Page 1

Instructions - Parts List

3A0149C

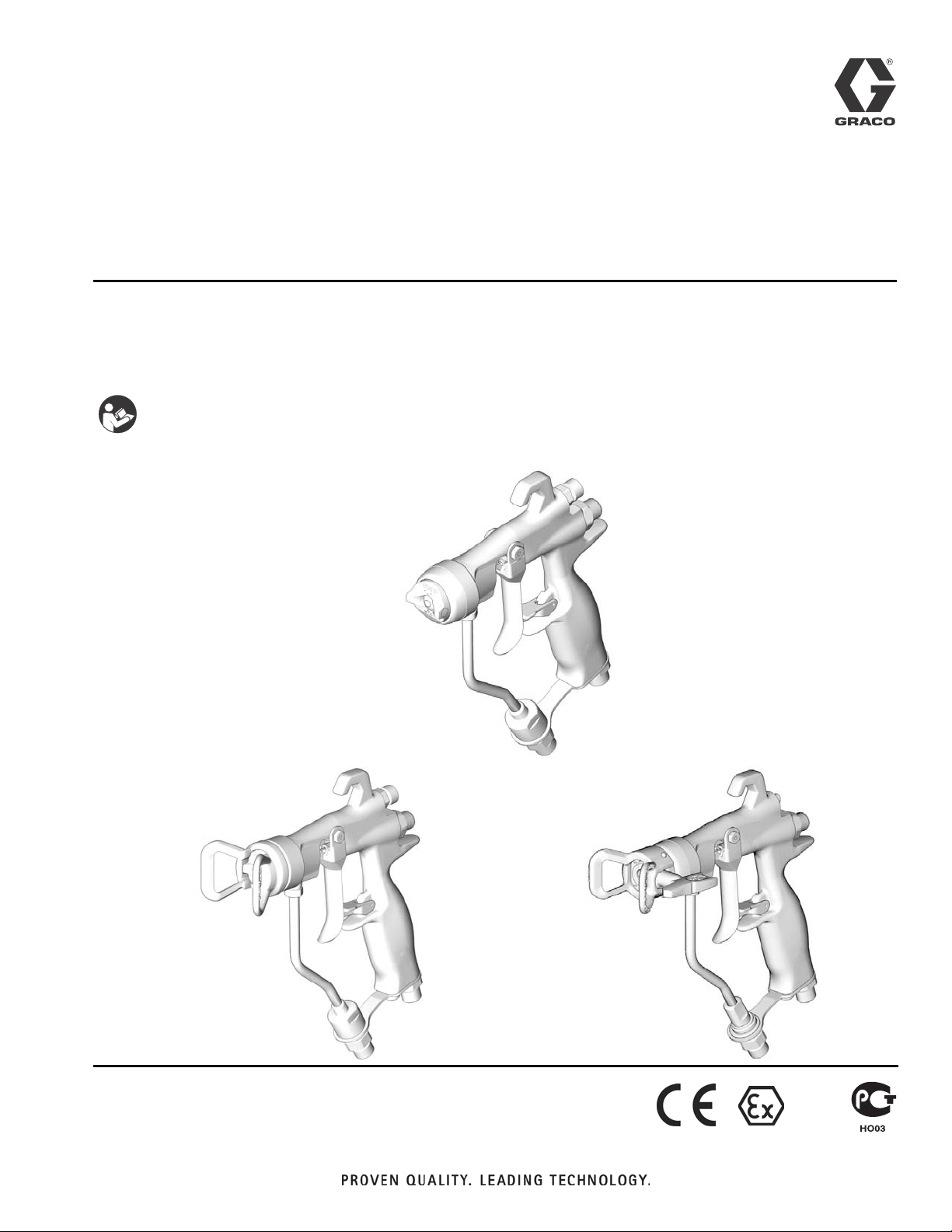

G15/G40 Spray Gun

A lightweight line of air-assisted spray guns for spraying and finishing a variety of paints

and coatings, particularly in applications requiring uniform atomization and high transfer

efficiency. For professional use only.

Important Safety Instructions:

Read all warnings and instructions in this manual. Save these

instructions. See page 2 for model information including maximum working pressure.

ENG

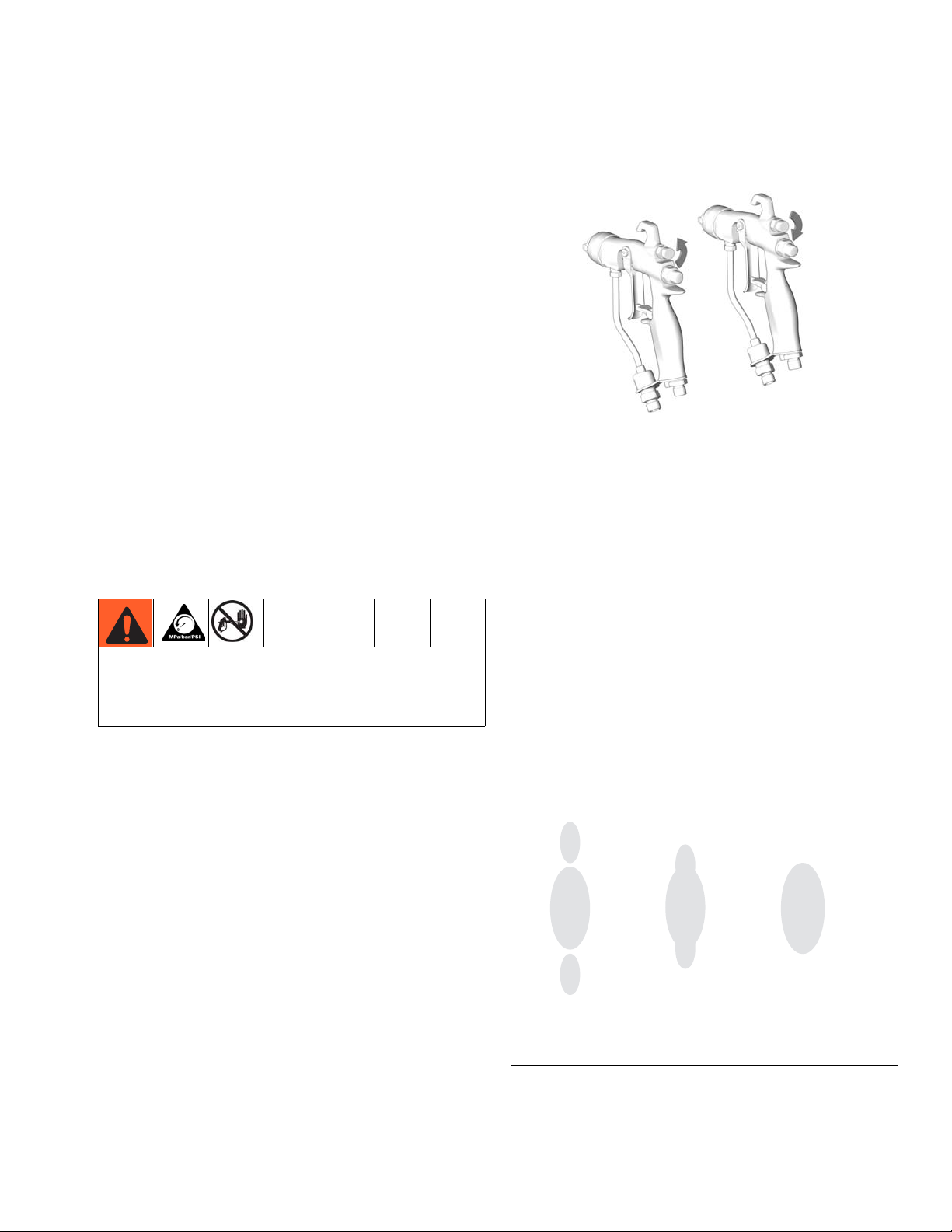

Model G40

Model G15

TI6844A

TI6553A

Model G40 w/RAC tip

TI7204B

II 2 G

Page 2

Models

Contents

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Typical Installation . . . . . . . . . . . . . . . . . . . . . . . . 6

Ventilate the Spray Booth . . . . . . . . . . . . . . . . . . 6

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Air Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Fluid Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Flush Before Using Equipment . . . . . . . . . . . . . . 8

Select a Spray Tip and Air Cap . . . . . . . . . . . . . . 8

Install a Spray Tip . . . . . . . . . . . . . . . . . . . . . . . . 8

Position the Air Cap . . . . . . . . . . . . . . . . . . . . . . 8

Air Cap Alignment Pin . . . . . . . . . . . . . . . . . . . . . 8

®

Reverse-A-Clean

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Pressure Relief Procedure . . . . . . . . . . . . . . . . 10

Trigger Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

How the Air-Assisted Spray Gun Operates . . . . 11

Spray Pattern Adjustment . . . . . . . . . . . . . . . . . 11

HVLP Operation . . . . . . . . . . . . . . . . . . . . . . . . 12

Fluid Application . . . . . . . . . . . . . . . . . . . . . . . . 12

(RAC) Tip . . . . . . . . . . . . . . . 9

Daily Gun Care, Flushing, and Cleaning . . . . . . . 13

General System Maintenance . . . . . . . . . . . . . . 14

Fluid Filter Maintenance . . . . . . . . . . . . . . . . . . 14

Flushing and Cleaning . . . . . . . . . . . . . . . . . . . . 14

®

Reverse-A-Clean

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Repair Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Fan Valve Replacement . . . . . . . . . . . . . . . . . . . 20

Complete Gun Packing Repair . . . . . . . . . . . . . 20

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Spray Tip Selection Chart . . . . . . . . . . . . . . . . . . . 32

Spray Tips, for use with G15/G40 Air Cap . . . . . 32

RAC SwitchTips, for use with

G40 RAC Air Cap . . . . . . . . . . . . . . . . . . . . 33

RAC SwitchTips, for use with

G40 RAC Air Cap, Continued . . . . . . . . . . . 34

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Part Interchangeability Guide . . . . . . . . . . . . . . 37

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 40

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 40

(RAC) Tip . . . . . . . . . . . . . . 16

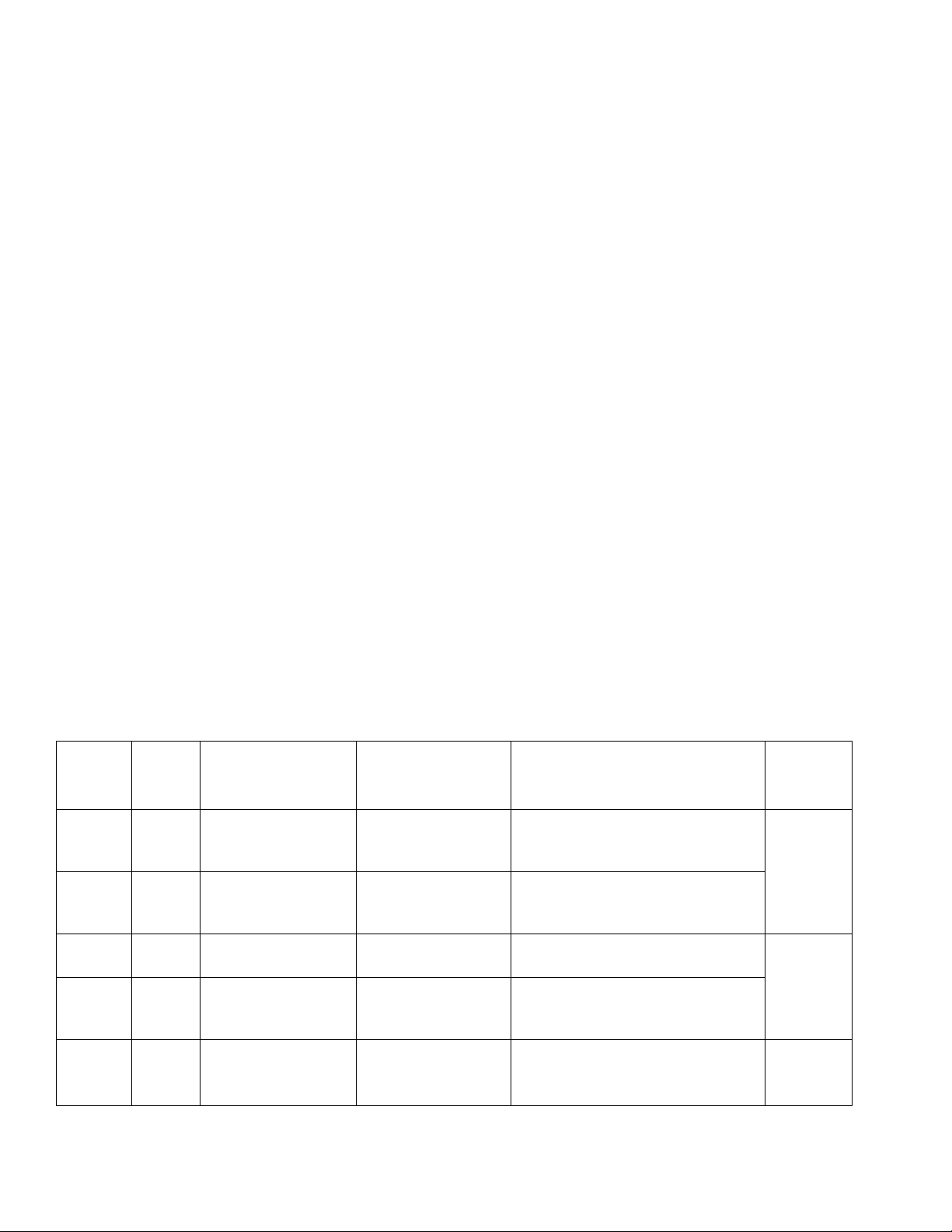

Models

Part Series

24C853 A

24C854 A

24C855 A

24C856 A

24C857 A

Maximum Working

Air Pressure

psi (MPa, bar)

100 (0.7, 7.0) 1500 (10.5, 105)

100 (0.7, 7.0) 1500 (10.5, 105)

100 (0.7, 7.0) 4000 (28, 280)

100 (0.7, 7.0) 4000 (28, 280)

100 (0.7, 7.0) 4000 (28, 280)

Maximum Working

Fluid Pressure

psi (MPa, bar) Description Includes:

G15 Medium Pressure

Air-Assisted Spray Gun,

Carbide Seat and Ball

G15 Medium Pressure

Air-Assisted Spray Gun,

Plastic Seat, SST Ball

G40 High Pressure Air-Assisted

Spray Gun, Carbide Seat and Ball

G40 High Pressure, High Flow

Air-Assisted Spray Gun,

Carbide Seat and Ball

G40 High Pressure Air-Assisted

Spray Gun, Carbide Seat and

®

Ball, Reverse-A-Clean

(RAC) Tip

24C866

Air Cap

with pin

249180

Air Cap

without

pin

24C921

RAC

Air Cap

2 3A0149C

Page 3

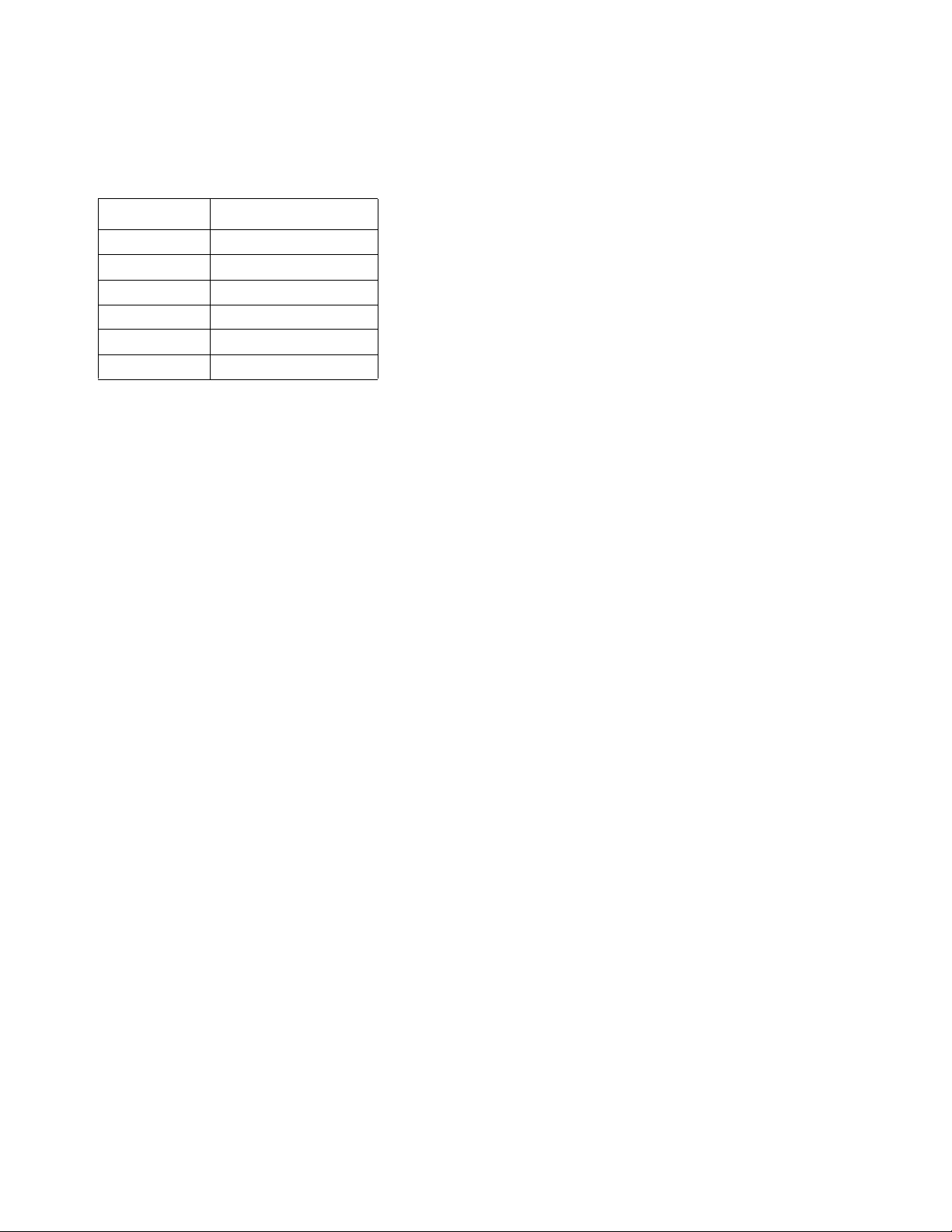

Related Manuals

This manual is available in the following languages:

Manual Language

3A0149A English

3A0283A French

3A0282A Spanish

3A0442 Chinese

3A0443 Japanese

3A0444 Korean

Related Manuals

3A0149C 3

Page 4

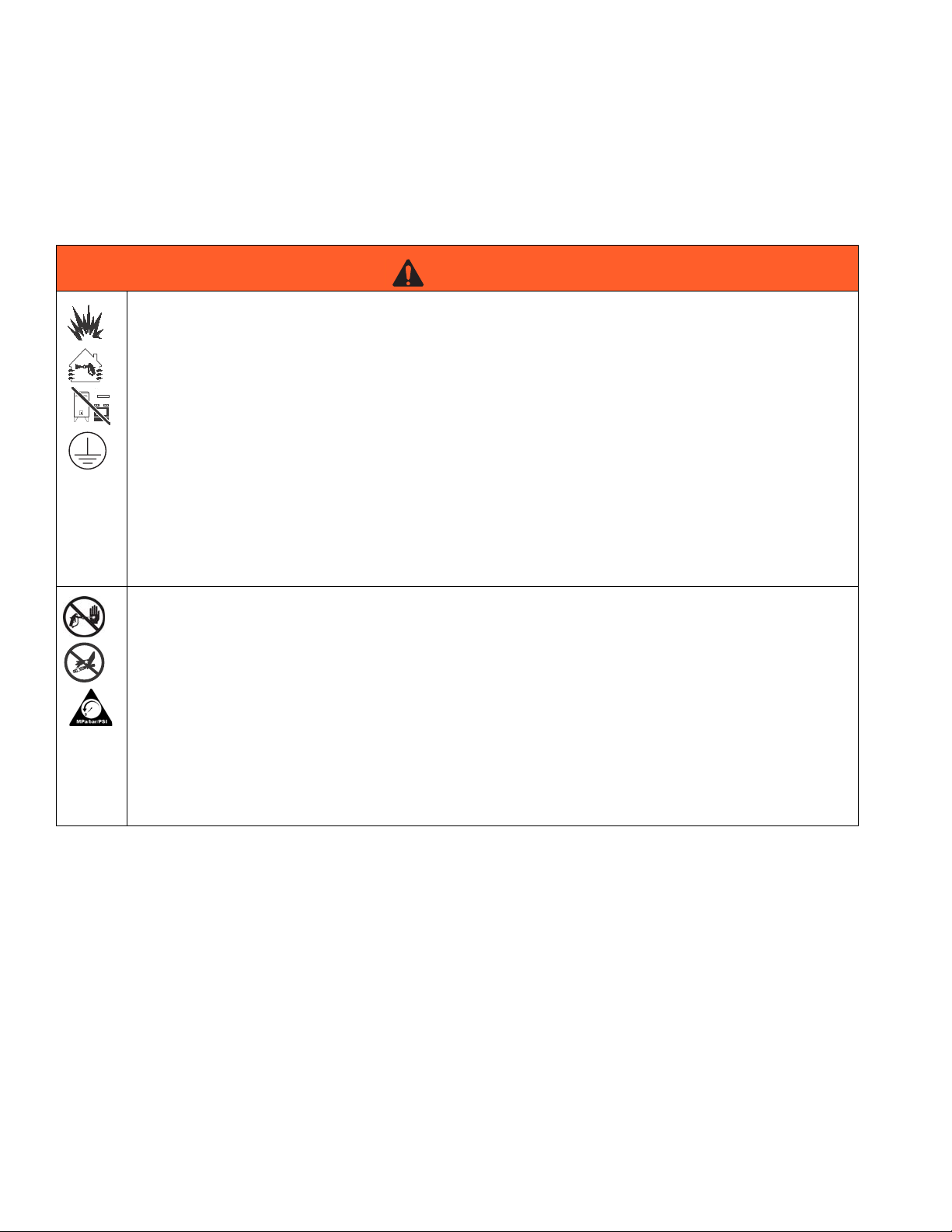

Warnings

Warnings

The following are general warnings related to the setup, use, grounding, maintenance, and repair of this equipment.

Additional, more specific warnings may be found throughout the body of this manual where applicable. Symbols that

appear in the body of the manual refer to these general warnings. When these symbols appear throughout the manual, refer back to these pages for a description of the specific hazard.

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

4 3A0149C

Page 5

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure. Turn off all equipment

and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, hearing loss, inhalation of toxic fumes, and burns. This equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer

3A0149C 5

Page 6

Installation

Installation

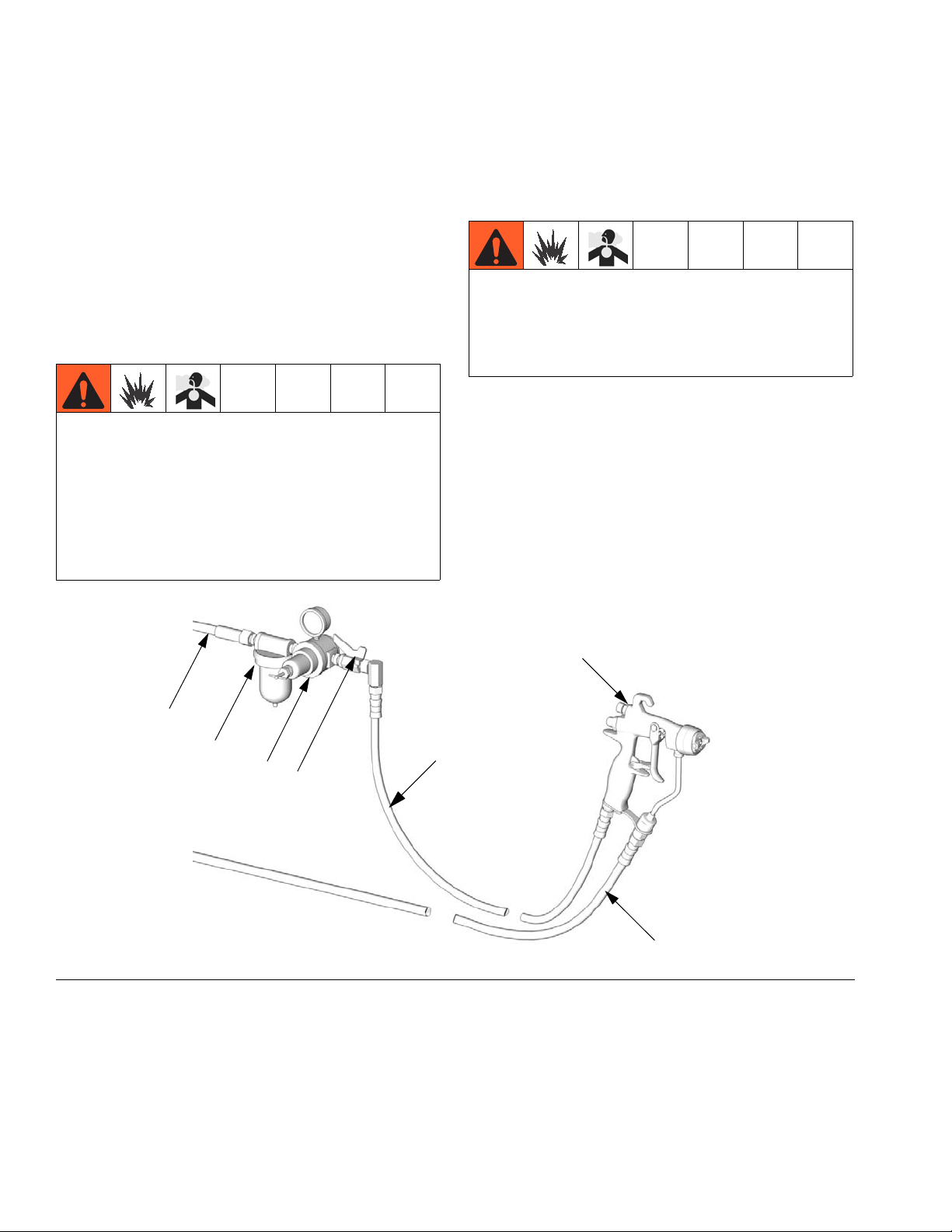

Typical Installation

NOTE: The typical installation shown in FIG. 1 is only a

guide for selecting and installing air-assisted spray systems. Contact your Graco distributor for assistance in

designing a system to meet your needs.

Ventilate the Spray Booth

• To prevent hazardous concentrations of toxic

and/or flammable vapors, spray only in a properly

ventilated spray booth. Do not operate the spray

gun unless ventilation fans are operating.

• Check and follow all of the National, State, and

Local codes regarding air exhaust velocity

requirements.

• Check and follow all local safety and fire codes.

Grounding

• Check your local electrical code and pump manual for detailed grounding instructions. Use only

electrically conductive fluid hoses.

• Ground the spray gun through connection to a

properly grounded fluid supply hose and pump.

D

A

C

B

FIG. 1: Typical Installation (Model G15 Shown)

Key:

A Air Line Filter

B Air Shutoff Valve

C Gun Air Pressure Regulator

DAir Line

ESpray Gun

F Electrically Conductive Fluid Hose

G Gun Air Supply Hose

E

G

TI6554A

F

6 3A0149C

Page 7

Installation

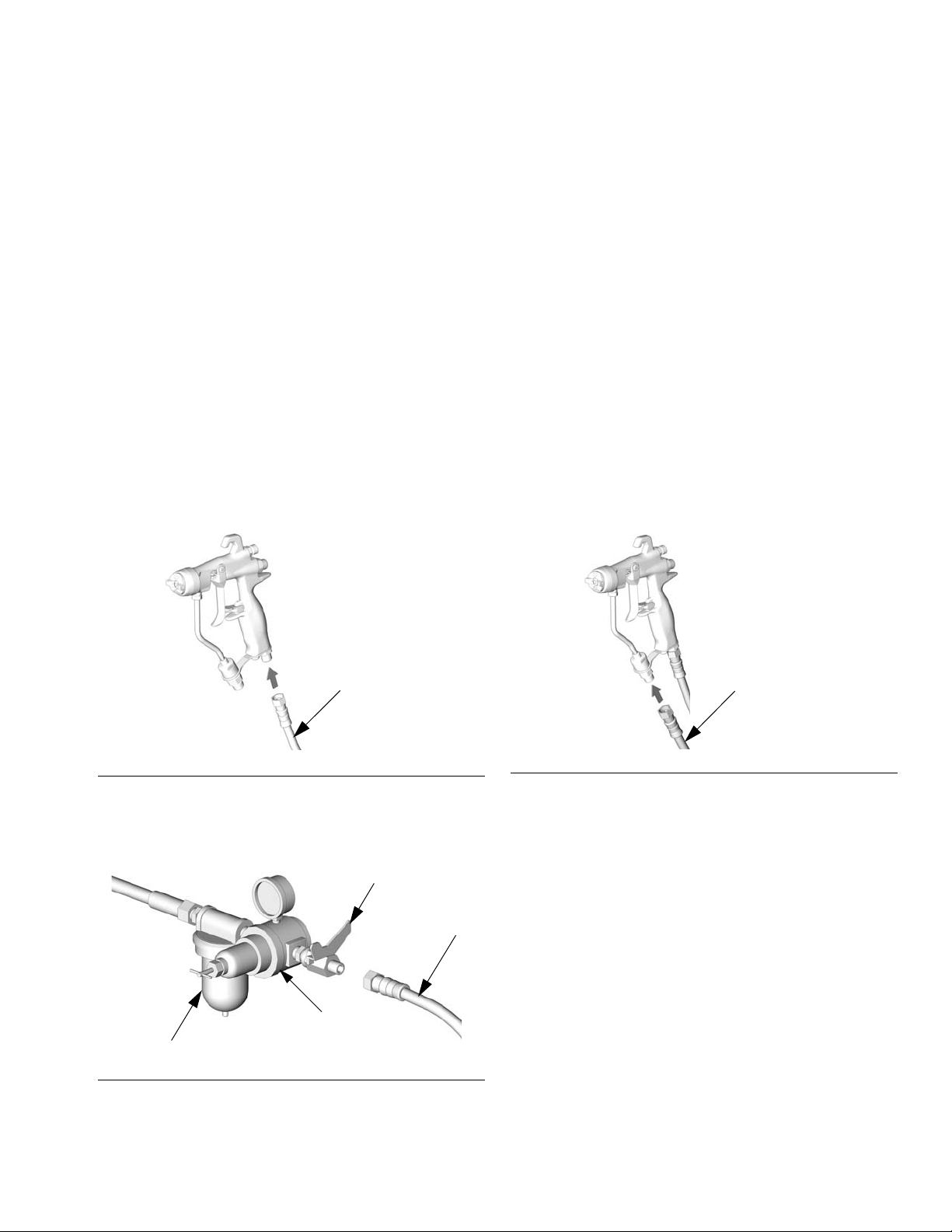

Air Line

1. Install an air filter (A) on the gun air line to ensure a

dry, clean air supply to the gun. Dirt and moisture

can ruin the appearance of your finished workpiece.

IG. 1.

See F

2. Install an air pressure regulator (C) on the gun air

line to control air pressure to the gun.

3. Install an air shutoff valve (B) on the gun air line and

on the pump air line, to shut off air to the gun.

4. Use a 3/16 in. (5 mm) I.D. or larger air hose to minimize excessive pressure drop in the hose.

NOTE: The gun air inlet has a 1/4-18 npsm (R1/4-19)

compound male thread that is compatible with NPSM

and BSP female swivel connectors.

5. Connect the air hose (G) to the 1/4 npsm gun air

inlet. See F

IG. 2.

Fluid Line

• Before connecting the fluid line, blow it out with air

and flush it with solvent. See Flushing and Clean-

ing, page 14. Use solvent which is compatible with

the fluid to be sprayed.

• If better control of fluid pressure is needed, install a

fluid regulator on the fluid line to better control fluid

pressure to the gun.

1. Use a fluid filter to remove coarse particles and sediment, to avoid clogging the spray tip and causing

finishing defects.

NOTE: Guns are equipped with a built-in 100 mesh fluid

filter to provide final filtering just before spraying.

2. Connect the fluid hose (F) to the gun fluid inlet. See

IG. 4. If desired, install a fluid swivel connector

F

(189018) at the gun inlet for best maneuverability.

See Accessories, page 35.

G

TI6556A

IG. 2

F

6. Connect the other end of the air hose (G) to the outlet of the air shutoff valve. See F

IG. 3.

B

G

C

TI4838A

F

A

IG. 3

F

TI6846A

IG. 4

F

3. Connect the other end of the fluid hose (F) to the

pump fluid outlet.

3A0149C 7

Page 8

Setup

Setup

Flush Before Using Equipment

1. The equipment was tested with lightweight oil, which

is left in the fluid passages to protect parts. To avoid

contaminating your fluid with oil, flush the equipment

with a compatible solvent before using the equipment. See Flushing and Cleaning, page 14.

2. Relieve the pressure. See Pressure Relief Proce-

dure, page 10.

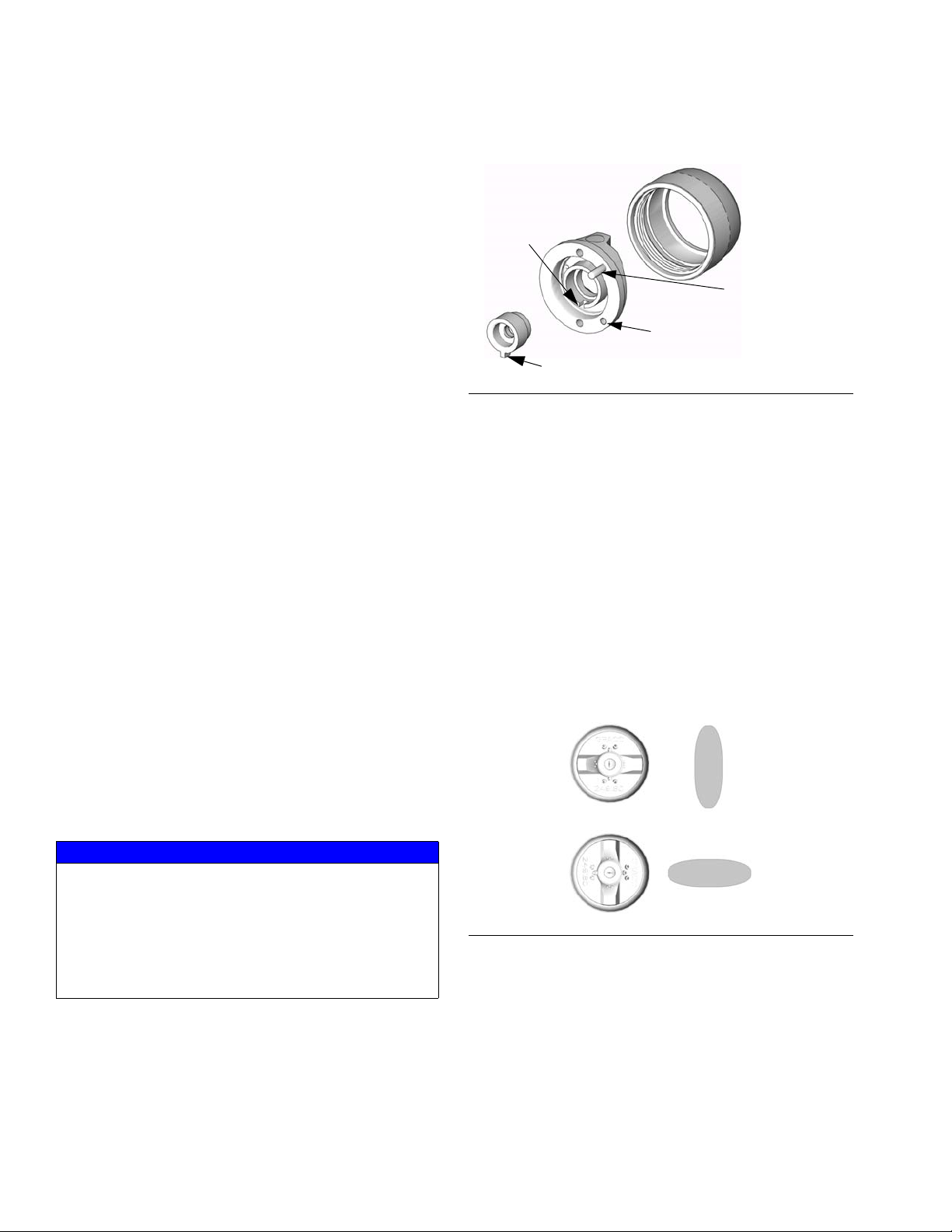

Select a Spray Tip

FIG. 5

Slot

Tip locating tab

Horizontal air

cap position

(standard)

Vertical air

cap position

TI6847A

The fluid flow and pattern width depend on the size of

the spray tip, the fluid viscosity, and the fluid pressure.

See Spray Tip Selection Chart, page 32. Contact your

Graco distributor for assistance in selecting an appropriate spray tip for your application.

Air Cap Alignment Pin

Model G15 guns use an air cap alignment pin to position

the air cap. The standard location of the air cap alignment pin is the horizontal air cap position.

If you would like to change the spray pattern direction,

use a needle nose pliers to unscrew the pin and relocate

it to the desired position. See F

the pin use low-strength thread locker. Torque to 1.5-2.5

in-lb (0.2-0.3 N•m). DO NOT OVERTIGHTEN.

The air cap alignment pin can be removed according to

preference. Air cap alignment pins will not work with

model G40 guns.

NOTICE

The alignment pin and retaining ring for current model

guns are different from the earlier model guns. They

are not interchangeable. Use of the incorrect pin will

result in fluid leakage or loss of the alignment feature.

Use of the wrong retaining ring will damage retaining

ring and gun threads. See Part Interchangeability

Guide, page 37.

IG. 5. When relocating

Install a Spray Tip

Install a spray tip in the air cap. Ensure that the tip locating tab is positioned in the slot of the air cap. See F

IG. 5.

Position the Air Cap

Assemble the air cap to the gun. The air cap and spray

tip position determine the direction of the spray pattern.

Rotate the air cap (the spray tip rotates with it) as

needed to achieve the desired spray pattern direction.

IG. 6. For the G15 air cap, the alignment pin will

See F

stop the rotation in the proper orientation.

TI6558A

IG. 6

F

Tighten the air cap retaining ring (6) firmly by hand to

ensure a good seal between the tip gasket and the diffuser (5).

8 3A0149C

Page 9

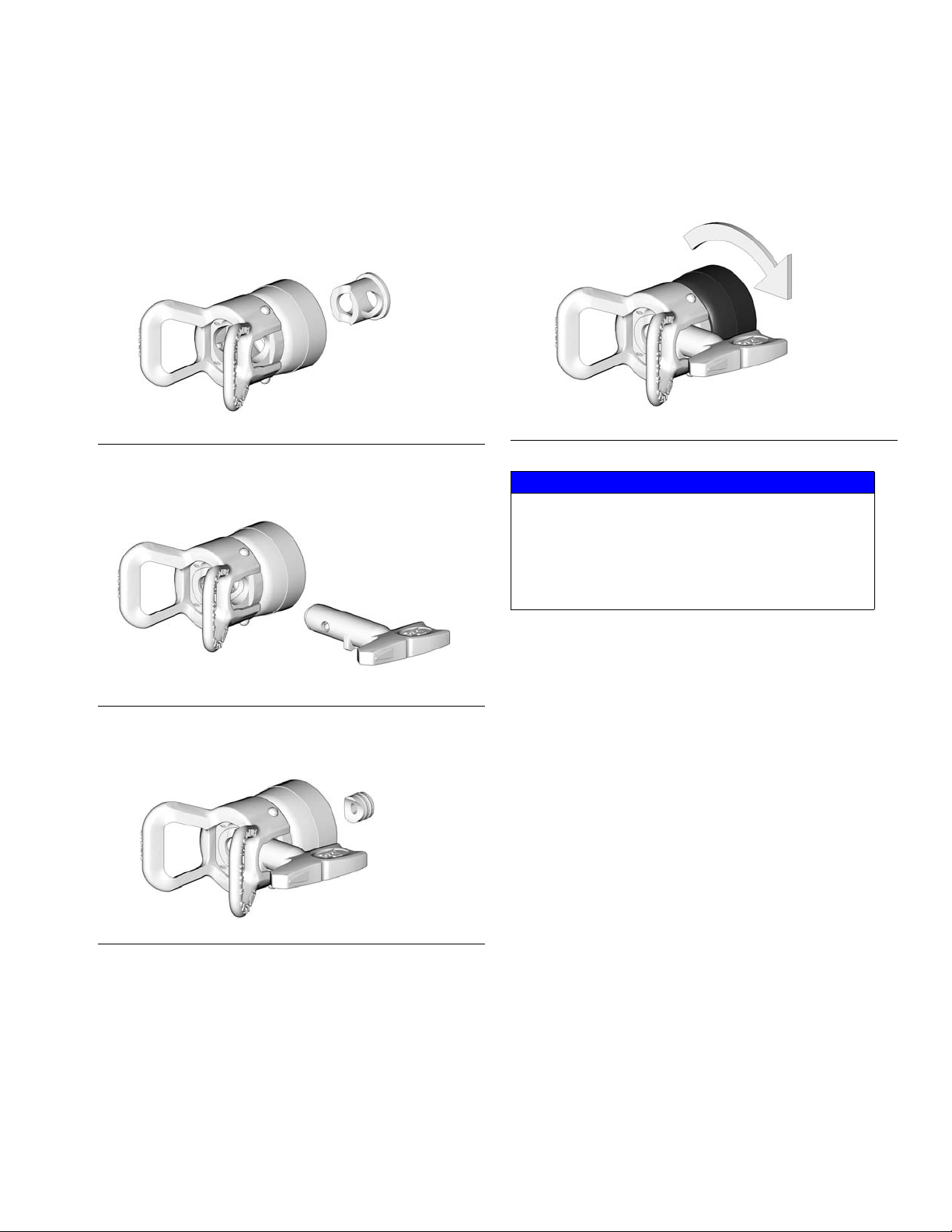

Reverse-A-Clean® (RAC) Tip Assembly

Setup

Model 24C857 guns use a Reverse-A-Clean® (RAC) tip.

To assemble the RAC tip, insert the seat housing into

the air cap assembly.

TI7196A

IG. 7

F

Insert the SwitchTip.

Screw the RAC tip assembly onto the gun and tighten

firmly by hand.

TI7199A

FIG. 10

NOTICE

The RAC assembly for current model guns uses a

different seat housing and has a coarser thread

than the RAC assembly for earlier model guns.

They are not interchangeable. Use of the incorrect RAC assembly will damage the threads. See

Part Interchangeability Guide, page 37.

IG. 8

F

Insert the gasket seat.

IG. 9

F

TI7197A

TI7198A

3A0149C 9

Page 10

Operation

Operation

Be sure to read and follow the Warnings on pages 4

and 5 and throughout the text of this instruction manual.

Keep the wallet sized warning card (222385), provided

with the gun, with the operator of this equipment at all

times. The card contains important treatment information should a skin injection injury occur. Additional cards

are available at no charge from Graco.

Pressure Relief Procedure

Trapped air can cause the pump to cycle unexpectedly, which could result in serious injury from splashing or moving parts.

To reduce the risk of an injury from injection, splashing

fluid, or moving parts, follow the Pressure Relief Procedure whenever you:

• are instructed to relieve the pressure,

• stop spraying,

• check or service any of the system equipment,

or install or clean the spray tip.

1. Engage the trigger lock. See F

2. Shut off the pump. See your pump manual.

3. Shut off the gun air supply.

4. Disengage the trigger lock. See F

IG. 12.

IG. 12.

TI6555A

FIG. 11

6. Open all fluid drain valves in the system, having a

waste container ready to catch drainage. Leave

drain valve(s) open until you are ready to spray

again.

7. Engage the trigger lock. See F

8. If you suspect the spray tip or hose is clogged or

that pressure has not been fully relieved after following the steps above, VERY SLOWLY loosen the tip

guard retaining ring or hose end coupling to relieve

pressure gradually, then loosen completely. Clear

hose or tip obstruction.

IG. 12.

Trigger Lock

Always engage the trigger lock when you stop spraying

to prevent the gun from being triggered accidentally by

hand or if dropped or bumped.

5. Hold a metal part of the gun firmly to a grounded

metal pail. Trigger the gun to relieve pressure. See

IG. 11.

F

ENGAGED

TI6581A TI6582A

IG. 12

F

10 3A0149C

DISENGAGED

Page 11

Operation

How the Air-Assisted Spray Gun Operates

The air-assisted spray gun combines airless and air

spraying concepts. The spray tip shapes the fluid into a

fan pattern, as does a conventional airless spray tip. Air

from the air cap further atomizes the fluid and completes

the atomization of the paint tails into the pattern to produce a more uniform pattern. The width of the pattern

can be adjusted by the pattern adjustment valve.

The air-assisted spray gun differs from an air spray gun

in that increasing the pattern air reduces the pattern

width. To increase the pattern width, use less pattern air

or a larger size tip.

The spray gun has a built-in lead and lag operation.

When triggered, the gun begins emitting air before the

fluid is discharged. When the trigger is released, the

fluid stops before the air flow stops. This helps assure

the spray is atomized and prevents fluid buildup on the

air cap.

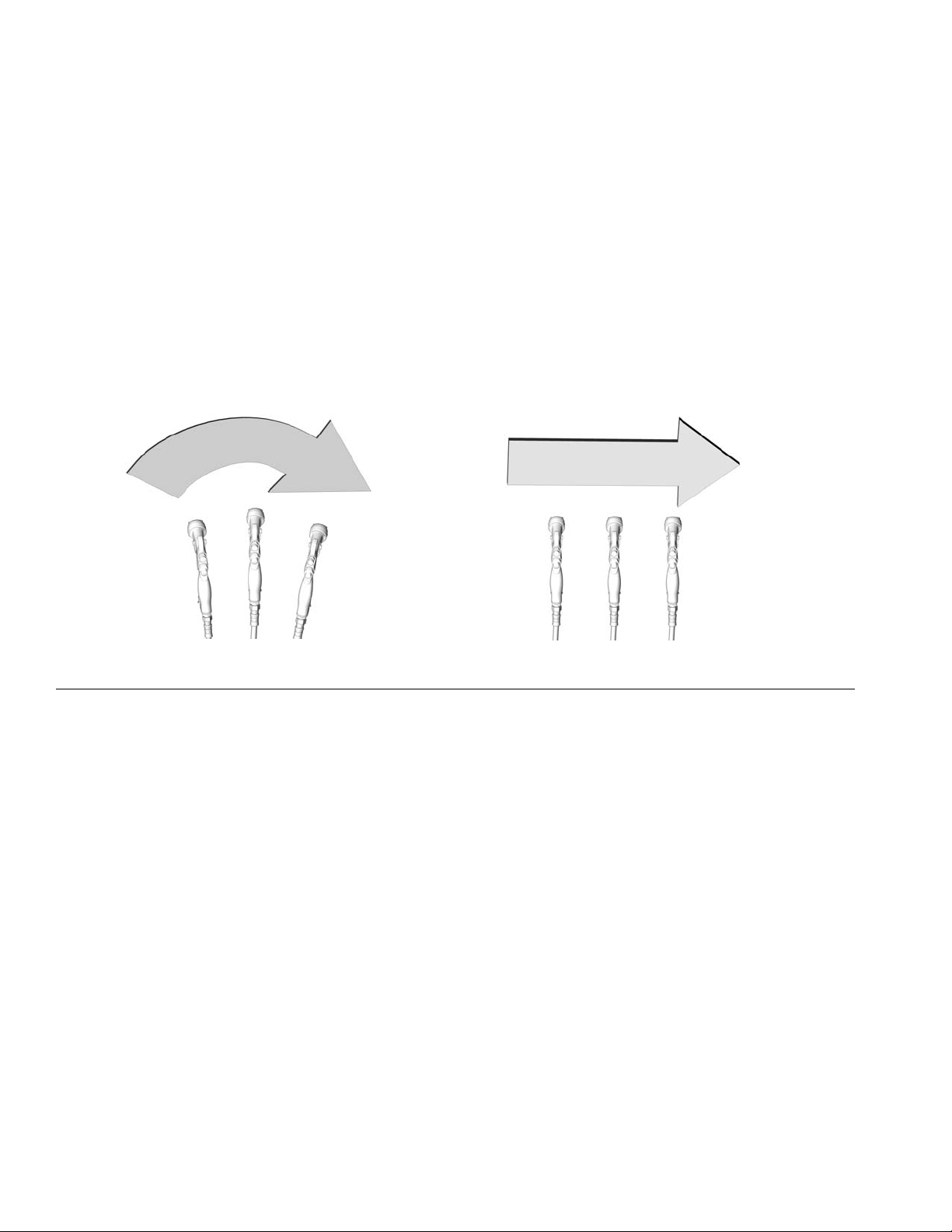

Spray Pattern Adjustment

To reduce the risk of component rupture and serious

injury, including injection, do not exceed the gun’s maximum fluid working pressure or the maximum working

pressure of the lowest rated component in the system.

1. Do not turn on the gun air supply yet. Set the fluid

pressure at a low starting pressure. If a fluid pressure regulator is installed, use it to make adjustments.

4. Close off the pattern adjustment air by turning the

knob clockwise (in) all the way. See F

sets the gun for its widest pattern.

OPEN

FIG. 13

5. Set the atomizing air pressure at about 5 psi

(3.5 kPa, 0.35 bar) when triggered. Check the spray

pattern, then slowly increase the air pressure until

the tails are completely atomized and pulled into the

spray pattern. See F

7.0 kPa, 0.49 to 0.7 bar) air pressure is typically

enough to atomize the tails, especially for low viscosity materials. Setting the air pressure too high

will cause material to build up on the air cap and

decrease transfer efficiency. Do not exceed 100 psi

(0.7 MPa, 7 bar) air pressure to the gun.

For a narrower pattern, turn the pattern adjustment

valve knob counterclockwise (out). See F

the pattern is still not narrow enough, increase the

air pressure to the gun slightly or use a different size

tip. (Not available for RAC tip guns.)

IG. 14. Seven to 10 psi (4.9 to

IG. 13. This

CLOSE

TI6559A

IG. 13. If

If your system does not have a fluid regulator, the

fluid pressure is controlled by the air regulator supplying the pump, per the formula below:

Pump

Ratio

2. Trigger the gun to check the atomization; do not be

concerned about the pattern shape yet.

3. Slowly increase the fluid pressure, just to the point

where a further increase in fluid pressure does not

significantly improve fluid atomization.

3A0149C 11

x Pump Air Regulator

Setting

=Fluid

Pressure

F

IG. 14

no air

TI0792A

too little air correct amount

of air

Page 12

Operation

HVLP Operation

NOTE: For HVLP operation, the atomization air must not

exceed 10 psi. Use HVLP Verification Kit 24C788 to verify air psi.

NOTE: There is no fan adjustment when using RAC tips

and caps.

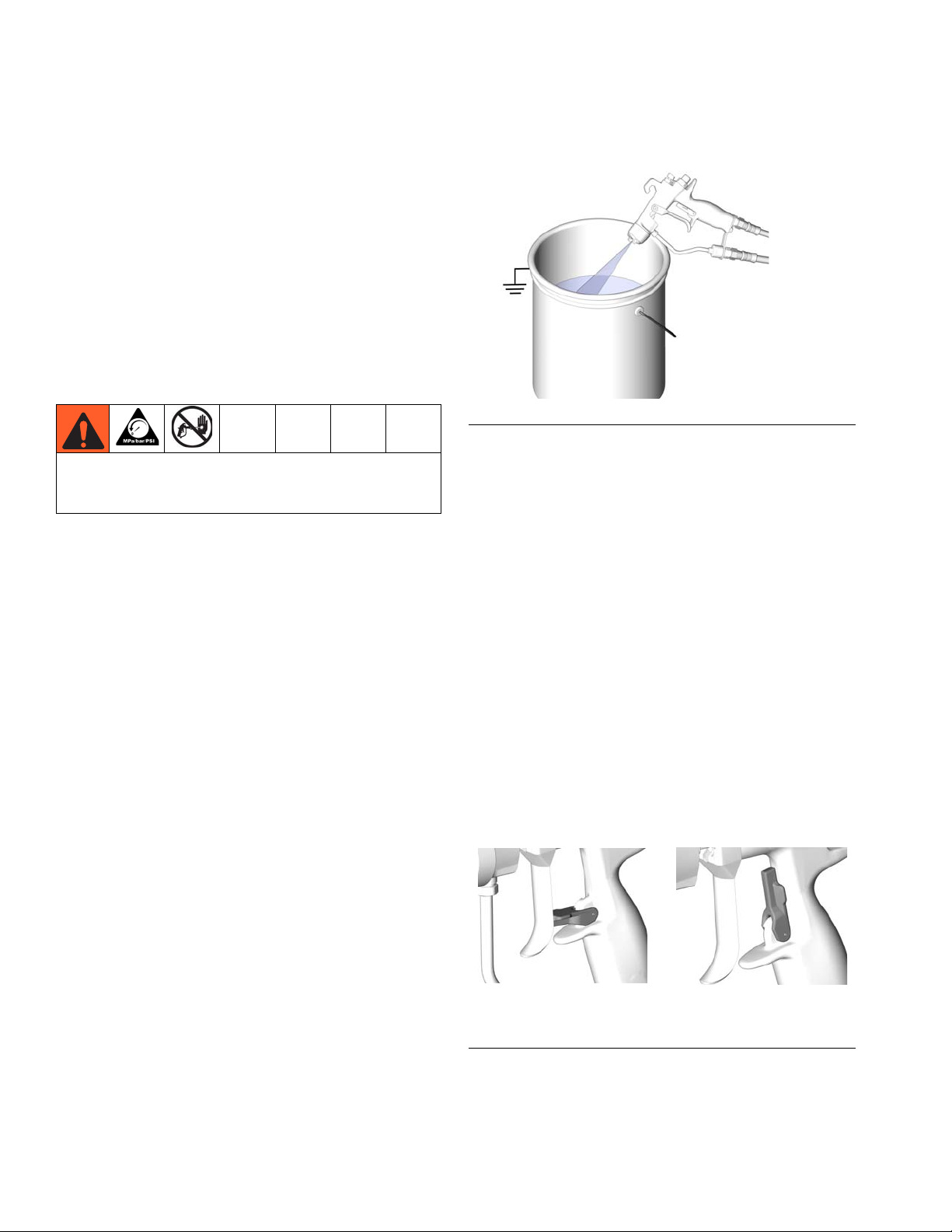

Fluid Application

Always hold the gun at a right angle from the surface.

Do not make an arc with the gun as it causes an uneven

coat of fluid. See F

IG. 15.

1. To achieve the best results when applying fluid,

keep the gun perpendicular to the surface and maintain a consistent distance of approximately 8 to 12

in. (200 to 300 mm) from the object being sprayed.

2. To obtain an even finish, use smooth, even strokes

across the object being sprayed with 50% overlap.

3. Paint using parallel strokes. This spray gun applies

all coatings evenly without cross coating.

IG. 15

F

INCORRECT

TI6561A

TI6562A

CORRECT

12 3A0149C

Page 13

Daily Gun Care, Flushing, and Cleaning

Daily Gun Care, Flushing, and Cleaning

NOTICE

Methylene chloride with formic or propionic acid is

not recommended as a flushing or cleaning solvent

with this gun as it will damage aluminum and nylon

components.

NOTICE

Do not use any cleaning method which may allow solvent into the gun air passages. Solvent left in gun air passages could result in a poor quality paint finish.

Do not point the gun up while cleaning it.

TI6563A

Do not immerse the gun in solvent.

Do not wipe the gun with a cloth soaked in solvent;

wring out the excess.

TI4827A

Do not use metal tools to clean the air cap holes

as this may scratch them; scratches can distort

the spray pattern.

TI6564A

3A0149C 13

TI6565A

Page 14

Daily Gun Care, Flushing, and Cleaning

General System Maintenance

1. Relieve the pressure, page 10.

2. Clean the fluid and air line filters daily.

3. Check for any fluid leakage from the gun and fluid

hoses. Tighten fittings or replace equipment as

needed.

4. Flush the gun before changing colors and whenever

you are done operating the gun.

Fluid Filter Maintenance

1. Unscrew the fluid inlet fitting (18).

2. Remove and inspect the inline fluid filter (12). Clean

or replace the filter as necessary.

Flushing and Cleaning

NOTE:

• Flush before changing colors, before fluid can dry in

the equipment, at the end of the day, before storing,

and before repairing equipment.

• Flush at the lowest pressure possible. Check connectors for leaks and tighten as necessary.

• Flush with a fluid that is compatible with the fluid

being dispensed and the equipment wetted parts.

1. Relieve the pressure, page 10.

2. Remove the air cap retaining ring (6), air cap (21),

and spray tip (33). Soak the spray tip in a compatible solvent.

3. Disconnect the fluid supply hose (F) and air supply

hose (G) from the gun.

18

IG. 16

F

12

TI6735A

NOTICE

The threads on the fluid inlet fitting for new model

guns are slightly finer than the threads on the old

model guns. The fluid inlet fittings are not inter-

changeable. Use of an incorrect fitting will damage the threads.

G

F

F

IG. 17

TI6566A

TI6567A

4. Connect the solvent supply hose (T) to the gun.

T

TI6566A

F

IG. 18

14 3A0149C

Page 15

Daily Gun Care, Flushing, and Cleaning

5. Increase the pressure slowly. Point the gun down

into a grounded metal container, and flush the gun

with solvent until all traces of fluid are removed from

the gun passages.

TI6729A

IG. 19

F

6. Turn off the solvent supply.

7. Relieve the pressure.

10. Dip the end of a soft-bristle brush into a compatible

solvent. Do not continuously soak the brush's bristles with solvent and do not use a wire brush.

TI4845A

FIG. 21

11. With the gun pointed down, clean the front of the

gun, using the soft-bristle brush and solvent.

8. Disconnect the solvent supply hose (T) from the

gun.

T

TI6730A

F

IG. 20

NOTICE

Trigger the gun whenever you tighten or remove the

diffuser (5). This keeps the needle ball away from

the seating surface and prevents the seat from

being damaged.

TI6569A

IG. 22

F

12. Scrub the air cap retaining ring (6), air cap (21), diffuser (5), and spray tip (33) with the soft-bristle

brush. To clean out air cap holes, use a soft tool,

such as a toothpick, to avoid damaging critical surfaces. Blow air through the spray tip to ensure the

orifice is clean. Clean the air cap and spray tip daily,

minimum. Some applications require more frequent

cleaning.

9. If it is necessary to remove the diffuser (5) to clean,

trigger the gun while you remove the diffuser with

the gun tool (30).

3A0149C 15

Page 16

Daily Gun Care, Flushing, and Cleaning

16. After cleaning the gun, lubricate the following parts

with lubricant 111265 weekly:

• Trigger pivot pin (A)

• Boss on both sides of the gun where the trigger

contacts the gun body (B)

• Fluid needle shaft, behind trigger (C)

TI6570A

F

IG. 23

13. If the diffuser was removed, trigger the gun while

you reinstall the diffuser (5) with the gun tool (30).

Tighten the diffuser securely to obtain a good seal.

Torque to 155-165 in-lb (18-19 N•m). When properly

tightened, the flange will bottom out on the gun.

14. Install the air cap retaining ring (6), air cap (21), and

spray tip (33).

A

B

C

TI6553A

FIG. 26

Reverse-A-Clean® (RAC) Tip

NOTE: Do not soak the RAC tip seat gasket (33a) in sol-

vent for extended periods of time or swelling may occur.

Clearing a clogged RAC tip

Release the trigger and engage the trigger lock.

TI6568A

F

IG. 24

15. Dampen a soft cloth with solvent and wring-out the

excess. Point the gun down and wipe off the outside

of the gun.

TI6571A

IG. 25

F

16 3A0149C

IG. 27

F

ENGAGED

TI6581A

Page 17

Daily Gun Care, Flushing, and Cleaning

Rotate the SwitchTip.

F

IG. 28

Disengage the trigger lock.

TI7200A

Engage the trigger lock.

TI6581A

ENGAGED

FIG. 31

Return the SwitchTip to its original position.

TI6580A

IG. 29

F

DISENGAGED

Trigger the gun into a pail to clear the clog.

Do not point gun at anyone or at any part of the body.

TI7202A

F

IG. 30

TI7201A

IG. 32

F

Disengage the trigger lock and continue spraying.

TI6582A

DISENGAGED

IG. 33

F

3A0149C 17

Page 18

Troubleshooting

Troubleshooting

Problem Cause Solution

NOTE:

• Check all possible remedies in the troubleshooting

charts before disassembling the gun.

• Some improper patterns are caused by the

improper balance between air and fluid.

Fluid leakage from back of fluid

packing area.

Air leakage from gun. Air valve not seating properly. Clean or replace air valve (8).

Fluid leakage from front of gun. Needle ball worn or damaged. Replace needle assembly (2) and seat (5c).

Fluid in air passages. Spray tip seal leaking. Tighten retaining ring (6) or replace spray tip

Slow fluid shut-off. Fluid buildup on fluid needle

No fluid output when triggered. Spray tip plugged. Clean spray tip. See page 14.

Worn packings or needle shaft. Replace needle assembly (2).

Worn seat assembly. Replace the seat (5c) and gasket (5b, carbide

models only). The gasket must be replaced

whenever the seat assembly is removed.

Do not reverse the direction of the plastic seat

(5c, model 24C854 gun only) if it is worn. The

seat must be replaced it if is worn.

Fluid viscosity too low for proper

seal with carbide seat.

Leaking around seat housing. Replace the gasket (5b, carbide models only).

Fluid inlet fitting leaking. Replace the fluid tube gasket (22). The gas-

components.

Fluid filter or fluid hose plugged. After tip removal (see above), very slowly

Install plastic seat (5c).

(33).

The gasket must be replaced whenever the

seat assembly is removed.

ket must be replaced whenever the fluid tube

connector is removed.

Remove and clean or replace the fluid needle

assembly (2).

loosen the hose end coupling at the gun and

relieve pressure gradually. Then loosen completely to clear the obstruction. Clean or

replace filter (12).

18 3A0149C

Page 19

Troubleshooting

Problem Cause Solution

Fluttering or spitting spray. Insufficient fluid supply. Adjust fluid regulator or fill fluid supply tank.

Air in paint supply line. Check, tighten pump siphon hose connec-

tions, bleed air from paint line.

Attempting to “feather” (partially

trigger the gun).

Cannot “feather” with an AA gun. Feather will

cause drastic reduction of pressure at the tip,

resulting in poor atomization and/or spitting.

Striping spray. Spray tip partially plugged. Clean or replace spray tip. See page 14.

Irregular pattern. Fluid build-up on spray tip, or

Clean or replace spray tip. See page 14.

spray tip partially plugged.

On defective side of pattern, air

horn holes are partially or totally

Clean air horn holes with solvent and soft

brush. See page 14.

plugged.

Pattern pushed to one side,

same side of air cap gets dirty.

Air horn holes partially or totally

plugged.

Clean air horn holes with solvent and soft

brush or toothpick. See page 14.

Material build up on air cap. Air pressure setting too high. Reduce inlet air pressure. Seven to 10 psi

(4.9 to 7.0 kPa, 0.49 to 0.7 bar) air pressure

when triggered is recommended.

3A0149C 19

Page 20

Repair

Repair

Complete Gun Packing Repair

Disassembly

Repair Kits

NOTE:

• Seal Repair Kit 249422 is available. For best results,

use all the new parts in the kit. Kit parts are marked

with an asterisk, for example (7*).

• Plastic Seat Repair Kit 249424 and Carbide Seat

Repair Kit 249456 are available and can be used

with both Model G15 guns and Model G40 guns. For

best results, use all new parts in the kit. Kit parts are

marked with a symbol in the Parts list, for example

(5c†).

• Plastic Seat Kit 249424 is intended for low pressure

usage.

Fan Valve Replacement

1. Relieve the pressure, page 10.

2. Unscrew the fan valve packing nut (A) from the back

of the gun body (1). Slide the fan valve assembly (4)

out of the gun body. See F

3. Before reinstalling, turn the pattern adjustment valve

(C) of the replacement fan valve assembly (4) completely counterclockwise to prevent damage to the

seat (5c). Install the replacement fan valve assembly into the gun body (1). Screw the packing nut (A)

into the gun body and torque to 90 in-lb (10.5 N•m).

IG. 34.

Seat Repair

NOTE:

• See Repair Kits, page 20.

• Clean parts with a solvent that is compatible with

the parts and the fluid being sprayed.

1. Relieve the pressure, page 10. Remove the fluid

and air hoses from the gun.

2. Remove the air cap retaining ring (6), air cap (21),

and spray tip (33). See F

6

33

FIG. 35

3. Trigger the gun to pull the needle housing off the

seat while you unscrew the diffuser (5) from the gun

body (1), using the gun tool (30).

21

IG. 35.

TI6568A

1

FIG. 34

20 3A0149C

4

C

1

A

1

Torque to 90 in-lb

(10.5 N•m).

TI6576A

4. Inspect the o-rings (5e*, 5f*, and 5g*) in place.

Carefully remove the o-rings from the diffuser housing (5a) and replace if necessary.

5. Remove the seat nut (5d), seat (5c) and seat gasket

(5b, carbide models only) using a 7/32 in. hex

wrench.

6. Inspect the seat (5c) and seat gasket (5b) and

replace if necessary.

Page 21

7. Reinstall the seat gasket (5b, carbide models only),

seat (5c), and seat nut (5d). Torque to 45-50 in-lb.

Be sure not to overtighten the nut.

NOTE:

• When reinstalling the carbide seat (5c), the tapered

end of the seat (red side) must point toward the gun

tip.

• The plastic seat (5c, model 24C854 guns), can be

reinstalled in either direction. To avoid fluid leakage,

do not reverse the direction of the plastic seat (5c) if

it is worn. The seat must be replaced if it is worn.

1

5c

5g*

IG. 37

F

13‡

3‡

14‡

Repair

TI6574A

5a

5e*

5d

5f*

5b

(carbide only)

30

TI6572A

IG. 36

F

Needle Repair

1. Remove the diffuser, see Seat Repair, page 20.

2. Remove the trigger pivot pin nut (14‡), pivot pin

(13‡), and trigger (3‡) using the gun tool (30) and

nut driver (29). See F

IG. 37.

3. Remove the fluid needle assembly (2) from the front

of the gun by using the nut driver tool (29). If the

needle is bent or damaged, or the packing is worn

or leaking, replace the entire needle assembly. If

replacement is necessary, be sure to remove the

o-ring (2a*) as it may stick inside the gun body. See

IG. 38.

F

1

29

2a*

2

TI6575A

IG. 38

F

3A0149C 21

Page 22

Repair

Air Valve Repair

1. Unscrew the spring cap (11) from the back of the

gun body (1) using the gun tool (30). Remove the

two springs (15 and 19) and the shaft (9).

2. Push the air valve assembly (8*) out the back of the

gun. See F

IG. 39.

3. Inspect the u-cup (7*) in the gun body (1). If the

u-cup is worn or leaking, carefully remove the u-cup

from the front of the gun body, using a pick.

15

8*

7*

1

11

19

9

Fluid Tube Replacement

1. Remove the air inlet fitting (17) using the gun tool

(30) and remove the screw (20) using a 3/16 in. hex

wrench.

2. Unscrew the fluid inlet fitting (18). Remove and

clean or replace the inline fluid filter (12).

3. Unscrew the fluid tube connector (C) from the gun’s

fluid inlet. Carefully remove the gasket (22*).

22*

17

C

20

IG. 39

F

TI6577B

F

IG. 40

12

18

TI6573A

22 3A0149C

Page 23

Repair

3A0149C 23

Page 24

Repair

Reassembly

NOTE: See Repair Kits, page 20.

1. Install the tube gasket (22*) in the gun. Handtighten

the fluid tube connector (C) into the gun’s fluid inlet.

Handtighten the air inlet fitting (17) and screw (20).

Torque the fluid tube connector to 150-160 in-lb

(17-18 N•m). Torque the air inlet fitting to

210-220 in-lb (24-25 N•m). Torque the fluid tube

bracket screw to 50-60 in-lb (6-7 N•m). See F

2. Install the inline fluid filter (12) into the base of the

fluid tube. Screw the fluid inlet fitting (18) into the

base of the tube. Torque to 175-185 in-lb

(20-21 N•m). See F

IG. 43.

3. Place the new u-cup (7*) on the seal installation tool

(28*), with the u-cup lips facing the tool as shown in

IG. 41. Push the u-cup into the back of the gun until

F

you feel a definite snap.

3

Lubricate lightly.

8

Lips face out of gun body.

7*

8

3

28*

IG. 43.

8. Insert the fluid needle assembly (2) into the front of

the gun. Use the nut driver (29) to screw the fluid

needle assembly into the gun body (1) and torque to

50-60 in-lb (6-7 N•m). See F

IG. 42.

1

29

2a*

2†

TI6575A

FIG. 42

9. Install the trigger (3), pivot pin (13), and nut (14).

Use low strength thread locker and be sure that the

brass piece of the fluid needle assembly (2) is

behind the trigger. See F

IG. 43. Lubricate both sides

of the pivot pin where the trigger contacts the pin

and lubricate the boss on both sides of the gun

where the trigger contacts the gun body. Torque the

nut to 20-30 in-lb (2-3 N•m).

TI6578A

IG. 41

F

4. Lubricate the front end of the air valve assembly

(8*). Gently slide the air valve assembly into the

back of the gun, passing through the u-cup (7*), as

far as it will go. Be careful not to damage the u-cup.

IG. 43.

See F

5. Carefully insert the thinner end of the shaft (9) into

the air valve (8*).

6. Install the two springs (15 and 19). Screw the spring

cap (11) into the back of the gun body. Torque to

210-220 in-lb (24-25 N•m).

7. Lightly lubricate the needle assembly o-rings and

shaft where the packing slides. Be sure that the

o-ring (2a*) is in place in the gun body (1).

10. Trigger the gun to pull the needle back while you

screw the diffuser assembly (5) into the gun body

(1) using the gun tool (30). Torque to 155-165 in-lb

(18-19 N•m). When properly tightened, the flange

will bottom out on the gun.

11. Attach the retaining ring (6), air cap (21), and spray

tip (33).

24 3A0149C

Page 25

12

21a (G15 only)

6 (G40 only)

*6a (G40 only)

21

*6b

*6a

33

Repair

5b✖ (carbide only)

5c†✖

6

*5g

6

*5f

4

5a

6

*5e

5d†✖

11

15

11

10

*7

4

3

8

*8

13

6 (G15 only)

1

Torque to 150-160 in-lb (17-18 N•m).

3

Lubricate lightly.

4

Torque to 155-165 in-lb (18-19 N•m).

5

Torque to 20-30 in-lb (2-3 N•m).

6

Do not lubricate diffuser o-rings.

7

Brass part must be behind trigger.

8

Lips face out of gun body.

9

Torque to 50-60 in-lb (6-7 N•m).

10

Torque to 210-220 in-lb (24-25 N•m).

11

Torque to 45-50 in-lb (5-6 N•m).

12

Use low-strength thread locker.

13

Torque to 175-185 in-lb (20-21 N•m).

3

*2a

7

3

2

9

*22

1

16

(24C856 &

24C857)

9

16

(24C853, 24C854 and

24C855 only)

3

20

18

3

(24C853, 24C854, and 24C855)

13

3

9

1a

14

17

12

1

5

12

10

(24C853, 24C854, and 24C855)

19

TI6579D

FIG. 43

3A0149C 25

Page 26

Parts

Parts

Part No. 24C853 and 24C854, G15 Gun

Part No. 24C855, G40 Gun

Part No. 24C856, G40 Gun, High Flow

21a (G15 only)

*6a (G40 only)

33

6 (G40 only)

21

◆*6b

◆*6a

*5e

5a

*5f

13‡

5b✖ (carbide only)

5c†✖

*5g

*7

5d†✖

4

15

*8

6 (G15 only)

(24C853, 24C854, and

24C855 only)

2

*22

16

(24C856 only)

16

18

(24C853, 24C854, and

24C855 only)

*2a

20

3‡

9

1

1a

14‡

17

12

(24C853, 24C854, and

24C855 only)

29

19

11

30

TI6579D

28

*

26 3A0149C

Page 27

Part No. 24C854, G15 Gun with Plastic Seat

Part No. 24C853, G15 Gun with Carbide Seat

Parts

Ref.

No. Part No. Description Qty.

1BODY, gun 1

1a 249423 STOP, trigger 1

2 24B790 NEEDLE, assy; 3/32 ball; sst

includes items 2a (24C854 only)

and 9

24B789 NEEDLE, assy; 3/32 ball; carbide

includes items 2a (24C853 only)

and 9

2a*✓ 110004 PACKING, o-ring; PTFE 1

3‡ TRIGGER, gun 1

4 249135 VALVE, fan, assy 1

5 249132 DIFFUSER, assy (24C854 only) 1

249133 DIFFUSER, assy (24C853 only) 1

5a DIFFUSER, housing 1

5b✖ 288619 GASKET, seat; nylon (24C853

only)

5c† SEAT; plastic (24C854 only) 1

5c✖ SEAT; carbide (24C853 only) 1

5d†✖ NUT, seat 1

5e* 111116 PACKING, o-ring, seat; PTFE 1

5f*✓ 109450 PACKING, o-ring; PTFE 1

5g*✓ 111457 PACKING, o-ring; PTFE 1

6 24D438 RING, retaining; includes 6a and 6b1

6a*◆✓ 109213 PACKING, o-ring; PTFE 1

6b*◆✓ 15G320 WASHER; PTFE 1

7*✓ 188493 PACKING, u-cup; UHMWPE 1

8* VALVE, air, assy 1

9 16A529 SHAFT, fluid spring 1

11 15F195 CAP, spring 1

12 224453 FILTER, tip (pkg of 5) 1

13‡ 15F739 PIN, pivot 1

14‡ 15F740 PIN, pivot, nut 1

15 114069 SPRING, compression 1

16 24D436 TUBE, assy.; includes item 22 1

17 15F202 FITTING, air inlet 1

18 24D437 FITTING, hose; see Accessories

for fitting with JIC threads

Ref.

No. Part No. Description Qty.

19 119767 SPRING, compression (24C854

1

20 119996 SCREW, cap, socket hd; 1/4-20 x

1

21 24C866 AIR CAP, includes item 21a 1

21a 24D627 PIN, air cap; indexing

22*✓ 115133 GASKET, tube, acetal 1

28* TOOL, installation; seal 1

29 117642 TOOL, nut driver 1

30 15F446 TOOL, gun 1

31▲ 222385 CARD, warning (not shown) 1

32▲ 172479 TAG, warning (not shown) 1

1

33 SPRAY TIP, customer’s choice

33a 183616 GASKET, tip (not shown) 1

▲ Replacement Danger and Warning labels, tags, and

* Included in Seal Repair Kit 249422 (purchase

† Included in Plastic Seat Repair Kit 249424

✖ Included in Carbide Seat Repair Kit 249456

‡ Included in Trigger Repair Kit 249585

◆ Included in Air Cap Seal Kit 253032

✓ Not for sale separately.

1

115141 SPRING, compression (24C853

cards are available at no cost.

separately).

(purchase separately).

(purchase separately).

(purchase separately).

(purchase separately).

1

only)

1

only)

1

3/8 in. (10 mm)

1

(package of 3)

3A0149C 27

Page 28

Parts

Part No. 24C855, G40 Gun with Standard Tip

Part No. 24C856, G40 Gun, High Flow

Ref.

No. Part No. Description Qty.

1 BODY, gun 1

1a 249423 STOP, trigger 1

2 24B789 NEEDLE, assy; 3/32 ball; carbide

includes items 2a and 9

2a*✓ 110004 PACKING, o-ring; PTFE 1

3‡ TRIGGER, gun 1

4 249135 VALVE, fan, assy 1

5 249133 DIFFUSER, assy 1

5a DIFFUSER, housing 1

5b✖ 288619 GASKET, seat; nylon 1

5c✖ SEAT; carbide 1

5d✖ NUT, seat 1

5e* 111116 PACKING, o-ring, seat; PTFE 1

5f*✓ 109450 PACKING, o-ring; PTFE 1

5g*✓ 111457 PACKING, o-ring; PTFE 1

6 24D439 TIP GUARD, includes items 6a

and 6b (24C855 & 24C856 only)

6a*◆✓ 109213 PACKING, o-ring; PTFE 2

6b*◆✓ 15G320 WASHER; PTFE 1

7*✓ 188493 PACKING, u-cup; UHMWPE 1

8* VALVE, air, assy 1

9 16A529 SHAFT, fluid spring 1

11 15F195 CAP, spring 1

12 224453 FILTER, tip (pkg of 5, 24C855

only)

13‡ 15F739 PIN, pivot 1

14‡ 15F740 PIN, pivot, nut 1

15 114069 SPRING, compression 1

16 24D436 TUBE, assy, includes item 22

(24C855 only)

249317 TUBE, assy (24C856 only) 1

17 15F202 FITTING, air inlet 1

Ref.

No. Part No. Description Qty.

18 24D437 FITTING, hose (24C855 only);

see Accessories for fitting with

1

19 115141 SPRING, compression 1

20 119996 SCREW, cap, socket hd; 1/4-20 x

21 249180 AIR CAP 1

22*✓ 115133 GASKET, tube, acetal 1

28* TOOL, installation; seal 1

29 117642 TOOL, nut driver 1

30 15F446 TOOL, gun 1

31▲ 222385 CARD, warning (not shown) 1

32▲ 172479 TAG, warning (not shown) 1

33 SPRAY TIP, customer’s choice

33a 183616 GASKET, tip (not shown) 1

1

▲ Replacement Danger and Warning labels, tags, and

cards are available at no cost.

* Included in Seal Repair Kit 249422 (purchase

separately).

✖ Included in Carbide Seat Repair Kit 249456

1

1

(purchase separately).

‡ Included in Trigger Repair Kit 249585

(purchase separately).

◆ Included in Air Cap Seal Kit 253032

(purchase separately).

✓ Not for sale separately.

JIC threads.

3/8 in. (10 mm) (24C855 only)

1

1

28 3A0149C

Page 29

Parts

3A0149C 29

Page 30

Parts

Part No. 24C857, G40 Gun with RAC Tip

★6

★*6a

33

★35

33a

★5a

★*5f

2

★*5g

*22

★✖5b

*2a

5c✖★

5d✖★

3‡

13‡

*7

★4

1a

14‡

17

15

11

*8

19

9

1

16

20

TI7203B

29

30

28*

TI6580A

30 3A0149C

Page 31

Part No. 24C857, G40 Gun with RAC Tip

Parts

Ref. No.Part No. Description Qty.

1 BODY, gun 1

1a 249423 STOP, trigger 1

2 24B789 NEEDLE, assy; 3/32 ball; carbide

includes items 2a and 9

2a*✓ 110004 PACKING, o-ring; PTFE 1

3‡ TRIGGER, gun 1

4★ 15G713 NUT, air plug 1

5★ 249877 DIFFUSER, assy, RAC 1

5a★ DIFFUSER, housing 1

5b✖★ 288619 GASKET, seat; nylon 1

5c✖★ SEAT; carbide 1

5d✖★ NUT, seat 1

5e*★✓ 111116 PACKING, o-ring, seat; PTFE 1

5f*★✓ 109450 PACKING, o-ring; PTFE 1

5g*★✓ 111457 PACKING, o-ring; PTFE 1

6★ 24C921 TIP GUARD/AIR CAP ASSY,

includes item 35

6a*★✓ 109213 PACKING, o-ring, PTFE 1

7*✓ 188493 PACKING, u-cup; UHMWPE 1

8* VALVE, air, assy 1

9 16A529 SHAFT, fluid spring 1

11 15F195 CAP, spring 1

13‡ 15F739 PIN, pivot 1

14‡ 15F740 PIN, pivot, nut 1

15 114069 SPRING, compression 1

16 249317 TUBE, assy 1

17 15F202 FITTING, air inlet 1

19 115141 SPRING, compression 1

20 119996 SCREW, cap, socket hd; 1/4-20 x

3/8 in. (10 mm)

Ref. No.Part No. Description Qty.

22*✓ 115133 GASKET, tube, acetal 1

28* TOOL, installation; seal 1

29 117642 TOOL, nut driver 1

1

30 15F446 TOOL, gun 1

31▲ 222385 CARD, warning (not shown) 1

32▲ 172479 TAG, warning (not shown) 1

33 SPRAY TIP, customer’s choice,

see tip selection chart page 32,

includes item 33a

33a 246453 RAC GASKET, standard, black 1

248936 RAC GASKET, solvent resistant,

orange

35★ 15F442 HOUSING, cylinder 1

▲ Replacement Danger and Warning labels, tags, and

1

1

cards are available at no cost.

* Parts included in Seal Repair Kit 249422 (purchase

separately).

✖ Parts included in Carbide Seat Repair Kit 249456

(purchase separately).

‡ Parts included in Trigger Repair Kit 249585 (pur-

chase separately).

★ Parts included in RAC Conversion Kit 24C791 (pur-

chase separately).

✓ Not for sale separately.

1

3A0149C 31

Page 32

Spray Tip Selection Chart

Spray Tip Selection Chart

Spray Tips, for use with G15/G40 Air Cap

AAM Fine Finish Spray Tips

Recommended for high finish quality applications at low and medium pressures.

Order desired tip, Part No. AAMxxx, where xxx = 3-digit number from matrix below.

GG4 Industrial Spray Tips

Recommended for high wear applications at high pressures.

Order desired tip, Part No. GG4xxx, where xxx = 3-digit number from matrix below.

NOTE:

• All tips in the Spray Tip Selection Chart below can

be used with Model G40 guns. Use tips in the gray

shaded area of the chart with Model G40 guns only.

• Do not use tips in the gray shaded area of the chart

with Model G15 guns.

Do not use tips in the gray shaded area of the Spray

Tip Selection Chart with Model G15 guns. G15 guns

are not designed for use at high pressures. Failure to

follow this warning can result in serious injury, including fluid injection and splashing in the eyes or on the

skin.

* Fluid Output

fl oz/min (lpm)

at 600 psi

Orifice Size

in. (mm)

† 0.007 (0.178) 4.0 (0.1) 5.2 (0.15)

† 0.009 (0.229) 7.0 (0.2) 9.1 (0.27)

† 0.011 (0.279) 9.5 (0.28) 12.5 (0.37)

0.013 (0.330) 12.0 (0.35) 16.0 (0.47)

0.015 (0.381) 16.0 (0.47) 21.0 (0.62)

0.017 (0.432) 20.0 (0.59) 26.5 (0.78)

0.019 (0.483) 28.0 (0.8) 36.3 (1.09)

0.021 (0.533) 35.0 (1.0) 45.4 (1.36)

‡ 0.023 (0.584) 40.0 (1.2) 51.9 (1.56)

‡ 0.025 (0.635) 50.0 (1.5) 64.8 (1.94)

‡ 0.027 (0.686) 58.5 (1.7) 75.8 (2.27)

‡ 0.029 (0.737) 68.0 (1.9) 88.2 (2.65)

‡ 0.031 (0.787) 78.0 (2.2) 101.1 (3.03)

‡ 0.033 (0.838) 88.0 (2.5) 114.1 (3.42)

‡ 0.035 (0.889) 98.0 (2.8) 127.1 (3.81)

‡ 0.037 (0.940) 108.0 (3.1) 140.0 (4.20)

‡ 0.039 (0.991) 118.0 (3.4) 153.0 (4.59)

(4.1 MPa,

41 bar)

at 1000 psi

(7.0 MPa,

70 bar)

Maximum Pattern Width at 12 in. (305 mm)

in. (mm)

2 to 4

(100)

4 to 6

(150)

6 to 8

(200)

8 to 10

(250)

10 to 12

(300)

Spray Tip

12 to 14

(350)

14 to 16

(400)

★107 207 307

109 209 309 409 509

111 211 311 411 511 611 ❄711

213 313 413 513 613 713

215 315 415 515 615 715 815

217 317 417 517 617 717 817 917

219 319 419 519 619 719 819 919

321 421 521 621 721 821 921

423 523 623 723 923

425 625 725 825 ★925

527 627 827

629

431 631

633 ★833

435

737

539 639 839

16 to 18

(450)

18 to 20

(500)

* Tips are tested in water.

Fluid output (Q) at other pressures (P) can be calculated by this formula: Q = (0.041) (QT)

P

where QT = fluid output (fl oz/min) at 600 psi from the above table for the selected orifice size.

† These tip sizes include a 150 mesh tip filter.

‡ Do not use these tips with Model G15 guns.

32 3A0149C

★ GG4 tips only.

❄ AAM tips only.

Page 33

Spray Tip Selection Chart

AAF Fine Finish Pre-Orifice Spray Tips

Recommended for high finish quality applications at low and medium pressures. AAF tips have a pre-orifice that

assists in atomizing sheer thinning materials, including lacquers.

Order desired tip, Part No. AAFxxx, where xxx = 3-digit number from matrix below.

* Fluid Output

fl oz/min (lpm)

Orifice Size

in. (mm)

0.011 (0.279) 9.5 (0.28) 12.5 (0.37)

0.013 (0.330) 12.0 (0.35) 16.0 (0.47)

0.015 (0.381) 16.0 (0.47) 21.0 (0.62)

0.017 (0.432) 20.0 (0.59) 26.5 (0.78)

at 600 psi

(4.1 MPa, 41 bar)

at 1000 psi

(7.0 MPa, 70 bar)

Maximum Pattern Width at 12 in. (305 mm)

in. (mm)

6 to 8

(200)

8 to 10

(250)

Spray Tip

10 to 12

(300)

12 to 14

(350)

310 410 510 610

312 412 512 612

414 514 614

416 516 616

* Tips are tested in water.

Fluid output (Q) at other pressures (P) can be calculated by this formula: Q = (0.041) (QT)

where QT = fluid output (fl oz/min) at 600 psi from the above table for the selected orifice size.

RAC SwitchTips, for use with G40 RAC Air Cap

NOTE: All tips in the Spray Tip Selection Charts below

can be used with Model G40 guns equipped with RAC

air cap 24C921.

LTX RAC Spray Tips

Order desired tip, Part No. LTXxxx, where xxx = 3-digit number from matrix below.

NOTE: Tips are sometimes packaged with other promo-

tional parts intended for the airless market. Disregard

extra parts.

P

❖ Maximum Pattern Width at 12 in. (305 mm)

in. (mm)

Orifice Size in.

(mm)

* Fluid Output,

at 2000 psi

(14.0 MPa, 140 bar)

fl oz/min (lpm)

2 to 4

(100)

4 to 6

(150)

6 to 8

(200)

8 to 10

(250)

10 to 12

(300)

Spray Tip

12 to 14

(350)

14 to 16

(400)

16 to 18

(450)

18 to 20

(500)

0.009 (0.229) 11.2 (0.33) 109 209 309 409 509

0.011 (0.279) 16.6 (0.49) 111 211 311 411 511 611

0.013 (0.330) 23.3 (0.69) 213 313 413 513 613

0.015 (0.381) 30.8 (0.91) 115 215 315 415 515 615

0.017 (0.432) 39.5 (1.17) 217 317 417 517 617 817

0.019 (0.483) 49.7 (1.47) 219 319 419 519 619 819

0.021 (0.533) 60.5 (1.79) 221 321 421 521 621 721 821

0.023 (0.584) 72.7 (2.15) 323 423 523 623 723

0.025 (0.635) 85.9 (2.54) 225 325 425 525 625

0.027 (0.686) 100.0 (2.96) 227 327 427 527 627 827

0.029 (0.737) 115.6 (3.42) 329 429 529 629 729

0.031 (0.787) 131.8 (3.90) 231 331 431 531 631 831

0.033 (0.838) 149.4 (4.42) 433 533 633 833

0.035 (0.889) 168.4 (4.98) 235 335 435 535 635 735 835

* Tips are tested in water.

Fluid output (Q) at other pressures (P) can be calculated by this formula: Q = (0.041) (QT)

P

where QT = fluid output (fl oz/min) from the above table for the selected orifice size.

❖ Measured with NO airflow. Air assist will tend to reduce pattern lengths by 1 in. to 2 in.

3A0149C 33

Page 34

Spray Tip Selection Chart

RAC SwitchTips, for use with G40 RAC Air Cap, Continued

NOTE: All tips in the Spray Tip Selection Charts below

can be used with Model G40 guns equipped with RAC

air cap 24C921.

FFT Fine Finish RAC Spray Tips

Order desired tip, Part No. FFTxxx, where xxx = 3-digit number from matrix below.

❖ Maximum Pattern Width at 12 in. (305 mm)

in. (mm)

4 to 6

(150)

Orifice Size in.

(mm)

* Fluid Output at

2000 psi (14.0 MPa, 140 bar)

fl oz/min (lpm)

0.008 (0.203) 8.8 (0.26) 208 308

0.010 (0.254) 13.9 (0.41) 210 310 410 510

0.012 (0.305) 19.9 (0.59) 212 312 412 512 612

0.014 (0.356) 27.0 (0.80) 214 314 414 514 614

6 to 8

(200)

8 to 10

(250)

Spray Tip

10 to 12

(300)

12 to 14

(350)

WRX WideRAC Spray Tips

Order desired tip, Part No. WRxxxx, where xxxx = 4-digit number from matrix below.

❖ Maximum Pattern Width at 12 in. (305 mm)

24 in. (610 mm)

Spray Tip

Orifice Size

in. (mm)

* Fluid Output at

2000 psi (14.0 MPa, 140 bar)

fl oz/min (lpm)

0.021 (0.533) 60.5 (1.79) 1221

0.023 (0.584) 72.7 (2.15) 1223

0.025 (0.635) 85.9 (2.54) 1225

0.027 (0.686) 100.0 (2.96) 1227

0.029 (0.737) 115.6 (3.42) 1229

0.031 (0.787) 131.8 (3.90) 1231

0.033 (0.838) 149.4 (4.42) 1233

0.035 (0.889) 168.3 (4.98) 1235

0.037 (0.940) 187.9 (5.56) 1237

0.039 (0.991) 208.9 (6.18) 1239

* Tips are tested in water.

Fluid output (Q) at other pressures (P) can be calculated by this formula: Q = (0.041) (QT)

where QT = fluid output (fl oz/min) from the above table for the selected orifice size.

P

❖ Measured with NO airflow. Air assist will tend to reduce pattern lengths by 1 in. to 2 in.

34 3A0149C

Page 35

Accessories

Use Only Genuine Graco Parts and Accessories

Accessories

Air Fitting and Tubing Kit 249473

Alternative-style connector for air inlet and hose. 3/8 in.

to 1/4 npt(f) Push-To-Lock fitting, 25 ft (7.62 m) long, 3/8

in. (9.5 mm) ID, nylon tubing.

Air Hose 241811

100 psi (0.7 MPa, 7 bar) Maximum Working Pressure

1/4-18 npsm(fbe), 1/4 in. (6 mm) ID, 25 ft (7.62 m) long

polyurethane tubing.

Air Line Quick Disconnect

208536 Air Line Quick Disconnect Coupling

169967 Air Line Quick Disconnect Pin

Fluid Filter Kits

224453 100 mesh (.005 gap spacing) replacement

fluid filters. Quantity. of 5.

238563 60 mesh (.009 gap spacing) replacement

fluid filters for coarser particle filtering to

replace standard 100 mesh filters. Quantity of 3.

Fluid Hose 241812

3500 psi (24 MPa, 242 bar) Maximum Working Pressure

1/4-18 npsm(fbe), 3/16 in. (5 mm) ID, 25 ft (7.62 m) long,

nylon tubing with polyurethane cover.

Fluid Swivel Connector 189018

5800 psi (40 MPa, 400 bar) Maximum Working Pressure

Connector to ease movement of the gun and fluid hose.

1/4-18 npsm. 17-4 PH SST wetted parts.

Gun Brush 101892

Use to clean the gun.

G15 Gun Flush Box Insert 15G093

Insert for use with Gun Flush Box 244105 and G15

Spray Guns.

G40 Gun Flush Box Insert 15G346

Insert for use with Gun Flush Box 244105 and G40

Spray Guns.

Gun Lubricant 111265

One 4 oz. (113 g) tube sanitary (non-silicone) lubricant

for fluid seals and wear areas.

High Pressure Fluid Ball Valve 238694

5000 psi (35 MPa, 350 bar) Maximum Working Pressure

3/8 npt(mbe). SST wetted parts, PEEK seats, PTFE

seals. Compatible with acid-catalyzed materials. Can be

used as fluid drain valve.

HVLP Verification Kit 24C788

Use to check air cap air pressure at various air supply

air pressures. Do not use for actual spraying.

NOTE: To be HVLP compliant, the atomizing air pressure must not exceed 10 psi (70 kPa, 0.7 bar).

RAC Gasket 246453

Pack of five standard replacement RAC gaskets (item

33a).

Acetal RAC Gasket 248936

Pack of five plastic (acetal) replacement RAC gaskets

(item 33a).

G40 RAC Conversion Kit 24C791

Kit includes parts to convert a standard G40 gun to a

RAC gun. LTX spray tip not included.

Air Cap Lacquer Kit 289080

Kit includes air cap optimized to spray lacquer.

Air Cap Seal Kit 253032

Pack of five seals and five o-rings for the air cap assy.

Seal Repair Kit 249422

Kit includes replacement o-rings, gasket, u-cup, air

valve assembly, and seal installation tool.

3A0149C 35

Page 36

Accessories

Plastic Seat Repair Kit 249424

Kit includes replacement plastic seat (pack of 10), and

seat nut for Model G15 gun.

SST Seat Repair Kit 287962

Kit includes assembled diffuser with SST seat for use

with pigmented acid catalyzed materials. For use with

gun 24C854 only.

Carbide Seat Repair Kit 249456

Kit includes replacement carbide seat, seat gasket, and

seat nut for Model G40 gun. Kit also can be used with

Model G15 guns.

Carbide Seat Gasket Kit 288619

Kit includes replacement nylon seat gaskets (qty. of ten)

for Model G40 guns and G15 guns with a carbide seat.

Tip Filter Kit 241804

Replacement filters for spray tip orifice sizes 0.007,

0.009, and 0.011. Quantity of 10.

Trigger Repair Kit 249585

Kit includes replacement trigger, pivot pins (qty. of 5),

and pivot pin nuts (qty. of 5).

Trigger Stop Kit 249423

Kit includes replacement trigger stop and pin.

Ultimate Gun Cleaning Kit 15C161

Kit includes brushes and tools for gun maintenance.

Unclogging Needle Kit 249598

Kit includes picks for unclogging gun tip.

Fan Valve Fine Adjustment Kit 289499

Kit includes a replacement fan valve assembly with

more adjustment accuracy.

Fluid Fitting Kit 24C356, JIC Threads

Kit includes a 1/2-20 JIC threaded fluid inlet fitting.

36 3A0149C

Page 37

Part Interchangeability Guide

Part Number

Description

Fluid spring shaft

Locating pin

G15 retaining ring kit

Includes retaining ring,

PTFE o-ring, and PTFE

washer

G40 retaining ring/tip

guard kit

Includes retaining ring

with guard, PTFE o-ring,

and PTFE washer

RAC seat housing

AA RAC guard kit

Includes guard assembly

(with retaining ring) and

mating cylinder housing.

Needle, carbide ball,

G15 and G40

Needle, stainless steel

ball, G15

HVLP verification kit

RAC gun conversion kit

G15 air cap

Fluid tube assembly

Fluid fitting,

standard threads

Fluid fitting,

JIC threads

New Models

(24Cxxx)

16A529 15F193

24D627 15G618 No New pin is shorter to match the new gun body.

24D438 15F192 No See note below table.

24D439 249256 No See note below table

15F442 15J770 No Works properly only with RAC Tip Guard/Air Cap

24C921 288465 No See note below table.

24B789 288559 Yes Directly replaceable.

24B790 288558 Yes Directly replaceable.

24C788 249140 No See note below table.

24C791 287917 No Can only be used on the new gun due to a differ-

24C866 249596 No Uses new shorter locating pin. See note for

24D436 249136 Yes The new fluid tube assembly will fit an older gun

24D437 15F186 No

24C356 NA No

Part Number,

Older Models* Interchangeable?

15F194

Accessories

Yes 16A529 combines the fluid spring shaft and seat

into a single part. Directly replaceable.

Using a new pin/air cap combo on an old model

gun results in loss of the alignment feature.

Using an old pin/air cap combo on a new model

gun causes leakage due to improper fit.

Assembly 24C921 and is included in that kit.

Seat will fit into older model assemblies, but

spray performance may be affected.

ent RAC guard. See note below table.

Locating pin, this table.

only if a new fluid fitting is purchased, 24D437

(standard threads) or 24C356 (JIC threads).

New fluid fittings have different threads that fit

only the new fluid tube assembly (24D436). Any

interchange will damage the threads.

NOTE: The new retaining ring is black and has coarse threads, while the old retaining ring is silver and has fine

threads. Any interchange will damage the threads on the ring and gun body.

* Older model part numbers include 288xxx, 287xxx, 249xxx.

3A0149C 37

Page 38

Dimensions

Dimensions

(17.5 cm)

8.0 in.

(20.3 cm)

Model G15

6.9 in.

5.0 in. (12.7 cm)

8.0 in.

(20.3 cm)

TI6583A

6.1 in. (15.5 cm)

Model G40

6.9 in.

(17.5 cm)

5.8 in. (14.7 cm)

6.9 in. (17.5 cm)

TI6845A

38 3A0149C

Page 39

Technical Data

Technical Data

Category Data

Maximum Working Fluid Pressure . . . . . . . . . . . . . . . . . . Model G15: 1500 psi (10 MPa, 105 bar)

Model G40: 4000 psi (28 MPa, 280 bar)

Maximum Working Air Pressure . . . . . . . . . . . . . . . . . . . . 100 psi (0.7 MPa, 7 bar)

Maximum Gun Inlet Air Pressure for HVLP Operation . . . 14 psi (0.098 MPa, 0.98 bar)

Maximum Working Fluid Temperature . . . . . . . . . . . . . . .

Fluid Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/4-18 npsm

Air Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/4-18 npsm (R1/4-19) compound male thread

Gun Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 oz (450 grams)

*Sound Pressure at 20 psi (140 kPa, 1.4 bar) . . . . . . . . . 66.9 dB(A)

*Sound Pressure at 100 psi (0.7 kPa, 7 bar) . . . . . . . . . . 80.0 dB(A)

*Sound Power at 20 psi (140 kPa, 1.4 bar) . . . . . . . . . . . 76.8 dB(A)

*Sound Power at 100 psi (0.7 kPa, 7 bar) . . . . . . . . . . . . 89.9 dB(A)

Wetted Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Stainless Steel, Carbide, Ultra High Molecular Weight

°F (43°C)

110

Polyethylene, Engineered Plastic, PTFE, Nylon, Fluoro-

elastomer

* All readings were taken with the fan valve fully closed (full fan size), at 20 psi (140 kPa, 1.4 bar) and 100 psi (0.7

kPa, 7 bar), and at the assumed operator position. Sound Power was tested to ISO 9614-2.

Air Flow, Standard Air Cap

12

Air Flow

(SCFM)

10

8

6

4

2

4.2

2.6

8.6

6.4

4.6

3.8

10.6

5.8

0

10 20

Gun Inlet Pressure (PSI)

Fan Valve Open Fan Valve Closed

3A0149C 39

30 400

50

Page 40

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211, Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 3A0149

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2009, Graco Inc. is registered to ISO 9001

www.graco.com

Revised 05/2010

Loading...

Loading...