rate should be between 3 and 20 cycles per minute. Max flow rate is determined for continuous service at

120°F (39°C) at stated cpm and pressure. Higher cycle rates are possible at lower temperatures/pressures and

intermittent use. Lower cycle rates may be possible, but should be tested under application conditions.

† Flow rates are established @ 2500 psi (17 MPa, 172 bar). Dispense rate in excess of max flow and pressure may

result in an elevated temperature of the hydraulic system, resulting in a thermal shutdown (T4H1). Other system

models are available for sustained flow rates and pressures in excess of above.

B Pump

Size cc/cycle

Required cpm@

Maximum Flow**

Minimum Flow †

cc/sec

Maximum Flow †

cc/sec Ratio

6 3A2176J

Page 7

Models

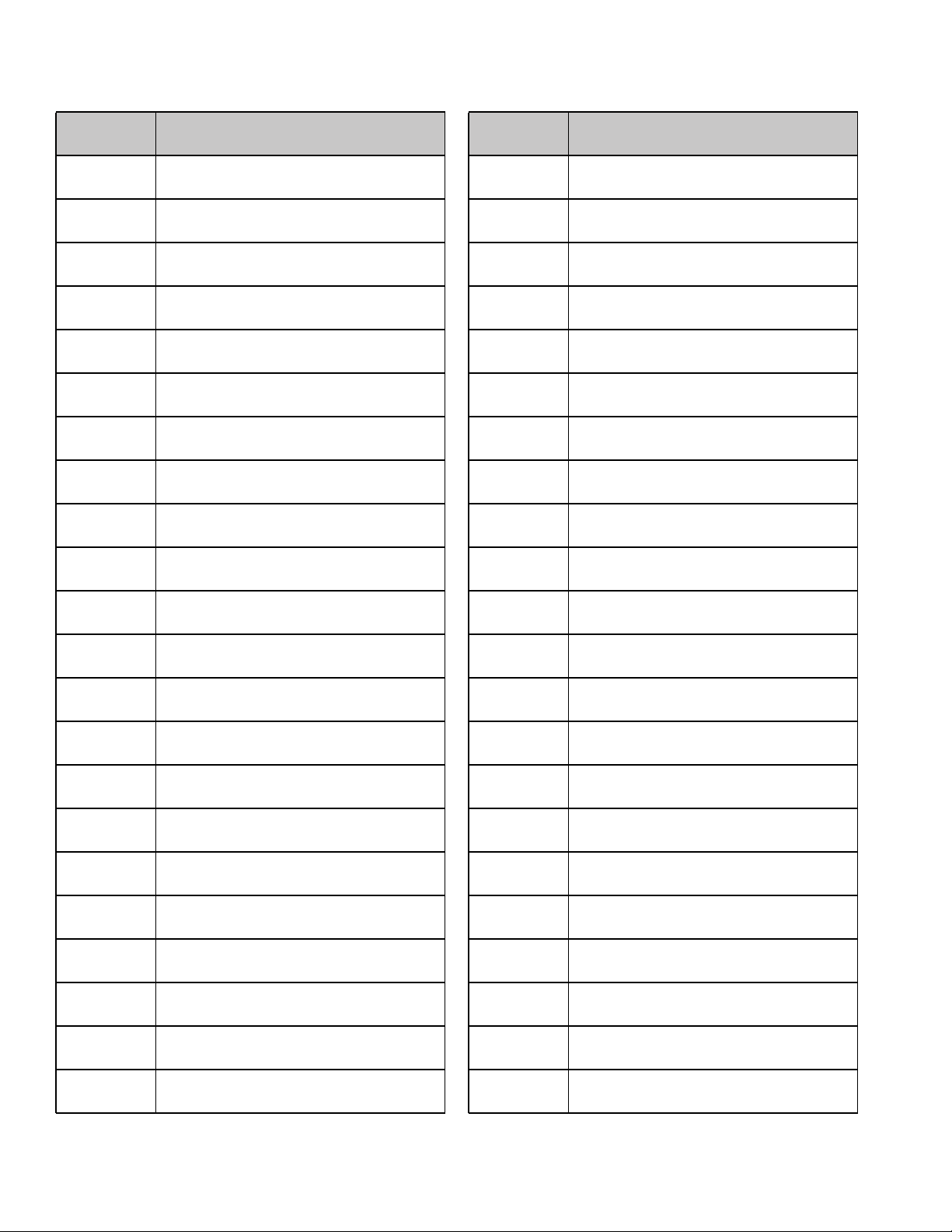

HFRS Models

Part Number Description

HFRS01 HFR for Silicone, 230/1, 1:1, Carbon

Steel, 55/55 Feed, (10/10 pumps)

HFRS02 HFR for Silicone, 230/1, 1:1, Carbon

Steel, 5/5 Feed, (10/10 pumps)

HFRS03

★✖

HFRS04

★✖

HFRS05 HFR for Silicone, 230/1, 1:1, Stainless

HFRS06 HFR for Silicone, 230/1, 1:1, Stainless

HFRS07

★✖

HFRS08

★✖

HFRS09 HFR for Silicone, 230/1, 4:1, Carbon

HFRS10 HFR for Silicone, 230/1, 4:1, Carbon

HFRS11 HFR for Silicone, 230/1, 4:1, Carbon

HFRS12

★✖

HFRS13

★✖

HFRS14

★✖

HFRS15 HFR for Silicone, 230/1, 4:1, Stainless

HFRS16 HFR for Silicone, 230/1, 4:1, Stainless

HFRS17 HFR for Silicone, 230/1, 4:1, Stainless

HFRS18

★✖

HFRS19

★✖

HFRS20

★✖

HFRS21 HFR for Silicone, 230/1, 5.33:1, Carbon

HFRS22 HFR for Silicone, 230/1, 5.33:1, Carbon

HFR for Silicone, 400/3, 1:1, Carbon

Steel, 55/55 Feed, (10/10 pumps)

HFR for Silicone, 400/3, 1:1, Carbon

Steel, 5/5 Feed, (10/10 pumps)

Steel, 55/55 Feed, (10/10 pumps)

Steel, 5/5 Feed, (10/10 pumps)

HFR for Silicone, 400/3, 1:1, Stainless

Steel, 55/55 Feed, (10/10 pumps)

HFR for Silicone, 400/3, 1:1, Stainless

Steel, 5/5 Feed, (10/10 pumps)

Steel, 55/55 Feed

Steel, 55/5 Feed

Steel, 5/5 Feed

HFR for Silicone, 400/3, 4:1, Carbon

Steel, 55/55 Feed

HFR for Silicone, 400/3, 4:1, Carbon

Steel, 55/5 Feed

HFR for Silicone, 400/3, 4:1, Carbon

Steel, 5/5 Feed

Steel, 55/55 Feed

Steel, 55/5 Feed

Steel, 5/5 Feed

HFR for Silicone, 400/3, 4:1, Stainless

Steel, 55/55 Feed

HFR for Silicone, 400/3, 4:1, Stainless

Steel, 55/5 Feed

HFR for Silicone, 400/3, 4:1, Stainless

Steel, 5/5 Feed

Steel, 55/55 Feed

Steel, 55/5 Feed

Part Number

Description

HFRS23 HFR for Silicone, 230/1, 5.33:1, Carbon

Steel, 5/5 Feed

HFRS24

★✖

HFRS25

★✖

HFRS26

★✖

HFR for Silicone, 400/3, 5.33:1, Carbon

Steel, 55/55 Feed

HFR for Silicone, 400/3, 5.33:1, Carbon

Steel, 55/5 Feed

HFR for Silicone, 400/3, 5.33:1, Carbon

Steel, 5/5 Feed

HFRS27 HFR for Silicone, 230/1, 5.33:1, Stain-

less Steel, 55/55 Feed

HFRS28 HFR for Silicone, 230/1, 5.33:1, Stain-

less Steel, 55/5 Feed

HFRS29 HFR for Silicone, 230/1, 5.33:1, Stain-

less Steel, 5/5 Feed

HFRS30

★✖

HFRS31

★✖

HFRS32

★✖

HFR for Silicone, 400/3, 5.33:1, Stainless Steel, 55/55 Feed

HFR for Silicone, 400/3, 5.33:1, Stainless Steel, 55/5 Feed

HFR for Silicone, 400/3, 5.33:1, Stainless Steel, 5/5 Feed

HFRS33 HFR for Silicone, 230/1, 6:1, Carbon

Steel, 55/55 Feed

HFRS34 HFR for Silicone, 230/1, 6:1, Carbon

Steel, 55/5 Feed

HFRS35 HFR for Silicone, 230/1, 6:1, Carbon

Steel, 5/5 Feed

HFRS36

★✖

HFRS37

★✖

HFRS38

★✖

HFR for Silicone, 400/3, 6:1, Carbon

Steel, 55/55 Feed

HFR for Silicone, 400/3, 6:1, Carbon

Steel, 55/5 Feed

HFR for Silicone, 400/3, 6:1, Carbon

Steel, 5/5 Feed

HFRS39 HFR for Silicone, 230/1, 6:1, Stainless

Steel, 55/55 Feed

HFRS40 HFR for Silicone, 230/1, 6:1, Stainless

Steel, 55/5 Feed

HFRS41 HFR for Silicone, 230/1, 6:1, Stainless

Steel, 5/5 Feed

HFRS42

★✖

HFRS43

★✖

HFRS44

★✖

HFR for Silicone, 400/3, 6:1, SS 55/55

Feed

HFR for Silicone, 400/3, 6:1, Stainless

Steel, 55/5 Feed

HFR for Silicone, 400/3, 6:1, Stainless

Steel, 5/5 Feed

3A2176J 7

Page 8

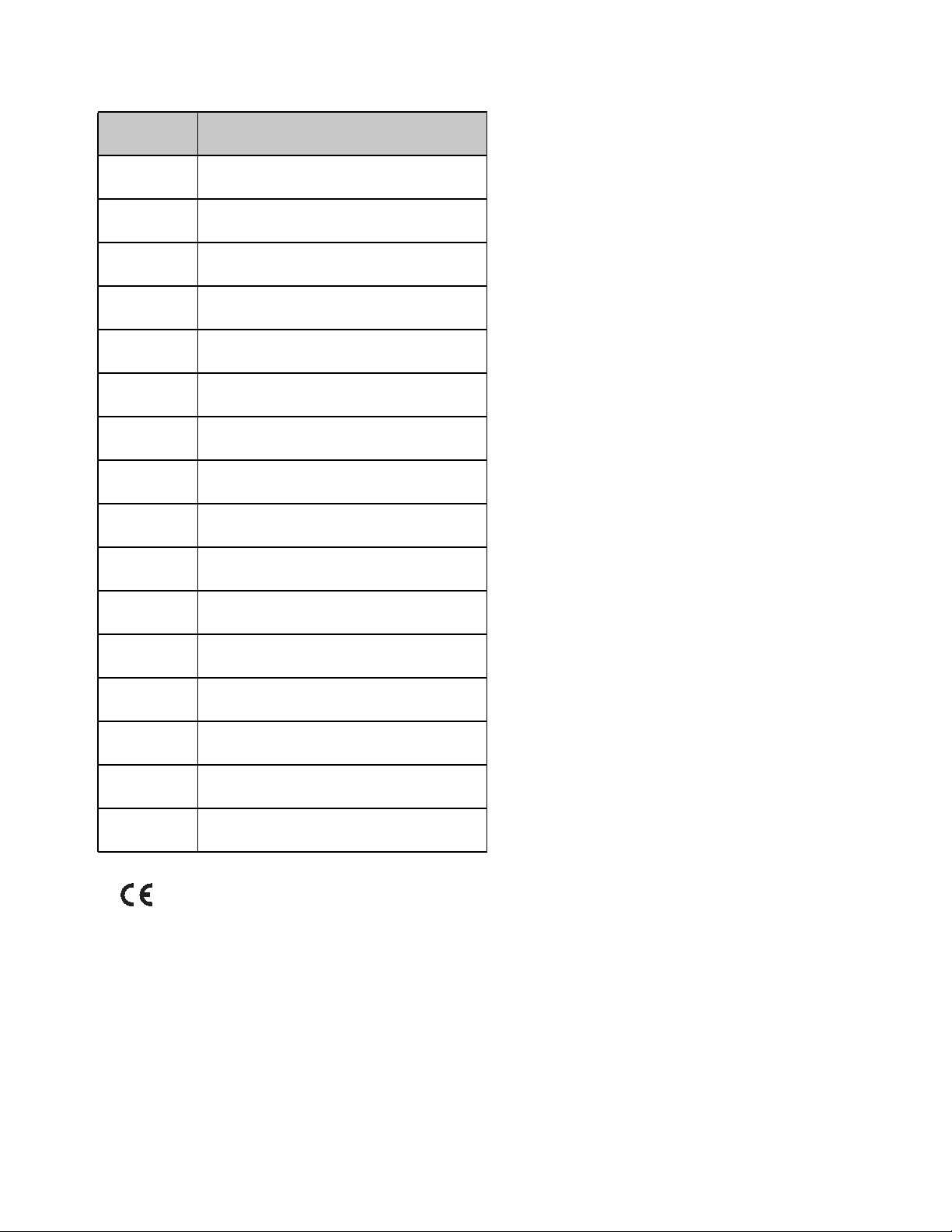

Models

Part Number

Description

HFRS45 HFR for Silicone, 230/1, 10:1, Carbon

Steel, 55/55 Feed

HFRS46 HFR for Silicone, 230/1, 10:1, Carbon

Steel, 55/5 Feed

HFRS47 HFR for Silicone, 230/1, 10:1, Carbon

Steel, 5/5 Feed

HFRS48

★✖

HFRS49

★✖

HFRS50

★✖

HFR for Silicone, 400/3, 10:1, Carbon

Steel, 55/55 Feed

HFR for Silicone, 400/3, 10:1, Carbon

Steel, 55/5 Feed

HFR for Silicone, 400/3, 10:1, Carbon

Steel, 5/5 Feed

HFRS51 HFR for Silicone, 230/1, 10:1, Stainless

Steel, 55/55 Feed

HFRS52 HFR for Silicone, 230/1, 10:1, Stainless

Steel, 55/5 Feed

HFRS53 HFR for Silicone, 230/1, 10:1, Stainless

Steel, 5/5 Feed

HFRS54

★✖

HFRS55

★✖

HFRS56

★✖

HFR for Silicone, 400/3, 10:1, Stainless

Steel, 55/55 Feed

HFR for Silicone, 400/3, 10:1, Stainless

Steel, 55/5 Feed

HFR for Silicone, 400/3, 10:1, Stainless

Steel, 5/5 Feed

HFRS57 HFR for Silicone, 230/1, 2:1, Carbon

Steel, 55/55 Feed

HFRS58

★✖

HFR for Silicone, 230/1, 2:1, Carbon

Steel, 55/5 Feed

HFRS59 HFR for Silicone, 230/1, 2:1, Carbon

Steel, 5/5 Feed

HFRS60

★✖

HFR for Silicone, 400/3, 2:1, Carbon

Steel, 55/55 Feed

HFRS61 HFR for Silicone, 400/3, 2:1, Carbon

Steel, 55/5 Feed

HFRS62

★✖

HFR for Silicone, 400/3, 2:1, Carbon

Steel, 5/5 Feed

HFRS63 HFR for Silicone, 230/1, 2:1, Stainless

Steel, 55/55 Feed

HFRS64

★✖

HFR for Silicone, 230/1, 2:1, Stainless

Steel, 55/5 Feed

HFRS65 HFR for Silicone, 230/1, 2:1, Stainless

Steel, 5/5 Feed

HFRS66

★✖

HFR for Silicone, 400/3, 2:1, Stainless

Steel, 55/55 Feed

Part Number

Description

HFRS67 HFR for Silicone, 400/3, 2:1, Stainless

Steel, 55/5 Feed

HFRS68

★✖

HFR for Silicone, 400/3, 2:1, Stainless

Steel, 5/5 Feed

HFRS69 HFR for Silicone, 230/1, 1:1, Carbon

Steel, No Feed, (10/10 pumps)

HFRS70

★✖

HFR for Silicone, 400/3, 1:1, Carbon

Steel, No Feed, (10/10 pumps)

HFRS71 HFR for Silicone, 230/1, 1:1, Stainless

Steel, No Feed, (10/10 pumps)

HFRS72

★✖

HFR for Silicone, 400/3, 1:1, Stainless

Steel, No Feed, (10/10 pumps)

HFRS73 HFR for Silicone, 230/1, 2:1, Carbon

Steel, No Feed

HFRS74

★✖

HFR for Silicone, 400/3, 2:1, Carbon

Steel, No Feed

HFRS75 HFR for Silicone, 230/1, 2:1, Stainless

Steel, No Feed

HFRS76

★✖

HFR for Silicone, 400/3, 2:1, Stainless

Steel, No Feed

HFRS77 HFR for Silicone, 230/1, 4:1, Carbon

Steel, No Feed

HFRS78

★✖

HFR for Silicone, 400/3, 4:1, Carbon

Steel, No Feed

HFRS79 HFR for Silicone, 230/1, 4:1, Stainless

Steel, No Feed

HFRS80

★✖

HFR for Silicone, 400/3, 4:1, Stainless

Steel, No Feed

HFRS81 HFR for Silicone, 230/1, 5.33:1, Carbon

Steel, No Feed

HFRS82

★✖

HFR for Silicone, 400/3, 5.33:1, Carbon

Steel, No Feed

HFRS83 HFR for Silicone, 230/1, 5.33:1, Stain-

less Steel, No Feed

HFRS84

★✖

HFR for Silicone, 400/3, 5.33:1, Stainless Steel, No Feed

HFRS85 HFR for Silicone, 230/1, 6:1, Carbon

Steel, No Feed

HFRS86

★✖

HFR for Silicone, 400/3, 6:1, Carbon

Steel, No Feed

HFRS87 HFR for Silicone, 230/1, 6:1, Stainless

Steel, No Feed

HFRS88

★✖

HFR for Silicone, 400/3, 6:1, Stainless

Steel, No Feed

8 3A2176J

Page 9

Models

Part Number

HFRS89 HFR for Silicone, 230/1, 10:1, Carbon

HFRS90

★✖

HFRS91 HFR for Silicone, 230/1, 10:1, Stainless

HFRS92

★✖

HFRS93 HFR for Silicone, 230/1, 1:1, Carbon

HFRS94 HFR for Silicone, 230/1, 1:1, Carbon

HFRS95

★✖

HFRS96

★✖

HFRS97 HFR for Silicone, 230/1, 1:1, Stainless

HFRS98 HFR for Silicone, 230/1, 1:1, Stainless

HFRS99

★✖

HFRSA0

★✖

HFRSA1 HFR for Silicone, 230/1, 1:1, Carbon

HFRSA2

★✖

HFRSA3 HFR for Silicone, 230/1, 1:1, Stainless

HFRSA4

★✖

Description

Steel, No Feed

HFR for Silicone, 400/3, 10:1, Carbon

Steel, No Feed

Steel, No Feed

HFR for Silicone, 400/3, 10:1, Stainless

Steel, No Feed

Steel, 55/55 Feed, (40/40 pumps)

Steel, 5/5 Feed, (40/40 pumps)

HFR for Silicone, 400/3, 1:1, Carbon

Steel, 55/55 Feed, (40/40 pumps)

HFR for Silicone, 400/3, 1:1, Carbon

Steel, 5/5 Feed, (40/40 pumps)

Steel, 55/55 Feed, (40/40 pumps)

Steel, 5/5 Feed, (40/40 pumps)

HFR for Silicone, 400/3, 1:1, Stainless

Steel, 55/55 Feed, (40/40 pumps)

HFR for Silicone, 400/3, 1:1, Stainless

Steel, 5/5 Feed, (40/40 pumps)

Steel, No Feed, (40/40 pumps)

HFR for Silicone, 400/3, 1:1, Carbon

Steel, No Feed, (40/40 pumps)

Steel, No Feed, (40/40 pumps)

HFR for Silicone, 400/3, 1:1, Stainless

Steel, No Feed, (40/40 pumps)

400 V Power Requirements

• 400 V systems are intended for International voltage

requirements. Not for voltage requirements in North

America.

• If a 400 volt configuration is operated in North America, a special transformer rated for 400 V (“Y” configuration (4 wire)) may be required.

• North America mostly employs a 3 wire or Delta

configuration. The two configurations are not interchangeable.

★ approved.

✖ See 400 V Power Requirements.

3A2176J 9

Page 10

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and regulations.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear chemically impermeable gloves when spraying, dispensing, or cleaning equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, hearing loss, inhalation of toxic fumes, and burns. This equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This

may look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispensing device at anyone or at any part of the body.

+

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking,

or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

10 3A2176J

Page 11

Warnings

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic

drop cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on skin and

cause serious injury.

• Follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure. Turn off all equipment

and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving par ts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

3A2176J 11

Page 12

Warnings

WARNING

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment, follow the Pressure Relief Procedure and disconnect all power sources.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe

burns:

• Do not touch hot fluid or equipment.

12 3A2176J

Page 13

Warnings

3A2176J 13

Page 14

Important Two-Component Material Information

Important Two-Component Material Information

Isocyanate Conditions

Spraying or dispensing materials containing isocyanates creates potentially harmful mists, vapors, and

atomized particulates.

Read material manufacturer’s warnings and material

MSDS to know specific hazards and precautions

related to isocyanates.

Prevent inhalation of isocyanate mists, vapors, and

atomized particulates by providing sufficient ventilation in the work area. If sufficient ventilation is not

available, a supplied-air respirator is required for

everyone in the work area.

To prevent contact with isocyanates, appropriate personal protective equipment, including chemically

impermeable gloves, boots, aprons, and goggles, is

also required for everyone in the work area.

Material Self-ignition

Some materials may become self-igniting if applied

too thickly. Read material manufacturer’s warnings

and material MSDS.

Keep Components A (Red) and

Moisture Sensitivity of Isocyanates

Isocyanates (ISO) are catalysts used in two component

foam and polyurea coatings. ISO will react with moisture

(such as humidity) to form small, hard, abrasive crystals,

which become suspended in the fluid. Eventually a film

will form on the surface and the ISO will begin to gel,

increasing in viscosity. If used, this partially cured ISO

will reduce performance and the life of all wetted parts.

NOTE: The amount of film formation and rate of crystallization varies depending on the blend of ISO, the

humidity, and the temperature.

To prevent exposing ISO to moisture:

• Always use a sealed container with a desiccant

dryer in the vent, or a nitrogen atmosphere. Never

store ISO in an open container.

• Keep the ISO lube pump reservoir (if installed) filled

with IsoGuard Select™, part 24F516. The lubricant

creates a barrier between the ISO and the atmosphere.

• Use moisture-proof hoses specifically designed for

ISO, such as those supplied with your system.

• Never use reclaimed solvents, which may contain

moisture. Always keep solvent containers closed

when not in use.

• Never use solvent on one side if it has been contaminated from the other side.

• Always lubricate threaded parts with ISO pump oil

or grease when reassembling.

B (Blue) Separate

Cross-contamination can result in cured material in

fluid lines which could cause serious injury or damage equipment. To prevent cross-contamination of

the equipment’s wetted parts, never interchange

component A (Red) and component B (Blue) parts.

14 3A2176J

Page 15

Changing Materials

• When changing materials, flush the equipment multiple times to ensure it is thoroughly clean.

• Always clean the fluid inlet strainers after flushing.

• Check with your material manufacturer for chemical

compatibility.

• Most materials use ISO on the A (Red) side, but

some use ISO on the B (Blue) side. See the following section.

A (Red) and B (Blue) Components

IMPORTANT!

Material suppliers can vary in how they refer to plural

component materials.

A (Red) and B (Blue) Components

Be aware that when standing in front of the manifold on

proportioner:

• Component A (Red) is on the left side.

• Component B (Blue) is on the right side.

For all machines:

• The A (Red) side is intended for ISO, hardeners,

and catalysts.

• If one of the materials being used is moisture-sensitive, that material should always be in the A (Red)

side.

• The B (Blue) side is intended for polyols, resins, and

bases.

For HFRS Systems:

The high volume material is typically the ISO and is

located on the A (Red) side. Some material chemistries

may have an ISO which is the low volume material. The

ISO must always be in the A (Red) side containing the

Isolube.

NOTE: For HFRL Systems:

The high volume material will always be the B (Blue)

side.Typical Installation

3A2176J 15

Page 16

Operation

Operation

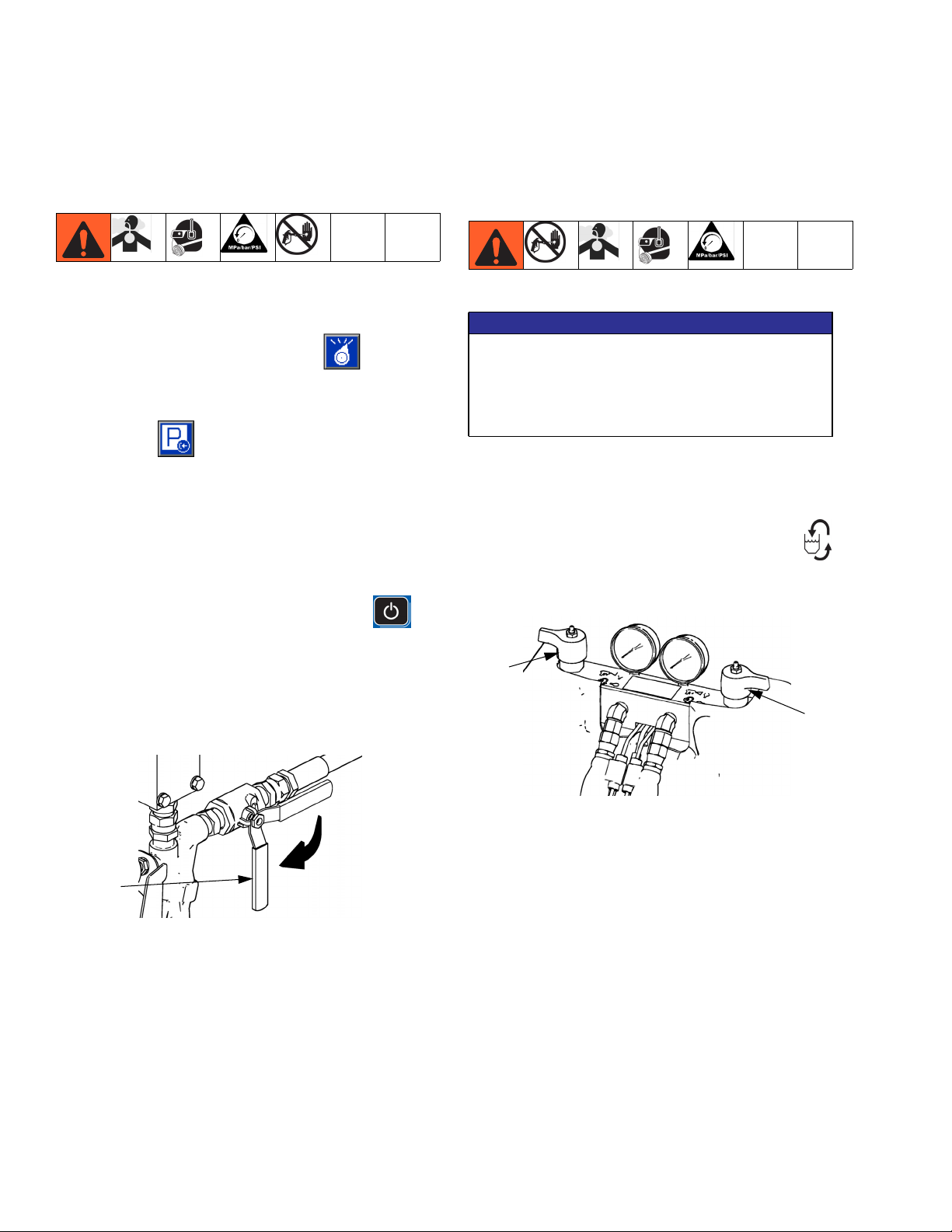

Shutdown

1. Park pumps.

a. From the Home screen, press and select

Standby mode.

b. Press . Material will dispense. Pump will

park automatically. Once pump is parked, pump

will stop moving.

If a dispense gun with a trigger is installed,

pulling the trigger will begin a park operation.

Material will dispense.

2. Press the enable/disable key on the ADM to

disable the ADM.

Pressure Relief Procedure

NOTICE

The fittings on the pressure relief hoses are zinc

plated carbon steel. The hose cores are cured with

sulfur. Check your materials for compatibility with

zinc plating and sulfur before reusing any material

that passed through them, as it may inhibit curing.

1. Shut off feed pumps and agitator, if used.

2. Turn PRESSURE RELIEF/DISPENSE valves (SA,

SB) to PRESSURE RELIEF/CIRCULATION .

Route fluid to waste containers or supply tanks.

Ensure gauges drop to 0.

3. Turn main power switch (MP) to OFF position.

4. Close A (Red) and B (Blue) fluid supply valves (FV),

if equipped, or remove fluid pressure at supply

device.

FV

ti9883a1

5. Perform Pressure Relief Procedure on page 16.

6. Shut down feed pumps as required. See feed pump

manual.

SA

SB

ti9879a1

3. For models with an dispense valve with a safety

lock, engage gun safety lock.

4. Relieve pressure in dispense valve. See dispense

valve manual.

16 3A2176J

Page 17

Operation

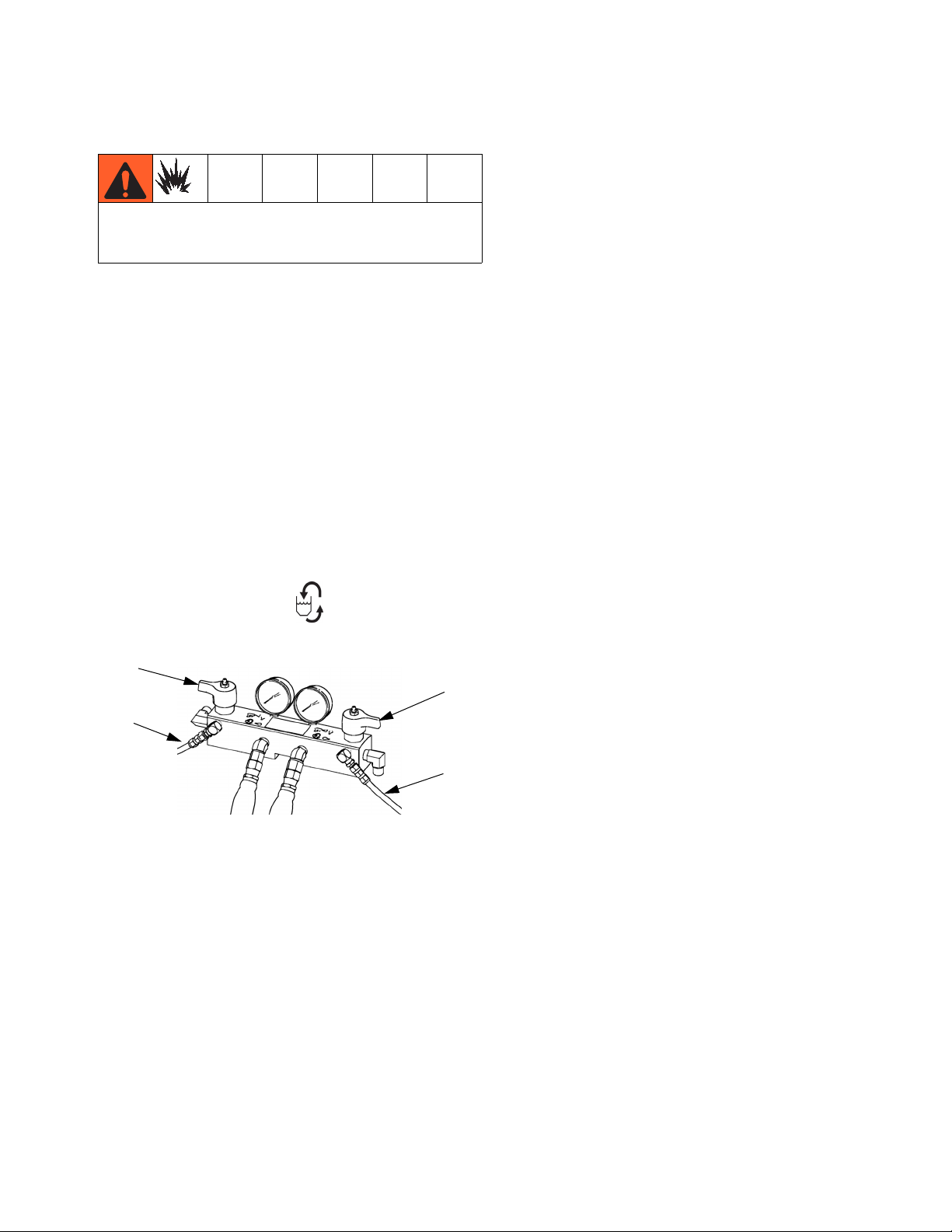

Flushing

Flush equipment only in a well-ventilated area. Do not

dispense flammable fluids. Do not turn on heaters

while flushing with flammable solvents.

• Flush out old fluid with new fluid, or flush out old

fluid with a compatible solvent before introducing

new fluid.

• Use the lowest possible pressure when flushing.

• All fluid components are compatible with common

solvents. Use only moisture-free solvents. See

Technical Data on page 70 for list of wetted components to verify compatibility of solvent with wetted

materials. See solvent manufacturers information for

material compatibility.

• To flush feed hoses, pumps, and heaters separately

from heated hoses, set PRESSURE RELIEF/DISPENSE valves (SA, SB) to PRESSURE

• To maintain grounding continuity when flushing or

relieving pressure, hold a metal part of dispense

gun firmly to the side of a grounded metal pail, then

trigger gun.

RELIEF/CIRCULATION . Flush through bleed

lines (N).

SA

SB

N

N

ti9880a1

• To flush entire system, circulate through gun fluid

manifold (with manifold removed from gun).

• To prevent moisture from reacting with isocyanate,

always leave the system dry or filled with a moisture-free plasticizer or oil. Do not use water. See

Important Two-Component Material Information

on page 14.

• Solvent pails used when flushing: follow your local

code. Use only metal pails, which are conductive,

placed on a grounded surface. Do not place pail on

a nonconductive surface, such as paper or cardboard, which interrupts grounding continuity.

3A2176J 17

Page 18

Repair

Repair

Pumpline

See Z-Series Chemical Pumps manual, HFR Hydraulic

Driver manuals for more detailed pumpline repair information.

Remove Chemical Pumps

This procedure removes the chemical pumps so that

replacement parts can be installed. See Z-Series Chemical Pumps manual for replacement parts installation

procedure.

1. Flush system, see page 17.

2. Perform Operation, see page 16.

3. Remove the front pump shroud.

4. Disconnect the chemical pump inlet and outlet fluid

lines. Do not disconnect the fluid manifold inlet line

or the fluid line connections at the heater.

Fluid Manifold Inlet

Pump Outlet

Pump Inlet

24C352_313998_4g1

18 3A2176J

Page 19

Repair

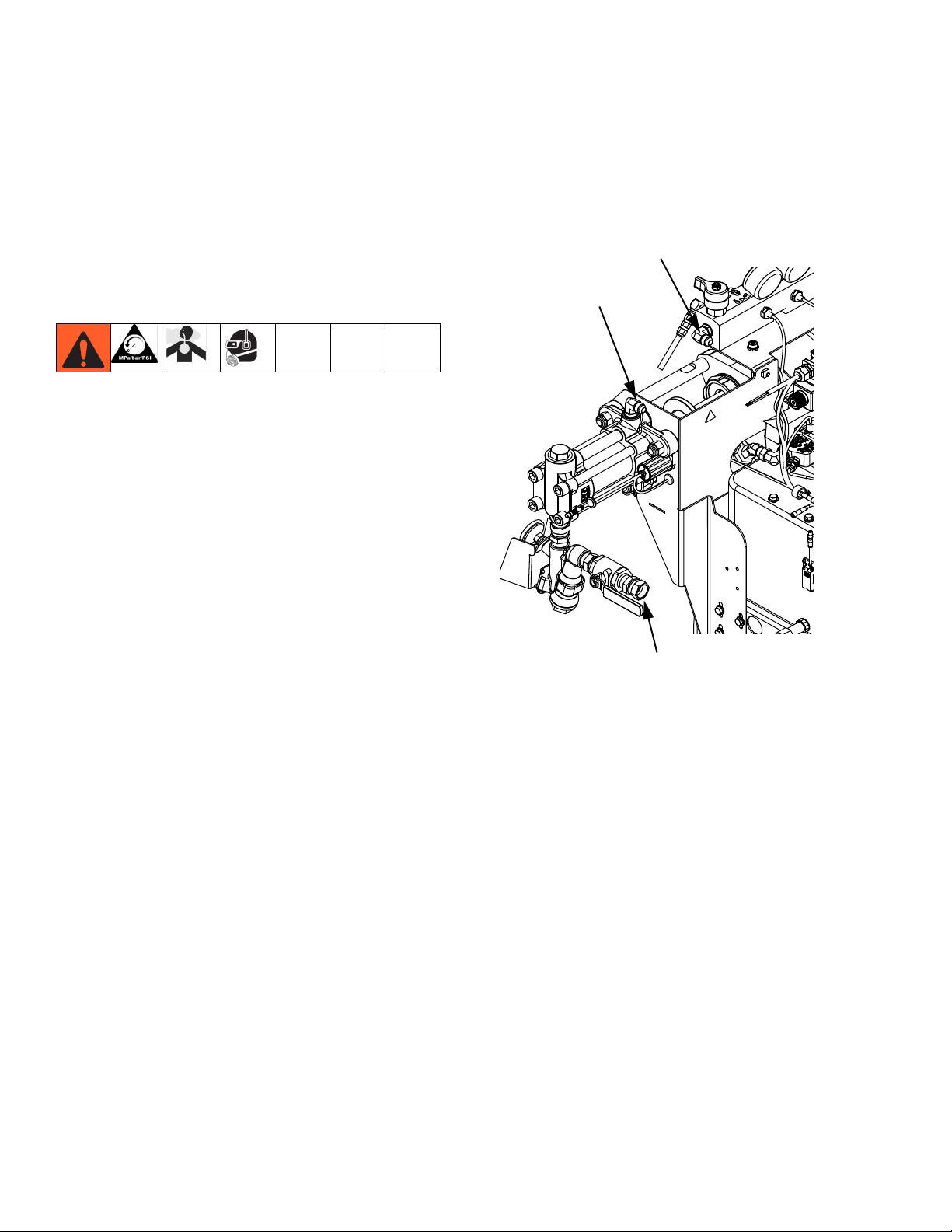

5. Unthread smaller cylinder from hydraulic driver and

slide inside larger cylinder. Use punch slots in lube

cylinder to aid rotation if necessary. See FIG.1.

Lube Cylinder Outlet Fitting

Punch Slot (same on opposite side)

24C352_313998_2g1

Lube Cylinder Inlet Fitting (behind cylinder)

7. Remove coupler from the A and B side pump shafts.

See FIG.2.

8. Unscrew LVDT sensor assembly and spool assembly from pump outlet housing. Wipe off spool

assembly. See F

IG.2.

9. Remove three nuts securing pump to tie rods. See

F

IG.2.

FIG. 1: Lube Cylinder

6. Remove two shoulder bolts from LVDT collar then

remove collar from B side pump shaft. See FIG.2.

Pump Outlet Housing

LVDT Sensor Assembly

(behind pump)

LVDT Spool Assembly

24C352_313998_2g1

LVDT Collar

Coupler

Nuts

FIG.2

3A2176J 19

Page 20

Repair

Install Chemical Pumps

Reconnect or install a different size chemical pump to

achieve desired ratio.

1. Install ISO lube cylinder on A side pump. Apply light

coating of lubricant on o-rings on outside of small

cylinder.

2. Install nuts on tie rods after the pumps have been

installed. Torque to 50-60 ft-lb (68-81 N•m).

3. Install coupler on A and B side pump shafts.

4. Install LVDT Assembly.

a. Apply a very light coat of hydraulic oil on LVDT

sensor tube and install through pump outlet

housing. Install spool assembly.

b. Install LVDT collar on coupler and pump shaft.

Ensure that the split on the LVDT collar does not

ride in the spool assembly.

c. Apply thread sealant to shoulder bolts then

install in LVDT collar. Torque to 40-50 in-lb

(4.5-5.6 N•m).

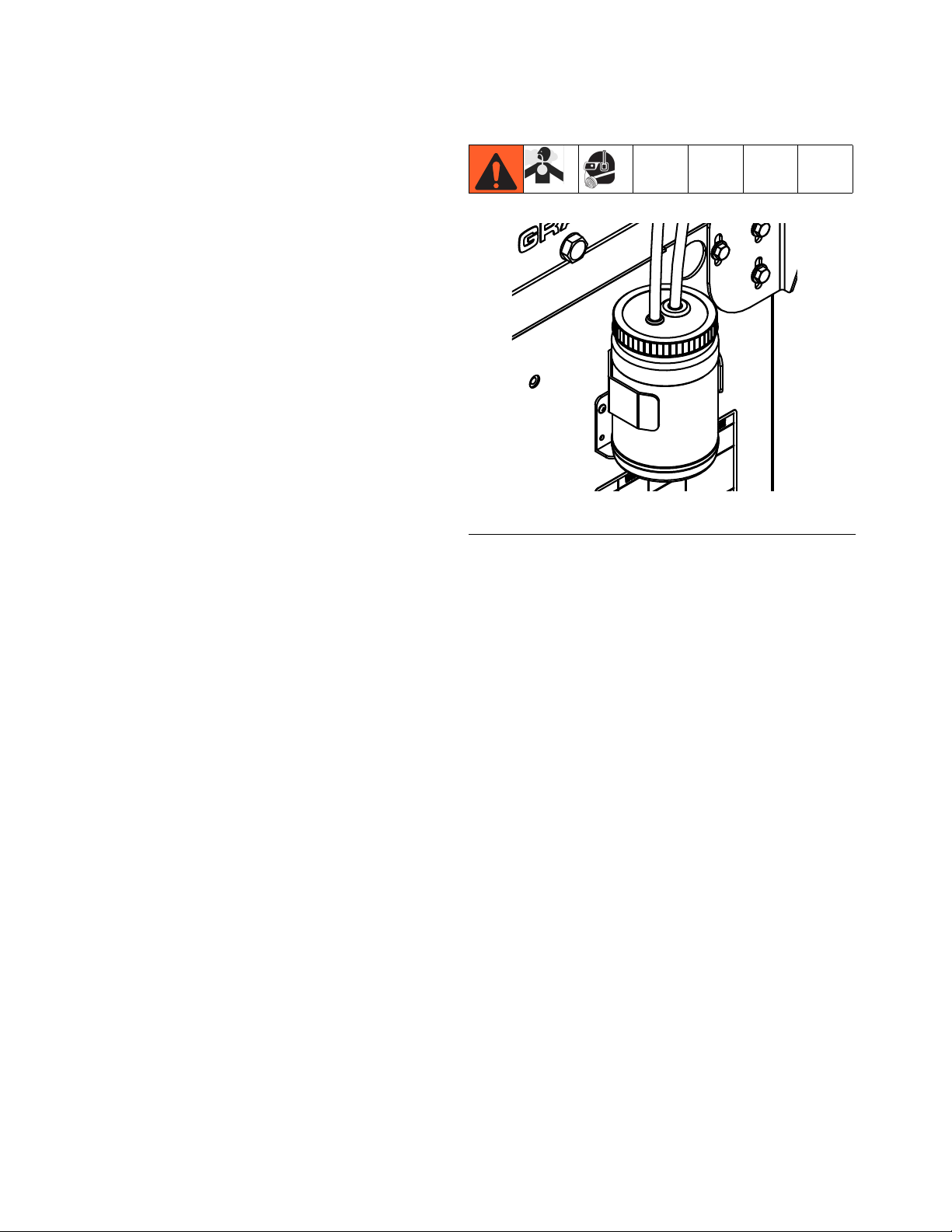

Prime IsoGuard Select™Cylinder

24C352_313998_8g1

FIG. 3: IsoGuard Select System

NOTE: The IsoGuard Select cylinder is installed on all

HFRL systems and is available separately as kit

24M154 for HFRS systems.

5. After the IsoGuard Select cylinder has been

installed on the A side pump, apply pipe sealant on

cylinder outlet fitting.

6. Perform Prime IsoGuard Select™Cylinder procedure, see page 20.

7. Reconnect inlet and outlet fluid lines.

Ensure that the IsoGuard Select cylinder outlet faces

upward for air to exhaust.

1. Install IsoGuard Select cylinder inlet fitting and inlet

tube into bottom of cylinder. The inlet tube is the

tube with a check valve installed in it which points in

the direction of flow towards the IsoGuard Select

cylinder.

2. Install IsoGuard Select cylinder outlet fitting and outlet tube into top of cylinder. The outlet tube is the

tube with a check valve installed in it which points in

the direction of flow away from the IsoGuard Select

cylinder.

3. Remove check valve from end of outlet tube.

4. Use funnel to pour IsoGuard Select into tube to fill

cylinder.

5. With check valve arrow pointing away from the

IsoGuard Select cylinder, install check valve in end

of outlet tube.

6. Install tubes into reservoir and install reservoir into

holder.

20 3A2176J

Page 21

Repair

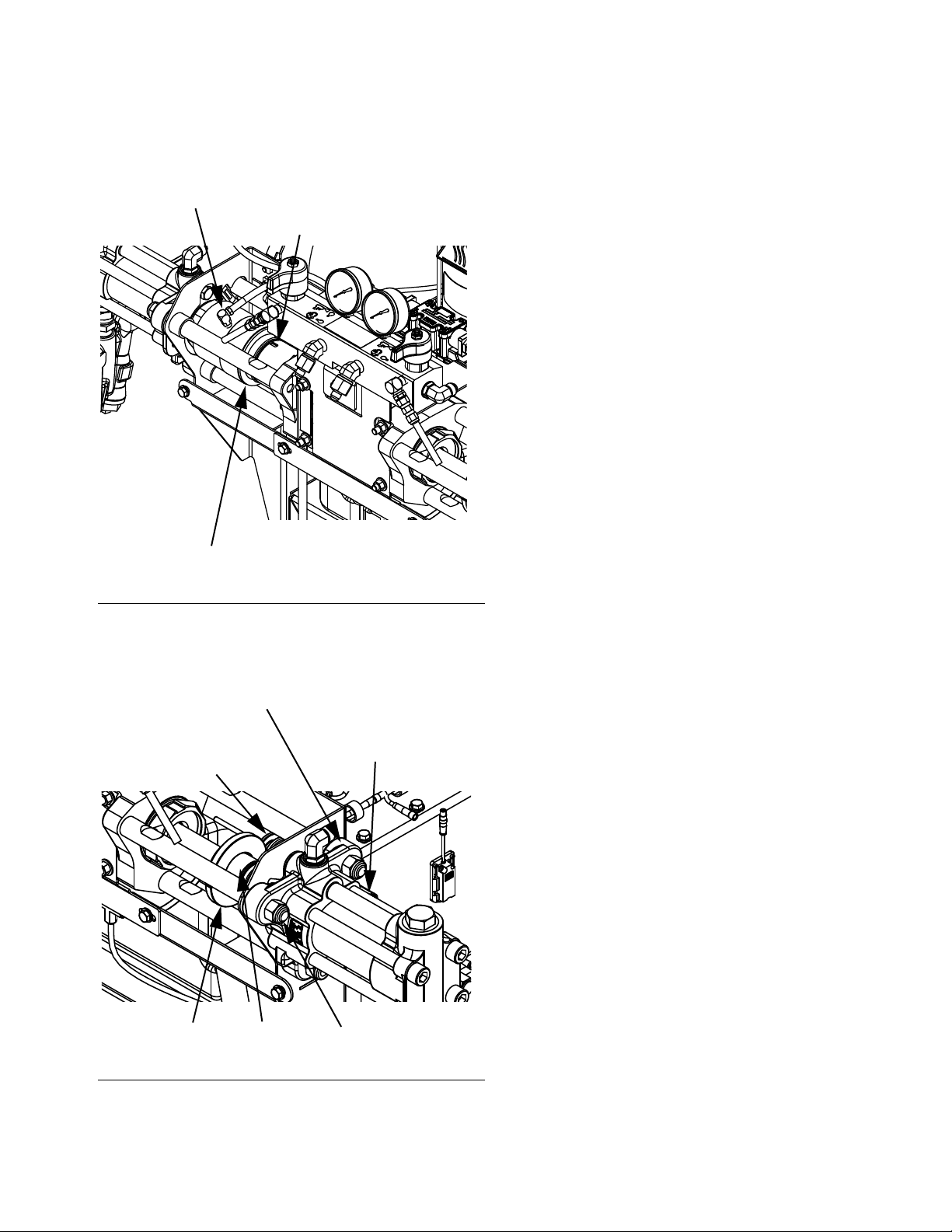

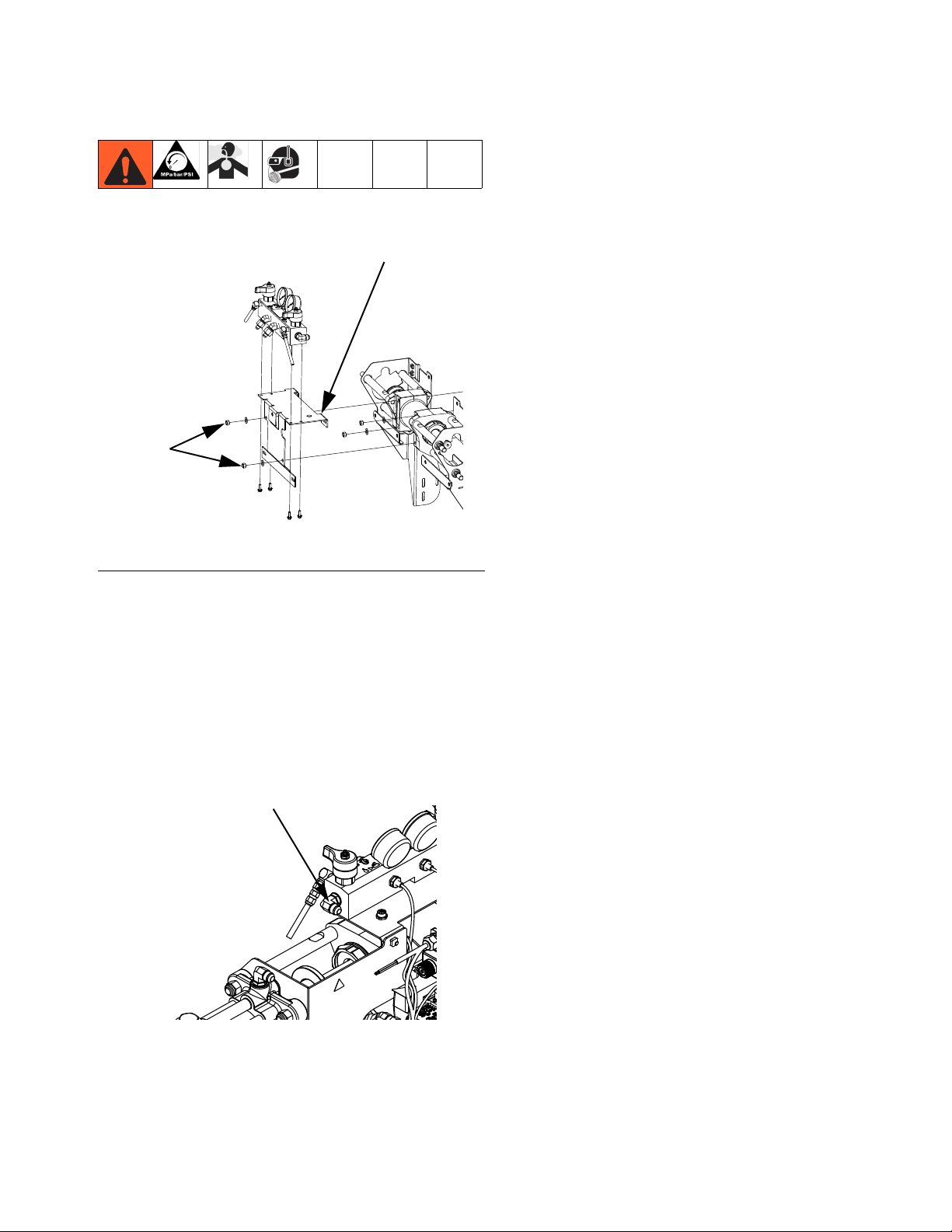

Remove HFR Hydraulic Driver

D88

24C352_313998_5g1

FIG.4

4. See FIG.4. Remove four nuts (D88) securing

hydraulic driver to hydraulic power pack. This will

also loosen manifold plate (MP) from hydraulic

driver. Remove manifold plate. Remove hydraulic

driver.

Install HFR Hydraulic Driver

MP

This procedure installs the hydraulic driver after replacement parts have been installed and actuator has been

reassembled. See HFR Hydraulic Driver manual for

replacement parts installation procedure.

1. Hang the hydraulic driver on the studs. Verify o-rings

between driver and hydraulic power pack are

installed and lubricated. Secure the driver with nuts

and washer at bottom-left and top-right corners.

2. Install manifold bracket. Secure at top-left and bottom-right corners.

3. Install pump support brackets, torque to 300 in-lb

(33.9 N•m). This will also install manifold plate (MP)

to hydraulic driver.

4. Connect fluid manifold inlet lines.

This procedure removes the HFR Hydraulic Driver so

replacement parts can be installed. See HFR Hydraulic

Driver manual for replacement parts installation procedure.

1. Perform Remove Chemical Pumps procedure, see

page 18.

2. Disconnect the fluid manifold inlet lines. Do not disconnect the fluid line connections at the heater.

Fluid Manifold Inlet

24C352_313998_4e1

5. Perform Install Chemical Pumps procedure, see

page 20.

3. Remove pump support brackets. Each bracket is

secured with three screws at the base frame and

two screws at the manifold bracket.

3A2176J 21

Page 22

Repair

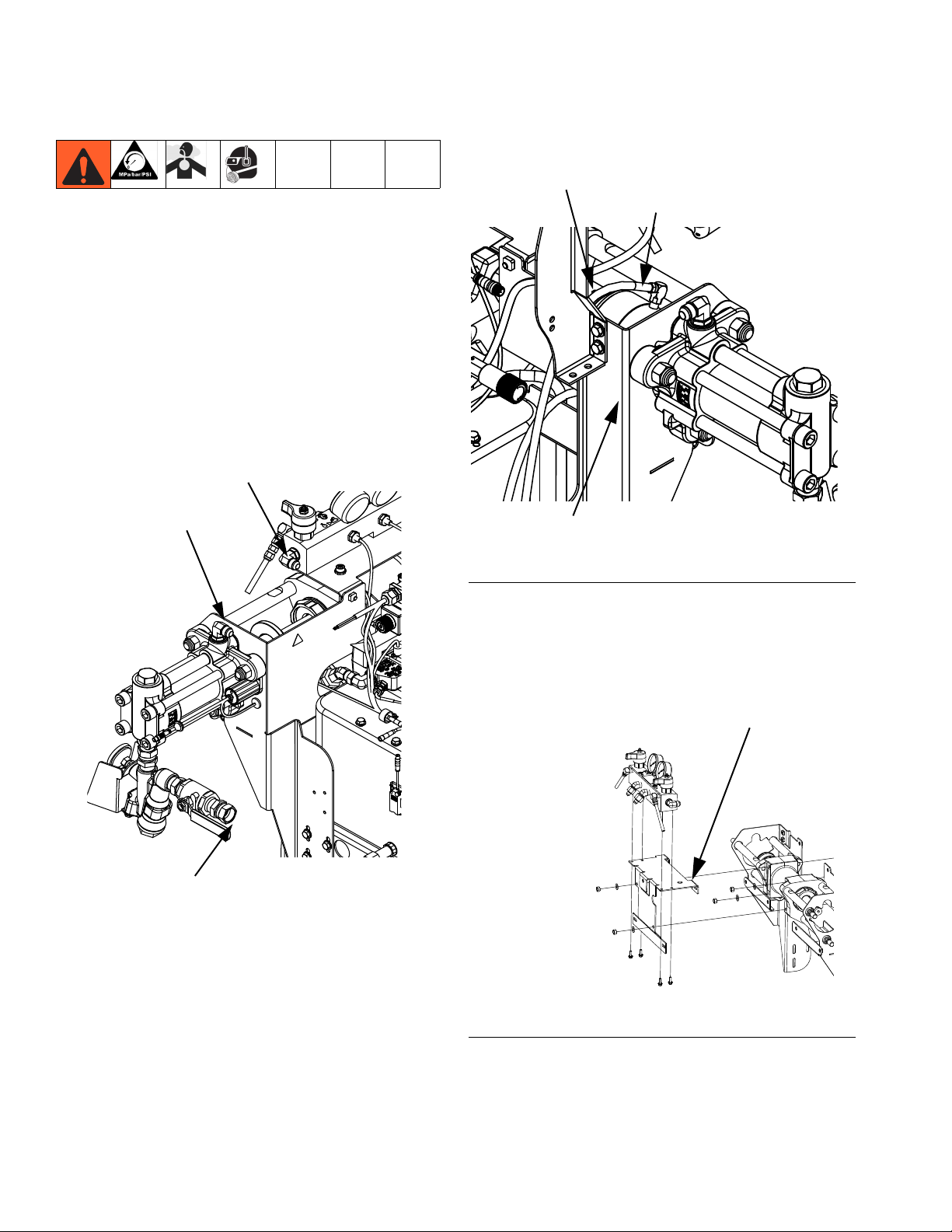

Remove PowerHouse Pumpline

The Hydraulic Power Pack must be removed to perform

some Hydraulic Power Pack repair procedures. In order

to remove the Hydraulic Power Pack, the PowerHouse

pumpline must be removed. See Hydraulic Power

Pack Repair starting on page 25 for more information.

1. Perform Operation procedure, see page 16.

2. Flush the system, see page 17.

3. Disconnect the chemical pump inlet, pump outlet,

and fluid manifold inlet lines. Do not disconnect the

fluid line connections at the heater.

Fluid Manifold Inlet

Pump Outlet

4. Remove lube cylinder inlet and outlet fittings. Let

cylinder drain.

Punch Slot (same on opposite side)

Lube Cylinder Outlet Fitting

24C352_313998_8e1

Lube Cylinder Inlet Fitting

FIG. 5: Lube Cylinder, Viewed from Rear Left of

Machine

Pump Inlet

5. See FIG.6. Remove four screws securing pumpline

to hydraulic power pack. This will also loosen manifold plate (MP) from hydraulic driver.

MP

24C352_313998_4e1

24C352_313998_5g1

FIG.6

22 3A2176J

Page 23

6. While supporting the pumpline, remove the three

bolts on each side of the machine securing the

pump support brackets to the machine base. See

FIG.7. Remove pumpline.

Repair

FIG.7

24C352_313998_4e1

3A2176J 23

Page 24

Repair

Install PowerHouse Pumpline

The Hydraulic Power Pack must be removed to perform

some Hydraulic Power Pack repair procedures. In order

to remove the Hydraulic Power Pack, the PowerHouse

pumpline must be removed. This procedure is for installing the PowerHouse pumpline at the end of the Hydraulic Power Pack Repair procedure. See Hydraulic Power

Pack Repair starting on page 25 for more information.

1. While supporting the pumpline, install the three

bolts on each side of the machine securing the

pump support brackets to the machine base. See

FIG.7. Torque to 150 in-lb (16.9 N•m).

2. See FIG.6. Align manifold plate (MP) with hydraulic

driver. Align hydraulic driver with hydraulic power

pack. Install four screws securing hydraulic driver to

hydraulic power pack. This will also install manifold

plate (MP) to hydraulic driver. Torque to 300 in-lb

(33.9 N•m).

3. Install lube cylinder inlet and outlet fittings. See FIG.

5. Apply thread sealant to threads.

4. Perform Prime IsoGuard Select™Cylinder procedure, see page 20.

5. Connect the chemical pump inlet, pump outlet, and

fluid manifold inlet lines.

Fluid Manifold Inlet

Pump Outlet

24C352_313998_4e1

Pump Inlet

24 3A2176J

Page 25

Hydraulic Power Pack Repair

Repair

H15

H16

H04

H14

H09

H12

H13

H08

H24

H35

11 26

8

2

12

H34

H21, H22

11

5

11

H46

6

7

14

11

6

11

H28

H30H33H32H31H45

11

15

H29

H18

2

10

3

11

10

2

12

2

12

10

11

3

9

13

H17

H19

H06

H05

H10

H11

H23

H25

12

5

11

H21,

H27

H44

4

11

H37

2

12

H26

H01

H38

11

8

9

12

10

H07

H02

5

11

257442_3A0998_1j

H02

H20

1

Assemble coupler to specified dimensions

prior to mounting assembly to housing.

2

Torque to 40 ft-lb (54 N•m).

3

Torque to 35 ft-lb (47 N•m).

4

Torque to 20 ft-lb (27 N•m).

5

Torque to 15 ft-lb (20 N•m).

6

Torque to 10 ft-lb (14 N•m).

7

Torque to 58 in-lb (6.5 N•m).

+.00

.45

-.02

H02

1

8

Torque to 34 in-lb (3.8 N•m).

9

Torque 1/4 turn past hand-tight.

10

Apply PTFE tape on installation end only.

11

Apply medium strength thread locker before

assembly.

12

Apply light coating of lubricant to seals.

13

Fill reservoir with hydraulic fluid.

1

+.01

.30

-.00

14

Orient with airflow arrow pointing toward

mounting bracket.

15

Prior to installing Ref. 728 into Ref. 726,

install Ref. 729 into Ref. 728 and adjust

head 1/8 in. from surface.

24

Align fan plug as shown.

26

Apply thermal lubricant to contact side.

H31

24

FIG. 8: Hydraulic DC Power Pack

3A2176J 25

Page 26

Repair

Remove Hydraulic Power Pack Shroud

1. Remove four screws from base of shroud.

2. Lift shroud off of Hydraulic Power Pack.

Install Hydraulic Power Pack Shroud

NOTICE

Do not over-torque any item that threads into the

hydraulic tank. This will strip the threads and

require tank replacement.

1. Place shroud on top of Hydraulic Power Pack.

2. Install four screws securing shroud to hydraulic tank.

Replace Hydraulic Filter

Filter is located at right rear of hydraulic power pack.

See FIG.8on page 25.

NOTICE

If any debris falls into the hydraulic tank, the debris

must be removed or machine damage will result.

3. Remove four screws (H32) connecting fan to mounting plate.

4. Remove fan and install new fan.

5. Install four screws (H32) connecting fan to Motor

and Motor Control Module.

6. Install Hydraulic Power Pack Shroud, see procedure on this page.

Remove Motor Control Module

See FIG.8on page 25.

1. Perform Operation procedure, see page 16.

2. Remove Hydraulic Power Pack Shroud, see procedure on this page.

3. Remove four screws (H32) connecting fan to Motor

and Motor Control Module. Remove fan and mounting plate.

1. Perform Operation procedure, see page 16.

2. Use compressed air to remove any loose debris

around the hydraulic filter.

3. Remove new filter from wrapping.

4. Apply a light coat of hydraulic fluid to the o-ring on

the face of the hydraulic filter.

5. Being careful not to allow any debris into the

hydraulic tank remove old filter from tank then

quickly install new filter.

Replace Fan

See FIG.8on page 25.

1. Perform Operation procedure, see page 16.

2. Remove Hydraulic Power Pack Shroud, see procedure on this page.

4. Note the location of each Motor Control Module

cable then remove all electrical cables on the left

and right sides of the Motor Control Module.

5. Remove six screws (H29) securing Motor Control

Module in place.

6. Slowly and carefully slide the Motor Control Module

up until the cable on the bottom of the Motor Control

Module can be accessed and removed. Disconnect

the cable.

7. Slide the Motor Control Module up and remove.

26 3A2176J

Page 27

Adjust Motor Control Module Selector

Switch

NOTICE

Repair

If the Motor Control Module is replaced, the selector switch must be set prior to initial startup of the

Motor Control Module or damage may occur.

The Motor Control Module uses an 8-position selector

switch (S) to set system maximum working pressure.

See FIG.9.

The system can be configured to run in two pressure

ranges:

• 0-3000 psi (0-20.7 MPA, 0-207 bar): For systems

will all components rated to 3000 psi maximum

working pressure or higher.

• 0-2000 psi (0-13.8 MPA, 0-138 bar): For systems

with one or more component rated less than

3000 psi maximum working pressure. For example,

if the dispense valve is rated to 2500 psi, then the

0-2000 psi range must be used.

NOTE:The Motor Control Module selector switch (S)

position #1 sets the system to 2000 psi maximum

working pressure. Selector switch position #3 sets

the system to 3000 psi maximum working pressure.

The factory setting for the Motor Control Module selector

switch is position #1 to set the machine to 2000 psi if the

machine is shipped with no hoses or hoses rated to

2000 psi maximum working pressure. If the machine is

shipped with hoses rated to 3000 psi maximum working

pressure or higher then the factory setting for the selector switch is position #3 to set the machine to 3000 psi.

• Do not install components rated to less than the

highest pressure in the selected pressure range.

For example, if the 0-2000 psi range is selected do

not install items rated less than 2000 psi. If the

0-3000 psi range is selected do not install items

rated less than 3000 psi. Doing so may lead to

overpressurization and ruptured components.

• High-pressure fluid from ruptured components will

pierce skin. This may look like just a cut, but it is a

serious injury that can result in amputation. Get

immediate surgical treatment.

To set the Motor Control Module selector switch:

1. Turn machine power off.

2. Remove the access cover (D). See FIG.9.

3. Set the selector switch (S).

4. Install access cover (D).

D

S

257396_3b9905_04b

FIG.9

The selector switch position will be properly set at the

factory for new systems. When a motor control module

is replaced, the selector switch must be set to the correct setting by the user prior to initial startup.

To change the maximum working pressure rating of the

system in the field, all outlet components including

hoses and dispense valve must be rated at or above the

new system maximum working pressure rating. For

example, if the new system rating will be 3000 psi, all

system components must be rated to at least 3000 psi

maximum working pressure.

3A2176J 27

Page 28

Repair

Install Motor Control Module

This procedure starts assuming that the old Motor Control Module is removed from the machine. See Remove

Motor Control Module procedure, see page 26.

See FIG.8on page 25.

1. Perform Adjust Motor Control Module Selector

Switch procedure on page 27.

NOTICE

Motor Control Module selector switch position must

be set prior to startup of Motor Control Module or

damage may occur.

2. Slide the Motor Control Module into the slot.

3. Attach the cable on the bottom of the Motor Control

Module.

4. Install the six screws (H29) securing Motor Control

Module in place.

This procedure removes the hydraulic power pack from

the machine as a single unit to enable further disassembly. User must purchase three 5/16-18 eye-bolts capable

of holding 300 lb to perform this procedure.

See FIG.8on page 25.

1. Perform Operation procedure, see page 16.

2. Perform Remove Hydraulic Power Pack Shroud,

see procedure on page 26.

3. Perform Remove Motor Control Module procedure, see page 26.

4. Perform Remove PowerHouse Pumpline proce-

dure, see page 22.

5. Disconnect heat exchanger inlet hose and fitting

from elbow fitting. Disconnect heat exchanger outlet

hose and fitting from elbow fitting.

6. Remove the two bolts (H46) from the fluid

housing (H03) and replace each with a strong

5/16-18 thread eye-bolt. Install a third strong

5/16-18 eye-bolt as indicated. See FIG.10. See FIG.

8 on page 25 for full hydraulic power pack view.

H03 H46

5. Install electrical cables on left and right sides of the

Motor Control Module.

6. Install four screws (H32) connecting fan to Motor

and Motor Control Module. Install fan and mounting

plate.

7. Install Hydraulic Power Pack Shroud, see procedure on page 26.

Remove Hydraulic Power Pack

The hydraulic power pack weighs up to 300 lb. To

avoid serious injury due the hydraulic power pack falling, secure the hydraulic lift when raising the hydraulic

power pack.

NOTICE

If any debris falls into the hydraulic tank, the debris

must be removed or machine damage will result.

H46

257442_313998_1j1

Install third eye-bolt here

FIG.10

7. Run a rope through the three eye-bolts and between

the motor and the Motor Control Module. Secure to

a hydraulic lift.

8. Remove the four bolts and washers securing the

tank to the electrical enclosure. See Power Pack

Module on page 44.

9. Lift the hydraulic power pack and place on a sturdy

location capable of supporting up to 300 lbs.

28 3A2176J

Page 29

Repair

Install Hydraulic Power Pack

NOTICE

If any debris falls into the hydraulic tank, the debris

must be removed or machine damage will result.

NOTICE

Do not over-torque any item that threads into the

hydraulic tank. This will strip the threads and

require tank replacement.

This procedure assumes the Hydraulic Power Pack has

been removed from the machine and is assembled

except for the Motor Control Module.

See FIG.8on page 25.

1. Run a rope through the three eye-bolts and between

the Motor and the Motor Control Module. Secure to

a hydraulic lift.

2. Lift the Hydraulic Power Pack and place onto the

electronic enclosure.

3. Align the holes with the tank then install finger-tight

the four bolts and washers securing the tank to the

electrical enclosure. Torque to 10 ft-lb (14 N•m).

Replace Tank Gasket, Tank

See FIG.8on page 25.

1. Perform Remove Hydraulic Power Pack procedure, see page 28.

2. Remove hex head cap screws (H22) securing

hydraulic housing (H03) to tank (H20). Carefully

remove motor (H01) and hydraulic housing assembly from tank.

3. Remove tank gasket. If tank is damaged, replace

tank.

NOTICE

Do not over-torque any item that threads into the

hydraulic tank. This will strip the threads and

require tank replacement.

4. Install thrust washers (H21) onto hex head cap

screws. Apply pipe sealant to threads of screws.

Align tank gasket (H19), hydraulic housing, and

tank (H20) then install screws. Torque to 15 ft-lb (20

N•m).

5. Perform Install Hydraulic Power Pack procedure,

see page 29.

4. Remove rope and lift.

5. Remove eye-bolts. Install original bolts (H46) into

fluid housing (H03). See FIG.10.

6. Perform Install PowerHouse Pumpline procedure,

see page 24.

7. Perform Install Motor Control Module procedure,

see page 28.

8. Connect heat exchanger inlet hose and fitting to

elbow fitting. Connect heat exchanger outlet hose

and fitting to elbow fitting located on rear right face

of tank. See Power Pack Module on page 44.

3A2176J 29

Remove Motor

See FIG.8on page 25.

1. Perform Remove Hydraulic Power Pack procedure, see page 28.

2. Remove four hex head cap screws (H22) securing

hydraulic housing (H03) and motor (H01) to tank.

Carefully remove motor and hydraulic housing

assembly from tank.

3. Remove four hex head cap screws (H27) connecting mounting bracket (H26) to motor.

4. Remove four socket head cap screws (H04) securing motor to hydraulic housing. Carefully remove

motor from hydraulic housing.

Page 30

Repair

5. Loosen set screw for motor coupler (H02) then

remove motor coupler.

Install Motor

See FIG.8on page 25.

1. Use four hex head cap screws (H27) and thrust

washers (H21) to install Motor Control Module

mounting bracket (H26) onto motor (H01).

2. Install motor coupler (H02) onto motor (H01). Coupler must be 0.65-0.67 in. from the face of the

motor. Torque motor coupler set screw to 15 ft-lb

(20 N•m).

3. Install spider coupler (H07) into motor coupler.

4. Use four socket head cap screws (H04) to attach

hydraulic housing (H03) to motor. Be sure to align

teeth of gear coupler with the teeth of the motor coupler. Apply pipe sealant to threads of screws. Torque

to 35 ft lb (47 N•m).

Remove Hydraulic Gear Pump

See FIG.8on page 25.

1. Perform Remove Hydraulic Power Pack procedure, see page 28.

2. Remove hex head cap screws (H22) securing

hydraulic housing (H03) to tank. Carefully remove

motor (H01) and hydraulic housing assembly.

3. Remove tube (H11).

4. Remove elbow fittings (H10, H12) from gear

pump (H05).

5. Remove two hex head cap screws (H08) securing

gear pump to hydraulic housing.

6. Remove spider coupler (H07).

7. Loosen set screw for gear coupler (H06) then

remove gear coupler from gear pump.

NOTICE

Do not over-torque any item that threads into the

hydraulic tank. This will strip the threads and

require tank replacement.

5. Install thrust washers (H21) onto hex head cap

screws (H22). Apply pipe sealant to threads of

screws. Align tank gasket (H19), hydraulic housing,

and tank (H20) then install screws. Torque to 15 ft-lb

(20 N•m).

6. Perform Install Hydraulic Power Pack procedure,

see page 29.

Install Hydraulic Gear Pump

See FIG.8on page 25.

1. Install gear coupler (H06) onto gear pump (H05).

Coupler must be 0.12 to 0.13 in. from the face of the

gear pump. Torque gear coupler set screw to 15 ft-lb

(20 N•m).

2. Install spider coupler (H07) into gear coupler.

3. Use two hex head cap screws (H08) to attach gear

pump to hydraulic housing. Be sure to align teeth of

gear coupler with the teeth of the motor coupler.

Torque screws to 35 ft-lb (47 N•m).

4. Apply a light coat of lubricant to seals of elbow

fittings (H10, H12). Install elbow fittings into gear

pump. See FIG.8on page 25. for fitting alignment.

Torque both fittings to 40 ft-lb (54 N•m).

30 3A2176J

Page 31

Repair

5. Apply a light coating of lubricant to seals of

tube (H11). Install tube (H11) onto elbow

fitting (H10) and straight fitting (H09). Hand-tighten

then use wrench to tighten 90 degrees further.

NOTICE

Do not over-torque any item that threads into the

hydraulic tank. This will strip the threads and

require tank replacement.

6. Install thrust washers (H21) onto hex head cap

screws (H22). Apply pipe sealant to threads of

screws. Align tank gasket (H19), hydraulic housing,

and tank (H20) then install screws. Torque to 15 ft-lb

(20 N•m).

7. Perform Install Hydraulic Power Pack procedure,

see page 29.

Replace Power Supply

7. Replace electrical enclosure door and turn on system power.

1c

1a

1d

ti18255a

Replace Circuit Breaker

1. Turn off system power.

2. Remove electrical enclosure door.

3. Disconnect power supply (1a) wires from the filter

(1c) splitter connector (1d).

4. Remove nuts and washers that secure the power

supply to the electrical enclosure.

5. Install new power supply to electrical panel. Secure

with nuts and washers.

6. Connect power supply wires to the filter and the

splitter connector.

1. Turn off system power.

2. Remove electrical enclosure door.

3. Disconnect wire harnesses from circuit breaker.

4. Remove circuit breaker.

5. Install new circuit breaker and connect wire harnesses.

6. Replace electrical door and turn on system power.

wire harness

circuit

breaker

wire harness

ti18255a

3A2176J 31

Page 32

Parts

Parts

HFRL Models

007

005

001

004

003

015

015

008,

009,

010

018

002

006

ti18209a

005

016

018

018

017

018

017

FIG. 11: HFRL Models

32 3A2176J

ti18271a

Page 33

Ref

001

002

003

004

005

006

007

008

009

010

011

015

016

017

Part

---

24M034

24M035

L020S1

L025S1

L030S1

L040S1

L050S1

L060S1

L065S1

L080S1

L086S1

L100S1

L160S1

L050S1

L060S1

L065S1

L080S1

L086S1

24M167

24M102

24M099

24M106

255179

24E505

24E250

120955

24M129

24M154

16A093

Description

MODULE, base, HFR, silicone, laminate

MODULE, power, HFR, 230v/1ph

MODULE, power, HFR, 400v/3ph, CE

LOWER, chemical, 20, SST, ucup

LOWER, chemical, 25, SST, ucup

LOWER, chemical, 30, SST, ucup

LOWER, chemical, 40, SST, ucup

LOWER, chemical, 50, SST, ucup

LOWER, chemical, 60, SST, ucup

LOWER, chemical, 65, SST, ucup

LOWER, chemical, 80, SST, ucup

LOWER, chemical, 86, SST, ucup

LOWER, chemical, 100, SST, ucup

LOWER, chemical, 160, SST, ucup

LOWER, chemical, 50, SST, ucup

LOWER, chemical, 60, SST, ucup

LOWER, chemical, 65, SST, ucup

LOWER, chemical, 80, SST, ucup

LOWER, chemical, 86, SST, ucup

MODULE, outlet, fluid, HFR, CS

KIT, hose, 1/4x15, CS, b

KIT, hose, 3/8x15, CS, b

KIT, hose, 3/8x15, CS, a

KIT, orifice block

KIT, orifices, 1/4”

CORD SET, euro, male, 4pin, 3wire, 4m

KIT, assembly, inlet, lamination

KIT, lube, ISO, HFR

HFRL01 1 1 1 1 1 1 1 1 2 1 1 2 1 2 4

VALVE, dispense, 1:1, soft seats

HFRL02 1 1 1 1 1 1 1 1 2 1 1 2 1 2 4

HFRL03 1 1 1 1 1 1 1 1 2 1 1 2 1 2 4

HFRL04 1 1 1 1 1 1 1 1 2 1 1 2 1 2 4

HFRL05 1 1 1 1 1 1 1 1 2 1 1 2 1 2 4

HFRL06 1 1 1 1 1 1 1 1 2 1 1 2 1 2 4

HFRL07 1 1 1 1 1 1 1 1 2 1 1 2 1 2 4

HFRL08 1 1 1 1 1 1 1 1 2 1 1 2 1 2 4

HFRL09 1 1 1 1 1 1 1 1 2 1 1 2 1 2 4

HFRL10 1 1 1 1 1 1 1 1 2 1 1 2 1 2 4

HFRL11 1 1 1 1 1 1 1 1 2 1 1 2 1 2 4

HFRL12 1 1 1 1 1 1 1 1 2 1 1 2 1 2 4

HFRL13 1 1 1 1 1 1 1 1 2 1 1 2 1 2 4

HFRL14 1 1 1 1 1 1 1 1 2 1 1 2 1 2 4

HFRL15 1 1 1 1 1 1 1 1 2 1 1 2 1 2 4

HFRL16 1 1 1 1 1 1 1 1 2 1 1 2 1 2 4

HFRL17 1 1 1 1 1 1 1 1 2 1 1 2 1 2 4

HFRL18 1 1 1 1 1 1 1 1 2 1 1 2 1 2 4

HFRL19 1 1 1 1 1 1 1 1 2 1 1 2 1 2 4

HFRL20 1 1 1 1 1 1 1 1 2 1 1 2 1 2 4

HFRL21 1 1 1 1 1 1 1 1 2 1 1 2 1 2 4

HFRL22 1 1 1 1 1 1 1 1 2 1 1 2 1 2 4

HFRL23 1 1 1 1 1 1 1 1 2 1 1 2 1 2 4

HFRL24 1 1 1 1 1 1 1 1 2 1 1 2 1 2 4

HFRL25 1 1 1 1 1 1 1 1 2 1 1 2 1 2 4

HFRL26 1 1 1 1 1 1 1 1 2 1 1 2 1 2 4

HFRL27 1 1 1 1 1 1 1 1 2 1 1 2 1 2 4

HFRL28 1 1 1 1 1 1 1 1 2 1 1 2 1 2 4

HFRL29 1 1 1 1 1 1 1 1 2 1 1 2 1 2 4

HFRL30 1 1 1 1 1 1 1 1 2 1 1 2 1 2 4

SENSOR, pressure, fluid outlet

Parts

018

121399

PACKING, o-ring 012 fx75

--- Not for sale.

3A2176J 33

Page 34

Parts

HFRS Models

113

104

115

107

114

106

108,

109,

110

101

105

103

102

(Inside base)

114

115

112

ti18208a

018

018

018

017

018

ti18272a

017

FIG. 12: HFRS Models

34 3A2176J

Page 35

Parts

Ref

101

102

Part

---

24M034

24M035

Description

MODULE, base, HFR, silicone, laminate

MODULE, power, HFR, 230v/1ph

HFRS01 1 1 2 1 1 1 1 2 1 1 2 2 2 2 2

HFRS02 1 1 2 1 1 1 1 2 1 1 2 2 2 2 2

HFRS03 1 1 2 1 1 1 1 2 1 1 2 2 2 2 2

HFRS04 1 1 2 1 1 1 1 2 1 1 2 2 2 2 2

HFRS05 1 1 2 1 1 1 1 2 1 1 2 2 2 2 2

HFRS06 1 1 2 1 1 1 1 2 1 1 2 2 2 2 2

HFRS07 1 1 2 1 1 1 1 2 1 1 2 2 2 2 2

HFRS08 1 1 2 1 1 1 1 2 1 1 2 2 2 2 2

HFRS09 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS10 1 1 1 1 1 1 1 1 2 1 1 1 1 2 2 2 2

HFRS11 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS12 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS13 1 1 1 1 1 1 1 1 2 1 1 1 1 2 2 2 2

HFRS14 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS15 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS16 1 1 1 1 1 1 1 1 2 1 1 1 1 2 2 2 2

HFRS17 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS18 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS19 1 1 1 1 1 1 1 1 2 1 1 1 1 2 2 2 2

HFRS20 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS21 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS22 1 1 1 1 1 1 1 1 2 1 1 1 1 2 2 2 2

HFRS23 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS24 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS25 1 1 1 1 1 1 1 1 2 1 1 1 1 2 2 2 2

HFRS26 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS27 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS28 1 1 1 1 1 1 1 1 2 1 1 1 1 2 2 2 2

HFRS29 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS30 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS31 1 1 1 1 1 1 1 1 2 1 1 1 1 2 2 2 2

HFRS32 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

MODULE, power, HFR, 400v/3ph, ce

L010S1

L040S1

LOWER, chemical, 10, SST, ucup

LOWER, chemical, 40, SST, ucup

103

L060S1

L080S1

LOWER, chemical, 60, SST, ucup

LOWER, chemical, 80, SST, ucup

L100S1

L010S1

LOWER, chemical, 100, SST, ucup

LOWER, chemical, 10, SST, ucup

104

L015S1

L020S1

LOWER, chemical, 15, SST, ucup

LOWER, chemical, 20, SST, ucup

105

24M167

24M168

MODULE, outlet, fluid, HFR,CS

MODULE, outlet, fluid, HFR, SST

106

24M100

24M103

KIT, hose, 1/2x10, CS, B, silicone

KIT, hose, 1/2x10, SS, B, silicone

24M105

24M108

KIT, hose, 1/2x10, CS, A, silicone

KIT, hose, 1/2x10, SS, A, silicone

107

24M107

24M109

KIT, hose, 1/4x10, CS, A, silicone

KIT, hose, 1/4x10, SS, A, silicone

108

24M110

255179

KIT, hose, 3/16x10, SS, A, silicone

VALVE, dispense, 1:1, soft seats

109

110

24E505

24E250

KIT, orifice block

KIT, orifices, 1/4”

111

120955

CM7A59

CORD SET, euro, male, 4pin, 3wire, 4 meter

SUPPLY UNIT, 20:1, 0 volt, d200, 200l, CS

112&113

CM7C58

CM7A3C

SUPPLY UNIT, 20:1, 0 volt, d200, 200l, SS

SUPPLY UNIT, 20:1, 0 volt, s20, 20l, CS

114

CM7C3F

24M181

SUPPLY UNIT, 20:1, 0 volt, s20, 20l, SS

KIT, hose, 3/4x15, inlet, CS

115

24M182

24M132

KIT, hose, 3/4x15, inlet, SS

KIT, assy, inlet, regulator, CS

117

24M133

16A093

KIT, assy, inlet, regulator, SS

SENSOR, pressure, fluid outlet

118

121399

PACKING, o-ring 012 fx75

3A2176J 35

Page 36

Parts

Ref

101

102

Part

---

24M034

24M035

Description

MODULE, base, HFR, silicone, laminate

MODULE, power, HFR, 230v/1ph

HFRS33 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS34 1 1 1 1 1 1 1 1 2 1 1 1 1 2 2 2 2

HFRS35 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS36 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS37 1 1 1 1 1 1 1 1 2 1 1 1 1 2 2 2 2

HFRS38 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS39 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS40 1 1 1 1 1 1 1 1 2 1 1 1 1 2 2 2 2

HFRS41 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS42 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS43 1 1 1 1 1 1 1 1 2 1 1 1 1 2 2 2 2

HFRS44 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS45 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS46 1 1 1 1 1 1 1 1 2 1 1 1 1 2 2 2 2

HFRS47 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS48 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS49 1 1 1 1 1 1 1 1 2 1 1 1 1 2 2 2 2

HFRS50 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS51 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS52 1 1 1 1 1 1 1 1 2 1 1 1 1 2 2 2 2

HFRS53 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS54 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS55 1 1 1 1 1 1 1 1 2 1 1 1 1 2 2 2 2

HFRS56 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS57 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS58 1 1 1 1 1 1 1 1 2 1 1 1 1 2 2 2 4

HFRS59 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS60 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS61 1 1 1 1 1 1 1 1 2 1 1 1 1 2 2 2 2

HFRS62 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS63 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS64 1 1 1 1 1 1 1 1 2 1 1 1 1 2 2 2 2

MODULE, power, HFR, 400v/3ph, ce

L010S1

L040S1

LOWER, chemical, 10, SST, ucup

LOWER, chemical, 40, SST, ucup

103

L060S1

L080S1

LOWER, chemical, 60, SST, ucup

LOWER, chemical, 80, SST, ucup

L100S1

L010S1

LOWER, chemical, 100, SST, ucup

LOWER, chemical, 10, SST, ucup

104

L015S1

L020S1

LOWER, chemical, 15, SST, ucup

LOWER, chemical, 20, SST, ucup

105

24M167

24M168

MODULE, outlet, fluid, HFR,CS

MODULE, outlet, fluid, HFR, SST

106

24M100

24M103

KIT, hose, 1/2x10, CS, B, silicone

KIT, hose, 1/2x10, SS, B, silicone

24M105

24M108

KIT, hose, 1/2x10, CS, A, silicone

KIT, hose, 1/2x10, SS, A, silicone

107

24M107

24M109

KIT, hose, 1/4x10, CS, A, silicone

KIT, hose, 1/4x10, SS, A, silicone

108

24M110

255179

KIT, hose, 3/16x10, SS, A, silicone

VALVE, dispense, 1:1, soft seats

109

110

24E505

24E250

KIT, orifice block

KIT, orifices, 1/4”

111

120955

CM7A59

CORD SET, euro, male, 4pin, 3wire, 4 meter

SUPPLY UNIT, 20:1, 0 volt, d200, 200l, CS

112&113

CM7C58

CM7A3C

SUPPLY UNIT, 20:1, 0 volt, d200, 200l, SS

SUPPLY UNIT, 20:1, 0 volt, s20, 20l, CS

114

CM7C3F

24M181

SUPPLY UNIT, 20:1, 0 volt, s20, 20l, SS

KIT, hose, 3/4x15, inlet, CS

115

24M182

24M132

KIT, hose, 3/4x15, inlet, SS

KIT, assy, inlet, regulator, CS

117

24M133

16A093

KIT, assy, inlet, regulator, SS

SENSOR, pressure, fluid outlet

118

121399

PACKING, o-ring 012 fx75

36 3A2176J

Page 37

Parts

Ref

101

102

Part

---

24M034

24M035

Description

MODULE, base, HFR, silicone, laminate

MODULE, power, HFR, 230v/1ph

HFRS65 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS66 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS67 1 1 1 1 1 1 1 1 2 1 1 1 1 2 2 2 2

HFRS68 1 1 1 1 1 1 1 1 2 1 1 2 2 2 2 2

HFRS69 1 1 2 1 1 1 1 2 1 1 2 2 2

HFRS70 1 1 2 1 1 1 1 2 1 1 2 2 2

HFRS71 1 1 2 1 1 1 1 2 1 1 2 2 2

HFRS72 1 1 2 1 1 1 1 2 1 1 2 2 2

HFRS73 1 1 1 1 1 1 1 1 2 1 1 2 2 2

HFRS74 1 1 1 1 1 1 1 1 2 1 1 2 2 2

HFRS75 1 1 1 1 1 1 1 1 2 1 1 2 2 2

HFRS76 1 1 1 1 1 1 1 1 2 1 1 2 2 2

HFRS77 1 1 1 1 1 1 1 1 2 1 1 2 2 2

HFRS78 1 1 1 1 1 1 1 1 2 1 1 2 2 2

HFRS79 1 1 1 1 1 1 1 1 2 1 1 2 2 2

HFRS80 1 1 1 1 1 1 1 1 2 1 1 2 2 2

HFRS81 1 1 1 1 1 1 1 2 1 1 2 2 2

HFRS82 1 1 1 1 1 1 1 1 2 1 1 2 2 2

HFRS83 1 1 1 1 1 1 1 1 2 1 1 2 2 2

HFRS84 1 1 1 1 1 1 1 1 2 1 1 2 2 2

HFRS85 1 1 1 1 1 1 1 1 2 1 1 2 2 2

HFRS86 1 1 1 1 1 1 1 1 2 1 1 2 2 2

HFRS87 1 1 1 1 1 1 1 1 2 1 1 2 2 2

HFRS88 1 1 1 1 1 1 1 1 2 1 1 2 2 2

HFRS89 1 1 1 1 1 1 1 1 2 1 1 2 2 2

HFRS90 1 1 1 1 1 1 1 1 2 1 1 2 2 2

HFRS91 1 1 1 1 1 1 1 1 2 1 1 2 2 2

HFRS92 1 1 1 1 1 1 1 1 2 1 1 2 2 2

HFRS93 1 1 2 1 1 1 1 2 1 1 2 2 2 2 2

HFRS94 1 1 2 1 1 1 1 2 1 1 2 2 2 2 2

HFRS95 1 1 2 1 1 1 1 2 1 1 2 2 2 2 2

HFRS96 1 1 2 1 1 1 1 2 1 1 2 2 2 2 2

MODULE, power, HFR, 400v/3ph, ce

L010S1

L040S1

LOWER, chemical, 10, SST, ucup

LOWER, chemical, 40, SST, ucup

103

L060S1

L080S1

LOWER, chemical, 60, SST, ucup

LOWER, chemical, 80, SST, ucup

L100S1

L010S1

LOWER, chemical, 100, SST, ucup

LOWER, chemical, 10, SST, ucup

104

L015S1

L020S1

LOWER, chemical, 15, SST, ucup

LOWER, chemical, 20, SST, ucup

105

24M167

24M168

MODULE, outlet, fluid, HFR,CS

MODULE, outlet, fluid, HFR, SST

106

24M100

24M103

KIT, hose, 1/2x10, CS, B, silicone

KIT, hose, 1/2x10, SS, B, silicone

24M105

24M108

KIT, hose, 1/2x10, CS, A, silicone

KIT, hose, 1/2x10, SS, A, silicone

107

24M107

24M109

KIT, hose, 1/4x10, CS, A, silicone

KIT, hose, 1/4x10, SS, A, silicone

108

24M110

255179

KIT, hose, 3/16x10, SS, A, silicone

VALVE, dispense, 1:1, soft seats

109

110

24E505

24E250

KIT, orifice block

KIT, orifices, 1/4”

111

120955

CM7A59

CORD SET, euro, male, 4pin, 3wire, 4 meter

SUPPLY UNIT, 20:1, 0 volt, d200, 200l, CS

112&113

CM7C58

CM7A3C

SUPPLY UNIT, 20:1, 0 volt, d200, 200l, SS

SUPPLY UNIT, 20:1, 0 volt, s20, 20l, CS

114

CM7C3F

24M181

SUPPLY UNIT, 20:1, 0 volt, s20, 20l, SS

KIT, hose, 3/4x15, inlet, CS

115

24M182

24M132

KIT, hose, 3/4x15, inlet, SS

KIT, assy, inlet, regulator, CS

117

24M133

16A093

KIT, assy, inlet, regulator, SS

SENSOR, pressure, fluid outlet

118

121399

PACKING, o-ring 012 fx75

3A2176J 37

Page 38

Parts

Ref

101

102

Part

---

24M034

24M035

Description

MODULE, base, HFR, silicone, laminate

MODULE, power, HFR, 230v/1ph

HFRS97 1 1 2 1 1 1 1 2 1 1 2 2 2 2 2

HFRS98 1 1 2 1 1 1 1 2 1 1 2 2 2 2 2

HFRS99 1 1 2 1 1 1 1 2 1 1 2 2 2 2 2

HFRSA0 1 1 2 1 1 1 1 2 1 1 2 2 2 2 2

HFRSA1 1 1 2 1 1 1 1 2 1 1 2 2 2

HFRSA2 1 1 2 1 1 1 1 2 1 1 2 2 2

HFRSA3 1 1 2 1 1 1 1 2 1 1 2 2 2

HFRSA4 1 1 2 1 1 1 1 2 1 1 2 2 2

MODULE, power, HFR, 400v/3ph, ce

L010S1

L040S1

LOWER, chemical, 10, SST, ucup

LOWER, chemical, 40, SST, ucup

103

L060S1

L080S1

LOWER, chemical, 60, SST, ucup

LOWER, chemical, 80, SST, ucup

L100S1

L010S1

LOWER, chemical, 100, SST, ucup

LOWER, chemical, 10, SST, ucup

104

L015S1

L020S1

LOWER, chemical, 15, SST, ucup

LOWER, chemical, 20, SST, ucup

105

24M167

24M168

MODULE, outlet, fluid, HFR,CS

MODULE, outlet, fluid, HFR, SST

106

24M100

24M103

KIT, hose, 1/2x10, CS, B, silicone

KIT, hose, 1/2x10, SS, B, silicone

24M105

24M108

KIT, hose, 1/2x10, CS, A, silicone

KIT, hose, 1/2x10, SS, A, silicone

107

24M107

24M109

KIT, hose, 1/4x10, CS, A, silicone

KIT, hose, 1/4x10, SS, A, silicone

108

24M110

255179

KIT, hose, 3/16x10, SS, A, silicone

VALVE, dispense, 1:1, soft seats

109

110

24E505

24E250

KIT, orifice block

KIT, orifices, 1/4”

111

120955

CM7A59

CORD SET, euro, male, 4pin, 3wire, 4 meter

SUPPLY UNIT, 20:1, 0 volt, d200, 200l, CS

112&113

CM7C58

CM7A3C

SUPPLY UNIT, 20:1, 0 volt, d200, 200l, SS

SUPPLY UNIT, 20:1, 0 volt, s20, 20l, CS

114

CM7C3F

24M181

SUPPLY UNIT, 20:1, 0 volt, s20, 20l, SS

KIT, hose, 3/4x15, inlet, CS

115

24M182

24M132

KIT, hose, 3/4x15, inlet, SS

KIT, assy, inlet, regulator, CS

117

24M133

16A093

KIT, assy, inlet, regulator, SS

SENSOR, pressure, fluid outlet

118

121399

PACKING, o-ring 012 fx75

--- Not for sale.

38 3A2176J

Page 39

Parts

3A2176J 39

Page 40

Parts

Base Module

243

242

1

253

231

233,

234

203

227,

228

235,

236,

237

244

208

207

232

239

1

Torque to 17 ft-lb (23 N•m).

2

Apply sealant #247 to threads.

3

Apply sealant #248 to threads.

4

Set MCM rotary ID switch to 3.

6

Torque to 62 ft-lb (84 N•m).

7

238

240

6

Apply sealant #250 to threads.

8

Apply lubricant #251.

9

Torque to 300 in-lb (34 N•m).

10

Torque to 60 ft-lb (81 N•m).

11

Torque to 50 ft-lb (68 N•m).

12

Apply a thin layer of lubricant #251 to

the sensor tube of sensor assembly

#221.

13

Torque to 50 in-lb (6 N•m).

14

Pump couplers and retainer cups are

supplied with the material pumps.

15

Fill powerpack tank with hydraulic oil

#252. Check after initial start up to

ensure proper fluid level.

246

15

201

206

1 2

203

ti18251a

FIG. 13: Base Module, Image 1 of 2

202

229

212

213

203

1 2

2 9

245

203

40 3A2176J

Page 41

241

Parts

4

230

225

254,

220

218,

219

255

1 2

3

204

205

11

14

214

10

209

7

211

8

226

223,

224

203

210,

13

222

212,

213

2

9

ti18252a

See Lubrication Kit,

24M154, on page specific flow rate and pres-

215

216

214

10

221

12

220

11

sure information

if equipped.

217,

1 2

219

203

FIG. 14: Base Module, Image 2of 2

3A2176J 41

Page 42

Parts

Ref Part Description Qty

201 ---

202 24M024

MODULE, powerpack, enclosure, no cooler

BRACKET, anchor, cube, CS,

painted

203 111800 SCREW, cap, hex head 23

204 122970

FITTING, adapter,

jic(08)xsae(08)

205 123140 FITTING, cap, 1/2 jic, CS 1

206 ▲ 15M511 LABEL, warning, eng/span/fre 1

207 123313 VALVE, directional, hydraulic 1

208 123366 SCREW, SHC, 10-24x1.125, s 4

209 16E281 STUD, threaded, 3/8-16 x 6.0 4

210 258771

DRIVER, hydraulic, horizontal,

3.0"stroke

211 103413 PACKING, o-ring 2

212 100731 WASHER 4

213 U90126 NUT, hex, 3/8-16, MS 4

214 15X519 ROD, tie, 12 long, 5/8-11 UNC 6

215 123112

FITTING, tee, 1/4 tube, prestolock, brass

216 054175 TUBE, nylon, rd 5

217 24E168

218 24E169

219 16E277

BRACKET, pump, right, HFR,

painted

BRACKET, pump, left, HFR,

painted

BUSHING, flanged, nylon,

1.0x1.25x1.0

220 101712 NUT, lock 6

221 258669 SENSOR, assembly 1

222 258704 SPOOL, assembly 1

223 16A509 COLLAR, sensor 1

224 119999 BOLT, shoulder 2

225 125966 CLIP, hairpin, 3/4 1

226 123798

CABLE, m8, 4-pin, malexfe-

male, 1m, molded

227 16G251 HOUSING, filter, painted 1