Page 1

Instructions-Parts

Flow Control

3A2097B

Modules

Precisely regulates the flow of material to a gun in an automatic proportioning system.

For professional use only.

Approved for use in explosive atmospheres only when used in conjunction with ProMix

Electronic Proportioners.

190 psi (1.31 MPa, 13.1 bar) Maximum Fluid Working Pressure

Model 249849 Flow Control Module

With integrated air-operated fluid regulator.

EN

Model 24H989 Flow Control Module

For use with a remotely mounted, air-operated fluid regulator (not included).

Model 249849

Important Safety Instructions

Read all warnings and instructions in this

manual and in your ProMix instruction

manuals. Save these instructions.

Model 24H989

TI18058a

TI18016a

Page 2

Related Manuals

Related Manuals

ProMix Manuals in English

Manual Description

312778 ProMix 2KS Automatic System

Installation

312779 ProMix 2KS Automatic System

Operation

312780 ProMix 2KS Automatic System

Repair-Parts

3A1163 ProMix 1KS Installation

3A1080 ProMix 1KS Automatic System

Operation

3A1164 ProMix 1KS Repair-Parts

313881 ProMix 3KS Installation

313885 ProMix 3KS Automatic System

Operation

313883 ProMix 3KS Repair-Parts

Grounding

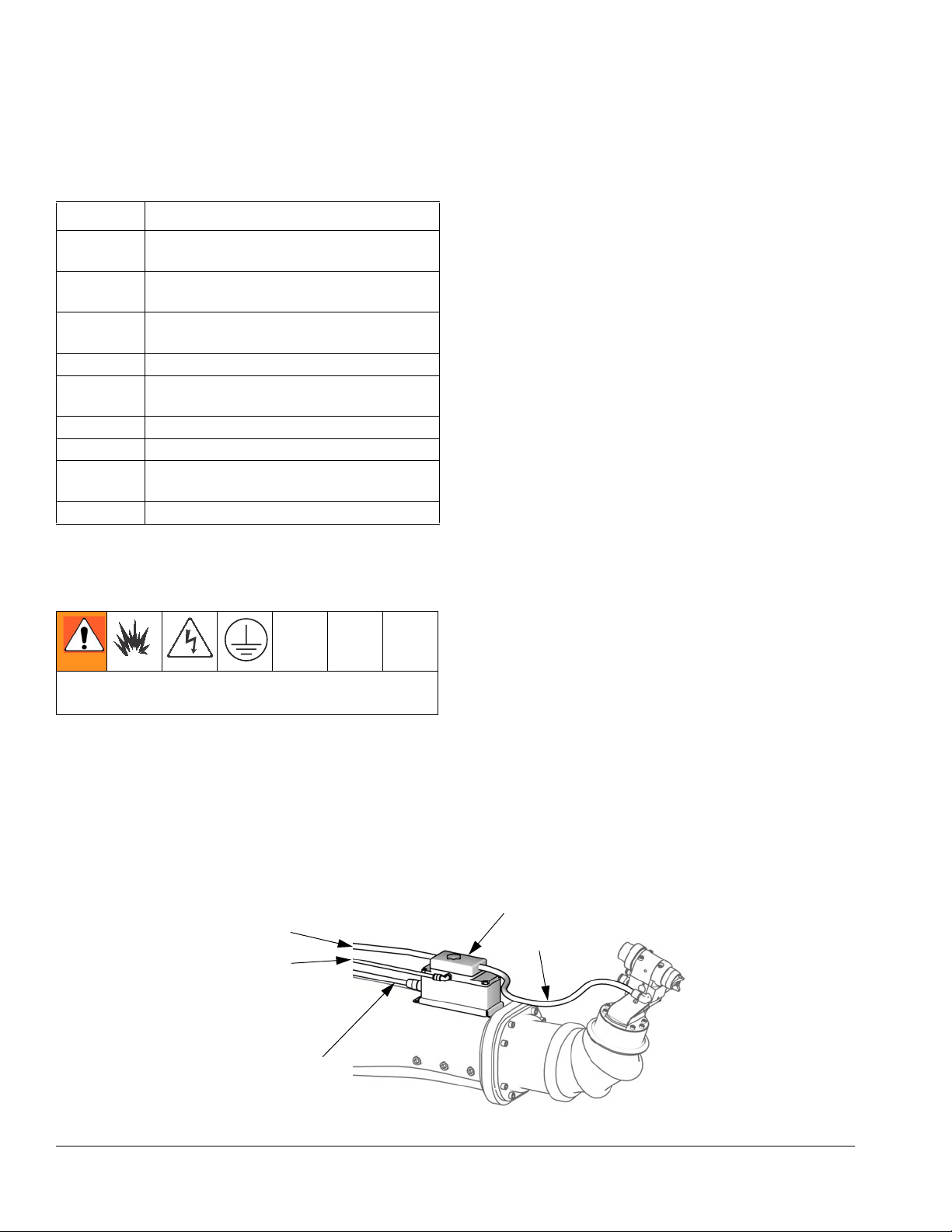

Installation (Model

249849)

The intrinsically safe flow control module (FC) is

required to use flow control in your system. See F

1. Connect a 1/4 in. (6 mm) OD air supply line to the

air inlet fitting of the flow control module (FC). Connect the other end of this line as follows:

a. Wall Mount Systems: Connect to the air mani-

fold at the rear of the wall mount fluid station.

b. RoboMix Systems: Install a 1/4 in. (6 mm) OD

tube tee at the air logic inlet of the RoboMix.

Connect the flow control air line to one branch

of the tee and the main air line to the other

branch.

2. Connect a fluid line from the proportioner to the 1/8

npt(f) fluid inlet of the flow control module (FC).

3. Connect a fluid line from the 1/8 npt(f) fluid outlet of

the flow control module (FC) to the spray gun inlet.

IG. 1.

Your system must be grounded. See the Grounding

instructions in your ProMix Installation manual.

Ground all components in your system, as explained in

your ProMix Installation manual.

Ground a remote fluid regulator (used with Model

24H989 only) by connection to a properly grounded fluid

hose.

Fluid to Flow Control Module

Air to Flow Control

4. See the Electrical Schematic in your ProMix

instruction manual. Connect the flow control cable to

the fluid station control board and to the cable connector on the flow control module (FC).

FC

Fluid to Gun

Flow Control Cable

TI13656a

FIG. 1. 249849 Flow Control Module

2 3A2097B

Page 3

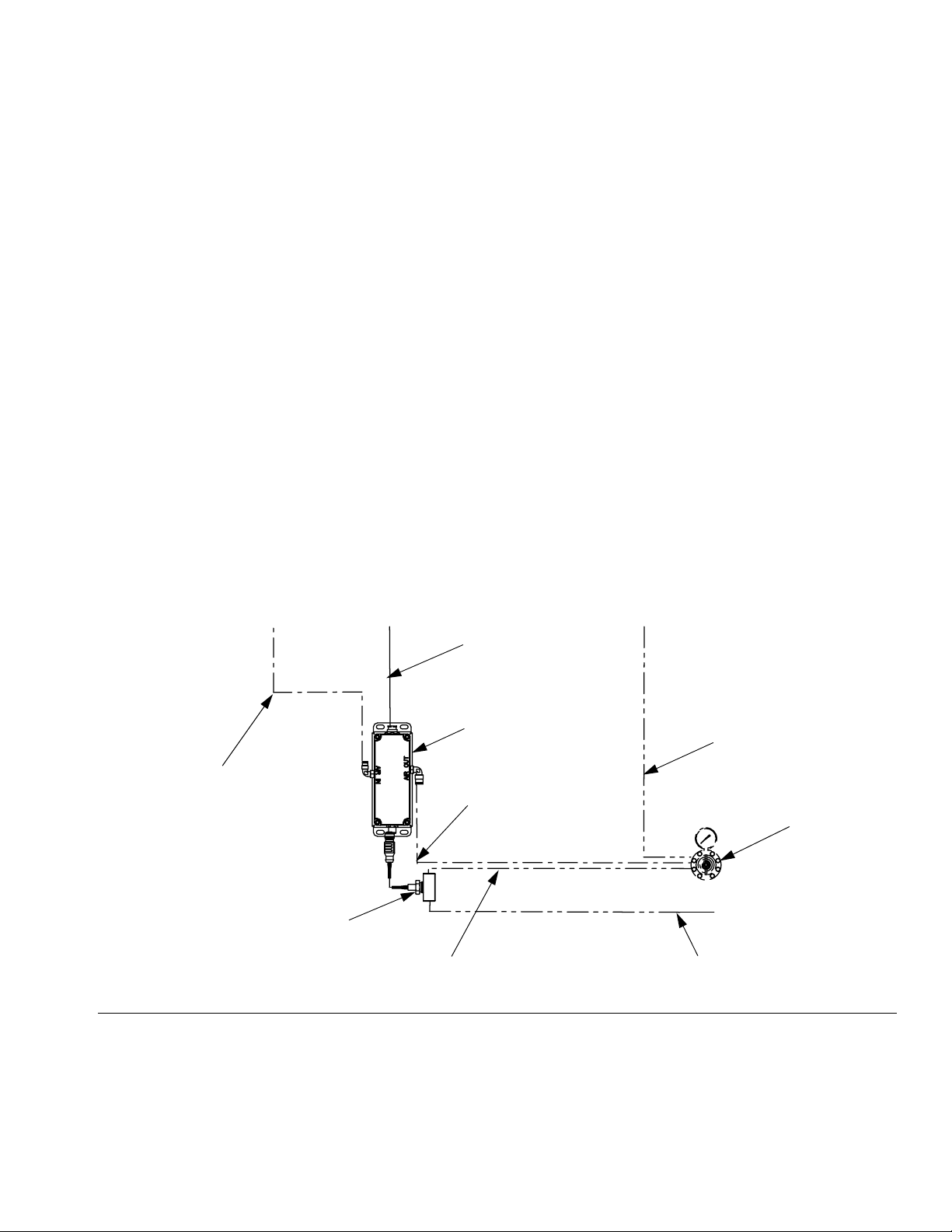

Installation (Model 24H989)

Installation (Model

24H989)

The intrinsically safe flow control module (FC) is

required to use flow control in your system. It is for use

with a remotely mounted, air-operated fluid regulator

(FR, not included). See F

1. Connect a 1/4 in. (6 mm) OD air supply line to the

air inlet fitting of the flow control module (FC). Connect the other end of this line as follows:

a. Wall Mount Systems: Connect to the air mani-

fold at the rear of the wall mount fluid station.

b. RoboMix Systems: Install a 1/4 in. (6 mm) OD

tube tee at the air logic inlet of the RoboMix.

Connect the flow control air line to one branch

of the tee and the main air line to the other

branch.

IG. 2.

2. Connect a 5/32 in. (4 mm) OD air supply line to the

air outlet fitting of the flow control module (FC). Connect the other end of this line to the air inlet fitting of

a remotely mounted fluid regulator (FR).

3. Connect a fluid line from the proportioner to the fluid

inlet of the remote fluid regulator (FR).

4. Connect a fluid line from the outlet of the fluid regulator (FR) to the 1/8 npt(f) inlet of the pressure sensor (PS).

5. Connect a fluid line from the 1/8 npt(f) outlet of the

pressure sensor (PS) to the spray gun inlet.

6. Connect the pressure sensor cable to the cable connector on the flow control module (FC).

7. See the Electrical Schematic in your ProMix

instruction manual. Connect the flow control cable to

the fluid station control board and to the cable connector on the flow control module (FC).

From Proportioner From Proportioner

Flow Control Cable

FC

Air to Flow Control

Air to Fluid Regulator

PS

Fluid to Pressure Sensor

F

IG. 2. 24H989 Flow Control Module, with Remotely Mounted Fluid Regulator

Fluid to Fluid Regulator

FR

262376_1

Fluid to Gun

3A2097B 3

Page 4

Service

Service

Before Servicing

NOTICE

To avoid damaging circuit board when servicing, wear

Part No. 112190 grounding strap on wrist and ground

appropriately.

1. Flush system and follow Pressure Relief Proce-

dure in your ProMix Repair-Parts manual.

2. Close main air shutoff valve on air supply line and

on ProMix.

3. Shut off power (0 position). F

4. Shut off power at main circuit breaker.

IG. 3.

0 = OFF

Servicing the Regulator and Pressure Sensor (Model 249849 only)

Regulator Service Kit 15G843 is available. Kit parts are

marked with an asterisk, for example (602*). For best

results, use all parts in the kit.

Sensor Service Kit 15G867 is available to service the

pressure sensor only. Kit parts are marked with a symbol, for example (602‡). For best results, use all parts in

the kit.

1. Follow Before Servicing, above.

2. Remove the four screws (605) and the nut (601)

from the underside of the air plate (607). Separate

the air plate and fluid plate. F

3. Unscrew the pressure sensor (620) from the fluid

plate (606).

NOTE: If you are only replacing the pressure sensor

kit 15G867, skip to step 6.

IG. 4.

TI12657a

F

IG. 3: Power Off

5. Disconnect all air and fluid lines from the flow control module.

6. Model 24H989 only: Disconnect all fluid lines from

the pressure sensor fitting (626).

7. Disconnect the flow control cable from the flow control harness (624). F

IG. 4 or FIG. 5.

After Servicing

After servicing, be sure to follow the Start Up checklist

and procedure in the ProMix Operation manual.

4. Remove the plug (615) and o-ring (604) from the top

of the fluid plate (606). Remove the parts of the diaphragm assembly (613, 610, 609, 612, 617, 616).

Remove and discard the dowels (623).

5. Reassemble the diaphragm assembly using the new

parts from the kit. Be sure the AIR SIDE of the diaphragm (617) faces down. Torque the nut (601) to

8-10 in-lb (0.9-1.1 N•m).

6. Install a new o-ring (602) on the pressure sensor

(620) and screw the sensor into the fluid plate (606).

7. Reinstall the fluid plate on the air plate. Be careful

not to pinch the pressure sensor cable. Torque the

screws (605) to 30-40 in-lb (3.4-4.5 N•m).

8. Reconnect the three cables to J1, J2, and J4 on the

circuit board (618). F

9. Reattach the air plate (607) to the housing (611).

Torque the screws (605) to 30-40 in-lb (3.4-4.5

N•m).

10. Reattach the flow control cable and all air and fluid

lines.

IG. 6.

4 3A2097B

Page 5

615

Service

*623

2

605

622

*613

*610

*609

*612

*617

*616

604*

Flow

direction

606

602*‡

620‡

601*

607

611

605

1

603

2

624

619b

619

619a

3

614

1

Torque to 8-10 in-lbs (0.9-1.1 N•m)

2

Torque to 30-40 in-lbs (3.4-4.5 N•m)

3

Torque to 5-7 in-lbs (0.6 -0.8 N•m)

FIG. 4: 249849 Flow Control Module

621

618

605

TI12506a

2

3A2097B 5

Page 6

Service

Servicing the Pressure Sensor (Model 24H989 only)

1. Follow Before Servicing, page 4.

2. Disconnect the pressure sensor (620) from the

pressure sensor wire harness (620b). F

3. Unscrew the pressure sensor (620) from the pressure sensor fitting (626).

4. Install a new o-ring (602) on the new pressure sensor (620).

5. Reassemble in the reverse order.

IG. 5.

Servicing the Pressure Sensor Wire Harness (Model 24H989 only)

1. Follow Before Servicing, page 4.

2. Disconnect the pressure sensor (620) from the

pressure sensor wire harness (620b). F

IG. 5.

Servicing the Flow Control Board (all Models)

1. Follow Before Servicing, page 4.

2. Remove the four screws (605) holding the bracket

(614) to the housing (611). F

3. Carefully separate the bracket from the housing and

disconnect the three cables from J1, J2, and J4 on

the circuit board (618). F

4. Remove the screws (621). Replace the old board

with the new board. Install the screws (621).

5. Reconnect the three cables to J1, J2, and J4 on the

circuit board (618). F

6. Reattach the bracket (614) to the housing (611).

Torque the screws (605) to 30-40 in-lb (3.4-4.5

N•m).

IG. 6.

IG. 4 or FIG. 5.

IG. 6.

Servicing the V/P Valve (all Models)

3. Remove the four screws (605) holding the air plate

(607) to the housing (611). Unscrew the nut from the

pressure sensor wire harness connector (620b).

4. Carefully lift the plate (607) off the housing. Disconnect the wire harness from J4 on the circuit board

(618) and remove the wire harness. F

5. Install the new wire harness (620b) in the reverse

order.

6. Reattach the air plate (607) to the housing (611).

Torque the screws (605) to 30-40 in-lb (3.4-4.5

N•m).

IG. 6.

1. Follow Before Servicing, page 4.

2. Remove the four screws (605) holding the bracket

(614) to the housing (611). F

3. Carefully separate the bracket from the housing and

disconnect the V/P valve cable from J2 on the circuit

board (618). F

4. Remove the two screws (619a) and o-rings (619b).

Install the new valve (619) with new screws and

o-rings. Torque the screws to 5-7 in-lb (0.6-0.8

N•m).

5. Reconnect the V/P valve cable to J2 on the circuit

board (618). F

6. Reattach the bracket (614) to the housing (611).

Torque the screws (605) to 30-40 in-lb (3.4-4.5

N•m).

IG. 6.

IG. 6.

IG. 4 or FIG. 5.

6 3A2097B

Page 7

Service

620a

621

626

602

620

620b

611

2

605

603

607

608

624

619b

619

619a

3

J2 (V/P Valve)

D7 D8 D9

J4

R25

U3

R7

R27

J1

R3

J2

U1

R4

C12

FIG. 6: 249179 Flow Control Board

R21

C11

U5

R22

L1

C10

R20

J1 (Power Input)J4 (Pressure Sensor)

618

614

605

2

2

Torque to 30-40 in-lb (3.4-4.5 N•m)

3

Torque to 5-7 in-lb (0.6 -0.8 N•m)

FIG. 5: 24H989 Flow Control Module

TI18017b

3A2097B 7

Page 8

Parts

Parts

249849 Flow Control Module

Ref.

No. Part No. Description Qty

601* 102980 NUT, full, hex; 4-40 1

602‡* --- O-RING; chemically resistant

fluoroelastomer

603 112698 ELBOW; 1/8 npt(m) x 1/4 in.

(6 mm) OD tube

604* --- O-RING; chemically resistant

fluoroelastomer

605 --- SCREW, cap, socket-hd;

10-32 x 1/2 in. (13 mm)

606 --- PLATE, fluid, regulator 1

607 15F799 PLATE, air, regulator 1

609* --- SEAT, regulator 1

610* --- RETAINER, seat 1

611 --- HOUSING, flow control 1

612* --- SPACER, regulator 1

613* --- NEEDLE, regulator 1

614 --- BRACKET, flow control 1

615 15F806 PLUG, regulator 1

616* 168881 GASKET; acetal 1

617* 178321 DIAPHRAGM, regulator 1

618 249179 BOARD, circuit assembly 1

619 120013 VALVE, proportional, V/P;

includes items 619a and 619b

619a --- • SCREW, cap, socket-hd;

M3 x 0.5 x 44 mm

619b --- • O-RING, mounting 2

620‡ --- SENSOR, pressure control;

includes ptfe o-ring

621 107295 SCREW, machine, pan-hd;

4-40 x 3/16 in. (5 mm)

622 104765 PLUG, pipe; 1/8 ptf 1

623* 192387 PIN, dowel 2

624 15G613 WIRE HARNESS, flow control 1

* Parts included in Regulator Service Kit 15G843.

Purchase separately.

12

615

*613

1

*610

1

1

1

2

1

4

*609

*612

*617

*616

*623

605

622

624

619b

619

619a

604*

Flow

direction

606

602*‡

620‡

601*

607

603

611

605

621

618

605

‡ Parts included in Sensor Service Kit 15G867.

Purchase separately.

Parts labeled --- are not available separately.

8 3A2097B

614

TI12506a

Page 9

24H989 Flow Control Module for Remote Fluid Regulator

Parts

Ref.

No. Part No. Description Qty

602 --- O-RING; chemically resistant

fluoroelastomer

603 112698 ELBOW, air inlet; 1/8 npt(m) x

1/4 in. (6 mm) OD tube

605 --- SCREW, cap, socket-hd;

10-32 x 1/2 in. (13 mm)

607 --- PLATE, air, regulator 1

608 114151 ELBOW, air outlet; 1/8 npt(m)

x 5/32 in. (4 mm) OD tube

611 --- HOUSING, flow control 1

614 --- BRACKET, flow control 1

618 249179 BOARD, circuit assembly 1

619 120013 VALVE, proportional, V/P;

includes items 619a and 619b

619a --- • SCREW, cap, socket-hd;

M3 x 0.5 x 44 mm

619b 106560 • O-RING, mounting, 007 2

620 24R099 KIT, sensor, pressure control;

includes 620a and 620b

620a --- • O-RING; ptfe 1

620b --- • WIRE HARNESS, pres-

sure sensor

621 107295 SCREW, machine, pan-hd;

4-40 x 3/16 in. (5 mm)

624 15G613 WIRE HARNESS, flow control 1

626 --- FITTING, pressure sensor;

two 1/8 npt(f) ports

603

1

1

8

620a

1

1

2

1

1

4

1

626

621

618

614

605

602

620

620b

611

605

607

608

624

619b

619

619a

TI18017b

Parts labeled --- are not available separately.

3A2097B 9

Page 10

Dimensions and Mounting Hole Layouts

Dimensions and Mounting Hole Layouts

Module

249849 Flow

Control Module

24H989 Flow

Control Module

B

A

Overall

Length

in. (mm)

7.13

(181.1)

7.13

(181.1)

A

TI18018a

B

Overall

Width

in. (mm)

2.52 (64.0) 3.86 (98.0) 6.63 x 1.50 (168.4 x 38.1) 0.25 (6.3) 3.9 (1.78)

2.52 (64.0) 3.86 (98.0) 6.63 x 1.50 (168.4 x 38.1) 0.25 (6.3) 2.5 (1.13)

Overall

Height

in. (mm)

Mounting Dimensions,

Length (C) x Width (D)

in. (mm)

E

Mounting

Hole Size

in. (mm)

Weight

lb (kg)

[includes pressure

sensor and fitting]

249849 Flow Control Module

D

C

TI14135a

E

24H989 Flow Control Module

E

B

D

C

A

TI18018a

10 3A2097B

TI14135a

Page 11

Technical Data

Technical Data

Maximum fluid working pressure . . . . . . . . . . . . . . . 190 psi (1.31 MPa, 13.1 bar)

Maximum working air pressure. . . . . . . . . . . . . . . . . 100 psi (0.7 MPa, 7 bar)

Air supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75 - 100 psi (0.5 - 0.7 MPa, 5.2 - 7 bar)

Air inlet size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/8 npt(m) x 1/4 in. (6 mm) OD tube

Air outlet size (Model 24H989 only) . . . . . . . . . . . . . 1/8 npt(m) x 5/32 in. (4 mm) OD tube

Fluid inlet and outlet sizes . . . . . . . . . . . . . . . . . . . . 1/8 npt(f)

Wetted parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Model 249849: 303 Stainless Steel, chemically resistant fluoro-

elastomer, titanium, ptfe

Model 24H989: 316 Stainless Steel, chemically resistant fluoroelastomer, titanium, ptfe

3A2097B 11

Page 12

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com. For patent information, see

www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2011, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 3A2097

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised February 2013

Loading...

Loading...