Page 1

Instructions

™

HFR

Gateway Module Kits

For external control of the HFR system. For professional use only. Not approved for use in

European explosive atmosphere locations.

Single Discrete Gateway Module Kit, 24F843

Dual Discrete Gateway Modules Kit, 24F844

Discrete Gateway Module, 24G830

Important Safety Instructions

Read all warnings and instructions in the

HFR operation manual 313997. Save all

instructions.

Discrete

3A1149D

ENG

r_24B681_2B9904_1b

Page 2

Related Manuals

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

DGM Presence . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Automation Presence . . . . . . . . . . . . . . . . . . . . . 3

Typical Installation . . . . . . . . . . . . . . . . . . . . . . . . . 4

Component Identification . . . . . . . . . . . . . . . . . . . . 5

Module Requirements . . . . . . . . . . . . . . . . . . . . . . . 6

I/O Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

DGM Digital Input Overview . . . . . . . . . . . . . . . . 7

DGM Digital Outputs Overview . . . . . . . . . . . . . . 8

DGM Analog Inputs Overview . . . . . . . . . . . . . . . 9

DGM Analog Outputs Overview . . . . . . . . . . . . . 9

Primary DGM Pin Assignments . . . . . . . . . . . . 10

Secondary DGM Pin Assignments . . . . . . . . . . 12

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Primary DGM Digital Inputs . . . . . . . . . . . . . . . 16

Primary DGM Digital Outputs . . . . . . . . . . . . . . 18

Primary DGM Analog Inputs . . . . . . . . . . . . . . . 19

Primary DGM Analog Outputs . . . . . . . . . . . . . 20

Secondary DGM I/O Overview . . . . . . . . . . . . . 21

Secondary DGM Digital Inputs . . . . . . . . . . . . . 22

Secondary DGM Digital Outputs . . . . . . . . . . . . 22

Secondary DGM Analog Inputs . . . . . . . . . . . . 23

Secondary DGM Analog Outputs . . . . . . . . . . . 24

Timing Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Heartbeat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Activate System Stop Button . . . . . . . . . . . . . . . 25

System Requests . . . . . . . . . . . . . . . . . . . . . . . 26

Select an Operating Mode or Shot Number . . . 26

Change Setpoint . . . . . . . . . . . . . . . . . . . . . . . . 27

Toggle On/Off . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Shot Mode Dispense . . . . . . . . . . . . . . . . . . . . 28

Shot Mode Dispense and Termination . . . . . . . 28

Operator Mode Dispense . . . . . . . . . . . . . . . . . 29

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Install Upgrade Token . . . . . . . . . . . . . . . . . . . . 30

Check Cable Connections . . . . . . . . . . . . . . . . . 30

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Diagnostic Information . . . . . . . . . . . . . . . . . . . . 31

Fault Code Bit Pattern Table . . . . . . . . . . . . . . . 31

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 36

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 36

Related Manuals

The following manuals are available at www.graco.com.

Manuals are in English.

Part Description

313997 HFR Operation

313998 HFR Repair-Parts

2 3A1149D

Page 3

Overview

Overview

This Discrete Gateway Module (DGM) allows the user to

control an HFR through an external control device such

as a PLC. The DGM will operate in conjunction with the

existing Advanced Display Module (ADM) such that both

devices can be used to control the machine. Each HFR

can be controlled using up to two DGM’s which will be

referred to as the primary and secondary DGM’s.

The primary DGM allows the user to monitor and control

general machine functions. This includes the following

capabilities:

• Dispensing

• Operating mode selection

• Shot selection

• Fault code monitoring

• Fault acknowledgment

• Pump parking

• Monitoring working pressures of each pump

• Monitoring the combined flow or B (Blue) pump

pressure while dispensing

• System Stop button

• Changing the combined flow or B (Blue) pump pressure in operator mode

Automation Presence

The primary DGM includes a heartbeat monitor. This

serves as a verification that the PLC and DGM are communicating. In the event that the PLC becomes unresponsive, the DGM will terminate any active dispenses

and set the machine to disabled mode.

The secondary DGM is used for monitoring and controlling the temperature conditioning components. These

features include:

• Monitoring which conditioning zones are enabled

• Monitoring temperatures of enabled zones

• Turning on or off the enabled zones

• Changing temperature setpoints of enabled zones

NOTE: Changing temperature setpoints is only available

on machines with 2nd generation ADMs. 2nd generation

ADMs are distinguishable by having only 2 cable connections on the bottom of the ADM. 1st generation

ADMs have 4 cable connections.

DGM Presence

The DGM will broadcast a heartbeat to the HFR every

5 seconds. In the event that the DGM fails to broadcast

a heartbeat after 10 seconds, the system will go into disabled mode.

The system can be taken out of disabled mode after

acknowledging the alarm on the ADM.

3A1149D 3

Page 4

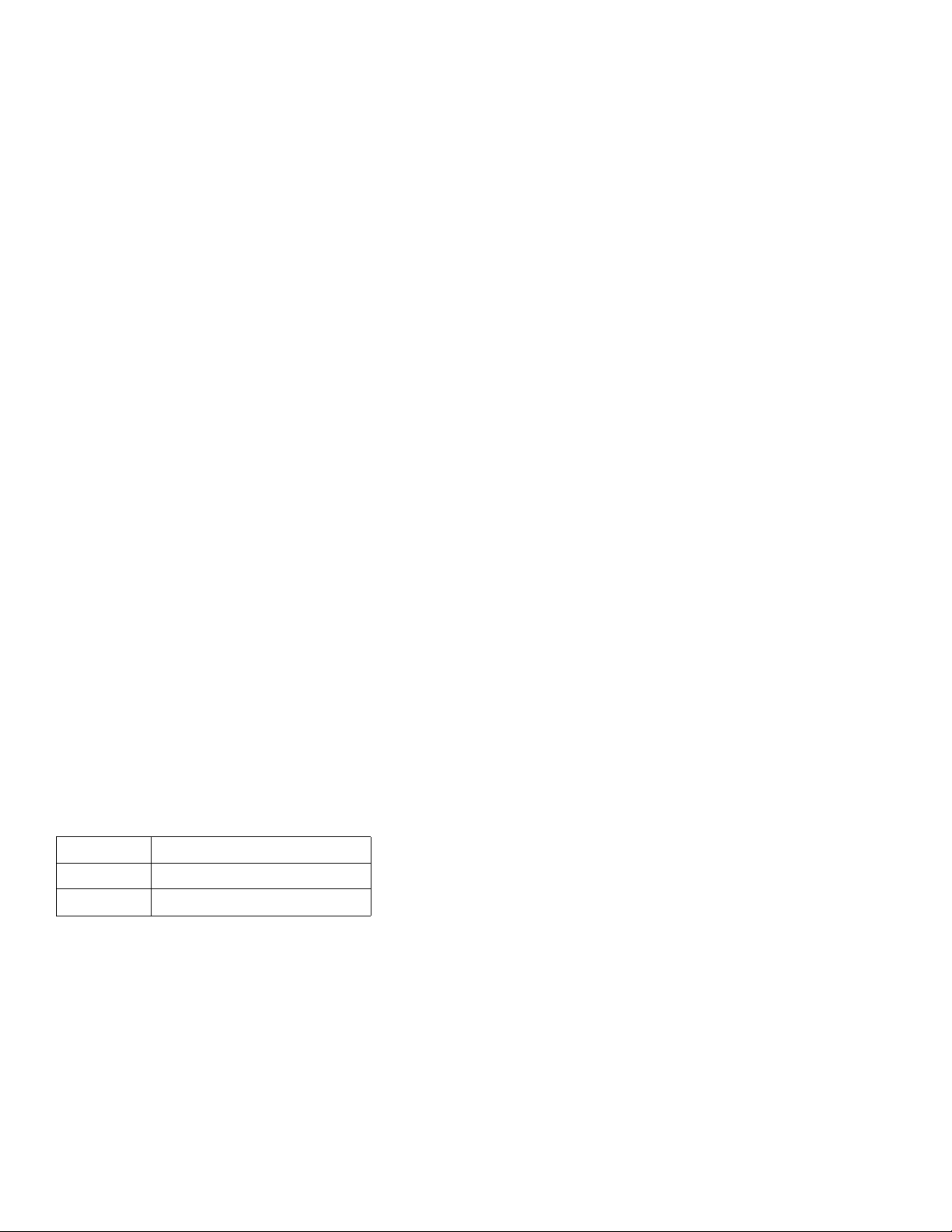

Typical Installation

Typical Installation

D

A

B

1

2

C

F

FIG. 1

Key:

A Discrete Gateway Module (DGM)

B Breakout Board

CCAN Cables

D 78 Pin D-Sub Cables (Male to Female)

E Ground screw

F Connects to HFR

G Ferrite Suppressor

G

E

r_24F843_3A1149_1b

4 3A1149D

Page 5

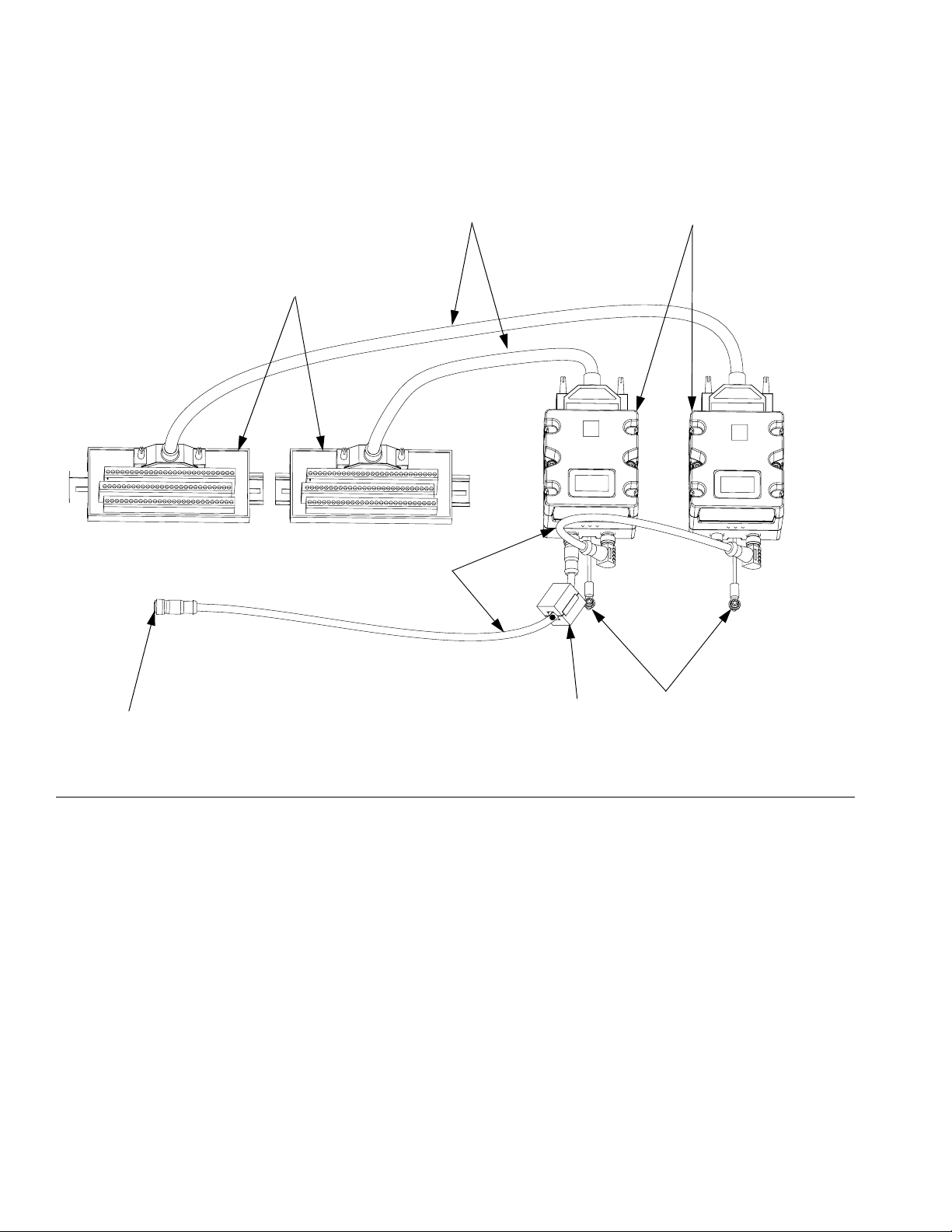

Component Identification

Component Identification

AB

AF

AA

AE

r_24B681_2B9904_1b

AC

AJ

r_24B681_2B9904_2b

AD

AG

AH

FIG. 2:

Key:

AA Discrete Gateway Module (DGM)

AB Base

AC Module Connection Screws

AD Access Cover

AE Module Status LEDs

AF CAN Connectors

AG Rotary Switch

AH Token Slot

AJ D-Sub Connection

r_24B681_2B9904_4b

3A1149D 5

Page 6

Module Requirements

Module Requirements

Each DGM requires a 9-30 VDC NEC Class 2 power

supply. This is supplied to the DGM through pins 27, 51,

68, 69 on the D-Sub connection. Ground from this supply should only be connected to pin 70 of the D-Sub

connection.

I/O Setup

NOTE: Each DGM is set as the primary or secondary

DGM by setting the rotary switch (AG) position. See

Setup on page 14.

NOTICE

To avoid ground loops and noise immunity issues, do

not ground the shield of the D-sub connector cable.

The shield is already grounded through the mounting

screw on the base of the DGM. If using a breakout

board, do not make any connections to the pins with

ground symbols.

See the Digital and Analog I/O Overview sections beginning on the following page for I/O setup details. See the

Primary DGM Pin Assignments and Secondary DGM

Pin Assignments sections beginning on page 10 for

individual pin assignments.

1

21

20

39

7859

F

IG. 3: D-sub Connector - Pin References

40

60

6 3A1149D

Page 7

I/O Setup

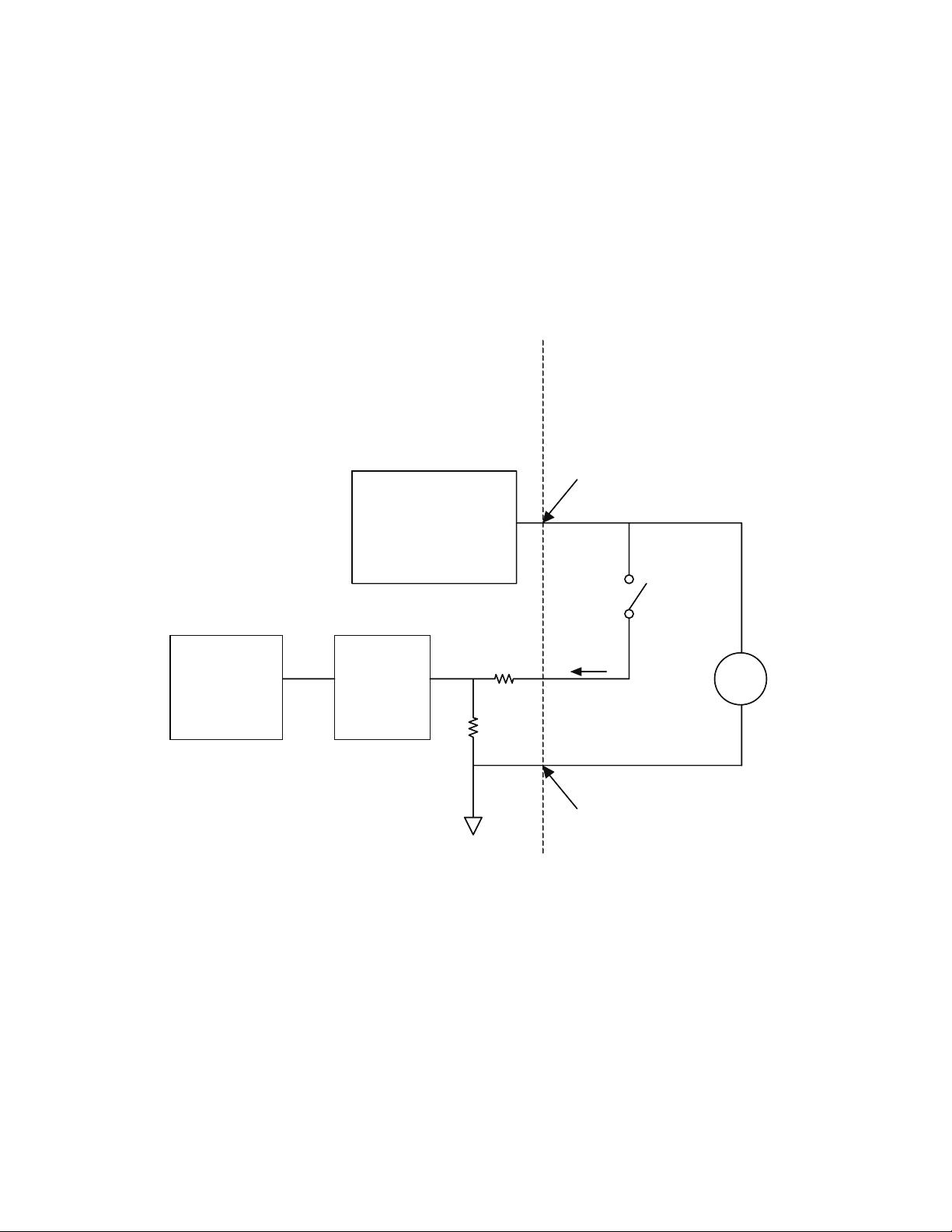

DGM Digital Input Overview

The digital inputs function only when power is supplied to pin 51 and there is a ground connection to pin 70. The digital input is rated at 0-30 VDC, and requires an NEC Class 2 power supply connected to pin 51. The DGM provides

optical isolation as shown in the following illustration.

• Pins: 52 – 59, 71-78

• Type: Sinking

• Maximum current draw: 3.6 mA

Discrete Gateway

Discrete Gateway

Customer Automation

Customer Automation

D-Sub Pin 51 (Isolated

D-Sub Pin 51 (Isolated

Logic Supply)

Logic Supply)

Microcontroller

Microcontroller

Isolated Logic ICs

Isolated Logic ICs

Optical

Optical

Isolator

Isolator

Digital Input

D-Sub Pin 70

D-Sub Pin 70

(Isolated Ground)

(Isolated Ground)

24VDC

24VDC

3A1149D 7

Page 8

I/O Setup

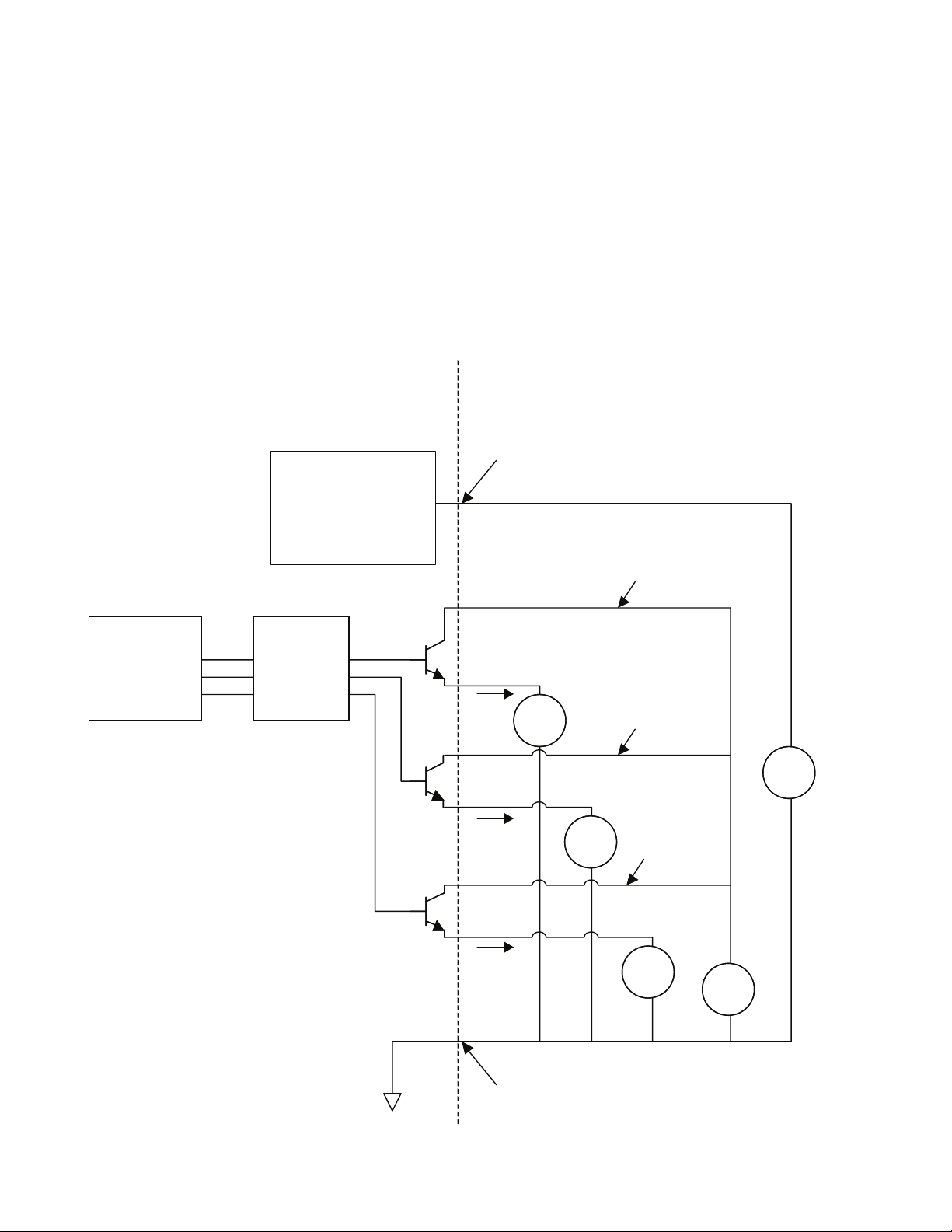

DGM Digital Outputs Overview

The digital outputs function only when power is supplied to pins 27, 68, and 69 and there is a ground connection to

pin 70. The digital output is rated at 0-30 VDC, and requires an NEC Class 2 power supply connected to pin 27 for

supply bank 1, pin 69 for supply bank 2, and pin 68 for supply bank 3. The DGM provides optical isolation as shown

in the following illustration.

• Pins: 9-20, 28-39

• Type: Sourcing

• Maximum continuous current output: 350 mA

(sourced from customer supply)

• Recommended continuous current: 100 mA

Microcontroller

Disc rete Gate way

Isolated Logic ICs

Optical

Isolator

Customer Automation

D-Sub Pin 51 (Isolated

Logic Supply)

D-Sub

Pin 27

Digital

Output

1-8

D-Sub

Pin 69

LOADLOAD

Digital

Output

9-16

Digital Input

Supply Bank 1

Digital Input

Supply Bank 2

24VDC24VDC

LOADLOAD

D-Sub

Pin 68

Digital

Output

17-24

D-Sub Pin 70

(Isolated Ground)

Digital Input

Supply Bank 3

LOADLOAD

24VDC24VDC

8 3A1149D

Page 9

I/O Setup

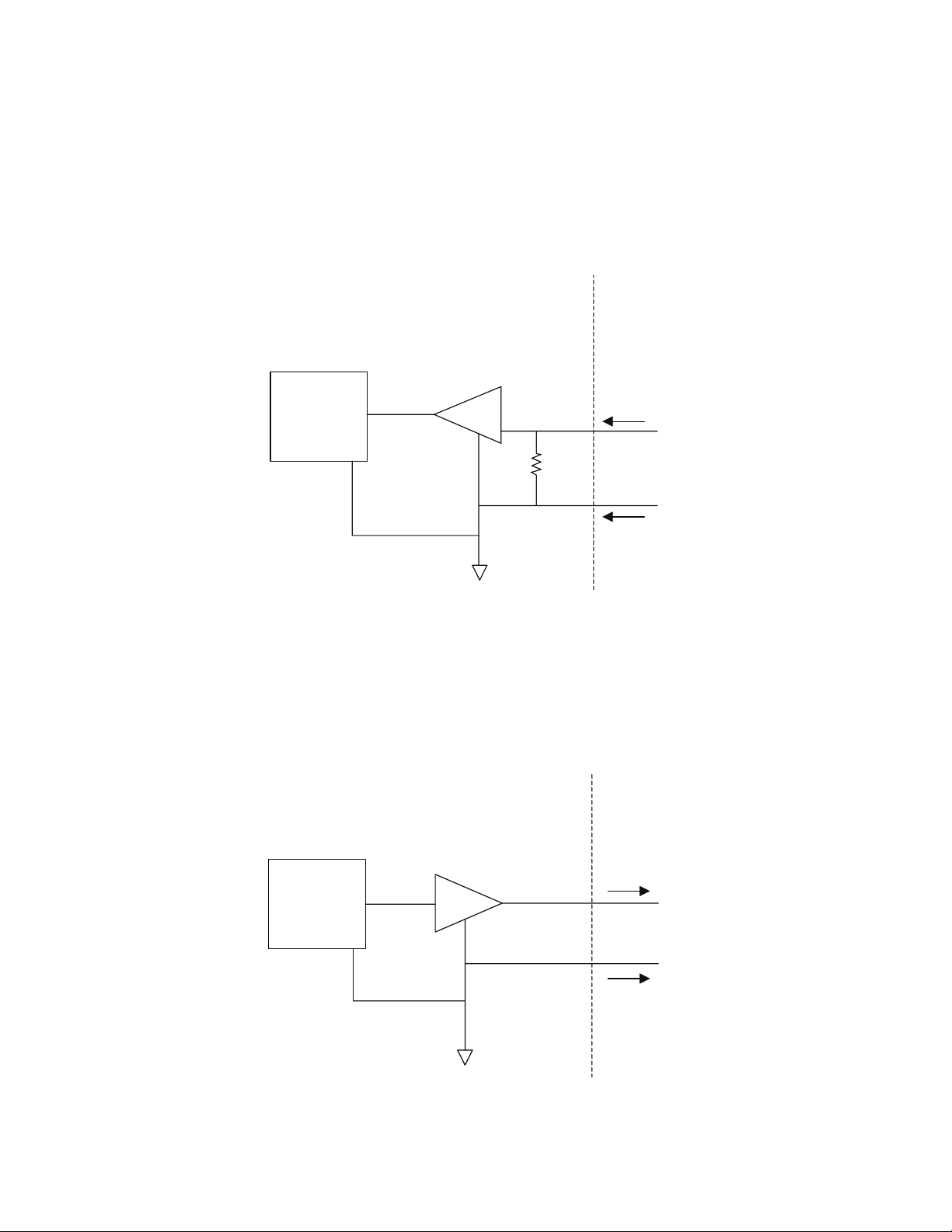

DGM Analog Inputs Overview

The analog inputs function only when the DGM is connected to a power supply through the CAN connection; see

Setup, page 14. Each analog input has a corresponding reference (ground) pin.

• Type: Sinking

• Voltage Rating: 0-10 Vdc

• Input Impedance: 20 k

Ω

Discrete Gateway Customer Automation

Microcontroller

Analog Input +

+

20kΩ

-

Analog Input -

DGM Analog Outputs Overview

The analog outputs function only when the DGM is connected to a power supply through the CAN connection; see

Setup on page 14. Each analog output has a corresponding reference (ground) pin.

• Type: Sourcing

• Voltage Rating: 0-10 Vdc, 10 mA at 10 Vdc

Discrete Gateway Customer Automation

Analog Output +

Microcontroller

0-10VDC @10mA

+

-

Analog Output -

3A1149D 9

Page 10

I/O Setup

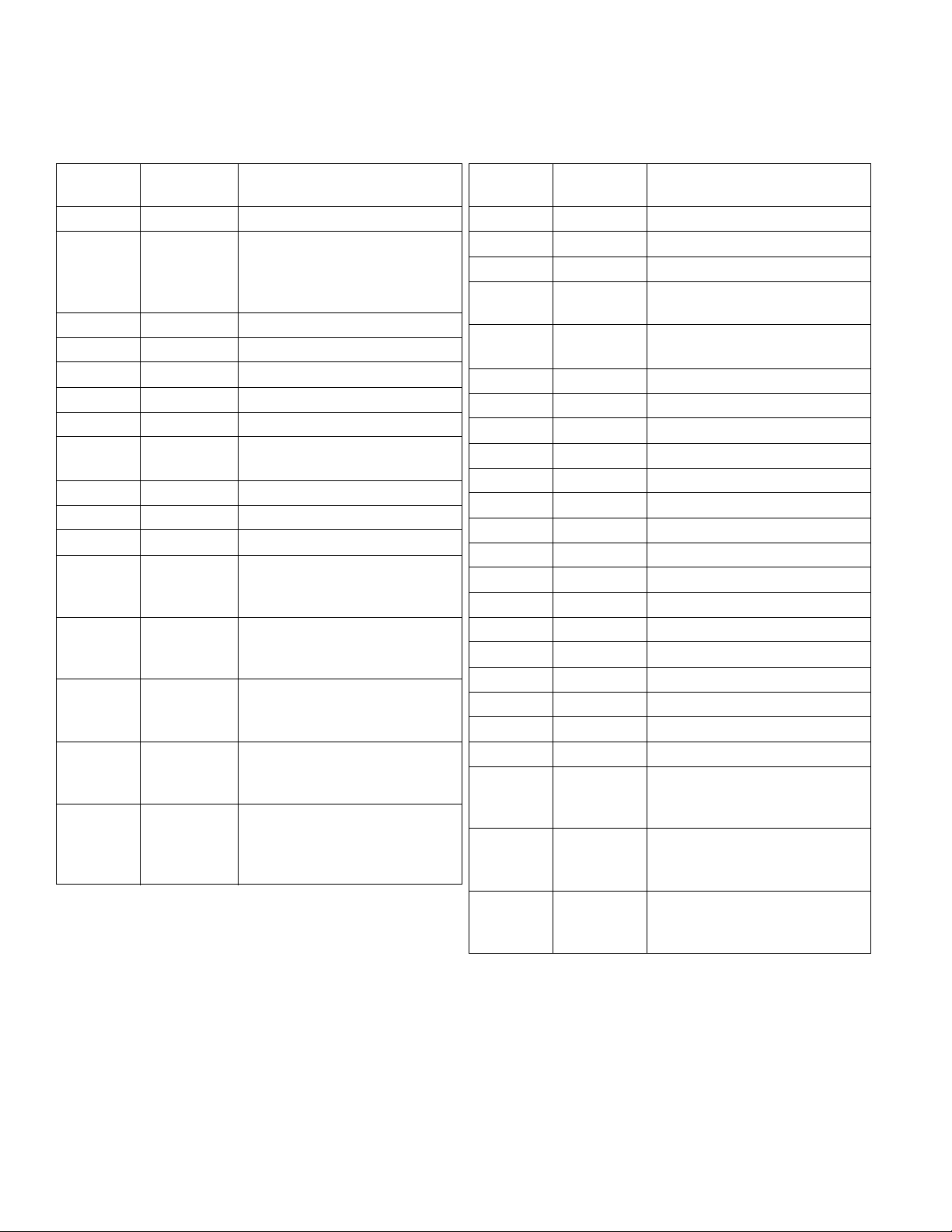

Primary DGM Pin Assignments

Pin

Number

52 1 PLC to DGM Heartbeat

53 2 Dispense Request / Terminate

54 3 System Stop

55 4 Acknowledge Active Error

56 5 Set Operating Mode, Bit 2

57 6 Set Operating Mode, Bit 1

58 7 Set Operating Mode, Bit 0

59 8 Accept Operating Mode

71 9 Select Shot, Bit 6 (Shot Mode)

72 10 Select Shot, Bit 5 (Shot Mode)

73 11 Select Shot, Bit 4 (Shot Mode)

74 12 Select Shot, Bit 3 (Shot Mode),

75 13 Select Shot, Bit 2 (Shot Mode),

76 14 Select Shot, Bit 1 (Shot Mode),

77 15 Select Shot, Bit 0 (Shot Mode),

78 16 Accepted Selected Shot (Shot

DGM Digital

Inputs Functional Description

(Shot, Operator modes), or

Start/Stop Recirculation

(Standby Mode)

Change

or Enable Dispensing (Active

Low)

or Enable ADM (System in Disabled mode)

or Lock/Unlock the Dispense

Valve (Standby Mode)

or Open/Close Dispense

Valve (Standby Mode)

Mode), or Accepted Pressure/Flow (Operator Mode), or

Park Pump (Standby Mode)

Pin

Number

9 1 DGM to PLC Heartbeat

10 2 Ready to Dispense

11 3 Dispense in Progress

12 4 Requested Flow Rate/Pres-

13 5 Dispense Mode Selected:

14 6 Error Present

15 7 Fault Code, Bit 7

16 8 Fault Code, Bit 6

17 9 Fault Code, Bit 5

18 10 Fault Code, Bit 4

19 11 Fault Code, Bit 3

20 12 Fault Code, Bit 2

28 13 Fault Code, Bit 1

29 14 Fault Code, Bit 0

30 15 Operating Mode Selected, Bit 2

31 16 Operating Mode Selected, Bit 1

32 17 Operating Mode Selected, Bit 0

33 18 Shot Selected, Bit 6

34 19 Shot Selected, Bit 5

35 20 Shot Selected, Bit 4

36 21 Shot Selected, Bit 3

37 22 Shot Selected, Bit 2 (Shot

38 23 Shot Selected, Bit 1 (Shot

39 24 Shot Selected, Bit 0 (Shot

DGM Digital

Outputs Functional Description

sure Setpoint Rejected

Flow (Low) or Pressure (High)

Mode), or Dispense Valve

Locked (Standby Mode)

Mode), or Dispense Valve

Open (Standby Mode)

Mode), or Pump Parked

(Standby Mode)

10 3A1149D

Page 11

DGM

Pin

Number

Analog

Inputs Functional Description

1 1 Set B (Blue) Pump Dispensing

Pressure or Combined Dispensing Flow Rate

2 1 - GND Grounding Pin for Analog Input

1

32Not Used

4 2 - GND Not Used

21 3 Not Used

22 3 - GND Not Used

23 4 Not Used

24 4 - GND Not Used

DGM

Pin

Number

Analog

Outputs Functional Description

40 1 B (Blue) Pump Pressure

41 1 - GND Grounding Pin for Analog Out-

put 1

42 2 A (Red) Pump Pressure

43 2 - GND Grounding Pin for Analog Out-

put 2

60 3 Combined Flow Rate or B

(Blue) Pump Pressure

61 3 - GND Grounding Pin for Analog Out-

put 3

62 4 Not Used

63 4 - GND Not Used

I/O Setup

Pin

Number

Power

Supply Functional Description

27

51

68

+ 9-30V Power Supply Pins

69

70 - Grounding Pin

3A1149D 11

Page 12

I/O Setup

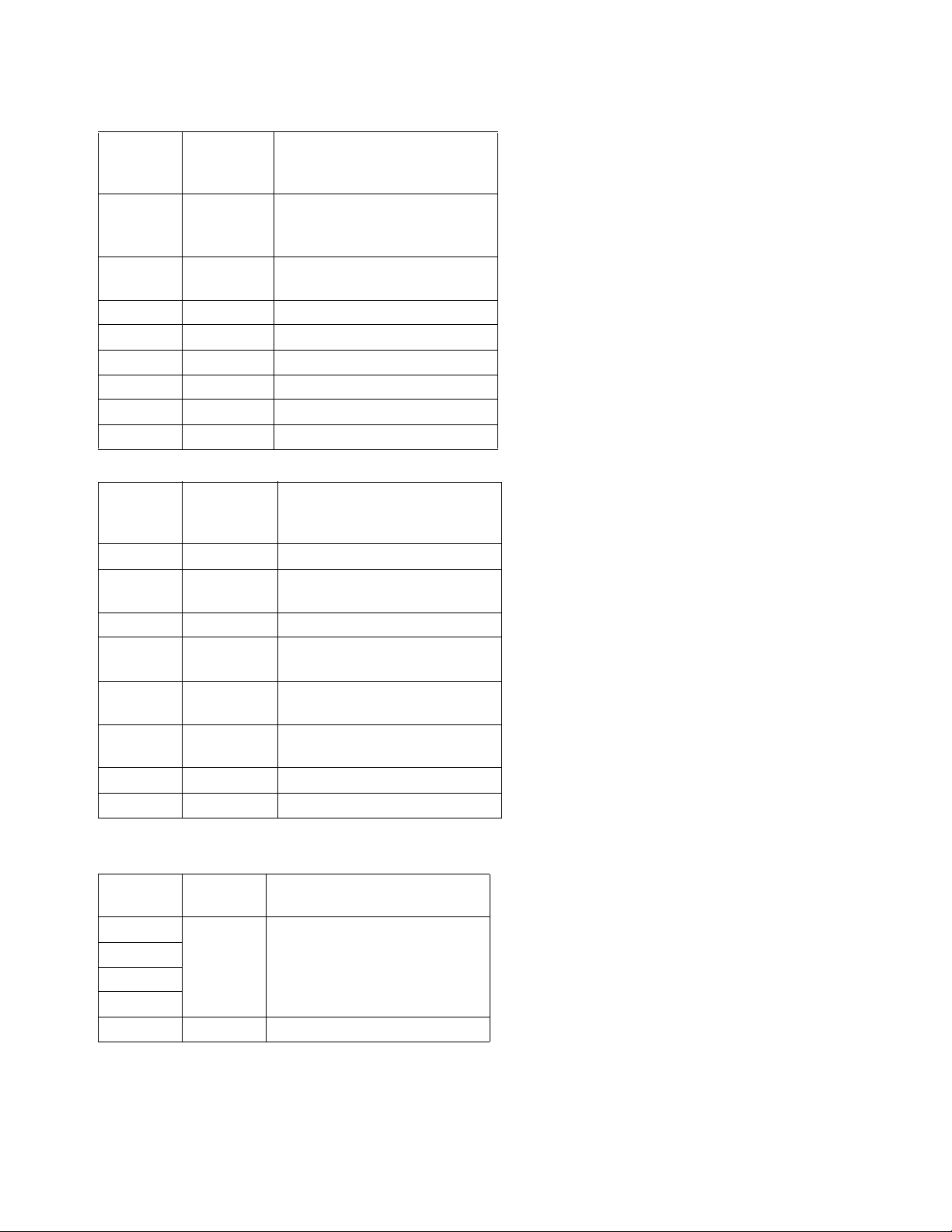

Secondary DGM Pin Assignments

Pin

Number

52

53

54

55

56

57

58

59

71

72

73

74

75

76

77

78

DGM Digital

Inputs Functional Description

1 Set Zone 1 On

2 Set Zone 2 On

3 Set Zone 3 On

4 Set Zone 4 On

5 Accept Zone 1 Setpoint

Change

6 Accept Zone 2 Setpoint

Change

7 Accept Zone 3 Setpoint

Change

8 Accept Zone 4 Setpoint

Change

9Not Used

10 Not Used

11 Not Used

12 Not Used

13 Not Used

14 Not Used

15 Not Used

16 Not Used

Pin

Number

9

10

11

12

13

14

15

16

17

18

19

20

28

29

30

31

32

33

34

35

36

37

38

39

DGM

Digital

Outputs Functional Description

1Not Used

2 Ready To Dispense

3 Dispense in Progress

4 Zone 1 On

5 Zone 2 On

6 Zone 3 On

7 Zone 4 On

8 Zone 1 Temperature Setpoint

Rejected

9 Zone 2 Temperature Setpoint

Rejected

10 Zone 3 Temperature Setpoint

Rejected

11 Zone 4 Temperature Setpoint

Rejected

12 Tank Heater A (Red) Enabled

13 Tank Heater B (Blue) Enabled

14 Inline Heater A (Red) Enabled

15 Inline Heater B (Blue) Enabled

16 Hose Heater A (Red) Enabled

17 Hose Heater B (Blue) Enabled

18 Chiller A (Red) Enabled

19 Chiller B (Blue) Enabled

20 Not Used

21 Not Used

22 Not Used

23 Not Used

24 Not Used

12 3A1149D

Page 13

DGM

Pin

Number

Analog

Inputs Functional Description

11

2 1 - GND

32

4 2 - GND

21 3

22 3 - GND

23 4

24 4 - GND

DGM

Pin

Number

Analog

Outputs Functional Description

40 1

41 1 - GND

42 2

43 2 - GND

60 3

61 3 - GND

62 4

63 4 - GND

I/O Setup

Set Zone 1 Temperature

Grounding Pin for

Analog Input 1

Set Zone 2 Temperature

Grounding Pin for

Analog Input 2

Set Zone 3 Temperature

Grounding Pin for

Analog Input 3

Set Zone 4 Temperature

Grounding Pin for

Analog Input 4

Actual Zone 1 Temperature

Grounding Pin for

Analog Output 1

Actual Zone 2 Temperature

Grounding Pin for

Analog Output 2

Actual Zone 3 Temperature

Grounding Pin for

Analog Output 3

Actual Zone 4 Temperature

Grounding Pin for

Analog Output 4

Pin

Number

Power

Supply Functional Description

27

51

+ 9-30V Power Supply Pins

68

69

70 - Grounding Pin

3A1149D 13

Page 14

Setup

Setup

See Typical Installation on page 4 for an assembled

view.

1. Install the DGM in the desired location.

a. Remove access cover (AD).

AC

AA

AD

r_24B681_2B9904_3b

F

AB

IG. 4

b. Loosen two screws (AC) and remove DGM (AA)

from base (AB).

c. Attach ground wire to bottom of base.

d. Mount base (AB) in desired location with four

screws. See the following mounting dimensions.

2. Adjust DGM selector switch (AG) according to the

following table.

Setting Zone

1Primary DGM

2 Secondary DGM

AG

r_24B681_2B9904_4b

3. Install access cover (D).

4. Connect CAN and D-Sub cables.

CAN Connector 1

CAN Connector 2

r_24B681_2B9904_1b

#10-32 UNF

(M5 x 0.8)

2.75 in.

(69.9 mm)

3.25 in.

(82.6 mm)

e. Insert screws through top of base and tighten.

f. Insert screw through ground wire and tighten.

g. Mount DGM (AA) on base (AB) with two

screws (C).

h. If applicable, repeat with second DGM.

D-sub Connector

r_24B681_2B9904_2b

F

IG. 5: Cable Connections

a. Connect CAN cable from Connector 1 on DGM

to ADM or any available CAN connection on the

machine. Attach the ferrite suppressor to DGM

end of the CAN cable.

NOTE: In the previous step if more than one DGM is

used the connection can be made with either DGM.

b. If a second DGM is installed, connect CAN

cable from CAN Connector 1 on the second

DGM to Connector 2 on the first DGM.

14 3A1149D

Page 15

c. Connect D-Sub cable from D-Sub Connector on

first DGM to a breakout board or to an external

control device.

d. If second DGM is installed, connect D-Sub

cable from D-Sub Connector on second DGM to

a breakout board or to an external control

device.

Setup

3A1149D 15

Page 16

Operation

Operation

Primary DGM Digital Inputs

See DGM Digital Inputs table in the Primary DGM Pin

Assignments section beginning on page 10 for pin

numbers associated with each bit description.

The primary DGM allows the PLC to control and monitor

the HFR’s dispensing properties.

Digital Input 1: PLC to DGM Heartbeat

The external control device (PLC) and DGM will each

have Heartbeat inputs and outputs. The heartbeat

serves as a verification that both devices are communicating. The PLC does not need to implement any timers

to regulate the period of the heartbeat. To successfully

complete a heartbeat, the PLC must match the output

state of the DGM heartbeat. This can happen as soon

as the PLC detects the change in output state, or within

6 seconds of detecting a change in heartbeat state. If

the PLC does not match the output state of the DGM

after 6 seconds, the DGM will disable the system. This

will only happen once, and the HFR can be reactivated

and operated from the ADM. The DGM will not accept

any more requests until the heartbeat resumes between

the PLC and DGM.

Digital Input 3: System Stop

Toggle this bit high to place the dispensing system in

disabled mode.

Digital Input 4: Acknowledge Active Error

Toggle this bit high to acknowledge any errors detected

by the system.

Digital Inputs 5-7: Set Operating Mode Bits

The operating mode is selected through the use of 3

bits. The following table describes the bit pattern to indicate selection of each operating mode. A “1” means the

bit is high and a “0” means the bit is low.

Operating Mode Bit Pattern

Digital

Input 5

0 0 1 Disabled

0 1 0 Standby

011 Shot*

1 0 1 Operator

111 Night**

Digital

Input 6

Digital

Input 7

Operating Mode

Digital Input Bit 2

The function of this bit is based on the selected operating mode:

NOTE: The Enable Dispensing bit must be pulled low

prior to dispensing.

• Shot Mode: Toggle this bit high to dispense a single

shot. Toggle the bit in the middle of a shot to terminate the dispense.

• Operator Mode: The machine will dispense while

the bit is pulled high. As soon as the bit falls low, the

dispense terminates.

• Operator Mode with Fusion

to stop/start stalling the system to pressure.

• Standby Mode: Toggle this bit high to start/stop

recirculation (recirculation systems only).

®

Gun: Toggle this bit

Digital Input 8: Accept Operating Mode

Change

Toggle this bit high while the bit pattern is set to change

the operating mode. After toggling this bit, use the analog output bits to verify the operating mode was successfully changed.

* Shot definitions must be configured through the

ADM.

** Night mode settings must be configured through the

ADM.

16 3A1149D

Page 17

Operation

Digital Inputs 9-15: Select Shot Bits

The shot selection bits are used to select one of the 100

different defined shots. The user must use the ADM to

define each shot. The DGM will use a 7-bit pattern to

select one of the shots.

The machine must be in Shot mode to select a shot.

Shot Selection Bit Pattern

Digital

Digital

Digital

Digital

Digital

Digital

Input

Input

Input

Input

9

10

11

0000000Not Defined

0000001 Shot 1

0000010 Shot 2

0000011 Shot 3

1100100Shot 100

1100101Not Defined

1111111Not Defined

Input

12

13

…

…

Input

14

Digital

Input

15

Digital Inputs 12-15 have alternate functionality in Operator, Shot and Standby modes. Below are their alternate

functions:

Shot

Selected

Digital Input 16

The function of this bit is based on the selected operating mode:

• Shot Mode: Sets the shot number. To use, set the

Shot Selection Bits to the desired bit pattern then

toggle this bit low then high then low to change the

shot. After toggling this bit, the PLC programmer

should verify that the current shot number matches

the request.

• Operator Mode: Sets the dispense pressure or

flow. To use, set Analog Input 1: Set Pressure/Set

Flow to the voltage for the corresponding desire flow

or pressure. After 185 mS of settling, toggle this bit

to set the new analog value. The PLC programmer

should check Digital Output 4 to make sure the setpoint was accepted.

See the Primary DGM Analog Inputs section on

page 19 for analog input voltage calculation.

• Standby Mode: Hold the bit high to park the pump.

Use the Digital Output 24 to verify the pump has

successfully parked. Release the bit when the pump

is successfully parked.

Digital Input 12 becomes:

(used in Operator, Shot, and Standby modes)

• Enable Dispensing: Keep this bit low when not

selecting a shot. If this bit is high during a dispense

request or park pump request, the request will be

ignored. If this bit goes high during a dispense the

system will go into Disabled mode.

Digital Input 13 becomes:

(used in Disabled mode)

• Enable ADM: Toggle this bit to enable the ADM.

Digital Input 14 becomes:

(used in Standby mode)

• Dispense Valve Open: While this bit is pulled high

the dispense valve will remain open. When it is

pulled low the dispense valve will be closed.

Digital Input 15 becomes:

(used in Standby mode)

• Set/Release Dispense Valve Lock: Toggle this bit

high to lock or unlock the dispense valve in Standby

Mode.

3A1149D 17

Page 18

Operation

Primary DGM Digital Outputs

See DGM Digital Outputs table in the Primary DGM Pin

Assignments section beginning on page 10 for pin

numbers associated with each bit description.

Digital Output 1: DGM to PLC Heartbeat

See the DGM to PLC Heartbeat description in the Primary DGM Digital Inputs section beginning on page

16.

Digital Output 2: Ready To Dispense

This bit is high when the system is ready to begin dispensing.

Digital Output 3: Dispense In Progress

This bit is high when the machine is dispensing.

Digital Output 4: Flow Rate/Pressure

Setpoint Rejected

This bit is high when the requested setpoint change is

rejected.

Digital Outputs 18-24: Shot Selected Bits

When in Shot mode, these bits are used to form a bit

pattern to indicate which shot is selected. See the shot

selection bit patterns table in the Primary DGM Digital

Inputs section beginning on page 16.

When in Standby mode, Digital Outputs 22-24 each perform a different function:

Digital Output 22:

• Dispense Valve Locked: This bit is high when the

dispense valve is locked.

Digital Output 23:

• Dispense Valve Open: This bit is high when the

dispense valve is open.

Digital Output 24:

• Pump Parked: This bit is high when the pump is in

the parked position.

Digital Output 5: Dispense Mode Selected

When this bit is low, the selected Dispense mode is

Flow. When this bit is high, the selected Dispense mode

is Pressure.

Digital Output 6: Error Present

If an error is generated this output will be high. The PLC

programmer should monitor the Fault Code bits to determine if the system is in a healthy state but this will serve

as an additional and redundant alert.

Digital Output 7-14: Fault Codes

This 8-bit pattern indicates what error is being displayed.

See the Fault Code Bit Pattern Table on page 31. The

fault code is removed when it is acknowledged. For best

results, check the ADM.

Digital Output 15-17: Operating Mode

Selected Bits

These bits form a bit pattern to indicate which operating

mode is selected. See the operating mode bit patterns

table in the Primary DGM Digital Inputs section begin-

ning on page 16.

18 3A1149D

Page 19

Primary DGM Analog Inputs

Operation

See Analog Inputs table in the Primary DGM Pin

Assignments section beginning on page 10 for pin

numbers associated with each bit description.

The DGM provides 4 analog inputs and 4 analog outputs. Each analog I/O point has a voltage range of

0-10 VDC. Analog Inputs 2, 3, and 4 are not used.

It is the responsibility of the PLC programmer to verify

the HFR system and PLC have matching values for

pump sizes, material specific gravities, maximum working pressure, and units of measure for pressure. These

are verified using the Setup screens in the ADM.

Analog Input 1: Set Combined Flow Rate or

B (Blue) Dispensing Pressure

To calculate the input voltage for the desired flow or

pressure, use the following formulas.

Volumetric Flow:

V = ( 10 x F

Weight Flow:

V = ( 10 x F

) / ( Ap + Bp )

v

) / ( Ap x Asg + Bp x B

w

sg

)

If the A (Red) pump is 120 cc, the A (Red) specific gravity is 1.09, the B (Blue) pump is 160 cc, the B (Blue)

specific gravity is 1.21, and the desired flow rate is 200

grams per second then:

V = (10 x 200) / (120 x 1.09 + 160 x 1.21)

= 6.17 volts

If the desired pressure is 1500 psi and the maximum

working pressure is 2000 psi then:

P

= 1250

d

P

= 2000

mwp

V = (10 x 1500) / (2000 )

= 7.5 volts

To set the flow or pressure:

1. Calculate the voltage to use.

2. Set the Analog Input 1 to the calculated voltage and

hold.

Pressure:

V = ( 10 x P

) / ( P

d

mwp

)

where,

V = Voltage

A

= A (Red) pump size in cc

p

B

= B (Blue) pump size in cc

p

= A (Red) material specific gravity

A

sg

B

= B (Blue) material specific gravity

sg

= Desired volumetric flow rate in cc per second

F

v

F

= Desired flow rate in grams per second

w

= Desired pressure

P

d

P

= Maximum working pressure

mwp

For example, if the A (Red) pump is 120 cc, the B (Blue)

pump is 160 cc, and the desired flow rate is 180 cc per

second then:

V = (10 x 180) / (120 + 160)

= 6.43 volts

3. After 185 mS, pull the corresponding Digital

Input 16 bit for 185 mS then release Digital Input 16.

4. Check Digital Output 4 to verify the setpoint request

was not rejected.

3A1149D 19

Page 20

Operation

Primary DGM Analog Outputs

See Analog Outputs table in the Primary DGM Pin

Assignments section beginning on page 10 for pin

numbers associated with each function. Each analog I/O

point has a voltage range of 0-10 VDC. The primary

DGM analog outputs are used to provide feedback

regarding operating pressures and flows.

Analog Output 1: B (Blue) Pump Pressure

and Analog Output 2: A (Red) Pump

Pressure

An analog voltage representation of the pump pressure

will be presented at the respective output. The DGM will

use the 0-10V range to represent pressures from 0 to

500 psi plus the maximum working pressure. Due to this

limit, pressures beyond 500 psi above the maximum

working pressure will be represented as 10V.

To calculate the pump pressure based on the output

voltage, the maximum working pressure must be known.

See the HFR system manual to determine the system

maximum working pressure.

When units of measure are psi:

P

= 0.1 x V x ( P

a

When units of measure are bar:

= 0.1 x V x ( P

P

a

When units of measure are MPa:

P

= 0.1 x V x ( P

a

where,

V = Voltage

P

= Actual pump pressure

a

P

= Maximum working pressure

mwp

For example, if the output voltage is 6 and the maximum

working pressure is 2000 psi then:

P

= 0.1 x 6 x ( 2000 + 500)

a

= 1500 psi

mwp

mwp

mwp

+ 500)

+ 34.5)

+ 3.45)

Analog Output 3: B (Blue) Pressure or

Combined Flow Rate

To use the Analog Output 3 voltage to calculate the

B (Blue) pump pressure or combined flow rate, use the

following formulas.

Volumetric Flow:

F

= 0.1 x V x (Ap + Bp)

v

Weight Flow:

F

= 0.1 x V x (Ap x Asg + Bp x Bsg)

w

Pressure:

When units of measure are psi:

Pa = 0.1 x V x ( P

When units of measure are bar:

= 0.1 x V x ( P

P

a

When units of measure are MPa:

= 0.1 x V x ( P

P

a

where

= Actual volumetric flow rate in cc per second

F

v

= Actual flow rate in grams per second

F

w

P

= Actual B (Blue) pump pressure

a

V = Voltage

= A (Red) pump size in cc

A

p

B

= B (Blue) pump size in cc

p

= A (Red) material specific gravity

A

sg

= B (Blue) material specific gravity

B

sg

P

= Maximum working pressure

mwp

For example, if the A (Red) pump is 120 cc, the B (Blue)

pump is 160 cc, and the output voltage is 2.3 then:

F

= 0.1 x 2.3 x (120 + 160)

v

= 64.4 cc/sec

If the A (Red) pump is 120 cc, the A (Red) specific gravity is 1.09, the B (Blue) pump is 240 cc, the B (Blue)

specific gravity is 1.21, and the output voltage is 2.3

then:

mwp

mwp

mwp

+ 500 )

+ 34.5 )

+ 3.45 )

F

= 0.1 x 2.3 x (120 x 1.09 + 160 x 1.21)

w

= 74.6 g/sec

If the output voltage is 6 and the maximum working

pressure is 2000 psi then:

P

= 0.1 x 6 x ( 2000 + 500 )

a

= 1500 psi

20 3A1149D

Page 21

Operation

Secondary DGM I/O Overview

The secondary DGM is used for controlling and monitoring the status of the heaters and chillers.

NOTE: The HFR has a total of 8 possible conditioning

zones that can be implemented in the system. In any

given instance, a maximum of 4 conditioning zones can

be enabled.

Each temperature conditioning item is assigned a zone

number. Most temperature conditioning bits relate to a

zone number rather than to a specific temperature conditioning item’s name. Knowing the correct zone number

is important for desired machine operation. The zone

numbers are always assigned in the order shown in the

following table. Going down the list, the first enabled

item is zone 1, the second is zone 2, the third is zone 3,

and the fourth is zone 4.

NOTE: There will be less than four zones if less than

four temperature conditioning items are installed or

enabled on the ADM.

Order Temperature Conditioning Item

1 Tank Heater, A (Red)

2 Tank Heater, B (Blue)

3 Inline Heater, A (Red)

4 Inline Heater, B (Blue)

5 Hose Heater, A (Red)

6 Hose Heater, B (Blue)

7 Chiller, A (Red)

8 Chiller, B (Blue)

The following is an example of a system with Tank

Heater A (Red), Inline Heater B (Blue), Hose Heater B

(Blue), and Chiller A (Red) enabled and shows the

assigned zone numbers for each.

Zone Order Temperature Conditioning Item

1 1 Tank Heater, A (Red)

2 Tank Heater, B (Blue)

3 Inline Heater, A (Red)

2 4 Inline Heater, B (Blue)

5 Hose Heater, A (Red)

3 6 Hose Heater, B (Blue)

4 7 Chiller, A (Red)

8 Chiller, B (Blue)

See the Secondary DGM Digital Outputs section

beginning on page 22 for information about finding out

which temperature conditioning components are

enabled.

3A1149D 21

Page 22

Operation

Secondary DGM Digital Inputs

Digital Inputs 1-4: Toggle Zone

Conditioning On/Off Bits

Pulling this input high turns the zone on. Pulling it low

turns the zone off. It is also possible to control the zones

using the ADM.

Digital Inputs 5-8: Accept Zone Setpoint

Change Bits

NOTE: This function is only available on 2nd Generation

ADM’s.

Toggle one of these bits high to tell the DGM to set the

new zone setpoint based on the corresponding analog

input voltage. See Secondary DGM Analog Inputs on

page 23 for voltage calculation and procedure for

changing the setpoint.

Secondary DGM Digital Outputs

Digital Output 2: Ready To Dispense

The ADM can be configured to prevent dispensing if the

conditioning zones are not the correct temperature. If

this feature is enabled, this bit will be low when at least

one temperature zone is not up to temperature.

NOTE: This bit gets pulled low during a dispense.

Digital Output 3: Dispense in Progress

This bit is high when a dispense is in progress.

Digital Outputs 4-7: Zone Conditioning On

When one of these bits is high, it indicates that the

respective heater/chiller in that zone is on.

Digital Outputs 8-11: Zone Temperature

Setpoint Rejected

This bit indicates the requested setpoint has been

rejected. This occurs when the requested setpoint is too

high or low. This bit should be checked after requesting

to change a setpoint to verify that the setpoint was

accepted.

NOTE: Changing the setpoint on the ADM does not

affect this bit.

Digital Outputs 12-19: Temperature

Conditioning Component Enabled

When one of these bits is high, the corresponding temperature conditioning component is enabled.

22 3A1149D

Page 23

Secondary DGM Analog Inputs

Set Zone Temperature

The external control device interfacing with the DGM

can use a varying voltage to specify the desired setpoint

for the zone. See Secondary DGM Pin Assignments

on page 12.

To calculate the voltage to use based on the desired

temperature in degrees Fahrenheit:

Voltage = 0.074 x °F - 4.074

For example, the voltage for 86°F would be:

Voltage = 0.074 x 86 - 4.074

= 2.29

Operation

To calculate the voltage to use based on the desired

temperature in degrees Celsius:

Voltage = 0.133 x °C - 1.707

For example, the voltage for 30°C would be:

Voltage = 0.133 x 30 - 1.707

= 2.28

To set the zone temperature:

1. Calculate the voltage to use.

2. Set the desired “Set Zone Temperature” Analog

Input to the calculated voltage and hold.

3. After 185 mS, pull high the corresponding “Accept

Zone Setpoint Change” Digital Input for 185 mS

then release.

4. Check the Zone Temperature Setpoint Rejected bit.

If it is asserted, check the ADM.

3A1149D 23

Page 24

Operation

Secondary DGM Analog Outputs

Actual Zone Temperature

The analog output voltages indicate the actual temperature of the material at the specified zone.

To calculate the temperature in degrees Fahrenheit

based on the output voltage:

°F = 13.5 x Voltage + 55

For example, if the output voltage is 2.3 then:

°F = 13.5 x 2.3 +55

= 86°F

To calculate the temperature in degrees Celsius based

on the output voltage:

°C = 7.5 x Voltage + 12.8

For example, if the output voltage is 2.3 then:

°C = 7.5 x 2.3 +12.8

= 30°C

24 3A1149D

Page 25

Timing Diagrams

Once the last line has been set in any of the following

timing diagrams, a 10 mS settle time should be

observed to allow the PLC and DGM hardware to reach

a steady state.

Heartbeat

Timing Diagrams

3 Sec

DGM

Heartbeat

PLC

Heartbeat

FIG. 6: Heartbeat Timing Diagram

Activate System Stop Button

System Stop

6 Sec

>185 mS

Heartbeat

Timed out

Heartbeat

System Disabled until

turned back on through

dispense request key or

Resuming

F

IG. 7: Activate System Stop Button Timing Diagram

3A1149D 25

Page 26

Timing Diagrams

System Requests

>185 mS

Input

Signal

IG. 8: System Requests Timing Diagram

F

The following are system requests:

• Enabling the ADM

• Acknowledging Errors

• Parking the pump

Select an Operating Mode or Shot Number

10 mS

settle

Shot Sel 6

Shot Sel 5

Shot Sel 4

Shot Sel 3

Shot Sel 2

Shot Sel 1

Shot Sel 0

Set New

Shot Number

>185 mS

Performing

Request

FIG. 9: Select a Shot Number Timing Diagram

The individual lines can change independently in any

order.

26 3A1149D

Page 27

Change Setpoint

Timing Diagrams

Analog Voltage

10 mS

settle

Set New Value

F

IG. 10: Change Setpoint Timing Diagram

This procedure applies to the following functions:

• Changing the dispense pressure setpoint

• Changing the material temperature setpoint

Toggle On/Off

Hold Analog Voltage

>185 mS

Input

Signal

>185 mS

Feature

Activity

FIG. 11: Toggle On/Off Timing Diagram

This diagram applies to the following functions:

• Open/Close the Dispense Valve

• Lock/Unlock the Dispense Valve

• Activate/Deactivate the Hydraulic Power Pack

>185 mS

>185 mS

FFO NO FFO

3A1149D 27

Page 28

Timing Diagrams

Shot Mode Dispense

Dispense

Request

>185 mS

Dispense

Activity

Dispensing

FIG. 12: Shot Mode Dispense Timing Diagram

Shot Mode Dispense and Termination

Dispense

Request

Dispense

Activity

>185 mS

>185mS >185mS

Dispensing

Remainder of

shot not taken.

IG. 13: Shot Mode Dispense Termination Timing Diagram

F

28 3A1149D

Page 29

Operator Mode Dispense

Dispense

Request

Dispense

Activity

FIG. 14: Operator Mode Dispense Timing Diagram

>185 mS

Timing Diagrams

>185mS

Dispensing

3A1149D 29

Page 30

Maintenance

Maintenance

Install Upgrade Token

Note: The DGM connection to the system is temporarily

disabled during the installation of the upgrade token.

1. Ensure system is inactive.

2. Remove access cover (D).

D

r_24B681_2B9904_3b

IG. 15

F

4. Press and hold the push-button (M) for three seconds then release.

NOTE: The LED will flash red until software is done

uploading.

5. Remove token (T) when software has successfully

uploaded.

6. Replace access cover (D).

7. Cycle system power.

Check Cable Connections

Ensure all cables are securely connected to DGM connectors.

3. Insert and press token (T) firmly into slot.

NOTE: There is no preferred orientation of token.

L

G

M

r_24B681_2B9904_4b

F

IG. 16

T

30 3A1149D

Page 31

Troubleshooting

Diagnostic Information

7

Module Status LED Signal Diagnosis

Green on System is powered up

Yellow Internal communication in progress

Red solid DGM hardware failure, replace DGM

Red flashing fast Uploading software

Red flashing slow Token error, remove token then

re-install software token

Fault Code Bit Pattern Table

Troubleshooting

This is an 8-bit pattern indicating the current error number in the system. The bit pattern is accompanied by the

Error Present bit.

If the PLC displays error messages, the PLC programmer should translate the bit pattern to the corresponding

descriptive string. See the following table to translate the

fault code bit pattern to a descriptive string. The Error

Number column is used for reference to aid the PLC

programmer in translating from fault code bit pattern to

error string. When error number 255 with bit pattern

“11111111” occurs the user should check the ADM for

error details.

NOTE: This manual is available at Graco.com. To prevent having to manually re-type these error codes and

strings into your PLC program, go to Graco.com and

retrieve the electronic version of this manual then copy

the following table from the PDF.

Fault Code

Bit Pattern

(Bit 7 --> Bit 0)

00000000 No Active Errors 0 0 0000

00000001

00000010 Motor Temp. Cutback B (Blue) 2 V T 3 N 1

00000011 Oil Temp. Shutdown B (Blue) 3 A T 4 H 1

00000100 Oil Temp. Cutback B (Blue) 4 D T 3 H 1

00000101 Low Oil Level B (Blue) 5 A M B H 1

00000110 Motor Over Current B (Blue) 6 A A 4 H 1

00000111 Motor Over Current B (Blue) 7 A A 4 N 1

00001000 Motor Over Current B (Blue) 8 A A 4 M 1

00001001 Motor Over Current B (Blue) 9 A A 9 C 1

00001010

00001011

00001100

Error String

Motor Temp. Shutdown B

(Blue)

Motor Control High Temp. B

(Blue)

Motor Control Overvoltage B

(Blue)

Motor Control Undervoltage B

(Blue)

Error

Number

1AT4N1

10 A T 4 C 1

11 A V 4 H 0

12 A V 1 H 1

Error Code

Shown on the

ADM

Fault Code

Bit Pattern

(Bit 7 --> Bit 0)

00001101 Motor Encoder Fault B (Blue) 13 A W B H 1

00001110 Motor Controller Fault B (Blue) 14 D W M H 1

00001111

00010000 High Motor Speed B (Blue) 16 A W K H 1

00010001 B (Blue) Pump Failed to Move 17 D N 4 A 1

00010010 Invalid Setpoint Request 18 D W S C 0

00010011 Small Shot Request 19 D B 9 C 0

00010100 Pressure Imbalance 20 A P 4 D 0

00010101 Pumps Not Defined 21 A D S C 0

00010110

00010111 Invalid Weight Cal. Data 23 D 0500

00011000 B (Blue) Position Sensor Fault 24 A D 6 A 1

00011001

00011010

00011011

00011100

00011101 B (Blue) Setpoint Exceeded 29 D D 4 A 1

00011110 B (Blue) Setpoint Exceeded 30 D D 3 A 1

00011111 A (Red) Pressure Shutdown 31 A P 4 A 1

00100000 B (Blue) Pressure Shutdown 32 A P 4 B 2

00100001 B (Blue) Pump Not Parked 33 D D F A 1

00100010 B (Blue) Pump Failed to Stall 34 D F 7 D 1

00100011 Invalid Gel Timer Definition 35 D W S D 0

00100100 A (Red) Pump Cavitation 36 D D D A 1

00100101 B (Blue) Pump Cavitation 37 D D D B 2

00100110 Pressure Terminated Cal. 38 V P 9 A 1

00100111 Pressure Terminated Cal. 39 V P 9 B 2

00101000 Flow Terminated Cal. 40 V D A A 1

00101001 Thermal Pressure Rise 41 D P 4 0 0

00101010 Setpoint Outside Cal. Range 42 V 0 9 C 1

00101011

00101100 A (Red) Motor Temp. Cutback 44 V T 3 N 2

Error String

Low Motor Performance B

(Blue)

Invalid Learn Mode Data B

(Blue)

A (Red) Pressure Sensor

Faul t

B (Blue) Pressure Sensor

Faul t

B (Blue) Setpoint Not

Reached

B (Blue) Setpoint Not

Reached

A (Red) Motor Temp. Shutdown

Error

Number

15 V M B N 1

22 D D 5 A 1

25 A P 6 A 1

26 A P 6 B 2

27 D D 1 A 1

28 D D 2 A 1

43 A T 4 N 2

Error Code

Shown on the

ADM

3A1149D 31

Page 32

Troubleshooting

Fault Code

Bit Pattern

(Bit 7 --> Bit 0)

00101101 A (Red) Oil Temp. Shutdown 45 A T 4 H 2

00101110 A (Red) Oil Temp. Cutback 46 D T 3 H 2

00101111 A (Red) Low Oil Level 47 A M B H 2

00110000 A (Red) Motor Over Current 48 A A 4 H 2

00110001 A (Red) Motor Over Current 49 A A 4 N 2

00110010 A (Red) Motor Over Current 50 A A 4 M 2

00110011 A (Red) Motor Over Current 51 A A 9 C 2

00110100

00110101

00110110

00110111 A (Red) Motor Encoder Fault 55 A W B H 2

00111000 A (Red) Motor Controller Fault 56 A W M H 2

00111001

00111010 A (Red) High Motor Speed 58 A W K H 2

00111011 A (Red) Pump Failed to Move 59 A N 4 B 0

00111100 Invalid Requested Ratio 60 A R 9 C 0

00111101 Invalid Learn Mode Data 61 A D 5 B 2

00111110 Invalid Auto Cal B (Blue)? 62 0 0000

00111111 A (Red) Position Sensor Fault 63 A D 6 B 2

01000000 A (Red) Setpoint Not Reached 64 D D 1 A 2

01000001 A (Red) Setpoint Not Reached 65 D D 2 A 2

01000010 A (Red) Setpoint Exceeded 66 D D 4 A 2

01000011 A (Red) Setpoint Exceeded 67 D D 3 A 2

01000100 A (Red) Pressure Shutdown 68 A P 4 A 1

01000101 A (Red) Pump Not Parked 69 D D F B 2

01000110 A (Red) Pump Failed to Stall 70 A F 7 D 2

01000111 Another Cal Error? 71 0 0000

01001000

01001001 A (Red) Blanket Temp. Cutoff 73 A T 9 A 6

01001010 B (Blue) Blanket Temp. Cutoff 74 A T 9 B 5

01001011 A (Red) Inline Temp. Cutoff 75 A T 9 A 3

01001100 B (Blue) Inline Temp. Cutoff 76 A T 9 B 1

01001101 No A (Red) Blanket Current 77 A A 8 A 6

01001110 No B (Blue) Blanket Current 78 A A 8 B 5

01001111 No A (Red) Inline Current 79 A A 8 A 3

01010000 No B (Blue) Inline Current 80 A A 8 B 1

01010001 No A (Red) Hose Current 81 A A 8 A 2

01010010 No B (Blue) Hose Current 82 A A 8 B 4

01010011 No A (Red) Chiller Current 83 A A 8 B 7

01010100 No B (Blue) Chiller Current 84 A A 8 B 8

01010101 A (Red) Blanket Overcurrent 85 A A 4 A 6

01010110 B (Blue) Blanket Overcurrent 86 A A 4 B 5

01010111 A (Red) Inline Overcurrent 87 A A 4 A 3

01011000 B (Blue) Inline Overcurrent 88 A A 4 B 1

01011001 A (Red) Hose Overcurrent 89 A A 4 A 2

01011010 B (Blue) Hose Overcurrent 90 A A 4 B 4

01011011 A (Red) Chiller Overcurrent 91 A A 4 A 7

01011100 B (Blue) Chiller Overcurrent 92 A A 4 B 8

01011101 A (Red) Blanket Control Fault 93 A A 7 A 6

01011110 B (Blue) Blanket Control Fault 94 A A 7 B 5

01011111 A (Red) Inline Control Fault 95 A A 7 A 3

01100000 B (Blue) Inline Control Fault 96 A A 7 B 1

01100001 A (Red) Hose Control Fault 97 A A 7 A 2

01100010 B (Blue) Hose Control Fault 98 A A 7 B 4

Error String

A (Red) Motor Control High

Te mp .

A (Red) Motor Control Overvoltage

A (Red) Motor Control Undervoltage

A (Red) Low Motor Performance

A (Red) Thermal Pressure

Rise?

Error

Number

52 A T 4 C 2

53 A V 4 H 0

54 A V 1 H 2

57 A M B N 2

72 DP401

Error Code

Shown on the

ADM

Fault Code

Bit Pattern

(Bit 7 --> Bit 0)

01100011 A (Red) Chiller Control Fault 99 A A 7 A 7

01100100 B (Blue) Chiller Control Fault 100 A A 7 B 8

01100101 A (Red) Blanket Overvoltage 101 A V 4 A 6

01100110 B (Blue) Blanket Overvoltage 102 A V 4 B 5

01100111 A (Red) Inline Overvoltage 103 A V 4 A 3

01101000 B (Blue) Inline Overvoltage 104 A V 4 B 1

01101001 A (Red) Hose Overvoltage 105 A V 4 A 2

01101010 B (Blue) Hose Overvoltage 106 A V 4 B 4

01101011 A (Red) Chiller Overvoltage 107 A V 4 A 7

01101100 B (Blue) Chiller Overvoltage 108 A V 4 B 8

01101101 A (Red) Blanket Undervoltage 109 A V 4 A 6

01101110 B (Blue) Blanket Undervoltage 110 A V 4 B 5

01101111 A (Red) Inline Undervoltage 111 A V 4 A 3

01110000 B (Blue) Inline Undervoltage 112 A V 4 B 1

01110001 A (Red) Hose Undervoltage 113 A V 4 A 2

01110010 B (Blue) Hose Undervoltage 114 A V 4 B 4

01110011 A (Red) Chiller Undervoltage 115 A V 4 A 7

01110100 B (Blue) Chiller Undervoltage 116 A V 4 B 8

01110101

01110110

01110111 A (Red) Inline Ctrl Shutdown 119 A T 9 C 3

01111000 B (Blue) Inline Ctrl Shutdown 120 A T 9 C 1

01111001 A (Red) Hose Ctrl Shutdown 121 A T 9 C 2

01111010 B (Blue) Hose Ctrl Shutdown 122 A T 9 C 4

01111011 A (Red) Chiller Ctrl Shutdown 123 A T 9 C 7

01111100 B (Blue) Chiller Ctrl Shutdown 124 A T 9 C 8

01111101 A (Red) Tank Con. Cutback 125 V W M C 6

01111110 B (Blue) Tank Con. Cutback 126 V W M C 5

01111111 A (Red) Inline Con. Cutback 127 V W M C 3

10000000 B (Blue) Inline Con. Cutback 128 V W M C 1

10000001 A (Red) Hose Con. Cutback 129 V W M C 2

10000010 B (Blue) Hose Con. Cutback 130 V W M C 4

10000011 A (Red) Chiller Con. Cutback 131 V W M C 7

10000100 B (Blue) Chiller Con. Cutback 132 V W M C 8

10000101 A (Red) Tank High Fluid Temp. 133 A T 4 A 6

10000110

10000111

10001000

10001001

10001010

10001011

10001100

10001101 A (Red) Blanket High Temp. 141 A W M A 6

10001110 B (Blue) Blanket High Temp. 142 A W M B 5

10001111 A (Red) Tank Low Fluid Temp. 143 D T 1 A 6

10010000 B (Blue) Tank Low Fluid Temp. 144 D T 1 B 5

10010001

10010010

10010011 A (Red) Hose Low Fluid Temp. 147 D T 1 A 2

Error String

A (Red) Blanket Ctrl Shutdown

B (Blue) Blanket Ctrl Shutdown

B (Blue) Tank High Fluid

Te mp .

A (Red) Inline High Fluid

Te mp .

B (Blue) Inline High Fluid

Te mp .

A (Red) Hose High Fluid

Te mp .

B (Blue) Hose High Fluid

Te mp .

A (Red) Chiller High Fluid

Te mp .

B (Blue) Chiller High Fluid

Te mp .

A (Red) Inline Low Fluid

Te mp .

B (Blue) Inline Low Fluid

Te mp .

Error

Number

117 A T 9 C 6

118 A T 9 C 5

134 A T 4 B 5

135 A T 4 A 3

136 A T 4 B 1

137 A T 4 A 2

138 A T 4 B 4

139 D T 4 A 7

140 D T 4 B 8

145 D T 1 A 3

146 D T 1 B 1

Error Code

Shown on the

ADM

32 3A1149D

Page 33

Troubleshooting

Fault Code

Bit Pattern

(Bit 7 --> Bit 0)

10010100

10010101

10010110

10010111 No Heat A (Red) Tank 151 A T 8 A 6

10011000 No Heat B (Blue) Tank 152 A T 8 B 5

10011001 No Heat A (Red) Inline 153 A T 8 A 3

10011010 No Heat B (Blue) Inline 154 A T 8 B 1

10011011 No Heat A (Red) Hose 155 A T 8 A 2

10011100 No Heat B (Blue) Hose 156 A T 8 B 4

10011101 No Cooling A (Red) Chiller 157 A T 8 A 7

10011110 No Cooling B (Blue) Chiller 158 A T 8 B 8

10011111 A (Red) Tank RTD Fault 159 A T 6 A 6

10100000 B (Blue) Tank RTD Fault 160 A T 6 B 5

10100001 A (Red) Inline RTD Fault 161 A T 6 A 3

10100010 B (Blue) Inline RTD Fault 162 A T 6 B 1

10100011 A (Red) Hose FTS Fault 163 A T 6 A 2

10100100 B (Blue) Hose FTS Fault 164 A T 6 B 4

10100101 A (Red) Chiller RTD Fault 165 A T 6 A 7

10100110 B (Blue) Chiller RTD Fault 166 A T 6 B 8

10100111 A (Red) Blanket RTD Fault 167 A T 6 C 6

10101000 B (Blue) Blanket RTD Fault 168 A T 6 C 5

10101001 A (Red) Chiller RTD Fault 169 A T 6 C 7

10101010 B (Blue) Chiller RTD Fault 170 A T 6 C 8

10101011 A (Red) Tank Con. Fault 171 A W M 0 6

10101100 B (Blue) Tank Con. Fault 172 A W M 0 5

10101101 A (Red) Inline Con. Fault 173 A W M 0 3

10101110 B (Blue) Inline Con. Fault 174 A W M 0 1

10101111 A (Red) Hose Con. Fault 175 A W M 0 2

10110000 B (Blue) Hose Con. Fault 176 A W M 0 4

10110001 A (Red) Chiller Con. Fault 177 A W M 0 7

10110010 B (Blue) Chiller Con. Fault 178 A W M 0 8

10110011 A (Red) Tank Con. Fault 179 A W M C 6

10110100 B (Blue) Tank Con. Fault 180 A W M C 5

10110101 A (Red) Inline Con. Fault 181 A W M C 3

10110110 B (Blue) Inline Con. Fault 182 A W M C 1

10110111 A (Red) Hose Con. Fault 183 A W M C 2

10111000 B (Blue) Hose Con. Fault 184 A W M C 4

10111001 A (Red) Chiller Con. Fault 185 A W M C 7

10111010 B (Blue) Chiller Con. Fault 186 A W M C 8

10111011 High Accumulator Pressure 187 A P 4 H 3

10111100 Low Accumulator Pressure 188 A P 1 H 3

10111101 High Mix Head Oil Temp. 189 A T 4 H 3

10111110 Low Mix Head Oil Level 190 A M B H 3

10111111 Soft Stop Asserted 191 A D E H 3

11000000 Mix Head Motor Overload 192 A A 4 H 3

11000001 M1 Material Extend Fault 193 A W D F 3

11000010 M1 Cleanout Extend Fault 194 A W D D 3

11000011 M2 Material Extend Fault 195 A W D F 4

11000100 M2 Cleanout Retract Fault 196 A W D D 4

11000101 A (Red) Low Material Level 197 D L111

11000110 B (Blue) Low Material Level 198 D L122

11000111 A (Red) High Material Level 199 D L311

11001000 B (Blue) High Material Level 200 D L322

11001001 A (Red) Auto Refill Timeout 201 D L 6 A 1

11001010 B (Blue) Auto Refill Timeout 202 D L 6 B 2

Error String

B (Blue) Hose Low Fluid

Te mp .

A (Red) Chiller Low Fluid

Te mp .

B (Blue) Chiller Low Fluid

Te mp .

Error

Number

148 D T 1 B 4

149 A T 1 A 7

150 A T 1 B 8

Error Code

Shown on the

ADM

Fault Code

Bit Pattern

(Bit 7 --> Bit 0)

11001011 A (Red) Fill Sensor Fault 203 D L 8 A 1

11001100 B (Blue) Fill Sensor Fault 204 D L 8 B 2

11001101 A (Red) Circ. Valve Fault 205 A W E R 1

11001110 B (Blue) Circ. Valve Fault 206 A W E R 2

11001111 High Ratio 207 A W D F 3

11010000 High Ratio 208 A W D D 3

11010001 Low Ratio 209 A W D F 4

11010010 Low Ratio 210 A W D D 4

11010011 High Flow A (Red) 211 D L111

11010100 High Flow A (Red) 212 D L122

11010101 High Flow B (Blue) 213 D L311

11010110 High Flow B (Blue) 214 D L322

11010111 Low Flow A (Red) 215 D L 6 A 1

11011000 Low Flow A (Red) 216 D L 6 B 2

11011001 Low Flow B (Blue) 217 D L 8 A 1

11011010 Low Flow B (Blue) 218 D L 8 B 2

11011011 Low Dispense Amount 219 A N 1 D 0

11011100 High Dispense Amount 220 A N 4 D 0

11011101 Low Dispense Amount 221 D N 2 D 0

11011110 High Dispense Amount 222 D N 3 D 0

11011111 Comm. Error Motor 223 A C A C 1

11100000 Comm. Error Motor 224 A C A C 2

11100001 Comm. Error A (Red) Tank 225 A C A C 3

11100010 Comm. Error B (Blue) Tank 226 A C A C 4

11100011 Comm. Error Mix Head 227 A C A C 5

11100100 Comm. Error Mix Head 2 228 A C A C 6

11100101 Comm. Error Ratio Monitor 229 A C A C 7

11100110 Comm. Error A (Red) Blanket 230 A C A A 6

11100111 Comm. Error B (Blue) Blanket 231 A C A B 5

11101000 Comm. Error A (Red) Inline 232 A C A A 3

11101001 Comm. Error B (Blue) Inline 233 A C A B 1

11101010 Comm. Error A (Red) Hose 234 A C A A 2

11101011 Comm. Error B (Blue) Hose 235 A C A B 4

11101100 Comm. Error A (Red) Chiller 236 A C A A 7

11101101 Comm. Error B (Blue) Chiller 237 A C A B 8

11101110 Comm. Error Field Bus 238 A C A C N

11101111 Comm. Error Discrete I/O 239 A C A C P

11110000 Comm. Error Pendant 240 A C A C R

11110001 No or Invalid Key Token 241 A W R C 0

11110010 USB Logs Near Capacity 242 D M 0 U 0

11110011 USB Update Failed 243 A W 0 U 0

11111111 See ADM For Details 255

Error String

Error

Number

Error Code

Shown on the

ADM

3A1149D 33

Page 34

Parts

Parts

5

4

1

1

11

6

r_24f843_3A1149_1b

2

13

3, 9, 10

7

3, 9, 10

Quantity

Ref Part Description

24F843,

Single DGM

Kit

24F844,

Dual DGM

Kit

24G830,

DGM only

1 24B681 MODULE, GCA, cube, DGM 1 2 1

2 289697 MODULE, cube, GCA, base 1 2 1

3 24C476 HARNESS, wire, ground, term, 4 in. 1 2 1

4 124638 CABLE, 78 pin, 2.5 ft, D-sub, male

1 2

to female

5 123783 BOARD, DGM, 78 pin break out 1 2

6 121003 CABLE, CAN, female / female 3.0m 1 1

7 123762 CABLE, CAN, 90 x 90, female /

1

female, 0.5m

9 114993 SCREW, mach, pan wash head 1 2 1

10 102063 WASHER, lock, ext 2 4 2

11 113003 SCREW, socket head cap,

5 10 5

#10-32 x 0.62, stainless steel

12 277674 ENCLOSURE, cube door 1 2 1

13† 121901 SUPPRESSOR, box snap, ferrite 1 1

14 16D942 TOKEN, upgrade, software * * *

1

2

11

2

* These kits ship with software loaded. Upgrade token

the DGM end of the long CAN cable.

16D942 is listed for reference only.

† The DGM must have a ferrite suppressor attached to

34 3A1149D

Page 35

Accessories

Part Description

124415 CAN Cable Extension, 9.8 ft (3.0 m)

24E898 CAN Cable Extension, 27.9 ft (8.5 m)

24E897 CAN Cable Extension, 52.5 ft (16.0 m)

124654 CAN Splitter, 1 male to 2 female

24B861 78 pin d-sub cable; 50 ft (15.2 m), male to female

Technical Data

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-30 VDC NEC Class 2

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 oz. (0.4 kg)

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.3 x 3.8 x 3.8 in. (109 x 97 x 97 mm)

Accessories

3A1149D 35

Page 36

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 3A1149

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2010, Graco Inc. is registered to ISO 9001

www.graco.com

Revised 6/2011

Loading...

Loading...