Page 1

Repair/Parts

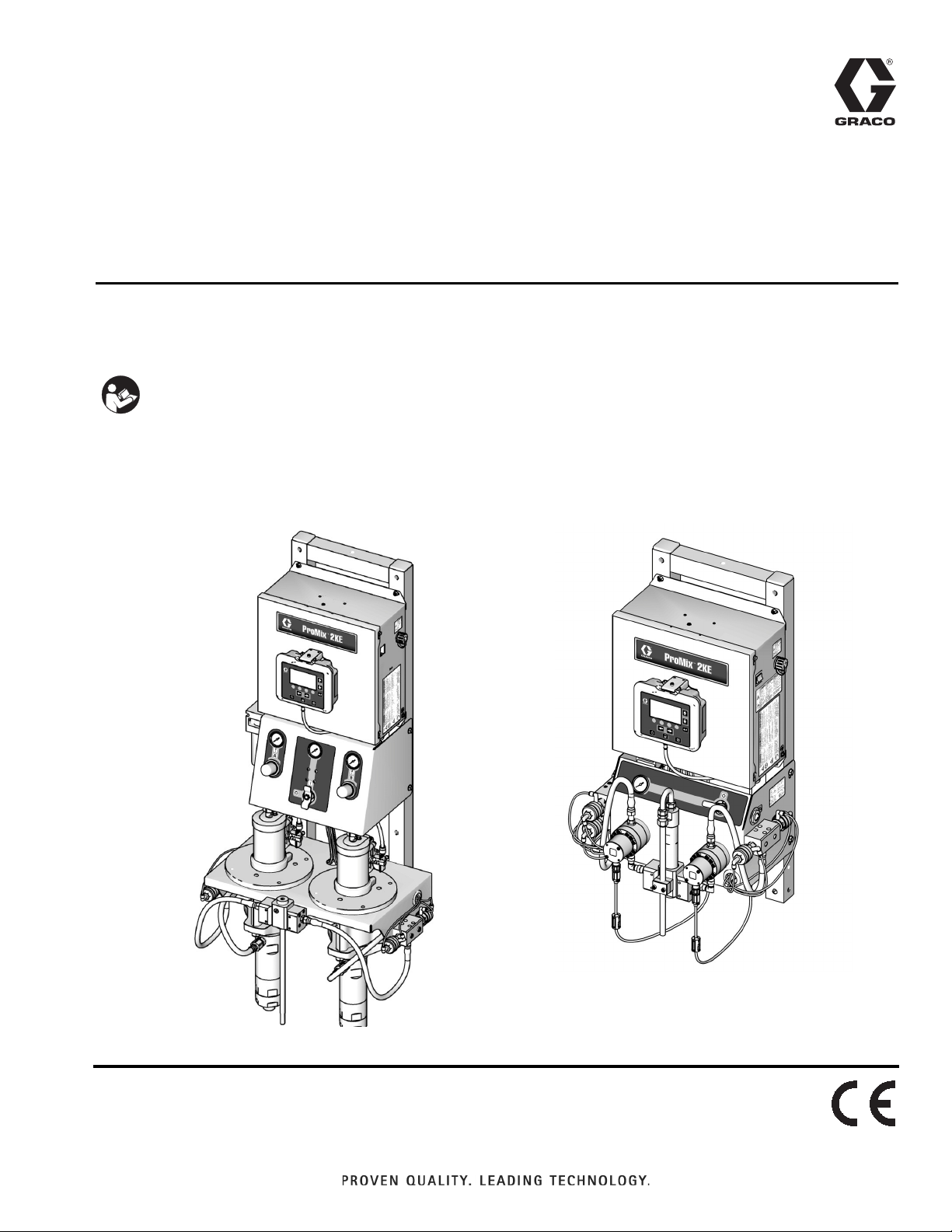

ti15698ati15696a

Pump System Meter System

ProMix

®

2KE

3A0870L

Plural Component Proportioner

Self-contained, electronic plural component paint proportioner. For professional use only.

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

See pages 3 and 4 for model information, including maximum working pressure and approvals.

For patent information, see www.graco.com/patents

EN

Page 2

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Non-Hazardous Location Models . . . . . . . . . . . . . . 3

Hazardous Location Models . . . . . . . . . . . . . . . . . . 4

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Important Two-Component Material Information . 8

Isocyanate Conditions . . . . . . . . . . . . . . . . . . . . . 8

Material Self-ignition . . . . . . . . . . . . . . . . . . . . . . 8

Keep Components A and B Separate . . . . . . . . . 8

Moisture Sensitivity of Isocyanates . . . . . . . . . . . 8

Changing Materials . . . . . . . . . . . . . . . . . . . . . . . 8

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . 9

Pump Systems . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Meter Systems . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Purging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Pump Systems . . . . . . . . . . . . . . . . . . . . . . . . . 10

Meter Systems . . . . . . . . . . . . . . . . . . . . . . . . . 11

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Maintenance Recommendations . . . . . . . . . . . . . . . 12

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Before Servicing . . . . . . . . . . . . . . . . . . . . . . . . 13

Replace the Air Filter Element . . . . . . . . . . . . . 13

Replace Solenoids . . . . . . . . . . . . . . . . . . . . . . 14

Replace the Power Supply . . . . . . . . . . . . . . . . 15

Replace Alternator Regulator . . . . . . . . . . . . . . 18

Replace Advanced Fluid Control

Module (AFCM) . . . . . . . . . . . . . . . . . . . . . 18

Replace Alarm . . . . . . . . . . . . . . . . . . . . . . . . . 19

Replace Display Module . . . . . . . . . . . . . . . . . . 19

Replace USB Module . . . . . . . . . . . . . . . . . . . . 20

Update Software . . . . . . . . . . . . . . . . . . . . . . . . 20

Pump System Air Controls . . . . . . . . . . . . . . . . 22

Meter System Air Controls . . . . . . . . . . . . . . . . 23

Fluid Controls . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Repair Flow Meters . . . . . . . . . . . . . . . . . . . . . . 27

Repair Mix Manifold . . . . . . . . . . . . . . . . . . . . . 27

Pump Assembly . . . . . . . . . . . . . . . . . . . . . . . . 29

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Pump-Based Proportioners, Models

24F088-24F115 . . . . . . . . . . . . . . . . . . . . . 30

Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Air Controls, Pump-Based Models

24F088-24F115 . . . . . . . . . . . . . . . . . . . . . 35

Tubing Chart, Pump-Based Models

24F088-24F115 . . . . . . . . . . . . . . . . . . . . . 36

Meter-Based Proportioners, Models

24F080-24F087 . . . . . . . . . . . . . . . . . . . . . 38

Tubing Chart, Meter-Based Models

24F080-24F087 . . . . . . . . . . . . . . . . . . . . . 41

Control Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

USB Module . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Electric Power Assembly . . . . . . . . . . . . . . . . . . 45

Alternator Power Assembly . . . . . . . . . . . . . . . . 46

Alternator Module 255728 . . . . . . . . . . . . . . . . . 47

Sequential Dosing Mix Manifold 262398 . . . . . . 48

Dynamic Dosing Mix Manifold 262399 . . . . . . . 48

1-Color/1 Solvent Valve Stack . . . . . . . . . . . . . . 49

3-Color/1 Solvent Valve Stack . . . . . . . . . . . . . . 49

Pump Stand Kit 24F301

Meter Stand Kit 24G611 . . . . . . . . . . . . . . . 50

Air Flow Switch Kit 15T632 . . . . . . . . . . . . . . . . 50

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 60

2 3A0870L

Page 3

Related Manuals

#53

Related Manuals

Manual Description

3A0868 ProMix 2KE, Pump-Based, Operation

3A0869 ProMix 2KE, Meter-Based, Operation

313599 Coriolis Meter

308778 G3000 Flow Meter

312781 Fluid Mix Manifold

312782 Dosing Valve

312784 Gun Flush Box Kit 15V826

312792 Merkur Displacement Pump

312793 Merkur Bellows Displacement Pump

312796 NXT Air Motor

Manual Description

406714 Rebuild Kit for High Pressure

406823 Dispense Valve Seat Kits

3A1244 Graco Control Architecture

3A1323 16G353 Alternator Conversion Kit

3A1324 16G351 Electric Power Conversion Kit

3A1325 ProMix 2KE Stand Kits

3A1332 24H255 3-Color Valve Stack Kit

3A1333 24H253 USB Module Kit

313542 Beacon Tower

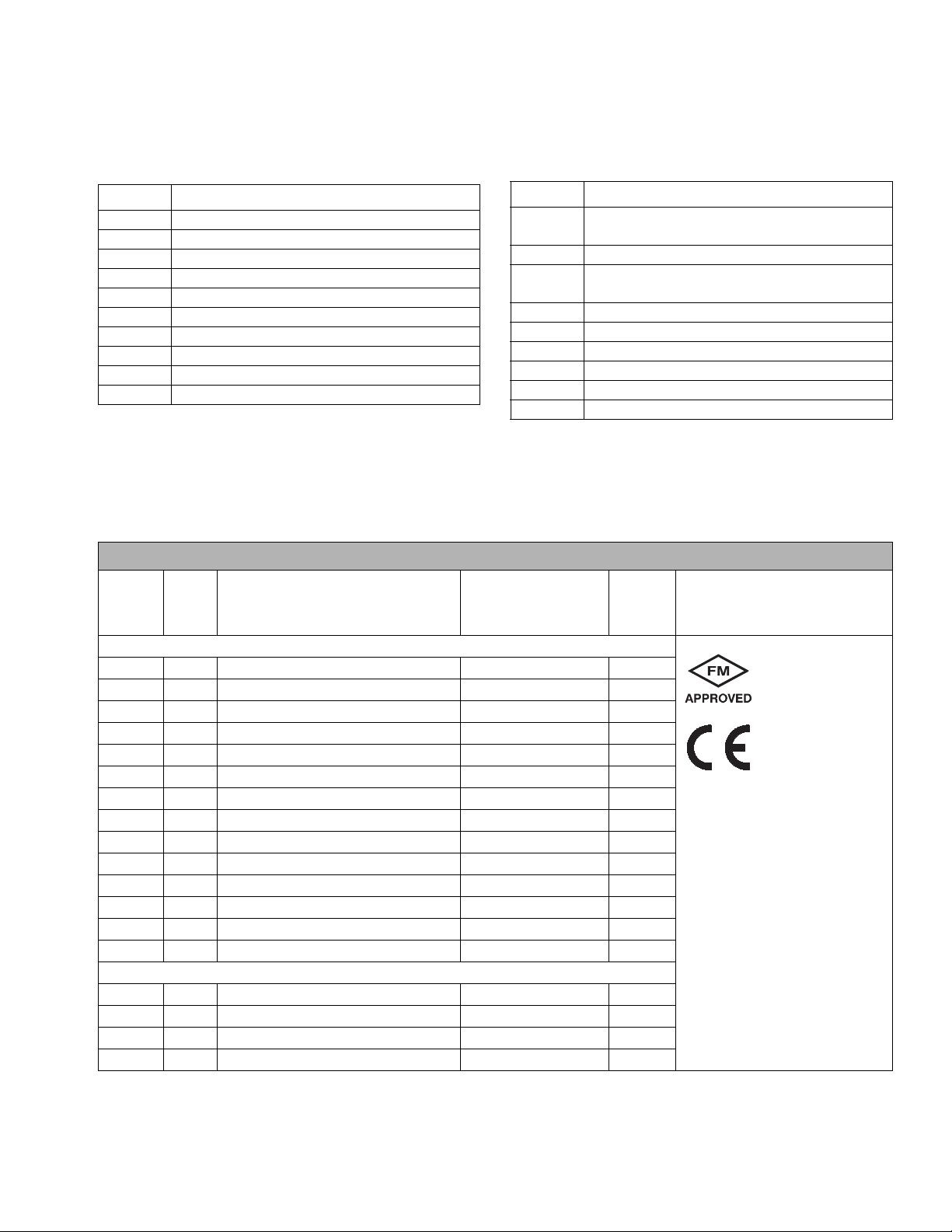

Non-Hazardous Location Models

*

Approved for Non-Hazardous Location

Maximum Working

Pressure

Part No. Series Description

Pump Systems

24F088 A 3:1, Merkur, A and B 300 (2.1, 21)

24F089 A 23:1, Merkur, A and B 2300 (15.8, 158)

24F090 A 30:1, Merkur, A and B 3000 (20.7, 207)

24F091 A 45:1, Merkur, A and B 4500 (31.0, 310)

24F092 A 3:1, Merkur A, Merkur Bellows B 300 (2.1, 21)

24F093 A 23:1, Merkur A, Merkur Bellows B 2300 (15.8, 158)

24F094 A 35:1, Merkur A, Merkur Bellows B 3500 (24.1, 241)

24F095 A 3:1, Merkur, A and B 300 (2.1, 21)

24F096 A 23:1, Merkur, A and B 2300 (15.8, 158)

24F097 A 30:1, Merkur, A and B 3000 (20.7, 207)

24F098 A 45:1, Merkur, A and B 4500 (31.0, 310)

24F099 A 3:1, Merkur A, Merkur Bellows B 300 (2.1, 21)

24F100 A 23:1, Merkur A, Merkur Bellows B 2300 (15.8, 158)

24F101 A 35:1, Merkur A, Merkur Bellows B 3500 (24.1, 241)

Meter Systems

24F080 A G3000, 1 color/1 catalyst 3000 (27.58, 275.8)

24F081 A G3000, 3 colors/1 catalyst 3000 (27.58, 275.8)

24F082 A G3000, 1 color/1 catalyst 3000 (27.58, 275.8)

24F083 A G3000, 3 colors/1 catalyst 3000 (27.58, 275.8)

psi (MPa, bar)

Dispense Valve

Module Programming

USB

Module Approvals*

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

* ProMix 2KE non-hazardous location equipment manufactured in the United States, with serial number beginning

with A or 01, has FM and CE approvals. Equipment manufactured in Belgium, with serial number beginning with

M or 38, has CE approval.

3A0870L 3

Page 4

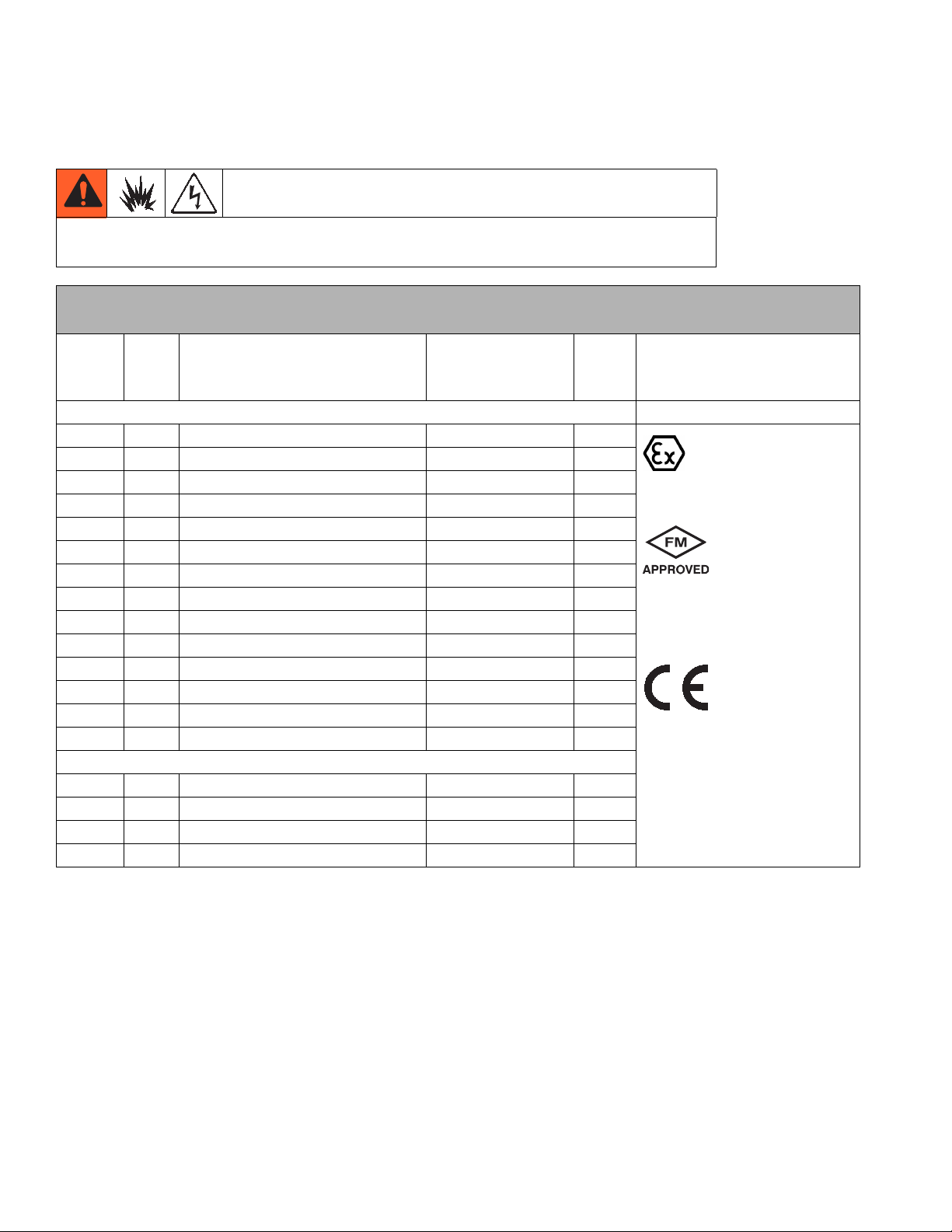

Hazardous Location Models

#53

0359

Ex ia px IIA T3 Ta = 0°C to 54°C

FM10 ATEX 0025 X

II 2 G

Intrinsically safe and purged

equipment for

Class I, Division 1, Group D, T3

Ta = 0°C to 54°C

See Special Conditions for Safe

Use in Warnings, page 5.

Hazardous Location Models

ProMix 2KE systems are not approved for use in hazardous locations unless the base model,

all accessories, all kits, and all wiring meet local, state, and national codes.

Approved for Hazardous Location

Class 1, Div 1, Group D (North America); Class 1, Zones 1 and 2 (Europe)

Maximum Working

Pressure

Part No. Series Description

psi (MPa, bar)

Pump Systems

24F102 A 3:1, Merkur, A and B 300 (2.1, 21)

24F103 A 23:1, Merkur, A and B 2300 (15.8, 158)

24F104 A 30:1, Merkur, A and B 3000 (20.7, 207)

24F105 A 45:1, Merkur, A and B 4500 (31.0, 310)

24F106 A 3:1, Merkur A, Merkur Bellows B 300 (2.1, 21)

24F107 A 23:1, Merkur A, Merkur Bellows B 2300 (15.8, 158)

24F108 A 35:1, Merkur A, Merkur Bellows B 3500 (24.1, 241)

24F109 A 3:1, Merkur, A and B 300 (2.1, 21)

24F110 A 23:1, Merkur, A and B 2300 (15.8, 158)

24F111 A 30:1, Merkur, A and B 3000 (20.7, 207)

24F112 A 45:1, Merkur, A and B 4500 (31.0, 310)

24F113 A 3:1, Merkur A, Merkur Bellows B 300 (2.1, 21)

24F114 A 23:1, Merkur A, Merkur Bellows B 2300 (15.8, 158)

24F115 A 35:1, Merkur A, Merkur Bellows B 3500 (24.1, 241)

Meter Systems

24F084 A G3000, 1 color/1 catalyst 3000 (27.58, 275.8)

24F085 A G3000, 3 colors/1 catalyst 3000 (27.58, 275.8)

24F086 A G3000, 1 color/1 catalyst 3000 (27.58, 275.8)

24F087 A G3000, 3 colors/1 catalyst 3000 (27.58, 275.8)

USB

Module Approvals*

✔

✔

✔

✔

✔

✔

✔

✔

✔

* ProMix 2KE hazardous location equipment manufactured in the United States, with serial number beginning with

A or 01, has ATEX, FM, and CE approvals, as noted. Equipment manufactured in Belgium, with serial number

beginning with M or 38, has ATEX and CE approvals, as noted.

4 3A0870L

Page 5

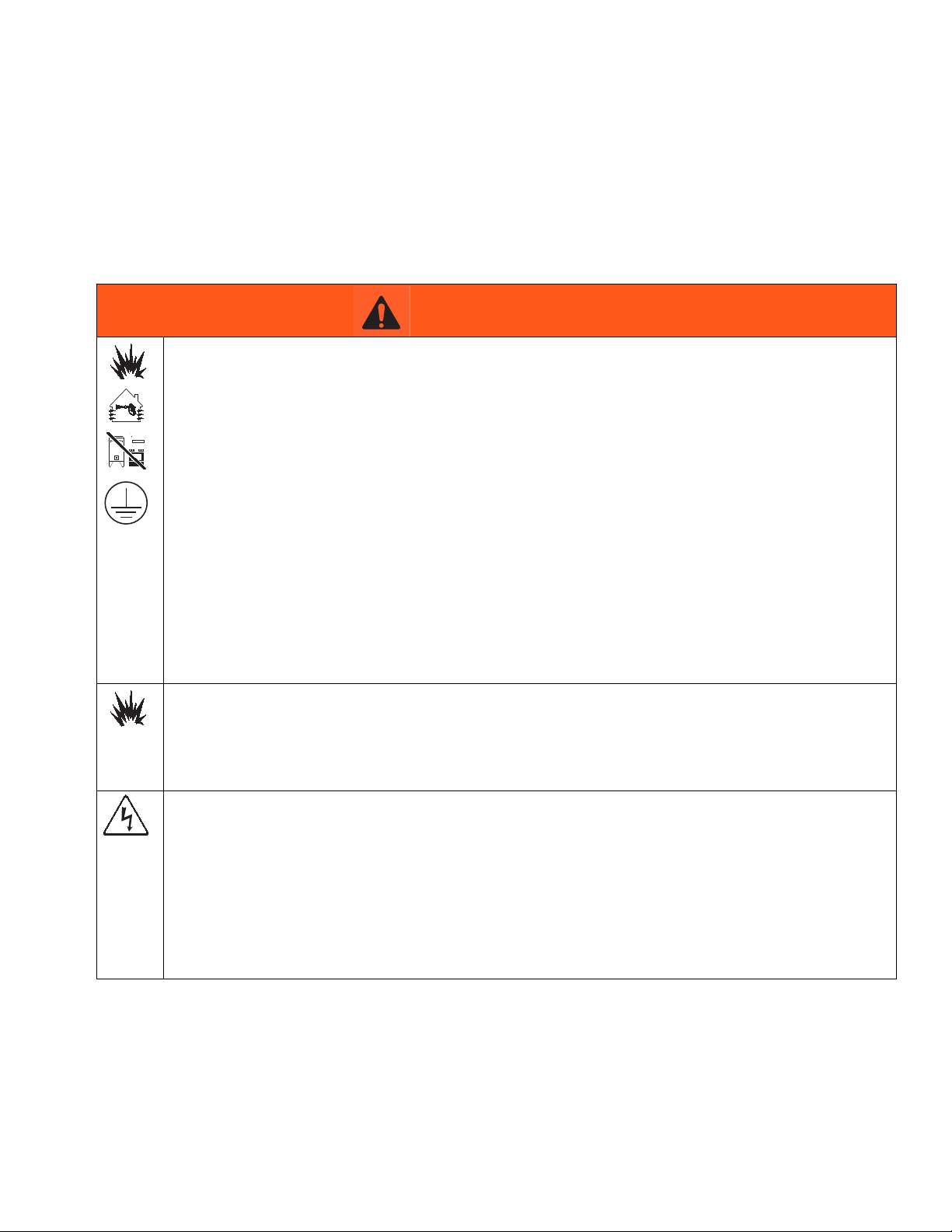

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual, refer back to these Warnings. Product-specific hazard symbols and

warnings not covered in this section may appear throughout the body of this manual where applicable.

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes are

present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment until

you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

SPECIAL CONDITIONS FOR SAFE USE

• To prevent the risk of electrostatic sparking, the equipment’s non-metallic parts should be cleaned only

with a damp cloth.

• Pump Systems: The aluminum adapter plate may spark upon impact or contact with moving parts,

which may cause fire or explosion. Take precautions to avoid such impact or contact.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric

shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

3A0870L 5

Page 6

Warnings

WARNING

INTRINSIC SAFETY

Intrinsically safe equipment that is installed improperly or connected to non-intrinsically safe equipment

will create a hazardous condition and can cause fire, explosion, or electric shock. Follow local regulations

and the following safety requirements.

• Only models with model numbers 24F084-24F087 and 24F102-24F115, utilizing the air-driven

alternator, are approved for installation in a Hazardous (explosive atmosphere) Location. See

Hazardous Location Models, page 4.

• Be sure your installation complies with national, state, and local codes for the installation of electrical

apparatus in a Class I, Group D, Division 1 (North America) or Class I, Zones 1 and 2 (Europe)

Hazardous Location, including all of the local safety fire codes, NFPA 33, NEC 500 and 516, and

OSHA 1910.107.

• To help prevent fire and explosion:

•Do not install equipment approved only for a non-hazardous location in a hazardous location. See

model ID label for the intrinsic safety rating of your model.

•Do not substitute system components as this may impair intrinsic safety.

• Equipment that comes in contact with the intrinsically safe terminals must be rated for Intrinsic Safety.

This includes DC voltage meters, ohmmeters, cables, and connections. Remove the unit from the

hazardous area when troubleshooting.

• The equipment is intrinsically safe when no external electrical components are connected to it.

• Do not connect, download, or remove USB device unless unit is removed from the hazardous

(explosive atmosphere) location.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

6 3A0870L

Page 7

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about

your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure. Turn off all equipment and

follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure and disconnect all power sources.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear chemically impermeable gloves when spraying, dispensing, or cleaning equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area

of the equipment to help protect you from serious injury, including eye injury, hearing loss, inhalation of

toxic fumes, and burns. This equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

3A0870L 7

Page 8

Important Two-Component Material Information

Important Two-Component Material Information

Isocyanate Conditions

Spraying or dispensing materials containing

isocyanates creates potentially harmful mists, vapors,

and atomized particulates.

Read material manufacturer’s warnings and material

MSDS to know specific hazards and precautions

related to isocyanates.

Prevent inhalation of isocyanate mists, vapors, and

atomized particulates by providing sufficient

ventilation in the work area. If sufficient ventilation is

not available, a supplied-air respirator is required for

everyone in the work area.

To prevent contact with isocyanates, appropriate

personal protective equipment, including chemically

impermeable gloves, boots, aprons, and goggles, is

also required for everyone in the work area.

Material Self-ignition

Some materials may become self-igniting if applied

too thickly. Read material manufacturer’s warnings

and material MSDS.

Moisture Sensitivity of

Isocyanates

Isocyanates (ISO) are catalysts used in two component

coatings. ISO will react with moisture (such as humidity)

to form small, hard, abrasive crystals, which become

suspended in the fluid. Eventually a film will form on the

surface and the ISO will begin to gel, increasing in viscosity. If used, this partially cured ISO will reduce performance and the life of all wetted parts.

NOTE: The amount of film formation and rate of crystallization varies depending on the blend of ISO, the

humidity, and the temperature.

To prevent exposing ISO to moisture:

• Always use a sealed container with a desiccant

dryer in the vent, or a nitrogen atmosphere. Never

store ISO in an open container.

• Use moisture-proof hoses specifically designed for

ISO, such as those supplied with your system.

• Never use reclaimed solvents, which may contain

moisture. Always keep solvent containers closed

when not in use.

• Never use solvent on one side if it has been contaminated from the other side.

• Always lubricate threaded parts with ISO pump oil

or grease when reassembling.

Changing Materials

Keep Components A and B

Separate

Cross-contamination can result in cured material in

fluid lines which could cause serious injury or

damage equipment. To prevent cross-contamination

of the equipment’s wetted parts, never interchange

component A (resin) and component B (isocyanate)

parts.

8 3A0870L

• When changing materials, flush the equipment multiple times to ensure it is thoroughly clean.

• Always clean the fluid inlet strainers after flushing.

• Check with your material manufacturer for chemical

compatibility.

Page 9

Pressure Relief Procedure

Pressure Relief Procedure

Meter Systems

To reduce the risk of skin injection, relieve pressure

when you stop spraying, before changing spray tips,

and before cleaning, checking, or servicing

equipment.

NOTE: The following procedure relieves all fluid and air

pressure in the ProMix 2KE system.

Pump Systems

1. Press on Run Mix Spray (Screen 2) or

from any screen to put the system in Standby.

2. Follow procedure for Purging Fluid Supply Sys-

tem, page 10, if desired or necessary.

3. Shut off air supply to A and B pumps and solvent

supply pumps.

4. With the gun triggered, push the manual override on

the A and B dose and solvent valve solenoids to

relieve pressure. See FIG. 1, page 12. Verify that

fluid pressure is reduced to 0.

1. Press on Run Mix Spray (Screen 2) or

from any screen to put the system in Standby.

2. Shut off the A1 (A2 and A3, if using multiple colors)

and B fluid supply pumps/pressure pots.

3. Remove the Control Box cover.

4. With the gun triggered, push the manual override on

the A1 (A2, A3), and B dose valve solenoids to

relieve pressure. See FIG. 1, page 12.

5. Follow Purging procedure, page 11.

6. Shut off the fluid supply to solvent valves A and B.

7. With the gun triggered, push the manual override on

the A and B solvent valve solenoids to relieve solvent pressure. See FIG. 1. Verify that solvent pressure is reduced to 0.

8. Reinstall the Control Box cover.

5. Reinstall the Control Box cover.

3A0870L 9

Page 10

Purging

Purging

Pump Systems

There are 2 pump purging procedures in this manual:

• Purging Mixed Material

• Purging Fluid Supply System

Use the criteria listed for each procedure to determine

which procedure to use.

Purging Mixed Material

There are times when you only want to purge the fluid

manifold, such as:

• end of potlife

• breaks in spraying that exceed the potlife

• overnight shutdown

• before servicing the fluid manifold assembly, hose

or gun.

1. Press on Run Mix Spray (Screen 2) or

from any screen to put the system in Standby.

2. Trigger the gun to relieve pressure.

If the gun flush box is not used, trigger the gun into a grounded metal

pail until the purge sequence is complete.

When done purging, the system automatically

switches to Standby mode.

7. If the system is not completely clean, repeat step 6.

NOTE: If necessary, adjust purge sequence so only

one cycle is required.

8. Trigger the gun to relieve pressure. Engage trigger

lock.

9. If spray tip was removed, reinstall it.

10. Adjust the solvent supply regulator back to its normal operating pressure.

NOTE: If your system uses 2 guns, you must trigger

both guns simultaneously during a purge to purge both

guns and lines. Verify that clean solvent flows from each

gun. If not, repeat purge or clear clog/blockage in system.

3. If you are using a high pressure gun, engage the

trigger lock. Remove spray tip and clean tip separately.

4. If using an electrostatic gun shut off the electrostatics before flushing the gun.

5. Set the solvent supply pressure regulator at a pressure high enough to completely purge the system in

a reasonable amount of time but low enough to

avoid splashing or an injection injury. Generally, a

setting of 100 psi (0.7 MPa, 7 bar) is sufficient.

6. If using a gun flush box, place the gun into the box

and close the lid. Press on Run Mix Spray

(Screen 2). The purge sequence automatically

starts.

10 3A0870L

Purging Fluid Supply System

Follow this procedure before:

• the first time material is loaded into equipment

• servicing

• shutting down equipment for an extended period of

time

• putting equipment into storage

1. Press on Run Mix Spray (Screen 2) or

from any screen to put the system in Standby.

2. Trigger the gun to relieve pressure.

3. If you are using a high pressure gun, engage the

trigger lock. Remove spray tip and clean tip separately.

4. If using an electrostatic gun, shut off the electrostatics before flushing the gun.

Page 11

5. Disconnect the component A and B fluid supplies at

the pump inlets, and connect solvent supply lines.

6. Adjust the solvent fluid supply pressure. Use the

lowest possible pressure to avoid splashing.

Purging

1. Press on Run Mix Spray (Screen 2) or

from any screen to put the system in Standby.

2. Trigger the gun to relieve pressure.

7. Remove the Control Box cover to access the solenoid valves. See FIG. 1, page 12.

8. Purge as follows:

• Purge component A side. See FIG. 1, page 12.

Press the manual override on the Dose Valve A

solenoid valve and trigger the gun into a

grounded metal pail.

Purge component B side. Press the manual

override on the Dose Valve B solenoid valve

and trigger the gun into a grounded metal pail

until clean solvent flows from the gun.

Repeat to thoroughly clean the mix manifold.

9. Reinstall the Control Box cover.

10. Shut off the solvent fluid supply.

11. Disconnect the solvent supply lines and reconnect

the component A and B fluid supplies.

NOTE: If your system uses 2 guns, you must trigger

both guns simultaneously during a purge to purge both

guns and lines. Verify that clean solvent flows from each

gun. If not, repeat purge or clear clog/blockage in system.

NOTE: The system remains full of solvent.

Meter Systems

Purge the system:

• at the end of potlife

• breaks in spraying that exceed the potlife

• overnight shutdown or end of shift

• the first time material is loaded into equipment

• servicing

• shutting down equipment for an extended period of

time

3. If you are using a high pressure gun, engage the

trigger lock. Remove spray tip and clean tip separately.

4. If using an electrostatic gun shut off the electrostatics before flushing the gun.

5. Set the solvent supply pressure regulator at a pressure high enough to completely purge the system in

a reasonable amount of time but low enough to

avoid splashing or an injection injury. Generally, a

setting of 100 psi (0.7 MPa, 7 bar) is sufficient.

6. If using a gun flush box, place the gun into the box

and close the lid.

7. Press on Run Mix Spray (Screen 2). The

purge sequence automatically starts.

If the gun flush box is not used, trigger the gun into a grounded metal

pail until the system returns to

Standby mode.

8. If the system is not completely clean, repeat step 6.

NOTE: If necessary, adjust purge sequence so only

one cycle is required.

9. Trigger the gun to relieve pressure. Engage trigger

lock.

10. If spray tip was removed, reinstall it.

11. Adjust the solvent supply regulator back to its normal operating pressure.

NOTE: The system remains full of solvent.

NOTE: If your system uses 2 guns, you must trigger

both guns simultaneously during a purge to purge both

guns and lines. Verify that clean solvent flows from each

gun. If not, repeat purge or clear clog/blockage in system.

3A0870L 11

Page 12

Purging

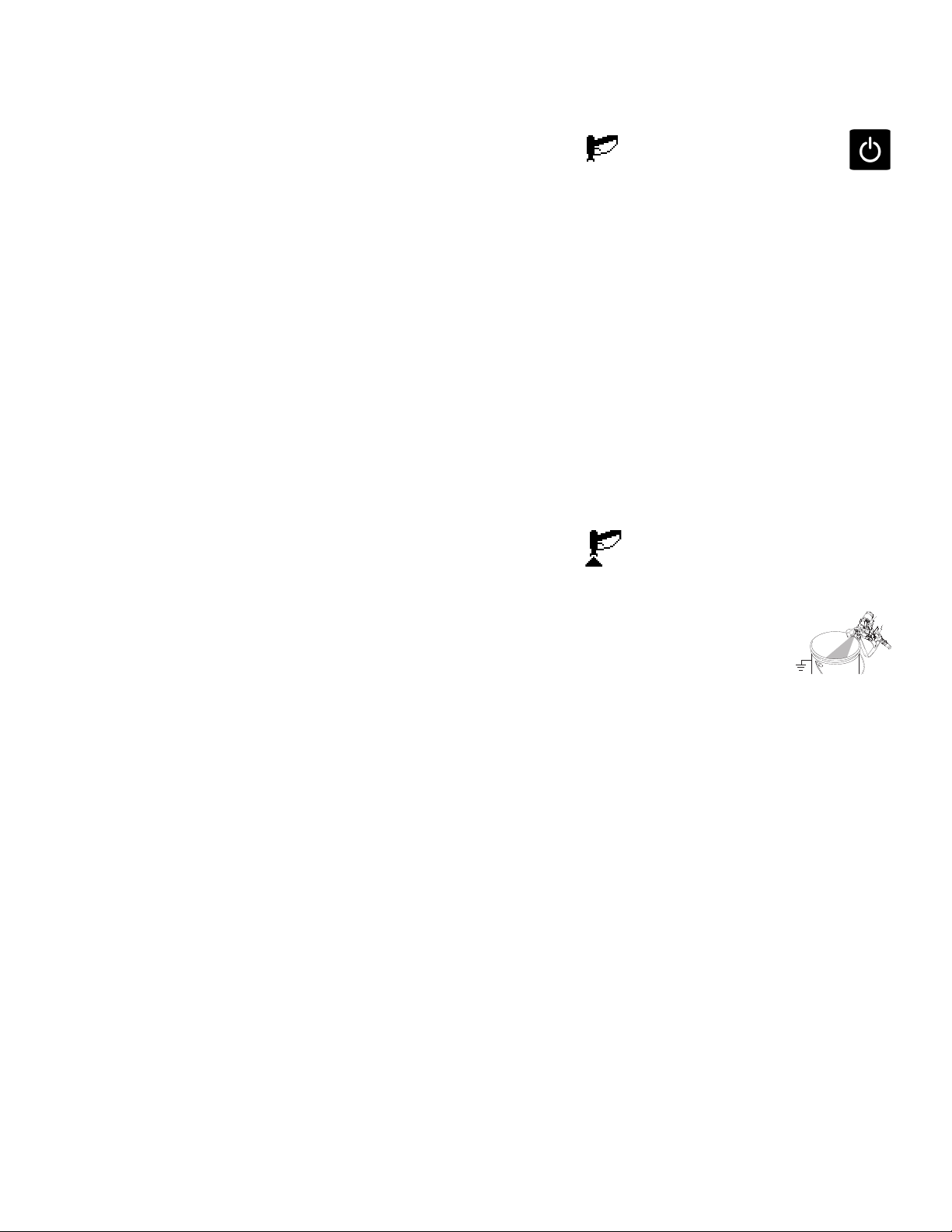

Solvent Valve A

Solenoid

Manual Overrides

Dose Valve A1

Solenoid

Solvent Valve B

Solenoid

Dose Valve B

Solenoid

Dose Valve A2

Solenoid Location

Dose Valve A3

Solenoid Location

ti15730a

Gun Flush Box

Solenoid Location

FIG. 1. Solenoid Valves in Control Box

Shutdown

1. Follow Purging procedure for your system, page 10

or 11.

2. Close main air shutoff valve on air supply line and

on ProMix 2KE.

3. Non-IS Systems: Shut off ProMix 2KE power

(0 position). NOTE: Meter-based systems will

restart in Recipe 0.

Maintenance

Recommendations

The following table shows starting maintenance recommendations. Maintenance needs will vary based on individual applications and material differences.

Recommended Maintenance

Component

Solvent Valves 1,000,000 cycles

Fluid Filter daily

Air Filter monthly

Pumps 250,000 cycles

Dose Valves 1,000,000 cycles

Meters 5,000 gallons

Frequency

12 3A0870L

Page 13

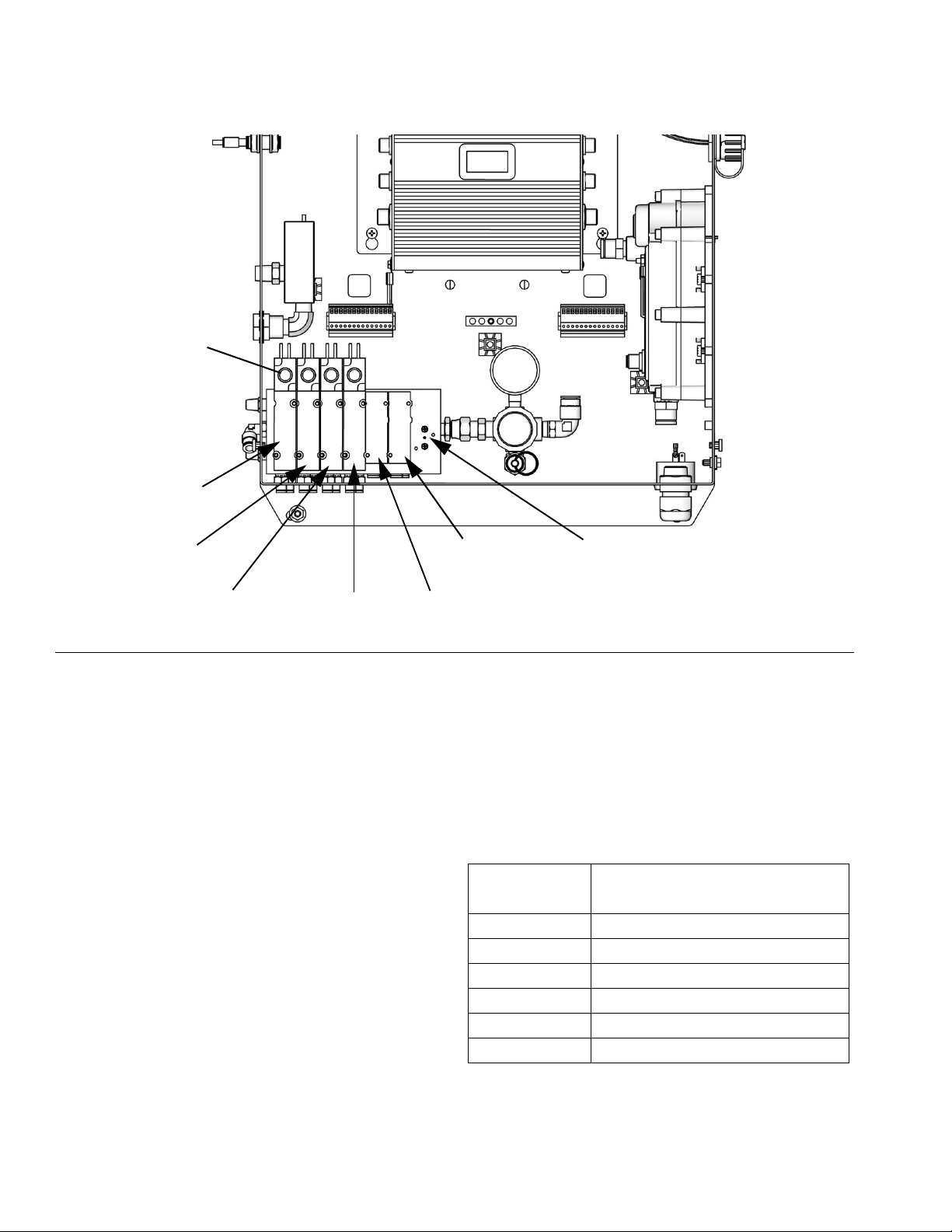

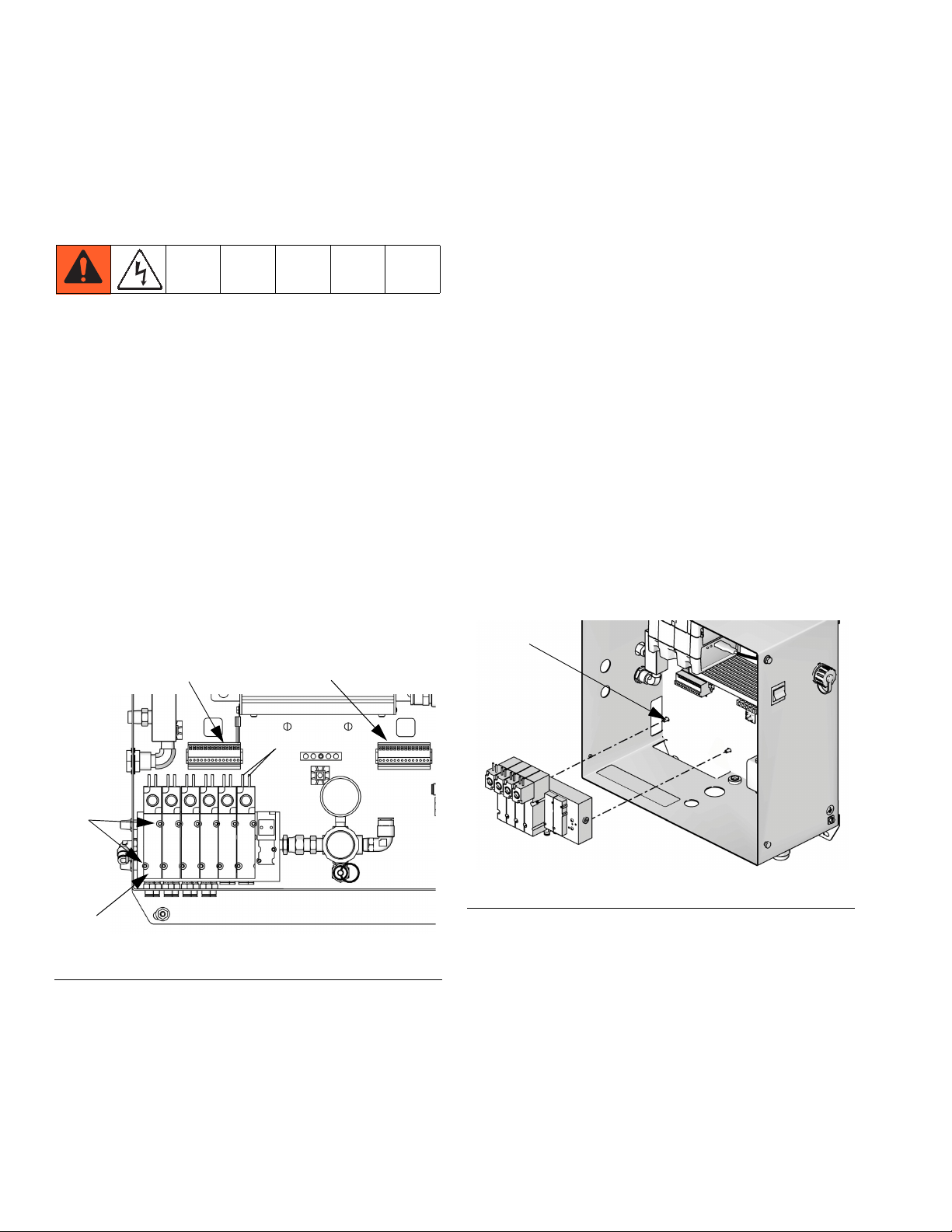

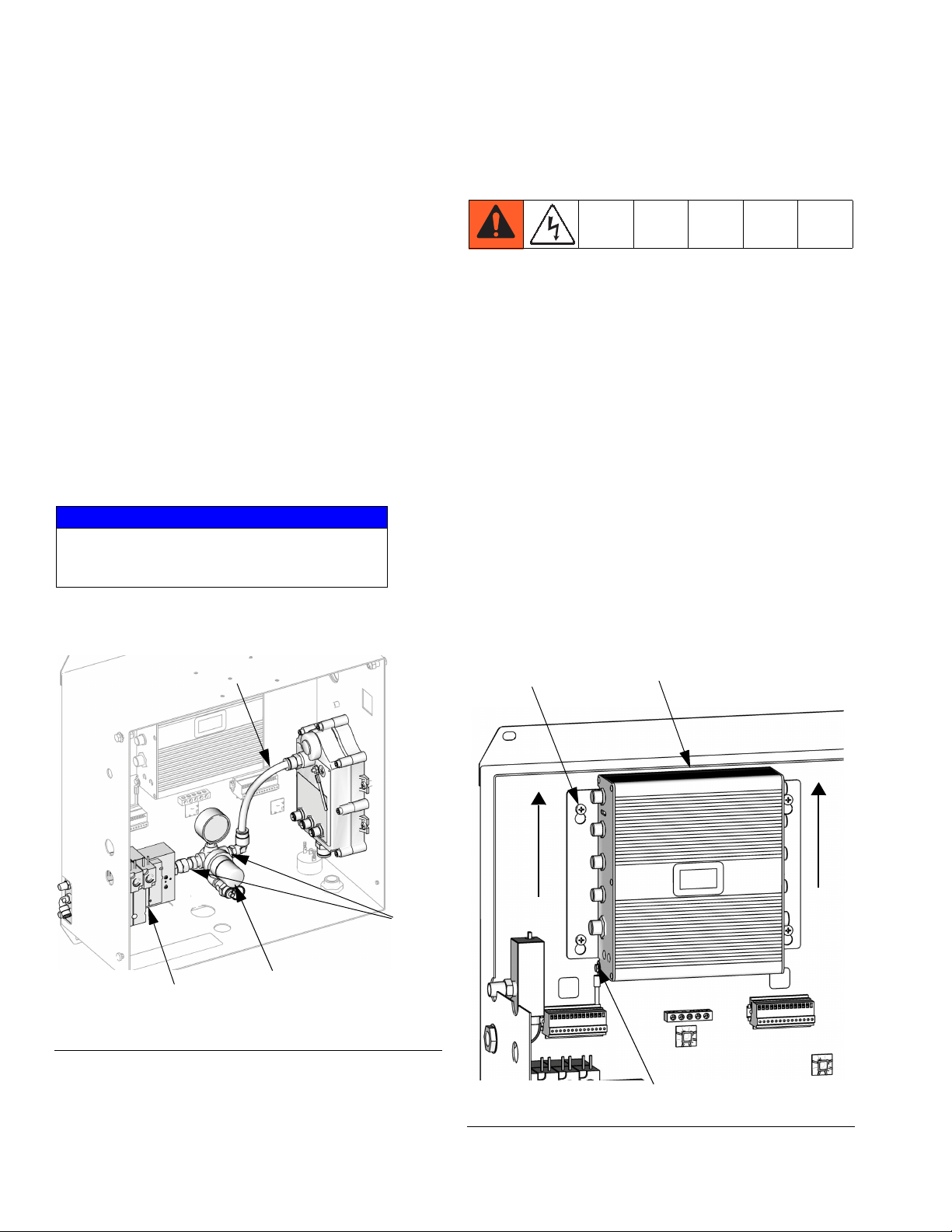

Service

Pump

System

Meter

System

209

206

209

A

B

206a, 209a

ti15708a

ti16437a

ti12691a

Service

Before Servicing

• To avoid electric shock, turn off power before

servicing.

• Servicing the Control Box exposes you to high

voltage. Shut off power at main circuit breaker

before opening enclosure.

• All electrical wiring must be done by a qualified

electrician and comply with all local codes and

regulations.

• Do not substitute system components as this may

impair intrinsic safety.

• Read Warnings, pages 5- 8.

1. Follow Pressure Relief Procedure, page 9, if ser-

vice time may exceed pot life time, before servicing

fluid components, and before transporting equipment to a service area.

2. Close air shutoff valves.

4. Remove and replace element (206a, 209a).

5. Screw filter bowl (B) on securely. Install cover (A).

3. Non-IS Systems: Shut off power (0 position).

4. If servicing Control Box, also shut off power at main

circuit breaker.

Replace the Air Filter Element

Removing a pressurized air filter bowl could cause serious injury. Depressurize air line before servicing.

Pump systems have two air filters: the 5 micron air manifold filter (209) and the 40 micron pump air filter (206).

Meter systems have only the 5 micron filter (209). Check

filters daily and replace element(s) as needed. Order

15D909 (5 micron) or 15D890 (40 micron).

1. Close main air shutoff valve on air supply line and

on system. Depressurize air line.

2. Remove the filter cover (A).

3. Unscrew the filter bowl (B).

FIG. 2. Replace Air Filter Element(s)

3A0870L 13

Page 14

Service

ti16646a

N

320

306

P

320

305

ti16450a

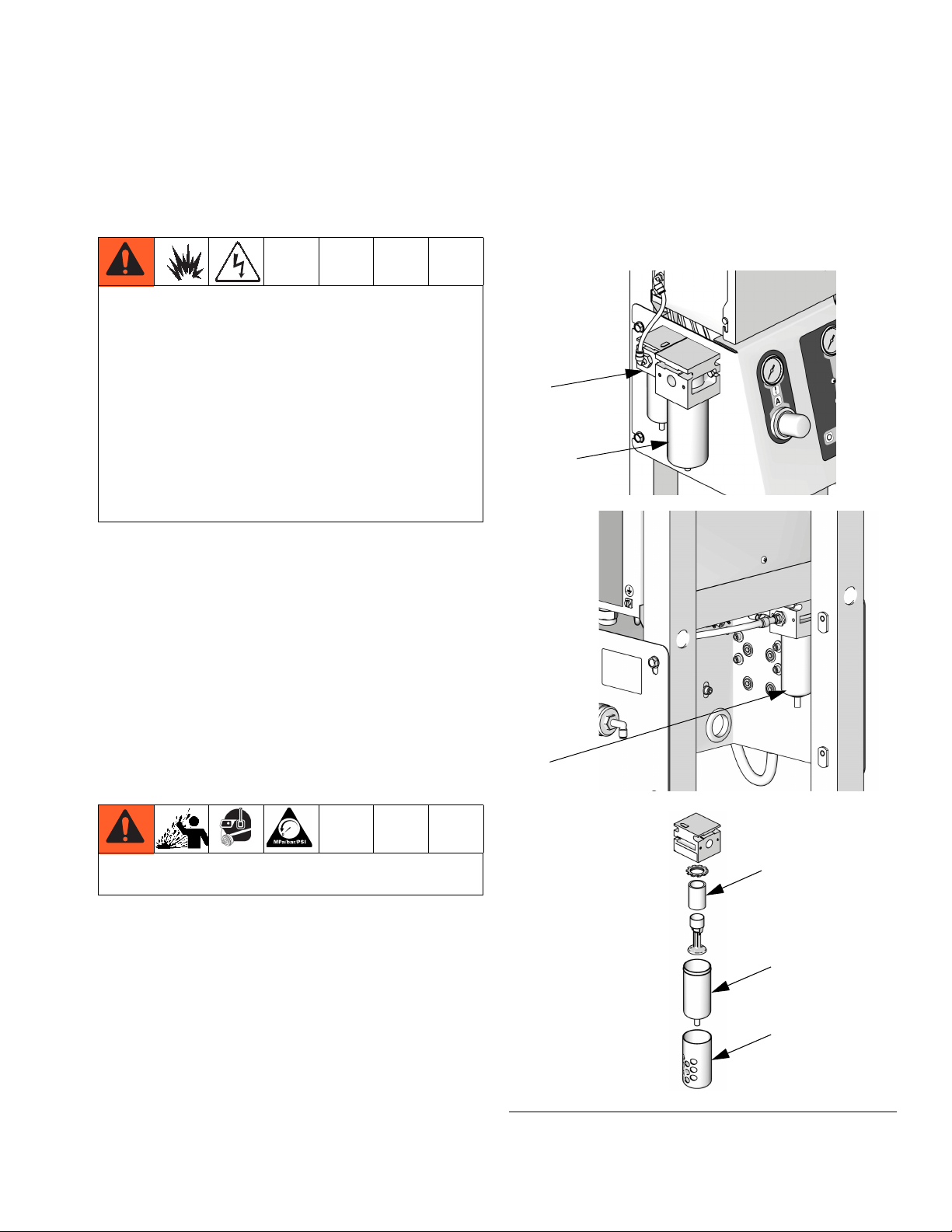

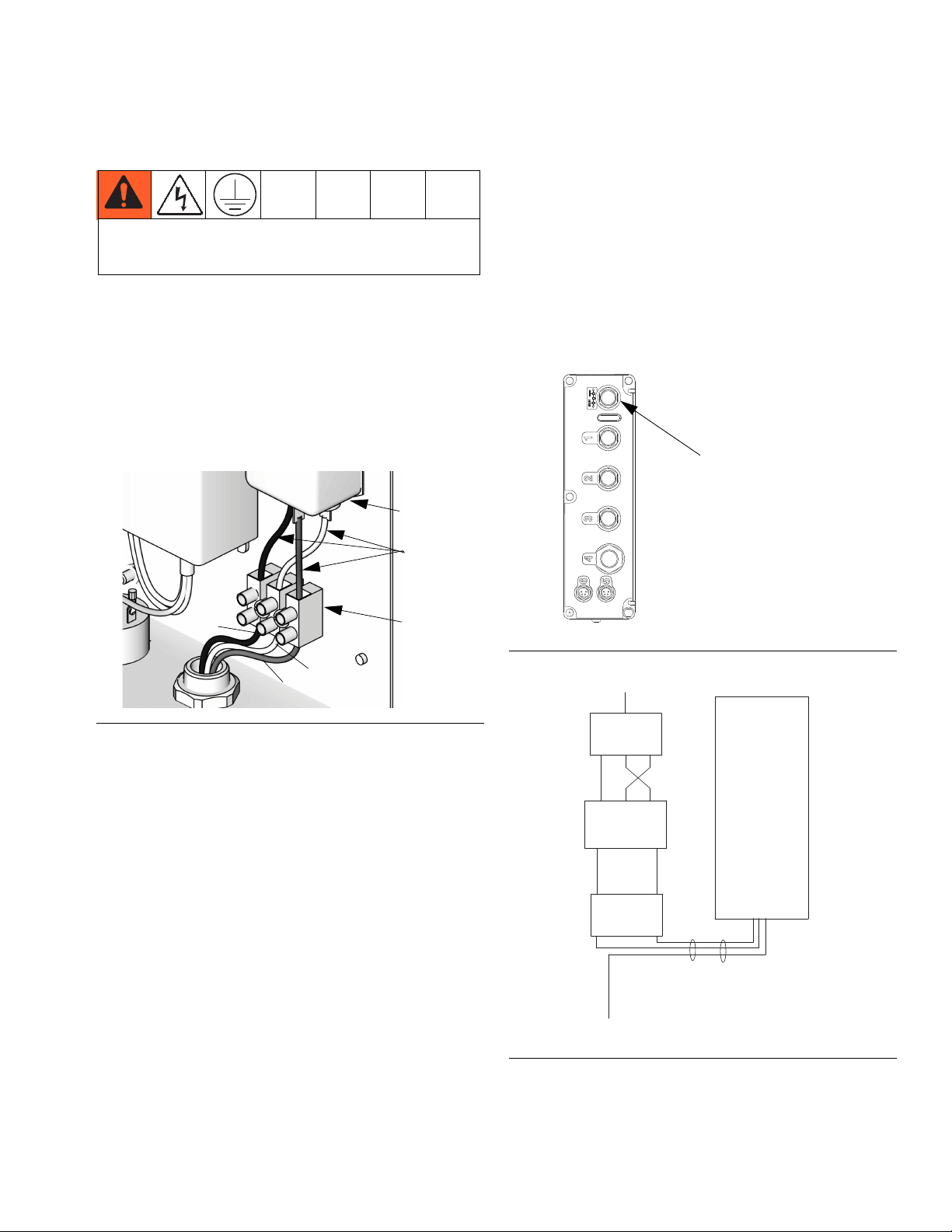

Replace Solenoids

The system has a minimum of 4 solenoids. If you have a

3-color system or a gun flush box, you have additional

(optional) solenoids for each.

To replace a single solenoid:

1. Follow Before Servicing, page 13. Disconnect

main power.

2. Open Control Box.

3. Disconnect 2 solenoid wires (N) from harness (320).

See FIG. 3.

4. Unscrew 2 screws (P) and remove solenoid (306).

5. Install new solenoid (306).

6. Connect 2 wires (N) to harness (320). Solenoid

wires are polarized (red+, black-). Refer to System

Electrical Schematics, pages 54-57.

To replace the solenoid module:

1. Follow Before Servicing, page 13. Disconnect

main power.

2. Open Control Box.

3. Disconnect all solenoid wires (N) from harnesses

(320).

NOTE: If you have an intrinsically safe model, you will

need to remove the alternator air regulator from the

solenoid module. See page 18 for removal instructions.

4. Remove two screws (305).

5. Remove and replace solenoid module.

6. Connect all wires (N) to harnesses (320). Solenoid

wires are polarized (red+, black-). Refer to System

Electrical Schematics, pages 54-57.

7. Replace Control Box cover.

7. Replace Control Box cover.

FIG. 3. Replace a Single Solenoid

FIG. 4. Replace Solenoid Module

14 3A0870L

Page 15

Service

Line

Neutral

Ground

411

404

403

ti16391a

Connect cable

(401a) here.

ti16602a

LINE POWER

FILTER

POWER

SUPPLY

TERMINAL

BLOCK

SWITCH

ROCKER

1A

1

2A

2

L N GRND

L GRND N

L N

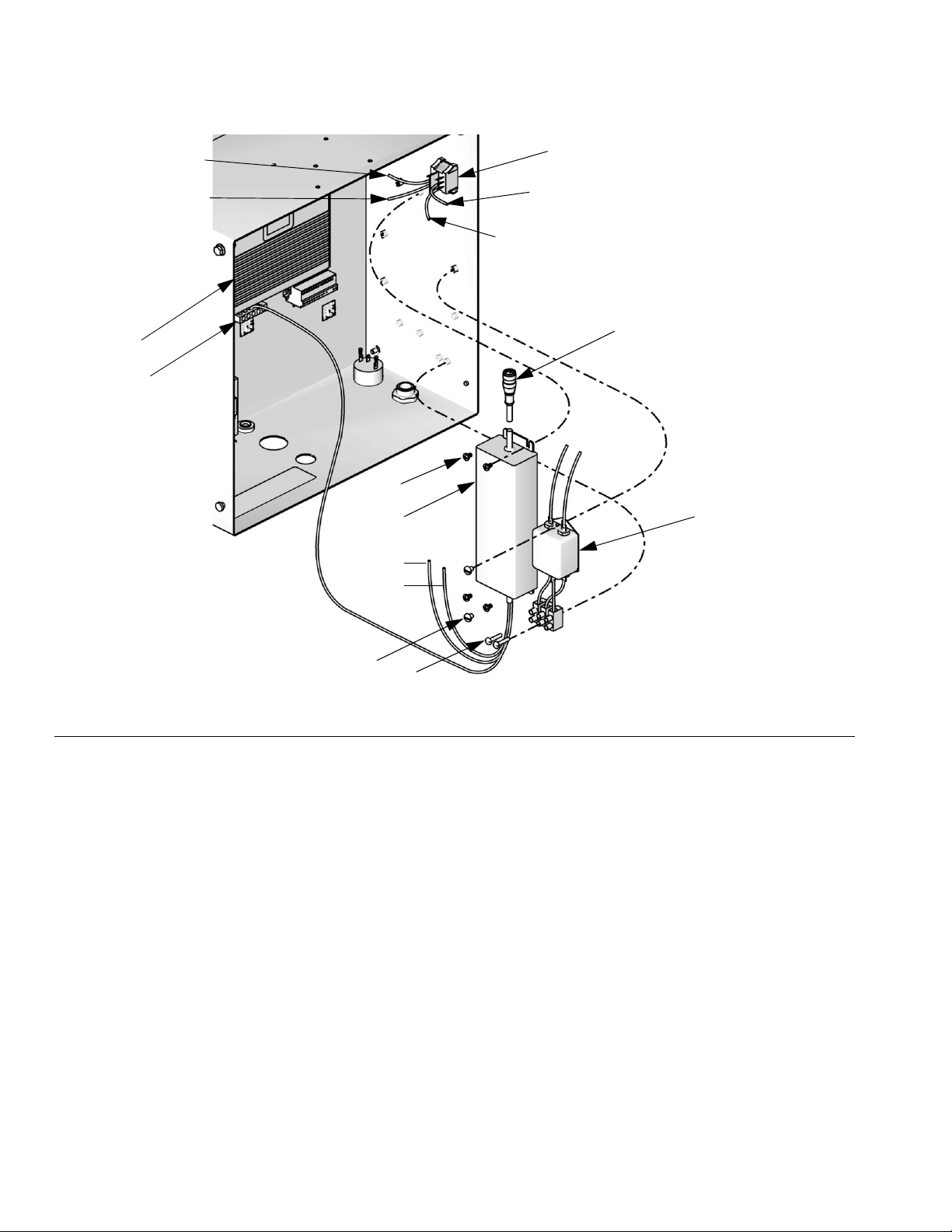

Replace the Power Supply

All electrical wiring must be completed by a qualified

electrician and comply with all local codes and

regulations.

Wall Power Supply and Filter

1. Follow Before Servicing, page 13. Disconnect

main power.

2. Open Control Box.

3. Disconnect the three input wires from the line filter

(403).

10. Connect the power supply wire harness (411/PS) to

the switch (402), as shown. See also Electrical

Schematic. Connect the PS ground wire to the

ground terminal (T) of the advanced fluid control

module.

11. See FIG. 5. Connect wire harness (411) to the line

filter (403) and terminal block (404) as shown. See

also Electrical Schematic.

12. Connect CAN cable (401a) to the advanced fluid

control module.

FIG. 5. Terminal Block Electrical Connections

4. See FIG. 8. Disconnect the power supply CAN cable

(401a) from the advanced fluid control module

(302).

5. Disconnect line filter wires and power supply wires

from the power switch (402).

6. Disconnect the power supply ground wire,

PS(GND), from the advanced fluid control module

ground terminal (T).

7. Remove four screws (405) and remove power supply (401). If replacing filter, remove two screws

(407) and the filter (403).

8. Install the new power supply (401) and line filter

9. See FIG. 8. Connect wire harness (410/LF) to the

(403), using supplied screws (405, 407), as shown.

line filter (403) and to the power switch (402), as

shown. See also Electrical schematic.

FIG. 6. Reconnect CAN cable.

FIG. 7. Electrical Schematic

3A0870L 15

Page 16

Service

405

401

407

ti16454a

401a

302

1: PS(N)

1A: LF(N)

2: PS(L)

1A: LF(N)

403

402

LF(L)

LF(N)

PS(L)

PS(N)

PS(GND)

T

406

FIG. 8. Replace Wall Power Supply

16 3A0870L

Page 17

Service

501

Supply line

disconnect

Exhaust air line

disconnect

509

G

T

Cable

connectors

Air regulator line

501h

501d

ti16456a

ti16455a

Alternator Power Supply and Turbine

1. Follow Before Servicing, page 13. Disconnect

main air.

2. Open Control Box.

3. See FIG. 9. Disconnect output power cable connections from alternator module (501). Disconnect

ground lead (G) from control box ground terminal

(T).

4. Disconnect the power supply cables from the

Advanced Fluid Control Module, the USB Module,

and the Display Module.

5. Disconnect air regulator line and exhaust air line

from alternator module.

6. Remove four screws (509) from mounting to remove

alternator from control box.

7. Remove seven screws (501h) to separate alternator

housings.

8. Replace turbine (501d) if necessary. Lightly lubricate turbine o-ring to ease alternator housing reassembly.

9. Follow steps in reverse order to reassemble alternator regulator assembly and to reconnect power

FIG. 9. Remove Alternator Module (and Turbine)

3A0870L 17

Page 18

Service

ti16456a

506

505

Solenoid

Module

Air regulator line

303

302

ti16452a

GS

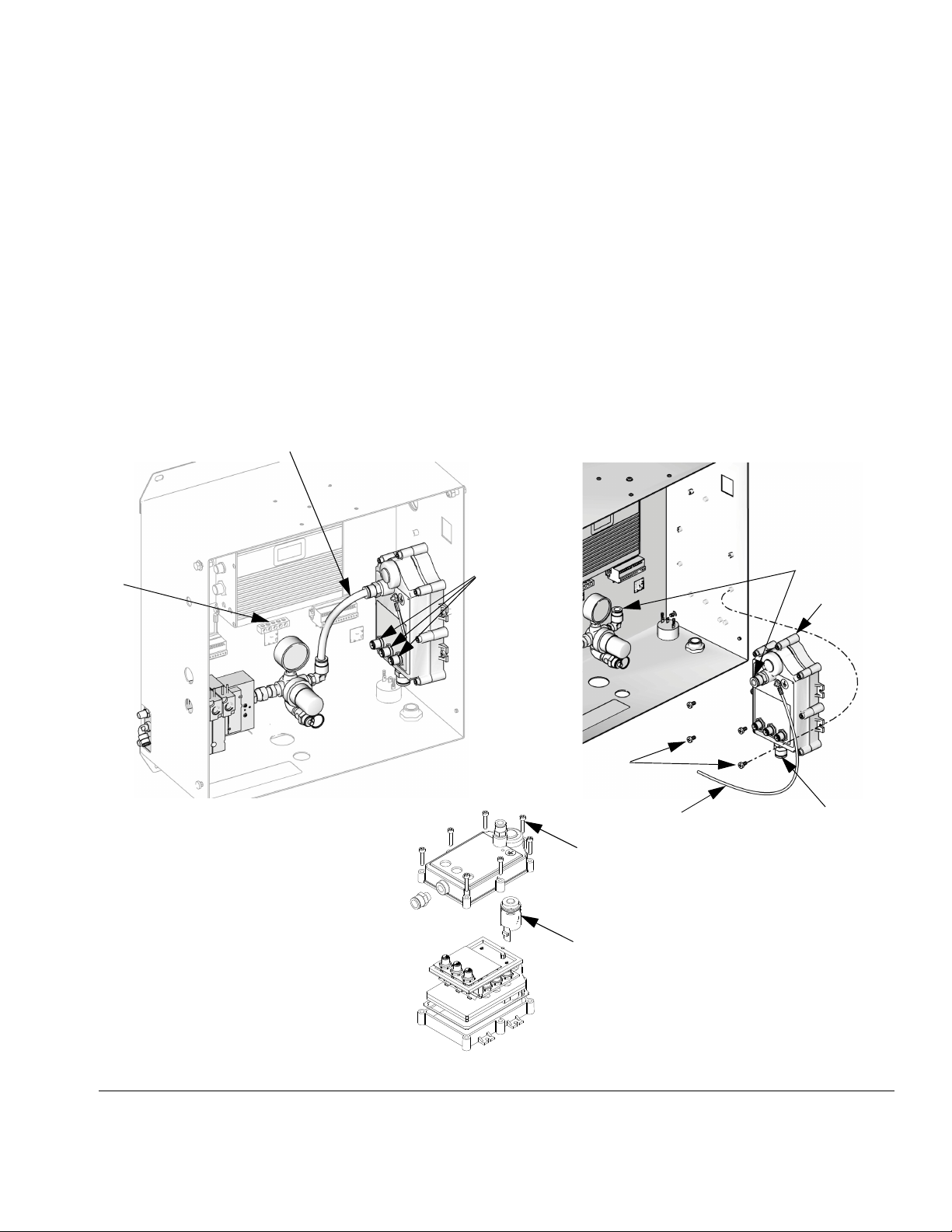

Replace Alternator Regulator

1. Follow Before Servicing, page 13. Disconnect

main air.

2. Open Control Box.

3. Disconnect supply air line from regulator assembly

(505).

4. Loosen air regulator swivel fittings (506) and

remove from solenoid module.

5. Repair or replace alternator regulator parts as necessary. See Alternator Power Assembly, page 46,

for repair parts. Replace air regulator swivel fitting

(506).

6. Reconnect air line. Set regulator air pressure to

18 psi (0.12 MPa, 1.2 bar).

NOTICE

To avoid damage to the alternator, do not set

the regulator air pressure higher than 18 psi

(0.12 MPa, 1.2 bar).

7. Close Control Box and restore power.

Replace Advanced Fluid Control

Module (AFCM)

1. Follow Before Servicing, page 13. Disconnect

main power.

2. Open Control Box.

3. Remove all cables from AFCM (302). Take note of

cable locations.

4. Disconnect ground wire from ground screw (GS).

5. Loosen four mounting screws (303).

6. Slide AFCM up and out of keyhole slots.

7. Follow steps in reverse order to install a new AFCM.

See electrical schematic for cable connection information.

8. Follow instructions in Manual 3A1244 to update the

software on the new AFCM.

9. Close Control Box and restore power.

FIG. 10. Replace Alternator Regulator

18 3A0870L

FIG. 11. Replace AFCM

Page 19

Service

311

ti16453a

Lift here.

Connect cable (64) here

(either port).

J6

ti16672a

ti16604a

64

Replace Alarm

1. Follow Before Servicing, page 13. Disconnect

main power.

2. Open Control Box.

3. Disconnect alarm wires from alarm (311).

4. Unscrew alarm jam/mounting nut to remove alarm.

5. Assemble new alarm. Reconnect alarm wires.

6. Close Control Box and restore power.

Replace Display Module

1. Follow Before Servicing, page 13.

2. The Display Module (63) snaps tightly into the

mounting bracket (49). To remove it, lift up on the

front of the bracket and, at the same time, pull the

Display Module out.

3. Disconnect the CAN cable (64).

4. Replace with a new Display Module.

5. Reconnect the CAN cable (64) as shown.

6. Follow instructions in Manual 3A1244 to update the

software on the new Display Module.

FIG. 12. Replace Alarm

FIG. 13. Replace Display Module

3A0870L 19

Page 20

Service

USB Module

Advanced

Fluid Control

Module

Display Module

P4

P3

J6

J8

ti16580a

ti16604a

ti16579a

P3

J2

USB Module

Alternator Module

ti15710a

ti16580a

Replace USB Module

1. Follow Before Servicing, page 13. Disconnect

main power.

2. Open Control Box.

3. Non-IS Systems: Disconnect Display Module CAN

cable, Advanced Fluid Control Module CAN cable

and USB cable from the USB module (340).

IS Systems: Disconnect Alternator CAN cable and

USB cable from the USB module (340).

4. Remove ground screw (343) from top of Control Box

for USB module and bracket.

5. Remove four mounting screws (341) from USB

module and remove module.

6. Follow steps in reverse order to install a new USB

7. Follow instructions in Manual 3A1244 to update the

8. Close Control Box and restore power.

module.

Non-IS Systems Cable Connections:

• CAN cable from J6 (either port) on the Display

Module to P3 on the USB Module.

• CAN cable from J8 on the Advanced Fluid Con-

trol Module to P4 on the USB Module

• USB cable (345) from the port on the Control

Box to the port on the USB Module.

IS Systems Cable Connections:

• CAN cable from J2 on the Alternator Module to

P3 on the USB Module.

• USB cable (345) from the port on the Control

Box to the port on the USB Module.

software on the new USB Module.

To help prevent fire and explosion, do not connect,

download, or remove the USB flash drive unless the

unit is removed from the hazardous (explosive

atmosphere) location. Never leave the USB flash

drive in the USB port.

FIG. 14. USB Non-IS Cable Connections

FIG. 15. USB IS Cable Connections.

Update Software

Order Software Token Kit 16D922 to update software.

Manuals 3A1244 and 406905 will accompany all software updates. Follow all instructions and warnings in

these manuals to update your Display Module,

Advanced Fluid Control Module, and USB Module (if

used).

20 3A0870L

Page 21

Service

ti16451a

340

343

341 (X 4)

345

348

349

342

342

FIG. 16. Replace USB Module

3A0870L 21

Page 22

Service

ti16457a

8

ti15708a

Solenoid air

Main air

Pump

air

Pump System Air Controls

Replace Pressure Gauge(s)

1. See Remove Air Control Assembly, page 22.

Remove Air Control Assembly

1. Follow Before Servicing, page 13.

2. See FIG. 17. Disconnect pump air lines, main air

line, and solenoid air line.

NOTE: You may prefer to remove the A side air motor

air line after you remove the assembly from the frame.

3. Loosen four screws (8) from sides of frame. Slide

the assembly up and out to remove.

4. Follow steps in reverse order to reinstall air control

assembly after repair.

See FIG. 18, page 23, for a full diagram of the pump air

controls.

2. Disconnect air lines to gauges (203).

3. Remove mounting screws (203a).

4. Remove fittings (211) and gauges (203). Replace

as needed.

5. Follow steps in reverse order to reassemble.

Replace Air Regulators

1. See Remove Air Control Assembly, page 22.

2. See FIG. 18, page 23. Remove regulator nut (205)

and disconnect air lines running to regulator (204).

3. Remove regulator assembly and replace with new.

See Air Controls, Pump-Based Models

24F088-24F115, page 35.

4. Follow steps in reverse order to reassemble.

Replace Manifold/Ball Valve/Safety Valve

1. See Remove Air Control Assembly, page 22.

2. See FIG. 18, page 23. Remove nut (202b) and handle (202a) from front of air control plate.

FIG. 17. Remove Air Control Assembly

22 3A0870L

3. Remove four screws (222) from front of air control

plate.

4. Disconnect all air lines.

5. Disconnect fittings (207, 212, 214, 215). Replace as

necessary.

6. Disconnect ball valve (202) and safety valve (219).

Replace parts as necessary, including manifold.

See Air Controls, Pump-Based Models

24F088-24F115, page 35.

7. Follow steps in reverse order to reassemble.

Page 23

Service

201

202

203

204

204

205

205

206207 209 210

211

212

212

215

219

220

221

222

224

ti16325a

214

212

212

212

208

208

207

202b

202a

8

ti16458a

Main air

Solenoid

air

Fluid inlets

FIG. 18. Air Controls, Pump System

Meter System Air Controls

Remove Air/Fluid Panel

1. Follow Before Servicing, page 13.

2. Disconnect main air line and solenoid air line. Disconnect fluid lines where they enter the valve

stacks.

3. Remove four screws (8) from sides of frame.

4. Remove air/fluid panel assembly.

5. Follow steps in reverse order to reinstall assembly

after repair.

3A0870L 23

FIG. 19. Remove Air/Fluid Panel

Page 24

Service

105

209

112

114113122 121

120

106

ti16298a

116 114

115

117

106a

106c

106b

Replace Ball Valve

1. See Remove Air/Fluid Panel, page 23.

2. Remove screw (106b) and washer (106c) from the

handle on the front of the panel.

3. Remove fittings (113, 114, 121, 122) and ball valve

(106).

4. Replace fittings and/or valve as needed.

5. Follow steps in reverse order to reassemble.

Replace Pressure Gauge(s)

1. See Remove Air/Fluid Panel, page 23.

2. Disconnect air line to gauge (105).

3. Remove mounting screws (105a).

4. Remove fitting (114) and gauge (105). Replace as

needed.

5. Follow steps in reverse order to reassemble.

FIG. 20. Air Controls, Meter System

24 3A0870L

Page 25

Fluid Controls

ti16675a

710

37

6

5

Solvent

supply

inlet

52

53

4

108

ti16674a

Fluid inlets, meter-based system.

Remove Dosing Valve Stacks

1. Follow Before Servicing, page 13.

2. Meter-based systems: See Remove Air/Fluid

Panel, page 23.

3. Pump-based systems: On inside of panel, remove

fluid inlet hose (37). Remove fluid outlet pressure

sensor (6). Disconnect fluid fitting (5) from dosing

valve stacks (4, 108 if 3-color system). Disconnect

fluid outlet lines from fitting (710). Disconnect solvent supply hose from inlet.

Service

FIG. 22. Remove valve stacks

6. 3-Color System. Remove four bolts (711) from top

of valve stack. Separate the two manifolds (701 and

706).

7. Replace Seat(s): To replace a seat on a single

valve, order Kit 16A560 (see page 49). Remove

dosing valve (705) from manifold (701 or 706), then

remove and replace seat (703) and o-rings (702 and

704).

8. Service Dosing Valve: Order Kit 15U933 (see

page 49). Follow all instructions and warnings in

manual 312782 to rebuild the dosing valve.

9. Valve Manifold Rebuild: For full service of your

valve stack (1-color or 3-color), order Kit 24H254

(see page 49). Follow directions in Dosing Valve

Manifold Rebuild, page 26.

FIG. 21. Disconnect fluid lines

4. Meter-based systems: Disconnect fluid inlet lines

from valve stacks. See FIG. 22.

5. Remove four bolts (52) and washers (53) from

inside the panel to remove each valve stack (4, 108

if 3-color system).

3A0870L 25

Page 26

Service

701

702

703

704

705

706

708

707

709

708

710

711

712

ti16302a

Dosing Valve Manifold Rebuild

Order Kit 24H254 (see page 49). Use all parts in the kit.

1. Follow Steps 1 - 5 in Remove Dosing Valve

Stacks, page 25.

2. Remove fitting (710) and o-ring (708).

3. Remove the dosing valve (705), then remove seat

(703) and o-rings (702 and 704) from each side of

each manifold (701, 706).

4. 3-Color Systems. Remove the spacer (707) and

o-rings (708 and 709) from between the two manifolds (706).

5. 3-Color Systems. Install new o-ring (708) on fitting

(710). Install fitting on bottom of 3-color manifold

(701).

NOTE: Relieve spring tension prior to installing the

valve (705) into the manifold (701 or 706).

6. Install the small o-ring (702), the seat retainer (703)

and the large o-ring (704) into the manifold, then

install the valve (705). Torque to 35-40 ft-lb (47-54

N•m). Repeat for each valve.

7. 3-Color Systems. Install new o-ring (708) on the

spacer (707). Install new o-ring (709) on the bottom

of the 1-color manifold (706). Align manifolds (701

and 706). Install four screws (711). Torque to 8-10

ft-lb (11-14 N•m).

8. Use four bolts (52) and washers (53) to reattach the

valve stacks (4, 108 if present).

9. Reconnect fluid lines. See FIG. 21, page 25.

10. Reconnect air lines. See System Pneumatic Schematic, pages 52- 53. See also the Tubing Chart

and Diagrams, page 36 for pump-based systems

or page 41 for meter-based systems.

FIG. 23. Rebuild Dosing Valve Stacks

26 3A0870L

Page 27

Service

118

Disconnect fluid lines.

109, 110

52, 53

101

103

104

13

ti16683a

ti15699a

Repair Flow Meters

Coriolis Meter

1. Follow Before Servicing, page 13.

2. To remove and service the Coriolis meter, see manual 313599.

G3000 Meter

Removal

1. Follow Before Servicing, page 13.

2. Remove cable harness (118) and fluid lines.

3. Remove two screws (110) and washers (109) holding the meter (103) and the spacer (104) to the fluid

plate (101).

4. Service meter as instructed in the meter manual

308778.

Installation

1. Secure meter (103) and spacer (104) to the fluid

plate (101) with screws (110) and washers (109).

2. Connect cable harness (118) and fluid line.

3. Calibrate meter as instructed in the Operation manual 3A0869.

Repair Mix Manifold

1. Follow Before Servicing, page 13.

2. See FIG. 25, page 28. Disconnect fluid lines.

3. Holding onto the mix manifold (13), remove four

screws (52) and washers (53) that hold the mix

manifold (13) to the fluid plate (101, meter systems)

or to the pump frame (pump systems). Remove the

manifold.

4. Service mix manifold as instructed in Mix Manifold

manual 312781.

FIG. 24. Meter System Manifold Removal

3A0870L 27

Page 28

Service

ti16682a

ti15697a

Disconnect fluid lines.

13

52, 53

FIG. 25. Pump System Manifold Removal

28 3A0870L

Page 29

Pump Assembly

ti14531a

Disconnect fluid line.

16

ti12812a

ti12813a

16

16

15

25

14

Prior to service, remove the displacement pump first,

then the air motor.

Remove the Displacement Pump

See pages 30-31 for detailed illustration.

1. Follow Pressure Relief Procedure, page 9.

2. Disconnect the fluid line from the pump outlet. See

FIG. 26.

3. Merkur Pumps: Remove the tie rod shield (26).

Merkur Bellows Pumps: Remove the coupler

shield (79).

Service

FIG. 27. Remove the coupling collars

6. Merkur Pumps: Pull up on the TSL reservoir (25) to

remove.

7. Use a socket to remove the tie rod nuts (14).

8. Carefully remove the displacement pump, with the

pump adapter attached.

4. Merkur Pumps: Hold the flats of the air motor shaft

with a wrench. Use another wrench to loosen the

coupling nut (16).

Merkur Bellows Pumps: Hold the coupling nut (16)

with a wrench. Use another wrench to turn the

motor shaft. To avoid damage to the bellows top

cap and the D-shaped seal, do not turn the cou-

pling nut.

FIG. 26. Loosen the coupling nut

5. Lower the coupling nut (16) enough to remove the

coupling collars (15), and then lift up the motor shaft

and remove the coupling nut (16).

9. Clamp the adapter plate in a vise to service the displacement pump.

10. See your displacement pump manual (312792 for

Merkur standard or 312793 for Merkur bellows) for

service and parts information.

Remove the Air Motor

1. Follow Pressure Relief Procedure, page 9.

2. Follow Remove the Displacement Pump, page 29.

3. Disconnect air lines, the reed switch CAN cable,

and the linear sensor cable.

4. Remove four screws (8) then remove the air control

panel (3). See Remove Air Control Assembly,

page 22.

5. Remove four mounting screws (49) and washers

(48) from the under side of the pump frame.

6. Systems with M02LH0 air motor (2.5 in.):

Remove three screws (49) and washers (48), then

remove the adapter plate (17) from the bottom of

the air motor.

7. Carefully lift the air motor up and out. Leave the tie

rods and muffler attached or remove them, as you

prefer.

3A0870L 29

Page 30

Parts

1

4

8

10

17

19

20

38

38

37

37

37

37

39

53

52

58

58

63

9

ti16324a

82

83

See page 31

for pump

parts.

3 - See page

35 for air

controls parts.

4 - See page 49 for

valve stack parts.

2 - See page 43

for control box

parts.

13 - See page

48 for mix

manifold parts.

64 - connects

inside box

Parts

Pump-Based Proportioners, Models 24F088-24F115

30 3A0870L

Page 31

Pumps

5

5

57

6

14

14

15

16

17

18

19

15

16

21

22

23

23

24

24

25

25

26

37

37

46

54

54

55

57

6

62

62

77

77

78

79

ti16326a

20

78

37

37

48

49

48

49

1

Connects reed switch (54) and

linear sensor (62) to AFCM

(302, see page 43).

1

2

Connects fluid outlet pressure

sensor (6) to AFCM (302, see

page 43).

2

2

Parts

3A0870L 31

Page 32

Parts

Pump-Based Models 24F088-24F115

-

Ref. Part Description Qty.

1 ----- FRAME 1

2 ----- CONTROL BOX, see page 43, Refs. 301-339 1

3 ----- CONTROLS, air; see page 35, Refs. 201-226 1

4 ----- VALVE, stack, 1 color/1 solvent; see page 49, Refs. 702-706, 708, and 710 2

5 16F164 FITTING, pressure sensor, fluid outlet 2

6 15M669 SENSOR, pressure, fluid outlet 2

8 ----- SCREW, machine, serrated flange, hex head, 5/16-18 x 2.25 in. 4

9 112547 SCREW, flange, hex head, 1/4-20 4

10 109478 NUT 4

13 262399 MIX MANIFOLD, dynamic dosing, see page 48, Refs. 601-632 1

14 15U606 NUT, lock, m16 x 2 6

15 184128 COLLAR, coupling 4

16 15T311 NUT, coupler 2

17 16F249 ADAPTER, plate, see Table, page 34 2

18

M02LH0

M12LN0

M18LN0

19

LW050A

LW075A

LW100A

LW125A

LW150A

20

LB100B

LB150B

LW050A

LW075A

LW100A

LW125A

LW150A

21 15M662 ROD, tie, pump A 3

22

15M662

15U691

23 See

Table

24 16G463 COUPLING, adapter; see Table, page 34 2

25 See

Table

26 24A959 SHIELD, tie rod 1

27 ----- USB MODULE, see page 44, Refs. 340-347

37

206966

239083

38 166421 FITTING, pipe 2

39 277853 BRACKET, mounting, display module 1

40▲ 15X214 LABEL, warning, USB, not shown 1

45 105335 SCREW, machine, pan head, M4 x 0.7, for tie rod guard, not shown 1

AIR MOTOR, Merkur, see Table, page 34, see manual 312796 for repair/parts

2.5 in. (M02xxx) with linear sensor

6.0 in. (M12xxx) with linear sensor

7.5 in. (M18xxx) with linear sensor

DISPLACEMENT PUMP A, see Table, page 34, see manual 312792 for repair/parts

Merkur, 50cc

Merkur, 75cc

Merkur, 100cc

Merkur, 125cc

Merkur, 150cc

DISPLACEMENT PUMP B, see Table, page 34, see manual 312793 for repair/parts

Merkur Bellows with u-cup, 100cc

Merkur Bellows with u-cup, 150cc

Merkur, 50cc

Merkur, 75cc

Merkur, 100cc

Merkur, 125cc

Merkur, 150cc

ROD, tie, pump B

Merkur pump

Merkur Bellows pump

ADAPTER, displacement pump 1

RESERVOIR, tsl 1

HOSE, coupled

3:1, 23:1, and 30:1 systems

45:1 systems

2

1

1

3

4

32 3A0870L

Page 33

Parts

Ref. Part Description Qty.

46

115841

C38211

ELBOW, air inlet

M02xxx air motors

All other air motors

2

47 15T632 KIT, Air Flow Switch, see page 50, Refs. 900-904, not used on 45:1 systems 1 or

2

48 100133 WASHER, lock

M02xxx air motors

All other air motors

14

8

49 100680 SCREW, cap, hex hd

M02xxx air motors

All other air motors

14

8

51 101970 PLUG, pipe, hdls, not shown 4

52 C19798 SCREW, cap, socket head 12

53 100527 WASHER, plain 12

54 24A032 SWITCH, reed assembly 2

55 16E917 CABLE, IS and reed 2

57 120685 GROMMET 3

58 115313 PLUG, tube 2

62

24G849

24G848

KIT, LINEAR SENSOR, IS; includes sensor, fitting, magnet with holder, and o-ring

M02xxx air motor

All other air motors

2

63 16E883 MODULE, display 1

64 123278 CABLE, CAN, IS, yel m std x f rev. 1

66 ----- ELECTRIC POWER ASSEMBLY, Models 24F088-24F101, see page 45, Refs. 401-411 1

67 ----- ALTERNATOR POWER ASSEMBLY, Models 24F102-24F115, see page 46, Refs.

1

501-517

68▲ 15W776 LABEL, warning, not shown 1

77 156971 FITTING, nipple, short 2

78

16H491

512351

ADAPTER

M02xxx air motor

All other air motors

2

79 24A640 SHIELD, Bellows 2

82 111307 WASHER, shipped loose, for Display Module 2

83 121224 SCREW, shipped loose, for Display Module 2

84 16G475 MAGNET, with holder 2

87 16F793 CARD, alarm/icon, not shown 1

325▲ 15W598 LABEL, warning 1

--- Not sold separately.

▲ Replacement Danger and Warning labels, tags, and

cards are available at no cost.

3A0870L 33

Page 34

Parts

Parts that Vary by Model, Pump-Based

Model Adapter

Non-IS IS

Plate

(Item 17)

Air

Motor

(Item 18)

“A”

Lower

(Item 19)

“B”

Lower

(Item 20)

“A”

Tie Rod

(Item 21)

“B”

Tie Rod

(Item 22)

Lower

Adapter

(Item 23)

Coupling

(Item 24)

TSL

Reservoir

(Item 25)

24F088 24F102 16F249 M02LH0 LW125A LW125A 15M662 15M662 15T394 16G463 24A627

24F089 24F103 ----- M12LN0 LW100A LW100A 15M662 15M662 15T393 ----- 24A626

24F090 24F104 ----- M12LN0 LW075A LW075A 15M662 15M662 15T392 ----- 24A625

24F091 24F105 ----- M12LN0 LW050A LW050A 15M662 15M662 15T391 ----- 24A622

24F092 24F106 16F249 M02LH0 LW150A LB150B 15M662 15U691 15T395 16G463 24A628

24F093 24F107 ----- M12LN0 LW100A LB100B 15M662 15U691 15T393 ----- 24A626

24F094 24F108 ----- M18LN0 LW100A LB100B 15M662 15U691 15T393 ----- 24A626

24F095 24F109 16F249 M02LH0 LW125A LW125A 15M662 15M662 15T394 16G463 24A627

24F096 24F110 ----- M12LN0 LW100A LW100A 15M662 15M662 15T393 ----- 24A626

24F097 24F111 ----- M12LN0 LW075A LW075A 15M662 15M662 15T392 ----- 24A625

24F098 24F112 ----- M12LN0 LW050A LW050A 15M662 15M662 15T391 ----- 24A622

24F099 24F113 16F249 M02LH0 LW150A LB150B 15M662 15U691 15T395 16G463 24A628

24F100 24F114 ----- M12LN0 LW100A LB100B 15M662 15U691 15T393 ----- 24A626

24F101 24F115 ----- M18LN0 LW100A LB100B 15M662 15U691 15T393 ----- 24A626

34 3A0870L

Page 35

Air Controls, Pump-Based Models 24F088-24F115

201

202

203

204

204

205

205

206

207

209 210

211

212

212

215

219

220

221

222

224

ti16325a

214

212

212

212

208

208

207

202b

202a

223

Parts

Ref. Part Description Qty.

201 ----- PLATE, air controls 1

202 110225 VALVE, vented, 2-way 1

202a ----- HANDLE 1

202b ----- NUT, handle 1

202c 290167 TAG, warning, not shown 1

203 15T500 GAUGE, air pressure 3

203a ----- SCREW, mounting, gauge 6

204 116513 REGULATOR, air 2

205 116514 NUT, air regulator 2

206 15D795 FILTER, air 1

206a 15D890 ELEMENT, 40 micron 1

207 ----- ELBOW, male 2

208 15T866 ELBOW, swivel, 1/8 npt x 5/32 T 2

209 114124 FILTER, air 1

209a 15D909 ELEMENT, 5 micron 1

3A0870L 35

Ref. Part Description Qty.

210 114153 ELBOW 1

211 15T498 ELBOW 3

212 115841 ELBOW 5

214 114469 ELBOW 1

215 502524 CONNECTOR, tube 1

219 113498 VALVE, safety 1

220 114485 CONNECTOR, male, 3/8 npt 1

221 16F701 MANIFOLD, pump 1

222 551787 SCREW, cap 4

223 109478 NUT, lock 2

224 100022 SCREW, cap, hex 2

Page 36

Parts

GFB1-A

GFB1-C

GFB1-S

GFB1-S

ATOM-1

1R 2R 3R 4R

1G

2G

3G

4G

GFB1-C

A8*

A9*

*

IS Models

ti16771a

ti13863a

ti13861a

ti16770a

GFB1-P

(Pressurized air line)

Tubing Chart, Pump-Based Models 24F088-24F115

Type Color Description Starting Point Ending Point Tube OD in. (mm)

Air Green Solvent Valve A On 1G 1G 0.156 (4.0)

Air Green Dose Valve A On 2G 2G 0.156 (4.0)

Air Green Solvent Valve B On 3G 3G 0.156 (4.0)

Air Green Dose Valve B On 4G 4G 0.156 (4.0)

Air Red Solvent Valve A Off 1R 1R 0.156 (4.0)

Air Red Dose Valve A Off 2R 2R 0.156 (4.0)

Air Red Solvent Valve B Off 3R 3R 0.156 (4.0)

Air Red Dose Valve B Off 4R 4R 0.156 (4.0)

Air Natural Solenoid Air A1 A1 0.25 (6.3)

Air Natural Air Regulator to Pump B A2 A2 0.375 (9.5)

Air Natural Air Regulator to Pump A A3 A3 0.375 (9.5)

Fluid ---- Pump B to Valve Stack B A4 A4 ----Fluid ---- Pump A to Valve Stack A A5 A5 ----Fluid ---- Valve Stack A to Mix Manifold A6 A6 ----Fluid ---- Valve Stack B to Mix Manifold A7 A7 ----Air Natural Air Regulator to Alternator* A8 A8 0.375 (9.5)

Air Black Alternator Air Exhaust* A9 A9 0.5 (12.7)

* Used only on IS models.

36 3A0870L

Page 37

GFB1-A

ATOM-1

ATOM-2

A1

A4

A5

B Side

A Side

A4

A5

A Side B Side

3R

3G

4G

4R

1R

1G

2G

2R

A6

A7

ti16765a

ti16766a

ti16764a

A3

A2

A3

ti16772a

B Side

A Side

See Manual 312784 for full

setup instructions for a gun

flush box.

Parts

3A0870L 37

Page 38

Parts

101

38

102

103

104

118

104

103

118

105

106

4 - See page 49

for valve stack

parts.

109

110

53

52

111

111

ti16297a

63

39

9

10

1

37

37

8

58

82

83

52

53

68

2 - See page 43

for control box

parts.

108 - See page 49

for valve stack

parts.

13 - See page

48 for mix

manifold parts.

64 - connects

inside box

Meter-Based Proportioners, Models 24F080-24F087

38 3A0870L

Page 39

Meter-Based Models 24F080-24F087

105

209

112

123113122 121

120

106

ti16298a

116 114115

117

106a

106c

106b

Parts

Ref. Part Description Qty.

1 ----- FRAME, meter 1

2 ----- CONTROL BOX, see page 43, Refs. 301-339 1

4 ----- VALVE, stack, 1 color/1 solvent; see page 49, Refs. 702-706, 708, and 710

1-Color Models

3-Color Models

2

1

8 ----- SCREW, machine, serrated flange, hex head, 5/16-18 x 2.25 in. 4

9 112547 SCREW, flange, hex hd 4

10 109478 NUT 4

13 262398 MIX MANIFOLD, sequential dosing, see page 48, Refs. 601-623 1

27 ----- USB MODULE, see page 44, Refs. 340-347

35 117356 VALVE, solenoid (3-color models; see page 43) 2

37 206966 HOSE, coupled, 1.5 ft 2

38 114339 FITTING, union, swivel, 1/4 npt, sst 4

39 277853 BRACKET, mounting, display module 1

40▲ 15X214 LABEL, warning, USB, not shown 1

47 15T632 KIT, Air Flow Switch, see page 50, Refs. 900-904 1 or 2

52 C19798 SCREW, cap, socket head 12

53 100527 WASHER, plain 12

57 120685 GROMMET 2

58 115313 PLUG, tube 2

63 16E883 MODULE, display 1

64 123278 CABLE, IS, CAN, yellow, m std x f rev. 1

66 ----- ELECTRIC POWER ASSEMBLY, Models 24F080-24F083, see page 45, Refs. 401-411 1

67 ----- ALTERNATOR POWER ASSEMBLY, Models 24F084-24F087, see page 46, Refs.

1

501-517

68▲ 15W776 LABEL, warning 1

82 111307 WASHER, shipped loose, for Display Module 2

83 121224 SCREW, shipped loose, for Display Module 2

87 16F793 CARD, alarm/icon, not shown 1

90 16G607 BUSHING, strain relief 1

101 ----- PLATE, fluid 1

102 114342 ELBOW, 1/4-18 npsm 2

103 289813 METER, gear, G3000 2

104 16F063 SPACER, meter 2

3A0870L 39

Page 40

Parts

Ref. Part Description Qty.

105 15T500 GAUGE, air pressure 1

105a ----- SCREW, mounting, gauge 6

106 118762 VALVE, ball, vented, 1/2 in. 1

106a ----- HANDLE, ball valve 1

106b ----- SCREW 1

106c ----- WASHER 1

108 ----- VALVE, stack, 3 clr/1 fl, see page 49, 3-Color Models only 1

109 100527 WASHER, plain 4

110 117029 SCREW, M6x25 4

111 501867 VALVE, check 2

112 107404 SCREW, cap, sockethead 2

113 100081 BUSHING, pipe 1

114 C19675 BUSHING, reducer 2

115 15T498 SWIVEL, 90°, 5/32T x 1/8 npt(f) 1

116 C20365 FITTING, tee 1

117 517312 CONNECTOR, male 1

118 258528 HARNESS, cable, w/connector, G3000 2

120 114153 ELBOW, male, swivel 1

121 158491 FITTING, nipple 1

122 512905 FITTING, bulkhead 1

123 114366 FITTING, tube 1

124 117793 HOLDER, tie 6

209 114124 FILTER, air, 3/8 npt, see page 51 for filter elements. 1

230 262028 TOOL KIT, installation 1

325▲ 15W598 LABEL, warning 1

▲Replacement Danger and Warning labels, tags, and cards are available at no cost.

40 3A0870L

Page 41

Tubing Chart, Meter-Based Models 24F080-24F087

GFB1-A

GFB1-C

GFB1-S

GFB1-S

ATOM-1

1R 2R 3R 4R

5R 6R

1G

2G

3G

4G

5G

6G

GFB1-C

A7*

A6*

*

IS Models

ti16771a

ti13863a

ti13861a

ti16770a

A1

A3

ti16773a

GFB1-P

(Pressurized air line)

Parts

Type Color Description

Starting

Point

Ending

Point

Tube OD

in. (mm)

Air Green Solvent Valve A On 1G 1G 0.156 (4.0)

Air Green Dose Valve A1 On 2G 2G 0.156 (4.0)

Air Green Solvent Valve B On 3G 3G 0.156 (4.0)

Air Green Dose Valve B On 4G 4G 0.156 (4.0)

Air Green Dose Valve A2 On 5G 5G 0.156 (4.0)

Air Green Dose Valve A3 On 6G 6G 0.156 (4.0)

Air Red Solvent Valve A Off 1R 1R 0.156 (4.0)

Air Red Dose Valve A1 Off 2R 2R 0.156 (4.0)

Air Red Solvent Valve B Off 3R 3R 0.156 (4.0)

Air Red Dose Valve B Off 4R 4R 0.156 (4.0)

Air Red Dose Valve A2 Off 5R 5R 0.156 (4.0)

Air Red Dose Valve A3 Off 6R 6R 0.156 (4.0)

Air ----- Main Air to Pressure Gauge A1 A1 0.156 (4.0)

Air Natural Solenoid Air A2 A2 0.25 (6.3)

Air Natural Main Air to Filter A3 A3 0.25 (6.3)

Fluid ----- Valve Stack A to Meter A A4 A4 0.375 (9.5)

Fluid ----- Valve Stack B to Meter B A5 A5 0.375 (9.5)

Air Black Alternator Air Exhaust* A6 A6 0.5 (12.7)

Air Natural Air Regulator to Alternator* A7 A7 0.375 (9.5)

* Used only on IS models.

3A0870L 41

Page 42

Parts

A Side

A Side

B Side

B Side

GFB1-A

ATOM-1

ATOM-2

A2

6R

6G

1G

1R

A4

A5

2R

5R

2G

5G

4R

4G

3R

3G

ti16767a

ti16769a

ti16768a

See Manual 312784 for full

setup instructions for a gun

flush box.

42 3A0870L

Page 43

Control Box

301

302

303

304

305

306

307

308

309310

311

313

330

314

315

316

317

318

320

321

326

329

338 - 3-color models have

2 additional solenoids here.

ti16303a

ti16421a

339

325

68

Parts

Ref. Part Description Qty.

68▲ 15W776 LABEL, warning 1

301 ----- ENCLOSURE, control box 1

302 16F357 MODULE, advanced fluid control 1

302a 103854 SCREWS, access cover, not shown 2

302b ----- COVER, access, not shown 1

303 110637 SCREW, machine, panhead 4

304 16E943 MANIFOLD, solenoid 1

305 121628 SCREW, self-sealing 2

306 117356 VALVE, solenoid

307 114263 CONNECTOR, male

308 100139 PLUG, pipe 4

309 C06061 MUFFLER, 2

310 112698 ELBOW 1

311 122000 ALARM, 1

312 15V778 CABLE, IS, CAN female-female,

313 113796 SCREW 2

314 ----- PLUG, hole 2

3A0870L 43

Pump and 1-Color Meter Systems

3-Color Meter Systems

Pump and 1-Color Meter Systems

3-Color Meter Systems

not shown

4

6

8

12

1

Ref. Part Description Qty.

315 102040 NUT, lock, hex 2

316 117625 NUT, locking 1

317 117745 BUSHING, strain relief 1

318 119257 CONNECTOR, bar, ground 1

319 16G607 BUSHING, strain relief 1

320 16E890 HARNESS, solenoid/meter 2

321 24F208 COVER, control box 1

325▲ 15W598 LABEL, warning 1

326 116343 SCREW, ground 1

327 223547 WIRE, not shown

328 112512 FERRULE, wire, orange, not shown 10

329 117793 HOLDER, tie 3

330 103833 SCREW, machine 2

338 552183 PLATE, solenoid mounting; 3-color

models have solenoids on this

plate.

339 195889 CONNECTOR, cord strain relief 1

340 15D906 SUPPRESSOR 1

▲Replacement Danger and Warning labels, tags, and

cards are available at no cost.

A/R

2

Page 44

Parts

ti16427a

340

341

342

343

346

345

Purchase cable separately.

See CAN Cable options

below.

342

349

348

USB Module

Ref. Part Description Qty.

340 16F358 USB MODULE with TOKEN 1

341 121417 SCREW 4

342 102063 WASHER 2

343 195875 SCREW, grounding 1

345 24H084 USB HARNESS 1

346 15R325 COVER, bulkhead 1

347 15X214 LABEL, warning 1

348 16G873 BRACKET, grounding 1

349 195874 SCREW, grounding 1

CAN Cables

Part Description Qty.

15V782 CABLE, for Non-IS models 1

15V778 CABLE, for IS models 1

Software Updates

Part Description Qty.

16D922 TOKEN, latest version of software for

Advanced Fluid Control Module,

Display Module, and USB Module

NOTE: Order Kit 24H253 to add a USB Module.

Includes all parts shown and instructions.

1

44 3A0870L

Page 45

Electric Power Assembly

401

402

403

404

405

406

407

ti16454b

410

411

Parts

Ref. Part Description Qty.

401 15V747 POWER SUPPLY, 24 VDC, 2.5 A,

60 watt, B-code, with cable

402 116320 SWITCH, rocker, power 1

403 115306 FILTER, power line 1

404 114095 BLOCK, terminal 1

405 112144 SCREW, machine, pan head 4

406 109467 SCREW, machine, pan head 2

407 103832 SCREW, mach 2

408 100139 PLUG, pipe, not shown 1

410 ----- HARNESS, 2-wire; 8 in. (203 mm) 1

411 ----- HARNESS, 3-wire; 4 in. (102 mm) 1

----- Not sold separately.

1

NOTE: Order Electric Power Conversion Kit 16G351 to

convert an intrinsically safe air-powered alternator

power supply to a non-intrinsically safe electric power

supply.

3A0870L 45

Page 46

Parts

501

502

504

505

506

503

507

508

509

ti16300b

510

511

J1

J2

J3

Connect cable

517 to fluid control module.

Connect cable 516

to USB module, if

present.

Connect cable 515

to display module.

Alternator Power Assembly

Ref. Part Description Qty.

501 255728 ALTERNATOR, module, see page

502 15W017 VALVE, safety 1

503 156971 FITTING, nipple, short 1

504 115841 ELBOW 1

505 115243 REGULATOR, air, 1/4 npt 1

506 113915 UNION, swivel 1

507 112307 ELBOW 1

508 104655 GAUGE, pressure 1

509 103833 SCREW, machine 4

510 100284 NUT, hex 1

511 15B090 WIRE, grounding 1

512 112514 FERRULE, not shown 1

513 ----- TUBE, exhaust, black; 1/2 in.

514 ----- TUBE, air; 3/8 in. (10 mm) OD 1

46 3A0870L

47 for parts

(13 mm) OD

1

3

CAN Cables

Ref. Part Description Qty.

515 123278 CABLE, CAN; 10 ft (3.05 m) 1

516 15V782 CABLE, CAN; 2 ft (0.6 m) 1

517 15V778 CABLE, CAN; 20 in. (0.5 m) 1

NOTE: Order Alternator Conversion Kit 16G353 to convert from an electric power supply to an air-powered

alternator power supply.

Page 47

Alternator Module 255728

501h

501j

501a

501f

501k

501e

501d

501c

501b

501a

Parts

Ref. Part Description Qty.

501a ----- HOUSING, upper and lower 1

501b ----- GASKET, stacked, internal 1

501c ----- GASKET, housing 1

501d 257147 TURBINE 1

501e ----- BOARD, assy. 1

501f 122161 FITTING, air 1

501g▲ 15R337 LABEL, warning, not shown 1

501h 114380 SCREW, cap, socket head 7

591j 122848 FITTING, air 1

501k▲ 172953 LABEL, grounding 1

3A0870L 47

Page 48

Parts

601

602

603

604

605

606

607

608

609

610

611

613

614

615

617

618

611

619

620

621

622

623

ti16301a

611

617

616

ti16327a

601

602

611

613

618

625

619

603

611

624

614

605

615

617

616

617

606

629

630

631

632

627

628

626

Sequential Dosing Mix Manifold 262398 Dynamic Dosing Mix Manifold 262399

Ref. Part Description Qty.

601 ----- BODY, integrator manifold 1

602 15T592 PLUG, integrator manifold 1

603 ----- O-RING 2

605 15B588 SCREW, cap, socket hd 8

606 15D430 TUBE, static mixer 1

607 118822 ELEMENT, static mixer 2

611 ----- O-RING 3

613 15T943 BASE, integrator 1

614 ----- MANIFOLD, end 2

615 15T748 SEAL, screw 1

616 15T749 SEAL, screw 1

617 ----- O-RING 2

618 ----- O-RING 1

619 16D658 VALVE, check 2

624 15U955 CAP, injection, 0cc, includes part

625

625 ----- RESTRICTOR, injection, 0.070 1

626 16G872 BRACKET, mounting 1

627 105510 WASHER, lock 2

1

628 100609 SCREW, machine, panhead 2

629 118830 CLAMP 2

630 118831 COVER, clamp 1

631 101885 SCREW, cap, sockethead 2

632 112223 NUT, hex 2

Ref. Part Description Qty.

601 ----- BODY, integrator manifold 1

602 15T592 PLUG, integrator manifold 1

603 ----- O-RING 2

604 118823 TUBE, outlet 1

605 15B588 SCREW, cap, socket hd 8

606 15D430 TUBE, static mixer 1

607 118822 ELEMENT, static mixer 2

608 118830 CLAMP, body, integrator tube 1

609 118831 COVER, clamp, integrator tube 1

610 101885 SCREW, cap, socket hd 2

611 ----- O-RING 3

613 15T943 BASE, integrator 1

614 ----- MANIFOLD, end 2

615 15T748 SEAL, screw 1

616 15T749 SEAL, screw 1

617 ----- O-RING 2

618 ----- O-RING 1

619 16D658 VALVE, check 2

620 15V021 MIXER, integrator, 50cc, includes

parts 621-623

621 ----- HOUSING, integrator, 50cc 1

622 ----- CAP, mix, integrator 1

623 ----- CAP, integrator 1

48 3A0870L

1

Page 49

1-Color/1 Solvent Valve Stack

702

703

704

705

706

708

710

ti16791a

701

702

703

704

705

706

708

707

709

708

710

711

712

ti16302a

Ref. Part Description Qty.

702*† ----- O-RING 2

703*† ----- SEAT, valve 2

704*† ----- O-RING, PTFE 2

705 15X303 VALVE, dispense 2

706◆ 16F057 MANIFOLD, valve, 1-color, 303

stainless steel

708* 110004 O-RING 2

710 16F064 FITTING, CC 1

Parts

1

--- Parts not sold separately.

* Parts included in Valve Stack Rebuild Kit 24H254.

This kit includes wear parts for 1-color and 3-color

valve stacks. Order Kit 16A560 to replace a single

seat (includes 702-704). Order Kit 15U933 to repair

a single dispense valve.

† The standard valve seat (703) is SST. To install a

carbide seat, order Kit 24U054. The kit includes a

single carbide seat and o-rings 702 and 704.

◆ The standard manifold (706) is 303 SST. To install a

316 SST manifold, order Kit 24V017.

NOTE: Order Kit 24H255 to convert an existing 1-color

system to a 3-color system.

3-Color/1 Solvent Valve Stack

Ref. Part Description Qty.

701 16F058 MANIFOLD, valve, 3-color 1

702*† ----- O-RING 4

703*† ----- SEAT, dump valve 4

704*† ----- O-RING, PTFE 4

705 15X303 VALVE, dispense 4

706◆ 16F057 MANIFOLD, valve, 1-color, 303

stainless steel

707* ----- SPACER, manifold 1

708* 110004 O-RING 2

709* 111116 O-RING 1

710 16F064 FITTING, CC 1