Page 1

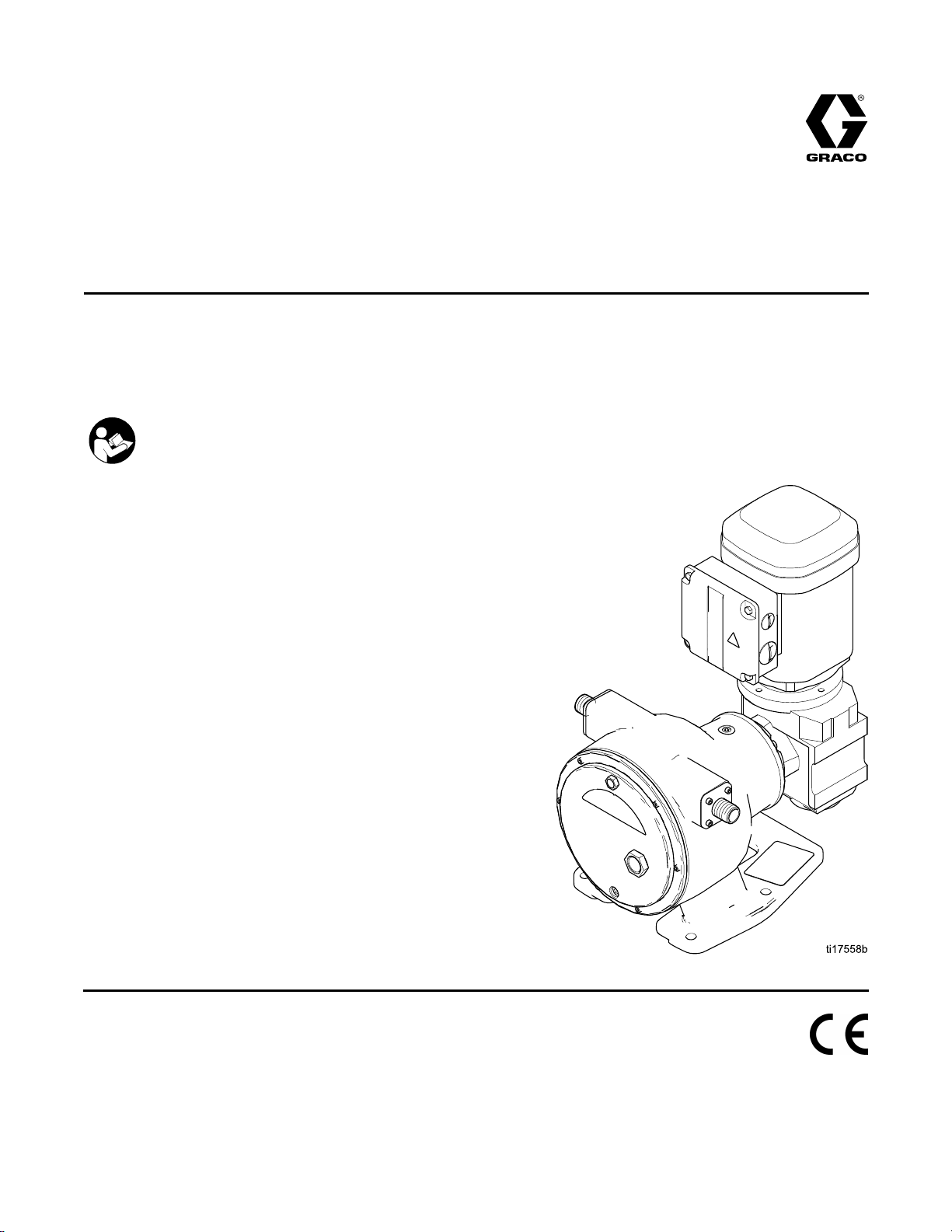

Repair-Parts

EP2

EP2 EP2

Electric

Electric Electric

only.

only. only.

Not

approved

Not Not

approved approved

125 psi (0.9 MPa, 9 bar) Maximum Fluid

Working Pressure

See page 2 for model part numbers and

information.

Hose

Hose Hose

powered

- --powered powered

Important

Important Important

Readallwarningsandinstructionsinthismanual.Savethese

instructions.

hose

hose hose

for

use

for for

use use

Safety

Safety Safety

Pump

Pump Pump

pump

pump pump

explosive

in ininexplosive explosive

Instructions

Instructions Instructions

3A1940G

EN

for

use

for for

use use

uid

in ininuid uid

atmospheres

atmospheres atmospheres

transfer

transfer transfer

and

metering

and and

metering metering

or

hazardous

or or

hazardous hazardous

applications.

applications. applications.

locations.

locations. locations.

For

professional

For For

professional professional

use

use use

PROVENQUALITY.LEADINGTECHNOLOGY.

Page 2

Contents

Contents Contents

Models...............................................................2

Warnings...........................................................3

Troubleshooting..................................................6

Repair................................................................8

BeforeYouStart..........................................8

Disassembly................................................8

Reassembly................................................12

Notes.................................................................17

Parts..................................................................18

Models

Models Models

Pump

Model

Pump Pump

Model Model

EP2006

EP2006 EP2006

EP2013

EP2013 EP2013

Hose

ID

Hose Hose

(mm)

(mm) (mm)

6

13

Size

ID ID

Size Size

EP2HosePumpAssembly...........................18

BarePumpAssembly...................................20

PumpMatrix................................................22

PumpKitMatrix...........................................24

VariableFrequencyDrives(VFD)..................27

Notes.................................................................28

TechnicalData...................................................29

GracoStandardWarranty....................................30

Reference

Reference Reference

SeeModelEP2006Pumps,page22foracompletelistof

pumppartnumbersanddescriptiveinformation.

SeeModelEP2013Pumps,page23foracompletelistof

pumppartnumbersanddescriptiveinformation.

2

3A1940G

Page 3

Warnings

Warnings Warnings

Thefollowingwarningsareforthesetup,use,grounding,maintenanceandrepairofthisequipment.The

exclamationpointsymbolalertsyoutoageneralwarningandthehazardsymbolreferstoprocedure-specic

risks.Whenthesesymbolsappearinthebodyofthismanualoronwarninglabels,referbacktothese

Warnings.Product-specichazardsymbolsandwarningsnotcoveredinthissectionmayappearthroughout

thebodyofthismanualwhereapplicable.

WARNING

WARNING WARNING

FIRE

AND

FIRE FIRE

Flammablefumes,suchassolventandpaintfumes,inwork work

preventreandexplosion:

•Useequipmentonlyinwellventilatedarea.

•Eliminateallignitionsources;suchaspilotlights,cigarettes,portableelectriclamps,and

plasticdropcloths(potentialstaticarc).

•Keepworkareafreeofdebris,includingsolvent,ragsandgasoline.

•Donotplugorunplugpowercords,orturnpowerorlightswitchesonoroffwhenammable

fumesarepresent.

•Groundallequipmentintheworkarea.SeeGrounding Grounding

•Useonlygroundedhoses.

•Holdgunrmlytosideofgroundedpailwhentriggeringintopail.

•Ifthereisstaticsparkingoryoufeelashock,stop stop

equipmentuntilyouidentifyandcorrecttheproblem.

•Keepaworkingreextinguisherintheworkarea.

ELECTRIC

ELECTRIC ELECTRIC

Thisequipmentmustbegrounded.Impropergrounding,setup,orusageofthesystemcan

causeelectricshock.

EXPLOSION

AND AND

EXPLOSION EXPLOSION

SHOCK

SHOCK SHOCK

HAZARD

HAZARD HAZARD

work

area

area area

canigniteorexplode.Tohelp

Grounding

stop

HAZARD

HAZARD HAZARD

instructions.

operation

operation operation

immediately.

immediately. immediately.

Donotuse

Warnings

•Turnoffanddisconnectpoweratmainswitchbeforedisconnectinganycablesandbefore

servicingorinstallingequipment.

•Connectonlytogroundedpowersource.

•Allelectricalwiringmustbedonebyaqualiedelectricianandcomplywithalllocalcodes

andregulations.

MOVING

MOVING MOVING

Movingpartscanpinch,cutoramputatengersandotherbodyparts.

•Keepclearofmovingparts.

•Donotoperateequipmentwithprotectiveguardsorcoversremoved.

•Pressurizedequipmentcanstartwithoutwarning.Beforechecking,moving,orservicing

equipment,followthePressure Pressure

3A1940G 3

PARTS

PARTS PARTS

HAZARD

HAZARD HAZARD

Pressure

Relief

Procedure

Relief Relief

Procedure Procedure

anddisconnectallpowersources.

Page 4

Warnings

WARNING

WARNING WARNING

ENTANGLEMENT

ENTANGLEMENT ENTANGLEMENT

Rotatingpartscancauseseriousinjury.

•Keepclearofmovingparts.

•Donotoperateequipmentwithprotectiveguardsorcoversremoved.

•Donotwearlooseclothing,jewelryorlonghairwhileoperatingequipment.

•Equipmentcanstartwithoutwarning.Beforechecking,movingorservicingequipment,follow

Pressure

thePressure Pressure

TOXIC

TOXIC TOXIC

Toxicuidsorfumescancauseseriousinjuryordeathifsplashedintheeyesoronskin,

inhaled,orswallowed.

•ReadMSDSstoknowthespecichazardsoftheuidsyouareusing.

•Storehazardousuidinapprovedcontainers,anddisposeofitaccordingtoapplicable

PERSONAL

PERSONAL PERSONAL

Youmustwearappropriateprotectiveequipmentwhenoperating,servicing,orwheninthe

operatingareaoftheequipmenttohelpprotectyoufromseriousinjury,includingeyeinjury,

hearingloss,inhalationoftoxicfumes,andburns.Thisequipmentincludesbutisnotlimitedto:

FLUID

FLUID FLUID

guidelines.

HAZARD

HAZARD HAZARD

Relief

Procedure

Relief Relief

Procedure Procedure

OR

FUMES

OR OR

FUMES FUMES

PROTECTIVE

PROTECTIVE PROTECTIVE

anddisconnectallpowersources.

EQUIPMENT

EQUIPMENT EQUIPMENT

•Protectiveeyewear,andhearingprotection.

•Respirators,protectiveclothing,andglovesasrecommendedbytheuidandsolvent

manufacturer.

PRESSURIZED

PRESSURIZED PRESSURIZED

Fluidfromtheequipmentleaks,orrupturedcomponentscansplashintheeyesoronskin

andcauseseriousinjury.

•FollowthePressure Pressure

cleaning,checking,orservicingequipment.

•Tightenalluidconnectionsbeforeoperatingtheequipment.

•Checkhoses,tubes,andcouplingsdaily.Replacewornordamagedpartsimmediately.

EQUIPMENT

EQUIPMENT EQUIPMENT

Pressure

Relief

Relief Relief

HAZARD

HAZARD HAZARD

Procedure

Procedure Procedure

whenyoustopspraying/dispensingandbefore

4

3A1940G

Page 5

WARNING

WARNING WARNING

EQUIPMENT

EQUIPMENT EQUIPMENT

Misusecancausedeathorseriousinjury.

•Donotoperatetheunitwhenfatiguedorundertheinuenceofdrugsoralcohol.

•Donotexceedthemaximumworkingpressureortemperatureratingofthelowestrated

systemcomponent.SeeTechnical Technical

•Useuidsandsolventsthatarecompatiblewithequipmentwettedparts.SeeTechnical Technical

inallequipmentmanuals.Readuidandsolventmanufacturer’swarnings.Forcomplete

informationaboutyourmaterial,requestMSDSfromdistributororretailer.

•Donotleavetheworkareawhileequipmentisenergizedorunderpressure.

•TurnoffallequipmentandfollowthePressure Pressure

•Checkequipmentdaily.Repairorreplacewornordamagedpartsimmediatelywithgenuine

manufacturer’sreplacementpartsonly.

•Donotalterormodifyequipment.

•Useequipmentonlyforitsintendedpurpose.Callyourdistributorforinformation.

•Routehosesandcablesawayfromtrafcareas,sharpedges,movingparts,andhotsurfaces.

•Donotkinkoroverbendhosesorusehosestopullequipment.

•Keepchildrenandanimalsawayfromworkarea.

•Complywithallapplicablesafetyregulations.

MISUSE

MISUSE MISUSE

HAZARD

HAZARD HAZARD

Technical

Data

Data Data

Pressure

inallequipmentmanuals.

Relief

Relief Relief

Procedure

Procedure Procedure

whenequipmentisnotinuse.

Warnings

Technical

Data

Data Data

3A1940G 5

Page 6

Troubleshooting

Troubleshooting

Troubleshooting Troubleshooting

NOTE:

NOTE: NOTE:

Checkallpossibleremediesbeforedisassemblingthepump.

Problem

Problem Problem

Hammeringinpiping.

Highpumptemperature.

Highoutletpressure.

Cause

Cause Cause

Inletoroutletpipediameterstoo

small.

Highpumpspeed.

Inletoroutletconnectionsnot

properlyanchored.

Highinletoroutletpressures.Addpulsationdampeners.

Lowlubricantlevel.Addhoselubetotheproperlevel.

Improperlubricant.

Pumpeduidtemperaturetoo

high.

Highpumpspeed/pump

undersized.

Blockedoutletline.

Narrowedpipediameterdueto

settledsolids.

Solution

Solution Solution

Increasepipesizeoraddpulsation

dampeners.

Reducespeedofpump.

Securepiping.

UseonlyGracohoselubeforlow

temperatureoperation.

ConsultyourGracodistributorfor

maximumtemperaturelimitsof

yourpump.

Reducethepumpspeedorswitch

toalargerpump.

Clearanyobstructionsintheoutlet

line.

Determineifsolidshavesettled

inpipingandush/removeas

required.

Viscosityorspecicgravityof

pumpeduidtoohigh.

Lowinletpressure.

Lowow.

Failedhose.

Blockedinletline.

Inletlinetoolongortoosmall.Trytolocatethepumpasnear

Viscosityorspecicgravityof

pumpeduidtoohigh.

Failedhose.

ConsultyourGracodistributorfor

suitableoperatingconditionsfor

yourpump.

Checktoseeifthehosehasfailed.

Ifso,replacewithanewhoseand

lubricant.

Clearanyobstructionsintheinlet

line.

totheuidsourceaspossible.

Oversizetheinletpipingwhen

possible.

ConsultyourGracodistributorfor

suitableoperatingconditionsfor

yourpump.

Checktoseeifthehosehasfailed.

Ifso,replacewithanewhoseand

lubricant.

6 3A1940G

Page 7

Troubleshooting

Problem

Problem Problem

Poorhoselife.

Lubricantleaks.

Cause

Cause Cause

Chemicalincompatibility.ConsultyourGracodistributorto

Normalwear.

Failureduetopulsations.

Toohighoutletpressure.

Settledsolidsinhose.

Hoselubeleakingfromfrontcover.Coverboltsover-tightened.

Hoselubeleakingfromhose

clamps.

Solution

Solution Solution

seeifyouhavethecorrecthose

foryourapplication.

Thehosemayhavefaileddueto

normalwear.Replaceasrequired.

Ifyourpumpisequippedwitha

pulsationdampener,adjustits

pressure.Ifyoudonothavea

dampener,consultyourGraco

distributor.

Checkitemslistedin“Highoutlet

pressure.”Runningthepump

againstaclosedvalve,evenfora

shortamountoftime,maydamage

hose.

Flushthepumpandhosepriorto

turningthepumpoff.

Refertotorquespecicationsin

InstalltheFrontCover,page16.

Pumphousingoverlled.Check

hoselubelevelandadjustas

necessary.

Hosefailedbecauseitwrapped

aroundroller.

Pumpwasoperatedagainsta

closedoutletvalveorblockedline.

Replacehose.Checkpressure

reliefsystem.Checkthatvalves

areopen.Clearanyblockages.

3A1940G

7

Page 8

Repair

Disassembly

Repair

Repair Repair

Disassembly Disassembly

Before

Before Before

1.Flushthepump.

2.Relievethepressure.

3.Disconnectpowertothepump.

4.Makesurethepumpiselectricallyisolated.

You

Start

You You

Start Start

Unexpectedoperationofthepumpcancause

seriousinjury.Removethefancoveronlyafter

themotorhasbeenlockedout.

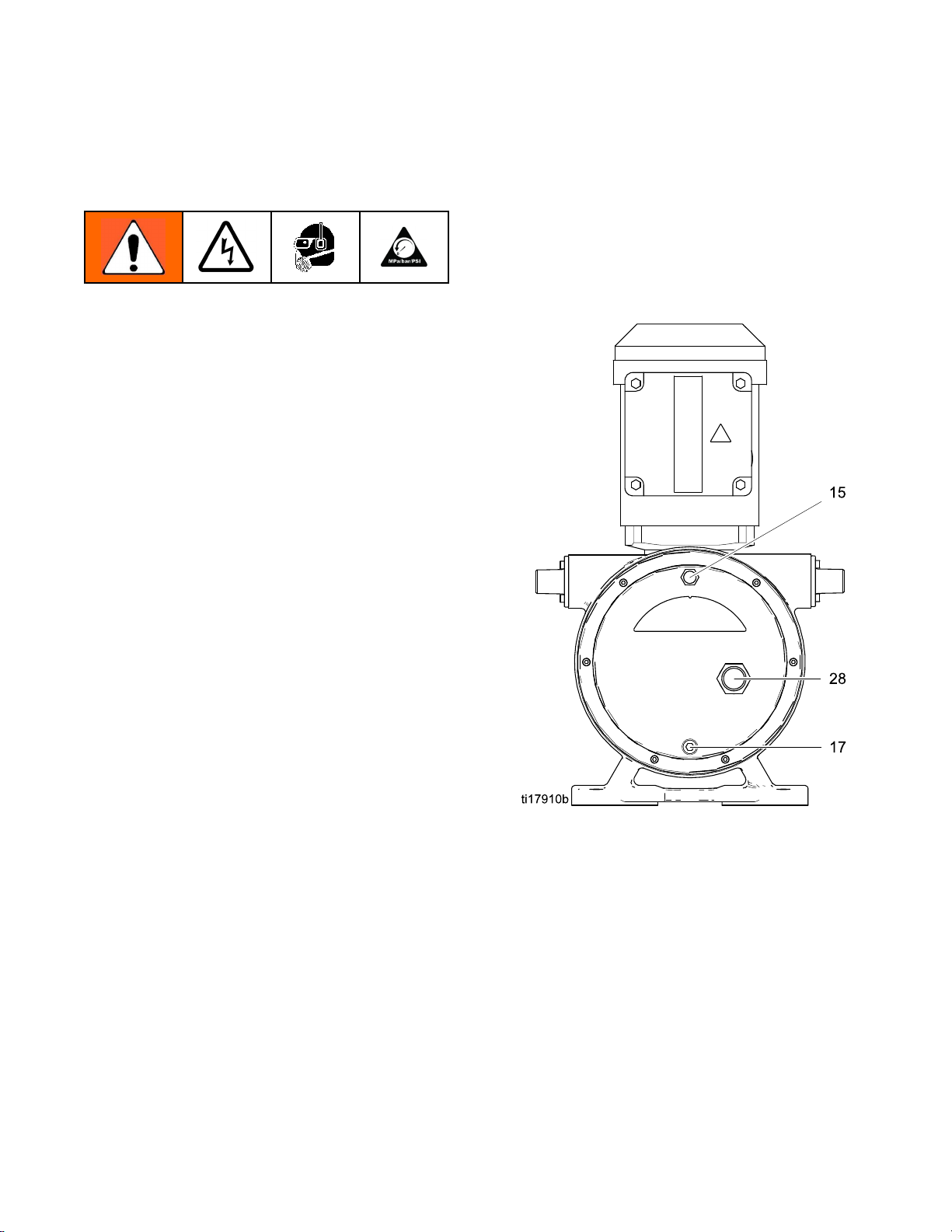

Drain

Drain Drain

1.Holdapailunderthedrainplug(17)andunscrew

2.Removetheventplug(15)andushthepump

the

Oil

the the

Oil Oil

theplugtodrainthelubricatingoil.Disposeof

theoilproperly.Takecare,astheoilmaybe

contaminatedbythepumpeduid.

housingwithacompatiblesolvent.

Figure1PumpDrainandVent

Remove

Remove Remove

1.Unscrewthesocketheadcapscrews(14)and

washers(13)thatholdthefrontcover(12),

removingthetopscrewandwasherlast.Take

thecoveroffthepump.SeeFigure5,page11.

2.Removethefrontcovergasket(11).

3.Inspectandcleanthecover(12),thensetaside.

8 3A1940G

the

Front

the the

Front Front

Cover

Cover Cover

Page 9

Repair

Remove

Remove Remove

1.SeeFigure5,page11.Removethescrews

holdingthemotorfancover(FC).Turnthefanby

handuntiltheroller(102)stopsatthebottomof

thepumphousing(1)inthe6o’clockposition.

NOTE:

NOTE: NOTE:

gearboxesmayrequiremanyturnsofthemotor

fantomovetherollertothe6o’clockposition.

2.Removethefourscrews(115)fromthebarbed

tting(105)ontheinletandoutletportsofthe

pump.

3.Gentlypullthebarbedttings(105)awayfrom

thepumphousing(1)sothehoseextendsabout

2–3in.(51–76mm)outofthepump.

4.Ifpossible,ensurethatthehoseclamps(104)

arepositionedwiththeclampportionatthetop.

Cutthroughtheclampwithahacksaworrotary

tool.Becarefulnottodamagethehose(103)or

thepumphousing(1).

the

Hose

the the

Hose Hose

LowRPMpumpsandhighratio

6.Removeonebarbedtting(105)fromthehose

(103).

7.Graspthehose(103)fromtheinsideofthepump

housing(1)andpullitintothehousing.The

centerofthehosewillstillbeheldbytherollerin

the6o’clockposition.

8.Removethesecondbarbassemblyasdescribed

above.

9.Turnthemotorbyhanduntiltheroller(102)isnot

compressingthehose(103).Thiswillbenear

the9o’clockor3o’clockposition.

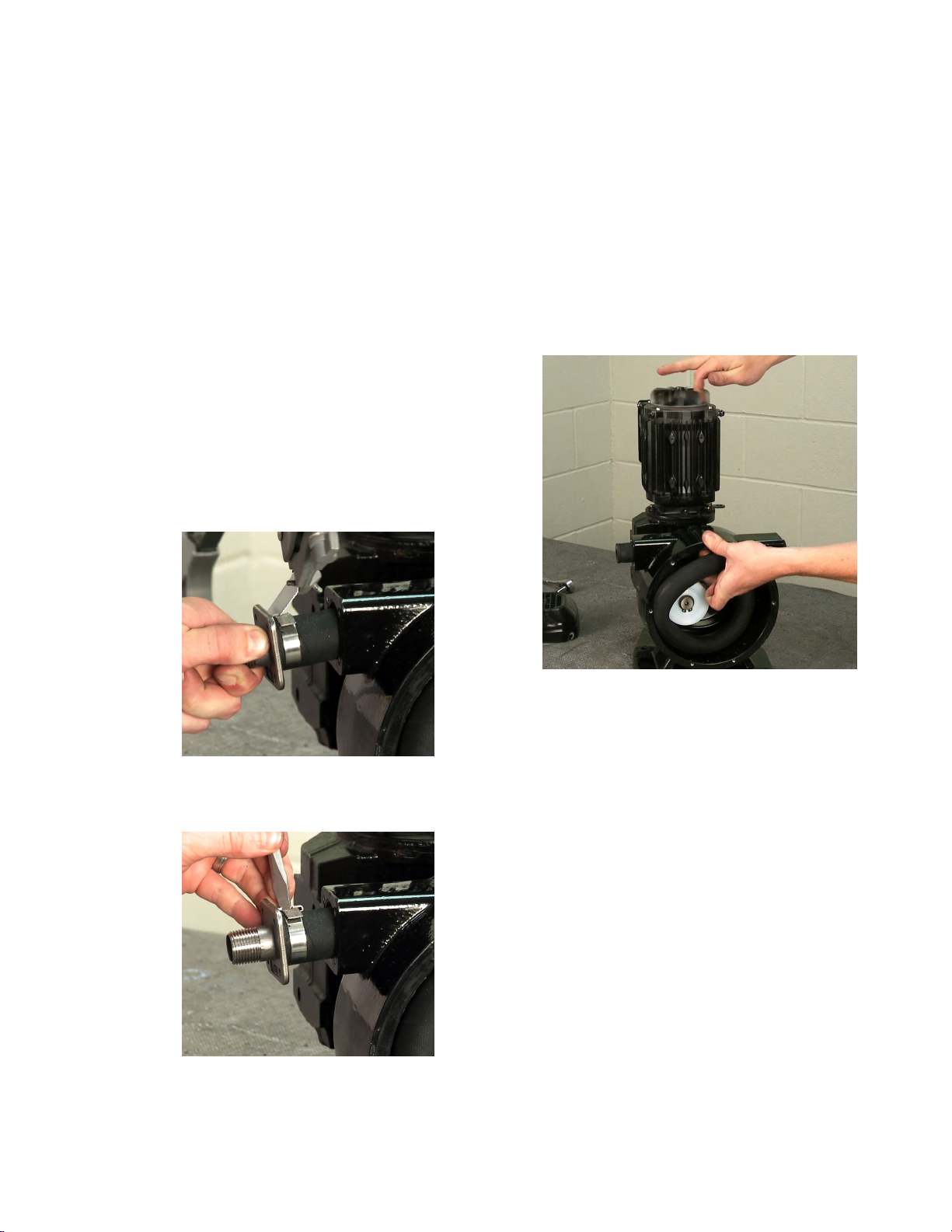

Figure2CuttheClamp

5.Usingascrewdriver,removetheclamp,then

removetheband.

Figure3RemovetheClamp

Figure4Rollerin9O’ClockPosition

10.Pulltheotherendofthehoseintothepump

housing(1).

11.Removeandsafelydiscardtheusedhose,per

yourfacility’swastedisposalpolicy.

3A1940G 9

Page 10

Repair

Remove

Remove Remove

1.Usingexternalsnapringpliers,removetheroller

retainingring(8)fromthefrontoftheeccentric

shaft(7).

the

Roller

the the

Roller Roller

2.Pulltheroller(102)offtheshaft.Itshouldslide

offeasily.

3.Inspecttheinsideandoutsidediameterofthe

roller(102),andreplaceitifwornordamaged.

Figure5RemovetheHoseandRoller

10 3A1940G

Page 11

Repair

8

7

4

3

6

2

106

1

5

108

109

107

Remove

Remove Remove

1.Usingexternalsnapringpliers,removethe

eccentricshaftretainingring(8)fromthemotor

outputshaft(2).

2.Removetheeccentricshaft(7)fromthemotor

outputshaft.Be Be

key

key key

NOTE:

NOTE: NOTE:

disengagetheeccentricshaftfromthemotor

outputshaft.

Remove

Remove Remove

NOTE:

NOTE: NOTE:

aretainingring(3)locatedbehindtheouteru-cup

seal(4).Theoutersealmustberemovedbefore

removingtheretainingring.Thissealwilllikelybe

damagedwhenremovedsinceitisheldinplaceby

atightpresst.

the

Eccentric

the the

Eccentric Eccentric

Be

(6).

(6). (6).

Youmayneedtouseapullerto

the

Motor

the the

Motor Motor

Themotoroutputshaftisheldinplacewith

Shaft

Shaft Shaft

sure

sure sure

retain

the

to totoretain retain

Output

Output Output

eccentric

the the

eccentric eccentric

Shaft

Shaft Shaft

1.Usingaatheadscrewdriver,removetheouter

u-cupseal(4).

2.Usinginternalsnapringpliers,removethe

retainingring(3)fromthepumphousing(1).

3.Removethefourscrews(109)andwashers(108)

shaft

shaft shaft

holdingthegearboxandmotorassembly(107)

tothepumphousing(1).Removethegearbox

andmotorassemblytoallowaccesstotheinner

Be

u-cupseal(5).Be Be

shaft

key

shaft shaft

NOTE:

NOTE: NOTE:

contactSEW-Eurodrive.

4.Removetheinneru-cupseal(5).Thissealwill

likelybedamagedwhenremovedsinceitisheld

inplacebyatightpresst.

5.Tapthegearboxendoftheshaft(2)witharubber

mallettodrivetheshaftoutthroughthefrontof

thepumphousing(1).

(106).

key key

(106). (106).

Formotorandgearboxrepairinformation,

sure

sure sure

retain

the

to totoretain retain

motor

the the

motor motor

output

output output

Figure6RemovetheEccentricShaftandMotorOutputShaft

3A1940G

11

Page 12

Repair

Reassembly

Reassembly Reassembly

Clean

Clean Clean

•Discardallusedseals,gasketsandwornparts.

•Ensurethatallnewandexistingpartsareclean

•Thoroughlycleanallpartswithacompatible

•Inspecttheinnerdiameterofthepumproller.Ifthe

•Inspectthebearingsonthemotoroutputshaft(2).

•Inspecttheshaftandbearingboreinthepump

•Inspectallmetalpartsforsignsofwearorcracks.

and

Inspect

and and

Inspect Inspect

UseonlygenuineGracoreplacementparts.

Non-standardpartswillvoidyourwarrantyand

maydamageyourequipment.

andundamaged.

solventandinspectfordamageorwear.Replace

allgaskets,washers,wornpartsandhardwareas

necessary.

surfacehasbeenworn,replacetheroller.

Ifthebearingsareworn,replacetheshaft.

housing(1).Ensureitisround,withoutgroovesor

othersignsofwear,andfreeofdirt,lings,orother

debris.Adirtyordamagedbearingborewillgreatly

reducethelifeofthebearings.

Replaceallwornparts.

Thepumphousingisaluminum.Tohelpprevent

galling,blowoutthethreadswithcompressedair

beforeinstallinganyttingsorfasteners.

All

Parts

All All

Parts Parts

NOTICE

NOTICE NOTICE

NOTICE

NOTICE NOTICE

2.Coattheouterracesoftheshaftbearingsand

theinnerdiameterofthebearingborewithlight

lubricatingoil.Makesurethereisnodirtordebris

oneitherthebearingsorthebearingbore.

3.Inserttheshaft(2)intothepumphousing(1)from

thefront,makingsurethatthebearingsengage

thebearingboreushandstraight.Taptheroller

endoftheshaftwitharubbermalletuntilthe

shaftisrmlyseatedinthepumphousing.

NOTICE

NOTICE NOTICE

Donotforcetheshaftandbearingsintothe

pumphousing.Thismaycausedamagetothe

bearingsorthehousing.

4.Installthebearingretainingring(3)infrontofthe

outerbearing.

Install

Install Install

1.Pressanewinneru-cupseal(5)ontothegearbox

2.GreasethepumpwithNLGI#2typegrease.

3.Pressanewouteru-cupseal(4)ontothepump

the

Seals

the the

Seals Seals

endoftheshaft(2)andintotheboreattherear

ofthepumphousing(1).Thelipsoftheu-cup

mustfaceintothepumphousing.SeeFigure7.

Removetheplug(18)fromthepumphousing

andreplaceitwithazerktting.Addgreaseuntil

itpassesthroughtheouterbearingoftheshaft.

Thisprovidesavisualreferenceoftheproper

amountofgrease.Donotover-grease.Remove

thezerkttingandreinstalltheplug(18).

endoftheshaft(2)andintotheboreatthefront

ofthepumphousing(1).Thelipsoftheu-cup

mustfacetowardtheshaftbearings.

Install

Install Install

1.Inspectthebearingsandmakesurethatallrotate

12

the

Motor

the the

Motor Motor

freelyandareseatedagainsttheshoulderofthe

shaft(2).SeeFigure6.

Output

Output Output

Shaft

Shaft Shaft

4.Makesurethattheshaftrotatessmoothly.

3A1940G

Page 13

Repair

1

2

3

Figure7InstalltheMotorOutputShaftandEccentricShaft

Key

for

Key Key

Note

Note Note

Install

Install Install

1.Lubricatethemotoroutputshaft(2)andthe

2.Thegearboxismanufacturedwithahollow

3.Slidethemotorandgearboxassembly(107)onto

Install

Install Install

1.Ensurethatthekeywayonthemotoroutputshaft

Figure

for for

Figure Figure

the

the the

keywaywithananti-seizecompound.

bore.Removetheplasticcaponthebackofthe

gearboxtohelpwithalignmentoftheshaft.

theshaft(2).Typicallytheassemblyismounted

withthemotorabovethegearbox.Installthekey

(106).Securetothepumphousing(1)withthe

fourscrews(109)andwashers(108).

the

the the

(2)isfacingup.Itmaybenecessarytoturnthe

motorfanbyhandtopositiontheshaft.

7

7 7

Description

Description Description

Lipsoftheu-cup(4)mustfacetowardtheshaftbearings.

Lipsoftheu-cup(5)mustfaceintothepumphousing.

Lubricatewithhoselube.

Motor

Motor Motor

Eccentric

Eccentric Eccentric

and

Gearbox

and and

Gearbox Gearbox

Shaft

Shaft Shaft

2.Slidetheeccentricshaft(7)overtheendof

themotoroutputshaft(2).Installthekey(6).

Theeccentricandthekeyshouldslideeasily

together.

3.Securetheeccentricshaft(7)withtheeccentric

shaftretainingring(8).

Install

Install Install

NOTE:

NOTE: NOTE:

roller.Verifythatyouhavethecorrectlysizedroller.

1.Lubricatetheeccentricshaft(7)withhoselube.

2.Installtherollerretainingring(8).Verifythatthe

the

Roller

the the

Roller Roller

Therollersizeistypicallymarkedonthe

Slidetheroller(102)ontotheshaft.Theroller

shouldtontotheshaftsnuglywithminimal

radialmovement.SeeFigure8.

roller(102)turnsfreelyontheshaft(7).

3A1940G 13

Page 14

Repair

4

5

Figure8InstalltheRoller,Hose,andFrontCover

Key

for

Key Key

Note

Note Note

Figure

for for

Figure Figure

8

8 8

Description

Description Description

Torqueto115in-lb(13.0N•m).

Torqueto25in-lb(2.8N•m).

14

3A1940G

Page 15

Repair

Install

Install Install

1.Movetheroller(102)byturningthemotorfan

2.Installoneendofthehose(103)throughthe

3.Slidethehoseclamp(104)overthehoseand

4.Positionthehoseclampabout1/4in.(6mm)

the

Hose

the the

Hose Hose

untiltherollerreachesthe6o’clockposition.

Figure9Rollerin6O’ClockPosition

rearportofthepumphousingonthelefthand

sidewhenlookingatitfromthefront.Extend

thehose2-3in.(51–76mm)beyondthepump

housing(1).

installthebarbedtting(105).

fromtheendofthehose.Usingthe24L497

ClampingTool,tightentheclamptosecurethe

hoseontothebarbedtting.

5.Cuttheexcessband,thenattentheendwitha

rubbermallet.

Figure11FlattentheBand

6.Installthescrews(115)andtorqueto115in-lb

(13.0N•m).

7.Loopthehose(103)360degreesandpassthe

otherendthroughthefrontportontherighthand

sideofthepumphousing(1).Assemblethe

barbedtting(105)andclamp(104)asexplained

insteps3–6.

8.Turntheroller(102)tothe12o’clockposition

andpushthehoseintothepumphousing.Usea

rubbermalletifthehoseisdifculttoseat.

9.Returntheroller(102)tothe6o’clockposition,

compressingthehose.Itiscriticalthattheroller

isatthebottomofthepumptoensurethecorrect

capacityofhoselube.Reinstallthemotorfan

cover.

NOTICE

NOTICE NOTICE

Therollermustbereturnedtothe6o’clock

positionbeforeinstallingthefrontcover.

Failuretodosowillresultinoverllingofthe

pumpwithhoselube.

Figure10TightentheClamp

3A1940G 15

Page 16

Repair

Install

Install Install

1.Scrapealldebrisfromthegasketmatingsurfaces

2.Placeabeadofcompatiblesealantonthegasket

3.Lineuptheholesinthegasket(11)withtheholes

4.Lineupthefrontcoverandgasketwiththepump

5.Installtheremainingfrontcoverscrews(14)and

Lubricate

Lubricate Lubricate

1.Wrapthedrainplug(17)threadswithPTFEtape

2.Usingafunnel,llthepumphousingwithhose

the

Front

the the

Front Front

onthefrontcover(12)andthepumphousing

(1),thencleanwithacetoneorbrakecleanerto

removeanyresidue.Thisiscriticaltoensurea

leak-freeassembly.

NOTE:

NOTE: NOTE:

befreeofdirt,debrisandresiduetoensurea

leak-freeseal.

surfaceofthefrontcover(12),toholdthegasket

inplaceduringassembly.

NOTE:

NOTE: NOTE:

gasket(11),andhousingareasymmetric.This

ensuresthatthegasketandcovergooninonly

onedirection.

inthecover(12)beforeplacingthegasketonthe

sealantbead.Placethegasketonthecover.

housing(1)byplacingasocketheadcapscrew

(14)andwasher(13)inthetopholeandscrewing

itintothepumphousing(1).

washers(13).Torquethescrewsoppositelyto

25in-lb(2.8N•m).

NOTE:

NOTE: NOTE:

screws.Thiswillcausethegaskettodeformand

thepumptoleak.

andinstalltheplug.

lubethroughtheventport.Thepumpwillrequire

approximately8oz(250ml).

NOTE:

NOTE: NOTE:

housingwithhoselubewillincreasepressure

inthepumphousing,causinghoselubetoleak

Thepumphousingandfrontcovermust

Theholepatternofthefrontcover(12),

Donotover-tightenthefrontcover

the

the the

Do

Do Do

Cover

Cover Cover

Pump

Pump Pump

not

overll.

not not

overll. overll.

Overllingthepump

fromthecoverortheclamparea.Pre-measuring

thecorrectamountwillhelppreventoverlling.

Figure12LubricatethroughVentPort(15)

3.Wraptheventplug(15)threadswithPTFEtape

andscrewitintotheventportcarefully.

NOTE:

NOTE: NOTE:

vigorouslubrication,whichmaycausesplashingof

oil.Whenoperatingataspeedof85RPMorgreater,

reducetheamountofhoselubeasshowninthe

tablebelow.

Higheroperatingspeedsprovidemore

Operating

Operating Operating

0–84Usequantity

85–104

105–114

115andabove

Speed

Speed Speed

(RPM)

(RPM) (RPM)

Reduction

Reduction Reduction

recommendedinstep2.

Use70%of

recommendedquantity

Use60%of

recommendedquantity

Use50%of

recommendedquantity

Oil

in ininOil Oil

16 3A1940G

Page 17

Notes

Notes

Notes Notes

3A1940G

17

Page 18

Parts

Parts

Parts Parts

EP2

EP2 EP2

EP2006

EP2006 EP2006

Includesitems101–119

Hose

Hose Hose

Pump

Pump Pump

and

EP2013

and and

EP2013 EP2013

Assembly

Assembly Assembly

Pumps,

Pumps, Pumps,

Series

Series Series

A

A A

18 3A1940G

Page 19

Parts

Part

Ref.

Ref. Ref.

No.

No. No.

No.

Part Part

No. No.

Description

Description Description

Qty

Qty Qty

Ref.

Ref. Ref.

No.

No. No.

Part

No.

Part Part

No. No.

Description

Description Description

Qty

Qty Qty

10124L887

102

103

10424M116KIT,hoseclamp;

105

106

24K562

24K564

SeePump

Matrix,

page22

SeePump

Matrix,

page22

---

ASSEMBLY,pump;

seeBarePump

Assembly,page20.

ROLLERKIT;for

EP2006;includes

oneofitem8(page

21)

ROLLERKIT;for

EP2013;includes

oneofitem8(page

21)

HOSEKIT;includes

twohoseclamps

(104)

packageof10

BARBEDFITTING

KIT;kitincludesone

barbedtting,one

clamp(104),andfour

screws(115)

KEY,motorshaft

1

1

1

1

1

2

1

107

108

109

115

119u24K692

MOTORandGEARBOXASSEMBLY

(seePumpMatrix,

page22,forthemo-

torandgearboxused

onyourpump)

24L9820.5HP;51.30gear

ratio;EP2006

24L9830.75HP;35.10gear

ratio;EP2013

24L9850.33HP;157.43gear

ratio;EP2006and

EP2013

---

---

---

WASHER,splitlock;

M6

SCREW,cap,hexhd;

M6x16mm

SCREW,sockethd;

M4x12mm

HOSELUBE;

glycerin;1quart

(0.95liter);notshown

1

4

4

8

1

u

Hose lube is also available in a 1 gallon (3.8 liter)

bottle. Order Part No. 24K694.

Parts labeled --- are not available separately.

3A1940G 19

Page 20

Parts

Bare

Bare Bare

Model

Model Model

Includesitems1–23

Pump

Pump Pump

24L887

24L887 24L887

Assembly

Assembly Assembly

Pump

Assembly,

Pump Pump

Assembly, Assembly,

Series

Series Series

A

A A

20 3A1940G

Page 21

Parts

Part

No.

Ref.

Ref. Ref.

No.

No. No.

1

Part Part

---

Description

No. No.

Description Description

HOUSING,pump

Qty

Qty Qty

1

Ref.

Ref. Ref.

No.

No. No.

1124K572

Part

No.

Part Part

Description

No. No.

Description Description

GASKETKIT

Qty

Qty Qty

1

224K574

3

4

5

6

7

8

▲

---

---

---

---

24K573

---

Replacement Danger and Warning labels, tags,

SHAFTKIT,output,

motor;includesitems

3,4,5,6,8,18,and

greasezerktting

RING,retaining,

bearing

SEAL,u-cup,outer

SEAL,u-cup,inner

KEY,eccentricshaft

ECCENTRICSHAFT

KIT;includesitems6

and8

RING,retaining,

eccentricshaft

and cards are available at no cost.

1

1

1

1

1

1

2

1224K571

13

14

15

17

18

23

---

---

---

---

---

16K630LABEL,warning;all

▲

28

---

COVERKIT;includes

items11,13,14,15,

17,and28

WASHER,at;no.8

SCREW,cap,socket

hd;M4x16mm

VENT,breatherplug1

PLUG,drain;1/4npt

PLUG,pipe,headless;

1/8npt

models

SIGHTGLASS,3/4npt

1

6

6

2

1

1

1

Parts labeled --- are not available separately.

3A1940G

21

Page 22

Parts

Pump

Pump Pump

Model

Model Model

With6mmIDHoseandRollerInstalled

Pump

Pump Pump

No.

No. No.

24L100

24L100 24L100

24L101

24L101 24L101

24L104

24L104 24L104

24L105

24L105 24L105

24L106

24L106 24L106

24L107

24L107 24L107

24L108

24L108 24L108

24L114

24L114 24L114

24L115

24L115 24L115

24L118

24L118 24L118

24L119

24L119 24L119

24L120

24L120 24L120

24L121

24L121 24L121

24L122

24L122 24L122

24L128

24L128 24L128

24L129

24L129 24L129

24L132

24L132 24L132

24M735

24M735 24M735

24M736

24M736 24M736

24M739

24M739 24M739

24M740

24M740 24M740

24M741

24M741 24M741

24M742

24M742 24M742

24M743

24M743 24M743

24W549

24W549 24W549

24W550

24W550 24W550

24W551

24W551 24W551

Matrix

Matrix Matrix

EP2006

EP2006 EP2006

Part

Part Part

Pumps

Pumps Pumps

Hose

Pump

Pump Pump

Series

Series Series

B24K483EPDMBlue24K565

B24K483EPDMBlue24K566Hastelloy24L985

B24K482Natural

B24K487

B24K487

B24K484NitrileYellow24K565

B24K484NitrileYellow24K566Hastelloy24L985

B24K483EPDMBlue24K565

B24K483EPDMBlue24K566Hastelloy24L982

B24K482Natural

B24K487

B24K487

B24K484NitrileYellow24K565

B24K484NitrileYellow24K566Hastelloy24L982

B24K483EPDMBlue24K565

B24K483EPDMBlue24K566Hastelloy24L984

B24K482Natural

A24K483EPDMBlue24K565

A24K483EPDMBlue24K566HastelloyNone

A24K482Natural

A24K487

A24K487

A24K484NitrileYellow24K565

A24K484NitrileYellow24K566HastelloyNone

A24K487

A24K487

A24K487

Kit

Hose Hose

Kit Kit

(Ref.

103)

(Ref. (Ref.

103) 103)

Hose

Hose Hose

Material

Material Material

Rubber

CSMOrange

CSMOrange

Rubber

CSMOrange

CSMOrange

Rubber

Rubber

CSMOrange

CSMOrange

CSMOrange

CSMOrange

CSMOrange

* Food grade hose inner material is white in color.

Motor

Inner

Inner Inner

Hose

Hose Hose

Stripe

Stripe Stripe

Color

Color Color

None24K565

None24K565

None24K565

None24K565

Barbed

Barbed Barbed

Fitting

Fitting Fitting

(Ref.

(Ref. (Ref.

24K565

24K566Hastelloy24L985

24K565

24K566Hastelloy24L982

24K565

24K566HastelloyNone

24V970PVDF24L982

24V970PVDF24L985

24V970PVDFNone

Kit

Kit Kit

105)

105) 105)

Barbed

Barbed Barbed

Fitting

Fitting Fitting

Material

Material Material

SST

SST

SST

SST

SST

SST

SST

SST

SST

SST

SST

SST

SST

SST

and

Motor Motor

and and

Gearbox

Gearbox Gearbox

(Ref.

107)

(Ref. (Ref.

107) 107)

24L985

24L985

24L985

24L985

24L982

24L982

24L982

24L982

24L984

24L984

None

None

None

None

22

3A1940G

Page 23

Parts

Model

Model Model

With13mmIDHoseandRollerInstalled

Pump

Pump Pump

No.

No. No.

24L184

24L184 24L184

24L185

24L185 24L185

24L188

24L188 24L188

24L189

24L189 24L189

24L190

24L190 24L190

24L191

24L191 24L191

24L192

24L192 24L192

24L198

24L198 24L198

24L199

24L199 24L199

24L202

24L202 24L202

24L203

24L203 24L203

24L204

24L204 24L204

24L205

24L205 24L205

24L206

24L206 24L206

24L212

24L212 24L212

24L213

24L213 24L213

24L216

24L216 24L216

24M763

24M763 24M763

24M764

24M764 24M764

24M767

24M767 24M767

24M768

24M768 24M768

24M769

24M769 24M769

24M770

24M770 24M770

24M771

24M771 24M771

24W552

24W552 24W552

24W553

24W553 24W553

24W554

24W554 24W554

EP2013

EP2013 EP2013

Part

Part Part

Pumps

Pumps Pumps

Hose

Pump

Pump Pump

Series

Series Series

B24K503EPDMBlue24K569

B24K503EPDMBlue24K570Hastelloy24L985

B24K502Natural

B24K507

B24K507

B24K504NitrileYellow24K569

B24K504NitrileYellow24K570Hastelloy24L985

B24K503EPDMBlue24K569

B24K503EPDMBlue24K570Hastelloy24L983

B24K502Natural

B24K507

B24K507

B24K504NitrileYellow24K569

B24K504NitrileYellow24K570Hastelloy24L983

B24K503EPDMBlue24K569

B24K503EPDMBlue24K570Hastelloy24L984

B24K502Natural

A24K503EPDMBlue24K569

A24K503EPDMBlue24K570HastelloyNone

A24K502Natural

A24K507

A24K507

A24K504NitrileYellow24K569

A24K504NitrileYellow24K570HastelloyNone

A24K507

A24K507

A24K507

Kit

Hose Hose

Kit Kit

(Ref.

103)

(Ref. (Ref.

103) 103)

* Food grade hose inner material is white in color.

Hose

Hose Hose

Material

Material Material

Rubber

CSMOrange

CSMOrange

Rubber

CSMOrange

CSMOrange

Rubber

Rubber

CSMOrange

CSMOrange

CSMOrange

CSMOrange

CSMOrange

Motor

Inner

Inner Inner

Hose

Hose Hose

Stripe

Stripe Stripe

Color

Color Color

None24K569

None24K569

None24K569

None24K569

Barbed

Barbed Barbed

Fitting

Fitting Fitting

(Ref.

(Ref. (Ref.

24K569

24K570Hastelloy24L985

24K569

24K570Hastelloy24L983

24K569

24K570HastelloyNone

24V971PVDF24L983

24V971PVDF24L985

24V971PVDFNone

Kit

Kit Kit

105)

105) 105)

Barbed

Barbed Barbed

Fitting

Fitting Fitting

Material

Material Material

SST

SST

SST

SST

SST

SST

SST

SST

SST

SST

SST

SST

SST

SST

and

Motor Motor

and and

Gearbox

Gearbox Gearbox

(Ref.

107)

(Ref. (Ref.

107) 107)

24L985

24L985

24L985

24L985

24L983

24L983

24L983

24L983

24L984

24L984

None

None

None

None

3A1940G 23

Page 24

Parts

Pump

Pump Pump

Model

Model Model

With6mmIDHose(installed)andRoller(notinstalled)

Pump

Pump Pump

Part

Part Part

24L370

24L370 24L370

24L371

24L371 24L371

24L374

24L374 24L374

24L375

24L375 24L375

24L376

24L376 24L376

24L377

24L377 24L377

24L378

24L378 24L378

24L384

24L384 24L384

24L385

24L385 24L385

24L388

24L388 24L388

24L389

24L389 24L389

24L390

24L390 24L390

24L391

24L391 24L391

24L392

24L392 24L392

24L398

24L398 24L398

24L399

24L399 24L399

24L402

24L402 24L402

24L403

24L403 24L403

24L404

24L404 24L404

24L405

24L405 24L405

24L406

24L406 24L406

24N020

24N020 24N020

24N021

24N021 24N021

24N024

24N024 24N024

24N025

24N025 24N025

24N026

24N026 24N026

24N027

24N027 24N027

24N028

24N028 24N028

Kit

Matrix

Kit Kit

Matrix Matrix

EP2006

EP2006 EP2006

No.

No. No.

Pump

Pump Pump

Roller

Roller Roller

(Ref.

102)

(Ref. (Ref.

102) 102)

24K56224K483EPDMBlue24K565

24K56224K483EPDMBlue24K566Hastelloy24L985

24K56224K482Natural

24K56224K487

24K56224K487

24K56224K484NitrileYellow24K565

24K56224K484NitrileYellow24K566Hastelloy24L985

24K56224K483EPDMBlue24K565

24K56224K483EPDMBlue24K566Hastelloy24L982

24K56224K482Natural

24K56224K487

24K56224K487

24K56224K484NitrileYellow24K565

24K56224K484NitrileYellow24K566Hastelloy24L982

24K56224K483EPDMBlue24K565

24K56224K483EPDMBlue24K566Hastelloy24L984

24K56224K482Natural

24K56224K487

24K56224K487

24K56224K484NitrileYellow24K565

24K56224K484NitrileYellow24K566Hastelloy24L984

24K56224K483EPDMBlue24K565

24K56224K483EPDMBlue24K566HastelloyNone

24K56224K482Natural

24K56224K487

24K56224K487

24K56224K484NitrileYellow24K565

24K56224K484NitrileYellow24K566HastelloyNone

Kits

Kits Kits

Hose

Kit

Kit Kit

Kit

Hose Hose

Kit Kit

(Ref.

103)

(Ref. (Ref.

103) 103)

* Food grade hose inner material is white in color.

Hose

Hose Hose

Material

Material Material

Rubber

CSMOrange

CSMOrange

Rubber

CSMOrange

CSMOrange

Rubber

CSMOrange

CSMOrange

Rubber

CSMOrange

CSMOrange

Motor

Inner

Inner Inner

Hose

Hose Hose

Color

Color Color

None24K565

None24K565

None24K565

None24K565

Stripe

Stripe Stripe

Barbed

Barbed Barbed

Fitting

Fitting Fitting

(Ref.

(Ref. (Ref.

24K565

24K566Hastelloy24L985

24K565

24K566Hastelloy24L982

24K565

24K566Hastelloy24L984

24K565

24K566HastelloyNone

Kit

Kit Kit

105)

105) 105)

Barbed

Barbed Barbed

Fitting

Fitting Fitting

Material

Material Material

SST

SST

SST

SST

SST

SST

SST

SST

SST

SST

SST

SST

SST

SST

SST

SST

and

Motor Motor

and and

Gearbox

Gearbox Gearbox

(Ref.

107)

(Ref. (Ref.

107) 107)

24L985

24L985

24L985

24L985

24L982

24L982

24L982

24L982

24L984

24L984

24L984

24L984

None

None

None

None

24

3A1940G

Page 25

Parts

Model

Model Model

With13mmIDHose(installed)andRoller(notinstalled)

Pump

Pump Pump

Part

Part Part

24L454

24L454 24L454

24L455

24L455 24L455

24L458

24L458 24L458

24L459

24L459 24L459

24L460

24L460 24L460

24L461

24L461 24L461

24L462

24L462 24L462

24L468

24L468 24L468

24L469

24L469 24L469

24L472

24L472 24L472

24L473

24L473 24L473

24L474

24L474 24L474

24L475

24L475 24L475

24L476

24L476 24L476

24L482

24L482 24L482

24L483

24L483 24L483

24L486

24L486 24L486

24L487

24L487 24L487

24L488

24L488 24L488

24L489

24L489 24L489

24L490

24L490 24L490

24N048

24N048 24N048

24N049

24N049 24N049

24N052

24N052 24N052

24N053

24N053 24N053

24N054

24N054 24N054

24N055

24N055 24N055

24N056

24N056 24N056

24N048

24N048 24N048

24N049

24N049 24N049

EP2013

EP2013 EP2013

No.

No. No.

Pump

Pump Pump

Roller

Roller Roller

(Ref.

102)

(Ref. (Ref.

102) 102)

24K56424K503EPDMBlue24K569

24K56424K503EPDMBlue24K570Hastelloy24L985

24K56424K502Natural

24K56424K507

24K56424K507

24K56424K504NitrileYellow24K569

24K56424K504NitrileYellow24K570Hastelloy24L985

24K56424K503EPDMBlue24K569

24K56424K503EPDMBlue24K570Hastelloy24L983

24K56424K502Natural

24K56424K507

24K56424K507

24K56424K504NitrileYellow24K569

24K56424K504NitrileYellow24K570Hastelloy24L983

24K56424K503EPDMBlue24K569

24K56424K503EPDMBlue24K570Hastelloy24L984

24K56424K502Natural

24K56424K507

24K56424K507

24K56424K504NitrileYellow24K569

24K56424K504NitrileYellow24K570Hastelloy24L984

24K56424K503EPDMBlue24K569

24K56424K503EPDMBlue24K570HastelloyNone

24K56424K502Natural

24K56424K507

24K56424K507

24K56424K504NitrileYellow24K569

24K56424K504NitrileYellow24K570HastelloyNone

24K56424K503EPDMBlue24K569

24K56424K503EPDMBlue24K570HastelloyNone

Kits

Kits Kits

Hose

Kit

Kit Kit

Kit

Hose Hose

Kit Kit

(Ref.

103)

(Ref. (Ref.

103) 103)

Hose

Hose Hose

Material

Material Material

Rubber

CSMOrange

CSMOrange

Rubber

CSMOrange

CSMOrange

Rubber

CSMOrange

CSMOrange

Rubber

CSMOrange

CSMOrange

Motor

Inner

Inner Inner

Hose

Hose Hose

Color

Color Color

None24K569

None24K569

None24K569

None24K569

Stripe

Stripe Stripe

Barbed

Barbed Barbed

Fitting

Fitting Fitting

(Ref.

(Ref. (Ref.

24K569

24K570Hastelloy24L985

24K569

24K570Hastelloy24L983

24K569

24K570Hastelloy24L984

24K569

24K570HastelloyNone

Kit

Kit Kit

105)

105) 105)

Barbed

Barbed Barbed

Fitting

Fitting Fitting

Material

Material Material

SST

SST

SST

SST

SST

SST

SST

SST

SST

SST

SST

SST

SST

SST

SST

SST

SST

and

Motor Motor

and and

Gearbox

Gearbox Gearbox

(Ref.

107)

(Ref. (Ref.

107) 107)

24L985

24L985

24L985

24L985

24L983

24L983

24L983

24L983

24L984

24L984

24L984

24L984

None

None

None

None

None

3A1940G 25

Page 26

Parts

Hose

Roller

Pump

Pump Pump

Part

No.

Part Part

No. No.

24N052

24N052 24N052

24N053

24N053 24N053

24N054

24N054 24N054

24N055

24N055 24N055

24N056

24N056 24N056

Kit

Roller Roller

Kit Kit

(Ref.

102)

(Ref. (Ref.

102) 102)

24K56424K502Natural

24K56424K507

24K56424K507

24K56424K504NitrileYellow24K569

24K56424K504NitrileYellow24K570HastelloyNone

Kit

Hose Hose

Kit Kit

(Ref.

103)

(Ref. (Ref.

103) 103)

* Food grade hose inner material is white in color.

Hose

Hose Hose

Material

Material Material

Rubber

CSMOrange

CSMOrange

Motor

Inner

Inner Inner

Hose

Hose Hose

Color

Color Color

None24K569

Stripe

Stripe Stripe

Barbed

Barbed Barbed

Fitting

Fitting Fitting

(Ref.

(Ref. (Ref.

24K569

24K570HastelloyNone

Kit

Kit Kit

105)

105) 105)

Barbed

Barbed Barbed

Fitting

Fitting Fitting

Material

Material Material

SST

SST

SST

and

Motor Motor

and and

Gearbox

Gearbox Gearbox

(Ref.

107)

(Ref. (Ref.

107) 107)

None

None

None

26 3A1940G

Page 27

Parts

Variable

Variable Variable

VFD

VFD VFD

16K905EP20060.5

16K906EP20060.5

16K907EP20131.0

16K908EP20131.0

Frequency

Frequency Frequency

Part

No.

Part Part

No. No.

Drives

Drives Drives

Used

With

Used Used

Pump

With With

Pump Pump

(VFD)

(VFD) (VFD)

Horsepower

Horsepower Horsepower

Input

Voltage

Input Input

Voltage Voltage

120or240Vac(1

phase)

208–240Vac(1or

3phase)

120or240Vac(1

phase)

208–240Vac(1or

3phase)

Output

Output Output

240Vac(3phase)

208–240Vac(3

phase)

240Vac(3phase)

208–240Vac(3

phase)

Voltage

Voltage Voltage

3A1940G

27

Page 28

Notes

Notes

Notes Notes

28 3A1940G

Page 29

TechnicalData

Technical

Technical Technical

EP2

Pumps

EP2 EP2

Pumps Pumps

MaximumFluidWorkingPressure125psi0.9MPa,9bar

MotorHorsepower/GearRatio

MaximumPumpSpeed

MaximumEnvironmental

Temperature

MinimumEnvironmental

Temperature

Maximum

Maximum Maximum

EP2006Pump0.14gpm0.5lpm

EP2013Pump0.80gpm3.0lpm

Fluid

Fluid Fluid

EP2006Pump0.004gal.0.015liters

EP2013Pump0.016gal.0.06liters

Hose

Hose Hose

EP2006Pump6mm

EP2013Pump13mm

Noise

Noise Noise

SoundPressureLessthan80dB(A)

Dimensions

Dimensions Dimensions

Height17.20in.437mm

Widthwithhoseinstalled11.02in.280mm

Flow

Flow Flow

Capacity

Capacity Capacity

Inner

Diameter

Inner Inner

Diameter Diameter

Data

Data Data

U.S.

U.S. U.S.

SeethePumpMatrix,page22,forthemotor/gearra-

tiousedonyourpump:

0.5/51.30

0.75/35.10

0.33/157.43

6mm:35rpm;13mm:50rpm

122°F50°C

14°F–10°C

per

Revolution

per per

Revolution Revolution

Metric

Metric Metric

Widthwithouthoseinstalled8.98in.228mm

Length13.35in.339mm

Weight51.7lb23.5kg

FluidInletandOutletSize1/2npt(m)

Wetted

Wetted Wetted

PumpPowdercoatedaluminum.

Hose

BarbedFitting

Parts

Parts Parts

SeethePumpMatrix,page22.

StainlesssteelorHastelloy.SeethePumpMatrix,page22.

3A1940G 29

Page 30

Graco

Graco Graco

GracowarrantsallequipmentreferencedinthisdocumentwhichismanufacturedbyGracoandbearingits

nametobefreefromdefectsinmaterialandworkmanshiponthedateofsaletotheoriginalpurchaserfor

use.Withtheexceptionofanyspecial,extended,orlimitedwarrantypublishedbyGraco,Gracowill,fora

periodoftwelvemonthsfromthedateofsale,repairorreplaceanypartoftheequipmentdetermined

byGracotobedefective.Thiswarrantyappliesonlywhentheequipmentisinstalled,operatedand

maintainedinaccordancewithGraco’swrittenrecommendations.

Thiswarrantydoesnotcover,andGracoshallnotbeliableforgeneralwearandtear,oranymalfunction,

damageorwearcausedbyfaultyinstallation,misapplication,abrasion,corrosion,inadequateorimproper

maintenance,negligence,accident,tampering,orsubstitutionofnon-Gracocomponentparts.Norshall

Gracobeliableformalfunction,damageorwearcausedbytheincompatibilityofGracoequipment

withstructures,accessories,equipmentormaterialsnotsuppliedbyGraco,ortheimproperdesign,

manufacture,installation,operationormaintenanceofstructures,accessories,equipmentormaterials

notsuppliedbyGraco.

Thiswarrantyisconditionedupontheprepaidreturnoftheequipmentclaimedtobedefectivetoan

authorizedGracodistributorforvericationoftheclaimeddefect.Iftheclaimeddefectisveried,Graco

willrepairorreplacefreeofchargeanydefectiveparts.Theequipmentwillbereturnedtotheoriginal

purchasertransportationprepaid.Ifinspectionoftheequipmentdoesnotdiscloseanydefectinmaterial

orworkmanship,repairswillbemadeatareasonablecharge,whichchargesmayincludethecostsof

parts,labor,andtransportation.

THIS

WARRANTY

THIS THIS

WARRANTY WARRANTY

IMPLIED,

IMPLIED, IMPLIED,

OF

OF OF

Graco’ssoleobligationandbuyer’ssoleremedyforanybreachofwarrantyshallbeassetforthabove.

Thebuyeragreesthatnootherremedy(including,butnotlimitedto,incidentalorconsequentialdamages

forlostprots,lostsales,injurytopersonorproperty,oranyotherincidentalorconsequentialloss)shall

beavailable.Anyactionforbreachofwarrantymustbebroughtwithintwo(2)yearsofthedateofsale.

GRACO

GRACO GRACO

MERCHANTABILITY

MERCHANTABILITY MERCHANTABILITY

ACCESSORIES,

ACCESSORIES, ACCESSORIES,

GRACO.

GRACO. GRACO.

aresubjecttothewarranty,ifany,oftheirmanufacturer.Gracowillprovidepurchaserwithreasonable

assistanceinmakinganyclaimforbreachofthesewarranties.

InnoeventwillGracobeliableforindirect,incidental,specialorconsequentialdamagesresultingfrom

Gracosupplyingequipmenthereunder,orthefurnishing,performance,oruseofanyproductsorother

goodssoldhereto,whetherduetoabreachofcontract,breachofwarranty,thenegligenceofGraco,or

otherwise.

FORGRACOCANADACUSTOMERS

ThePartiesacknowledgethattheyhaverequiredthatthepresentdocument,aswellasalldocuments,

noticesandlegalproceedingsenteredinto,givenorinstitutedpursuantheretoorrelatingdirectlyor

indirectlyhereto,bedrawnupinEnglish.Lespartiesreconnaissentavoirconvenuquelarédactiondu

présentedocumentseraenAnglais,ainsiquetousdocuments,avisetprocéduresjudiciairesexécutés,

donnésouintentés,àlasuitedeouenrapport,directementouindirectement,aveclesprocédures

concernées.

INCLUDING

INCLUDING INCLUDING

FITNESS

FITNESS FITNESS

MAKES

MAKES MAKES

Theseitemssold,butnotmanufacturedbyGraco(suchaselectricmotors,switches,hose,etc.),

IS

EXCLUSIVE,

IS IS

EXCLUSIVE, EXCLUSIVE,

BUT

NOT

BUT BUT

FOR

FOR FOR

PARTICULAR

A AAPARTICULAR PARTICULAR

NO

NO NO

EQUIPMENT,

EQUIPMENT, EQUIPMENT,

NOT NOT

WARRANTY,

WARRANTY, WARRANTY,

AND

FITNESS

AND AND

FITNESS FITNESS

Standard

Standard Standard

AND

IS

IN

LIEU

AND AND

IS IS

LIMITED

LIMITED LIMITED

PURPOSE.

PURPOSE. PURPOSE.

AND

AND AND

FOR

FOR FOR

MATERIALS

MATERIALS MATERIALS

IN IN

TO

TO TO

DISCLAIMS

DISCLAIMS DISCLAIMS

PARTICULAR

A AAPARTICULAR PARTICULAR

OR

OR OR

OF

LIEU LIEU

OF OF

WARRANTY

WARRANTY WARRANTY

ALL

ALL ALL

COMPONENTS

COMPONENTS COMPONENTS

Warranty

Warranty Warranty

ANY

OTHER

ANY ANY

OTHER OTHER

OF

OF OF

IMPLIED

IMPLIED IMPLIED

PURPOSE,

PURPOSE, PURPOSE,

WARRANTIES,

WARRANTIES, WARRANTIES,

MERCHANTABILITY

MERCHANTABILITY MERCHANTABILITY

WARRANTIES

WARRANTIES WARRANTIES

IN

CONNECTION

IN IN

SOLD

SOLD SOLD

CONNECTION CONNECTION

BUT

NOT

BUT BUT

NOT NOT

EXPRESS

EXPRESS EXPRESS

OR

WARRANTY

OR OR

WARRANTY WARRANTY

OF

OF OF

MANUFACTURED

MANUFACTURED MANUFACTURED

OR

OR OR

WITH

WITH WITH

BY

BY BY

Graco

Graco Graco

To

To To

Phone:

Phone: Phone:

Allwrittenandvisualdatacontainedinthisdocumentreectsthelatestproductinformationavailableatthetimeofpublication.

Information Information

place

an

place place

an an

612-623-6921or or

GRACO

GRACO GRACO

Information

order,

order, order,

contactyourGracoDistributororcalltoidentifythenearestdistributor.

or

Toll

Free:

Toll Toll

Free: Free:

1-800-328-0211Fax: Fax:

Gracoreservestherighttomakechangesatanytimewithoutnotice.

OriginalInstructions.ThismanualcontainsEnglish,MM3A1940

Forpatentinformation,seewww.graco.com/patents.

Graco

International

International International

INC.

AND

INC. INC.

Copyright

Copyright Copyright

SUBSIDIARIES

AND AND

SUBSIDIARIES SUBSIDIARIES

2011,

Graco

2011, 2011,

Graco Graco

Graco Graco

Inc.

Inc. Inc.

Ofces:

Ofces: Ofces:

All

Graco

All All

Graco Graco

Headquarters:

Headquarters: Headquarters:

P.O.

• ••P.O. P.O.

www.graco.com

RevisionG,July2014

Fax:

612-378-3505

Belgium,China,Japan,Korea

BOX

BOX BOX

manufacturing

manufacturing manufacturing

Minneapolis

1441

1441 1441

MINNEAPOLIS,

• ••MINNEAPOLIS, MINNEAPOLIS,

locations

locations locations

are

are are

MN

MN MN

registered

registered registered

55440-1441

55440-1441 55440-1441

ISO

to totoISO ISO

USA

• ••USA USA

9001.

9001. 9001.

Loading...

Loading...