Page 1

Instructions/Parts

16G351 Electric Power

3A1324B

Conversion Kit

Converts ProMix 2KE Electronic Proportioners from an intrinsically safe air-powered

alternator power supply to a non-intrinsically safe electric power supply.

For professional use only.

Not approved for use in European explosive atmosphere locations.

Important Safety Instructions

Read all warnings and instructions in this

manual and your separate ProMix 2KE

manuals. Save these instructions.

Converting the ProMix 2KE proportioner from an

air-powered alternator power supply to an electric

power supply voids the intrinsically safe rating of the

equipment.

EN

Kit Parts

Ref. Part Description Qty.

401 15V747 POWER SUPPLY, 24 VDC, 2.5 A,

60 watt, B-code

402 116320 SWITCH, rocker, power 1

403 115306 FILTER, power line 1

404 114095 BLOCK, terminal 1

405 112144 SCREW, machine, pan head 4

406 109467 SCREW, machine, pan head 2

407 103833 SCREW, machine 2

408 100139 PLUG, pipe 1

410 16H077 HARNESS, 2-wire; 8 in. (203 mm) 1

411 16H078 HARNESS, 3-wire; 4 in. (102 mm) 1

413 15V206 CABLE, CAN; 10 ft (3 m) 1

1

Page 2

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual, refer back to these Warnings. Product-specific hazard symbols and

warnings not covered in this section may appear throughout the body of this manual where applicable.

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes are

present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment until

you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric

shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

2 3A1324B

Page 3

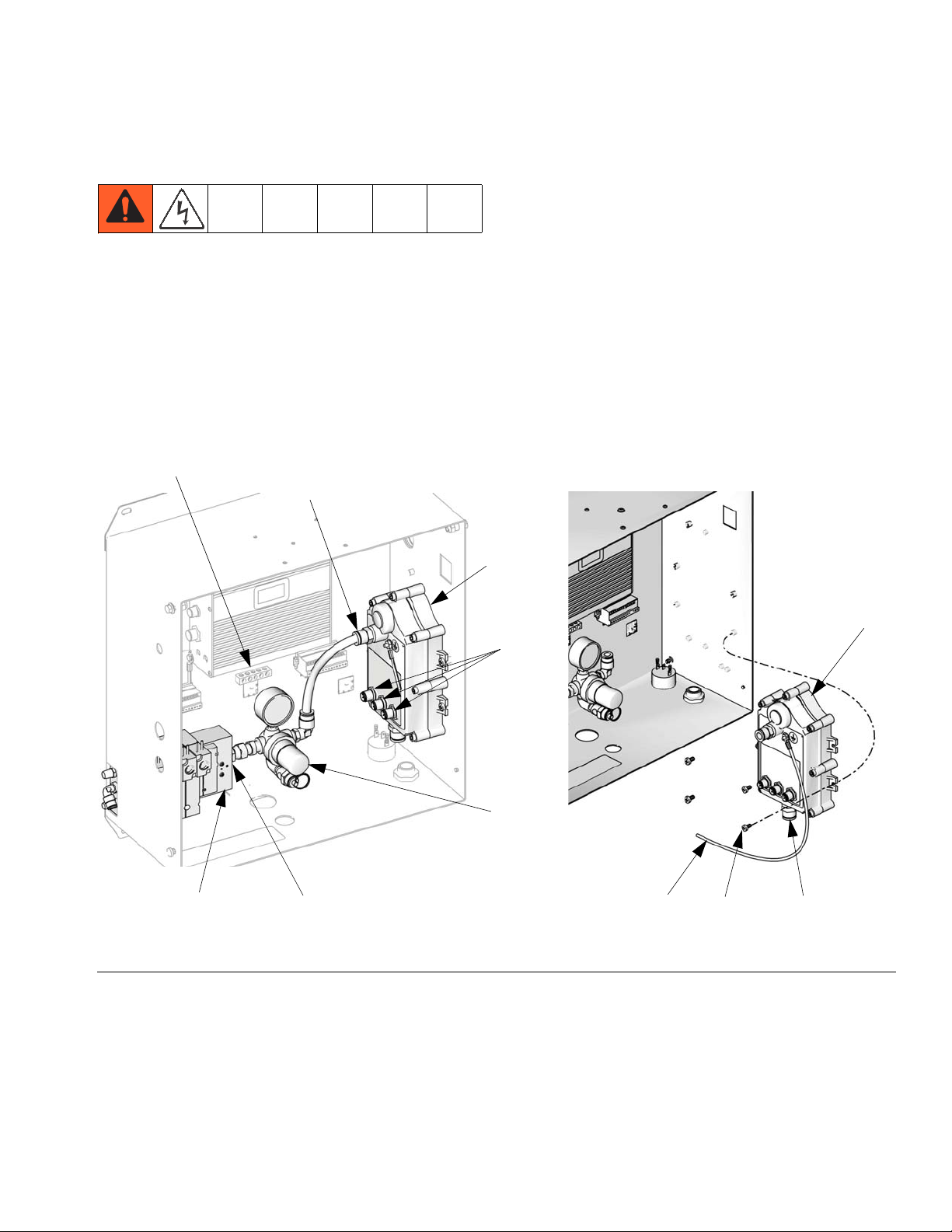

Remove the Alternator

Remove the Alternator

4. Systems with a USB Module: Disconnect and

save the cable (412) that runs from the AFCM to the

alternator.

1. Shut off the system’s main air valve. Open the control box.

2. See F

3. Disconnect the power supply cables from the

IG. 1. Disconnect output power cable connec-

tions from alternator module (A). Disconnect ground

lead (G) from control box ground terminal (T).

Advanced Fluid Control Module (AFCM),

USB Module, and Display Module.

T

Air regulator

line

5. Disconnect air regulator line and exhaust air line

from alternator module. Remove air regulator

assembly (R) from solenoid manifold (M). Install

plug (408) from kit in the open manifold port.

6. Remove four screws (S) from mounting to remove

alternator from control box.

A

Cable

connectors

A

R

ti16456a

M

FIG. 1. Remove Alternator Module

3A1324B 3

Install plug (408)

in open port

GS

ti16455a

Air exhaust

line

Page 4

Install the Kit

Install the Kit

Component Installation

1. Shut off electrical power at the main panel.

2. See F

IG. 2. Remove the square knockout in the side

of the control box. Install the power switch (402).

3. Install the power supply (401), line filter (403), and

terminal block (404), using supplied screws (405,

407, 406), as shown.

4. See F

IG. 2. Connect wire harness (410/LF) to the

line filter (403) and switch (402), as shown. See also

F

IG. 6, Electrical Schematic.

2: PS(L)

2A: LF(L)

FCM

5. Connect the power supply wire harness (PS) to the

switch (402), as shown. See also F

IG. 6, Electrical

Schematic. Connect the PS ground wire to the

ground terminal (T) of the control box.

6. See F

IG. 5. Connect wire harness (411) to the line

filter (403) and terminal block (404), as shown. See

also F

IG. 6, Electrical Schematic.

402

1: PS(N)

1A: LF(N)

T

PS(GND)

FIG. 2. Install Power Supply Kit

405

401

PS(L)

407

406

PS(N)

LF(L)

LF(N)

C

410

403

411 (see F

404

IG. 5)

ti16454b

4 3A1324B

Page 5

Install the Power CAN Cables

Install the Kit

Systems with a USB Module

1. See FIG. 3. Connect cable (413) to J6 of the display

module and to connector P3 of the USB module.

2. Connect saved cable (412) to connector P4 of the

USB module and to J8 of the Advanced Fluid Control Module.

3. Connect the power supply CAN cable (C, F

J7 on the Advanced Fluid Control Module (F

4. See your ProMix 2KE Operation manual for instructions on using the USB module.

USB Module (if present)

P4

Connect cable

(412) here

P3

Connect cable

(413) here

TI16580a

IG. 2) to

IG. 3).

Systems without a USB Module

1. See FIG. 4. Connect cable (413) to J6 of the display

module and to J8 of the Advanced Fluid Control

Module.

2. Connect the power supply CAN cable (C, F

J7 on the Advanced Fluid Control Module (F

Display Module

IG. 2) to

IG. 4).

TI16604a

J6

Connect cable (413) here

Advanced Fluid Control Module

J8

Connect

cable

(412) here

Display Module

TI16604a

J6

Connect cable (413) here

Advanced Fluid Control Module

J7

Connect

cable (C)

here

J8

Connect

cable

(413) here

TI16579a

FIG. 4. Install Power CAN Cables (without USB

Module)

TI16602a

J7

Connect

cable (C)

here

TI16579a

FIG. 3. Install Power CAN Cables (with USB Module)

3A1324B 5

TI16602a

Page 6

Install the Kit

Power Connection

All electrical wiring must be completed by a qualified

electrician and comply with all local codes and

regulations.

Enclose all cables routed in the spray booth and high

traffic areas in conduit to prevent damage from paint,

solvent, and traffic.

The ProMix 2KE operates with 85-250 VAC, 50/60 Hz

input power, with a maximum of 2 amp current draw.

The power supply circuit must be protected with a 15

amp maximum circuit breaker.

Not included with kit:

• Power supply cord compatible to your local power

configuration. Wire gauge size must be 8-14 AWG.

• The input power access port is 22.4 mm (0.88 in.) in

diameter. It accepts a bulkhead strain relief fitting or

conduit.

1. Verify that electrical power at the main panel is shut

off.

2. Connect electrical cord to the terminal block (404)

as shown in F

IG. 5.

3. Close the Control Box. Restore power.

4. Follow instructions in Grounding in your ProMix

2KE Operation Manual.

5. See your ProMix 2KE Operation manual for operating instructions.

Line

Neutral

FIG. 5. Terminal Block Electrical Connections

TERMINAL

BLOCK

L N GRND

WIRE

HARNESS

(411)

L N GRND

LINE POWER

FILTER

L N

WIRE

HARNESS

(410)

2A

SWITCH

ROCKER

2

Ground

1A

1

POWER

SUPPLY

411

404

ti16391a

POWER SUPPLY

WIRE HARNESS

GRND

FIG. 6. Electrical Schematic

6 3A1324B

Page 7

Install the Kit

3A1324B 7

Page 8

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2010, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 3A1324

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised 08/2011

Loading...

Loading...