Page 1

Repair Instructions

LD Grease Pump

Repair Kits

Instructions for repairing the LD Grease Pump.

Maximum Fluid Pressure - 7500 psi (51.7 MPa, 517 bar)

Maximum Air Pressure - 150 psi (1.03 MPa, 10.3 bar)

Important Safety Instructions

Read all warnings and instructions in this manual and

in your LD Series Oil or Grease Pump manual. Save

all instructions.

3A1495C

EN

Repair Kits:

24H854: Throat and Piston Seal Replacement Kit

24H856: O-Ring and Seal Replacement Kit

24U984: Air Piston Replacement Kit

Page 2

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual, refer back to these Warnings. Product-specific hazard symbols and

warnings not covered in this section may appear throughout the body of this manual where applicable.

WARNING

SKIN INJECTION HAZARD

High-pressure fluid from dispense valve, hose leaks, or ruptured components will pierce skin. This may

look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispense valve at anyone or at any part of the body.

• Do not put your hand over the end of the dispense nozzle.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical

reaction and equipment rupture. Failure to follow this warning can result in death, serious injury, or

property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material supplier

for compatibility.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area

of the equipment to help protect you from serious injury, including eye injury, hearing loss, inhalation of

toxic fumes, and burns. This equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

2 3A1495C

Page 3

Instructions

1

Instructions

Always use all new parts included in your kit and dispose of replaced parts according to all state and local

regulations for disposal of discarded components.

Inspect all parts when disassembling the pump. Replace

any and all worn and damaged parts.

Pressure Relief Procedure

The equipment stays pressurized until pressure is manually

relieved. To reduce the risk of serious injury from pressurized fluid, fluid from the valve, or splashing fluid, follow the

procedure whenever you:

• are instructed to relieve pressure

• stop dispensing

• check, clean, or service any system equipment

• install or clean dispensing devices.

1. Close the pump’s bleed-type master air valve.

2. Close the pump air regulator and disconnect the air

supply hose.

Disassembly

The following disassembly instructions describe the procedure for completely disassembling the LD grease

pump. Depending on the repair/maintenance procedure

you are performing on the pump, it may not be necessary to entirely disassemble the pump or perform all

steps in this procedure.

The reference numbers used in the following instructions correspond to the reference numbers used in the

LD Series Oil and Grease Pump instruction manual.

1. Stop the pump. Follow Pressure Relief Procedure,

page 3.

2. Disconnect and remove the pump from its installed

location.

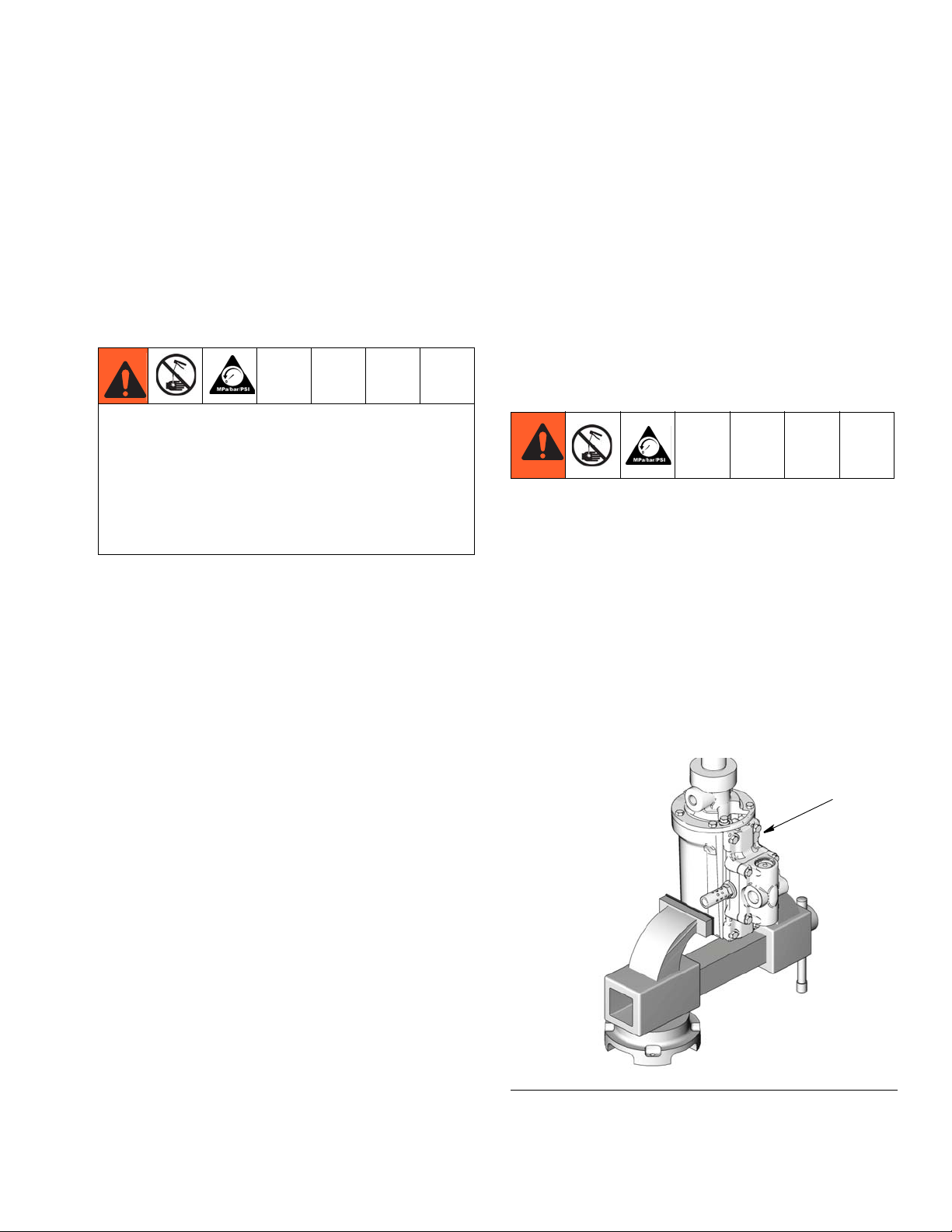

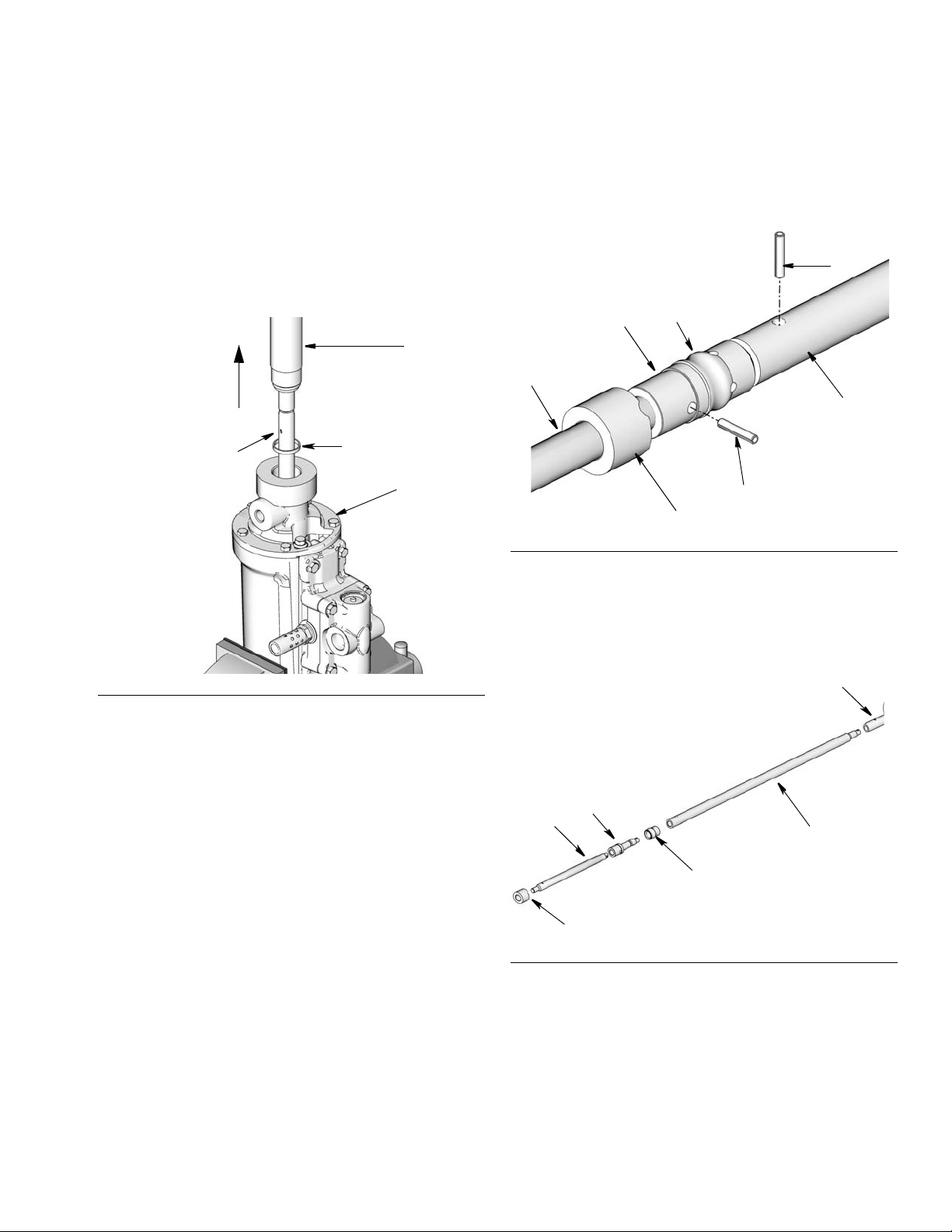

3. Clamp the pump (1) upside down in a vise as shown

in Fig. 1.

3. Open the dispensing valve and dispense fluid into a

waste bucket/container until pressure is fully

relieved.

If you suspect that the dispensing valve is clogged, or

that pressure has not been fully relieved after following

the steps above, very slowly loosen the dispensing

valve coupler or hose end coupling to relieve pressure

gradually, then loosen completely.

NOTE: Take care to only use enough clamping

force to hold the pump in position. The pump cylinder is aluminum and could be damaged by using

excessive clamping force.

Fig. 1

If you are only servicing the air valve (40) and seals

(18) or air piston (15), skip Steps 4 - 14.

3A1495C 3

Page 4

Instructions

34

27

34

19, 35

29

19

35

34

36

26

28

30

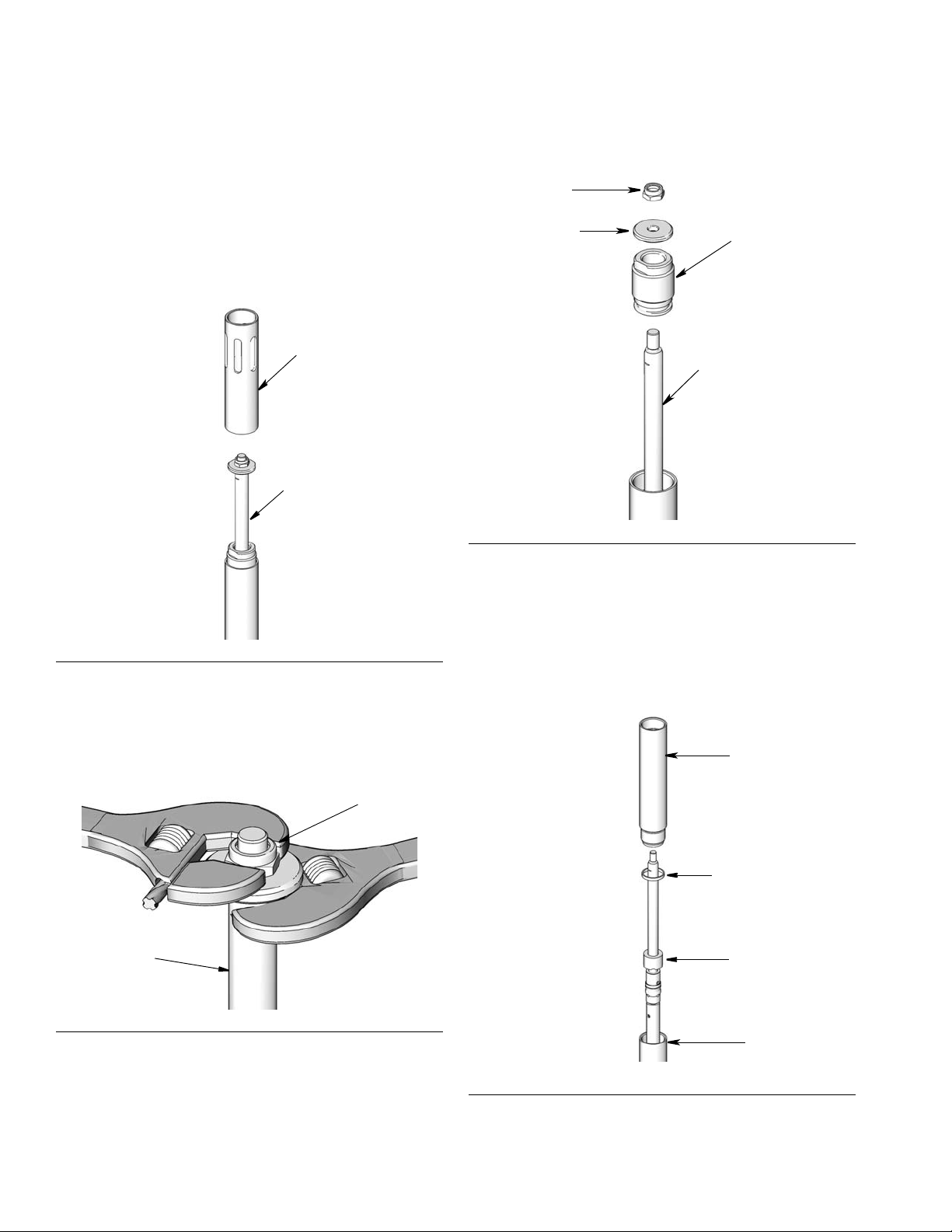

4. Secure a strap wrench around the shovel cylinder

(27). Use the strap wrench to turn the shovel cylinder counter-clockwise to loosen and remove it from

the pump assembly (Fig. 2).

NOTE: After a few turns, the shovel cylinder should

be loose enough to finish turning it with your hand to

remove this part.

6. Use a wrench to loosen and remove the seal

retainer (29) (Fig. 4).

Fig. 4

Fig. 2

5. Use an adjustable wrench to hold the priming rod

(34) securely. Use a second adjustable wrench to

loosen and remove the nut (19) and priming piston

(35) (Fig. 3, Fig. 4).

Fig. 3

7. Tighten a strap wrench on the spacer cylinder (36)

and use it to prevent this part from moving. Secure a

strap wrench around the cylinder (26) and use it to

turn the cylinder to loosen and remove it from the

pump assembly. (Fig. 5). Remove the intake seal

(28).

Fig. 5

4 3A1495C

Page 5

Instructions

22

36

PULL

8

30

8

34

23

8

28

32

24

24

23

34

28

32

25

8. If the gasket (30) is still inside the spacer cylinder

(36) use a pick to remove.

9. Secure a strap wrench around the spacer cylinder

(36) and use it to turn the cylinder counter clockwise

to loosen and remove it from the flange (22) (Fig. 6).

NOTE: After a few turns, the spacer cylinder should

be loose enough to finish loosening it with your

hand to remove this part.

13. Use a rubber hammer and small punch to drive out

pin (8), holding together the priming rod (34) and

piston rod (23). Turn the priming rod (34) counter

clockwise to loosen and remove it from the piston

rod (Fig. 7).

Fig. 7

Fig. 6

10. Use a pick to remove gasket (30) from inside the

flange (22).

11. Use a rubber hammer and small punch to drive out

pin (8), holding together the piston rod (23) and the

connection rod (32). Turn the piston rod (23)

counter clockwise to loosen and remove it from the

connection rod. Remove the piston seal (24) from

the piston rod (Fig. 8).

12. Remove the pump assembly from the vise and set it

down on a clean, hard work surface.

NOTE: When removing the pin (8) in Steps 12 - 14,

it is helpful to place a support such as a piece of

wood, below the rods.

14. Use a rubber hammer and small punch to drive out

pin (8), holding together the connection rod (32) and

displacement rod (25). Turn the connection rod (32)

counter clockwise to loosen and remove it from the

displacement rod (Fig. 8).

Fig. 8

If you are only replacing or repairing the pump lower

continue instructions beginning with Step 14, page

8 of the Reassembly instructions and the related

O-Ring and Seal Replacement Kit 24H856, page 12.

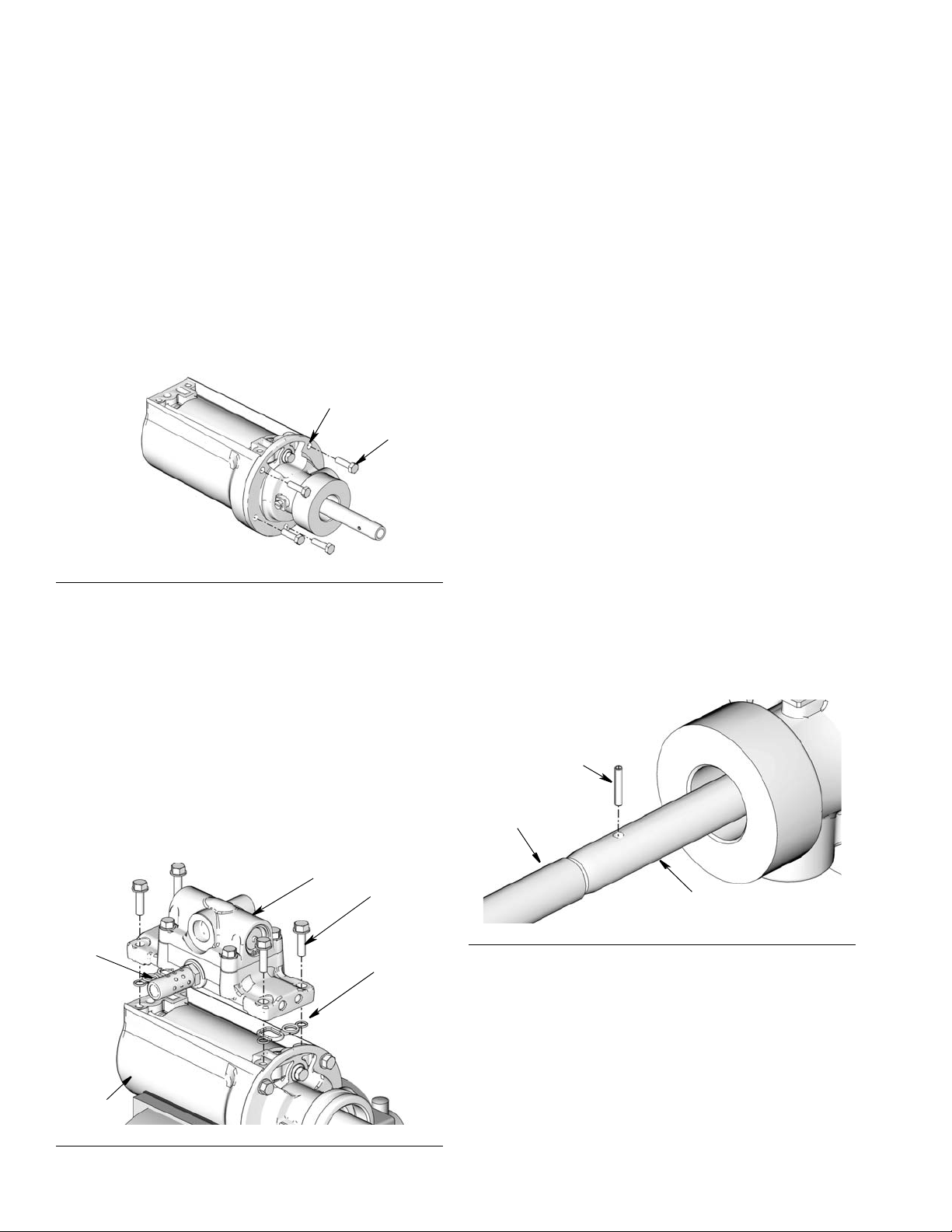

15. Clamp the air cylinder (21) horizontally in a vise as

shown in Fig. 9.

NOTE: Take care to only use enough clamping

3A1495C 5

Page 6

Instructions

43

40

21

18

21

21

6

3

14

22

force to hold the pump in position. The pump cylinder is aluminum and could be damaged by using

excessive clamping force.

16. Using a 10 mm socket wrench, remove the 4 screws

(43) from the air valve (40) and completely remove

air valve assembly from air cylinder (21). Also

remove the two cover gaskets 18). If you are replacing these parts, discard gaskets. (Fig. 9).

NOTE: Sliding the flat blade of a screw driver between

the flange (22) and air cylinder (21) will help separate

the two parts. Be careful not to damage the o-ring (6)

(Fig. 10).

Fig. 10

19. Pull the flange assembly off the displacement rod

(25). Set the displacement rod aside. You will not

need it until you reassemble the pump.

20. Using a 5 mm socket wrench remove the 3 screws

(3) from the bottom cover (14) (Fig. 11).

Fig. 9

Repair and replacement instructions for the Air

Valve are included in a separate repair manual

included with the kit:

• Air Valve Replacement Kit - 24H848, 24H849,

24H850

• Air Valve Repair Kit - 24H798

• Air Motor Service Kit - 24J757, 24J758, 24J759

• Pilot Valve Kit - 24H749

• Air Valve Seal Kit - 24H851

• Air Valve End Cap Kit - 24H852

17. Using a 10 mm socket wrench, remove the 5 screws

(4) from the flange (22).

18. Using your hand, firmly grasp the flange (22) and

remove the entire assembly from inside the air cylinder (21).

Fig. 11

21. Separate the bottom cover (14) from the flange (22)

(Fig. 11).

NOTE: Insert the flat blade of a screwdriver

between the flange and bottom cover to help loosen

the seal between these two pieces and pull them

apart more easily.

If you are replacing the o-rings and seals installed in

the flange, bottom cover, and air piston continue

instructions with Step 1, page 7 of the Reassembly

instructions and the Throat and Piston Seal

Replacement Kit 24H854 instructions beginning on

page 11.

6 3A1495C

Page 7

Instructions

20

a

22

3

50

14

22

14

21

Pump Reassembly

NOTE: The following instructions describe the proce-

dure to follow to reassemble a completely disassembled

LD grease pump. Depending on the repair/maintenance

procedure you are performing on the pump, it may not

be entirely disassembled. See the specific section(s)

related to your repair/replacement kit.

For all reassembly procedures:

• Clean all the parts carefully in a compatible solvent,

and inspect for wear or damage. Use all the repair

kit parts during reassembly, and replace other parts

as necessary.

• Check the all polished surfaces for scratches or

wear.

• Lubricate all parts with a light, water-resistant

grease.

1. Install new o-rings and seals in bottom cover (14)

and flange (22) as described in the Throat and Piston Seal Replacement Kit 24H854, page 11. Be

sure to apply a thin coat of water-resistant grease to

all o-rings and seals.

3. Install 3 screws (3) (Fig. 13). Tighten with a 5 mm

socket wrench and torque to 60-70 in lbs (6.8 – 7.9

N.m).

Fig. 13

4. Apply a thin coat of grease round the top of the displacement rod (50). Push the displacement rod

through the opening in the bottom cover and into the

flange assembly as shown in Fig. 14.

2. Align pilot valve (20) installed in bottom cover with

opening (a) in flange (22) as shown in Fig. 12. Compress the bottom cover (14) and flange (22)

together.

Fig. 12

Fig. 14

5. Install the air cylinder (21) over the bottom cover

(14). Place the top of the air cylinder down on a

clean hard surface. Use the palms of your hands to

press the bottom cover firmly into the air cylinder

(Fig. 15).

Fig. 15

3A1495C 7

Page 8

Instructions

4

14

43

40

21

18

17

25

32

8

6. Install the 5 screws (4) wrench tight only.

NOTE: If installing a new air cylinder (27), the mating holes are not threaded by design. Use thread

forming screws (4) to form threads as they are being

installed. Torque to 95-105 in.-lbs (10.7 - 11.8 N.m)

to ensure full thread formation.

7. To ensure there is a proper seal between the air

valve and manifold, loosen all 5 screws (Fig. 16)

approximately 1/8 to 1/4 turn. These screws will be

torqued in Step 12, AFTER the air valve (40) is

installed.

Fig. 16

11. Install screws (43). Torque to 60-70 in. lbs (6.8 - 7.9

N.m).

12. Torque screws (4) installed in Step 6 to 60-70 in. lbs

(6.8 - 7.9 N.m).

Muffler (17) Installation (Fig. 17)

13. Depending on your installation, the air valve (40)

can be mounted with the muffler (17) on either side

of the air valve.

To change the installation location:

a. Remove the 4 screws (43).

b. Remove the air valve (40) from its current

mounted position on the air cylinder (21) and

rotate the air valve 180 degrees, which will

reposition the muffler to face the other side of

the pump.

NOTE: When installing the pin (8) in Steps 14 - 20, it is

helpful to place a support, such as a piece of wood,

below the rods.

8. Secure pump assembly in a vise as shown in Fig.

17.

9. Perform any air valve repairs / maintenance

needed. See separate instruction manual included

with the related air valve repair kit.

10. Be sure seals (18) are lightly greased and installed

on air valve (40). Install air valve on air cylinder (21).

NOTE: The air valve (40) can be installed in any

configuration. There is not just one correct way to

install these parts.

Fig. 17

14. Screw the connecting rod (32) and the displacement

rod (25) together, aligning the pin hole in both

pieces to allow the pin to be pushed through (Fig.

18).

Fig. 18

15. Replace the pin (8). Use a rubber hammer to tap the

pin into place, being careful to make sure the sides

of the pin are flush with the outside surface of the

connecting rod (Fig. 18).

16. Install piston seal (24) over the end of the piston rod

(23). Note the correct orientation of the piston seal

on the piston rod as shown in Fig. 19.

8 3A1495C

Page 9

Instructions

24

23

32

8

30

28

34

23

Correct Alignment

Permits end play

Fig 3 - Correct

Fig 1 - 1/2 Turn Too Shallow

Incorrect Alignment

Fig 2 - 1/2 Turn Too Deep

Does not permit

end play

ti10469a

ti10468a

Does not permit

end play

ti10479a

17. Screw the piston rod (23) and the connecting rod

(32) together aligning the pin hole in both pieces to

allow the pin to be pushed through (Fig. 19).

Fig. 19

18. Replace the pin (8). Use a rubber hammer to tap the

pin into place, being careful to make sure the sides

of the pin are flush with the outside surface of the

connecting rod (Fig. 19).

19. Screw the piston rod (23) and priming rod (34)

together aligning the pin hole in both pieces to allow

the pin to be pushed through (Fig. 20).

NOTE: When there is end play at the pinned connec-

tion, you should be able to slightly move from

side-to-side, the displacement rod (25) pinned to the

connecting rod (32) and the connecting rod (32) pinned

to the piston rod (23) and piston rod (23) pinned to the

priming rod (34).

22. If these connections seem too rigid remove the pin

and adjust hole alignment by 1/2 turn in the direction

that aligns the through holes as close as possible,

axis-to-axis (Fig. 21).

NOTICE

Improper alignment will take the self-aligning feature

out of the design which could result in damage to the

pump.

Fig. 20

20. Replace the pin (8). Use a rubber hammer to tap the

pin into place, being careful to make sure the sides

of the pin are flush with the outside surface of the

piston rod (Fig. 20)

21. Check to make sure there is end play at all pinned

connections.

3A1495C 9

Fig. 21

23. Install spacer cylinder (36) over rod assembly. Use

a strap wrench to tighten spacer cylinder securely.

24. Install cylinder (26) and seal (30). Torque to 45 - 55

ft. lbs (61 - 75 N.m).

25. Install the intake seal (28) over the end of the priming rod (34). Note the correct orientation of the

Page 10

Instructions

29

19

35

34

34

19, 35

34

27

intake seal on the priming rod as shown in Fig. 20.

26. Install seal retainer (29) over priming rod (34) (Fig.

22).

27. Use an adjustable wrench to tighten seal retainer

securely, then torque to 45 - 55 ft lbs (61 - 75 N.m).

der securely then torque to 45 - 55 ft. lbs (61 - 75

N.m).

Fig. 24

Fig. 22

28. Install the priming piston (35 and nut (19) (Fig. 3,

Fig. 4) on priming rod (34) Use an adjustable

wrench to hold the priming rod (34) securely. Use a

second adjustable wrench to tighten nut. Then

torque nut to 70 - 80 in. lbs (7.9 - 9.0 N.m) (Fig. 22

and Fig. 23).

Fig. 23

29. Install shovel cylinder (27) over priming rod (34)

(Fig. 24). Use a strap wrench to tighten shovel cylin-

Repair Kits

All Repairs:

• Unless otherwise stated, entirely disassemble pump

as described in the pump disassembly instruction

section of this manual.

• Properly discard all replaced parts according to

local and state regulations for disposal of discarded

components.

• Always use all new parts included in the kit to

replace the identical part on the pump.

• Grease all parts prior to reassembly with a thin coat

of lightweight grease.

• Reassemble pump as described in the reassembly

instruction section of this manual.

10 3A1495C

Page 11

Instructions

7

6

18

5

12

8

11

30

37

5

15

7

22

30

22

Throat and Piston Seal Replacement Kit 24H854 (Fig. 25)

Replacement parts for o-ring (5) installed on air piston

(15), o-rings (6 and 12) installed in bottom cover (14),

o-ring (7), u-cup seal (11) and gasket (30) installed on

flange (22), pin (8) used to reassemble rod sections,

and gasket (18) used later in reassembly of the air valve

(40). A replacement part for the retainer nut (37) is also

included in this kit.

Qty

Ref. Description

5 O-RING, air piston 1

6O-RING 1

7O-RING 1

8 PIN, slotted, straight 3

11 SEAL, u-cup 1

12 O-RING 3

18 GASKET, cover, small 2

30 GASKET 1

37 NUT, retainer 1

.

2. Use a pick to remove the o-ring (5) installed around

the circumference of the air piston (15) (Fig. 26).

Grease the new o-ring included in the kit and install

it around the air piston.

Fig. 26

3. Use a pick to remove o-ring (7) and gasket (30) from

inside flange (22) (Fig. 27). Grease the o-ring and

replace the o-ring and gasket in flange.

Fig. 25

1. Disassemble the pump following Disassembly

Steps 1-3 (page 3), Steps 9-12 (page 5) and 15-21

(pages 5-6).

3A1495C 11

Fig. 27

Page 12

Instructions

22

37

22

11

31

Lips down

37

12

14

25

6

28

10

24

30

8

4. Remove nut retainer (37) from flange (22) (Fig. 28).

Fig. 28

5. Remove u-cup seal (11) from flange (22) (Fig. 29).

Grease and replace the u-cup seal with the new part

included in the kit and install them in the order

shown in Fig. 29.

NOTE:

• The bearing (31) is not included in the kit. This

part is reused. The bearing can be installed with

either side facing up. There is not just one way

to install this part.

• The bearing (31) is a transition fit and in some

installations it may not be removed.

• Be sure u-cup seal (11) is installed with the lips

facing down as shown in Fig. 29.

the new o-rings (12) and o-ring (6) included in the kit

and install them in the bottom cover housing.

Fig. 30

8. Reassemble the pump as described in the Reassembly instructions, page 7.

O-Ring and Seal Replacement Kit - 24H856

(Fig. 31)

Replacement parts for gasket (30) installed in the flange

and around the circumference of the cylinder (26), o-ring

(10) installed around the seal retainer (29), pin (8) used

to reassemble rod sections, and replacement seals (24

and 28) installed on the displacement rod assembly.

Qty

Ref. Description

8 PIN, slotted, straight 3

10 O-RING 1

24 SEAL, piston 1

28 SEAL, intake 1

30 GASKET 2

.

Fig. 29

6. Install displacement rod (25) through flange assembly (22) (Fig. 30).

Fig. 31

7. Remove and discard the 3 small o-rings (12) and

o-ring (6) in the bottom cover (14) (Fig. 30). Grease

12 3A1495C

Page 13

Instructions

30

22

36

30

26

36

29

10

101/102

18

21

19

13

15

5

38

25

8

18

30

1. Disassemble the pump following Disassembly

Steps 1-14 (pages 3-5) only.

2. Use a pick to remove the gasket (30) installed

between the flange (22) and tube (36) (Fig. 32).

Grease the new gasket included in the kit and install

it inside the flange.

Fig. 32

3. Use a pick to remove the other gasket (30) installed

between the cylinder (26) and tube (36) (Fig. 33).

Grease the new gasket included in the kit and install

it around the cylinder.

Air Piston Replacement Kit - 24U984 (Fig. 35)

Qty

Ref. Description

5O-RING 1

8 PIN, straight, slotted, 2.5 x 16 1

13 GASKET, 32 OD 1

15 PISTON, air, plastic 1

18 GASKET, cover small 2

19 NUT, hex 1

21 CYLINDER, air, machined 1

25 ROD, displacement, 50:1 1

30 GASKET 1

38 WASHER, 32 OD 1

101 LABEL, identification 1

102 LABEL, overlay, clear 1

.

Fig. 33

4. Use a pick to remove the o-ring (10) installed

around the top of the seal retainer (29) (Fig. 34).

Grease the new o-ring included in the kit and install

it over the seal retainer.

Fig. 34

5. Reassemble the pump as described in the Reassembly instructions, page 7.

3A1495C 13

Fig. 35

Pump Disassembly,

1. Follow Pump Disassembly instructions Steps 1-3

beginning on page 3.

2. Secure a strap wrench around the spacer cylinder

(36) and use it to turn the cylinder counter clockwise

to loosen and remove it from the flange (22) (Fig.

36).

NOTE: After a few turns, the spacer cylinder should

be loose enough to finish loosening it with your

hand to remove this part.

Page 14

Instructions

22

36

PULL

8

30

25

15

19

38

25

13

5

25

15

13

19

38

3. Pull spacer cylinder (36) away from pump to access

pin (8) (Fig. 36).

Fig. 36

Pump Reassembly

Always use all new parts included in the kit for reassembly.

1. Apply a thin coat of grease around the threaded end

of the new displacement rod (25).

2. Assemble washer (38), air piston (15), gasket (13),

o-ring (5) and hex nut (19) to displacement rod (25)

as shown in Fig. 37. Be sure the male boss on gasket (13) mates with the counter bore in air piston

(15). Tighten and torque nut (19) to 155 - 165 in.

pounds (17.5 - 18.6 N.m).

4. Use a rubber hammer and small punch to drive the

pin (8) out.

5. Unscrew the pump lower from displacement rod

(25). Set aside pump lower for reassembly.

6. Use a pick to remove gasket (30) from inside the

flange (22).

7. Continue pump disassembly instructions Steps 15 19, beginning on page 5.

8. Discard pin (8), air piston (15) and displacement rod

(25) according to all applicable safety regulations for

disposal of these parts.

Fig. 37

3. Apply a thin coat of grease around the chamfered

end of the displacement rod assembly (25). Push

the displacement rod through the opening in the bottom cover and into the flange assembly as shown in

14 3A1495C

Page 15

Instructions

25

14

22

21

20

14

21

4

14

Fig. 38.

Fig. 38

4. Remove pilot valve (20) from the old air cylinder

(21). Apply a light coat of grease to o-rings.

5. Install pilot valve (20) into new air cylinder included

in the kit (Fig. 39). Torque to 95-105 in. lbs

(10.7-11.9 N.m).

the bottom cover firmly into the air cylinder (Fig. 40).

Fig. 40

7. Install the 5 screws (4) wrench tight only.

NOTE: If installing a new air cylinder (27) the mating

holes are not threaded by design. Use thread forming screws (4) to form threads as they are being

installed. Torque to 95-105 in.-lbs (10.7 - 11.8 N.m)

to ensure full thread formation.

8. To ensure there is a proper seal between the air

valve and manifold, loosen all 5 screws (4) approximately 1/8 to 1/4 turn (Fig. 41). These screws will be

torqued AFTER the air valve (40) is installed.

Fig. 41

Fig. 39

9. Continue reassembly instructions Steps 8 - 13,

6. Apply a thin coat of grease to o-rings (5) and o-ring

on bottom cover (14). Install the air cylinder (21)

over the bottom cover (14) / air piston (15) assembly. Place the top of the air cylinder down on a clean

hard surface. Use the palms of your hands to press

beginning on page 8.

10. Install gasket (30) into bottom cover (14) (Fig. 42).

11. Screw the connecting rod (32) and the displacement

rod (25) together, aligning the pin hole in both

3A1495C 15

Page 16

pieces to allow the pin to be pushed through (Fig.

25

32

8

30

14

42).

Fig. 42

NOTE: When there is end play at the pinned connec-

tion, you should be able to slightly move from

side-to-side, the displacement rod (25) pinned to the

connecting rod (32) and the connecting rod (32) pinned

to the piston rod (23) and piston rod (23) pinned to the

priming rod (34).

14. If these connections seem too rigid remove the pin

and adjust hole alignment by 1/2 turn in the direction

that aligns the through holes as close as possible,

axis-to-axis (Fig. 21).

NOTICE

Improper alignment will take the self-aligning feature

out of the design which could result in damage to the

pump.

12. Replace the pin (8). Use a rubber hammer to tap the

pin into place, being careful to make sure the sides

of the pin are flush with the outside surface of the

connecting rod (Fig. 42).

13. Check to make sure there is end play at all pinned

connections.

Graco Information

15. Slide spacer cylinder (36) into bottom cover (14).

16. Using a strap wrench, tighten and torque spacer cylinder (36) to 45 - 55 ft. lbs (61.0 - 74.5 N.m).

17. Use a permanent marker to record the pump part

number, serial number and series code shown the

original label located on the old air cylinder, onto the

new label (101) included in the kit.

18. Apply label (101) to the new cylinder. Apply the

clear overlay (102) over the new label.

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM3A1495

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2011, Graco Inc. is registered to ISO 9001

Graco Headquarters: Minneapolis

www.graco.com

June 2011, revised November 2014

Loading...

Loading...