Page 1

Instructions

LD Series Oil and Grease

Pump

For dispensing non-corrosive and non-abrasive lubricants, oil, grease, and automatic

transmission fluids in stationary or mobile installations. Use with compressed air only. For

professional use only. Not for use with windshield washer fluid.

List of models, including Maximum Fluid Pressure:

• Oil Pump Models: page 2

• Grease Pump Models: page 3

Important Safety Instructions

Read all warnings and instructions in

this manual. Save these instructions.

3A1334S

EN

Related Translated Manuals

Manual Number Language

3A1339 Spanish

3A1345 French

3A1350 German

3A1360 Russian

3A1365 Chinese

3A1370 Japanese

3A1375 Korean

3A2329 Czech

II 2 G Ex h T6 Gb

Page 2

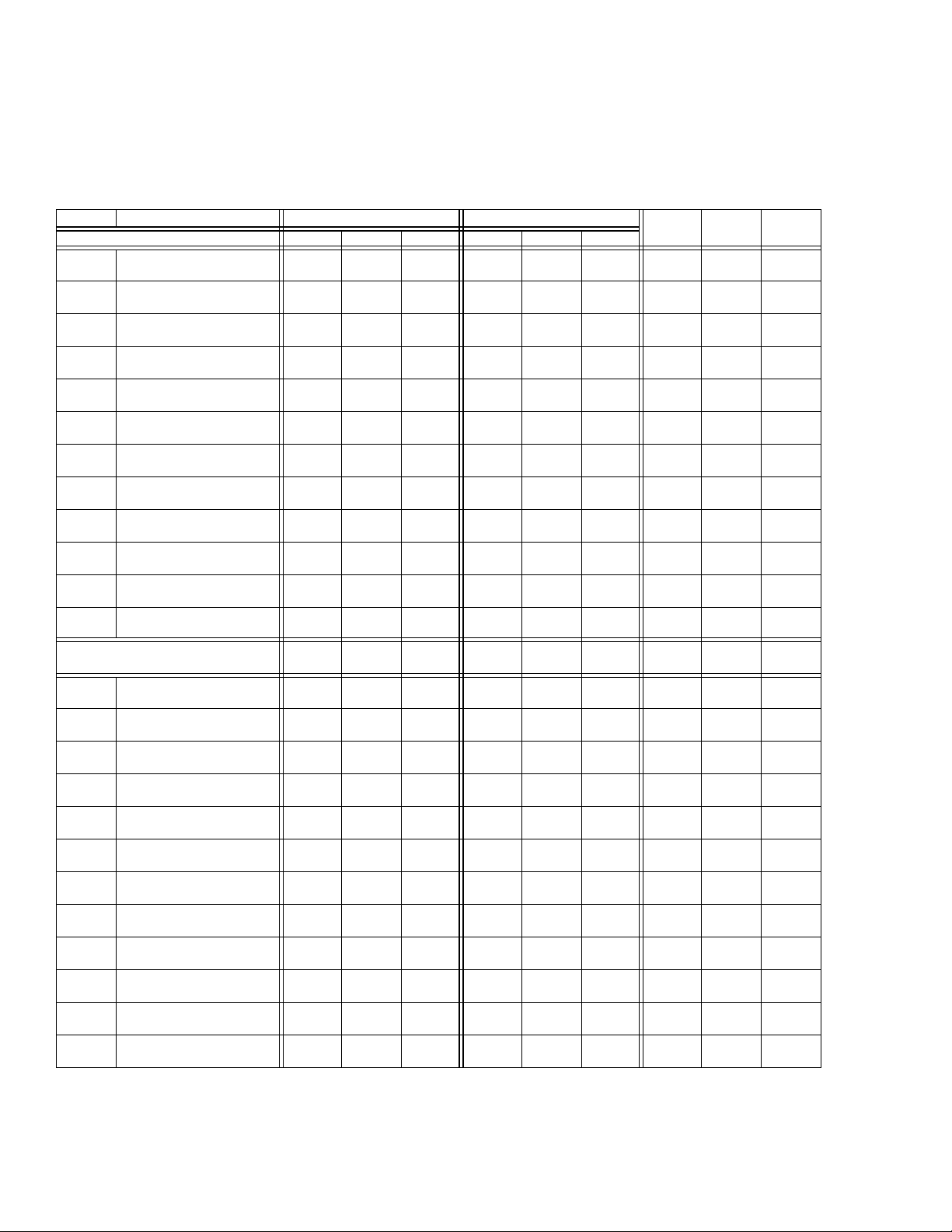

Oil Pump Models

Oil Pump Models

All oil models include a 2” npt(m) bung adapter.

PN Description Max air pressure Max Fluid Pressure

3:1 PUMPS psi Mpa bar psi Mpa bar

24G576 Universal 150 1.03 10.3 450 3.10 31.0

24G577 Universal 150 1.03 10.3 450 3.10 31.0

24G578 Universal 150 1.03 10.3 450 3.10 31.0

24G579* Multilength 150 1.03 10.3 450 3.10 31.0

24G580* Multilength 150 1.03 10.3 450 3.10 31.0

24G581* Multilength 150 1.03 10.3 450 3.10 31.0

24G582* 200L (55gal) drum 150 1.03 10.3 450 3.10 31.0

24G583* 200L (55gal) drum 150 1.03 10.3 450 3.10 31.0

24G584* 200L (55gal) drum 150 1.03 10.3 450 3.10 31.0

24G585* 1040 liter (275gal) tote 150 1.03 10.3 450 3.10 31.0

24G586* 1040 liter (275gal) tote 150 1.03 10.3 450 3.10 31.0

24G587* 1040 liter (275gal) tote 150 1.03 10.3 450 3.10 31.0

5:1 PUMPS psi Mpa bar psi Mpa bar Air inlet

24G588 Universal 150 1.03 10.3 750 5.17 51.7

24G589 Universal 150 1.03 10.3 750 5.17 51.7

24G590 Universal 150 1.03 10.3 750 5.17 51.7

24G591* 5:1 Multilength 150 1.03 10.3 750 5.17 51.7

24G592* 5:1 Multilength 150 1.03 10.3 750 5.17 51.7

24G593* 5:1 Multilength 150 1.03 10.3 750 5.17 51.7

24G594* 200L (55gal) drum 150 1.03 10.3 750 5.17 51.7

24G595* 200L (55gal) drum 150 1.03 10.3 750 5.17 51.7

24G596* 200L (55gal) drum 150 1.03 10.3 750 5.17 51.7

24G597* 1040 liter (275gal) tote 150 1.03 10.3 750 5.17 51.7

24G598* 1040 liter (275gal) tote 150 1.03 10.3 750 5.17 51.7

24G599* 1040 liter (275gal) tote 150 1.03 10.3 750 5.17 51.7

* Includes universal pump and down tube, packaged separately.

Air inlet

1/4"-18

NPT

1/4"-19

BSPP

1/4"-19

BSPT

1/4"-18

NPT

1/4"-19

BSPP

1/4"-19

BSPT

1/4"-18

NPT

1/4"-19

BSPP

1/4"-19

BSPT

1/4"-18

NPT

1/4"-19

BSPP

1/4"-19

BSPT

1/4"-18

NPT

1/4"-19

BSPP

1/4"-19

BSPT

1/4"-18

NPT

1/4"-19

BSPP

1/4"-19

BSPT

1/4"-18

NPT

1/4"-19

BSPP

1/4"-19

BSPT

1/4"-18

NPT

1/4"-19

BSPP

1/4"-19

BSPT

Fluid

Inlet

1"-11.5

NPT

1-11

BSPP

1-11

BSPT

1"-11.5

NPT

1-11

BSPP

1-11

BSPT

1"-11.5

NPT

1-11

BSPP

1-11

BSPT

1"-11.5

NPT

1-11

BSPP

1-11

BSPT

Fluid

Inlet

1"-11.5

NPT

1-11

BSPP

1-11

BSPT

1"-11.5

NPT

1-11

BSPP

1-11

BSPT

1"-11.5

NPT

1-11

BSPP

1-11

BSPT

1"-11.5

NPT

1-11

BSPP

1-11

BSPT

Fluid

Outlet

1/2"-14

NPT

1/2"-14

BSPP

1/2”-14

BSPT

1/2"-14

NPT

1/2"-14

BSPP

1/2”-14

BSPT

1/2"-14

NPT

1/2"-14

BSPP

1/2”-14

BSPT

1/2"-14

NPT

1/2"-14

BSPP

1/2”-14

BSPT

Fluid

Outlet

1/2"-14

NPT

1/2"-14

BSPP

1/2”-14

BSPT

1/2"-14

NPT

1/2"-14

BSPP

1/2”-14

BSPT

1/2"-14

NPT

1/2"-14

BSPP

1/2”-14

BSPT

1/2"-14

NPT

1/2"-14

BSPP

1/2”-14

BSPT

2 3A1334S

Page 3

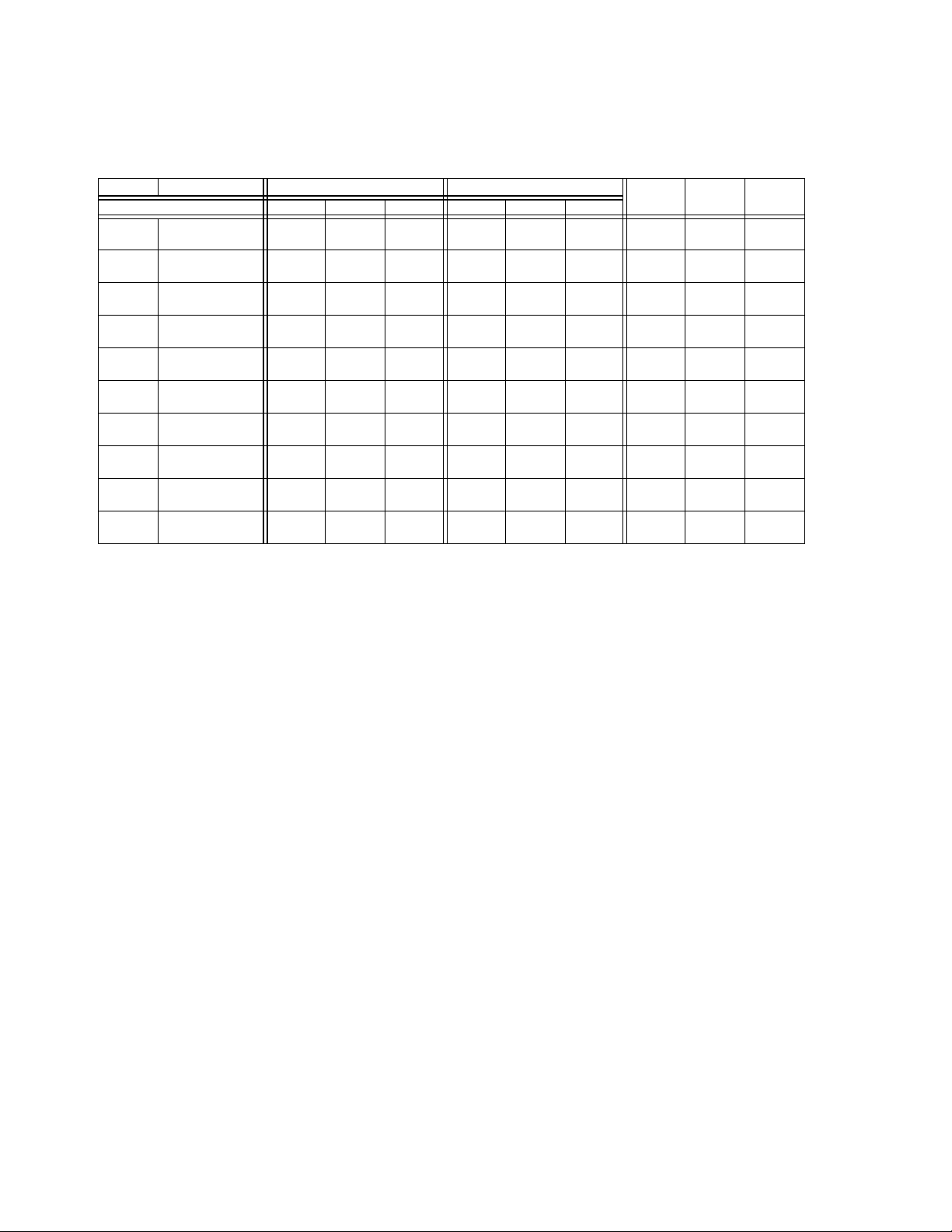

Grease Pump Models

Grease Pump Models

PN Description Max Air Pressure Max Fluid Pressure

50:1 PUMPS psi Mpa bar psi Mpa bar

24G600 16kg (35lb) 150 1.03 10.3 7500 51.7 517

24G601 16kg (35lb) 150 1.03 10.3 7500 51.7 517

24G602 16kg (35lb) 150 1.03 10.3 7500 51.7 517

24G603 55kg (120lb) 150 1.03 10.3 7500 51.7 517

24G604 55kg (120lb) 150 1.03 10.3 7500 51.7 517

24G605 55kg (120lb) 150 1.03 10.3 7500 51.7 517

24G606 180kg (400lb) 150 1.03 10.3 7500 51.7 517

24G607 180kg (400lb) 150 1.03 10.3 7500 51.7 517

24G608 180kg (400lb) 150 1.03 10.3 7500 51.7 517

24X871 16kg (35lb) 150 1.03 10.3 7500 51.7 517

Air Inlet

1/4"-18

Npt

1/4"-19

BSPP

1/4"-19

BSPT

1/4"-18

Npt

1/4"-19

BSPP

1/4"-19

BSPT

1/4"-18

Npt

1/4"-19

BSPP

1/4"-19

BSPT

1/4"-19

BSPT

Fluid

Inlet

Priming

piston

Priming

piston

Priming

piston

Priming

piston

Priming

piston

Priming

piston

Priming

piston

Priming

piston

Priming

piston

Priming

piston

Fluid

Outlet

1/4"-18

Npt

1/4"-19

BSPP

1/4"-19

BSPT

1/4"-18

Npt

1/4"-19

BSPP

1/4"-19

BSPT

1/4"-18

Npt

1/4"-19

BSPP

1/4"-19

BSPT

1/4"-19

BSPT

3A1334S 3

Page 4

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual, refer back to these Warnings. Product-specific hazard symbols

and warnings not covered in this section may appear throughout the body of this manual where applicable.

WARNING

SKIN INJECTION HAZARD

High-pressure fluid from dispense valve, hose leaks, or ruptured components will pierce skin. This may

look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispense valve at anyone or at any part of the body.

• Do not put your hand over the end of the dispense nozzle.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

FIRE AND EXPLOSION HAZARD

When flammable fluids are present in the work area, such as gasoline and windshield wiper fluid, be

aware that flammable fumes can ignite or explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources, such as cigarettes and portable electric lamps.

• Keep work area free of debris, including rags and spilled or open containers of solvent and gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Ground all equipment in the work area.

• Use only grounded hoses.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

4 3A1334S

Page 5

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical

reaction and equipment rupture. Failure to follow this warning can result in death, serious injury, or

property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material

supplier for compatibility.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, hearing loss,

inhalation of toxic fumes, and burns. This equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

3A1334S 5

Page 6

Warnings

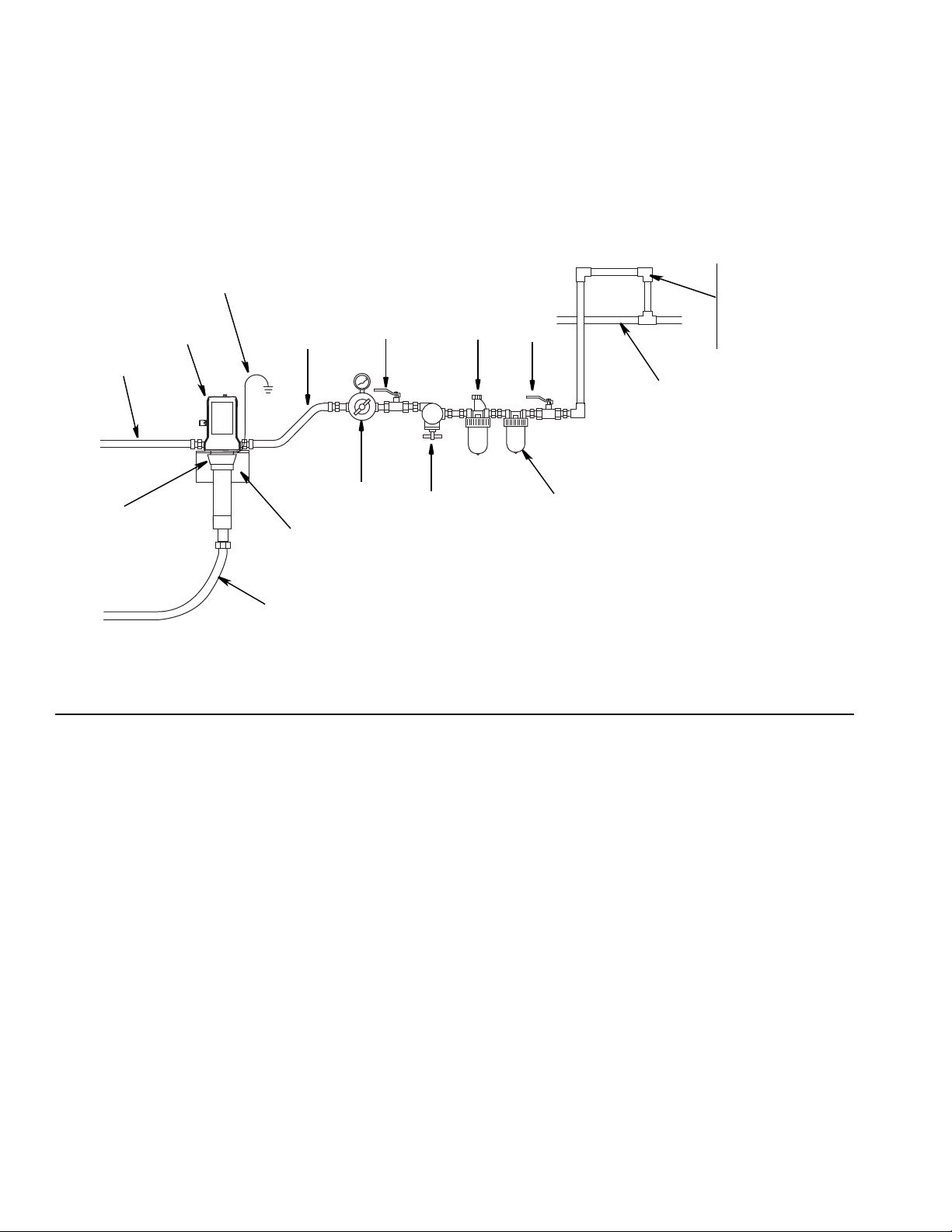

Typical Installation

The typical installation shown in FIG. 1 is only an installation guide. It is not an actual system design. Contact your

Graco Distributor for assistance in designing a system to suit your needs.

Stationary Mountings

FIG. 1

C

air line

configuration

Recommended

B

M

F

E

F

to reduce

moisture in pump

A

J

K

N

G

D

H

L

ti16120

Key (FIG. 1)

A Fluid outlet line (flexible connection required)

B Pump

C Ground wire

D Pump runaway valve

E Air lubricator

F Bleed-type master air valve (required)

• NPT - Part No. 110223

• BSP - Part No. 125272

G Air regulator (self-relieving regulator required)

• NPT - Part No. 24H420

• BSP - Part No. 24H419

H Air filter

J Main air line

K Bung adapter - Part No. 24F918

L Fluid inlet line (flexible connection required)

M Air inlet line (flexible connection required)

N Wall mount bracket - Part No. 24F910

6 3A1334S

Page 7

Installation

Installation

NOTE: Reference letters and numbers in parentheses in the text refer to callouts in the figures and drawings.

Grounding

To reduce the risk of static sparking, ground the pump

and all other components used or located in the

dispensing area. Check your local electrical code for

detailed instructions for your area and type of

equipment.

Ground all equipment:

• Pump: Use a ground wire and clamp as shown in FIG.

2.

a. Remove the ground screw (Z) and insert through

the eye of the ring terminal at end of ground wire

(Y).

b. Fasten the ground screw back onto the pump and

tighten securely.

NOTE: To order a ground wire and clamp, order Graco

Part No. 222011.

• Air and fluid hoses: Use only electrically conductive

hoses.

• Air compressor: Follow manufacturer’s recommendations.

• Dispensing valve: Ground through connection to a

properly grounded fluid hose and pump.

• Object being dispensed to: Follow your local code.

• Solvent pails used when flushing: Follow your local

code. Use only metal pails, which are conductive,

placed on a grounded surface. Do not place the pail

on a nonconductive surface, such as paper or cardboard, which interrupts the grounding continuity.

• To maintain grounding continuity when flushing or

relieving pressure, hold a metal part of the dispensing valve firmly to the side of a grounded metal pail,

then trigger the dispense valve.

Installation Guidelines

Reference letters found in the following instructions,

refer to Typical Installation diagram provided on page 6.

• A ball valve must be installed upstream of the regulator (G).

• The fluid outlet line (A), fluid inlet line (L) and air inlet

line (M) must be flexible (such as a hose).

NOTE: To prevent damage to the pump, remove sediment

from the bottom of the container before installing a pump

on an existing container.

Y

Z

ti16123

FIG. 2

3A1334S 7

Page 8

Installation

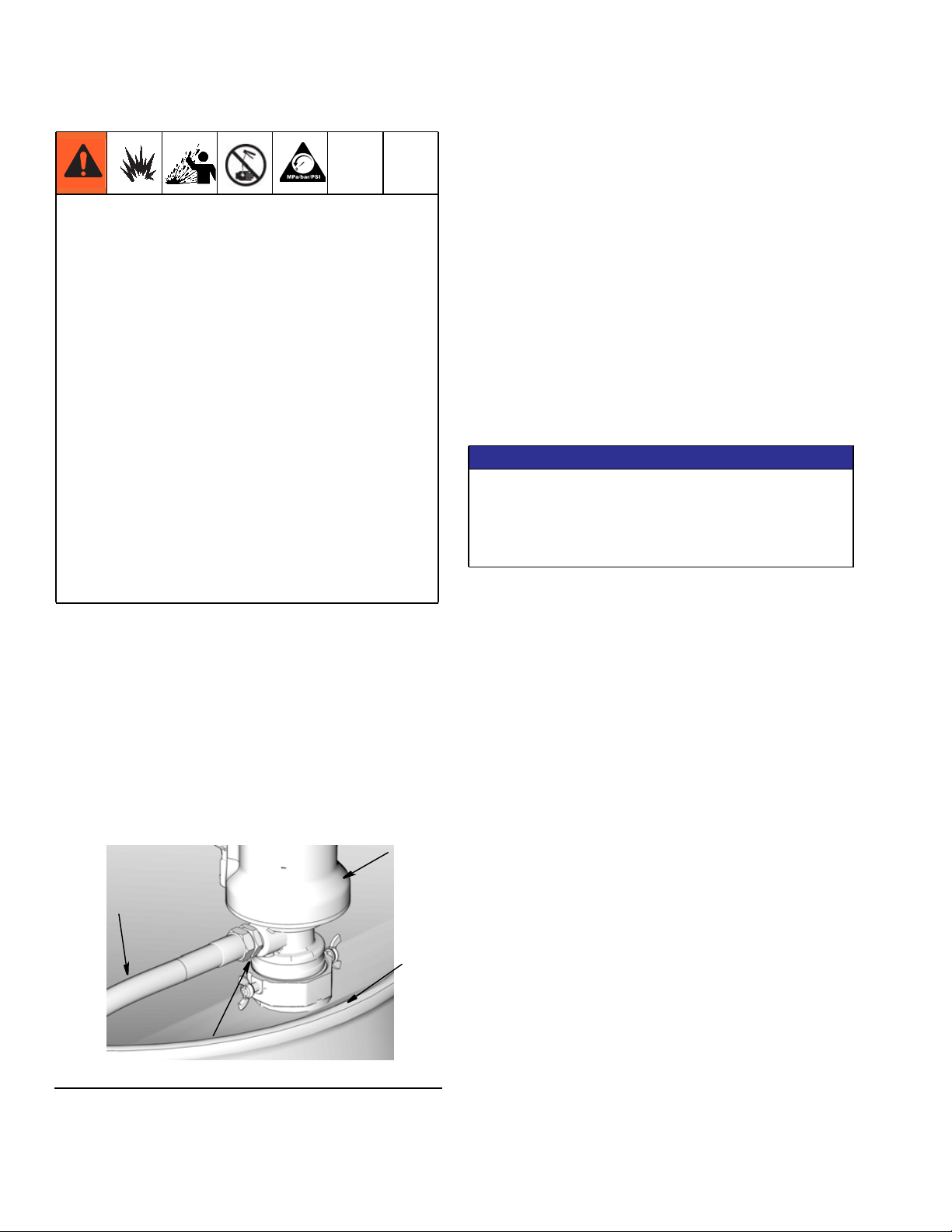

1. Connect the swivel adapter (aa) to the pump fluid

outlet. Tighten securely and torque as recommended below:

The maximum working pressure of each pump in your

system may not be the same. To reduce the risk of

over-pressurizing any part of your system, which may

result in component rupture, fire or explosion and

cause serious bodily injury, be sure you know the

maximum working pressure rating of each pump and

its connected components.

• Never exceed the maximum working pressure of the

lowest rated component connected to a particular

pump.

• Be sure you know the maximum working pressure of

each component.

• Do not exceed the maximum pump cycle rate.

• Regulate air pressure to prevent over pressurization

at fluid section of the pump.

• Regulate air pressure to the pump so that no fluid

line component or accessory is over pressurized.

Stationary Mounting Layout

Plan the layout for easy operator access to the pump air

controls, sufficient room to change drums and a secure

platform.

Pump Mounting

1. Install bung adapter (K) into bung mount/bracket/or

drum cover.

2. Install pump (B) into bung adapter (K).

B

• For NPT models: 1 to 1-1/2 turns past hand

tight.

• For BSPT models: 1-1/2 to 2 turns past hand

tight.

2. Connect fluid hose (A) to the swivel adapter (aa).

3. Connect a suitable dispensing valve or extra hose

to the 6-ft hose.

Air Line and Accessories

NOTE: Install the air line accessories in the order shown

in the Typical Installation on page 6.

NOTICE

Do not hang the air accessories directly on the air

inlet. Mount them on brackets. Always use a flexible

hose between all connections. The air inlet is not

strong enough to support accessories and may

cause one or more to break.

• Use thread sealant on all male threads except

swivel connections.

• Install a pump runaway valve (D) to shut off the air

to the pump if the pump accelerates beyond the

pre-adjusted setting. A pump that runs too fast can

be seriously damaged.

• Install the air regulator (G) to control pump speed

and pressure.

For NPT models order Graco Part No. 24H420 or

for BSP models order Graco Part No. 24H419.

• Install a bleed-type master air valve (F) upstream

from the pump air regulator (G) but within easy

reach of the pump.

A

For NPT models order Graco Part No. 110223 or for

BSP models order Graco Part No. 125272.

• On the main air supply line from the compressor,

K

install an air line filter (H) to remove harmful dirt and

contaminants from the compressor air supply.

Follow Plate - Grease Models Only

aa

FIG. 3

Installing Outlet Hose (FIG. 3)

8 3A1334S

For grease models only a follow plate is required for

pumping fluid from the drum. See page 11 for follow

plate installation instructions.

Page 9

Operation

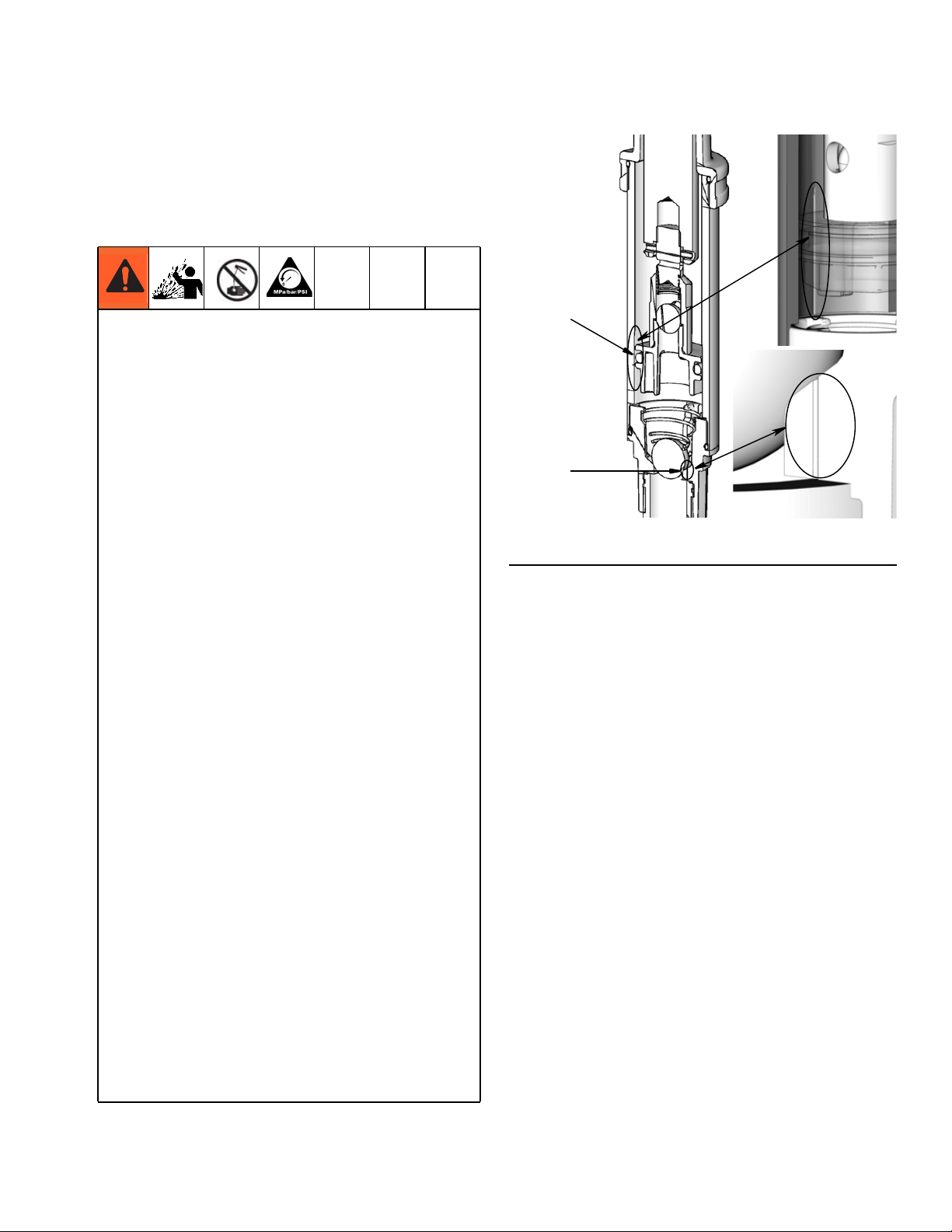

Thermal Induced Pressure Relief (Oil pumps only)

Operation

THERMAL EXPANSION HAZARD

Fluids subjected to heat in confined spaces,

including hoses, can create a rise in pressure due to

the thermal expansion. Over-pressurization can

result in equipment rupture and serious injury.

Oil pumps have a built-in, thermal induced, pressure

relief as shown in FIG. 4. To ensure system pressure

will automatically bleed excess thermal induced

system pressure through the pump and back to the

oil reservoir:

• Always use a relieving air pressure regulator to

allow the pump/motor to run backwards. The regulator bleeds excess air pressure.

• There should not be any obstructions between air

inlet of pump and regulator.

• There should not be any obstructions between the

downstream plumbing and pump outlet such as

closed ball valves or check valves.

• There should not be any obstructions between the

pump inlet and fluid container such as closed ball

valves or check valves.

• Only use Graco designed suction tubes for

in-drum or in-tank applications.

• Only use Graco designed suction tubes with a

built-in relief device for wall mount applications.

• Always use an inlet screen to prevent debris from

plugging relief passages from entering the pump.

- Do not operate the pump with out an inlet

screen.

a

b

FIG. 4 a = Pump cylinder relief passage

b = Inlet check relief passage

Thermal Relief Theory of Operation

The pump operation is similar to most double acting

reciprocating pumps. The pump only comes to a complete stop on the up stroke. The pump will stroke

through on the down stroke due to the inlet check relief

passage.

Excess pressure due to downstream thermal expansion

causes the air motor/pump to run backwards (downward). Fluid pressure is relieved through the inlet check

relief passage as the pump piston moves downward.

Air pressure is simultaneously relieved through the air

inlet passage. The pump piston moves downward

exposing the pump cylinder relief passage at the bottom of the stroke. Additional excess pressure is then

relieved through both the inlet check relief passage and

the pump cylinder relief passage.

Pressure is relieved at the pump through the pump inlet

relief passage. The pump will not change over on the

bottom of the stroke as a result of relieving excess

pressure due to the positioning of the pump cylinder

groove with respect to the air motor pilot valve.

NOTE:

• Periodically inspect the inlet screen for plugging.

Graco recommends inspecting the inlet screen

every time the container is changed out.

3A1334S 9

• The air supply does not have to be turned off to

enable thermal relief activation.

• The Thermal Induced Pressure Relief design feature

of the pump will cause the pump to dive on the

downstroke when a dispensing valve is closed.

Page 10

Operation

Install only one pump per delivery system. Do not use

the pumps in a parallel pump installation.

Loss of pump prime can occur if all the following events

occur in sequence:

1. A thermal relief event occurs.

2. The air supply valve is closed.

3. A dispense valve located at an elevation higher

than the tank level, is open.

To prevent loss of prime, ensure the air supply valve is

turned on before attempting to dispense fluid.

Pressure Relief Procedure

The equipment stays pressurized until pressure is

manually relieved. To reduce the risk of serious injury

from pressurized fluid, fluid from the valve, or splashing fluid, follow this procedure whenever you:

• are instructed to relieve pressure

• stop dispensing

• check, clean, or service any system equipment

• install or clean dispensing devices.

Start-up

Determining Output Pressure Using the Air

Regulator

To determine the fluid output pressure using the air regulator reading, multiply the ratio of the pump by the air

pressure shown on the regulator.

For example a 3:1 ratio oil pump:

3:1 ratio x 100 psi air = 300 psi fluid outlet

A 3:1 pump is capable of 5:1 on the downstroke and

will develop 5:1 pressures under normal operation.

A grease pump has a ratio of 50:1. However it is capable of reaching a stall pressure equal to 60 times the air

input pressure. To calculate the fluid output pressure

using the air regulator reading, multiply the regulator

gauge by 60.

For example:

140 psi air x 60 = 8400 psi fluid output

0.97 MPa air x 60 = 58.2 MPa

99.7 bar x 60 = 582 bar

Regulate air to the pump so that no air line or fluid line

component or accessory is over pressurized.

Priming the pump

1. Close the pump’s bleed-type master air valve.

2. Close the pump air regulator and disconnect the air

supply hose.

3. Open the dispensing valve and dispense fluid into a

waste bucket/container until pressure is fully

relieved.

If you suspect that the dispensing valve is clogged, or

that pressure has not been fully relieved after following

the steps above, very slowly loosen the dispensing

valve coupler or hose end coupling to relieve pressure

gradually, then loosen completely.

1. Close the air regulators and bleed-type master air

valves to all but one pump.

2. Open the master air valve from the compressor.

3. For the pump that is connected, trigger the dispensing valve into a grounded metal waste container making firm, metal-to-metal contact between

the container and the valve.

4. Slowly open the bleed-type master air valve and

open the pump air regulator just until the pump is

running. When the pump is primed and all air has

been pushed out of the lines, release the trigger.

5. If you have more than one pump, repeat this process for each pump in your system.

NOTE: When the pump is primed and has sufficient

air supplied to it, it starts when the dispensing valve

is open and shuts off when closed.

10 3A1334S

Page 11

Operation

Step 6 is for Oil Pumps Only:

6. The thermal relief feature of this oil pump can

increase the amount of time needed to fully prime

the pump when compared to pumps without a thermal relief feature. To minimize this effect, prime the

pump before connecting it to an already primed

distribution system.

NOTICE

Never allow the pump to run dry of the fluid being

pumped. A dry pump will quickly accelerate to a high

speed, possibly damaging itself. If your pump accelerates quickly, or is running too fast, stop it immediately and check the fluid supply. If the supply

container is empty and air has been pumped into the

lines, prime the pump and lines with fluid, or flush it

and leave it filled with a compatible solvent. Be sure

to eliminate all air from the fluid system.

NOTE: A pump runaway valve can be installed on the

air line to automatically shut off the pump if it starts to

run too fast.

7. Read and follow the instructions supplied with each

component in your system.

3. Remove pump and cover from drum and place on a

clean paper, cardboard, or clean shop rags. DO

NOT PLACE ON SHOP FLOOR.

4. If this is an existing installation, reach into drum and

pull on follow plate ring (b) to remove follow plate

(FIG. 6). Place follow plate on a clean paper, cardboard or clean shop rags. DO NOT PLACE ON

SHOP FLOOR.

Remove drum and install new one.

b

8. When shutting off the system and before checking

or servicing, relieve pressure following pressure

relief procedure, page 9.

Changing Grease Drum and Installing

Follow Plate (grease models only)

1. Relieve pressure, page 9.

2. Remove drum cover by loosening thumb screws (a)

(FIG. 5).

a

FIG. 6

5. Examine follow plate to make sure rubber grommet

(c) is in place in center of the plate (FIG. 7).

c

FIG. 7

6. Set follow plate on top of fresh grease (FIG. 8).

Remove air by pushing on the follow plate until the

FIG. 5

3A1334S 11

Page 12

Repair

grease level is flush with the opening in the middle

of the follow plate (d).

d

FIG. 8

7. Insert pump drop tube through center of rubber

grommet in follow plate (FIG. 9).

Se

8. Tighten thumb screws (a) to secure cover to drum.

a

FIG. 10

9. For the pump that is connected, trigger the dispensing valve into a grounded metal waste container making firm, metal-to-metal contact between

the container and the valve.

10. Slowly open the bleed-type master air valve and

open the pump air regulator just until the pump is

running. When the pump is primed and all air has

been pushed out of the lines, release the trigger.

FIG. 9

Repair

Replacing Pilot Valves

Reference letters shown in the following instructions

refer to Typical Installation diagram, page 6. Part numbers refer to the Parts pages beginning on page 14.

1. Stop pump at the middle of its stroke.

2. Relieve pressure, page 10.

3. Disconnect the air line (M).

4. Use a 10 mm socket wrench to remove the old pilot

valve (20).

5. Lubricate o-rings and install the new pilot valve

(20). Torque to 20 - 30 in-lb (2.3 - 3.4 N.m).

12 3A1334S

Page 13

Notes

Notes

3A1334S 13

Page 14

Parts

Parts

3:1 Oil Pump Models: 24G576 - 24G587: 5:1 Oil Pump Models: 24G588 - 24G599

Ref Part No Description Qty

2 116343 SCREW, ground 1

3 SCREW 3

4 SCREW M6 x 22 mm 5

5

✚@

6

✚

7

✚

8

✚

9

✚

10

✚e

11 ★ BALL, steel 1

12 e BALL, steel 1

✓e O-RING, (models 24G576 - 24G578) 1

13

✓e O-RING (models 24G588 - 24G590) 1

14 ✓ O-RING 1

15 ✓★ O-RING 1

16 SCREW 1

17

✚

18

@

19 @ WASHER 1

20 ◆ ✖ VALVE, pilot 2

21

@

22 BEARING, delrin 1

15M182

23

❖ †✺ ◆

15M213 MUFFLER, 3/8 1

24

112933 MUFFLER, quiet (optional) 1

25

✚@

26 COVER, bottom, machining 1

27 @ CYLINDER air, machined 1

28 ★

29 FLANGE, oil, machined 1

30 ROD, displacement 1

31 GUIDE, air 1

32 CYLINDER, fluid 1

33 e PISTON, pump, 3:1, machining 1

34 e HOLDER, ball 1

35 ★ SPRING, compression 1

36 e SPRING, compression 1

37 HOUSING, manifold, machined 1

38 ✺ VALVE, air, small 1

16F541 LABEL, identification, lD 3:1 1

▲

39

O-RING, air piston 1

O-RING 1

O-RING 1

O-RING, 1

SEAL, u-cup 1

PIN, spring 1

O-RING 3

BOLT M8 X 25 1

PISTON, air, plastic 1

SEAL, air valve, manifold (not shown) 1

GASKET, cover, small 2

HOUSING, intake valve, machined

1

Ref Part No Description Qty

16G243◆ LABEL, safety, warning, multiple 1

40 ▲

43 ✺ SCREW, M6 x 25 mm 8

50 24F918 ADAPTER, bung, LD pump 1

51 16G121★ STRAINER 1

16F878

16F948

52‡

16F949

16F886

53‡

16F950

16F951

16F885

54‡

16F962

16F963

55 ✚@

TUBE, PVC, LD pump (models

24G579, 24G591)

TUBE, PVC, LD pump (models

24G580, 24G592)

TUBE, PVC, LD pump (models

24G581, 24G593)

TUBE, metal, LD pump (models

24G582, 24G594)

TUBE, metal, LD pump (models

24G583, 24G595)

TUBE, metal, LD pump (models

24G584, 24G596)

TUBE, metal, LD pump (models

24G585, 24G597)

TUBE, metal, LD pump (models

243G586, 24G598)

TUBE, metal, LD pump (models

24G587, 24G599)

O-Ring

1

1

1

1

1

1

1

1

1

1

▲ Replacement Danger and Warning labels, tags, and

cards are available at no cost.

‡ Packaged separately with universal pump.

Included in kit 24H853. Includes 5,6, 7, 8, 9, 10, 17,

✚

25, 55

Included in kits 24K293 - 3:1; 24H855 - 5:1. Includes

✓

13-15.

Included in kits 24H611 (npt), 24J430 (bspp) 24J431

★

(bspt). Includes 11, 15, 28, 35 and 51.

❖

Included in kit 24H798. Includes 23.

†

Included in kit 24H851. Includes 23.

Included in kit 24H848 (npt), 24H849 (bspp), 24H850

✺

(bspt). Includes 23, 38, and 43.

Included in kit 24J757 (npt), 24J758 (bspp), 24J759

◆

(bspt). Includes 20, 23, and 40.

✖

Included in kit 24H749. Includes 20.

Included in kit 24U230 Series B. Includes 5, 18, 19,

@

21, 25, 27, 55.

Included in kits 25R018-3:1; 25R019-5:1. Includes 10,

e

12, 13, 33, 34, 36

14 3A1334S

Page 15

Kits

Page

20

27

Parts

18

1

18

6

19

21

40

39

5

55

30

3

3

6

10

34

17

31

4

12

26

20

1

7

36

33

13

5

52, 53

or 54,

Page

14

14

22

11

9

8

32

2

4

3

29

35

11

15

28

1

Torque to 20-30 in lbs (2.3 - 3.4 N•m)

2

Torque to 20 - 25 ft lbs (27- 34 N•m)

3

Torque to 60 - 70 in lbs (6.8 - 7.9 N•m)

4

Torque to 25 - 35 in lbs (2.8 - 3.9 N•m)

5

Torque to 110 - 120 in lbs (12.4 - 13.6 N•m)

6

Torque to 155-160 in lbs (17.5 - 18.0 N•m)

11

Lips face down

3A1334S 15

4

2

2

51

50

Page 16

Parts

50:1 Grease Pump Models: 24G600 - 24G608; 24X871

Ref Part No. Description Qty

2 116343 SCREW, ground 1

3 SCREW 3

4 SCREW, M6 X 22 mm 5

5

+❊

6

+

7

+

8

+@❊

9 SCREW 1

10

@

11

+

12

+

13 ❊ GASKET, 32 OD 1

14 COVER, bottom, machining 1

15 ❊ PISTON, air, plastic 1

15M182

16

❖ † ✺◆

15M213 MUFFLER, 3/8 1

17

112933 MUFFLER, quiet (optional) 1

18

+❊

19 ❊ NUT, hex 2

20 ◆ ✖ VALVE, pilot 2

21 ❊ CYLINDER, air, machined 1

22 FLANGE, bottom cover, grease, 1

23 ROD, piston, 50:1 1

O-RING, air piston 1

O-RING (not shown) 1

O-RING 10

PIN, straight, slotted, 2.5x16 3

O-RING 1

SEAL, u-cup 1

O-RING 3

SEAL, air valve, manifold 1

GASKET, cover, small 2

Ref Part No. Description Qty

34 ROD, priming 1

35 PISTON, shovel, 50:1 1

36 CYLINDER, spacer 1

37

+

38 ❊ WASHER, 32 OD 1

39 HOUSING, manifold, machined 1

40 ✺◆ VALVE, air, small 1

41 ▲ 1GH013 LABEL, identification, LD 50:1 1

42 ▲ 16G243 LABEL, safety, warning, multiple 1

43 ✺ SCREW, M6 x 25 mm 8

▲ Replacement Danger and Warning labels, tags, and

cards are available at no cost.

+

Included in kit 24H854

@

Included in kits 24H856

Included in kits 24H611 (npt), 24J430 (bspp) 24J431

★

(bspt)

❖

Included in kit 24H798

†

Included in kit 24H851

Included in kit 24H848 (npt), 24H849 (bspp), 24H850

✺

(bspt)

Included in kit 24J757 (npt), 24J758 (bspp), 24J759

◆

(bspt)

✖

Included in kit 24H749

❊

Included in kit 24U984

NUT, retainer 1

24

@

25 ❊ ROD, displacement, 50:1 1

26 CYLINDER, HP 50:1 1

27 24J380 KIT, cylinder, shovel 1

28

@

29 RETAINER, seal, al 1

30

+@

31 BEARING, throat 1

32 ROD, connection 1

33 GUIDE, air 1

16 3A1334S

SEAL, piston 1

SEAL, intake 1

GASKET 2

Page 17

Kits, page

18

15

Parts

1

Torque to20 - 30 in lbs (2.3 - 3.4 N•m)

3

20

1

42

21

41

30

8

36

Torque to 60 - 70 in lbs (6.8 - 7.9 N•m)

7

Torque to 155 -160 in lbs (17.5-18.0 N•m)

8

Torque to 45 - 55 ft lbs (61 - 75 N•m)

9

Torque to 30 - 40 in lbs (3.4 - 4.5 N•m)

10

Torque to 30 - 35 in lbs (3.4 - 4.0 N•m)

11

Lips face down

30

19

7

13

8

26

5

38

10

37

8

24

11

11

31

23

28

10

29

3

3

25

12

8

8

6

9

33

20

1

7

14

34

35

22

4

3

9

32

2

19

27

7

8

3A1334S 17

Page 18

Parts

Related Oil Pump Kits

Kit No. Description Qty

24H611

24J430

24J431

O-Ring Replacement Kit - 24K293 for 3:1

pumps; 24H855 for 5:1 pumps (F

NOTE: When replacing seals in the pump lower also

service the throat and piston seals. Order repair kit

24H853. Instructions related to this kit are included in

instruction manual 3A1494 (included with the kit).

Ref. Description

13 O-RING 1

14 O-RING 1

15 O-RING 1

KIT, repair, intake valve, npt,

includes 11, 15, 28, 35, 51

KIT, repair, intake valve, bspp,

includes 11, 15, 28, 35, 51

KIT, repair, intake valve, bspt,

includes 11, 15, 28, 35, 51

1

1

1

IG. 11)

Qty

.

Throat and Piston Seal Replacement Kit 24H853 (F

NOTE: When servicing the throat and piston seals, it is

recommended to also replace seals in the pump lower.

Order repair kit: 24K293 for 3:1 pumps or 24H855 for

5:1 pumps. Instructions related to this kits are included

in instruction manual 3A1494 (included with the kit).

Ref. Part No. Description

5 O-RING, air piston 1

6 O-RING 1

7 O-RING 1

8 O-RING, wiper 1

9 SEAL, u-cup 1

17 O-RING 3

25 15R001 GASKET, cover, small 2

55 O-RING (not shown) 1

IG. 12)

Qty

.

7

9

5

FIG. 11

14

15

13

8

25

FIG. 12

17

6

18 3A1334S

Page 19

Parts

Air Piston Replacement Kit - 24U230 (FIG.

13)

NOTE: Instructions related to this kit are included in

instruction manual 3A1494 (included with the kit).

Qty

Ref. Part No. Description

5 O-RING 1

18 BOLT 1

19 WASHER 1

21 AIR PISTON 1

25 15R001 GASKET, cover, small 2

27 AIR CYLINDER 1

55 O-RING 1

101 LABEL, identification 1

102 LABEL, overlay 1

101/102

.

25

Related Grease Pump Kits

Throat and Piston Seal Replacement Kit 24H854 (F

Instructions related to this kit are included in instruction

manual 3A1495 (included with the kit).

Ref. Description

5 O-RING, air piston 1

6 O-RING 1

7 O-RING 1

8 PIN, slotted, straight 3

11 SEAL, u-cup 1

12 O-RING 3

18 GASKET, cover, small 2

30 GASKET 1

37 NUT, retainer 1

IG. 14)

7

Qty

.

18

FIG. 13

27

21

5

55

19

11

6

18

8

12

37

30

5

FIG. 14

3A1334S 19

Page 20

Parts

O-Ring and Seal Replacement Kit - 24H856

IG. 15)

(F

Instructions related to this kit are included in instruction

manual 3A1495 (included with the kit).

Qty

Ref. Description

8 PIN, slotted, straight 3

10 O-RING 1

24 SEAL, piston 1

28 SEAL, intake 1

30 GASKET 2

30

24

8

.

28

Air Piston Replacement Kit - 24U984 (FIG.

16)

NOTE:. Instructions related to this kit are included in

instruction manual 3A1494 (included with the kit).

Qty

Ref. Description

5 O-RING 1

8 PIN, straight, slotted, 2.5 x 16 1

13 GASKET, 32 OD 1

15 PISTON, air, plastic 1

18 GASKET, cover small 2

19 NUT, hex 1

21 CYLINDER, air, machined 1

25 ROD, displacement, 50:1 1

38 WASHER, 32 OD 1

101 LABEL, identification 1

102 OVERLAY, label 1

101/102

21

.

18

FIG. 15

10

FIG. 16

13

38

19

15

5

25

8

20 3A1334S

Page 21

Parts

Oil or Grease Pump Air Valve Repair and Replacement Kits

Instructions related to the following kits are included in

instruction manual 3A1496 (included with the kit).

Replace Seals or Rebuild Air Valve Kits

Air Valve Repair Kit - 24H798, Air Valve Seal Kit 24H851 and Air Valve End Cap - 24H852.

Air Valve Repair Kit - 24H798

Ref.

Oil Grease

23 16 SEAL, air valve, manifold 1

381 381 O-RING, 018 buna 2

382 382 SEAL, u-cup, bevel lip 2

383 383 SCREW, M3, thread forming 2

386 386 PISTON, air valve 1

387 387 ROLLER, assembly, detent 1

388 388 PLATE, air valve 1

389 389 SPRING, detent, small 1

390 390 CUP, air valve, small 1

391 391 CAM, detent, small 1

391

Description

381

1

382

Lips face down

1

2

Lips face up

Qty

.

Air Valve Seal Kit - 24H851

Ref.

Oil Grease

23 16 SEAL, air valve, manifold 1

381 381 O-RING, 018 buna 2

382 382 SEAL, u-cup, bevel lip 2

383 383 SCREW, M3, thread forming 2

381

2

382

381

FIG. 18

Description

382

1

383

23/16

Lips face down

1

Lips face up

2

Air Valve End Cap Kit - 24H852

Ref. Description

381 O-RING, 018 buna 2

384 PLUG, air valve 2

385 RING, snap 2

Qty

.

Qty

.

386

390

387

389

382

2

381

FIG. 17

3A1334S 21

383

23/16

388

381

384

385

FIG. 19

Page 22

Parts

Air Valve Replacement Kit - 24H848 (npt),

24H849 (bspp), 24H850 (bspt) (F

43

23/16

FIG. 20

Ref.

Oil Grease

23 16 SEAL, air valve 1

38 40 VALVE, air, small 1

43 43 SCREW, M6 x 25 4

Description

IG. 20)

38/40

Qty

.

Pilot Valve Replacement Kit - 24H749

This kit only includes the pilot valves (20). If you also

are repairing/replacing the air valve (38/40) and air

valve seal (23/16) order the Air Motor Service Kit 24J757 (npt), 24J758 (bspp) or 24J759 (bspt).

Ref. Description Qty.

20

VALVE, pilot

2

Air Motor Service Kit - 24J757 (npt), 24J758

(bspp), 24J759 (bspt) (F

I

20

23/16

FIG. 21

IG. 21)

38/40

Ref.

Oil Grease

Description

20 20 VALVE, pilot

23 16 SEAL, air valve

40 40 VALVE, air, small

Qty

.

2

1

1

22 3A1334S

Page 23

Troubleshooting

Oil Models

Problem Cause Solution

Troubleshooting

NOTE: Check all other possible problems and solutions

before disassembling the pump. Before you troubleshoot problems using the table below, relieve the

pressure and disconnect the pump fluid line. If the

pump starts when the air is turned on again, the fluid

line, dispensing valve, etc. clogged.

Crack a fitting at the outlet of the

Pump is not fully primed

Oil leakage Check connection and tighten.

pump to allow a slow leak to purge

any air in the pump. Repeat start up

procedure, page 10.

Pump runs but no fluid output

Pump fails to operate or stops

The piston valve is not seating properly or the piston o-ring is damaged

Exhausted fluid supply Refill and reprime.

The pump inlet filter is blocked Clear the filter

The suction tube (hose) has an air

leak

Damaged pilot valve

Damaged main air valve

Inadequate air supply pressure or

restricted air lines.

Closed or clogged dispensing valve

Clogged fluid lines, hose valves, etc. Clear clogs.

Damaged air motor Service air motor.

Exhausted fluid supply Refill and reprime.

Check and replace parts as needed.

Check the connection and tighten as

needed.

Service pilot valve.

Lower air pressure to prevent reoccurrence.

Replace air valve.

Lower air pressure to prevent reoccur an ce.

Increase air supply; clear.

Open valve if closed. Clear clog if

necessary.

Erratic or accelerated operation

Damaged valve gasket

3A1334S 23

Replace valve gasket.

Lower air pressure to prevent reoccurrence.

Page 24

Troubleshooting

Problem Cause Solution

Intermittent air leakage coming from

behind the air manifold. Pump continues to function normally.

Gasket is leaking

Thermal relief inlet check relief passage in inlet housing is plugged

Replace gasket.

Lower air pressure to prevent reoccurrence.

Clear obstruction.

Replace inlet filter.

Continuous air exhaust through

muffler

Pump operates but output is low

Worn or damaged piston o-ring or

valve cup.

Service air motor / valve

Replace valve gasket.

Damaged valve gasket

Lower air pressure to prevent reoccurrence.

Lower compressed air dewpoint.

Ice build-up on the valve plate

allows air leakage past valve u-cup

sealing surface

Increase compressed air temperature.

Decrease air pressure.

Increase ambient room temperature.

Held open or worn intake valve Clear; service.

Held open or worn pump piston

packings

Clear; service.

The muffler is partially blocked Clear muffler.

The inlet filter is partially blocked Clear the filter.

Inadequate air supply pressure or

restricted air lines

Partially closed or clogged pilot

valves

Increase air supply; clear restrictions.

Open valves. Clear clog as necessary.

Partially clogged fluid line, hose,

valves, etc.

Clear clog as necessary.

Oil leakage through air exhausts Throat seal is damaged Replace throat seal (u-cup).

24 3A1334S

Page 25

Grease Models

Troubleshooting

Inadequate air supply pressure or

restricted air lines

Closed or clogged pump valves Open and/or clean.

Pump fails to operate

Continuous air exhaust through muffler

Erratic pump operation

Errataic or accelerated pump speed

Pump operates but output is low

Grease leaking from muffler Worn throat seal Replace.

Clogged fluid line, hose, valve, or

other accessory

Damaged air motor

Exhausted fluid supply Refill and reprime or flush.

Worn or damaged piston o-ring or

valve cup

Ice build up on the valve plate allows

air leakage past valve u-cup sealing

surface

Exhausted fluid supply Refill and reprime or flush.

Worn pump seals Replace.

Damaged shovel tube Replace.

Damaged check seat

Exhausted fluid supply Refill and reprime of flush.

Fluid too heavy for pump priming Use inductor or follow plate.

Damaged valve gasket

Worn piston seal Replace.

Damaged upper check seat Replace pump piston.

Worn fluid intake seal Replace.

Damaged lower check seat Replace shovel rod.

Inadequate air supply pressure or

restricted air lines

Partially closed or clogged pump

valves

Air pockets in the grease inlet Eliminate the air pockets.

Partially clogged fluid line, hose,

valve, or other accessory

Worn seals Replace.

Increase air supply and/or clear

restriction.

Relieve pressure.

Clear obstruction.

Assess damage, and service air

motor.

Assess wear or damage, and service

air motor.

Lower compressed air dewpoint.

Increase compressed air temperature.

Decease air pressure.

Increase ambient room temp.

Replace pump piston or shovel rod

(or other damaged part).

Replace valve gasket.

Lower air pressure to prevent reoccurrence.

Increase air supply and/or clear

restriction.

Open and/or clean.

Relieve pressure.

Clear obstruction.

3A1334S 25

Page 26

Technical Data

Technical Data

3:1 or 5:1 Oil Models

US Metric

Fluid pressure ratio 3:1 or 5:1

Air pressure operating range 20 to 150 psi 1.37 to 10.3 bar, 0.137 to 1.03

MPa

Maximum fluid working pressure 3:1 - 450 psi

5:1 - 750 psi

Cycles per gallon (liter) 3:1 - 29 cycles per gallon

5:1 - 37 cycles per gallon

Maximum recommended pump speed 3:1 - 120 cycles per minute

5:1 - 180 cycles per minute

Air consumption (at 100 psi) See performance curves, page 28

Wetted Parts zinc plated carbon, steel, aluminum , nitrile, polyurethane, nickel

plated aluminum

Approximate weight 3:1 - 7 pounds

5:1 - 7.7 pounds

Recommended air pressure for optimum

pump life

Recommended speed for optimum pump life 75 cycles per minute and lower

Performance curve See charts page 28

Dimensions See page 30

<125 psi <8.6 bar, 0.86 MPa

3:1 - 2.6 gallons per minute

5:1 - 2 gallons per minute

3:1 - 31.0 bar, 3.10 MPa

5:1 - 51.7 bar, 5.17 MPa

3:1 - 7 cycles per liter

5:1 - 10 cycles per liter

3:1 - 3.2 kg

5:1 - 3.5 kg

3:1 - 9.8 liters per minute

5:1 - 7.6 liters per minute

Sound Level

Sound Pressure Level†* 72.9 dB(A)

Sound Power Level‡* 82.0 dB(A)

† Calculated at a distance of 1 meter from measurements taken per ISO 9614-2 @ 100 psi air pressure (6.89 bar,

0.68 MPa) and 20 cycles per minutes.

‡ Measured per ISO 9614-2 at 100 psi air pressure (6.89 bar, 0.68 MPa) and 20 cycles per minute.

* Muffler 112933 can be ordered separately for reduced sound levels.

California Proposition 65

CALIFORNIA RESIDENTS

WARNING: Cancer and reproductive harm – www.P65warnings.ca.gov.

26 3A1334S

Page 27

Dimensions

Technical Data

Model

Universal Pump

Only

L

inches (mm)

(Overall Length)

6.9 (175) 16 (406)

Multi* 42.4 (1076) 51.5 (1307)

Drum 35.7 (907) 44.8 (1138)

Tote 42.8 (1087) 51.9 (1318)

Universal Pump

O

d

e

c

L

O

inches (mm)

a

*Multi down tube

is angle cut to the

desired length as

required

3/8” (10 mm)

minimum

Multi/Drum/Tote

a

d

e

c

b

O

a = 1/4 inch air inlet

b = 1 inch fluid inlet

L

c = 2 inch npt bung adapter

d = ground screw

e = 1/2 inch fluid outlet - opposite of d

b

3A1334S 27

Page 28

Technical Data

Performance Curve

3:1 Oil Models

3:1 Performance Curve

Tested with ISO 46 Hyd Oil

EDU

)OXLG3UHVXUHSVL

5:1 Oil Models

400

(27.6)

300

(20.7)

200

(13.8)

100

(6.9)

0

&\FOHVSHUPLQXWH

58 116 174 232

$

$

%

&

5HFRPPHQGHG2SHUDWLQJ5DQJH

0 1

(3.8) 2(7.6) 3(11.4) 4(15.1) 5(18.9) 6(22.7) 7(26.5) 8(30.3) 9(34.1)

600

(41.4)

500

(34.5)

$

400

EDU

(27.6)

)OXLG3UHVXUHSVL

300

%

(20.7)

200

(13.8)

&

100

(6.9)

0

0 1

&

)OXLG)ORZJSP

OSP

5:1 Performance Curve

Tested with ISO 46 Hyd Oil

74 148 222

5HFRPPHQGHG2SHUDWLQJ5DQJH

(3.84)2(7.6) 3(11.4) 4(15.1) 5(18.9) 6(26.5)

%

&\FOHVSHUPLQXWH

&

)OXLG)ORZJSP

%

OSP

$

7

(26.5)

40

(1.1)

30

(.8)

20

(.6)

10

(.3)

0

PPLQ

$LU)ORZVFIP

,QOHW$LU3UHVVXUHV

40

(1.1)

30

(.8)

PPLQ

20

$LU)ORZVFIP

(.6)

10

(.3)

0

,QOHW$LU3UHVVXUHV

SVL

$

EDU

SVL

%

EDU

SVL

&

EDU

SVL

$

EDU

SVL

%

EDU

SVL

&

EDU

28 3A1334S

Page 29

Technical Data

50:1 Grease Models

50:1 Grease Models

US Metric

Fluid pressure ratio 50:1

Air pressure operating range 20 to 150 psi 1.37 to 10.3 bar; 0.137 to 1.03 MPa

Maximum fluid working pressure 7500 psi 517 bar, 51.7 MPa

Pump cycles per pound (cycles per kg) 47 cycles per pound 103 cycles per kg

Maximum recommended pump speed 120 cycles per minute

Air consumption (at 100 psi) See Performance Curve, See below

Wetted Parts Steel, brass, nitrile rubber, polyurethane, UHMWPE, acetal

Approximate weight 35 pound drum - 11.2 pounds

120 pound drum - 15.0 pounds

400 pound drum - 17.0 pounds

Recommended speed for optimum pump life 60 cycles per minute or lower flow

rate

1.3 pounds per minute

Performance curve See chart below

Dimensions See illustration page 30

35 pound drum - 5.1 kg

120 pound drum - 6.8 kg

400 pound drum - 7.7 kg

0.6 kg per minute

Sound Level

Sound Pressure Level†* 72.9 dB(A)

Sound Power Level‡* 82.0 dB(A)

† Calculated at a distance of 1 meter from measurements taken per ISO 9614-2 @ 100 psi air pressure (6.89 bar, 0.68 MPa) and 20

cycles per minutes.

‡ Measured per ISO 9614-2 at 100 psi air pressure (6.89 bar, 0.68 MPa) and 20 cycles per minute.

* Muffler 112933 can be ordered separately for reduced sound levels.

Performance Curve

Grease Models

50:1 Performance Curve

8000

(551.6)

7000

(482.6)

6000

(413.7)

5000

(344.7)

4000

EDU

(275.8)

3000

)OXLG3UHVXUHSVL

(206.8)

2000

(137.9)

1000

(68.9)

0

0.00 0.50

&

%

Tested with ISO 46 Hyd Oil

47 94 141

&\FOHVSHUPLQXWH

$

5HFRPPHQGHG2SHUDWLQJ5DQJH

1.00

1.50

2.00

(.23)

(.45)

(.68)

)OXLG)ORZOEVP

(.91)

NJP

2.50

(1.13)

3.00

(1.36)

$

%

&

3.50

(1.59)

4.00

(1.81)

,QOHW$LU3UHVVXUHV

50

(1.4)

40

(1.1)

30

(.8)

PPLQ

$LU)ORZVFIP

20

(.6)

10

(.3)

0

$

%

&

SVL

EDU

SVL

EDU

SVL

EDU

3A1334S 29

Page 30

Technical Data

Dimensions

a = 1/4 inch air inlet

b = 1/4 inch fluid outlet

c = 2 inch npt mounting configuration

d = ground screw

a

b

14.5 in.

370 mm

35 pound drum

23.6 in.

600 mm

d

c

a

d

c

b

37.2 in.

945 mm

28.1 in.

715 mm

120 pound drum

a

b

36.0 in.

915 mm

d

c

45.0 in.

1145 mm

400 pound drum

30 3A1334S

Page 31

Notes

Notes

3A1334S 31

Page 32

Graco 5-Year Pump Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period from the date of sale as defined in the table below, repair or replace equipment covered by this

warranty and determined by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in

accordance with Graco’s written recommendations.

Graco 5-Year Pump Extended Warranty

Components Warranty Period

Structural Components

Wear Parts - including but not limited to o-rings, packings and seal

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification

of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be

returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or

workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental

or consequential loss) shall be available. Any action for breach of warranty must be brought within one (1) year past the warranty period, or two

(2) years for all other parts.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder,

or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered

into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu

que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés,

à la suite de ou en rapport, directement ou indirectement, avec les procédures concernées.

5 years

1 year

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2011, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 3A1334

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised March, 2021

Loading...

Loading...