Page 1

Instructions

2

1

3

4

5

1

2

3

1

4

G3 Reservoir and O-Ring

Replacement Kit

Instructions for replacing G3 reservoir and o-rings. For professional use only.

Part No.:

571042, 571069, 571179 - 2 Liter

models

571182, 571183 - 4 Liter models

Important Safety Instructions

Read all warnings and instructions in this

manual and the G3 Pump Instruction manual

included with your unit. Save these instructions.

3A0534F

EN

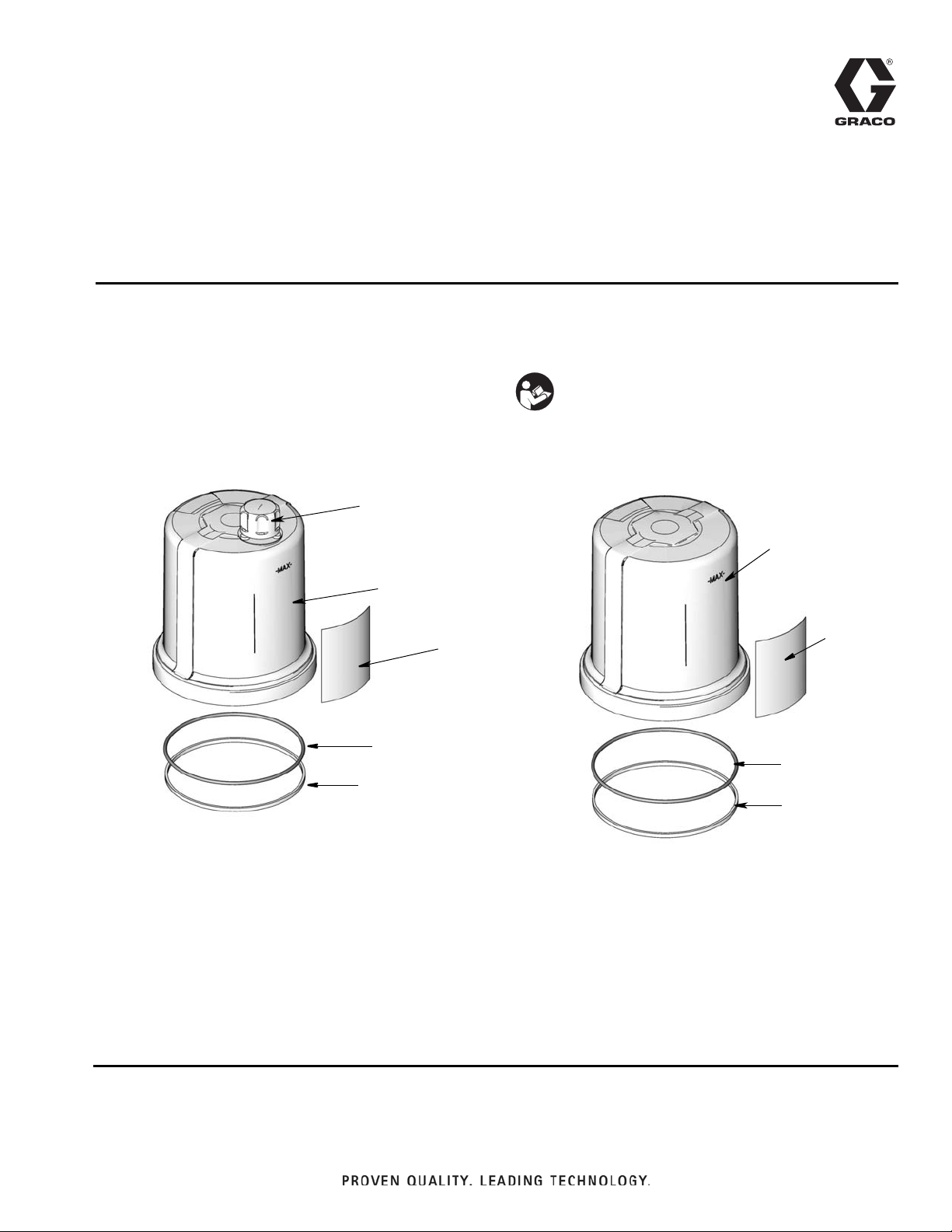

Kit Parts 571179, 571182

Ref. Description Qty

1 RESERVOIR 1

2 CAP, oil, fill 1

3 LABEL 1

4O-RING 1

5 O-RING, square 1

Kit Parts 571042, 571069, 571183

Ref. Description Qty

1O-RING 1

2 RESERVOIR 1

3 LABEL 1

4 O-RING, square 1

Page 2

Instructions

R

S

FP

FPS

Instructions

Pressure Relief

SKIN INJECTION HAZARD

High-pressure fluid from dispense device, hose leaks, or

ruptured components will pierce skin. This may look like

just a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

Follow Pressure Relief Procedure in this manual, when

you stop dispensing and before cleaning, checking, or

servicing equipment.

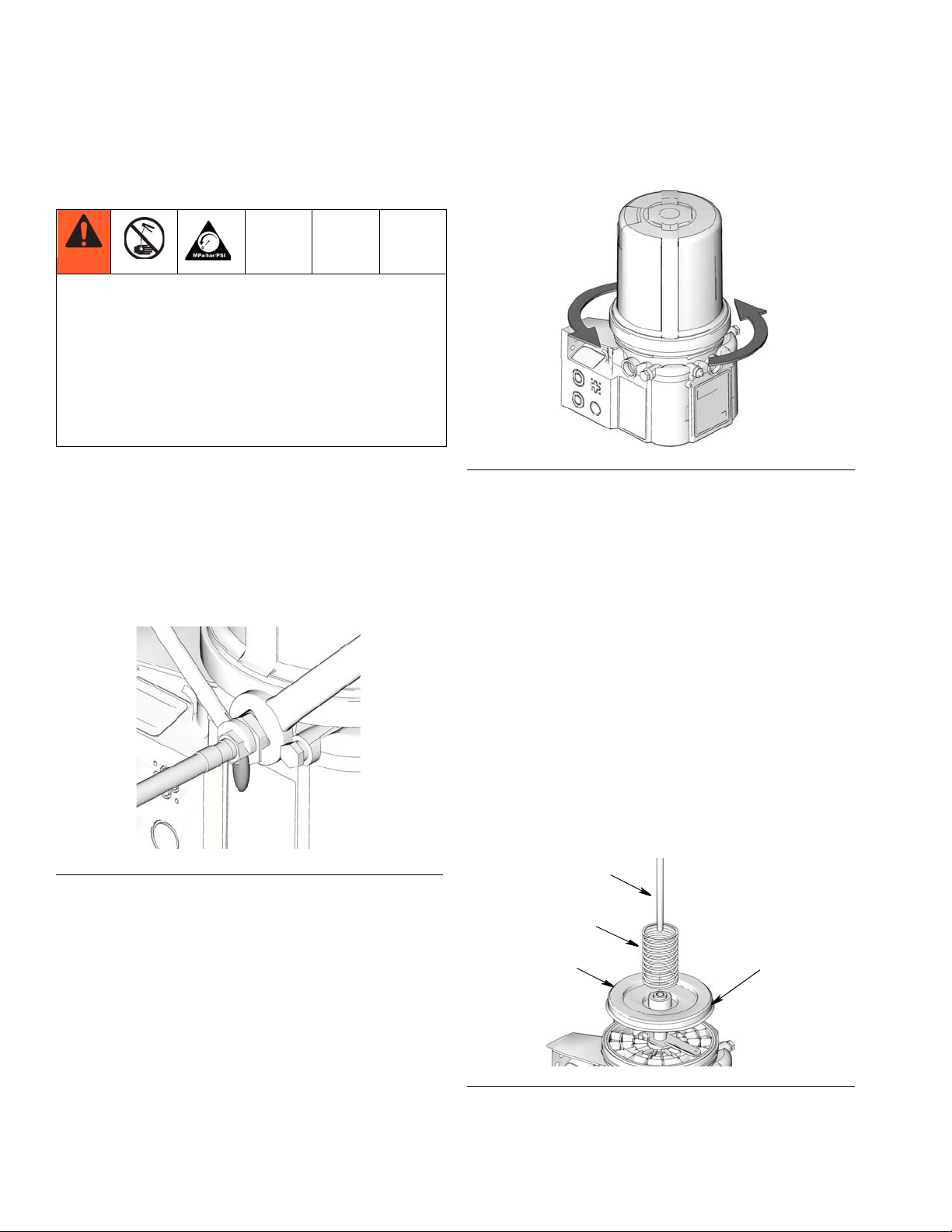

Relieve pressure in system by using two wrenches

working in opposite directions on pump element and

pump element fitting to only loosen fitting.

NOTE: When loosening pump element fitting, do NOT

loosen pump element. Loosening pump element will

change the output volume.

3. Use a strap wrench around reservoir to turn reservoir 1/4 turn counter-clockwise (F

FIG. 2

4. Remove reservoir from G3 base and discard reservoir according to local codes for proper disposal.

NOTE: If your unit includes a follower plate, remove any

parts noted in Step 1 of the Follower Plate Disassembly

section and keep those parts for reassembly.

IG. 2).

F

IG. 1

Disassembly

Reference numbers used in these instructions correspond to parts included in Kit and are provided on page

1. Parts identified with an alpha character are user provided or already installed components.

Reservoir Disassembly

1. Disconnect power source.

2. Relieve pressure using Pressure Relief Procedure

provided.

Follower Plate Disassembly

If your unit does not have a follower plate, continue

disassembly with O-Ring Disassembly instructions,

page 3.

1. Verify the following parts were removed with reservoir (F

IG. 3):

•Spring (S)

• Follower Pate (FP)

• Follower Plate Seal (FPS)

• Rod (R)

FIG. 3

2. Remove any parts still installed in the G3 base.

2 3A0534F

Page 3

Instructions

a

b

c

d

f

b

e

3. Be sure parts remaining in reservoir were removed

to reuse them for reassembly.

4. Examine follower plate seal referenced in Step 1 for

wear or damage. If it is damaged, it must be

replaced. Part No. 278139 is available from Graco.

Contact customer service to order this part or your

local Graco distributor.

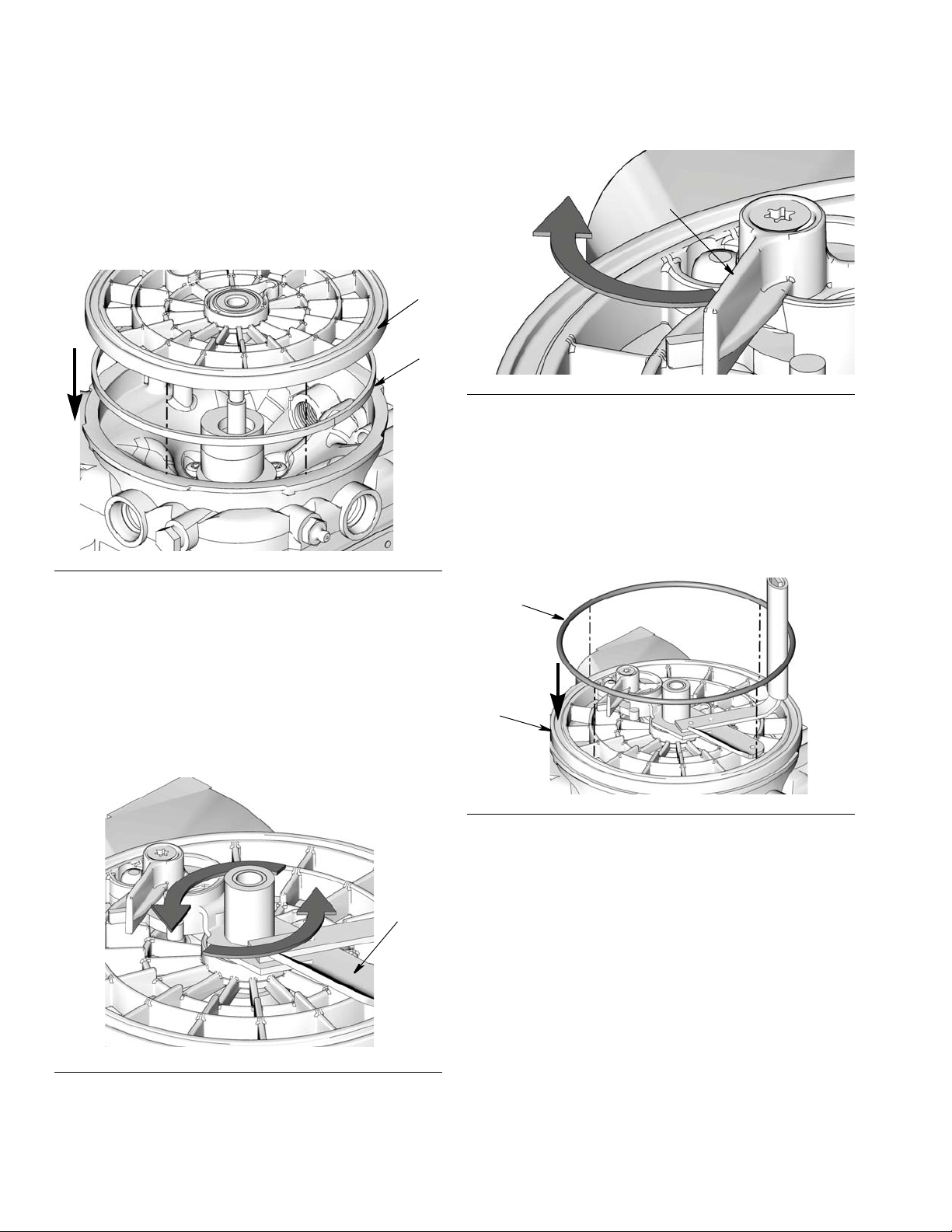

Upper O-Ring Disassembly

If o-ring (a) did not come out of the groove in ricer plate

(b) when reservoir was removed, remove and discard

o-ring according to local codes for proper disposal (F

4).

IG.

Lower O-Ring Disassembly Instructions

1. Perform all applicable previous disassembly instructions for reservoir, follower plate (if applicable) and

upper o-ring.

2. Turn paddle (c) clockwise to loosen and remove it

from G3 base (F

NOTE: For models that include a Low Level paddle

and/or follower plate only, be careful when removing

stirring paddle from G3 that bearing (f) does not fall

into the unit.

IG. 5).

FIG. 4

The lower o-ring is located beneath the ricer plate

(b). If replacing this o-ring, continue with Lower

O-Ring Disassembly instructions.

If lower o-ring is not replaced, begin Reassembly

FIG. 5

3. Remove ricer plate (b) from G3 base.

instructions starting on page 4.

FIG. 6

4. Remove o-ring (e) located under ricer plate (F

IG. 6).

3A0534F 3

Page 4

Instructions

b

1

c

d

b

1

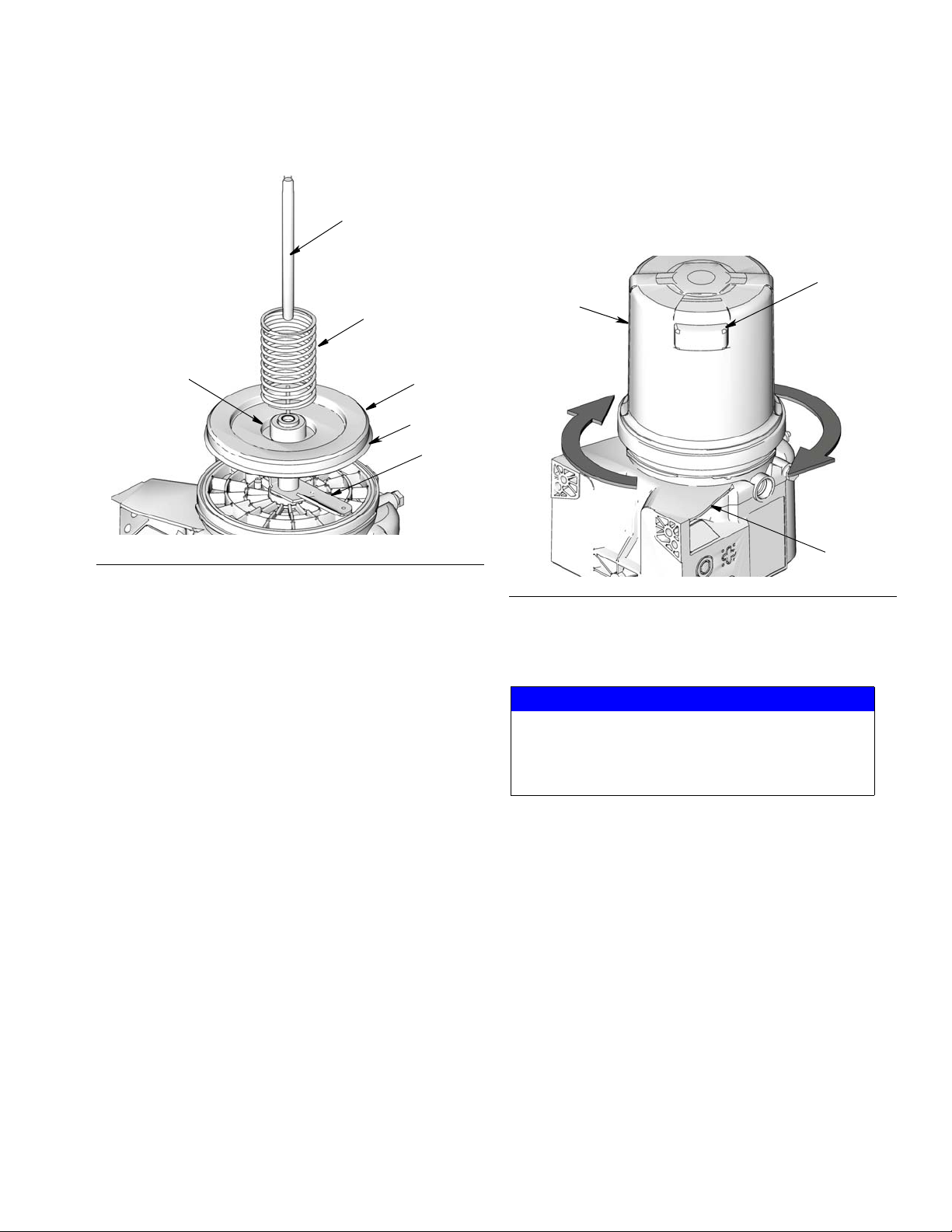

Reassembly

Lower O-Ring Installation

1. Coat new o-ring (1) with grease (user supplied) and

install o-ring in bottom groove of ricer plate (b).

FIG. 9

4. Complete installation following instructions for Top

O-ring and Reservoir installation, page 4.

Top O-ring Installation

1. Coat new o-ring (1) with grease (user supplied).

FIG. 7

2. Replace ricer plate (b), aligning circular sections

with the round bosses in the base.

NOTE: It may be necessary to use a press to seat

the plate properly in the G3 base.

3. Reinstall paddle (c) by turning it counter-clockwise

till tight - hand tighten only (F

IG. 8).

2. Install o-ring in groove of ricer plate (b) (F

FIG. 10

IG. 10).

Follower Plate Installation

If your unit does not have a follower plate, continue

installation instructions with Top O-Ring Installation, page 5.

1. Verify low level paddle (d) is in full out position as

shown in F

IG. 9.

2. Install follower plate (FP) on stirring paddle (c). Be

FIG. 8

NOTE: If a low level paddle (d) is installed, to pre-

vent damage, hold low level paddle in its full out

position while installing stirring paddle (F

4 3A0534F

IG. 9).

sure the seal (FPS) is facing down (toward ricer

Page 5

Instructions

c

FP

S

R

FPS

f

2

g

h

plate) as shown in FIG. 11.

FIG. 11

Reservoir Installation

1. Install new reservoir (2) with vent (g) facing toward

the rear left (h) of the G3 base. See F

rect orientation of these parts to ensure proper

installation.

IG. 12 for cor-

3. Install spring (S) into spring pocket (f).

4. Install Rod (R) into reservoir (2).

5. Slide rod (R) through center of spring (S) and follower plate (FP).

6. Seat spring in spring pocket in top of reservoir.

7. Compress spring to install reservoir. See Reservoir

Installation instructions.

FIG. 12

2. Position strap wrench over reservoir and use it to

turn reservoir 1/4 turn clockwise till reservoir will not

turn any farther (F

IG. 12).

NOTICE

Be careful when installing reservoir that o-ring is not

pinched. If the o-ring is not correctly installed,

grease could leak out of the bottom of the G3 reservoir.

3A0534F 5

Page 6

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents

Original instructions. This manual contains English. MM 3A0534

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2010, Graco Inc. is registered to ISO 9001

www.graco.com

Revised April 2014

Loading...

Loading...