Page 1

Instructions - Parts

™

PCF

with

™

PrecisionSwirl

3A2098H

Precision Dispense System

Electronically-controlled fluid metering system that provides precise continuous flow of up

to four single-component sealants and adhesives through closed-loop technology.

Not for use in explosive atmospheres or hazardous locations.

For professional use only.

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

EN

See page 4 for model information. See page 5 for

maximum working pressure and approvals.

IMPORTANT:

This manual does not apply to some PCF systems. See note on page 3 to verify this is the

correct manual for your PCF system.

Optional PrecisionSwirl Orbital

Dispenser (sold separately)

PCF Control Center

PCF Fluid Plate

Page 2

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Fluid Plate Kits . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Expansion Swirl Enclosure Assemblies . . . . . . . 6

PrecisionSwirl Orbital Dispenser Assemblies . . . 6

Automation Gateway Assemblies . . . . . . . . . . . 7

Swirl Control DGM . . . . . . . . . . . . . . . . . . . . . . . 7

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

System Configurations . . . . . . . . . . . . . . . . . . . . . 10

Typical Installation - Single Swirl, Single Fluid Plate

10

Typical Installation - Multiple Fluid Plates, No Swirl

Dispensers . . . . . . . . . . . . . . . . . . . . . . . . . 11

Typical Installation - Multiple Fluid Plates, Multiple

Swirl Dispensers . . . . . . . . . . . . . . . . . . . . 12

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

System Overview . . . . . . . . . . . . . . . . . . . . . . . 13

System Components . . . . . . . . . . . . . . . . . . . . . 13

Fluid Plate Assembly Overview . . . . . . . . . . . . 14

Control Center Assembly Overview . . . . . . . . . 16

Key Tokens . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Before Installation . . . . . . . . . . . . . . . . . . . . . . . 21

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Install Control Center . . . . . . . . . . . . . . . . . . . . 22

Install Fluid Plate Assemblies . . . . . . . . . . . . . . 24

Install Cable Assemblies . . . . . . . . . . . . . . . . . . 28

Install Gateway Module Interface . . . . . . . . . . . 30

System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Configure System . . . . . . . . . . . . . . . . . . . . . . . 32

Configure Control Settings . . . . . . . . . . . . . . . . 33

Configure Mode Settings . . . . . . . . . . . . . . . . . 34

Configure Delay Settings . . . . . . . . . . . . . . . . . 34

Configure Flow Meter Settings . . . . . . . . . . . . . 35

Configure Pressure Loop Settings . . . . . . . . . . 35

Adjust Pressure Sensors . . . . . . . . . . . . . . . . . 36

Configure Errors . . . . . . . . . . . . . . . . . . . . . . . . 36

Setup Maintenance Schedule/Parameters . . . . 37

Configure Valve to Swirl Association and Motor

Error Type . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Configure Swirl Settings . . . . . . . . . . . . . . . . . . 38

Configure Gateway Settings . . . . . . . . . . . . . . . 38

Setup Styles . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Configure Advanced Settings . . . . . . . . . . . . . . 38

On/Off Delays . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Load Material . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Maintenance Mode Operation . . . . . . . . . . . . . . 41

Automation Control (Normal Operation) . . . . . . 45

Jobs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Styles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Precharge Modes . . . . . . . . . . . . . . . . . . . . . . . 47

Typical Job Cycle . . . . . . . . . . . . . . . . . . . . . . . 49

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 57

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

USB Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

USB Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

System Configuration Settings File . . . . . . . . . . 60

Custom Language File . . . . . . . . . . . . . . . . . . . 60

Download Procedure . . . . . . . . . . . . . . . . . . . . . 61

Upload Procedure . . . . . . . . . . . . . . . . . . . . . . . 61

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Fluid Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Flow Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Fluid Regulator . . . . . . . . . . . . . . . . . . . . . . . . . 63

Dispense Valves . . . . . . . . . . . . . . . . . . . . . . . . 64

Gateway Module . . . . . . . . . . . . . . . . . . . . . . . . 65

LED Diagnostic Information . . . . . . . . . . . . . . . . 65

Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

View Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Diagnose Errors . . . . . . . . . . . . . . . . . . . . . . . . . 66

Event and Error Codes and Troubleshooting . . 67

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Maintenance Schedule . . . . . . . . . . . . . . . . . . . 76

Advanced Display Module (ADM) . . . . . . . . . . . 77

Upgrade Gateway Module Software . . . . . . . . . 77

Upgrade Gateway Module Fieldbus Map . . . . . 78

Upgrade Fluid Control Module (FCM) Software 79

Air Filter Maintenance . . . . . . . . . . . . . . . . . . . . 79

Swirl Dispensers . . . . . . . . . . . . . . . . . . . . . . . . 79

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Fluid Plate Assembly . . . . . . . . . . . . . . . . . . . . . 80

Control Center Assembly . . . . . . . . . . . . . . . . . 87

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Control Centers . . . . . . . . . . . . . . . . . . . . . . . . . 91

Control Center and Expansion Swirl Enclosure

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Fluid Plate Assembly Parts . . . . . . . . . . . . . . . . 94

2 3A2098H

Page 3

Related Manuals

Appendix A - Advanced Display Module (ADM) . 99

Display Overview . . . . . . . . . . . . . . . . . . . . . . . . 99

Display Details . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Setup Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Run Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Appendix B - Discrete Gateway Module (DGM)

Connection Details . . . . . . . . . . . . . . . . . . . . 115

D-Sub Cable 123793 . . . . . . . . . . . . . . . . . . . . 115

D-Sub Cable 123792 and Breakout Board 123783

116

DGM Digital Input . . . . . . . . . . . . . . . . . . . . . . 119

DGM Digital Outputs . . . . . . . . . . . . . . . . . . . . 120

DGM Analog Inputs . . . . . . . . . . . . . . . . . . . . . 121

DGM Analog Outputs . . . . . . . . . . . . . . . . . . . 121

Appendix C - Communications Gateway Module

(CGM) Connection Details . . . . . . . . . . . . . . 122

Install Fieldbus Connections . . . . . . . . . . . . . . 122

CGM I/O Data Map . . . . . . . . . . . . . . . . . . . . . 125

Appendix D - I/O Signal Descriptions . . . . . . . . 138

Automation Inputs . . . . . . . . . . . . . . . . . . . . . . 138

Automation Outputs . . . . . . . . . . . . . . . . . . . . . 139

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Control Center Assembly Technical Data . . . . 140

Fluid Plate Assembly Technical Data . . . . . . . 141

Swirl Dispenser Technical Data . . . . . . . . . . . 141

Graco Standard Warranty . . . . . . . . . . . . . . . . . . 142

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . 142

Related Manuals

The following is a list of component manuals written in

English. These manuals and any available translations

can be found at www.graco.com.

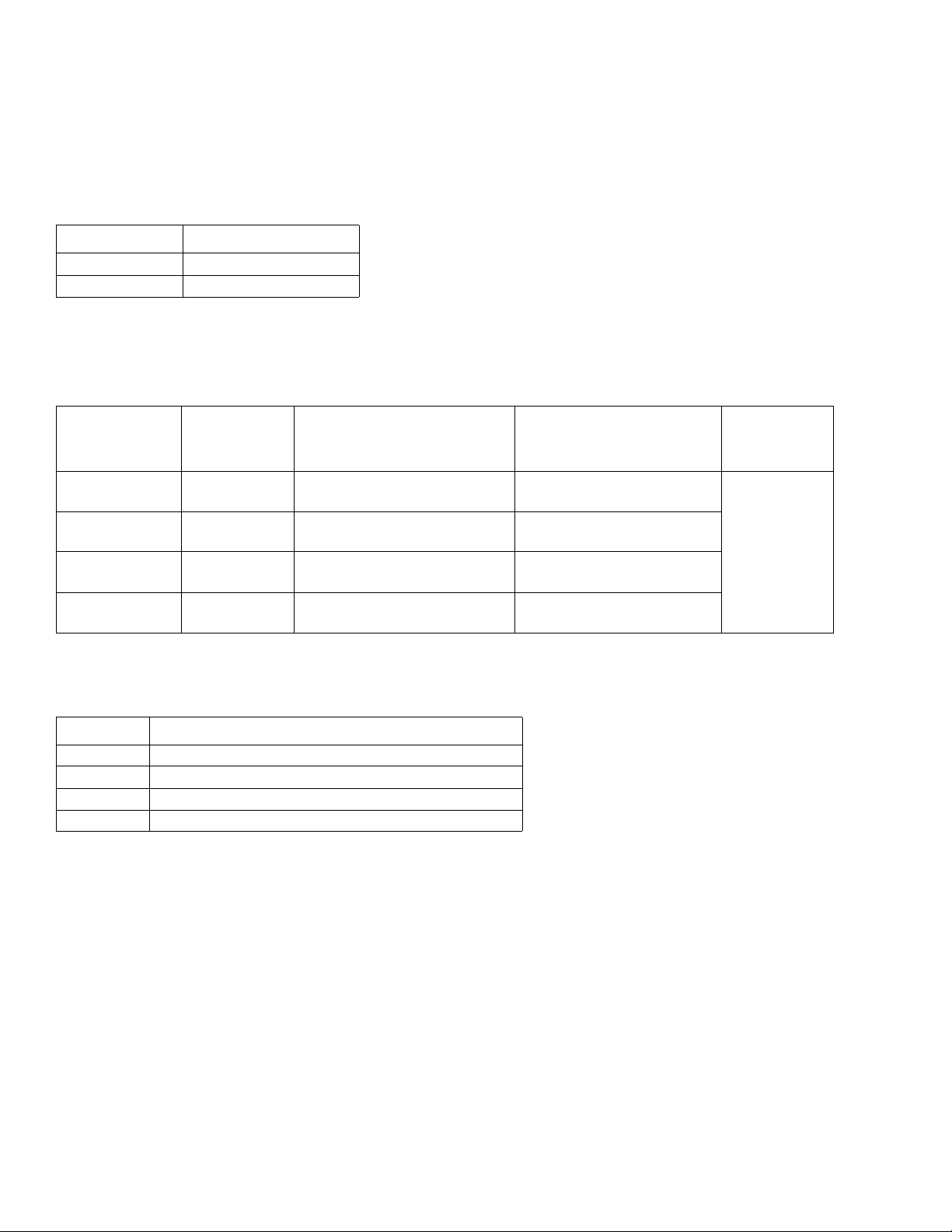

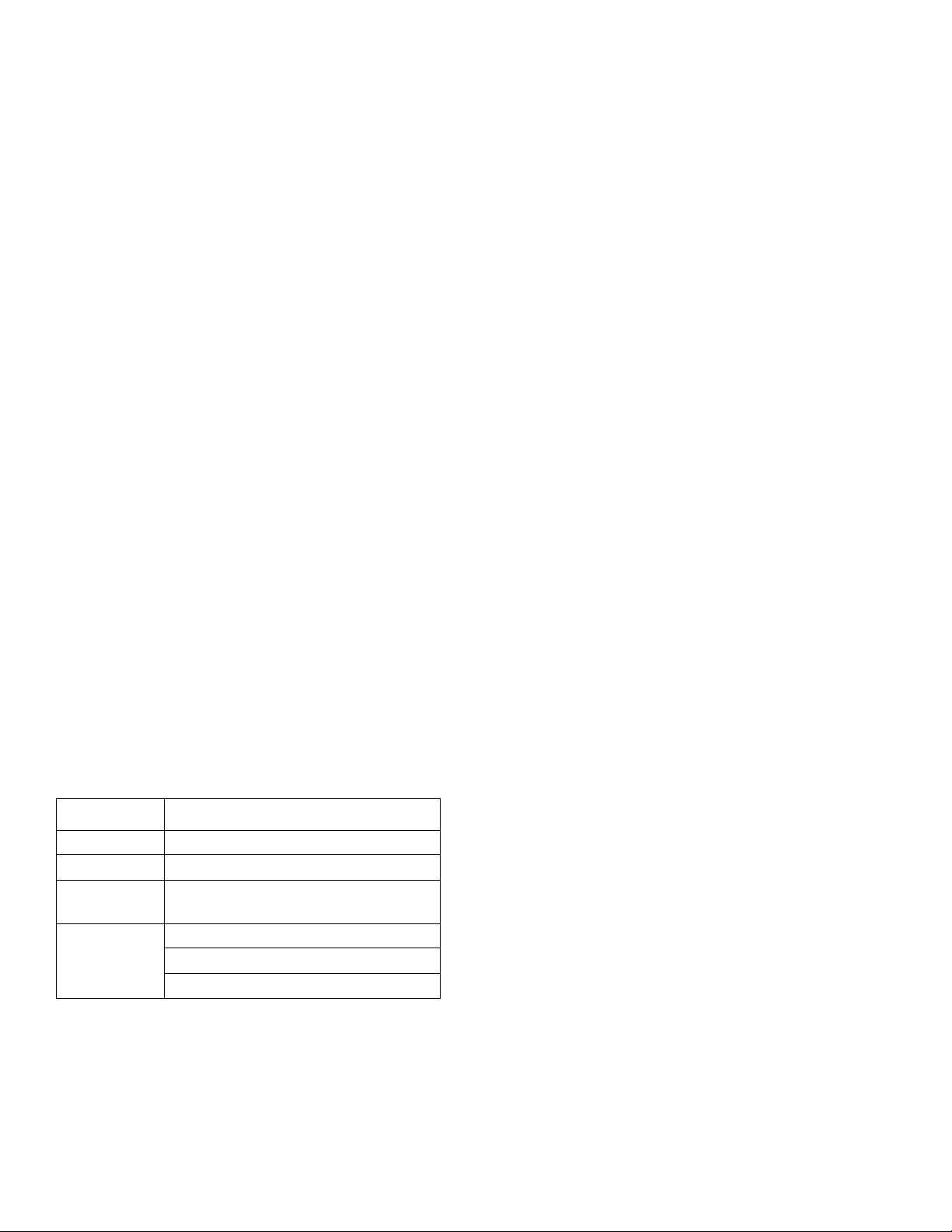

Manual Description

313377

309403 PrecisionSwirl Orbital Dispenser

307517

308647

309834

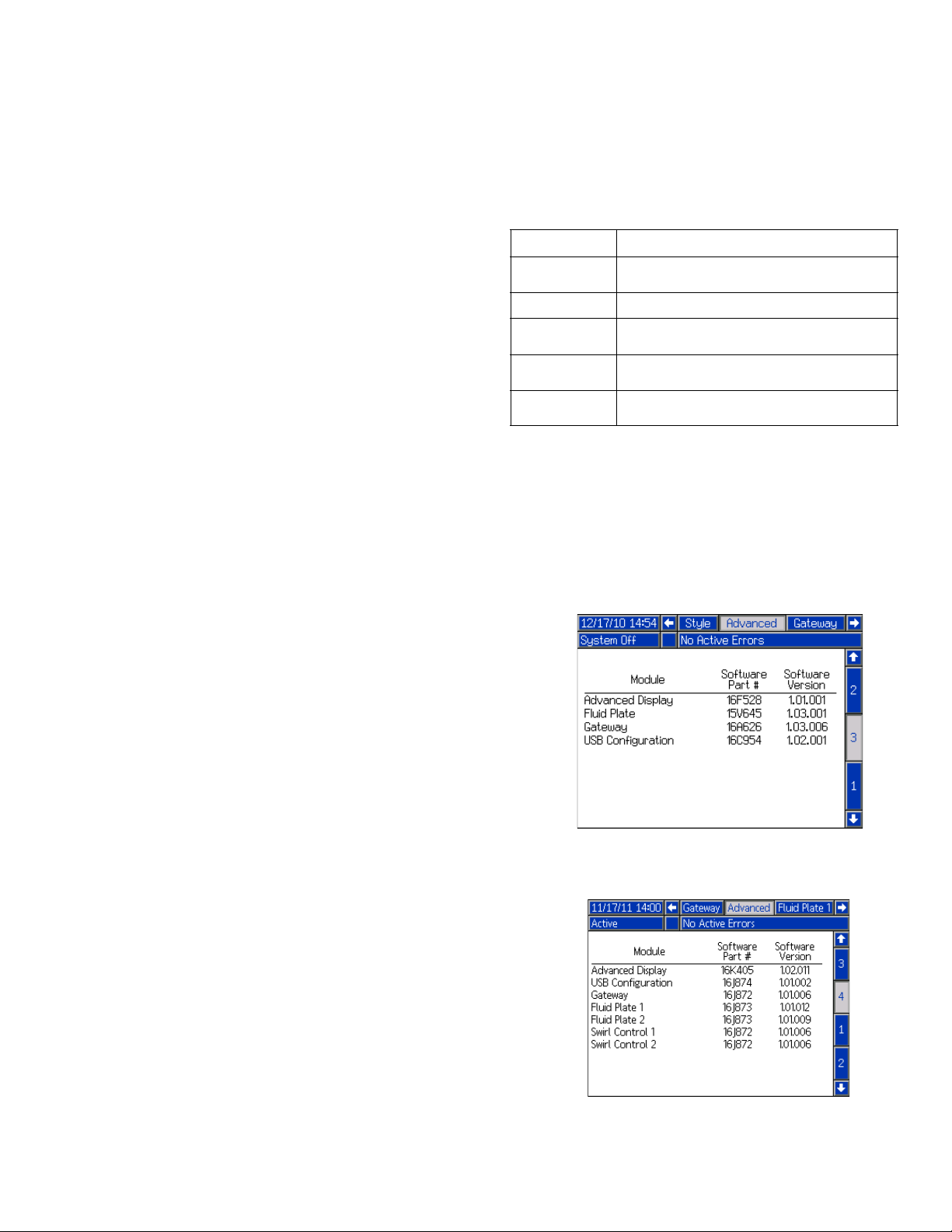

NOTE: In the Advanced screens on your system, if the

Advanced Display software part number shown is

16F528 or 15V769 then this manual does not apply to

your system; refer to manual 313377 for your system.

Otherwise, the part number shown should be 16K405

and you should use this manual.

ADM Software Part No. 16F528 or 15V769

Original PCF Instructions - Parts

(see the note below)

Mastic Fluid Regulators Instructions-Parts

Fluid Pressure Regulators Instructions-Parts

Helical Gear Fluid Flow Meters Instructions-Parts

(see manual 313377)

✖

✓

ADM Software Part No. 16K405

(use this manual)

3A2098H 3

Page 4

Models

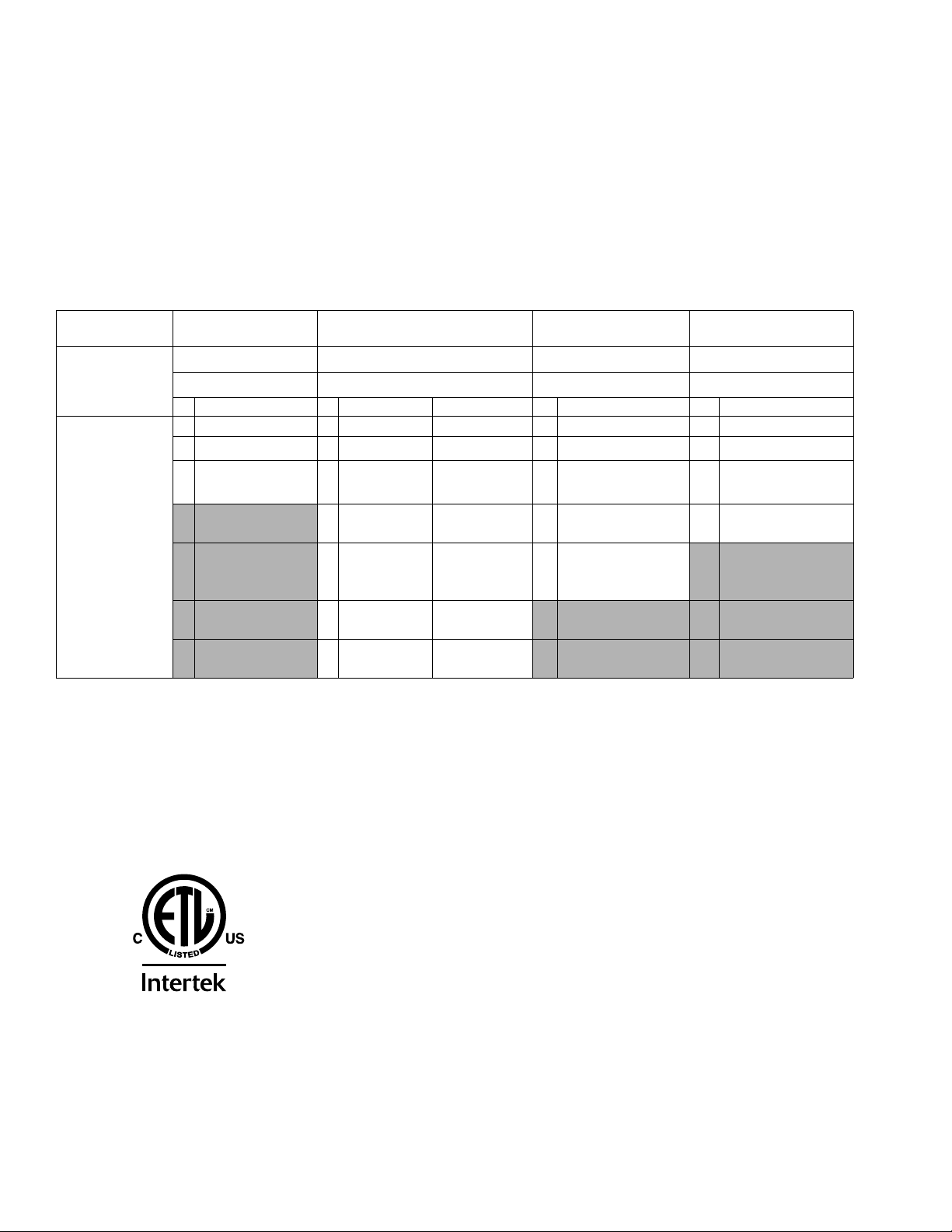

Models

Check the identification (ID) plate for the 6-digit part number of the fluid metering system. Use the following matrix to

define the construction of the system, based on the six digits. For example, Part PF1110 represents a PCF fluid

metering system (PF), a two style system (1), a fluid plate with a cartridge regulator and no meter (1), a DeviceNet

user interface (1) with a 100-240 Vac power supply (0).

NOTE: To order replacement parts, see Parts section in this manual. The digits in the matrix do not correspond to the

Ref. Nos. in the Parts drawings and lists.

™

PF 1

First and

Second Digits

PF

(Precision

Continuous

Flow)

Discrete Gateway systems do not include automation interface cables. The following Graco accessories are avail-

◆

able for wiring to the automation system. Installers should follow Appendix B - Discrete Gateway Module

(DGM) Connection Details, page 115, for custom wiring.

For single fluid plate systems only: 50 ft (15 m) cable with flying leads (123793)

All systems: Breakout board (123783) and 50 ft (15 m) cable (123792)

NOTE: 256 styles option is not available with Discrete Gateway systems.

Third Digit

Style/Size

Description Regulator Meter Description Description

1 2 Styles 1 ❄Cartridge None 0 ◆Discrete 0 100 - 240 Vac

16 Styles 2 ❄Mastic None 1

2

3 256 Styles 3 ❄Cartridge High

4 ❄Mastic High

5 Heated

Mastic

6 Heated

Mastic

7 ❄Cartridge Ultra High

1

Fourth Digit

Fluid Plate

Resolution

Resolution

Standard

Resolution

Resolution

Heated

None

Fifth Digit

User Interface

DeviceNet

2

EtherNet/IP

3

PROFIBUS

4

PROFINET

1

™

1 24 Vdc

™

2 100 - 240 Vac with

™

3 24 Vdc with

™

0

Sixth Digit

Voltage

Integrated Swirl

Integrated Swirl

❄

These fluid metering systems have ETL certification.

NOTE: Fluid metering systems with heated mastic regulators are not ETL certified.

Certified to CAN/CSA C22.2 No. 61010-1

1

This product has been tested to the requirements of CAN/CSA-C22.2 No. 61010-1, second edition, including

C

Amendment 1, or a later version of the same standard incorporating the same level of testing requirements.

4 3A2098H

9902471

Conforms to

UL 61010-1

Page 5

Models

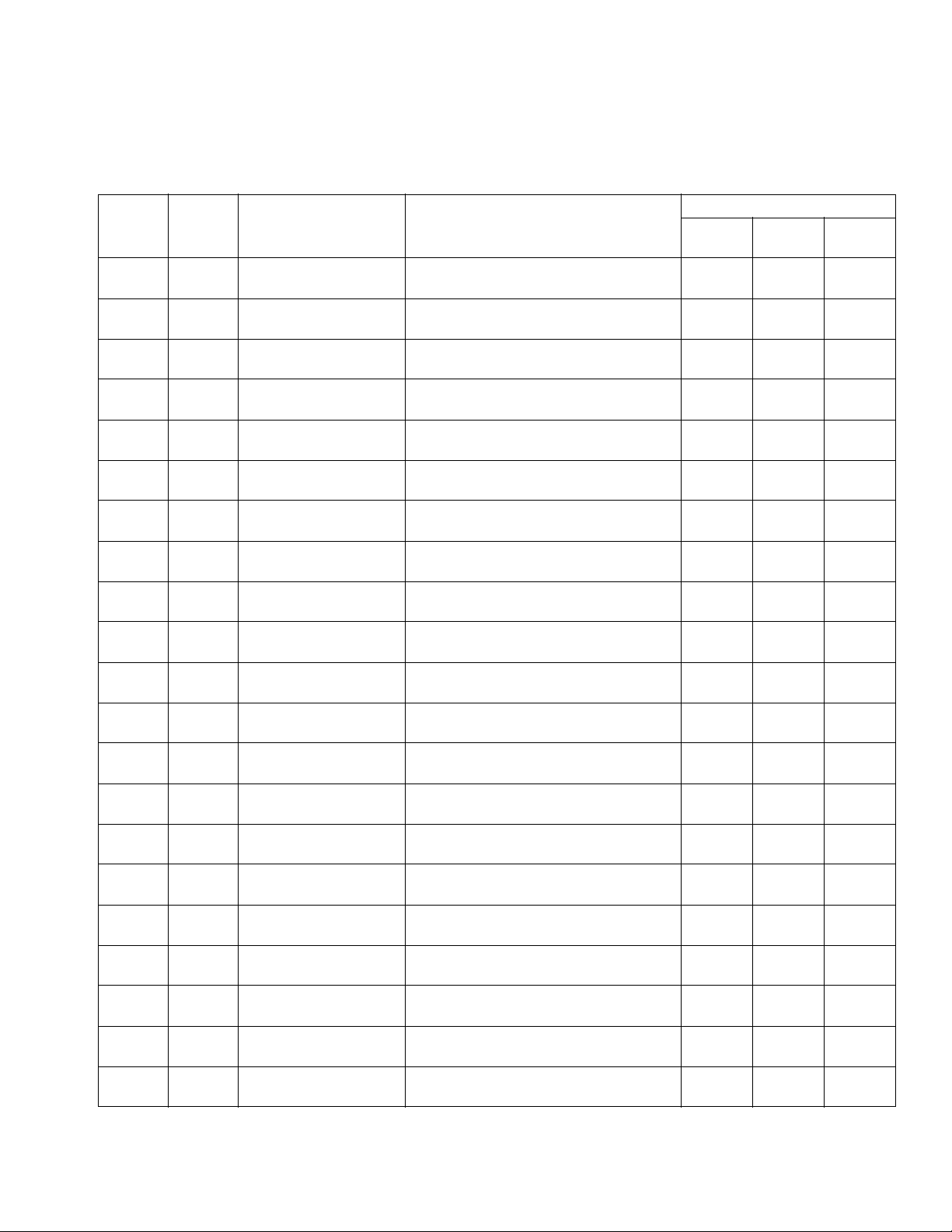

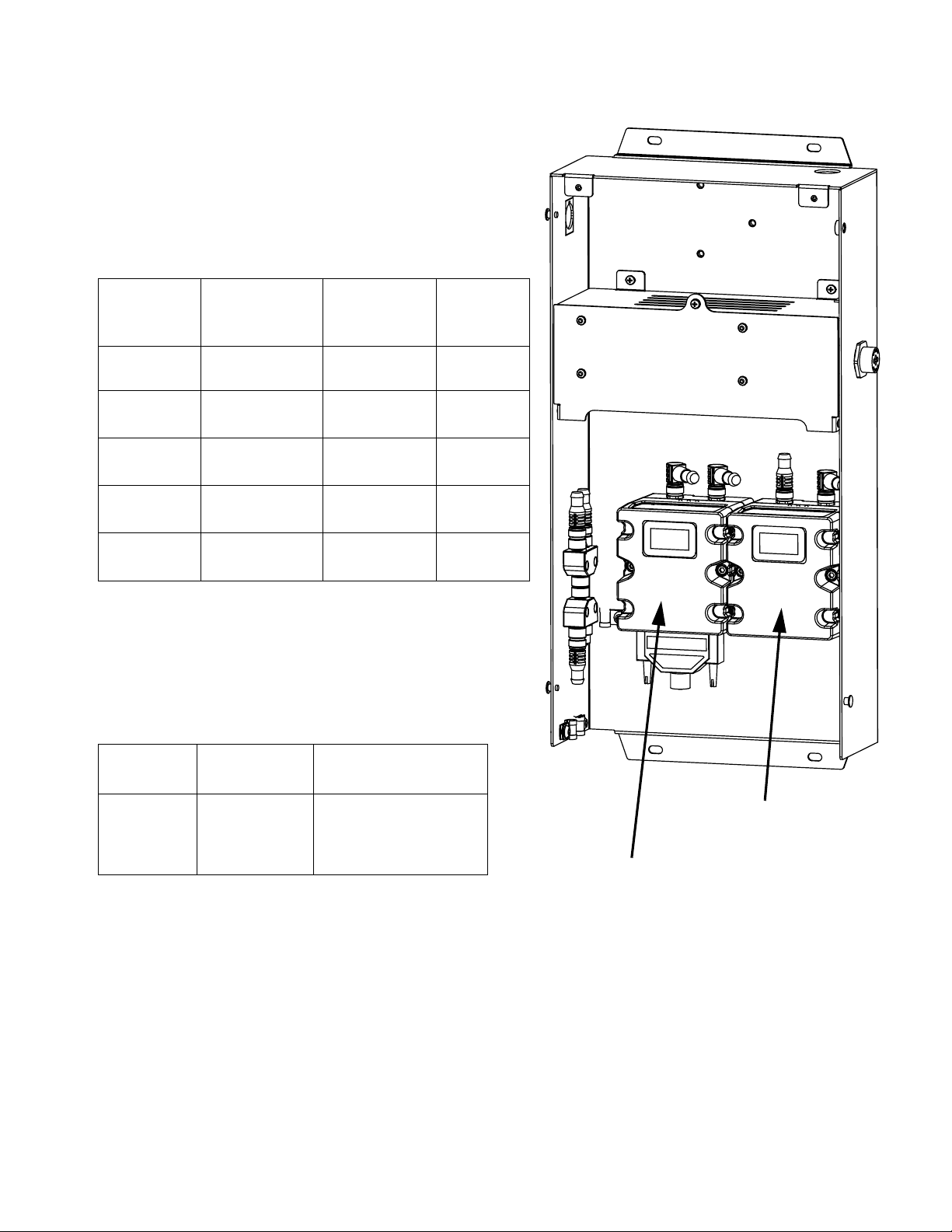

Fluid Plate Kits

NOTE: The fluid plate kit numbers listed below include a CAN splitter. The fluid plate assembly included in each

PFxxxx assembly does not include a CAN splitter.

Includes:

Fluid

Plate Kit

24B958 PF13xx

24B959 PF11xx

24B960 PF14xx

24B961 PF12xx

24B962 PF15xx

24C901 PF16xx

24J873 PF17xx

24K801 PF23xx

24K802 PF21xx

24K803 PF24xx

24K804 PF22xx

24K805 PF25xx

24K806 PF26xx

24K807 PF27xx

24K808 PF33xx

24K809 PF31xx

24K810 PF34xx

24K811 PF32xx

24K812 PF35xx

24K813 PF36xx

24K814 PF37xx

Used by

Model

Maximum Working

Pressure

6000 psi

(41 MPa, 414 bar)

6000 psi

(41 MPa, 414 bar)

5000 psi

(35 MPa, 345 bar)

5000 psi

(35 MPa, 345 bar)

5000 psi

(35 MPa, 345 bar)

5000 psi

(35 MPa, 345 bar)

6000 psi

(41 MPa, 414 bar)

6000 psi

(41 MPa, 414 bar)

6000 psi

(41 MPa, 414 bar)

5000 psi

(35 MPa, 345 bar)

5000 psi

(35 MPa, 345 bar)

5000 psi

(35 MPa, 345 bar)

5000 psi

(35 MPa, 345 bar)

6000 psi

(41.4 MPa, 414 bar)

6000 psi

(41 MPa, 414 bar)

6000 psi

(41 MPa, 414 bar)

5000 psi

(35 MPa, 345 bar)

5000 psi

(35 MPa, 345 bar)

5000 psi

(35 MPa, 345 bar)

5000 psi

(35 MPa, 345 bar)

6000 psi

(41 MPa, 414 bar)

Regula-

Description

Cartridge Regulator, High Resolution Flow

Meter, 2 styles

Cartridge Regulator, No Flow Meter,

2 styles

Mastic Regulator, High Resolution Flow

Meter, 2 styles

Mastic Regulator, No Flow Meter, 2 styles 246642 --- 16M101

Heated Mastic Regulator, Standard Resolu-

tion Heated Flow Meter, 2 styles

Heated Mastic Regulator, No Flow Meter,

2 styles

Cartridge Regulator, Ultra High Resolution

Flow Meter, 2 styles

Cartridge Regulator, High Resolution Flow

Meter, 16 styles

Cartridge Regulator, No Flow Meter,

16 styles

Mastic Regulator, High Resolution Flow

Meter, 16 styles

Mastic Regulator, No Flow Meter, 16 styles 246642 --- 16M103

Heated Mastic Regulator, Standard Resolu-

tion Heated Flow Meter, 16 styles

Heated Mastic Regulator, No Flow Meter,

16 styles

Cartridge Regulator, Ultra High Resolution

Flow Meter, 16 styles

Cartridge Regulator, High Resolution Flow

Meter, 256 styles

Cartridge Regulator, No Flow Meter,

256 styles

Mastic Regulator, High Resolution Flow

Meter, 256 styles

Mastic Regulator, No Flow Meter,

256 styles

Heated Mastic Regulator, Standard Resolu-

tion Heated Flow Meter, 256 styles

Heated Mastic Regulator, No Flow Meter,

256 styles

Cartridge Regulator, Ultra High Resolution

Flow Meter, 256 styles

tor

244734 246652 16M100

244734 --- 16M101

246642 246652 16M100

246643 246340 16M100

246643 --- 16M101

244734 16E993 16M100

244734 246652 16M102

244734 --- 16M103

246642 246652 16M102

246643 246340 16M102

246643 --- 16M103

244734 16E993 16M102

244734 246652 16M104

244734 --- 16M105

246642 246652 16M104

246642 --- 16M105

246643 246340 16M104

246643 --- 16M105

244734 16E993 16M104

Flow

Meter

FCM Key

Token

3A2098H 5

Page 6

Models

Expansion Swirl Enclosure Assemblies

The following enclosures are ETL approved. Assemblies PFxxx2, and PFxxx3 are setup for one PrecisionSwirl

Orbital Dispenser. If you wish to have additional swirl dispensers, order one expansion PrecisionSwirl assembly

below for each. Systems with a DGM as the automation gateway can have up to two swirl dispensers total. Systems

with a CGM as the automation gateway can have up to four swirl dispensers total.

Part Description

16M350 100 - 240 Vac

16M351 24 Vdc

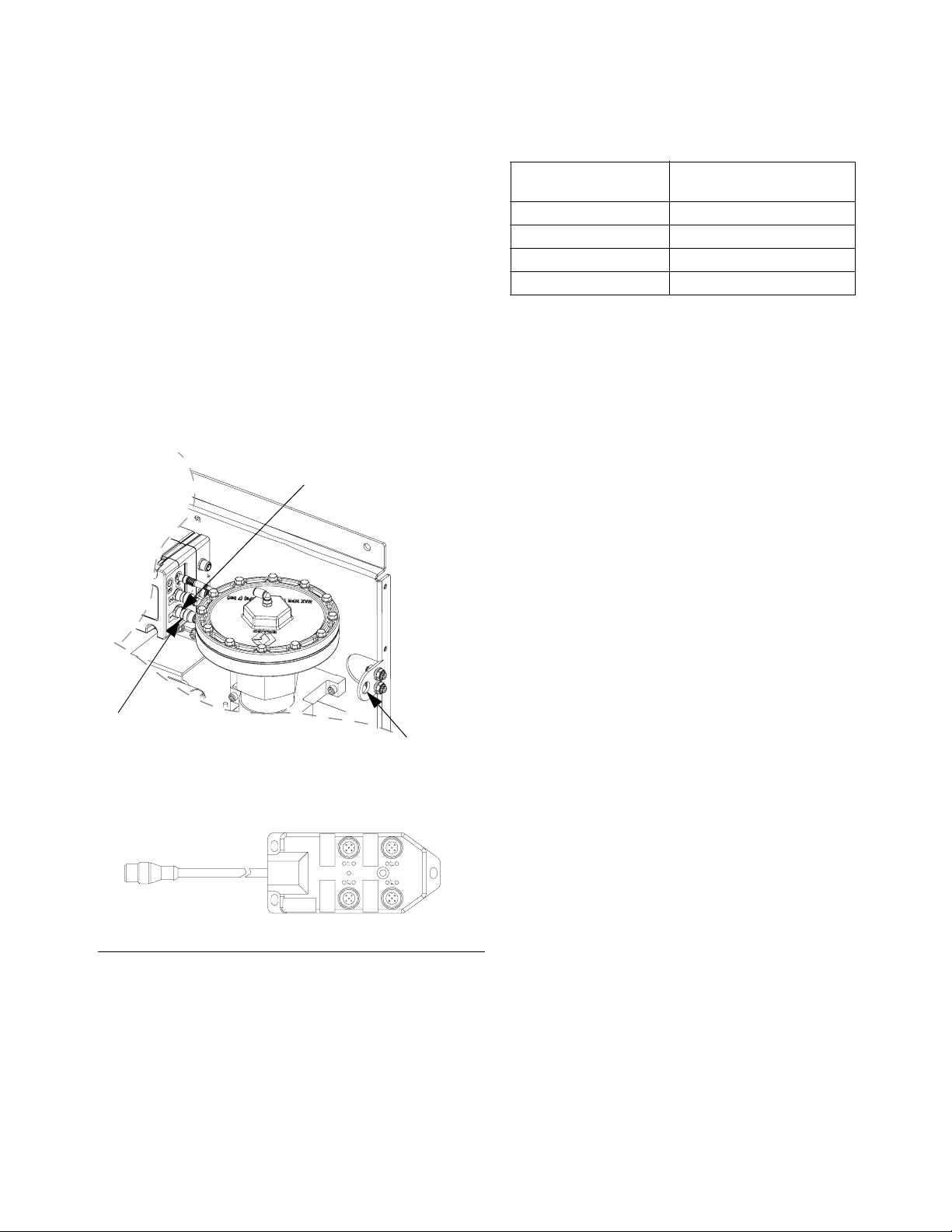

PrecisionSwirl Orbital Dispenser Assemblies

See manual 309403.

Maximum

Working

Version Part, Series Coupler Offset Typical Application

Standard 243402, B 0.012 in. for narrow bead

widths

Standard 243403, B 0.028 in. for wide bead

widths

Compact 289262, A 0.012 in. for narrow bead

widths

Compact 289261, A 0.018 in. for medium bead

widths

Hem flange and after hem

Seam sealing

Hem flange and after hem

Seam sealing

Pressure

3500 psi

(24.1 MPa,

241 bar)

PrecisionSwirl Orbital Dispenser Cable

Assemblies

Part Description

233125 6 ft (1.8 m) motor extension cable assembly

233124 9 ft (2.7 m) motor extension cable assembly

233123 15 ft (4.6 m) motor extension cable assembly

617870 55 ft (16.8 m) motor extension cable assembly

6 3A2098H

Page 7

Models

Automation Gateway Assemblies

Each control center comes with one automation gateway

assembly. The automation gateway module is either a Discrete Gateway Module (DGM) or one of the Communications

Gateway Modules (CGM).To order a replacement, see the

following table. You will also need to order software upgrade

token (16K743).

Gateway

User Interface

PCF Model

PFxx0x Discrete

PFxx1x

PFxx2x

PFxx3x

PFxx4x

Description

(DGM)

DeviceNet

(CGM)

EtherNet/IP

(CGM)

PROFIBUS

(CGM)

PROFINET

(CGM)

™

™

™

™

Part Number

To Order

24B681 0

15V759 Any

15V760 Any

15V761 Any

15V762 Any

Rotary

Switch

Position

Swirl Control DGM

The assemblies below each contain one swirl control DGM

used to control one Swirl Dispenser. To order a replacement,

see the following table. You will also need to order software

upgrade token (16K743).

Assembly

PFxxx2,

PFxxx3,

16M350,

16M351

Part Number

To Order

24B681

Rotary Switch

Position

1, 2, 3, or 4;

see Swirl Control

DGM on page 19

Automation Gateway

(DGM or CGM)

Swirl Control DGM

3A2098H 7

Page 8

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual, refer back to these Warnings. Product-specific hazard symbols and

warnings not covered in this section may appear throughout the body of this manual where applicable.

WARNING

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause

electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

or installing equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This

may look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispensing device at anyone or at any part of the body.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

8 3A2098H

Page 9

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe

burns:

• Do not touch hot fluid or equipment.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, hearing loss, inhalation of toxic fumes, and burns. This equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer

3A2098H 9

Page 10

System Configurations

System Configurations

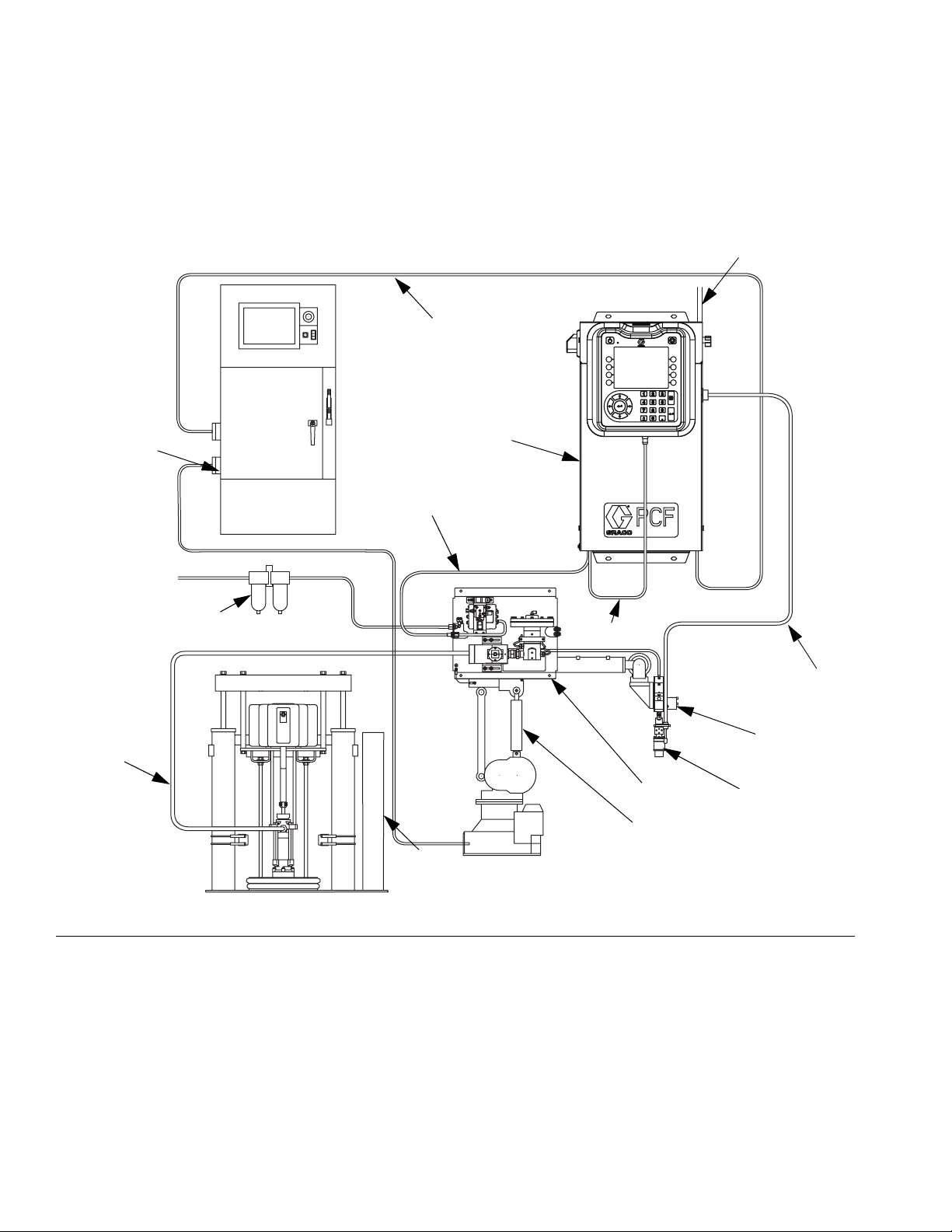

Typical Installation - Single Swirl, Single Fluid Plate

NOTE: Shown with one fluid plate and one swirl dispenser.

E

Power In

J

Air Supply

Drop Site

H

K*

F*

A*

F*

M

C

B*

D

G

L

F

IG

. 1: Typical Ambient System Installation

Key:

A *Control Center (User Interface)

B *Fluid Plate Assembly

C Applicator/Dispense Valve

D Sealer Automation

E Automation Interface Cable

F *CAN Cable

G Fluid Supply System

10 3A2098H

H Fluid Supply Hose

J Automation Controller

K *Air Filter Assembly

L ◆PrecisionSwirl Orbital Dispenser (Swirl Dispenser)

M ◆PrecisionSwirl Cable

* Included

◆ Optional

Page 11

System Configurations

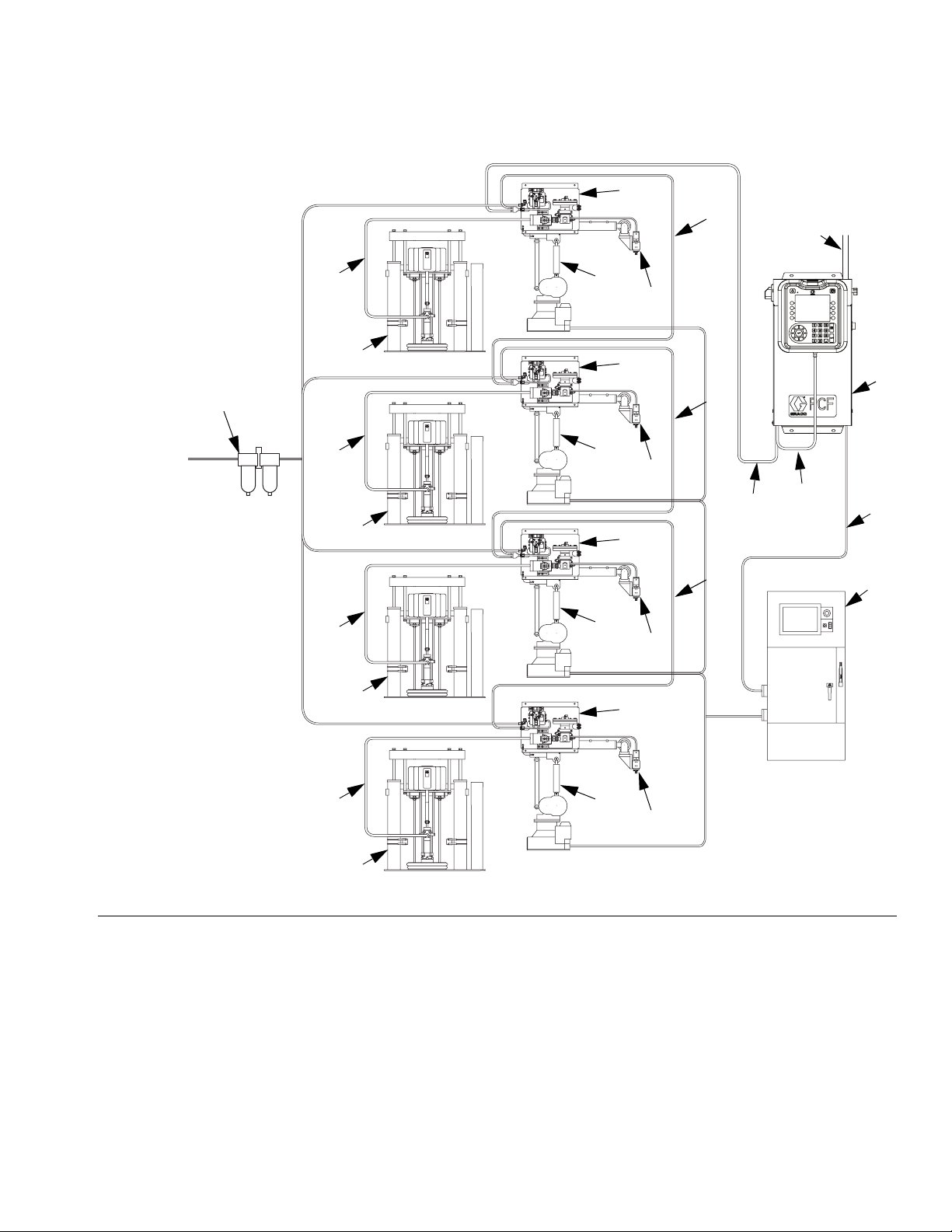

Typical Installation - Multiple Fluid Plates, No Swirl Dispensers

B*

F*

Power In

Air Supply

Drop Site

K*

H

G

H

G

H

G

D

C

B*

F*

D

C

F*

F*

B*

F*

D

C

B*

A

E

J

H

G

F

IG

. 2: Typical Multiple Fluid Plate System Installation

Key:

A *Control Center (User Interface)

B *Fluid Plate Assembly

C Applicator/Dispense Valve

D Sealer Automation

E Automation Interface Cable

3A2098H 11

F *CAN Cable

G Fluid Supply System

H Fluid Supply Hose

J Automation Controller

K *Air Filter Assembly

* Included

D

C

Page 12

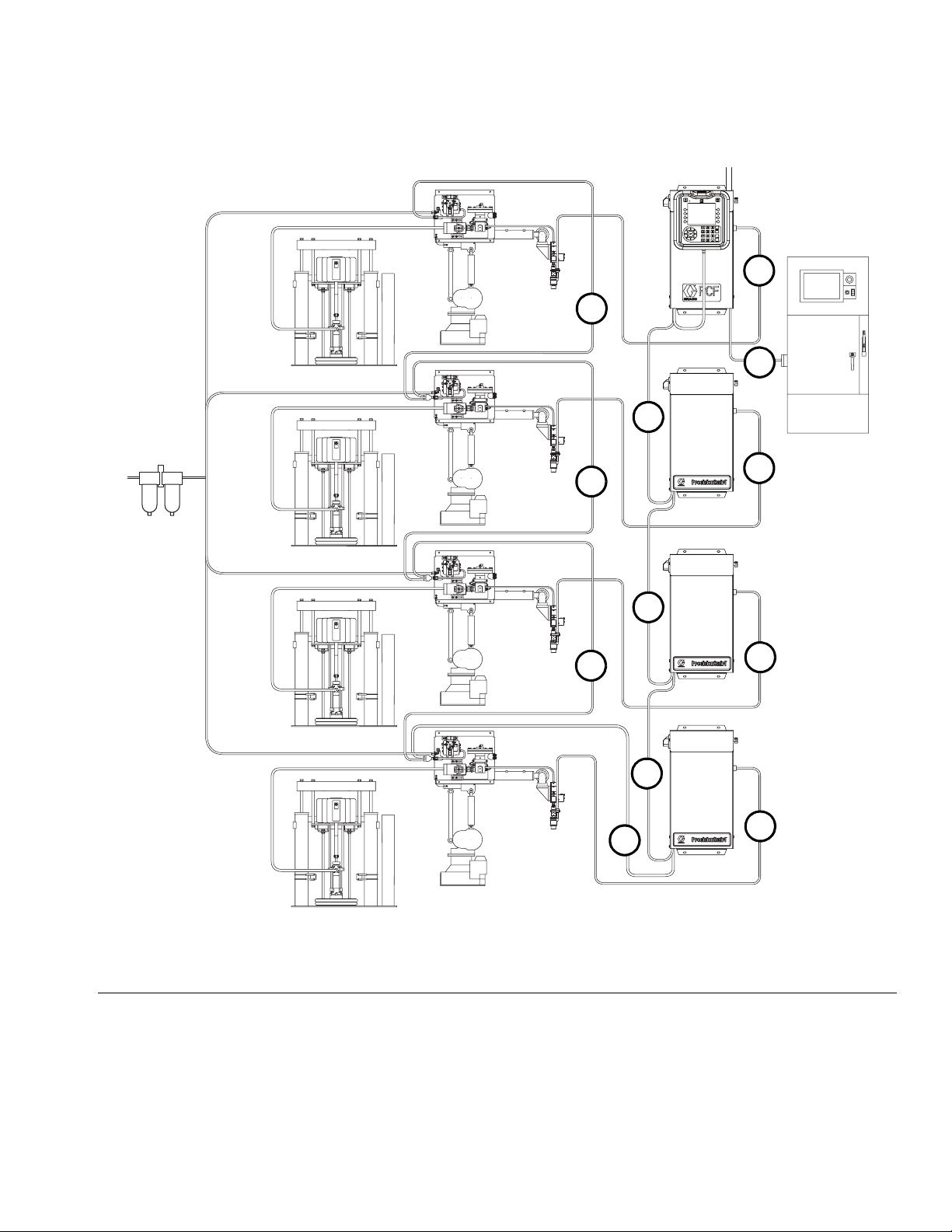

System Configurations

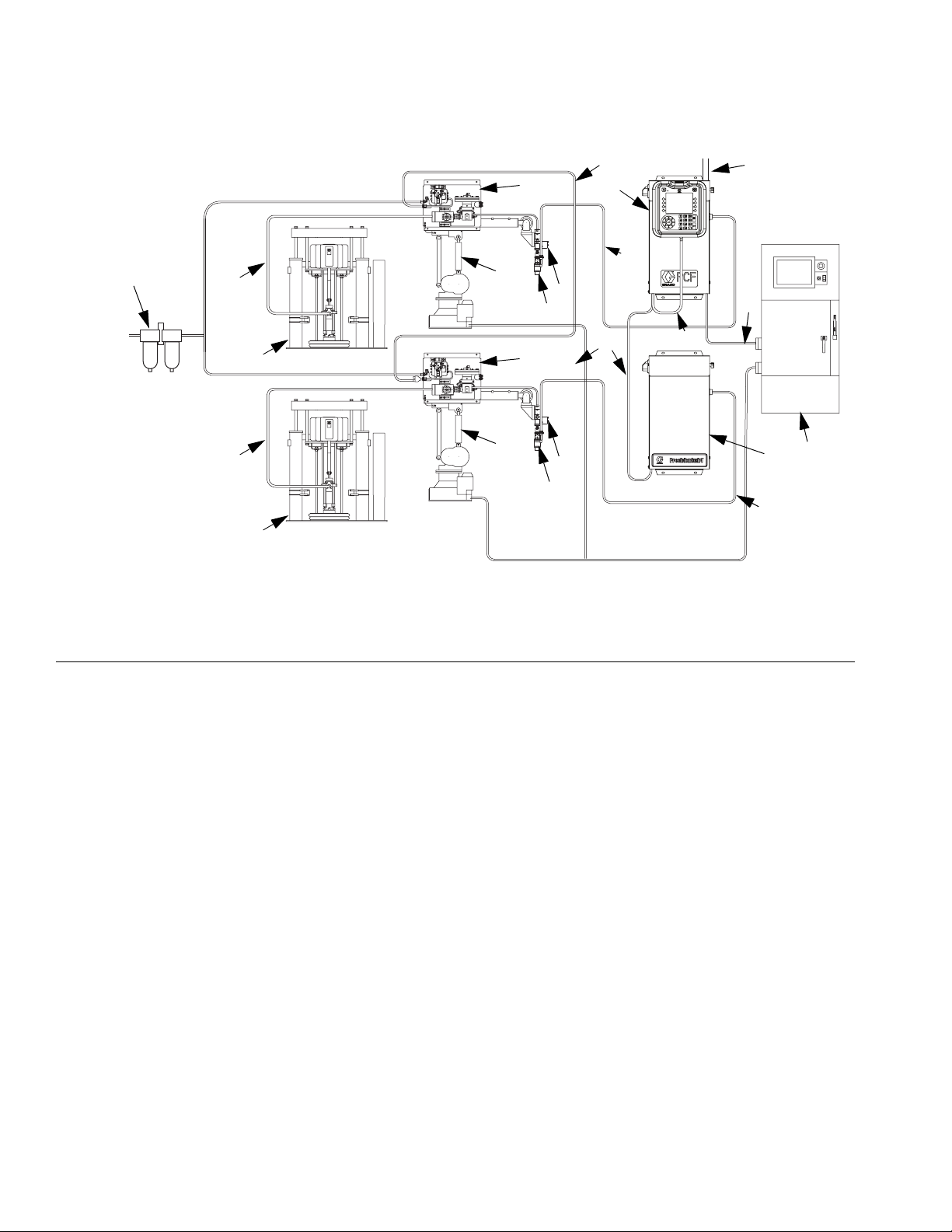

Typical Installation - Multiple Fluid Plates, Multiple Swirl Dispensers

Air

Supply

Drop Site

K*

F*

B*

H

G

H

G

D

L

B*

D

L

A

M

C

F*

C

F*

Power In

E

N

M

J

F

IG

. 3: Typical Multiple Fluid Plate System Installation

Key:

A *Control Center (User Interface)

B *Fluid Plate Assembly

C Applicator/Dispense Valve

D Sealer Automation

E Automation Interface Cable

F *CAN Cable

G Fluid Supply System

H Fluid Supply Hose

J Automation Controller

K *Air Filter Assembly

L ◆PrecisionSwirl Orbital Dispenser (Swirl Dispenser)

M ◆PrecisionSwirl Cable

N ◆Expansion Swirl Enclosure

* Included

◆ Optional

12 3A2098H

Page 13

Overview

Overview

System Overview

The PCF fluid metering system combines closed-loop

pressure control with the ability to change bead profiles

quickly. When used with an optional flow meter, the system automatically adjusts for fluctuations in the operating environment, such as material viscosity,

temperature and tip wear, in order to maintain the

desired dispense rate. The module responds to automation signals to provide an accurate and consistent output

flow based on a comparison of actual to desired flow

rates.

Typical Applications

• Bead dispensing

• Gasketing

• Seam sealing

• Hem flange

• Sound deadening

• Anti-flutter

• Body panel reinforcement

• Profile wrapping

• Cable filling

Control Center (User Interface)

The control center communicates with the PCF fluid

plate assembly to control fluid pressure and dispense

valve operation.

The control center receives input from the automation

controller, and uses these inputs to determine communication to the fluid plate assembly.

Fluid Plate Assembly

The fluid plate assembly contains components that control and monitor fluid dispensing. A PCF fluid metering

system can have up to four fluid plates. Each fluid plate

can control up to four dispense valves. The system supports up to 16 dispense valves and can simultaneously

dispense from up to 10 dispense valves.

PrecisionSwirl Orbital Dispenser

(Swirl Dispenser), Sold Separately

The swirl dispenser dispenses material in a circular pattern at speeds from 6600 to 24000 rpm. A PCF fluid

metering system can have up to four swirl dispensers.

See manual 309403 for detailed information.

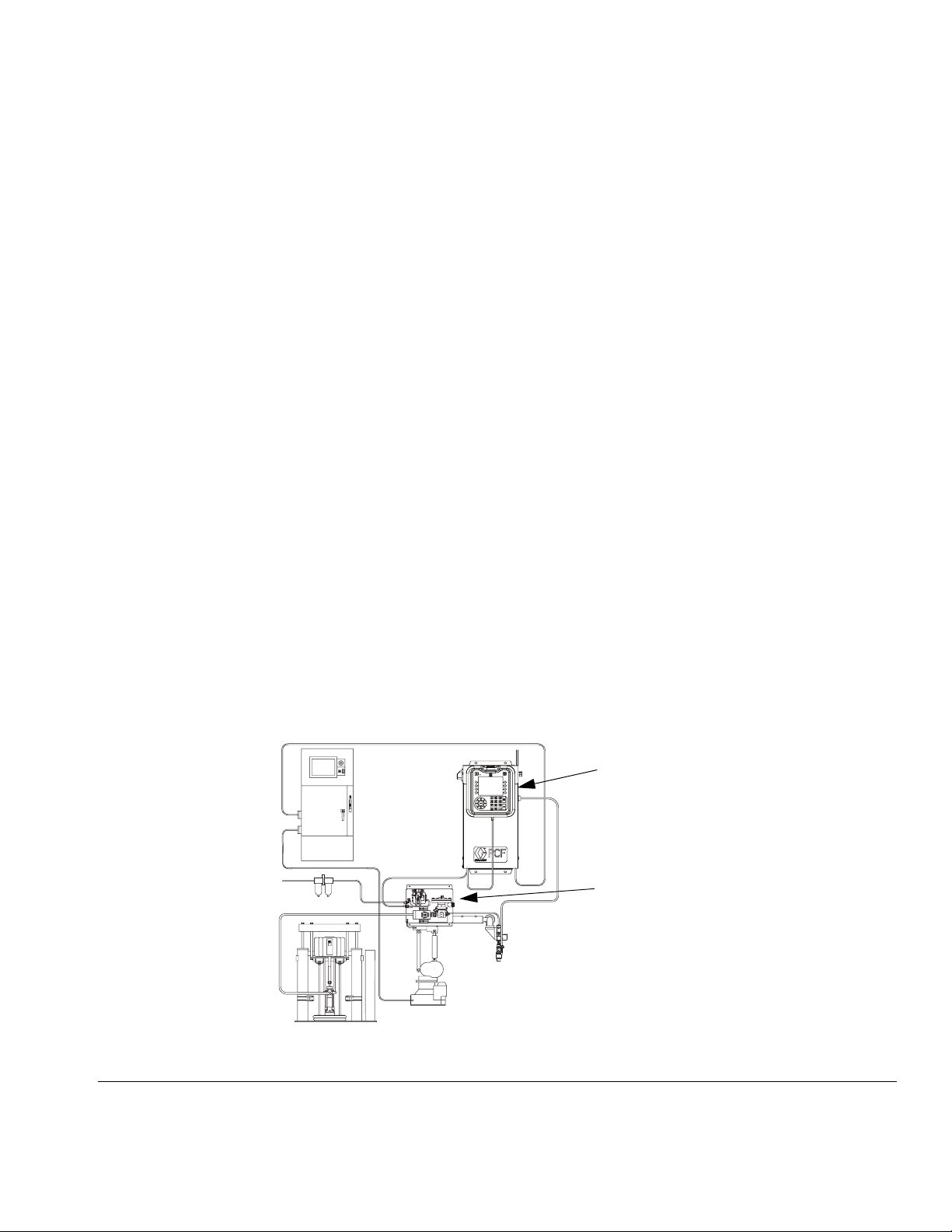

System Components

The diagram in FIG. 4 shows an example of the PCF

module and cables.

System shown with one fluid plate and one swirl dispenser

F

IG

. 4: PCF System Components

Control Center

(User Interface)

Fluid Plate Assembly

3A2098H 13

Page 14

Overview

Fluid Plate Assembly Overview

Fluid Plate Components

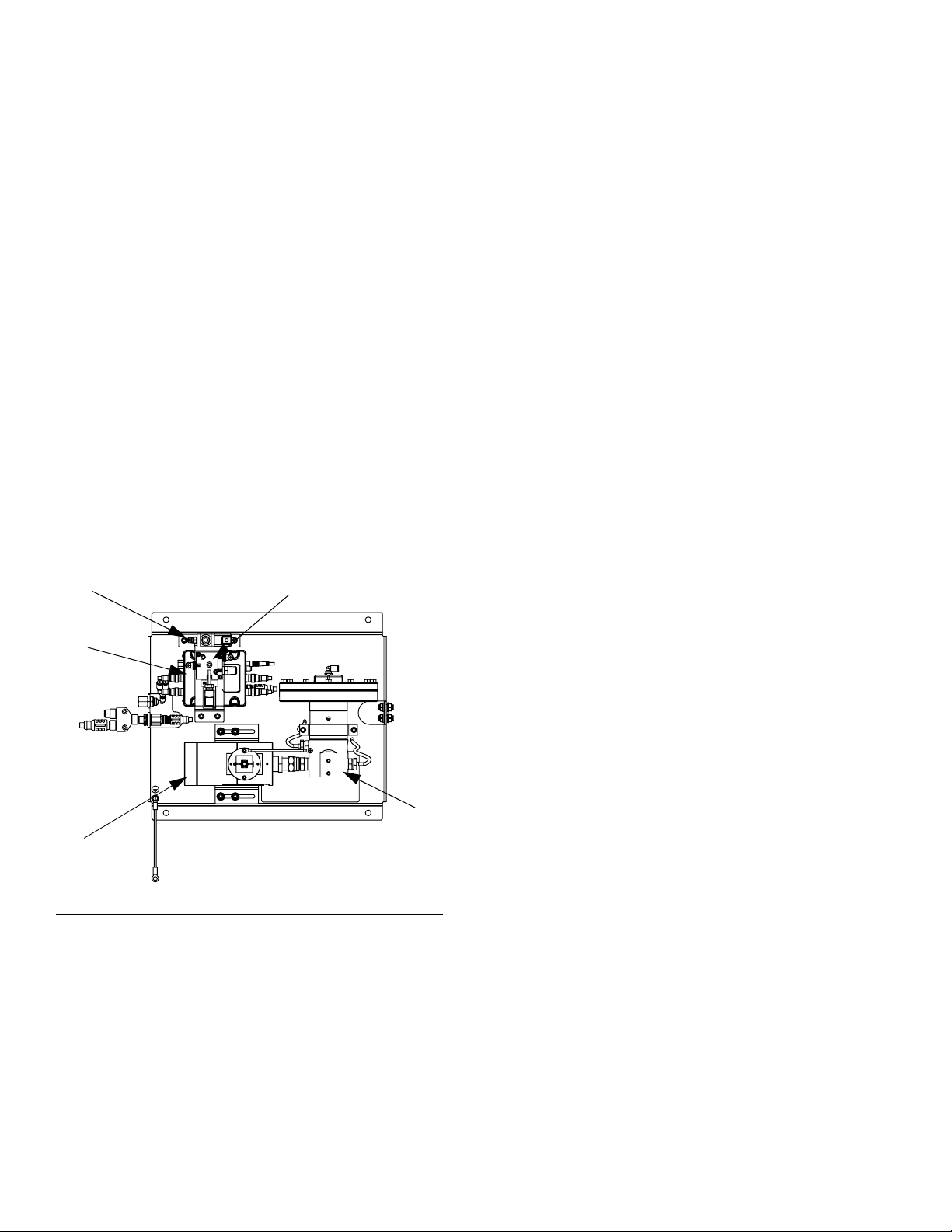

The fluid plate assembly in FIG. 5 can be attached to an

automation arm or mounted on a pedestal. The main

components of the fluid plate assembly include:

• Fluid regulator (cartridge, ambient mastic, or heated

mastic) (P).

• Flow meter (R) (optional) precisely measures the

flow rate of fluid dispensed.

• Solenoid air valve (S) controls the dispense valve.

• Voltage to Pressure Transducer (T), abbreviated V/P

transducer, adjusts the air pressure to the fluid regulator (P).

• Fluid Control Module (FCM) (U) receives pulse readings from the flow meter (R) and pressure readings

from the regulator. It also controls the fluid regulator

(P) and solenoid air valve (S).

The PCF fluid regulator is electrically controlled by the

PCF fluid control module. Consistent material flow is

assured by a closed-loop pressure or closed-loop flow

control design. The module responds to automation-supplied signals to provide an accurate and consistent output flow based on a comparison of actual to

desired flow rates. The fluid regulator uses air pressure

to control fluid pressure and to provide fast response to

electronic commands and ensure a precisely controlled,

continuous flow of material.

The fluid plate assembly is available in two versions:

ambient and heated.

Ambient Fluid Plate Assembly

There are four ambient versions available:

• cartridge regulator without a flow meter;

• ambient mastic regulator without a flow meter;

• cartridge regulator with a high resolution meter;

• ambient mastic regulator with a high resolution

meter;

• cartridge regulator with an ultra high resolution

flow meter.

S

U

R

F

IG

. 5: Fluid Plate Components

T

P

Heated Fluid Plate Assembly

There are two heated versions available:

• heated mastic fluid regulator with a heated flow

meter,

• and a heated mastic fluid regulator without a

flow meter.

14 3A2098H

Page 15

Overview

Fluid Regulator

There are three fluid regulator options:

• cartridge

• ambient mastic

• heated mastic

All of the fluid regulator options use air pressure to control fluid pressure, provide fast response to electronic

commands, and ensure a precisely controlled, continuous flow of material.

Cartridge

The cartridge regulator (244734) is ideal for low to

medium viscosity sealants and adhesives.

Ambient Mastic

The ambient mastic regulator (246642) is ideal for

medium to high viscosity sealants and adhesives.

Heated Mastic

The heated mastic regulator (246643) is ideal for low to

high viscosity warm-melt and hot-melt sealants or adhesives.

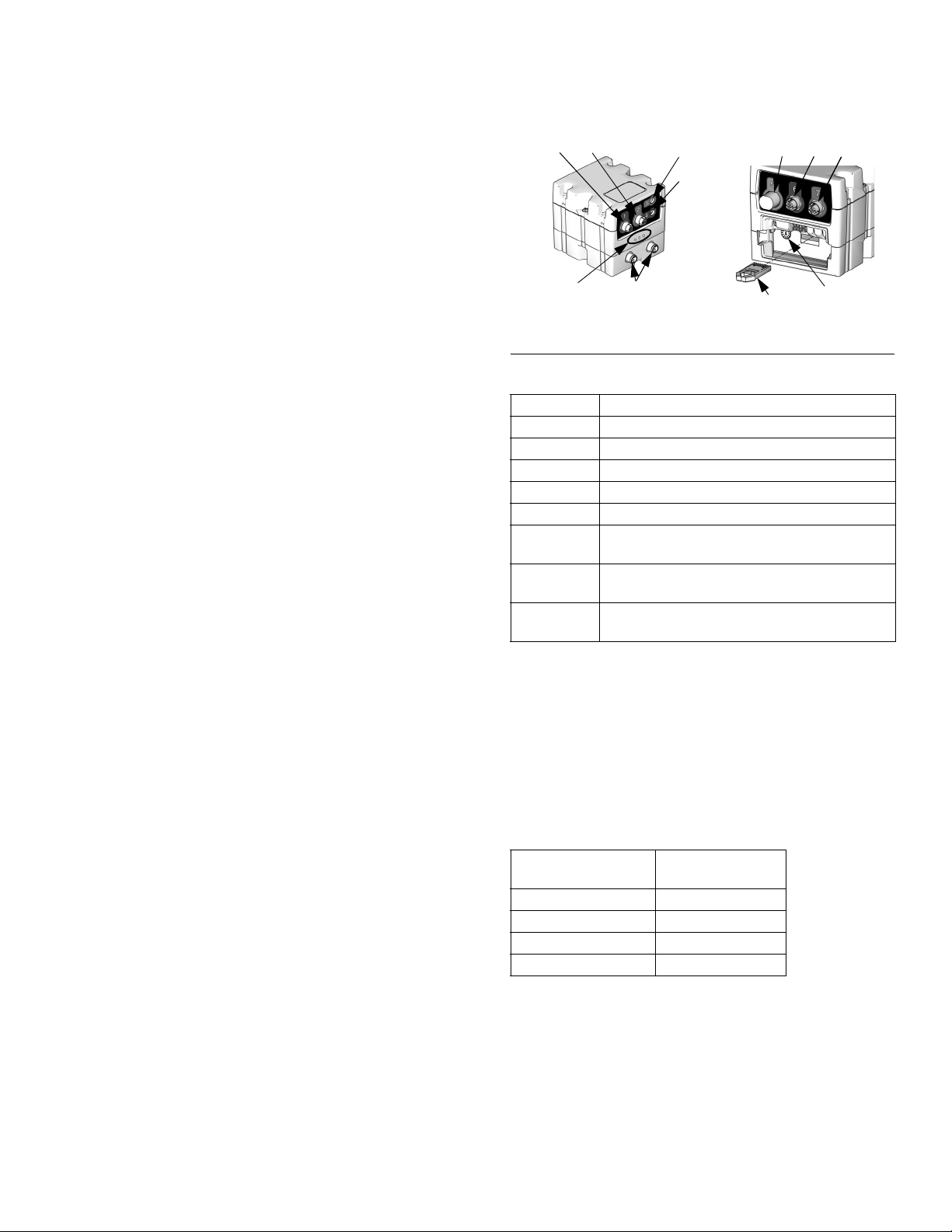

Fluid Control Module (FCM)

12

3

5

6

7

4

Status

LEDs

F

IG

. 6: FCM Sensor Connections

Connection Sensor Description

1 Dispense solenoid

2Flow meter

3 Outlet pressure sensor (heated systems only)

4 Voltage to Pressure (V/P) Transducer

5 Command cable (optional accessory kit)

6 Inlet pressure sensor (non-heated systems

7 Outlet pressure sensor (non-heated systems

CAN

Connectors

CAN

Connectors

Key

token

Table 1: FCM Sensor Connections

only)

only)

---

Rotary

Switch

Rotary Switch on FCM

The rotary switch on the FCM, see FIG. 6, must be set to

a valid position and each FCM must have a unique

rotary switch position. The FCM rotary switch position

determines which number to assign to that fluid plate.

The settings, including defined styles, for each fluid

plate are stored in each FCM so changing the rotary

switch position causes the settings to be shown under

the new number on the ADM.

Rotary Switch

Item

Fluid Plate 1 0 or 1

Fluid Plate 2 2

Fluid Plate 3 3

Fluid Plate 4 4

Position

NOTE: See LED Diagnostic Information, page 65, for

signal definitions.

3A2098H 15

Page 16

Overview

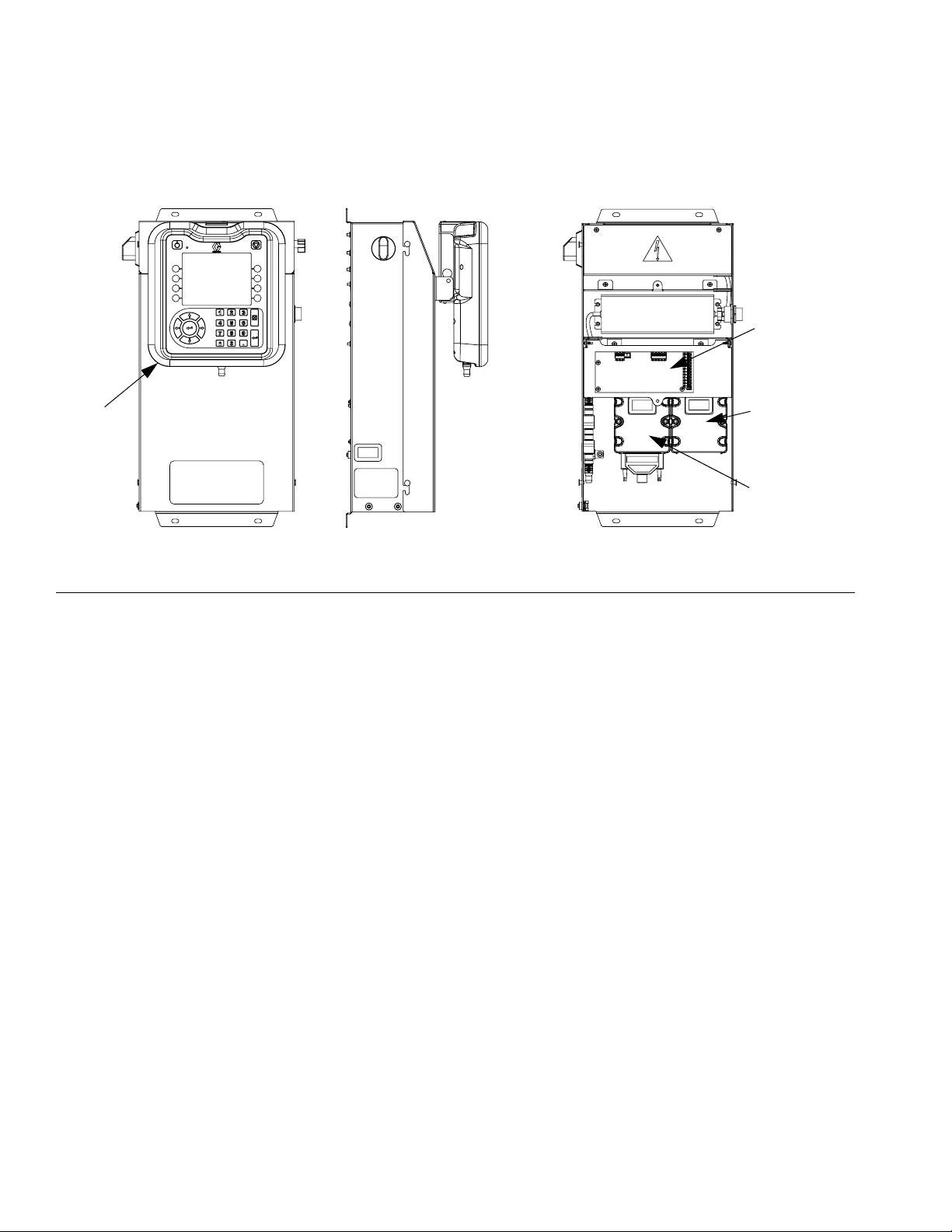

Control Center Assembly Overview

Front View Side View

Front View

100-240 Vac Assembly

Swirl Board

ADM

F

IG

. 7: Control Center Components

The control center includes the following components:

• Advanced Display Module (ADM) with USB; see

page 17 for details.

• USB enables users to download job, event, and

data logs; save and restore system settings; and

customize the language. See USB Data on

page 59.

• 24 Vdc and 100-240 Vac customer-wired options

available.

Gateway

Module

Swirl Control

DGM

•

If system has a swirl dispenser:

(the module on the left) and Swirl Board.

• Automation Gateway Module (the module on the

right), which can be one of the following five types:

•Discrete

• DeviceNet

• EtherNet/IP

•PROFIBUS

• PROFINET

Swirl Control DGM

Expansion Swirl Enclosure

If more than one swirl dispenser is installed, the system will have one Expansion Swirl Enclosure for each additional

swirl dispenser. The Expansion Swirl Enclosure is similar to the primary control center, but it does not include the

ADM or the Automation Gateway module.

16 3A2098H

Page 17

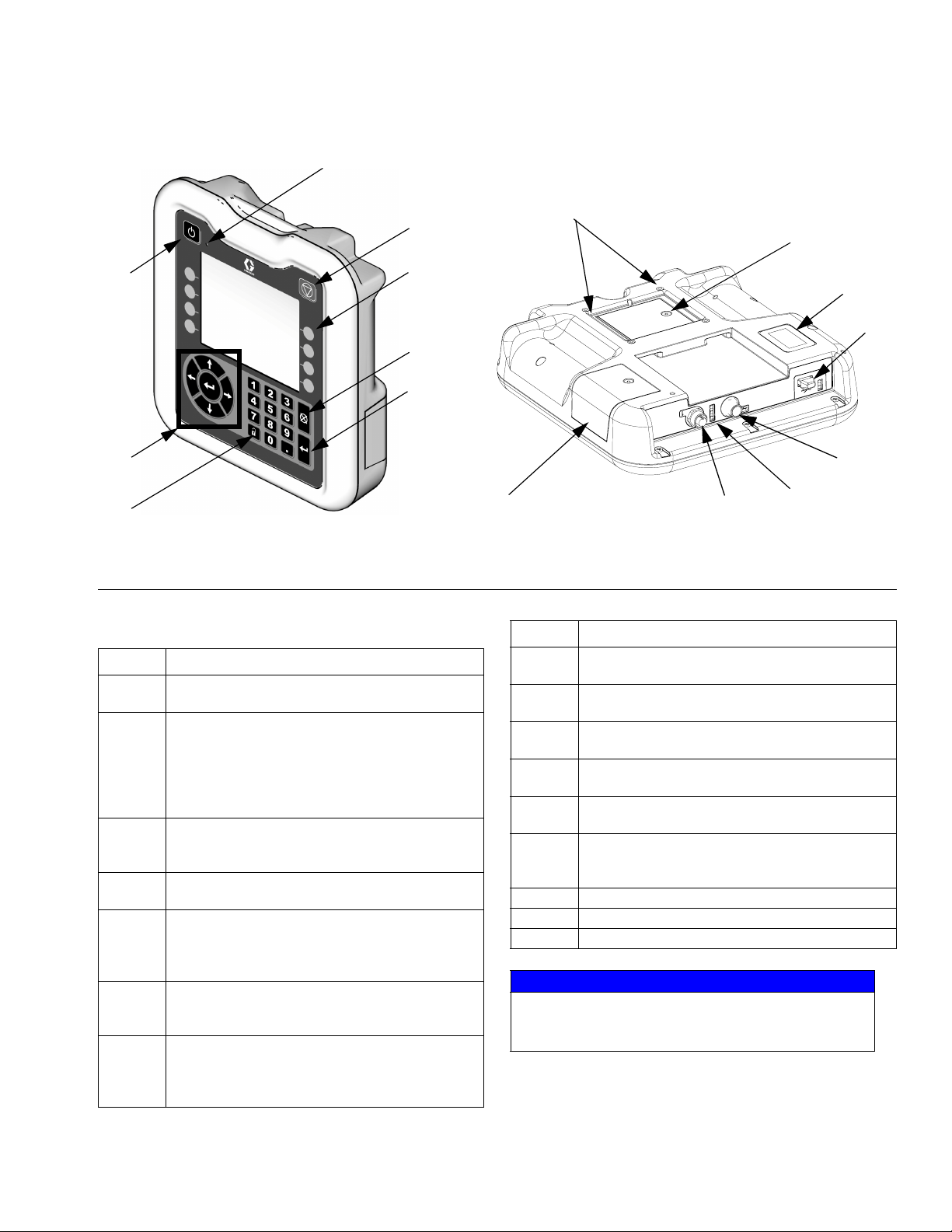

Advanced Display Module (ADM)

BB

BC

Overview

BJ

BP

BA

BD

BE

BF

BH

BG

IG

. 8: Advanced Display Module Component Identification

F

TI12362a

KEY:

Callout Function

BA Power On/Off Button

Enables/disables system.

BB System Status Indicator LED

Displays system status. Green LED indicates the

system is active. Orange LED indicates the system is off. Solid LEDs (green or orange) indicate

the system is in Run mode. Flashing LEDs (green

or orange) indicate the system is in Setup mode.

BC Stop Button

Stops all system processes. However, it is not a

safety or emergency stop.

BD Soft Keys

Functions vary depending on the screen.

BE Cancel Button

Clears system errors and cancels a selection or

number entry while in the process of entering a

number or making a selection.

BF Enter Button

Acknowledge changing a value or making a selection.

BG Lock/Setup

Toggle between run and setup screens. If setup

screens are password protected, button toggles

between run and password entry screens.

BR

Callout Function

BH Navigation Buttons

Navigate within a screen or to a new screen.

BJ Flat Panel Mount

Mounts to control center bracket (optional).

BK Model Number Tag

Model number.

BL USB Module Interface

USB port and USB indicator LEDs.

BM CAN Connector

Power connection.

BN Module Status LEDs

See LED Diagnostic Information, page 65, for

signal definitions.

BP Battery Cover

BR Token Access Cover

BS Digital I/O Port for Light Tower

BS

BN

r_24E451_3B9900_1a

NOTICE

To prevent damage to the soft key buttons, do not

press the buttons with sharp objects such as pens,

plastic cards, or fingernails.

BK

BL

BM

3A2098H 17

Page 18

Overview

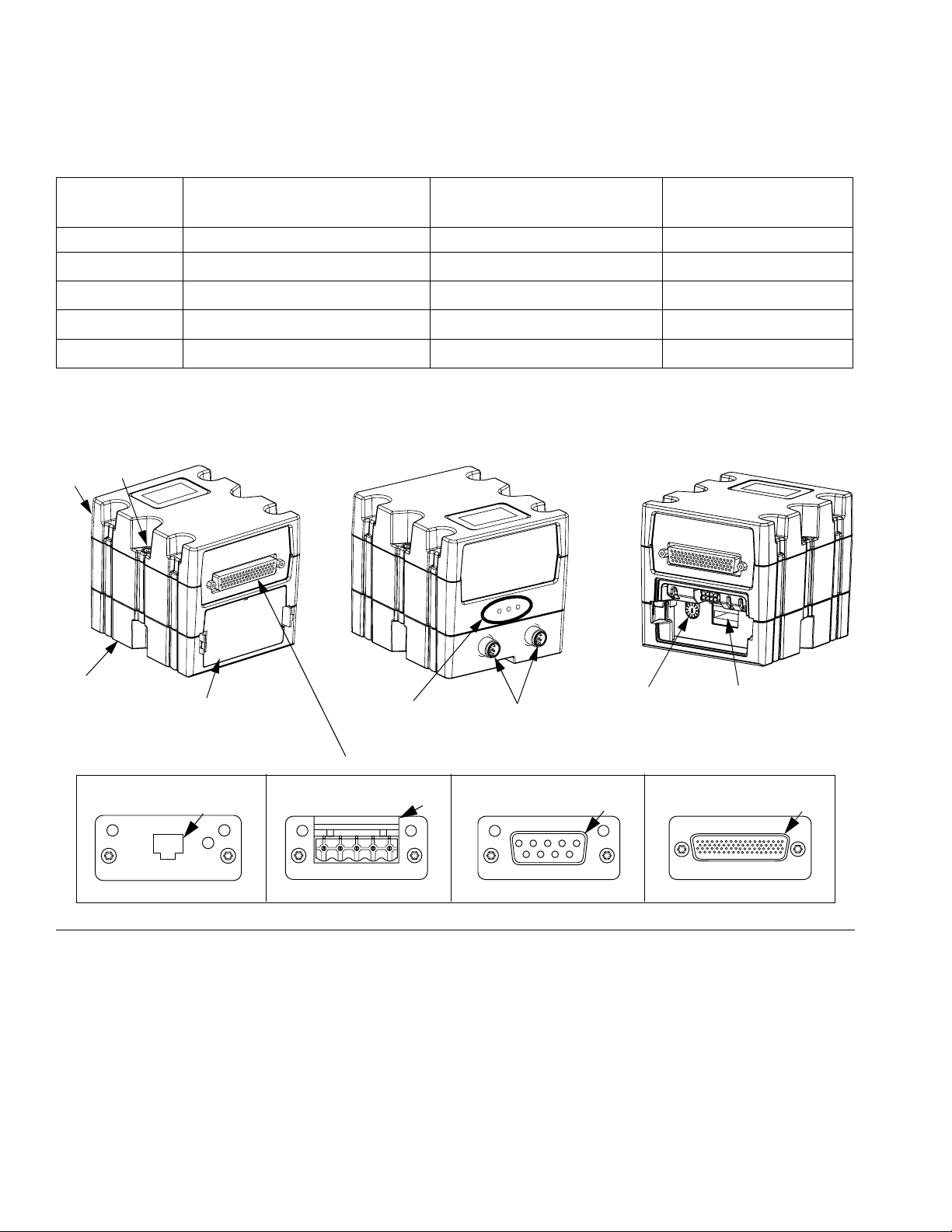

Automation Gateway Module

See the following table for the appropriate rotary switch position for your automation gateway module.

Gateway Part Number To

PCF Model User Interface Description

PFxx0x Discrete (DGM) 24B681 0

PFxx1x

PFxx2x

PFxx3x

PFxx4x

DeviceNet

EtherNet/IP

PROFIBUS

PROFINET

™

(CGM)

™

(CGM)

™

(CGM)

™

(CGM)

NOTE: See Control Center Assembly Overview on page 16 for automation and swirl control DGM identification.

Front Back

CD

CA

Order Rotary Switch Position

15V759 Any

15V760 Any

15V761 Any

15V762 Any

Front

(Access Cover Removed)

CB

CE

CF

Gateway Module Connectors

PROFINET or EtherNet/IP

CC

TI11814A

IG

. 9: Automation Gateway Module Components

F

DeviceNet

CC

TI11815A

Key:

CA Gateway Module

CB Base

CC Fieldbus Connector (see Appendix C - Communi-

cations Gateway Module (CGM) Connection

Details, page 122, for more information)

CD Module Connection Screws

CE Access Cover

CF Module Status LEDs (see LED Diagnostic Infor-

mation, page 65)

CH

PROFIBUS

Rotary

Switch

CC

TI11816A

Software

Token Slot

Discrete

CG

CG D-Subminiature (D-Sub) Connector (see Appendix

B - Discrete Gateway Module (DGM) Connection

Details, page 115, for pinout details)

CH CAN Connectors

18 3A2098H

Page 19

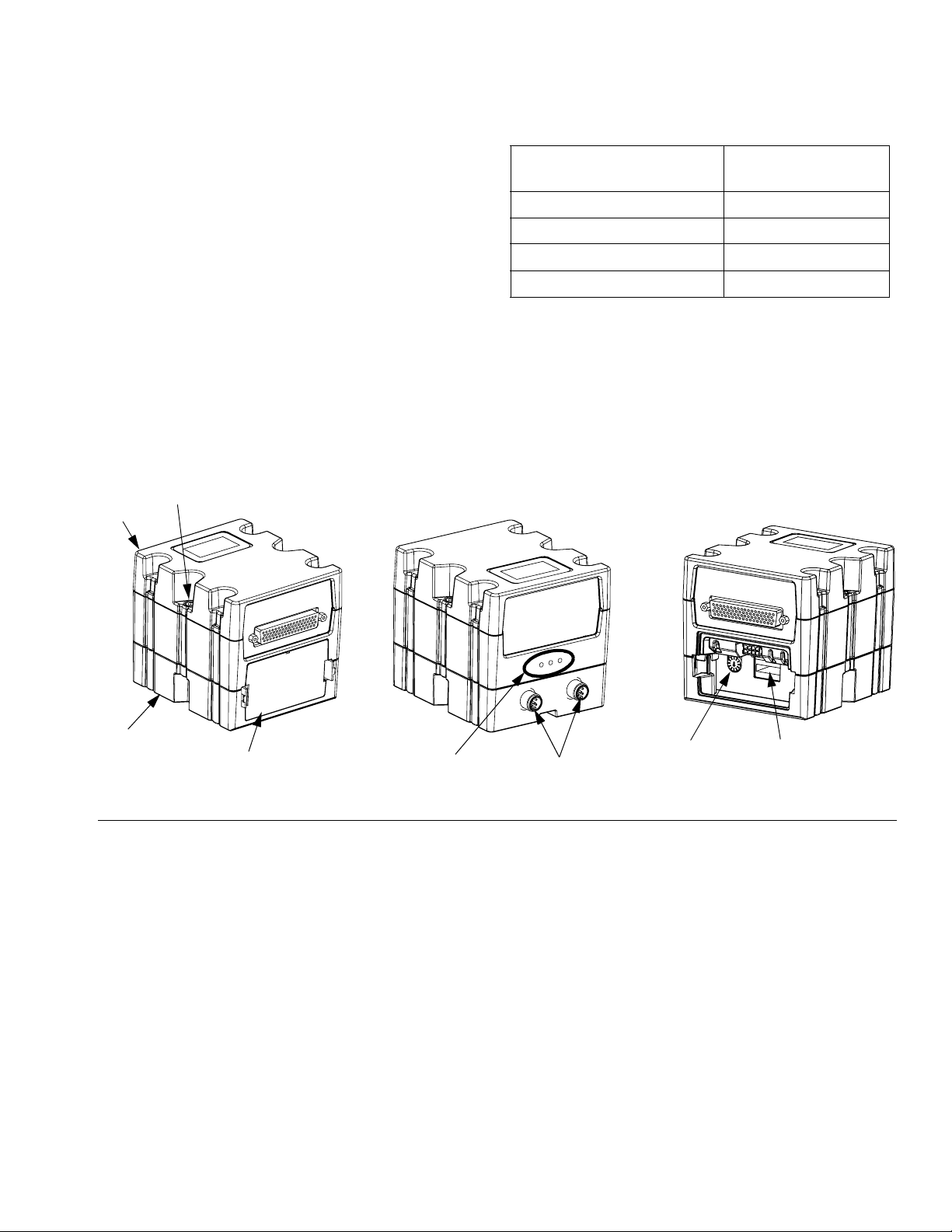

Swirl Control DGM

Overview

One swirl control DGM is included in the integrated Swirl

control center, and in each expansion swirl enclosure.

Each Swirl control DGM controls one swirl orbiter.

Each swirl control DGM must have a unique rotary

switch position. The rotary switch position determines

the number assigned to the swirl dispenser attached to

that DGM. If the rotary switch position must be changed,

do so with the power off.

Each integrated swirl control center and swirl enclosure

comes with a pre-installed cable between the swirl control DGM and the swirl board. The customer does not

need to make any external connections with the swirl

control DGM.

Front

CD

CA

Back

DGM Function

Swirl Control 1 1

Swirl Control 2 2

Swirl Control 3 3

Swirl Control 4 4

(Access Cover Removed)

Rotary Switch

Position

Front

CB

CE

FIG. 10: Swirl Control DGM

3A2098H 19

CF

CH

Rotary

Switch

Software

Token Slot

Page 20

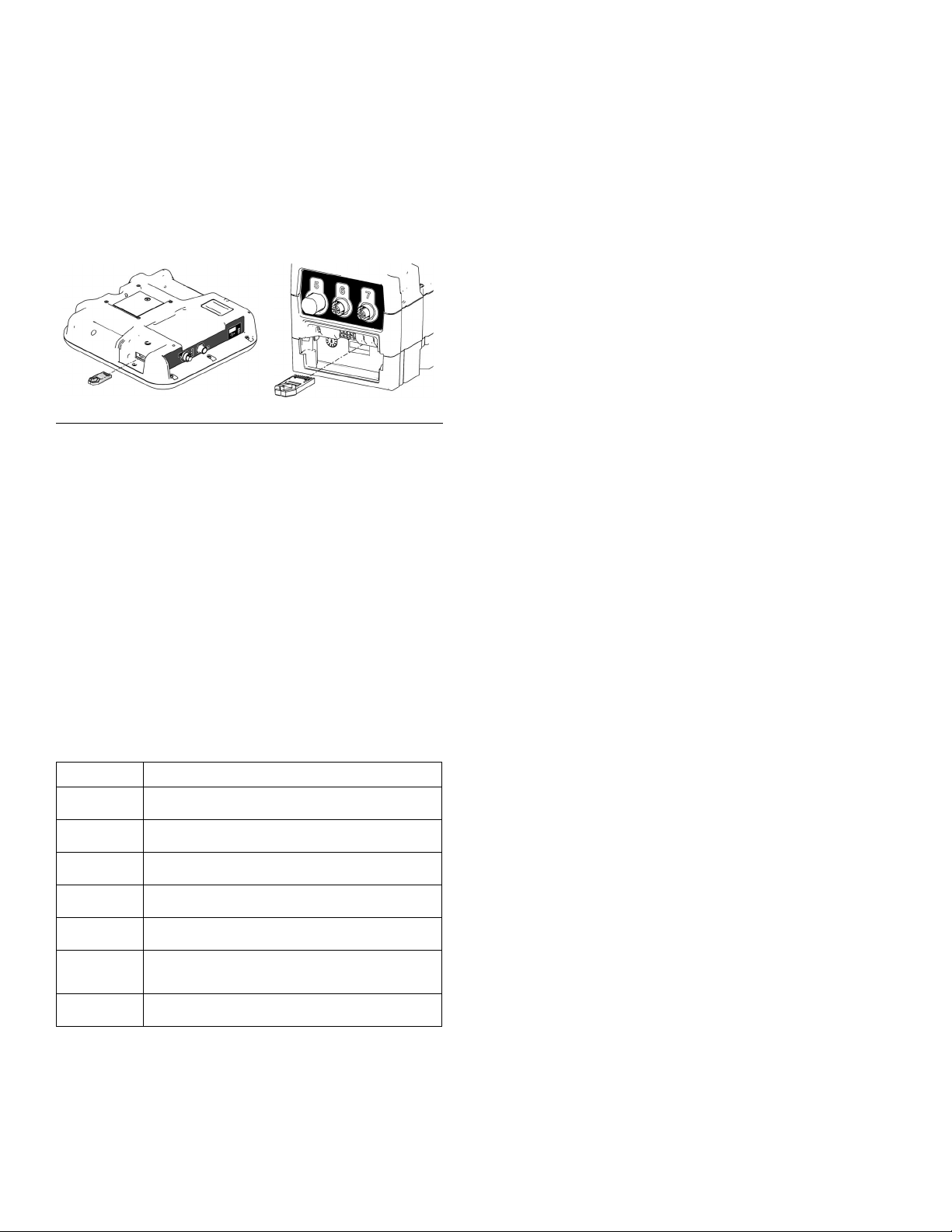

Overview

Key Tokens

The ADM and FCM must each have a key token

installed in order to operate. If the incorrect key token is

installed, the module will not operate. The DGM does

not require a key token.

FCMADM

F

IG

. 11

NOTE: There is one FCM located on each fluid plate.

If a new ADM or FCM is installed, follow the instructions

on page 77 to upgrade the software in the new module

and to install the key token from the old module in the

new module.

The following is a list of key token part numbers. If you

lose your key token be sure to order the correct item to

ensure proper system operation.

NOTE: The key tokens for the ADM and FCM look alike

but only work in one module or the other. If the key

tokens for the ADM and FCM become mixed, locate the

part number on each token then refer to the following

table to determine which module each token applies to.

Part Description

16M100 FCM Key Token, 2 styles, Flow Meter

16M101 FCM Key Token, 2 styles, No Flow Meter

16M102 FCM Key Token, 16 styles, Flow Meter

16M103 FCM Key Token, 16 styles, No Flow Meter

16M104 FCM Key Token, 256 styles, Flow Meter

16M105 FCM Key Token, 256 styles, No Flow

Meter

16M217 ADM Key Token, Standard PCF

20 3A2098H

Page 21

Installation

Installation

Before Installation

• Have all system and component documentation

available during installation.

• See component manuals for specific data on component requirements. Data presented here applies to

the PCF assemblies only.

• Be sure all accessories are adequately sized and

pressure-rated to meet system requirements.

• Use the PCF control center only with the PCF fluid

plate assembly.

Overview

The basic steps to install a PCF system are shown

below. See the separate component manuals for

detailed information.

To avoid injury and damage to equipment, use at

least two people to lift, move, or disconnect the system. The system is too heavy for one person to lift or

move.

10. Connect other fluid and air lines to additional system

components as instructed in their manuals.

11. Install fluid plate, swirl, and gateway cable assemblies, page 28.

12. Install Gateway interface, page 30.

Installation Steps

1. Mount control center, page 22.

For systems with multiple swirl dispensers,

2.

expansion Swirl enclosures, page 22.

3. Connect and ground control center and expansion

Swirl enclosures, page 23.

4. Mount each fluid plate assembly, page 24.

5. Ground each fluid plate assembly, page 27.

6. Check ground continuity.

7. Connect fluid lines between each fluid plate and

applicator. Connect fluid supply line and air supply

to module. See page 27.

8. Plumb air filter assembly near air supply drop site

that will be used for fluid plate assembly.

9. For systems with swirl dispensers,

dispenser onto outlet of a dispense valve.

install each swirl

mount

3A2098H 21

Page 22

Installation

Install Control Center

NOTE: This section applies to both the primary control

center and the expansion Swirl enclosures.

Mount

Ensure the following criteria are met before mounting

the PCF control center:

• Select a location for the control center that allows

adequate space for installation, service, and use of

the equipment.

• For best viewing, the ADM should be 60-64 in.

(152-163 cm) from the floor.

• Ensure there is sufficient clearance around the control unit to run cables to other components.

• Ensure there is safe and easy access to an appropriate electrical power source. The National Electric

Code requires 3 ft (0.91 m) of open space in front of

the control center.

Secure the control center with appropriate size bolts

through the 0.27 in. (7 mm) diameter holes in the mounting tabs. See the following mounting dimensions.

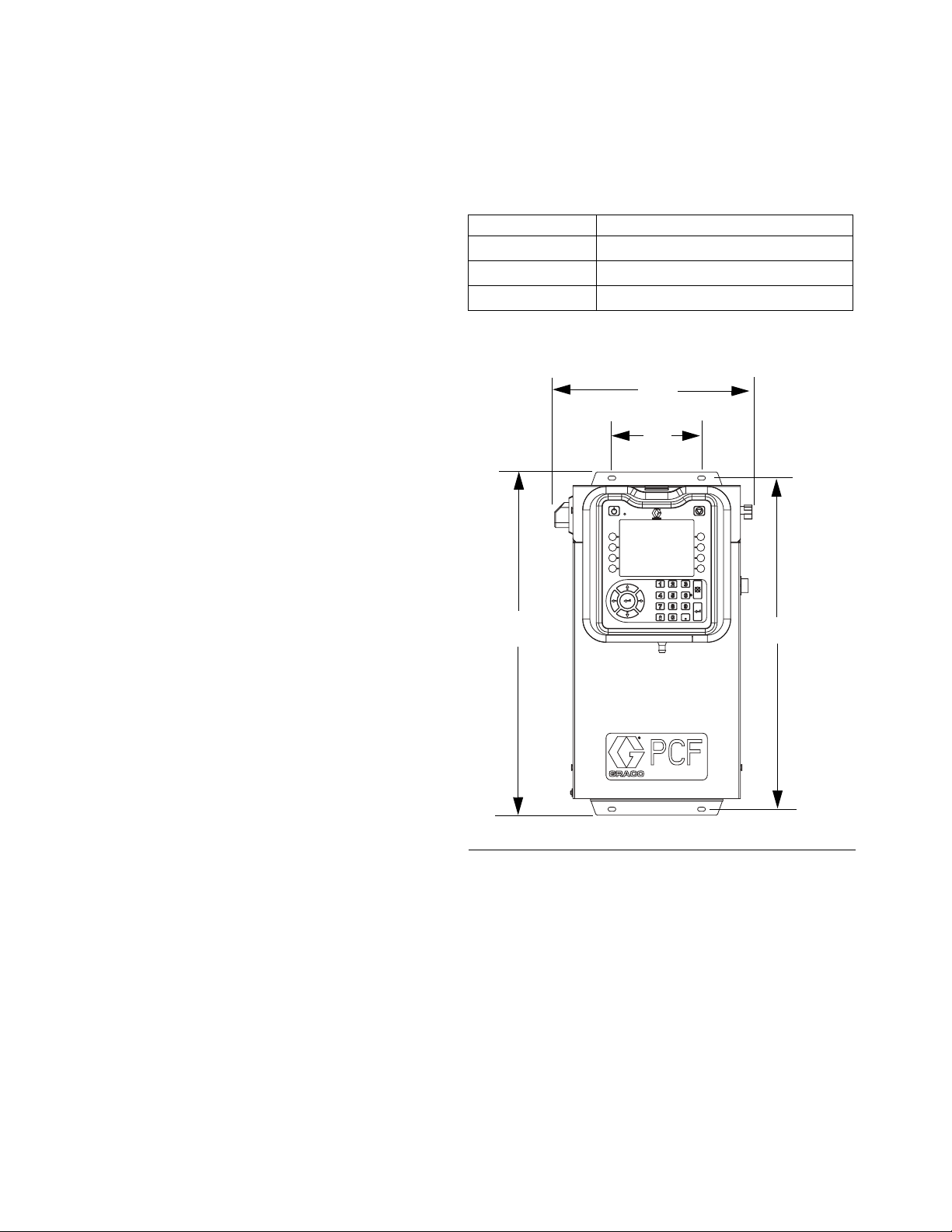

Table 2: Control Center Assembly Measurement

A

B

C

D

10.50 in. (267 mm)

5.75 in. (146 mm)

22.00 in. (559 mm)

21.25 in. (540 mm)

A

B

• Ensure there is easy access to the power switch.

• Ensure the mounting surface can support the weight

of the control center and the cables attached to it.

C

F

IG

. 12: Control Center Dimensions

D

22 3A2098H

Page 23

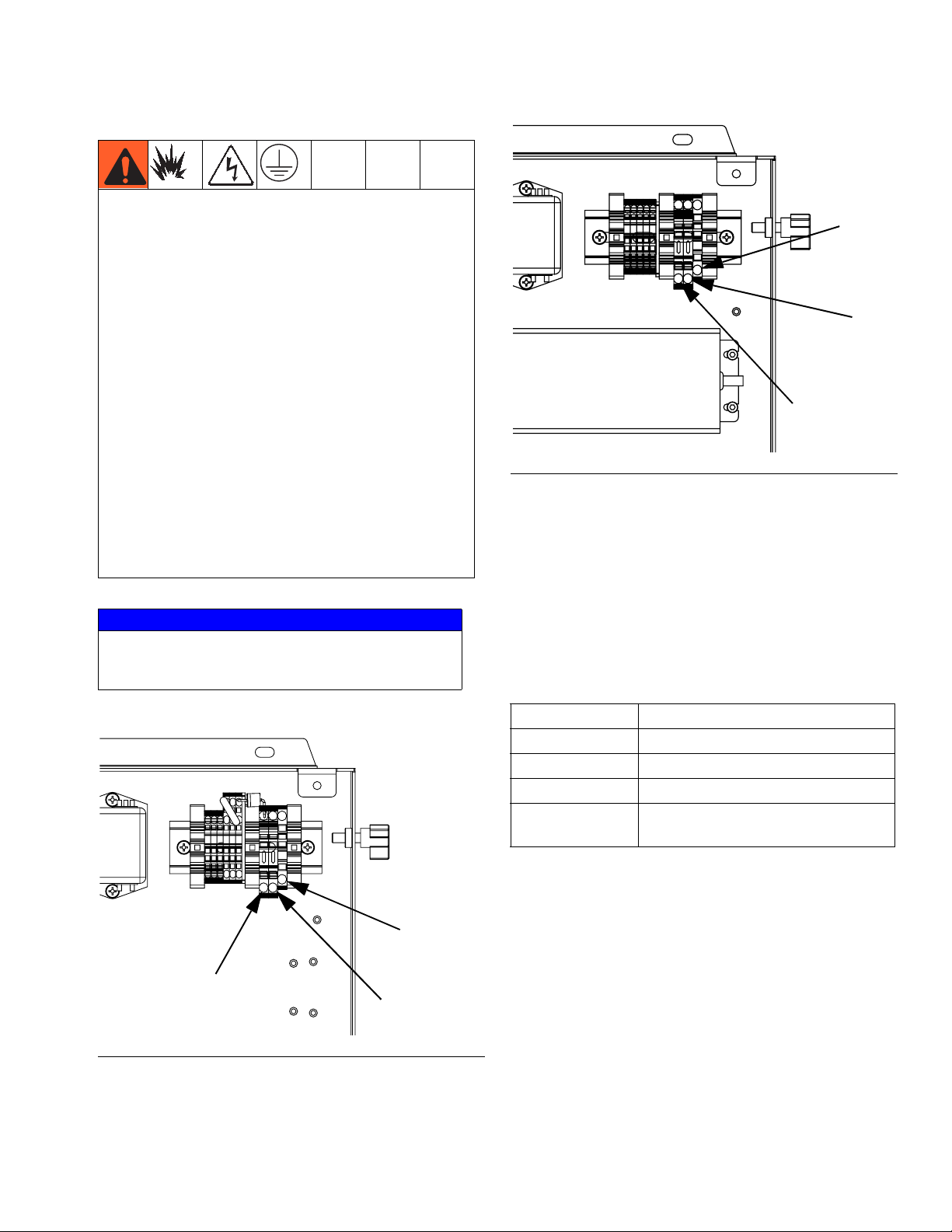

Electrical Connections

To reduce the risk of fire, explosion, or electric shock,

when grounding, connecting cables, connecting to a

power source or making other electrical connections:

• The control center must be electrically connected

to a true earth ground; the ground in the electrical

system may not be sufficient. Refer to your local

code for the requirements for a “true earth ground”

in your area.

• All wires used for grounding must be 18 AWG minimum.

• A qualified electrician must complete all grounding

and wiring connections.

• For 24 Vdc wiring refer to F

IG

. 13.

IG

. 14: 100-240 Vac Wiring

F

Installation

Ground

N

L

• For 100-240 Vac wiring refer to F

IG

. 14.

• Incoming power wiring must be guarded from the

enclosure. Use a protective grommet where the

power wiring enters the enclosure to prevent wear.

NOTICE

If power and grounding connections are not done

properly, the equipment will be damaged and the

warranty voided.

Ground

Connect Light Tower Accessory

1. Order the 255468 Light Tower Accessory as a diagnostic indicator for the PCF system.

2. Connect the cable from the light tower to the digital

I/O port (BS) on the ADM.

See Table 3 for a description of light tower signals.

Table 3: Light Tower Signals

Signal Description

Green No errors.

Yellow An advisory exists.

Yellow flashing A deviation exists.

Red solid An alarm exists. One or more fluid

plates may be shutdown.

NOTE: See Errors, page 66, for error definitions.

+

-

F

IG

. 13: 24 Vdc Wiring

3A2098H 23

Page 24

Installation

Install Fluid Plate Assemblies

To install the PCF fluid plate assemblies:

• Mount the fluid plate assemblies, page 24

• Ground fluid plate assemblies, page 27

• Connect one fluid plate assembly to the control cen-

ter. See Install Cable Assemblies on page 28.

•

If multiple fluid plates,

together. See Install Cable Assemblies on

page 28.

• Connect fluid lines, air lines, and cables; page 27

Mount

Before Mounting Assembly

• See component manuals for specific information on

component requirements. Information presented

here pertains to the PCF fluid plate assembly only.

connect the fluid plates

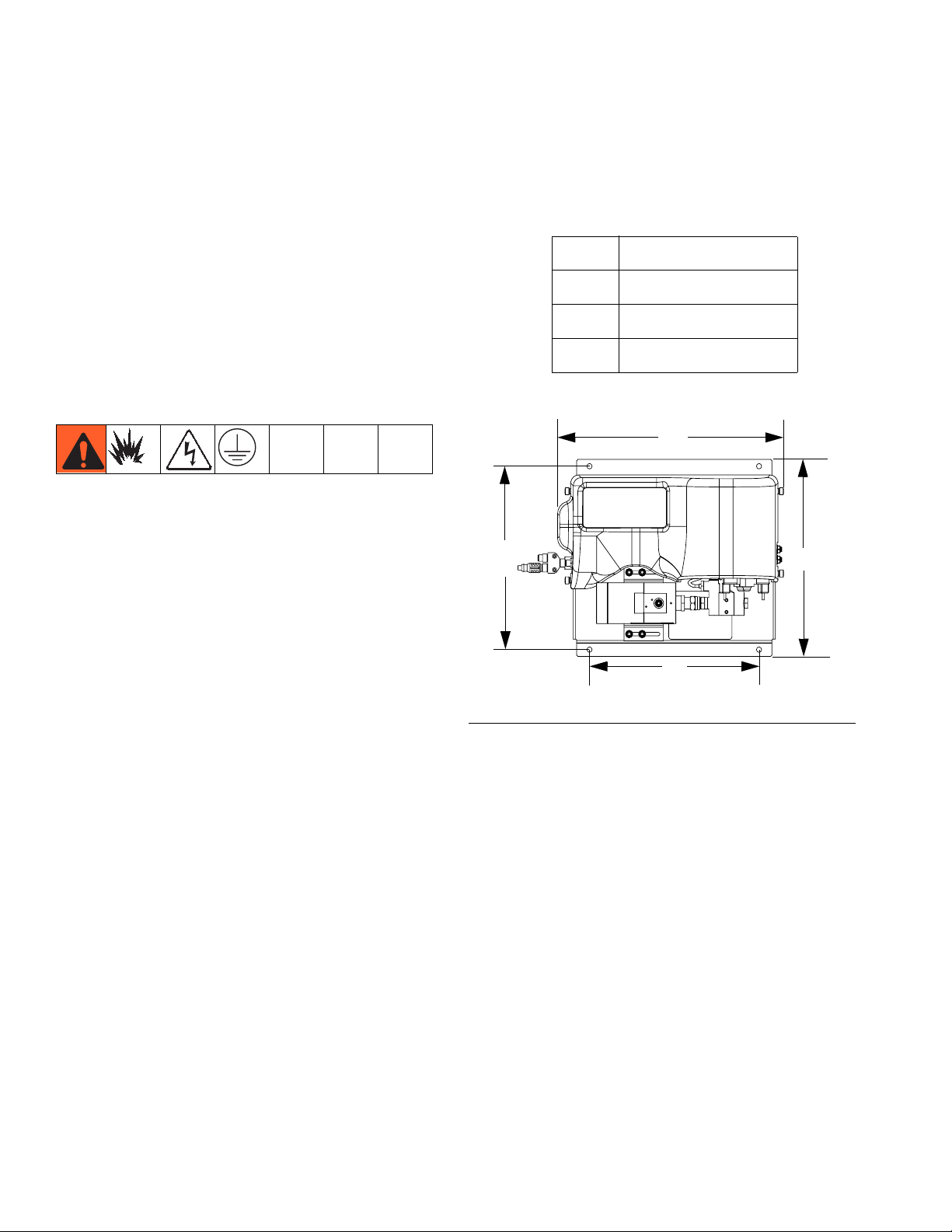

2. Mount and secure the fluid plate assembly to the

automation unit (or other mounting surface) with

appropriate size bolts through the 0.397 in. (10 mm)

diameter holes in the base plate. See the mounting

dimensions in Table 4 and F

Table 4: Fluid Plate Assembly Measurement

A

B

C

D

D

IG

. 15.

16.5 in. (419 mm)

14.0 in. (356 mm)

14.4 in. (366 mm)

13.4 in. (340 mm)

A

C

• Have all system and subassembly documentation

available during installation.

• Be sure all accessories are adequately sized and

pressure-rated to meet the system's requirements.

• Use only the Graco PCF fluid plate assembly with

the Graco PCF control center.

Mount Assembly

1. Select a location for the fluid plate assembly. Keep

the following in mind:

• Allow sufficient space for installing the equipment.

• Make sure all fluid lines, cables and hoses easily reach the components to which they will be

connected.

• Make sure the fluid plate assembly allows the

automation unit to move freely along all axis.

• Make sure the fluid plate assembly provides

easy access for servicing its components.

B

IG

. 15: Fluid Plate Assembly Dimensions

F

24 3A2098H

Page 25

Installation

Mount Four-Valve Breakout Kit 24B693

PCF is capable of controlling up to four separate dispense valves from port 1 on the FCM. A four-valve

breakout kit (24B693) is available to split the dispense

solenoid connector (port 1 on the FCM) into four separate dispense solenoid connectors. For each additional

dispense valve, order one dispense valve

solenoid (258334) and one solenoid cable (121806).

Follow this procedure if using the four-valve breakout

kit.

1. Remove the existing dispense solenoid and cable

from the fluid plate.

2. Install bulkhead fitting (included in the kit) into the

empty hole on the fluid plate.

GCA Cable

5. Connect the dispense valve cable(s) to the connections on the splitter assembly.

Connects to Splitter

Cable for:

Dispense Valve 1 J1

Dispense Valve 2 J2

Dispense Valve 3 J3

Dispense Valve 4 J4

Connection Labeled:

6. Mount splitter assembly and dispense valves, and

connect air lines as necessary for application.

Custom Breakout Cable

If desired, the following connector pinout information

may be used to build a custom breakout cable:

Pinout of FCM Port 1

Pin 1: Dispense Solenoid 4

Pin 2: Dispense Solenoid 2

Pin 3: Voltage - (common for all solenoids)

Pin 4: Dispense Solenoid 1

Pin 5: Dispense Solenoid 3

Connection 1

Hole for bulkhead fitting

Splitter Assembly

J1 J3

J2 J4

F

IG

. 16: Mount Breakout Kit

3. Connect one end of the extension cables (included

in the kit) to connection 1 on the FCM and the other

end of the cable to the bulkhead fitting.

Dispense solenoid outputs are 24 Vdc. Dispense solenoid outputs are capable of sourcing up to 0.5A each

(maximum 12W coil).

4. Connect the splitter assembly to the bulkhead fitting.

3A2098H 25

Page 26

Installation

Install Command Cable Kit 24B694

Follow this procedure if using the command cable kit.

1. Install bulkhead fitting (included in the kit) into the

empty hole on the fluid plate. See F

IG

. 16 on

page 25.

2. Connect one end of the extension cable (included in

the kit) to connection 5 on the FCM and the other

end of the cable to the bulkhead fitting.

3. Connect command cable to bulkhead fitting and

wire to automation controller per the following pinout

table.

Function

FCM

Port

Pin #

Command

Cable Wire

Color

1 White Command voltage (0-10 Vdc) Command voltage (0-10 Vdc)

2 Brown No connection Valve 3 dispense trigger (*sourcing

3 Green Dispense trigger (*sourcing input) Valve 1 dispense trigger (*sourcing

4 Yellow No connection Valve 2 dispense trigger (*sourcing

5 Gray Dispense trigger ground Dispense trigger ground

6 Pink No connection No connection

7 Blue Command signal ground Command signal ground

8 Red No connection No connection

Dispense Trigger Source:

‘Command Cable’ or

‘Combined’

Dispense Trigger Source:

‘Command Cable 3x’

input)

input)

input)

NOTE: Command cable inputs are not isolated from

PCF 24 Vdc power.

* To turn on the dispense trigger, connect the dis-

pense trigger pin to the dispense trigger ground pin

(pin 5).

26 3A2098H

Page 27

Installation

Ground

To reduce the risk of fire, explosion, or electric shock,

when grounding, connecting cables, connecting to a

power source or making other electrical connections:

• The control center must be electrically connected

to a true earth ground; the ground in the electrical

system may not be sufficient. Refer to your local

code for the requirements for a “true earth ground”

in your area.

• All wires used for grounding must be 18 AWG minimum.

• A qualified electrician must complete all grounding

and wiring connections.

• For 24 Vdc wiring refer to F

• For 100-240 Vac wiring refer to F

• Incoming power wiring must be guarded from the

enclosure. Use a protective grommet where the

power wiring enters the enclosure to prevent wear.

NOTICE

If power and grounding connections are not done

properly, the equipment will be damaged and the

warranty voided.

IG

. 13.

IG

. 14.

Connect Fluid and Air Lines

NOTICE

Route all fluid and air lines carefully. Avoid pinching

and premature wear due to excessive flexing or rubbing. Hose life is directly related to how well they are

supported.

Follow the instructions in your separate component

manuals to connect air and fluid lines. The following are

only general guidelines.

• The PCF fluid plate assembly should be installed on

the automation unit or in another appropriate place,

as close as practical to the dispense valve.

• Connect a fluid line between the fluid plate outlet and

the dispense valve. Smaller diameter and shorter

fluid lines (hoses) will provide better fluid system

response.

• Connect a fluid line to the flow meter fluid inlet or to

the regulator inlet if your system does not have a

flow meter.

• Air must be clean and dry, between 60-120 psi

(0.41-0.82 MPa, 4.14-8.27 bar). Flush air line before

plumbing in air filter assembly (234967). Plumb in air

filter assembly near air drop site (upstream of fluid

plate module). Adding an air regulator to this line will

provide more consistent dispense valve response

times.

Ground the fluid plate assembly as instructed here and

in the individual component manuals. Make sure the

fluid plate assembly and its components are installed

correctly to ensure proper grounding.

Air and Fluid Hoses

For static dissipation, use only electrically conductive

hoses or ground the applicator / dispense valves.

Dispense Valve

Follow the grounding instructions in the dispense valve

manual.

• Connect an air supply line to the 1/4 npt inlet port on

the fluid plate(s) air supply inlet.

• Connect 5/32 in. or 4 mm OD air lines from the applicator's solenoid valve to the applicator. Plug any

unused solenoid ports.

NOTE: To maximize system performance keep the dispense hose length and ID as small as the application

will allow.

3A2098H 27

Page 28

Installation

Install Cable Assemblies

NOTE: To prevent system errors, only connect cables

with the power off.

NOTE: See F

IG

. 17 on page 29.

1. For systems with more than one swirl dispenser:

Use a CAN cable to connect the control center to

one swirl expansion enclosure. Use additional CAN

cables to connect any remaining expansion swirl

enclosures together in sequence.

2. For systems with one or more swirl dispensers,

motor cable to connect each swirl dispenser to an

expansion swirl enclosure or to the control center.

3.

Connect a CAN cable from the control center to one

fluid plate assembly.

4.

For multiple fluid plate systems,

connect each fluid plate to one other fluid plate

Repeat until all fluid plates are connected to one

other fluid plate.

NOTE: Use the connections on the CAN splitter on the

left side of each fluid plate to connect the fluid plates

together. There will be a CAN splitter on all but one fluid

plate.

use CAN cables to

use

NOTE: The control center, expansion swirl enclosures,

and fluid plates may be connected in any order as long

as each is connected to another system component with

a CAN cable. See the example shown in F

page 29.

5. Use the automation interface cable (not provided) to

connect the Gateway module to the automation

controller.

IG

. 17 on

28 3A2098H

Page 29

Installation

2

4

5

1

4

2

1

4

2

1

2

3

Multiple Fluid Plate and Multiple Swirl System shown

FIG. 17: Cable Installation Diagram

3A2098H 29

Page 30

Installation

Install Gateway Module Interface

NOTE: Systems with swirl dispensers will have two gateway modules in the control center. The gateway module on

the left is the swirl control DGM module, and does not need any setup or modification. The gateway module on the

right is the automation Gateway module. This section covers the automation Gateway module.

Fieldbus Communications Gateway Module

Module Description

The Communications Gateway Module (CGM) provides

a control link between the PCF system and a selected

fieldbus. This provides the means for remote monitoring

and control by external automation systems.

See Automation Control (Normal Operation), page

45, for details on controlling the PCF system through the

Gateway module.

Data Exchange

Data is available by block transfer, cyclic transfer,

change of state triggered, and explicit access to individual attributes as defined by the fieldbus specification.

Refer to Appendix C - Communications Gateway

Module (CGM) Connection Details, page 138, for

details about PCF/fieldbus data map.

NOTE: The following system network configuration files

are available at www.graco.com

• EDS file: DeviceNet or EtherNet/IP fieldbus networks

• GSD file: PROFIBUS fieldbus networks

• SDML: PROFINET fieldbus networks

CGM Status LED Signals

Signal Description

Green on System is powered up

Yellow Internal communication in progress

Red

Solid

*Red

(7 flashes)

*The red LED (CF) will flash a code, pause, then repeat.

CGM hardware failure

Data map load failure

Incorrect data map for fieldbus type

No data map loaded

Installation

NOTE: The following installation instructions assume

the person implementing the PCF fieldbus connection

fully comprehends the fieldbus being used. Ensure the

installer understands the automation controller communication architecture and the fieldbus being used.

1. Install interface cables between the PCF system

and the automation controller per the fieldbus standards. Refer to Appendix C - Communications

Gateway Module (CGM) Connection Details,

page 122, for details.

2. Turn on system power. Navigate to the Gateway

setup screens and ensure the data map name is:

PCF 4FP. Refer to Appendix A - Advanced Dis-

play Module (ADM), page 99, for details about the

data map.

3. Set the PCF Gateway configuration values as

required to interface with automation controller.

Refer to Appendix A - Advanced Display Module

(ADM), page 99, for details about the configuration

settings.

4. Retrieve the appropriate fieldbus configuration file

for the fieldbus being used from www.graco.com.

5. Install the configuration file on the automation controller (fieldbus master). Configure it for communication with the PCF Gateway (fieldbus slave).

6. Establish communication between the automation

controller and the PCF Gateway to confirm the successful configuration of the hardware and data.

NOTE: Use the ADM screens for troubleshooting fieldbus data communication problems. Refer to Appendix

A - Advanced Display Module (ADM), page 99, for

details. Also, use the LED status indicators on the PCF

Gateway module for fieldbus status information. Refer to

Appendix C - Communications Gateway Module

(CGM) Connection Details, page 122, for details.

30 3A2098H

Page 31

Installation

Discrete Gateway Module

Module Description

The Discrete Gateway Module (DGM) provides a control

link between the PCF system and an automation controller through discrete input and output connections.

This provides the means for remote monitoring and control by external automation systems.

See Automation Control (Normal Operation), page

45, for details on controlling the PCF system through the

Gateway module.

Connect D-Sub Cable

The DGM provides all I/O through the D-Sub cable.

Graco offers two options for connecting a D-Sub cable

to the D-Sub connector (CG). Both options are accessories and must be ordered separately.

•

For single fluid plate systems only:

ing leads cable (123793). See Appendix B -

Discrete Gateway Module (DGM) Connection

Details, page 115, for details and cable inter-

face signals.

D-Sub to fly-

DGM Rotary Switch Position

The Discrete Gateway Module (DGM) rotary switch

must be in position 0 for Automation Gateway DGMs

and positions 1-4 for Swirl Control DGMs in order for the

DGM to operate. See Automation Gateway Module on

page 18 and Swirl Control DGM on page 19.

•

For multiple fluid plate systems:

(123972) and 78-pin breakout board (123783).

See Appendix B - Discrete Gateway Module

(DGM) Connection Details, page 115, for

details and pin assignments.

CG

F

IG

. 18: Connect D-Sub Cable

DGM Status LED Signals

D-Sub cable

r_24B681_2B9904_2b

See LED Diagnostic Information, page 65, for signal

definitions.

3A2098H 31

Page 32

System Setup

System Setup

Overview

The PCF system compensates for temperature, flow, or

pressure fluctuations. However, if there is a hardware

change on the supply system or the dispense material is

changed, the PCF system must be set up again.

After material is loaded into the supply system, set up

the PCF system using the Setup screens. The following

procedure outlines the major system setup steps. The

following subsections provide instructions to complete

each setup step. Once these steps are complete the

module is ready for operation.

NOTE: See the Advanced Display Module (ADM) section, page 17, and Appendix A - Advanced Display

Module (ADM), page 99, for detailed operating instructions for the display keypad and each screen.

1. Configure System, page 32.

Configure System

Define the number of installed fluid plates (called “Dispenser” on this screen) and number of installed swirl

dispensers. If a fluid plate is listed as “Uninstalled” the

screens for that fluid plate will not appear in the run or

setup screens.

1. With the system in setup mode, navigate to the System screen.

2. Press to access the fields to make changes.

3. Use the arrow keys to navigate to the desired field.

4. Press to open the drop-down list, and select

the desired setting. Press to accept the selection.

5. Repeat for the other Dispensers and Swirl Dispensers.

6. Press to exit edit mode.

2. Configure Control Settings, page 33.

3. Configure Mode Settings, page 34.

4. Configure Delay Settings, page 34.

5. Configure Flow Meter Settings, page 35.

6. Configure Pressure Loop Settings, page 35.

7. Adjust Pressure Sensors, page 36.

8. Configure Errors, page 36.

9. Setup Maintenance Schedule/Parameters, page 37.

10. For systems with swirl dispensers only:

a. Configure Swirl to valve association and error

type, page 37.

b. Configure Swirl settings, page 38.

11. Configure Gateway Settings, page 38.

12. Setup Styles, page 38.

IG

. 19

F

13. Configure Advanced Settings, page 38.

32 3A2098H

Page 33

System Setup

Configure Control Settings

Set the controls for the dispense source, how dispense

commands are sent, and job settings.

1. With the system in setup mode, navigate to Fluid

Plate x, screen 1 (Control Settings).

2. Press to access the fields to make changes.

7. Press to move to the Job End Delay field. Enter

the desired delay time (in seconds). Press to

enter the value.

8. Press to move to the Run Mode Bead Adjust

field. Press to open the drop-down list, and

select Enable or Disable. Press to enter the

value.

9. Press to move to the End Job on Alarm Check-

box. Press to enable or disable.

10. Press to move to the Display Control Password

field. Press to enter the value.

11. Press to exit edit mode.

If multiple fluid plates are installed,

12.

cedure for the other Fluid Plates.

repeat this pro-

F

IG

. 20

3. Press to open the Dispense Trigger Source

drop-down list, and select Gateway, Command

Cable, Command Cable 3x, or Combined. If Command Cable is selected, users can enable the

valves. Press to finalize the selection.

4. If the dispense trigger source is set to Command

Cable, press to move to the Enable Valves field.

Press and to enable valves.

5. Press to move to the Command Value Source

field. Press to open the drop-down list, and

select Gateway, Command Cable, or Display. Press

to enter the value.

6. Press to move to the Job End Mode field. Press

to open the drop-down list, and select Timer or

Gateway. Press to enter the value.

3A2098H 33

Page 34

System Setup

Configure Mode Settings

Set valve commands, including the dispense mode

(pressure, bead, shot, or full open) and flow rate or pressure for each valve. The bead scale is also adjustable

from this screen.

NOTE: For a description of each dispense mode, see

Dispense Control Modes, page 112.

1. With the system in setup mode, navigate to the Fluid

Plate x, screen 2 (Mode Settings).

2. Press to access the fields to make changes.

5. Press to move to the Bead Scale field. Enter a

scale value between 50% and 150%. Press to

enter the value.

6. Press to exit edit mode.

Configure Delay Settings

Set on and off delays (in milliseconds) for each valve

and the regulator. For an explanation of the on and off

delays, refer to the On/Off Delays section on page 39.

1. With the system in setup mode, navigate to the Fluid

Plate x, screen 3 (Delay Settings).

2. Press to access the fields to make changes.

F

IG

. 21

3. Press and to set the mode for each

valve that will be used to Pressure, Bead, Shot, or

Full Open. Press to enter each selection.

4. Use the four arrow buttons to navigate to each

Fixed Command field. Enter the desired value for

each valve that will be used. Press to enter

each value.

NOTE: The ability to dispense from multiple valves

simultaneously is only allowed in either of the following

scenarios.

• Each valve is set to Pressure mode and has

identical Fixed Command values.

• Each valve is set to Full Open mode.

Attempting to dispense from multiple valves simultaneously using any other combination will cause an Incompatible Valves Settings alarm.

FIG. 22

3. Use the four arrow buttons to navigate to each On

and Off field. Enter a desired delay value (in milliseconds) for each valve that will be used and the

regulator. Press to enter each value.

4. Press to exit edit mode.

34 3A2098H

Page 35

System Setup

Configure Flow Meter Settings

The accuracy of the PCF volume reporting depends on

precise adjustment of the K-factor(s). The fluid plate

uses the K-factor(s) to calculate the volume dispensed.

If the set value is not correct, the system still delivers

repeatable flow rates; however, the reported value may

not be correct. See Verify Flow Meter Calibration,

page 42, for additional K-factor information.

Table 5: Flow Meter K-Factors

Part Description K-Factor

246652 High Resolution Helical

Gear Meter

246340 Heated Helical Gear

Meter

16E993 Ultra High Flow Meter 33000

Set Flow Meter K-Factor

NOTE: In systems without a flow meter, the flow meter

settings will be grayed out.

1. With the system in setup mode, navigate to the Fluid

Plate x, screen 4 (Pressure Loop and Flowmeter Settings).

2. Press to access the fields to make changes.

7000

3500

3. Press to open the Meter Type drop-down list,

and select the meter type used by the system.

Select Volume for volumetric flow meters or Mass

for mass flow meters. Press to enter the selection.

4. Press to move to the K-Factor field. Key in the

K-factor value. See Table 5: Flow Meter K-Factors

for values. Press to enter the value.

5. Press to exit edit mode.

NOTE: If necessary, verify flow meter calibration. See

Verify Flow Meter Calibration, page 42, for instruc-

tions.

Configure Pressure Loop Settings

The PCF system uses variables (Kp, Ki, and Kd) in the

software calculations to accurately and precisely control

the fluid pressure.

NOTE: It is recommended that these values are not

changed from the factory defaults of 32.00 for Kp,

128.00 for Ki, and 0.00 for Kd. However, if the values

need to be adjusted, see Manually Adjust Control

Loop Parameters on page 43.

F

IG

. 23

3A2098H 35

Page 36

System Setup

Adjust Pressure Sensors

Set pressure offsets and pressure limits.

NOTE: Inlet sensor settings will be grayed out on this

screen for systems with heated fluid plates.

1. With the system in setup mode, navigate to the Fluid

Plate x, screen 5 (Pressure Sensors).

2. Press to access the fields to make changes.

F

IG

. 24

Configure Errors

Set the error type (alarm, deviation, or none) that will be

issued if the pressure, flow rate, volume, or computed

target goes outside the tolerance settings of the active

style. When an alarm occurs, the system stops dispensing. When a deviation occurs, the system will continue

dispensing. See Fluid Plate x, Screen 6 (Error Type)

on page 107 for more information.

NOTE: Only the low/high pressure errors will be

enabled for systems without a flow meter.

1. With the system in setup mode, navigate to Fluid

Plate x, screen 6 (Error Type).

2. Press to access the fields to make changes.

NOTE: For the following steps, press and

to navigate through each field, and to open

drop-down menus and enter changes or selections.

3. Set the desired offset for the inlet and outlet pressures between 0 and 100 psi (0.7 MPa, 7.0 bar).

Remove all pressure on the sensors, and then

adjust the offset so the measured value reads 0.

NOTE: It is recommended that offsets should not be

changed from the factory defaults of 0.

4. Set the desired minimum and maximum pressure

limits for the inlet, and the desired maximum pressure limit for the outlet.

5. Set the error type (alarm or deviation) that will be

issued:

• If the minimum inlet pressure decreases below

the setting.

• If the maximum inlet pressure increases above

the setting.

• If the maximum outlet pressure increases above

the setting.

FIG. 25

3. Press to open the Low Pressure drop-down

list, and select either Alarm or Deviation for the error

type. Press to enter the selection.

4. Press to move to the next field. Repeat Step 4

for each field.

5. Press to exit edit mode.

6. Press to exit edit mode.

36 3A2098H

Page 37

System Setup

Setup Maintenance Schedule/Parameters

Set the volume (or hours) limit that will trigger a maintenance advisory for the fluid supply, Voltage to Pressure

(V/P) Transducer, fluid regulator, flow meter, and all four

valves.

NOTE: Hours is shown instead of Volume for fluid plates

without a flow meter.

The Volume (or Hours) column displays the current

totalizer value. If this value exceeds the set limit, the

value will turn red and a maintenance advisory is issued.

See Fluid Plate x, Screen 7 (Maintenance Advisory

Limits), page 108, for more information about maintenance totalizers.

To set limits:

1. With the system in setup mode, navigate to the Fluid

Plate x, screen 7 (Maintenance Advisory Limits).

2. Press to access the fields to make changes.

To reset a totalizer value:

1. Follow Steps 1-3 of To set limits: to make changes

in

Fluid Plate x, screen 7 (Maintenance Advisory Lim-

its)

.

2. Press to scroll to the system component to

reset.

3. Press to reset the value.

Configure Valve to Swirl Association and Motor Error Type

Define which Swirl number is installed on which dispense valve.

Set the error type (alarm or deviation) that will be issued

if a motor fault occurs. When an alarm occurs, the fluid

plate stops dispensing. When a deviation occurs, the

fluid plate will continue dispensing.

F

IG

. 26

3. Enter the desired limit for the air supply and press

to enter the selection.

4. Press to move to the next field. Repeat Step 4

for each field.

5. Press to exit edit mode.

3A2098H 37

FIG. 27

Page 38

System Setup

Configure Swirl Settings

NOTE: This applies only to systems with swirl dispens-

ers.

Set the individual Swirl settings for each installed Swirl.

F

IG

. 28

Configure Gateway Settings

Gateway settings differ for each system. See Automation Gateway Setup Screens, page 102, for guidelines

on configuring each type of Gateway interface.

Setup Styles

The PCF system can store up to 256 styles. See Styles,

page 46, for more information about styles and instructions on setting up styles. Style 0 is always the purge

style.

Configure Advanced Settings

Use the advanced settings to set or change the format

and display units, such as the language, date format,

and pressure units, for all PCF screens. See Setup

Mode, page 101, for advanced setting guidelines.

38 3A2098H

Page 39

On/Off Delays

The PCF fluid regulator can physically respond faster

than the dispense device and its solenoid. As a result,

the fluid regulator can supply material to the dispense

device before the device has time to open. Supplying

material to a closed device can create trapped-pressure.

At the end of a cycle, the dispense device can shut off

before the pressure has dissipated. This can cause a

dispense of an excess of material at the beginning of the

next cycle.

To eliminate these two problems, change the delay time

associated with the opening of the fluid regulator/dispense and/or the closing of the dispense device, see

Table 5: On/Off Delay Variables. For instructions setting on/off delays, see Configure Delay Settings, page

34.

NOTE: On/Off delay can be set for each dispense

device.

In general, delays should be adjusted so the outlet pressure during “no flow” is slightly below the outlet pressure

during dispense.

System Setup

F

IG

. 29 and Table 6: Delay On/Off Timing show delay

ON and OFF timing.

Table 6: Delay On/Off Timing

A Regulator ON

delay

The user sets the fluid regulator ON delay timing.

B Valve ON delay Usually set to zero. Can be

used to change the starting

point of a bead.

C Valve OFF Delay Usually set to zero. Higher

values will lower the trapped

pressure.

D Regulator OFF

delay

The user sets the regulator

OFF delay timing. Zero or

small values will lower the

trapped pressure.

E Valve Open

Reaction Time

Time delay for valve to physically open. Delay varies

based on pneumatic hose

length and valve air volume.

F Valve Close

Reaction Time

Time delay for valve to physically close. Delay varies

based on pneumatic hose

length and valve air volume.

Table 5: On/Off Delay Variables

Variable: Sets the Amount of Time:

Valve ON Sets time from Dispense Valve High

to Valve Open command

Regulator

ON

Sets time from Dispense Valve High

to Regulator ON

Valve OFF Sets time from Dispense Valve Low

to Valve Close command

Regulator

OFF

Sets time from Dispense Valve Low

to Regulator OFF

Dispense Valve

Signal

A

Fluid

Regulator

Valve Open

Command

B

C

D

Valve Actually

Open

E

F

FIG. 29: Timing Delay

3A2098H 39

Page 40

Operation

Operation

Pressure control may degrade at low output pressures.

It is not recommended to dispense at outlet pressures

less than 500 psi (3.4 MPa, 34 bar).

Startup

Initial Startup

1. Ensure the PCF control center is installed and all of

the proper connections to and from the control center have been made. Ensure fittings are tight.

2. Read and understand the Operation (page 40) and

Advanced Display Module (ADM) (page 17) sections of this manual.

3. Continue startup with step 2 in Standard Startup.

Standard Startup

1. Carefully inspect the entire system for signs of leakage or wear. Replace or repair any worn or leaking

components before operating the system.

Load Material

Before using the system material must be loaded into

the supply system.

1. If this is a new installation, follow the Initial Startup

procedure. Otherwise, follow the Standard Startup

procedure. See page 40.

2. Turn on the fluid supply pressure to the fluid plate

assembly.

3. Place the valve(s) over a waste container.

4. Enter the maintenance screen. See Dispense

From Maintenance Screen, page 43.