Page 1

Instructions and Parts

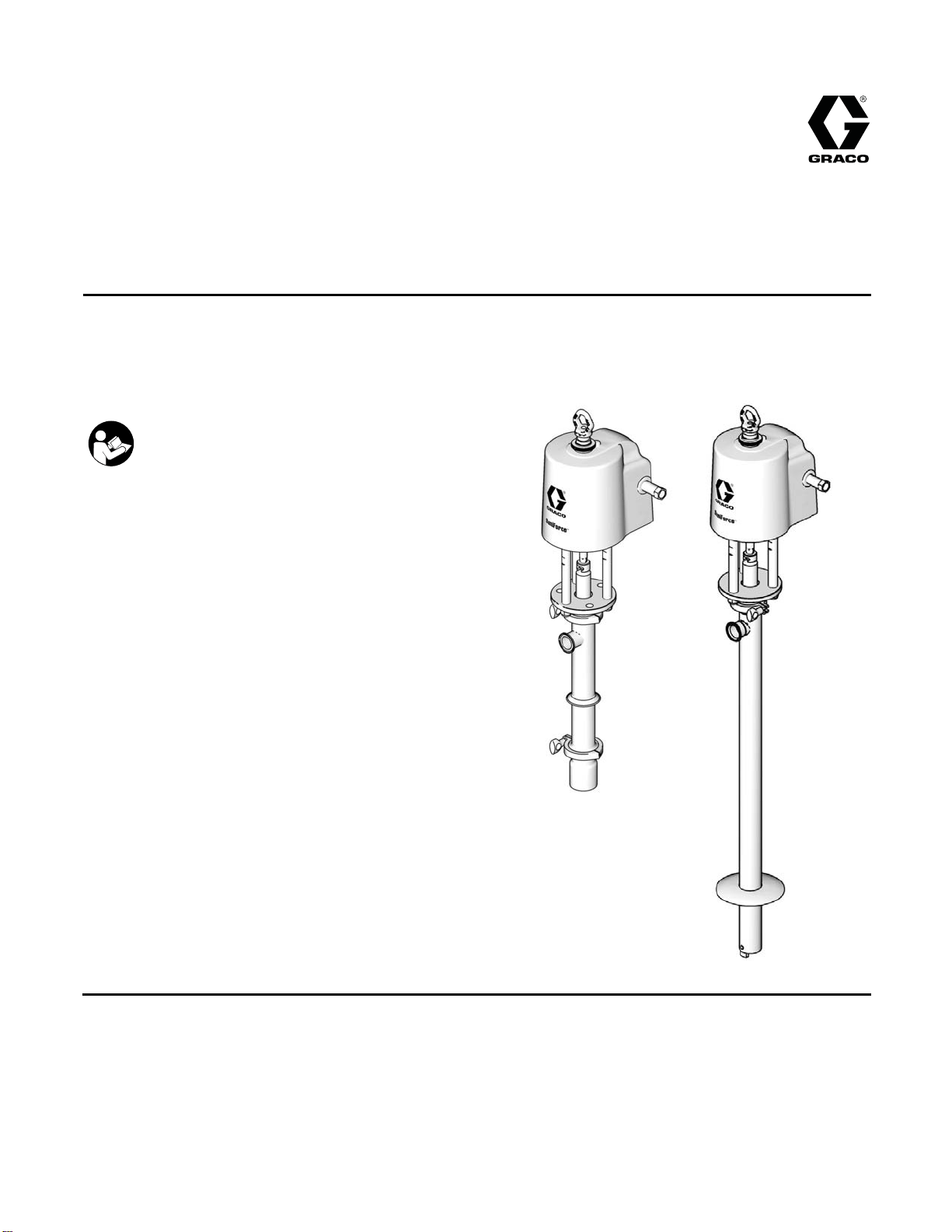

SaniForce™ 6:1

Sanitary

3A0733H

Pumps

For use in sanitary applications to transfer medium to high viscosity fluids. For professional use

only.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

Model 24E836

Model 24G740

EN

PROVEN QUALITY. LEADING TECHNOLOGY.

ti15637a

ti15721a

Page 2

Contents

Models............................................................... 3

Warnings ........................................................... 5

......................................................................... 5

Installation.......................................................... 7

Grounding ................................................... 7

Mounting ..................................................... 7

Setup .......................................................... 7

Operation........................................................... 9

Pressure Relief Procedure............................ 9

Flush Before First Use.................................. 9

Adjusting the Pump Speed and

Pressure ........................................ 9

Pump Shut Down ......................................... 9

Maintenance ...................................................... 10

Flushing Procedure ...................................... 10

Cleaning...................................................... 10

Tighten Threaded Connections..................... 10

Troubleshooting.................................................. 11

Priming P

iston Service ........................................ 12

Disconn

Disasse

ect the Pump ................................... 12

mble the Pump................................. 12

Reassemble After Cleaning .......................... 13

Double Ball Service ............................................ 14

Disconnect the Pump ................................... 14

Disassemble the Pump................................. 15

Reassemble After Cleaning .......................... 15

Parts.................................................................. 16

Kits.................................................................... 17

Priming Piston Displacement Pump Models

24G747 and 24G746 ............................. 18

Double bal

Double-Ball Displacement Pump Models

Notes ............................................................... 24

Product D

Performance chart .............................................. 26

Technical Data ...................................................27

Graco St

l Displacement Pump Models

24G748, 24

24G750 ................................................ 20

24G752 and 24G751 ............................. 22

imensions............................................ 25

andard Warranty.................................... 28

G749, 24G753, and

2

3A0733H

Page 3

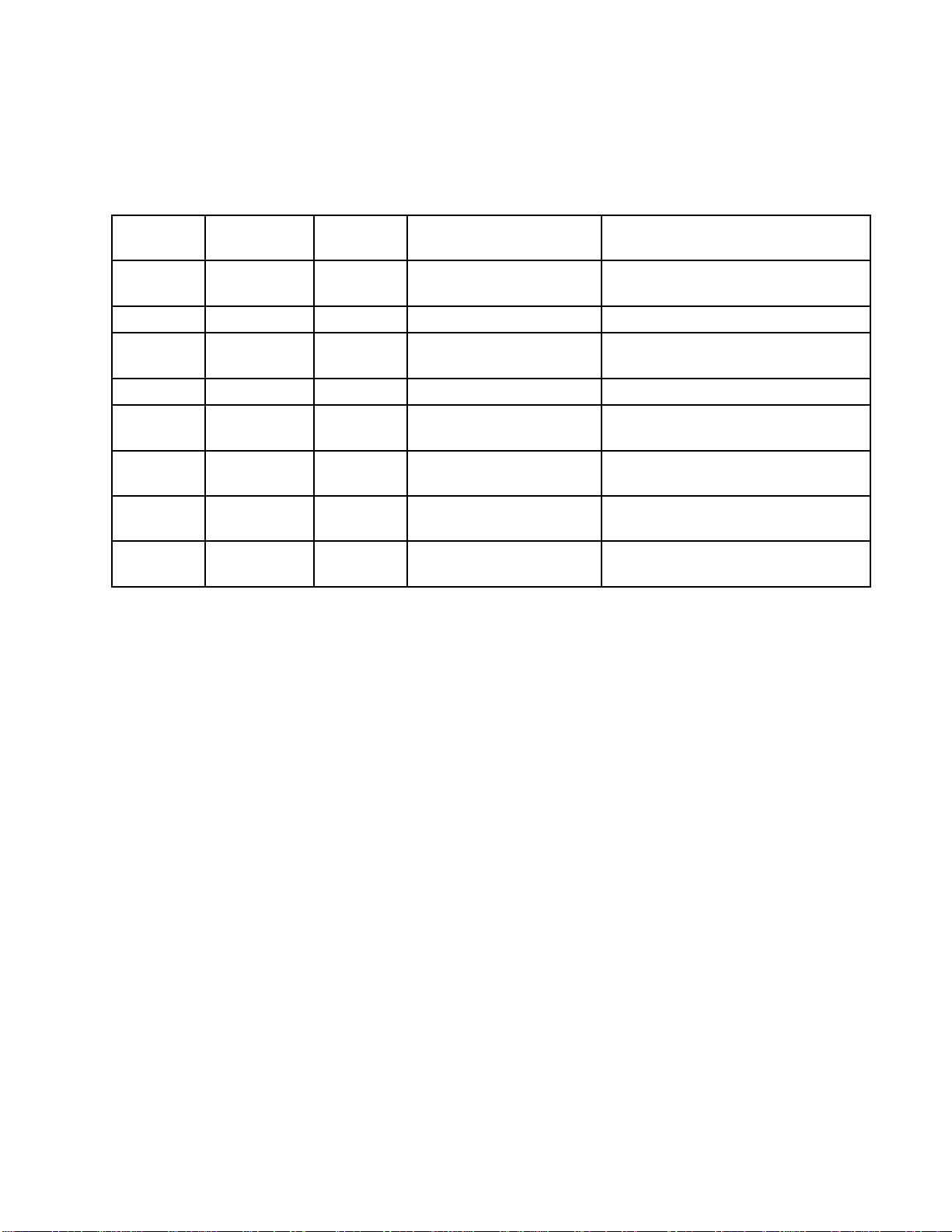

Models

Models

Maximum Air In

let Pressure: 100 psi (0.7 MPa, 6.9 bar)

Maximum Fluid

Pump

Model

24E836

24E837

24E838

24E839

24E840

24F942

24G739 24G747

24G740 24G748

Displacement

Pump Model

24G746

24G751

24G752

24G753

24G749

24G750

Working Pressure: 650 psi (4.5 MPa, 44.8 bar)

Pump Type Pump Length De

Priming

Piston

Double Ball

Double Ball

Double Ball Drum Length PTFE

Double Ball Drum Length Buna-N, Nitrile, Nylon, and

Double Ball Bin Length Buna-N, Nitrile, Nylon, and

Priming

Piston

Double Ball Drum Length, with Flange Buna-N, Nitrile, Nylon, and

Stubby

Stubby

Stubby

Stubby, with Flange

scription

Packings

Buna-N, Nitrile, Nylon, and

Polychloroprene

PTFE

Buna-N, Polychloroprene, and

UHMWPE

Polychloroprene

Polychloroprene

Buna-N,

Polychl

Polychloroprene

Nitrile, Nylon, and

oroprene

3A0733H 3

Page 4

Models

4

3A0733H

Page 5

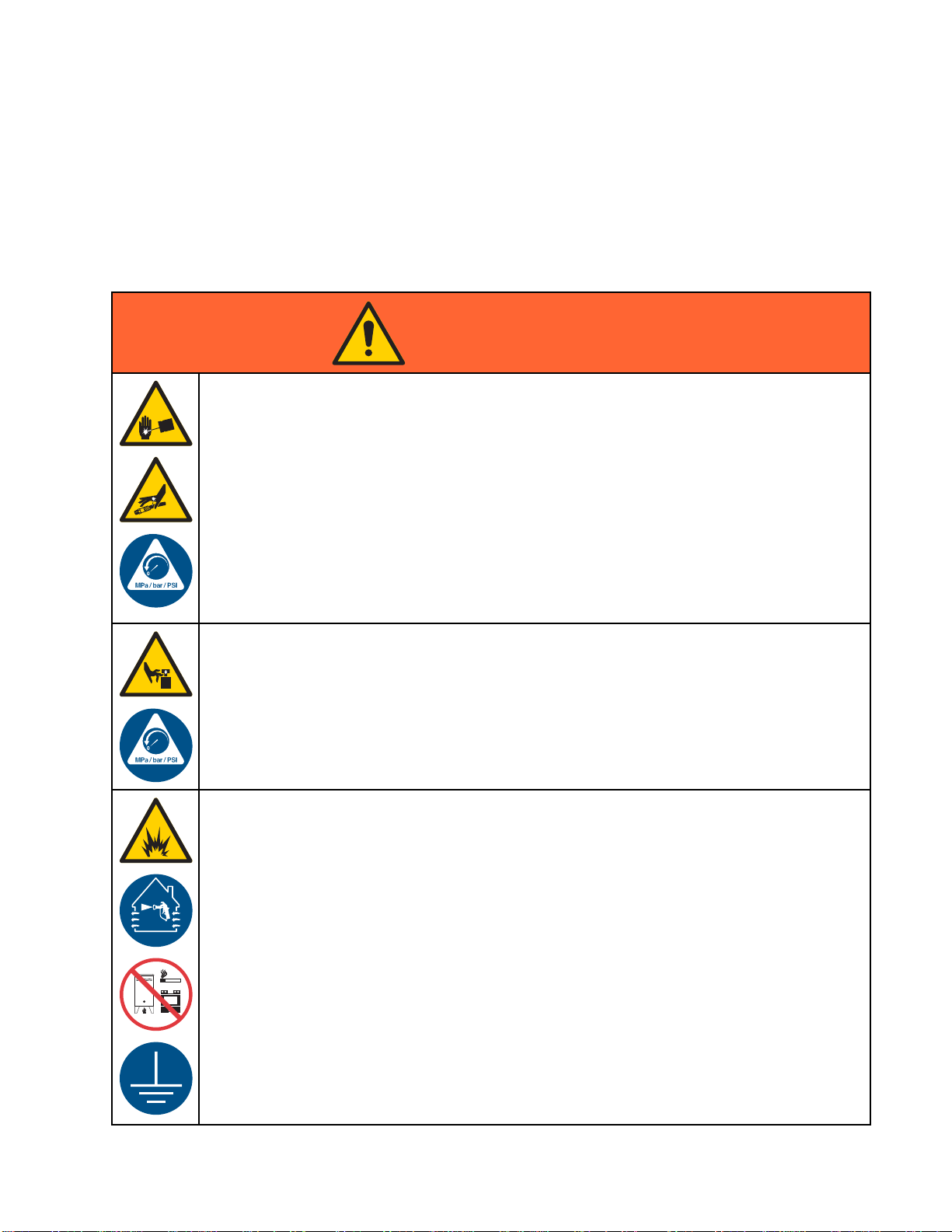

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance and repair of this equipment. The

exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific

risks. When these symbols appear in the body of this manual refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual

where applicable.

WARNING

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce

skin. This many look like just a cut, but it is a serious injury that can result in amputation.

Get immediate surgical treatment.

• Do not point dispensing device at anyone or at any part of the body.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with you hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning,

checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace work or damaged parts immediately.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing

equipment, follow the Pressure Relief Procedure and disconnect all power sources.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help

prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and

plastic drop cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use Only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use

equipment until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

3A0733H 5

Page 6

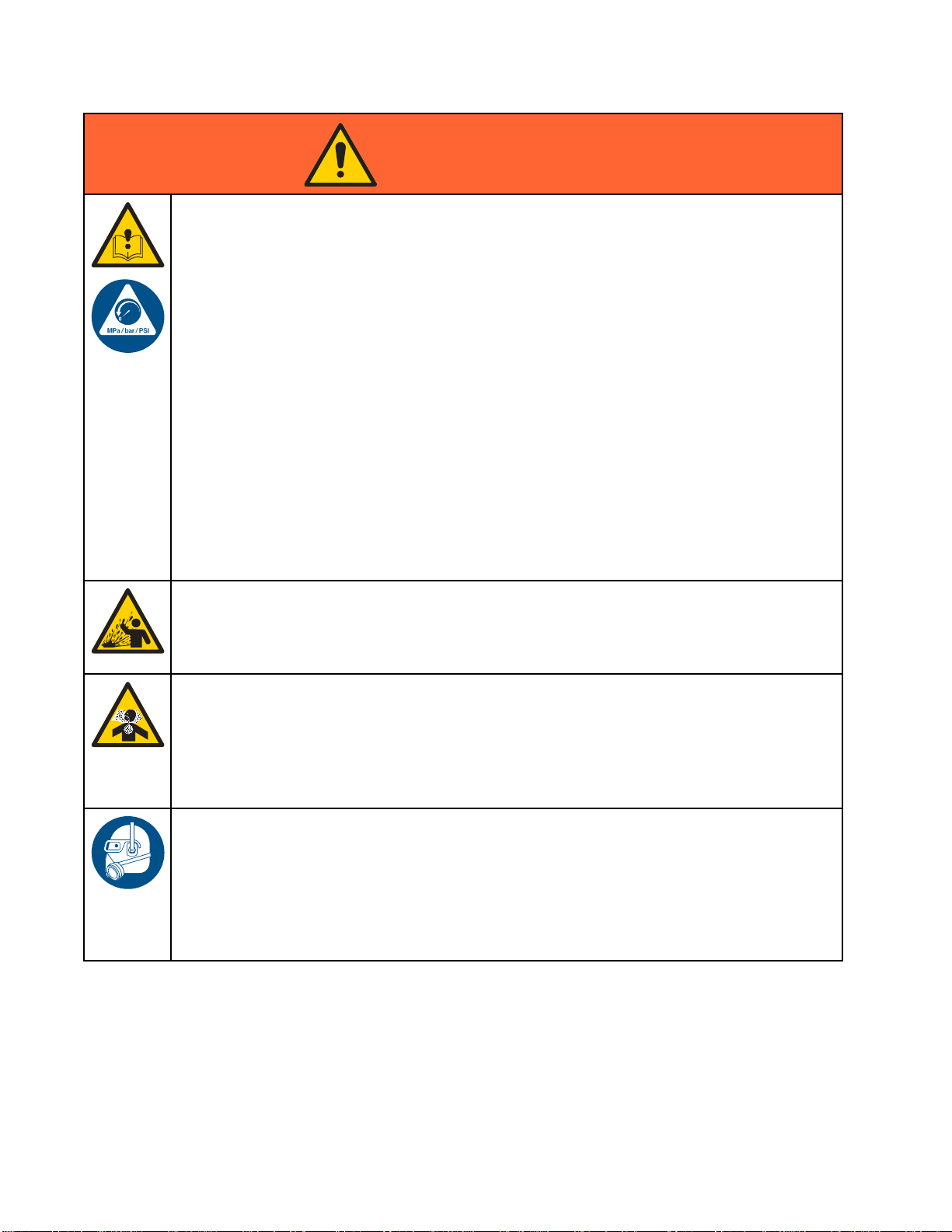

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operat

• Do not exceed the maximum working pressure or temperature rating of the lowest rated

system component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data

in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete

information about your material, request MSDS from distributor or retailer.

• Do not leave

equipment

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equip

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

•Keepchil

• Comply with all applicable safety regulations.

SPLATTER HAZARD

Hot or toxic fluid can cause serious injury if splashed in the eyes or on skin. During blow off of

platen, splatter may occur.

• Use minimum air pressure when removing platen from drum.

TOXIC FLUID OR FUMES

Toxic fluids or fumes can cause serious injury or death if splashed in the eyesoronskin,

inhaled, or swallowed.

e the unit when fatigued or under the influence of drugs or alcohol.

the work area while equipment is energized or under pressure. Turn off all

and follow the Pressure Relief Procedure when equipment is not in use.

ment only for its intended purpose. Call your distributor for information.

dren and animals away from work area.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable

guidelines.

ONAL PROTECTIVE EQUIPMENT

PERS

ust wear appropriate protective equipment when operating, servicing, or when in the

You m

rating area of the equipment to help protect you from serious injury, including eye injury,

ope

ring loss, inhalation of toxic fumes, and burns. This equipment includes but is not limited to:

hea

• Protective eyewear, and hearing protection.

pirators, protective clothing, and gloves as recommended by the fluid and solvent

•Res

ufacturer.

man

6 3A0733H

Page 7

Installation

Installation

Grounding

The equipment must be grounded. Grounding

reduces the risk of static and electric shock by

providing an escape wire for the electrical current

due to static build up or in the event of a short

circuit.

Pump: Connect a ground wire (Graco PN 238909)

to the ground screw on the bottom cover of the air

motor, under the shield. Connect the other end of the

ground wire to a true earth ground.

Air and fluid hoses: use only electrically conductive

hoses with a maximum of 500 ft. (150 m) combined

hose length to ensure grounding continuity. Check

electrical resistance of hoses. If total resistance

to ground exceeds 25 megohms, replace hose

immediately.

Air compressors: follow manufacturer’s

recommendations.

Dispense valve: ground through connection to a

properly grounded fluid hose and pump.

Material supply container: follow local code.

Container(s) that receive material: follow local code.

Solvent pails used when flushing: follow local

code. Use only conductive metal pails, placed on

a grounded surface. Do not place the pail on a

nonconductive surface, such as paper or cardboard,

which interrupts grounding continuity.

To maintain grounding continuity when flushing or

relieving pressure: hold metal part of the dispense

valve firmly to the side of a grounded metal pail, then

trigger the valve.

Mounting

Mount the pump

weight of the p

stress caused

fluid lines to s

To avoid serious injury, check the torque on the lift

ring (19) and nut (18) before using the lift ring to lift

the pump. Torque to 30–36 ft-lb (41–49 N•m).

on a surface than can support the

ump and accessories, as well as the

during operation. Do not use air or

upport the pump.

Setup

To avoid contaminating the fluid, pipe the exhaust

air to vent outside of the fluid product area, away

from people, animals, or food handling areas.

Note

Reference numbers and letters in

parentheses in the text refer to the callouts in

the figures and the parts drawings.

Accessories are available from Graco. Make certain

all accessories are sized and pressure rated to meet

your system requirements.

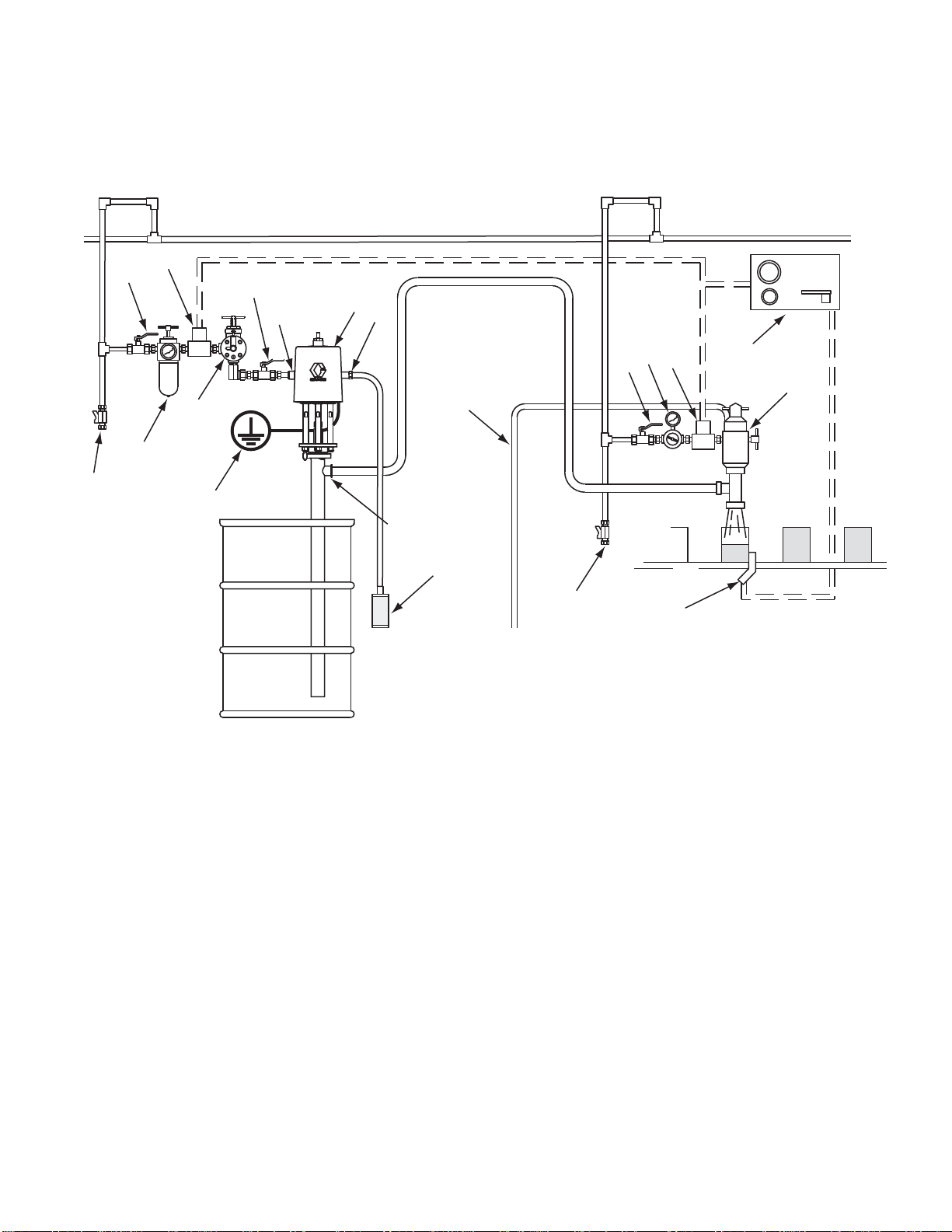

Fig 1 is only a guide for selecting and installing

system components and accessories. Contact your

Graco distributor for assistance in designing a system

to suit your particular needs.

Install a bleed-type master air valve (G) close to the

pump air inlet (D), to relieve air trapped between it

and the air motor.

Install an air filter/regulator (F) in the pump air

line,

upstream from the bleed valve,

air inlet pressure and to remove harmful dirt and

contaminants from your compressed air supply.

to control

3A0733H

Install a pump runaway valve (S) in the pump air line

to shut off air to the air motor automatically if the

pump starts to run too fast.

Install another bleed-type master air valve (G)

upstream from all air line accessories and use it to

isolate the accessories during cleaning and repair.

7

Page 8

Installation

On the air drop to the dispense valve (K), install an

air regulator (M) to control air pressure to the valve.

Install a bleed valve (G) to use as a shutoff when

servicing the dispense valve.

Main Air Line

H

G

G

D

S

F

J

R

A

C

E

Connect air solenoid valves (H) to a timer control

(L), and set so the dispense valve (K) will dispense

at proper intervals.

M

H

G

L

N

B

K

Figure

1 Typical Installation

Key

Pump C

A

B

C 3/4 npt Exhaust Air Outlet

D1/2

E

omponents (Included)

-Mounted Sanitary Pump

Bung

xhaust Muffler (may alternately be mounted

Air E

tely, using exhaust hose)

remo

npt Air Inlet

1-1/2 in. Tube Size Flanged Fluid Outlet

J

m Components/Accessories (sold separately)

Syste

F Air Line Filter/Regulator

GBlee

H

JAir

KDis

L

MAi

NDi

P

R

S

d-Type Master Air Valve (required)

Air Solenoid Valve

Line Drain Pipe and Valve

pensing Valve

Timer Control

r Regulator

spensing Valve Air Exhaust Hose

Sensing Device

Pump Ground Wire (required)

ump Runaway Valve

P

P

TI15638B

8 3A0733H

Page 9

Operation

Operation

NOTICE

Do not expose the air motor to temperatures

higher than 120°F (49°C) or the immersed fluid

pump to temperatures higher than 250°F (121°C).

Excessive temperatures may damage the pump

packings and seals

Pressure Relief Procedure

Trappedaircancausethepumptocycle

unexpectedly, which could result in serious injury

from injection, splashing or moving parts. Relieve

pressure when you stop pumping and before

cleaning, checking, or servicing equipment.

Flushing Procedure, page 10. Check national, state,

and local codes for specific limitations.

Adjusting the Pump Speed and

Pressure

Set pressure regulator to 0 psi. Open the bleed-type

master air valve. Adjust the pump air regulator until

the pump is running smoothly.

Allow the pump to cycle slowly until all air is pushed

out of the lines (the fluid will flow in a steady stream

from the fluid outlet) and the pump is primed.

With the air supply turned on, the pump will start

when the dispensing valve is opened and stall

against pressure when the valve is closed. In a

circulating system, the pump operates until the air

supply is turned off.

NOTICE

Never allow the pump to run dry of fluid. A dry

pump will accelerate to a high speed, possibly

damaging itself.

1. Shut off the air supply to the pump.

2. Close the bleed-type master air valve (required

in system).

3. Open the fluid ball valve and/or dispensing valve

to relieve fluid pressure.

Flush

The sanitary pump was assembled using sanitary

lubricant on moving parts and was tested in

water. Flush the pump thoroughly with an

appropriate cleaning solution or disassemble and

sanitize the parts before using the pump. See

Before First Use

If the pump accelerates quickly, or is running too

fast, stop the pump immediately and check the fluid

supply. If the supply is empty and air has been

pumped into the lines, refill the container and prime

the pump and lines with fluid. Be sure to eliminate all

air from the system.

Pump Shut Down

Follow the Pressure Relief Procedure, page 9 .

Always stop the pump at the bottom of its stroke to

prevent fluid from drying on the displacement rod.

(The air motor will exhaust at the bottom or top of

the stroke.)

3A0733H 9

Page 10

Maintenance

Maintenance

Flushing Procedure

Note:

•Flushbefor

end of the da

equipment

• Flush at the lowest pressure possible. Check

connectors for leaks and tighten as necessary.

• Flush with an appropriate cleaning solution.

1. Remove the pump from the fluid container.

Operate it to pump out as much fluid as possible.

2. Follow the Pressure Relief Procedure, page 9 .

3. Place siphon tube in grounded metal pail

containing an appropriate cleaning solution.

4. Set pump air regulator to lowest possible fluid

pressure, and start pump.

5. Run the pump long enough to thoroughly clean

thepumpandhoses.

6. Follow the .

Cleaning

e fluid can dry in the equipment, at the

y, before storing, and before repairing

.

3. Follow the Pressure Relief Procedure, page 9 .

4. Remove the air and fluid hoses and fittings from

the pump.

5. Ram-Mounted Pumps: Loosen the hand screw

and lift the upper shield straight up on the rod.

Other Pumps: Remove the upper shield.

6. Clean thoroughly the surface between the upper

and lower shields.

7. Disassemble the fluid pump and accessories.

See Priming Piston Service, page 12 or

Double Ball Service, page 14.

8. Wash all pump parts with an appropriate cleaning

solution at the cleaning product manufacturer’s

recommended temperature and concentration.

9. Rinse all pump parts again with water and allow

them to dry.

10. Inspect all pump parts and reclean if needed.

Note

Any damaged rubber parts must

be replaced as they could harbor

microorganisms that can contaminate

the fluid.

11. Immerse all pump parts in an appropriate

sanitizer before assembly. Take the pump parts

out of the sanitizer one-by-one as needed.

12. Lubricate the moving pump parts and o-rings,

packings, and seals with appropriate waterproof

sanitary lubricant.

• Be sur

• Use appropriate cleaning and disinfecting agents,

• Follow cleaning product manufacturer’s

Note

clea

1. Remove the pump from the fluid container.

2. Flush the system thoroughly with an

e to follow your national and state sanitary

ard codes and local regulations.

stand

at intervals appropriate for product processed.

instructions.

: The pump must be disassembled to thoroughly

nit.

Operate it to pump out as much fluid as possible.

appropriate cleaning solution. See

Flushing Procedure, page 10.

13. Circulate the sanitizing solution through the pump

and the system prior to use.

14. Ram-Mounted Pumps: Clean all ram surfaces.

Remove and clean the inflatable seal and ram

plate. See Manual 3A0591.

ten Threaded Connections

Tigh

Before each use, check all hoses for wear or damage.

Replace as necessary. Check that all connections

are tight and leak-free.

10 3A0733H

Page 11

Troubleshootin

Troubleshooting

1. Follow the Pressure Relief Procedure, page 9 .

2. Check all possible remedies in the Troubleshooting Chart before disassembling the pump.

g

Problem

Pump fails to operate.

Pump operates, but output low on

both strokes.

Pump operates, but output low on

down stroke.

Cause Solution

Restricted air line or inadequate air

supply.

Insufficient air pressure; closed or

clogged air valves, etc.

Exhausted fluid supply. Refill fluid supply.

Damaged air motor.

Restricted air line or inadequate air

supply.

Insufficient air pressure; closed or

clogged air valves, etc.

Exhausted fluid supply. Refill fluid supply.

Obstructed fluid line, valves,

dispensing valve, etc.

Worn throat packing (105).

Damaged cylinder o-ring (104).

Held open or worn fluid inlet valve. Clear or service fluid inlet valve.

Damaged cylinder o-ring (104).

Clear air line or increase air supply.

Open or clean air valves, etc.

Service.

Clear air line or increase air supply.

Open or clean air valves, etc.

Clear. Relieve pressure and

disconnect fluid line. Turn on air. If

pump starts, the fluid line is clogged.

Replace throat packing.

Replace o-ring.

Replace o-ring.

Pump operates, but output low on

up stroke.

Erratic or accelerated operation.

3A0733H

Heldopenorwornfluidpistonor

seal (120).

Exhausted fluid supply. Refill fluid supply.

Held open or worn fluid inlet valve. Clear or service fluid inlet valve.

Heldopenorwornfluidpistonor

seal (120).

Clear or service fluid piston or seal.

Clear or service fluid piston or seal.

11

Page 12

Priming Piston S

ervice

Priming Pisto

Disconnect th

ePump

n Service

1. Remove the pump from the fluid container.

Operate it to pump out as much fluid as possible.

2. Follow the Pressure Relief Procedure, page 9 .

3. Ram-mounted pumps: Remove the three clamps

(C) holding the pump to the ram plate. Raise ram

to lift pump.

122

102

117

ti15719a

Figure 3 Remove displacement pump.

Disassemble the Pump

Note: Pum

Purchase

with an *.

p Repair Kit 24G550 is available.

the kit separately. Kit parts are marked

C

123

C

C

C

ti16567a

Figure 2 Remove the clamps.

4. Remove the fluid hoses from the pump.

5. Release the upper clamp (123) holding the

displacement pump to the tie rod plate (122).

6. Slide the pump down from the air motor. Tilt the

pump and pull the displacement rod (117) out of

the coupler (C). Remove the gasket (102).

Note: Be careful not to scratch the displacement

rod.

1. Remove the retaining pin (116) from the

connecting rod (109). Slide off the priming piston

(108).

2. Release the lower clamp (123) to remove the

intake valve housing (107) from the pump

cylinder (101). Remove the gasket (102).

3. Remove the poppet (114), spring (113), and

valve stop (111) off the connecting rod (109).

4. Remove the bearing (112) from the center of the

valvestop(111).

5. Remove the packings (115) from the center of

the poppet (114).

123

111

113

107

115

108

101

109

112

114

102

gure 4 Remove priming piston.

Fi

116

ti15639a

6. Pu

2

1

sh the displacement rod (117) out through the

ttom of the cylinder (101).

bo

3A0733H

Page 13

Priming Piston S

ervice

7. Remove the retaining pin (118), o-ring (119), and

ball (110). Pull the connecting rod (109) from the

displacement rod (117). Remove the seal (120).

117

120

110

109

119

118

Figure 5 Disassemble piston valve.

8. Remove the packing housing (103) from the top

of the cylinder (101). Remove the bearing (106),

packing (105), and o-ring (104).

9. Clean and inspect all parts. Refer to

Cleaning, page 10. Replace the parts as

necessary.

ti15641a

106

104

Note: Lubricate the o-rings, throat packings, and

piston seals with waterproof appropriate sanitary

lubricant.

1. Install the v(106*) in the p

the packing mu

and the lip of

theo-ring(1

2. Install the s

at the top of t

the ball (11

the displac

connecting

Secure with

(119*).

3. Lubricate

the top of t

4. Lubricat

up throug

packing h

Make sure

cylinder

5. Lubrica

center o

block packing (105*) and bearing

acking housing (103). The lips of

st face down into the housing,

the bearing must face up. Install

04*) on the outside of the housing.

eal (120*) on the piston valve housing

he connecting rod (109). Place

0) on the seat of the housing. Install

ement rod (117) over the top of the

rod so the holes in both parts align.

the retaining pin (118) and o-ring

and place the packing housing (103) in

he cylinder.

e and slide the displacement rod (117)

h the cylinder so it protrudes from the

ousing (103). Model 24G746 only:

the drip shield (121) is in place on the

(101).

te and install the packings (115*) into the

f the poppet (114).

105

103

101

117

Figure 6 Remove packing housing.

Reassemble After Cleaning

: Any damaged parts must be replaced.

Note

ti15640a

6. Lubrica

center o

7. Slide t

poppet

8. Instal

9. Insta

10. Slide

l the gasket (102*) and the intake valve

housin

der (101) with the clamp (123).

cylin

ll the priming piston (108) and retaining pin

(116)

, attach the clamp (123) to hold the pump

Then

e motor base.

to th

te and install the bearing (112*) into the

f the valve stop (111).

he valve stop (111), spring (113*), and

(114) onto the connecting rod (109).

g (107). Secure the housing (107) to the

on the connecting rod (109).

the displacement rod (117) into the coupler.

3A0733H 13

Page 14

Double Ball Serv

ice

Double Ball Se

Disconnect th

1. Remove the pump from the fluid container.

Operate it to pump out as much fluid as possible.

2. Follow the Pressure Relief Procedure, page 9 .

3. Ram-mounted pumps: Remove the three clamps

holding the pump to the ram plate. Raise ram

to lift.

ePump

rvice

6. Slide the pump down from the air motor. Tilt the

pump and pull the displacement rod (117) out of

the coupler (C). Remove the gasket (102).

Note: Be caref

rod.

7. Carry the dis

service.

123

102

117

ul not to scratch the displacement

placement pump to the bench for

C

122

C

C

ti16555a

Figure 7 Remove the clamps.

4. Remove the fluid hoses from the pump.

5. Release the clamp (123) holding the

displacement pump to the tie rod plate (122).

C

re 8 Remove displacement pump.

Figu

Flange for

Ram Mounting

ti15720a

4

1

3A0733H

Page 15

Double Ball Serv

ice

Disassemble the Pump

Note: Pump Rep

the kit separa

displacement

displacement

1. Displacement Pump Models 24G748,

24G749, 24G750, and 24G753: Remove

the two o-rings/retaining clips (119) and

the retaining pin (127) from the inlet valve

housing (107). See the parts drawing for

Double ball Displacement Pump Models 24G748,

24G749, 24G753, and 24G750, page 20.

Displacement Pump Models 24G752 and

24G751: Remove the clamp (123) and gasket

(102), then remove the adapter (129). See the

parts drawing for Double-Ball Displacement

Pump Models 24G752 and 24G751, page 22.

2. Remove and disassemble the inlet valve

assembly. Clean and inspect the parts.

3. Push the displacement rod (117) out through the

bottom of the cylinder (101). Remove the piston

housing (124) by removing the retaining pin (118)

and the o-ring/retaining clip (119) and pulling the

piston from the displacement rod. Disassemble,

clean and inspect the parts.

4. Take the packing housing (103) off of the cylinder

(101) and remove the bearing (106), packing

(105), and o-ring (104).

5. Clean and inspect all parts. Refer to

Cleaning, page 10. Replace the parts as

necessary.

air Kits are available. Purchase

tely. See the Parts list for your

pump to select the correct kit for your

pump. Kit parts are marked with an *.

Reassemble Af

Note: Any damaged rubber parts must be replaced

as they could harbor microorganisms that can

contaminate the fluid.

Note: Lubric

piston seals

lubricant.

1. Displacement Pump Models 24G748, 24G749,

24G750, and 24G752: Lubricate and install the

piston seal (120*) on the piston housing (124).

Displacement Pump Models 24G751 and

24G753: Lubricate and install the piston u-cup

(128*) on the piston housing (124). The lips of

the u-cup must face up. Install the spacer (120*)

with its lip facing down.

2. Place the ball (110) on the seat of the piston

housing (124). Install the housing in the

displacement rod (117) so the holes in both parts

align. Secure with the retaining pin (118) and

one o-ring/retaining clip (119*).

3. Install the u-cup packing (105*) and throat

bearing (106*) in the throat packing housing

(103). The lips of the u-cup must face down into

the housing, and the lip of the bearing must face

up. Install the o-ring (104*) on the outside of the

housing.

4. Lubricate and install the throat packing housing

(103) in the top of the cylinder (101).

5. Lubricate and slide the displacement rod (117)

up through the cylinder (101) so it protrudes from

the top.

ate the o-rings, throat packings, and

with waterproof appropriate sanitary

ter Cleaning

6. Install the o-ring (104*) on the intake valve

housing (107). Place the ball (125) on the seat

of the housing (107), and install the ball stop pin

(126) in the top holes of the housing.

7. Displacement Pump Models 24G748, 24G749,

24G750, and 24G753: Lubricate and slide the

intake valve housing (107) up into the cylinder

(101) until the bottom holes of the housing align

with the holes in the cylinder. Secure using the

retaining pin (118) and two o-rings/retaining clips

(119*).

Displacement Pump Models 24G752 and

24G751: Lubricate and slide the intake valve

housing (107) up into the cylinder (101). Install

the gasket (102*), adapter (129), and clamp

(123).

3A0733H 15

Page 16

Parts

Parts

Complete Pump Models

24E836, 24E837, 24E838

24E839, 24E840, 24F942,

24G739, and 24G740

19

20

11

1

21b

5

14

5

3

13

12

6

3

21b

4

22

23

2

10

20

18

1

Apply PTFE tape to threads.

2

Hand tighten only.

3

Apply sanitary lubricant

to ease assembly.

4

Apply medium-strength (blue)

thread locker.

1

3

21a

8

3

7

21c

8

3

4

5

2

5

Apply an appropriate mediumstrength thread locker on the lift

ring (19) and nut (18) every time

it is installed to prevent it from

coming loose during operation.

Torque to 30-36 ft-lb (41-49 N•m).

Do not over tighten.

ti16015a

16 3A0733H

Page 17

Kits

Complete Pump

Models 24E836, 24E837, 24E838, 24E839, 24E840, 24F942,

24G739, and 24G740

Ref.

1

2

3 16A938

4 16A947

5

6

7

8 118134

10

Part

24G785 MOTOR, SaniForce; 3.5 in;

24G747

24G748

24G746

24G751

24G752

24G753

24G749

24G750

102216 NUT, lock, 5/8-11, sst 3

16G464 SHIELD, upper; includes

16G465 SHIELD, lower; includes

24G862 FITTING, air inlet, 1/2 npt,

Description Qty.

see manual 3A1211

DISPLACEMENT PUMP

Used on Pump Model

24G739; see page 18

Used on Pum

24G740; se

Used on Pump Model

24E836; see page 18

Used on Pu

24E837; s

Used on Pump Model

24E838; see page 22

Used on

24E839

Used on Pump Model

24E840; see page 20

Used o

24F94

COUPLER

TIE ROD, 7 in. (178 mm)

between shoulders

grommets (Ref. 21)

fasteners (Ref. 8) and

grommets (Ref. 21)

SCREW, cap; M8 x 1.25, sst

includes Ref. 23

Pump Model

; see page 20

nPumpModel

2; see page 20

p Model

epage20

mp Model

ee page 22

Ref.

1

1

1

3

1

1

11

12 165053

13

14

15

16

17

18

19

20

21

22

23 166702

▲ Replacement Danger and Warning labels, tags, and

cards are available at no cost.

‡

Used on Models 24E836, 24E837, 24E838, 24E839,

Part

16C946 FITTING, 3/4 npt

16C306

16C009 RING, lift

‡

280574 LABEL, warning, not shown 1

▲

102218

‡

‡

166130

680454

512914 MUFFLER;

‡

‡

‡

—

101818

—

16G084 FITTING, air inlet, 1/2 npt

Description Qty.

O-RING, PTFE

NUT, hand 1

CLAMP, toggle, fluid outlet;

not shown

GASKET, fluid outlet; not

shown

Buna-N,usedonpump

models 24E836, 24E838,

24E840, and 24F942

PTFE,usedonpumpmodels

24E837 and 24E839

see Kits

HOSE, exhaust;

CLAMP, hose;

GROMMET;

O-RING, air inlet, buna-n,

included with Ref. 10

see Kits

see Kits

see Kits

24E840, and 24F942 only. These parts are not used

with Models 24G739 and 24G740.

4

1

1

1

1

1

1

1

1

2

6

1

1

Kits

Muffler Kit 16G390

Ref.

18 512914 MUFFLER, polyethylene 2

Exhaust Assembly Kit 16G389

Ref.

18 512914 MUFFLER, polyethylene 1

19

20 101818

3A0733H

Part Description

Part Description

—

HOSE, exhaust, 6 ft.

CLAMP, hose

Qty.

Qty.

1

2

Grommet Kit 16G628

Ref.

21a*

21b

21c

* Order Kit 16H925 for qty. 3 of the piston rod grommet.

Part Description

—

—

—

GROMMET, air motor

piston rod

GROMMET, air fitting

GROMMET, tie rod

Qty.

1

2

3

Shield Fastener Kit 16G432

Ref.

8 118134

Part Description

SCREW, cap, M8 x 1.25,

sst

Qty.

4

17

Page 18

Priming Piston D

isplacement Pump Models 24G747 and 24G746

Priming Pisto

and 24G746

122

123

1

*102

3

*106

1

2

*105

1

103

1

*104

101

(24G747)

n Displacement Pump Models 24G747

1

117

1

119*

118

101

(24G746)

110

1

121

*113

120*

109

1

Apply appropriate waterproof,

sanitary lubricant.

Throat v-packing lips must

2

face DOWN.

Bearing lip must face up.

3

107

(24G747)

116

1

*115

111

112*

114

108

1

102*

123

(24G746)

ti16157a

1

107

18 3A0733H

Page 19

Priming Piston D

isplacement Pump Models 24G747 and 24G746

Priming Piston Displacement Pump Models 24G747 and 24G746

Ref. Part

101 902980

102*

103 180918

104*

105*

106*

107

108 195214

109

110 103462

111 195215

112*

166117

166119

180238

180919

16C193 Model 24G747

195213

16C195 ROD, connecting

604016

Description

CYLINDER, pum

GASKET, 2 1/2 i

buna-n

HOUSING, packing

O-RING, buna-n

V-PACKING, buna-n

BEARING, sleeve

HOUSING, inlet valve

Model 24G746

PISTON, priming

BALL, 3/4 in. (19 mm),

stainless steel

STOP, inlet valve

BEARING, priming piston

p

n. (64 mm),

113*

Qty.

1

114 604018

2

115*

1

116 604008 PIN, retain

1

117 902983

1

118 169845 PIN, retain

1

119*

1

120*

121 166129

122 16A945 PLATE, tie rod 1

1

123 620223

1

130 172687

1

1

*Partsi

1

501095

603778

167972

167971

SPRING, ball c

POPPET, inlet

PACKING, inl

neoprene

ROD, displacement

O-RING

SEAL, piston, neoprene

SHIELD, drip; Model 24G746

only

CLAMP, 2

TAG, Ins

ncluded in Repair Kit 24G550.

heck

valve

et valve,

ing, priming piston

er

1/2 in. (64 mm)

truction, not shown

1

1

2

1

1

1

1

1

1

2

1

3A0733H 19

Page 20

Double ball Disp

lacement Pump Models 24G748, 24G749, 24G753, and 24G750

Double ball Di

splacement Pump Models 24G748,

24G749, 24G753, and 24G750

122

123

*102

1

4

*106

1

2

*105

1

103

1

*104

101 (24G748)

101

(24G749,

24G750,

24G753)

117

1

Flange for

Ram Mounting

121

Piston

Assy

(24G748,

24G749,

24G750)

110

1

*120

1

119*

Piston

Assy

(24G753)

110

120*

128*

5

1

3

1

119*

124

118

1

Apply appropriate waterproof,

sanitary lubricant.

Throat v-packing/u-cup lips must

2

face DOWN.

3

Piston u-cup lips must face UP.

4

Bearing lip must face UP.

5

Spacer lips must face DOWN.

1

*119

126

118

125

104*

107

127

124

1

ti16158a

20 3A0733H

Page 21

Double ball Disp

lacement Pump Models 24G748, 24G749, 24G753, and 24G750

Double-Ball Displacement Pump

Models 24G748

, 24G749, and

24G750

Ref

101

102*

103 180918

104*

105*

106*

107 167970

110 103462

117

118 169845 PIN, re

119*

120*

121 1661

122 16A945 PLATE, tie rod 1

123 620223

124 169846

125 103869 BALL, bearing, 1 1/4

126 169626 PIN, ball stop; straight,

127 167968 PIN, retaining, intake

130 172687

Part Description

CYLINDER, pum

16G481 Model 24G748

207551

16G482 Model 24G75

166117

166119

180238

180919

207552

16F986

16797

16797

Models 24G74

GASKET, 2.5

mm), buna-n

HOUSING, packing

PACKING, o-ring;

buna-n

V-PACKING, buna-n

BEARING, sleeve

HOUSING, inlet valve

BALL, 3/4 in. (19 mm ),

stainless steel

ROD, displacement

Models 24G748, and

24G749

Model 24G750

taining, piston

ng

housi

2

O-RING

1

SEAL, piston,

neoprene

29

SHIELD, drip; Models

24G749 and 24G750

only

CLAMP, 2.5 in. (64

mm)

OUSING, piston

H

in. (32 mm), stainless

steel

headless

valve

TAG, instruction, not

shown

p

9

0

in. (65

Qty

1

1

1

2

1

1

1

1

1

1

3.

1

1

1

1

1

1

1

1

Double ball Displacement Pump

Model 24G753

Ref

101 207551

102*

103 180918

104*

105*

106*

107 167970

110 103462

117 207552

118 169845 PIN, ret

119*

120*

121 166129

122 16A945 PLATE,

123 620223

124 605837

125 103869 BALL, bearing, 1 1/4

126 1696

127 625916 PIN, retaining, intake

128*

130 172687

* Parts included in Repair Kit 24G547.

Part Description

CYLINDER, pum

502598

164846

605753

605752

551008

605756

605754

GASKET, 2.5 in

mm) dia.; PTF

HOUSING, packing

PACKING, o-ring;

PTFE

U-CUP, PTFE

BEARING, sleeve;

PTFE

HOUSING, inlet valve

BALL, 3/4 in. (19 mm ),

stainless steel

ROD, displacement

aining, piston

housing

RETAINING RING, sst

SPACER, PTFE

SHIELD, drip

tie rod

CLAMP, 2.5 in. (64

mm)

HOUSING, piston

in. (32 mm), stainless

steel

26

ball stop; straight,

PIN,

less

head

valve

U-CUP, piston, PTFE

TAG, instruction, not

shown

.(65

E

Qty

p

1

1

1

2

1

1

1

1

1

1

3.

1

1

1

1

1

1

1

1

1

1

* Parts included in Repair Kit 24G546 .

3A0733H

21

Page 22

Double-Ball Dis

placement Pump M odels 24G752 and 24G751

Double-Ball D

24G751

122

123

1

*102

4

*106

1

103

1

2

*105

*104

1

101

isplacement Pump Models 24G752 and

1

117

Piston

Assy

(24G752)

110

*120

1

118

Piston

Assy

(24G751)

110

120*

128*

124

5

1

3

1

121

1

Apply appropriate waterproof,

sanitary lubricant.

Throat u-cup lips must

2

face DOWN.

3

Piston u-cup lips must face UP.

4

Bearing lip must face UP.

5

Spacer lips must face DOWN.

118

126

119*

125

104*

107

102*

123

129

ti16160a

1

1

2

2

3A0733H

Page 23

Double-Ball Dis

placement Pump Models 24G752 and 24G751

Double-Ball Displacement Pump

Models 24G752

Ref

101 902980

102*

103 180918

104*

105*

106*

107 902979

110 103462

117 902981

118 169845 PIN, retaining, piston

119*

120 622142

121 166129

122 16A945PLATE, tie rod 1

123 620

4

12

25

1

126 169626 PIN, ball stop; straight

129 511192

130 172687

* Parts included in Repair Kit 24G548.

Part Description

CYLINDER, pu

166117

166119

178140

623059

167972

9846

16

03869BALL, bearing, 1.25 in.

1

GASKET, 2.5

mm), buna-n

HOUSING, pa

O-RING; bu

U-CUP, UH

BEARING,

HOUSING

BALL, 3

stainl

ROD, di

housing

O-RING

SEAL, piston, UHMWPE

SHIELD, drip

223

CLAMP, 2.5 in. (64 mm)

HOUSING, piston

32 mm), stainless steel

(

headless

ADAPTER, ferrule

TAG, instruction, not

shown

/4 in. (19 mm ),

ess steel

splacement

mp

in. (64

cking

na-n

MWPE

sleeve

,inletvalve

Qty

1

2

1

2

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

Double-Ball Displacement Pump

Model 24G751

Ref

101 902980

102*

103 180918

104*

105*

106*

107 902979

110 103462

117 902981

118 169845 PIN, retaining, piston

119*

120 605756

121 1661

122 16A

123 620223

124 605837

125 103869 BALL, bearing, 1.25 in.

126 169626 PIN, ball stop; straight

128*

129 511192

130 172687

Part Description

CYLINDER, pu

502598

166119

605753

623059

551008

5

605754

GASKET, 2.5

mm), PTFE

HOUSING, pa

O-RING; PT

U-CUP; PT

BEARING,

HOUSING

BALL, 3

stainl

ROD, di

housing

RETAINING RING, sst

SPACER, PTFE

29

SHIELD, drip

94

PLA

CL

HO

(32 mm), stainless steel

headless

U-CUP, piston, PTFE;

Model 24G751 only

ADAPTER, ferrule

TAG, instruction, not

shown

/4 in. (19 mm ),

ess steel

splacement

TE, tie rod

AMP, 2.5 in. (64 mm)

USING, piston

mp

in. (64

cking

FE

FE

sleeve

,inletvalve

Qty

1

2

1

2

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

* Parts included in Repair Kit 24G549.

3A0733H 23

Page 24

Notes

Notes

4

2

3A0733H

Page 25

Product Dimensions

Product Dimensi

ons

Stubby Length

A

B

C

ti15637a

D

Drum and Bin Length

A

B

C

ti15721a

D

cm)

in. (

l

Mode

24E836

24G739 35 (16)

24E837

24E838

24G740 38 (17)

24E839

24E840

24F942

ht

Weig

g)

lb (k

34 (15)

37 (17)

29 (13)

37 (17)

37 (17)

40 (18)

D

in. (

B

cm)

C

in. (cm)

Pump Style

Priming Piston Stubby 40.1 (102)* 20.6 (52)* 16.0 (41)* 2.5 (6.4)

Double ball, Stubby 39.2 (100) 19.7 (50) 15.1 (38) 2.0 (5.1)

Double Ball, Drum Length

Double ball, Bin Length

A

cm)

in. (

60.5 (154) 41.0 (104) 36.4 (92) 2.0 (5.1)

73.0 (185) 53.5 (136) 48.9 (124) 2.0 (5.1)

* Add 2.5 in. (6.3 cm) for priming piston models to allow for full extension of the priming piston rod.

3A0733H 25

Page 26

Performance cha

rt

Performance c

0

700

(4.8, 48)

600

(4.1, 41)

500

(3.4, 34)

400

(2.8, 28)

300

(2.1, 21)

A

B

C

hart

Cycles per Minute

15 30

45 60

A

C

B

35

(1.0)

30

(0.85)

25

(0.71)

20

(0.57)

15

(0.42)

/min)

3

200

(1.4, 14)

100

Fluid Outlet Pressure psi (MPa, bar)

(0.7, 7)

0

0

1.0

(3.8)

2.0

(7.6)

3.0

(11.4)

4.0

(15.1)

Fluid Flow gpm (lpm) tested in No. 10 weight oil

A = 100 psi (0.7 MPa, 7 bar)

B = 70 psi (0.5 MPa, 5 bar)

C = 40 psi (0.3 MPa, 3 bar)

= uid ow

= air consumption

10

(0.28)

5

(0.14)

Air Flow scfm (m

26 3A0733H

Page 27

Technical Data

Technical D ata

Maximum Fluid

Maximum Air Inlet Pressure

Maximum Recommended Pump Speed 60 cycles/min, 4 gpm (15 liters/min) delivery

Air Consumption

Pump Cycle

Ratio 6:1

Maximum Fluid Temperature

Maximum Ambient Temperature (Air

Motor)

Air Inle

Air Exhaust

Fluid Inlet Type

Fluid Outlet 1-1/2 in. (3.8 cm) Tri-clamp®

t

Working Pressure

s per Gallon (3.8 Liters)

24E837, 24E838

39 and 24E840

24E8

650 psi (4.5 MPa, 44.8 bar)

100 psi (0.7 M

Pa, 6.9 bar)

See Performance Chart

13.3

250°F (12

120°F (49°C)

1/2 npt (f)

3/4 npt

24E836

24G

24G740 1.44 in. (3.6 cm) Slotted with flange for 6 in. (15.2 cm) Clamp

2.3 in

2.5 in. (6.3 cm) Clamp

1.44 in. (3.6 cm) Slotted

739

2.3

1°C)

(m)

(5.8 cm) Priming Piston

in (5.8 cm) Priming Piston with flange for 6 in. (15.2 cm) Clamp

Weight

Wetted Parts

Sound data

Sound power*

Sound pressure**

* Sound power at 70 psi (0.48 MPa, 4.8 bar), 20 cpm. Sound power measured per ISO-9614-2.

** Sound pressure was tested 3.28 feet (1 m) from equipment.

ee Dimensions, page 25

S

316 Stainless Steel, Buna-N, Polychloroprene, Nitrile, Nylon,

UHMWPE. Certain models have PTFE packings.

78.5 dBA

71.6 dBA

3A0733H

27

Page 28

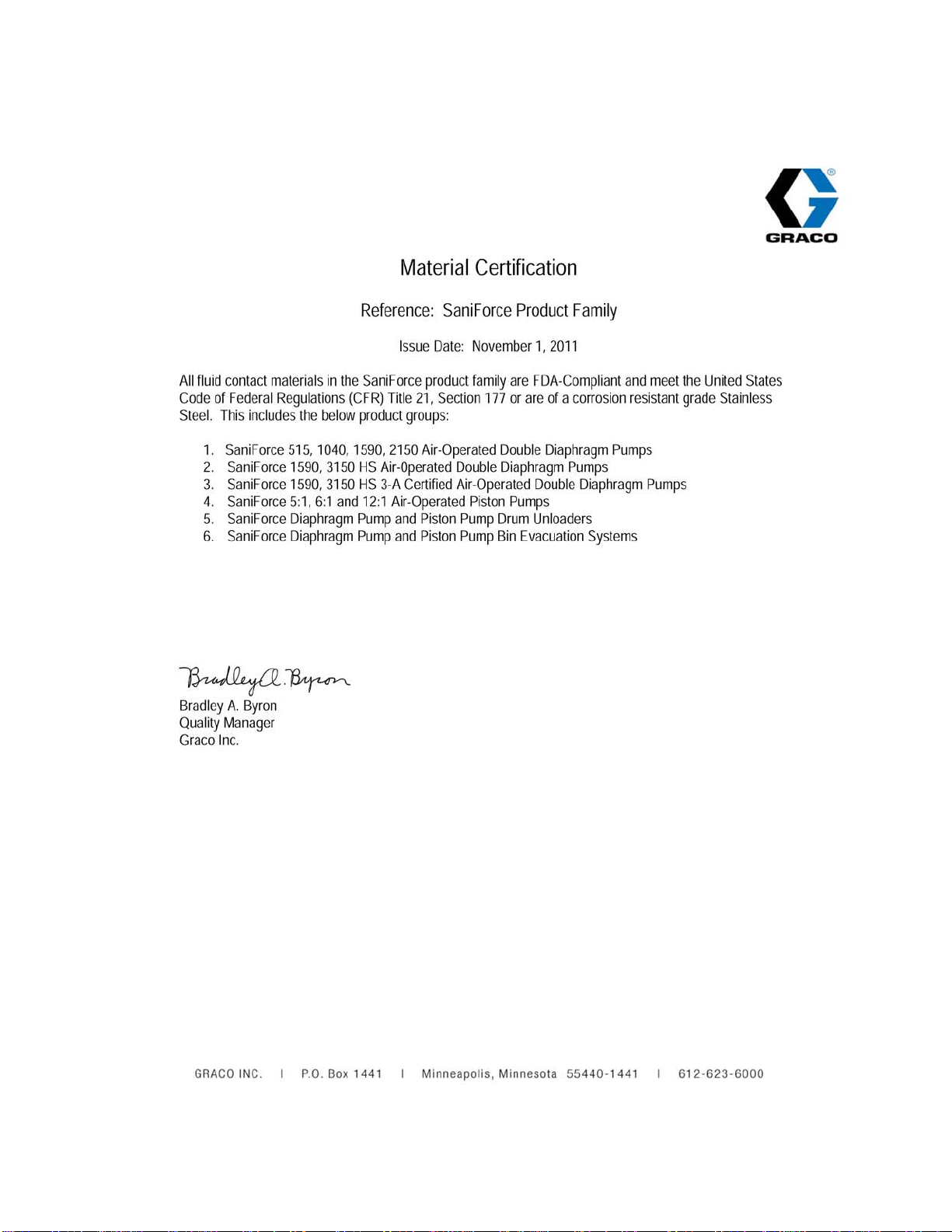

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its

name to be free from defects in material and workmanship on the date of sale to the original purchaser for

use. With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a

period of twelve months from the date of sale, repair or replace any part of the equipment determined

by Graco to be defective. This warranty applies only when the equipment is installed, operated and

maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction,

damage or wear caused by faulty installation, misapplication, abra

maintenance, negligence, accident, tampering, or substitution of non-Graco component parts. Nor shall

Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment

with structures, accessories, equipment or materials not suppli

manufacture, installation, operation or maintenance of structures, accessories, equipment or materials

not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an

authorized Graco distributor for verification of the claimed defect. If the claimed defect is verified, Graco

will repair or replace free of charge any defective parts. The equipment will be returned to the original

purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material

or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of

parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING BUT NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY

OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above.

The buyer agrees that no other remedy (including, but not limited to, incidental or consequential damages

for lost profits, lost sales, injury to person or property, or any other incidental or consequential loss) shall

be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, IN CONNECTION WITH

ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT MANUFACTURED BY

GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.),

are subject to the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable

assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from

Graco supplying equipment hereunder, or the furnishing, performance, or use of any products or other

goods sold hereto, whether due to a breach of contract, breach of warranty, the negligence of Graco, or

otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents,

notices and legal proceedings entered into, given or instituted pursuant hereto or relating directly or

indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du

présente document sera en Anglais, ainsi que tous documents

donnés ou intentés, à la suite de ou en rapport, directement ou indirectement, avec les procédures

concernées.

sion, corrosion, inadequate or improper

ed by Graco, or the improper design,

, avis et procédures judiciaires exécutés,

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

To place an order, contact your Graco Distributor or call to identify the neare

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

written and visual data contained in this document reflects the latest product information available at the time of publication.

All

Graco reserves the right to make changes at any time without notice.

Original Instructions. This manual contains English. MM 3A0733

International Offices: Belgium, China, Japan, Korea

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2014, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco Headquarters: Minneapolis

www.graco.com

Revision H, December 2014

st distributor.

Loading...

Loading...