Page 1

Instructions - Parts

3A0590G

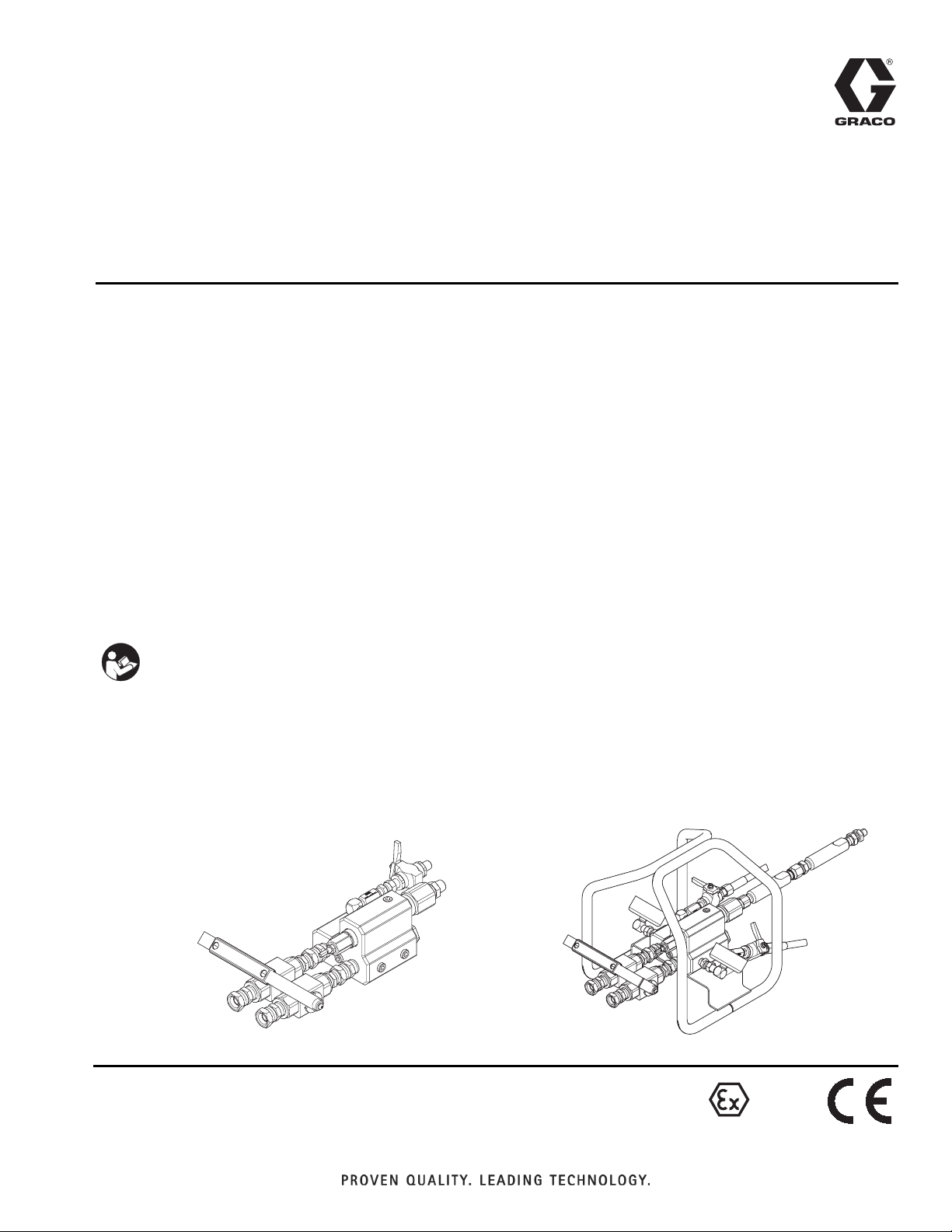

Mix Manifold

For mixing two component reactive materials with plural-component sprayers.

For professional use only.

Approved for use in explosive atmospheres.

Part No. 262807

Mix Manifold, Single Flush

Part No. 24M398

Quickset Mix Manifold, Dual Flush with Carriage, Gauges, and Static Mixers

EN

7250 psi (50 MPa, 500 bar) Maximum Working Pressure

5000 psi (34.5 MPa, 345 bar) Maximum Flush Inlet Pressure

160 °F (71 °C) Maximum Fluid Temperature

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

262807 24M398

ti19004a

ti18954a

II 2 G

cT5

Page 2

Related Manuals

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Important Two-Component Material Information . 6

Isocyanate Conditions . . . . . . . . . . . . . . . . . . . . . 6

Material Self-ignition . . . . . . . . . . . . . . . . . . . . . . 6

Keep Components A and B Separate . . . . . . . . . 6

Moisture Sensitivity of Isocyanates . . . . . . . . . . . 6

Foam Resins with 245 fa Blowing Agents . . . . . . 6

Changing Materials . . . . . . . . . . . . . . . . . . . . . . . 7

A and B Component Designations . . . . . . . . . . . 7

Component Identification . . . . . . . . . . . . . . . . . . . . 8

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Fluid Inlets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Solvent Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Fluid Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Flush Before Using Equipment . . . . . . . . . . . . . . 11

Ratio Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Pressure Relief Procedure . . . . . . . . . . . . . . . . 12

Trigger Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Dispensing and Spraying . . . . . . . . . . . . . . . . . . . 14

Volume Balancing the Mix Manifold . . . . . . . . . . . 15

Adjust Restriction at the Mix Manifold . . . . . . . . 15

Hose Selection for Feeding A Remote Mix Manifold

15

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Clean Static Mixers . . . . . . . . . . . . . . . . . . . . . . 17

Clean “B” Side Screen . . . . . . . . . . . . . . . . . . . . 17

Clean Mix Manifold Outlet . . . . . . . . . . . . . . . . . 17

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Cartridge Assemblies . . . . . . . . . . . . . . . . . . . . 19

Remove Restrictor . . . . . . . . . . . . . . . . . . . . . . . 20

Assemble Restrictor . . . . . . . . . . . . . . . . . . . . . 20

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Repair Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Accessory Ports . . . . . . . . . . . . . . . . . . . . . . . . 26

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 28

Related Manuals

Manuals are available at www.graco.com

Component Manuals in English:

Manual Description

3A0420

3A0421

306861

339361

2 3A0590G

XP Sprayer, Instructions-Parts

Ratio Check Kit, Instructions-Parts

Ball Valves, Check Valves, and Swivels,

Instructions-Parts

High Pressure Hose and Accessories Bro-

chure

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual, refer back to these Warnings. Product-specific hazard symbols and

warnings not covered in this section may appear throughout the body of this manual where applicable.

WARNING

WARNINGWARNINGWARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes are

present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment until

you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about

your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure. Turn off all equipment and

follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

3A0590G 3

Page 4

Warnings

WARNING

WARNINGWARNINGWARNING

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

THERMAL EXPANSION HAZARD

Fluids subjected to heat in confined spaces, including hoses, can create a rapid rise in pressure due to

the thermal expansion. Over-pressurization can result in equipment rupture and serious injury.

• Open a valve to relieve the fluid expansion during heating.

• Replace hoses proactively at regular intervals based on your operating conditions.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on skin and

cause serious injury.

• Follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear chemically impermeable gloves when spraying, dispensing, or cleaning equipment.

4 3A0590G

Page 5

Warnings

WARNING

WARNINGWARNINGWARNING

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical

reaction and equipment rupture. Failure to follow this warning can result in death, serious injury, or

property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material supplier

for compatibility.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area

of the equipment to help protect you from serious injury, including eye injury, hearing loss, inhalation of

toxic fumes, and burns. This equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

3A0590G 5

Page 6

Important Two-Component Material Information

Important Two-Component Material Information

Isocyanate Conditions

Spraying or dispensing materials containing

isocyanates creates potentially harmful mists, vapors,

and atomized particulates.

Read material manufacturer’s warnings and material

MSDS to know specific hazards and precautions

related to isocyanates.

Prevent inhalation of isocyanate mists, vapors, and

atomized particulates by providing sufficient

ventilation in the work area. If sufficient ventilation is

not available, a supplied-air respirator is required for

everyone in the work area.

To prevent contact with isocyanates, appropriate

personal protective equipment, including chemically

impermeable gloves, boots, aprons, and goggles, is

also required for everyone in the work area.

Material Self-ignition

Some materials may become self-igniting if applied

too thick. Read material manufacturer’s warnings and

material MSDS.

Keep Components A and B

Moisture Sensitivity of Isocyanates

Isocyanates (ISO) are catalysts used in two component

foam and polyurea coatings. ISO will react with moisture

(such as humidity) to form small, hard, abrasive crystals,

which become suspended in the fluid. Eventually a film

will form on the surface and the ISO will begin to gel,

increasing in viscosity. If used, this partially cured ISO

will reduce performance and the life of all wetted parts.

NOTE: The amount of film formation and rate of crystallization varies depending on the blend of ISO, the

humidity, and the temperature.

To prevent exposing ISO to moisture:

• Always use a sealed container with a desiccant

dryer in the vent, or a nitrogen atmosphere. Never

store ISO in an open container.

• Keep the ISO pump wetcup or reservoir (if installed)

filled with Graco Throat Seal Liquid (TSL

206995. The lubricant creates a barrier between the

ISO and the atmosphere.

• Use moisture-proof hoses specifically designed for

ISO.

• Never use reclaimed solvents, which may contain

moisture. Always keep solvent containers closed

when not in use.

• Never use solvent on one side if it has been contaminated from the other side.

• Always lubricate threaded parts with TSL or grease

when reassembling.

™

), Part

Separate

Foam Resins with 245 fa Blowing Agents

Some foam blowing agents will froth at temperatures

Cross-contamination can result in cured material in

fluid lines which could cause serious injury or

damage equipment. To prevent cross-contamination

of the equipment’s wetted parts, never interchange

component A (isocyanate) and component B (resin)

parts.

6 3A0590G

above 90°F (33°C) when not under pressure, especially

if agitated. To reduce frothing, minimize preheating in a

circulation system.

Page 7

Changing Materials

• Changing material types used in your sprayer

requires special attention to avoid equipment damage and downtime.

• Always clean the fluid inlet strainers after flushing.

• When changing between epoxies and urethanes or

polyureas, disassemble and clean all fluid components and changes hose sets.

• Check with your material manufacturer for chemical

compatibility.

• Most materials use ISO on the A side, but some use

ISO on the B side.

• Epoxies often have amines on the B (hardener)

side. Polyureas often have amines on the B (resin)

side.

Important Two-Component Material Information

A and B Component Designations

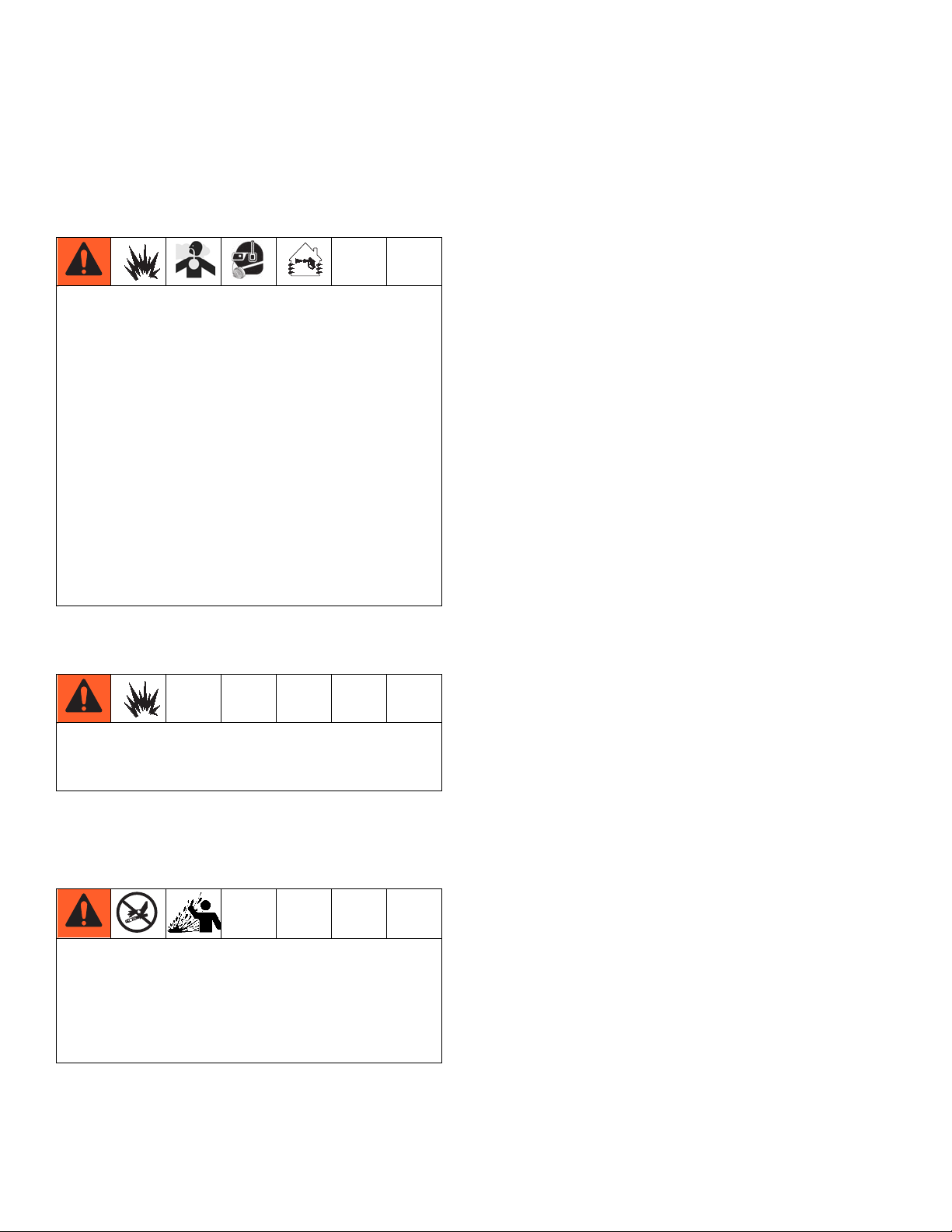

Material suppliers and markets refer to plural component materials differently. The table below summarizes the different designations for the components used in various machines.

Market Equipment Designations

Foam and Polyurea

Urethane Pour

Epoxy and Urethane

Protective Coatings

Epoxy, Silicone, Ure-

thanes, and other mate-

rials

All Reactors, HFR

and VRM

Hydra-Cat

™

Mix

, XM™, XP, and

PR70

PR70 and PR

™

®

, Xtreme-

™

Letter

Color

™

,

Component Names

Major or Minor Component

(when not 1:1 mix)

Letter

Color

Component Names

Major or Minor Component

(when not 1:1 mix)

Letter

Color

Component Names

Major or Minor Component

(when not 1:1 mix)

Machine Left

Side

AB

Red Blue

ISO, Hardener,

Catalyst

Low Volume

Side

AB

Blue Green

Resin, Base

High Volume

Side

AB

Red Blue

Polyol, Resin,

Base

High Volume

Side

Machine Right

Side

Polyol, Resin,

Base

High Volume

Side

Hardener, Cata-

lyst

Low Volume

Side

ISO, Hardener,

Catalyst

Low Volume

Side

3A0590G 7

Page 8

Component Identification

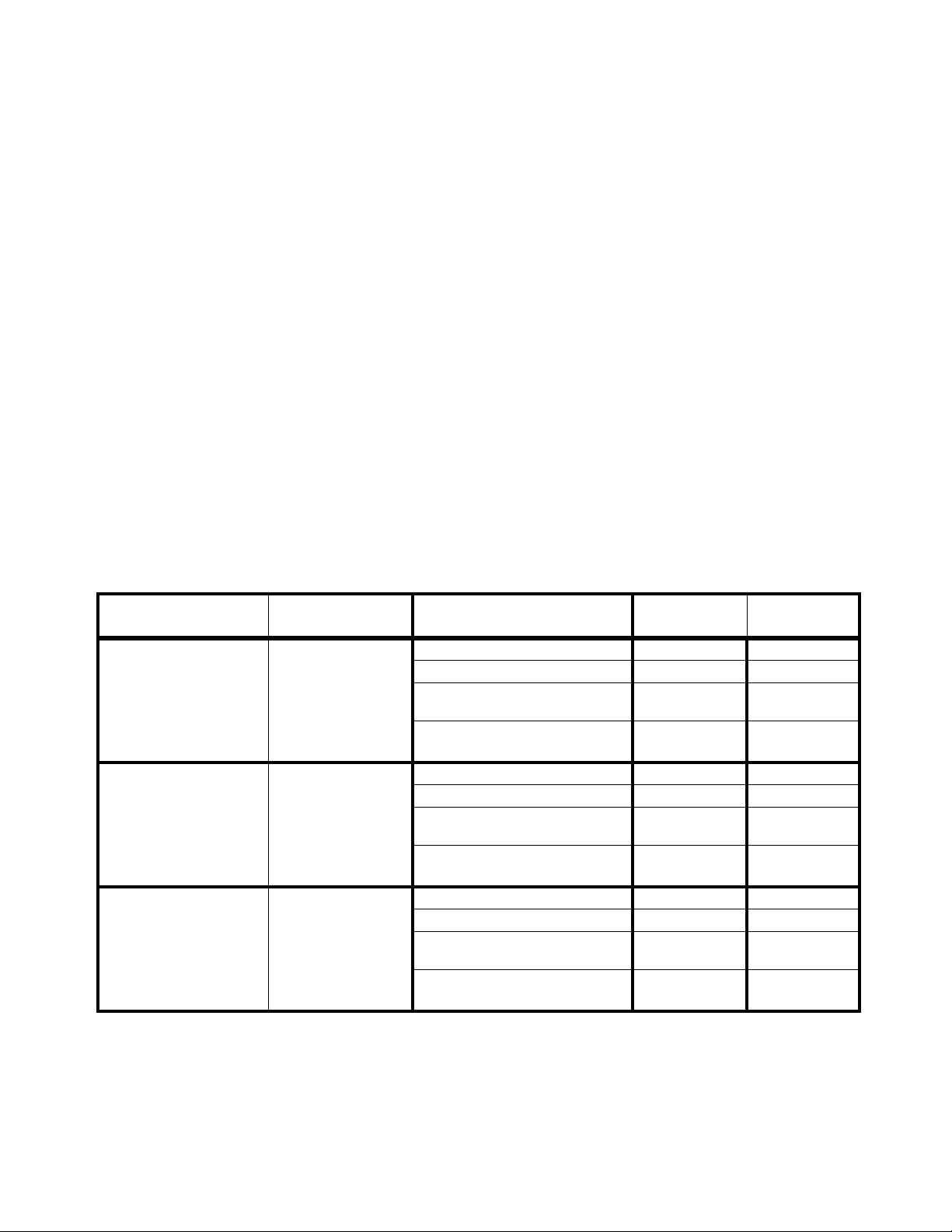

Component Identification

D

P

S

G, H

B

A

E

F

R

C

J, M★

J, M★

Key:

A Resin (High Volume) Inlet (A material)

B Hardener (Low Volume) Inlet (B material)

C Solvent Inlet Valve, 1/4 npt(m)

D Manifold

E Dual Shutoff Handle

F Hardener Restrictor Adjustment

G Hardener Center Inject Tube (not shown; inside outlet H)

H Mix Manifold Outlet, 1/2 npt(f) with 3/8 npt(m) adapter

J Static Mix Housing

K Fluid Whip Hose

L Airless Spray Gun

M Static Mixing Element (not shown; inside J)

N Fluid Mix Hose

P Accessory Ports (see Accessory Ports, page 26)

R B Side Flush Inlet Check Valve

S A Side Check Valve Cartridge (B side not shown)

T A Side Solvent Inlet Valve (Quickset Manifold)

U A Side Solvent Check Valve (Quickset Manifold)

N ★

J, M★

★ Not included with mix manifold. See Parts, starting

on page 22.

K ★

Quickset Manifold

FIG. 1: Typical Installation

L ★

ti19003a

T

U

ti18954a

8 3A0590G

Page 9

Overview

n

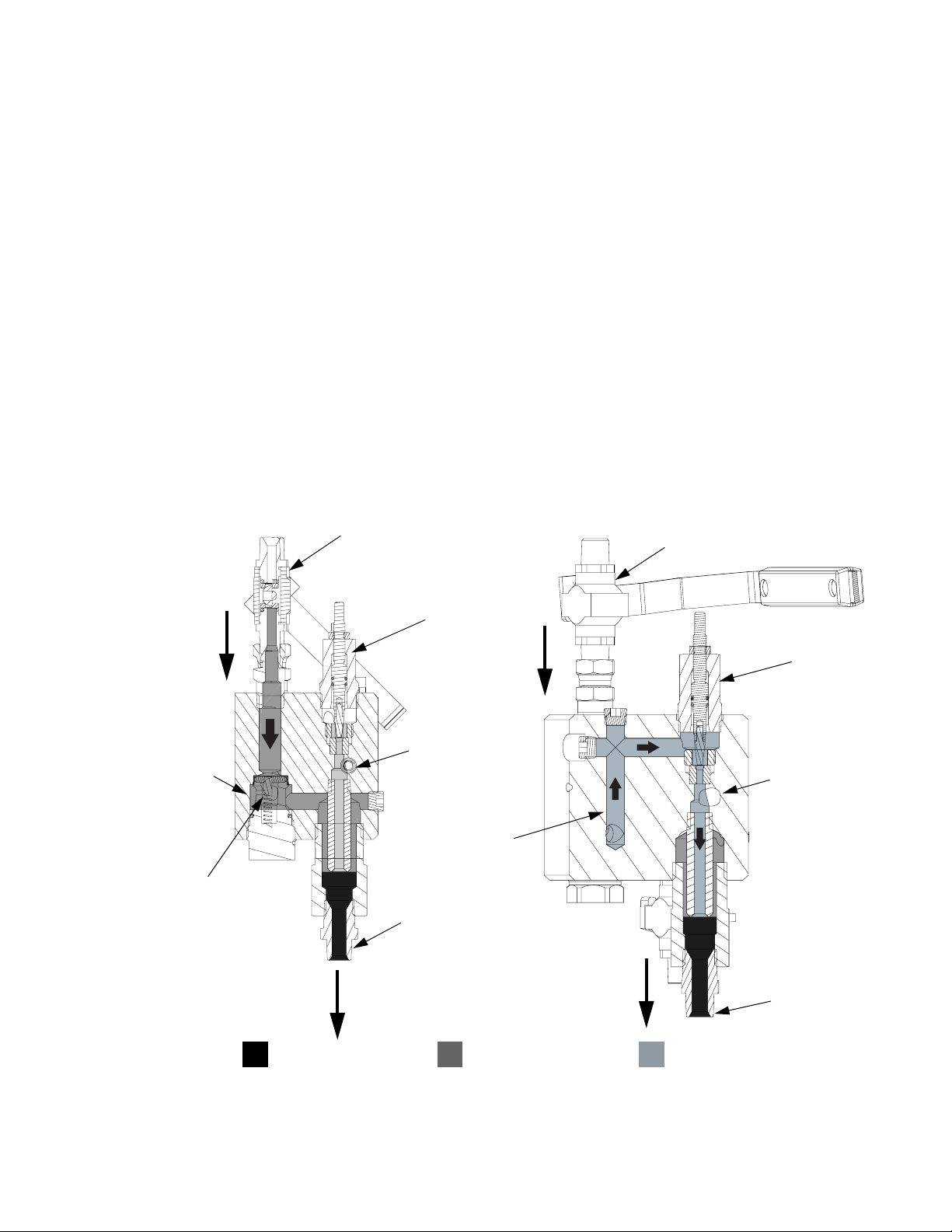

Overview

The left side of the mix manifold is intended for the major

volume material, or the higher viscosity material if using a

1:1 volume mix. This side is referred to throughout the

manual as the resin side or “A” side.

The right side is referred to as the Hardener side or “B”

side. The “B” side incorporates an adjustable restrictor for

balancing the system back pressure and flow.

See FIG. 2 to view flow of “A” and “B” material inside the

Mix Manifold.

“A” Inlet Ball Valve

F

The resin and hardener enter the mix manifold through the

manifold inlet ports and spring loaded carbide ball checks.

The “A” material flows through the manifold to the material

outlet port. The injector tube creates a hollow stream of “A”

material for the “B” material to fill once the hardener exits

the injector tube. The resin and hardener material mix after

they have left the mix manifold block (B).

When the manifold is mounted remote from the proportioner, adjust the “B” side restrictor (F) to balance the system back pressure and flow.

On the standard mix manifold, mixed material is flushed out

by sending a flush solvent through the B side center tube.

On the quickset mix manifold, solvent is also flushed across

the A side fluid check valve.

“B” Side of Mix Manifold“A” Side of Mix Manifold

“B” Inlet Ball Valve

“A” side solvent

flush inlet

across check

ball added on

Quickset model.

Carbide

Solvent Fluid Inlet

(on “B” side)

“B” side flow

after check

valve

Check Valve

(on each side)

H

r_258987_3a0420_3a

Mixed Material A Side Material B Side Material

FIG. 2: Cross-Section Side Views of A and B Flow

F

“B” side solvent

flush inlet after

restrictor (Used o

both models)

H

r_258987_3a0420_2a

3A0590G 9

Page 10

Installation

Installation

For assistance in setting up a plural component sprayer,

contact your Graco distributor, to ensure that you select

the proper type and size equipment for your system.

See illustration in F

IG. 1 on page 8.

Fluid Inlets

The A and B fluid inlets (A and B) are equipped with 1/2

npt(f) ball valves. Connect 1/2 in., 3/8 in., or 1/4 in.

npsm(f) fluid hoses with adapter nipples as needed. See

brochure 339361 for high pressure hose and fitting part

numbers.

NOTE: If the manifold is remote, the hoses must be

properly sized and balanced. See Volume Balancing

the Mix Manifold on page 15 for more remote setup

information.

Solvent Inlet

Connect the solvent supply line (D) from the solvent

pump to the 1/4 npt(m) solvent inlet valve (C), or inlet

tee on the Quickset model.

NOTE: Use a Graco approved grounded hose rated

to withstand the maximum fluid working pressure of

the solvent pump. The hose core must be chemically compatible with the solvent being used, such

as nylon or PTFE.

Fluid Outlet

Connect the outlet to two primary static mixer tubes (J),

with mixer elements (M), to the mix hose (N), cleanup

mixer (J), whip hose (K), and spray gun (L).

NOTICE

To prevent creating a flare on the mixer tube, do not

use a union swivel end on the mix tube inlet.

Add mixed material hose as necessary between the mix

hose and cleanup mixer.

NOTICE

Never split the flow to multiple guns until the two fluids are mixed after the mix manifold assembly.

Mounting

Remote Mix Manifold

The mix manifold can be removed from the proportioner

and mounted closer to the gun. This reduces the volume

of mixed material and flush solvent for quick setting

materials (less than 10 minute pot life). See Volum e

Balancing the Mix Manifold on page 15 for more

remote setup information.

Use Remote Mix Manifold Carriage 262522 for in-line

hose mount locations. The carriage protects the manifold and valves from accidental operation which could

cause a plugged line.

Bare Manifold

To mount the bare manifold, drill two holes in the mounting surface, and secure with the two 1/4-20 screws (28).

9/32 diameter

1.1 in. (27.94 mm)

10 3A0590G

Page 11

Grounding

Grounding

Your system must be grounded. Read warnings in

your sprayer manual. Check your local electrical

code.

• Pump: use ground wire and clamp as instructed in

your sprayer manual.

• Air and fluid hoses: use only electrically conductive hoses. with a maximum of 500 ft. (150 m) combined hose length to ensure grounding continuity.

Check electrical resistance of hoses. If total resistance to ground exceeds 29 megohms, replace

hose immediately.

• Air compressor: follow manufacturer’s recommendations.

• Spray gun: ground through connection to a properly grounded fluid hose and pump.

• Fluid supply container: follow local code.

Flush Before Using Equipment

The equipment was tested with lightweight oil, which is

left in the fluid passages to protect parts. To avoid contaminating your fluid with oil, flush the equipment with a

compatible solvent before using the equipment. See

Flushing, page 13.

Ratio Check

Perform the ratio check procedure after any changes to

the proportioning system. Use Ratio Check Kit 24F375

to check the ratio at the mix manifold. See manual

3A0421 for instructions and parts.

NOTICE

To prevent an inaccurate ratio check when feed

pumps are used in your system, the feed pressure

cannot be more than a maximum of 25% of the proportioner outlet pressure while dispensing. High

feed pressure can float the proportioner pump

check balls, resulting in an inaccurate ratio check.

• Object being sprayed: follow local code.

• Solvent pails used when flushing: follow local

code. Use only conductive metal pails, placed on a

grounded surface. Do not place the pail on a nonconductive surface, such as paper or cardboard,

which interrupts grounding continuity.

• To maintain grounding continuity when flushing

or relieving pressure: hold metal part of the spray

gun firmly to the side of a grounded metal pail, then

trigger the gun.

3A0590G 11

Page 12

Operation

Operation

Pressure Relief Procedure

Follow pressure relief procedure when you stop

spraying or dispensing; and before cleaning,

checking, servicing, or transporting equipment.

Relieve A and B Fluid Pressure

1. Engage the trigger lock.

ti1949a

2. Turn off the sprayer.

3. Close the bleed-type master air valve.

4. Open the dual shutoff handle (E).

8. Hold a metal part of the gun firmly to a grounded

metal pail. Trigger the gun to relieve pressure.

ti1953a

9. Engage the trigger lock.

ti1949a

10. Open all fluid drain valves in the system, having a

waste container ready to catch drainage. Leave

drain valves open until you are ready to spray again.

5. Shut off fluid heaters, if used on your sprayer.

6. Shut off feed pumps, if used.

7. Disengage the trigger lock.

ti1950a

11. If you suspect the spray tip or hose is clogged or

that pressure has not been fully relieved after following the steps above, VERY SLOWLY loosen tip

guard retaining nut or hose end coupling to relieve

pressure gradually, then loosen completely. Clear

hose or tip obstruction.

Trigger Lock

Always engage the trigger lock when you stop spraying

to prevent the gun from being triggered accidentally by

hand or if dropped or bumped.

12 3A0590G

Page 13

Operation

Flushing

Read warnings and grounding instructions in your

sprayer manual. If your system uses heaters, shut off

the main power to the heaters and heated hose

control before flushing.

NOTICE

To prevent fluid from setting up in the dispensing

equipment, flush the system frequently. Be sure

there is an adequate amount of solvent in the solvent supply before spraying.

NOTE:

• Ensure flushing fluid is compatible with dispense fluid and the equipment wetted parts.

• Use a solvent that dissolves the material you are

mixing.

4. Open the solvent inlet valve (C). For the quickset

manifold, close the A side flush valve (T).

T

C

ti18994a

C

5. Place the siphon tube in a grounded metal pail containing cleaning fluid.

6. Set pump to the lowest possible fluid pressure, and

start pump.

7. Trigger the gun into a grounded metal pail with lid.

Use a lid with a hole to dispense through to avoid

splashing. Trigger the gun until clean solvent dispenses.

• Solvent may channel through viscous fluids and

leave a coating of mixed fluid on the inner tube

of your hose. Be sure all fluid is thoroughly

flushed from the hose after each use.

• Remove spray tip for more thorough cleaning of

the whip hose and static mixers.

• Always leave equipment filled with fluid to avoid

drying and scaling.

• Frequently remove, clean and replace the static

mixer elements

1. Follow Pressure Relief Procedure, page 12.

2. Remove the spray tip and soak in solvent.

3. Close the dual shutoff handle (E).

ti1953a

a. For the standard mix manifold, go to step 8.

b. For the quickset mix manifold, after briefly flush-

ing with the B side valve, close the B side flush

valve (C) and open the A side flush valve (T).

Repeat step 7 until clean.

C

T

ti18995a

8. Turn off the solvent pump air supply.

9. Hold the metal part of the gun firmly to a grounded

metal pail with lid in place. Trigger the gun until all

fluid pressure is relieved.

3A0590G 13

Page 14

Dispensing and Spraying

10. Engage the trigger lock.

ti1949a

11. Close solvent inlet valve (C).

12. Remove the gun from the hose. See gun manual to

further clean the gun.

Dispensing and Spraying

1. Close the solvent inlet valve (C) and A side solvent

valve (T) if equipped.

4. Disengage the trigger lock.

ti1950a

5. Hold the metal part of the gun firmly to a grounded

metal pail with a lid to avoid splashing. Trigger the

gun until mixed coating material is evident and

purge solvent is gone.

ti1953a

2. Open the dual shutoff handle (E).

NOTICE

To prevent damage to the valve balls and seats,

always fully open or fully close the dual shutoff handle. Also increase the fluid pressure after opening

the ball valves to allow valves to last longer.

3. Turn on sprayer. See sprayer operation manual.

6. Proceed spraying.

14 3A0590G

Page 15

Volume Balancing the Mix Manifold

Volume Balancing the Mix Manifold

If the mix manifold is mounted on the machine, you do

not need to adjust the restrictor (F). Leave open two

turns minimum.

When the manifold is remote, two things must be done

to reduce momentary ratio errors that can occur due to

the compressible nature of paint hoses.

• Adjust Restriction

• Select correct sized hoses

Adjust Restriction at the Mix Manifold

The B side restrictor (F) in the mix manifold is only used

when the mix manifold is positioned remote from the

machine with a short mix hose to the spray gun.

The restrictor (F) controls “lead/lag” ratio errors of the A

and B flow into the static mixer tubes. These errors

occur momentarily when the gun opens. The error is

caused by differences in viscosity, volume, and hose

expansion between the proportioner outlets and the mix

point.

Adjust the restrictor (F) stem clockwise while spraying

until you see a slight rise in the B side pressure gauge.

The point where the pressure starts to rise is a good

adjustment setting.

restrictor stem

NOTE: Unless you are dispensing directly out of the

mix manifold and mixer, this an approximate adjustment.

For low viscosity fluids, an optional 40 mesh screen can

be installed in the mix manifold, in front of the restrictor.

This keeps the carbide tapered stem and seat from

plugging.

Hose Selection for Feeding A Remote Mix Manifold

The mix manifold can be removed from the machine and

used closer to the spray gun to minimize the mixed

material in the hoses and reduce flush solvent with the

following restrictions.

• Only one mix manifold can be used on a proportioner.

• Splitting flow to two or more guns can only be done

after the two fluids are mixed.

NOTE: This applies to applications that are not 1:1

ratio, and don’t have near balanced viscosities.

Balance the hoses inside area sizes in relation to the

mix ratio by volume. This is most important when the

mix manifold gets close to the spray gun.

The proportioner will put out the two materials in the

exact ratio by volume. If the hose sizes are not balanced

to the ratio, one hose will always come up to pressure

first. This ratio error at the mix point can occur anytime

that there is a change in pressure. Balance the hose

sizes by effective area, not by inside diameter.

Area = (3.1416 * radius

NOTE: For balancing purposes, it is always

assumed that the A side is the high volume side.

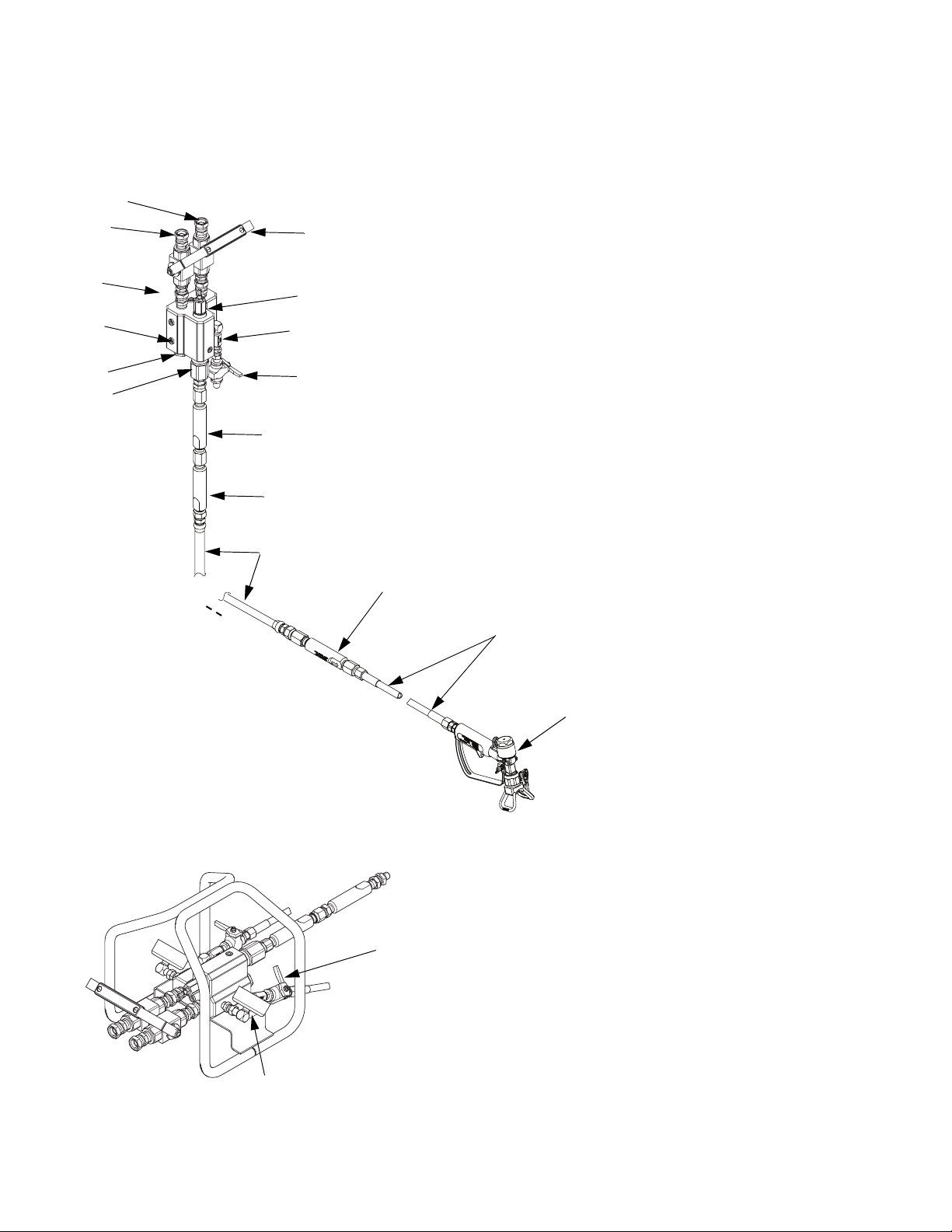

Table 1: Volume Ratio of “A” to “B” Hose

Mix Ratio

1:1 1/2 x 1/2 1.0:1

1.5:1, 2:1 1/2 x 3/8 1.78:1

2:1 3/8 x 1/4 2.25:1

2.5:1 3/8 x 1/4 2.25:1

3:1

4:1 1/2 x 1/4 4.0:1

Example: At a 4:1 mix ratio, a 1/2 in. ID resin hose and

a 1/4 in. ID hardener hose matches the 4:1 volume ratio.

2

) or see Table 1.

Hose Selection

“A” x “B”

3/8 x 3/8

Volume Ratio

For high viscosity 1:1 applications, the entire restrictor

assembly and seat can be removed and replaced by a

high pressure 3/4 npt plug.

3A0590G 15

Page 16

Volume Balancing the Mix Manifold

Use Table 2 and the examples provided to approximate

how much pressure drop you can expect for every 50 ft

(15.2 m) of hose at 1 gpm flow in that particular hose for

a 1000 cps viscosity material. Adjust for your applications flow rate and viscosity.

Table 2: Hose Selection by Pressure Drop

Pressure Drop per 15.24

meter section per 1000

cps at 1 liter/min.

Hose ID

(in.)

Pressure drop per 50 ft

section per 1000 cps at 1

gal/min.

(psi)

1/8 55910 1018

3/16 11044 201

1/4 3494 64

3/8 690 13

1/2 218 4

5/8 89 1.62

3/4 43 0.78

#1 Example: What is the pressure loss of a 2000 cps

material through 150 ft of 3/8 in. ID hose at 0.75 gpm?

NOTE: Typical flow rates are usually 0.4-0.8 gpm

(1.5-3 l/mn) per gun depending on tip size and viscosity.

Reference Formula

Pressure drop = 0.0273 QVL/D

(Bar)

Key:

Q = Vis poise (centipoise/100)

V= Gallons per minute

L= Length (ft)

D=Inside diameter (in.)

#2 Example: What is the pressure loss of a 2000 cps

material through 150 ft of 1/2 in. ID hose at 0.75 gpm?

4

690 psi (from chart) x 2 (viscosity factor 2 x 1000 cps) x

3 (3 x 50 ft hoses) x 0.75 (% of gpm) = 3105 psi loss

That is a lot of pressure loss before the spray gun. Let’s

try 1/2 in. hose. See example #2.

218 psi (from chart) x 2 (viscosity factor 2 x 1000 cps) x

3 (3 x 50 ft hoses) x 0.75 (% of gpm) = 981 psi loss

NOTE: Avoid under sizing the high volume side.

Pressure drop during flow conditions will increase

momentary hose induced ratio errors. See Table 2.

16 3A0590G

Page 17

Maintenance

Maintenance

Clean Static Mixers

See FIG. 1 on page 8. Typically, two static mixer housings are connected to the mix manifold outlet (H). These

housings use plastic mix elements, available in a package of 25 (Part No. 248927).

NOTICE

Never use a swivel union on the mixer inlets. The

union will compress the tube and make it impossible

to remove the mix element.

To clean the housing and replace the mix element:

1. Relieve pressure, see page 12. Remove mixer

housings (J) from whip hose (K).

2. Place flats of mixer housing (J) in a grounded vise.

Push mix element (P) out of the inlet end.

3. If necessary, use a 1/2 in. drill bit to drill out old

material and the mix element from the inlet end,

down to the internal shoulder at the outlet end.

4. Use a brush to clean any debris in housing (J).

NOTE: The o-ring (18) is used as a retainer ring, not a

seal. It may be scratched or deformed from pushing the

screen (17) back in.

21

20

19

18

17

5. Insert new mix element, wide end first.

Clean “B” Side Screen

NOTE: The following instructions apply only when

using the strainer accessory for low viscosity fluids.

See Accessories on page 26.

1. Loosen swivels (19) and remove shutoff handle (21)

and valves (20). See F

2. Remove “B” inlet union (19) from manifold block (1).

3. Pull “V” screen (17) and retainer o-ring (18) straight

up and out with a needle nose pliers.

4. Clean or replace screen (17).

5. Reinstall screen (17) and o-ring (18) with accessory

tool 15T630.

IG. 3.

FIG. 3: “B” Side Screen

6. Install “B” inlet union (19) from manifold block (1).

Clean Mix Manifold Outlet

1. Remove outlet fitting (5) to expose “B” center injection tube (4).

2. Clean any build-up on, around, or inside the tube

(4).

3. Reinstall outlet fitting (5).

4

5

3A0590G 17

Page 18

Troubleshooting

Troubleshooting

1. Relieve the pressure before you check or service any system equipment.

2. Check all possible causes and solutions in the troubleshooting chart before disassembling the manifold.

Problem Cause Solution

Little or no resin output. Fluid inlet is plugged. Clean inlet; remove obstruction.

Fluid container is empty. Refill.

Little or no hardener output. Fluid inlet is plugged. Clean inlet; remove obstruction.

Fluid container is empty. Refill.

Hardener screen (18) is plugged. Clean hardener screen. See Clean “B”

Side Screen, page 17.

Mixed fluid will not flush out. Fluid is hardened in static mixers or whip

hose.

Solvent supply container is empty. Refill.

Solvent is not compatible with fluid. Change to compatible solvent.

Hardener pressure higher than normal. Hardener is cold. Correct heat problem.

Restrictor or screen plugging up. Open restrictor or clean screen. See

Hardener pressure lower than normal. Resin is cold. Flow rate is low. Correct heat problem.

Worn hardener restrictor. Adjust restrictor. See Adjust Restriction

Spray pattern developing tails. Static mixer and/or whip hose plugging

up.

Low pressure from sprayer. Check air supply pressure. Check inlet air

Cold material. Increase heat.

Too much pressure drop. Use larger hoses or more heat.

Not enough air supply. Gauge drops

while spraying.

Motor is icing. Use De-Ice Bleed Air on motor. Dry or

Dirty filter in pumps or spray gun. Clean filters.

Resin or hardener does not shut off. Damaged ball or seat or seal in valve

(20).

Off ratio condition after increasing spray

pressure in spray mode with a remote mix

manifold.

Hoses not volume balanced. Volume balance A and B remote material

Clean with compatible solvent. See Main-

tenance, page 17. Replace as necessary.

Clean “B” Side Screen, page 17.

at the Mix Manifold, page 15.

Clean Static Mixers, page 17.

Clean spray gun and tip. See gun manual.

gauges while spraying.

Air hose is too small.

Compressor is too small.

cool air before use.

Wait for motor to thaw.

Replace or rebuild valve (2). See manual

306861.

hoses closer to volume mix ratio. See

Hose Selection for Feeding A Remote

Mix Manifold, page 15 and Maintenance, page 17.

18 3A0590G

Page 19

Repair

Follow pressure relief procedure when you stop

spraying or dispensing; and before cleaning,

checking, servicing, or transporting equipment.

NOTICE

Be sure to label all fluid parts “resin” or hardener”

when disassembling them. Doing so prevents interchanging resin and hardener parts during reassembly and prevents contamination of the materials and

fluid path through the equipment.

Color-coded chemically resistant tape may be used

to label the parts. Use blue for resin and green for

hardener.

Repair

5. Remove the seat (2e), ball (2d), spring (2c), and

o-ring (2b) from housing (2a).

2f

2e

2b

2d

2c

2a

Cartridge Assemblies

1. Follow Pressure Relief Procedure, page 12.

2. Use a wrench to remove the cartridge assemblies

(2) from the manifold.

3. Use a 90° allen wrench to pop the seat (2e) and

seal (2f) out of the housing, or tap them out from the

“A” and “B” inlet side.

NOTE: Seat retainer seal (2f) normally splits into two

pieces when it is fully torqued into the housing. The lip is

meant to retain the seat, spring, and ball during assembly. The seat retainer seal (2f) must always be replaced

once it is disassembled.

4. Use a soft bristle brush to clean the manifold passageways.

6. Inspect parts for damage and replace as necessary.

7. Assemble parts in reverse order from steps above.

Press the assembly against a flat clean surface until

seal (2f) snaps into place on the end of housing

(2a). The seal (2f) will hold the spring (2c), ball (2d),

seat (2e), and o-ring (2b) in place during assembly.

8. Apply lubricant to o-ring (2b) and end seal (2f).

9. Apply anaerobic sealant to external threads of cartridge.

10. Install cartridge assemblies in manifold and torque

to 125 ft-lbs (170 N•m).

NOTE: The high torque crushes the seal (2f) for a

reliable seal up to 7250 psi (50 MPa, 500 bar).

3A0590G 19

Page 20

Repair

Remove Restrictor

1. Note number of turns from open to closed position.

Remove restrictor housing (15) from manifold (1).

2. Place restrictor housing (15) in a vice and remove

nut (16).

16

15

1

r_258987_3a0590_4a

3. Unscrew stem (12) clockwise and remove from

restrictor housing (15).

16

12

13

14

15

Assemble Restrictor

1. Insert seat (10) with larger tapered end facing up in

manifold (1).

16

15

12

1

2. Apply blue thread lock to external threads to set

screw (11) and install in manifold.

3. Install o-rings (13, 14) and insert stem (12) into

restrictor housing (15). Turn stem (12) counter-clockwise until in open position.

13 (black)

14 (white)

11

10

r_255684_256980_312749_12a

r_258987_3a0590_5a

4. Remove and replace o-rings (13, 14).

5. Remove set screw (11) and seat (10) from manifold.

11

10

r_258987_3a0590_6a

4. Loosely install lock nut (16) on stem (12).

5. Tighten restrictor housing (15) into manifold (1).

6. Tighten stem (12) down until it bottoms on seat (10).

Then back stem out to previously noted position or

two full turns and lock in place with lock nut (16).

NOTE: For high volume or high viscosity “B” side

applications, the restrictor parts can be replaced by

a high pressure 3/4 npt plug.

20 3A0590G

Page 21

Repair

3A0590G 21

Page 22

Parts

Parts

262807 Mix Manifold

6

8

2

19

21

20

22

20

22

19

1

Apply lubricant to o-rings and cartridge o-ring and end seal.

2

Apply taper thread pipe sealant to all non-swiveling threads

except cartridge (2) and needle (12).

3

Apply anaerobic medium thread locker to external threads.

4

Torque to 125 ft-lbs (70 N•m).

5

Turn stem fully into manifold. Then back out two turns and

lock in place.

6

Large end of inside taper faces out.

7

Push assembly hard against a flat surface to snap retainer

seal (2f) in place.

8

2

Shipped loose. Use when a mix manifold is replaced on a

Series A XP Plural-Component Sprayer.

2

19

1

12

2

5

11

3

16

15

5

2

14

13

10

6

3

2

2

7

28

3

2

1

26

7

2f

3

2

51

8

1

2e

1

2

2b

2d

9

2c

31 4

2

4

2

2

ti18943c

5

2

6

3

2a

4

r_258987_3a0590_3a

22 3A0590G

Page 23

262807 Mix Manifold

Ref.

No. Part No. Description Qty.

1 24P869 BLOCK, manifold, mix 1

2 258986 CARTRIDGE, valve, check;

includes items 2a-2f

2a 16D614 HOUSING, check valve 1

2b★ 121138 O-RING, PTFE, white 1

2c★ 15M530 SPRING, check valve 1

2d★ 116166 BALL 1

2e★ 15A968 SEAT, foot valve 1

2f★ 15K692 SEAL, retainer 1

3 100721 PLUG, pipe; 1/4 npt 7

4 15R378 TUBE, injector, hardener 1

5 15R067 PIPE, outlet, mixer manifold 1

6 159239 FITTING, nipple, pipe, reducing 3

7 100840 ELBOW, street, lapped 1

8 156823 UNION, swivel; 1/4 m x f 1

9 214037 VALVE, ball, solvent; 1/4-18 npt;

see manual 306861

10 183951 SEAT, valve, carbide 1

11 15R382 SCREW, set, hollow, 3/4-16 1

12 235205 STEM, valve 1

13★ 110004 O-RING, PTFE, white 1

14★ 113137 O-RING, solvent resistant, black 1

15 15M969 NUT, packing, restrictor 1

16 110005 NUT, jam, hex 1

19 156684 UNION, swivel; 1/2 npt m x f 4

20 262740 VALVE, ball; 1/2 npt (f); see manual

306861

21 24M421 LEVER, valve 1

22 158491 NIPPLE, 1/2-14 npt 2

26† 501867 VALVE, check, mxm, 1/4 npt 1

28 113161 SCREW, flange, hex hd; 1/4-20 x

1/2 in. (12.7 mm)

50✖ 126786 TOOL, restrictor 1

51 113093 COUPLING, 1/4 npt

Parts

2

1

2

2

★ Provided in mix manifold repair kit 258992. See

Repair Kits, page 25.

✖ Not shown.

† Older models used mxf solvent check valves. If

replacing the mxf check valve (563210) with mxm

check valve (32), you must also order coupling (51).

3A0590G 23

Page 24

Parts

24M398 Quickset Mix Manifold

19

2

21

20

1

Apply lubricant to o-rings and cartridge o-ring and end seal.

2

Apply taper thread pipe sealant to all non-swiveling threads except

cartridge (2) and needle (12).

3

Apply anaerobic sealant to external threads.

4

Torque to 125 ft-lbs (70 N•m).

5

Turn stem fully into manifold. Then back out two turns and lock in place.

6

Large end of inside taper faces out.

7

Push assembly hard against a flat surface to snap retainer seal (2f) in

place.

30

49

36

19

2

16

30

5

34

45

46

35

37

43, 44

36

48

2

15

2 5

6

10

14

12

4

2

13

2

8

30

28

2

48

29

1

33

2

5

2

ti18946a

3

31

1

8 2

7

2f

2

30

32

3

2

1

2e

1

2b

2d

51

32

30

2

3

2

9

51

2c

31

3

2

9

31 4

2a

4

34

34

24 3A0590G

ti18945b

r_258987_3a0590_3a

Page 25

Repair Kits

24M398 Quickset Mix Manifold

Ref.

No. Part No. Description Qty.

1 24P866 BLOCK, manifold, mix 1

2 258986 CARTRIDGE, valve, check;

includes items 2a-2f

2a 16D614 HOUSING, check valve 1

2b★ 121138 O-RING, PTFE, white 1

2c★ 15M530 SPRING, check valve 1

2d★ 116166 BALL 1

2e★ 15A968 SEAT, foot valve 1

2f★ 15K692 SEAL, retainer 1

3 100721 PLUG, pipe; 1/4 npt 4

4 15R378 TUBE, injector, hardener 1

5 15R067 PIPE, outlet, mixer manifold 1

8 156823 UNION, swivel; 1/4 m x f 2

9 214037 VALVE, ball, solvent; 1/4-18 npt;

see manual 306861

10 183951 SEAT, valve 1

11 15R382 SCREW, set, hollow, 3/4-16 1

12 235205 STEM, valve 1

13★ 110004 O-RING; PTFE, white 1

14★ 113137 O-RING; solvent resistant, black 1

15 15M969 NUT, packing, restrictor 1

16 110005 NUT, jam, hex 1

19 156684 UNION, swivel; 1/2 npt m x f 4

20 262740 VALVE, ball; 1/2 npt (f); see manual

306861

21 24M421 LEVER, valve 1

22 158491 NIPPLE, 1/2-14 npt 2

Ref.

No. Part No. Description Qty.

28 113161 SCREW, flange, hex hd; 1/4-20 x

1/2 in. (12.7 mm)

29 262522 CARRIAGE, remote manifold 1

2

30 100840 ELBOW, street 5

31 114434 GAUGE, pressure, fluid, sst 2

32† 501867 VALVE, check, mxm, 1/4 npt 2

33 121433 BUSHING, 1/2 x 3/8, 7250 psi 1

34 H42503 HOSE, coupled, 1/4 ID, 3 ft 2

35 15R875 TEE, 1/4 (m x f x f) 1

36 162453 FITTING, 1/4 npsm x 1/4 npt 2

37 157705 UNION, swivel, 1/4 m x 3/8 f 1

43 262478 HOUSING, mixer 2

44 248927 MIXER, 1/2-12 element (bag of 25) 1

45 156173 UNION, swivel, 3/8 fbe 1

46 114958 STRAP, tie 2

47 119400 SEALANT, pipe, sst 1

2

48 15U654 LABEL, identification, A/B 1

49 158491 NIPPLE, 1/2 in. npt 2

50✖ 126786 TOOL, restrictor 1

51 113093 COUPLING, 1/4 npt

★ Provided in mix manifold repair kit 258992. See

Repair Kits.

✖ Not shown.

2

† Older models used mxf solvent check valves. If

replacing the mxf check valve (563210) with mxm

check valve (32), you must also order coupling (51).

2

Repair Kits

258992 Mix Manifold Repair Kit

Ref.

No. Part No. Description Qty.

2b 121138 O-RING, PTFE, white 2

2c 15M530 SPRING, check valve 2

2d 116166 BALL, carbide 2

2e 15A968 SEAT, foot valve 2

2f 15K692 SEAL, retainer 2

13 110004 O-RING, PTFE, white 1

14 113137 O-RING, solvent resistant, black 1

38✖ 113500 ADHESIVE, anaerobic 1

✖ Not shown.

3A0590G 25

217560 Flush Valve (9) Repair Kit

24M601 Inlet Ball Valve (20) Repair Kit

Page 26

Accessories

Accessories

10,000 psi Fluid Pressure Gauge (2.5 in)

114434 - 1/4 npt(m) back mount pressure gauge can be

used in ports as gun pressure gauge.

551387 - 1/4 npt bottom mount version.

High Pressure Hoses and Accessory

Fittings

See brochure 339361 for parts and accessories.

262522, Remote Mix Manifold Carriage

The carriage holds and protects the mix manifold

assembly. Use two screws (28) to mount the mix manifold to the carriage.

15E592, 7250 psi Static Mixer Housing

3/8 npt(m) holds 1/2 in. 12 element plastic sticks.

511352, Mixer

Stainless 3/8 npt(m) pipe with 12 element stainless

welded stick; 7250 psi (50 MPa, 500 bar).

Accessory Ports

P1 and P2:

These 1/4 npt ports are located after “A” and “B” shutoff

handle.

Can be used for an inlet pressure gauge. These are

before the fluid check valves and hardener restrictor.

P3 and P5:

Can be used for a pressure gauge to measure outlet

pressure or check ratio with the 24F375 kit. These ports

are downstream of the check valve.

The P3 port is used as the second flush inlet on the

quickset model of the mix manifold. It flushes across the

resin check ball, but not through it.

P4:

Can be used for a pressure gauge to measure hardener

pressure before the restrictor, but after the check valve.

248927, Plastic Mix Elements

25 pack of 1/2 in. x 12 element plastic sticks.

B-side screen

40 mesh strainer for low viscosity fluids only.

Ref.

No. Part No. Description Qty.

17 185416 STARINER, 40 mesh 1

18 121410 PACKING, screen retainer; PTFE 1

15T630, Screen Installation Tool

Use to reinstall B-side screen.

24F375, Ratio Check Kit

Use to check ratio at mix manifold. See manual 3A0421

for instructions.

P1

P3

P5

FIG. 4: Accessory Ports

P2

P4

r_258987_3a0590_9a

26 3A0590G

Page 27

Technical Data

Technical Data

Mix Manifolds

US Metric

Maximum A, B, and mix working pressure 7250 psi 50 MPa, 500 bar

Maximum fluid temperature 160° F 71° C

Fluid inlet 1/2 npt(f) ball valves

Fluid outlet 1/2 npt(f) with 3/8 npt(m) adapter nipple

Solvent inlet valve

Maximum working pressure at solvent inlet

Wetted parts

Manifold block and internal parts 302 and 303 stainless steel, PTFE, tungsten carbide, elec-

Flush valves and fittings 440 stainless steel, plated carbon steel, hardened alloy steel,

1/4 npt(m)

5000 psi 34.5 MPa, 345 bar

troless nickel plated steel, zinc plated steel, UHMWPE

acetal, PTFE, aluminum

3A0590G 27

Page 28

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2010, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 3A0590

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised June 2013

Loading...

Loading...