Page 1

Instructions-Parts

Z-Series

Chemical Pumps

For pumping plural component materials. For professional use only.

Not for use in explosive atmospheres.

3500 psi (24 MPa, 241 bar) Maximum Working Pressure

Important Safety Instructions

Read all warnings and instructions in this manual

and all supplied manuals. Save all instructions.

3A0019J

EN

See page 2 for model information.

r_257891_3a0019_1h

Page 2

Models

Contents

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Isocyanate Conditions . . . . . . . . . . . . . . . . . . . . . . 5

Material Self-ignition . . . . . . . . . . . . . . . . . . . . . . . 5

Moisture Sensitivity of Isocyanates . . . . . . . . . . . . 5

Keep Components A and B Separate . . . . . . . . . . 5

Foam Resins with 245 fa Blowing Agents . . . . . . . 5

Changing Materials . . . . . . . . . . . . . . . . . . . . . . . . . 5

Component Identification . . . . . . . . . . . . . . . . . . . . 6

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . 7

Flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

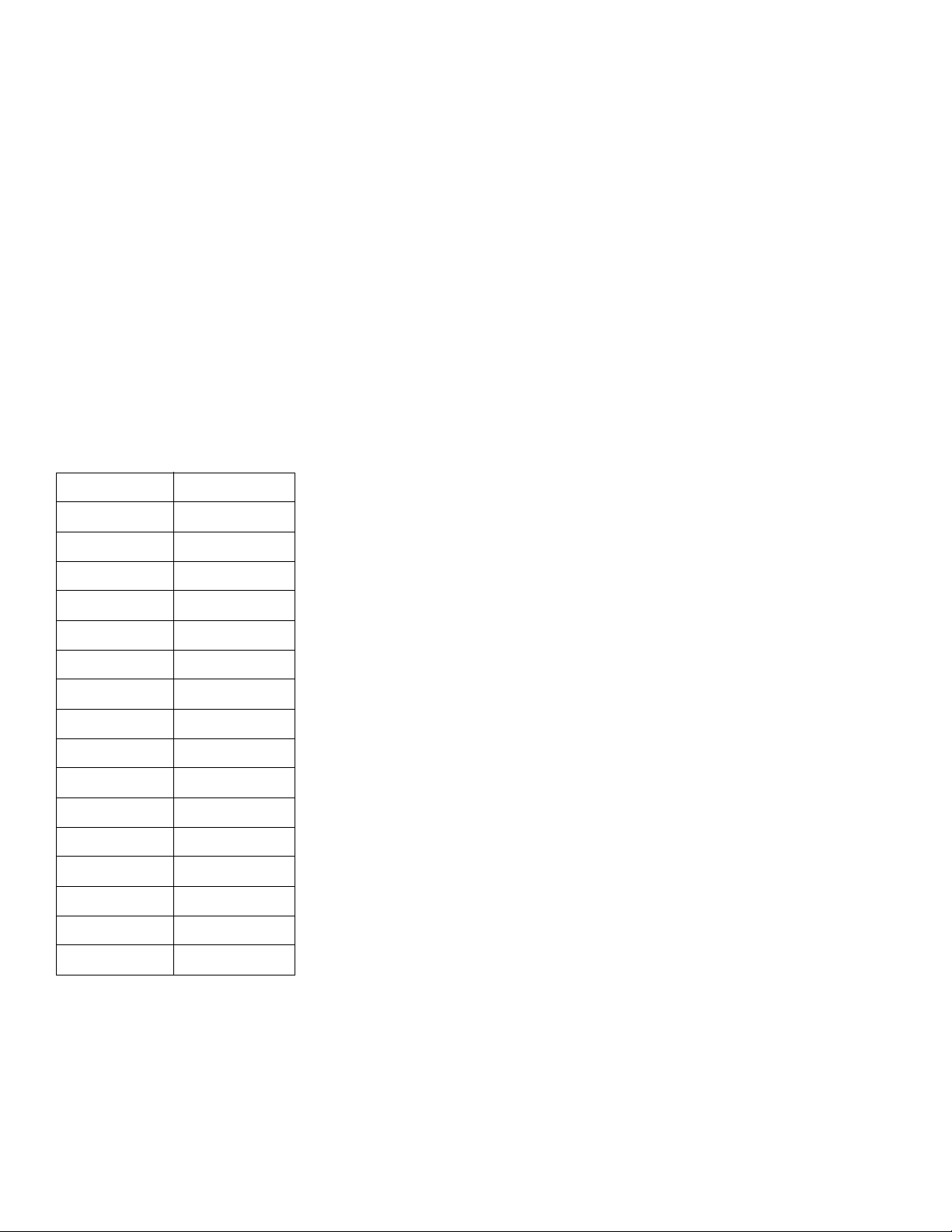

Models

Model Pump Size

*L005S1 5cc

L010S1 10cc

L015S1 15cc

L020S1 20cc

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Inlet Housing Disassembly . . . . . . . . . . . . . . . . . 8

Inlet Housing Assembly . . . . . . . . . . . . . . . . . . . . 8

Pump Disassembly . . . . . . . . . . . . . . . . . . . . . . . 9

Pump Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 11

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Outlet Housing Mounting Hole Layout . . . . . . . . . 24

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 26

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 26

L025S1 25cc

L030S1 30cc

L040S1 40cc

L050S1 50cc

L060S1 60cc

L065S1 65cc

L075S1 75cc

L080S1 80cc

L086S1 86cc

L100S1 100cc

L120S1 120cc

L160S1 160cc

* Due to a small seal cross-section, use unfilled

catalysts to achieve the best seal life results.

2 3A0019J

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Do not leave the work area while equipment is energized or under pressure. Turn off all equipment

and follow the Pressure Relief Procedure in this manual when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

3A0019J 3

Page 4

Warnings

WARNING

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear impervious gloves when spraying or cleaning equipment.

• If this equipment is used with isocyanate material, see additional information on isocyanates in Isocyanate Conditions Section of this manual.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe burns:

• Do not touch hot fluid or equipment.

• Wait until equipment/fluid has cooled completely.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

4 3A0019J

Page 5

Isocyanate Conditions

Isocyanate Conditions

Spraying materials containing isocyanates creates

potentially harmful mists, vapors, and atomized particulates.

Read material manufacturer’s warnings and material

MSDS to know specific hazards and precautions

related to isocyanates.

Prevent inhalation of isocyanate mists, vapors, and

atomized particulates by providing sufficient ventilation in the work area. If sufficient ventilation is not

available, a supplied-air respirator is required for

everyone in the work area.

To prevent contact with isocyanates, appropriate personal protective equipment, including chemically

impermeable gloves, boots, aprons, and goggles, is

also required for everyone in the work area.

Material Self-ignition

To prevent exposing ISO to moisture:

• Always use a sealed container with a desiccant

dryer in the vent, or a nitrogen atmosphere. Never

store ISO in an open container.

• Keep the ISO lube pump reservoir (if installed) filled

with Graco Throat Seal Liquid (TSL

The lubricant creates a barrier between the ISO and

the atmosphere.

• Use moisture-proof hoses specifically designed for

ISO, such as those supplied with your system.

• Never use reclaimed solvents, which may contain

moisture. Always keep solvent containers closed

when not in use.

• Never use solvent on one side if it has been contaminated from the other side.

• Always lubricate threaded parts with ISO pump oil

or grease when reassembling.

™

), Part 206995.

Keep Components A and B Separate

Some materials may become self-igniting if applied

too thickly. Read material manufacturer’s warnings

and material MSDS.

Moisture Sensitivity of Isocyanates

Isocyanates (ISO) are catalysts used in two component

foam and polyurea coatings. ISO will react with moisture

(such as humidity) to form small, hard, abrasive crystals,

which become suspended in the fluid. Eventually a film

will form on the surface and the ISO will begin to gel,

increasing in viscosity. If used, this partially cured ISO

will reduce performance and the life of all wetted parts.

NOTE: The amount of film formation and rate of

crystallization varies depending on the blend of ISO,

the humidity, and the temperature.

NOTICE

To prevent cross-contamination of the equipment’s

wetted parts, never interchange component A (isocyanate) and component B (resin) parts.

Foam Resins with 245 fa Blowing Agents

Some foam blowing agents will froth at temperatures

above 90°F (33°C) when not under pressure, especially

if agitated. To reduce frothing, minimize preheating in a

circulation system.

Changing Materials

• When changing materials, flush the equipment multiple times to ensure it is thoroughly clean.

• Always clean the fluid inlet strainers after flushing.

• Check with your material manufacturer for chemical

compatibility.

• Most materials use ISO on the A side, but some use

ISO on the B side.

• Epoxies often have amines on the B (hardener)

side. Polyureas often have amines on the B (resin)

side.

3A0019J 5

Page 6

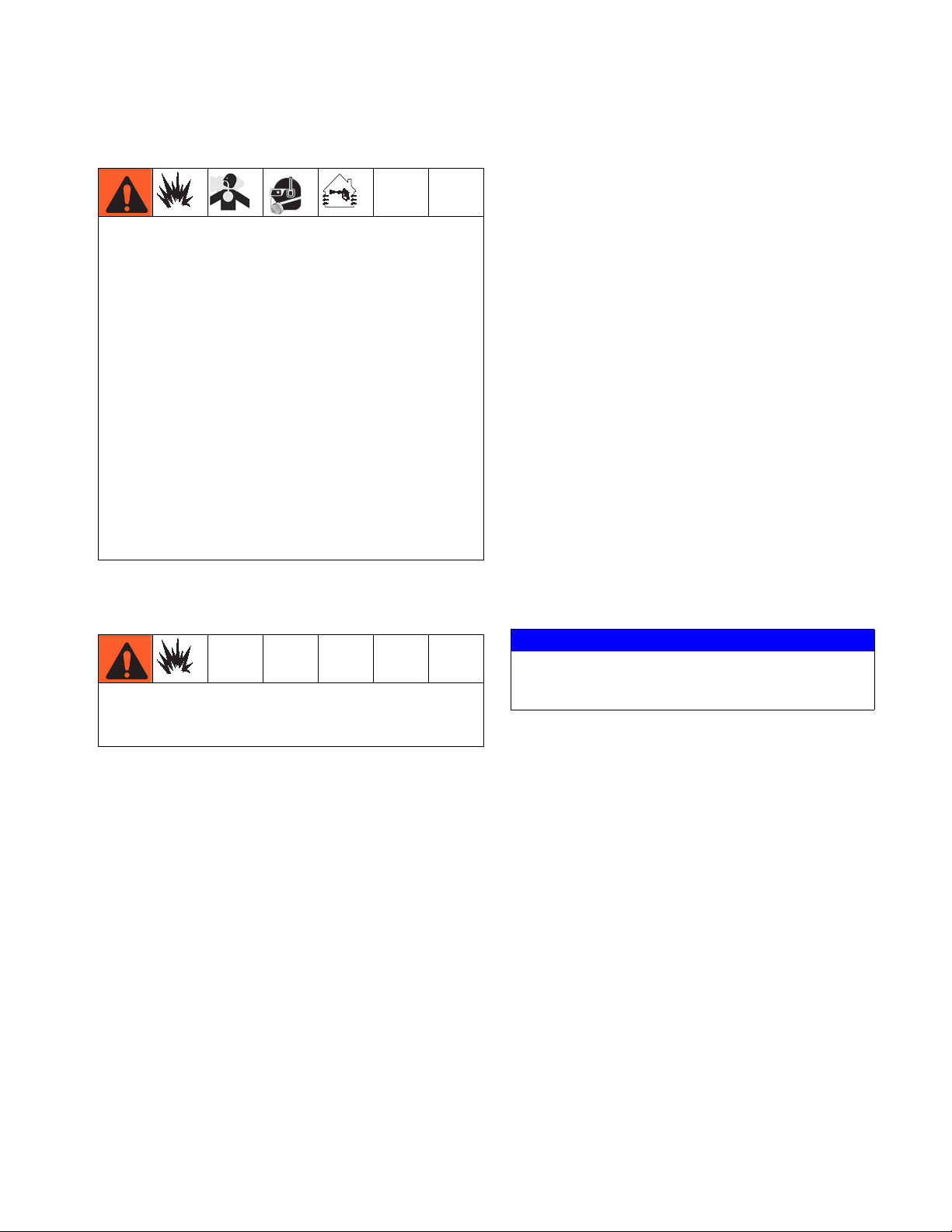

Component Identification

Component Identification

40cc pump shown

K

TU

S

F

HJ

Outlet Housing (D)

N

M

D

A

FIG. 1: Component Identification

Key:

A Displacement Rod (inside main cylinder)

B Throat Retainer

C Throat Cartridge

D Outlet Housing

E Main Cylinder

F Crossover Tube

GTie Bolt

H Inlet Housing

JInlet Cap

K Fluid Outlet

L Fluid Inlet (bottom of inlet housing)

M Pump Mounting Holes

N Pressure Transducer Port

P Linear Transducer Mounting Hole

R Identification Tag

S Rod Adapter (not on all models)

T Pump Coupler

U Coupler Cover

r_257891_3a0019_2h

R

E

G

L

P

C

r_257891_3a0019_3h

B

6 3A0019J

Page 7

Pressure Relief Procedure

Pressure Relief

Procedure

Trapped air can cause the pump to cycle unexpectedly, which could result in serious injury from splashing or moving parts.

1. Select Park on Pump Control Switch if available, or

turn off.

2. Turn off feed pumps.

3. Trigger gun to relieve pressure.

4. Close gun inlet valves.

5. Close fluid supply inlet valves.

6. Open all fluid drain valves in the system, having a

waste container ready to catch drainage. Leave

drain valve(s) open until you are ready to spray

again.

Flushing

Flush equipment only in a well-ventilated area. Do not

spray flammable fluids. Do not turn on heaters while

flushing with flammable solvents.

• Flush with a fluid that is compatible with the fluid

being dispensed and the equipment wetted parts.

• Flush out old fluid with new fluid, or flush out old

fluid with a compatible solvent before introducing

new fluid.

• Use lowest possible pressure when flushing.

7. If you suspect the spray tip or hose is clogged or

that pressure has not been fully relieved after following the steps above, VERY SLOWLY loosen tip

guard retaining nut or hose end coupling to relieve

pressure gradually, then loosen completely. Clear

hose or tip obstruction.

3A0019J 7

Page 8

Repair

Repair

Required Tools

• Large vise

• Set of adjustable wrenches

• O-ring pick

• 1/2 in. bit socket

• Rubber mallet

• Torque wrench

• 2 in. and 3 in. sockets

• Anti-seize lubricant

• Removable strength thread locker

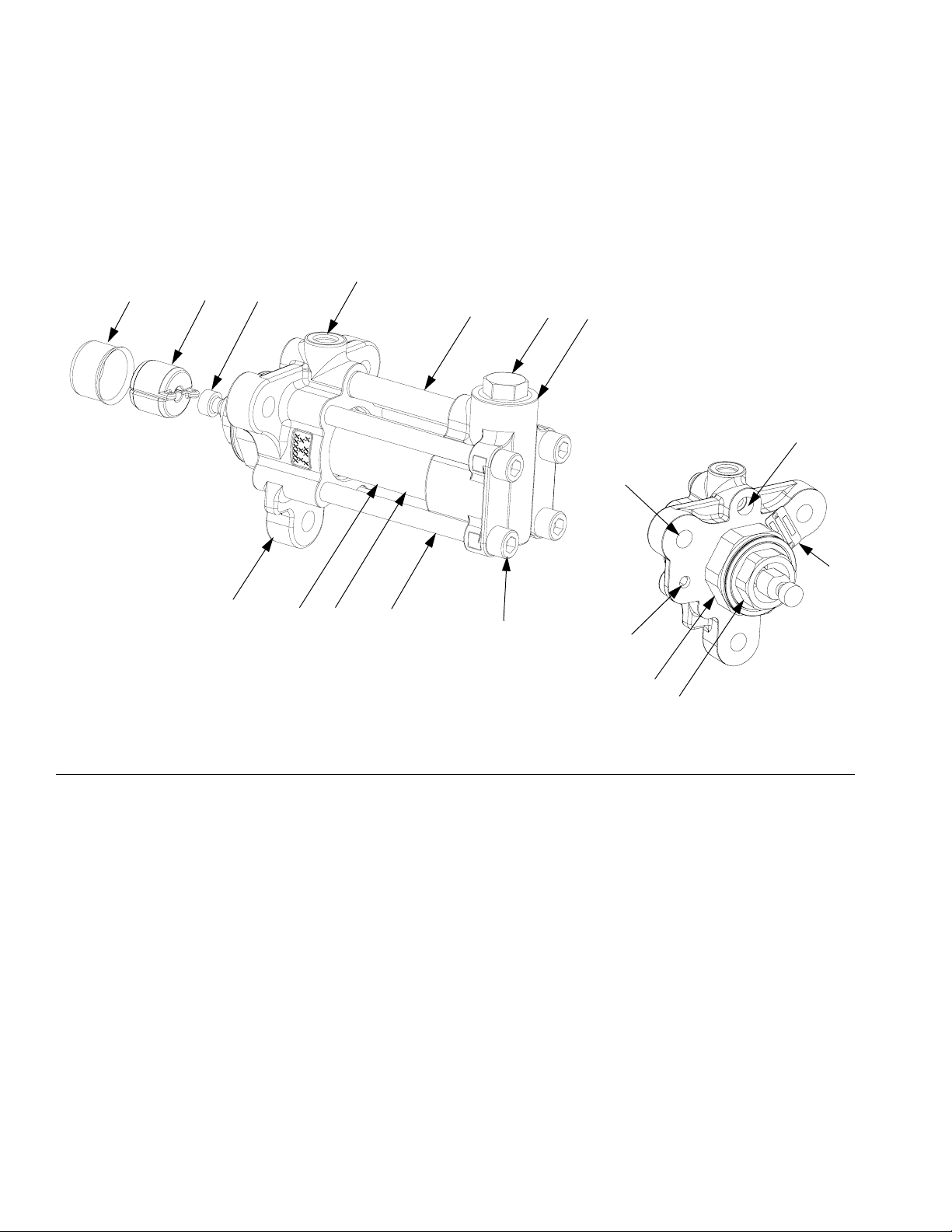

Inlet Housing Disassembly

1. Relieve pressure and flush system. See Pressure

Relief Procedure and Flushing, page 7.

2. Remove inlet hose and drain inlet housing (7).

13

a. Remove upper ball cage (12), spring (11), ball

(10), o-ring (8) and seat (9).

b. Press lower ball (10) off seat (9) from fluid inlet

and drain the inlet housing (7).

c. Remove o-ring (8), lower ball cage (12), spring

(11), ball (10), seat (9), and o-ring (8).

11

10

8

9

6

12

8

12

11

10

9

8

8

6

r_257891_3a0019_4h

3. Remove inlet cap (13) from inlet housing (6), and

remove o-ring (8).

r_257891_3a0019_5h

d. Clean all parts in a compatible solvent. Lay

them in order for easier reassembly. Inspect

each ball and seat for nicks or scratches;

replace as required.

Inlet Housing Assembly

1. Install inlet housing components in inlet housing (6).

2. Install o-ring (8) on inlet cap (13) and apply

anti-seize lubricant to inlet cap (13) threads. Fully

tighten inlet cap (13) with a wrench.

8 3A0019J

Page 9

Repair

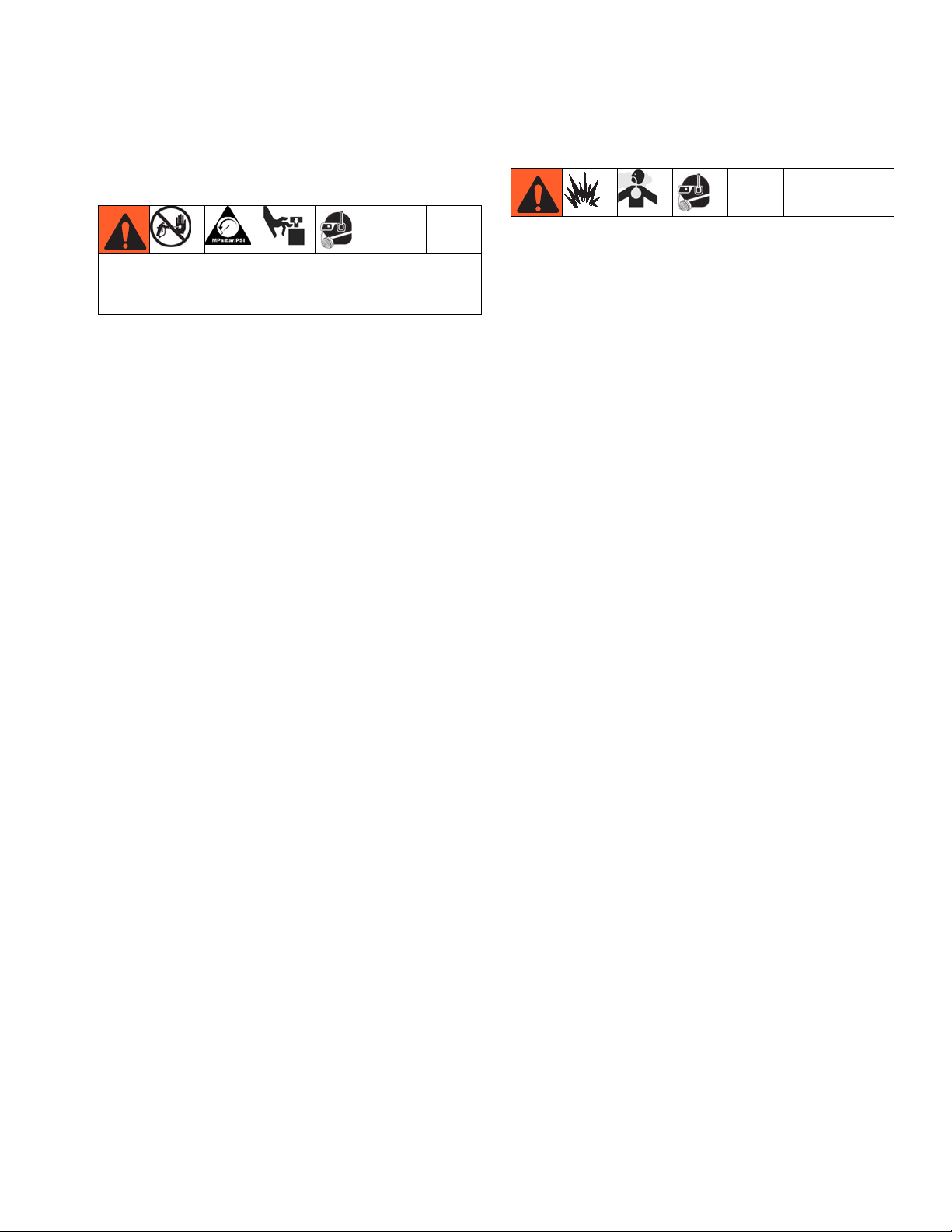

Pump Disassembly

1. Relieve pressure and flush system. See Pressure

Relief Procedure and Flushing, page 7.

2. Remove inlet hose and drain inlet housing (7).

3. Horizontally clamp pump on outlet housing (7) in

vise, use 1/2 in. hex bit socket to loosen all four tie

bolts (5) from inlet housing (6).

clamp here

21

4. For 40cc and 50cc pumps only: Use wrench to

remove rod adapter (21).

5. Remove pump assembly from vise and lay on a flat

surface with towels or in catch pan.

clamp here

6

5

7

r_257891_3a0019_6h

7. Remove inlet housing (6) from main cylinder (3).

Remove crossover tube (4) and o-rings (2).

2

4

6

2

21

15

3

r_257891_3a0019_7h

8. Pull main cylinder (3) and displacement rod (15)

away from outlet housing (7).

NOTICE

Be careful not to scratch the displacement rod (15);

place it on a smooth working surface. Damage to the

displacement rod will shorten pump life.

9. Remove displacement rod (15) from cylinder (3).

3

6. Fully unthread and remove tie bolts (5).

5

6

r_257891_3a0019_30h

15

r_257891_3a0019_8h

10. Remove two o-rings (1) from main cylinder (3).

1

1

3

r_257891_3a0019_9h

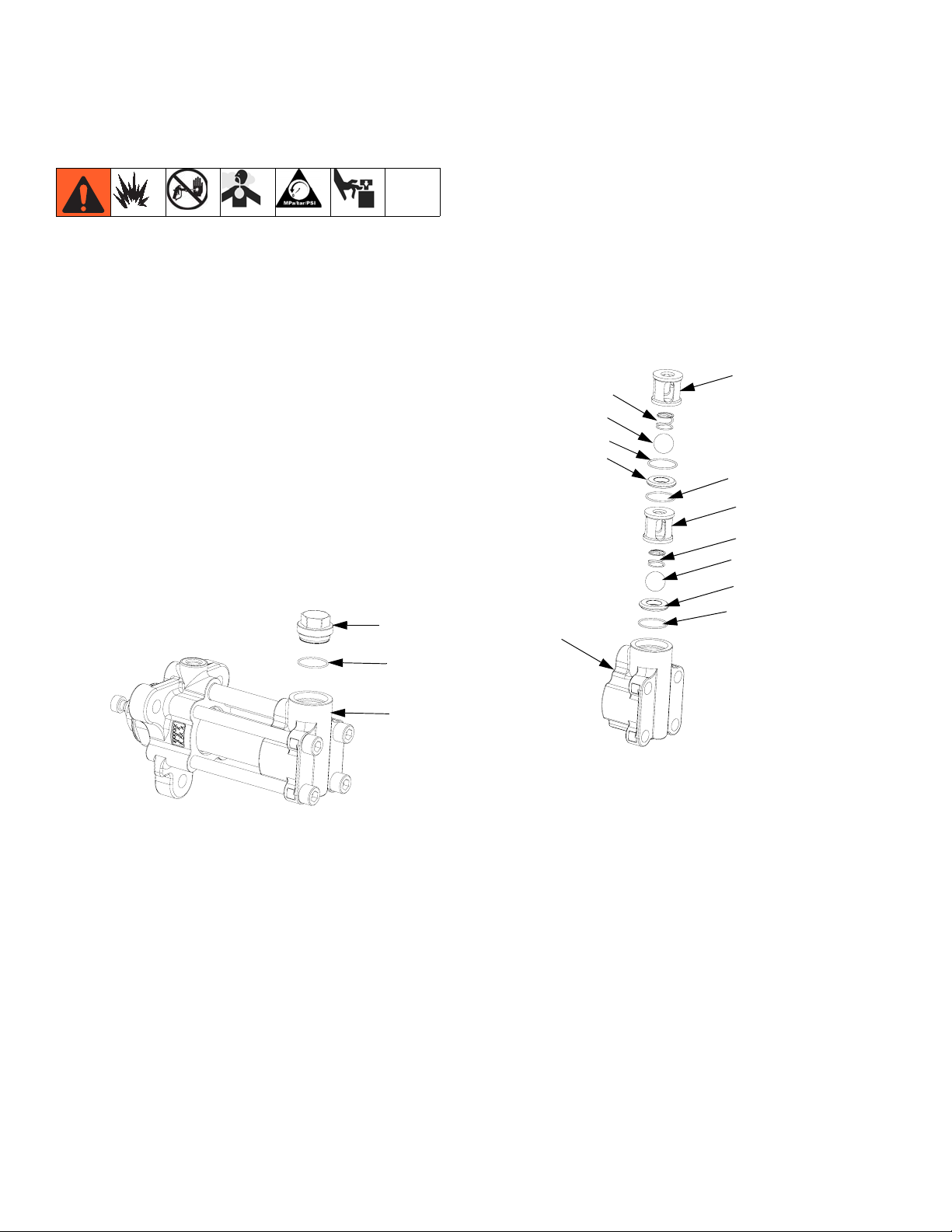

11. Place outlet housing (7) in vise so throat cartridge

(18) is facing up.

3A0019J 9

Page 10

Repair

12. Remove throat retainer (19).

16 or 25

19

17 or 26

7

18

20

r_257891_3a0019_10h

13. Use screwdriver and carefully press bearing (16 or

25) and u-cup (17 or 26) out of outlet housing (7).

NOTICE

To prevent damage to seals, carefully press seals

with a screwdriver.

14. If o-ring (20) is leaking, remove throat cartridge (18)

and o-ring (20).

15. Clamp flats on seal end of displacement rod (15) in

vise. Remove piston retainer (14), bearing (16), and

u-cup (17).

For 5cc, 10cc, and 15cc pumps

17

16

14

15

For 20cc-50cc pumps

17

16

14

15

For 60cc-160cc pumps

17

16

14

15

16. Thoroughly clean all metal parts in a compatible solvent.

10 3A0019J

Page 11

Repair

Pump Assembly

NOTICE

To prevent cross-contamination of the equipment’s

wetted parts, never interchange component A (isocyanate) and component B (resin) parts.

NOTICE

To prevent damage to seals always use piston

assembly tool (PT) and rod installation tool (RT) from

repair kit when assembling the piston seals and displacement rod.

NOTE: Piston assembly tool is NOT needed for

10cc-15cc pump sizes.

1. Install piston seal installation tool (PT) from pump

repair kit on displacement rod (15). Hand tighten.

2. Apply grease to seal and bearing surface of displacement rod (15).

3. Install u-cup (17) and bearing (16). Ensure u-cup

springs face displacement rod. Remove piston seal

installation tool (PT).

4. For 20cc-50cc pumps: Apply one stripe of removable strength thread locker to displacement rod (15)

male threads and install piston retainer (14).

NOTICE

Specification sheets and Graco testing indicate that

anaerobic sealant requires three days to fully cure.

Failure to allow three days for full cure may result in

parts coming loose during operation. If faster cure

time is needed, Rapid Sealant Cure Kit is available,

24N985.

17

16

15

PT

14

5. For 5cc, 10cc, 15cc, and 60cc-160cc pumps: Apply

one stripe of removable strength thread locker to

piston retainer (14) threads and assemble.

NOTICE

Specification sheets and Graco testing indicate that

anaerobic sealant requires three days to fully cure.

Failure to allow three days for full cure may result in

parts coming loose during operation. If faster cure

time is needed, Rapid Sealant Cure Kit is available,

24N985.

5cc, 10cc, and 15cc pumps

17

16

14

15

60cc-160cc pumps

16

14

15

PT

17

NOTICE

To prevent displacement rod damage, do not clamp

directly onto displacement rod surface.

6. Clamp flats on seal end of displacement rod (15) in

vise. See Torque Specification table for piston

retainer (14) torque according to pump size.

Pump Size Torque

5cc 38 in-lbs (3.2 ft-lbs) (4.3 N•m)

10cc 5.5 ft-lbs (7.4 N•m)

15cc 5.5 ft-lbs (7.4 N•m)

20cc 30 ft-lbs (40.6 N•m)

25cc 30 ft-lbs (40.6 N•m)

30cc 30 ft-lbs (40.6 N•m)

40cc 50 ft-lbs (67.5 N•m)

50cc 50 ft-lbs (67.5 N•m)

60cc 80 ft-lbs (108 N•m)

65cc 80 ft-lbs (108 N•m)

75cc 80 ft-lbs (108 N•m)

80cc 80 ft-lbs (108 N•m)

86cc 80 ft-lbs (108 N•m)

100cc 160 ft-lbs (216 N•m)

120cc 160 ft-lbs (216 N•m)

160cc 160 ft-lbs (216 N•m)

3A0019J 11

Page 12

Repair

7. If the throat cartridge (18) was removed, install

o-ring (20) on throat cartridge (18) and lubricate

with grease. Apply anti-seize lubricant to throat cartridge (18) threads and install in outlet housing (7).

Fully tighten throat cartridge (18) with a wrench.

8. Apply grease to u-cup (17 or 26) and set in throat

cartridge (18); ensure u-cup springs face throat cartridge. Set bearing (16 or 25) on top of u-cup (17 or

26).

19

15

16 or 25

17 or 26

7

RT

18

20

r_257891_3a0019_10h

2

4

2

1

1

3

r_257891_3a0019_15h

16. Install main cylinder (3) and crossover tube (4) in

outlet housing (7) with a rubber mallet.

4

3

7

9. Apply anti-seize lubricant to throat retainer (19)

threads and place on throat cartridge (18) above

bearing (16 or 25).

NOTE: Do not thread retainer(19) into throat cartridge (18).

10. Install rod installation tool (RT) on displacement rod

(15). Insert the displacement rod (15) through the

throat retainer (19), bearing (16 or 25), and u-cup

(17 or 26).

NOTE: The displacement rod (15) guides the bearing

(16 or 25) and u-cup (17 or 26) into the throat cartridge bore (18).

11. By hand, thread throat retainer (19) into throat cartridge (18) to gradually press bearing (16 or 25) and

u-cup (17 or 26) into bore.

12. When fully engaged, torque throat retainer (19) to

50 ft-lbs (67.5 N•m).

13. Remove displacement rod (15).

14. Clamp throat cartridge (18) in vise with outlet housing (7) facing up.

r_257891_3a0019_16h

17. Lubricate piston u-cup seal (17), and bearing (16)

with grease.

18. For 60cc-160cc pumps: Apply grease to coupler end

of displacement rod (15) before installing the rod

installation tool (RT).

NOTE: The grease will hold the rod installation tool

(RT) in place while assembling the displacement rod

into the cylinder.

19. Install rod installation tool (RT) on displacement rod

(15).

15. Install o-rings (1) on main cylinder (3) and o-rings

(2) on crossover tube (4). Lubricate o-rings (1, 2)

with grease.

12 3A0019J

Page 13

Repair

20. Install displacement rod (15) in main cylinder (3)

and throat cartridge (18). Gently tap displacement

rod with a rubber mallet until piston is flush or below

the surface of the main cylinder.

16

17

15

18

RT

r_257891_3a0019_17h

23. Lubricate tie bolt (5) threads and install. Tighten tie

bolts evenly in a star pattern until they are flush with

the inlet housing (6).

24. Tighten tie bolts (5) evenly in a star pattern to the

outlet housing (7). Ensure the inlet housing is evenly

seated onto the main cylinder (3) and crossover

tube (4). Torque tie bolts (5) evenly to 50-200 ft-lbs

(60-270 N•m), all to the same torque value.

3

25. For 10cc-50cc pumps only: Clean rod adapter (21)

threads with a wire brush and apply removable

strength thread locker to displacement rod (15)

threads. Install rod adapter (21) on displacement

rod (15). See Torque Specification table for rod

adapter (21) torque according to pump size.

Pump Size Torque

5cc 38 in-lbs (3.2 ft-lbs) (4.3 N•m)

10cc 8.5 ft-lbs (11.5 N•m)

15cc 8.5 ft-lbs (11.5 N•m)

20cc 30 ft-lbs (40.6 N•m)

25cc 30 ft-lbs (40.6 N•m)

30cc 30 ft-lbs (40.6 N•m)

40cc 45 ft-lbs (60.75 N•m)

50cc 45 ft-lbs (60.75 N•m)

21. Remove rod installation tool (RT).

22. Gently place inlet housing (6) on main cylinder (3)

and crossover tube (4).

NOTICE

To prevent damage to o-rings, do not press inlet

housing down on main cylinder and crossover tube.

6

5

4

3

15

21

r_257891_3a0019_19h

3A0019J 13

Page 14

Parts

Parts

5cc, 10cc, and 15cc Pumps

35

34

21

4

19

3

9

33

26

25

10

8

18

6

9

13

96

8

12

20

11

10

8

9

2

4

2

2

8

12

11

10

9

2

8

1

3

7

1

15

17

12

11

1. Lubricate seals, o-rings, lead-in’s and moving parts with

grease.

2

Apply one stripe of removable strength anaerobic sealant on

threads.

NOTICE

Specification sheets and Graco testing indicate that anaerobic sealant requires three days to fully cure. Failure to

allow three days for full cure may result in parts coming

loose during operation.

If faster cure time is needed,

Rapid Sealant Cure Kit is available, 24N985.

3

Torque to 50-ft-lbs (67.5 N•m).

4

Assemble and torque after displacement rod (15) is assembled

through throat retainer (19). See table on page 13 for torque

specification.

12

16

14

7

6

r_257886_3a0019_1d

5

5

5

Torque evenly to 50-200 ft-lbs (60-270 N•m), all to the same

torque value.

6

Fully tighten with a wrench.

7

See table on page 11 for torque specification.

8

Must be pressed straight into housing.

9

Apply anti-seize lubricant to threads.

10

Ensure u-cup (26) springs face throat cartridge (18).

11

Ensure u-cup (17) springs face displacement rod (15).

12

Fully assemble seal (17) and bearing (16) onto displacement

rod (15) before tightening piston retainer (14).

14 3A0019J

Page 15

20cc, 25cc, 30cc, 40cc, and 50cc Pumps

35

34

19

3

9

33

25

26

Parts

6

9

10

8

13

96

18

20

4

21

25

11

10

8

8

12

9

2

4

2

2

2

8

12

11

10

9

8

1

7

3

1

15

17

12

11

16

12

14

7

6

5

5

r_257891_3a0019_20h

1. Lubricate seals, o-rings, lead-in’s and moving parts with

grease.

2

Apply one stripe of removable strength anaerobic sealant on

threads.

NOTICE

Specification sheets and Graco testing indicate that anaerobic sealant requires three days to fully cure. Failure to

allow three days for full cure may result in parts coming

loose during operation.

If faster cure time is needed,

Rapid Sealant Cure Kit is available, 24N985.

3

Torque to 50-ft-lbs (67.5 N•m).

4

Assemble and torque after displacement rod (15) is assembled

through throat retainer (19). See table on page 13 for torque

specification.

5

Torque evenly to 50-200 ft-lbs (60-270 N•m), all to the same

torque value.

6

Fully tighten with a wrench.

7

See table on page 11 for torque specification.

8

Must be pressed straight into housing.

9

Apply anti-seize lubricant to threads.

10

Ensure u-cup (26) springs face throat cartridge (18).

11

Ensure u-cup (17) springs face displacement rod (15).

12

Fully assemble seal (17) and bearing (16) onto displacement

rod (15) before tightening piston retainer (14).

3A0019J 15

Page 16

Parts

60cc, 65cc, 75cc, 80cc, 86cc, 100cc, 120cc, and 160cc Pumps

35

34

19

3

9

17

16

10

8

18

96

20

6

9

13

8

11

12

10

8

9

2

4

2

8

12

11

10

9

8

1

7

3

1

15

17

12

11

12

16

2

1. Lubricate seals, o-rings, lead-in’s and moving parts with

grease.

2

Apply one stripe of removable strength anaerobic sealant on

threads.

NOTICE

Specification sheets and Graco testing indicate that anaerobic sealant requires three days to fully cure. Failure to

allow three days for full cure may result in parts coming

loose during operation.

If faster cure time is needed,

Rapid Sealant Cure Kit is available, 24N985.

3

Torque to 50-ft-lbs (67.5 N•m).

5

Torque evenly to 50-200 ft-lbs (60-270 N•m), all to the same

torque value.

14

7

6

Fully tighten with a wrench.

7

See table on page 11 for torque specification.

8

Must be pressed straight into housing.

9

Apply anti-seize lubricant to threads.

10

Ensure u-cup (17) springs face throat cartridge (18).

11

Ensure u-cup (17) springs face displacement rod (15).

12

Fully assemble seal (17) and bearing (16) onto displacement

rod (15) before tightening piston retainer (14).

6

5

5

r_257893_3a0019_21h

16 3A0019J

Page 17

Parts

Pump Parts

Ref. Part Description Qty.

1✓✿✠◆❄ O-RING, cylinder 2

2✓✿✠◆❄ O-RING, crossover tube 2

3✿ CYLINDER, pump 1

4✠ TUBE, crossover, pump 1

5 258790 BOLT, tie 4

6 258792 HOUSING, inlet 1

7 258791 HOUSING, outlet 1

8◆† O-RING, inlet 4

258775 KIT, package of 4 -

258776 KIT, package of 16 9† SEAT, carbide 2

10† BALL, sst 2

11 258784 SPRING, ball check 2

12 258785 HOUSING, ball cage 2

13 258787 CAP, inlet valve 1

14*❄ RETAINER, piston 1

15❄ ROD, displacement 1

16◆❄ BEARING, piston 1(2)

17◆❄ SEAL, piston 1(2)

18★ CARTRIDGE, throat 1

19✖ RETAINER, throat 1

20★❄ 117286 O-RING, throat cartridge 1

21❄ 258786 ADAPTER, rod; 40cc and

50cc

258966 ADAPTER, rod; 10cc and

15cc

258967 ADAPTER, rod; 20cc-30cc 1

25◆❄ BEARING, throat 1

26◆❄ SEAL, throat 1

28 PLATE, identification 1

29 SCREW, drive 2

33‡ SPACER, throat; 10cc-30cc

only

34❖ 247167 COUPLER, pump;

10cc-80cc

244819 COUPLER, pump;

100cc-160cc

35 197340 COVER, coupler 1

✓ Refer to Table 1: Cylinder O-ring Kits for kit number.

✿ Refer to Table 2: Cylinder Kits for kit number.

✠ Refer to Table 3: Crossover Tube Kits for kit number.

★ Refer to Table 4: Throat Cartridge Kits for kit number.

✖ Refer to Table 5: Throat Retainer Kits for kit number.

* Refer to Table 6: Piston Retainer Kits for kit number.

◆ Refer to Table 7: Seal Kits for kit number.

❄ Refer to Table 8: Displacement Rod Kits for kit num-

ber.

‡ Refer to Table 9: Throat Spacer Kits for kit number.

† Included in Kit 258783.

❖ Clip coupler cable before installing on to proportioner

pumpline.

1

1

1

1

1

3A0019J 17

Page 18

Parts

Table 1: Cylinder O-ring Kits

Pump Size Cylinder O-ring Kit

5cc

10cc

15cc

20cc

25cc

30cc

40cc

50cc

60cc

65cc

75cc

80cc

86cc

100cc

120cc

160cc

258774

258773

Table 2: Cylinder Kits

Pump Size Cylinder Kit

Table 3: Crossover Tube Kits

Pump Size Bar Stock Inlet* Cast inlet*

5cc

10cc

15cc

20cc

25cc

30cc

40cc

50cc

60cc

65cc

75cc

80cc

86cc

100cc

160cc

*See figure below for inlet types

Bar Stock Inlet Cast Inlet

258789 24E557

258788 24E556120cc

5cc 262557

10cc 258925

15cc 258931

20cc 258937

25cc 258943

30cc 258949

40cc 258795

50cc 258801

60cc 258807

65cc 24H998

75cc 24N821

80cc 258813

86cc 24H999

100cc 258819

120cc 258825

160cc 258831

18 3A0019J

Page 19

Parts

Table 4: Throat Cartridge Kits

Pump Size Throat Cartridge Kit

5cc 262558

10cc 258928

15cc 258934

20cc 258940

25cc 258946

30cc 258952

40cc 258798

50cc 258804

60cc 258810

65cc 24J007

75cc 24N819

80cc 258816

86cc 24J008

100cc 258822

120cc 258828

160cc 258834

Table 6: Piston Retainer Kits

Pump Size Piston Retainer Kit

5cc 262560

10cc 258926

15cc 258932

20cc 258938

25cc 258944

30cc 258950

40cc 258796

50cc 258802

60cc 258808

65cc 24J012

75cc 24N822

80cc 258814

86cc 24J013

100cc 258820

120cc 258826

160cc 258832

Table 5: Throat Retainer Kits

Pump Size Throat Retainer Kit

5cc 262559

10cc 258927

15cc 258933

20cc 258939

25cc 258945

30cc 258951

40cc 258797

50cc 258803

60cc 258809

65cc 24J010

75cc 24N818

80cc 258815

86cc 24J011

100cc 258821

120cc 258827

160cc 258833

3A0019J 19

Page 20

Parts

Seal Kits

5cc-30cc Throat Seals

40cc-160cc Throat Seals

Piston Seals

33

25

26

25

26

17

16

Table 7: Seal Kits

Reference Number and Quantity Included in Kit

Pump Size Seal Kit 1 2 8 16 17 25 26

5cc

10cc

15cc

20cc

25cc

30cc

40cc

50cc

60cc

65cc

75cc

80cc

86cc

262561 2241111

258923 2241111

258929 2241111

258935 2241111

258941 2241111

258947 2241111

258793 2241111

258799 2241111

258805 22422

24J00222422

24N82022422

258811 22422

24J00322422

100cc

120cc

160cc

20 3A0019J

258817 22422

258823 22422

258829 22422

Page 21

Displacement Rod Kits

16

17

15

60cc Displacement Rod Shown

16

17

14

Parts

40cc Displacement Rod Shown

16

33

25

26

25

26

15

10cc Displacement Rod Shown

16

14

17

17

14

3A0019J 21

Page 22

Parts

Table 8: Displacement Rod Kits

Reference Number and Quantity Included in Kit

Pump Size

5cc

10cc

15cc

20cc

25cc

30cc

40cc

50cc

60cc

65cc

75cc

80cc

86cc

100cc

Displacement

Rod Kit

262562 2 2 1 1 1 1 1 1 1 1

258924 2 2 1 1 1 1 1 1 1 1

258930 2 2 1 1 1 1 1 1 1 1

258936 2 2 1 1 1 1 1 1 1 1

258942 2 2 1 1 1 1 1 1 1 1

258948 2 2 1 1 1 1 1 1 1 1

258794 2 2 1 1 1 1 1 1 1 1

258800 2 2 1 1 1 1 1 1 1 1

258806 2 2 1 1 2 2 1

24J004 2211221

24N823 2211221

258812 2 2 1 1 2 2 1

24J005 2211221

258818 2 2 1 1 2 2 1

1 2 14 15 16 17 20 21 25 26

120cc

160cc

258824 2 2 1 1 2 2 1

258830 2 2 1 1 2 2 1

Table 9: Throat Spacer Kits

Pump Size Throat Spacer Kit

5cc

10cc

15cc

20cc

25cc

30cc

16E364

16D188

16D189

16D190

16D191

16D192

22 3A0019J

Page 23

Dimensions

All pump sizes have the same dimensions.

C

Dimensions

A

A

(Length)

in. (mm)

13.36 (339.34) 3/4-14 3/4-16

B

(Inlet)

in. npt (f)

C

(Outlet)

SAE (f)

r_257891_3a0019_22h

B

3A0019J 23

Page 24

Outlet Housing Mounting Hole Layout

Outlet Housing Mounting Hole Layout

All pumps have the same outlet housing mounting hole layout.

5.9 in (150 mm)

r_257891_3a0019_23h

24 3A0019J

Page 25

Technical Data

Technical Data

Maximum working pressure . . . . . . . . . . . . . . . . . . . . . . . 3500 psi (24MPa, 241 bar)

Maximum operating temperature . . . . . . . . . . . . . . . . . . . 180° F (82° C)

Maximum cycle rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65 cycles per minute

Minimum feed pressure at inlet . . . . . . . . . . . . . . . . . . . . 50 psi (0.35 MPa, 3.5 bar)

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 lbs (13.6 kg)

Wetted parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SST, tungsten carbide, acetal, PTFE, UHMWPE

3A0019J 25

Page 26

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Toll Free: 1-800-746-1334 Fax: 330-966-3006

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2009, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 3A0019

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised July 2012

Loading...

Loading...