Page 1

Instructions - Parts List

®

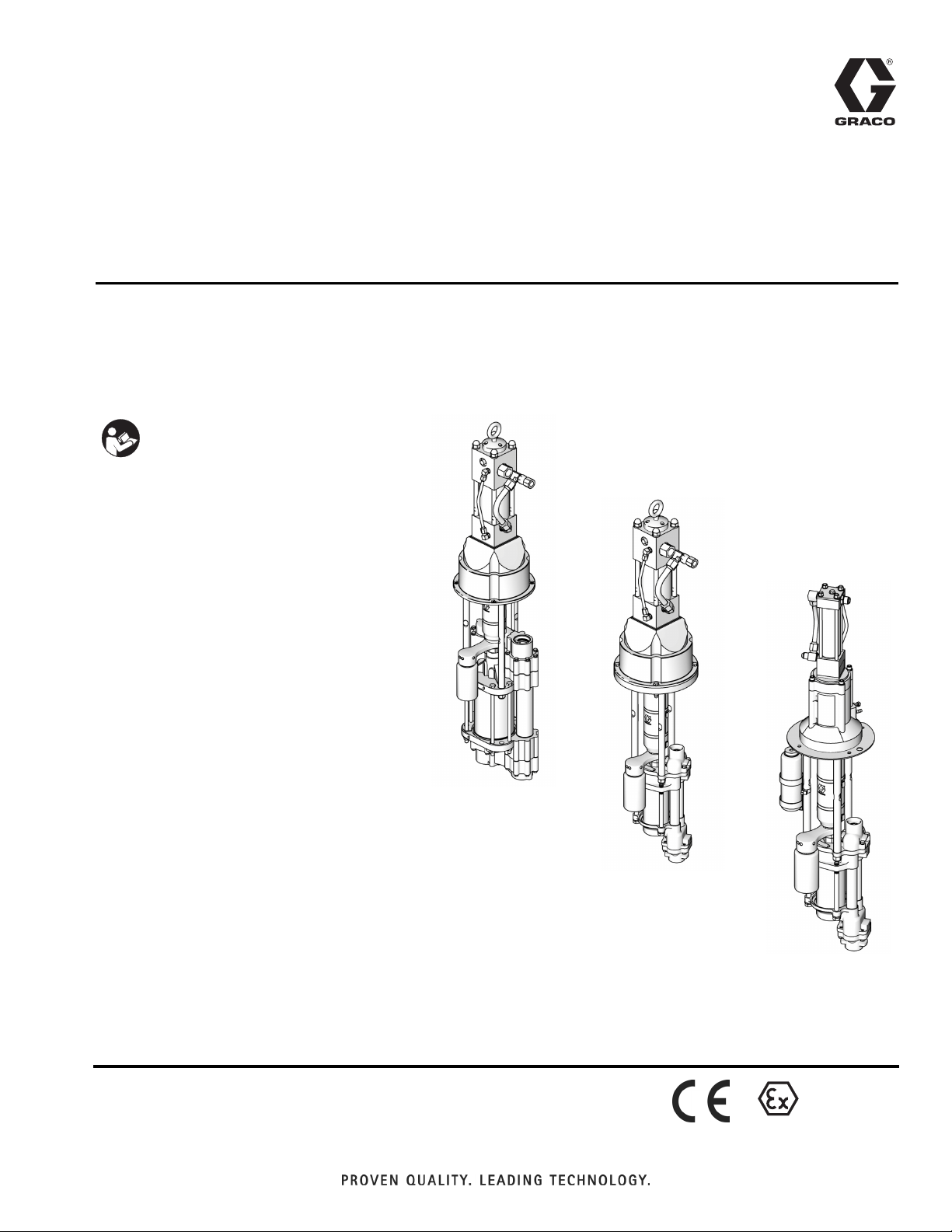

Viscount

Hydraulic-powered pumps for low pressure, high volume circulation of finishing materials.

Do not use for flushing or purging lines with caustics, acids, abrasive line strippers, and

other similar fluids. For professional use only.

Important Safety Instructions

Read all warnings and instructions in

this manual. Save these instructions.

See page 3 for model information, including

maximum working pressure and approvals.

4-Ball Pumps

3A0537G

EN

TI15609a

Viscount II

Pump with

4000cc 4-Ball

Lower

TI15600a

Viscount II

Pump with

2000cc 4-Ball

Lower

TI15601a

Viscount I Plus

Pump with

1000cc 4-Ball

Lower

c IIB T3

II 2 G

Page 2

Related Manuals

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Pumps with 750cc, 1000cc, 1500cc, or 2000cc

4-Ball Lowers . . . . . . . . . . . . . . . . . . . . . . . . 3

Pumps with 3000cc or 4000cc 4-Ball Lowers . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Stand Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Wall Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Flush Before Using Equipment . . . . . . . . . . . . . . 7

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Pressure Relief Procedure . . . . . . . . . . . . . . . . 11

Prime the Pump . . . . . . . . . . . . . . . . . . . . . . . . 11

Stop the Pump at the Bottom of Its Stroke . . . . 11

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Preventive Maintenance Schedule . . . . . . . . . . 12

Flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Mix Tank Volume . . . . . . . . . . . . . . . . . . . . . . . 12

Hydraulic Power Supply Check . . . . . . . . . . . . . 12

Stall Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Changing the TSL . . . . . . . . . . . . . . . . . . . . . . . 13

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Reassemble the Coupling Adapter and Tie Rods to

the Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Viscount I Plus Pumps with 750cc, 1000cc,

1500cc, or 2000cc 4-Ball Lowers . . . . . . . . 18

Viscount II Pumps with 2000cc 4-Ball Lower . . . 19

Viscount II Pumps with 3000cc or

4000 cc 4-Ball Lowers . . . . . . . . . . . . . . . . . 20

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Motor Mounting Hole Diagrams . . . . . . . . . . . . . . 22

Mounting Stand Hole Layouts . . . . . . . . . . . . . . . 22

255143 Wall Mount Bracket . . . . . . . . . . . . . . . . . . 23

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

750, 1000, 1500, and 2000cc Pumps with

Viscount I Plus Motor . . . . . . . . . . . . . . . . . 24

2000cc Pumps with Viscount II Motor . . . . . . . . 25

3000 and 4000cc Pumps with Viscount II Motor 25

Performance Charts . . . . . . . . . . . . . . . . . . . . . . . . 26

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 30

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 30

Related Manuals

Part No. Description

308330 Viscount I Plus Hydraulic Motor manual

308048 Viscount II Hydraulic Motor manual

3A0539 4-Ball Lower manual (750cc, 1000cc,

1500cc, and 2000cc)

3A0540 4-Ball Lower manual (3000cc and 4000cc)

2 3A0537G

Page 3

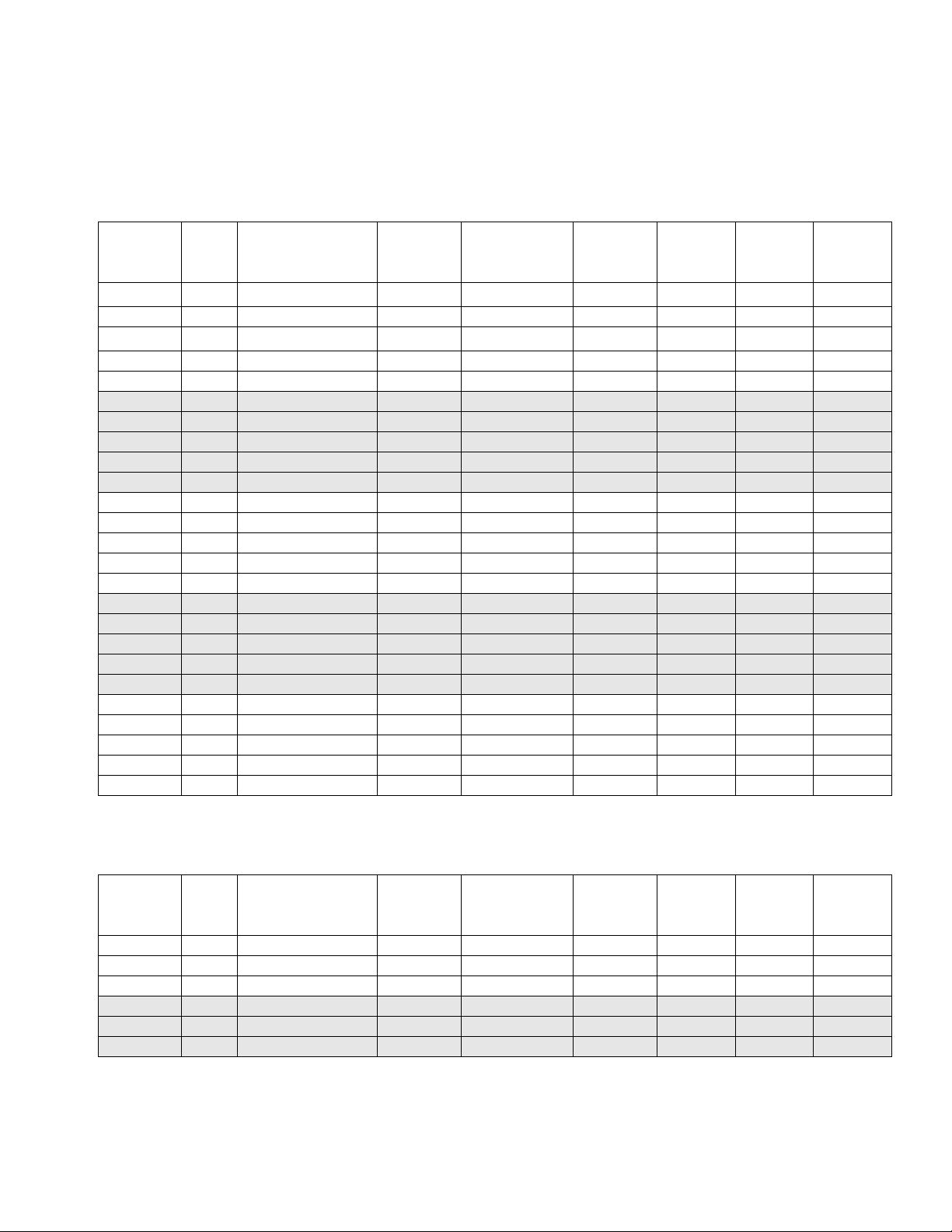

Models

Pumps with 750cc, 1000cc, 1500cc, or 2000cc 4-Ball Lowers

Maximum Pump

Working Pressure

Model No. Series

24E322 A 450 (3.1, 31.0) 750cc Viscount I Plus npt cst

24E323 A 450 (3.1, 31.0) 750cc Viscount I Plus tri-clamp sst Chromex Chrome

24E324 A 450 (3.1, 31.0) 750cc Viscount I Plus tri-clamp sst Chromex

24E485 A 450 (3.1, 31.0) 750cc Viscount I Plus npt sst Chromex Chrome

24E486 A 450 (3.1, 31.0) 750cc Viscount I Plus npt sst Chromex MaxLife

24E325 A 300 (2.1, 21.0) 1000cc Viscount I Plus npt cst Chromex Chrome

24E326 A 300 (2.1, 21.0) 1000cc Viscount I Plus tri-clamp sst Chromex Chrome

24E327 A 300 (2.1, 21.0) 1000cc Viscount I Plus tri-clamp sst Chromex MaxLife

24E487 A 300 (2.1, 21.0) 1000cc Viscount I Plus npt sst Chromex Chrome

24E488 A 300 (2.1, 21.0) 1000cc Viscount I Plus npt sst Chromex MaxLife

24E328 A 225 (1.6, 16.0) 1500cc Viscount I Plus npt cst Chromex Chrome

24E329 A 225 (1.6, 16.0) 1500cc Viscount I Plus tri-clamp sst Chromex Chrome

24E330 A 225 (1.6, 16.0) 1500cc Viscount I Plus tri-clamp sst Chromex MaxLife

24E489 A 225 (1.6, 16.0) 1500cc Viscount I Plus npt sst Chromex Chrome

24E490 A 225 (1.6, 16.0) 1500cc Viscount I Plus npt sst Chromex MaxLife

24E331 A 167 (1.2, 12.0) 2000cc Viscount I Plus npt cst Chromex Chrome

24E332 A 167 (1.2, 12.0) 2000cc Viscount I Plus tri-clamp sst Chromex Chrome

24E333 A 167 (1.2, 12.0) 2000cc Viscount I Plus tri-clamp sst Chromex MaxLife

24E491 A 167 (1.2, 12.0) 2000cc Viscount I Plus npt sst Chromex Chrome

24E492 A 167 (1.2, 12.0) 2000cc Viscount I Plus npt sst Chromex MaxLife

24E334 A 460 (3.2, 32.0) 2000cc Viscount II npt cst Chromex Chrome

24E335 A 460 (3.2, 32.0) 2000cc Viscount II tri-clamp sst Chromex Chrome

24E336 A 460 (3.2, 32.0) 2000cc Viscount II tri-clamp sst Chromex MaxLife

24E493 A 460 (3.2, 32.0) 2000cc Viscount II npt sst Chromex Chrome

24E494 A 460 (3.2, 32.0) 2000cc Viscount II npt sst Chromex MaxLife

psi (MPa, bar) Lower Size Motor

Connection

Style Material

Rod

Material

Chromex

Cylinder

Material

™

MaxLife

Models

Nitride

®

Pumps with 3000cc or 4000cc 4-Ball Lowers

Maximum Pump

Working Pressure

Model No. Series

24E337 A 400 (2.8, 28.0) 3000cc Viscount II npt cst Chromex Chrome

24E338 A 400 (2.8, 28.0) 3000cc Viscount II npt sst Chromex Chrome

24E339 A 400 (2.8, 28.0) 3000cc Viscount II npt sst Chromex MaxLife

24E340 A 300 (2.1, 21.0) 4000cc Viscount II npt cst Chromex Chrome

24E341 A 300 (2.1, 21.0) 4000cc Viscount II npt sst Chromex Chrome

24E342 A 300 (2.1, 21.0) 4000cc Viscount II npt sst Chromex MaxLife

3A0537G 3

psi (MPa, bar) Lower Size Motor

Connection

Style Material

Rod

Material

Cylinder

Material

Page 4

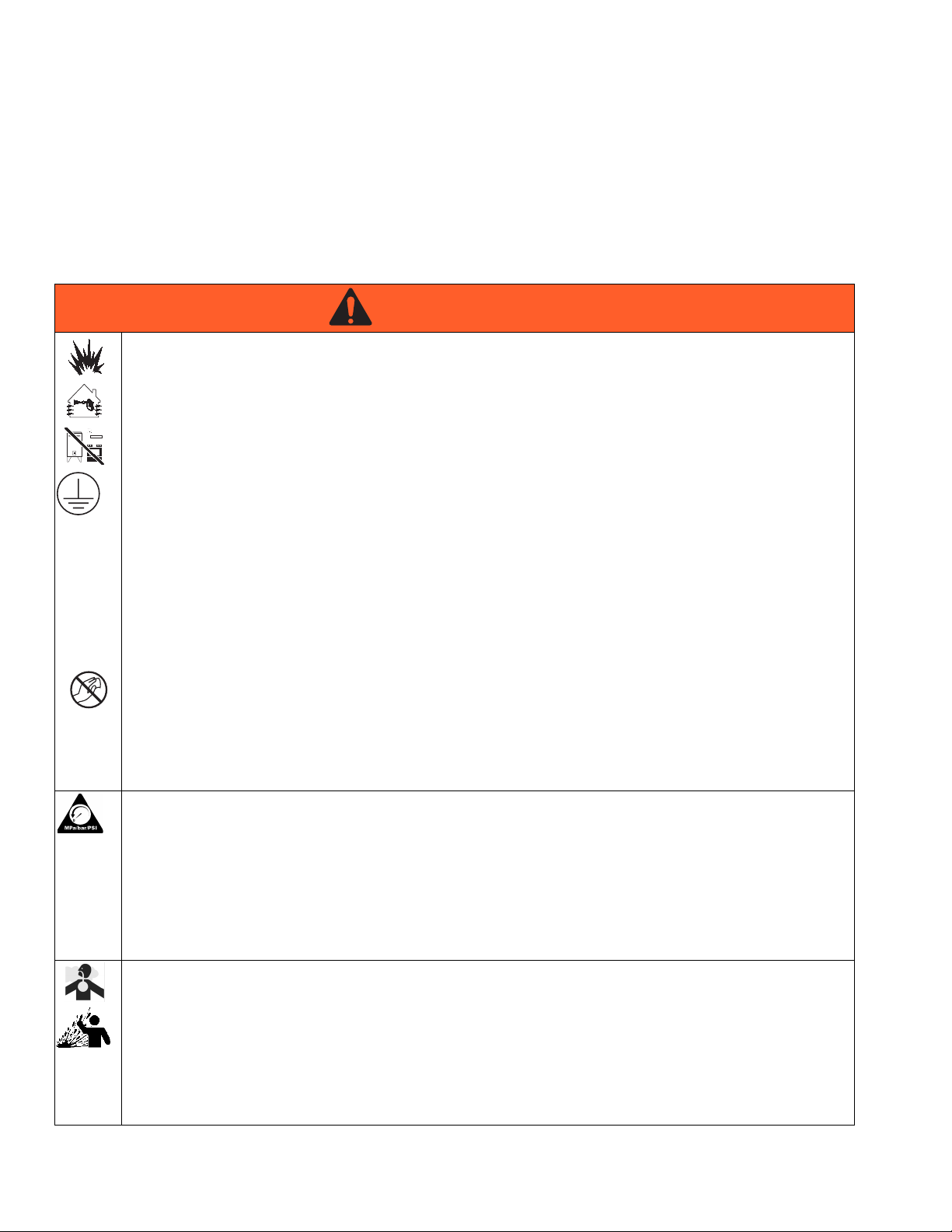

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual, refer back to these Warnings. Product-specific hazard symbols and

warnings not covered in this section may appear throughout the body of this manual where applicable.

WARNING

WARNINGWARNINGWARNING

PERIGO DE FOGO E EXPLOSÃO

Os vapores inflamáveis na área de trabalho, tais como os provenientes de solventes e tintas, podem

inflamar-se ou explodir. Para ajudar a evitar incêndio e explosão:

• Utilize o equipamento apenas em áreas bem ventiladas;

• Elimine todas as fontes de ignição, como, por exemplo, luzes piloto, cigarros, luzes elétricas portáteis

e plásticos de proteção (potencial arco estático).

• Mantenha a área de trabalho sem detritos, incluindo solvente, panos e gasolina;

• Não ligue nem desligue cabos de alimentação ou interruptores, na presença de vapores inflamáveis;

• Ligue à terra todo o equipamento na área de trabalho. Consulte as instruções de Ligação à terra .

• Utilize apenas tubos flexíveis com ligação à terra;

• Segure a pistola firmemente apoiando-a na parede do balde em contacto com a terra, quando estiver

a descarregar para dentro do mesmo;

• Se ocorrerem faíscas de estática ou se sentir um choque elétrico, interrompa a utilização imediatamente.

Não utilize o equipamento até identificar e corrigir o problema.

• Tenha sempre um extintor operacional na área de trabalho.

A carga estática pode-se acumular nas peças plásticas durante a limpeza e pode disparar e inflamar

vapores inflamáveis. Para ajudar a evitar incêndio e explosão:

• Limpe as peças plásticas apenas em áreas bem ventiladas.

• Não limpe com um pano seco.

• Não opere pistolas eletrostáticas numa área de trabalho de equipamento.

PERIGO DE EQUIPAMENTO PRESSURIZADO

O produto proveniente da pistola/pistola de distribuição, fugas ou componentes danificados poderá entrar

em contacto com os olhos ou com a pele e provocar ferimentos extremamente graves.

• Siga o Procedimento de Descompressão neste manual, quando parar de pintar e antes de dar

início aos procedimentos de limpeza, verificação ou manutenção.

• Aperte todas as ligações relativas ao produto antes de utilizar o equipamento.

• Verifique diariamente todos os tubos e uniões. Substitua imediatamente as peças gastas ou danificadas.

PERIGO EMERGENTE DE PRODUTOS OU VAPORES TÓXICOS

Os líquidos ou vapores tóxicos podem provocar lesões graves ou morte se entrarem em contacto com os

olhos e a pele, ou se forem inalados ou engolidos.

• Leia as folhas de dados de segurança do material (MSDS) para conhecer os perigos específicos dos

líquidos que está a utilizar.

• Armazene os líquidos perigosos em recipientes aprovados e elimine-os em conformidade com as

diretrizes aplicáveis.

4 3A0537G

Page 5

Warnings

WARNING

WARNINGWARNINGWARNING

EQUIPAMENTO DE PROTECÇÃO PESSOAL

Utilize equipamento de proteção adequado ao usar o equipamento ou se estiver na área de funcionamento

do mesmo. O equipamento protege-o de lesões graves, tais como lesões oculares, perda de audição,

inalação de vapores tóxicos e queimaduras. Este equipamento inclui, mas não é limitado a:

• Proteção para os olhos e ouvidos.

• Respiradores, roupa protetora e luvas, tal como recomendado pelo fabricante do líquido e solvente.

PERIGO DE MÁ UTILIZAÇÃO DO EQUIPAMENTO

A utilização incorreta do equipamento poderá resultar em ferimentos graves ou morte.

• Não utilize a unidade se estiver cansado ou sob a influência de drogas ou de álcool.

• Não exceda a pressão de trabalho ou o nível de temperatura máximo do componente do sistema com

a classificação mais baixa. Consulte a Dados Técnicos em todos os manuais do equipamento.

• Utilize líquidos e solventes compatíveis com as peças do equipamento em contacto com o líquido.

Consulte a Dados Técnicos em todos os manuais do equipamento. Leia as advertências dos

fabricantes do líquido e do solvente. Para obter informações completas relativas ao material que utiliza,

solicite a folha de dados de segurança do material (MSDS) ao distribuidor ou ao revendedor.

• Não abandone a área de trabalho enquanto o equipamento se encontrar energizado ou sob pressão.

Desligue todo o equipamento e siga o Procedimento de Descompressão quando o equipamento

não está a ser utilizado.

• Verifique diariamente o equipamento. As peças danificadas ou com desgaste devem ser imediatamente

reparadas ou substituídas apenas por peças genuínas do fabricante.

• Não altere nem modifique este equipamento.

• Utilize o equipamento apenas para o fim a que se destina. Solicite informações ao seu distribuidor.

• Afaste os tubos flexíveis e cabos de áreas com movimento, pontas afiadas, peças em movimento e

superfícies quentes.

• Não dê nós nem dobre os tubos flexíveis, nem os utilize para puxar o equipamento.

• Mantenha as crianças e os animais afastados da área de trabalho.

• Cumpra todas as normas de segurança aplicáveis.

PERIGO RESULTANTE DE PEÇAS EM MOVIMENTO

As peças em movimento podem entalar ou amputar os dedos e outras partes do corpo.

• Mantenha-se afastado das peças em movimento.

• Não utilize o equipamento tendo removido as respetivas proteções e coberturas.

• O equipamento sob pressão pode começar a funcionar sem aviso. Antes de efetuar ações de verificação,

deslocação ou assistência no equipamento, siga o Procedimento de Descompressão e desligue

todas as fontes de alimentação.

3A0537G 5

Page 6

Installation

Installation

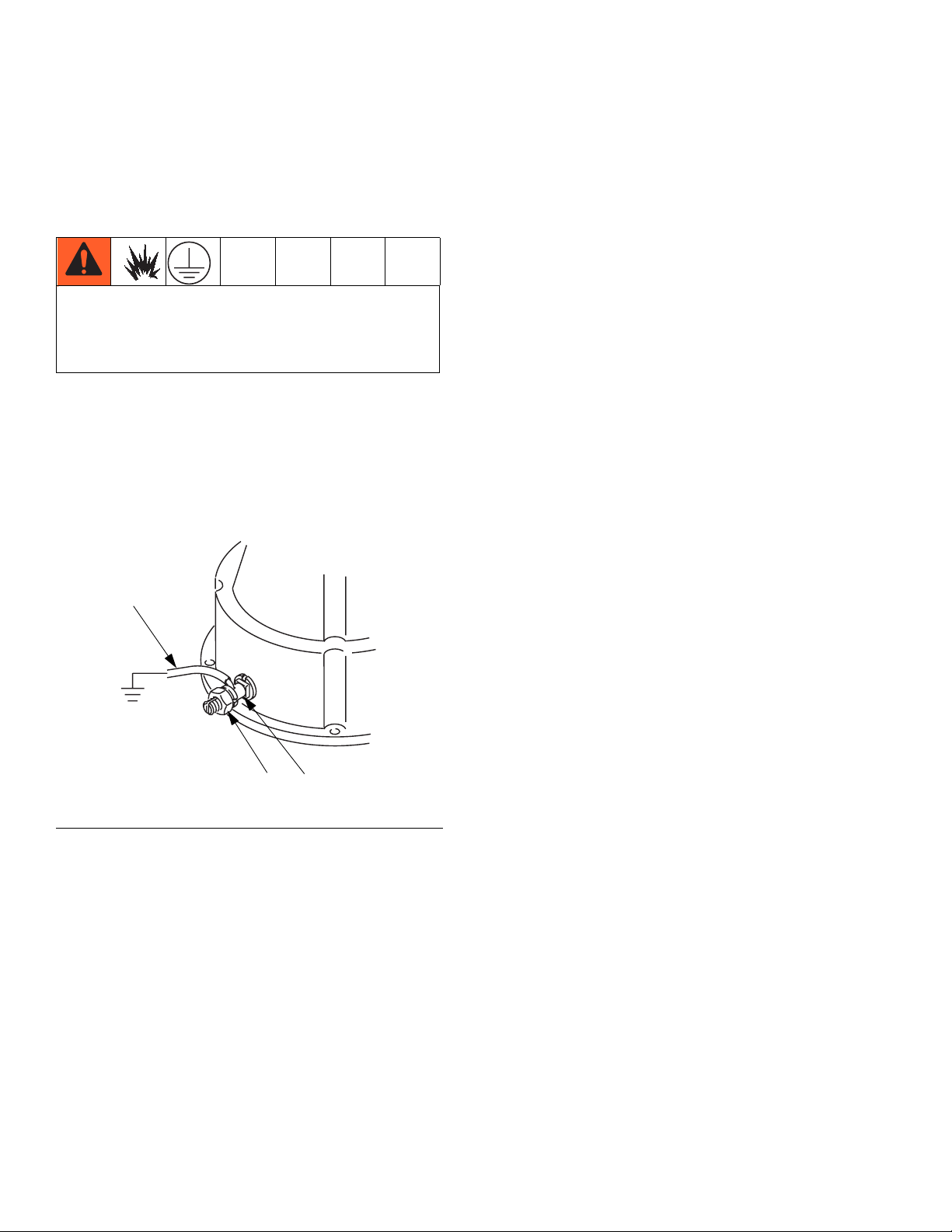

Grounding

The equipment must be grounded. Grounding

reduces the risk of static and electric shock by

providing an escape wire for the electrical current

due to static build up or in the event of a short circuit.

Pump: use a ground wire and clamp. See FIG. 1.

Loosen the locknut (W) of the grounding lug (Z). Insert

one end of the wire (Y) in the ground lug and tighten the

locknut securely. Connect the ground clamp to a true

earth ground. Order Part No. 237569, Ground Wire and

Clamp.

Y

Air and fluid hoses: use only electrically conductive

hoses

with a maximum of 500 ft. (150 m) combined

hose length to ensure grounding continuity. Check the

electrical resistance of hoses. If total resistance to

ground exceeds 25 megohms, replace hose immediately.

Hydraulic power supply: follow manufacturer’s recommendations.

Surge tank: use a ground wire and clamp.

Dispense valve: ground through a connection to a

properly grounded fluid hose and pump.

Fluid supply container: follow local code.

Object being sprayed: follow local code.

Solvent pails used when flushing: follow local code.

Use only conductive metal pails, placed on a grounded

surface. Do not place the pail on a nonconductive surface, such as paper or cardboard, which interrupts

grounding continuity.

F

IG

. 1 Ground Wire

W

To maintain grounding continuity when flushing or

relieving pressure: hold metal part of the spray gun

firmly to the side of a grounded metal pail, then trigger

the gun.

TI15854a

Z

6 3A0537G

Page 7

Installation

Stand Mount

Mount the pump in the accessory pump stand (B). Use

Part No. 253692 Stand for 750, 1000, 1500, and 2000cc

Pumps (see F

for 3000 and 4000cc Pumps (see F

See Mounting Stand Hole Layouts on page 22.

Secure the stand to the floor with M19 (5/8 in.) bolts

which engage at least 152 mm (6 in.) into the concrete

floor to prevent the pump from tipping.

IG

. 2, page 9) and Part No. 218742 Stand

IG

. 3, page 10).

Wall Mount

1. Ensure the wall is strong enough to support the

weight of the pump assembly and accessories, fluid,

hoses, and stress caused during pump operation.

2. Ensure that the mounting location has sufficient

clearance for easy operator access.

3. Position the wall bracket at a convenient height,

ensuring that there is sufficient clearance for the

fluid suction line and for servicing the lower.

Plumbing

Install a fluid shutoff valve (D) between the mix tank (A)

and the pump.

When using a stainless steel pump, use stainless steel

plumbing to maintain a corrosion-resistant system.

Flush Before Using Equipment

The equipment was tested with lightweight oil, which is

left in the fluid passages to protect parts. To avoid contaminating your fluid with oil, flush the equipment with a

compatible solvent before using the equipment. See

Flushing, page 12.

4. Drill four 7/16 in. (11 mm) holes using the bracket as

a template. Use any of the three mounting hole

groupings in the bracket. See 255143 Wall Mount

Bracket, page 23.

5. Bolt the bracket securely to the wall using bolts and

washers designed to hold in the wall’s construction.

6. Attach the pump assembly to the mounting bracket.

7. Connect air and fluid hoses.

3A0537G 7

Page 8

Installation

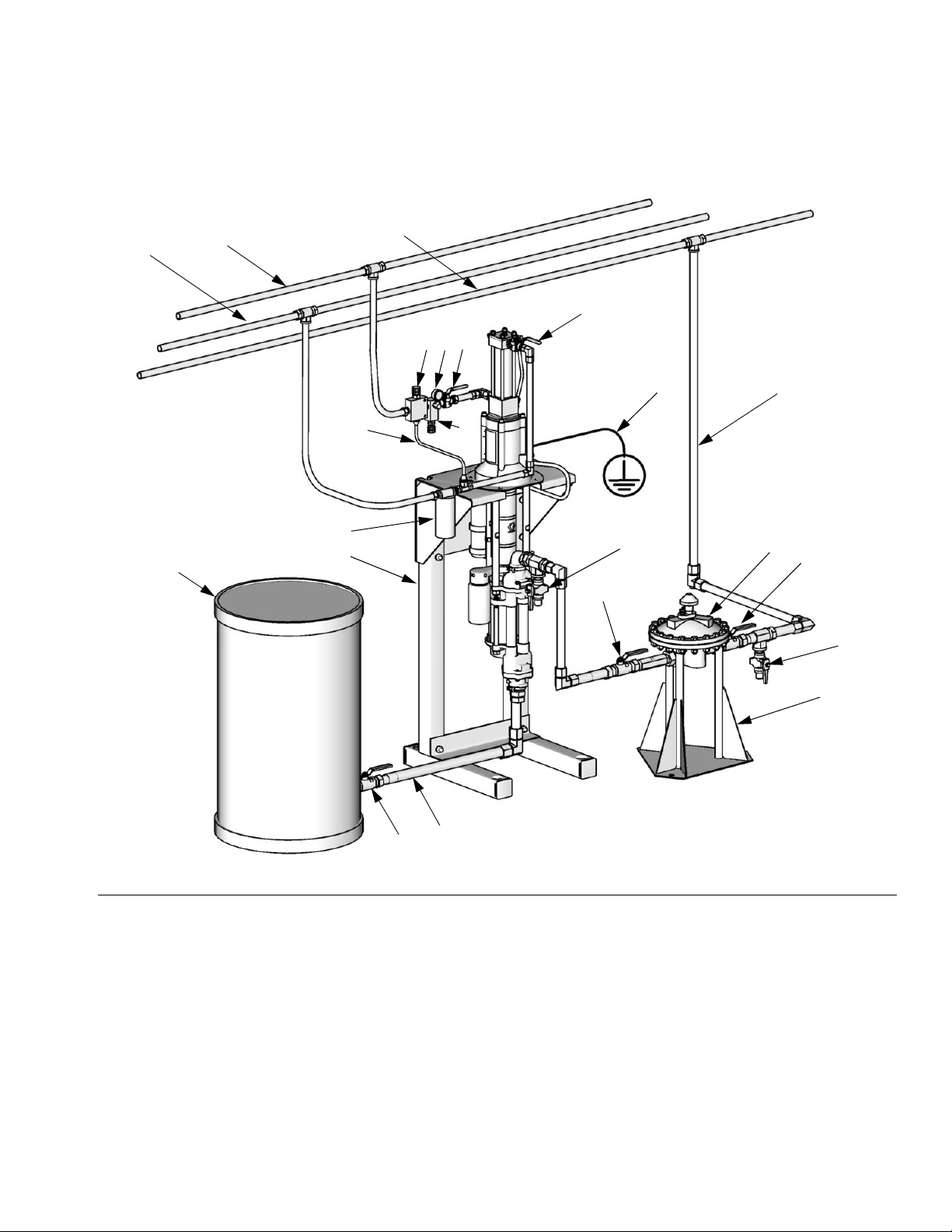

Accessories

Install the following accessories in the order shown in

F

IG

. 2, using adapters as necessary.

Hydraulic Power Supply

NOTICE

The hydraulic power supply must be kept clean at all

times to avoid damage to the motor and hydraulic

power supply.

1. Blow out hydraulic lines with air and flush thoroughly before connection to the motor.

2. Plug hydraulic inlets, outlets, and line ends when

disconnecting them for any reason.

Be sure the power supply can provide sufficient power

to the motor. Be sure the power supply is equipped with

a suction filter to the hydraulic pump.

Hydraulic Supply Line

• For Viscount I Plus motors, the hydraulic inlet on the

motor is 3/4 in., 37° flare. Use a minimum 1/2 in. (13

mm) ID hydraulic supply line (L).

• For Viscount II motors, use a minimum 13 mm (1/2

in.) ID supply line (L). The motor has a 3/4 npt(f)

hydraulic oil supply fitting.

• For Viscount II motors, use a minimum 22 mm (7/8

in.) ID return line (K). The motor has a 1 in. npt(f)

hydraulic oil return fitting.

• Return line shutoff valve (R): isolates the motor

when servicing the system.

NOTICE

To avoid damage to the pump, never use the return

line shutoff valve to control the hydraulic flow. Do not

install any flow control devices on the hydraulic return

line.

• Return fluid filter (J): removes residue from the

hydraulic fluid to help keep the system running

smoothly (10 micron size).

Fluid Line

For typical installation, see FIG. 2 on page 9.

• Fluid filter: with a 60 mesh (250 micron) stainless

steel element to filter particles from the fluid as it

leaves the pump.

• Fluid drain valve (U): required in your system, to

relieve fluid pressure in the hose and gun.

• Fluid shutoff valve (D): shuts off fluid flow.

• Supply line shutoff valve (S): isolates the motor

when servicing the system.

• Hydraulic fluid pressure gauge (P): monitors the

hydraulic oil pressure to the motor to avoid overpressurizing the motor or lower.

• Pressure- and temperature-compensated flow

control valve (T): prevents the motor from running

too fast, which can damage it.

• Pressure reducing valve (N), which has a drain

line (M) running to the return line (K): controls the

hydraulic pressure to the motor.

Hydraulic Return Line

• For Viscount I Plus motors, the hydraulic outlet on

the motor is 7/8 in., 37° flare. Use a minimum 5/8 in.

(16 mm) ID hydraulic return line (K).

8 3A0537G

Page 9

Installation

K

A

L

J

B

E

R

N P S

Y

M

T

U

D

E

G

D

U

C

D

FIG. 2. Typical Installation for 750, 1000, 1500, and 2000cc Pumps (Viscount I Plus Motor Shown)

Key:

A Mix Tank

B 253692 Pump Stand

C Fluid Supply Line; 1-1/2 in. (38 mm) minimum diameter

D Fluid Shutoff Valve

E Fluid Line; 1 in. (25 mm) minimum diameter

F Surge Tank Stand

G Surge Tank

J 10 Micron Return Filter

K Hydraulic Return Line

L Hydraulic Supply Line

M Drain Line

N Pressure Reducing Valve

P Hydraulic Pressure Gauge

R Return Line Shutoff Valve

S Supply Line Shutoff Valve

T Flow Control Valve

U Fluid Drain Valve (required)

Y Ground Wire (required see page 6 for installation)

F

TI15855a

3A0537G 9

Page 10

Installation

K

L

S

P

N

Y

T

M

U

A

J

D

R

D

B

C

FIG. 3. Typical Installation for 3000 and 4000cc Pumps (Viscount II Motor Shown)

Key:

A Mix Tank

B 218742 Pump Stand

C Fluid Supply Line; 1-1/2 in. (38 mm) minimum diameter

D Fluid Shutoff Valve

E Fluid Line; 1 in. (25 mm) minimum diameter

F Surge Tank Stand

G Surge Tank

J 10 Micron Return Filter

K Hydraulic Return Line

L Hydraulic Supply Line

M Drain Line

N Pressure Reducing Valve

P Hydraulic Pressure Gauge

R Return Line Shutoff Valve

S Supply Line Shutoff Valve

T Flow Control Valve

U Fluid Drain Valve (required)

Y Ground Wire (required see page 6 for installation)

G

D

F

E

U

TI15856a

10 3A0537G

Page 11

Operation

Operation

Pressure Relief Procedure

1. Shut off the hydraulic supply line valve (S) first, then

the return line valve (R).

2. Open the dispensing valve, if used.

3. Open all fluid drain valves (U) in the system, having

a waste container ready to catch drainage. Leave

drain valve(s) open until you are ready to pump

again.

NOTICE

When shutting down the hydraulic system, always

shut off the hydraulic supply line shutoff valve (S) first,

and then the return line shutoff valve (R) to prevent

overpressurizing the motor or its seals. When starting

the hydraulic system, open the return line shutoff

valve first.

7. Verify that pump actuations are priming the pump

wet-cup. If not, confirm that the TSL pump piston is

being depressed at bottom changeover, and that

reservoir check valves are not stuck closed.

8. Close the fluid shutoff valve (D) downstream of the

pump. The pump should stall against pressure.

NOTE: In a circulation system, the pump operates continuously until the power supply is shut off. In a

direct-supply system, the pump starts when the dispense valve is opened, and stops when the dispense

valve is closed.

Stop the Pump at the Bottom of Its Stroke

Relieve the pressure when you stop the pump for any

reason. Stop the pump on the downstroke, before the

motor changes over.

Prime the Pump

1. Fill the TSL reservoir to the Maximum fill line with

Throat Seal Liquid (TSL). See F

NOTE: During operation the TSL level in the reservoir

will fluctuate slightly at pump changeover.

2. Close the flow control valve (T) by turning knob

counterclockwise reducing pressure to zero. Close

the supply line shutoff valve (S) and the return line

shutoff valve (R). Also verify that all drain valves (U)

are closed.

3. Check that all fittings throughout system are tightened securely.

4. Start the hydraulic power supply.

5. Open the return line shutoff valve (R), then the supply line shutoff valve (S). Slowly turn the flow control

valve (T) clockwise, increasing pressure until pump

starts.

6. Cycle pump slowly until all air is pushed out and

pump and hoses are fully primed.

IG

. 4 on page 13.

NOTICE

Failure to stop the pump at the bottom of its stroke

allows fluid to dry on the piston rod, which can damage the throat packings and the TSL pump piston seal

when the pump is restarted.

Shutdown

Follow Pressure Relief Procedure, page 11.

Always flush the pump before the fluid dries on the displacement rod. See Flushing on page 12.

3A0537G 11

Page 12

Maintenance

Maintenance

Preventive Maintenance Schedule

The operating conditions of your particular system

determine how often maintenance is required. Establish

a preventive maintenance schedule by recording when

and what kind of maintenance is needed, and then

determine a regular schedule for checking your system.

Your maintenance schedule should include the following:

Flushing

• Flush before changing colors, before fluid can dry in

the equipment, at the end of the day, before storing,

and before repairing equipment.

• Flush at the lowest pressure possible. Check connectors for leaks and tighten as necessary.

• Flush with a fluid that is compatible with the fluid

being dispensed and the equipment wetted parts.

Mix Tank Volume

Stall Test

Perform a stall test periodically to ensure the piston seal

is in good working condition and prevent system overpressurization:

Close the fluid shutoff valve (D) closest to the pump on

the downstroke and be sure that the pump stalls. Open

the fluid shutoff valve to restart the pump. Close the fluid

shutoff valve (D) closest to the pump on the upstroke

and be sure that the pump stalls.

NOTICE

Do not allow the pump to run quickly for a long period

of time as this may damage the packings.

Stop the pump on the downstroke, before the air motor

changes over.

NOTICE

Failure to stop the pump at the bottom of its stroke

allows fluid to dry on the piston rod, which can damage the throat packings and the TSL pump piston seal

when the pump is restarted.

Don't let the mix tank run dry. When the tank is empty,

the pump demands more power as it tries to suck in

some fluid. This causes the pump to run too fast, which

can seriously damage the pump.

Hydraulic Power Supply Check

Carefully follow the hydraulic power supply manufacturer's recommendations on reservoir and filter cleaning,

and periodic changes of hydraulic fluid.

12 3A0537G

Page 13

Maintenance

Changing the TSL

Check the condition of the TSL and the level in the reservoir every week, minimum. TSL should be changed at

least every month.

Part No. 206995 Throat Seal Liquid (TSL) carries residue from the pump rod into the reservoir. Discoloration

of the TSL fluid is to be expected during normal operation. After some time the TSL will thicken and darken,

and must be replaced. Thick, dirty TSL will not pump

through the lines and will harden in the pump wet-cup.

How long TSL lasts depends on which chemicals are

used, how much is used, what pressure, and condition

of the pump seal and rod.

A drop in the level of TSL in the reservoir indicates that

the throat packings are starting to wear. Add TSL to the

reservoir and keep the level above the Minimum fill line.

Monitor the usage and condition of the TSL. If pumped

material bypasses the throat packings and enters the

TSL reservoir, replace the packings.

To change the TSL:

1. Shut off the pump.

To avoid the buildup of static charge, do not rub the

plastic bottle with a dry cloth while it is attached to the

pump. Remove the bottle to clean, if needed.

2. Remove and empty the reservoir bottle. Clean any

residue.

3. Clean screen (Z) of inlet check valve (VI). If check

valves are not sealing and dirty TSL is getting into

the wet-cup, replace the check valves (VI, VO). See

F

IG

. 4.

4. Fill the reservoir to the Maximum fill line with Throat

Seal Liquid (TSL).

5. Run pump. Each time pump rod reaches bottom of

stroke, check that some TSL is pumped from reservoir through wet-cup and back to reservoir.

VO

Maximum Fill Line

Minimum Fill Line

VI

Z

TI15853b

TI15857a

FIG. 4. Cutaway of TSL Reservoir, and Fill Lines

3A0537G 13

Page 14

Troubleshooting

Troubleshooting

Problem Cause Solution

Pump output low on both strokes. Restricted hydraulic supply lines. Clear any obstructions; be sure all shutoff

valves are open; increase pressure, but

do not exceed maximum working pressure.

Exhausted fluid supply. Refill and reprime pump.

Clogged fluid outlet line, valves, etc. Clear.

Worn piston packing. Replace. See lower manual.

Pump output low on only one stroke. Held open or worn ball check valves. Check and repair.

Worn piston packings. Replace. See lower manual.

No output. Improperly installed ball check valves. Check and repair.

Pump operates erratically. Exhausted fluid supply. Refill and reprime pump.

Held open or worn ball check valves. Check and repair.

Worn piston packing. Replace. See lower manual.

Excessive hydraulic fluid supply pressure to motor.

Pump will not operate. Restricted hydraulic supply lines. Clear any obstructions; be sure all shut

Exhausted fluid supply. Refill and reprime pump.

Clogged fluid outlet line, valves, etc. Clear.

Damaged hydraulic motor. See motor manual.

Fluid dried on piston rod. Disassemble and clean pump. See lower

See motor manual.

off valves are open; increase pressure,

but do not exceed maximum working

pressure.

manual. In future, stop pump at bottom of

stroke.

14 3A0537G

Page 15

Repair

Repair

Disassembly

NOTE: The 3000 and 4000cc pumps are easiest to

repair when left in the Part No. 218742 accessory pump

stand and disassembled as instructed in the lower manual. For repair at a remote location, have another pump

stand available.

1. Relieve the pressure, see Pressure Relief Proce-

dure page 11.

2. Disconnect the hoses from the lower and plug the

ends to prevent fluid contamination.

3. See F

4. Loosen the coupling nut (105) and remove the col-

IG

. 5. Remove the 2-piece shield (122) by

inserting a screwdriver straight into the slot, and

using it as a lever to release the tab. Repeat for all

tabs. Do not use the screwdriver to pry the shields

apart.

lars (106). Remove the coupling nut from the piston

rod (R). Unscrew the locknuts (104) from the tie

rods (103). Separate the motor (101) and lower

(102). See F

IG

. 6.

Reassembly

NOTE: If the coupling adapter (108) and tie rods (103)

have been disassembled from the motor, see Reassemble the Coupling Adapter and Tie Rods to the

Motor on page 17.

1. See F

2. Orient the lower (102) to the motor (101). Position

3. Insert the collars (106) into the coupling nut (105).

4. See F

IG

. 6. Assemble the coupling nut (105) to the

piston rod (R).

the lower on the tie rods (103). Lubricate the

threads of the tie rods. Screw the tie rod locknuts

(104) onto the tie rods. Torque the tie rod locknuts

to 50-55 ft-lb (68-75 N•m).

a.

750, 1000, 1500, and 2000cc Pumps:

the coupling nut onto the coupling adapter (108)

and torque to 90-100 ft-lb (122-135 N•m).

b.

3000 and 4000cc Pumps:

nut onto the motor shaft (S) and torque to 150

ft-lb (203 N•m).

IG

. 5. Install the shields (122) by engaging the

bottom lips with the groove in the wet-cup cap (C).

Snap the two shields together.

Tighten the coupling

Tighten

5. To repair the air motor or lower, see the separate

manuals listed under Related Manuals on page 2.

Shield Disassembly

ti15759a

FIG. 5. Disassembly and Reassembly of the Shields

3A0537G 15

5. Flush and test the pump before reinstalling it in the

system. Connect hoses and flush the pump. While it

is pressurized, check for smooth operation and

leaks. Adjust or repair as necessary before reinstalling in the system. Reconnect the pump ground wire

before operating.

Shield

ti15758a

ti15757a

ti15770a

Page 16

Repair

Viscount I Plus

Pump with

1000cc 4-Ball

Lower

103

2

Part of 101

101

111

110

109

107

108

106

105

122

R

102

Viscount II Pump

with 2000cc 4-Ball

Lower

Viscount II Pump

with 4000cc 4-Ball

Lower

101

101

6

103

111

S

2

S

106

1

103

2

109

108

112

2

4

105

5

122

106

105

1

R

122

102

104

2

3

102

TI15602a

R

104

2

3

TI15610a

104

2

3

1

Torque to 90-100 ft-lb (122-135 N•m).

2

Torque to 50-55 ft-lb (68-75 N•m).

3

Lubricate threads.

4

Torque to 75-80 ft-lb (102-109 N•m).

5

Torque to 150 ft-lb (203 N•m).

6

Torque to 15-17 ft-lb (20-23 N•m).

TI15599a

FIG. 6. Reassembly

16 3A0537G

Page 17

Repair

Reassemble the Coupling Adapter and Tie Rods to the Motor

NOTE: Use this procedure only if the coupling adapter

(108) and tie rods (103) have been disassembled from

the motor, to ensure proper alignment of the motor shaft

to the piston rod.

NOTE: 3000 and 4000cc Pumps do not have a coupling

adapter (108) or a mounting plate (111).

1.

750, 1000, 1500, and 2000cc Pumps only:

but do not remove, the screws holding the mounting

plate (111) to the motor (101). See F

2. Install the tie rods (103).

a.

750, 1000, 1500, and 2000cc Viscount I Plus

Pumps:

mounting plate (111) and into the threaded

holes in the base of the motor. Torque to 50-55

ft-lb (68-75 N•m).

b.

750, 1000, 1500, and 2000cc Viscount II

Pumps:

ing plate (111) and torque to 50-55 ft-lb (68-75

N•m).

c.

3000 and 4000cc Pumps:

(103) into the base of the motor and torque to

50-55 ft-lb (68-75 N•m).

Screw the tie rods (103) through the

Screw the tie rods (103) into the mount-

Screw the tie rods

IG

Loosen,

. 6.

5. Orient the lower (102) to the motor (101). Position

the lower on the tie rods (103). Lubricate the

threads of the tie rods. Loosely screw the tie rod

locknuts (104) onto the tie rods.

6. 750, 1000, 1500, and 2000cc Pumps only:

the mounting plate screws as follows.

a.

Viscount I Plus motors:

to 15-17 ft-lb (20-23 N•m).

b.

Viscount II motors:

50-55 ft-lb (68-75 N•m).

7. Torque the tie rod locknuts (104) to 50-55 ft-lb

(68-75 N•m).

8. Insert the collars (106) into the coupling nut (105).

a.

750, 1000, 1500, and 2000cc Pumps:

the coupling nut onto the coupling adapter (108)

and torque to 90-100 ft-lb (122-135 N•m).

b.

3000 and 4000cc Pumps:

nut onto the motor shaft (S) and torque to 150

ft-lb (203 N•m).

9. Flush and test the pump before reinstalling it in the

system. Connect hoses and flush the pump. While it

is pressurized, check for smooth operation and

leaks. Adjust or repair as necessary before reinstalling in the system. Reconnect the pump ground wire

before operating.

Torque the screws (109)

Torque the screws (109) to

Tighten the coupling

Tighten

Tighten

3. Fill the cavity in the bottom of the motor shaft with

grease.

4.

750, 1000, 1500, and 2000cc Pumps only:

the coupling adapter (108) as follows.

a.

Viscount I Plus motors:

adapter (108) into the motor shaft until the pin

holes align. Install the pin (107) in the first hole

from the end of the coupling.

b.

Viscount II motors:

onto the adapter (108). Screw the nut (112)

onto the motor shaft (S) and torque to 75-80

ft-lb (102-109 N•m).

3A0537G 17

Screw the coupling

Slide the adapter nut (112)

Install

Page 18

Parts

Parts

Viscount I Plus Pumps with 750cc, 1000cc, 1500cc, or 2000cc 4-Ball Lowers

Common Parts

103

Part of 101

104

101

111

110

109

107

108

106

105

122

102

TI15602a

Ref.

No. Description Part No.

101 MOTOR, Viscount I Plus, see manual

308330

102 LOWER, 4-Ball, see manual 3A0539 see tables 1

103 TIE ROD, 14.25 in. (362 mm) between

shoulders

104 NUT, lock, hex; 9/16-12 unc 108683 3

105 NUT, coupling 184059 1

106 COLLAR, coupling 184128 2

107 PIN, cotter 100103 1

108 ADAPTER, coupling 16C373 1

109 SCREW, cap 100001 4

110 WASHER, lock 100214 4

111 PLATE, mounting 16E086 1

122 SHIELD KIT; includes 2 shields 24F252 1

261466 1

15G924 3

Qty

Parts that Vary by Model

102

Pump

(see page 3) Lower Size

24E322

24E323 24F415

24E324 24F416

24E485 24F413

24E486 24F414

24E325

24E326 24F426

24E327 24F427

24E487 24F424

24E488 24F425

24E328

24E329 24F434

24E330 24F435

24E489 24F432

24E490 24F433

24E331

24E332 24F441

24E333 24F442

24E491 24F440

24E492 24F443

750cc

1000cc

1500cc

2000cc

4-Ball Lower

(see manual 3A0539)

24F420

24F431

24F439

24F447

.

18 3A0537G

Page 19

Viscount II Pumps with 2000cc 4-Ball Lower

Common Parts

Parts

111

103

122

101

109

108

112

106

105

Ref.

No. Description Part No.

101 MOTOR, Viscount II, see manual

308048

102 LOWER, 4-Ball, see manual 3A0539 see table 1

103 TIE ROD, 14.25 in. (362 mm) between

shoulders

104 NUT, lock, hex; 9/16-12 unc 108683 3

105 NUT, coupling 184059 1

106 COLLAR, coupling 184128 2

108 ADAPTER, coupling 15K736 1

109 SCREW, cap, socket hd C19789 3

111 PLATE, mounting 120558 1

112 NUT, adapter 183079 1

122 SHIELD KIT; includes 2 shields 24F252 1

223646 1

15G924 3

Qty

Parts that Vary by Model

102

Pump

(see page 3) Lower Size

24E334

24E335 24F441

24E336 24F442

24E493 24F440

24E494 24F443

2000cc

4-Ball Lower

(see manual 3A0539)

24F447

.

104

102

TI15599a

3A0537G 19

Page 20

Parts

Viscount II Pumps with 3000cc or 4000 cc 4-Ball Lowers

Common Parts

103

101

106

105

122

102

Ref.

No. Description Part No.

101 MOTOR, Viscount II, see manual

308048

102 LOWER, 4-Ball, see manual 3A0540 see table 1

103 TIE ROD, 12.72 in. (323 mm) between

shoulders

104 NUT, lock, hex; 9/16-12 unc 102216 3

105 NUT, coupling 186925 1

106 COLLAR, coupling 184129 2

122 SHIELD KIT; includes 2 shields 24F255 1

223646 1

180487 3

Qty

Parts that Vary by Model

102

Pump

(see page 3) Lower Size

24E337

24E338 24F448

24E339 24F449

24E340

24E341 24F451

24E342 24F452

3000cc

4000cc

4-Ball Lower

(see manual 3A0540)

24F450

24F453

.

104

TI15610a

20 3A0537G

Page 21

Dimensions

Dimensions

Viscount I Plus

Pump with

1000cc 4-Ball

Lower

A

Viscount II Pump with

2000cc 4-Ball Lower

A

B B

C C

Viscount II Pump with

4000cc 4-Ball Lower

A

B

C

A

TI15600a

B

in. (mm)

C

in. (mm)

TI15609a

Approx.

Weight

lb (kg)

74 (33.6)

215 (97.5)

TI15601a

Motor Lower Size

750cc

Viscount I Plus

Viscount II 2000cc 53.72 (1365) 28.78 (731) 17.4 (442) 150 (68.0)

Viscount II

3A0537G 21

1000cc 75 (34.0)

1500cc 76 (34.5)

2000cc 77 (34.9)

3000cc

4000cc 217 (98.4)

in. (mm)

49.00 (1245) 28.78 (731) 17.4 (442)

54.75 (1391) 29.0 (737) 23.0 (584)

Page 22

Motor Mounting Hole Diagrams

Motor Mounting Hole Diagrams

Viscount I Plus Adapter Plate 16E086

Four 0.45 (11.4 mm)

diameter holes

6.186 in.

(157 mm)

4.508 in.

(115 mm)

6.186 in.

(157 mm)

Four 0.344 (8.7 mm)

diameter holes

4.508 in.

(115 mm)

7.43 in.

(188 mm)

TI15860a

Mounting Stand Hole Layouts

Viscount II Motor Mounting Hole Layout

7.43 in.

(188 mm)

6.186 in.

(157 mm)

4X 3/8-16 UNC - 2B

TI10465a

6.186 in.

(157 mm)

19.88 in.

(505.0 mm)

and 2000cc Pumps)

17.0 in.

(431.8 mm)

14.50 in.

(368.3 mm)

TI15859a

16.88 in.

(428.8 mm)

218742 Floor Stand (for 3000 and 4000cc Pumps)253692 Floor Stand (for 750, 1000, 1500,

7.4 in.

(185 mm) radius

6.41 in.

(160 mm)

30°

6.41 in.

(160 mm)

30°

60°

11.1 in.

(278 mm)

Threaded 0.68 in.

(17 mm) holes

22 3A0537G

Page 23

255143 Wall Mount Bracket

14.5 in.

(368.3 mm)

5.4 in.

(136.5 mm)

17.8 in.

(450.9 mm)

255143 Wall Mount Bracket

2.0 in.

(50.8 mm)

7.4 in.

(187.3 mm)

1.6 in.

(41.4 mm)

1/2 in. (12.7 mm) diameter

holes for mounting to stand

9.0 in.

(228.6 mm)

12.4 in.

(314.3 mm)

5.3 in.

(133.4 mm)

1.0 in.

(25.4 mm)

7/16 in. (11 mm)

diameter holes for

mounting to wall

TI8614B

3A0537G 23

Page 24

Technical Data

Technical Data

750, 1000, 1500, and 2000cc Pumps with Viscount I Plus Motor

Maximum

Maximum

Working

Lower

Model

24E322 750cc 450 (3.1, 31.0)

24E323 750cc 450 (3.1, 31.0) 9.6 (36.4) 610

24E324 750cc 450 (3.1, 31.0) 9.6 (36.4) 610

24E485 750cc 450 (3.1, 31.0) 9.6 (36.4) 610

24E486 750cc 450 (3.1, 31.0) 9.6 (36.4) 610

24E325 1000cc 300 (2.1, 21.0) 14.1 (53.5) 890

24E326 1000cc 300 (2.1, 21.0) 14.1 (53.5) 890

24E327 1000cc 300 (2.1, 21.0) 14.1 (53.5) 890

24E487 1000cc 300 (2.1, 21.0) 14.1 (53.5) 890

24E488 1000cc 300 (2.1, 21.0) 14.1 (53.5) 890

24E328 1500cc 225 (1.6, 16.0) 19.4 (73.6) 1230

24E329 1500cc 225 (1.6, 16.0) 19.4 (73.6) 1230

24E330 1500cc 225 (1.6, 16.0) 19.4 (73.6) 1230

24E489 1500cc 225 (1.6, 16.0) 19.4 (73.6) 1230

24E490 1500cc 225 (1.6, 16.0) 19.4 (73.6) 1230

24E331 2000cc 167 (1.2, 12.0) 26.8 (101.5) 1690

24E332 2000cc 167 (1.2, 12.0) 26.8 (101.5) 1690

24E333 2000cc 167 (1.2, 12.0) 26.8 (101.5) 1690

24E491 2000cc 167 (1.2, 12.0) 26.8 (101.5) 1690

24E492 2000cc 167 (1.2, 12.0) 26.8 (101.5) 1690

Size

Pressure

psi (MPa, bar)

Hydraulic

Working

Pressure

psi (MPa, bar)

1500 (10.3,

103.0)

Hydraulic Oil

Consumption

See

Performance

Chart

Maximum

Hydraulic

Motor Fluid

Temperature

134°F (54°C)

Fluid Flow at

60 cycles

per minute

gpm (lpm)

9.6 (36.4) 610

per Cycle

Maximum

Output

Temperature

(cc)

150°F (66°C)

Fluid

Rating

Sound data: See Viscount I Plus manual 308330.

Wetted parts: See 4-Ball Lower manual 3A0539.

24 3A0537G

Page 25

2000cc Pumps with Viscount II Motor

Maximum

Lower

Model

24E334 2000cc

24E335 2000cc

24E336 2000cc

24E493 2000cc

24E494 2000cc

Size

Maximum

Working

Pressure

psi (MPa, bar)

460 (3.2, 32.0) 1200 (8.3, 83.0)

Hydraulic

Working

Pressure

psi (MPa, bar)

Hydraulic Oil

Consumption

See

Performance

Chart

Maximum

Hydraulic

Motor Fluid

Temperature

134°F (54°C) 31.5 (119.3) 2000 150°F (66°C)

Fluid Flow at

60 cycles

per minute

gpm (lpm)

Output

per Cycle

Sound data: See Viscount II manual 308048.

Wetted parts: See 4-Ball Lower manual 3A0539.

3000 and 4000cc Pumps with Viscount II Motor

Maximum

Maximum

Working

Lower

Model

24E337 3000cc 400 (2.8, 28.0)

24E338 3000cc 400 (2.8, 28.0) 47.3 (179) 3000

24E339 3000cc 400 (2.8, 28.0) 47.3 (179) 3000

24E340 4000cc 300 (2.1, 21.0) 63 (238.6) 4000

24E341 4000cc 300 (2.1, 21.0) 63 (238.6) 4000

24E342 4000cc 300 (2.1, 21.0) 63 (238.6) 4000

Size

Pressure

psi (MPa, bar)

Hydraulic

Working

Pressure

psi (MPa, bar)

1200 (8.3, 83.0)

Hydraulic Oil

Consumption

See

Performance

Chart

Maximum

Hydraulic

Motor Fluid

Temperature

134°F (54°C)

Fluid Flow at

60 cycles

per minute

gpm (lpm)

47.3 (179) 3000

Output

per Cycle

(cc)

(cc)

Technical Data

Maximum

Fluid

Temperature

Rating

Maximum

Fluid

Temperature

Rating

150°F (66°C)

Sound data: See Viscount II manual 308048.

Wetted parts: See 4-Ball Lower manual 3A0540.

3A0537G 25

Page 26

Performance Charts

Performance Charts

To find Fluid Outlet Pressure (psi/MPa/bar) at a spe-

cific fluid flow (lpm/gpm) and operating hydraulic pressure (psi/MPa/bar):

1. Locate desired flow along bottom of chart.

2. Follow vertical line up to intersection with selected

fluid outlet pressure curve (black). Follow left to

scale to read fluid outlet pressure.

See Models on page 3 for your pump part number.

Key:

A 10.3 MPa, 103 bar (1500 psi)

hydraulic pressure

B 7.2 MPa, 72.4 bar (1050 psi)

hydraulic pressure

C 4.1 MPa, 41 bar (600 psi)

hydraulic pressure

NOTE: The shaded area within

the table shows the recommended range for continuous

duty circulation applications.

To find Motor Hydraulic Oil Consumption (l/min. or

gpm) at a specific fluid flow (l/min. or gpm):

1. Locate desired flow along bottom of chart.

2. Read vertical line up to intersection with hydraulic oil

psi (MPa, bar)

500

3.4, 34)

400

(2.8, 28)

300

2.1, 21)

200

(1.4, 14)

100

(0.7, 7)

PUMP OUTLET PRESSURE

GPM

(l/min)

consumption curve (dashes). Follow right to scale to

read hydraulic oil consumption.

Viscount I Plus Motor, 750cc Lower

CPM

19 37 56 74

A

GPM

(l/min)

5 (19.0)

4 (15.2)

3 (11.4)

B

2 (7.6)

C

0

0

3

(11)

PUMP DELIVERY (Test Fluid: No. 10 Motor Oil)

(23)

6

9

(34)

12

(46)

1 (3.8)

15

(57)

Viscount I Plus Motor, 1000cc Lower

HYDRAULIC OIL CONSUMPTION

HYDRAULIC OIL CONSUMPTION

PUMP OUTLET PRESSURE

PUMP DELIVERY (Test Fluid: No. 10 Motor Oil)

26 3A0537G

Page 27

See Models on page 3 for your pump part number.

Key:

A 10.3 MPa, 103 bar (1500 psi)

hydraulic pressure

B 7.2 MPa, 72.4 bar (1050 psi)

hydraulic pressure

C 4.1 MPa, 41 bar (600 psi)

hydraulic pressure

NOTE: The shaded area within

the table shows the recommended range for continuous

duty circulation applications.

PUMP OUTLET PRESSURE

psi (MPa, bar)

160

(1.12, 11.2)

120

0.84, 8.4)

(0.56, 5.6)

(0.28, 2.8)

PUMP OUTLET PRESSURE

GPM

(l/min)

Viscount I Plus Motor, 1500cc Lower

PUMP DELIVERY (Test Fluid: No. 10 Motor Oil)

Viscount I Plus Motor, 2000cc Lower

CPM

12 24 36 48

A

80

40

B

C

0

0

5

(19)

PUMP DELIVERY (Test Fluid: No. 10 Motor Oil)

10

(38)

15

(57)

Performance Charts

GPM

(l/min)

60

3.0 (11.4)

2.5 (9.5)

2.0 (7.6)

1.5 (5.7)

1.0 (3.8)

0.5 (1.9)

20

(76)

25

(95)

HYDRAULIC OIL CONSUMPTION

HYDRAULIC OIL CONSUMPTION

3A0537G 27

Page 28

Performance Charts

See Models on page 3 for your pump part number.

450 (3.1, 31)

Key:

A 10.3 MPa, 103 bar (1500 psi)

hydraulic pressure

B 7.2 MPa, 72.4 bar (1050 psi)

hydraulic pressure

C 4.1 MPa, 41 bar (600 psi)

hydraulic pressure

400 (2.8, 28)

350 (2.4, 24)

300 (2.1, 21)

250 (1.7, 17)

NOTE: The shaded area within

the table shows the recom-

200 (1.4, 14)

mended range for continuous

duty circulation applications.

150 (1.0, 10)

100 (0.7, 7)

FLUID PRESSURE, psi (MPa, bar)

50 (0.3, 3)

Viscount II Motor, 2000cc Lower

CYCLES PER MIN.

048121620

A

B

C

24 28

32

GPM

(l/min)

36

8.0 (30.4)

7.0 (26.6)

6.0 (22.8)

5.0 (19.0)

4.0 (15.2)

3.0 (11.4)

2.0 (7.6)

1.0 (3.8)

HYDRAULIC OIL CONSUMPTIO

N

0 (0, 0)

0.0

(0.0)

2.0

(7.0)

4.0

6.0

8.0

(15.0)

(22.5)

(30.0)

10.0

(37.9)

FLUID FLOW, gpm (lpm)

12.0

(45.4)

14.0

(53.0)

16.0

(60.6)

18.0

(68.1)

0

28 3A0537G

Page 29

See Models on page 3 for your pump part number.

Key:

A 10.3 MPa, 103 bar (1500 psi) hydraulic pressure

B 7.2 MPa, 72.4 bar (1050 psi) hydraulic pressure

C 4.1 MPa, 41 bar (600 psi) hydraulic pressure

NOTE: The shaded area within the table shows the

recommended range for continuous duty circulation

applications.

Viscount II Motor, 3000cc Lower

psi

MPa, bar

400

2.8, 28

300

2.1, 21

200

1.4, 14

100

FLUID PRESSURE

0.7, 7

0

gpm

liters/minute

10 21 31 52

42 10 21 31 52 6042

A

B

C

40

32

24

16

8

0

30

FLUID FLOW (TEST FLUID: NO. 10 WEIGHT OIL)

91

60

121

151

60

48

181

gpm

l/min

HYDRAULIC OIL CONSUMPTION

gpm

liters/minute

Performance Charts

Hydraulic Oil ConsumptionFluid Outlet Pressure

cycles per minutecycles per minute

12

45

10

38

8

30

6

23

4

15

2

7.6

0

32

24

16

8

0

FLUID FLOW (TEST FLUID: NO. 10 WEIGHT OIL)

60

30

121

91

40

151

48

181

MPa, bar

2.1, 21

ERUSSERP DIULF

1.8, 17.5

1.4, 14

1.0, 10

0.7, 7

0.35, 3.5

gpm

liters/minute

Viscount II Motor, 4000cc Lower

Fluid Outlet Pressure

psi

A

B

C

FLUID FLOW (TEST FLUID: NO. 10 WEIGHT OIL)

cycles per minute

81523 3830

30 60 91 151 181

121

46

212

53

NOITPMUSNOC LIO CILUARDYH

gpm

l/min.

gpm

liters/minute

Hydraulic Oil Consumption

cycles per minute

81523 3830

60

45

30

15

30 60 91 151 18146212

FLUID FLOW (TEST FLUID: NO. 10 WEIGHT OIL)

121

53

3A0537G 29

Page 30

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissen

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

t avoir convenu que la

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2010, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions.

This manual contains English. MM 3A0537

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised September 2014

Loading...

Loading...