Page 1

Instructions

G3 Pump Element

3A0533D

Replacement Kit

Instructions for adding/replacing a Pump Element used in G3 pump. For professional use

only.

Part No.: 571041

Important Safety Instructions

Read all warnings and instructions in this

manual and the G3 Pump instruction manual

included with your unit. Save these instructions.

2

ENG

4

2

3

4

1

1

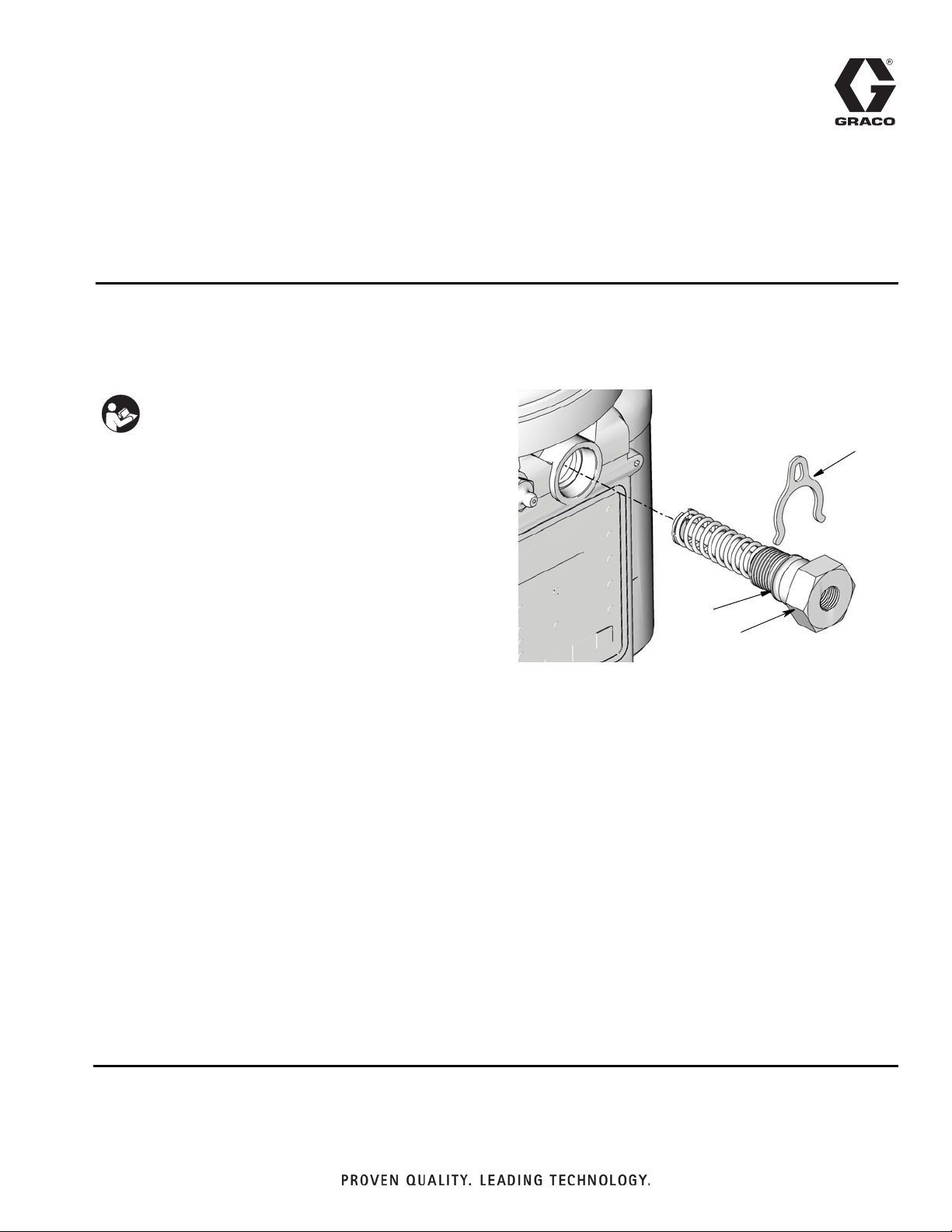

Kit Parts 571041

Ref. Description Qty

1 PUMP, element 1

2 SPACER, stroke adjust 2

3 LABEL, safety (not shown) 1

4O-RING 1

Page 2

Instructions

Instructions

Pressure Relief

SKIN INJECTION HAZARD

High-pressure fluid from dispense device, hose leaks,

or ruptured components will pierce skin. This may look

like just a cut, but it is a serious injury that can result in

amputation. Get immediate surgical treatment.

Follow Pressure Relief Procedure in this manual,

when you stop dispensing and before cleaning, checking, or servicing equipment.

Relieve pressure in system by using two wrenches

working in opposite directions on pump element and

pump element fitting to only loosen fitting.

NOTE: When loosening pump element fitting, do NOT

loosen pump element. Loosening pump element will

change the output volume.

1. Disconnect power source.

2. Relieve pressure following Pressure Relief Procedure provided.

3. Disconnect anything installed to pump element such

as pressure relief valves, output union, or other fittings.

4. Use a wrench to loosen pump element (1) and completely remove pump element and spacers (2) from

G3 housing.

Make sure spring (a), retainer (b) and piston (c) are

removed with pump element (F

b

a

IG. 2).

2

1

4

FIG. 2

5. Discard these parts. They are not required for installation of the new pump element.

F

IG. 1

Disassembly

The following instructions are for removing a pump element currently installed in the G3 Pump.

Reference numbers used in these instructions correspond to parts included in Kit and are provided on page

1. Parts identified with an alpha character are user provided or already installed components.

2 3A0533D

Installation

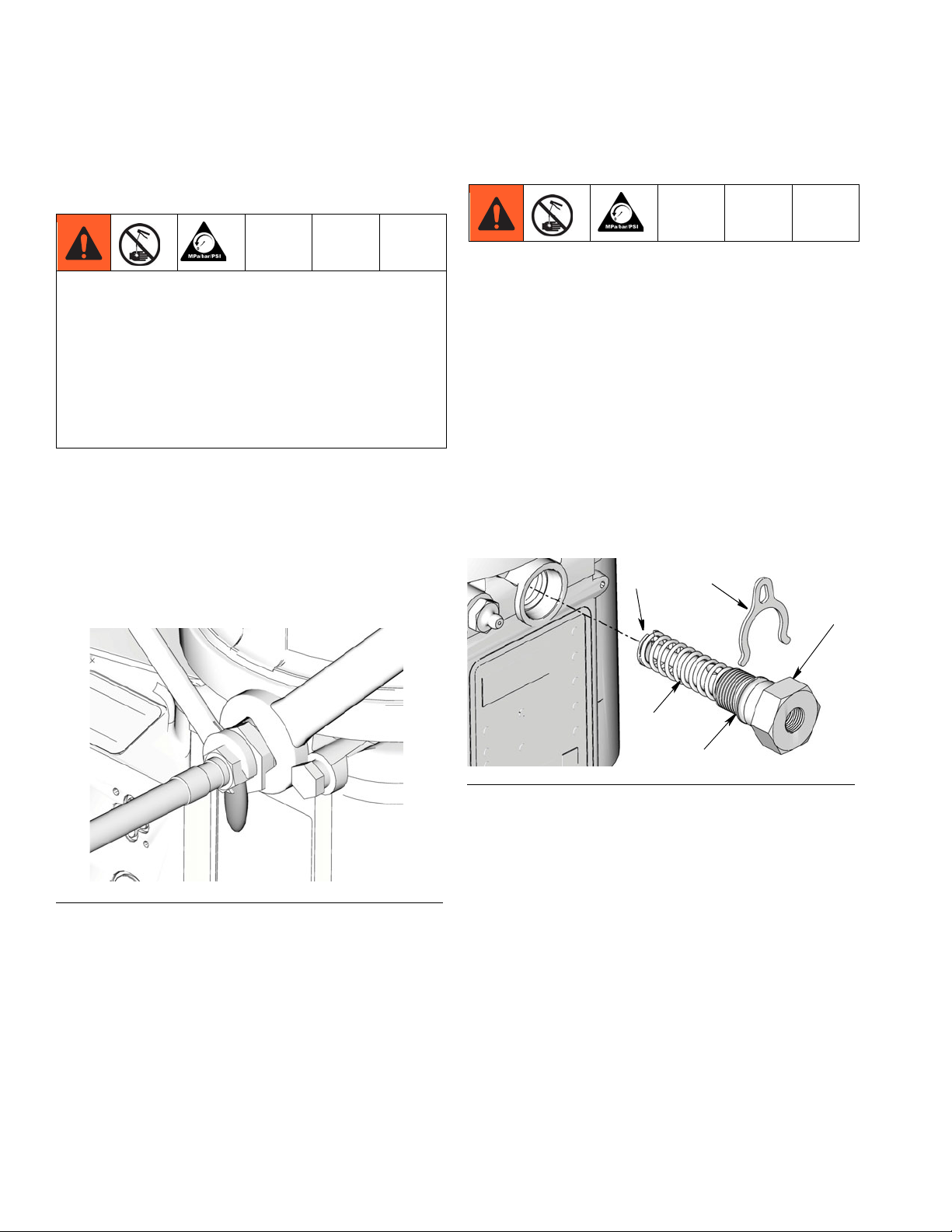

1. Examine new pump element (1) . Make sure spring

(a), retainer (b), o-ring (4) and piston are installed

(F

IG. 2).

2. Install stroke adjust spacers (2) (or no stroke adjust

spacers) as required for correct volume output.

• Discard old spacers you removed in Step 4.

Only use new, Graco supplied spacers included

in the kit to control output volume.

3. Slide pump element into G3 housing. Be careful not

to cross thread the pump element during installation.

Page 3

Instructions

4. Tighten pump element buy hand and then torque to

50 in. lbs (5.6 N•m) (F

F

IG. 3

IG. 3).

Adjusting Output Volume

NOTE:

• It may be necessary to repeat the outlet volume

setup procedure after the pump is operating to

re-adjust the volume of dispensed grease.

1. Use a wrench to turn pump element counter-clockwise to loosen.

2. If needed, remove or insert spacers to achieve

required pump output volume.

• Pump volume control is set using either no (0)

spacers, 1 or 2 spacers (F

IG. 4).

• Do not use more than 2 spacers on any pump

element.

Table 1: Output Volume

Output Volume / Minute

No. Spacers

cubic inches cubic cm

00.2474.0

10.182 3.0

20.1172.0

• The amount of dispensed volume can vary depending on external conditions such as lubricant temperature and back pressure from downstream

connections. Use the volume adjustments provided

in Table 1 as a starting point and adjust as necessary to ensure desired lubrication dispense.

F

IG. 4

3A0533D 3

Page 4

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 3A0533

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2010, Graco Inc. is registered to ISO 9001

www.graco.com

6/2010, Revised 1/2011

Loading...

Loading...