Page 1

Husky™ Chemical

Transfer Pumps

A Complete Family of 1/4 inch (6.3 mm) to 3 inch (76.2 mm)

Air-Operated Double Diaphragm Pumps

• Flow rates of 0.25 gpm (0.94 lpm) to 300 gpm (1135 lpm)

• Up to 30% more efficient than market leaders

• 30% increase in fluid flow

• Reinforced frame for increased strength and smaller profiles

• Up to 5 times longer diaphragm life compared to other diaphragm pumps in its class

• Chemical pumps available in polypropylene, PVDF, SST, and hastelloy fluid sections

Page 2

CHEMICAL TRANSFER PUMPS

Our Husky chemical transfer air-operated double

Find the Right Pump for

your Application

Graco is making it easy to select a pump

that’s right for you.

To order a Husky pump, go to

www.graco.com/husky to use the

selector tool or contact your distributor.

diaphragm pumps are loaded with features to help

you get the job done right, every time, and are built

to save you time and money.

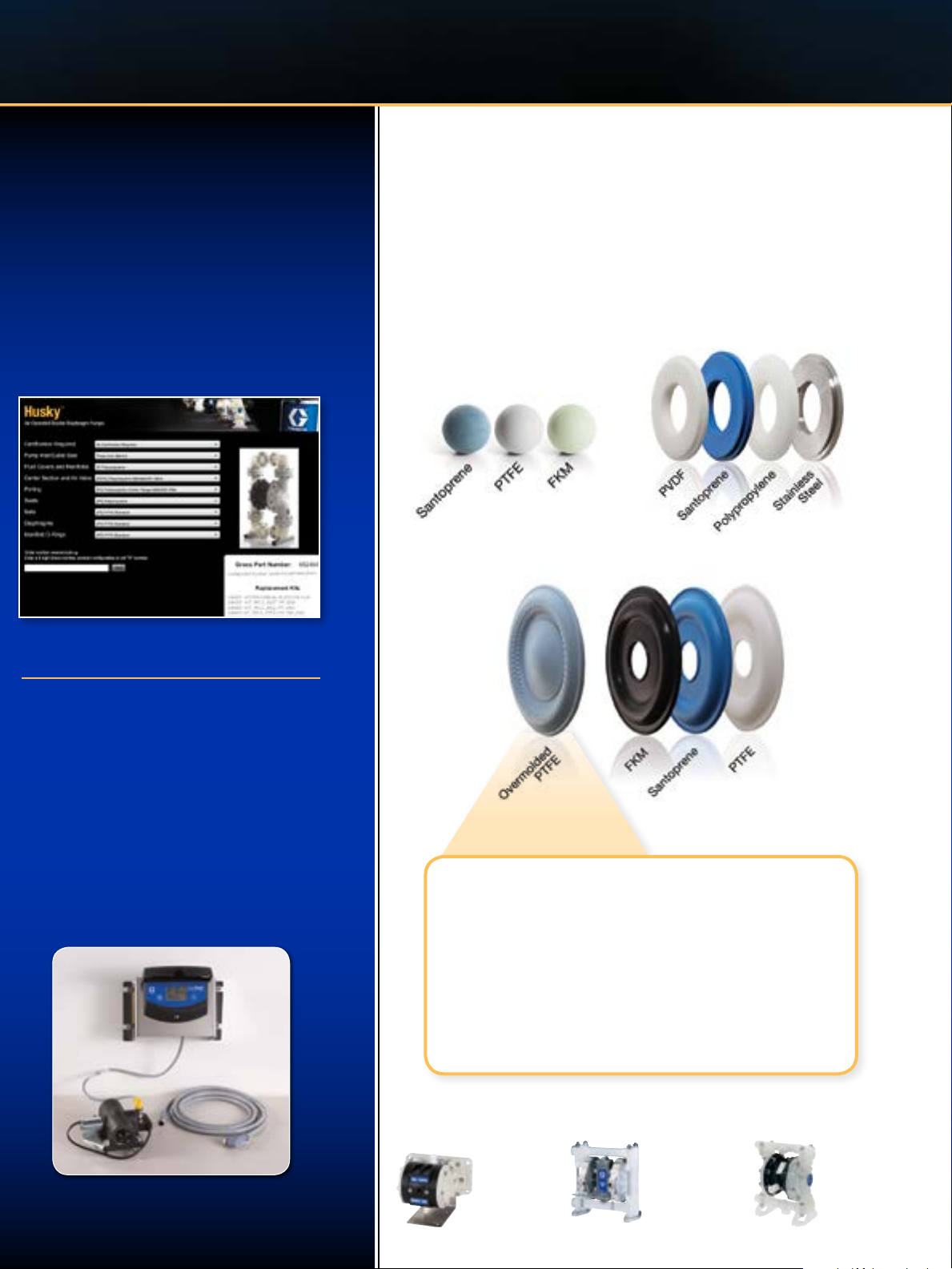

Chemical Pump Material Options

Seats

Balls

Diaphragms

Example of Product Selector Tool

Want to schedule maintenance?

Use DataTrak or Pulse Output!

• DataTrak™

– Ability to prevent pump runaway due to a

damaged line or empty container

– Tracks material usage

• Pulse Output

– Cycle count capability for preventative

maintenance measures

• Overmolded design improves wear and diaphragm

life with no exposed diaphragm plate on the fluid side

• Longer diaphragm life in more abrasive applications

that still require PTFE

• Available for Graco industrial diaphragm pumps –

Husky 515, 1050, 15120, 2200 and 3300

• Largest overmolded diaphragm range in the industry

(1/2 inch to 3 inch)

205

1/4 in (6.3 mm)

5 gpm (19 lpm)

307

3/8 in (9.4 mm)

6.5 gpm (24.6 lpm)

515

1/2 in (12.7 mm) or

3/4 in (19.1 mm)

15 gpm (57 lpm)

Page 3

New Center Connection!

• Available on polypropylene pumps

• End porting available on all material options

Modular Air Valve

• Stall-free operation

provides smooth and

rapid changeover along

with ease of maintenance

Increased Flow &

Efficiency

• Up to 30% more efficient

than the industry leaders

• Up to 10% more flow than

market leaders

Updated Diaphragm

Design

• Improved diaphragm

design for longer life

• Overmolded PTFE

diaphragm option

One-Piece Center

• Polypropylene for chemical compatibility

• Reduced air leakage

External Pilots

• Provides ease of maintenance

1050

1 in (25.4 mm)

50 gpm (189 lpm)

15120

1-1/2 in (38.1 mm)

120 gpm (454 lpm)

Reinforced Frame

• Reduced leakage & cold flow

• Increased strength with

smaller footprint

• Overmold maintains

chemical resistance

Four Bolt Joint Design

• Bolted design provides

even sealing pressure for

leak-free operation

Chemical Fluid Section Material Options

• Plastic models available in polypropylene or PVDF

• Metal models available in SST and Hastelloy

2200

2 in (50.8 mm)

200 gpm (757 lpm)

3300

3 in (76.2 mm)

300 gpm (1,135 lpm)

Page 4

Husky Technical Specifications

Husky 205

Material of Construction ......................................Acetal, Polypropylene, PVDF

Maximum fluid working pressure ........................100 psi (7 bar, 0.7 MPa)

Air pressure operating range ............................... 20 to 100 psi (1.4 to 7 bar,

0.14 to 0.7 MPa)

Maximum air consumption..................................9.0 scfm (0.252 m3/min)

Maximum free-flow delivery ...............................5.0 gpm (18.9 lpm)

Maximum suction lift ..........................................10 ft (3 m) dry

Air inlet size ........................................................1/4 npt(f) / 1/4 bsp(f)

Operational Manual .............................................308652

Husky 307

Material of Construction ......................................Acetal, Polypropylene

Maximum fluid working pressure ........................100 psi (7 bar, 0.7 MPa)

Air pressure operating range ............................... 20 to 100 psi (1.4 to 7 bar,

0.14 to 0.7 MPa)

Maximum air consumption..................................5.5 scfm (0.16 m3/min)

Maximum free-flow delivery ...............................6.5 gpm (24.6 lpm)

Maximum suction lift ..........................................7 ft (2.1 m) dry

Air inlet size ........................................................1/4 npt(f)

Operational Manual .............................................308553

Husky 515/716

Material of Construction ......................................Acetal, Polypropylene, PVDF, AL, SST

Maximum fluid working pressure ........................100 psi (7 bar, 0.7 MPa)

Air pressure operating range ............................... 30 to 100 psi (2.1 to 7 bar,

0.21 to 0.7 MPa)

Maximum air consumption..................................28 scfm (0.672 m3/min)

Maximum free-flow delivery ...............................15 gpm (57 lpm)

Maximum suction lift ..........................................15 ft (4.5 m) dry

Air inlet size ........................................................1/4 npt(f)

Operational Manual .............................................308981

Husky 1050

Material of Construction ...................................... Conductive Polypropylene,

Polypropylene, PVDF, AL, SST

Maximum fluid working pressure ........................125 psi (8.6 bar, 0.8 MPa)

Air pressure operating range ............................... 20-125 psi (1.4-8.6 bar,

0.14-0.86 MPa)

Maximum air consumption..................................67 scfm (1.9 m3/min)

Air consumption at 70 psi

(4.8 bar, 0.48 MPa), 20 gpm (76 lpm) .............25 scfm (0.7 m3/min)

Maximum free-flow delivery ...............................50 gpm (189 lpm)

Maximum suction lift ..........................................16 ft (4.9 m) dry, 29 ft (8.8 m) wet

Air inlet size ........................................................1/2 npt(f)

Operational Manual .............................................312877

Repair/Parts Manual ...........................................313435

Husky 1590

Material of Construction ...................................... Polypropylene, SST, AL

Maximum fluid working pressure ........................120 psi (8.4 bar, 0.84 MPa)

Air pressure operating range ............................... 20 to 120 psi (1.4 to 8.4 bar,

0.14 to 0.84 MPa)

Maximum air consumption .................................125 scfm (3.5 m3/min)

Maximum free-flow delivery ...............................100 gpm (378.5 lpm)

Maximum suction lift ..........................................20 ft (6.1 m) dry

Air inlet size ........................................................1/2 npt(f)

Operational Manual .............................................308549

Repair/Parts Manual ...........................................308549

Husky 15120

Material of Construction ............................................... Polypropylene, PVDF

Maximum fluid working pressure ................................. 125 psi (8.6 bar, 0.86 MPa)

Air pressure operating range ........................................ 20 to 125 psi (1.4 to 8.6 bar,

0.14 to 0.86 MPa)

Maximum air consumption...........................................85 scfm (2.4 m3/min.)

Air consumption at 70 psi/60 gpm ...............................43 scfm (2 m3/min)

Maximum free-flow delivery ........................................ 120 gpm (454 lpm)

Maximum suction lift ...................................................16 ft (4.9 m) dry

Air inlet size ................................................................. 1/2 npt(f)

Operational Manual ...................................................... 3A2888

Repair/Parts Manual ....................................................3A2889

Husky 2150

Material of Construction ............................................... Polypropylene, SST, AL

Maximum fluid working pressure ................................. 120 psi (8.4 bar, 0.84 MPa)

Air pressure operating range ........................................ 20 to 120 psi (1.4 to 8.4 bar,

0.14 to 0.84 MPa)

Maximum air consumption...........................................175 scfm (4.9m3/min)

Air consumption at 70 psi/60 gpm ............................... 60 scfm (1.7 m3/min.)

Maximum free-flow delivery ........................................ 150 gpm (568 lpm)

Maximum suction lift ...................................................18 ft (5.48 m) wet or dry

Air inlet size ................................................................. 1/2 npt(f)

Operational Manual ......................................................308550

Repair/Parts Manual ....................................................308550

Husky 2200

Material of Construction ............................................... Polypropylene, PVDF

Maximum fluid working pressure ................................. 125 psi (8.6 bar, 0.86 MPa)

Air pressure operating range ........................................ 20 to 125 psi (1.4 to 8.6 bar,

0.14 to 0.86 MPa)

Maximum air consumption

Standard diaphragms .............................................. 140 scfm (4 m3/min)

Overmolded diaphragms ......................................... 157 scfm (4.4 m3/min)

Air consumption at 70 psi/100 gpm ............................. 70-75 scfm (2-2.1 m3/min)

Maximum free-flow delivery ........................................ 200 gpm (757 lpm)

Maximum suction lift ...................................................16 ft (4.9 m) dry

Air inlet size ................................................................. 3/4 npt(f)

Operational Manual ......................................................3A2578

Repair/Parts Manual ....................................................3A2714

Husky 3300

Material of Construction ............................................... Polypropylene, SST, AL

Maximum fluid working pressure ................................. 100 psi (7.0 bar, 0.7 MPa)

Air pressure operating range ........................................ 20 to 100 psi (1.4 to 7.0 bar,

0.14 to 0.7 MPa)

Maximum air consumption...........................................335 scfm (9.5 m3/min)

Air consumption at 70 psi (4.8 bar, 0.48 MPa) ..............275 scfm (7.8 m3/min.)

Maximum free-flow delivery at 100 psi (7 bar, 0.7 MPa)

Standard diaphragms .............................................. 300 gpm (1135 lpm)

Overmolded diaphragms ......................................... 260 gpm (984 lpm)

Maximum suction lift ...................................................8 ft (2.4 m) dry

Air inlet size ................................................................. 3/4 npt(f)

Operational Manual ......................................................3A0410

Repair/Parts Manual ....................................................3A0411

All written and visual data contained in this document are based on the latest product information available at the time of publication. Graco reserves the right to make changes at any time without notice.

Call today for product information or to request a demonstration.

877.84GRACO (1-877-844-7226) or visit us at www.graco.com.

©2014 Graco Inc. Form No. 345059 Rev. B 10/14 Electronic Only.

All other brand names or marks are used for identification purposes and are trademarks of their respective owners.

Loading...

Loading...