Page 1

Instructions

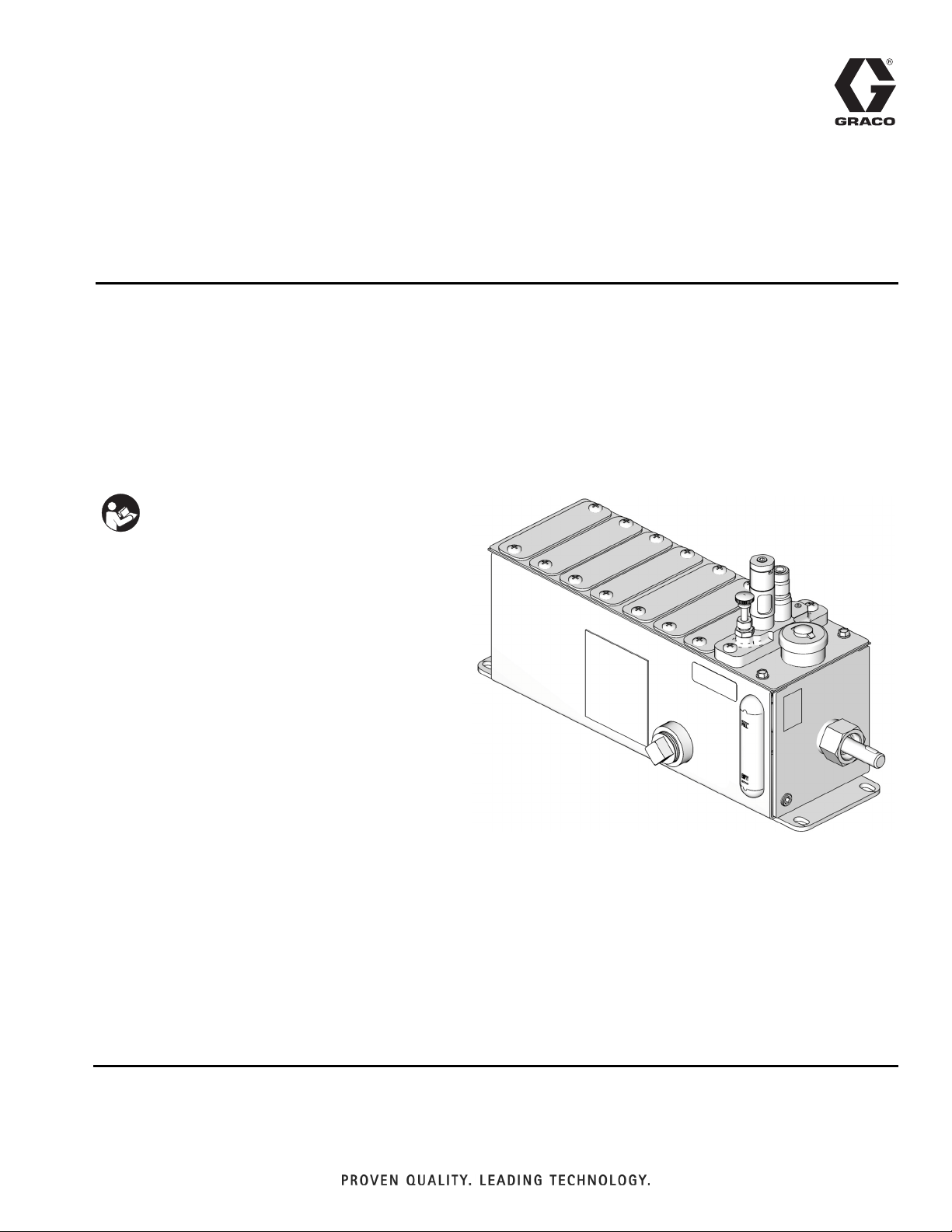

Modular Box

3A2100C

Lubricator

Fluid container used with GBL7500 Suction Fed, Gravity Fed or Pressure Fed Box

Lubricator Pumps used for dispensing non-corrosive and non-abrasive oils and lubricants.

For professional use only.

See Technical Data, page 13 for maximum outlet pressures per pump station.

Important Safety Instructions

Read all warnings and instructions in this

manual and your pump instruction

manual. Save all instructions.

EN

See page 2 for part number information.

ti17757

Page 2

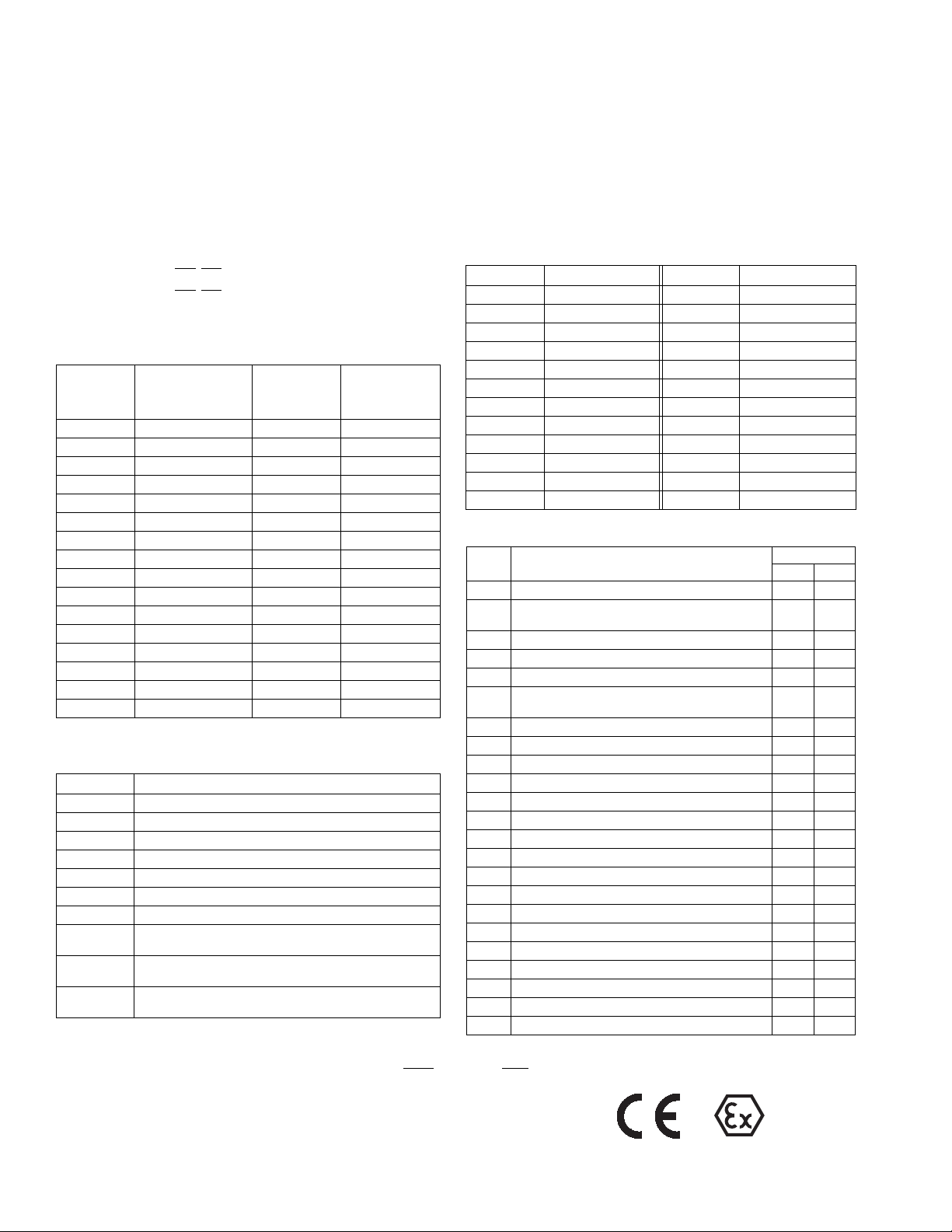

Part Number

Use the Part Number Key provided below to identify each system component. The Code for each Option that makes up the Part

Number are provided in the tables below. For example, MBB1DE is a Modular Box; 6 pint reservoir, (maximum of 3 pumping stations and no motor mount base); 3/16 suction fed pump; 3 pumps; and a direct end rotary drive.

NOTE: Some pump configurations are not available. Contact Graco Customer Service or your local Graco distributor for assistance.

Par t Key: MB

Part Example: MB

A-B -C-D

B-1 -D-E

MB = Identifies pump as Graco MB part

Option A: Reservoir Size and Motor Mount Base

Code

A 4 (1.89) 2 NA

B 6 (2.84) 3 NA

C 8 (3.79) 5 NA

D 12 (5.68) 8 NA

E 16 (7.57) 12 NA

F 24 (11.36) 16 NA

G 32 (15.14) 20 NA

H 40 (18.93) 24 NA

J 4 (1.89) 2 X

K 6 (2.84) 3 X

L 8 (3.79) 5 X

M 12 (5.68) 8 X

N 16 (7.57) 12 X

P 24 (11.36) 16 X

R 32 (15.14) 20 X

S 40 (18.93) 24 X

Reservoir Size:

pints (liters)

Max Number

of Pump

Stations

Motor Mount

Base

Option B: GBL7500 Pump and Level Controller

Code

0◆ No Pump

1◆ 3/16 Suction Fed Pump

2◆ 1/4 Suction Fed Pump

3◆ 3/8 Suction Fed Pump

4 3/16 Suction Fed Pump with RENS Level Controller

5 1/4 Suction Fed Pump with RENS Level Controller

6 3/8 Suction Fed Pump with RENS Level Controller

7

8

9

3/16 Suction Fed Pump with GARZO Level Controller

(Class 1, Group D)

1/4 Suction Fed Pump with GARZO Level Controller

(Class 1, Group D)

3/8 Suction Fed Pump with GARZO Level Controller

(Class 1, Group D)

Description

Option C: Pump Quantity

Code Quantity Code Quantity

A0N12

B1P13

C2R14

D3S15

E4T16

F5U17

G6V18

H7W19

J8X20

K9Y21

L10Z22

M11

Option D: Drive Type

Code Description

A◆ Direct end rotary X

End ratchet (w/out drive arm) - 800 rpm max

B

input

C End rotary ratchet 37.5:1 - 800 rpm max input X

D End rotary ratchet, 75:1 - 800 rpm max input X

E◆ Direct end rotary X

End ratchet (w/out drive arm) - 800 rpm max

F

input

G End rotary ratchet 37.5:1 - 800 rpm max input X

H End rotary ratchet, 75:1 - 800 rpm max input X

J Double reduction end rotary, 25:1 X

K Double reduction end rotary, 50:1 X

L Double reduction end rotary, 100:1 X

M Double reduction end rotary, 200:1 X

N Double reduction end rotary, 400:1 X

P Right angle rotary 25:1 X

R Right angle rotary 50:1 X

S Right angle rotary 188:1 X

T Right angle rotary 375:1 X

U 100:1 ratio gear reducer X

V 150:1 ratio gear reducer X

W 200:1 ratio gear reducer X

X 300:1 ratio gear reducer X

Y 400:1 ratio gear reducer X

Z Left angle rotary 188:1 X

Drive Side

Left Right

X

X

◆ Configurations containing these selections from both

Option B and Option D are CE and Atex certified.

II 2 G

cT6

2 3A2100C

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual, refer back to these Warnings. Product-specific hazard symbols and

warnings not covered in this section may appear throughout the body of this manual where applicable.

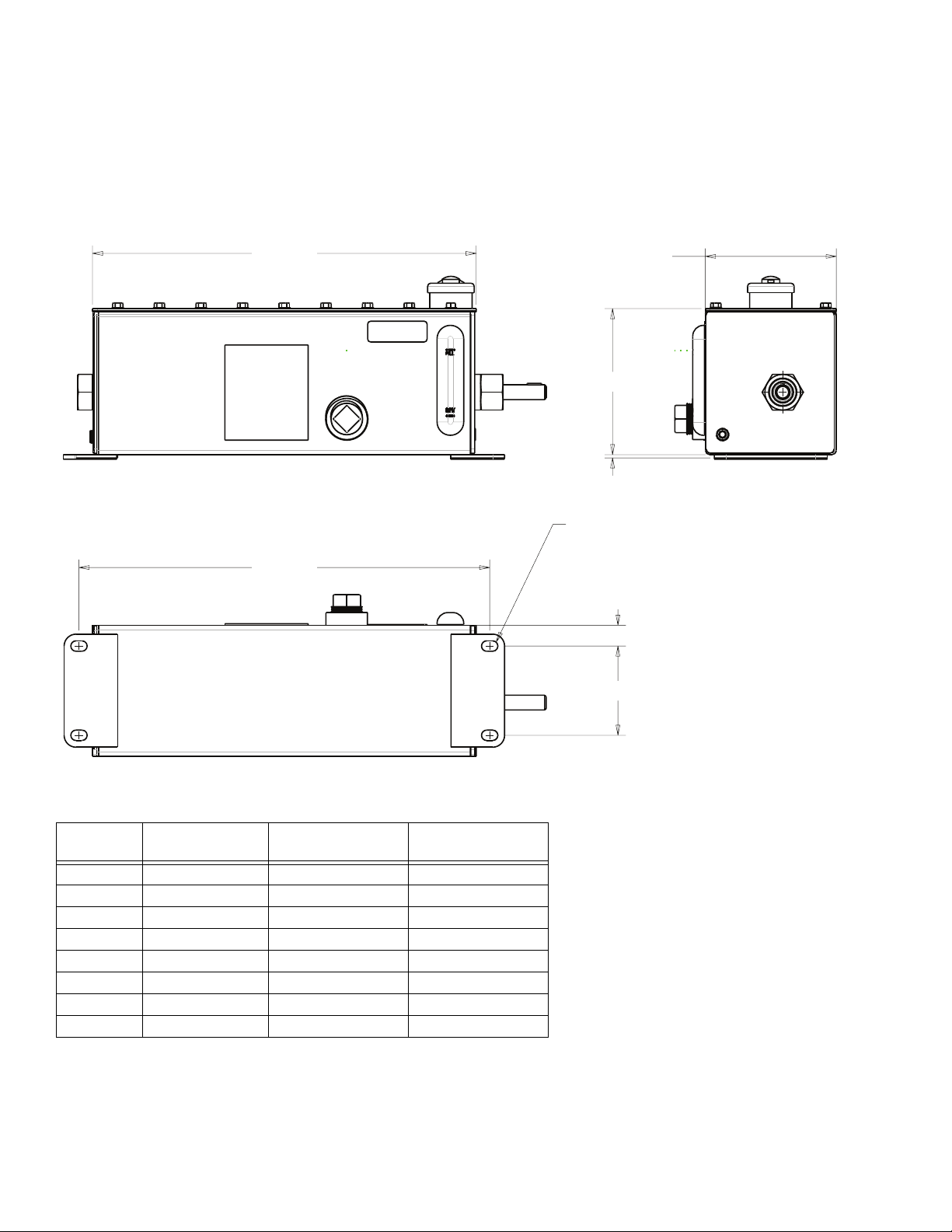

WARNING

FIRE AND EXPLOSION HAZARD

When flammable fluids are present in the work area, such as gasoline and windshield wiper fluid, be aware

that flammable fumes can ignite or explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources, such as cigarettes and portable electric lamps.

• Keep work area free of debris, including rags and spilled or open containers of solvent and gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Ground all equipment in the work area.

• Use only grounded hoses.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment until

you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

SKIN INJECTION HAZARD

+

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This may

look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical treat-

ment.

• Do not point dispensing device at anyone or at any part of the body.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

3A2100C 3

Page 4

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about

your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create

safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure and disconnect all power sources.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including eye

injury, hearing loss, inhalation of toxic fumes, and burns. This protective equipment includes but is not limited to:

• Protective eye wear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

4 3A2100C

Page 5

Installation

Installation

Modular box lubricators are not approved for use in

hazardous locations or explosive atmospheres

unless all accessories, components and wiring

meet all local and national codes.

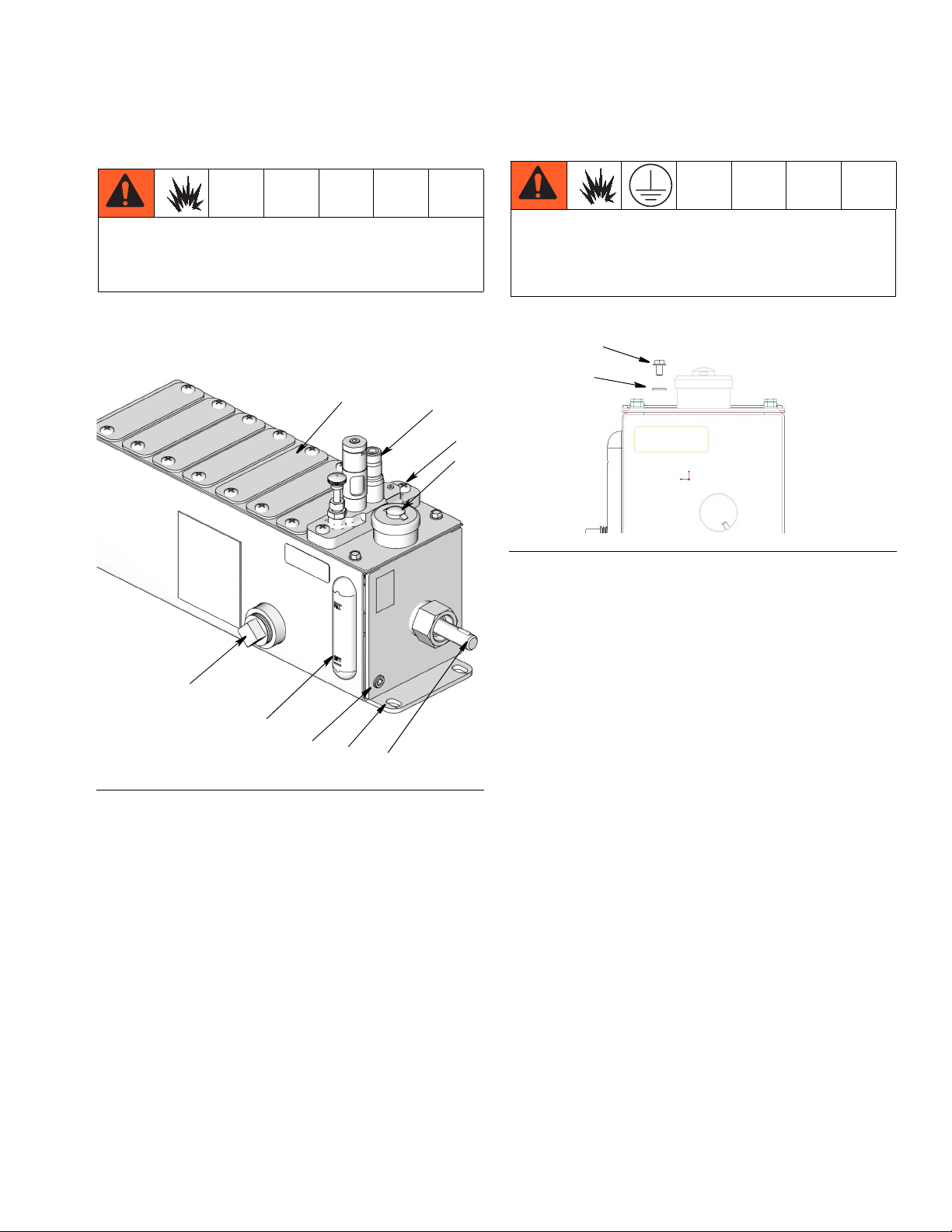

Component Identification

D

ti17757

H

Grounding

The equipment must be grounded to reduce the risk

of static sparking. Static sparking can cause fumes to

ignite or explode. Grounding provides an escape wire

for the electric current.

a

b

J

B

FIG. 2

1. Loosen grounding screw (a) (FIG. 2) and place one

end of a 12 gauge (1.5mm) minimum ground wire

between the grounding screw and washer (b).

G

A

FIG. 1

Key:

A Site glass

B Fill cap

CDrain plug

D Pump blank

E Drive shaft - (with woodruff key)

F Mounting holes

G Accessory plug (heater port)

H Pump (not on all models)*

J Mounting screw

*The GBL7500 Box Lubricator Pump and GBL Shaft Rotation/Low Level Alarm Pump are available from Graco. See

Accessories/Other Accessories, page 12 for information about

these pump models and the related instruction manual.

C

F

E

2. Tighten grounding screw (a) securely.

3. Connect other end of wire to a true earth ground.

Installation Procedure

Reference letters used in the following instructions, refer

to F

IG. 1.

1. Select a mounting surface that satisfies the following:

• Is able to support the weight of the reservoir

and fluid when filled to capacity.

NOTE: When possible, mount to a surface that

experiences little or no vibration.

• Allows easy access to the lubricator for filling

the reservoir and periodic maintenance.

• The lubricator must be connected to a ground

source.

2. Install reservoir to the mounting surface. See

mounting hole layout in the Reservoir and Mounting

Dimension section of this manual, page 14.

3. Install bolts through holes (F) in reservoir mounting

bracket and tighten securely.

3A2100C 5

Page 6

Installation

4. Remove fill cap (B) and fill reservoir with clean, filtered fluid until it reaches the full line on the sight

glass.

NOTE:

• Filter oil with a minimum 25 micron strainer.

Depending on machine requirements it may be

necessary to maintain a higher cleanliness

level.

• A pump blank is provided to install over all

unused pump stations.

• Refer to pump instruction manual for pump

installation and priming instructions. (See

page 12 for Graco pump model information.)

Drive Mechanism

A 5/8 in. diameter shaft is provided to connect the lubricator to a rotary power source. A woodruff key and key

way on the shaft are provided to aid in connecting this

source.

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid, such as skin injection, splashing

fluid and moving parts, follow the Pressure Relief

Procedure in your pump manual when you stop

dispensing and before cleaning, checking, or

servicing the equipment.

1. Stop lube pump.

2. If installed, close oil supply valve located upstream

from pump.

3. If installed, open drain valve located downstream

from the pump.

4. Slowly crack open fluid line fittings to relieve pressure.

Install protective guards around all drive components

upon installation.

Notice

The recommended speed of the box lubricator cam

shaft is 3 - 50 rpm. Do not exceed the maximum value

of 50 rpm to avoid pump damage.

Refilling the Reservoir

When necessary, fill the lubricator reservoir with clean

filtered lubricant until it reaches the fill line on the sight

glass. A sight level gauge is provided on the reservoir to

monitor the fluid level. The oil level should not be

allowed to drop below the line indicating an empty reservoir.

Service/Maintenance

1. Follow the Pressure Relief Procedure before per-

forming any service procedures.

2. Lubricator operation can be checked by observing

the drip tube located within the sight glass well of

your pump.

• If the correct pumping rate is maintained, no

servicing is required other than periodic replenishment of the reservoir.

• If the sight glass well pumps dry or no flow is

observed refer to the Troubleshooting Section,

page 8.

3. Inspect box for worn or damaged components.

Replace as necessary.

6 3A2100C

Page 7

4. Clean lubricator periodically to eliminate contamination that may have occurred in the oil. To accomplish

this:

Installation

a. Drain reservoir by removing drain plug (C) (F

IG.

1). Dispose of oil according to all applicable

safety regulations.

b. Remove all pumping units.

c. Clean the pumps and reservoir by brushing

loose all foreign matter, dipping in solvent and

blowing dry with compressed air.

d. Replace pumping units. Torque mounting

screws (J) to 110 in. lbs +

+

1.13 N.m).

10 in. lbs. (12.43 N.m

e. Apply thread sealant (user supplied) to drain

plug (C) (F

lbs +

IG. 1) and replace. Torque to 35 in.

5 in. lbs. (3.95 N.m + 0.6 N.m).

f. Fill reservoir. (See Refilling the Reservoir, page

6).

3A2100C 7

Page 8

Troubleshooting

Troubleshooting

Problem Cause Solution

Sight well pumps dry

Low oil level in reservoir Add oil. See Refilling the Reservoir,

page 6.

Pump issue Refer to the Troubleshooting Section

of your pump instruction manual.

Low oil level in reservoir Add oil. See Refilling the Reservoir,

page 6.

Camshaft not rotating because

rotatory power source is defective

No flow from pump outputs

Leaking from under pump Defective gasket Replace gasket.

Leaking from reservoir accessory

plug

Leaking from reservoir drain plug

Camshaft not rotating because

rotatory power source connection is defective

Broken camshaft Replace lubricator box.

Pump issue Refer to the Troubleshooting Section

Insufficient thread sealant

Replace rotary power source.

Fix rotary power source connection to

lubricator box.

of your pump instruction manual.

Clean and replace thread sealant

(user supplied).

8 3A2100C

Page 9

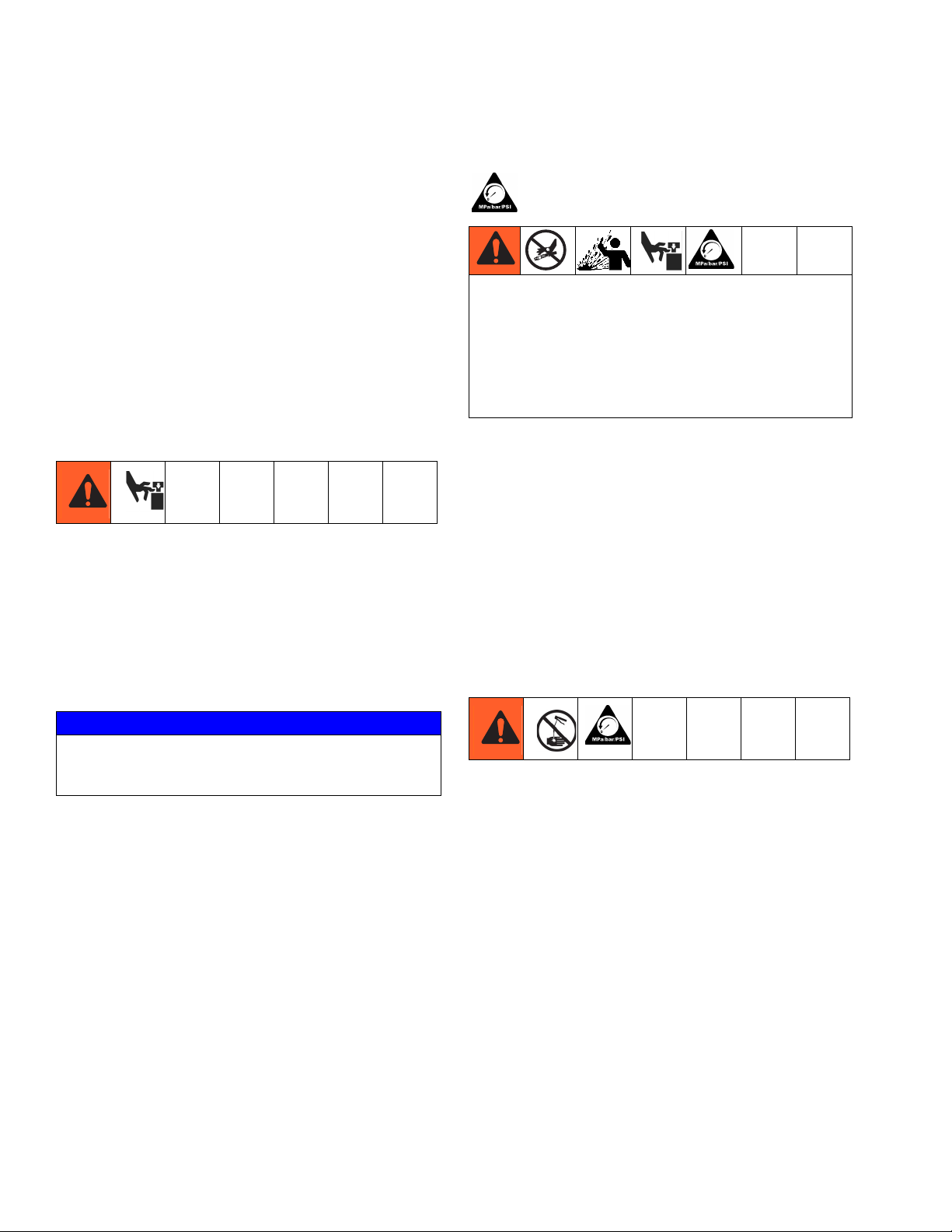

Bare Box Parts

Model: MBD0AA Shown

1

41

Bare Box Parts

1

39

40

12

11

2

17

18

5

Ref Part No. Description Qty

1 RESERVOIR 1

2COVER, assembly 1

4 557391 PLUG, dry seal, 1/4 NPTF 2

5 SIGHTGLASS, level 1

11 557149 STRAINER, filter 1

12 557171 COVER, oil, hole 1

14 555377 KEY, #3 USA 404 Woodruff

556368 KEY, #5 USA 405 Woodruff 1

17▲16G243 LABEL, warning, CE & Atex Models 1

16P808 LABEL, warning, not CE or Atex 1

18 16P807 LABEL, max working pressure 1

39 557128 PLATE, blankoff

40 556732 GASKET

41 119426 SCREW, mach, hex washer hd

*

*

*

14

4

1

Torque to 110 in. lbs + 10 in. lbs.

(12.43 N.m +

1.13 N.m)

* See Part Numbers, page 2 for quantity.

▲ Replacement Danger and Warning labels, tags, and

cards are available at no cost.

3A2100C 9

Page 10

Accessories

Accessories

Modular box lubricators are not approved for use in

hazardous locations or explosive atmospheres unless

all accessories, components and wiring meet all local

and national codes.

Pumps* - CE and ATEX certified

Part No. Description Special Features / Notes

24J391 3/16 in. Suction Fed Pump Available as a configured option. See Option B, page 2.

24J392 1/4 in. Suction Fed Pump Available as a configured option. See Option B, page 2.

24J393 3/8 in. Suction Fed Pump Available as a configured option. See Option B, page 2.

24J394 3/16 in. Gravity Fed Pump Not available as a configured option.

24J395 1/4 in. Gravity Fed Pump Not available as a configured option.

24J396 3/8 in. Gravity Fed Pump Not available as a configured option.

24J397 3/16 in. Pressure Fed Pump Not available as a configured option.

24J398 1/4 in. Pressure Fed Pump Not available as a configured option.

24J399 3/8 in. Pressure Fed Pump Not available as a configured option.

Not available as a configured option.

24K466 Alarm Pump

Senses shaft rotation and oil level.

Pressure switch operation is dependent upon shaft rotation and adequate oil level.

NOTE: Pressure switch is not included.

*See pump instruction manual 3A2257.

10 3A2100C

Page 11

Motors

Accessories

Part

No.

557270 1/2 1725 230/460 60 3 Class B Polyphase Continuous TENV 56C

557271 1/2 1725 115/230 60 1 Class B

558289 1/4 1725 115/230 60 1 Class B

558290 1/4 1725 230/460 60 3 Class F Polyphase

558291 1/2 1725 230/460 60 3 Class B Polyphase Continuous XPFC 56C

558292 1/3 1725 230/460 60 3 Class A Polyphase Continuous

558293 1/3 1725 115/230 60 1 Class B

558294 1/2 1725 115/230 60 1 Class FJ

558295 1/2 1725 230/460 60 3 Class BJ Polyphase Continuous

Horse

Power RPM Voltage Hertz Phase Insulation Type Duty Enclosure Frame

Capacitor

Start

Capacitor

Start

Capacitor

Start

Capacitor

Start

Continuous TEFC 56C

Continuous TENV 56

TENV FB56

56

Continuous TENV 56

Continuous

56C

Special

Features

NEMA B Ball

Bearings

NEMA B Ball

Bearings

NEMA B Ball

Bearings

Non-Ventilated

NEMA B Ball

Bearings

Explosion Proof

Class 1 Group D

Explosion Proof

Class 1 Group D

Non-Ventilated

NEMA B Ball

Bearings

Explosion Proof

Class 1 Group D

NEMA B Ball

Bearings

Explosion Proof

Class 1

Group C & D

Explosion Proof

Class 2

Group F & G

Outdoor & Chemi-

cal Duty (SXT)

Fan Cooled

Tropical Insulation

(Anti-Fungus)

Explosion Proof

Class 1

Group C & D

Explosion Proof

Class 2

Group F & G

Outdoor & Chemi-

cal Duty (SXT)

Fan Cooled

Tropical Insulation

(Anti-Fungus)

Thermal

Overload

Protected

Temperature Class

T3C

3A2100C 11

Page 12

Accessories

Electric Heaters

Part

No. Voltage Watts

564058 115 150 115/230

557207 12 200 120

Thermostat

Volt ag e

Temperature

Range

-100°F to 500°F

(38°C to 260°C)

60°F to 240°F

(16°C to 116°C)

Watt

Density

20w/in

22w/in

Hazardous

Area

Rating

Class 1

2

Group D

Class 1

2

Group B

Reservoir

Size: pints

(liters)

4 (1.89) N/A*

6 (2.84) 1

8 (3.79) 1

12 (5.68) 1

16 (7.57) 2

24 (11.36) 2

32 (15.14) 3

40 (18.93) 3

4 (1.89) N/A*

6 (2.84) 1

8 (3.79) 1

12 (5.68) 1

16 (7.57) 2

24 (11.36) 2

32 (15.14) 3

40 (18.93) 3

Number of

Heaters

Required

*Electric heaters are not available on 4 pint reservoir sizes.

Electric Heater 557207 cannot be used with the following configurations: MBB3-5**, MBC3-5**, MBD3-5**, MBJ3-5**,

MBK3-5**, MBL3-5**.

Other Accessories

Part No. Description Special Features/Notes

563005 Drive Arm For use with End Ratchet Drives. Option D, Codes B or F, page 2

Mounted in the last pump station opposite drive.

559037 Gravity Supply

563026

563013 Low Level Switch

564015 Low Level Switch

Pressurized

Supply

Exception is when an Alarm Pump is used, then this option is mounted in the second to the last

pump station.

Mounted in the last pump station opposite drive.

Exception is when an Alarm Pump is used, then this option is mounted in the second to the last

pump station.

Single-pole, double-throw.

Explosion Proof Class 1 Group C & D.

Explosion Proof Class 2 Group E, F & G.

Mounted in the last pump station opposite drive.

Exception is when an Alarm Pump is used, then this option is mounted in the second to the last

pump station.

Single-pole, single-throw.

N.C. Electric Rating is 10 watts @ 120 VAC (minimum).

Mounted in the last pump station opposite drive.

Exception is when an Alarm Pump is used, then this option is mounted in the second to the last

pump station.

12 3A2100C

Page 13

Technical Data

Modular Box Lubricator

US Metric

Pump Size Maximum Outlet

Pressure

3/16” 7500 psi 51.71 MPa

1/4” 6000 psi 41.37 MPa

3/8” 2500 psi 17.24 MPa

Temperature

Operating Temperature Range

Fluid Viscosity

Dispensing Fluid Viscosity 80 to 5000 SUS

Materials of Constructions

Wetted Materials spring steel, carbon steel, stainless steel, nylon,

Drive Speed

Drive Speed

Noise (dBa)**

Maximum sound pressure

Notes

**Sound pressure measured at the work station with 3/8” pumps running at 50 rpm with 3500 psi

(24.13 MPa, 241.3 bar) working pressure

-20°F to 140°F

fluoroelastomer

3 to 50 rpm

74 dBa

Maximum Outlet

Pressure

517.1 bar

413.7 bar

172.4 bar

(-29°C to 60°C)

Technical Data

3A2100C 13

Page 14

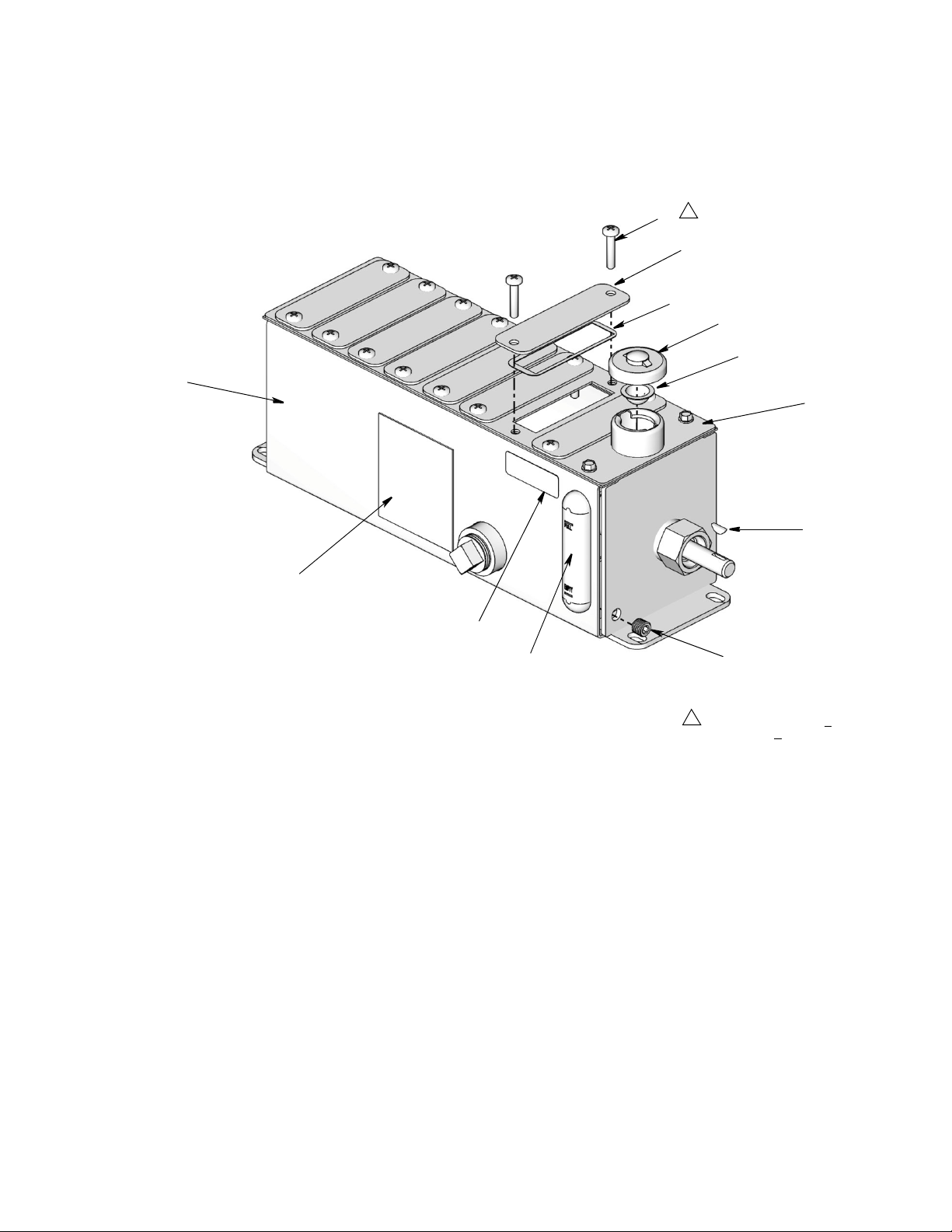

Reservoir and Mounting Dimensions

Reservoir and Mounting Dimensions

Dimensions are shown in inches (mm).

DIM A

DIM B

5.5 (139.7)

6.1 (154.94)

.13 (3.31)

4X SLOTS .438 X .688

(11.13 X 17.48)

.875 (22.23)

3.75 (95.25)

Dimensions: All Reservoirs

Option A

Code

A or J 4 (1.89) 5.63 (143.0) 6.89 (175.0)

B or K 6 (2.84) 7.38 (187.4) 8.64 (219.5)

C or L 8 (3.79) 10.88 (276.4) 12.14 (308.4)

D or M 12 (5.68) 16.13 (409.7) 17.39 (441.7)

E or N 16 (7.57) 23.13 (587.5) 24.39 (619.5)

F or P 24 (11.36) 30.13 (765.3) 31.39 (797.3)

G or R 32 (15.14) 37.13 (943.1) 38.39 (975.1)

H or S 40 (18.93) 44.13 (1120.9) 45.39 (1152.9)

14 3A2100C

Reservoir Size

Pints (Liters)

Dimension A

Inch (mm)

Dimension B

Inch (mm)

Page 15

Drive Options and Dimensions

Dimensions are shown in inches (mm).

Refer to the Part Number Key, page 2 to determine your specific drive.

Direct End Rotary

Option D, Code A or E (page 2) - Option D, Code A shown.

Drive Options and Dimensions

2.25 (57.15)

2.375 (60.33)

FROM C/L OF SLOT

.50 (12.7)

#5 WOODRUFF KEY

End Ratchet

Option D, Code B or F (page 2) - Option D, Code B shown

2.81 (71.37)

2.25 (57.15)

2.375 (60.33)

FROM C/L OF SLOT

.50 (12.7)

#5 WOODRUFF KEY

2.81 (71.37)

3A2100C 15

Page 16

Drive Options and Dimensions

End Rotary Ratchet

Option D, Code C, D, G, or H (page 2) - Option D, Code C or D shown

Code Ratio

Max Input

Speed

C or G 37.5:1 800 rpm

D or H 75:1 800 rpm

Double Reduction End Rotary

Option D, Code J - N (page 2) - Option D, Code J-N shown

Code Ratio

J25:1

K50:1

L 100:1

M 200:1

N 300:1

1.94 (49.28)

2.375 (60.33)

FROM C/L OF SLOT

.38 (9.65)

#3 WOODRUFF KEY

4.61 (117.09)

2.25 (57.15)

4.375 (111.13)

FROM C/L OF SLOT

.50 (12.7)

#3 WOODRUFF KEY

4.86 (123.44)

16 3A2100C

Page 17

Angle Rotary Drive

Option D, Code P - T and Z (page 2)

Code Ratio

P25:1

R50:1

S or Z 188:1

T 375:1

Right Hand Rear Drive Option D, Code P-T Shown

2.85 (72.39)

1.35 (34.37)

FROM C/L OF SLOT

Drive Options and Dimensions

6.735 (171.07)

FROM C/L OF SLOT

.50 (12.7)

#3 WOODRUFF KEY

8.359 (212.32)

FROM C/L OF SLOT

.50 (12.7)

#3 WOODRUFF KEY

/HIW+DQG5HDU'ULYH2SWLRQ'&RGH=6KRZQ

2.85 (72.39)

1.35 (34.37)

FROM C/L OF SLOT

3A2100C 17

Page 18

Drive Options and Dimensions

Gear Reducer

Option D, Code U - Y (page 2) - Option D, Code U-Y shown

Code Ratio

U 100:1

V 150:1

W 200:1

X 300:1

Y 400:1

4.95 (125.73)

11.75 (298.45)

5.75 (146.05)

18 3A2100C

Page 19

Motor Mounting Bases and Dimensions

Motor Mounting Bases and Dimensions

Dimensions are shown in inches (mm).

Refer to the Part Number Key, page 2 to determine your specific mounting base.

Motor Mounting Bases

Option A, Code J - N (page 2) - These selections may only be used with double reduction end rotary type drives,

Option D, Code J - N.

6.9 (175.26)

E X

.406 ( 10.32)

9.4 (238.76)D

3.0 (76.2)

C

A

7.3 (185.42)

.63 (16.00)

6.75 (171.45)

8.0 (203.2)

2.0 (50.8)B

.75 (19.05)

Dimensions

Option A

Code

J Base, Drip Pan 4 (1.89) 24.50 (622.3) 20.50 (520.7) 6.75 (171.5) 4

K Base, Drip Pan 6 (2.84) 26.25 (666.7) 22.25 (564.1) 8.50 (215.9) 4

L Base, Drip Pan 8 (3.79) 29.75 (755.6) 25.75 (654.0) 12.00 (304.8) 4

M Base, Drip Pan 12 (5.68) 35.00 (899.0) 15.50 (393.7) 31.00 (787.4) 17.25 (438.1) 6

N Base, Drip Pan 16 (7.57) 42.00 (1066.8) 19.00 (482.6) 38.00 (965.2) 24.25 (615.9) 6

3A2100C 19

Description

Pints (liters)

Dimension A

Inch (mm)

Dimension B

Inch (mm)

Dimension C

Inch (mm)

Dimension D

Inch (mm)

Quantity

E

Page 20

Motor Mounting Bases and Dimensions

Motor Mounting Bases

Option A, Code P - S (page 2) - These selections may only be used with gear reducer type drives, Option D, Code

U-Y.

14.0 (355.6)

12.0 (304.8)

10.0 (251.46)

4X

Dimensions

Option A

Code

P Base, Drip Pan 24 (11.36) 46.00 (1168.4) 16.00 (406.4)

R Base, Drip Pan 32 (15.14) 53.00 (1346.2) 23.00 (584.2)

S Base, Drip Pan 40 (18.93) 60.00 (1524.0) 30.00 (762.0)

.563

Description

Pint (liters)

B 15.0 (381.0)

A

Dimension A

Inch (mm)

11.75 (298.45)

2.74 (69.60)

.63 (16.00)

Dimension B

Inch (mm)

20 3A2100C

Page 21

Level Controller Dimensions

Level Controller Dimensions

Dimensions are shown in inches (mm).

Refer to part number key, page 2 to determine your specific level controller.

RENS Level Controller

Option B, Code 4 - 6 (page 2) - Automatic fill option. Does not require a pump station for mounting. Mounted only on

the front of the reservoir. Requires a maximum inlet pressure of 5 psi (0.03 MPa, 0.34 bar).

5.56 (141.22)

A

7.31 (185.93)

2.19 (55.63)

Dimensions

Option A

Code

A or J 4 (1.89) 1.00 (25.4)

B or K 6 (2.84) 2.75 (69.8)

C or L 8 (3.79) 3.63 (92.2)

D or M 12 (5.68) 3.63 (92.2)

E or N 16 (7.57) 11.50 (292.1)

F or P 24 (11.36) 15.00 (381.0)

G or R 32 (15.14) 12.38 (314.4)

H or S 40 (18.93) 14.13 (358.9)

Reservoir Size

Pints (Liters)

Dimension A

Inch (mm)

3A2100C 21

Page 22

Level Controller Dimensions

GARZO Level Controller

Option B, Code 7 - 9 (page 2) - Automatic fill option. Mounts on the front of the reservoir. Requires a 0 - 70 psi (0-

0.48 MPa, 0 - 4.82 bar) inlet supply. Switch actuates when a 1/2 to 3/4 loss of oil level occurs in the controller.

ELECTRICAL DATA

Contacts: Single Pole, Double-Throw

Contact Rating: 15 amps at 115/230 or 480 VAC

0.5 amps at 125 VDC

0.25 amps at 250 VDC

Switch Rating: Class 1, Group D

A

13.9 (353.06)

2.78 (70-63)

Dimensions

Option A

Code

A or J 4 (1.89) 1.00 (25.4)

B or K 6 (2.84) 2.75 (69.8)

C or L 8 (3.79) 3.63 (92.2)

D or M 12 (5.68) 3.63 (92.2)

E or N 16 (7.57) 11.50 (292.1)

F or P 24 (11.36) 15.00 (381.0)

G or R 32 (15.14) 12.38 (314.4)

H or S 40 (18.93) 14.13 (358.9)

Reservoir Size

Pints (Liters)

Dimension A

4.13 (104.9)

5.88 (149.36)

Inch (mm)

22 3A2100C

Page 23

Notes

Notes

3A2100C 23

Page 24

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2012, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 3A2100

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised December 2012

Loading...

Loading...