Page 1

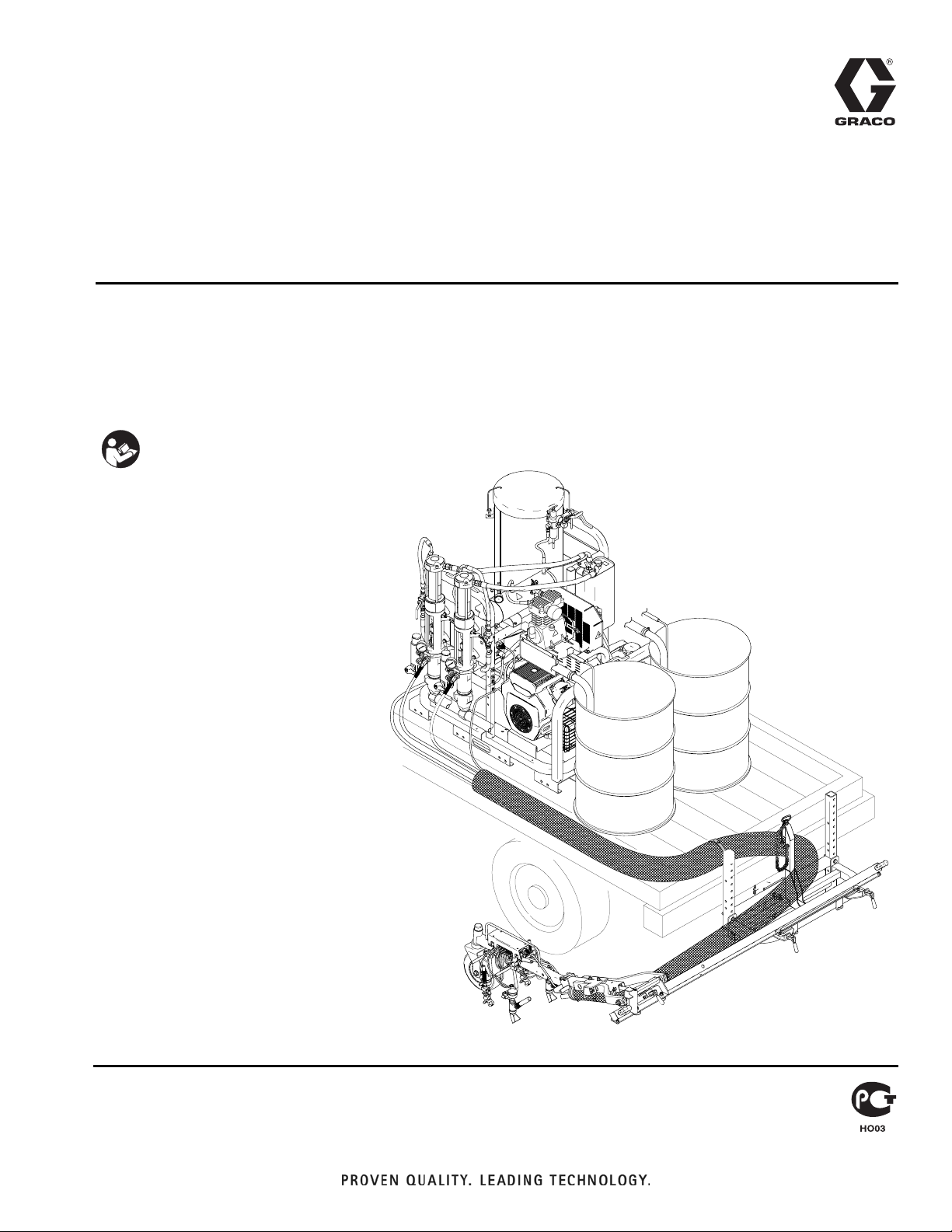

Operation

RoadLazer™ RoadPak™

Line Striping System

- For the Application of Road Marking and Reflective Coatings -

- For Professional Use Only -

List of Models (see page 2)

2900 psi (20 MPa, 200 bar) Maximum Working Pressure

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

3A1214B

ENG

ti15835a

Page 2

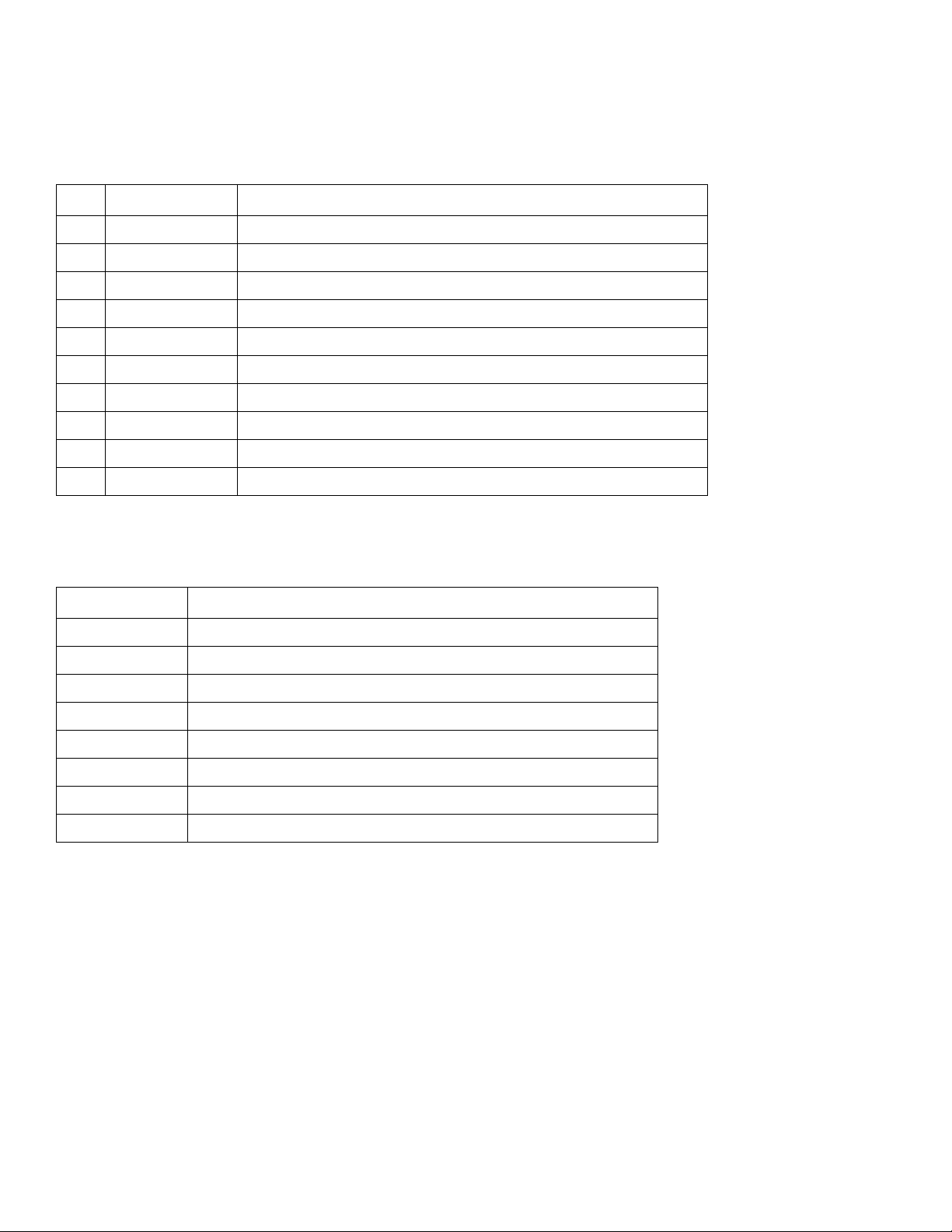

Models

Models

Ref. Model Number Description

1 24G624 1 Pump RoadPak

2 24G625 2 Pump RoadPak

3 24G626 Single Hitch Mounting Frame

4 24G627 RoadPak Slide in Mounting Frame

5 24G628 1 Pump RoadPak Gun Arm

6 24G629 2 Pump RoadPak Gun Arm

7 24G630 Gun Arm Beam

8 24G632 RoadLazer/RoadPak Control

9 24G633 Road View Camera System

10 24G634 RoadPak Pointer System

Complete Assemblies

Part Number Description

24G677 RoadPak System Option 1 (1, 3, 5, 7, 8, 10)

24G679 RoadPak System Option 2 (1, 3, 5, 7, 8, 9, 10)

24G681 RoadPak System Option 3 (1, 4, 5, 7, 8, 10)

24G683 RoadPak System Option 4 (1, 4, 5, 7, 8, 9, 10)

24G685 RoadPak System Option 5 (2, 3, 6, 7, 8, 10)

24G687 RoadPak System Option 6 (2, 3, 6, 7, 8, 9, 10)

24G689 RoadPak System Option 7 (2, 4, 6, 7, 8, 10)

24G691 RoadPak System Option 8 (2, 4, 6, 7, 8, 9, 10)

2 3A1214B

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual, refer back to these Warnings. Product-specific hazard symbols and

warnings not covered in this section may appear throughout the body of this manual where applicable.

WARNING

WARNINGWARNINGWARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire

and explosion:

• Use equipment only in well ventilated area.

• Do not fill fuel tank while engine is running or hot; shut off engine and let it cool. Fuel is flammable and can

ignite or explode if spilled on hot surface.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop cloths

(potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes are

present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment until you

identify and correct the problem.

• Keep a working fire extinguisher in the work area.

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This may look

like just a cut, but it is a serious injury that can result in amputation. Get immediate SURGICAL TREATMENT.

• Keep clear of fluid outlet and leaks.

+

• Use guns, hoses and other components with pressure ratings equal to or higher than the pump rating.

• Follow the Pressure Relief Procedure before servicing or cleaning.

• Do not point dispensing device at anyone or at any part of the body.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment, follow

the Pressure Relief Procedure and disconnect all power sources.

3A1214B 3

Page 4

Warnings

WARNING

WARNINGWARNINGWARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system component.

See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about your

material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure. Turn off all equipment and

follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s

replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

CARBON MONOXIDE HAZARD

Exhaust contains poisonous carbon monoxide, which is colorless and odorless. Breathing carbon monoxide

can cause death.

• Do not operate in an enclosed area.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe burns:

• Do not touch hot fluid or equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area of

the equipment to help protect you from serious injury, including eye injury, hearing loss, inhalation of toxic

fumes, and burns. This equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

4 3A1214B

Page 5

Introduction and General Information

Introduction and General Information

Introduction

This manual and those listed below provide pre-setup

requirements, parts lists, setup, operation, and maintenance instructions for the RoadLazer system. This manual includes instructions for a 2-pump system. For

1-pump systems, all parts remain the same with the

exception of plugged ports for missing pumps and

hoses.

General Information

The RoadLazer is mounted to a vehicle and is used to

stripe up to two stripes in one or two colors with glass

beading.

The RoadLazer consists of a Programmable Skipline

Controller, Displacement Pumps, two Paint Spray Guns,

and two Bead Spray Guns.

Programmable Skipline Controller

The Programmable Skipline Controller consists of the

control box and a 30 ft cable. It is the main control for the

RoadLazer system and turns the spray guns and accessories on and off.

Front Guidance System

The Front Mechanical Guidance System provides the

user with a pointer for alignment on either the left or right

side of the vehicle.

Video Guidance System™ (optional)

The Video Guidance System provides the user with

video of a bore sight view for alignment on either the left

or right side of the tow vehicle. The system consists of a

9 in. monitor, interfacing cables, video camera and

mounting bracket.

RPS 2900 Hydraulic Pumps

The RPS 2900 Hydraulic Pump supplies paint to the

spray guns. There are two displacement pumps. Two

displacement pumps allows the user to have a two-color

system.

Paint Spray Guns

The Paint Spray Guns are pneumatically triggered to

spray paint stripes when commanded by the Programmable Skipline Controller.

Bead Spray Guns

The Bead Spray Guns are pneumatically triggered to

spray reflective materials when commanded by the Programmable Skipline Controller.

3A1214B 5

Page 6

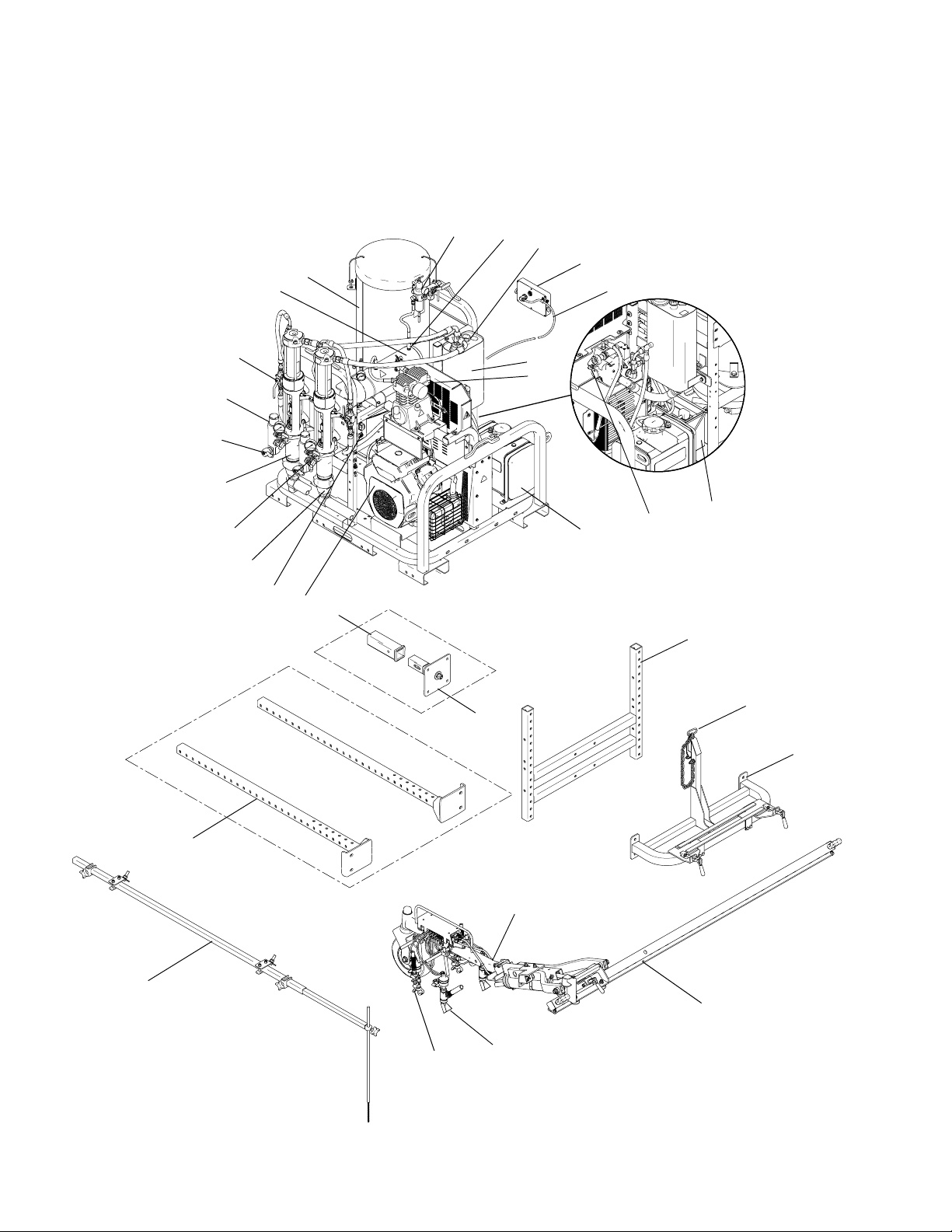

Component Identification

Component Identification

A

B

C

D

E

F

G

H

J

K

L

M

Y

X

W

T

S

R

N

P

Q

AA

AJ

AH

AG

Z

AB

AC

AE

ti15836a

AD

AF

6 3A1214B

Page 7

Component Function

Air Regulator Allows regulation of the bead tank air pressure

A

Bead Tank

B

Air Accumulator Tank Helps reduce air temperature from compressor

C

Hydraulic Valve Valve to shut off/on the hydraulic fluid to the hydraulic motor

D

Fluid Filter Filters fluid between the fluid source and the spray gun

E

Pressure Drain Valve Relieves Fluid Pressure when open

F

RPS 2900 Hydraulic Pump Provides fluid to be sprayed through the spray gun

G

Fluid Outlet Supplies fluid from the displacement pump to the spray gun

H

Fluid Inlet Displacement Pump entry for fluid from the paint drums (paint drums not shown)

J

Electrical Junction Box Allows the user access to electrical system

K

18 HP Engine Powers the hydraulic pump and the air compressor

L

2 in. Hitch Receiver (not provided) Needed to hook-up the gun arm to the back of a truck

M

Fuel Tank Holds 6 gallons (23 liters) of gasoline

N

Hydraulic Pressure Control Knob Provides adjustment of hydraulic pressure (clockwise increases pressure)

P

Battery Provides power to start the Engine and Control Box

Q

Compressor Provides an air supply for the solenoids and pressurizes the bead tanks

R

Hydraulic Reservoir Holds 4 gallons (15.1 liters) of hydraulic oil for the hydraulic pump

S

I/O Cable Carries electronic control signals from the Controller to the RoadLazer

T

Programmable Skipline Controller Allows the user to program the operation of the RoadLazer

W

Breather Cap Provides a means for hydraulic reservoir ventilation, oil check, and fill

X

Air Pressure Quick Release Allows the user to use pressurized air

Y

Hitch Insert Allows the user to connect the gun arm to a single hitch vehicle

Z

Mounting Bracket Allows the user to connect the gun arm mount to the optimum height

AA

Stow Bracket Pin Secures the spray gun boom arm when the RoadLazer is in transport mode

AB

Gun Arm Mount Supports the main beam and the gun arm

AC

Slide Beam Supports the spray gun boom arm

AD

Spray Gun Boom Arm Allows striping on either side of the vehicle at adjustable distances

AE

Bead Spray Gun Sprays beads when commanded by the Controller

AF

Paint Spray Gun Sprays fluid when controller by the Controller

AG

Slide in Mounting Frame Allows user to connect the gun arm to the RoadPak frame

AH

RoadPak Pointer System Allows the user an alignment tool

AJ

Holds up to 36 gallons of reflective materials or element for single or double drop

beading

Component Function

3A1214B 7

Page 8

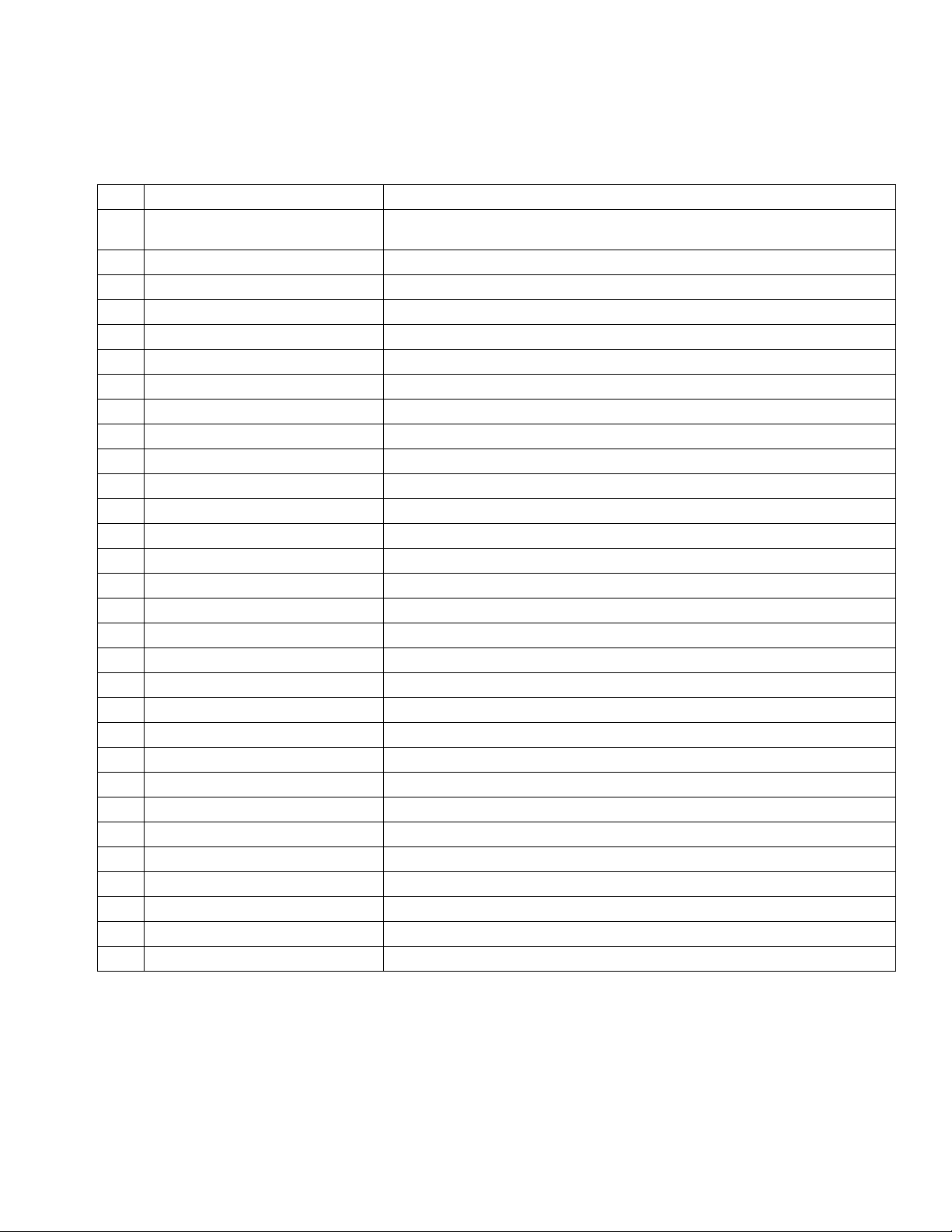

Setup

Setup

Charge Battery

If the battery is newly purchased or has not been used

for a long time, charge it before you use it.

Installing RoadLazer Into Vehicle

RoadLazer needs to be properly secured to prevent it

from moving during transportation and operation.

Paint drums are heavy and could shift from side to side

when the vehicle is cornering. The paint drums could

fall from the vehicle and cause injury or death. Secure

the drums when the vehicle is in transport or spraying.

Paint could splash from the paint drum bung adapters

when the paint drums are full and the vehicle is moving. Do not overfill the paint drums.

The RoadPak can be mounted in the front or rear of the

vehicle bed as well as in any orientation desired. The

base of the RoadPak is 39.5 in. x 49.5 in. (1.0m x

1.25m).

ti16653a

ti16654a

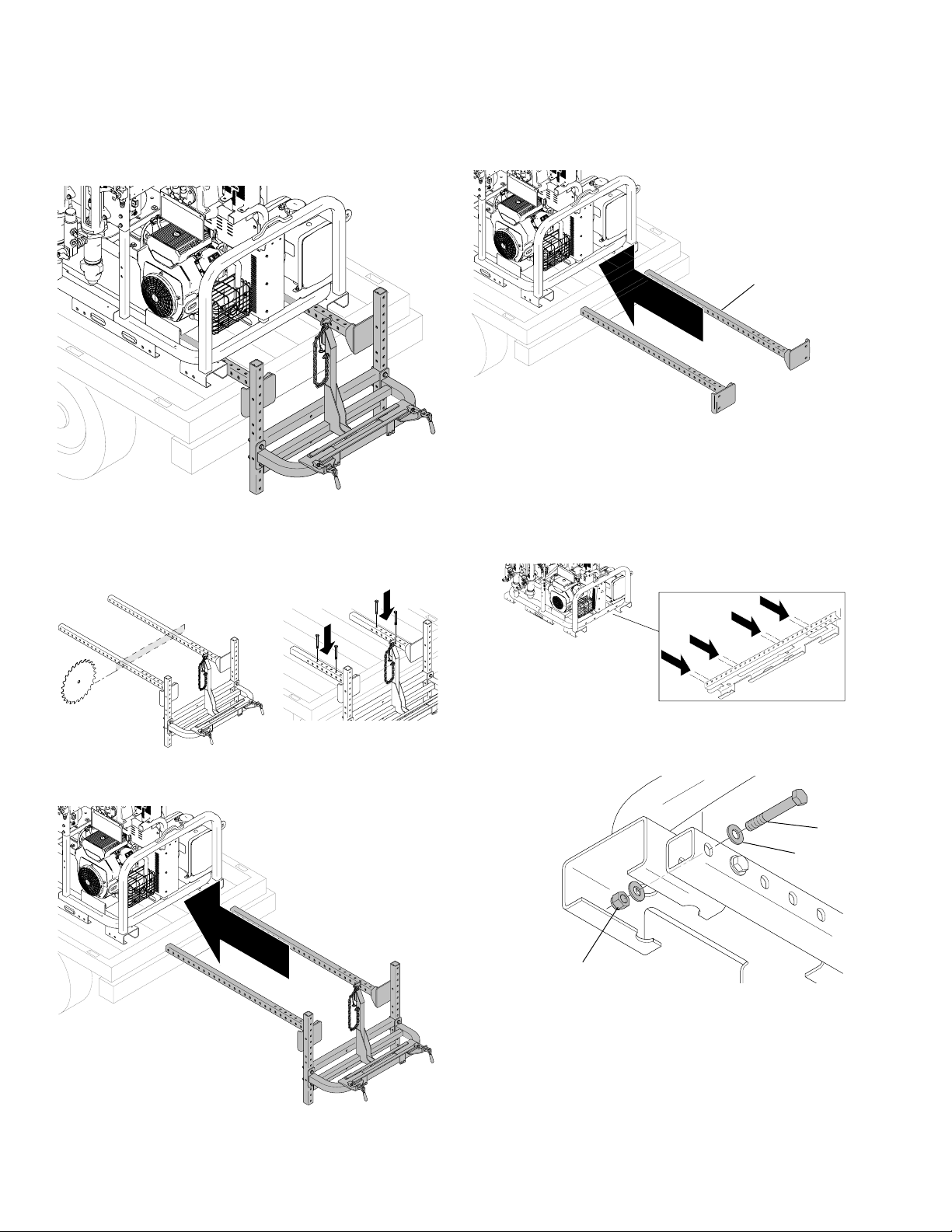

RoadPak Installation (24G624, 24G625)

Load RoadPak into vehicle using a forklift or a hoist that

is rated for the weight capacity of the RoadPak. For

RoadPak weight information see Technical Data, page

27.

ti16442a

ti16664a

After mounting the RoadPak on the vehicle, firmly

secure the RoadPak to the vehicle using the tie-down

brackets at all four corners, or by bolting the RoadPak

through the bed of the truck to the frame in all four locations.

ti16443a

ti16665a

ti16599a

8 3A1214B

Page 9

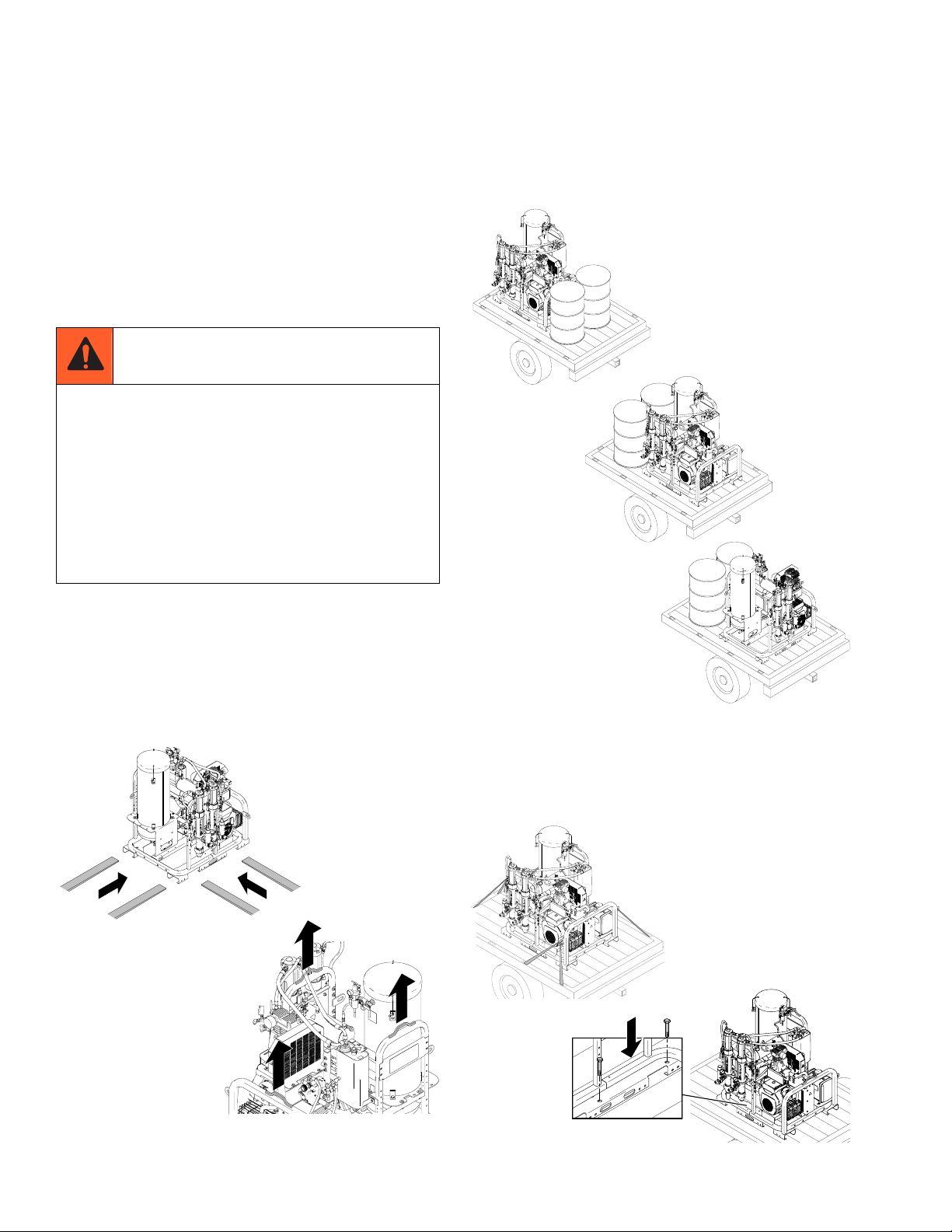

Setup

Filter Orientation

After mounting and securing the RoadPak to the vehicle,

position the filter assemblies as desired.

1. Use a hammer to loosen the large jam nut on the

pump assembly.

ti16782a

2. Rotate the filter assembly to the desired orientation

and use a hammer to tighten the jam nut and lock

the assembly into place.

ti16783a

ti16784a

2. Tighten nut until the hitch insert bracket is pulled

securely to the receiver and no play is seen

between the two parts.

ti16785a

3. Install the height adjustment bracket (303) to the

hitch insert bracket with bolts (312), washers (307),

and nuts (315). Ensure the height adjustment

bracket is installed level.

315

307

307

312

303

ti15956a

Gun Arm Bracket Mount

Single Hitch Mounting Bracket (24G626)

Installation (Option 1)

ti15839a

1. Install hitch insert bracket (A) into receiver (C).

Ensure hitch pin (B) goes through tightening rod

hole (D).

ti16648a

AC

D

4. Install stow bracket (302) to height adjustment

bracket (303) with bolts (312), washers (307), and

nuts (315). Locate the bottom of the stow-bracket

21-in. to 25-in. (53cm - 63cm) from the ground.

Ensure the stow-bracket is installed level.

315

307

312

302

302

21 in. - 25 in.

(53 cm - 63 cm)

B

3A1214B 9

ti15955a

ti15957a

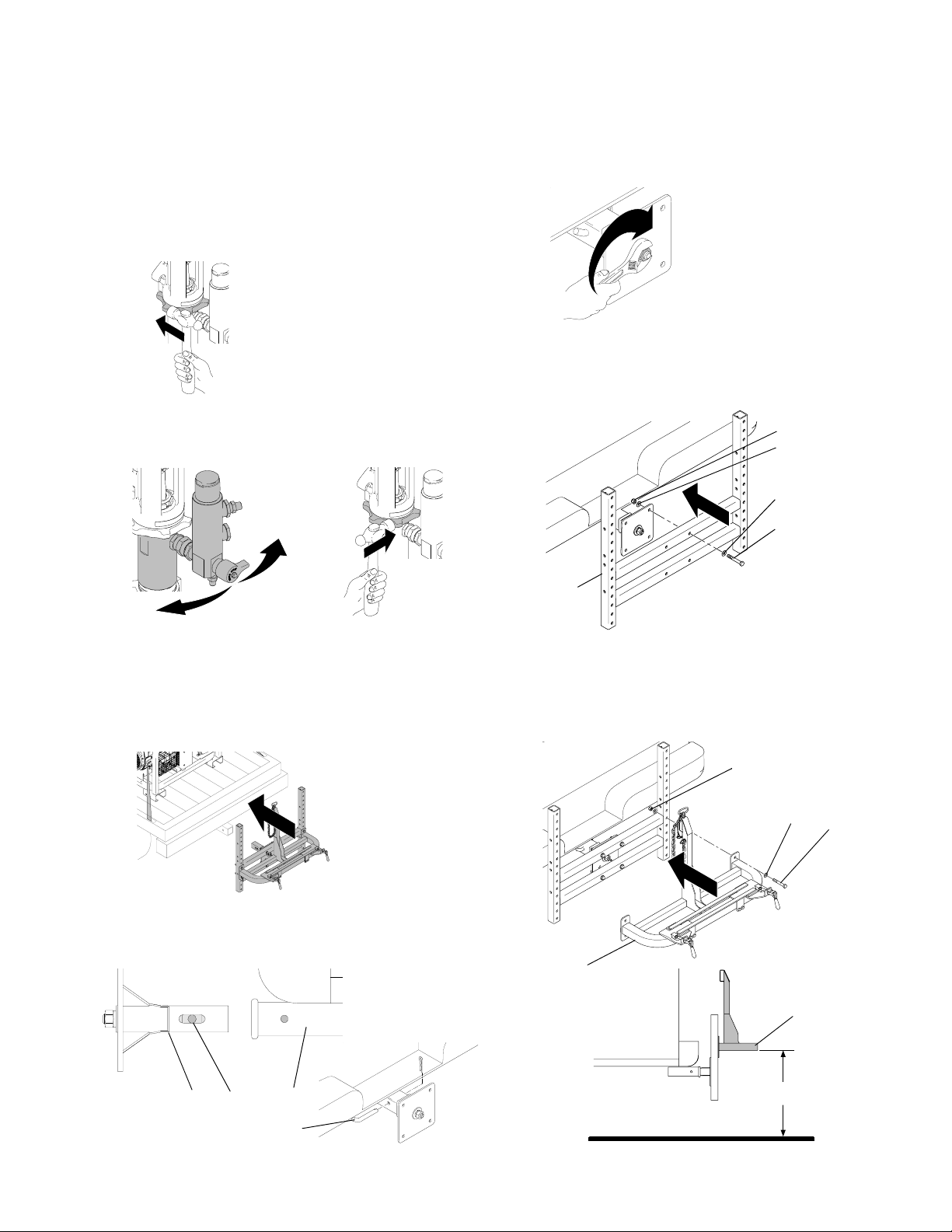

Page 10

Setup

RoadPak Mounting Bracket (24G627)

Installation (Option 2)

ti16441a

NOTE: Cutting the RoadPak mounting arms and bolting

them through the bed to the frame of the vehicle is an

option in addition to the following mounting techniques:

1. Slide the RoadPak mounting arms (304) between

the two fork lift channels in the frame.

304

ti16917a

2. Depending on where the RoadPak is located on the

vehicle determines which holes to bolt through on

the RoadPak frame. There are 8 possible mounting

holes for each mounting arm. Fasten to at least two

holes on each side.

Narrow Orientation

ti16656a

ti16661a

ti16659a

3. Hand-tighten bolts (312), nuts (315), and washers

(307) to mounts.

312

307

315

ti16660a

10 3A1214B

Page 11

Setup

4. Install the height adjustment bracket (303) to the

RoadPak mounting arms (304) with bolts (312),

washers (307), and nuts (315).

315

307

312

ti16912a

303

5. Use wrench to tighten all bolts to lock into place

(torque to 28 ft-lb).

6. Install stow-bracket (302) to height adjustment

bracket (303). Locate the bottom of the stow-bracket

21 in. to 25 in. (53cm - 63cm) from the ground.

Ensure the stow-bracket is installed level.

NOTE: It is recommended to bolt the mounting

bracket through the bed of the vehicle to the frame

of the vehicle.

ti16916a

302

21 in. - 25 in.

53 cm - 63 cm

ti16787a

3A1214B 11

Page 12

Setup

Wide Orientation

ti16657a

1. Bolt brackets (316) to the RoadPak in four locations

with bolts (312), washers (307), and nuts (315). It is

ideal to locate the brackets as far apart as possible

to provide optimal support. The mounting location of

the brackets will depend on where the RoadPak is

mounted on the vehicle.

315

316

3. Install the height adjustment bracket to the RoadPak

mounting arms (303).

315

307

312

303

ti16921a

4. Use wrench to tighten all bolts to lock into place

(torque to 28 ft-lb).

307

ti16786a

318

2. Slide the RoadPak mounting brackets (304) through

the cut out holes in the frame and hand-tighten the

mounting arms to the brackets with bolts (312),

washers (307), and nuts (315).

316

304

ti16911a

315

307

ti16924a

ti16913a

12 3A1214B

312

Page 13

Setup

5. Install stow-bracket (302) to height adjustment

bracket (303). Locate the bottom of the stow-bracket

21 in. to 25 in. (53cm - 63cm) from the ground.

Ensure the stow-bracket is installed level.

ti16960a

302

21 in. - 25 in.

53 cm - 63 cm

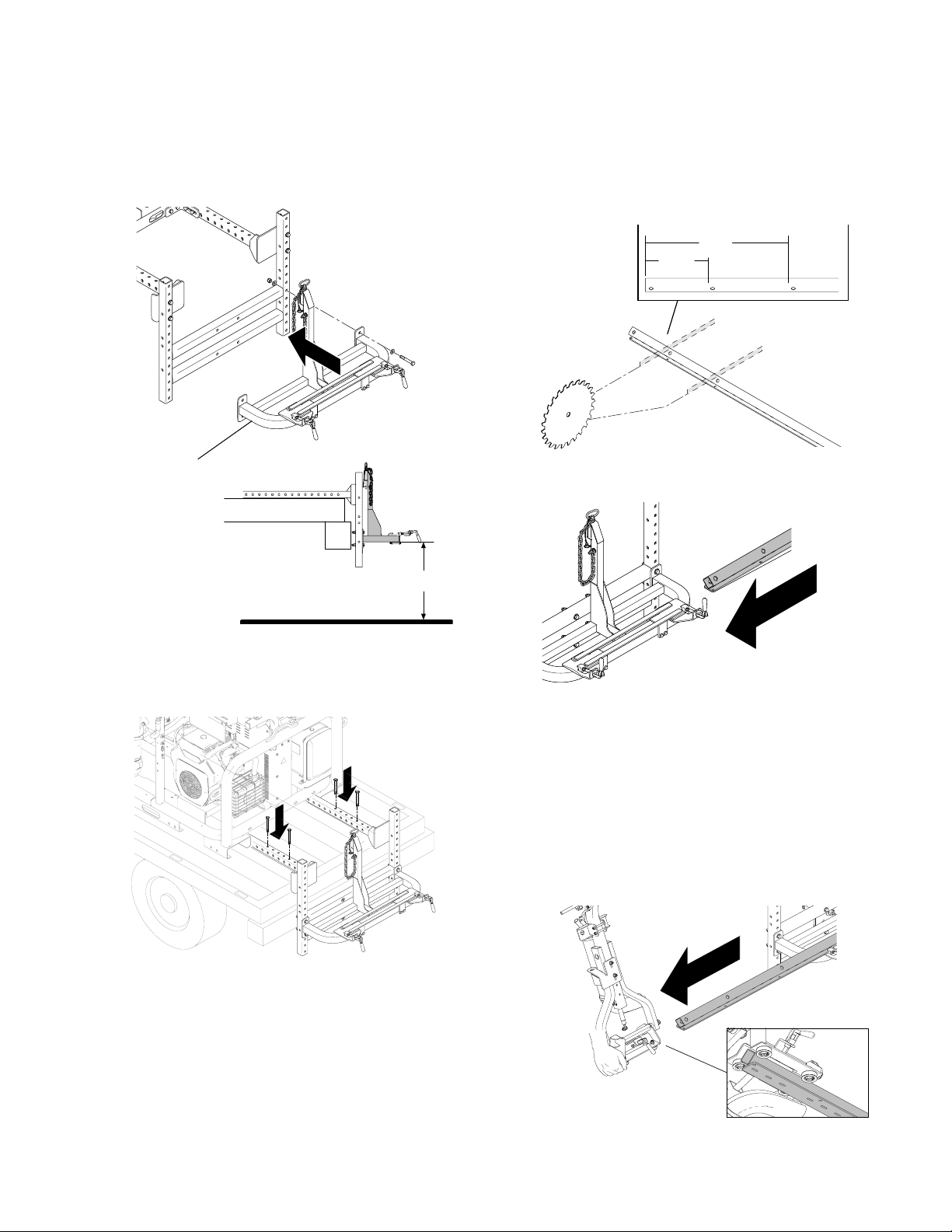

1. To shorten the beam to 75.75 in. long, cut 12 in.

from the end the beam towards the next hole on the

beam. To shorten the beam to 60 in., cut 27.75 in.

from the end of the beam towards the third hole as

shown below.

27.75 in.

12 in.

ti16600a

2. After determining the desired length, slide the beam

into the bracket on the channel.

ti16787a

NOTE: It is recommended to bolt the mounting

bracket through the bed of the vehicle to the frame

of the vehicle.

ti16916a

Slide Beam Installation (24G630)

The slide beam is 87.75 in. (2.2m) long. The Slide Beam

is shipped to accommodate wider vehicles. The beam

can be cut down to 75.75 in. (1.9m) long or 60 in. (1.5m)

long to accommodate different vehicle sizes.

ti16647a

Gun Arm Installation (24G628, 24G629)

1. Position the gun arm assembly next to the vehicle.

2. Pull the slide beam out to the side of the vehicle

where the gun arm is located. Lift the gun arm and

hold the traverse bracket in the position shown

below. Slide the beam through the wheels so they

are mounted on the track of the slide beam as

shown below.

ti15959a

3A1214B 13

Page 14

Setup

3. Attach the handle (702) to each end of the slide

beam. Press the cotter pin (707) through the handle

to hold it in place. Fasten nut (706) and bolt (705)

through the slide beam on both ends to act as stops

on the channel.

708

707

704

706

ti16662a

705

4. Route hoses for the gun arm before moving arm to

prevent hoses from being pinched.

6. Lift gun arm to a vertical position and slide it over

the stow bracket.

ti16422a

7. Rest the gun arm on the stow bracket and position

the stop to sit properly on the stow bracket. Slide the

pin (321) through the gun arm bracket and stow

bracket to secure the gun arm. Tighten the two bolts

(579) down to lock the gun arm bracket into place.

ti16658a

5. Position gun arm at the end of the slide beam and

secure the hose bundle to the height adjustment

bracket with a rubber pad and hose clamp (320).

302

ti16788a

579

ti15837a

ti16918a

14 3A1214B

Page 15

Hose Routing to Pumps and Tanks

Setup

ti16548a

3A1214B 15

Page 16

Setup

Hose Routing

1. Pull slide beam out to one side of the vehicle. Pull

gun arm out and lower it to make sure the hose bundle has been secured at the proper location to

ensure full movement for the gun arm to move from

one side to the other. Make adjustments to the hose

clamp that secures the bundle as needed.

ti16658a

2. Lift gun arm back to the stow position. Pull slide

beam out to other side of vehicle and pull the gun

arm to that side to ensure the hose length is adequate for full movement.

Hose Connection

1. Install suction tubes to the RPS 2900 pump and

route to paint drum.

ti16444a

2. Install return line from the RPS 2900 filter assembly

and route back to the paint drum.

ti16597a

ti16445a

ti16655a

3. Put gun arm back to the stow position and pin it into

place. Center the slide beam to the vehicle. Lock the

slide beam and gun arm into place by engaging the

clamps for each.

ti15954a

3. Install paint lines to RPS 2900 filter assemblies. For

a two color system, route the hose from paint gun 1

to pump 1 and route one hose from paint gun 2 to

pump 1. Route the second hose from paint gun 2 to

pump 2.

ti16446a

4. Install bead lines to the bead tank.

ti16598a

16 3A1214B

Page 17

Setup

5. Install air hose to quick connect fitting on air tank.

ti16914a

Electrical Cable Connections

1. Connect gun arm cable to the junction box. Fasten

cable to cable clamp for strain relief (S) on the connection.

2. Connect control cable to the junction box. Fasten

cable to cable clamp for strain relief (S) on the connection.

ti16595a

S

3. Route the control cable to the cab of the vehicle

without pinching the cable. Connect the cable to the

control box. Route cable through the cable clamp for

strain relief on the connection.

ti16596a

S

ti16601a

3A1214B 17

Page 18

Setup

Install Front Pointer Instructions

1. Locate an area on the vehicle to mount the RoadPak pointer system that will allow the user to see the

indicator rod from the driving position or with the

help of the Road View Camera System.

ti16408a

2. If needed, drill two 9/16 in. holes in the desired location.

3. Assemble mounting bracket (355) to desired location with bolt (359), washer (360), and nut (361).

361

5. Slide support bar (351) through brackets (355) and

tighten fasteners to secure in place.

355

351

ti17000a

6. Assemble extension clamp to support bar.

ti16925a

7. Insert indicator rod (362) into guide extension arm

(352) and secure in place with knob(354).

8. Adjust the indicator rod by loosening extension

clamps and sliding the guide extension arm (352) to

desired position. Secure by tightening knob (354).

Install and Align Front Mechanical

360

355

359

ti16927a

4. Hand tighten lock bar (6) to mounting bracket (355)

with bolts (357) and nuts (358).

358

6

357

18 3A1214B

ti16926a

Guidance System (Optional)

See Guidance System manual.

Install and Align Video Guidance System

(Optional)

See RoadView Camera System manual.

Install Winch Kit (Optional)

See Winch Kit manual.

Page 19

Operation

Operation

Pressure Relief Procedure

INJECTION HAZARD

The system pressure must be manually relieved to prevent the system from starting or spraying accidentally.

Fluid under high pressure can be injected through the

skin and cause serious injury. To reduce the risk of an

injury from injection, splashing fluid, or moving parts,

follow the Pressure Relief Procedure whenever you:

• are instructed to relieve the pressure

• stop spraying

• check or service any of the system equipment

• install or clean the spray tip

FIRE AND EXPLOSION HAZARD

When Flushing system, always connect grounding

cord.

RPS 2900 Pump Fluid Pressure Relief

1. Set hydraulic valve to OFF position.

4. Relieve hose pressure through guns. Use Programmable Skipline Controller to trigger each gun for at

least 3 seconds each.

NOTE: Always relieve pressure with the guns--not

with the filter drain valves.

5. Close paint gun ball valves.

ti15953a

6. Open all drain valves, one at a time.

7. Close valves immediately to prevent paint from drying in system.

NOTE: If you suspect that the spray gun or hose is completely clogged, or that pressure has not been fully

relieved after following the steps above, very slowly

loosen the hose end coupling, and relieve pressure

gradually. Then loosen it completely. Then clear the

valve or hose.

Bead System Pressure Relief

1. Relieve air pressure in bead tank by turning bead

system valve to OFF position.

ti15838a

2. Run engine at half throttle.

3. Place empty pail under paint guns to catch drainage.

3A1214B 19

ti16550a

Page 20

Operation

Air System Pressure Relief

1. Relieve air pressure in air tank by turning air valve to

OPEN position.

ti16961a

EMERGENCY SHUT OFF

To shut down the entire RoadLazer system, set POWER

ON/OFF on the Programmable Skipline Controller to the

OFF position.

Load Reflecting Materials

1. Set POWER ON/OFF on Programmable Skipline

Controller to OFF.

2. Set RoadLazer engine ignition key to OFF.

2. Pull slide beam to left or right side of vehicle. Lock

slide beam clamps.

3. Remove gun arm from upright stowed position, and

slide to end of boom. Slowly lower gun arm, and

lock into position with clamp.

ti16423a

Prepare System to Paint

Initial Settings

1. Ground RoadLazer ground strap to earth ground.

3. Relieve air system pressure by opening ball valve

until gauge reads 0.

4. Relieve air pressure in bead tank by turning bead

system valve to OFF position.

5. Remove cover from bead tank.

6. Screen reflective materials to prevent debris from

entering tank.

7. Load bead tank with reflective materials.

Set Up Slide Beam and Gun Arm

1. Unlock gun arm clamp and slide beam clamps.

TI3058A

2. Fill throat packing nut with TSL to prevent premature

packing wear. Do this each time you spray and

store.

Approximate

Fill Level

ti5240a

ti16425a

20 3A1214B

Page 21

Operation

3. Check engine oil level. Add SAE 10W-30 (summer)

or 5W-20 (winter), if necessary.

(cold)

ti16447a

4. Fill fuel tank.

5. Check hydraulic oil level. Add only Graco Hydraulic

Oil, ISO 46 169236 (5 gallon/18.9 liter) or 207428 (1

gallon/3.8 liter). Hydraulic tank capacity is approximately 4.0 gallons (15.14 liters).

9. Turn pump lever by guns clockwise 1/4 turn to OFF

position.

ti15953a

10. Place suction tube and drain tube in grounded metal

pail partially filled with flushing fluid. Attach ground

wire to pail and to earth ground.

ti16547a

11. Turn prime valve down.

ti5243a

Safe Range (cold)

6. Check oil level in compressor. NOTE: If red dot is

visible, add oil.

ti16789a

7. Verify all hose/fitting connections are tight.

8. Turn hydraulic lines to closed position.

ti16552a

12. Install clean inlet strainer. NOTE: There must be a

minimum of 0.5 in. between bottom of strainer and

suction tube.

ti16553a

0.5 in.

13. Turn pressure control counterclockwise to lowest

pressure.

ti15838a

ti16919a

3A1214B 21

Page 22

Operation

Start Engine

Gasoline is extremely flammable and explosive under

certain conditions. Fuel could spray from the fuel line

connector when it is disconnected from engine. Fuel

could come in contact with the hot muffler and cause

fire or explosion. To reduce the risk of fire or explosion,

always vent the fuel tank and allow engine muffler to

cool before you disconnect the fuel line.

1. Set POWER ON/OFF on Programmable Skipline

Controller to ON.

2. Set engine to choke position ON.

3. Set throttle to half speed and turn key.

2. Slowly turn pressure control clockwise until pump

begins to stroke.

ti16922a

3. When flushing fluid comes out of return lines, set

hydraulic valve to OFF position.

4. After engine starts, set choke to OFF.

Select/Prime Pumps

1. Open hydraulic valve to activate pumps.

ti15838a

4. Place suction hoses in paint drums.

ti16645a

5. Open hydraulic valve to activate pumps.

ti16920a

ti16920a

22 3A1214B

Page 23

Operation

6. When paint comes out of return lines, set hydraulic

valve to OFF position.

7. Close all dump valves.

ti16551a

8. Place return lines into paint drum.

Prime Guns

1. Close air valve to pressurize air system.

ti16959a

2. Open only spray gun ball valves corresponding to

paint pumps or color used. NOTE: Never open both

ball valves on the two-color gun at the same time.

Paint color contamination could result.

6. Turn off guns with Programmable Skipline Controller.

Turn on Bead System

1. Turn bead system valve to ON position.

ti16549a

2. Set desired bead tank pressure by turning regulator

knob.

+

ti15657a

3. Turn guns on with Programmable Skipline Controller

(see Skipline Controller manual).

4. Place an empty pail under spray guns to catch

drainage from spray guns.

5. Set hydraulic valve(s) to ON position to activate

pumps.

ti16920a

3A1214B 23

3. Remove and secure ground strap from earth

ground.

4. System is now ready for painting. Select guns 1 or 2

with the Programmable Skipline Controller.

Begin to Spray

Select appropriate procedure from menu on RoadLazer

control system. See Skipline Controller manual.

ti16910a

Page 24

Operation

Flushing the System

1. Perform Pressure Relief Procedure, see page 19.

2. Flush the system with compatible solvent. Check

the system under pressure for leaks. If any are

found, relieve the pressure, and repair the leaks.

Pressurize the system again, and check for leaks.

3. Ground RoadLazer with grounding clamp to earth

ground.

NOTE: The grounding clamp and ground strap are

both required for safe RoadLazer operation. The

grounding clamp is for stationary use.

4. Set pump hydraulic valves to OFF position.

8. Turn on Programmable Skipline Controller.

NOTE: Unit will not start until Controller is turned

ON.

9. Start Engine as follows:

a. Set Choke ON.

b. Set throttle.

c. Turn key.

d. After engine starts, set choke to OFF.

e. Set throttle to half speed.

FIRE AND EXPLOSION HAZARD To reduce static

sparking and splashing, always remove the spray tip

from the gun, and hold a metal part of the gun firmly to

the side of a grounded metal pail during flushing.

10. Set hydraulic valve to ON position to activate

pumps.

ti15838a

5. Fill a 5-gallon pail with water or compatible solvent.

Place paint suction hose in pail.

6. Place paint return lines in empty pail.

7. Open all paint pump dump valves.

ti16552a

ti16920a

11. When water/solvent comes out of spray gun, set

hydraulic valve to OFF position.

12. Close dump valves.

ti16551a

24 3A1214B

Page 25

Operation

13. Open only spray gun ball valves corresponding to

paint pumps or color used. NOTE: Never open both

valves on the two-color gun at the same time. Paint

color contamination could result.

14. Place empty pail under spray guns to catch

drainage from spray guns.

15. Turn guns on with Programmable Skipline

Controller.

16. Set hydraulic valves to ON position to activate

pumps.

ti16920a

17. When water/solvent comes out of spray gun, set

hydraulic valve to OFF position.

18. Turn off guns with Programmable Skipline

Controller.

19. Shut off engine and Programmable Skipline Controller.

20. Leave paint pump dump valves and spray gun ball

valves open.

21. Remove and secure ground strap from earth

ground.

3A1214B 25

Page 26

Operation

Securing Gun Arm for Transportation

NOTE: Never transport the RoadLazer while the paint

gun ball valves are open, the system is under pressure,

and the engine is running, as this could cause damage

to components.

1. Unlock gun arm red-handled clamp on slide beam.

ti16425a

2. Lift gun arm up from ground, and push in to center

of RoadLazer.

5. Unlock two red-handled clamps and center the slide

beam on the vehicle.

ti16923a

6. Lock three red-handle clamps to secure the slide

beam and gun arm.

ti16915a

ti16422a

3. Pull gun arm hitch pin out of frame.

4. Put gun arm hitch pin back in frame and secure with

clip.

ti15837a

26 3A1214B

RoadLazer in Storage Position

ti15954a

Page 27

Technical Data

Technical Data

Maximum Working Pressure

Paint 2900 psi (200 bar)

Hydraulics 1950 psi (134 bar)

Glass bead system 75 psi (5 bar)

Maximum paint flow 4.5 gpm @ 2000 psi (138 bar)

Operating pressure of air-actuated trigger

Minimum 80 psi (5.5 bar)

Maximum 200 psi (14 bar)

Sound levels - measured at 6.2 ft (2 m)

under maximum operating conditions per ISO-3744

Sound power level 111.7 dB(A)

Sound pressure level 91.7 dB(A)

Weight

24G624 (1) Pump RoadPak 850 lb (386 kg)

24G625 (2) Pump RoadPak 950 lb (431 kg)

24G629 (2) Pump Gun Arm 134 lb (61 kg)

24G627 Slide-in Mounting Frame 170 lb (77 kg)

24G626 Hitch Mounting Frame 120 lb (54 kg)

Engine

Hydraulic oil reservoir capacity 4 gallons (15 liters)

Compressor Oil 9502 SAE 30W non-detergent oil

Hydraulic Oil Graco approved 169236 (5 gal) 207428 (1 gal) ISO 46

Glass bead capacity 450 lb (204 kg)

Kohler

®

18 HP

®

Kohler

3A1214B 27

is a registered trademark of the Kohler Co.

Page 28

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 3A1214

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2010, Graco Inc. is registered to ISO 9001

www.graco.com

Revision A, 02/2011

Loading...

Loading...