Page 1

Instructions

24H372

3A0006D

ACS Module

Advanced Motor Control System for Graco E-Flo® Electric Circulation Pumps. See page 4

for Required System Components. For professional use only.

Not approved for use in explosive atmospheres or hazardous locations.

Important Safety Instructions

Read all warnings and instructions in this manual

and in your E-Flo pump manuals. Save these

instructions.

EN

ti17553a

Page 2

Related Manuals

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Glossary of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Required System Components . . . . . . . . . . . . . . 4

Optional Components . . . . . . . . . . . . . . . . . . . . . 4

E-Flo Pump Operational Overview . . . . . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . 6

Indicators and Pushbutton . . . . . . . . . . . . . . . . . 6

Critical Item Checklist . . . . . . . . . . . . . . . . . . . . . 7

Schematic Diagrams . . . . . . . . . . . . . . . . . . . . . . 8

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Ground the ACS Control Module . . . . . . . . . . . 11

ACS Modbus Registers . . . . . . . . . . . . . . . . . . . 12

ACS Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . 16

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Set up a Static IP Address for the Computer . . . 17

ACS System Status Screen . . . . . . . . . . . . . . . . 21

Run Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Configuration Screen . . . . . . . . . . . . . . . . . . . . . 24

Alarms Screen . . . . . . . . . . . . . . . . . . . . . . . . . . 31

ACS Software Update . . . . . . . . . . . . . . . . . . . . . . 32

ACS System Setup Checklist . . . . . . . . . . . . . . . . 39

ACS Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Drive Active (System ON) Output . . . . . . . . . . . 40

Back Pressure Regulator (BPR) Production/Sleep

Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Flow Rate Monitoring . . . . . . . . . . . . . . . . . . . . . 40

Operational Envelope Limit . . . . . . . . . . . . . . . . 40

Pressure Limits . . . . . . . . . . . . . . . . . . . . . . . . . 40

Diagnostic Procedures . . . . . . . . . . . . . . . . . . . . . 41

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 44

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 44

Related Manuals

Manual Description

311592 E-Flo Installation Manual

311593 E-Flo Operation Manual

311594 E-Flo Repair-Parts Manual

311603 24J305 Sensor Circuit Option

311690 4-Ball Lowers with open wet-cup

3A0539 4-Ball Lowers with enclosed wet-cup

2 3A0006D

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual, refer back to these Warnings. Product-specific hazard symbols and

warnings not covered in this section may appear throughout the body of this manual where applicable.

WARNING

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause

electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

Glossary of Terms

Term Description

ACS Advanced Control System

VFD Variable Frequency Drive

TDC Top Dead Center; measures position of pump drive

I/O Input/output

PCB Printed Circuit Board

Run Set of commands enabling motor to run in designated direction

Stop Set of commands authorizing motor to stop running

3A0006D 3

Page 4

Overview

Overview

Required System Components

NOTE: The following components must be installed in

every ACS system.

24J305 Sensor Circuit Kit for E-Flo Pump

(Series D and later)

Verify that the 24J305 Sensor Circuit Kit is installed on

your E-Flo Pump. If the pump does not have the sensor

circuit, order Part No. 24J305. The kit contains the circuit board and TDC, position, and pressure sensors

necessary to utilize the Graco ACS module, taking

advantage of flow control and pressure control mode

delivered by Graco ACS software. See manual 311603.

For E-Flo Pumps Series C and earlier, check with

your local Graco Distributor for compatibility.

16D612 Power Module Assembly

Transforms AC power to a 24 Vdc power supply for the

pump sensor circuit. See manual 311608. This assembly includes the following required power supply and

barriers, which are also available separately:

121314 Power Supply (required)

24 Vdc, 2 A. DIN rail mount.

Optional Components

Optional ACS components can be ordered through your

Graco Distributor.

15V342 Ethernet Switch

Enables connection of ACS module to multiple network

components through an Ethernet.

TI15660a

Local I/O Box

120373 (UL/CSA)

120991 (ATEX)

Allows the operator to control the E-Flo locally at the

pump when performing maintenance or troubleshooting.

See page 12. Includes the following features:

• secure disable switch

• start/stop switch

• fault reset

TI15662a

16A630 TDC and Position Sensor Barrier

(2 channel) [required]

16A633 Transducer Barrier (1 channel) [required]

TI15663a

CAT5 Ethernet Cables

121994, 1 ft (0.305 m)

121998, 25 ft (7.6 m)

121999, 50 ft (15.2 m)

15V842, 100 ft (30.5 m)

15V843, 200 ft (61.0 m)

4 3A0006D

Page 5

Overview

E-Flo Pump Operational Overview

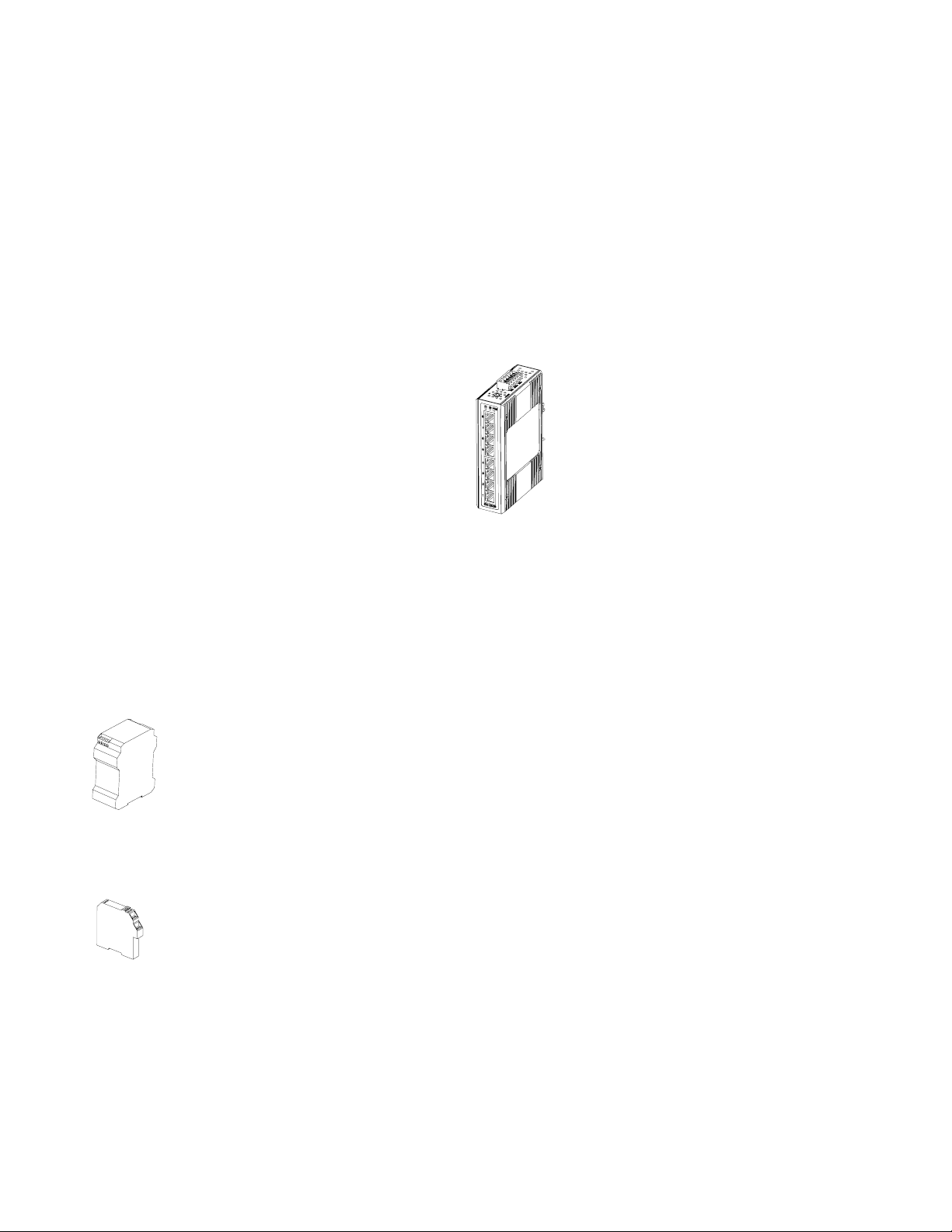

An electric motor (B) provides input to a 75:1 gear reducer (GR), which drives two fluid pumps (FP). See FIG. 1. The

stroke positions of the two pumps are offset to achieve consistent flow from the pump assembly. See F

The optional sensor circuit includes a top dead center (TDC) sensor to measure motor speed, a position sensor (PS)

to measure motor position, and a pressure transducer (PT) to measure fluid pressure at the pump outlet. The Graco

ACS control module software mimics the effect of a camshaft, constantly adjusting motor speed to keep steady fluid

flow and achieve minimal pressure variation. The output shaft of the gearbox and the connecting rods experience the

electrical control module simulating the function of a camshaft by speeding up when the pressure drops (pump lower

is at a changeover) and slowing down when pressure increases (both lowers are pumping).

The ACS module provides an analog drive signal to the VFD. Use one ACS module for each E-Flo pump. The ACS

module can be controlled by a local control box mounted in the hazardous area, or via communication protocol (such

as modbus).

IG

. 2.

B

TDC and

Position

Sensors

(behind

cover)

FP

F

IG

. 1. Electric Circulation Pump

GR

PT

FP

ti8317c

ti8321a

FIG. 2. Cutaway Showing Offset Stroke Positions

3A0006D 5

Page 6

Installation

Installation

All electrical wiring must be completed by a qualified

electrician and comply with all local codes and

regulations.

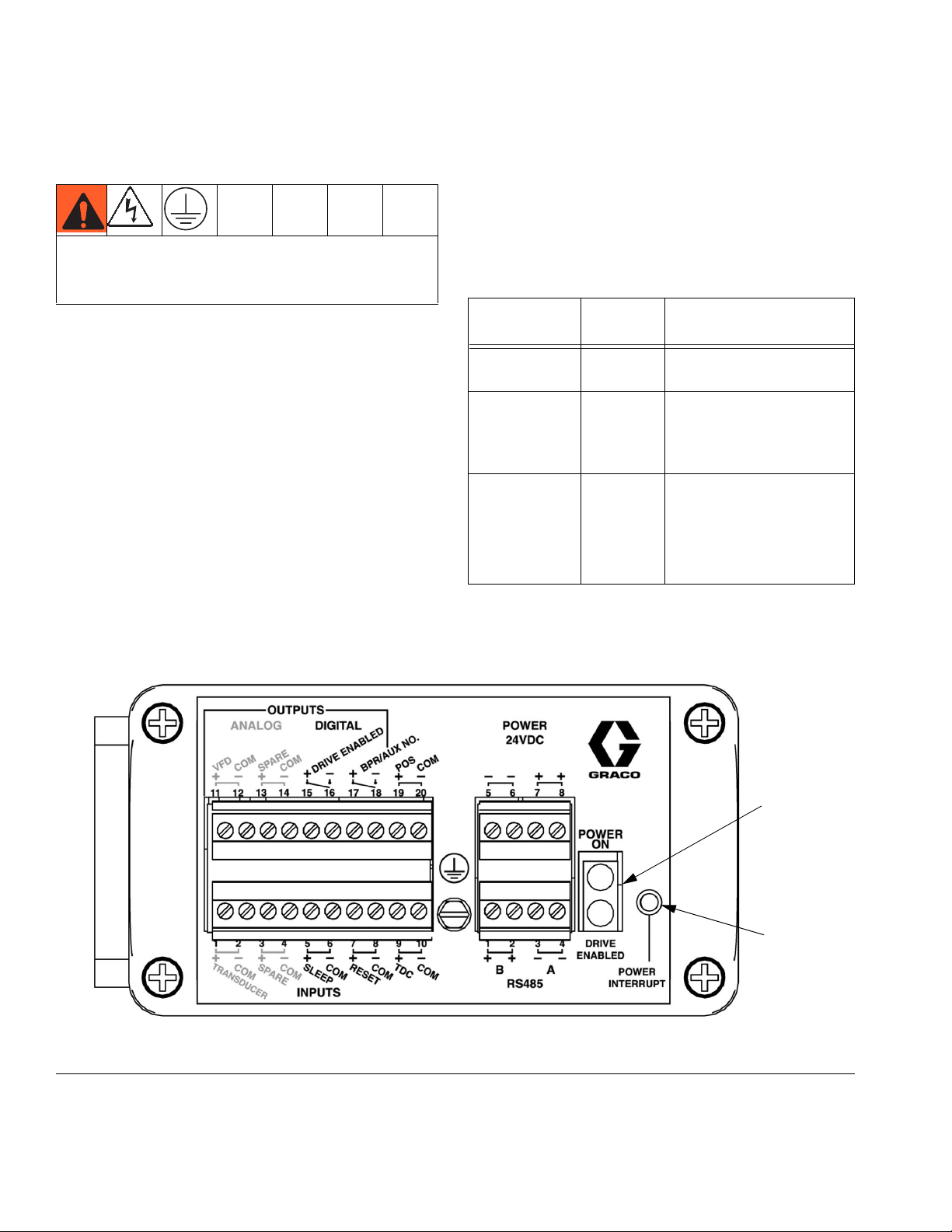

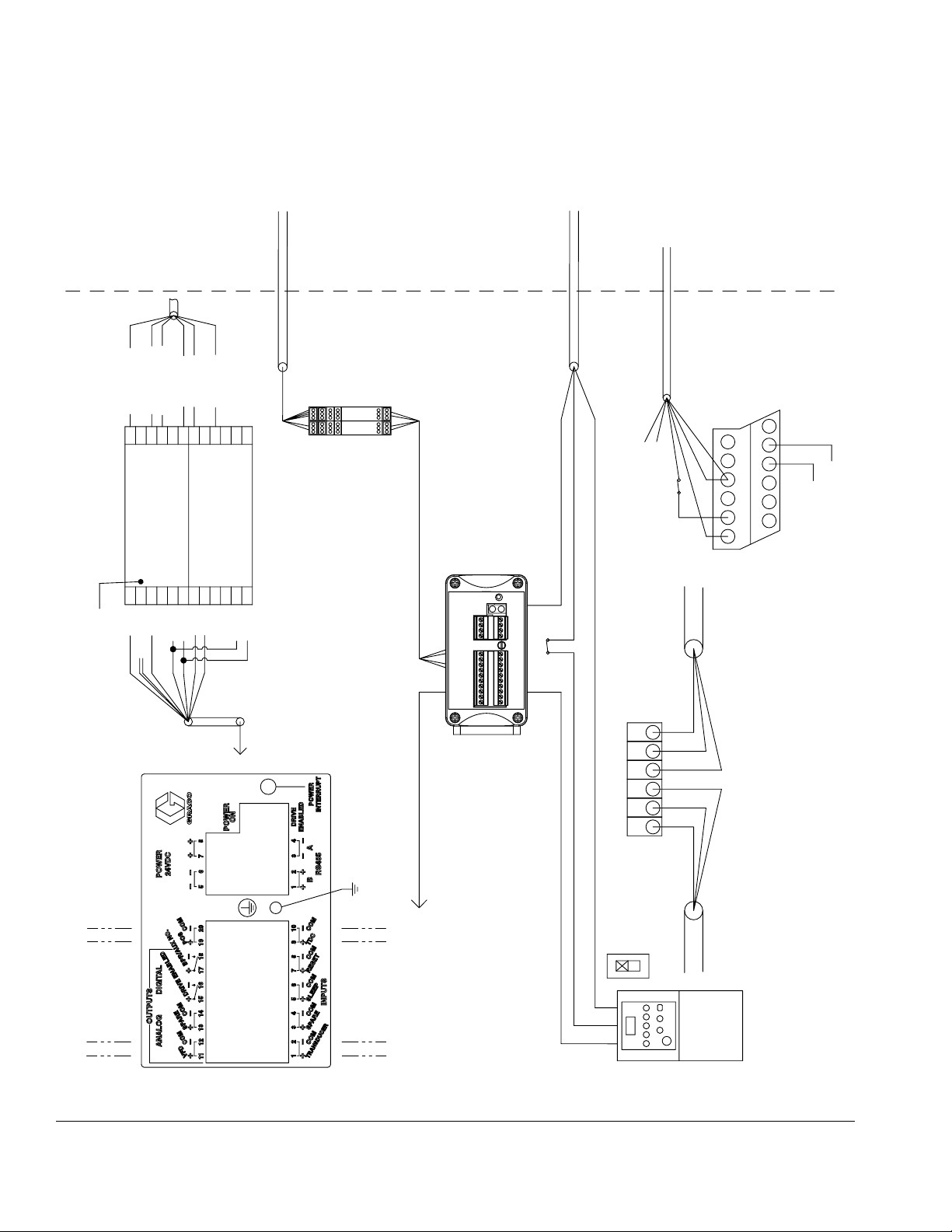

FIG. 3 shows the ACS panel. See FIG. 4, and FIG. 5 for

schematic diagrams showing wiring connection points of

all required and optional system components.

Indicators and Pushbutton

FIG. 3 shows the ACS Module indicators and POWER

INTERRUPT pushbutton. See also F

Table 1: ACS Module Indicators and Pushbutton

Indicator or

Button Color Condition

POWER ON

indicator

Solid

Green

IG

. 4 and FIG. 5.

The ACS is powered and

the pump is running.

See F

IG

. 6 for a detailed schematic of VFD, Barrier, and

Start/Stop connections.

Inputs and Outputs

FIG. 3 shows the ACS Module input and output terminal

block. See also F

Indicators, page 30.

IG

. 4, FIG. 5, and System Diagnostic

DRIVE

ENABLED

indicator

POWER

INTERRUPT

pushbutton

Solid

Red

n/a Press momentarily to

Turns on if the ACS is

sending an analog drive

command and the drive

enabled relay is closed.

interrupt power, for system reboot.

Power is restored when

released.

Indicators;

see Table

Power

Interrupt

Pushbutton;

see Table 1

FIG. 3. ACS Module Indicators and Input/Output Terminals

6 3A0006D

Page 7

Critical Item Checklist

Wire according to FIG. 4 on page 8 and FIG. 5 on

❑

page 9.

Use Belden 8777 cable or equivalent. It is impor-

❑

tant to use multiconductor cable with 3 individually shielded pairs.

Ferrite (15D906) must be installed on pressure

❑

transducer wires.

Do not place signal wires in the same conduit as

❑

AC Power wires. For example, the TDC/Position

sensor wires should not share a conduit with the

VFD wires.

Use the following VFD configuration settings:

❑

• analog input scaling

• 4 mA = 0 (zero) Hz

• 20mA = 80 Hz

• Acceleration rate = 1.0 second (for full

range 0-80 Hz)

• Deceleration rate = 0.5 second (for full

range)-80 Hz)

Installation

3A0006D 7

Page 8

Installation

Schematic Diagrams

POS - BLK

POS + WHT

TDC - J2 - 4 BLK

TDC + J2 - 3 GRN

12345612345

NON-HAZARDOUS

BARRIER

WIRING DETAIL

SENSOR BARRIER

TDC AND POSITION

ALL SWITCHES "ON"

(16A630)

POSITION / POSITION I

+ J3 - 1 RED

- J3 - 2 BLK

6

(16A633)

4-20ma BARRIER

PRESSURE TRANSDUCER

TDC AND POSITION

SENSOR BARRIER

4-20ma BARRIER

PRESSURE TRANSDUCER

ACS CONTROL HANDLES:

- TDC INPUT

- 4 TO 20ma PRESSURE FEEDBACK

(0 - 500 PSI)

- CALCULATES POSITION (DEG)

- DRIVE ANALOG OUT RELATIVE TO

REQUIRED SPEED PER DEGREE

B = SLEEP MODE INPUT FROM PLC

OR FROM COMMUNICATIONS/TOUCH

SCREEN

ALARM INTERUPT OF START/STOP INPUT

RESET TO +

ACS MODULE -

TO ACS SWITCH

01 STOP INPUT/

SECURE DISABLE

02 RUN/FWD

03 RUN/REV

04 COM

05 DIGITAL IN 1

02 04 05 060301

11 13 16151412

06 DIGITAL IN 2

11 +24VDC

12 +10VDC

13 0 - 10VDC IN

14 ANALOG COM

15 4-20ma IN

16 RS485 SHLD

ACS ANALOG VFD +

ACS ANALOG VFD -

7891314157891314

TDC+

POS+

TDC- / POS-

TERMINAL 8

2 WIRES ON

ACS MODULE

WIRING DETAIL

FROM 16A630

9

8

FROM VFD

14

15

24 VDC

COMMON

15

+

-

24 VDC

COMMON

ACS MODULE

8 CONDUCTOR CABLE

WITH SHIELD

BELDEN #9504 OR EQUIV.

RS485 COMS / 24VDC POWER

8

7

7

8

FROM 16A630

TO MULTIPLE ACS MODULES AND

FROM 16A633

OPTIONAL EITHERNET ROUTER/SWITCH

RESET

ALARM OUTPUT

(ACS RUNNING)

ANALOG DRIVE SIGNAL

SECURE

DISABLE

EXAMPLE:

ALLEN BRADLEY VFD

W/T3V/T2U/T1S/L2

LINE LOAD

R/L1 T/L3

I/O SWITCH

MUST BE IN

SNK POSITION

ENSURE

THERMISTOR

WIRES ARE

CONNECTED

FROM MOTOR

WIRING DETAIL

EFLO MOTOR

TERMINALS 01 AND 04 CONNECT TO THE SECURE DISABLE

SWITCH. (LIKE AN E-STOP BUT THIS DOES NOT

DISCONNECT POWER, JUST DISABLES THE VFD.) TERMINALS 02 IS FOR STOPPING AND STARTING THE PUMP.

02 OR 03 TO RUN THE PUMP IN A SPECIFIC DIRECTION.

THE REQUIRED MOTOR DIRCTION IS CCW WHEN LOOKING

AT FAN. TO CHANGE MOTOR DIRECTION, SWAP 3 PHASE

OUTPUT T1/T2 OR T2/T3 OR T3/T1.

3 PHASE AC IN

EXAMPLE:

ALLEN BRADLEY VFD

(22A-D8P7N104)

CONNECTION DETAILS

FIG. 4. System Schematic Diagram, Non-Hazardous Area

8 3A0006D

Page 9

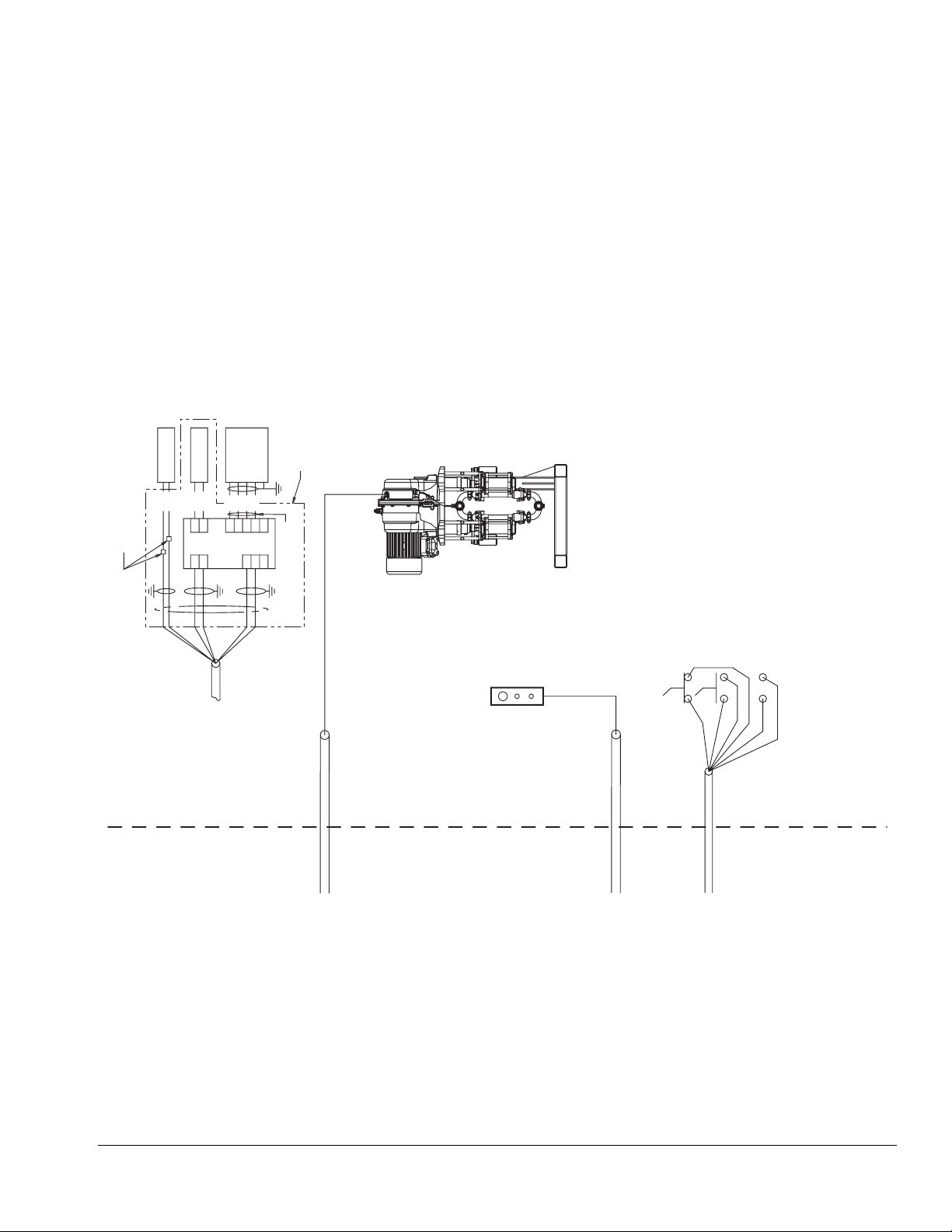

16J588

POSITION

SENSOR

-BLU

+BRN

TDC NAMUR

SENSOR

1 +BRN

2 -BLU

J2

3

4

PRESSURE

1 RED

2 GRN

3 WHT

J1

123

J3

TRANSDUCER

4 BLK

5

E-FLO JUNCTION BOX

IS CIRCUIT PRESSURE TRANSDUCER

FERRITE

(16G496)

TDC SENSOR

POSITION SENSOR

E-FLO

NOTE: 3 PHASE WIRING PLUS WIRING

FOR THERMISTORS ARE NOT SHOWN TO

AND FROM THE VFD/EFLO FOR CLARITY

Installation

E-FLO PUMP JUNCTION BOX

HAZARDOUS

3 PAIRS INDIVIDUALLY

WIRING DETAIL

(SEE MANUAL FOR DETAILS)

BELDEN 8777 OR EQUIV

WITH FERRITE (123375)

SHIELDED CABLE

STATION

OPERATOR

SECURE / DISABLE

START / STOP

RESET

OPERATION STATION

EXPLOSION PROOF

CONDUIT

WIRING DETAIL

SECURE

DISABLE

EXPLOSION

PROOF CONDUIT

RESET

START/STOP

FIG. 5. System Schematic Diagram, Hazardous Area

3A0006D 9

Page 10

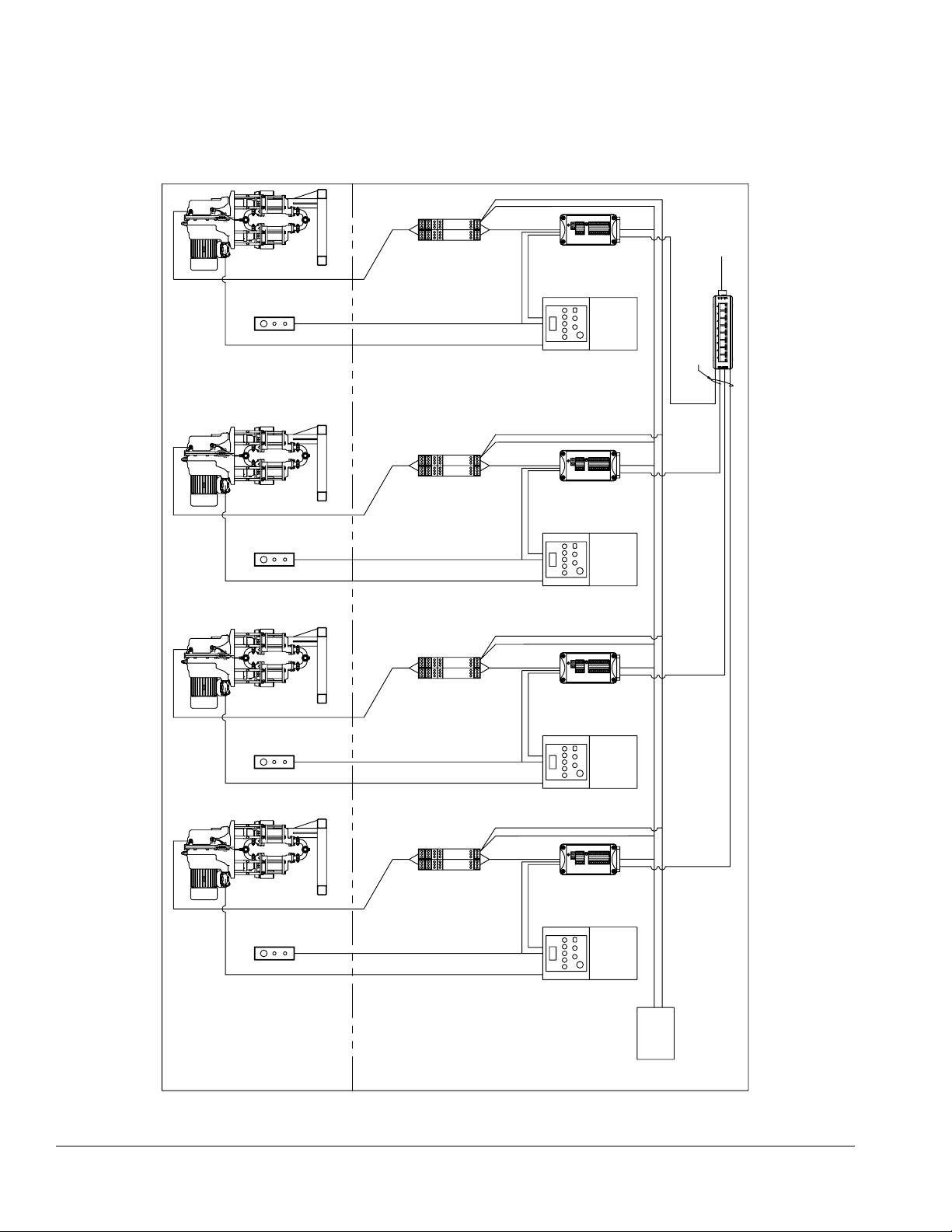

Installation

PRESSURE

ETHERNET COMS

MONITOR

PLC CONTROL /

OPTIONAL ETHERNET ROUTER/SWITCH

E-FLO #N

PRESSURE / TDC + POS

STATION

OPERATOR

E-FLO #3

PRESSURE / TDC + POS

STATION

OPERATOR

TDC/POS

BARRIERS #N

DISABLE

SECURE START / STOP / RESET

3 PHASE POWER

PRESSURE

TDC/POS

BARRIERS #3

DISABLE

SECURE START / STOP / RESET

3 PHASE POWER

RESET

SIGNAL

ANALOG DRIVE

RESET

SIGNAL

ANALOG DRIVE

ACS MODULE #N

VFD #N

GENERIC

ACS MODULE #3

VFD #3

GENERIC

PRESSURE

E-FLO #2

PRESSURE / TDC + POS

STATION

OPERATOR

E-FLO #1

PRESSURE / TDC + POS

STATION

OPERATOR

HAZARDOUS

NON-HAZARDOUS

TDC/POS

BARRIERS #2

DISABLE

SECURE START / STOP / RESET

3 PHASE POWER

PRESSURE

TDC/POS

BARRIERS #1

DISABLE

SECURE START / STOP / RESET

3 PHASE POWER

RESET

SIGNAL

ANALOG DRIVE

RESET

SIGNAL

ANALOG DRIVE

ACS MODULE #2

VFD #2

GENERIC

ACS MODULE #1

VFD #1

GENERIC

24 VDC

FIG. 6: Detailed Schematic, Connections to VFD

10 3A0006D

Page 11

Location

This equipment is not for use in explosive

atmospheres. Do not install equipment approved

only for non-hazardous location in a hazardous area.

Install the ACS Module and components in a non-hazardous area.

Mounting

See Dimensions, page 43.

The ACS Module and associated components are

designed to be mounted on a DIN rail inside of the motor

control enclosure.

Installation

The ACS Module DIN rail bracket may be reversed if

desired, to accommodate installation requirements.

Remove the screws, turn the bracket 180°, and reattach.

DIN rail bracket may be

reversed if desired.

ti17553a

Ground the ACS Control Module

The equipment must be grounded. Grounding

reduces the risk of static and electric shock by

providing an escape wire for the electrical current

due to static build up or in the event of a short circuit.

Ground the ACS Module through a proper

connection to a power source.

3A0006D 11

Page 12

Installation

ACS Modbus Registers

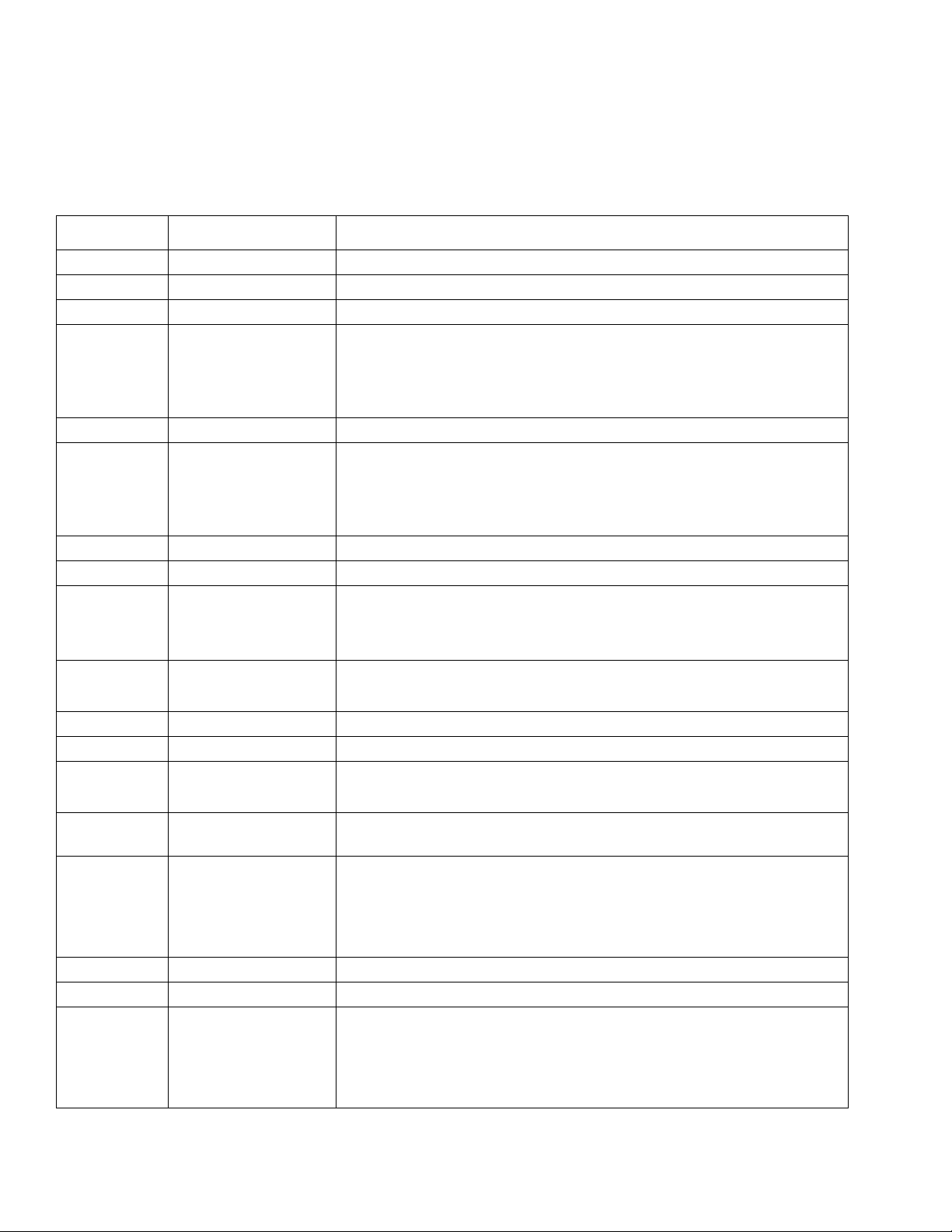

Modbus Registers 401800 to 401828 are used for ACS system control and setup.

See Table 2.

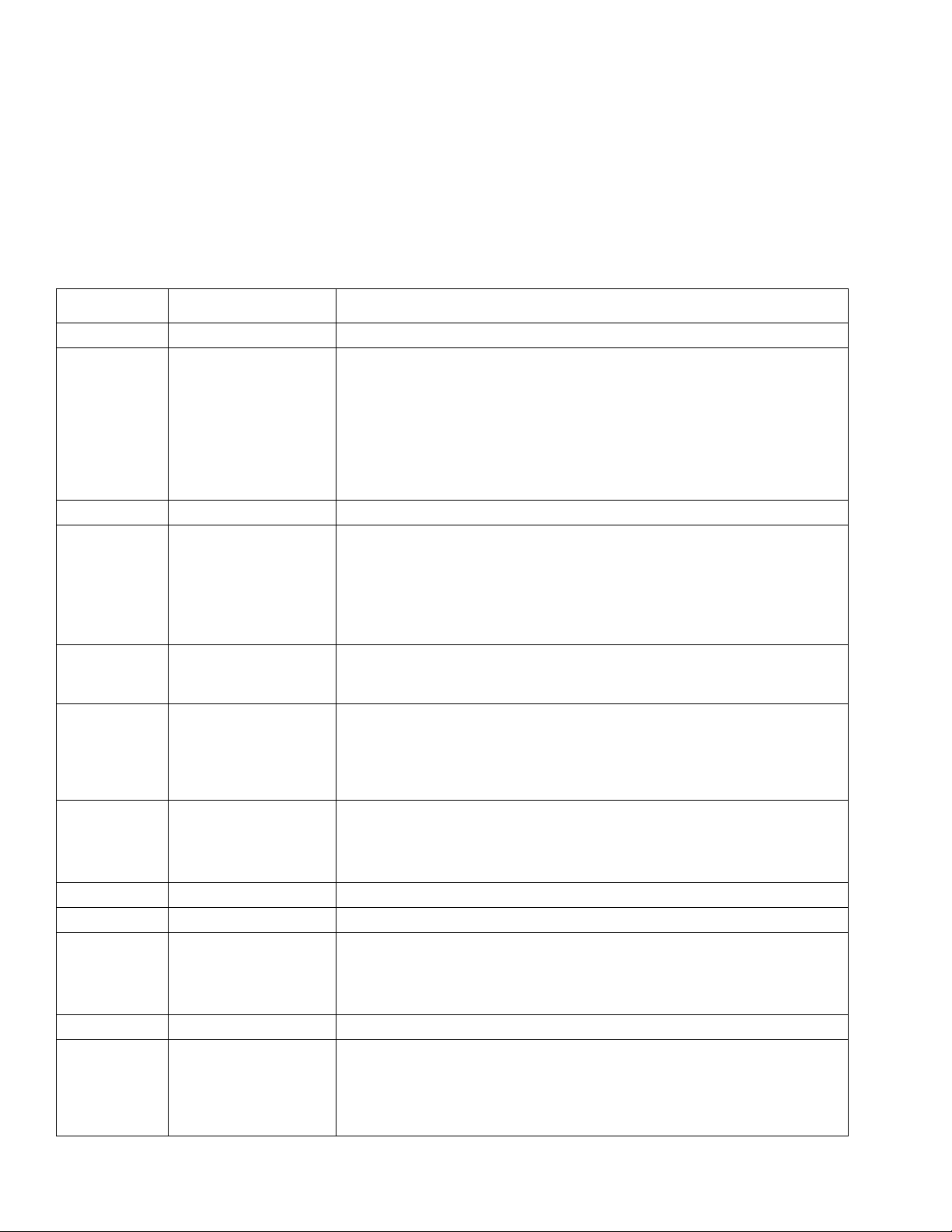

Table 2: ACS Modbus Registers 401800 to 401828

Register No. Register Name

401800 None Not used.

401801 Model Sets the pump model. Range of 1-4:

0 = Not used

1 = E-Flo 1500

2 = E-Flo 2000

3 = E-Flo 3000

4 = E-Flo 4000

401802 Units 0 = US GPM/PSI; 1 = Metric LPM/BAR

401803 ClrCtrFlg Clear the Cycle Counters:

1 = Clear Batch Total.

2 = Clear Grand Total.

This register is set to 0 by the ACS when done.

401804 CamMode 1 = Cam Mode enabled. Pump is compensated to provide constant flow.

0 = Constant speed mode. Motor will run at a constant speed.

401805 Modbus Baud Rate 0 = 19,200 (Default)

1 = 38,400

2 = 57,600

Description

Changes take effect on next power up.

401806 AutoCAMoff Determines how the ACS responds to a TDC or Position Sensor failure.

1 = Run at constant speed determined by Run or Sleep setpoint.

0 = Stop the pump.

401807 HipressLim High Pressure Alarm Limit x 10; ie, 2500 = 250 psi.

401808 None Not used.

401809 AuxOn Aux Relay ON/OFF control.

1 = ON

0 = OFF

401810 LowPressLim Low Pressure Alarm Limit x 10; ie, 400 = 40 psi.

401811 RemoteReset 1 = Reset the ACS to clear alarms. ACS will set to 0 when Reset is com-

plete, and the pump will start.

The Reset pin is edge triggered; a low to high will reset the ACS. Short the

Reset pin to Common, then release to reset.

12 3A0006D

Page 13

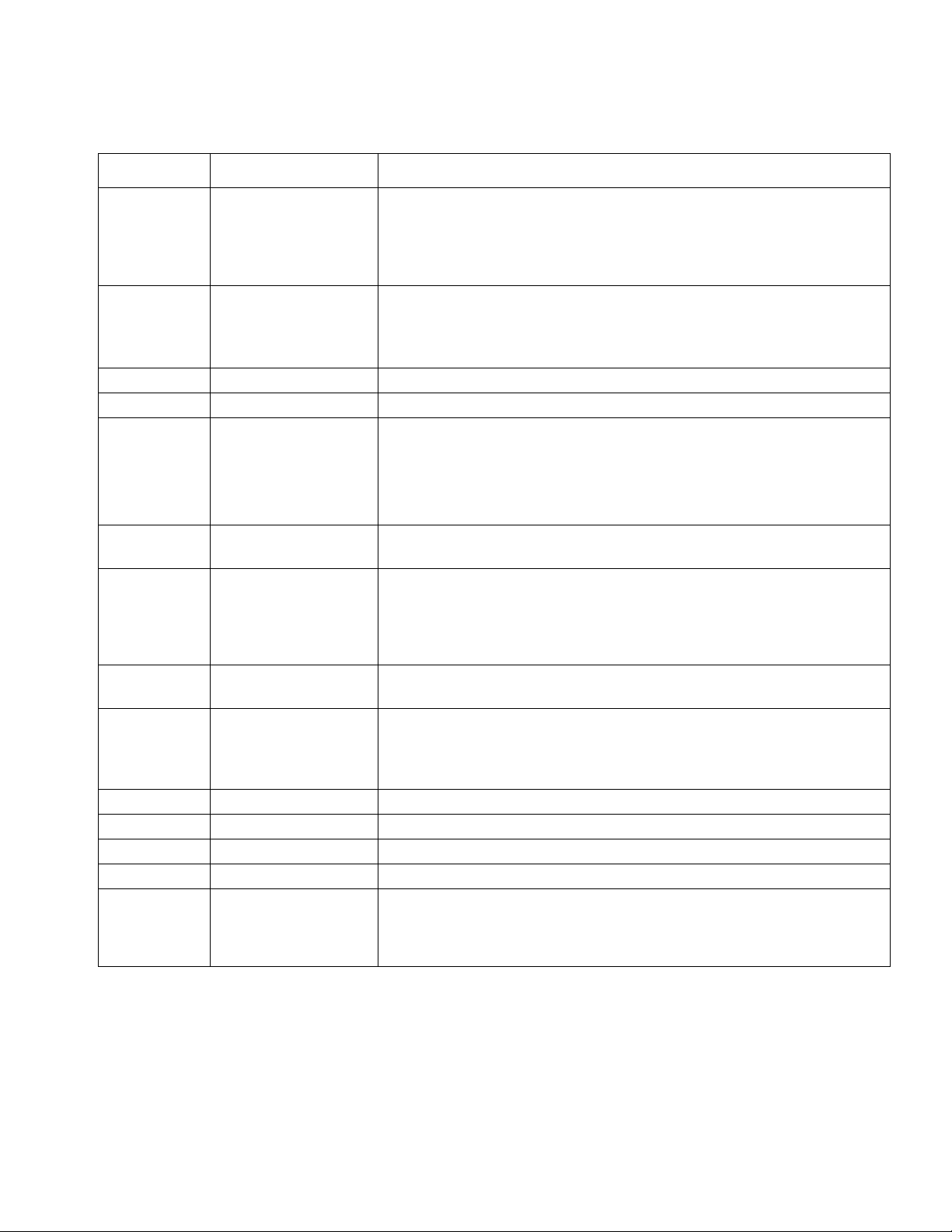

Table 2: ACS Modbus Registers 401800 to 401828

Installation

Register No. Register Name

401812 PressAlrmEnable

0 = No alarms.

Description

1 = High Pressure only.

2 = Low Pressure only.

3 = High and Low Pressure.

401813 Press_Mon Indicates to the system that a transducer is present to read.

1 = Enable pressure transducer reads.

0 = Disable pressure transducer reads.

401814 SleepSetpt Setpoint for Sleep Mode x 10 (GPM or LPM)

401815 RunSetpt Setpoint for Run Mode x 10 (GPM or LPM)

401816 SleepEnable

1 = Sleep Mode is on. The Sleep Setpoint is used as the target flow rate.

0 = Sleep off. The Run Setpoint is used as the target flow rate.

Sleep can also be enable by the external AutoSleep input pin. Sleep

Mode is enabled when either control is active.

401817 PressSetPt Pressure Mode setpoint x 10. This is the target pressure for Pressure

Control Mode.

401818 Cntrl_Mode 0 = Flow Control. Maintains a constant flow rate. Flow rate is either Sleep

or Run Setpoint, depending on 1816_SleepEnable input.

1 = Pressure Control. Maintains a constant pressure defined by

401817_PressSetPt.

401820 AutoDecrement 1 = Enabled; automatically minimizes the flow rate in pressure mode,

allowing the BPR to close. See Auto Decrement, page 27.

401821 RunStop 1 = Run

0 = Stop

Power up or Reset will set RunStop to 1.

401822 GaugePresH High Gauge Pressure entered during calibration, PSI only

401823 GaugePresL Low Gauge Pressure entered during calibration, PSI only

401824 ADmAHigh High pressure CAL, Transducer current xx.x mA.

401825 ADmAHigh Low pressure CAL, Transducer current xx.x mA.

401828 AutoXducerFail Determines how the ACS responds to a pressure transducer failure.

1 = Run at constant flow rate determined by Run or Sleep setpoint.

0 = Stop the pump.

3A0006D 13

Page 14

Installation

Modbus Registers 401900 to 401950 provide ACS operation status information and are

Read only. They must never be written to. See Table 3.

Table 3: ACS Modbus Registers 401900 to 401950

Register No. Register Name

401900 None Not used.

401901 CalcCPM Pump cycles per minute x 100.

401902 GT_CyclesL Grand Total cycles low word.

401903 GT_CyclesH Grand Total cycles high word.

To calculate the Grand Total, use the following formula:

Grand Total = (10000 * GT_CyclesH) + GT_CyclesL.

401904 Batch_CyclesL Batch Total cycles low word.

401905 Batch_CyclesH Batch Total cycles high word.

To calculate the Batch Total, use the following formula:

Batch Total = (10000 * Batch_CyclesH) + Batch_CyclesL.

401906 AVG_Press Average of last 5 pressure readings.

401907 Rev SOFTWARE VERSION.

401908 EventFlag

401909 RunningFlag

401910 AutoSlpStat Status of the AutoSleep input. 1 = the AutoSleep input is active (low).

401911 CalcFlow Current flow rate x 100 in GPM or LPM.

401912 XducerValidFlg

401913 to

401919

401920 ToothStat Status of the Position Sensor. The motor must be rotating for the system

None Not used.

Modbus Display only.

7 = Start Event.

8 = Stop Event.

1 = The motor is rotating.

0 = The motor is stopped.

1 = Pressure transducer is valid (> 2mA).

0 = Pressure transducer has failed (< 2mA).

to determine the validity of the position sensor.

Description

1 = Valid; the ACS is receiving Position Sensor pulses.

0 = Failed; the ACS is not receiving Position Sensor pulses.

401921 PLC_ID Modbus node number assigned to this ACS.

401922 ResetStat Status of the ACS Reset input pin. 1 = the Reset pin is active (low).

401923 TDCStat Status of the TDC (Top Dead Center) Sensor. The motor must be rotating

for the system to determine the validity of the TDC Sensor.

1 = Valid; the ACS is receiving TDC Sensor pulses.

0 = Failed; the ACS is not receiving TDC Sensor pulses.

14 3A0006D

Page 15

Table 3: ACS Modbus Registers 401900 to 401950

Installation

Register No. Register Name

Description

401924 HeartBeat Alternately set to 1 and 0 every second. This indicates that the ACS pro-

gram is operating.

401925 DriveCmdHz Current drive speed command x 10; ie, 0 to 800 = 0 to 80 Hz.

401926 Current_Alarm Represent the current alarm code.

Alarm Code No. Description

0 = No alarm No current alarm/event.

1 = OVERPRESS System stopped due to overpressure.

2 = UNDERPRESS System stopped due to underpressure.

3 = Xducer Fail Pressure Sensor failure, pump stops.

4 = NO TDC/STALL TDC failure, pump stops.

5 = MAXFLOW

Attempted to drive > 80 Hz.

WARNING

6 = AUTO CAM

OFF-TDC

TDC Sensor failure. Pump continues to run in con-

stant speed mode. The CAM function is disabled.

7 = START EVENT Logged only.

8 = STOP EVENT Logged only.

9 = AutoXducerFail Pressure Sensor failure. Pump continues to run

without pressure monitoring.

10 = MINFLOW Minimum Flow Warning, see page 30.

11 = Position Error Position sensor failure, pump stops.

12 = AUTO CAM

OFF-Position

13 = AUTO CAM

ACTIVATED

Pump continues to run in constant speed mode.

The CAM function is disabled.

CAM automatically reactivated, sensor signal

found

401927 MaxFloFlg Set when ACS attempts to drive the motor at more than 80 Hz. Cleared

after two pump cycles.

401928 AuxOutStat Status of the AuxOut Relay.

1 = Relay closed.

0 = Relay open.

401929 DrvEnableRlyStat Status of the Drive Enable Relay.

1 = Relay closed.

0 = Relay open.

401930 MinFloFlg 1 = Minimum Flow Warning, see page 30.

401931 AnalogIN2 Spare Input Pins 3 and 4:

Value 0 - 4095 represents 0-20 mA current

401932 to

None Not used.

401946

401947 ID1 ‘A’ Device ID

401948 ID2 ‘C’ Device ID

401949 ID3 ‘S’ Device ID

3A0006D 15

Page 16

ACS Control Mode

ACS Control Mode

The ACS module provides an analog drive signal to the

VFD.

• Run command refers to an input command to the

VFD, requesting the motor to run in designated

direction.

• Stop command refers to an input command

removed, requesting the motor to stop running.

120373 UL/CSA Control Box

SECURE

DISABLE

(wired to VFD)

The VFD drives the pump if the following conditions are

met:

• SECURE/DISABLE switch is ON

• START/STOP switch is ON

• There are no VFD or ACS faults

NOTE: The local control box cannot make flow rate

changes. Use automation (PC, VB software, or process

controller) to change the flow rate.

A control with interface must be used to select a drive

speed.

NOTE: See the schematic diagrams on pages 8-10 for

wiring details to complete the installation.

SECURE

DISABLE

(wired to

VFD)

START/STOP

(wired to VFD)

FAULT RESET

(wired to ACS)

Not Used

120991 ATEX Control Box

START/STOP

(wired to VFD)

FAULT

RESET

(wired to

ACS)

Not Used

F

IG

. 7. Local Control Box

16 3A0006D

TI10719A

Page 17

Operation

Set up a Static IP Address for the Computer

Operation

NOTE: Screen views in this manual are shown using

Microsoft Windows XP.

NOTE: To run the program, Java Version 6 Update 10+

(Version 7 not compatible) must be loaded on your computer. This is a free download.

CAT5 Ethernet Crossover Cable

1. Before connecting your computer to the ACS, verify

that Java Version 6 Update 10+ (Version 7 not compatible) is loaded on your computer. To verify, go to

Java.com using your Internet browser and click on

“Do I Have Java?” for further information.

2. After verifying that Java is loaded on the computer,

connect the computer directly to the Ethernet Port

on the bottom of the ACS module, using a CAT5

Ethernet crossover cable. See F

ACS Module

IG

. 8.

Computer

IG

. 8. Connect the Computer to the ACS Module

F

ACS Module

Ethernet Port

TI17645a

TI17556a

3A0006D 17

Page 18

Operation

3. Before running the software you must manually

assign an IP address to your computer:

a. On your computer, click on the Start button

to open the menu, then click

on Control Panel .

IG

b. See F

. 9. Double click on Network Connections. Double click on Local Area Connection to

open the Local Area Connection Status window.

Click on Properties to open the Local Area Connection Properties window. See F

IG

. 10.

FIG. 9. Control Panel, Network Connections, and Local Area Connection Status Windows

18 3A0006D

Page 19

Operation

c. In the Local Area Connection Properties win-

dow (F

IG

. 10), scroll to Internet Protocol

(TCP/IP) and double click, to open the Internet

Protocol (TCP/IP) Properties window (F

IG

. 11).

f. Type in the following Subnet mask:

255.255.255.0

NOTE: To reconnect to the user network, change the

setting back to “Obtain an IP Address Automatically.”

g. Click on OK to accept the changes and close

the Internet Protocol (TCP/IP) Properties window.

h. Click on OK to close the Local Area Connection

Properties window.

i. Close the Local Area Connection Status win-

dow and Network Connections window.

F

IG

. 10: Local Area Connection Properties Window

IG

d. See F

. 11. Set to “Use the following IP

address:”

NOTE: The IP address being created in step e

must be different from any other IP address

used in the network.

e. Type in the following 10 characters (including

the dots):

192.168.1.

then type additional numbers (for example, 201)

to create a unique IP address for the computer.

192 . 168 . 1 . 201

FIG. 11: Internet Protocol (TCP/IP) Window

3A0006D 19

Page 20

Operation

NOTE: Verify that the wireless connection is turned off

(disabled) before performing step 4.

4. In a web browser, enter: http://192.168.1.5:9080

5. Press Enter. The ACS Module Setup Screen

appears. See F

IG

. 12.

6. Each ACS module is provided with a default IP

address (192.168.1.5). The assigned ACS IP

address must be different from any other IP

address in the network. Only the last digit of the

address is editable. Type a new number in the edit-

able field, then click to

enter.

7. Set the Node ID number only if the ACS is connected to a Graco Gateway. The ID number must

be unused by other ACS modules. Click on

to access the default

Node ID number, which will then appear following

Device ID:. Type a new number in the Enter New

ID field, then click to enter.

FIG. 12: ACS Module Setup Screen

20 3A0006D

Page 21

ACS System Status Screen

Operation

See FIG. 13. The System Status screen appears when

the ACS Module is powered up. The screen displays the

current conditions and status of up to 50 pumps (numbered 0-49) in the system.

Click on a Pump Name key to open the Run screen for

that pump. F

If communication is interrupted due to a loose cable or

broken wire, first correct the problem, then click on

Click on a Pump Name

key to open the Run

screen for that pump

IG

. 14 shows the Run screen.

to re-establish communication.

(see page 23).

NOTE: The Visual Basic software program for the ACS

Module is available as a free download from

www.graco.com/Finishing. Navigate to the E-Flo Pump

product page for the download link.

NOTE: Open the program (Start>All Programs>GracoACS>GracoACS). The program will search for all

pumps in the ACS system and populate the ACS System Status Screen. See F

NOTE: This program does not require the PC be configured with Static IP Address.

Configured through web browser, see

IG

. 13.

page 20.

FIG. 13. ACS System Status Screen

3A0006D 21

Page 22

Operation

Run Screen

See FIG. 14. Use the Run screen to start or stop the

pump, reset faults, access the Configuration or Alarm

screen, view setpoints, and monitor the pump’s operation by viewing performance data.

The Run screen displayed depends on which pump was

selected on the ACS System Status Screen, page 21.

Each Run screen applies only to the selected pump.

Information Bar

The Run screen information bar displays the unique

pump name, the ACS IP address, the date, and the

time.

The Pump Name is not editable on the Run screen, but

may be input on the Configuration screen. See page 24.

Pump Performance Data

Pump Speed

The pump speed is displayed in cycles per minute

(CPM).

Pressure Setpoint

The Pressure Setpoint is displayed, as set on the Configuration screen (see page 26).

Fault Status

The screen displays if there is a fault:

•None

• High Pressure

• Low Pressure

• Xducer (Transducer) Fail

• Pressure Sensor

• Auto Xducer Fail

• MIN FLOW Warning

• Position Error

• Auto Cam Off-Position

• Auto Cam Activated

• No TDC Signal

•Max Flow

• Auto Cam Off-TDC

• Start Event

•Stop Event

Flow

The flow is expressed in gpm or lpm, as selected on the

Configuration screen (see page 25).

Motor Command Hz

The speed command, in Motor VFD frequency (4-20mA

scaled 0-80 Hz). This is not the frequency output by the

VFD.

Fluid Pressure

The fluid pressure is displayed in psi or bar, as selected

on the Configuration screen (see page 25).

Pump Setpoints

Run Setpoint

The Run Setpoint is displayed, as set on the Configuration screen (see page 27).

Sleep Setpoint

The Sleep Setpoint is displayed, as set on the Configuration screen (see page 27).

NOTE: See page 41 for alarm descriptions and troubleshooting.

Click on the Reset key to clear.

NOTE: The pump starts after a Reset.

Run Button

Click on the Run key to start the pump.

Stop Button

Click on the Stop key to stop the pump.

NOTE: The Run/Stop buttons function as enable/disable, active management is not necessary. This can be

left in Run and the pump/motor controlled from a physical start/stop switch connected to VFD.

Motor Status

The screen displays the status of the pump motor:

• Stopped - ACS module receiving position pulses

• Motor Running - ACS module not receiving position

pulses.

22 3A0006D

Page 23

Operation

Config Button

Click on the Config key to open the Configuration

screen. See page 24.

Pump Name, ACS IP Address,

Date, and Time

Alarms Button

Click on the Alarms key to open the Alarms screen. See

page 31.

Pump Performance

Data

Pump Setpoints

Run

Key

Fault

Display

F

IG

. 14. Run Screen

Reset Fault Key

Stop Key

Click to open

Configuration

screen (page 24).

Motor

Status

Display

Click to open

Alarm screen

(page 31).

3A0006D 23

Page 24

Operation

Configuration Screen

See FIG. 15. Use this screen to set the configuration for

each pump.

Pump

Parameters

(see page 25)

System

Features

(see page 27)

Transducer

Calibration

(see page 28)

System

Diagnostics

(see page 30)

Run and Sleep

Setpoints

(see page 27)

IG

. 15. Configuration Screen

F

24 3A0006D

Reset Totals

(see page 29)

Alarm Settings

(see page 29)

Set the Clock

(see page 28)

Software

Levels (see

page 30)

Page 25

Operation

Set Pump Parameters

F

IG

. 16. Pump Setup Fields

Select Pump Model

Click on the button to view the drop-down menu.

Select the pump being controlled and monitored by the

IG

ACS module. See F

rate setpoint range, based on the size of the pump

selected.

. 17. The selection activates a flow

Measurement Units

Click on the button to view the drop-down menu.

Select the desired units of measure:

• US Units (gpm and psi)

• Metric Units (lpm and bar)

NOTE: Changing the measurement units will stop the

pump.

FIG. 18. Units Drop-down Menu

NOTE: Changing the pump model will stop the pump.

F

IG

. 17. Pump Model Drop-down Menu

3A0006D 25

Page 26

Operation

Select Control Mode

Click on the button to view the drop-down menu.

Select the desired control mode:

• Flow (The pump will run at a constant flow rate)

• Pressure (This selection turns on Cam Mode and

Pressure Transducer Enable, see page 27. The

pump will make two revolutions before entering

pressure control mode.The pump will vary

speed/flow to maintain a constant pressure.)

NOTE: The Hz command will fluctuate in pressure

mode or in flow mode if cam is enabled.

Select Language

Click on the button to view the drop-down menu.

Select the desired language:

•English

•French

•German

• Chinese

• Japanese

• Korean

• Spanish

•Italian

•Polish

•Russian

•Swedish

F

IG

. 19. Control Mode Drop-down Menu

Select Pressure Setpoint

Click on the button to raise or lower the setpoint, as

desired.

Set Unique Pump Name

Input a unique name for each pump monitored by the

ACS. The name may have up to 20 characters.

FIG. 20. Language Drop-down Menu

26 3A0006D

Page 27

Operation

Select System Features

See FIG. 21.

Auto Decrement

Auto Decrement helps extend pump life by operating the

pump at the lowest speed necessary to maintain the

selected pressure range. Auto Decrement is operable in

pressure mode only. It reduces the flow rate incrementally by 1 Hz every 1 second until the Run Flow Setpoint

is reached while still maintaining target pressure.

Auxiliary Relay On

Enables peripherals such as a back pressure regulator.

Cam Mode

Enables the Cam profile. If turned off, pressure mode is

disabled.

Sensor Fault Override

Check this box to allow the pump to continue to run if

the TDC or Position sensors fail. The pump will run in

flow mode.

Run and Sleep Setpoints

Check the Sleep Enable box to turn on the Sleep mode.

Sleep mode will remain on until it is turned off.

Click on the button to raise or lower the setpoints, as

desired. These values are expressed in gpm or lpm.

There are two setpoint fields:

• Run Setpoint sets the rate of the pump when it exits

Sleep mode and enters Run mode.

• Sleep Setpoint sets the rate of the pump during

Sleep mode.

FIG. 22. Sleep Settings

Transducer Fault Override

Under normal operation, the ACS will shut down the

pump if the transducer fails. Selecting Transducer Fault

Override bypasses that safeguard and allows the pump

to continue to run. This selection cannot be made on

this screen; it can only be selected through Modbus.

Pressure Transducer Enable

Check this box if a pressure transducer is monitoring the

pressure. This is automatically enabled if Pressure is

selected as the Control Mode (see page 26).

F

IG

. 21. System Features Menu

3A0006D 27

Page 28

Operation

Calibrate the Transducer

NOTE: Only a 4-20 mA output transducer can be used

with the ACS.

NOTE: Calibration values for a Graco transducer are

listed on the label attached to the pump gearbox circuit

board cover. See F

refer to the manufacturer’s label or data sheet.

IG

. 23. Calibration Label Location

F

IG

. 23. For a non-Graco transducer,

ti17606a

Set the Clock

On the Configuration screen, click on

to access the clock screen

IG

(see F

• To input the values yourself, use the buttons.

• To synchronize the ACS clock with your PC, click on

. 25). There are two methods to set the clock:

Click on to enter.

. All values will be

loaded from the PC and the window will close.

Enter the transducer calibration values where shown in

F

IG

. 24, using the button to raise or lower the set-

point, as desired.

After the values are entered, the ACS will perform the

calibration.

F

IG

. 24. Calibration Values

FIG. 25. Set the Clock

28 3A0006D

Page 29

Operation

Reset Totals

The screen displays the batch total and grand total

cycles for each ACS module.

• To reset the batch total, click on .

Click to reset batch total

IG

. 26. Reset Batch Total

F

• To reset the grand total, click on . You

will be prompted to confirm the selection.

Alarm Enable

There are two alarm pressure fields: Maximum Pressure

and Minimum Pressure. Check the boxes to enable the

alarms. Click on the buttons to raise or lower the

pressure setpoints, as desired. These values are

expressed in psi or bar.

FIG. 28. Alarm Settings

1. Click to reset grand total.

2. Click to confirm.

F

IG

. 27. Reset Grand Total (GT)

3A0006D 29

Page 30

Operation

System Diagnostic Indicators

See FIG. 29. The diagnostic indicators light under certain conditions, as detailed in the following paragraphs.

Motor Running

Light is on steady when the motor is running.

ACS Heartbeat

Light blinks when power is supplied to the ACS.

Maximum Flow Warning

Lights if the maximum flow setpoint exceeds the pump’s

capability.

Minimum Flow Warning

Lights if the flow rate in pressure mode is less than 80

percent of the Run Setpoint. The system reverts to flow

mode at the Run Setpoint.

The system will return to pressure mode once the pressure has dropped back below 5% of the pressure setpoint for two cycles.

Autosleep Input

Transducer

Lights if the system detects a pressure transducer is

present.

ACS ID#

Automatic input (Modbus node number). Not editable.

ACS Software Revision

Automatic input. Not editable.

PC Software Revision

Automatic input. Not editable.

Lights if a Sleep Enable input is received from the PLC.

Closes the Auxiliary Relay.

Reset Input

Lights if a Reset Fault input is received from the PLC.

TDC Sensor

Status of the TDC (Top Dead Center) Sensor. The

motor must be rotating for the system to detect the TDC

Sensor.

Position Sensor

Status of the Position Sensor. The motor must be rotating for the system to detect the Position Sensor.

NOTE: TDC and position sensor indicators will both be

lit when the motor is moving and the ACS module is

receiving proper signals.

Auxiliary Relay

Lights if Auxiliary Relay is turned on (page 27).

Drive Enable Relay

F

IG

. 29. System Diagnostic Indicators

Lights if Drive Enable Relay is turned on.

30 3A0006D

Page 31

Alarms Screen

Operation

See FIG. 30. The Alarms screen logs the date, time, and

description of each alarm.

See page 41 for descriptions and explanations of each

alarm/warning.

Click to refresh the screen.

F

IG

. 30. ACS Alarms Screen

3A0006D 31

Page 32

ACS Software Update

ACS Software Update

This process is required to load files to the Graco ACS

module for an upgrade of the ACS application software.

The process allows update of application software

through the Ethernet port.

It is critical that the directions be followed in the correct

order and with detail.

Required data and equipment:

• The Graco Firmware file will be loaded through the

web browser. It will be 16J859G.CO5 (or a file of

this format with a xxx.CO5 extension of a later version). This software is available at www.graco.com.

• Any PC/Laptop with an Ethernet port, and Mozilla

Firefox web browser program preloaded (version

3.0 or higher). Use only Mozilla Firefox. Internet

Explorer (IE) will not work properly.

1. Connect the ACS module Ethernet port to the

PC/Laptop using an Ethernet cable.

NOTE: Some laptops will allow connections with or without a crossover cable. A standard Ethernet patch cord

should work, but a crossover cable may be required

depending on how your PC/Laptop is wired.

2. Set the Static IP Address on the PC/Laptop. Ensure

the PC/Laptop network settings are configured for a

static IP Address. The PC/Laptop should be set to

the same network settings as the ACS module. The

default ACS module IP is 192.168.1.5. Therefore

set the static IP of the PC/Laptop to 192.168.1.XXX

where XXX = 200 as an example. See F

IG

. 31.

IG

. 31. Setting the Static IP Address on a PC or Laptop

F

32 3A0006D

Page 33

3. When the Digital Signature Verification window

appears, click Run. Be sure that the “Always trust

content from this publisher” box is not selected. See

F

IG

. 32.

ACS Software Update

Click Run

Do Not Select

IG

. 32. Digital Signature Verification Window

F

3A0006D 33

Page 34

ACS Software Update

4. Open Mozilla Firefox web browser. In the address

bar enter: http://192.168.1.5:9080. See F

IG

. 33.

Enter

http://192.168.1.5:9080

Use this page for configuring the

ACS module after the latest firmware upgrade to 1.02.

F

IG

. 33. Standard ACS Module Setup Page

5. Click the button first. See

F

IG

. 34.

FIG. 34. Get ACS Version # Button

DO THIS FIRST

34 3A0006D

Page 35

6. Click the button, then the

button. The Get Device ID and

Get Device IP values must be populated on the

page before installing the new ACS software. See

IG

. 35.

F

ACS Software Update

GET DEVICE ID and GET DEVICE IP

values must be populated on the

page before installing the new ACS

software.

FIG. 35. Get Device ID and Get Device IP Buttons

3A0006D 35

Page 36

ACS Software Update

7. Click the button and navigate to the

16J859G.C05 (or later revision) file. Click the

button when the file link is loaded.

See F

IG

. 36.

Click Browse and navigate to the

16J859G.C05 (or later revision) file.

FIG. 36. Browse Button and Program ACS Button

Click Program ACS when

the file link is loaded.

36 3A0006D

Page 37

8. After performing steps 6 and 7, the screen will show

window pop ups while the software is downloading

to the ACS module. See F

IG

. 37.

If necessary, move the window to

view the line numbers incrementing.

ACS Software Update

F

IG

. 37. Window Popup During Software Download

Line numbers will increment to 2200+

when the download is complete.

3A0006D 37

Page 38

ACS Software Update

9. Click OK when the download is complete. The

popup window will clear automatically. See F

IG

. 37.

Click OK when download

is complete.

F

IG

. 38. Click OK When Download is Complete

NOTE: A new feature allows for setting of the default IP

Address of “192.168.1.5” if you cannot remember the

previous configured IP. To reset to the default IP

Address:

• Power OFF the ACS Module.

• Activate the RESET INPUT (or short to

ground/common) and HOLD.

• Power ON the ACS Module.

Window will clear automatically.

• The IP Address has now been changed to

192.168.1.5, but the change will not take affect

until power is cycled again.

• Cycle power to the ACS Module OFF then ON,

to apply the change.

NOTE: The white power button on the ACS Module can

be used to cycle power during this process. It is not necessary to unplug the 24 Vdc supply.

• Hold the RESET INPUT (pins 7-8 of input connector on ACS module) for 5 to 10 seconds,

then remove the RESET INPUT (with power still

applied).

38 3A0006D

Page 39

ACS System Setup Checklist

1.

Pressure Sensor Calibration

4.

ACS System Setup Checklist

User VFD Setup

NOTE: Only a 4-20 mA output pressure transducer can

be used with the ACS.

NOTE: Calibration values for a Graco transducer are

listed on the label attached to the pump gearbox circuit

board cover. See F

transducer, refer to the manufacturer’s label or data

sheet.

Pressure sensor calibration information must be

entered into the ACS control module. Failure to do so

will result in Pressure Sensor Calibration Trip, nuisance trips, or system malfunctions.

2.

Pump Lower Size Selection

NOTE: If the pump lowers are changed to a different

size after purchase, the plate information is no longer

valid.

3.

Unit Selection

IG

. 23, page 28. For a non-Graco

NOTICE

NOTE: Each VFD brand will have varying setup param-

eters. ACS and E-Flo performance is optimized by the

following key VFD settings:

• analog input scaling

• 4 mA = 0 (zero) Hz

• 20 mA = 80 Hz

• Acceleration rate = 1.0 sec (for full range 0-80 Hz)

• Deceleration rate = 0.5 sec (for full range 0-80 Hz)

NOTE: If the ACS is used with an E-Flo 1500 pump and

a 3 HP motor, activating the VFD slip compensation feature may reduce motor heat and improve performance

under certain conditions.

5.

E-Flo Motor Specific Parameters

Verify that the parameters entered in the VFD match the

motor parameters (rated voltage, maximum rated current limit, rated frequency, rated speed in rpm).

The defaults are psi and gpm.

Table 4: Measurement Unit Summary

Measurement English Metric

Pressure psi bar

Flow gpm lpm

Other setting selections will be required to allow for the

recognition of an analog speed command and motor ID

match and limits.

Contact Graco for motor information and/or a list of

locally supplied pre-approved motors.

3A0006D 39

Page 40

ACS Features

ACS Features

Drive Active (System ON) Output

The output can be mapped to most of the parameters.

The most common is Drive Enable. This relay output will

be closed when ACS module is running. It is used as the

Start or Run input to the VFD. It is not the Secure Disable input. See F

information.

IG

. 4-FIG. 6 on pages 8-10 for further

Back Pressure Regulator (BPR) Production/Sleep Modes

NOTE: See FIG. 4-FIG. 6 on pages 8-10 and manual

311606 for wiring and installation details.

Flow Rate Monitoring

Table 5: E-Flo Pump Displacement Volumes

Volume per

Lower Size

2000cc 4278 1.13

1500cc 3070 0.81

Cycle (cc)

Volume per

Cycle (Gal)

Operational Envelope Limit

Explosion-proof electric motors have constant torque

and variable torque limits. E-Flo system is a constant

torque application, and therefore the motor’s constant

torque limits must not be violated. The system is available from Graco with two motors: the UL/CSA explosion-proof motor and the ATEX explosion-proof motor.

Pressure Limits

If a pressure transducer is present, set the maximum

pressure limits as shown in T

Enable, page 29.

Table 6: System Pressure Limits

Lower

E-Flo

Model

E-Flo 4000 2000 250 17 250 17

E-Flo 3000 1500 330 23 330 23

E-Flo 2000 1000 460 32 460 32

E-Flo 1500 750 425 29 500 35

Size

(cc)

ABLE

6. See Alarm

Non-Graco

Graco Motor

psi bar psi bar

Motor

1000cc 2263 0.60

750 cc 1537 0.41

40 3A0006D

Page 41

Diagnostic Procedures

The ACS module contains two diagnostic LEDs:

• POWER ON: Solid green when the ACS is powered

and the pump is running.

• DRIVE ENABLED: ON (solid red) if the pump is

stopped and the drive enabled relay is open. OFF if

the pump is running and the drive enabled relay is

closed.

Table 7: Faults and Diagnostic Procedures

Fault Description Diagnostic

Diagnostic Procedures

High Pressure (System

pressure is higher than the

entered high pressure trip

point.)

Low Pressure (System

pressure is lower than the

entered low pressure trip

point. This alarm is disabled for 1 minute after the

pump starts to prevent premature alarms.)

Xducer Fail Loss of pressure transducer analog signal, cause by:

Max Flow (The requested

flow rate is beyond the

pump’s capability.)

1. Check High Pressure Alarm setting. Verify that system desired operational pressure is lower then High Pressure Alarm setting.

2. Check for flow restrictions (closed valves, unexpected restrictions).

3. Check pump fluid section for proper operation (piston seals, ball checks). Refer

to pump maintenance manual for additional information.

1. Check Low Pressure Alarm setting. Verify that system desired operational pressure is higher then Low Pressure Alarm setting.

2. Check fluid level. Low fluid level will cause system to run at low pressure.

3. Check fluid supply to the pump.

4. Check pump fluid section for proper operation (piston seals, ball checks). Refer

to pump maintenance manual for additional information.

• wiring problem

• pressure transducer failure

• circuit board failure

• EMF noise on the control cable

Reduce the requested flow rate. (A 20 mA analog drive signal is the maximum.)

NOTE: This trip is a Warning and will not shut off the pump.

Min Flow (The flow rate is

too low for the Run Setpoint.)

Auto Cam Off (TDC/Position)

Start Event ACS has received a start command.

Stop Event ACS has received a stop command.

3A0006D 41

Decrease the back pressure regulator pressure or increase the Pressure Setpoint.

NOTE: This warning only occurs in pressure mode.

Cam mode is not functional due to loss of TDC or position sensor signal (required

for CAM operation). Verify wiring is shielded and installed correctly. See Schematic

Diagrams, page 8.

Page 42

Diagnostic Procedures

Table 7: Faults and Diagnostic Procedures

Fault Description Diagnostic

No TDC Signal (Top Dead

Center Sensor is not

detected, or motor is not

able to develop torque,

and therefore cannot put

the pump into motion)

No Position Sensor Signal (Position Sensor is not

detected, or motor is not

able to develop torque,

and therefore cannot put

the pump into motion)

No TDC Signal:

1. Verify that output shaft is turning.

2. Check all of the wiring.

3. Verify that sensor is operational. Remove PCB cover and monitor LED light on

the top of the sensor. The light should be normally on and it should be off for

only short period of time when top dead center is reached.

Stall:

1. Relieve system pressure.

2. Check lowers, slider cylinders, and output shaft with connecting rods for visible

damage. If no damage is visible, check for excessive heat which is a sign of friction.

3. Check the system control circuit wiring.

4. Check that the motor is turning. If not, check motor wiring.

5. Disconnect lowers and try running just the motor and gearbox.

No Position Sensor Signal:

1. Verify that output shaft is turning.

2. Check all of the wiring.

3. Verify that sensor is operational. Remove PCB cover and monitor LED light on

the top of the sensor. The light should be normally on and it should be off for

only short period of time when position is reached.

Stall:

1. Relieve system pressure.

2. Check lowers, slider cylinders, and output shaft with connecting rods for visible

damage. If no damage is visible, check for excessive heat which is a sign of friction.

3. Check the system control circuit wiring.

4. Check that the motor is turning. If not, check motor wiring.

5. Disconnect lowers and try running just the motor and gearbox.

42 3A0006D

Page 43

Technical Data

ACS Modul

Technical Data

Inputs

Power: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-30 Vdc, 200mA, reverse polarity protected

Analog inputs: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 inputs for 4-20mA current loop sensing. Inputs pro-

tected from direct application of 24 Vdc.

Digital inputs: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 inputs: TDC, Position Sensor, AutoSleep, and Reset.

Digital inputs are 24V logic level NPN.

Outputs

4-20 mA loop:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 channels, adjustable offset and span.

Digital outputs: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 open contact, normally open relay outputs, 24V, 1A,

used for BPR control and Drive Enable.

Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 Ethernet port and 1 RS485 port

Ambient Conditions

Operating temperature range. . . . . . . . . . . . . . . . . . 0-50°C (32-121°F)

Operating humidity . . . . . . . . . . . . . . . . . . . . . . . . . . 10-90% relative humidity, non-condensing

Dimensions

e

NOTE: Designed for DIN rail mounting.

A

Module A B C Weight

ACS 2.31 in.

(59 mm)

4.49 in.

(114 mm)

B

5.13 in.

(130 mm)

C

1.1 lb

(0.50 kg)

ti17553a

3A0006D 43

Page 44

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissen

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

t avoir convenu que la

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2011, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions.

This manual contains English. MM 3A0006

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revision D, April 2014

Loading...

Loading...