Page 1

Repair-Parts

Horizontal

3A0020A

Hydraulic Driver

For use with two horizontally mounted proportioning pumps. For professional use only.

Not for use in explosive atmospheres.

258771 - Horizontal Hydraulic Driver

1200 psi (8.2 MPa, 82.7 bar) Maximum Working Pressure

Important Safety Instructions

Read all warnings and instructions in this manual

and all supplied manuals. Save all instructions.

ENG

r_258640_3A0020A_1h

Page 2

Warnings

Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Mounting Hole Layout . . . . . . . . . . . . . . . . . . . . . . . 8

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 10

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 10

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Do not leave the work area while equipment is energized or under pressure. Turn off all equipment

and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe

burns:

• Do not touch hot fluid or equipment.

• Wait until equipment/fluid has cooled completely.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

2 3A0020A

Page 3

Repair

Repair

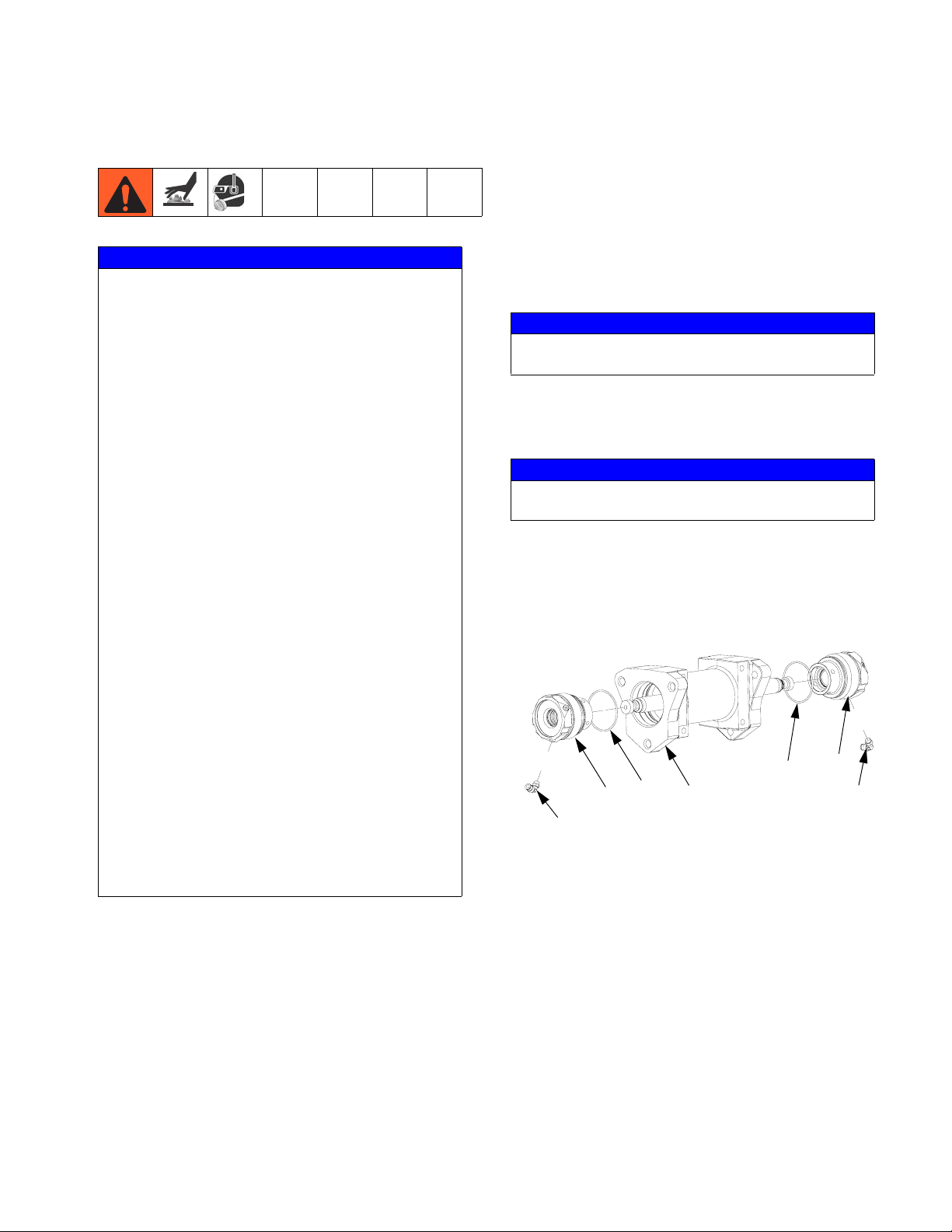

Disassembly

1. Relieve pressure. See system manual for pressure

relief instructions.

NOTICE

Recommended Hydraulic Oil

Use Graco-approved Hydraulic Oil, Part No. 169236

(5 gal) or 207428 (1 gal)) or a premium, ISO grade

46 petroleum-based hydraulic oil containing rust and

oxidation inhibitors and anti-wear agents.

Before using any other type of oil in this motor, contact your Graco distributor. Unauthorized use of

lesser grade oil or substitutes may void the warranty.

Hydraulic Oil Working Temperature

The maximum hydraulic oil operating temperature is

160 °F (71 °C). The motor seals will wear faster and

leakage may occur if the pump is operated at higher

oil temperatures.

If the hydraulic oil temperature approaches 160 °F

(71 °C), check the hydraulic fluid supply cooling system, filters, etc. and clean or repair as needed.

Keep the hydraulic system clean

To reduce the risk of damaging the hydraulic driver,

verify that the hydraulic power supply fluid lines and

reservoir are clean and free from contaminants.

Carefully follow the manufacturer’s recommendations on reservoir and filter cleaning, flushing, and

periodic changes of hydraulic fluid.

Always plug the hydraulic inlets, outlets and lines

when disconnecting them to avoid introducing dirt

and other contaminants into the system.

2. Use two people to lift and clamp the cylinder (1) in a

vise.

NOTICE

To prevent damage to sealing surfaces, do not clamp

any sealing surfaces in the vise.

3. Remove elbow fittings (4) from outside of seal housings (2).

NOTICE

To prevent damage to the driver, avoid getting dust

or dirt in the driver during service.

4. Use a 3 1/4 in. socket or wrench to remove one seal

housing (2). Place a waste container below the seal

housing and cylinder (1) to drain any residual

hydraulic oil.

2a

2

4

5. Remove second seal housing (2).

6. Remove o-rings (2a) from seal housings (2).

1

2a

r_258640_3A0020A_2h

2

4

Required Tools

• Vise with soft jaws

• Set of adjustable wrenches

• O-ring pick

• 3/16 in. hex key

• Rubber mallet

• 3 1/4 in. socket

• Torque wrench capable of 150 ft-lbs (203 N•m).

• Anti-seize lubricant

• Pipe sealant

3A0020A 3

Page 4

Repair

Residual hydraulic oil in the cylinder can spray out of

ports during removal of the piston assembly.

NOTE: Be careful not to damage piston rod assembly (9).

7. Place a cloth over the hydraulic ports (P). Use a rubber mallet to tap piston rod assembly (9) out of cylinder (1).

Do not clamp vise on this surface.

91

Assembly

NOTE: Be careful not to damage piston rod assembly (9).

1. Clamp piston rod (9) flats or hex in a vise to prevent

damage to the piston rod.

2. Lubricate piston lead-in (L) with hydraulic oil to

ensure rubber energizing ring of bidirectional seal

(9b) seats properly. Install one edge of rubber energizing ring in deep piston groove and press the rest

of the o-ring down while preventing the o-ring from

twisting.

NOTICE

Prevent rubber energizing ring from twisting during

installation. The bidirectional seal (9b) will not function properly if the rubber energizing ring is twisted.

P

r_258640_3A0020A_3h

NOTICE

To avoid damaging piston rod, do not clamp on piston rod surface.

8. Clamp piston rod flats (9) in a vise to prevent damage to piston rod.

9. Use o-ring pick to remove sealing ring and rubber

energizing ring of bidirectional seal (9b). Remove

bearing (9c).

hex

flats

9b

L

9c

9

r_258640_3A0020A_4h

3. Install sealing ring of bidirectional seal (9b) over rubber energizing ring and install bearing (9c) in shallow piston groove.

NOTICE

Only expand the sealing ring of bidirectional seal

(9b) and bearing (9c) as much as needed to fit over

the piston. Damage will occur when the sealing ring

or bearing are opened wider than necessary.

4. Remove piston assembly (9) from vise and lubricate

bidirectional seal (9b) and bearing (9c) with hydraulic oil.

9b

9c

9

r_258640_3A0020A_4h

10. Thoroughly clean all metal parts in a compatible solvent and inspect for wear or damage. Replace as

necessary.

4 3A0020A

Page 5

Repair

5. Lubricate inside of cylinder (1) with hydraulic oil to

allow easy installation of piston assembly. Continue

to next step if the cylinder hasn’t been flushed and

there is residual hydraulic oil.

1

lubricate with

hydraulic oil

r_258640_3A0020A_6h

6. Install o-rings (2a) on seal housings (2). Lubricate

o-rings (2a) with hydraulic oil. Lubricate seals and

bearing inside seal housing with hydraulic oil.

2

2a

lubricate with

r_258640_3A0020A_7h

hydraulic oil

9. Install second seal housing (2) on cylinder (1).

Torque to 150-160 ft-lbs (203-216 N•m).

NOTE: Use a rubber mallet to gently tap seal housing while turning by hand to start threading the seal

housing into cylinder.

1

2

r_258640_3A0020A_10h

10. Apply pipe sealant on two elbow fittings (4) and pipe

plugs (5) and install in each seal housing (2).

NOTE: Elbow fitting should be placed in lowest port.

5

7. Install one assembled seal housing (2) on cylinder

(1). Torque to 150-160 ft-lbs (203-216 N•m).

1

2

r_258640_3A0020A_8h

8. Install piston rod assembly (9) in cylinder (1) with

bidirectional seal (9b) facing away from the cylinder

(1). Apply hydraulic oil to bidirectional seal and

bearing (9c). Use rubber mallet to tap piston rod

assembly until the piston is approximately at the

middle of the cylinder.

9

1

5

4

5

r_258640_3A0020A_11h

4

9c

r_258640_3A0020A_9h

3A0020A 5

9b

Page 6

Parts

Parts

5

3

2a

2

5

3

1

1

9

1

2

1

2x

2

4

3

1

Lubricate seals and surfaces with hydraulic oil.

2

Torque to 150-160 ft-lbs (203-216 N•m).

3

Apply pipe sealant.

2a

2

1

1

Ref. Part Description Qty.

1 258835 KIT, cylinder, hydraulic 1

2 258768 HOUSING, rod seals, assembly;

includes item 2a

2a 113570 O-RING 1

4 112698 FITTING, elbow, street 2

5 100139 PLUG, pipe 4

9 258769 ROD, piston, hydraulic, assembly;

includes 9a-9c

9a ROD, piston, hydraulic 1

9b◆ SEAL, piston, bidirectional;

includes rubber energizing ring and

sealing ring

9c◆ BEARING, wear, piston 1

r_258640_3A0020A_12h

9c

4

3

1

9a

r_258640_3A0020A_13h

9b

1

2

1

1

◆ Parts included in Kit 258770 (purchase separately).

6 3A0020A

Page 7

Parts

3A0020A 7

Page 8

Dimensions

Dimensions

17.375 in.

(441.3 mm)

Mounting Hole Layout

C

B

A

E

r_258640_3A0020A_15h

r_258640_3A0020A_14h

F

D

G

r_258640_3A0020A_17h

6.165 in. (156.6 mm)

A

5.114 in. (129.9 mm)

B

6.5 in. (165.1 mm)

C

4.43 in. (112.5 mm)

D

5.906 in. (150 mm) 120° bolt circle

E

6.26 in. (159.0 mm)

F

4 in. (101.6 mm)

G

8 3A0020A

Page 9

Technical Data

Maximum hydraulic working pressure . . . . . . . . . . . . . . . 1200 psi (8.3 MPa, 83 bar)

Maximum fluid temperature . . . . . . . . . . . . . . . . . . . . . . . 160°F (71°C)

Maximum hydraulic fluid flow . . . . . . . . . . . . . . . . . . . . . . 10.3 gpm (38.9 liter/min)

Maximum cycle rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65 cycles per minute

Hydraulic fluid consumption . . . . . . . . . . . . . . . . . . . . . . . 1 gal. (3.8 liters) per 6.3 cycles

Effective piston area . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Piston rod diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.125 in (28.6 mm)

Stroke length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 in. (76.2 mm)

Thrust at 1200 psi (8.3 MPa, 83 bar) . . . . . . . . . . . . . . . . 7300 lbf (32,472 N)

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . approx. 40 lb. (18.1 kg)

6.1 sq. in. (39.2 cm

2

)

Technical Data

3A0020A 9

Page 10

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Toll Free: 1-800-746-1334 Fax: 330-966-3006

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO OHIO INC. 8400 PORT JACKSON AVE NW, NORTH CANTON, OH 44720

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 3A0020

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

Copyright 2009, Graco Inc. is registered to ISO 9001

www.graco.com

Loading...

Loading...