Page 1

Instructions/Parts

®

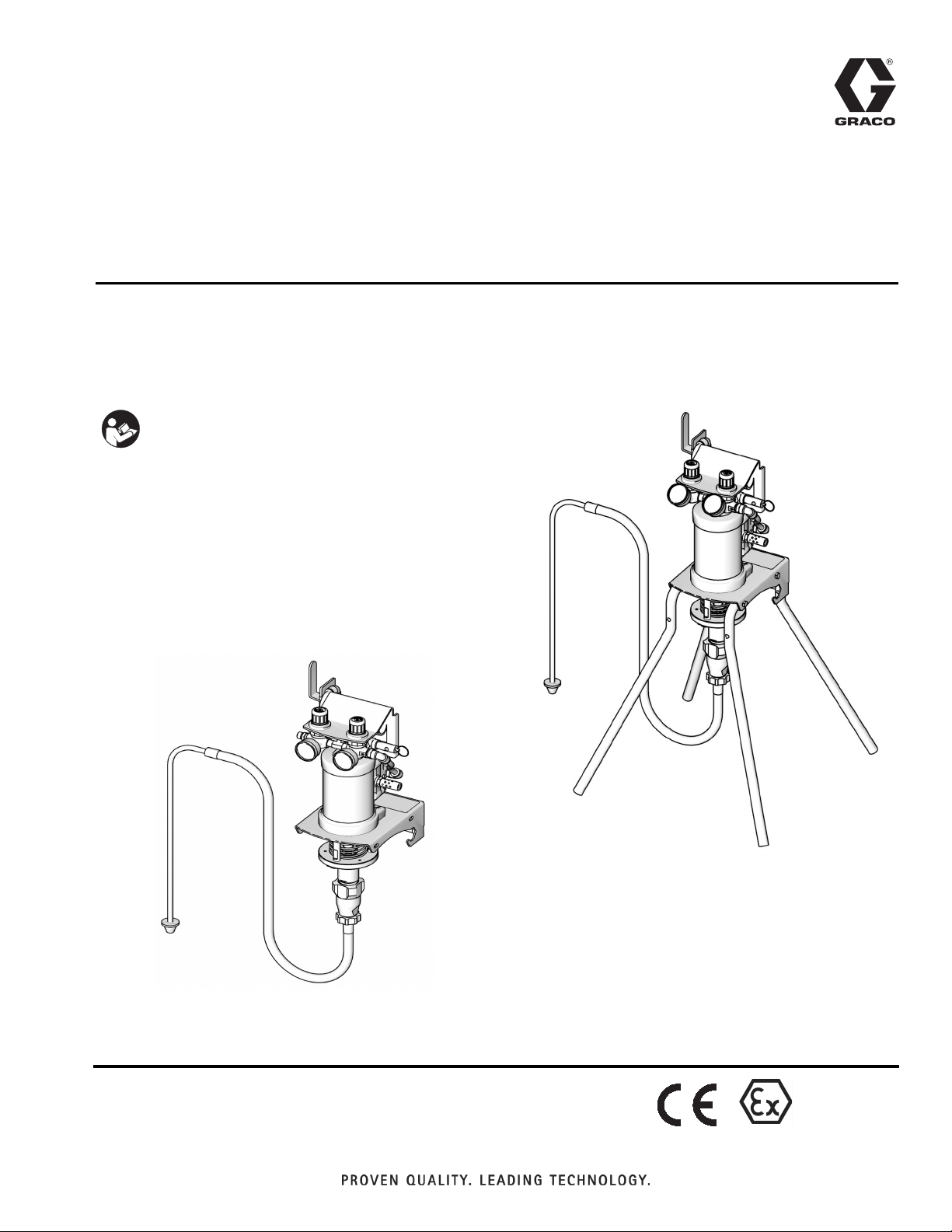

Merkur

ES

Spray Packages

For low-volume fine finish spray applications. For professional use only.

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

15:1 Spray Packages

30:1 Spray Packages

3A0732J

EN

100 psi (0.7 MPa, 7.0 bar) Maximum Air Inlet Pressure

See page 3 for model information, including maximum fluid

working pressure.

ti15589a

ti15590a

II 2 G c T5 X

Page 2

Contents

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Prepare the Operator . . . . . . . . . . . . . . . . . . . . . 7

Prepare the Site . . . . . . . . . . . . . . . . . . . . . . . . . 7

Supplied Components . . . . . . . . . . . . . . . . . . . . . 7

Inline Fluid Filter Kits . . . . . . . . . . . . . . . . . . . . . . 7

Air Line Accessories . . . . . . . . . . . . . . . . . . . . . . 7

Wall Mount Packages . . . . . . . . . . . . . . . . . . . . . 8

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Flush Before Using Equipment . . . . . . . . . . . . . . 8

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Pressure Relief Procedure . . . . . . . . . . . . . . . . 10

Trigger Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Prime the Pump . . . . . . . . . . . . . . . . . . . . . . . . 10

Install the Spray Tip . . . . . . . . . . . . . . . . . . . . . 11

Adjust the Atomization . . . . . . . . . . . . . . . . . . . 11

Adjust the Spray Pattern . . . . . . . . . . . . . . . . . . 12

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Tighten Threaded Connections . . . . . . . . . . . . . 13

Flush the Pump . . . . . . . . . . . . . . . . . . . . . . . . . 13

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

General Information . . . . . . . . . . . . . . . . . . . . . . 15

To Remove Intake Valve Only . . . . . . . . . . . . . . 15

Disconnect the Displacement Pump . . . . . . . . . 15

Disassemble the Pump . . . . . . . . . . . . . . . . . . . 16

Reassemble the Pump . . . . . . . . . . . . . . . . . . . 16

Reconnect the Displacement Pump . . . . . . . . . 16

Repair Air Valve . . . . . . . . . . . . . . . . . . . . . . . . . 18

Replace Pilot Valves . . . . . . . . . . . . . . . . . . . . . 20

Disconnect the Air Motor . . . . . . . . . . . . . . . . . . 21

Reconnect the Air Motor . . . . . . . . . . . . . . . . . . 21

Repair Air Motor . . . . . . . . . . . . . . . . . . . . . . . . 22

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Package Parts . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Hose and Gun . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Displacement Pump Parts . . . . . . . . . . . . . . . . . 30

Air Motor Parts . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Air Valve Parts . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Air Control Parts . . . . . . . . . . . . . . . . . . . . . . . . 36

Kits and Accessories . . . . . . . . . . . . . . . . . . . . . . . 38

Package Dimensions . . . . . . . . . . . . . . . . . . . . . . . 39

Package Weights . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Wall Bracket Mounting Hole Diagram . . . . . . . . . 40

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Performance Charts . . . . . . . . . . . . . . . . . . . . . . . . 42

15:1 Ratio Pumps . . . . . . . . . . . . . . . . . . . . . . . 42

30:1 Ratio Pumps . . . . . . . . . . . . . . . . . . . . . . . 43

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 44

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 44

2 3A0732J

Page 3

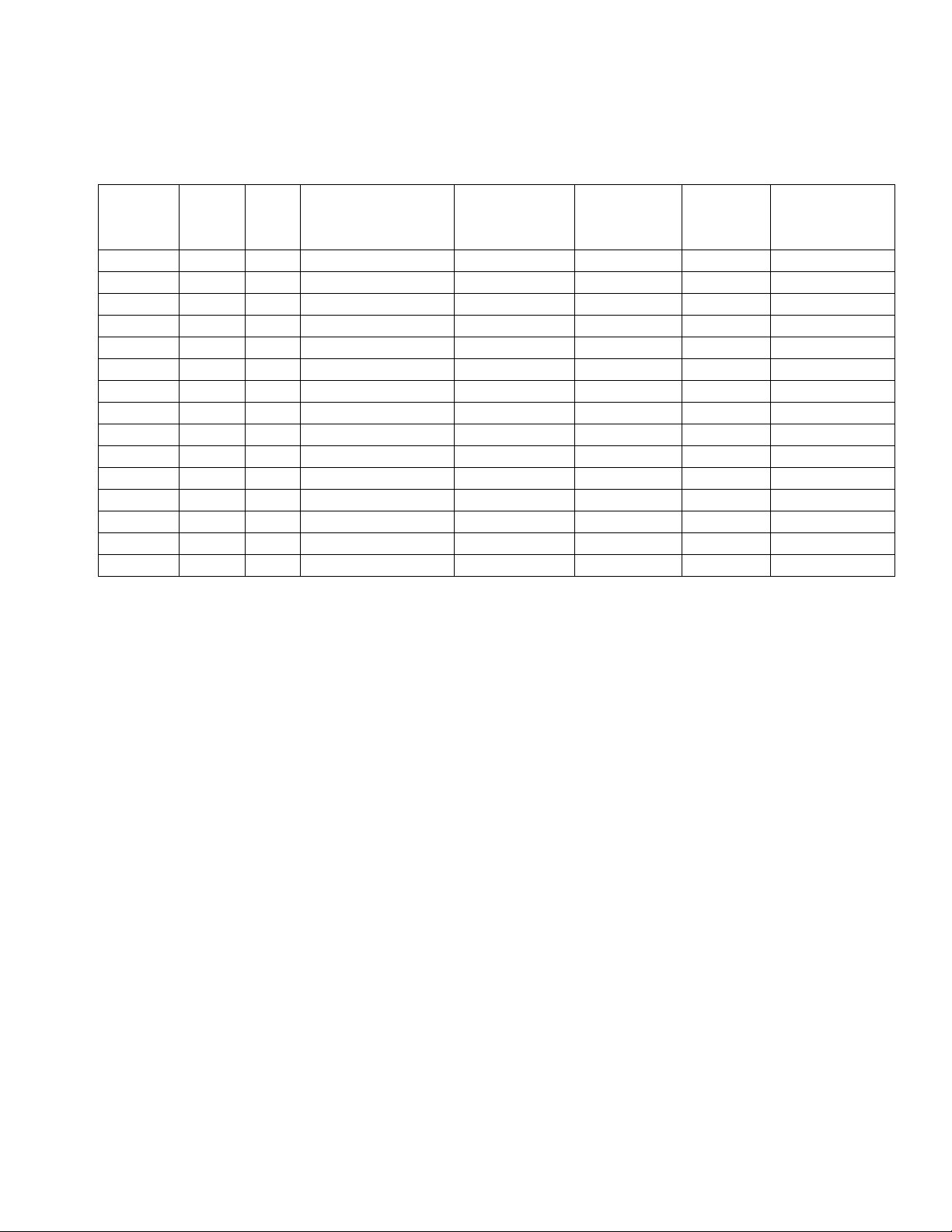

Models

Models

Maximum Fluid

Working Pressure

Package Series Ratio

24F150 A 15:1 1500 (10.3, 103) Air-assisted G15 Carbide Wall Plated Steel

24F151 A 15:1 1500 (10.3, 103) Air-assisted G15 Carbide Stand Plated Steel

24F152 A 30:1 3000 (20.7, 207) Air-assisted G40 Wall Stainless Steel

24F153 A 30:1 3000 (20.7, 207) Air-assisted G40 Stand Stainless Steel

24F154 A 30:1 3000 (20.7, 207) Airless Silver Plus Wall Plated Steel

24F155 A 30:1 3000 (20.7, 207) Airless Silver Plus Stand Plated Steel

24F156 A 30:1 3000 (20.7, 207) Air-assisted G40 Wall Plated Steel

24F157 A 30:1 3000 (20.7, 207) Air-assisted G40 Stand Plated Steel

24F158 A 15:1 1500 (10.3, 103) Air-assisted G15 Carbide Wall Stainless Steel

24F159 A 15:1 1500 (10.3, 103) Air-assisted G15 Carbide Stand Stainless Steel

24N548* A 30:1 3000 (20.7, 207) WB3000 ----- ----- Stainless Steel

24W281 A 15:1 1500 (10.3, 103) Air-assisted G15 Carbide Stand Plated Steel

24W283 A 15:1 1500 (10.3, 103) Air-assisted G15 Carbide Stand Stainless Steel

24W285 A 30:1 3000 (20.7, 207) Air-assisted G40 Stand Plated Steel

24W287 A 30:1 3000 (20.7, 207) Air-assisted G40 Stand Stainless Steel

psi (MPa, bar)

Package Type Gun Mounting Material

* Part No. 24N548 is used as a supply pump in the WB3000 Waterborne Isolation System. It includes a pump

bracket and items 7-19, 21, 23, and 28-42 on page 25. See manual 3A2497 for warnings and instructions for a

waterborne system.

3A0732J 3

Page 4

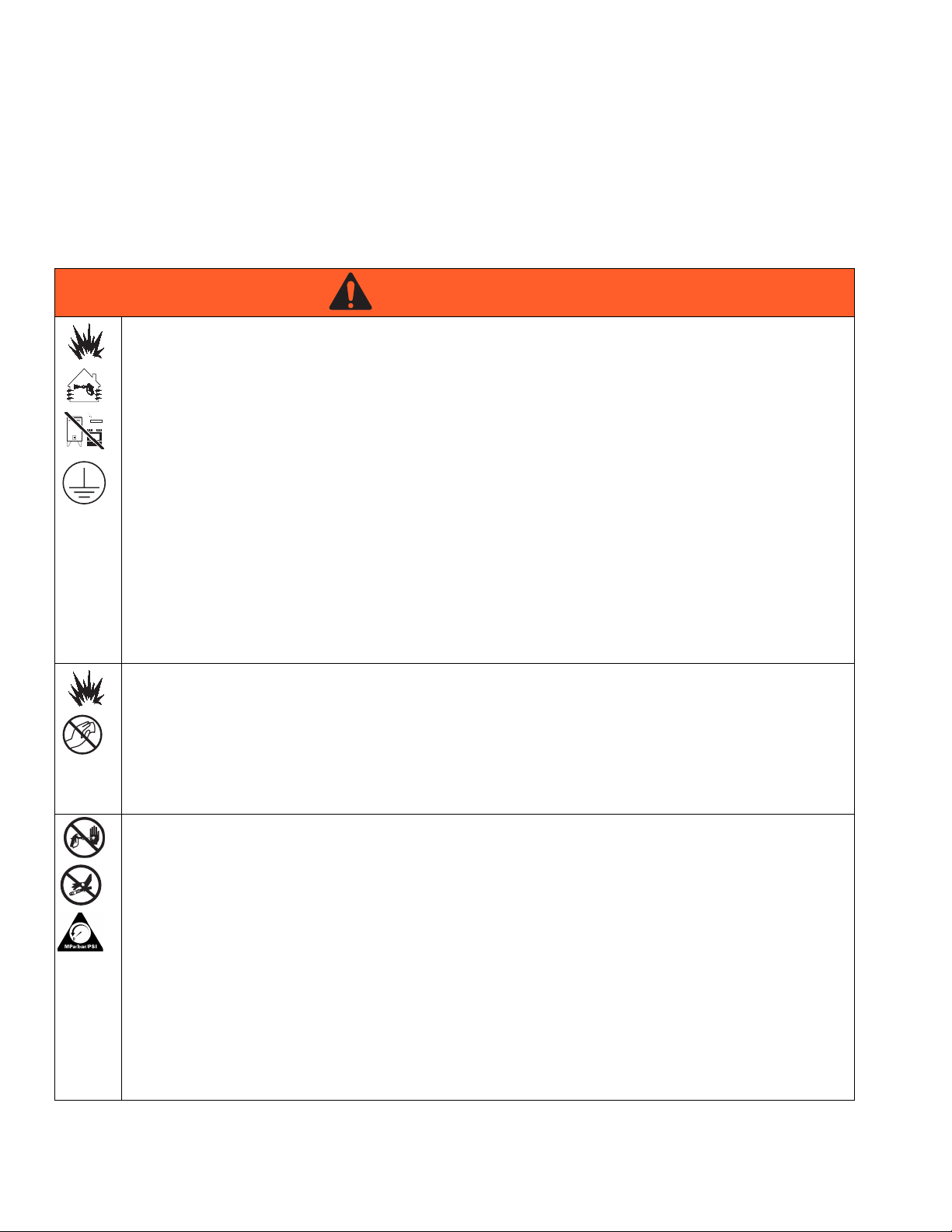

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual, refer back to these Warnings. Product-specific hazard symbols and

warnings not covered in this section may appear throughout the body of this manual where applicable.

WARNING

WARNINGWARNINGWARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes are

present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

SPECIAL CONDITIONS FOR SAFE USE

Static charge may build up on plastic parts during cleaning and could discharge and ignite flammable

vapors. To help prevent fire and explosion:

• Clean plastic parts only in well ventilated area.

• Do not clean with a dry cloth.

• Do not operate electrostatic guns in equipment work area.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

4 3A0732J

Page 5

Warnings

WARNING

WARNINGWARNINGWARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about

your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure. Turn off all equipment

and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure and disconnect all power sources.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area

of the equipment to help protect you from serious injury, including eye injury, hearing loss, inhalation of

toxic fumes, and burns. This equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

3A0732J 5

Page 6

Warnings

6 3A0732J

Page 7

Installation

Installation

Prepare the Operator

All persons who operate the equipment must be trained

in the safe, efficient operation of all system components

as well as the proper handling of all fluids. All operators

must thoroughly read all instruction manuals, tags, and

labels before operating the equipment.

Prepare the Site

Ensure that you have an adequate compressed air

supply.

Bring a compressed air supply line from the air compressor to the pump location. Be sure all air hoses are

properly sized and pressure-rated for your system. Use

only electrically conductive hoses. The air hose should

have a 3/8 npt(m) thread. A quick disconnect coupling is

recommended.

Keep the site clear of any obstacles or debris that could

interfere with the operator's movement.

Have a grounded, metal pail available for use when

flushing the system.

•The spray gun (H) dispenses the fluid. The gun

houses the spray tip (not shown), which is available

in a wide range of sizes for different spray patterns

and rates of flow. Refer to gun manual for tip installation.

•The red hose (G) provides the gun air supply.

•The blue hose (K) provides the gun fluid supply.

•The suction kit with strainer (J) allows the pump

to draw fluid from a 5 gallon (19 liter) pail.

Inline Fluid Filter Kits

Inline fluid filter kits are available as an accessory in

stainless steel (24F271) or aluminum (24F272), to filter

particles from fluid as it leaves the pump. Kits include a

60 mesh (250 micron) stainless steel element.

Air Line Accessories

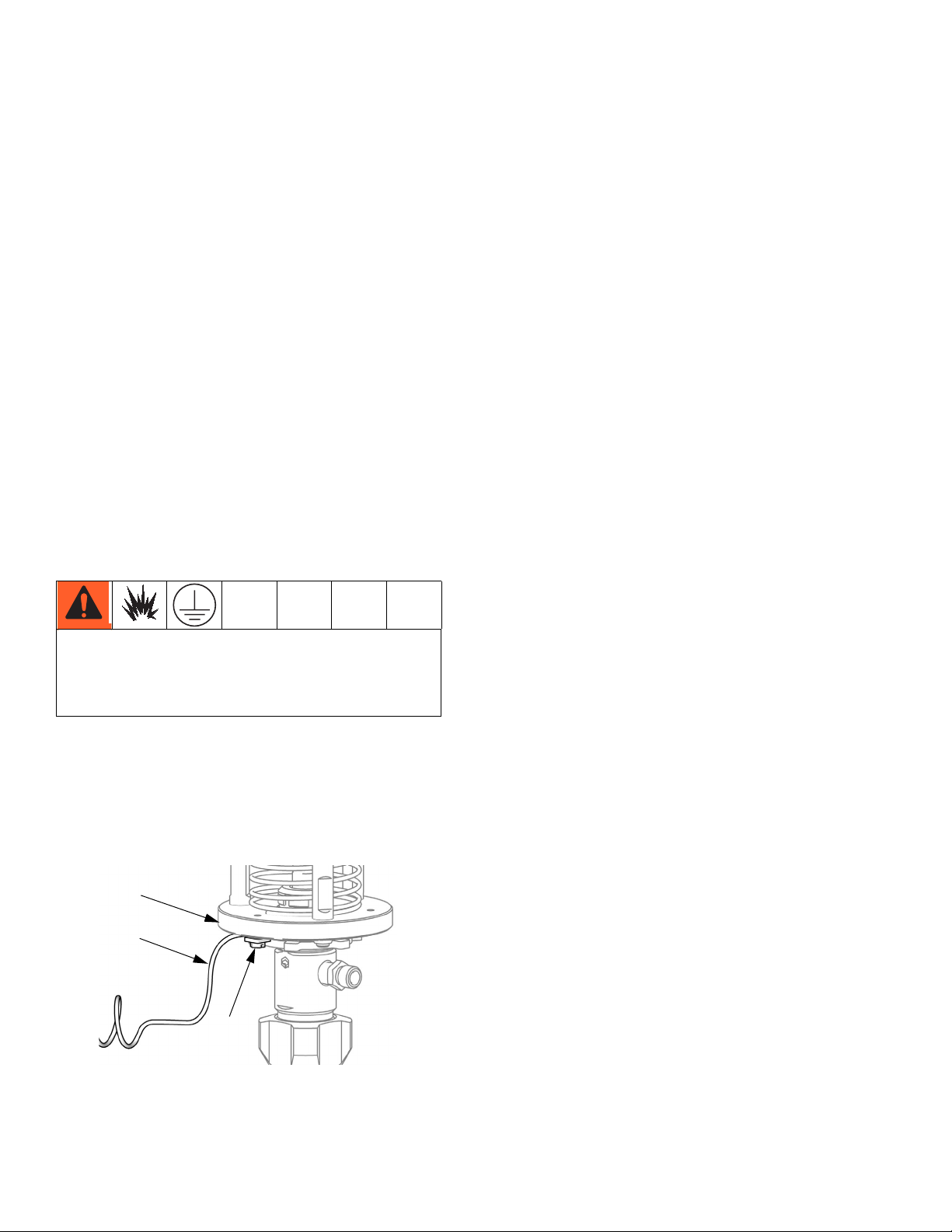

Install the following accessories in the order shown in

F

IG

. 2, using adapters as necessary.

Supplied Components

See FIG. 2 on page 9.

• The red-handled bleed-type master air valve (D)

is required in your system to relieve air trapped

between it and the air motor and gun when the valve

is closed. Do not block access to the valve.

• The pump air regulator (F) controls pump speed

and outlet pressure by adjusting the air pressure to

the pump.

• The air pressure relief valve (P) opens automatically to prevent overpressurization of the pump.

• The gun air regulator (E) adjusts the air pressure

to the air-assisted spray gun.

•An air-line filter (C) removes harmful dirt and mois-

ture from the compressed air supply.

• A second bleed-type air shutoff valve (B) isolates

the air line accessories for servicing. Locate

upstream from all other air line accessories.

3A0732J 7

Page 8

Installation

Wall Mount Packages

1. Be sure the wall can support the weight of the

pump, bracket, hoses and accessories, as well as

the stress caused during operation.

2. Position the wall bracket at a convenient height. Do

not stretch the suction hose tight; let it hang to assist

fluid flow into the pump. For ease of operation and

service, make sure the pump air inlet, fluid inlet, and

fluid outlet ports are easily accessible.

3. Using the wall bracket as a template, drill mounting

holes in the wall. Hole diameters and wall mounting

dimensions are shown on page 40.

4. Attach the bracket to the wall. Use screws that are

long enough to keep the pump from vibrating during

operation.

NOTE: Be sure the bracket is level.

Grounding

2. Air and fluid hoses: Static electricity may build up

when fluids flow through pumps, hoses, and sprayers. At least one hose must be electrically conductive, with a maximum of 500 ft. (150 m) combined

hose length to ensure grounding continuity. Check

electrical resistance of hoses. If total resistance to

ground exceeds 25 megohms, replace hose immediately.

3. Air compressor: follow manufacturer's recommendations.

4. Spray gun: ground through connection to a properly grounded fluid hose and pump.

5. Fluid supply container: follow your local code.

6. Object being sprayed: follow your local code.

7. Solvent pails used when flushing: follow your

local code. Use only metal pails, which are conductive, placed on a grounded surface. Do not place the

pail on a nonconductive surface, such as paper or

cardboard, which interrupts the grounding continuity.

The equipment must be grounded. Grounding

reduces the risk of static and electric shock by

providing an escape wire for the electrical current

due to static build up or in the event of a short circuit.

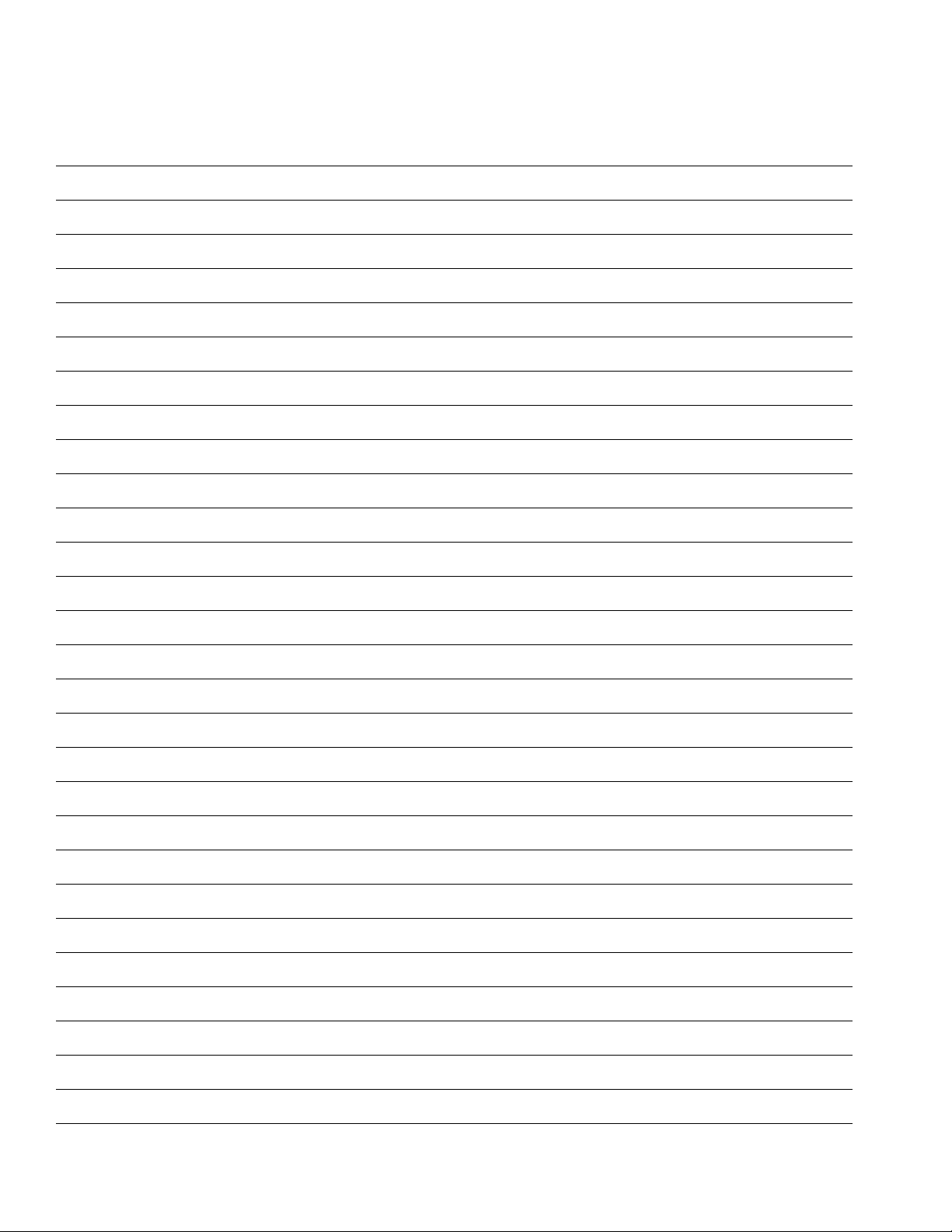

1. Pump: See FIG. 1. Verify that the ground wire (26)

is attached to the ground screw (23), and the screw

is tightened securely to the adapter plate (10). Use

any of the three threaded holes in the adapter plate.

Connect the other end of the ground wire to a true

earth ground.

10

26

23

8. To maintain grounding continuity when flushing or

relieving pressure, hold a metal part of the spray

gun firmly to the side of a grounded metal pail, then

trigger the gun.

Flush Before Using Equipment

The equipment was tested with lightweight oil, which is

left in the fluid passages to protect parts. To avoid contaminating your fluid with oil, flush the equipment with a

compatible solvent before using the equipment. See

Prime the Pump, page 10.

ti16282a

FIG. 1. Ground Wire

8 3A0732J

Page 9

Setup

Installation

1. See FIG. 2. Attach one end of fluid hose (K) to pump

outlet (or optional inline fluid filter outlet).

2. Attach other end of fluid hose to gun fluid inlet at

base of gun (H).

3. Attach one end of the air hose (G) to gun air regulator (E).

A

D

E

J

G

4. Attach remaining end of the air hose to air inlet at

base of gun (H).

5. Clip fluid and air hoses together with the supplied

hose clips (qty. of 7). Space clips as needed.

6. Attach the fluid suction kit (J) to the pump inlet.

B

C

F

P

M

L

K

Key:

A Main Air Supply Line

B Air Shutoff Valve

C Air Filter

D Bleed-type Master Air Valve (required)

E Gun Air Pressure Regulator

F Pump Air Pressure Regulator

G Gun Air Supply Line

H Spray Gun

J Fluid Suction Kit

K Gun Fluid Supply Line

L Pump Ground Wire (required)

M Mounting Bracket (used for wall mounting or stand)

N Pump Stand

P Air Pressure Relief Valve

N

H

ti15591a

FIG. 2. Typical Installation (Air-Assisted Stand Mount Package Shown)

3A0732J 9

Page 10

Operation

Operation

Pressure Relief Procedure

Trapped air can cause the pump to cycle unexpectedly, which could result in serious injury from skin

injection, splashing or moving parts.

1. Lock the gun trigger.

2. See F

3. Unlock the gun trigger.

4. Hold a metal part of the gun firmly to a grounded

5. Lock the gun trigger.

6. If you suspect that pressure has not been fully

IG

. 2. Turn off the bleed-type master air valve

(D).

metal waste container. Trigger the gun to relieve

fluid pressure.

relieved after following the steps above, check the

following:

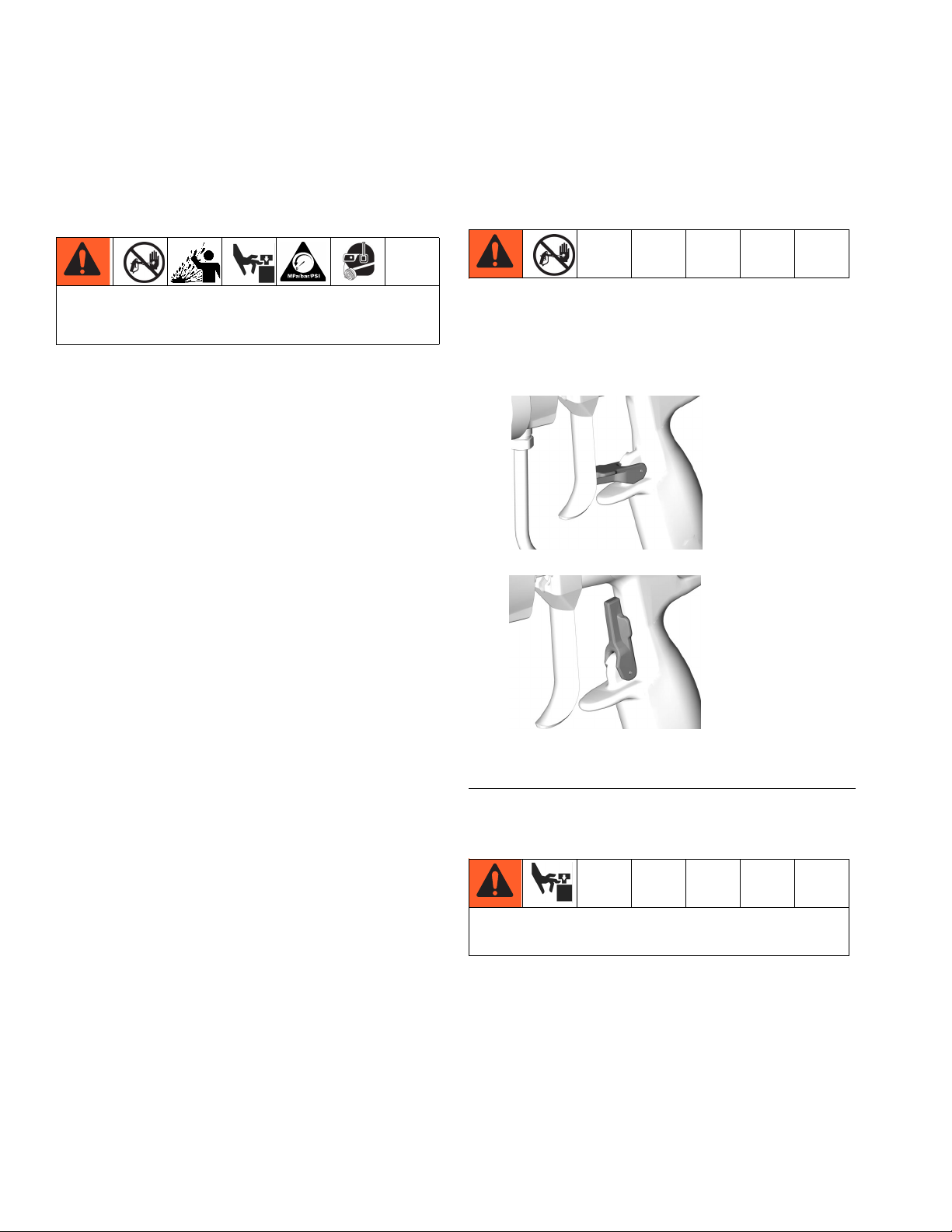

Trigger Lock

See FIG. 3. Always engage gun trigger lock when you

stop spraying to prevent gun from being triggered accidentally by hand or if dropped or bumped.

Gun Trigger

Locked

tiI6581A

Gun Trigger

Unlocked

a. The spray tip may be completely clogged. Very

slowly loosen the air cap retaining ring to relieve

pressure in the cavity between the ball/seat

shutoff and the plugged tip. Clear the tip orifice.

b. The gun fluid filter or the fluid hose may be com-

pletely clogged. Very slowly loosen the hose

end coupling at the gun and relieve pressure

gradually. Then loosen completely to clear the

obstruction.

c. After following the steps above, if the spray tip

or hose still seems completely clogged, very

slowly loosen the tip guard retaining nut or hose

end coupling and relieve pressure gradually,

then loosen completely. With tip removed, trigger gun into waste container.

ti6582A

FIG. 3. Trigger Lock

Prime the Pump

Have safety spring (9) in place during operation to

reduce risk of pinching or loss of fingers.

1. See FIG. 3. Lock gun trigger. Remove tip guard and

spray tip from gun. Refer to gun manual.

10 3A0732J

Page 11

Operation

2. See FIG. 2. Close gun air regulator (E) and pump air

regulator (F) by turning knobs counterclockwise

reducing pressure to zero. Close bleed-type air

valve (D).

3. Connect air line to bleed type air valve.

4. Check that all fittings throughout system are tightened securely.

5. Position pail close to pump. Suction hose is 3 ft

(0.9 m) long. Do not stretch hose tight; let it hang to

assist fluid flow into pump.

6. Hold metal part of gun firmly to side of grounded

metal pail, unlock trigger, and hold trigger open.

7. Open bleed-type air valve. Slowly turn pump air regulator clockwise, increasing pressure until pump

starts.

8. Cycle pump slowly until all air is pushed out and

pump and hoses are fully primed.

9. Release gun trigger and lock trigger safety. Pump

should stall against pressure.

Adjust the Atomization

NOTE: Use this procedure with airless and air-assisted

spray guns.

1. Do not turn on atomizing air supply. Fluid pressure

is controlled by the air pressure supplied to the

pump (pump air regulator). Set fluid pressure at low

starting pressure. For low viscosity fluids (less than

25 sec, #2 Zahn cup) with lower percent solids (typically less than 40%), start at 300 psi (2.1 MPa, 21

bar) at pump outlet. For fluids with higher viscosity

or higher solids content, start at 600 psi (4.2 MPa,

42 bar). Refer to the following example.

Example:

Pump Air

Pump

Ratio

15:1 x 20 (0.14, 1.4) = 300 (2.1, 21)

30:1 x 20 (0.14, 1.4) = 600 (4.2, 42)

Regulator Setting

psi (MPa, bar)

Approximate

Fluid Pressure

psig (MPa, bar)

Install the Spray Tip

Follow Pressure Relief Procedure, page 10. Install the

spray tip and tip guard as explained in your separate

gun manual, supplied.

The fluid output and pattern width depend on the size of

the spray tip, the fluid viscosity, and the fluid pressure.

Use the Spray Tip Selection Chart in your gun instruction manual as a guide for selecting an appropriate

spray tip for your application.

NOTE: The maximum recommended spray tip size is

.019 in. (0.483 mm).

2. Hold gun perpendicular and approximately 12

inches (304 mm) from surface.

3. Move gun first, then pull gun trigger to spray onto

test paper.

4. Increase fluid pressure in 100 psi (0.7 MPa, 7 bar)

increments, just to the point where a further

increase in fluid pressure does not significantly

improve fluid atomization. Refer to the following

example.

Example:

Pump Air Regulator

Pump

Ratio

15:1 x 7 (.05, 0.5) = 100 (0.7, 7.0)

30:1 x 3.3 (0.02, 0.2) = 100 (0.7, 7.0)

5. If you are using an air-assisted spray gun, see

Adjust the Spray Pattern on page 12.

Increment

psi (MPa, bar)

Incremental

Fluid Pressure

psi (MPa, bar)

3A0732J 11

Page 12

Operation

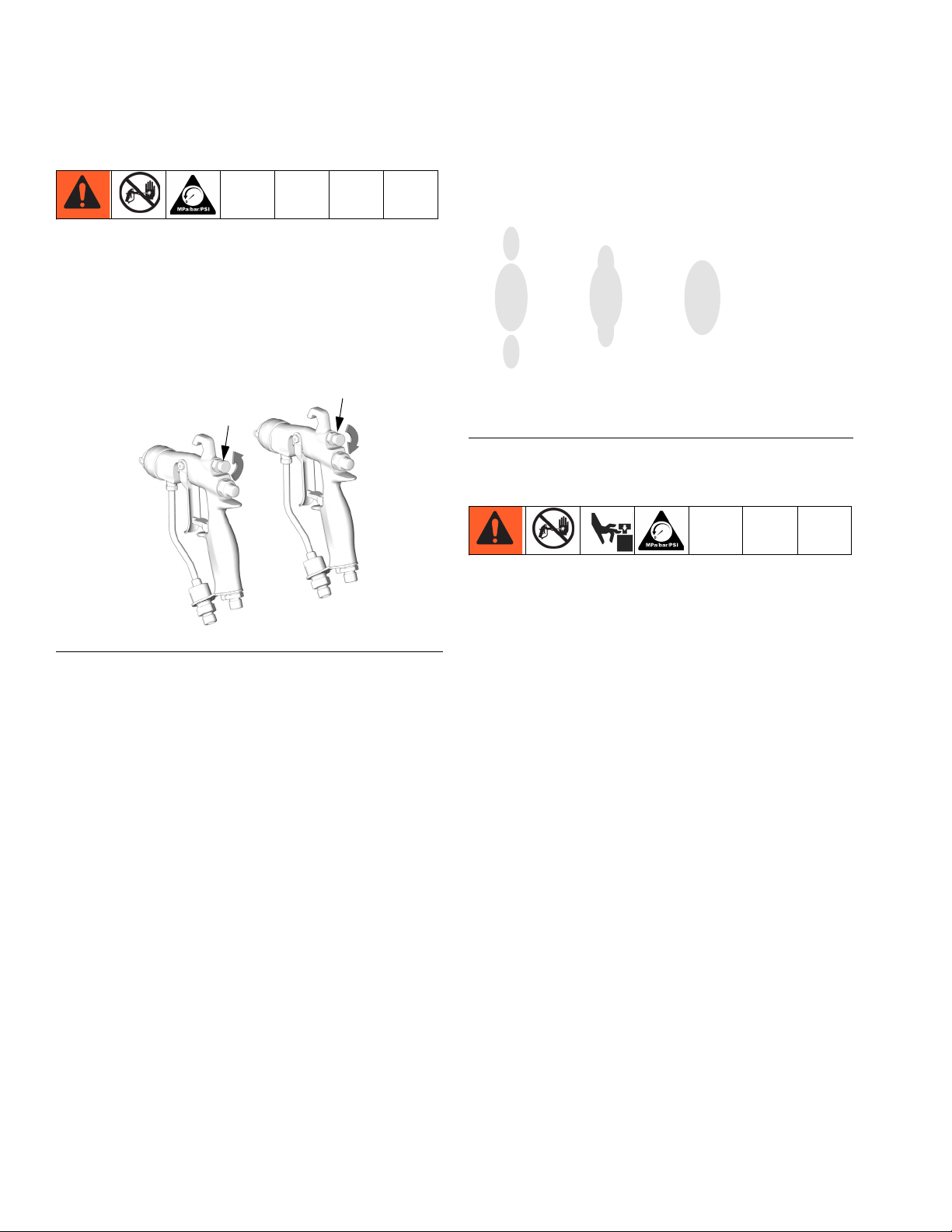

Adjust the Spray Pattern

NOTE: Use this procedure with air-assisted spray guns

only.

1. See F

OUT (narrower

pattern)

IG

. 4. Close off pattern adjustment air by turning knob (AA) clockwise (in) all the way. This sets

gun for its widest pattern.

AA

AA

IN (wider

pattern)

3. See F

IG

. 4. For narrower pattern, turn pattern

adjustment valve knob (AA) counterclockwise (out).

If pattern is still not narrow enough, increase air

pressure to gun slightly or use different size tip.

no air

too little air

correct

amount of

air

TI0792A

FIG. 5. Spray Pattern Problems

Shutdown

ti6559A

FIG. 4. Pattern Air Knob

2. See F

IG

. 5. Set atomizing air pressure at about 5 psi

(0.35 bar, 35 kPa) when triggered. Check spray pattern, then slowly increase air pressure until tails are

completely atomized and pulled into spray pattern.

Do not exceed 100 psi (0.7 MPa, 7 bar) air pressure

to gun.

Follow Pressure Relief Procedure, page 10.

Always flush the pump before the fluid dries on the displacement rod. See Flush the Pump on page 13.

12 3A0732J

Page 13

Maintenance

Maintenance

Tighten Threaded Connections

Before each use, check all hoses for wear or damage.

Replace as necessary. Check that all threaded connections are tight and leak-free.

Flush the Pump

Read all Warnings. Follow all Grounding instructions. See page 8.

Flush the pump:

• Before first use

• When changing colors or fluids

• Before repairing equipment

• Before fluid dries or settles out in a dormant pump

(check the pot life of catalyzed fluids)

Flush at the lowest pressure possible. Flush with a fluid

that is compatible with the fluid you are pumping and

with the wetted parts in your system. Check with your

fluid manufacturer or supplier for recommended flushing

fluids and flushing frequency.

1. Follow Pressure Relief Procedure, page 10.

2. Remove tip guard and spray tip from gun. Refer to

separate gun manual.

3. Place suction tube in grounded metal pail containing

cleaning fluid.

4. Set pump to lowest possible fluid pressure, and start

pump.

5. Hold a metal part of the gun firmly to a grounded

metal pail.

6. Trigger gun. Flush system until clear solvent flows

from gun.

7. Follow Pressure Relief Procedure, page 10.

8. Clean the tip guard, spray tip, and fluid filter element

separately, then reinstall them.

• At the end of the day

• Before storing the pump.

9. Clean inside and outside of suction tube and suction

hose.

3A0732J 13

Page 14

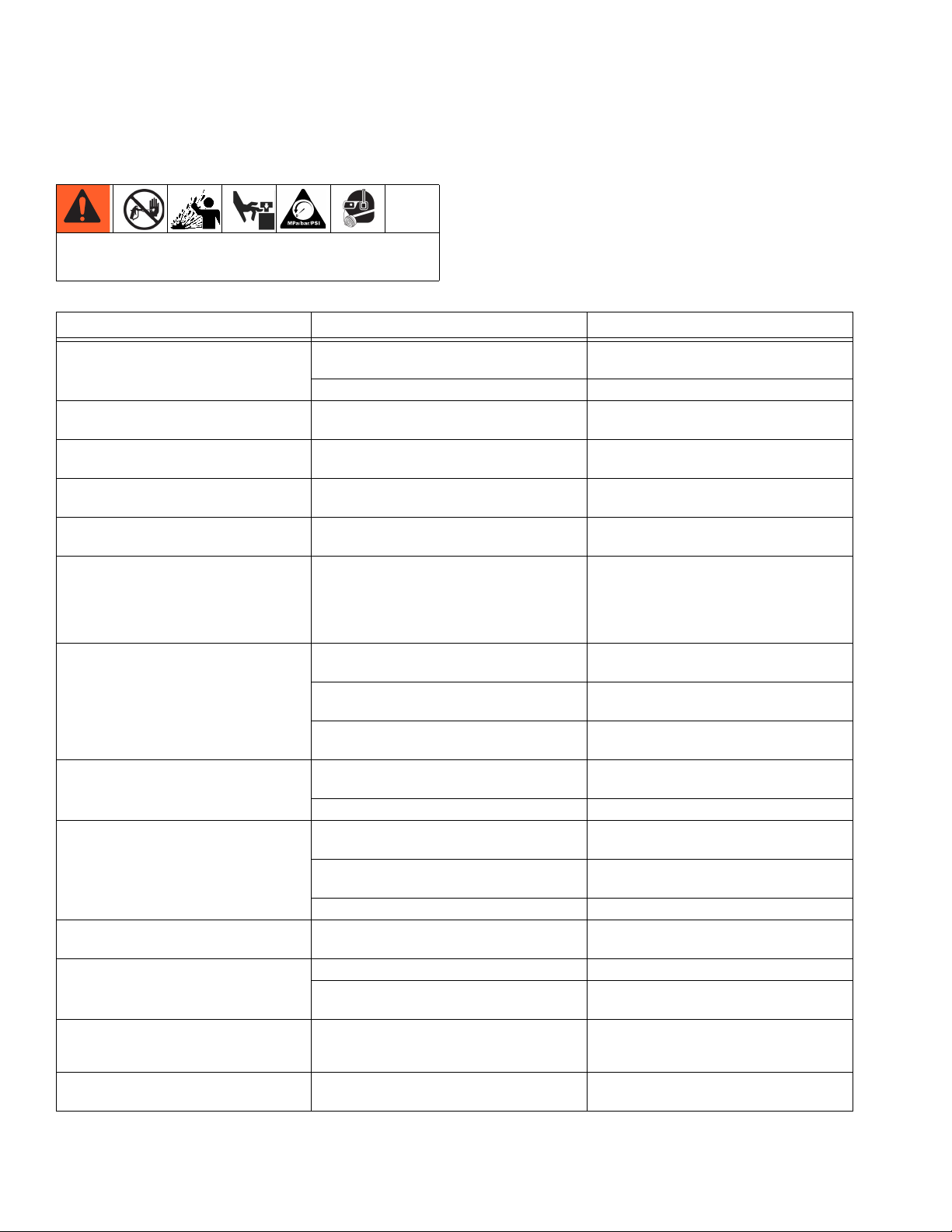

Troubleshooting

Troubleshooting

NOTE: Check all possible problems and causes before

disassembling the pump.

Relieve the pressure before checking or servicing

the equipment.

Problem Cause Solution

Air motor will not run. Damaged air valve (214). Replace or service air valve (214). See

page 18.

Damaged pilot valve (213). Replace pilot valves (213). See page 20.

Air continuously exhausting around air

motor piston rod.

Air continuously exhausting from muffler.

Air motor “bounces” at top of stroke. Damaged bottom pilot valve (213). Replace bottom pilot valve (213). See

Air motor “bounces” at bottom of

stroke.

Icing inside motor. Air motor operating at high pressure or

Damaged u-cups (207). Replace piston rod u-cups (207). See

page 22.

Damaged air valve plate (305) or cup

(312).

Damaged top pilot valve (213). Replace top pilot valve (213). See page

high cycle rate.

Replace or service air valve (214). See

page 18.

page 20.

20.

Reduce pressure, cycle rate, or duty

cycle of motor.

Reduce dew point of compressed air in

moisture coalescing filter.

Pump fails to operate. Restricted line or inadequate air supply;

closed or clogged valves.

Obstructed fluid hose or gun; fluid hose ID

is too small.

Fluid dried on the displacement rod (119). Clean; keep the packing nut wet-cup filled

Pump operates but does not prime. Held open or worn ball check valves or pis-

ton packings.

Worn suction hose o-ring (38). Replace suction hose o-ring (38).

Pump operates, but output is low on

both strokes.

Pump operates, but output is low on

downstroke.

Erratic or accelerated pump speed. Exhausted fluid supply. Refill and prime.

Fluid being pumped is visible in the

packing nut wet-cup.

Bad spray pattern. Clean or repair spray gun or tip. See G15/G40 air-assisted gun manual or

Restricted line or inadequate air supply;

closed or clogged valves.

Obstructed fluid hose or gun; fluid hose ID

is too small.

Worn packings in displacement pump. Replace packings. See page 16.

Held open or worn ball check valves or piston packings.

Held open or worn ball check valves or

packings.

Worn throat packings. Tighten packing nut.

Clear line or increase air supply. Check

that the valves are open.

Open, clear*; use hose with larger ID.

with Graco throat seal liquid (TSL).

Clear valve; replace packings. See page

16.

Clear line or increase air supply. Check

that the valves are open.

Open, clear*; use hose with larger ID.

Clear valve; replace packings. See page

16.

Clear valve, replace packings. See page

16.

Replace throat packings. See page 16.

Silver Plus airless gun manual.

14 3A0732J

Page 15

Repair

Repair

General Information

• Reference numbers and letters in parentheses in

the text refer to the callouts in the figures and the

parts drawing.

• Always use Genuine Graco Parts and Accessories,

available from your Graco distributor. If you supply

your own accessories, be sure they are adequately

sized and pressure rated for your system.

To Remove Intake Valve Only

The intake ball and seat may be cleaned or serviced

without disconnecting the displacement pump.

1. Stop the pump.

2. Flush the pump, if possible (see page 13). Follow

Pressure Relief Procedure, page 10.

Disconnect the Displacement Pump

1. Stop the pump.

2. Flush the pump, if possible (see page 13). Follow

Pressure Relief Procedure, page 10.

3. Disconnect the air hose, fluid hose, and suction

hose.

4. See F

5. Loosen the jam nut (13).

6. Unscrew the displacement pump by hand and place

IG

. 6. Push the safety spring (9) down and

hold to access the coupling pin (18). Push the

retaining spring (19) up and push out the pin, using

a screwdriver or punch.

on work bench.

3. Disconnect the suction hose.

4. Remove the intake housing (110). See F

5. Clean or replace the ball guide (109), ball (116),

seat (117), and o-ring (111).

6. Install the o-ring (111‡), seat (117), intake ball

(116‡), and ball guide (109) in the intake housing

(110).

7. Screw the intake housing (110) onto the cylinder

(105). Torque to 70-80 ft-lb (95-108 N•m).

IG

. 7.

19

10

13

FIG. 6. Safety Spring and Connecting Pin

18

9

TI16261A

3A0732J 15

Page 16

Repair

Disassemble the Pump

NOTE: Pump Repair Kits are available. See page 31 to

order the correct kit for your pump. Parts are marked

with an ‡.

1. Follow the instructions under Disconnect the Dis-

placement Pump, page 15.

1. See F

2. Unscrew the cylinder (105) from the intake housing

3. Remove the ball guide (109), intake ball (116), seat

4. Drive the rod and piston assembly out the bottom of

5. Insert a plastic rod in the bottom of the cylinder and

6. Put the rod (119) in a vise and unscrew the piston

IG

. 7. Loosen the packing nut (103), using a

screwdriver and hammer. Remove the o-ring (104).

(110). The rod and piston assembly will come with

the cylinder.

(117), and o-ring (111) from the intake housing

(110).

the cylinder. Remove the o-ring (107) from the cylinder.

drive the throat packings and glands out the top.

(124). Be careful not to drop the piston ball (120).

Disassemble the piston packings from the piston.

3. Install the male gland (114‡) in the cylinder (105).

Install the throat packings in the following order with

the lips facing down: blue UHMWPE (106‡), leather

(113‡), UHMWPE, leather, UHMWPE. Install the

female gland (112‡).

4. Install the o-ring (104‡) on the packing nut (103).

Loosely install the packing nut in the cylinder.

5. Liberally lubricate the piston packings and the top 2

in. (51 mm) of the displacement rod (119).

6. Push the displacement rod (119) into the cylinder

(105) from the bottom until the piston is completely

in the cylinder and the rod protrudes from the packing nut (103).

7. Grease the o-ring (107‡) and install it on the cylinder (105).

8. Install the o-ring (111‡), seat (117), intake ball

(116‡), and ball guide (109) in the intake housing

(110).

9. Place the intake housing (110) in a vise. Screw the

cylinder (105) into the intake housing. Torque to

70-80 ft-lb (95-108 N•m).

10. Tighten the packing nut (103) 1/2 turn past handtight, or torque to 60-80 in-lb (6.7-9.0 N•m).

7. Clean and inspect all parts. Replace any damaged

parts.

Reassemble the Pump

NOTE: Soak the leather packings (113‡, 125‡) in

hydraulic oil for one hour before installing them in the

pump.

1. Install the piston wiper (123‡) on the piston (124),

with the lips facing down. Install the female gland

(122‡). Install the piston packings in the following

order with the lips facing up: blue UHMWPE (126‡),

leather (125‡), UHMWPE, leather, UHMWPE.

Install the male gland (121‡).

2. Put the displacement rod (119) in a vise. Place the

piston ball (120‡) in the cavity of the rod. Screw the

piston assembly into the rod. Torque to 24-30 ft-lb

(33-40 N•m).

11. Ensure that the button plug (102‡) is in place on the

packing nut (103).

12. Follow the instructions under Reconnect the Dis-

placement Pump, page 16.

Reconnect the Displacement Pump

NOTICE

The displacement pump can be damaged if the stroke

is not centered when the pump is reconnected. Be

sure to fully screw the displacement pump into the

adapter plate (10).

1. Screw the displacement pump into the adapter plate

(10) until it stops. Back off pump less than 1 turn, to

align pump outlet as desired.

16 3A0732J

Page 17

Repair

2. Tighten the jam nut (13). Torque to 65-75 ft-lb

(88-102 N•m).

3. Align the hole in the displacement rod with the hole

in the air motor rod. Use a screwdriver to push in the

pin (18).

‡102

103

‡104

‡112

‡106

1

‡114

113‡

1

4. Push the retaining spring (19) into place to cover the

pin.

5. Fill throat packing nut wet-cup with TSL to prevent

premature packing wear.

105

15

107‡

109❖

2

1

119

‡121

‡126

‡122

‡123

‡120

124

125‡

2

116‡❖

117❖

111‡❖

110

1

Lips must face down.

2

Lips must face up.

TI16131a

FIG. 7. Displacement Pump

3A0732J 17

Page 18

Repair

Repair Air Valve

Replace Complete Air Valve

1. Stop the pump. Follow Pressure Relief Procedure,

page 10.

2. Disconnect the air line to the motor.

3. See F

IG

. 14 on page 23. Remove four screws (211).

Remove the air valve (214) and gasket (209*◆).

4. To repair the air valve, go to Disassemble the Air

Valve, page 18. To install a replacement air valve,

continue with step 5.

5. Align the new air valve gasket (209*◆) on the manifold, then attach the air valve (214). Torque screws

(211) to 95-105 in-lb (11-12 N•m).

6. Reconnect the air line to the motor.

Replace Seals or Rebuild Air Valve

NOTE: Air Valve Seal Kits are available. See page 35.

Parts are marked with an †.

312◆

311◆

305◆

309†◆

ti16284a

FIG. 8. Air Plate Removal

3. See F

IG

. 9. Remove the snap ring (310✠ ) from each

end. Use the piston to push the end caps (307✠ ) out

of the ends. Remove end cap o-rings (306†✠◆).

4. Remove the piston (302◆). Remove the u-cup seals

(308†◆) from each end and the detent assembly

(303◆) and detent cam (304◆) from the center.

Air Valve Repair Kits are available. See page 35. Parts

are marked with an ◆.

Air Valve End Cap Kits are available. See page 35.

Parts are marked with an ✠ .

Disassemble the Air Valve

1. Perform steps 1-3 under Replace Complete Air

Valve, page 18.

2. See F

IG

. 8. Use a 2 mm or 5/64 hex key to remove

two screws (309†◆). Remove the valve plate

(305◆), cup (312◆), and spring (311◆).

18 3A0732J

Page 19

◆312

1

1

◆311

◆303

1

◆304

301

†✠◆306

1

◆✠

✠

Repair

310

307

◆305

†◆309

Apply lubricant.

1

FIG. 9. Air Valve Assembly

1

1

1

†✠◆306

1

†◆308

◆302

†◆

308

✠ 307

◆✠ 310

ti16213a

3A0732J 19

Page 20

Repair

Reassemble the Air Valve

1. See F

IG

. 9. Lubricate detent cam (304◆) and install

into housing.

IG

2. See F

. 10. Lubricate the u-cups (308†◆) and

install on the piston (302◆) with lips facing toward

the center of the piston.

†◆308

Lips face down

◆302

7. Install the spring (311◆). Lubricate and install the air

valve cup (312◆), see F

IG

. 11. Align the small round

magnet with the air inlet.

8. Install the valve plate (305◆). Tighten the screws

(309†◆) to hold it in place.

312◆

Magnet

ti16283a

FIG. 11. Air Valve Cup Installation

†◆308

Lips face up

ti12754a

F

IG

. 10. Air Valve U-cup Installation

3. See F

IG

. 9. Lubricate both ends of the piston (302◆)

and install it in the housing.

4. Lubricate and install the detent assembly (303◆)

into the piston.

5. Lubricate new o-rings (306†✠◆) and install on the

end caps (307✠ ). Install the end caps into the housing.

6. Install a snap ring (310◆✠ ) on each end to hold end

caps in place.

Replace Pilot Valves

1. Stop the pump. Follow Pressure Relief Procedure,

page 10.

2. Disconnect the air line to the motor.

3. See F

4. See F

5. Lubricate and install the new pilot valves (213).

IG

. 12. Push the safety spring (9) down and

hold to access the pilot valve on the bottom cover.

IG

. 14 on page 23. Use a 10 mm wrench to

remove the old pilot valves (213) from the top and

bottom covers.

Torque to 95-105 in-lb (11-12 N•m).

20 3A0732J

Page 21

Disconnect the Air Motor

1. Stop the pump.

2. Flush the pump, if possible (see page 13). Follow

Pressure Relief Procedure, page 10.

Repair

19

18

8

3. Disconnect the air hose, fluid hose, and suction

hose.

IG

4. See F

hold to access the coupling pin (18). Push the

retaining spring (19) up and push out the pin, using

a screwdriver or punch.

5. Remove the nuts (11) from the bottom of the tie rods

(8).

6. Remove the pump lower (12). The adapter plate

(10) will remain attached to the lower.

7. Remove the safety spring (9).

8. Loosen the nuts (17) at the top of the tie rods, then

remove the tie rods. The mounting bracket (1) is

loosened from the motor as the tie rods are

removed.

9. Take the motor to a work bench. See Repair Air

Motor on page 22.

. 12. Push the safety spring (9) down and

1 17

10

FIG. 12. Disconnect the Air Motor

9

11

TI16261A

Reconnect the Air Motor

1. Replace the motor on the mounting bracket (1).

2. Screw the tie rods into the motor, with the top hex

nuts (17) attached. Torque the tie rods to 5-10 ft-lb

(7-13 N•m).

NOTE: Always tighten the tie rods before tightening the

top hex nuts (17).

3. Tighten the top hex nuts (17) to secure the mounting bracket (1).

4. Slide the pump with the adapter plate (10) attached

onto the tie rods (8). Ensure that the safety spring

(9) is in place and the pump outlet is oriented as

desired.

5. Install the tie rod nuts (11). Torque to 100 in-lb (11

N•m).

6. Align the hole in the displacement rod with the hole

in the air motor rod. Use a screwdriver to push in the

pin (18).

7. Push the retaining spring (19) into place to cover the

pin.

3A0732J 21

Page 22

Repair

Repair Air Motor

NOTE: Complete Air Motor Replacement Kits are avail-

able. Order 24G693 (2.5 in. motor) or 24G694 (3.5 in.

motor).

Reassemble the Air Motor

NOTE: For easier reassembly, start with the top cover

(210) turned over on the workbench and assemble the

air motor upside-down.

1. Lubricate and install the o-ring (202*) on the top

cover (210).

NOTE: Air Motor Seal Kits are available. See page 33

for the correct kit for your motor. Parts included in the kit

are marked with an asterisk (*). For best results, use all

the parts in the kit.

Disassemble the Air Motor

1. See FIG. 14. Use a 10 mm socket wrench to remove

four screws (211). Remove the air valve (214) and

gasket (209*◆†).

2. Remove four screws (211) and remove the manifold

(220) and two gaskets (208*).

3. Use a 10 mm socket wrench to remove the pilot

valves (213) from the top and bottom cover.

4. Use a 13 mm socket wrench to remove the tie bolts

(212).

5. Remove the top cover (210). Remove the o-ring

(202*).

(231) and o-ring (230*).

6. Remove the shield (206) and cylinder (205).

7. Remove the o-ring (204*) from the piston.

8. Secure the piston (219) in a vise with soft jaws. Use

a wrench on the flats of the rod (218) to remove the

rod and bottom cover assembly (201) from the piston.

On 3.5 in. motors only,

remove the plug

2. Lubricate the inside of the cylinder (205). Lower the

cylinder onto the top cover (210).

3. Install the shield (206) around the cylinder (205) and

in the groove on the top cover (210).

4. See F

FIG. 13. Air Motor U-cup Installation

IG

. 13. Lubricate and install new u-cup seal

(207*) in the bottom of the bearing in the bottom

cover (201). The lips must face down. Lubricate and

install new u-cup seal (207*) in the top of the bearing. Lips must face up Install retaining ring (217).

*207

*207

Lips face up

Lips face down.

ti16285a

9. Remove the rod from the bottom cover assembly.

10. Remove retaining ring (217), u-cup seals (207*),

and o-ring (202*) from the bottom cover.

22 3A0732J

Page 23

1

Apply lubricant.

Repair

231

*230

1

213

210

202*

1

205

1

1

204*

1

211

214

211

220

219

1

208*

*202

*217

*207

1

209*◆†

215

203

208*

FIG. 14. Air Motor Assembly

206

*207

1

218

201

213

212

1

TI16130a

3A0732J 23

Page 24

Repair

5. Lubricate and install the o-ring (202*) on the bottom

cover (201).

6. Carefully push the threaded end of the rod (218) up

through the bottom cover (201).

7. Apply 16G561 adhesive to the threads of the rod

(218). Screw the piston (219) onto the rod. Place

the piston in a vise with soft jaws and torque to

35-40 ft-lb (47-54 N•m).

8. Lubricate and install the o-ring (204*) on the piston

(219).

9. See F

IG

. 15. Carefully place the bottom cover/piston

assembly on the cylinder (205), sliding the piston

(219) into the cylinder. The manifold surfaces of the

top and bottom covers must align. Be sure the

shield (206) is in the groove on both the top and bottom covers.

201

10. Install the tie bolts (212) hand tight.

11. Install two gaskets (208*) on the manifold (220).

Install the manifold (220). Torque screws (211) to

95-105 in-lb (10.7-11.9 N•m).

NOTE: The manifold is reversible for ease of placement

of muffler or remote exhaust.

12. Align the air valve gasket (209*◆†) on the manifold,

then attach the air valve (214). Torque screws (211)

to 95-105 in-lb (11-12 N•m).

13. Tighten the tie bolts (212) halfway. Work in a crisscross pattern. Check that the shield (206) remains in

the grooves on both covers. Continue tightening the

bolts in pattern to 11-13 ft-lb (15-18 N•m).

14.

On 3.5 in. motors only,

lubricate the o-ring (230*).

Install it and the plug (231) in the top cover (210).

15. Lubricate and install pilot valves (213) in top and

bottom cover. Torque to 95-105 in-lb (11-12 N•m).

16. See Reconnect the Air Motor on page 21.

groove

206

groove

F

IG

. 15. Align Shield in Grooves on Covers

210

ti16281a

24 3A0732J

Page 25

Parts

Package Parts

NOTE: For hose and gun, see page 29.

7

Parts

20

Part of air motor (7)

22

21

16

37

26

15

Detail of Stand Kit (2)

4

2

1 (Ref)

4

5

43

6

43

TI16438a

1

9

23

17

8

10

11

13

19

18

3

12

38

42

TI16129a

3A0732J 25

Page 26

Parts

Package Parts 15:1 Ratio Pumps

Ref.

No. Description

1 BRACKET, wall 24H102 24H102 24H102 24H102 24H102 24H102 1

2 KIT, stand; includes items 3, 4, 5, 6, and 43

below, and 418 on page 36

3 PLUG 108175 108175 108175 108175 4

4 SCREW, cap, hex hd; 1/4-20 x 1.5 in. (38 mm) 100058 100058 100058 100058 6

5 SPACER, tube

6 NUT, hex; 1/4-20 100015 100015 100015 100015 6

7 MOTOR, air; see page 32 24G693 24G693 24G693 24G693 24G693 24G693 1

8 KIT, rod, tie; includes rods and items 11 and 17

(3 of each)

9 SPRING, safety 24H103 24H103 24H103 24H103 24H103 24H103 1

10 ADAPTER, pump lower 24H104 24H104 24H104 24H104 24H104 24H104 1

11 NUT, lock 104541 104541 104541 104541 104541 104541 3

12 LOWER, pump; see page 30;

also includes items 15, 18, and 19

13 NUT, jam 195150 195150 195150 195150 195150 195150 1

NIPPLE; 1/4 npsm x 1/4 npt; plated steel 162453 162453 162453 1

‡

15

NIPPLE; 1/4 npsm x 1/4 npt; sst 166846 166846 166846 1

16 KIT, suction hose, 5 gal. (19 l); 3/8 in. (10 mm)

OD; includes items 37 (qty 1), 38, and 42

17 NUT, hex; 7/16-20 Not sold separately. Order Tie Rod Kit, item 8. 3

PIN, straight 196762 196762 196762 196762 196762 196762 1

‡

18

SPRING, retaining 196750 196750 196750 196750 196750 196750 1

‡

19

20 AIR CONTROL ASSEMBLY; see page 36 24H162 24H163 24H163 24H162 24H163 24H163 1

21 ELBOW, swivel;

1/4 npt(m) x 3/8 in. (10 mm) OD tube

22 TUBE, polyurethane; 3/8 in. (10 mm) OD; 2 ft

(0.61 m)

23 SCREW, ground 116343 116343 116343 116343 116343 116343 1

26 WIRE, grounding 238909 238909 238909 238909 238909 238909 1

28 THROAT SEAL LIQUID; 4 oz (not shown) 238049 238049 238049 238049 238049 238049 1

37 STRAINER, suction; 3/8 in. (10 mm) OD tube;

pack of 3

38 O-RING; fluoroelastomer 117559 117559 117559 117559 1

42 NUT, jam, suction 15E813 15E813 15E813 15E813 1

43 WASHER, lock; 1/4; part of stand kit (2)

44* HOPPER, kit 17A493 17A493 1

24G707 24G707 24G707 24G707 24G707 24G707 1

24G701 24G701 24G701 24G702 24G702 24G702 1

24F148 24F148 24F148 24F148 1

121141 121141 121141 121141 121141 121141 1

24H008 24H008 24H008 24H008 24H008 24H008 1

24F160 24F160

24F164 24F164 24F164 24F164 1

--- --- --- ---

--- --- --- ---

Package

Qty24F150 24F151 24W281 24F158 24F159 24W283

24F160 24F160 1

4

6

‡

Included in Pump Lower Rebuild Kit. See page 31.

* Not shown. See Merkur ES Hopper Kit manual 334011 for more information.

26 3A0732J

Page 27

Package Parts 30:1 Ratio Pumps

Parts

Ref.

No. Description

1 BRACKET, wall 24H102 24H102 24H102 24H102 24H102 24H102 24H102 24H102 1

2 KIT, stand; includes items 3, 4, 5, 6, and

43 below, and 418 on page 36

3 PLUG 108175 108175 108175 108175 108175 4

4 SCREW, cap, hex hd; 1/4-20 x 1.5 in. (38

mm)

5 SPACER, tube

6 NUT, hex; 1/4-20 100015 100015 100015 100015 100015 6

7 MOTOR, air; see page 32 24G694 24G694 24G694 24G694 24G694 24G694 24G694 24G694 1

8 KIT, rod, tie; includes rods and items 11

and 17 (3 of each)

9 SPRING, safety 24H103 24H103 24H103 24H103 24H103 24H103 24H103 24H103 1

10 ADAPTER, pump lower 24H104 24H104 24H104 24H104 24H104 24H104 24H104 24H104 1

11 NUT, lock 104541 104541 104541 104541 104541 104541 104541 104541 3

12 LOWER, pump; see page 30;

also includes items 15, 18, and 19

13 NUT, jam 195150 195150 195150 195150 195150 195150 195150 195150 1

NIPPLE; 1/4 npsm x 1/4 npt; plated steel 162453 162453 162453 162453 162453 1

‡

15

NIPPLE; 1/4 npsm x 1/4 npt; sst 166846 166846 166846

16 KIT, suction hose, 5 gal. (19 l);

3/8 in. (10 mm) OD; includes items 37 (qty

1), 38, and 42

17 NUT, hex; 7/16-20 Not sold separately. Order Tie Rod Kit, item 8. 3

PIN, straight 196762 196762 196762 196762 196762 196762 196762 196762 1

18

‡

SPRING, retaining 196750 196750 196750 196750 196750 196750 196750 196750 1

‡

19

20 AIR CONTROL ASSEMBLY; see page 36 24H162 24H163 24H163 24H164 24H165 24H162 24H163 24H163 1

21 ELBOW, swivel; 1/4 npt(m) x 3/8 in. (10

mm) OD tube

22 TUBE, polyurethane; 3/8 in. (10 mm) OD;

2 ft (0.61 m)

23 SCREW, ground 116343 116343 116343 116343 116343 116343 116343 116343 1

26 WIRE, grounding 238909 238909 238909 238909 238909 238909 238909 238909 1

28 THROAT SEAL LIQUID; 4 oz (not shown) 238049 238049 238049 238049 238049 238049 238049 238049 1

37 STRAINER, suction; 3/8 in. (10 mm) OD

tube; pack of 3

38 O-RING; fluoroelastomer 117559 117559 117559 117559 117559 117559 1

42 NUT, jam, suction 15E813 15E813 15E813 15E813 15E813 15E813 1

43 WASHER, lock; 1/4; part of stand kit (2)

44* HOPPER, kit

24G707 24G707 24G707 24G707 24G707 24G707 24G707 24G707 1

24G702 24G702 24G702 24G701 24G701 24G701 24G701 24G701 1

24F148 24F148 24F148 24F148 24F148 24F148 1

121141 121141 121141 121141 121141 121141 121141 121141 1

24H008 24H008 24H008 24H008 24H008 24H008 24H008 24H008 1

24F160 24F160

24F164 24F164 24F164 24F164 24F164 1

100058 100058 100058 100058 100058 6

--- --- --- --- ---

--- --- --- --- ---

17A493 17A493 1

Package

Qty24F152 24F153 24W287 24F154 24F155 24F156 24F157 24W285

24F160 24F160 24F160 24F160 1

4

1

6

‡

Included in Pump Lower Rebuild Kit. See page 31.

* Not shown. See Merkur ES Hopper Kit manual 334011 for more information.

3A0732J 27

Page 28

Parts

28 3A0732J

Page 29

Hose and Gun

Air-Assisted Packages Airless Packages

30

37

Parts

30

36

32

33

Ref. No. Description

29 HOSE, air, gun 241811 241811

30 GUN, air-assisted, G15; see 3A0149 24C853

32 HOSE, fluid; 1/8 in. (3 mm) ID nylon;

33 CLIP, hose; pack of 7 24H005 24H005 24H005 24H005 7

36★ TIP; G15, G40 AAF412 AAF412 AAF412 AAF412 1

29

TI16230a

GUN, air-assisted, G40; see 3A0149

GUN, airless; see 311254

1/4 npsm(f) plated steel couplings;

25 ft (7.6 m) long

HOSE, fluid; 1/8 in. (3 mm) ID nylon;

1/4 npsm(f) sst couplings; 25 ft (7.6 m)

long

TIP; airless

32

36

Package

24F150

24F151

24W281

24F165 24F165 24F165 1

24F152

24F153

24W287

24C855 24C855 1

24F166 24F166 1

24F154

24F155

235460 1

163515 1

24F156

24F157

24W285

241811 241811 1

24F158

24F159

24W283

24C853 1

TI16231a

Qty

★

Additional tip sizes are available. See manual 3A0149 for G15 and G40 AA Guns.

See tip manual 306686 for Silver Plus Airless Guns.

3A0732J 29

Page 30

Parts

Displacement Pump Parts

Part No. 24G701, Plated Steel

Part No. 24G702, Stainless Steel

‡102

103

‡104

‡112

‡106

‡114

105

15, see page 26

113‡

107‡

119

‡121

‡126

‡122

‡123

‡120

124

109❖

116‡❖

117❖

111‡❖

110

125‡

TI16131a

30 3A0732J

Page 31

Parts

Displacement Pump Parts

Part No. 24G701, Plated Steel

Part No. 24G702, Stainless Steel

Ref. Description 24G701 24G702 Qty

102‡ BUTTON, plug --- --- 1

103 NUT, packing; plated steel 193047

NUT, packing; sst

104‡ O-RING; buna-N; 1.262 in. (32.05 mm) OD --- --- 1

105 CYLINDER, pump 243176 24G706 1

106‡

107‡ O-RING; PTFE; 1.254 in. (31.85 mm) OD --- --- 1

109❖ GUIDE, ball 15C011 15C011 1

110 VALVE, intake housing; plated steel 15B611

111‡❖O-RING; PTFE; 0.941 in. (23.90 mm) OD --- --- 1

V-PACKING, throat; V-Max

VALVE, intake housing; sst

™

UHMWPE

--- --- 3

24H161 1

24H007 1

1

1

112‡ GLAND, female, throat; acetal --- --- 1

113‡ V-PACKING, throat; leather --- --- 2

114‡ GLAND, male, throat; acetal --- --- 1

116‡❖BALL, intake; sst; 0.500 in. (13 mm) dia. 105445 105445 1

117❖ SEAT, carbide 15A968 15A968 1

119

120‡ BALL, piston; sst; 0.3125 in. (7.94 mm) dia. 105444 105444 1

121‡ GLAND, male, piston; plated steel ---

122‡ GLAND, female, piston; plated steel ---

123‡ WIPER, piston --- --- 1

124 VALVE, piston; plated steel Order

125‡ V-PACKING, piston; leather --- --- 2

126‡

KIT, rod, displacement; Chromex

on page 25

GLAND, male, piston; sst

GLAND, female, piston; sst

VALVE, piston; sst

V-PACKING, piston; V-Max

™

™

UHMWPE

; includes item 124, and items 18 and 19

24G703 24G704 1

--- 1

--- 1

item 119

Order

item 119

--- --- 3

1

1

1

1

‡

Included in Pump Lower Rebuild Kit. Order Kit 24H006 for Pump 24G701, or Kit 24G705 for Pump 24G702.

❖

Included in Intake Check Valve Kit 246429.

3A0732J 31

Page 32

Parts

Air Motor Parts

Part No. 24G693, 2.5 in. (63.5 mm)

Part No. 24G694, 3.5 in. (88.9 mm), shown

231

*230

213

210

202*

205

219

*202

*217

*207

203

208*

204*

211

214

211

220

209*◆†

215

208*

206

*207

218

32 3A0732J

201

213

212

TI16130a

Page 33

Parts

Air Motor Parts

Part No. 24G693, 2.5 in. (63.5 mm)

Part No. 24G694, 3.5 in. (88.9 mm), shown

Ref. Description 24G693 24G694 Qty

201 KIT, cover, bottom; includes 202 (qty 1),

203, 207, 213 (qty 1), and 217

202* O-RING, cover Not sold separately. See Air Motor Seal Kit (below), Bottom Cover Kit

203 BEARING Not sold separately. See Bottom Cover Kit (201, this table) 1

204* O-RING, piston Not sold separately. See Air Motor Seal Kit (below) or

205 CYLINDER, motor 15M289 15M211 1

206▲ COVER, cylinder (includes English

warning label)

207* SEAL, u-cup Not sold separately. See Air Motor Seal Kit (below) or

208* GASKET, manifold Not sold separately. See Air Motor Seal Kit (below) or

209*◆† GASKET, air valve Not sold separately. See Air Motor Seal Kit, Valve Repair Kit 24A537,

Valve Seal Kit 24A535 (below), or Manifold Assembly (220, this table)

210 KIT, cover, top; includes 202 and 213

(qty 1 of each). 15X353 also includes

230 and 231.

211 SCREW, M6 x 25 Not sold separately. See Manifold Assembly (220, this table) or

212 BOLT, tie, hex head 15M314

BOLT, tie, hex head

213 VALVE, pilot (pack of 2) 24A366 24A366 1

214 VALVE, air; includes items 209 and 211

(qty 4)

215 MUFFLER 15M213 15M213 1

217* RING, retaining Not sold separately. See Air Motor Seal Kit (below) or

218 ROD, air motor Not sold separately. See Motor Piston Kit (219, this table) 1

219 KIT, piston, motor; includes 204 and

218, and 16G561 adhesive.

220 MANIFOLD, assembly, includes 208,

209, and 211 (qty. 4)

229▲ LABEL, warning (French and

Spanish)

230* O-RING, top plug (24G694 only)

231 PLUG, top cover (24G694 only) Not sold separately. See Top

24G695 24G696 1

(201, this table), or Top Cover Kit (210, this table)

Piston Kit (219, this table)

15M302 15M212 1

Bottom Cover Kit (201, this table)

Manifold Assembly (220, this table)

24H004 15X353 1

Air Valve Replacement Kit (page 35)

15M314 3

24A351 24A351 1

Bottom Cover Kit (201, this table)

24G697 24G698 1

24A579 24A579 1

15W719 15W719 1

Not sold separately. See Air Motor

Seal Kit (below)

Cover Kit (210, this table)

2

1

2

2

1

8

2

1

1

1

▲

Replacement Danger and Warning labels, tags, and cards are available at no cost.

† Included in Air Valve Seal Kit 24A535. See page 35.

◆

Included in Air Valve Repair Kit 24A537. See page 35.

* Included in Air Motor Seal Kit:

24G693

(2.5 in. Motor)

24G699 24G700

24G694

(3.5 in. Motor)

3A0732J 33

Page 34

Parts

Air Valve Parts

◆311

◆312

◆303

◆304

301

✠

310

†✠◆306

✠

307

◆305

†◆309

†◆308

◆302

†◆

308

✠ 307

†✠◆306

✠ 310

ti16213a

34 3A0732J

Page 35

Parts

Air Valve Parts

Complete Air Valve Replacement Kit 24A351

To replace the complete air valve, order Air Valve Replacement Kit 24A351. The kit includes items 301-312 below,

and items 209 and 211 on page 33.

Air Valve Repair Kits

Air valve parts are not sold individually. The table below shows possible kit options for each part.

Qty

Ref. Description

301 HOUSING 1

302◆ AIR VALVE PISTON 1

303◆ DETENT PISTON ASSEMBLY 1

304◆ DETENT CAM 1

305◆ PLATE, air valve 1

306†✠◆ O-RING 2

307✠ CAP 2

308†◆ U-CUP 2

309†◆ SCREW 2

310✠ SNAP RING 2

311◆ DETENT SPRING 1

312◆ CUP 1

.

Air Valve

Repair Kit

24A537

✔

✔

✔

✔

✔✔✔

✔✔

✔ ✔

✔✔

✔

✔

Air Valve

Seal Kit

24A535

† Included in Air Valve Seal Kit 24A535.

◆

Included in Air Valve Repair Kit 24A537.

✠

Included in Air Valve End Cap Kit 24A360.

Replacement screws (309) are available in a pack of 10. Order Kit 24A359.

Air Valve

End Cap Kit

24A360

✔

3A0732J 35

Page 36

Parts

Air Control Parts

Part No. 24H162, Air-Assisted, Wall Mount

Part No. 24H163, Air-Assisted, Stand Mount

409

1

413

407

420

401

1

Part of 402

1

Connect tubing (406) between these two fittings.

2

Used on stand mount units only.

405

408

402

418

410

422

411

412

404

403

402

418

2

TI16132a

404

2

Part No. 24H164, Airless, Wall Mount

Part No. 24H165, Airless, Stand Mount

1

409

1

407

421

420

401

410

405

1

36 3A0732J

402

Connect tubing (406) between these two fittings.

2

Used on stand mount units only.

413

422

411

412

404

418

2

TI16229a

Page 37

Parts

Air Control Parts

Part No. 24H162, Air-Assisted, Wall Mount

Part No. 24H163, Air-Assisted, Stand Mount

Part No. 24H164, Airless, Wall Mount

Part No. 24H165, Airless, Stand Mount

Ref. Description 24H162 24H163 24H164 24H165 Qty

401 BRACKET, handle 24H105 24H105 24H105 24H105 1

402 REGULATOR, air 15T499 15T499

REGULATOR, air

403 TEE; 1/4 npt(m) 115219 115219

404 GAUGE, air pressure 108190 108190

GAUGE, air pressure 108190 108190 1

405 ELBOW, tube; 1/4 npt(f) x 3/8 in. (10 mm) OD tube C38161 C38161

FITTING, tube; 1/4 npt(m) x 3/8 in. (10 mm) OD tube

406 TUBE, polyurethane; 3/8 in. (10 mm) OD tube; 2 ft (0.61 m) 24H008 24H008 24H008 24H008 1

407 VALVE, ball, air; 3/8 npt(fbe) 114362 114362 114362 114362 1

408 NIPPLE; 1/4 npsm x 1/4 npt 162453 162453

409 ELBOW, swivel; 3/8 npt(m) x 3/8 in. (10 mm) OD tube 16F151 16F151 16F151 16F151 1

410 ELBOW; 1/4 npt(f) x 1/8 npt(m) 121150 121150 121150 121150 1

411 VALVE, safety relief; 110 psi 113498 113498 113498 113498 1

412 ELBOW, swivel; 1/4 npt(m) x 3/8 in. (10 mm) OD tube 121141 121141 121141 121141 1

413 NUT, regulator 115244 115244

NUT, regulator

418 ELBOW, street, 45°; 1/8 npt (mxf)

ELBOW, street, 45°; 1/8 npt (mxf)

420 SCREW, cap, button-hd; 10-24 x 3/8 in. (10 mm) 114381 114381 114381 114381 2

421 PLUG, panel

422 RING, grounding 24P812 24P812 24P812 24P812 1

113630 2

15T499 15T499 1

120389 120389 1

115244 115244 1

113630 1

16F547 16F547 1

2

1

2

1

1

2

3A0732J 37

Page 38

Kits and Accessories

Kits and Accessories

Kit Description Part No.

Airless to Air-Assisted Conversion Kit 24F161

Inline Fluid Filter, stainless steel 24F271

Inline Fluid Filter, aluminum 24F272

Standard Suction Hose, 5 gal. (19 l), 3/8 in. (10 mm) OD

Suction Hose, 5 gal. (19 l), 5/8 in. (16 mm) OD

Suction Tube, 1 gal. (3.8 l), 11/32 in. (9 mm) OD

Standard Push-on Strainer Kit

Screw-on Strainer Kit (for 24F149 5/8 in. Suction Hose Kit)

Air Gauge Lens Cover Kit (sheet of 12 covers)

Throat Seal Liquid (TSL); 4 oz (118 ml)

Throat Seal Liquid (TSL); 8 oz (236 ml)

Alternate U-Cup Pump Packing Kit (UHMWPE)

Hopper Kit

Hopper Screens (Pack of 5)

Hopper O-Ring Kit

Hopper Bungee Cord Kit

24F148

24F149

24F147

24F160

256426

193199

238049

206994

24H665

17A493

17B207

17B208

17C166

38 3A0732J

Page 39

Package Dimensions

Package Dimensions

Package

Wall Mount

Stand Mount

Stand Mount

with Hopper

A

A, inch

(mm)

29.0 (737)

29.0 (737) 17.4 (442) 26.5 (673)

B

B, inch

(mm)

20.2 (513)

Front View Top View

C

inch (mm)Dinch (mm)

17.4 (442) 18.4 (467)

D

C

ti16287a

ti16288a

Package Weights

Package Description lb kg

24F150 15:1 plated steel, AA, wall

24F151 15:1 plated steel, AA, stand

24F152 30:1 stainless steel, AA, wall

24F153 30:1 stainless steel, AA, stand

24F154 30:1 plated steel, airless, wall

24F155 30:1 plated steel, airless, stand

24F156 30:1 plated steel, AA, wall

24F157 30:1 plated steel, AA, stand

3A0732J 39

20 9

23 10

23 10

26 12

22 10

25 11

23 10

26 12

Package Description lb kg

24F158 15:1 stainless steel, AA, wall

24F159 15:1 stainless steel, AA, stand

24W281 15:1 plated steel, AA, stand, hopper

24W283

24W285 30:1 plated steel, AA, stand, hopper

24W287

15:1 stainless steel, AA, stand,

hopper

30:1 stainless steel, AA, stand,

hopper

20 9

23 10

32 15

32 15

35 16

35 16

Page 40

Wall Bracket Mounting Hole Diagram

Wall Bracket Mounting Hole Diagram

2 x 0.35 in.

2 x 0.281 (9/32) in. (7 mm).

For wall mount only.

4.40 in. (112 mm)

(9 mm)

2 x 0.62 in.

(16 mm)

2.69 in.

(68 mm)

2 x 0.312 (5/16) in. (8 mm).

For wall mount or to attach

stand to bracket.

5.10 in. (130 mm)

2 x 0.48 in.

(12 mm)

TI16289a

40 3A0732J

Page 41

Technical Data

Maximum fluid working pressure

15:1 Pumps. . . . . . . . . . . . . . . . . . . . . . . . . . . .

30:1 Pumps. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum air inlet pressure . . . . . . . . . . . . . . . . . . . 100 psi (0.7 MPa, 7.0 bar)

Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15:1 or 30:1 (see Models, page 3)

Maximum fluid temperature. . . . . . . . . . . . . . . . . . . 160°F, 71°C

Ambient air temperature range . . . . . . . . . . . . . . . . 35-120°F, 2-49°C

Package air inlet size . . . . . . . . . . . . . . . . . . . . . . . 3/8 npt(f)

Package fluid outlet size . . . . . . . . . . . . . . . . . . . . . 1/4 npsm(m)

Maximum motor speed . . . . . . . . . . . . . . . . . . . . . .

(Do not exceed maximum recommended speed of

fluid pump, to prevent premature pump wear.)

Maximum spray tip orifice size . . . . . . . . . . . . . . . . .019 in. (0.483 mm)

Sound data

24G693 Air Motor

Sound power* . . . . . . . . . . . . . . . . . . . . . . .

Sound pressure**. . . . . . . . . . . . . . . . . . . . .

24G694 Air Motor

Sound power* . . . . . . . . . . . . . . . . . . . . . . .

Sound pressure**. . . . . . . . . . . . . . . . . . . . .

Wetted parts

Plated steel pumps . . . . . . . . . . . . . . . . . . . . . . Stainless steel, nickel plated carbon steel, tungsten

Stainless steel pumps . . . . . . . . . . . . . . . . . . . . Stainless steel, tungsten carbide, ptfe, acetal,

Spray guns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See manual 3A0149 (G15 and G40 AA guns) or

Fluid hose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Nylon, plated or stainless steel

Suction assembly . . . . . . . . . . . . . . . . . . . . . . . . Stainless steel, nylon, acetal, fluoroelastomer,

1500 psi (10.3 MPa, 103 bar)

3000 psi (20.7 MPa, 207 bar)

240 cycles per minute

83.2 dBA

76.5 dBA

84.5 dBA

77.9 dBA

carbide, ptfe, acetal, leather, ultra-high molecular

weight polyethylene

leather, ultra-high molecular weight polyethylene

311254 (Silver Plus airless gun)

polyethylene

Technical Data

* Sound power at 70 psi (0.48 MPa, 4.8 bar), 80 cpm. Sound power measured per ISO-9614-2.

** Sound pressure was tested 3.28 feet (1 m) from equipment.

3A0732J 41

Page 42

Performance Charts

Performance Charts

15:1 Ratio Pumps

1400

(10, 100)

1200

(8, 80)

1000

(7, 70)

800

(5.5, 55)

600

(4, 40)

400

(3, 30)

200

(1.4, 14)

Fluid Outlet Pressure psi (MPa, bar)

0

0

30 60 90 120 150 180 210

A

B

C

0.05

(0.2)

Fluid Flow gpm (lpm) tested in No. 10 weight oil

KEY

A = 100 psi (0.7 MPa, 7 bar)

B = 70 psi (0.5 MPa, 5 bar)

C = 40 psi (0.3 MPa, 3 bar)

= fluid flow

= air flow

Cycles per Minute

0.10

(0.4)

0.15

(0.6)

0.20

(0.75)

0.25

(0.9)

0.30

(1.1)

A

B

C

0.35

(1.3)

240

0.40

(1.5)

10.5

(0.3)

9.0

(0.25)

7.5

(0.2)

6.0

(0.17)

4.5

(0.13)

3.0

(0.08)

1.5

(0.04)

/min)

3

Air Flow scfm (m

42 3A0732J

Page 43

30:1 Ratio Pumps

3000

(21, 210)

2500

(17.5, 175)

KEY

A = 100 psi (0.7 MPa, 7 bar)

B = 70 psi (0.5 MPa, 5 bar)

C = 40 psi (0.3 MPa, 3 bar)

= fluid flow

= air flow

Cycles per Minute

30 60 90 120 150 180 210 240

A

Performance Charts

18.0

(0.5)

15

(0.42)

(14, 140)

(10.5, 105)

(7, 70)

(3.5, 35)

Fluid Outlet Pressure psi (MPa, bar)

2000

1500

1000

500

B

A

C

B

C

0

0.05

0

(0.2)

Fluid Flow gpm (lpm) tested in No. 10 weight oil

0.10

(0.4)

0.15

(0.6)

0.20

(0.75)

0.25

(0.9)

0.30

(1.1)

0.35

(1.3)

12.0

(0.34)

9.0

(0.25)

6.0

(0.17)

3.0

(0.08)

0.40

(1.5)

/min)

3

Air Flow scfm (m

3A0732J 43

Page 44

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER,

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2010, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

contact your Graco distributor or call to identify the nearest distributor.

Graco reserves the right to make changes at any time without notice.

Original instructions.

International Offices: Belgium, China, Japan, Korea

This manual contains English. MM 3A0732

Graco Headquarters: Minneapolis

www.graco.com

Revision G - July 2014

Loading...

Loading...