Page 1

Operation

ti14752a

ti14763a

GrindLazer 270 and 390

GrindLazer 630

(Drums, cutters, and LineDriver

™

sold separately)

Related Manuals:

Repair - 3A0102

Parts - 3A0103

ti25371a

™

GrindLazer

Designed to grind flat, horizontal concrete or asphalt surfaces. For removal of materials

from concrete and asphalt surfaces. For professional outdoor use only

Model 571002 - Forward cut

GrindLazer 270 (270 cc / 9 hp)

Model 571003 - Forward cut

GrindLazer 390 (390 cc / 13 hp)

Model 571004 - Reverse up-cut (Must be used with LineDriver

GrindLazer 480 (480cc / 16 hp)

™

)

3A0101C

EN

Model 571260 - Reverse up-cut (Must be used with LineDriver

GrindLazer 630 (627 cc / 21 hp)

IMPORTANT SAFETY INSTRUCTIONS

Read all warnings and instructions in this

manual. Save these instructions.

™

)

Page 2

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The

exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk.

Refer back to these warnings. Additional, product-specific warnings may be found throughout the body of this manual

where applicable.

WARNING

DUST AND DEBRIS HAZARD

Use of this equipment to grind concrete and other paving materials can result in the release of potentially

harmful dust or chemicals from the materials.

• For use only by sophisticated users familiar with applicable governmental safety and industrial

hygiene regulations.

• Use equipment only in a well-ventilated area.

• Wear a properly fit-tested and government approved respirator suitable for the dust conditions.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not leave the work area while equipment is energized. Turn off all equipment when equipment is

not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

• Maintain a safe operating distance from other people in the work area.

• Avoid any pipes, columns, openings, or any other objects protruding from work surface.

MOVING VEHICLE HAZARD

Careless and reckless behavior causes accidents. Falling from vehicle, running into people or object, or

being struck by other vehicles may result in serious injury or death.

• Do not step on forward/reverse pedals.

• Make turns slowly. Do not make turns greater than 45°.

• Loss of traction may occur going downhill. Do not operate on slopes greater than 15°.

• Do not carry passengers.

• Do not tow.

• Use with line striping equipment only.

• Use appropriate traffic control in all traffic areas. Refer to Manual on Uniform Traffic Control Devices

(MUTCD), U.S. Department of Transportation, Federal Highway Administration or local highway and

transportation regulations.

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Before checking, moving, or servicing equipment, disable power supply.

BURN HAZARD

Equipment surfaces that are heated can become very hot during operation. To avoid severe burns, do

not touch hot equipment. Wait until equipment has cooled completely.

2 3A0101C

Page 3

Warnings

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Do not fill fuel tank while engine is running or hot; shut off engine and let it cool. Fuel is flammable

and can ignite or explode if spilled on hot surface.

• Keep work area free of debris, including solvent, rags and gasoline.

• Keep a fire extinguisher in work area.

CARBON MONOXIDE HAZARD

Exhaust contains poisonous carbon monoxide, which is colorless and odorless. Breathing carbon

monoxide can cause death. Do not operate in an enclosed area.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of dust or

chemicals, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eye wear

• Protective shoes

• Gloves

• Hearing protection

• Properly fit-tested and government approved respirator suitable for the dust conditions

CALIFORNIA PROPOSITION 65

The engine exhaust from this product contains a chemical known to the State of California to cause

cancer, birth defects or other reproductive harm.

This product contains a chemical known to the State of California to cause cancer, birth defects or other

reproductive harm. Wash hands after handling.

3A0101C 3

Page 4

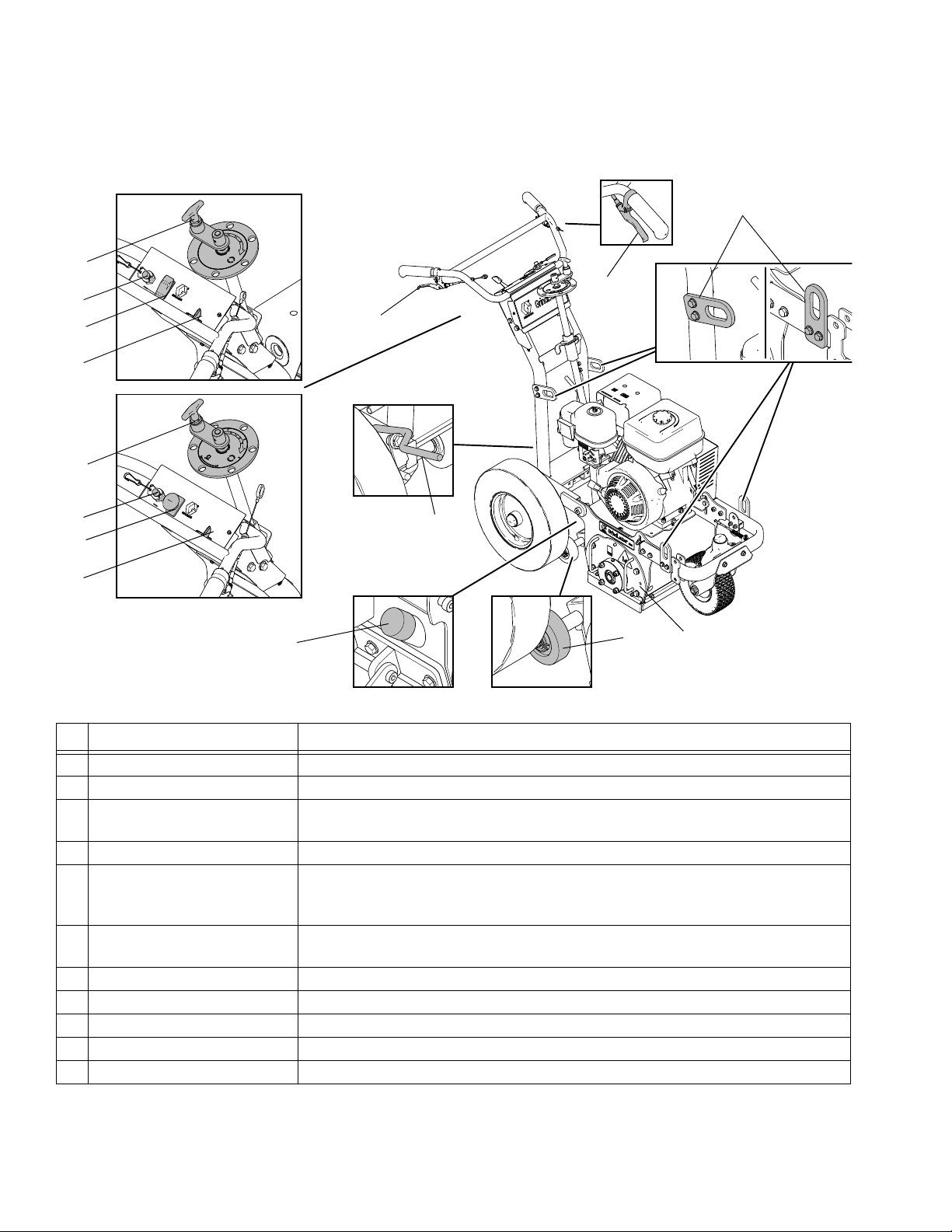

Component Identification

ti14753a

G

E

C

B

A

F

D

H

K

C

B

A

270 and 390 Models

480/630 Models

M

N

D

Component Identification

Component Description

A Engine Throttle Lever Adjusts engine speed.

B Engine Stop Switch Supplies power to Engine

C Emergency Shut-Off Clamps onto the operator and shuts engine off if cord is disconnected during

operation.

D Drum Adjustment Dial Sets depth of drum cut.

E Drum Engage Lever When lever is engaged, handle bars can be pushed down to raise the cutting

F Front Wheel Lock Lever Front wheel is usually locked to guide GrindLazer in a straight line. When lever

G Rear Wheel Parking Brake Prevents rear wheel from moving.

H Drum Access Panel Removable plate that allows access to replace cutting drum.

K Depth Control Wheels Levels cutting drum.

M Vacuum Port Port to attach vacuum to reduce dust and debris during operation.

N Lift Points Reinforced points used for lifting GrindLazer during transportaton or repair.

drum off of surface and locked into UP position. Once drum is locked in UP

position, GrindLazer can be moved around without drum touching surface.

is engaged, front wheel becomes unlocked and is allowed to turn freely.

4 3A0101C

Page 5

Operation

Operation

The GrindLazer is designed to plane flat, horizontal concrete or asphalt slabs.

GrindLazer 270 (270 cc) and GrindLazer 390 (390 cc)

models are designed to be operated by a single

operator positioned at the back of the unit, or in

conjunction with LineDriver. GrindLazer 480 (480 cc)

and GrindLazer 630 (627 cc) can ONLY be operated

with LineDriver.

Maintain a safe operating distance from other people in

the work area. Avoid any pipes, columns, openings, or

any other objects protruding from work surface.

Start-Up

Before starting engine, perform the following:

• Read and understand engine manual

• Make sure all guards are in place and secure

• Make sure all mechanical fasteners are secure

• Inspect for damage to engine and other exterior

surfaces

• Use correct cutters for each job. Make sure drum is

balanced and the correct number, size and type of

cutter wheels are being used. Make sure drum shaft

is locked and secured.

• Inspect work area to locate any pipes, columns,

deck inserts, or other objects protruding from work

surface. Avoid these objects during operation.

3A0101C 5

Page 6

Operation

Carbide Miller

Diamond Blade

ti15142a

ti15141a

Forward Cut (270/390 Models)

Reverse (up cut) 480/630

ti15138a

ti15137a

ti14766a

ti14764a

ti14756a

ti14755a

ti15256a

ti15257a

ti14767a

ti14765a

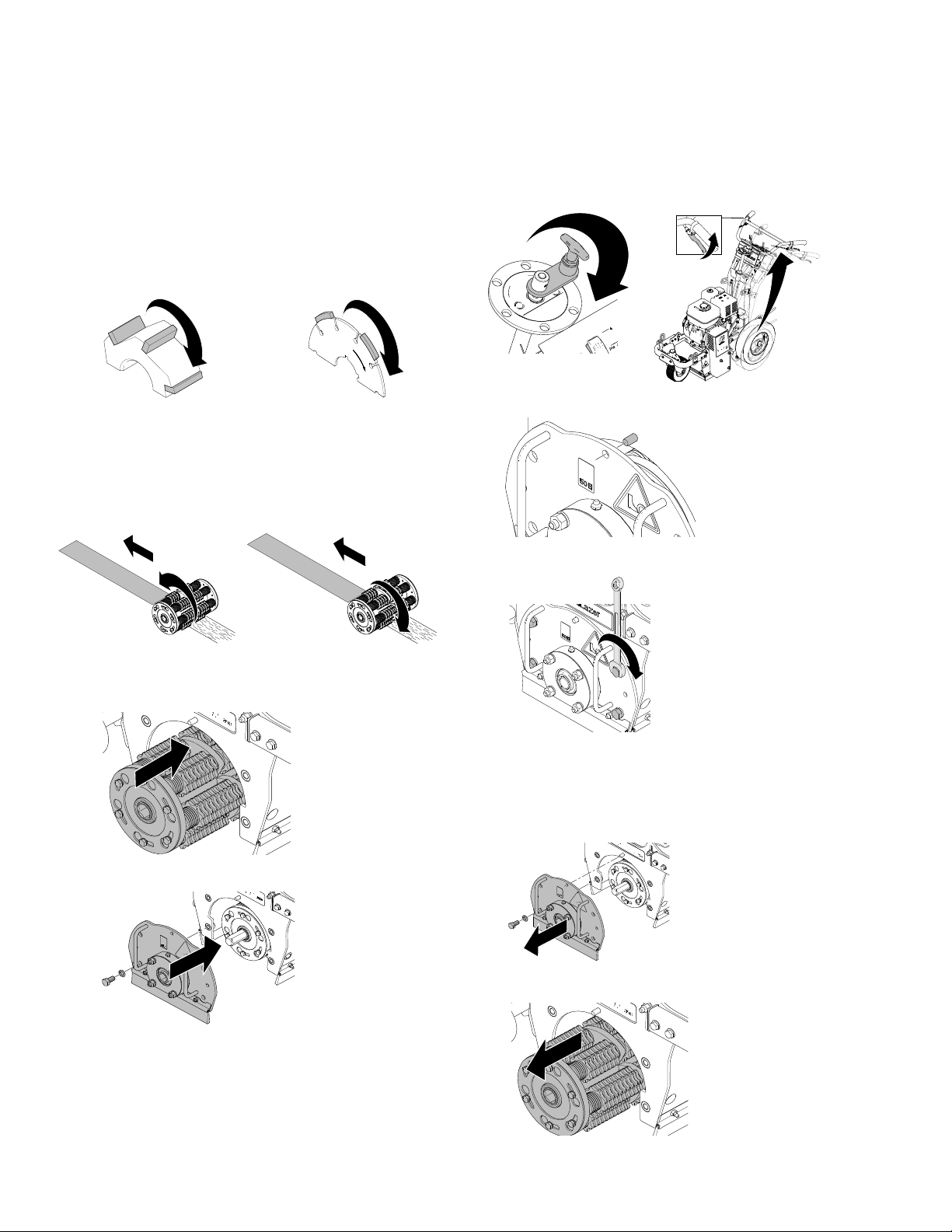

Drum Installation/Replacement

Installation

NOTE: Carbide Flail Cutter drums do not require

specific orientation or direction. Carbide Millers and

Diamond Blades are directional. They should be

stacked so that the arrows on the Millers and Blades

face the same direction as the rotation of the drum.

270 and 390 models are designed for “forward cut”

grinding (the drum rotates in the same direction that it

travels). 480 and 630 models are design for “reverse (up

cut)” grinding (the drum rotates in the opposite direction

that it travels).

3. Lower Drum Adjustment Dial (D) and pull Drum

Engage Lever (E) so drum rests on ground.

Door pin and hole should line up.

4. Tighten four bolts on Drum Access Panel (H).

1. Slide replacement Drum onto hex shaft.

2. Replace Drum Access Panel (H).

5. Turn Drum Adjustment Dial (D) to maximum height.

Removal

1. Remove four bolts and Drum Access Panel (H).

2. Slide drum off of hex shaft.

6 3A0101C

Page 7

Starting the Engine

ti14754a

ti15089a

ti14758a

ti15088a

ti5248a

480 Models270/390 Models

ti15091a

ti5249a

480 Models

270/390 Models

630 Models

ti3315a

ti14872a

270 & 390 Models

480/630 Models

ti5263a

TIA

480 Models270/390 Models

630 Models

ti6483a

3. Engage Rear Wheel Brake (G) to prevent GrindLazer from moving.

4. 480/630 Models Only: Attach LineDriver to

GrindLazer.

Operation

7. Start Engine:

a. Move fuel valve to open.

b. Move choke to closed.

c. Set Engine Power Switch (B) to ON.

5. Push down on handle bars until drum is locked into

UP position.

6. 480/630 Models Only: Make sure Engine Stop

Switch (C) is in UP position.

d. Pull starter cord.

e. After engine starts, move choke to open.

f. Set throttle to desired setting.

3A0101C 7

Page 8

Operation

ti14762a

ti14757a

ti6483a

ti14755a

ti14756a

Cutting Material

1. Start Engine, see page 7.

2. Connect Emergency Shut-Off Cord (C) to operator.

3. Disengage Rear Wheel Brake (G).

5. Push down on handle bars, pull engagement lever,

and lower drum into DOWN position.

6. Rotate Drum Adjustment Dial (D) until drum comes

into contact with surface and desired depth is

reached.

4. Slide Engine Throttle Lever (A) to desired setting.

NOTE: Drum clutch will not engage when engine is

running at idle. 480/630 Models: LineDriver must

be attached to GrindLazer.

NOTE: Several test cuts may be needed to dial-in

desired cutting depth.

NOTE: On harder surfaces, it may be best to make

several passes in increments of 1/32 in. to 1/8 in.

8 3A0101C

Page 9

Operation

S

S

K

K

ti15095a

5 in.

S

S

K

K

ti15094a

10 in.

T

ti15229a

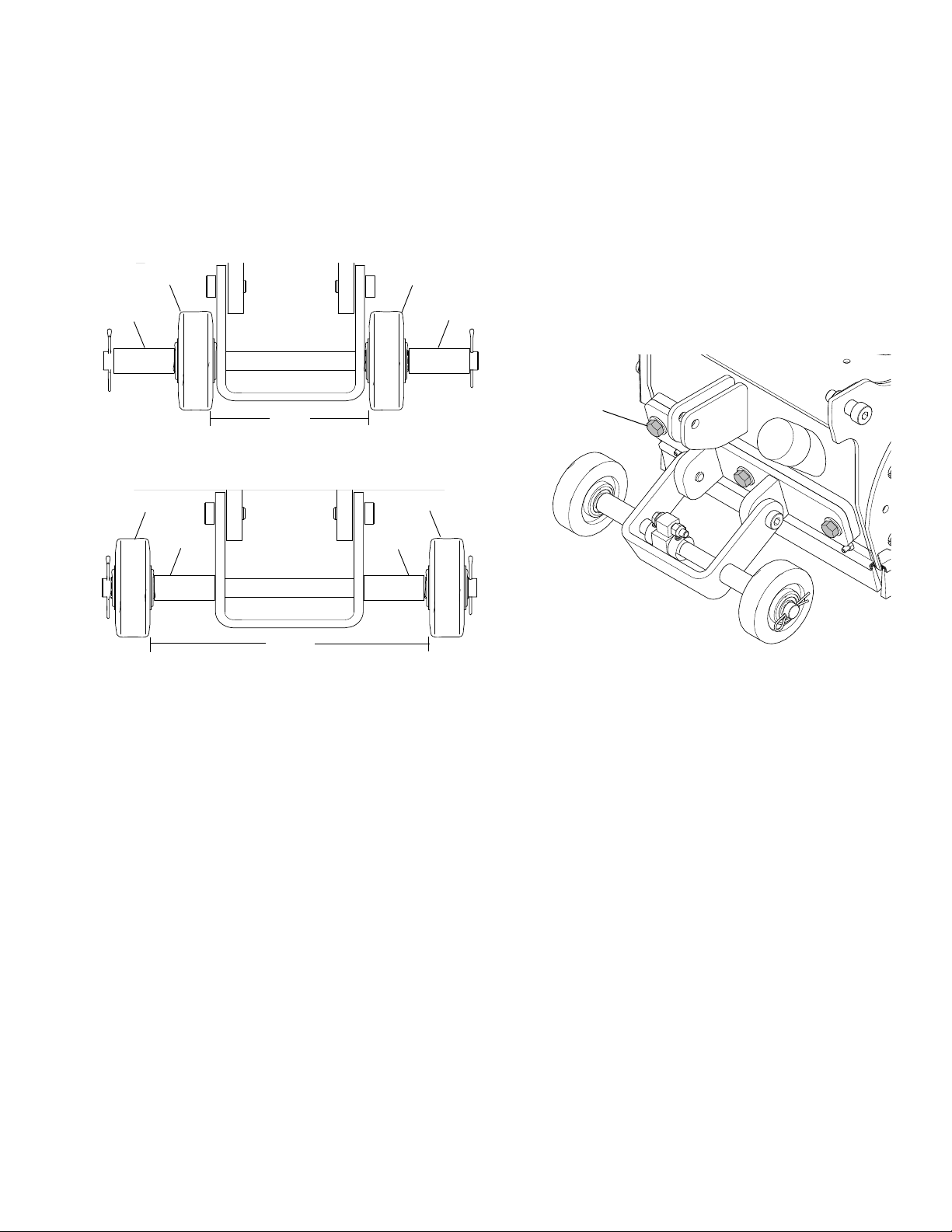

Depth Control Wheels

Using Depth Control Wheels as a 5 in. or

10 in. Wide Cutting Guide

To make a 5 in. cut, install two spacers (S) on outside

of Depth Control Wheels (K).

To make a 10 in. cut, install two spacers (S) on inside

of Depth Control Wheels (K).

How to Level the Drum

To properly level the drum, GrindLazer must be resting

on a flat level surface.

1. Make sure drum is properly installed (see Drum

Replacement, page 6).

2. Push down on handle bars, pull engagement lever,

and lower drum into DOWN position.

3. Loosen (but do not remove) three bolts (T) on Depth

Control Wheel plate.

4. Adjust plate until guide wheels lay flat on surface.

5. Tighten three bolts (T) on plate.

3A0101C 9

Page 10

Operation

ti14758a

ti6482a

ti15176a

270 & 390 Models

480/630 Models

ti15177a

Stop Cutting Material

1. Push down on handle bars until drum is locked into

UP position.

3. Turn Engine Power Switch (B) OFF.

Clean Up

Clean the entire exterior of the machine after it has

cooled at the end of each work day. Check for worn or

damaged parts and perform any required Maintenance,

page 12.

2. Slide Engine Throttle Lever (A) to low setting.

10 3A0101C

Page 11

Cutting Drum Assemblies

S

S

Avoid touching or handling drum after use until it has

completely cooled.

Different drum configurations can be used for different

applications. There are three different types of drum

assemblies compatible with the GrindLazer: carbide

flails, carbide millers, and diamond blades.

Carbide Flail Cutter/Assembly

Gradually adjust depth down to remove marking line

(minimal amount of paved surface should be removed).

Carbide Miller Cutter/Assembly

Best results for deep cuts are achieved by making several thin passes. A single pass should be no deeper

than 1/32 in. or damage to rods and cutters could occur.

Cutting Drum Assemblies

NOTE: Each increment on Drum Adjustment Dial (D) is

0.010 in. (0.25 mm) depth change of cutting drum.

Diamond Blade Assembly

(480/630 Models Only)

Watch Depth Control Wheels (K) during operation; if

wheels are spinning, proper depth is being achieved.

NOTICE

Diamond Blades are designed to be cooled by airflow around the blades. Lift blade out of cut every

10 to 15 seconds, then run at full speed for several

seconds to prevent excessive heat build-up which

could damage the blades.

Cutter and Drum Assemblies

• The engine should not labor. Run engine at full

speed and adjust forward speed to fit the work being

performed. Harder concrete surfaces will have to be

cut at a slower pace than asphalt or other softer surfaces.

Handle Bar Adjustment

To adjust handle bar: remove four screws (S), slide

handle bar to desired height, and replace screws and

tighten.

3A0101C 11

Page 12

Maintenance

ti14760a

Maintenance

Avoid touching engine and drum after use until they

have completely cooled.

The following steps should be performed to maintain

proper operation and sustain the life of the GrindLazer.

BEFORE OPERATION:

• Visually inspect the entire unit for damage or loose

connections

• Insert grease into the grease fittings on the drum

mount and center hinge

• Check engine oil (see engine manual)

• Check drum bushings and cutters

• Check drum for uneven wear

• Check for proper tire pressure

DAILY:

• Insert and clean air filter element

• Clean dust and debris from exterior of unit (do NOT

use pressure washer or other high pressure cleaning equipment)

• Check engine oil level and fill as necessary

• Check and fill gas tank

• Remove air filter cover and clean element. Replace

element if necessary. Replacement elements can

be purchased from your local engine dealer.

AFTER THE FIRST 20 HOURS OF OPERATION:

• Drain engine oil and refill with clean oil. See engine

manual for correct viscosity.

EVERY 40-50 HOURS OF OPERATION:

• Change engine oil (see engine manual)

• Grease wheel bearings

AS REQUIRED:

• Check drive belt and tension and tighten or replace

as needed

For additional information about engine maintenance, see Honda (270 and 390 models) or Briggs

and Stratton (480 models) engine manual.

Caster Wheel Maintenance

EVERY MONTH:

• Grease wheel bearing

• Check pin for wear. If pin is worn out there will be

play in caster wheel. Reverse or replace pin as

needed.

• Check caster wheel alignment as necessary. To

align: loosen set screw, align wheel, and tighten

screw.

Front Swivel Tire Alignment

1. Loosen cap screw.

2. Rotate front wheel fork left or right, as necessary, to

straighten alignment.

3. Tighten cap screw. Push GrindLazer and let it roll

with hands off of GrindLazer.

NOTE: If GrindLazer rolls right or left, repeat steps 1

and 3 until GrindLazer rolls straight.

12 3A0101C

Page 13

Technical Data

GrindLazer 270 (Model 571002)

Dimensions

Unpackaged Packaged

Height in./cm: 46 (116.8) 50.5 (128.3)

Width in./cm: 28 (71.1) 37 (94.0)

Length in.cm: 62 (157.5) 73 (185.4)

Weight lb/kg: 300 (136) 400 (181)

Noise (dBa)

Sound Power per ISO 3744: 107.3

Sound Pressure measured at

3.1 feet (1m):

Vibration (m/sec

Without LineDriver: 7.9

With LineDriver: 8.3

Power Rating (HorsePower) per SAE J1349

8.0 @ 3600 rpm

Maximum storage time

Maximum lifetime

Power efficiency factor

2

) per ISO 3744

5 years

10 years

200 ground meters per liter fuel

GrindLazer 390 (Model 571003)

Dimensions

Unpackaged Packaged

Height in./cm: 46 (116.8) 50.5 (128.3)

Width in./cm: 28 (71.1) 37 (94.0)

Length in.cm: 62 (157.5) 73 (185.4)

Weight lb/kg: 310 (141) 410 (186)

Noise (dBa)

Sound Power per ISO 3744: 109.3

Sound Pressure measured at

3.1 feet (1m):

Vibration (m/sec

Without LineDriver: 7.5

With LineDriver: 5.9

Power Rating (HorsePower) per SAE J1349

11.0 @ 3600 rpm

2

) per ISO 3744

GrindLazer 480 (Model 571004)

Dimensions

Unpackaged Packaged

Height in./cm: 46 (116.8) 50.5 (128.3)

Width in./cm: 28 (71.1) 37 (94.0)

Length in.cm: 62 (157.5) 73 (185.4)

Weight lb/kg: 330 (150) 430 (195)

Noise (dBa)

Sound Power per ISO 3744: 108.6

Sound Pressure measured at

3.1 feet (1m):

Vibration (m/sec

With LineDriver: 4.9

Power Rating (HorsePower) per SAE J1349

16.0 @ 3600 rpm

2

) per ISO 3744

91.6

93.6

92.1

Technical Data

3A0101C 13

Page 14

Technical Data

GrindLazer 630 (Model 571260)

Dimensions

Unpackaged Packaged

Height in./cm: 46 (116.8) 50.5 (128.3)

Width in./cm: 28 (71.1) 37 (94.0)

Length in.cm: 62 (157.5) 73 (185.4)

Weight lb/kg: 338 (153) 438 (199)

Noise (dBa)

Sound Power per ISO 3744: 108.6

Sound Pressure measured at

3.1 feet (1m):

Vibration (m/sec

With LineDriver: 4.9

Power Rating (HorsePower) per SAE J1349

21.0 @ 3600 rpm

2

) per ISO 3744

92.1

14 3A0101C

Page 15

Notes

Notes

3A0101C 15

Page 16

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441 USA

Copyright 2009, Graco Inc. All Graco manufacturing locations are is registered to ISO 9001

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 3A0101

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised C, December 2014

Loading...

Loading...