Page 1

Operation

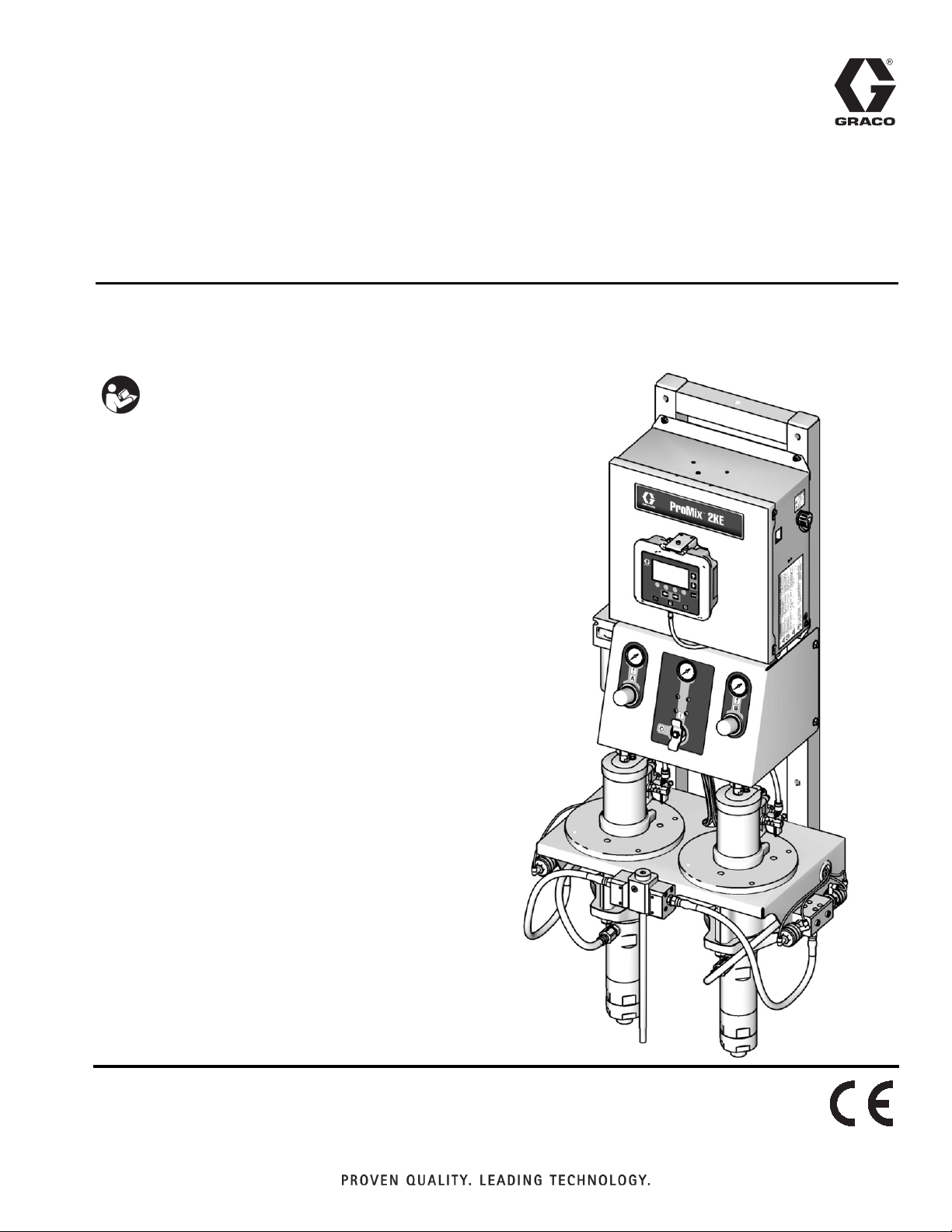

ProMix

®

2KE

3A0868G

Pump-Based Plural Component Proportioner

Self-contained, electronic two-component paint proportioner. For professional use only.

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

See pages 3-4 for model information, including maximum working pressure and approvals.

EN

ti15696a

Page 2

Contents

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Important Two-Component Material Information . 8

Isocyanate Conditions . . . . . . . . . . . . . . . . . . . . . 8

Material Self-ignition . . . . . . . . . . . . . . . . . . . . . . 8

Keep Components A and B Separate . . . . . . . . . 8

Moisture Sensitivity of Isocyanates . . . . . . . . . . . 8

Changing Materials . . . . . . . . . . . . . . . . . . . . . . . 8

Glossary of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Component Identification and Definition . . . . . . 10

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

General Information . . . . . . . . . . . . . . . . . . . . . 10

Intrinsically Safe Installation Requirements . . . 11

Display Module . . . . . . . . . . . . . . . . . . . . . . . . . 13

Air Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Fluid Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Tubing Chart and Diagrams . . . . . . . . . . . . . . . 16

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Display Module . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Icon Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

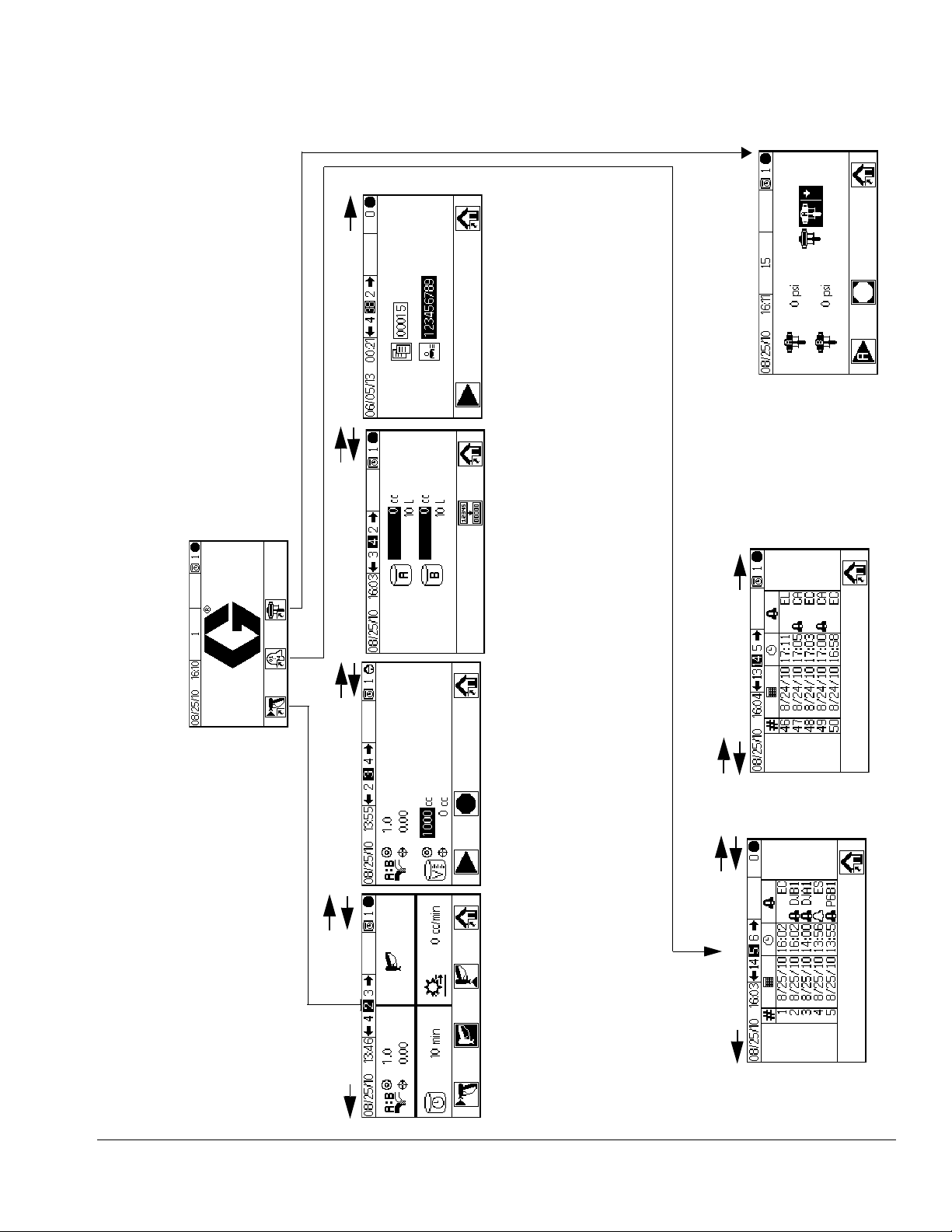

Screen Summary . . . . . . . . . . . . . . . . . . . . . . . 23

Ranges for User Inputs . . . . . . . . . . . . . . . . . . . 24

Basic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Pre-Operation Tasks . . . . . . . . . . . . . . . . . . . . . 29

Power On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Initial System Setup . . . . . . . . . . . . . . . . . . . . . 29

Prime the System . . . . . . . . . . . . . . . . . . . . . . . 30

Pump Calibration . . . . . . . . . . . . . . . . . . . . . . . 31

Spraying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Purging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Pressure Relief Procedure . . . . . . . . . . . . . . . . 35

Lock Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Valve Settings . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Use of Optional USB Module . . . . . . . . . . . . . . . . 36

USB Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Download Procedure . . . . . . . . . . . . . . . . . . . . 38

Recommended USB Flash Drives . . . . . . . . . . 38

Run Mode Details . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Run Mix Spray (Screen 2) . . . . . . . . . . . . . . . . . 39

Run Home (Screen 1) . . . . . . . . . . . . . . . . . . . . 39

Run Mix Batch (Screen 3) . . . . . . . . . . . . . . . . . 39

Run Mix Totals (Screen 4) . . . . . . . . . . . . . . . . . 40

Run Job Number (Screen 38) . . . . . . . . . . . . . . 40

Run Log Errors (Screens 5-14) . . . . . . . . . . . . . 40

Run Pump Control (Screen 15) . . . . . . . . . . . . . 41

Setup Mode Details . . . . . . . . . . . . . . . . . . . . . . . . 42

Password (Screen 16) . . . . . . . . . . . . . . . . . . . . 42

Setup Home (Screen 17) . . . . . . . . . . . . . . . . . . 42

Configure 1-4 (Screens 18-21) . . . . . . . . . . . . . 43

Recipe 1-1 (Screen 28) . . . . . . . . . . . . . . . . . . . 44

Recipe 1-2 (Screen 29) . . . . . . . . . . . . . . . . . . . 44

Maintenance 1-3 (Screens 24-26) . . . . . . . . . . . 45

Maintenance Recommendations . . . . . . . . . . . . 45

Calibration 1 and 2 (Screens 22 and 23) . . . . . . 46

Troubleshooting (Screens 35-37) . . . . . . . . . . . 46

Dynamic Dosing . . . . . . . . . . . . . . . . . . . . . . . . 48

System Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

System Alarms . . . . . . . . . . . . . . . . . . . . . . . . . 50

System Advisory/Record Codes . . . . . . . . . . . . 50

To Clear Error and Restart . . . . . . . . . . . . . . . . 50

Air Flow Switch (AFS) Function . . . . . . . . . . . . . 50

System Idle Warning (IDLE) . . . . . . . . . . . . . . . 51

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Alarm Troubleshooting . . . . . . . . . . . . . . . . . . . 53

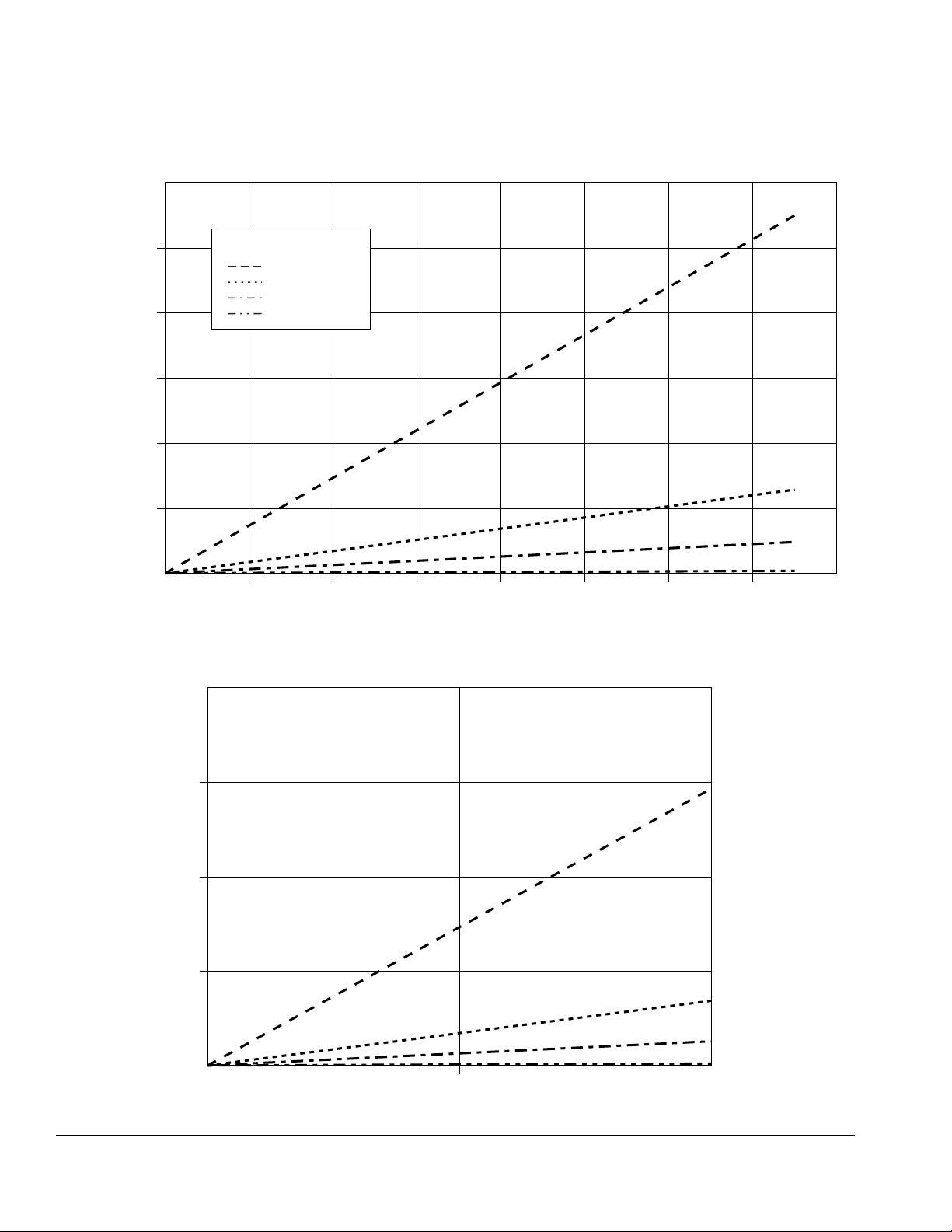

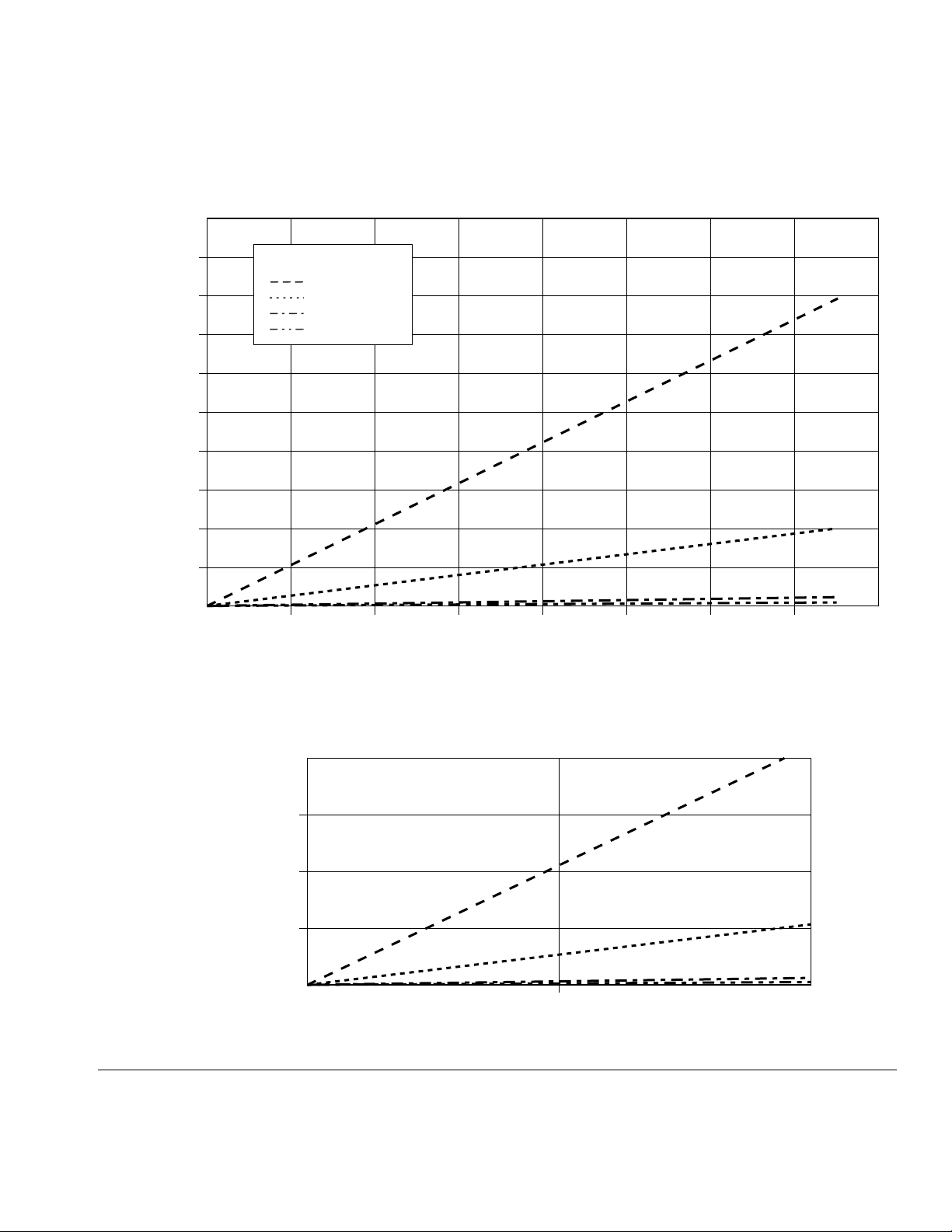

Dynamic Dosing Restrictor Selection Graphs . . 60

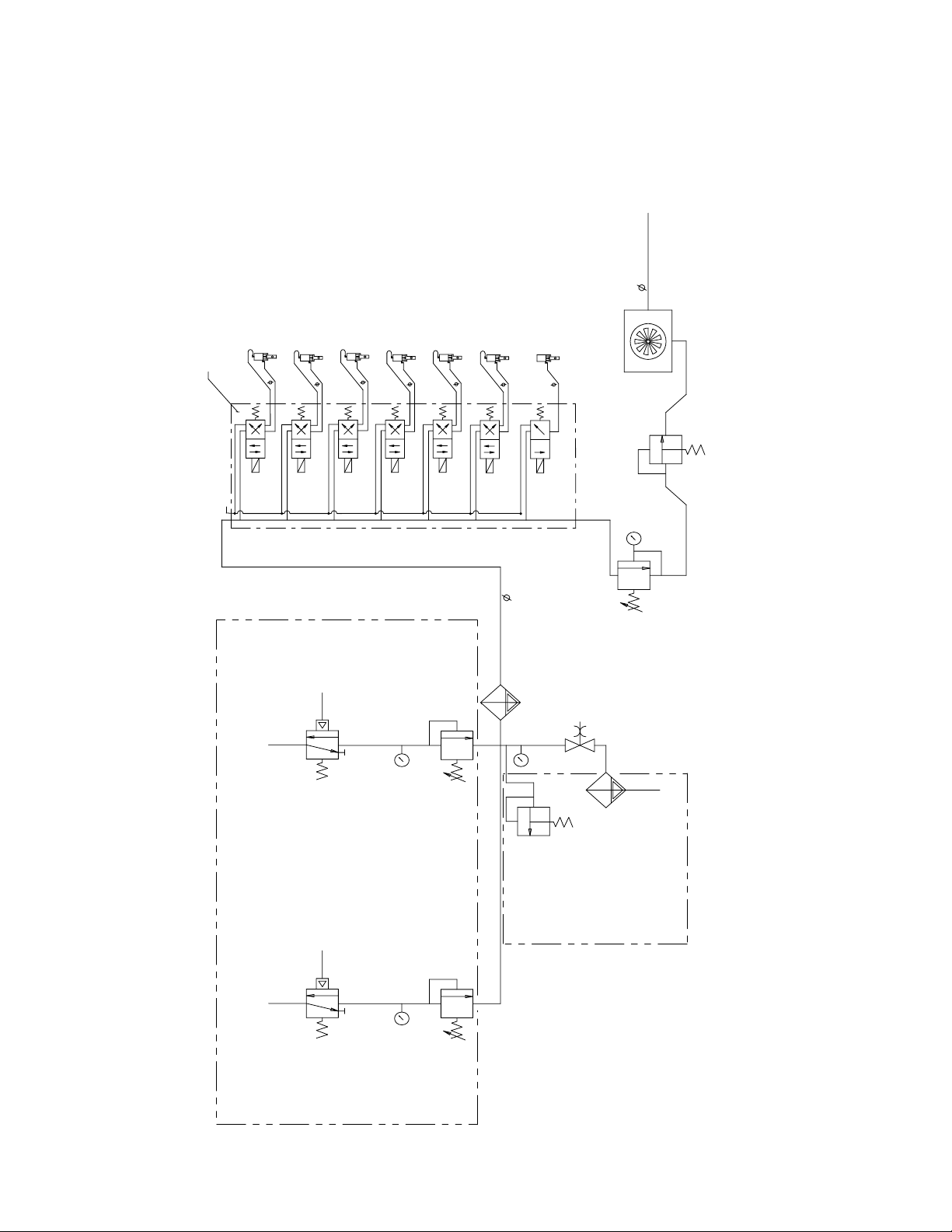

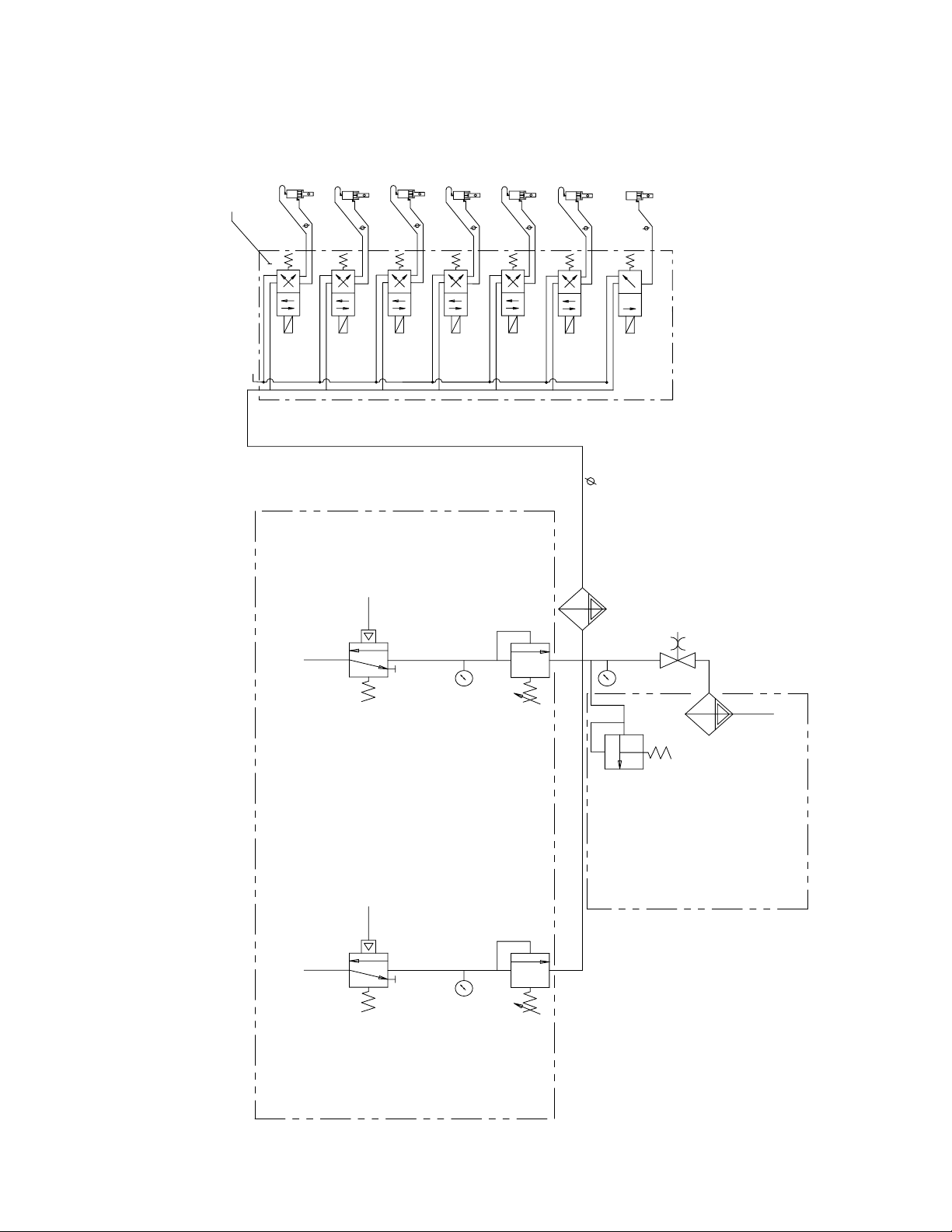

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

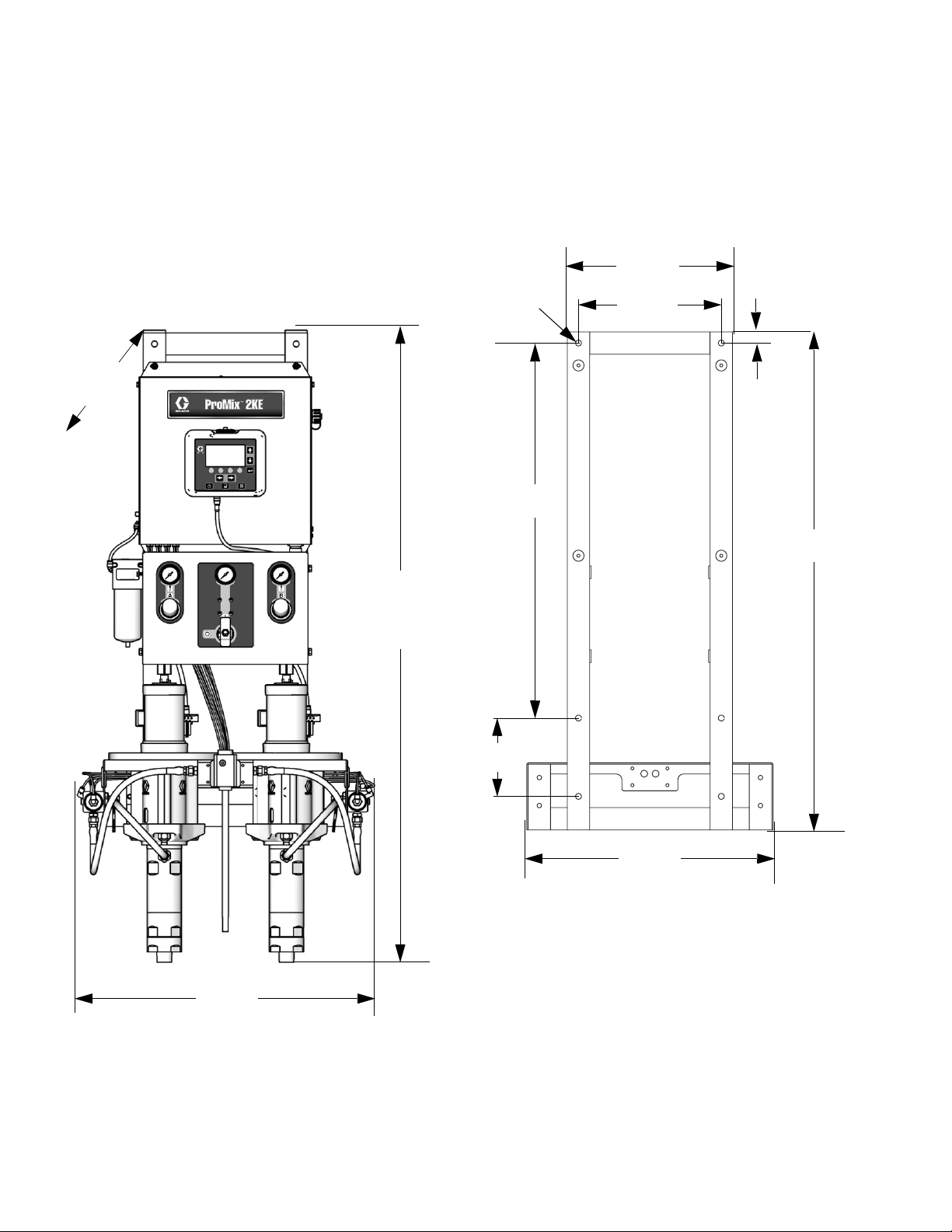

Dimensions and Mounting . . . . . . . . . . . . . . . . . . 72

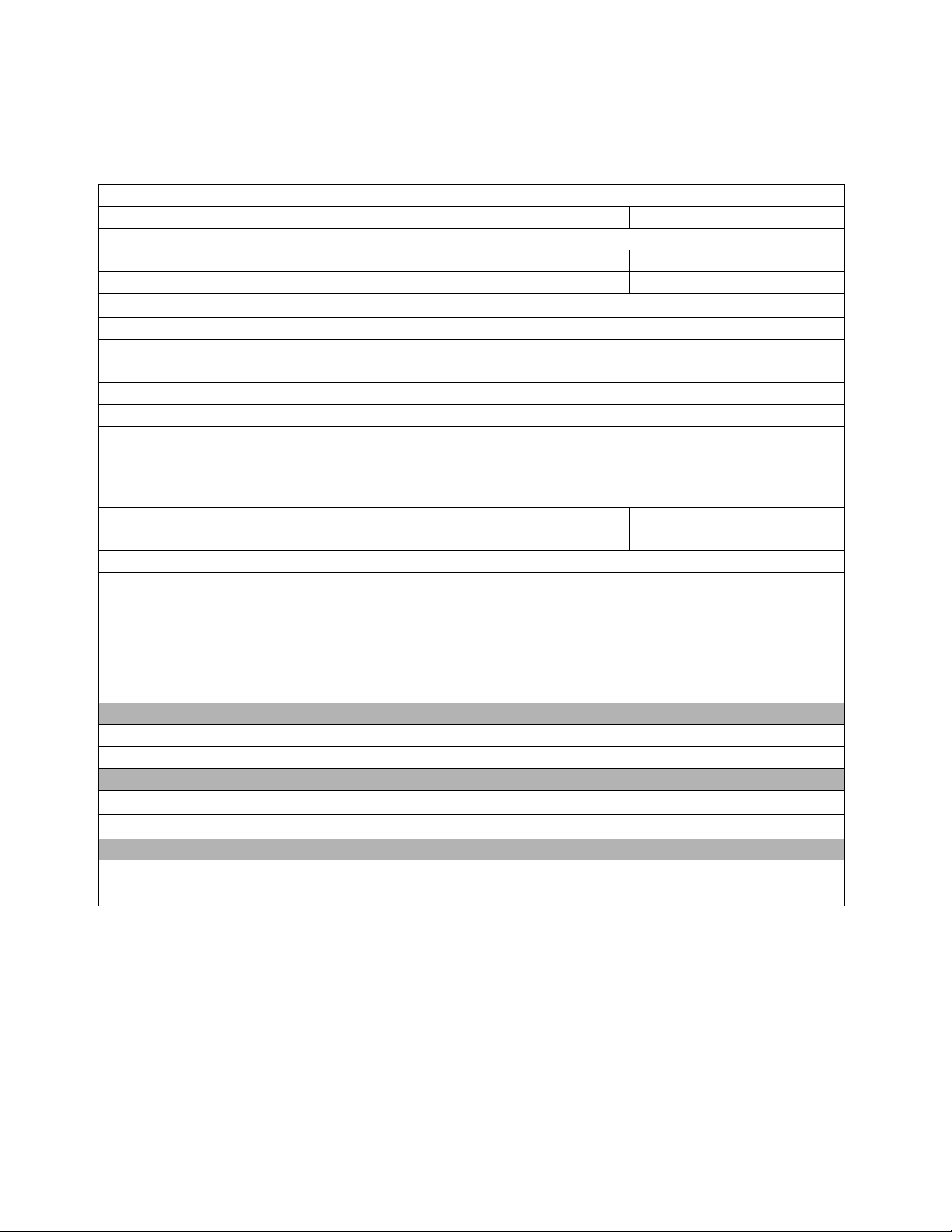

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 74

2 3A0868G

Page 3

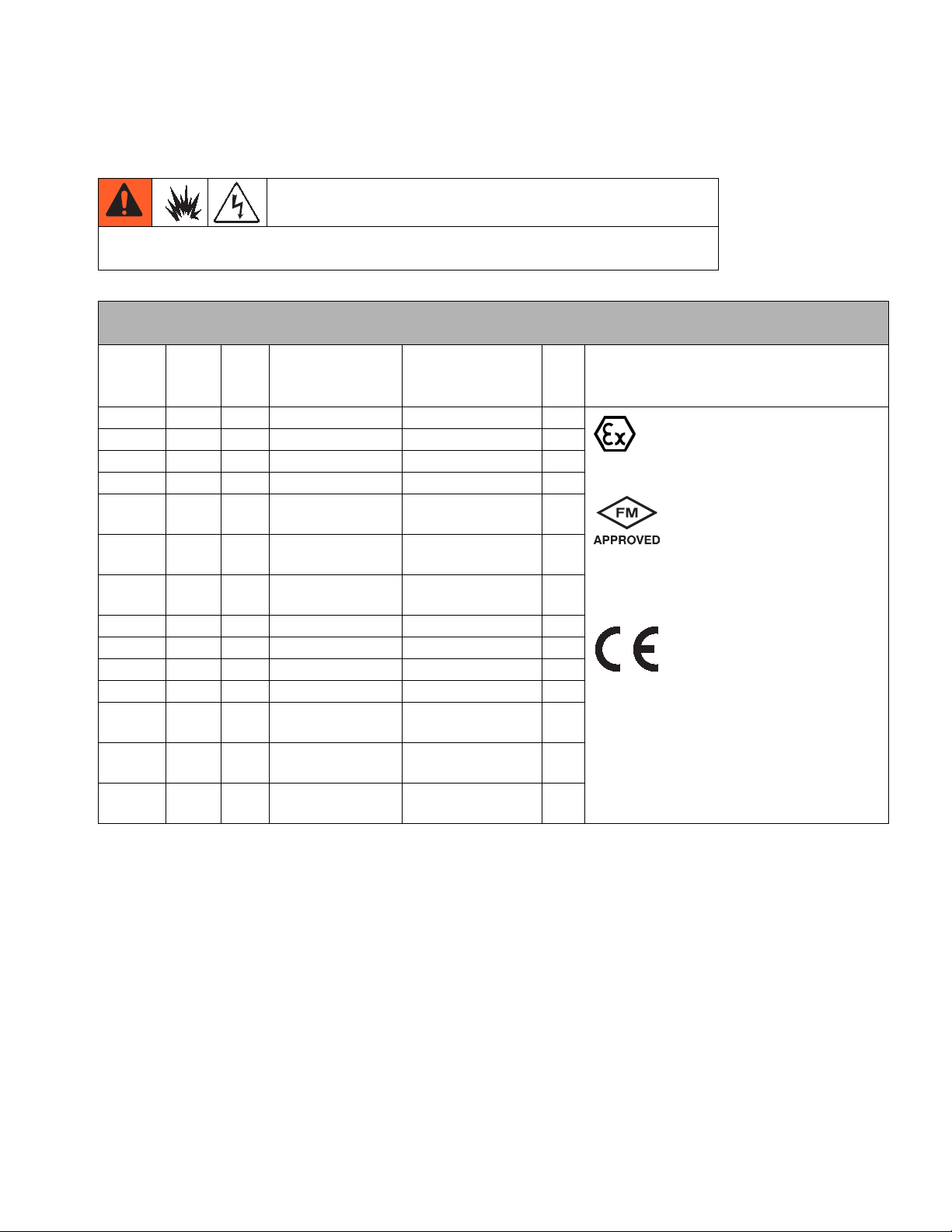

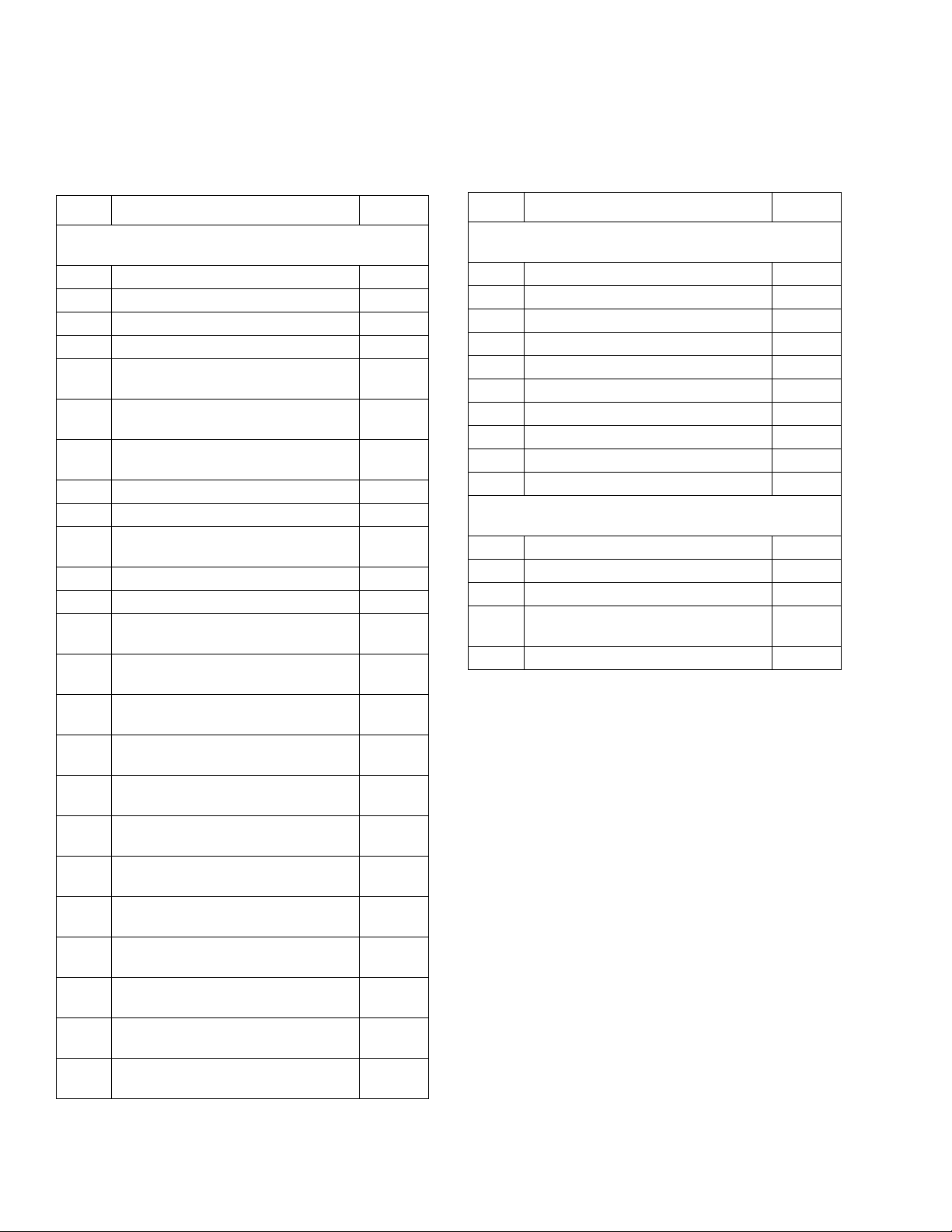

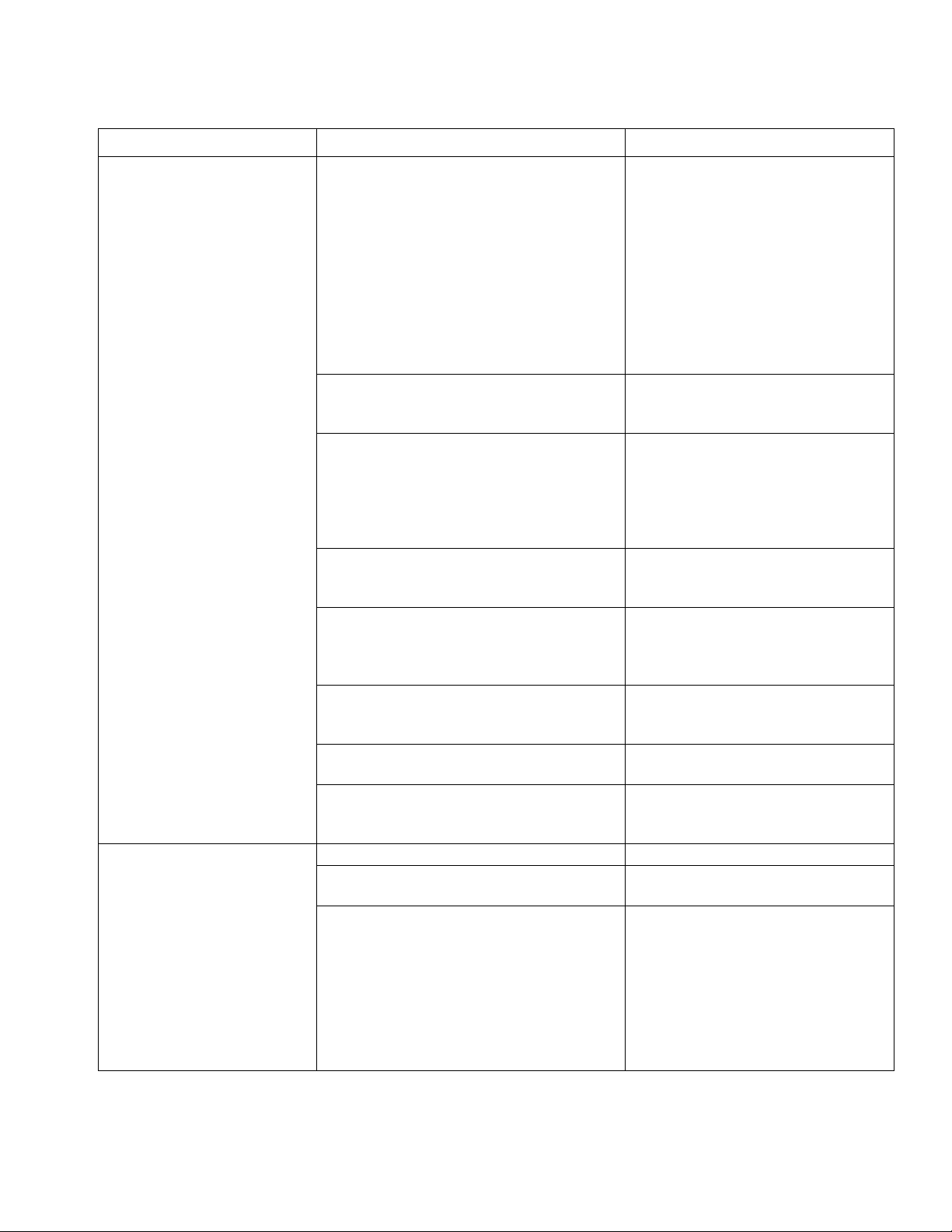

Models

ProMix 2KE systems are not approved for use in hazardous locations unless the base

model, all accessories, all kits, and all wiring meet local, state, and national codes.

Approved for Hazardous Location

Class 1, Div 1, Group D (North America); Class 1, Zones 1 and 2 (Europe)

Maximum

Working Pressure

Part No. Series Ratio Pumps

psi (MPa, bar)

24F102 A 3:1 Merkur, A and B 300 (2.1, 21)

24F103 A 23:1 Merkur, A and B 2300 (15.8, 158)

24F104 A 30:1 Merkur, A and B 3000 (20.6, 206)

24F105 A 45:1 Merkur, A and B 4500 (31.0, 310)

24F106 A 3:1

24F107 A 23:1

24F108 A 35:1

Merkur A,

Merkur Bellows B

Merkur A,

Merkur Bellows B

Merkur A,

Merkur Bellows B

300 (2.1, 21)

2300 (15.8, 158)

3500 (24.1, 241)

24F109 A 3:1 Merkur, A and B 300 (2.1, 21)

24F110 A 23:1 Merkur, A and B 2300 (15.8, 158)

24F111 A 30:1 Merkur, A and B 3000 (20.6, 206)

24F112 A 45:1 Merkur, A and B 4500 (31.0, 310)

24F113 A 3:1

24F114 A 23:1

24F115 A 35:1

Merkur A,

Merkur Bellows B

Merkur A,

Merkur Bellows B

Merkur A,

Merkur Bellows B

300 (2.1, 21)

2300 (15.8, 158)

3500 (24.1, 241)

USB

Port

II 2 G

Ex ia px IIA T3 Ta = 0°C to 54°C

FM10 ATEX 0025 X

#53

Intrinsically safe and purged equipment for

Class I, Division 1, Group D, T3

Ta = 0°C to 54°C

✔

✔

✔

✔

See Special Conditions

for Safe Use in

✔

Warnings, page 5.

0359

✔

✔

Models

Approvals*

* ProMix 2KE hazardous location equipment manufactured in the United States, with serial number beginning with

A or 01, has ATEX, FM, and CE approvals, as noted. Equipment manufactured in Belgium, with serial number

beginning with M or 38, has ATEX and CE approvals, as noted.

See page 4 for models approved for non-hazardous locations.

3A0868G 3

Page 4

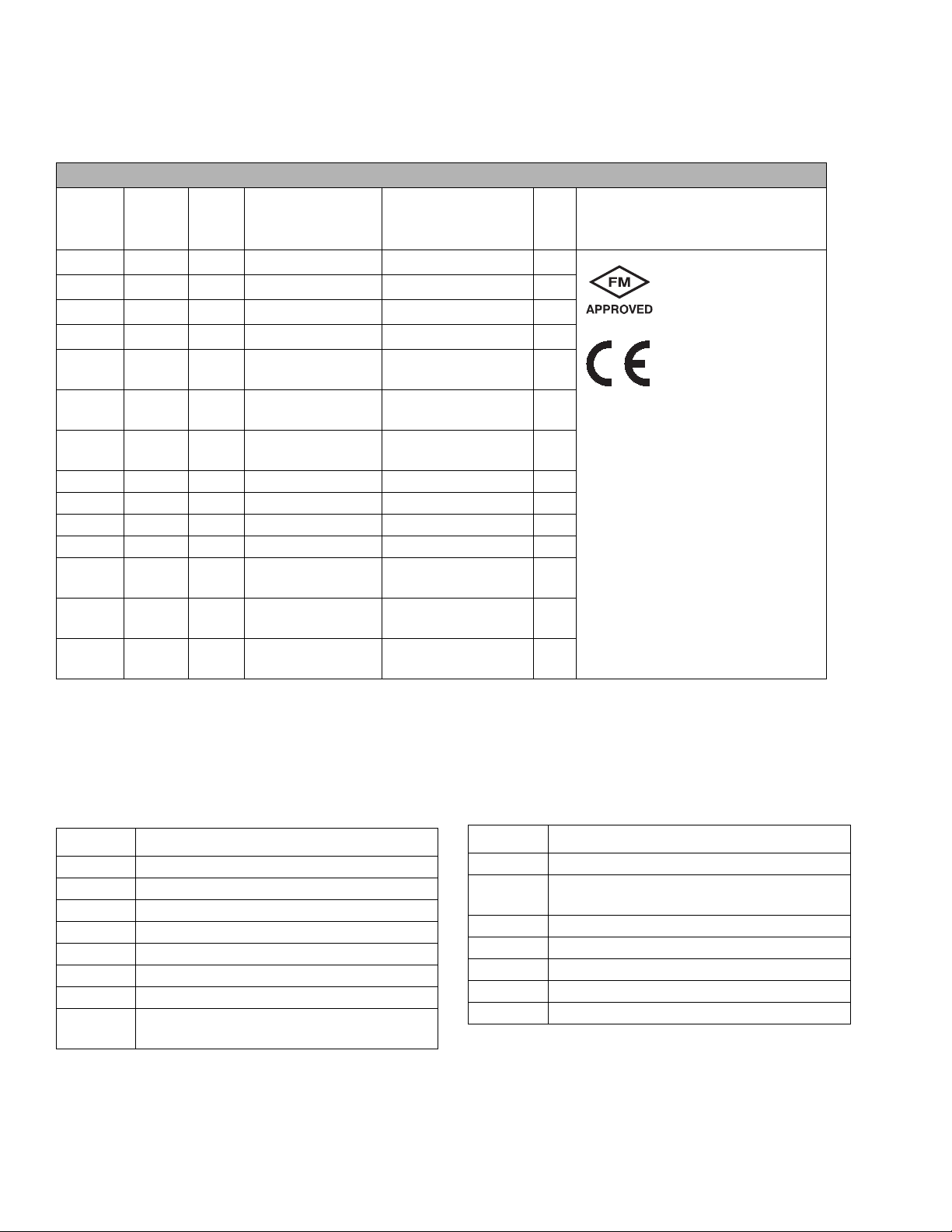

Models

Models (continued)

Approved for Non-Hazardous Location

Maximum Working

Part

No.

24F088 A 3:1 Merkur, A and B 300 (2.1, 21)

24F089 A 23:1 Merkur, A and B 2300 (15.8, 158)

24F090 A 30:1 Merkur, A and B 3000 (20.6, 206)

24F091 A 45:1 Merkur, A and B 4500 (31.0, 310)

24F092 A 3:1

24F093 A 23:1

24F094 A 35:1

24F095 A 3:1 Merkur, A and B 300 (2.1, 21)

24F096 A 23:1 Merkur, A and B 2300 (15.8, 158)

24F097 A 30:1 Merkur, A and B 3000 (20.6, 206)

24F098 A 45:1 Merkur, A and B 4500 (31.0, 310)

24F099 A 3:1

24F100 A 23:1

24F101 A 35:1

Series Ratio Pumps

Merkur A,

Merkur Bellows B

Merkur A,

Merkur Bellows B

Merkur A,

Merkur Bellows B

Merkur A,

Merkur Bellows B

Merkur A,

Merkur Bellows B

Merkur A,

Merkur Bellows B

Pressure

psi (MPa, bar)

300 (2.1, 21)

2300 (15.8, 158)

3500 (24.1, 241)

300 (2.1, 21)

2300 (15.8, 158)

3500 (24.1, 241)

USB

Port

✔

✔

✔

✔

✔

✔

✔

Approvals*

#53

* ProMix 2KE non-hazardous location equipment manufactured in the United States, with serial number beginning

with A or 01, has FM and CE approvals. Equipment manufactured in Belgium, with serial number beginning with

M or 38, has CE approval.

Related Manuals

Manual Description

3A0870 ProMix 2KE, Repair/Parts

312781 Fluid Mix Manifold, Instructions/Parts

312782 Dosing Valve, Instructions/Parts

312784 Gun Flush Box Kit 15V826

312792 Merkur Displacement Pump

312793 Merkur Bellows Displacement Pump

312796 NXT Air Motor

406714 Rebuild Kit for High Pressure

Dispense Valve

Manual Description

406823 Dispense Valve Seat Kit

3A1244 Graco Control Architecture

Module Programming

3A1323 16G353 Alternator Conversion Kit

3A1324 16G351 Electric Power Conversion Kit

3A1325 ProMix 2KE Stand Kits

3A1333 24H253 USB Module Kit

313542 Beacon Tower

4 3A0868G

Page 5

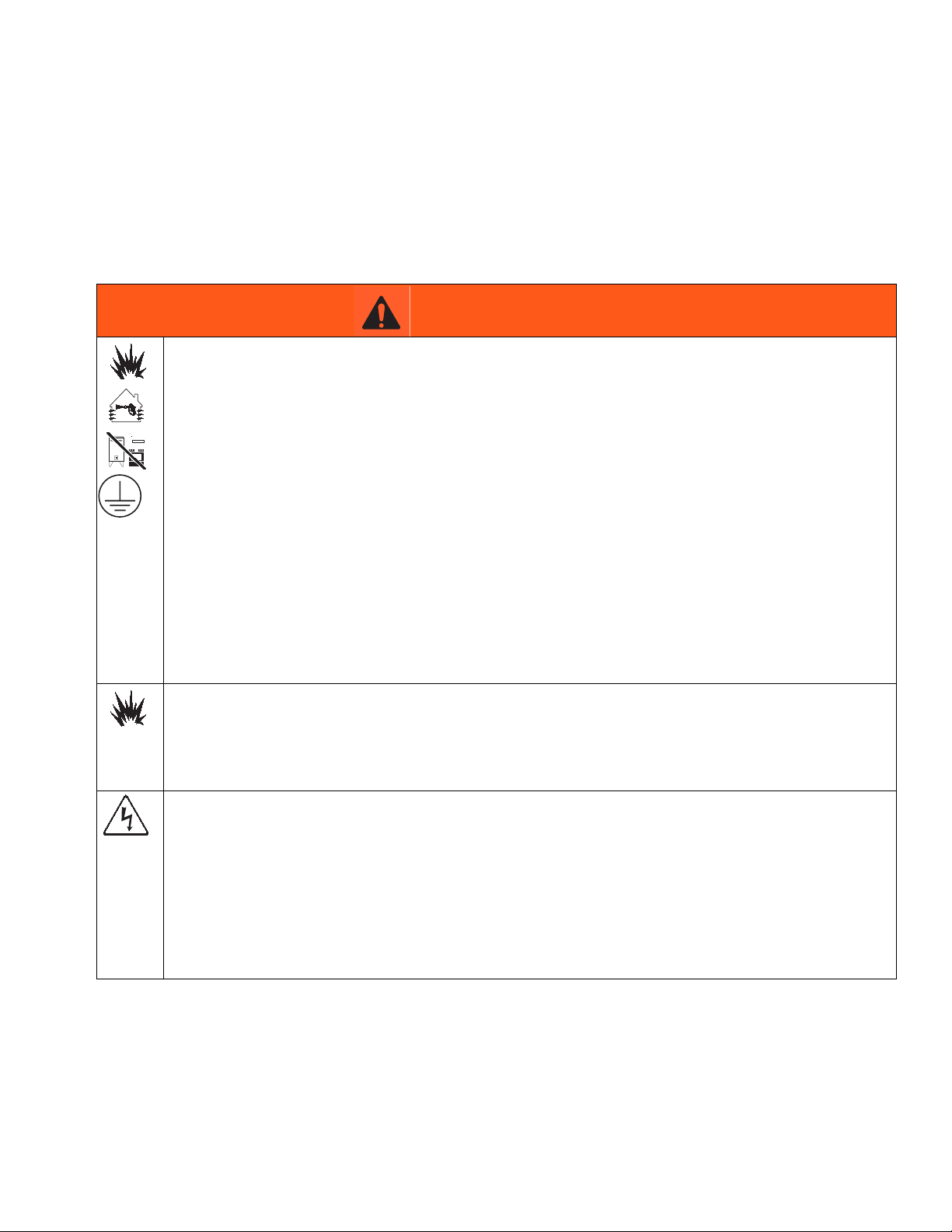

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual, refer back to these Warnings. Product-specific hazard symbols and

warnings not covered in this section may appear throughout the body of this manual where applicable.

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes are

present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

SPECIAL CONDITIONS FOR SAFE USE

• To prevent the risk of electrostatic sparking, the equipment’s non-metallic parts should be cleaned only

with a damp cloth.

• The aluminum adapter plate may spark upon impact or contact with moving parts, which may cause

fire or explosion. Take precautions to avoid such impact or contact.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric

shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

3A0868G 5

Page 6

Warnings

WARNING

INTRINSIC SAFETY

Intrinsically safe equipment that is installed improperly or connected to non-intrinsically safe equipment

will create a hazardous condition and can cause fire, explosion, or electric shock. Follow local regulations

and the following safety requirements.

• Only models with model numbers 24F102-24F115, utilizing the air-driven alternator, are approved for

installation in a Hazardous (explosive atmosphere) Location. See Models, page 3.

• Be sure your installation complies with national, state, and local codes for the installation of electrical

apparatus in a Class I, Group D, Division 1 (North America) or Class I, Zones 1 and 2 (Europe)

Hazardous Location, including all of the local safety fire codes, NFPA 33, NEC 500 and 516, and

OSHA 1910.107.

• To help prevent fire and explosion:

• Do not install equipment approved only for a non-hazardous location in a hazardous location. See

model ID label for the intrinsic safety rating of your model.

• Do not substitute system components as this may impair intrinsic safety.

• Equipment that comes in contact with the intrinsically safe terminals must be rated for Intrinsic Safety.

This includes DC voltage meters, ohmmeters, cables, and connections. Remove the unit from the

hazardous area when troubleshooting.

• The equipment is intrinsically safe when no external electrical components are connected to it.

• Do not connect, download, or remove USB device unless unit is removed from the hazardous

(explosive atmosphere) location.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

6 3A0868G

Page 7

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about

your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure. Turn off all equipment

and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure and disconnect all power sources.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear chemically impermeable gloves when spraying, dispensing, or cleaning equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area

of the equipment to help protect you from serious injury, including eye injury, hearing loss, inhalation of

toxic fumes, and burns. This equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

3A0868G 7

Page 8

Important Two-Component Material Information

Important Two-Component Material Information

Isocyanate Conditions

Spraying or dispensing materials containing

isocyanates creates potentially harmful mists,

vapors, and atomized particulates.

Read material manufacturer’s warnings and material

MSDS to know specific hazards and precautions

related to isocyanates.

Prevent inhalation of isocyanate mists, vapors, and

atomized particulates by providing sufficient

ventilation in the work area. If sufficient ventilation is

not available, a supplied-air respirator is required for

everyone in the work area.

To prevent contact with isocyanates, appropriate

personal protective equipment, including chemically

impermeable gloves, boots, aprons, and goggles, is

also required for everyone in the work area.

Material Self-ignition

Some materials may become self-igniting if applied

too thickly. Read material manufacturer’s warnings

and material MSDS.

Moisture Sensitivity of Isocyanates

Isocyanates (ISO) are catalysts used in two component

coatings. ISO will react with moisture (such as humidity)

to form small, hard, abrasive crystals, which become

suspended in the fluid. Eventually a film will form on the

surface and the ISO will begin to gel, increasing in viscosity. If used, this partially cured ISO will reduce performance and the life of all wetted parts.

NOTE: The amount of film formation and rate of crystallization varies depending on the blend of ISO, the

humidity, and the temperature.

To prevent exposing ISO to moisture:

• Always use a sealed container with a desiccant

dryer in the vent, or a nitrogen atmosphere. Never

store ISO in an open container.

• Use moisture-proof hoses specifically designed for

ISO, such as those supplied with your system.

• Never use reclaimed solvents, which may contain

moisture. Always keep solvent containers closed

when not in use.

• Never use solvent on one side if it has been contaminated from the other side.

• Always lubricate threaded parts with ISO pump oil

or grease when reassembling.

Changing Materials

Keep Components A and B Separate

Cross-contamination can result in cured material in

fluid lines which could cause serious injury or

damage equipment. To prevent cross-contamination

of the equipment’s wetted parts, never interchange

component A (resin) and component B (isocyanate)

parts.

8 3A0868G

• When changing materials, flush the equipment multiple times to ensure it is thoroughly clean.

• Always clean the fluid inlet strainers after flushing.

• Check with your material manufacturer for chemical

compatibility.

Page 9

Glossary of Terms

Glossary of Terms

Dose Size - the amount of resin (A) and catalyst (B) that

is dispensed into an integrator.

Dose Time Alarm - the amount of time that is allowed

for a dose to occur before an alarm occurs.

Dynamic Dosing - Component A dispenses constantly.

Component B dispenses intermittently in the necessary

volume to attain the mix ratio.

Grand Total - a non-resettable value that shows the

total amount of material dispensed through the system.

Intrinsically Safe (IS) - refers to the ability to locate certain components in a hazardous location.

Idle - if the gun is not triggered for 2 minutes the system

enters Idle mode. Trigger the gun to resume operation.

Batch Total - a resettable value that shows the amount

of material dispensed through the system for one batch.

A batch is complete when the user resets the batch

counter to zero.

Mix - when cross-linking of the resin (A) and catalyst (B)

occurs.

Potlife Time - the amount of time before a material

becomes unsprayable.

Potlife Volume - the amount of material that is required

to move through the mix manifold, hose, and applicator

before the potlife timer is reset.

Pump Calibration Factor - the amount of material dispensed per inch of pump travel.

Purge - when all mixed material is flushed from the system.

Purge Time - the amount of time required to flush all

mixed material from the system.

Ratio Tolerance - the settable percent of acceptable

variance that the system will allow before a ratio alarm

occurs.

Standby - refers to the status of the system.

Overdose Alarm - when either the resin (A) or catalyst

(B) component dispenses too much material and the

system cannot compensate for the additional material.

3A0868G 9

Page 10

Overview

Overview

Usage

The ProMix 2KE is an electronic two-component paint

proportioner. It can blend most two-component paints. It

is not for use with quick-setting paints (those with a pot

life of less than 5 minutes).

• Has dynamic dosing capabilities. It dispenses material A, monitors fluid flow, and dispenses material B

in doses to cause the mixture to stay on ratio.

• Can proportion at ratios from 0.1:1 to 30.0:1.

• Will display the last 50 errors with date, time, and

event. The optional USB upgrade kit will log 500

errors and up to 2000 jobs.

• For systems with one gun, an optional Gun Flush

Box provides an automated flushing system for a

manual spray gun.

Component Identification and Definition

Component Description

Control Box • Advanced Fluid Control Module

• Power supply or alternator

• Solenoid valves

• Air flow switch(es)

• Optional USB Module

• Audible alarm

• Optional pressure switch for gun flush box

Fluid Module • Mix manifold, which includes the fluid integrator and static mixer.

• Color/catalyst valve stacks, includes pneumatically operated dose valves for material A

and B, as well as solvent valves.

• Pumps

Display Module Used to set up, display, operate, and monitor the system. Used for daily painting functions

including choosing recipes, reading/clearing errors, and placing the system in Spray,

Standby, or Purge mode.

Installation

General Information

• Reference numbers and letters in parentheses in

the text refer to numbers and letters in the illustrations.

• Be sure all accessories are adequately sized and

pressure-rated to meet system requirements.

• To protect the Display Module screens from paints

and solvents, clear-plastic protective shields are

available in packs of 10 (Part No. 24G821). Clean

the screens with a dry cloth if necessary.

10 3A0868G

Page 11

Intrinsically Safe Installation Requirements

1. The installation must meet the requirements of the

National Electric Code, NFPA 70, Article 504 Resp.,

Article 505, and ANSI/ISA 12.06.01.

Do not substitute or modify system components as

this may impair intrinsic safety. For installation,

maintenance, or operation instructions, read

instruction manuals. Do not install equipment

approved only for non-hazardous location in a

hazardous location. See the identification label for

the intrinsic safety rating for your model.

Hazardous (Classified) Locations

Class 1, Div 1, Group D, T3 (US and Canada)

Class 1, Zone 1, Group IIA, T3 (ATEX only)

2. Multiple earthing of components is allowed only if

high integrity equipotential system realized between

the points of bonding.

3. For ATEX, install per EN 60079-14 and applicable

local and national codes.

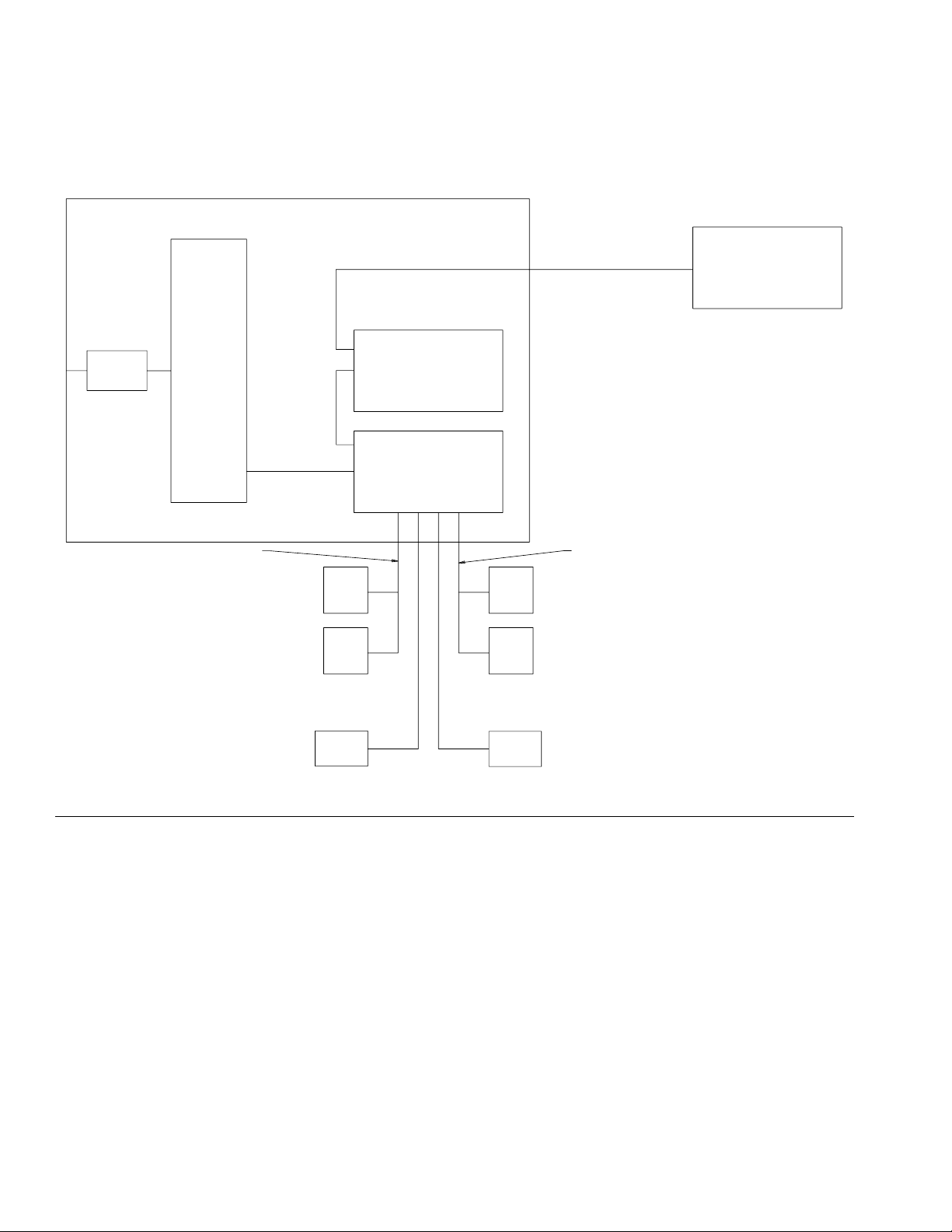

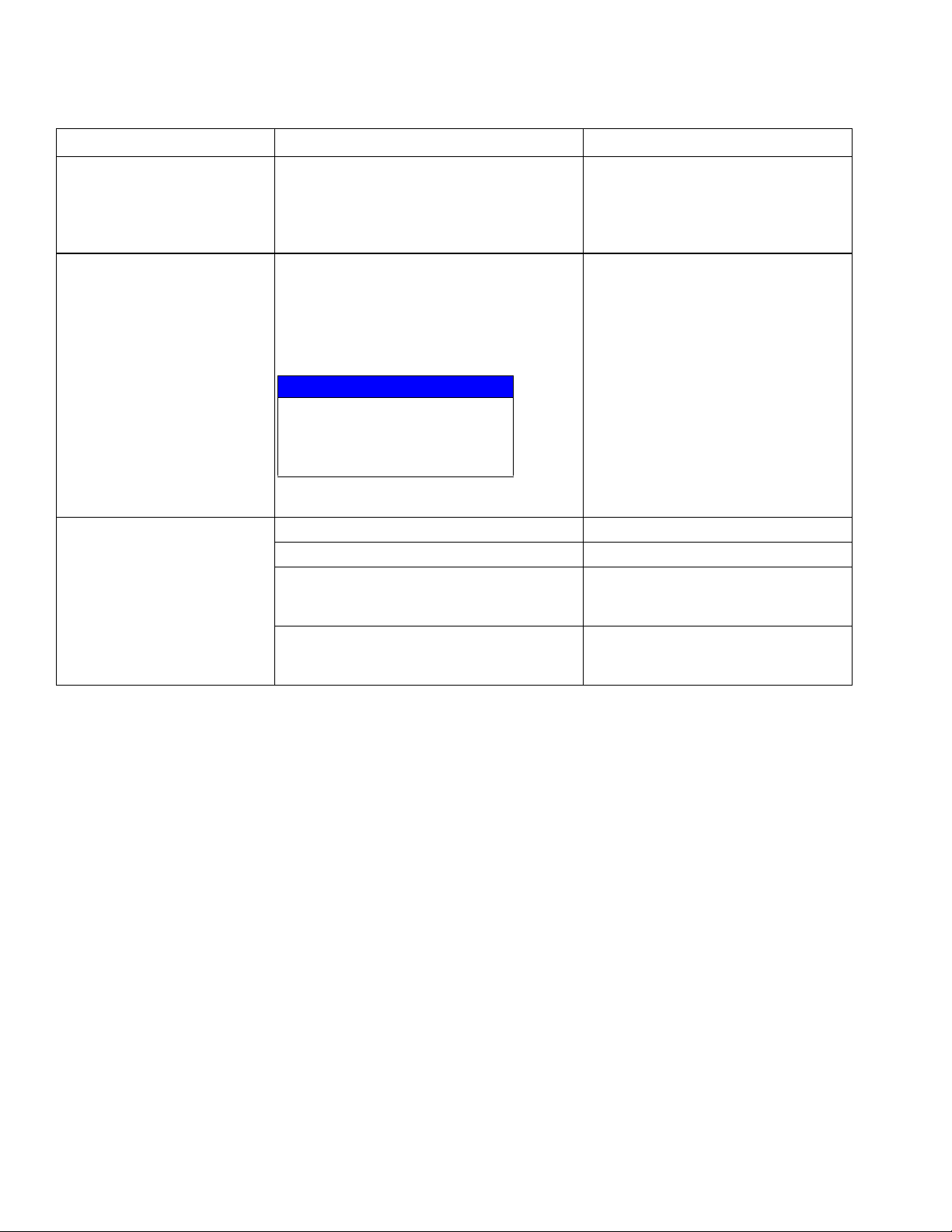

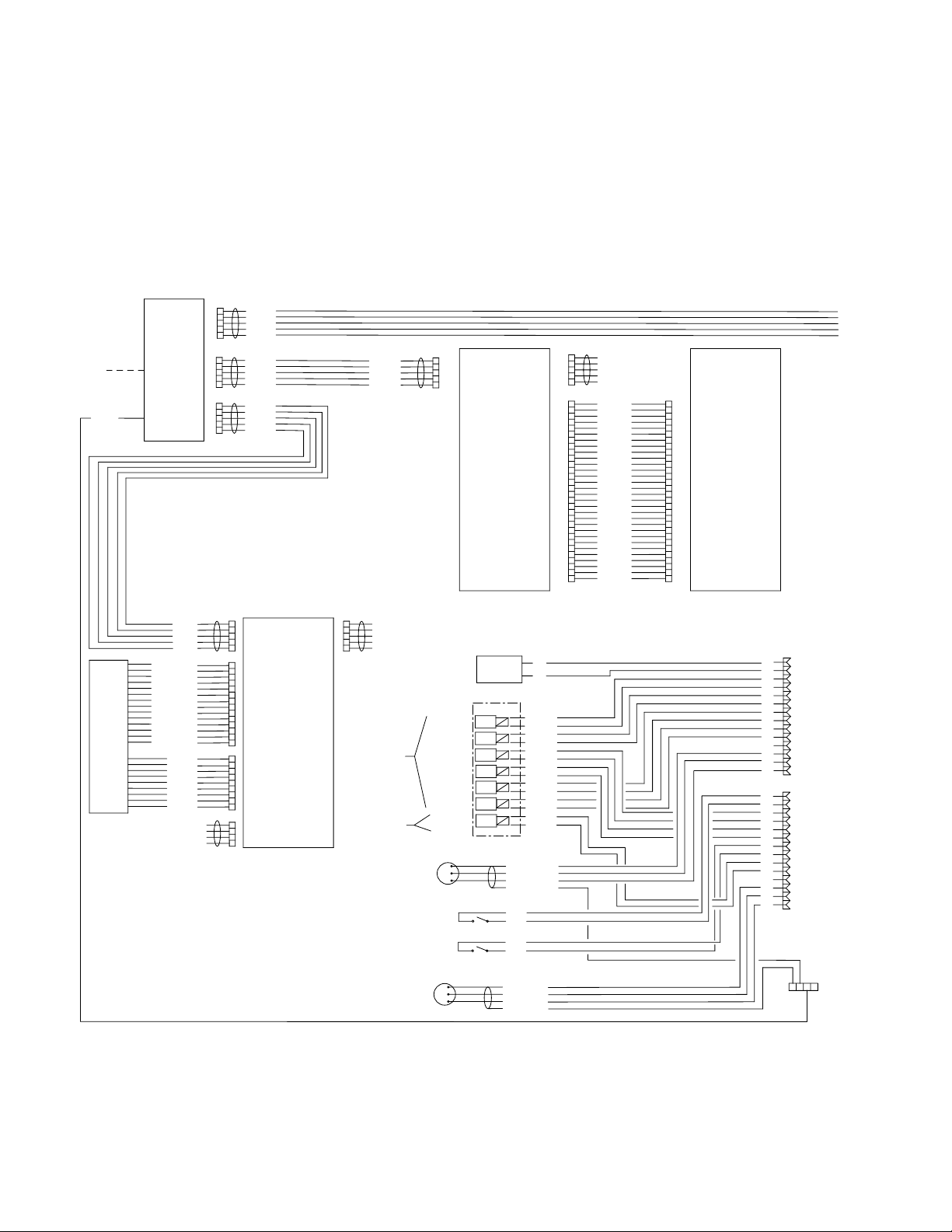

Installation

18 PSI

1.5 FCM

(MIN)

ALTERNATOR

MODULE

10' CAN CABLE

50' OPTION

2' CAN CABLE

20" CAN CABLE

LINEAR SENSOR/

REED SWITCH CABLE

"A" REED

SWITCH

"A" LINEAR

SENSOR

USB MODULE

FLUID

CONTROL

MODULE

"B" REED

SWITCH

"B" LINEAR

SENSOR

LINEAR SENSOR/

REED SWITCH CABLE

USER INTERFACE

MODULE

"A" PRESSURE

TRANSDUCER

"B" PRESSURE

TRANSDUCER

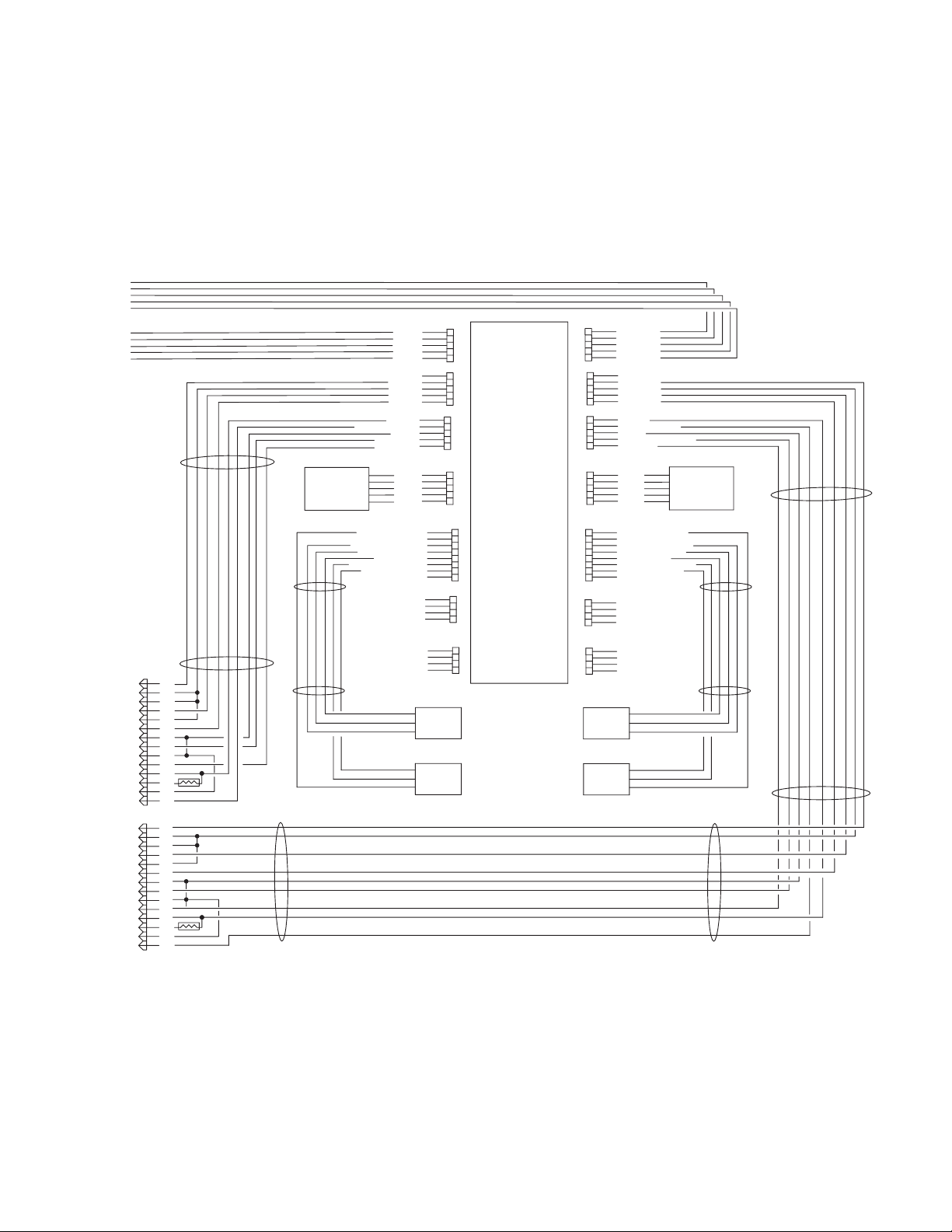

FIG. 1. Hazardous Location Installation

3A0868G 11

Page 12

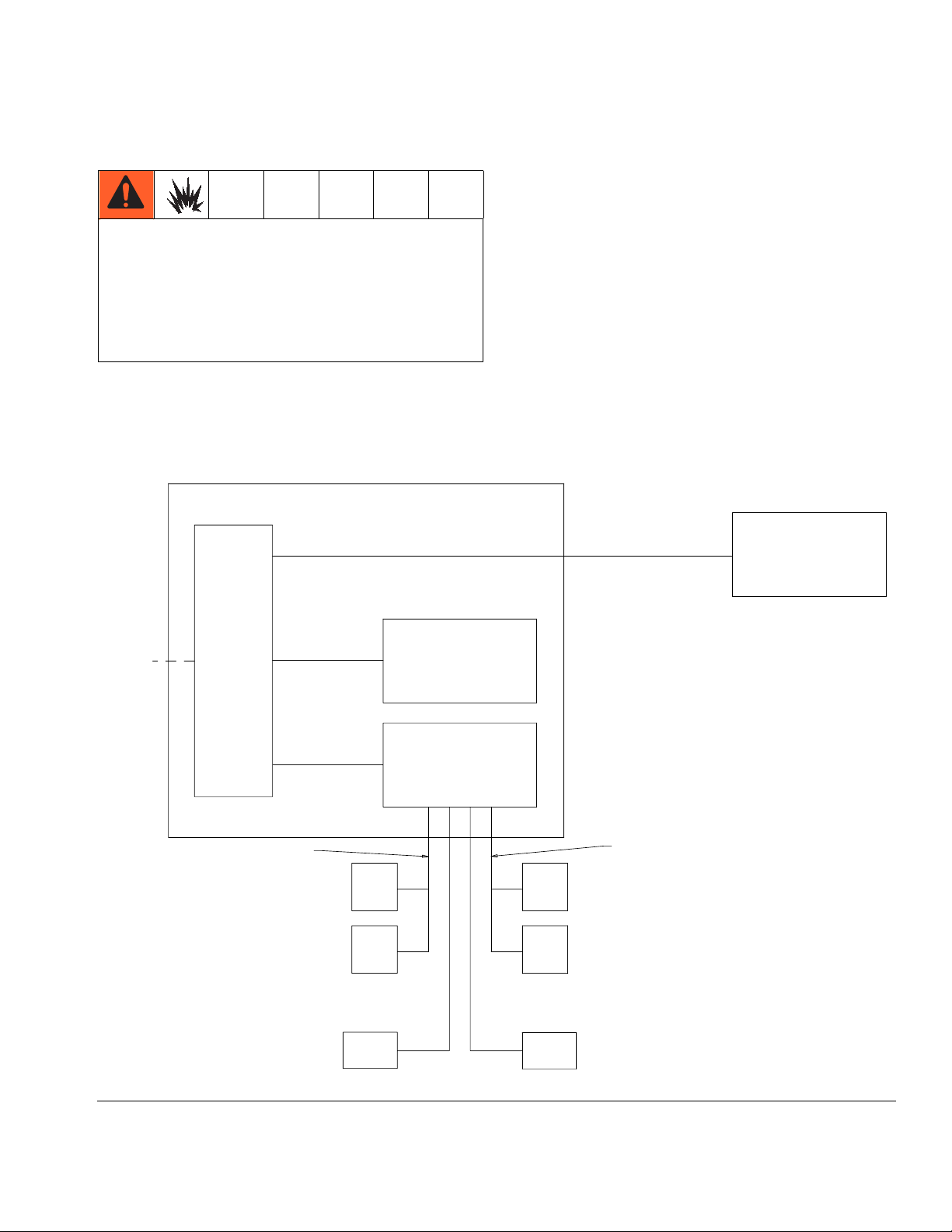

Installation

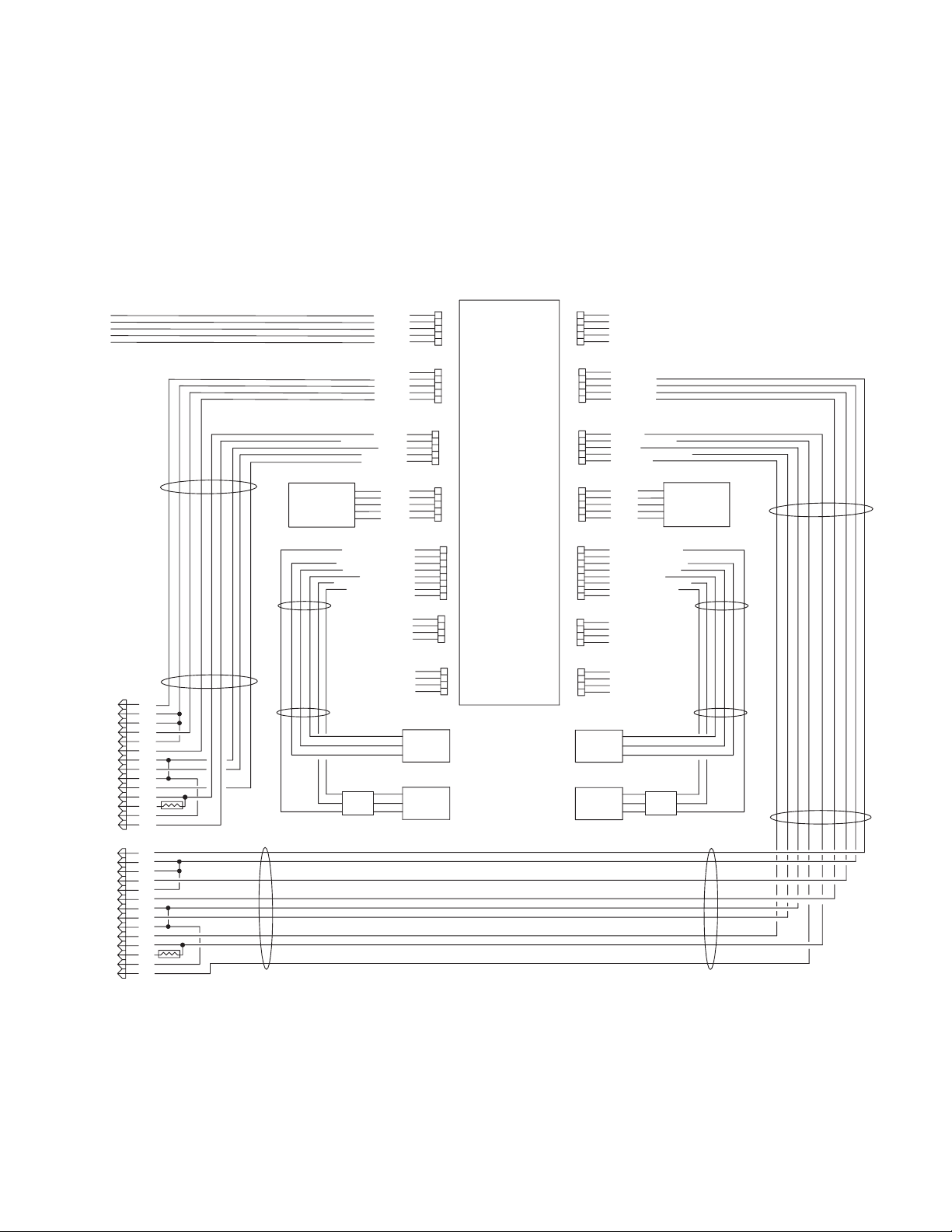

Non-Hazardous Locations

LINE POWER

FILTER

POWER

SUPPLY

LINEAR SENSOR/

REED SWITCH CABLE

CAN CABLE

20" CAN CABLE

"A" REED

SWITCH

"A" LINEAR

SENSOR

USB MODULE

FLUID

CONTROL

MODULE

"B" REED

SWITCH

"B" LINEAR

SENSOR

10' CAN CABLE

50' OPTION

LINEAR SENSOR/

REED SWITCH CABLE

USER INTERFACE

MODULE

"A" PRESSURE

TRANSDUCER

"B" PRESSURE

TRANSDUCER

FIG. 2. Non-Hazardous Location Installation

12 3A0868G

Page 13

Installation

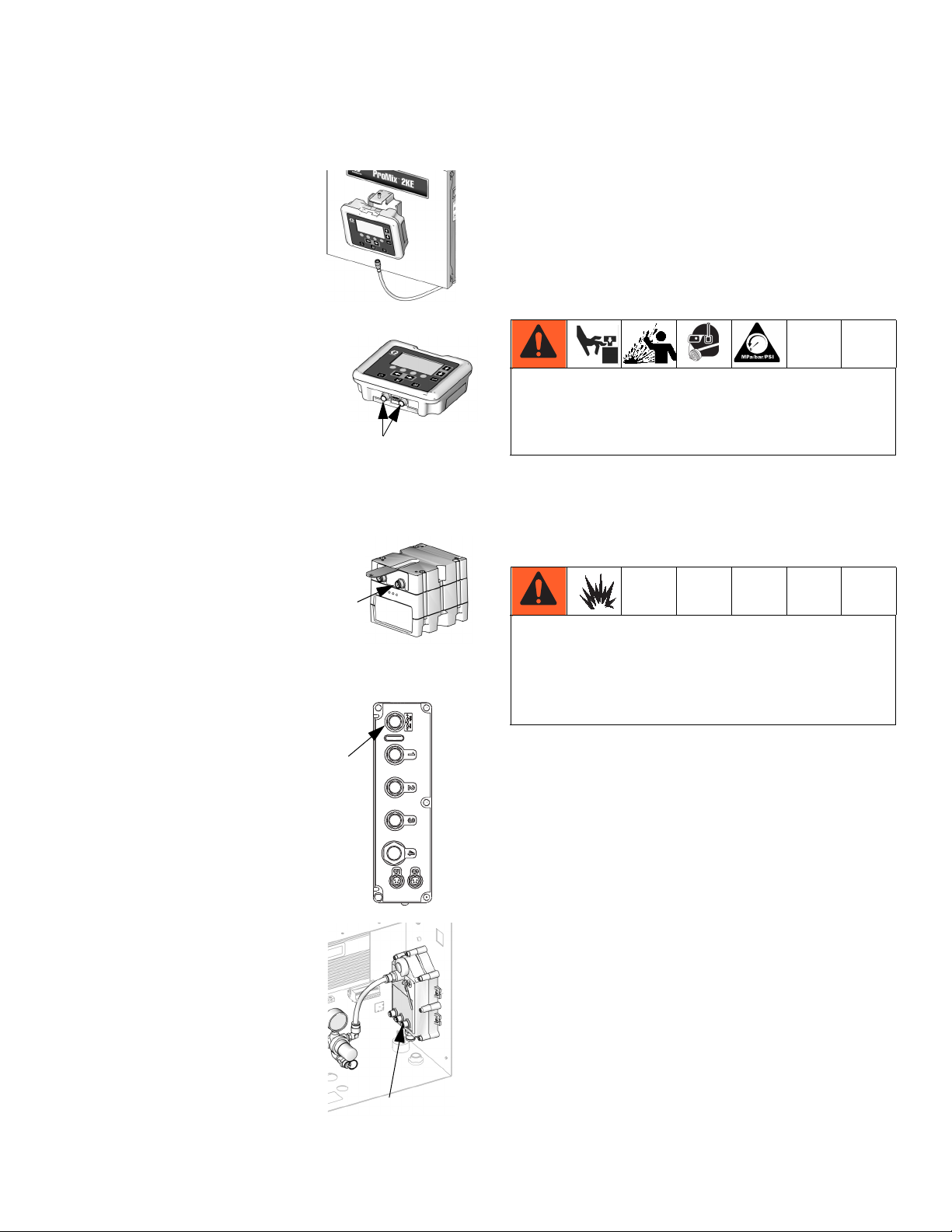

Display Module

1. Use the screws provided

to mount the bracket for

the Display Module on the

front of the Control Box or

on the wall, as you prefer.

2. Snap the Display Module

into the bracket.

3. Connect one end of the CAN

cable (provided) to J6 on the

Display Module (either port).

J6

4. The other end of the cable

comes from the factory connected as shown,

depending on the configuration of your system:

• Wall Power Systems

with USB Module:

Connect the CAN cable

to P3 on the USB Module.

• Wall Power Systems

without USB Module:

Connect CAN cable to

J8 on the Advanced

Fluid Control Module.

P3

J8

ti16672a

ti16604a

ti16580a

Air Supply

Requirements

• Compressed air supply pressure: 75-100 psi

(517-700 kPa, 5.2-7 bar).

• Air hoses: use grounded hoses that are correctly

sized for your system.

Trapped air can cause a pump or dispense valve to

cycle unexpectedly, which could result in serious

injury from splashing or moving parts. Use bleed-type

shutoff valves.

• Air regulator and bleed-type shutoff valve:

include in each air line to fluid supply equipment.

Install an additional shutoff valve upstream of all air

line accessories to isolate them for servicing.

If using a Graco electrostatic PRO™ Gun, a shutoff

valve must be installed in the gun air line to shutoff

the atomizing and turbine air to the gun. Contact your

Graco distributor for information on air shutoff valves

for electrostatic applications.

• Air line filter: a 10 micron or better air filter is recommended to filter oil and water out of the air supply

and help avoid paint contamination and clogged

solenoids.

ti16579a

• Alternator Power Sys-

tems (with or without

USB Module): Connect

CAN cable to J3 on the

alternator.

J3

ti16456a

3A0868G 13

Page 14

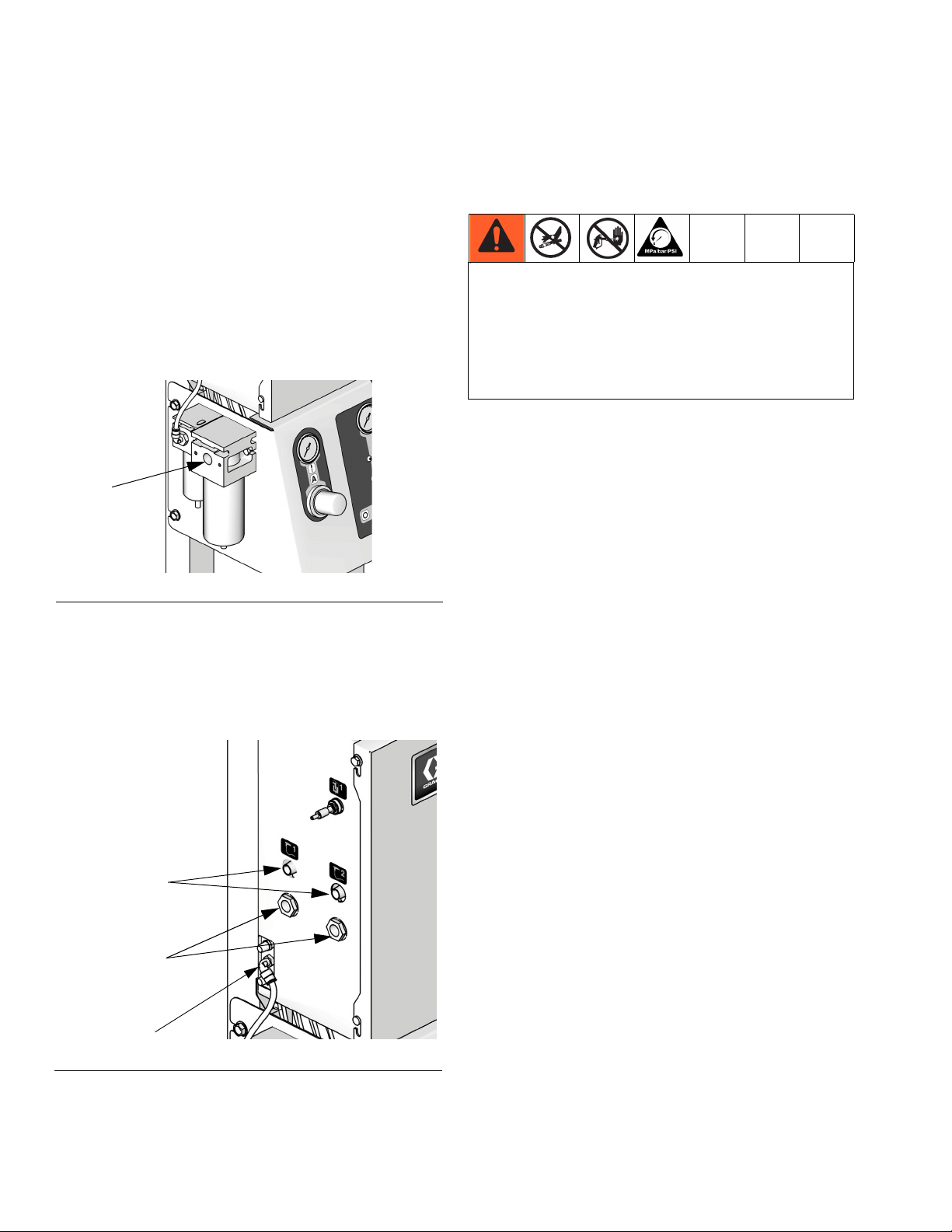

Installation

Air Connections

See the System Pneumatic Schematic on page 66

(hazardous location) or page 67 (non-hazardous location).

1. Tighten all ProMix 2KE system air and fluid line connections as they may have loosened during shipment.

2. Connect the main air supply line to the main air inlet.

This air line supplies the solenoids, valves, and

pumps. See F

Main Air

Inlet

F

IG

. 3. Air Supply Inlet

IG

. 3.

ti15708a

Fluid Supply

Requirements

• Do not exceed the pressure rating of the lowest

rated component. See the identification label.

• To reduce the risk of injury, including fluid

injection, you must install a shutoff valve between

each fluid supply line and the mix manifold. Use

the valves to shut off fluid during maintenance

and service.

ProMix 2KE models are available to operate airless

(high pressure, 50 cc pumps only), air spray, or

air-assisted systems with a capacity of up to 3800

cc/min.

• Fluid supply pressure tanks, feed pumps, or circulating systems can be used.

• Materials can be transferred from their original containers or from a central paint recirculating line.

3. For each gun in the system, connect a separate

clean air supply line to the air inlet of the air flow

switch. This air supplies gun atomizing air. The air

flow switch detects air flow to the gun and signals

the controller when the gun is being triggered.

Atomizing

air outlets

Atomizing

air inlets

Solenoid

air inlet

ti15709a

FIG. 4. Connect atomizing air

NOTE: The fluid supply must be free of pressure spikes,

which are commonly caused by pump stroke changeover. If necessary, install pressure regulators or a surge

tank on the ProMix 2KE fluid inlets to reduce pulsation.

Contact your Graco distributor for additional information.

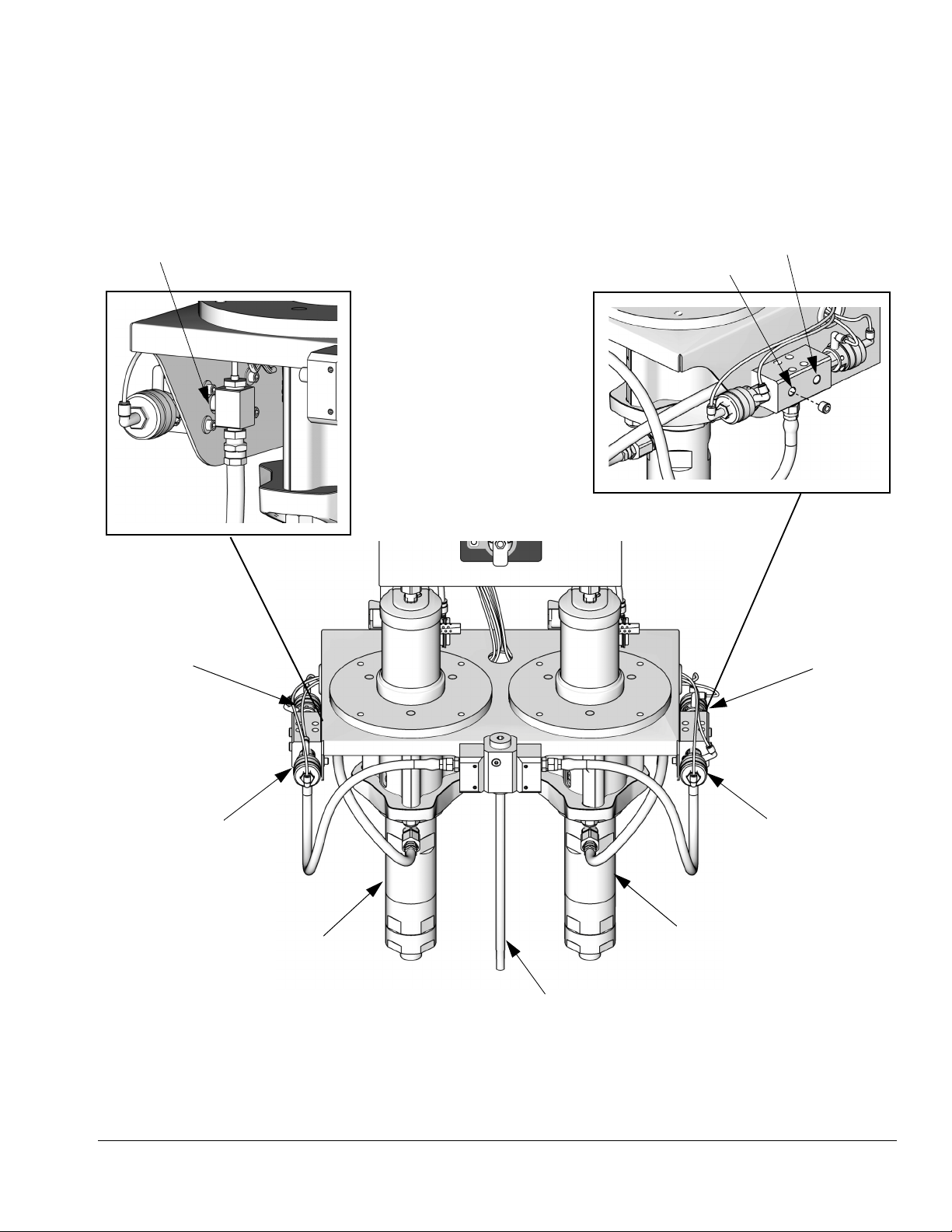

Fluid Connections

1. See FIG. 5, page 15. Connect the solvent supply line

to the 1/4 npt(f) solvent valve inlets (SVA and SVB).

2. Connect the component A supply line(s) to the component A dose valve inlet (DVA).

NOTE: Paint Recirculating System Only

• If you are recirculating paint, use the standard inlet

on Dose Valve A or Dose Valve B. Remove the plug

directly opposite it on the dose valve for the recirculation outlet. See F

3. Connect the component B line to the component B

dose valve inlet (DVB).

4. Connect the gun fluid supply line between the mix

manifold (MM) outlet and the gun fluid inlet.

IG

. 5.

14 3A0868G

Page 15

Installation

Component

Inlet

SVA

Remove plug;

Solvent inlet

recirculation outlet.

ti16755a

ti16754a

SVB

DVA

PA

PB

DVB

ti15697a

MM

Key:

PA Component A Pump

DVA Component A Dose Valve

SVA Solvent Valve A

PB Component B Pump

DVB Component B Dose Valve

SVB Solvent Valve B

MM Mix Manifold

FIG. 5. Fluid Connections

3A0868G 15

Page 16

Installation

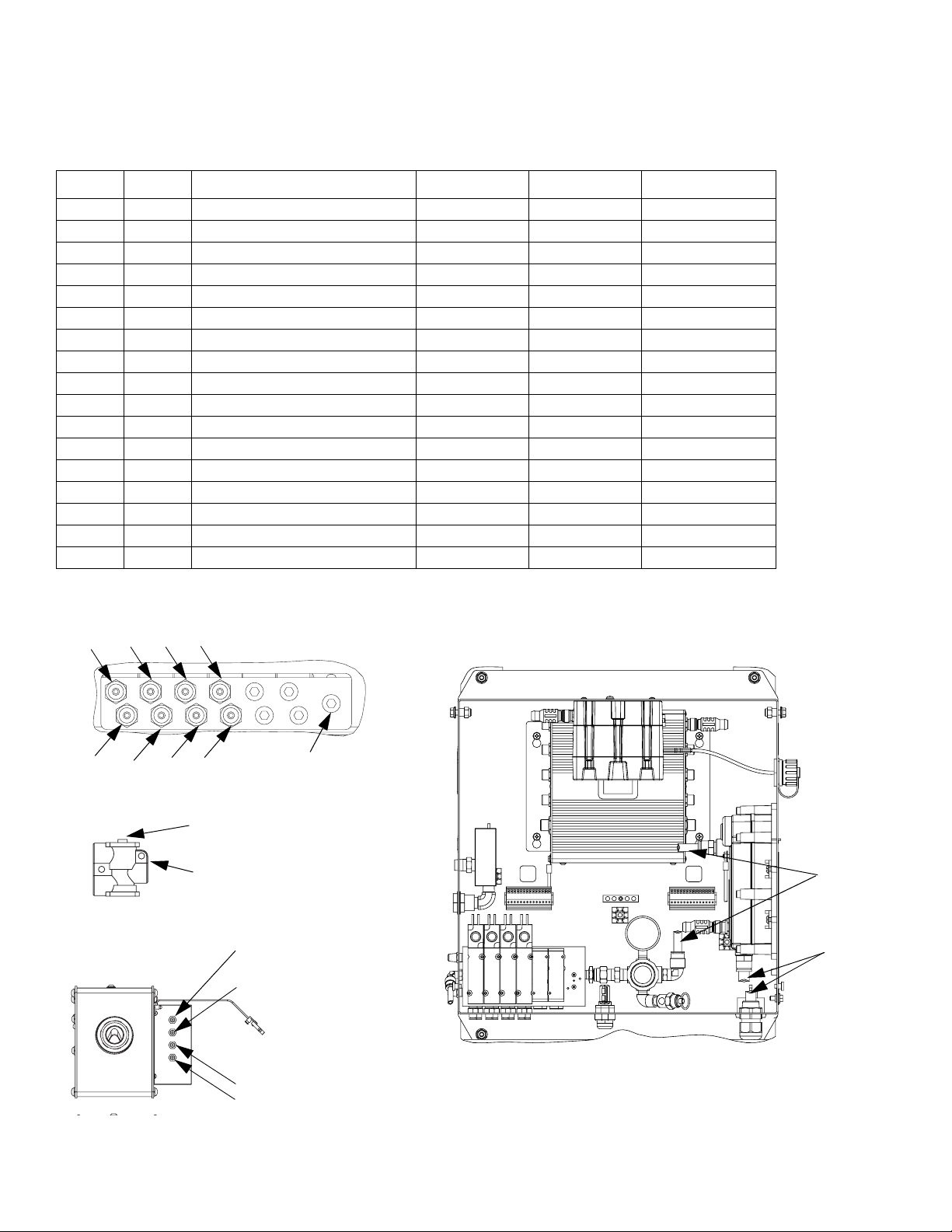

Tubing Chart and Diagrams

Type Color Description Starting Point Ending Point Tube OD in. (mm)

Air Green Solvent Valve A On 1G 1G 0.156 (4.0)

Air Green Dose Valve A On 2G 2G 0.156 (4.0)

Air Green Solvent Valve B On 3G 3G 0.156 (4.0)

Air Green Dose Valve B On 4G 4G 0.156 (4.0)

Air Red Solvent Valve A Off 1R 1R 0.156 (4.0)

Air Red Dose Valve A Off 2R 2R 0.156 (4.0)

Air Red Solvent Valve B Off 3R 3R 0.156 (4.0)

Air Red Dose Valve B Off 4R 4R 0.156 (4.0)

Air Natural Solenoid Air A1 A1 0.25 (6.3)

Air Natural Air Regulator to Pump B A2 A2 0.375 (9.5)

Air Natural Air Regulator to Pump A A3 A3 0.375 (9.5)

Fluid ---- Pump B to Valve Stack B A4 A4 ----Fluid ---- Pump A to Valve Stack A A5 A5 ----Fluid ---- Valve Stack A to Mix Manifold A6 A6 ----Fluid ---- Valve Stack B to Mix Manifold A7 A7 ----Air Natural Air Regulator to Alternator* A8 A8 0.375 (9.5)

Air Black Alternator Air Exhaust* A9 A9 0.5 (12.7)

* Used only on IS models.

1R 2R 3R 4R

1G

2G

ti13861a

3G

4G

GFB1-S

ATOM-1

ti16770a

GFB1-C

GFB1-P

(Pressurized air line)

GFB1-A

*

IS Models

A8*

A9*

ti16771a

GFB1-C

GFB1-S

16 3A0868G

ti13863a

Page 17

GFB1-A

ATOM-1

ATOM-2

Installation

1R

1G

A1

2G

2R

A2

B Side

A3

A3

A Side

ti16772a

4G

4R

3R

3G

A5

A Side B Side

ti16765a

A5

A4

A4

ti16766a

See Manual 312784 for full

setup instructions for a gun

flush box.

A6

A Side

B Side

ti16764a

3A0868G 17

A7

Page 18

Installation

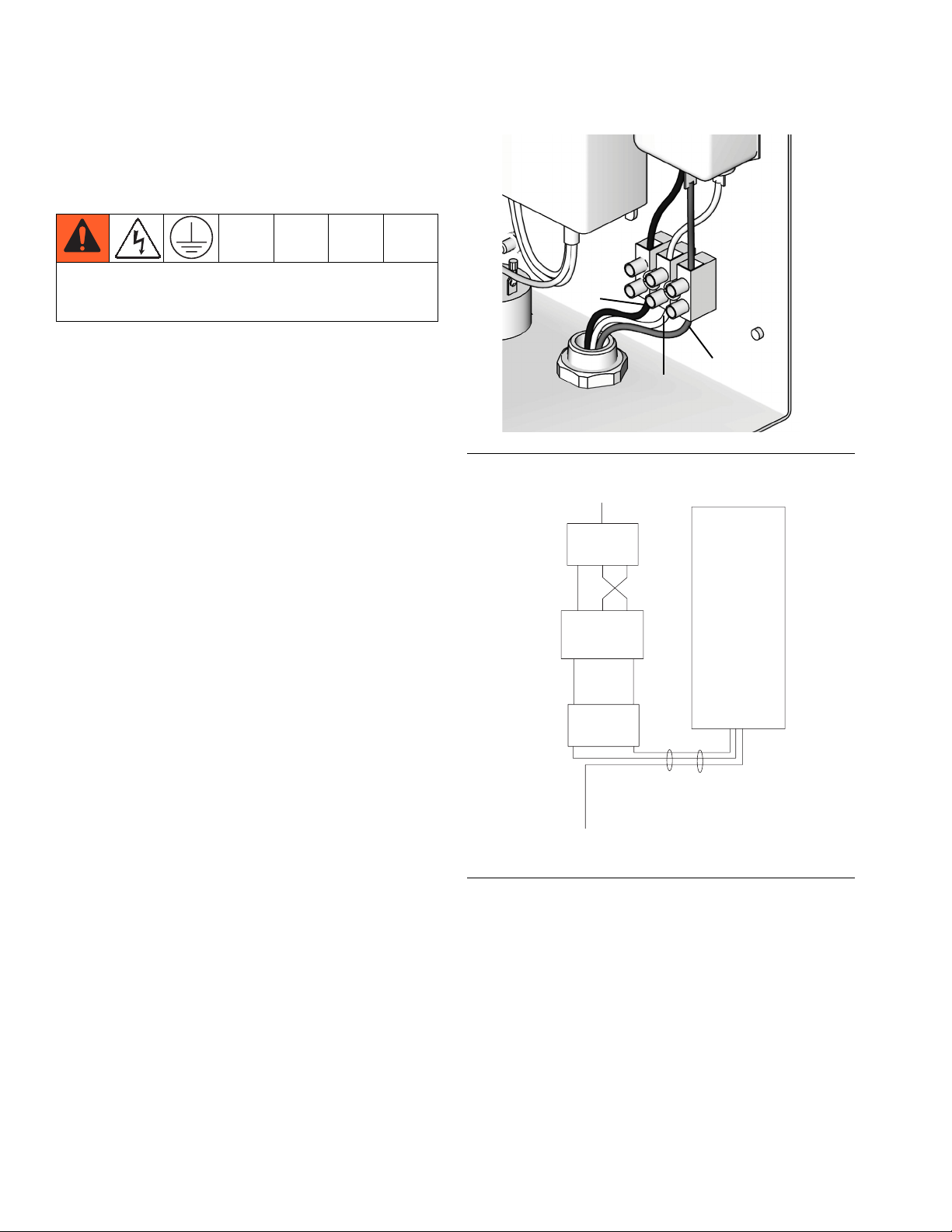

Electrical

Power Connection (non-IS units only)

All electrical wiring must be completed by a qualified

electrician and comply with all local codes and

regulations.

Enclose all cables routed in the spray booth and high

traffic areas in conduit to prevent damage from paint,

solvent, and traffic.

Line

Ground

Neutral

The ProMix 2KE operates with 85-250 VAC, 50/60 Hz

input power, with a maximum of 2 amp current draw.

The power supply circuit must be protected with a 15

amp maximum circuit breaker.

Not included with system:

• Power supply cord compatible to your local power

configuration. Wire gauge size must be 8-14 AWG.

• The input power access port is 22.4 mm (0.88 in.) in

diameter. It accepts a bulkhead strain relief fitting or

conduit.

1. Verify that electrical power at the main panel is shut

off. Open Control Box cover.

2. Connect electrical cord to the terminal block as

shown in F

IG

. 6.

3. Close the Control Box. Restore power.

4. Follow instructions in Grounding, page 19.

FIG. 6. Control Box Electrical Connection

TERMINAL

BLOCK

L N GRND

L GRND N

LINE POWER

FILTER

L N

2A

SWITCH

ROCKER

2

1A

1

POWER

SUPPLY

ti16391a

FIG. 7. Electrical Schematic

18 3A0868G

Page 19

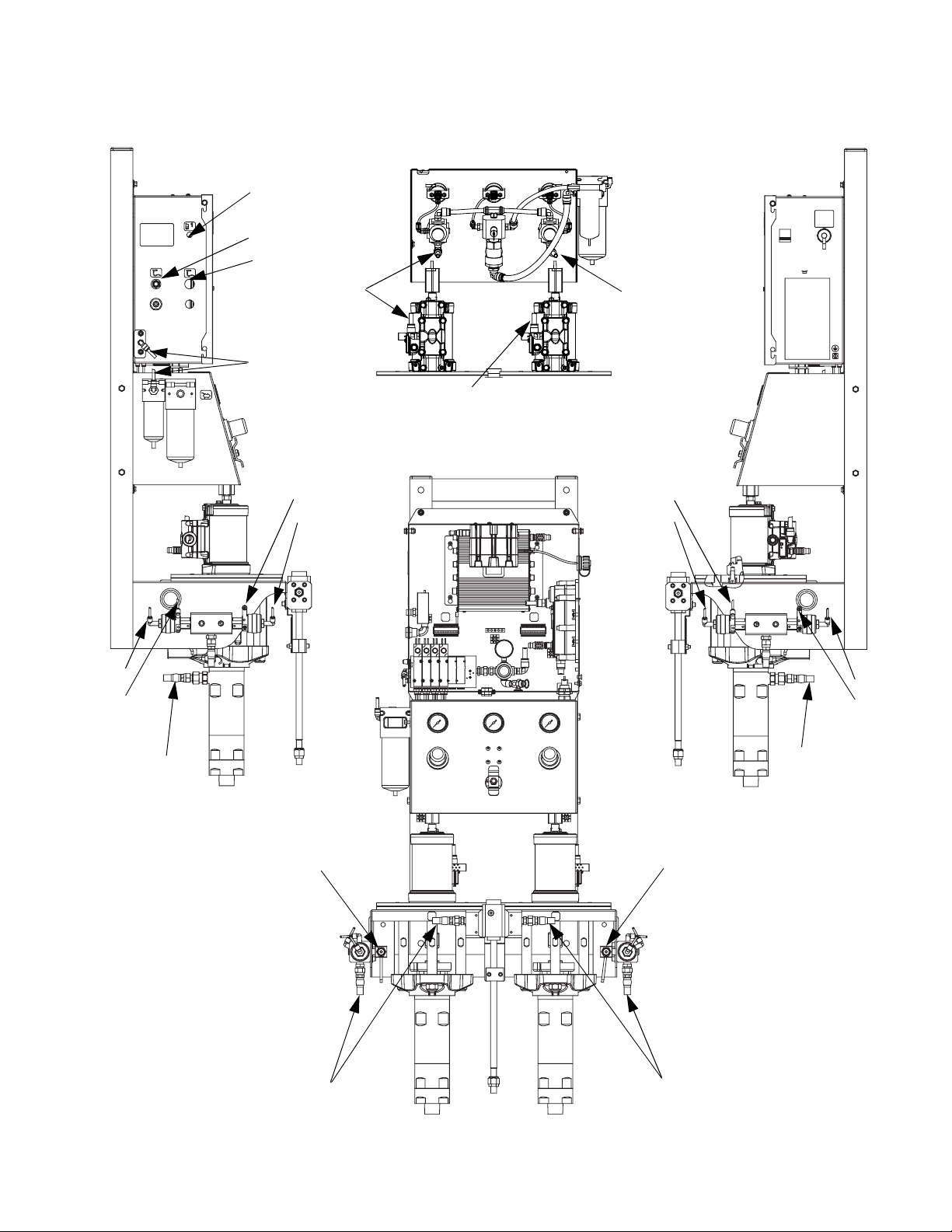

Grounding

Installation

Air and Fluid Hoses

Use grounded hoses only.

The equipment must be grounded. Grounding

reduces the risk of static and electric shock by

providing an escape wire for the electrical current

due to static build up or in the event of a short circuit.

Connect the ProMix 2KE ground wire to the ground

screw. Connect the clamp to a true earth ground. If wall

power is used to power controls, ground electrical connection according to local codes.

AC

Power

Ground

Screw

TI15712a

FIG. 8. Ground Screw and Power Switch

Gun Flush Box

Connect a ground wire from the Gun Flush Box ground

lug to a true earth ground.

Feed Pumps or Pressure Pots

Spray Gun

Follow the grounding instructions in your gun manual.

• Non-Electrostatic: Ground the spray gun through

connection to a Graco-approved grounded fluid supply hose.

• Electrostatic: Ground the spray gun through connection to a Graco-approved grounded air supply

hose. Connect the air hose ground wire to a true

earth ground.

Fluid Supply Container

Follow local code.

Object Being Sprayed

Follow local code.

All Solvent Pails Used When Purging

Follow local code. Use only conductive metal pails/containers placed on a grounded surface. Do not place the

pail/container on a nonconductive surface, such as

paper or cardboard, which interrupts the grounding continuity.

Check Resistance

Connect a ground wire and clamp from a true earth

ground to the pumps or pots. See pump or pressure pot

manual.

3A0868G 19

To ensure proper grounding, resistance between

components and true earth ground must be less than

1 ohm.

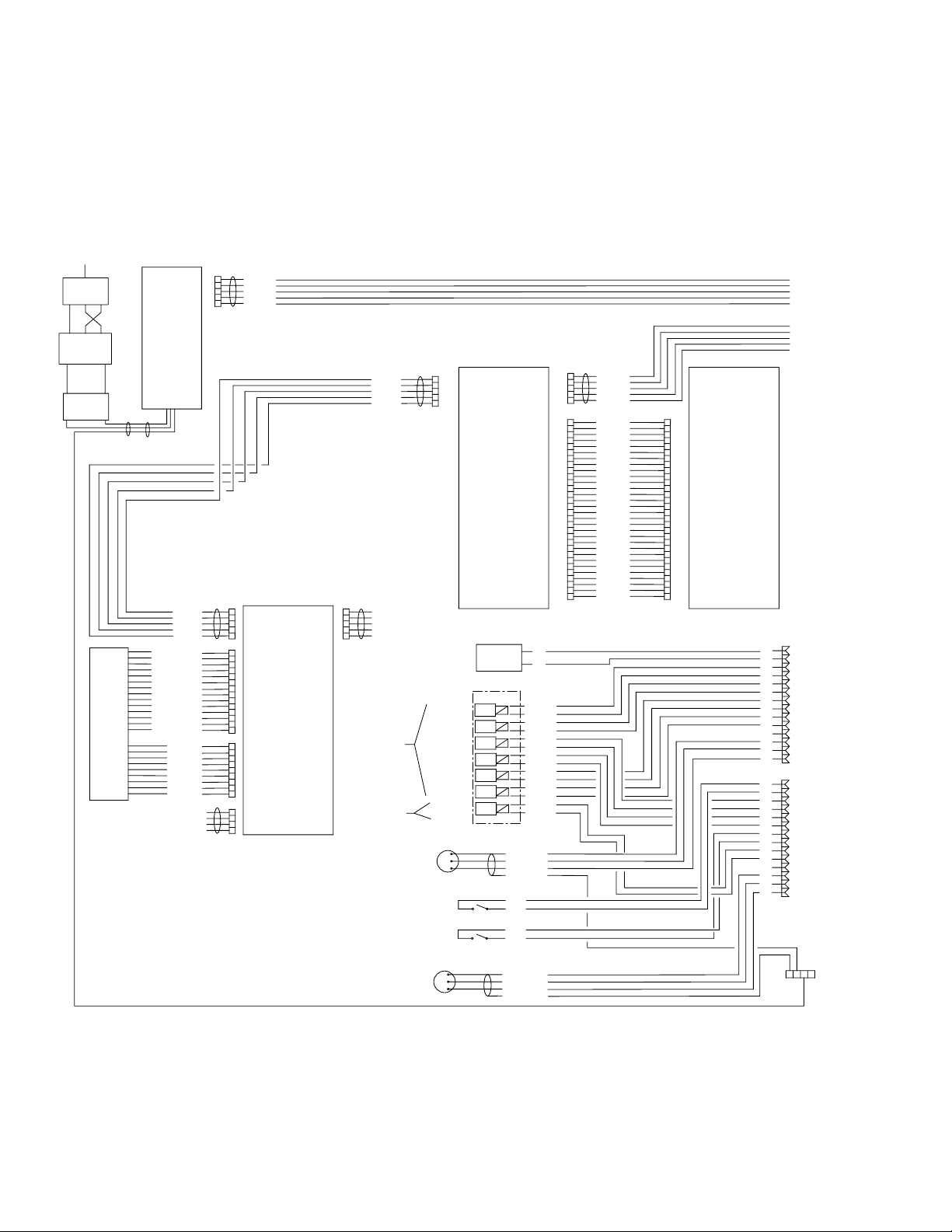

Page 20

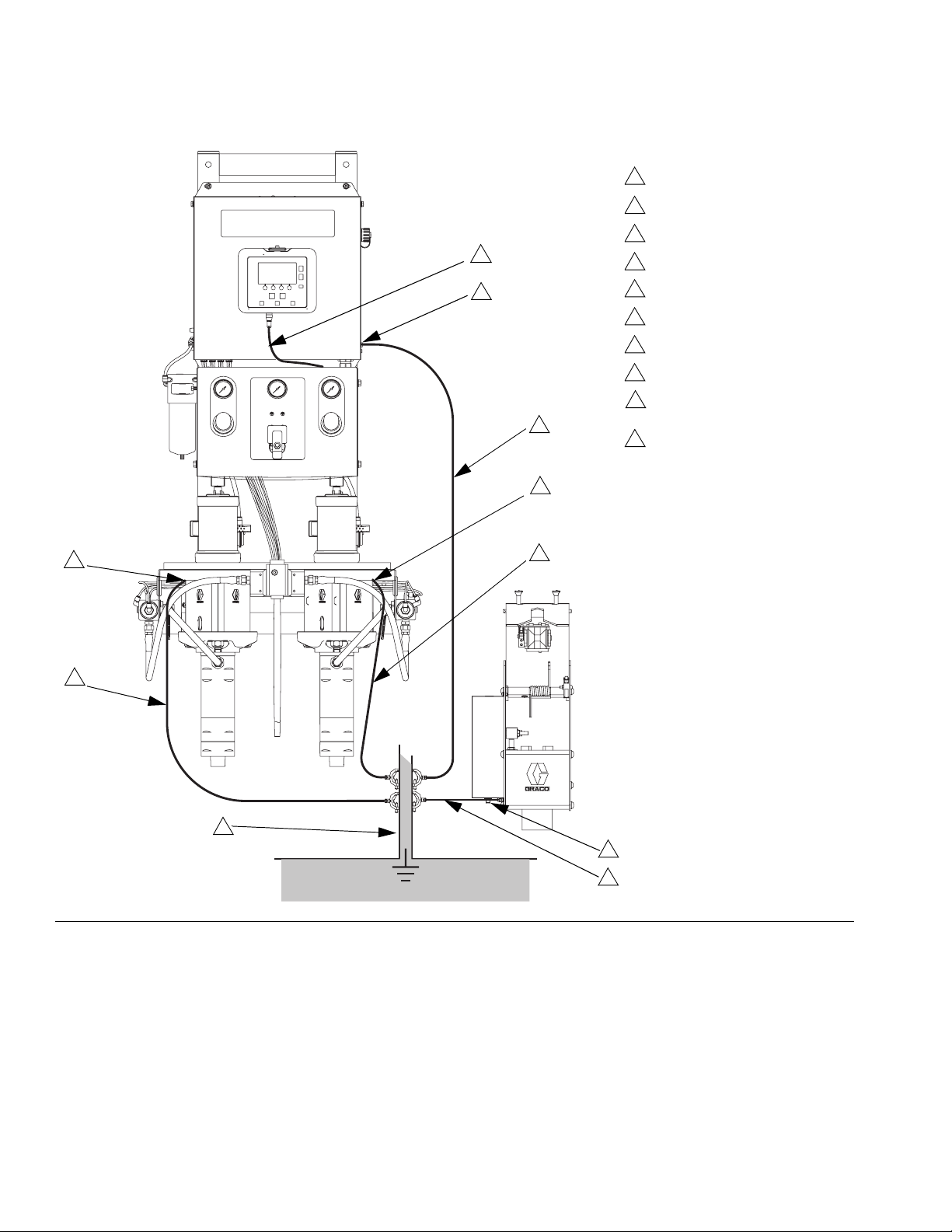

Installation

10

Key:

1

Control Box ground screw

2

Control Box ground wire

3

Pump B ground screw

4

Pump B ground wire

5

1

2

Pump A ground screw

6

Pump A ground wire

7

Gun Flush Box ground screw

8

Gun Flush Box ground wire

9

True Earth Ground - check your

local code for requirements.

Power cable, Display

10

Module/Control Box

3

5

6

FIG. 9. Grounding

4

9

7

8

ti16467a

20 3A0868G

Page 21

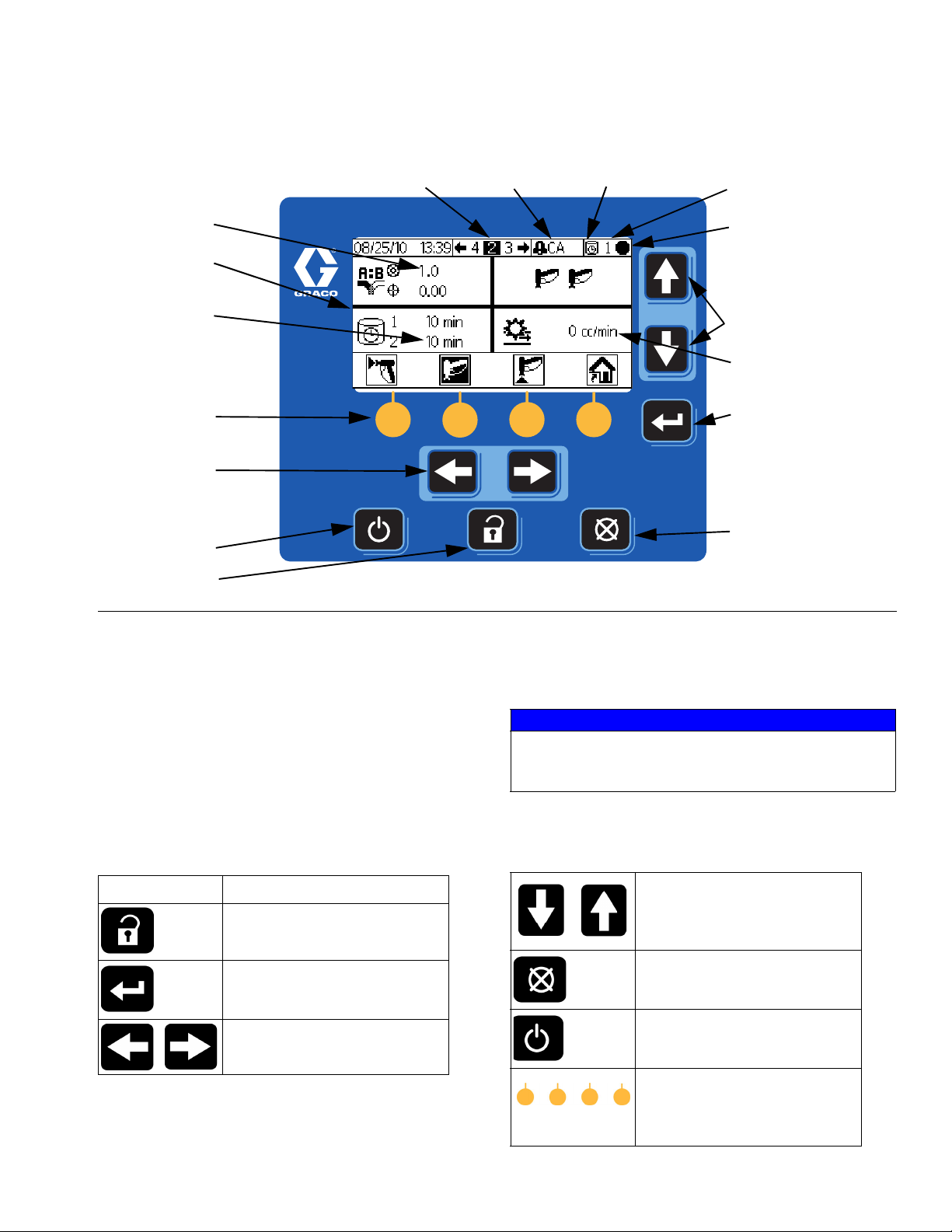

Display Module

Display Module

Ratio

LCD display

Potlife timers

Soft keys

Navigation keys

Standby key

Setup key

F

IG

. 10. Display Module

Screen number

Error code

Potlife state

ti16319a

Active recipe

Operation mode; see

page 22 for key

Navigation keys

Flow rate

Enter key

Error Reset

key

Display

Shows graphical and text information related to setup

and spray operations. The screen backlight is factory

set to remain on. The user may set a number of minutes

the screen can be inactive before the backlight dims.

See Configure 3 (Screen 20), page 44. Press any key

to restore.

NOTE: The Display Module and bracket can be

removed from the cover of the electrical box and

mounted remotely, if preferred.

Key Function

Setup:

Press to enter or exit

Setup mode.

Enter:

Press to choose a field to

update, to make a selection, or

to save a selection or value.

Left/Right Arrows:

from screen to screen.

Use to move

Keys are used to input numerical data, enter setup

screens, navigate within a screen, scroll through

screens, and select setup values.

NOTICE

To prevent damage to the soft key buttons, do not

press the buttons with sharp objects such as pens,

plastic cards, or fingernails.

Up/Down Arrows:

among fields on a screen, items

on a dropdown menu, or digits

in a settable field.

Error Reset:

so cause can be fixed. Also use

to cancel a data entry field.

Standby:

operation and puts the system

into standby.

Soft keys:

specific screen or operation

shown on the display directly

above each key

Stops the current

Press to select the

Use to move

Use to clear alarm

.

3A0868G 21

Page 22

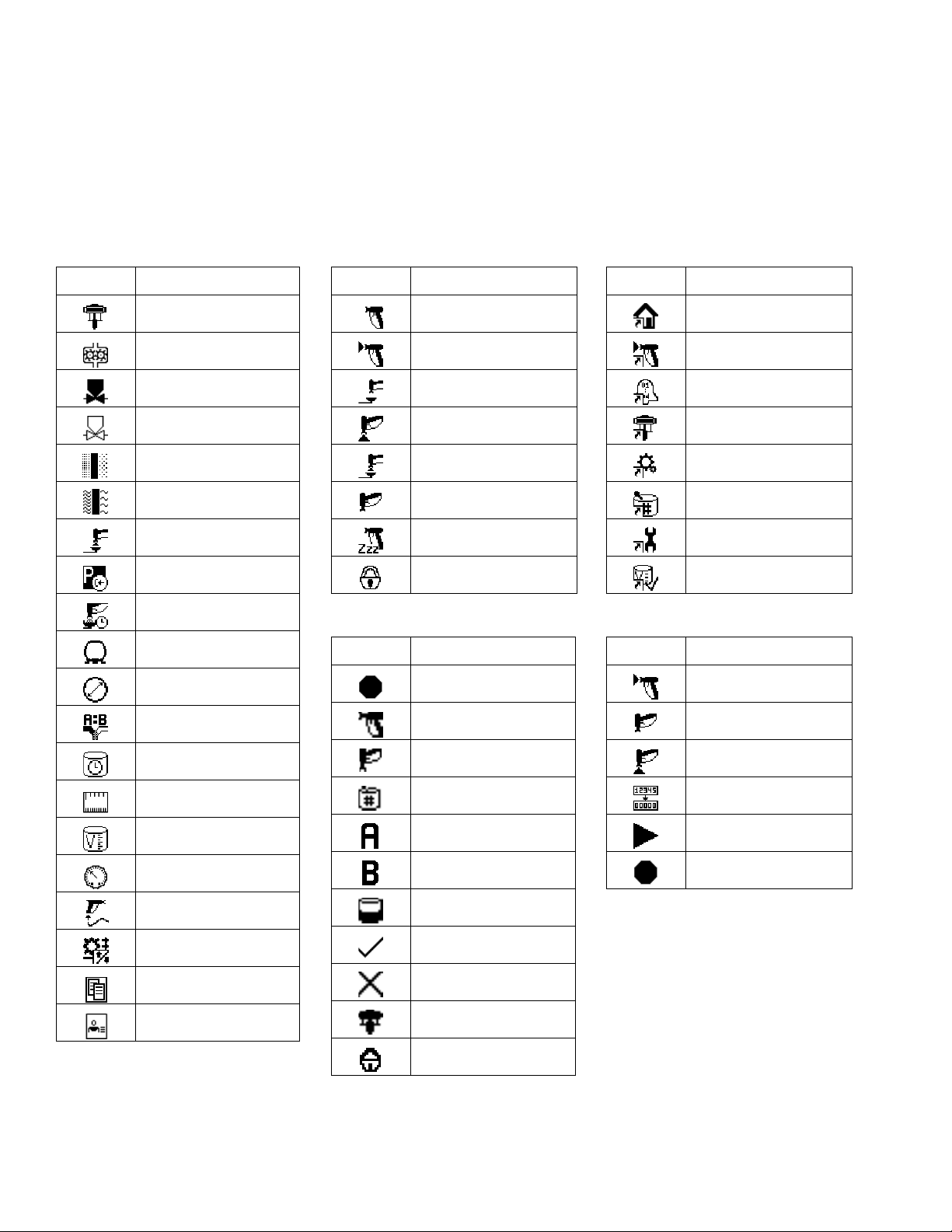

Display Module

Icon Key

The following tables present a printable version of the information on the ProMix 2KE icon card. See Table 3, page

52, for a printable version of the error code information on the reverse side of the card.

General Icons

I

Icon Description

Pump

Meter

Dose Valve

Solvent Valve

Air Filter

Fluid Filter

Gun Flush Box

Park Pumps

Flush Time

Hose Length

Hose Diameter

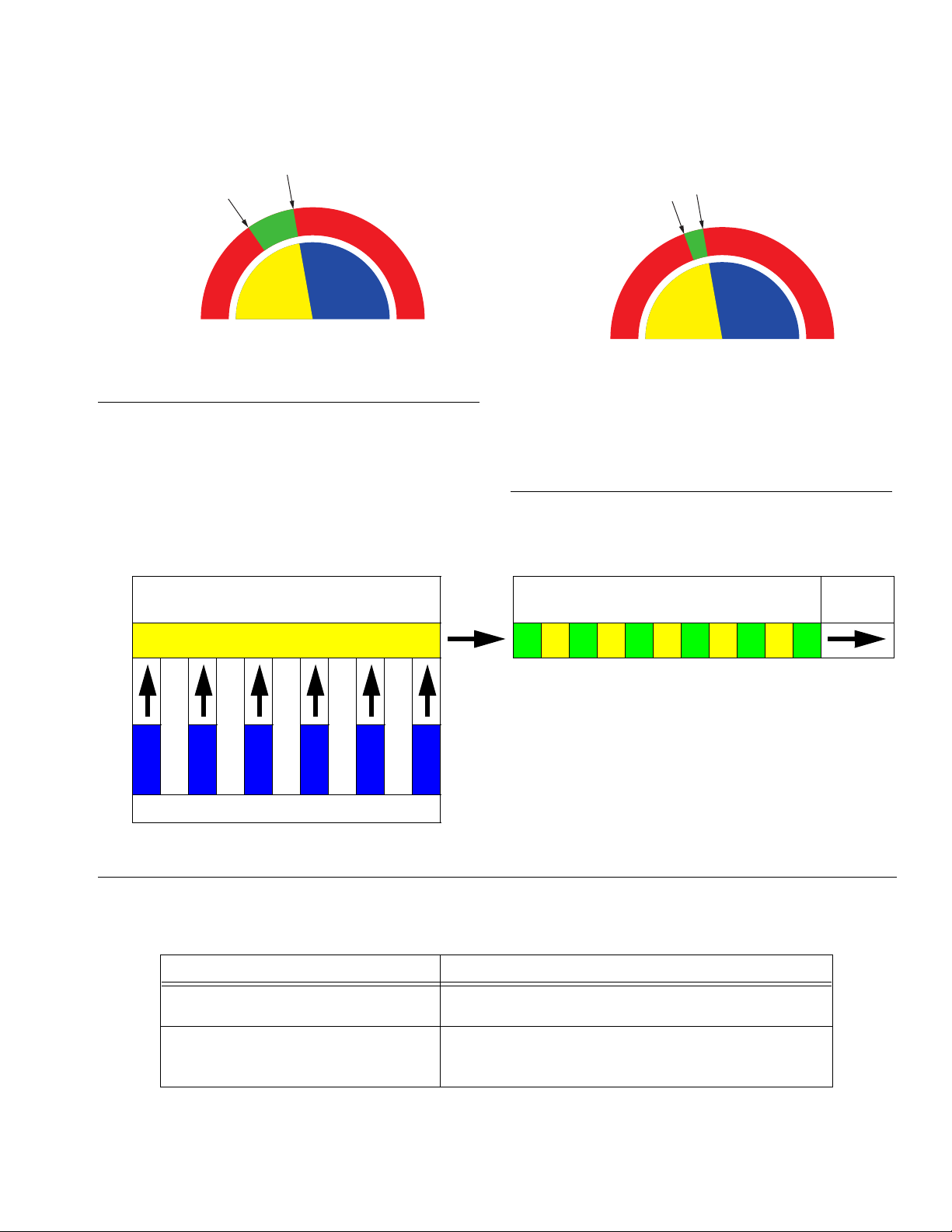

Spray Gun States

I

Icon Description

Mix

Mix Spray

In Flush Box

Purge

Purge in Flush Box

Standby

Idle

Locked

Operation Modes

I

Icon Description

Standby

Screen Shortcuts

I

Icon Description

Home

Spray

Alarm Log

Run Pumps

System Configuration

Recipes

Maintenance

Calibrate

Softkeys

I

Icon Description

Mix/Spray

Ratio

Potlife

Length

Volume

Pressure

Air Flow Switch

Flow Rate High/Low

Job Number

User Number

Mix

Purge

Color Change

Dispense A

Dispense B

Batch

Calibrate

Forced

Park

Locked

Standby

Purge

Reset Counter

Start

Stop/Standby

22 3A0868G

Page 23

Display Module

Screen Summary

NOTE: This summary is a one-page guide to the ProMix 2KE screens, followed by screen maps. For operating

instructions, see Basic Operation, page 29. For further detail on individual screens, see Run Mode Details, page

39, or Setup Mode Details, page 42.

Run Mode

The run mode has three screen sections that control the

mixing operations.

Mix (Screens 2-4, 38)

• Spray (Screen 2) controls most mixing operations.

• Batch (Screen 3) controls dispense of a set volume.

• Totals (Screen 4) displays grand and batch

totals for materials A and B.

• Job Number (Screen 38) displays job number

and user number

Error Log (Screens 5-14)

• 10 screens, 5 errors per page.

• Displays date, time, and error.

Pump Control (Screen 15)

• Manually start or stop a pump.

• Park pumps for brief shutdowns.

Setup Mode

Recipe (Screens 28 and 29)

• Recipe 1-1 (Screen 28) and 1-2 (Screen 29)

control Material 1/Color 1 parameters and flush.

Maintenance (Screens 24-26)

• Maintenance 1 (Screen 24) controls maintenance timer actual and target for Pump A,

Pump B, Solvent Valve A, and Solvent Valve B.

• Maintenance 2 (Screen 25) controls dose

valves A and B maintenance timers, actual and

target.

• Maintenance 3 (Screen 26) controls fluid and air

filter maintenance timers, actual and target.

Calibration (Screens 22 and 23)

• Calibration 1 (Screen 22) controls pump factors

for Pump A and Pump B.

• Calibration 2 (Screen 23) allows the user to perform a calibration.

Troubleshooting

The troubleshooting mode has three screen sections

that allow an authorized user to troubleshoot system

operation. See F

IG

. 14, page 28.

The setup mode has four screen sections that allow an

authorized user to choose the exact settings needed for

the system:

Configure (Screens 18-21)

• Configure 1 (Screen 18) controls system type

(pump or meter), gun flush box enable, and

number of guns (1 or 2).

• Configure 2 (Screen 19) controls hose length

and diameter for one or two guns, flow rate

region setting, and air flow switch enable or

disable.

• Configure 3 (Screen 20) controls language (for

optional USB Module), date format, date, time,

password setting, and backlight timer.

• Configure 4 (Screen 21) controls units for distance, volume and pressure.

3A0868G 23

System Inputs (Screen 35)

Membrane Test (Screen 36)

System Outputs and Manual Activation (Screen 37)

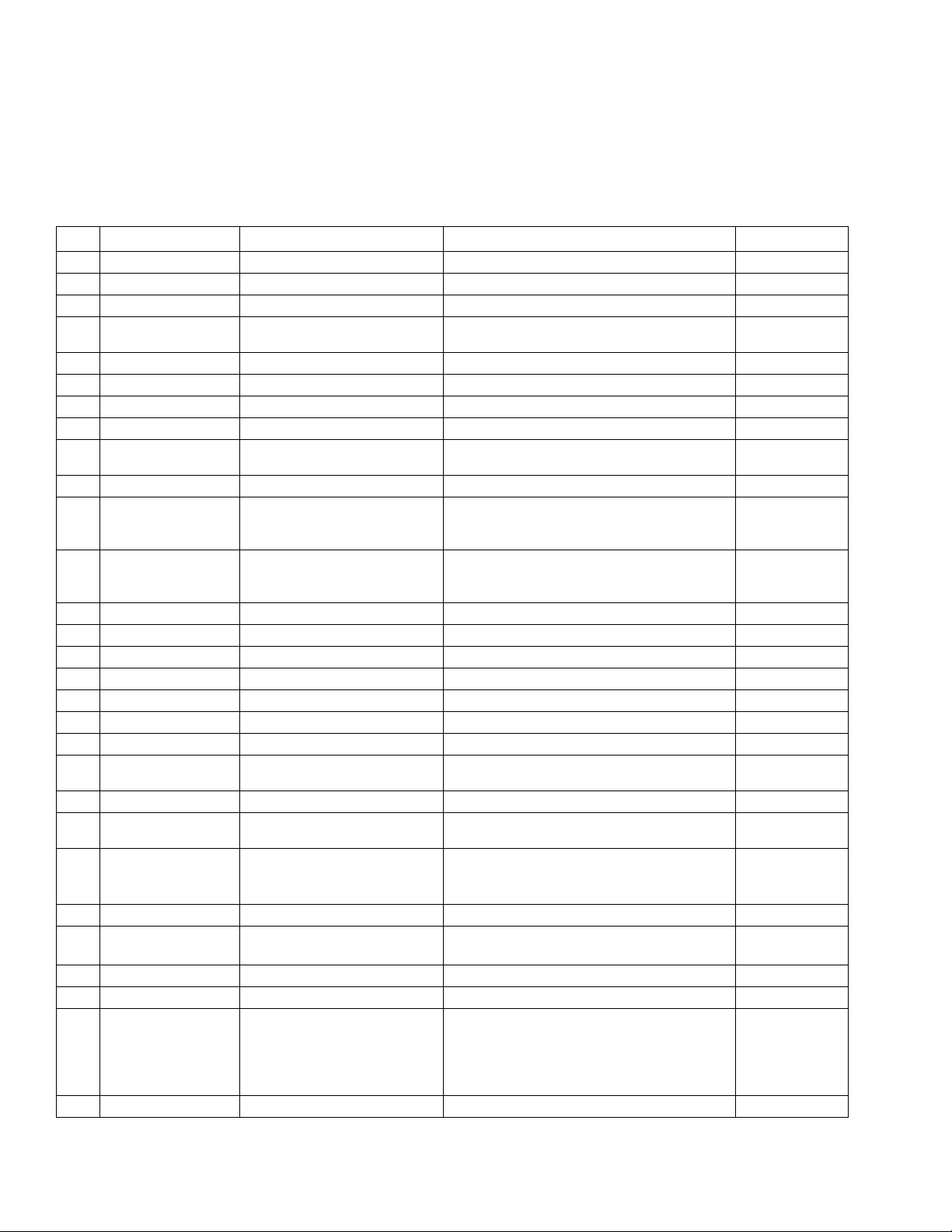

Page 24

Display Module

Ranges for User Inputs

This table is a one-sheet reference of the data range/options accepted for each user input and the default setting.

See the page indicated in the table for further screen information, if needed.

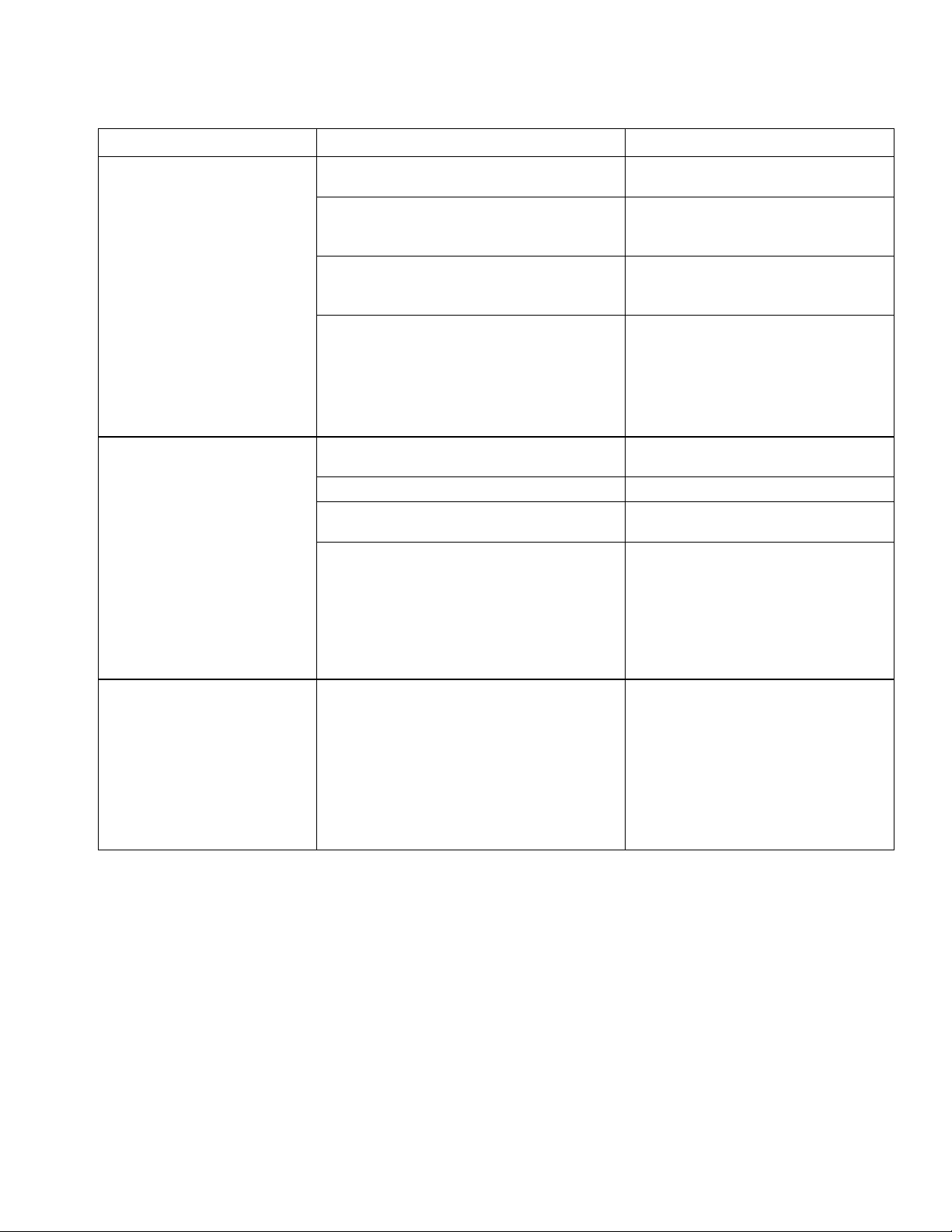

Page Screen User Input Range/Options Default

39 Run Mix Batch (3)

40 Run Job Number (38)

42 Password (16)

43 Configure 1 (18)

43 Configure 1 (18)

43 Configure 1 (18)

43 Configure 2 (19)

43 Configure 2 (19)

43 Configure 2 (19)

43 Configure 2 (19)

44 Configure 3 (20)

44 Configure 3 (20)

44 Configure 3 (20)

44 Configure 3 (20)

44 Configure 3 (20)

44 Configure 3 (20)

44 Configure 4 (21)

44 Configure 4 (21)

44 Configure 4 (21)

44 Recipe 1-1 (28)

44 Recipe 1-1 (28)

44 Recipe 1-1 (28)

44 Recipe 1-2 (29)

45 Maintenance 1 (24)

45 Maintenance 1 (24)

45 Maintenance 2 (25)

45 Maintenance 3 (26)

46 Calibration 1 (22)

46 Calibration 2 (23)

Target Volume

User Number

Password

System Type

Gun Flush Box Enable

Number of Guns

Gun 1 or Gun 2 hose length

Gun 1 or Gun 2 hose diameter

Flow Rate Region

Air Flow Switch

USB Log Language

Date Format

Date

Time

Password

Backlight Timer

Distance Units

Volume Units

Pressure Units

Ratio

Ratio Tolerance

Potlife Timer

Flush Times- First (A purge),

Second (B purge), or Third

(using A or B, chosen by user)

Pump A or Pump B

Solvent Valve A or Solvent

Valve B

Dose Valve A or Dose Valve B

Fluid Filter A or B, or Air Filter

Pump A or Pump B Factor

Actual Dispensed Volume

Meters; 50cc Pump; 75cc Pump; 100cc Pump;

High (250 cc/min or higher) or

Chinese; Dutch; English; French; German; Ital-

ian; Japanese; Korean; Portuguese;

Russian; Spanish; Swedish;

Liters; Gallons US; Gallons Imperial Gallons US

Note: Enter 0 to dispense A only.

Note: If set to 0, potlife alarm is disabled.

Note: If set to 0, the valve(s) will not flush.

1 to 9999 cc 0 cc

000000000 to 999999999 000000000

0000 to 9999 0000 (disabled)

Meters

125cc Pump; 150cc Pump

On or Off Off

1 or 2 guns 1 gun

0.1 to 45.7 m / 0.3 to 150 ft 1.53 m / 5.01 ft

0.1 to 1 inch 0.25 inches

High

Low (<250 cc/min)

On or Off On

English

mm/dd/yy;

dd/mm/yy;

yy/mm/dd

01/01/00 to 12/31/99 Set at factory

00:00 to 23:59 Set at factory

0000 to 9999 0000 (disabled)

0 to 99 minutes 0 minutes

Feet/inches or Meters/cm Feet/inches

psi; Bar; MPA psi

0:1 to 30:1

1 to 99 percent* 5 percent

0 to 240 minutes

0 to 240 seconds

0 to 9,999,999 0

0 to 9,999,999 0

0 to 9,999,999 0

0 to 9999 days 0 days

5 to 50 cc/in 50cc: 10 cc/in.

1 to 9999 cc 0 cc

mm/dd/yy

1:1

60 minutes

60 seconds

75cc: 15 cc/in.

100 cc: 20 cc/in.

125cc: 25 cc/in.

150cc: 30 cc/in.

* The system will attempt to hold whatever accuracy is entered. For some ratios and applications, testing shows that actual sys-

tem accuracy may be ±2% or ±5%. See Technical Data, page 73.

24 3A0868G

Page 25

Display Module

Pump Control

Job Number

Run Home

Totals

.

.

.

Errors

Mix

Spray Batch

FIG. 11. Run Mode Screen Map

3A0868G 25

Page 26

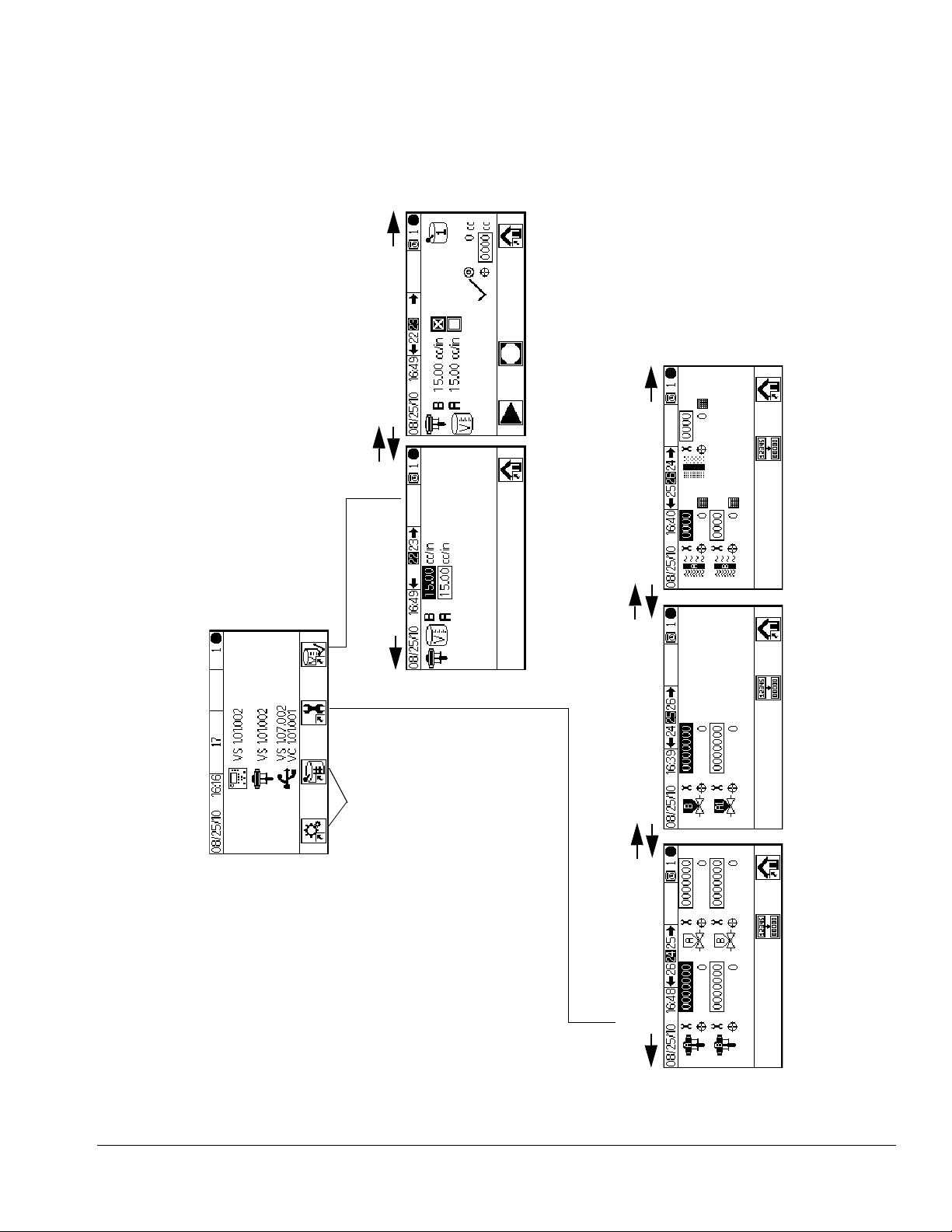

Display Module

Set-Up Home

.

IG

See F

.

13

Password

FIG. 12. Setup Mode Screen Map, page 1

26 3A0868G

Configure

Recipe

Page 27

Display Module

Set-Up Home

Calibration

. 12.

IG

See F

Maintenance

FIG. 13. Setup Mode Screen Map, page 2

3A0868G 27

Page 28

Display Module

Password

Set Password to 9909 (See Configure

3, Screen 20), then enter it here.

Press to exit Setup. Press to

reenter Setup. Setup Home (Screen 17)

displays, with Troubleshooting options.

To

System Outputs 1

Screen

36

Push to enter forced

mode, (System Outputs 2)

To Membrane Test

Membrane Test

Set-Up Home

System Outputs 2

System Inputs

To

Screen

36

To Setup Home

FIG. 14. Troubleshooting Screen Map

28 3A0868G

Page 29

Basic Operation

Basic Operation

Pre-Operation Tasks

Go through the Pre-Operation Checklist in Table 1.

Table 1: Pre-Operation Checklist

✓ Checklist

System grounded

Verify all grounding connections were made. See

Grounding, page 19.

All connections tight and correct

Verify all electrical, fluid, air, and system connections are tight and installed according to the manual instructions.

Fluid supply containers filled

Check component A and B and solvent supply

containers.

Dose valves set

Check that dose valves are set correctly. Start

with the settings recommended in Valve Set-

tings, page 35, then adjust as needed.

Fluid supply valves open and pressure set

Non-IS Systems (Wall Power Supplied): Turn the

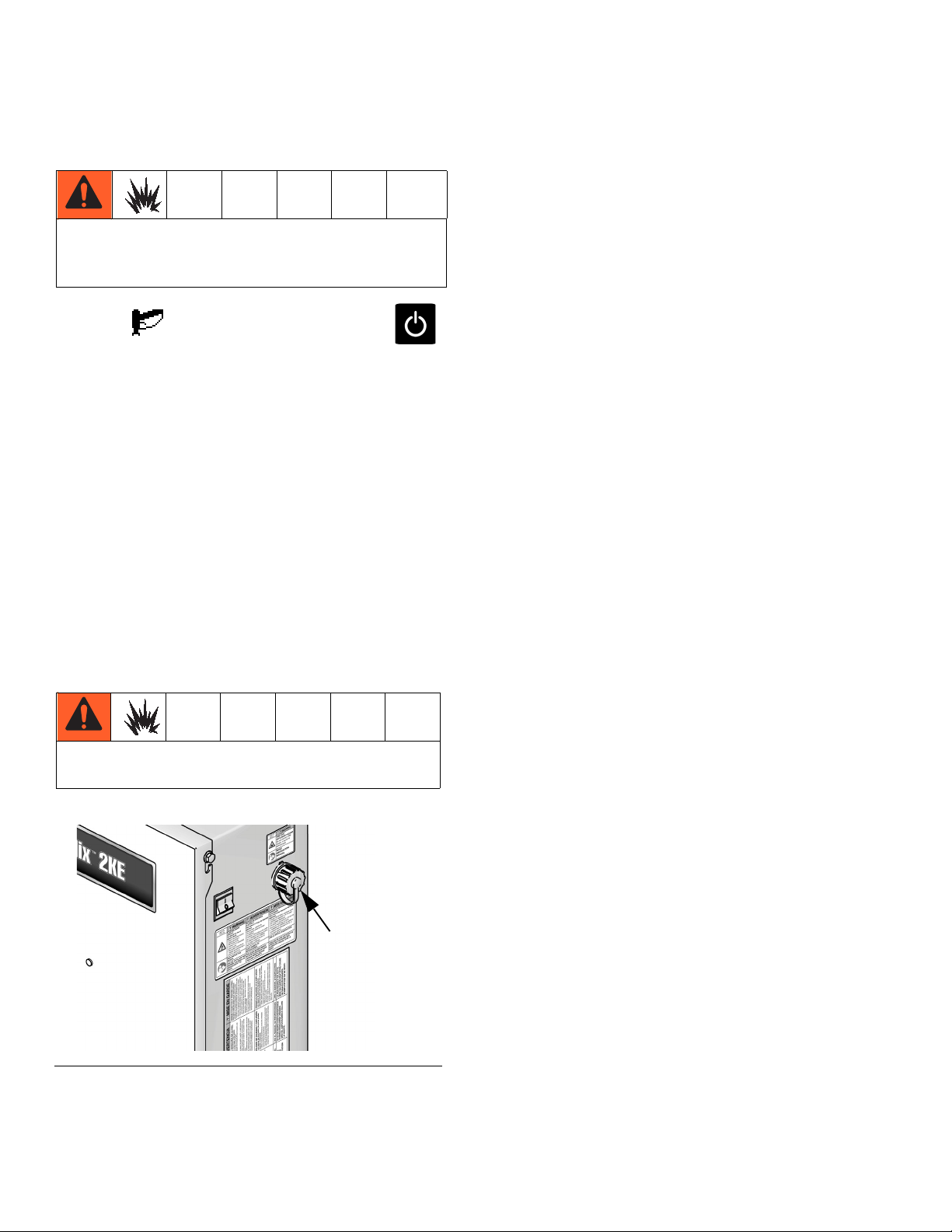

AC Power Switch ON (I = ON, 0 = OFF).

I = ON

TI16336a

FIG. 15. Power Switch

2. Graco logo will display after five seconds, followed

by Run Mix Spray (Screen 2).

Component A and B fluid supply pressures should

be equal unless one component is more viscous

and requires a higher pressure setting.

Solenoid pressure set

75-100 psi inlet air supply (0.5-0.7 MPa, 5.2-7

bar)

Power On

1. IS Systems (Alternator Power Supply): Set pump

air regulators to minimum setting. Open main air

valve to start air-powered alternator. Main air pressure is displayed on gauge.

IG

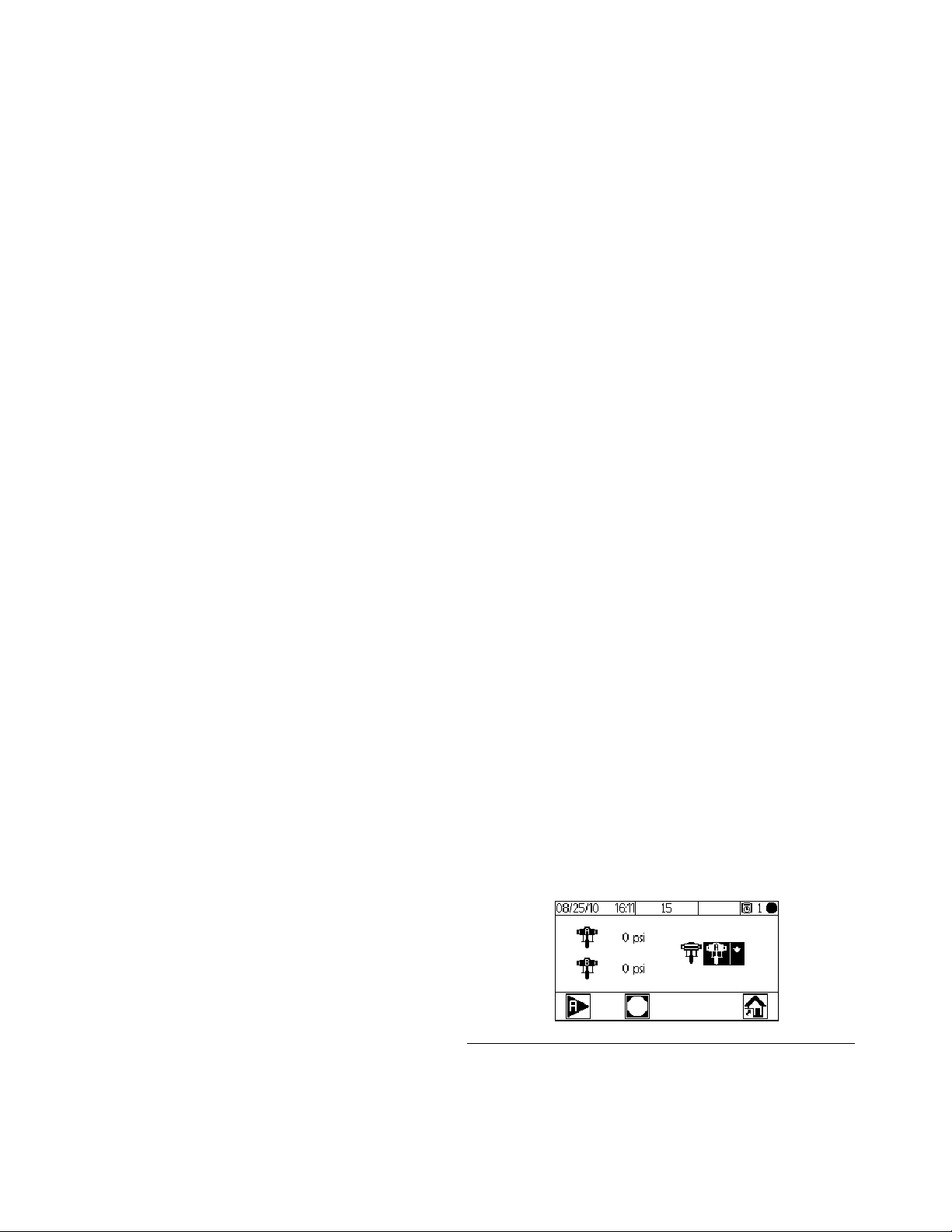

. 16. Run Mix Spray (Screen 2)

F

Initial System Setup

1. Change optional setup selections to desired parameters, as described in Configure 1-4 (Screens

18-21), page 43.

2. Set recipe and flush information as described in

Recipe 1-1 (Screen 28) and Recipe 1-2 (Screen

29), page 44.

3. Set maintenance timers for pumps, valves, fluid filters and air filters, as described in Maintenance 1-3

(Screens 24-26), page 45.

3A0868G 29

Page 30

Basic Operation

Prime the System

NOTE: See Run Mode Details, pages 39-41, for further

screen information, if needed.

1. Adjust the main air pressure. Most applications

require about 80 psi (552 kPa, 5.5 bar) air pressure

to operate properly. Do not use less than 75 psi

(517 kPa, 5.2 bar).

2. If this is the first time starting up the system, or if

lines may contain air, purge as instructed in Purg-

ing, page 32. The equipment was tested with lightweight oil, which should be flushed out to avoid

contaminating your material.

3. From Run Home (Screen 1), press . Make

sure that the system is in Standby mode.

Standby

8. Open the fluid supply valve to the

pump.

NOTE: If using an electrostatic gun,

shut off the electrostatics before

spraying.

9. If using a gun flush box, place the gun in the box

and close the lid. Press . The pump will run 12

cycles.

If the gun flush box is not used, trigger the gun into a grounded metal

pail until the system returns to

Standby.

10. Press to stop the pump before 12 cycles are

completed. If the pump is not fully primed after 12

cycles, press again.

11. Repeat for Pump B.

4. Press to show the dropdown menu.

5. Press to highlight Pump A, then press .

6. Put Pump A into supply pail.

7. Adjust air pressure to component A

pump for your application. Use lowest

pressure possible.

NOTE: Do not exceed the maximum rated working pressure shown on the system identification label or the lowest rated component in the system.

30 3A0868G

Page 31

Basic Operation

Pump Calibration

NOTE: See Calibration 1 and 2 (Screens 22 and 23),

page 46, for further screen information, if needed.

Calibrate the pump:

• The first time the system is operated.

• Whenever new materials are used in the system,

especially if the materials have viscosities that differ

significantly.

• At least once per month as part of regular maintenance.

• Whenever a pump is serviced or replaced.

NOTE:

• Pump factors on Calibration 1 (Screen 22) are

updated automatically after the calibration procedure is completed. You also may manually

edit them if desired.

• All values on this screen are in cc or cc/in.,

regardless of the units set in Configure 4

(Screen 21).

• During each calibration the dispense valve will

close during an up stroke and a down stroke (in

either order). This test is to verify that the pump

ball checks are seating properly and not leaking. If leaking occurs, the system will alarm after

the calibration for that particular valve.

1. Before calibrating pump A or B, prime the system

with material. See Prime the System, page 30.

2. If the display is on a Run Mode screen, press

to access setup screens.

6. Press to start the calibration on the checked

pump (A or B). Press to cancel the calibration.

7. Trigger gun into a graduated cylinder. Dispense a

minimum of 200-300cc of material.

NOTE: Stop triggering the gun when desired amount is

reached. Do not press , as it will cancel the calibration.

8. The volume that the ProMix measured displays on

the Display Module.

Volume measured

by system displays

here.

Enter dispensed

volume here.

FIG. 17. Dispensed Volume Comparison

9. Compare the amount on the Display Module to the

amount in the graduated cylinder.

NOTE: For maximum accuracy, use a gravimetric

(mass) method to determine the actual volumes dispensed.

• If the screen and actual volumes are different, press

to highlight the dispense volume field. Press

. Press to move between digits. Press

to change a digit. Press when field is

correct.

NOTE: If the value is substantially different, repeat the

calibration process until the dispensed volume and measured volume match.

3. Press to display Calibration1 (Screen 22).

Pump calibration factors are shown for Pump A and

Pump B.

4. Press to move to Calibration 2 (Screen 23).

5. Press to highlight the pump you wish to cali-

brate. Press . An X displays in the box.

3A0868G 31

Page 32

Basic Operation

10. After the volume for A or B is entered, the ProMix

2KE controller calculates the new pump factor and

shows it on Calibration 1 (Screen 22) and Calibration 2 (Screen 23).

11. Before you begin production, clear the system of

solvent and prime it with material.

a. Go to Mix mode.

b. Trigger the gun into a grounded metal pail until

mixed material flows from the gun nozzle.

Spraying

NOTE: See Run Mode Details, pages 39-41, for further

screen information, if needed.

1. Calibrate the pumps as described in Pump Calibra-

tion, page 31. Pump factors will update automatically based on calibration results. Make additional

manual changes, if desired, as described in Cali-

bration 1 and 2 (Screens 22 and 23), page 46.

Adjust the flow rate.

2. Press . The system will load the correct potlife

volume based on hose length and diameter entered

on Configure 2 (Screen 19). Once material is

loaded, the system returns to Standby. Press

again to spray the loaded recipe.

3. Adjust the flow rate. The fluid flow rate shown on the

Display Module screen is for either component A or

B, depending on which dose valve is open.

If the fluid flow rate is too low: increase air pressure to component A and B fluid supplies or

increase the regulated fluid pressure of mixed

material.

If the fluid flow rate is too high: reduce the air

pressure to component A and B fluid supplies,

close the dose valves further, or decrease the regulated fluid pressure of mixed material.

4. Turn on atomizing air to the gun. Check the spray

pattern as instructed in your spray gun manual.

NOTE:

• Pressure adjustments of each component will

vary with fluid viscosity. Start with the same fluid

pressure for component A and B, then adjust as

needed.

• Do not use the first 4-5 oz. (120-150 cc) of

material as it may not be thoroughly mixed due

to errors while priming the system.

NOTICE

Do not allow a fluid supply tank to run empty. It is possible for air flow in the supply line to turn gear meters

in the same manner as fluid. This can damage the

meters and lead to the proportioning of fluid and air

that meets the ratio and tolerance settings of the

equipment. This can further result in spraying

uncatalyzed or poorly catalyzed material.

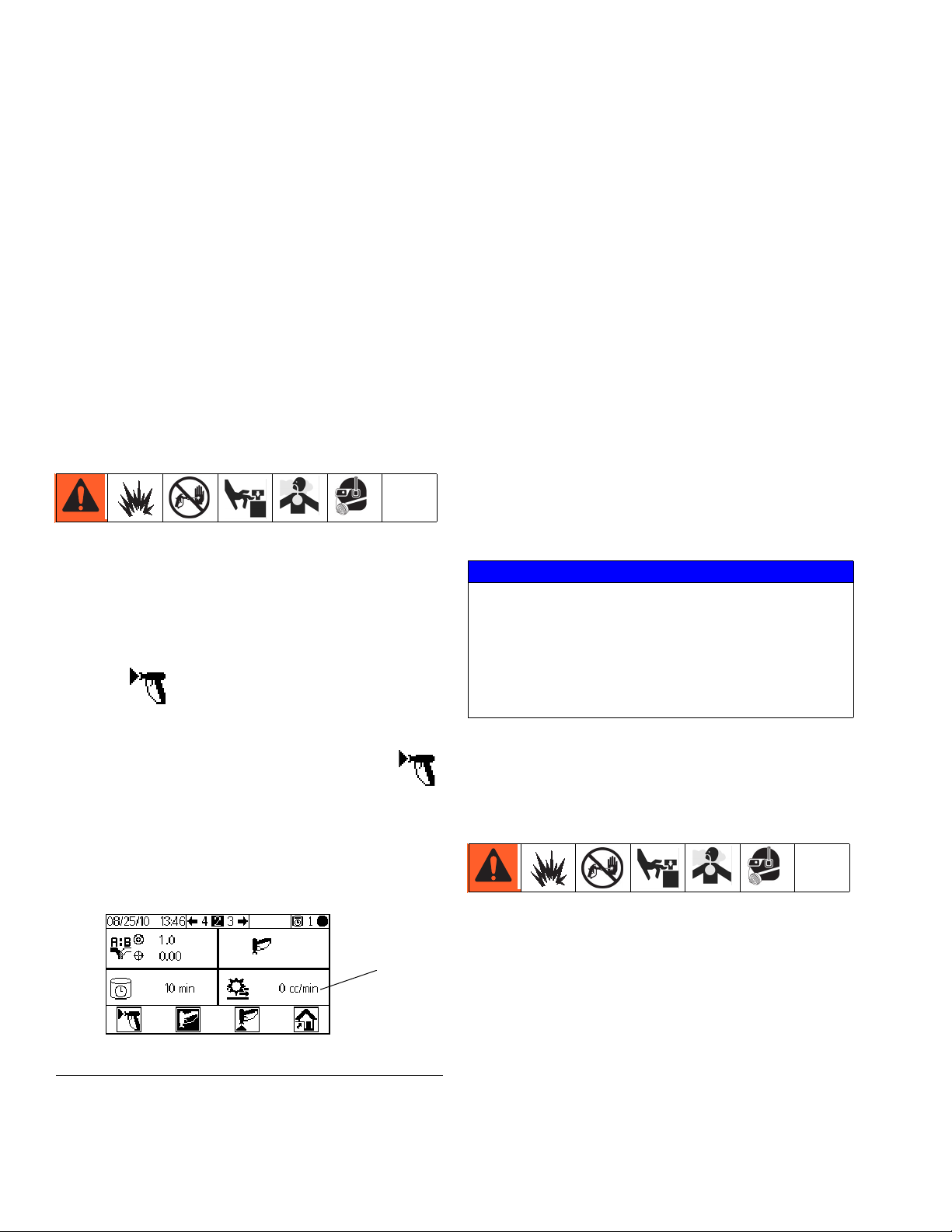

Purging

NOTE: See Run Mode Details, pages 39-41, for further

screen information, if needed.

There are 2 purging procedures in this manual:

• Purging Mixed Material

Flow

rate

FIG. 18. Flow Rate Display

32 3A0868G

• Purging Fluid Supply System

Use the criteria listed for each procedure to determine

which procedure to use.

Page 33

Basic Operation

Purging Mixed Material

There are times when you only want to purge the fluid

manifold, such as:

• end of potlife

• breaks in spraying that exceed the potlife

• overnight shutdown or end of shift

• before servicing the fluid manifold assembly, hose

or gun.

1. Press on Run Mix Spray (Screen 2) or

from any screen to put the system in Standby.

2. Trigger the gun to relieve pressure.

3. If you are using a high pressure gun, engage the

trigger lock. Remove spray tip and clean tip separately.

4. If using an electrostatic gun shut off the electrostatics before flushing the gun.

5. Set the solvent supply pressure regulator at a pressure high enough to completely purge the system in

a reasonable amount of time but low enough to

avoid splashing or an injection injury. Generally, a

setting of 100 psi (0.7 MPa, 7 bar) is sufficient.

9. Trigger the gun to relieve pressure. Engage trigger

lock.

10. If spray tip was removed, reinstall it.

11. Adjust the solvent supply regulator back to its normal operating pressure.

NOTE: The system remains full of solvent.

NOTE: If your system uses 2 guns, you must trigger

both guns simultaneously during a purge to purge both

guns and lines. Verify that clean solvent flows from each

gun. If not, repeat purge or clear clog/blockage in system.

Purging Fluid Supply System

Follow this procedure before:

• the first time material is loaded into equipment

• servicing

• shutting down equipment for an extended period of

time

• putting equipment into storage

1. Press on Run Mix Spray (Screen 2) or

from any screen to put the system in Standby.

6. If using a gun flush box, place the gun into the box

and close the lid.

7. Press on Run Mix Spray (Screen 2). The

purge sequence automatically starts.

If the gun flush box is not used, trigger the gun into a grounded metal

pail until the purge sequence is complete.

When done purging, the system automatically

switches to Standby mode.

8. If the system is not completely clean, repeat step 6.

NOTE: If necessary, adjust purge sequence times

so only one cycle is required.

2. Trigger the gun to relieve pressure.

3. If you are using a high pressure gun, engage the

trigger lock. Remove spray tip and clean tip separately.

4. If using an electrostatic gun, shut off the electrostatics before flushing the gun.

5. Disconnect the component A and B fluid supplies at

the pump inlets, and connect solvent supply lines.

6. Adjust the solvent fluid supply pressure. Use the

lowest possible pressure to avoid splashing.

7. Remove the Control Box cover to access the solenoid valves. See F

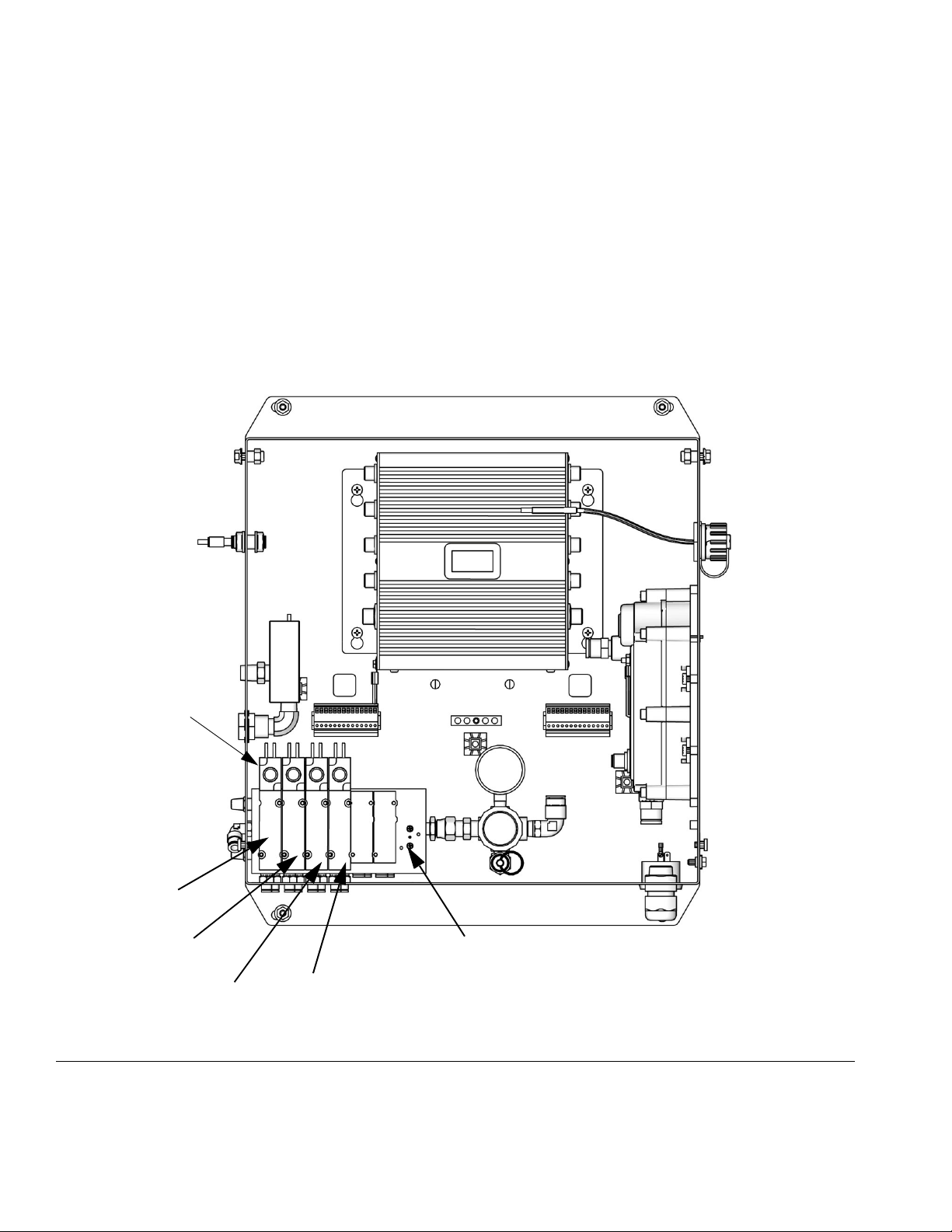

IG

. 19.

3A0868G 33

Page 34

Basic Operation

8. Purge as follows:

• Purge component A side. Press the manual

override on the Dose Valve A solenoid valve

and trigger the gun into a grounded metal pail.

• Purge component B side. Press the manual

override on the Dose Valve B solenoid valve

and trigger the gun into a grounded metal pail

until clean solvent flows from the gun.

• Repeat to thoroughly clean the mix manifold.

9. Reinstall the Control Box cover.

10. Shut off the solvent fluid supply.

11. Disconnect the solvent supply lines and reconnect

the component A and B fluid supplies.

NOTE: The system remains full of solvent.

Manual overrides

Solvent Valve A

Solenoid

Dose Valve A

Solenoid

Solvent Valve B

Solenoid

F

IG

. 19. Solenoid Valves in Control Box

Dose Valve B

Solenoid

Gun Flush Box Solenoid

location, if used.

ti15730a

34 3A0868G

Page 35

Basic Operation

Pressure Relief Procedure

To reduce the risk of skin injection, relieve pressure

when you stop spraying, before changing spray tips,

and before cleaning, checking, or servicing

equipment.

NOTE: The following procedure relieves all fluid and air

pressure in the ProMix 2KE system.

1. Press on Run Mix Spray (Screen 2) or

from any screen to put the system in Standby.

2. Follow procedure for Purging Fluid Supply Sys-

tem, page 33, if desired or necessary.

3. Shut off air supply to A and B pumps and solvent

supply pumps.

4. With the gun triggered, push the manual override on

the A and B dose and solvent valve solenoids to

relieve pressure. See F

sure is reduced to 0.

5. Reinstall the Control Box cover.

IG

. 19. Verify that fluid pres-

Power down and power back up again to clear the lock

and put the new settings into effect. The lock ensures

that the selection was intended and prevents the user

from attempting to operate with incorrect settings.

Valve Settings

Dose valves and purge valves are factory set with the

hex nut 1-1/4 turns out from fully closed. This setting

limits maximum fluid flow rate into integrator and minimizes valve response time. To open dose or purge

valves (for high viscosity materials), turn hex nut (E)

counterclockwise

low viscosity materials), turn

FIG. 21. Valve Adjustment

. To close dose or purge valves (for

clockwise.

See FIG. 21.

E

TI11581a

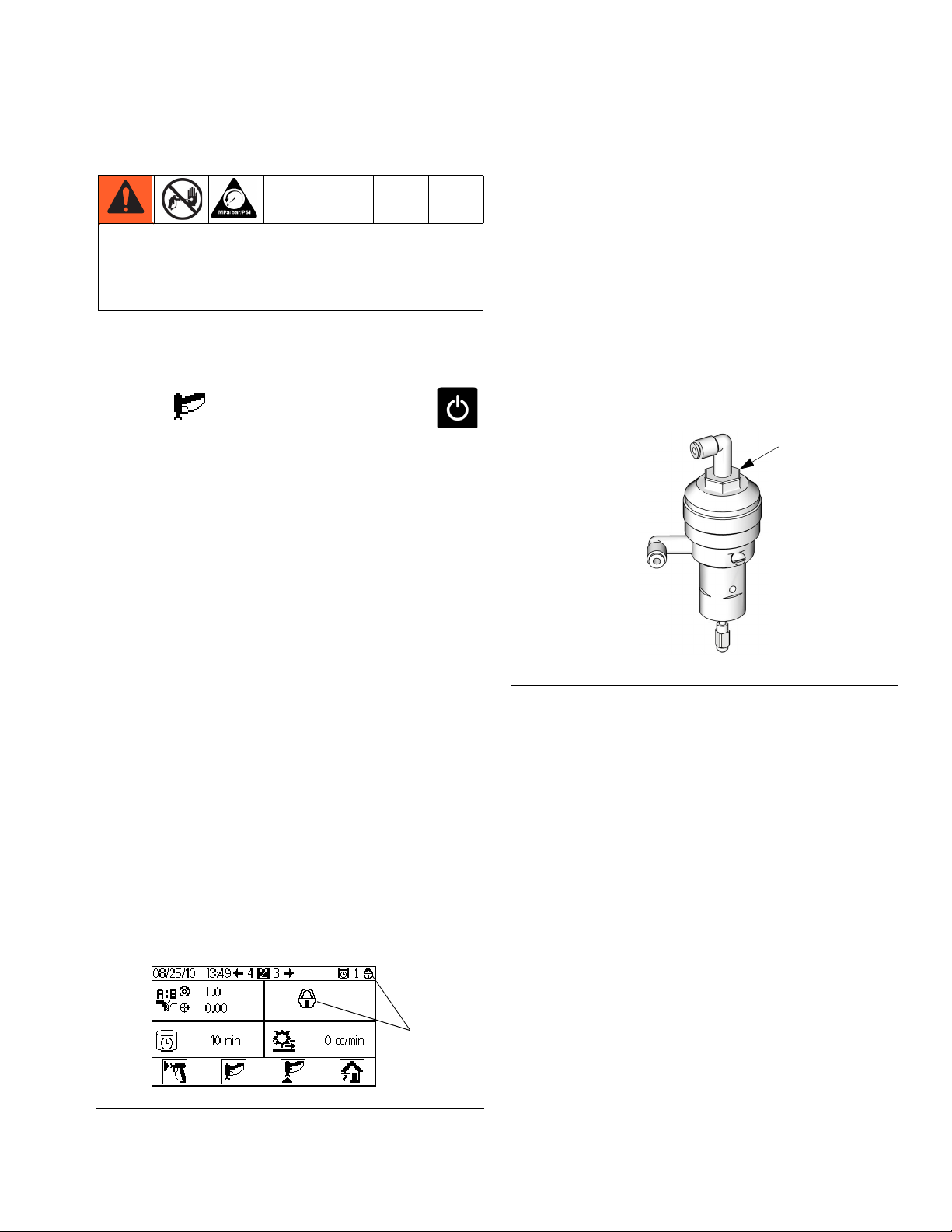

Lock Mode

NOTE: Do not change system type, number of guns,

hose length or hose diameter when material is loaded in

the system. Change these inputs only if system hardware is changed.

If you change one of these inputs, the system locks so

that you cannot spray or mix. If you have changed to a

meter system, the system also locks if you change the

dosing type or the number of colors. The lock icons display.

Lock

icons

FIG. 20. System Lock Mode

Shutdown

1. Follow Purging, on page 32.

2. Close main air shutoff valve on air supply line and

on ProMix 2KE.

3. Non-IS Systems: Shut off ProMix 2KE power

(0 position).

3A0868G 35

Page 36

Use of Optional USB Module

Use of Optional USB Module

USB Logs

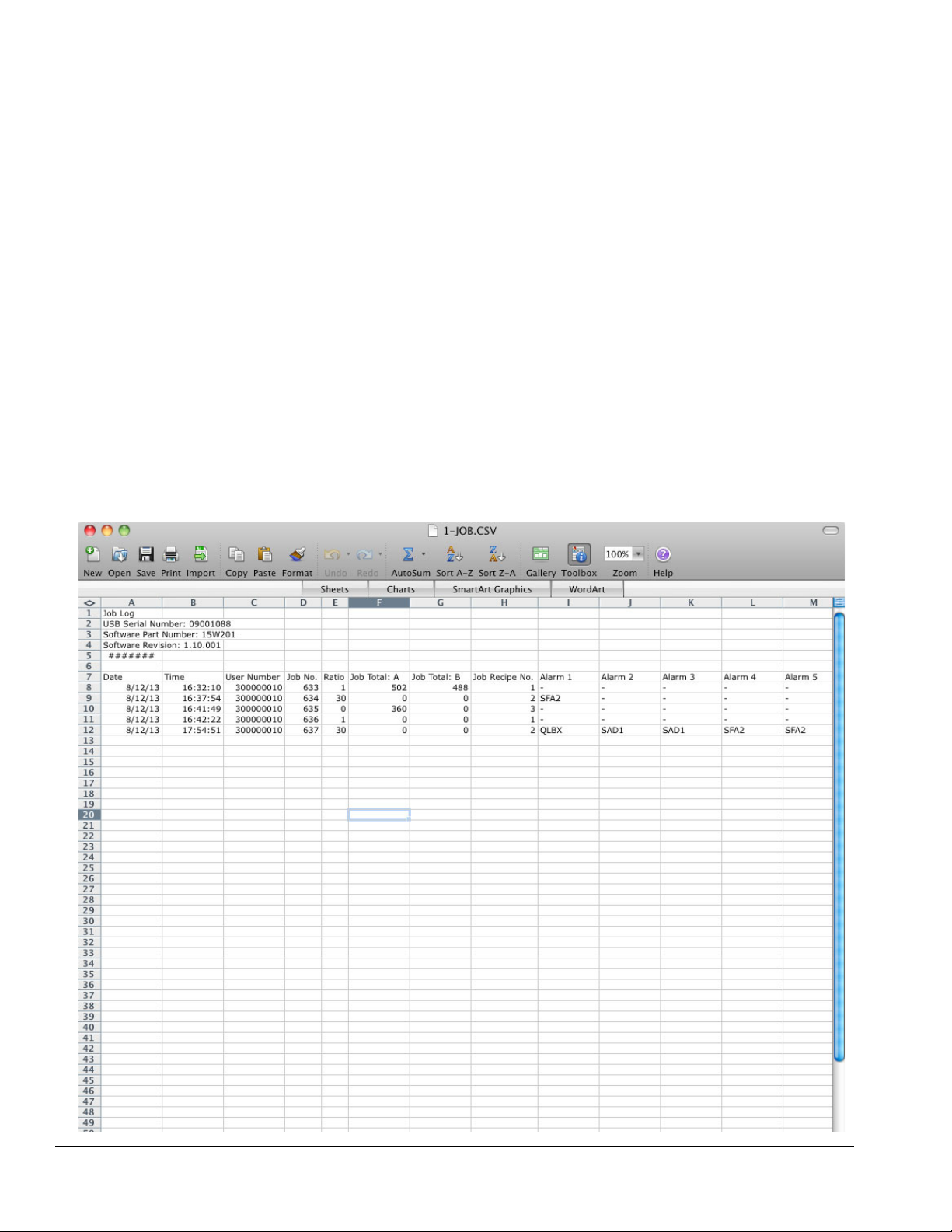

Job Log 1

See example in FIG. 22. The job log records total volumes for each job that the system performs, up to 2000.

It records the date, time, user number, job number, total

A volume, total B volume, and mix ratio. Job total volumes are in cubic centimeters. A log entry is made

when a new job is initiated, which occurs when batch

totals are cleared, or when the job number is incremented from Run Job Number (Screen 38). Job information is displayed on the Display Module only through

use of the optional USB Module.

NOTE: User Number, Ratio, and Alarm 1-5 are displayed as of 2KE System Software version 1.03.001

(USB Cube Software version 1.10.001).

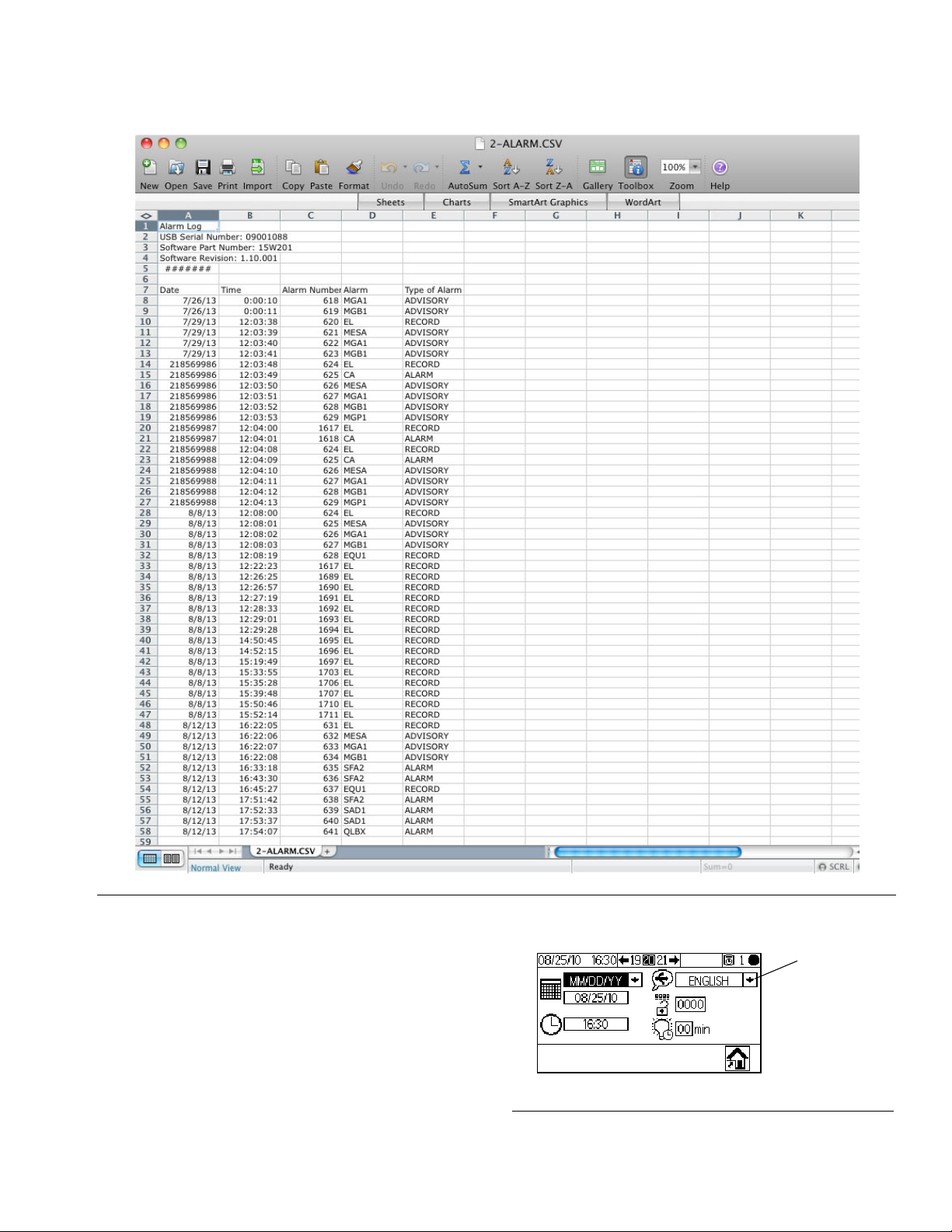

Error Log 2

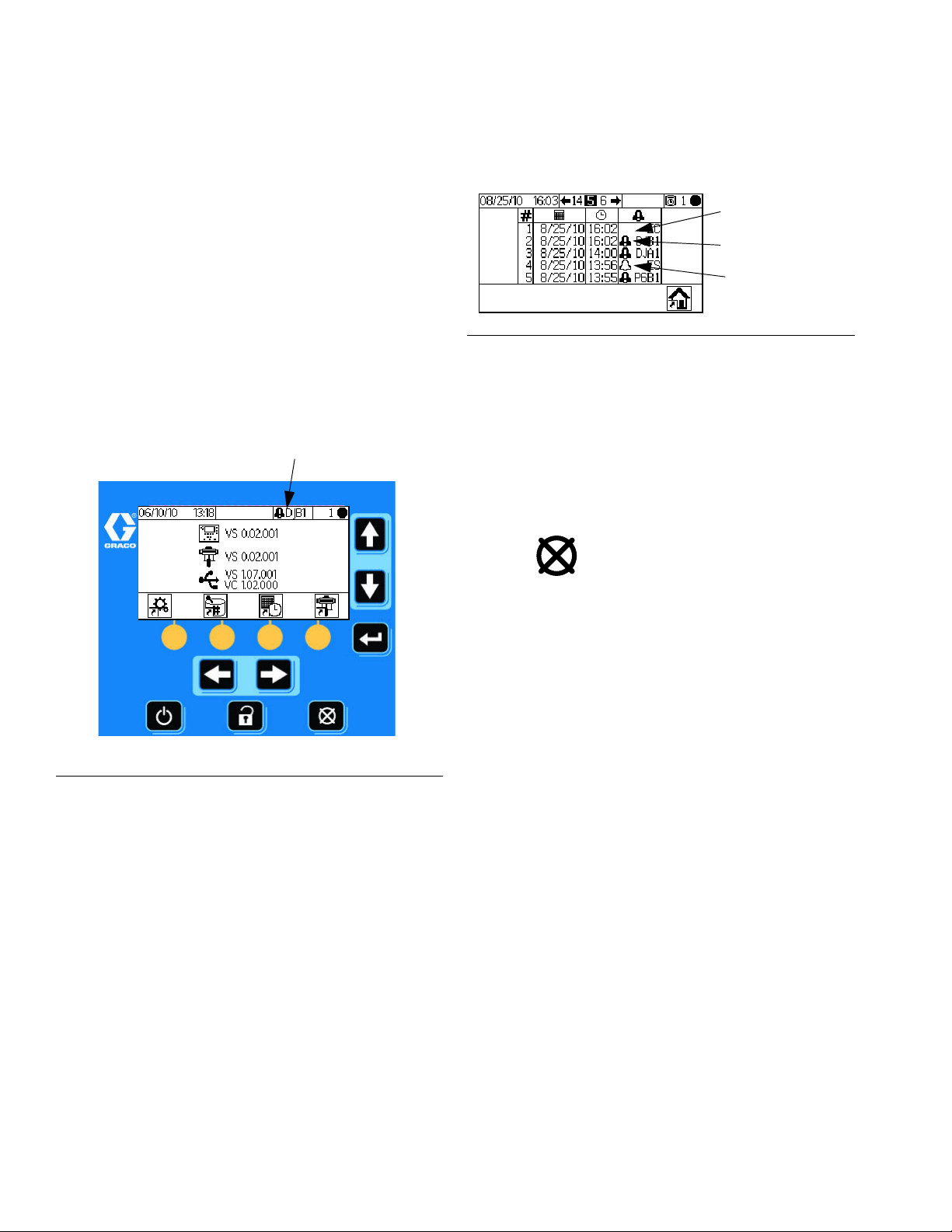

See example in FIG. 23. The error log records all errors

generated by the system, up to 500. It records the date,

time, error number, error code, and error type for each

error that occurs. Without the USB, the user can access

the 50 most recent errors via the Display Module.

NOTE: For both the Job Log and the Error Log, when

the log is full, new data automatically overwrites old

data. When data in either log is downloaded via the

USB, it remains in the module until it is overwritten.

FIG. 22. Sample Job Log

36 3A0868G

Page 37

Use of Optional USB Module

FIG. 23. Sample Error Log

Setup

The only setup required is to select the language in

which you want to view the downloaded data. (Screens

are icon-based and do not change.) Navigate to Configure 3 (Screen 20). Select your language from the language dropdown.

FIG. 24. Select Language for USB Logs

3A0868G 37

Language

dropdown

menu

Page 38

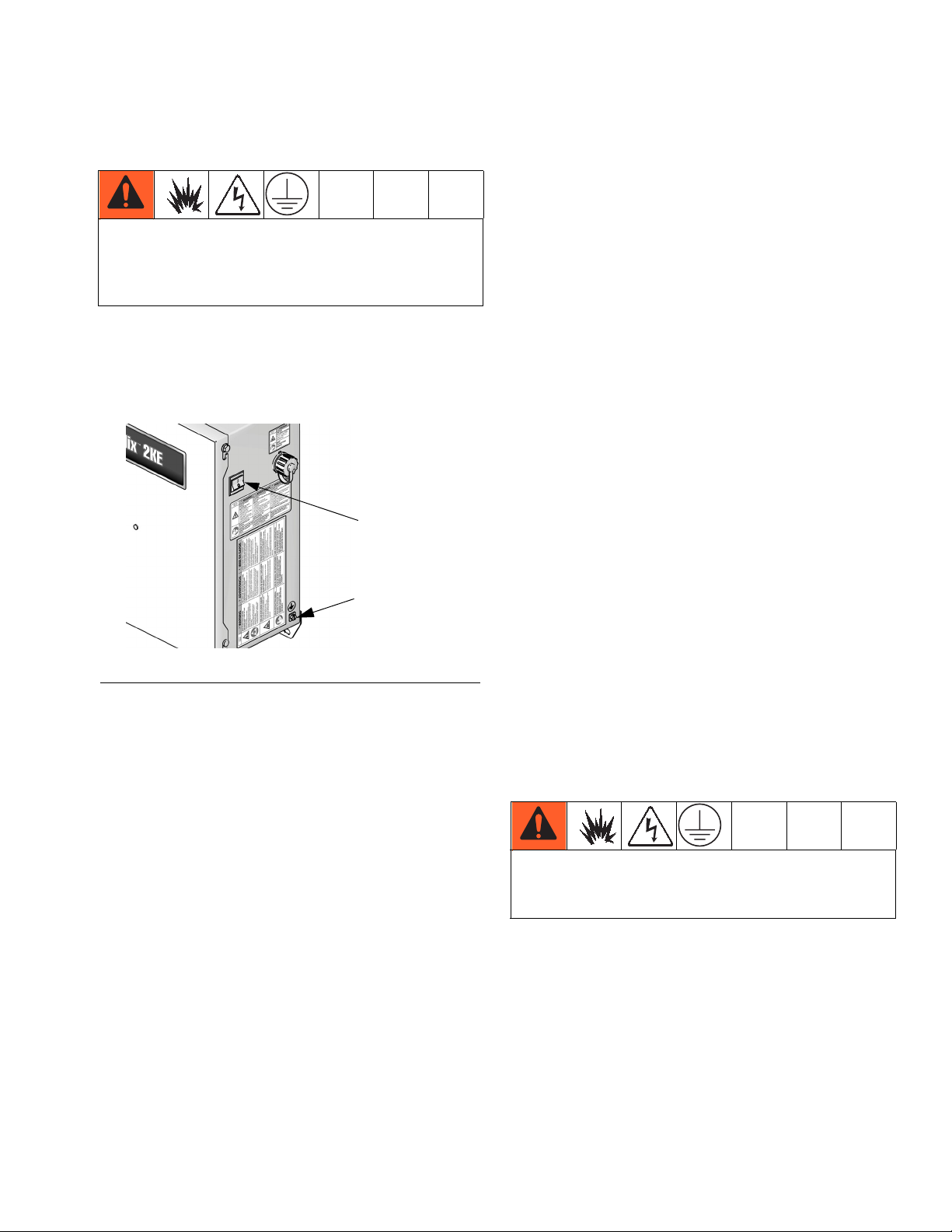

Use of Optional USB Module

Download Procedure

Remove proportioner from hazardous location before

inserting, downloading, or removing the USB flash

drive.

1. Press on Run Mix Spray (Screen 2) or

from any screen to place the system in Standby.

NOTE: The system will not operate with a USB flash

drive in the port. If you insert the flash drive while spraying, the system will stop and an alarm error will occur.

2. Insert USB flash drive into USB port. Use only

Graco-recommended USB flash drives; see Rec-

ommended USB Flash Drives, page 38.

3. Data download begins automatically. An LED on the

flash drive blinks until the download is complete.

NOTE: If you use a flash drive that does not have an

LED, open the Control Box. An LED near the USB module flashes until the download is complete.

6. The USB flash drive window automatically opens. If

it does not, open USB flash drive from within Win-

®

dows

Explorer.

7. Open Graco folder.

8. Open sprayer folder. If downloading data from more

than one sprayer, there will be more than one

sprayer folder. Each sprayer folder is labeled with

the corresponding USB serial number.

9. Open DOWNLOAD folder.

10. Open folder labeled with the highest number. The

highest number indicates the most recent data

download.

11. Open log file. Log files open in Microsoft

default. However, they can also be opened in any

®

text editor or Microsoft

NOTE:

All USB logs are saved in Unicode (UTF-16) format. If

opening the log file in Microsoft Word, select Unicode

encoding.

Word.

®

Excel® by

Recommended USB Flash

4. Remove flash drive from USB port.

To help prevent fire and explosion, never leave the

USB flash drive in the USB port.

USB Port

TI15712a

FIG. 25. USB Port

5. Insert USB flash drive into USB port of computer.

Drives

It is recommended that users use the 4GB USB flash

drive (16A004) available for purchase separately from

Graco. If preferred, users may use one of the following

4 GB or less USB flash drives (not available from

Graco).

• Crucial Gizmo!

JDO4GB-730)

• Transcend JetFlash

(model TS4GJFV30)

• OCZ Diesel

OCZUSBDSL4G)

™

4GB USB flash drive (model

®

V30 4GB USB flash drive

™

4GB USB flash drive (model

38 3A0868G

Page 39

Run Mode Details

Run Mode Details

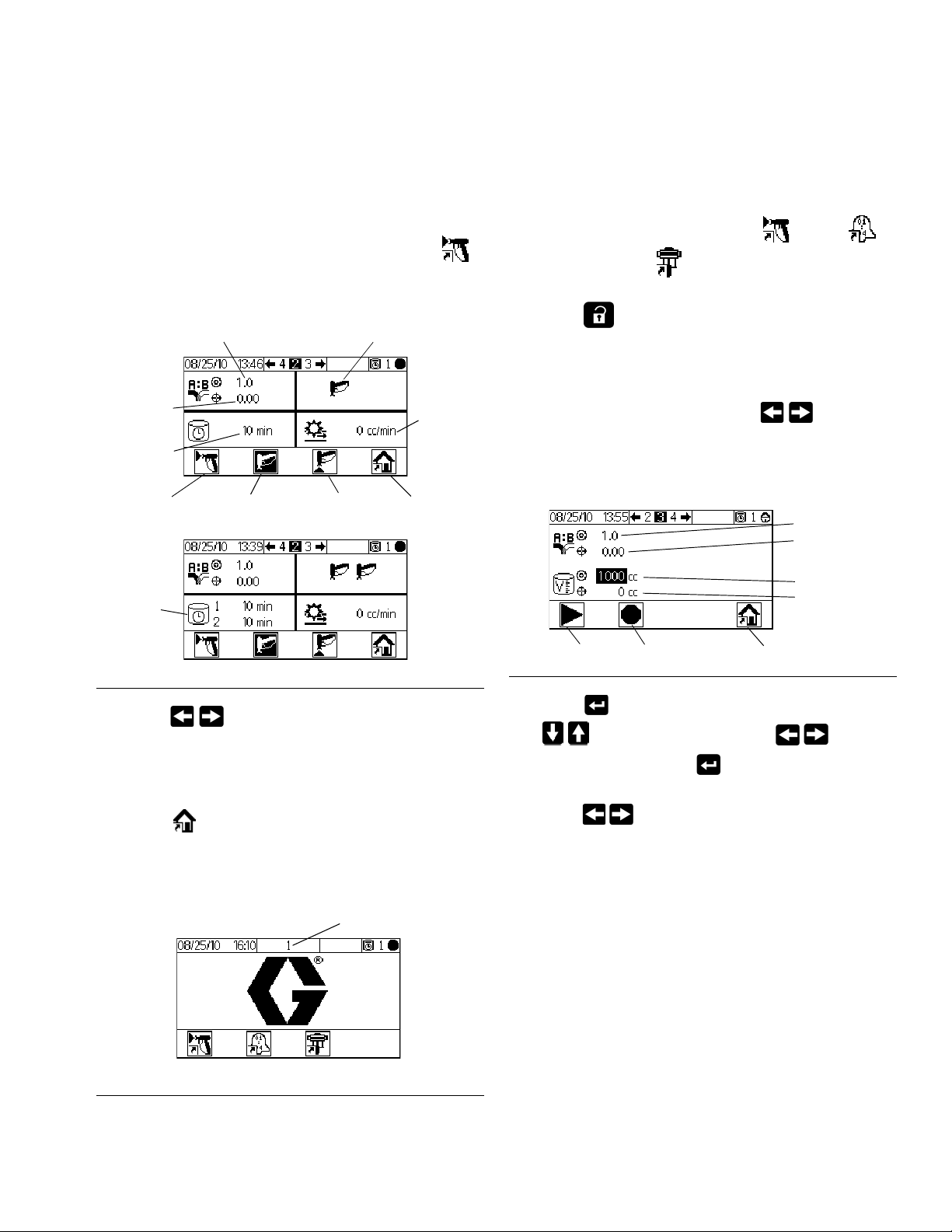

Run Mix Spray (Screen 2)

Run Mix Spray (Screen 2) displays at startup or if

is selected from Run Home (Screen 1). Use the Mix

Spray screen to control most mixing operations.

Target ratio

Actual

ratio

Potlife

time

Mix

Potlife for

each gun

FIG. 26. Run Mix Spray (Screen 2)

Standby

1 Gun

Purge

2 Guns

Gun status

Flow rate

Home

• Press a soft key button to select one of the main

Run Mode screen sections: Mix , Errors ,

or Pump Control .

• Press to enter the Setup screens.

Run Mix Batch (Screen 3)

Run Mix Batch (Screen 3) displays if is selected

from the Run Mix Spray Screen. Use the Mix Batch

screen to dispense set volumes. Target volume can be

set from 1 to 9999 cc.

Target ratio

Actual ratio

Target volume

Actual volume

Start

FIG. 28. Run Mix Batch (Screen 3)

Stop

Home

• Press to toggle between Run Mix Spray

(Screen 2), Run Mix Batch (Screen 3), Run Mix

Totals (Screen 4), and Run Job Number (Screen

38).

• Press to access Run Home (Screen 1).

Run Home (Screen 1)

Screen number

FIG. 27. Run Home (Screen 1)

• Press to set the target dispense volume. Use

to change each digit, then to move

to the next digit. Press when finished.

• Press to toggle between Run Mix Spray

(Screen 2), Run Mix Batch (Screen 3), Run Mix

Totals (Screen 4), and Run Job Number (Screen

38).

3A0868G 39

Page 40

Run Mode Details

Run Mix Totals (Screen 4)

Run Mix Totals (Screen 4) displays if is

selected from the Run Mix Batch Screen. Use this

screen to view grand and batch totals for material A and

material B, and to clear batch totals if desired.

Batch total

Grand tota

Clear batch totals/

increment job

FIG. 29. Run Mix Totals (Screen 4)

• Press to clear all batch totals. A verification

screen appears. Use to highlight and press

on the to clear the batch totals, or on the

to return to Run Totals (Screen 4) without clearing.

Home

Run Job Number (Screen 38)

Run Job Number (Screen 38) displays if is

selected from the Run Mix Totals Screen. Use this

screen to view and increment the job number as well as

view and assign a 9-digit user number to the job.

Job number

l

User number

Home

FIG. 31. Run Job Number (Screen 38)

• Press to set the user number. Use to

change each digit, then to move to the next

digit. Press when finished.

• Press increment the job number.

FIG. 30. Confirm Clear Batch Totals

• Press to toggle between Run Mix Spray

(Screen 2), Run Mix Batch (Screen 3), Run Mix

Totals (Screen 4), and Run Job Number (Screen

38).

• Press to toggle between Run Mix Spray

(Screen 2), Run Mix Batch (Screen 3), Run Mix

Totals (Screen 4), and Run Job Number (Screen

38).

Run Log Errors (Screens 5-14)

Run Log Errors (Screens 5-14) display if is

selected from Run Home (Screen 1). It displays the last

50 errors in the log. (Screen 5 displays errors 1-5;

Screen 6 displays errors 6-10, etc.).

Error codes

Error Icons

FIG. 32. Run Log Errors (Screen 5)

• Use to view the next page. See F

page 50, for an explanation of the different error

icons. See Table 3, page 52, for an explanation of

the different error codes.

IG

. 54,

40 3A0868G

Page 41

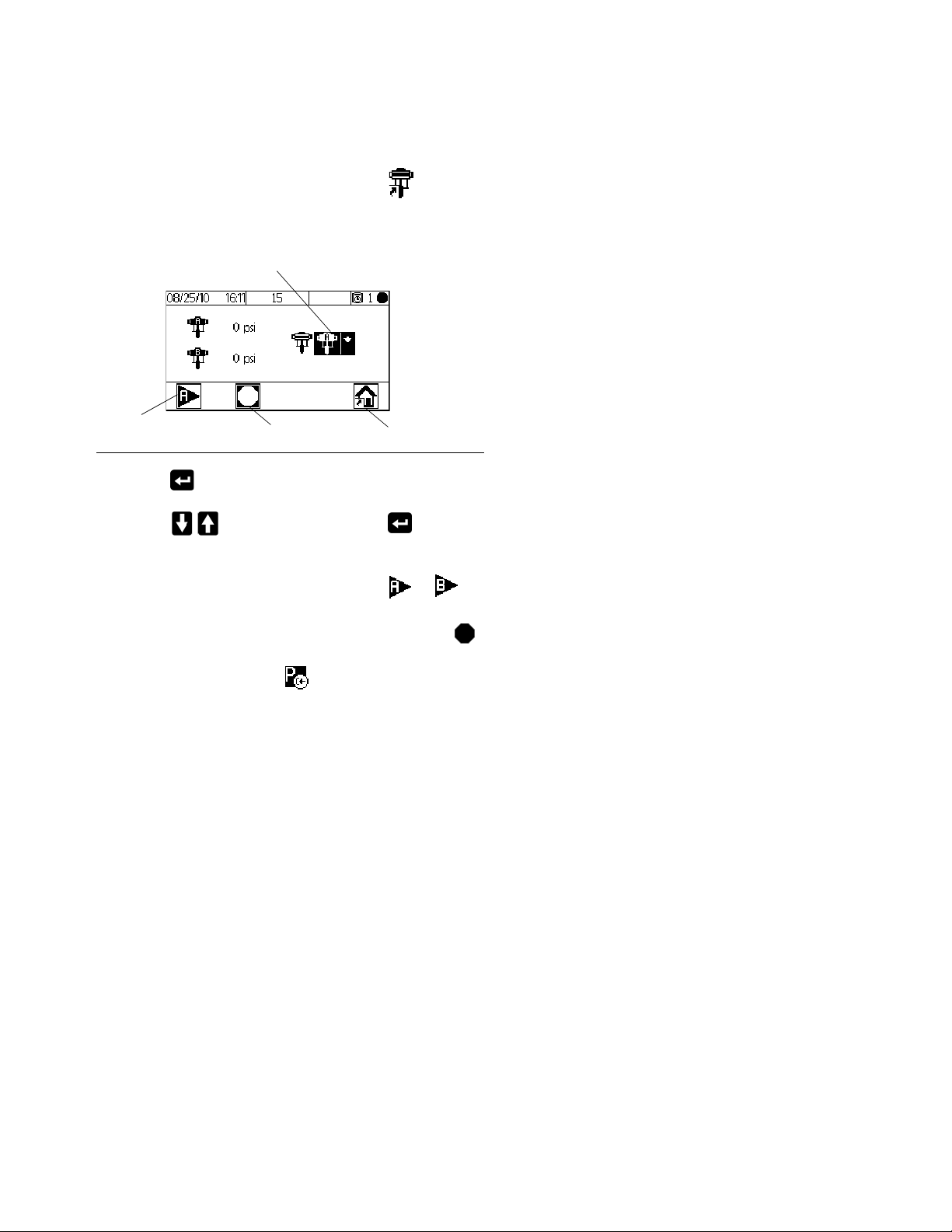

Run Pump Control (Screen 15)

Run Pump Control (Screen 15) displays if is

selected from the Run Home Screen. Use this screen to

manually start and stop a pump.

Pump/Park selection

dropdown

Run Mode Details

Start

Stop

Home

FIG. 33. Run Pump Control (Screen 15)

• Press to show the dropdown menu.

• Press to highlight, then press to select

a pump or the Park option.

• If Pump A or Pump B is selected, use or to

start. The selected pump will run for 12 cycles. To

stop before the 12 cycles are completed, press .

• If Park is selected, use to move the pump to the

bottom of the stroke to park it so pump rod is fully

enclosed in the lower and material can’t dry on shaft

during break or overnight.

3A0868G 41

Page 42

Setup Mode Details

Setup Mode Details

Press on any screen to enter the Setup screens. If

the system has a password lock, Password (Screen 16)

displays. If the system is not locked (password is set to

0000), Setup Home (Screen 17) displays.

Password (Screen 16)

Software Version:

Display Module

Fluid Control Module

USB Module

From any Run screen, press to access the password screen. The Password Screen displays if a pass-

word has been set. Set the password to 0000 to prevent

Password (Screen 16) from displaying. See Configure 3

(Screen 20), page 44, to set or change the password.

FIG. 34. Password (Screen 16)

• Press to enter the password (0000 to 9999).

Press to move between digits. Press

to change a digit. Press when field is

correct. Setup Home (Screen 17) displays.

Recipe MaintenanceConfigure Calibration

FIG. 35. Setup Home (Screen 17)

• Press a soft key button to select one of the four

Setup Mode screen sections:

Configure , Recipe , Maintenance , or

Calibration .

• Press to toggle between Run Mode and Setup

Mode.

• Press to toggle between Run Mode and Setup

Mode.

• Select to display Run Home (Screen 1). Entering an incorrect password also displays Run Home

(Screen 1).

Setup Home (Screen 17)

Setup Home (Screen 17) displays if is selected on

any screen and the system is not locked, or when a cor-

rect password is entered on the Password Screen. The

Setup Home screen displays the software versions of

the boards in the Display Module, Advanced Fluid Control Module, and the USB Module (if applicable).

42 3A0868G

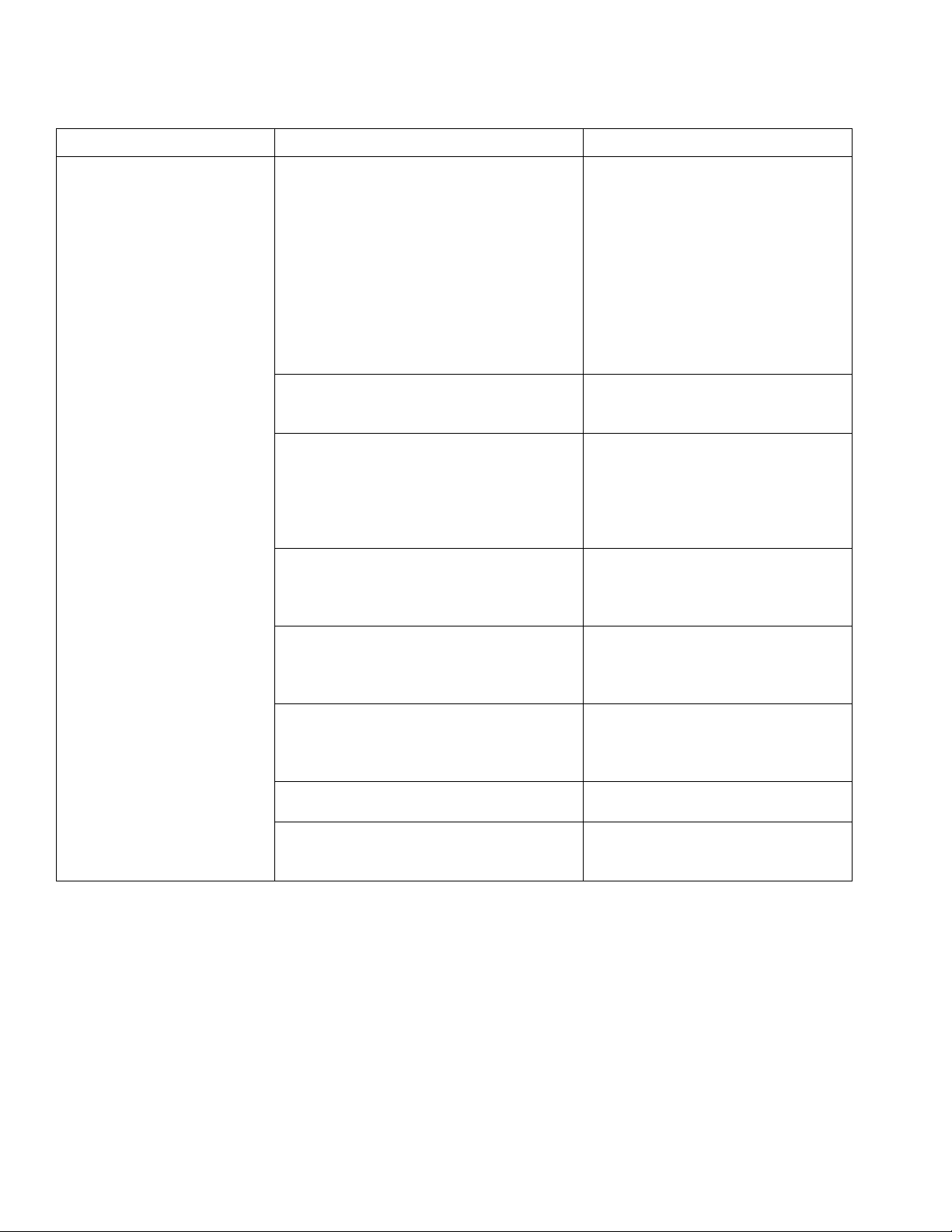

Page 43

Configure 1-4 (Screens 18-21)

Configure 1 (Screen 18) displays if is selected on

Setup Home (Screen 17). This screen allows users to

set up the system type (pump or meter) and number of

guns (1 or 2).

NOTE: If 1 gun is selected, users can enable a gun flush

box (✓ =yes; X=no). The gun flush box option is available only for 1-gun systems.

For all pump systems, the type of dosing is dynamic,

and the number of colors is 1. See Dynamic DosingDy-

namic Dosing, page 48, for more information.

Gun flush

box

System

type

FIG. 36. Configure 1 (Screen 18)

• Press to highlight the desired field. Press

to display the dropdown menu for that field.

Number

of guns

Home

Setup Mode Details

FIG. 37. Confirm Change of System Type

Configure 2 (Screen 19) allows users to set for each gun

the hose length (0.1 to 45.7 m, 0.3 to 150 ft) and hose

diameter (0.1 to 1 inch). The system uses this information to calculate pot life volume. The pot life volume tells

the system how much material must be moved to trigger

a reset of the pot life timer. It also tells the system the

volume needed to fill during a load sequence.

Users also can configure the flow rate region and the air

flow switch. The flow rate region (High/Low) determines

the sensitivity of the overdose alarm:

• Select the High setting if your flow rate is 250

cc/min or higher. The High setting has a 100cc overdose volume.

• Select the Low setting if your flow rate is less

than 250 cc/min. The Low setting has a 50 cc overdose volume.

Press to choose from the menu options and

to set. Press to move to the next field.

• Press to move through Configure 2 (Screen

19), Configure 3 (Screen 20), and Configure 4

(Screen 21).

NOTE: If you change system type (pump to meter) or

number of guns, a verification screen appears. Use

to highlight and press on the to make the

change, or on the to return to Configure 1 (Screen

18) without making a change. If a change is made, the

system locks so that you cannot spray or mix. Power

down and power back up again to clear the lock and put

the new settings into effect. The lock ensures that the

selection was intended, and prevents the user from

attempting to operate with incorrect settings.

The air flow switch can be disabled here for airless

applications. Select to enable or to disable.

A change in any of these fields will trigger the lock. See

NOTE in previous paragraph.

Gun 1

hose

length

Gun 1

hose

diameter

Flow rate

region

Gun 2

hose

length

Gun 2

hose

diameter

Air

flow

switch

Home

FIG. 38. Configure 2 (Screen 19)

Configure 3 (Screen 20) allows users to set preferred

language (for optional USB Module), date format, date,

time, password (0000 to 9999), and number of minutes

(0 to 99) of inactivity required before the backlight turns

off. Configure 4 (Screen 21) allows users to set preferred units for distance, volume, and pressure.

3A0868G 43

Page 44

Setup Mode Details

USB log

language

Date

format

Date

Time

Configure 3

Pressure

units

Configure 4

Password

Backlight

timer

Distance

units

Volume

units

Home