Page 1

Airless Spray Equipment

For Single-Component Protective Coatings

Need Photo

Page 2

Graco Has You Covered

No matter what the application, Graco has the solution

Whether it’s a large coating project like a bridge, ship or tank, or a simple touch-up project that only takes a few hours, you depend on your spray

equipment to deliver a flawless performance every time. Graco offers a complete lineup of the industry’s most dependable single-component

sprayers — in the exact size you need to accomplish any airless spray project.

Reduce your cost of ownership with Graco

Rugged, durable and dependable, Graco sprayers are built to last. They can easily handle the industry’s toughest high solids, 100% solids and

solvent-free coatings — even in the most severe conditions. Because Graco pumps are constructed with long-lasting parts and the highest quality

materials, you gain productivity and spend less downtime on maintenance. Which means you can complete your projects faster and more efficiently.

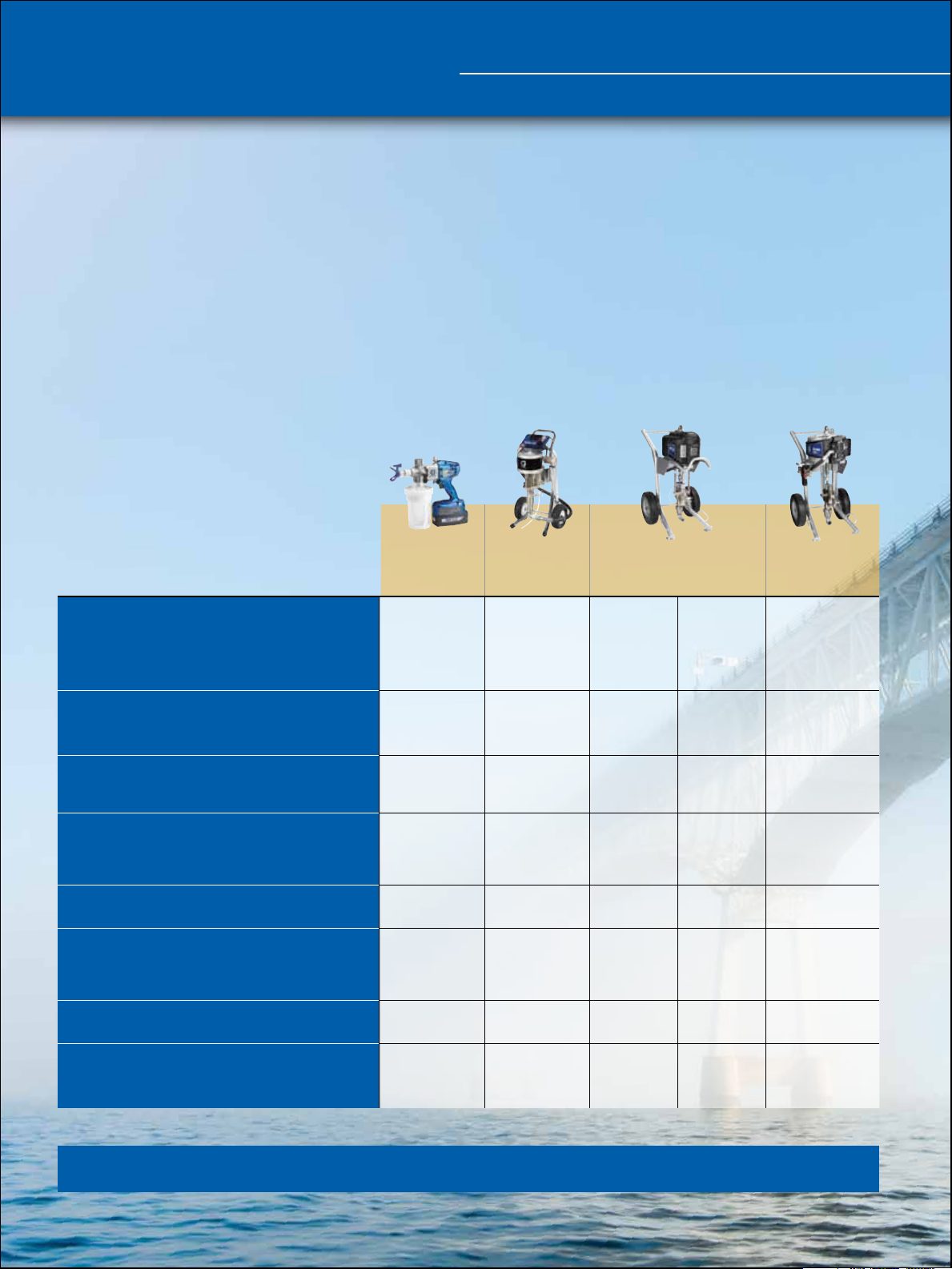

HOW TO CHOOSE YOUR SPRAYER

HOW LARGE IS YOUR PROJECT?

Typical Applications*

WHAT IS THE REQUIRED MATERIAL OUTPUT?

Output Range at 60 Cycles/min, gpm (lpm)

WHAT IS THE DUTY CYCLE OF THE SPRAYER?

Production

HOW MANY CREW MEMBERS CAN SPRAY

FROM ONLY ONE UNIT?

Motor Type

Motor Diameter, in (mm)

XForce™ HD

Touch-up and

spot repair

.09 –.67

(.33 –2.54)

Touch-up Low – Med Med –High High Very High

1 1 1 1–2

HD Brushless NXT 1800 NXT 3400 NXT 6500 XL 10000

N/A

Merkur®

X48 / X72 Xtreme® NXT® Xtreme® XL

Smaller

projects that

require power

and portability

.8 –1.2

(3.0 –4.5)

7.5

(190)

Medium

to large

projects

1.5 –3.4

(5.7–12.9)

7.5

(190)

Large

projects

2.3 –4.6

(4.6 –17.4)

10.375

(263)

Large projects

that require

continuous duty

or multi-gun

3.4 –6.7

(12.9– 25.4)

Multiple

1– 6**

13

(330)

Motor Displacement, cc/stroke

Working Pressure, psi (bar)

* General guidelines only. Please consult your Graco distributor to ensure you order the proper sprayer for your application.

** Depending on spray tip size and material.

2

N/A 1800 3400 6500 10330

1000–4000

(69 –276)

4800, 7200

(331, 496)

3150 –7250

(217–496)

4550 –7250

(314–496)

4800 –7250

(331– 496)

Page 3

Advantages of airless equipment

3

Airless equipment lets you finish jobs much faster,

resulting in saved labor costs and the ability to work

with tighter timelines. Airless sprayers also provide

a more consistent mil build, which improves coating

performance and a smooth, high-quality finish.

A new Graco powerhouse for high-volume projects

If you have large jobs that require a high-output sprayer, then you need the new Graco Xtreme XL Sprayer. Configured with the Graco

XL Air Motor, the largest air motor Graco has ever built, the Xtreme XL handles the workload equivalent of multiple sprayers.

Add the new Graco Xtreme XL to your equipment lineup

• Higher output per cycle means less total cycles for any given job —which means less wear and tear

on pump components, and ultimately, less downtime and maintenance expense for you.

• The high output, high efficiency 10,000 cc XL Air Motor lets you use multiple guns with almost

no perceivable pulsation. Multiple guns get the job done faster, which is better for your bottom line.

• The Xtreme XL eliminates non-restartable icing stalls for more uptime. External air passages are isolated

from cold exhaust air and warmed from the warmer ambient air.

Page 4

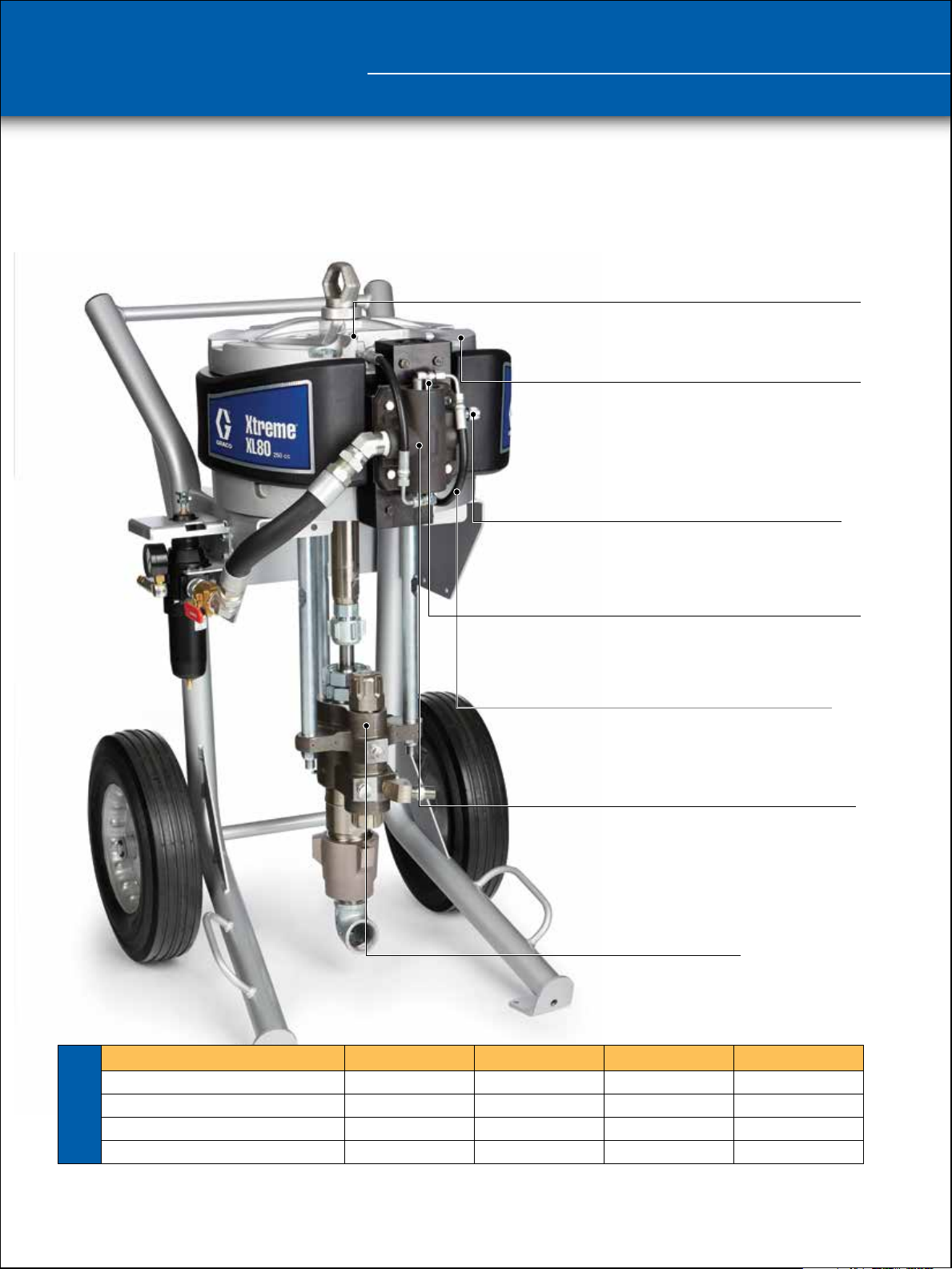

Xtreme® XL Series

The largest, most powerful air motor Graco has ever built

Designed with the new XL Air Motor, the Xtreme XL Sprayer can run up to six guns in a high-output environment with virtually no pulsation or

pattern fluctuation. The efficient design includes advanced features that ensure superior performance, even in oily, dirty and wet air environments.

Exposed Poppets

• Easy access for service and troubleshooting

10,000 cc XL Air Motor

• For 45:1, 70:1, 80:1, 95:1 sprayers

• 13 in (330 mm) diameter

• Air-piloted for sharp changeovers

• Low pulsation, even with multiple guns

De-Ice Bleed Air Control

• Maintains performance during heavy

icing conditions

Output per cycle (cc) 430 290 250 220

Maximum Working Pressure, psi (bar, MPa) 4800 (330.9, 33.1) 7250 (499.9, 49.9) 7250 (499.9, 49.9) 7250 (499.9, 49.9)

Maximum Air Input Pressure, psi (bar, MPa) 100 (6.9, .69) 100 (6.9, .69) 88 (6.1, .61) 76 (5.2, .52)

XL SPRAYER

SPECIFICATIONS

Output at 60 Cycles/min gpm (lpm) 6.7 (25.4) 4.6 (17.4) 4 (15.1) 3.4 (12.9)

* Uses Dura-Flo

™

lower

Manual Shuttle Override Button

• Allows manual restart of air motor if main

valve experiences ice buildup

External Pilot Lines

• Isolate lines from cold valve body

• Eliminates non-restartable icing stalls

Simplified Valve Design

• Fewer components for easier serviceability

• Little to no pulsation or pattern fluctuation,

even with multiple guns

• Quiet operation, even compared to

smaller motors

Xtreme Lowers

• Field-proven

• Easy to maintain

• Quick knockdown

XL45* XL70 XL80 XL95

For more information on Parts & Accessories for High Pressure Protective Coatings Equipment, see brochure 349329.

4

Page 5

With hose, gun and hopper

X L x x x x

P L x x C x

TIME

PSI

TIME

PSI

TIME

PSI

C

A

XTREME XL SPRAYER

XTREME XL SPRAYER

High Pressure and High Flow

Even at high cycle rates, the Xtreme XL Sprayer maintains the high pressure needed to effectively spray up to six guns.

Compare the difference in pressure drop and pulsation between the Xtreme XL Sprayer and a competitive brand sprayer at high flow rates.

A 500 psi (34.5 bar) dynamic pressure drop

XTREME XL SPRAYER

XTREME XL SPRAYER

C

COMPETITOR’S SPRAYER

A

COMPETITOR’S SPRAYER

D

B

A

An 1,800 psi (124 bar) dynamic pressure drop

B

Little to no perceivable pulsation

C

Slow changeover means pulsation and

D

pattern fluctuation

Ordering Information

PUMPSPACKAGES

Product Identifier

XL=Xtreme XL Sprayer

Package Ratio

45: 10,000cc/430 lower 80: 10,000cc/250 lower

70: 10,000cc/290 lower 95: 10,000cc/220 lower

Mount Type

H: Heavy-duty cart W: Wall-mount

Example:

XL45H2 is a 45:1,

heavy-duty, hose

and gun (no hopper)

Notes:

1. Wall mount systems are only available as bare sprayer – package #1.

2. Complete packages sold with XTR gun, 50ft x 3/8 hose and 6ft x 1/4 whip hose, 519 tip.

Package

1: Bare sprayer, no hopper 3:

2: With hose and gun, no hopper 4: Bare sprayer, no filter

Example:

PL70C2 is a 70:1

with built-in filter

Product Identifier

PL=Xtreme XL Pump

Pump Ratio

45: 10000cc motor / 430 lower

70: 10000cc motor / 290 lower

80: 10000cc motor / 250 lower

95: 10000cc motor / 220 lower

Lower Material

C: Carbon steel

Filter

1: No built-in filter

2: Built-in filter

Heavy-fluid, high pressure spray packages

Designed for materials that will gravity feed, but are higher viscosity and filled, requiring a filter-less pump lower for less plugging.

Packages include 10 gal (38 L) SST hopper, no fluid filter, ¾ in. outlet check valve, ¾ in. x 50 ft. (15 m) hose, ½ in. x 25 ft (7.6 m) whip and

XHF spray gun with 429 tip.

24X593 XL70 Heavy-fluid* spray package

24X594 XL80 Heavy-fluid* spray package

* Heavy-fluid materials vary and should be tested with a qualified distributor. Material should be pourable and self-leveling.

Optional Accessories

24X570* 10 gal (37.8 l), stainless steel

hopper with fittings for mounting

16U536 10 gal (37.8 l), stainless steel

hopper without fittings

*Adapts to XL Sprayers only

24X547 Hopper adapter kit for XL45

262826 Gun splitter

24X553 3/4 in hose to high flow gun kit

For more information on Parts & Accessories for High Pressure Protective Coatings Equipment, see brochure 349329.

24X550 DataTrak Control

with runaway solenoid

24X552 DataTrak Control

without runaway solenoid

5

Page 6

Xtreme® NXT Series

Long-lasting durability for high-performance spraying

The Xtreme NXT series of airless sprayers are built to handle the toughest protective coatings and corrosion control applications. The Xtreme NXT

also provides a smooth, rapid changeover, which minimizes pulsation, decreases user fatigue and achieves a more consistent finish. It offers a

modular design for convenient maintenance, a de-icing feature and reduced noise level.

DataTrak™ Control

• Runaway protection

• Pump diagnostics

NXT Air Motor

• Modular design for

easier maintenance

• Rugged body armor

won’t rust or dent

• Highest technology air

motor on the market

• Material usage

• Optional accessory

Modular Air Valve

• De-ice control reduces icing

• Up to 50% quieter than previous models

• Modular air valve

- Reduces stalling

- Easy-to-repair

Output per cycle

Motor Size

Maximum Working Pressure

psi (bar, MPa)

Maximum Air Input Pressure

psi (bar, MPa)

SPECIFICATIONS

XTREME SPRAYER

Output at 60 Cycles/min gpm (lpm)

Quick Disconnect

• Makes for easier service

Graco Xtreme

Pump Lower with Built-In Filter

• Lower cost of ownership

™

• Longer-lasting rod with Chromex

• Quick knockdown

Xtreme NXT 3400 Packages Xtreme NXT 6500 Packages

X30 X40 X55 X80 X45 X50 X60 X70 X90

220cc

NXT 3400

3150

(217, 21.7)

100

(7, 0.7)

3.4 (12.9)

180cc

NXT 3400

3800

(262, 26.2)

100

(7, 0.7)

2.9 (11)

115cc

NXT 3400

5950

(410, 41.0)

100

(7, 0.7)

2.0 (7.6)

85cc

NXT 3400

7250

(500, 50.0)

100

(7, 0.7)

1.5 (5.7)

290cc

NXT 6500

4550

(313, 31.3)

100

(7, 0.7)

4.6 (17)

250cc

NXT 6500

5200

(359, 35.9)

100

(7, 0.7)

4.0 (15.2)

220cc

NXT 6500

6000

(417, 41.7)

100

(7, 0.7)

3.4 (12.9)

180cc

NXT 6500

7250

(500, 50.0)

(7, 0.7)

2.9 (11)

coating

100

145cc

NXT 6500

7250

(500, 50.0)

80

(5.5, .55)

2.3 (8.7)

For more information on Parts & Accessories for High Pressure Protective Coatings Equipment, see brochure 349329.

6

Page 7

Ordering Information

X x x x x x

Product Identifier

X=Xtreme Sprayer

Package Ratio

3400 Packages 6500 Packages

30: 3400cc motor/220cc lower 45: 6500cc motor/290cc lower

40: 3400cc motor/180cc lower 50: 6500cc motor/250cc lower

55: 3400cc motor/115cc lower 60: 6500cc motor/220cc lower

80: 3400cc motor / 85cc lower 70: 6500cc motor/180cc lower

90: 6500cc motor/145cc lower

Motor Type

D: De-icing L: Low noise

Mount Type

H: Heavy-duty cart L : Lightweight cart W: Wall-mount

Example:

X46DH2 is a 46:1,

De-Ice, heavy-duty,

bare package with DataTrak

Notes: Packages sold with XSeal_LTH packings only. Packages sold with built-in filter only. Complete packages sold with

™

gun, 50 ft x 3/8 hose and 6 ft x 1/4 whip hose. Wall-mount packages are only available bare, but include 10 ft

XTR

suction hose with 55 gal suction tube.

*Only available on X45, X60 or X70 De-ice, heavy-duty or lightweight cart packages.

Package/DataTrak

1: Complete package with DataTrak 5: Complete hopper package with DataTrak

2: Bare package with DataTrak 6: Complete hopper package, no DataTrak

3: Complete package, no DataTrak 7: Complete package, no DataTrak,

4: Bare package, no DataTrak no built-in fluid filter*

PACKAGES

™

Special Package Configurations

Xtreme Zinc Packages

Special zinc

circulation system

keeps particles

in suspension,

making zinccoating applications easier.

Has standard

Xtreme lower

with no filter

and de-icing

NXT Air Motor.

Pictured: Xtreme Zinc Package with Circulation

and Heavy-Duty Cart

287971 25:1 Heavy-Duty Cart Zinc Package,

no hose or gun

287972 40:1 Heavy-Duty Cart Zinc Package,

no hose or gun

287973 25:1 Heavy-Duty Cart Zinc Package

(Silver Spray Gun 238591 and Hoses)

287974 40:1 Heavy-Duty Cart Zinc Package

(Silver Spray Gun 238591 and Hoses)

Xtreme Air Assisted Packages

Combines airless atomization speed with

the fine finish of air spray. Ideal for high production, smooth finish applications. Includes

De-Icing NXT Air Motor with DataTrak.

287975 30:1 Heavy-Duty Cart AA Package

287976 40:1 Heavy-Duty Cart AA Package

High Flow Dura-Flo Packages

Include De-Icing NXT Air Motor.

287980 23:1 Sprayer Package with

287979 23:1 Sprayer Package with

287981 32:1 Sprayer Package with

P x x x C x

Example:

P70DC2 is a 70:1

De-Ice, with built-in

filter and no air control

Note: Pumps sold with XSeal_LTH packings only.

(G40 Spray Gun and Hoses)

(G40 Spray Gun and Hoses)

a Dura-Flo 580 cc lower

plus DataTrak

(Silver Spray Gun and Hoses)

a Dura-Flo 580 cc lower

a Dura-Flo 430 cc lower

(Silver Spray Gun and Hoses)

PUMPS

Product Identifier

P=Xtreme Pump

Pump Ratio

3400 Packages 6500 Packages

30: 3400cc motor/220cc lower 45: 6500cc motor/290cc lower

40: 3400cc motor/180cc lower 50: 6500cc motor/250cc lower

55: 3400cc motor/115cc lower 60: 6500cc motor/220cc lower

80: 3400cc motor / 85cc lower 70: 6500cc motor/180cc lower

90: 6500cc motor/145cc lower

Motor/DataTrak

D: De-icing: None L: Low noise: None

E: De-icing: DataTrak M: Low noise: DataTrak

Lower Material

C: Carbon steel

Filter/Air Controls

1: No built-in filter, no air controls 3: No built-in filter, air controls

2: Built-in filter, no air controls 4: Built-in filter, air controls

Packages without Lowers

XN3DH2 NXT 3400 De-Icing with DataTrak

on a Bare Heavy Duty-Cart *

XN3DH4 NXT 3400 De-Icing on a Bare

Heavy-Duty Cart *

XN3DL2 NXT 3400 De-Icing with DataTrak

on a Bare Lightweight Cart *

XN3DL4 NXT 3400 De-Icing on a Bare

Lightweight Cart *

XN6DH2 NXT 6500 De-Icing with DataTrak

on a Bare Heavy-Duty Cart *

XN6DH4 NXT 6500 De-Icing on a Bare

Heavy-Duty Cart *

XN6DL2 NXT 6500 De-Icing with DataTrak

on a Bare Lightweight Cart *

XN6DL4 NXT 6500 De-Icing on a Bare

Lightweight Cart *

247312 Cart adapter for NXT2200 Air Motor

Carts

287919 Lightweight base cart

287884 Heavy-duty base cart

* Add any Xtreme Lower (Sizes 145cc–290cc) to make a Package. Includes tie rods, coupling kit and a suction hose.

For more information on Parts & Accessories for High Pressure Protective Coatings Equipment, see brochure 349329.

7

Page 8

Merkur® X48 and X72

Easy portability for areas requiring high solids coatings

Merkur X48 and X72 single component airless sprayers offer the ultimate combination of power and portability, giving you the ability to spray

tough materials in the most challenging situations. Weighing just 99 pounds (45 kg), the Merkur Sprayer can easily be positioned in tight areas,

without sacrificing spray quality or power.

High Pressure

• With up to 7200 psi (500 bar, 50 MPa)

• Sprays high solids coatings

• Supports longer hose runs

Easy to Maintain

• Easy to disassemble pump from air motor

Throat and Piston Packings

• Self-adjusting and spring loaded

to maintain packing life

Pressure Bleed Valve

• Floating ball design – zero cavity

• Reduces clogging and leaking

Merkur Pump Lower

• Improved handling of high viscosity coatings

™

• Long-lasting Chromex

coated rod

Inlet

• Smooth 1-1/4 in inlet reduces “dead spots”

and coating buildup

Quick Knock-Off Suction Hose

• Large 1 in x 6 ft (25.4 mm x 1.8 m) suction hose

Lightweight and Portable

• Weighs only 99 lb (45 kg)

Maximum Fluid Working Pressure, psi (bar, MPa) 4800 (330, 33) 7200 (500, 50)

Recommended Tip Size Up to 0.025 Up to 0.021

PRODUCT

* Varies by coating and duty cycle

Fluid Flow at 60 Cycles/min gpm (lpm) 1.2 gpm (4.5 lpm) 0.8 gpm (3.0 lpm)

SPECIFICATIONS

Pump Weight, lb (kg) 99 (45) 99 (45)

Merkur X48 Merkur V72

For more information on Parts & Accessories for High Pressure Protective Coatings Equipment, see brochure 349329.

8

Page 9

Ordering Information

16V174 Merkur X72 bare unit

16U918 Merkur X72 complete package

16V175 Merkur X48 bare unit

16U920 Merkur X48 complete package

Accessories

16U924 Repair kit, X72 fluid section

16U925 Repair kit, X48 fluid section

16V583 Fluid filter kit, 7250 psi (500 bar).

Includes 60 mesh filter element.

224459 60 mesh fluid filter element, 2-pack

224468 100 mesh fluid filter element, 2-pack

106149 Air line filter kit, ½ in npt (fbe), 20 micron (requires fittings)

24A576 Optional DataTrak

™

Kit

Complete package includes XTR gun with 519 tip

and 3/8 in x 25 ft (7.6 m) hose, 6 ft (1.8 m) whip

For more information on Parts & Accessories for High Pressure Protective Coatings Equipment, see brochure 349329.

9

Page 10

XForce™ HD Heavy-Duty

Optimized for Protective and Marine Coatings

The XForce HD heavy-duty cordless sprayer is the industry’s first cordless airless sprayer designed to spray the toughest protective coatings and

corrosion control materials. It’s an easy solution for touch-ups, spot repairs or small areas.

HD Brushless Motor

• Delivers the highest performance and longest life

• 1000–4000 psi (69-276 bar)

FullFlo Pressure Control

• Fully adjustable to achieve the finish you need

• Optimized for both thick and thin coatings

• Easy to read dial

Standard RAC X™ SwitchTip™ and Guard

• Accepts standard Graco RAC tips, guards and extensions

™

• Easy Out

• Supports .009–.025 tips

Tip Filter keeps spraying with fewer tip plugs

Easy Out Tip Filters

• Designed to decrease tip plugging

• Available in 30, 60 or 100 mesh sizes

• Thread-less design for easy removal

Spray-N-Throw Cup System

• Disposable 44 oz. (1.3 l) lid and liner system

virtually eliminates cleanup

• Sealed cup protects material while minimizing spills

• Spray at an angle — even upside down

28V High Power Lithium-Ion Power Packs

• Designed for maximum power to spray the most demanding materials

• Able to spray up to 1 gal (3.78 l) per battery charge

Ground Strap

• 25 ft (7.6 m)

Sprayable materials

• High solids epoxy primers and coatings —

up to 100% solids content

• Solvent-borne coatings

• Water-borne coatings

• Fire retardant coatings

10

• High solids polyurethane top coatings

• Plural component coatings

• Elastomerics

Ordering Information

165654 Complete kit with RAC X 517 tip

and 30 mesh filter

Page 11

Count On Graco

For more than 40 years, protective coatings contractors have placed their trust in the outstanding quality and durability

of Graco equipment. Here are just a few of the reasons why.

Superior support

and responsive service

With a global distribution network, you can count on quick turnaround times

for replacement parts and service. With Graco’s authorized distributors, you

have access to experts who understand the unique needs of your business.

In addition, Graco has close working relationships with many of the world’s

leading manufacturers and material suppliers. With Graco, you can expect

responsive service and support, as well as the accuracy and reliability you

demand from your manufacturing equipment.

Made with pride

Graco systems are designed, manufactured and built in the United States with

global components to Graco’s exacting standards. Graco makes significant

investments in product development and precision manufacturing to ensure

that the products you count on continue to evolve and meet the demands you

face in the future.

Training is also available

Graco offers valuable hands-on learning and equipment training at its training

centers in the U.S., Belgium and Shanghai, China. Convenient online training

courses are also available.

Trust genuine Graco parts and accessories for all your spray equipment

When you need replacement parts, you could purchase cheaper alternatives. But why risk it? Off-the-shelf parts may hinder performance

and possibly even damage your Graco equipment. You invest in Graco equipment because it is superior quality. Graco equipment is designed

as a unified system, not as a collection of stand-alone parts. Every part is designed with a careful eye toward the parts it will interact with,

and adjusted accordingly. Protect your investment and your future. Trust only genuine Graco parts. For more information on Parts & Accessories

for Protective Coatings High Pressure Equipment, refer to brochure 349329.

11

Page 12

ABOUT GRACO

Founded in 1926, Graco is a world leader in fluid handling systems and components. Graco products

move, measure, control, dispense and apply a wide range of fluids and viscous materials used

in vehicle lubrication, commercial and industrial settings.

The company’s success is based on its unwavering commitment to technical excellence, world-class

manufacturing and unparalleled customer service. Working closely with qualified distributors, Graco

offers systems, products and technology that set the quality standard in a wide range of fluid handling

solutions. Graco provides equipment for spray finishing, protective coating, paint circulation, lubrication,

and dispensing sealants and adhesives, along with power application equipment for the contractor

industry. Graco’s ongoing investment in fluid management and control will continue to provide

innovative solutions to a diverse global market.

GRACO LOCATIONS

MAILING ADDRESS

P.O. Box 1441

Minneapolis, MN 55440-1441

Tel: 612-623-6000

Fax: 612-623-6777

AMERICAS

MINNESOTA

Worldwide Headquarters

Graco Inc.

88 -11th Avenue N.E.

Minneapolis, MN 55413

EUROPE

BELGIUM

European Headquarters

Graco N.V.

Industrieterrein-Oude Bunders

Slakweidestraat 31

3630 Maasmechelen,

Belgium

Tel: 32 89 770 700

Fax: 32 89 770 777

ASIA PACIFIC

AUSTRALIA

Graco Australia Pty Ltd.

Suite 17, 2 Enterprise Drive

Bundoora, Victoria 3083

Australia

Tel: 61 3 9468 8500

Fax: 61 3 9468 8599

CHINA

Graco Hong Kong Ltd.

Shanghai Representative Office

Building 7

1029 Zhongshan Road South

Huangpu District

Shanghai 200011

The People’s Republic of China

Tel: 86 21 649 50088

Fax: 86 21 649 50077

INDIA

Graco Hong Kong Ltd.

India Liaison Office

Room 432, Augusta Point

Regus Business Centre 53

Golf Course Road

Gurgaon, Haryana

India 122001

Tel: 91 124 435 4208

Fax: 91 124 435 4001

JAPAN

Graco K.K.

1-27-12 Hayabuchi

Tsuzuki-ku

Yokohama City, Japan 2240025

Tel: 81 45 593 7300

Fax: 81 45 593 7301

KOREA

Graco Korea Inc.

Shinhan Bank Building

4th Floor #1599

Gwanyang-Dong, Dongan-Ku,

Anyang-si, Korea 431-060

Tel: 82 31 476 9400

Fax: 82 31 476 9801

SALES/

DISTRIBUTION/

SERVICE

North America

Customer Service

800-328-0211

Fax 877-340-6427

Call today for product information or to request a demonstration.

877-84GRACO (1-877-844-7226) or visit us at www.graco.com.

Graco Inc. is registered to I.S. EN ISO 9001

©2015 Graco Inc. 349325 Rev. A 1/15 All written and visual data contained in this document are based on the latest product information

available at the time of publication. Graco reserves the right to make changes at any time without notice. All other brand

names or marks are used for identification purposes and are trademarks of their respective owners.

Loading...

Loading...