Page 1

Operation

HTX 2030

-For Portable Airless and Air-Assisted Spraying of Water-Based Architectural Coatings with Base Coat Pump-

-For Airless Spraying Architectural Coatings and Paints with Top Coat Pump-

IMPORTANT SAFETY INSTRUCTIONS

Read all warnings and instructions in this

manual. Save these instructions.

Model Number: 257369 (HTX2030 FreeFlo Inline Gun)

Model Number: 278675 (HTX2030 AirSpray Trigger Gun)

Maximum Working Pressure:

Base Coat Pump: 1000 psi (69 bar, 6.9 MPa)

Top Coat Pump: 3300 psi (228 bar, 22.8 MPa)

Related Manuals

313891 - Operation (French)

313893 - Operation (Spanish)

313889 - Repair (English)

313892 - Repair (French)

313893 - Repair (Spanish)

313890 - Parts

313895 - HTX 2030 Flex Head and Pole Spray Applicator (English)

313896 - HTX 2030 Flex Head and Pole Spray Applicator (French)

313897 - HTX 2030 Flex Head and Pole Spray Applicator (Spanish)

310894 - Displacement Pump (Top Coat)

308491 - Airless Heavy Duty Texture Gun

313537 - HTX 2030 FreeFlo Inline Gun (English)

313603 - HTX 2030 FreeFlo Inline Gun (Chinese)

313908 - HTX 2030 FreeFlo Inline Gun (French)

313911 - HTX 2030 FreeFlo Inline Gun (Spanish)

332160 - HTX2030 AirSpray Trigger Gun (English)

332227 - HTX2030 AirSpray Trigger Gun (French)

332228 - HTX2030 AirSpray Trigger Gun (Spanish)

332229 - HTX2030 AirSpray Trigger Gun (Chinese)

313888E

EN

ti13632a

Page 2

Contents

Contents

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . 5

HTX 2030 with Base Coat Pump (257369) . . . . . 5

Top Coat Pump (Kit 24B140) . . . . . . . . . . . . . . . 6

Component Identification - Sprayer . . . . . . . . . . . 7

Component Identification - Base Coat Applicator 8

Component Identification - HTX2030 Air Spray

Trigger Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 10

Applicator (Base Coat Pump) . . . . . . . . . . . . . . 10

Spray Gun (Top Coat Pump) . . . . . . . . . . . . . . 11

Start Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Material and Sprayer Preparation . . . . . . . . . . . 13

Prime Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Spray With Airless Tip . . . . . . . . . . . . . . . . . . . . 14

Spray Without Air - Clear Clog . . . . . . . . . . . . . 15

Air Assisted Spray

(Base Coat Applicator) . . . . . . . . . . . . . . . . 15

Air Assisted Spray

(Air Spray Trigger Gun) . . . . . . . . . . . . . . . 16

Spray Gun (Top Coat Pump) . . . . . . . . . . . . . . 17

Cleanup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Digital Tracking System (DTS) . . . . . . . . . . . . . . . 21

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Secondary Menu - Stored Data Mode . . . . . . . 22

Digital Display Messages . . . . . . . . . . . . . . . . . . . 23

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 28

2 313888E

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire

and explosion:

•

Use equipment only in well ventilated area.

•

Do not fill fuel tank while engine is running or hot; shut off engine and let it cool. Fuel is flammable and can

ignite or explode if spilled on hot surface.

•

Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

•

Keep work area free of debris, including solvent, rags and gasoline.

•

Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes are

present.

•

Ground all equipment in the work area. See Grounding instructions.

•

Use only grounded hoses.

•

Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unless they are

antistatic or conductive.

•

Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment until you

identify and correct the problem.

•

Keep a working fire extinguisher in the work area.

SKIN INJECTION HAZARD (SPRAY GUN)

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just a

cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

•

Do not point gun at anyone or at any part of the body.

•

Do not put your hand over the spray nozzle.

•

Do not stop or deflect leaks with your hand, body, glove, or rag.

•

Follow Pressure Relief Procedure in this manual when you stop spraying and before cleaning, checking,

or servicing equipment.

SKIN INJECTION HAZARD (APPLICATOR AND AIR SPRAY TRIGGER GUN)

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This may

look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

•

Do not point dispensing device at anyone or at any part of the body.

•

+

Do not put your hand over the fluid outlet.

•

Do not stop or deflect leaks with your hand, body, glove, or rag.

•

Follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking, or servicing equipment.

•

Tighten all fluid connections before operating the equipment.

•

Check hoses and couplings daily. Replace worn or damaged parts immediately.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

•

Keep clear of moving parts.

•

Do not operate equipment with protective guards or covers removed.

•

Pressurized equipment can start without warning. Before checking, moving, or servicing equipment, follow the Pressure Relief Procedure and disconnect all power sources.

313888E 3

Page 4

Warnings

WARNING

RECOIL HAZARD

Gun may recoil when triggered. If you are not standing securely, you could fall and be seriously injured.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical reaction

and equipment rupture. Failure to follow this warning can result in death, serious injury, or property damage.

•

Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids containing such solvents.

•

Many other fluids may contain chemicals that can react with aluminum. Contact your material supplier for compatibility.

SUCTION HAZARD

Powerful suction could cause serious injury.

•

Never place hands near the pump fluid inlet when pump is operating or pressurized.

CARBON MONOXIDE HAZARD

Exhaust contains poisonous carbon monoxide, which is colorless and odorless. Breathing carbon monoxide can

cause death.

•

Do not operate in an enclosed area.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed.

•

Read MSDSs to know the specific hazards of the fluids you are using.

•

Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe burns:

•

Do not touch hot fluid or equipment.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including eye injury,

hearing loss, inhalation of toxic fumes, and burns. This protective equipment includes but is not limited to:

•

Protective eyewear, and hearing protection.

•

Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

•

Do not operate the unit when fatigued or under the influence of drugs or alcohol.

•

Do not exceed the maximum working pressure or temperature rating of the lowest rated system component.

See Technical Data in all equipment manuals.

•

Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all equipment

manuals. Read fluid and solvent manufacturer’s warnings. For complete information about your material,

request MSDS from distributor or retailer.

•

Do not leave the work area while equipment is energized or under pressure.

•

Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

•

Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s

replacement parts only.

•

Do not alter or modify equipment. Alterations or modifications may void agency approvals and create safety

hazards.

•

Make sure all equipment is rated and approved for the environment in which you are using it.

•

Use equipment only for its intended purpose. Call your distributor for information.

•

Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

•

Do not kink or over bend hoses or use hoses to pull equipment.

•

Keep children and animals away from work area.

•

Comply with all applicable safety regulations.

4 313888E

Page 5

Product Overview

Product Overview

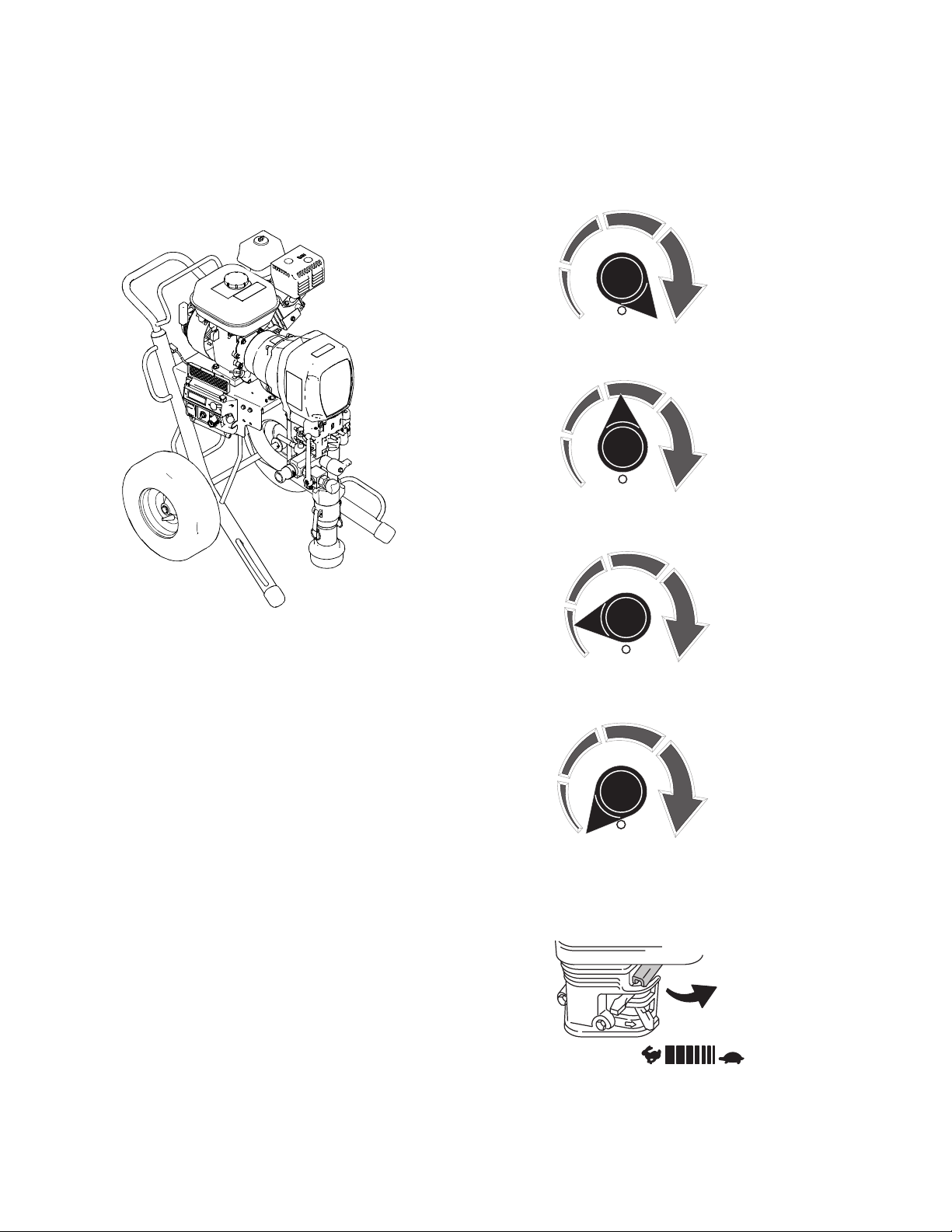

HTX 2030 with Base Coat Pump

(257369)

ti13632a

Flow rate is dependent on engine speed and the setting

of the pump control knob.

1. Flow 3 (fully clockwise) - allows the pump to run

continuously with minimal pulsation:

ti13756a

2. Flow 2 (near middle of the rotation) reduces flow

slightly by briefly interrupting pump:

ti13757a

3. Flow 1 (near counterclockwise end of pump control)

reduces flow more by interrupting pump longer:

The HTX 2030 Sprayer comes equipped with a Base

Coat Pump 24B321. Only water-based materials are to

be used with this configuration, such as:

• Smooth to heavily aggregated textures with silica

sand, perlite, vermiculite and polystyrene

• Smooth, medium, coarse and extra coarse textures

• Most materials with aggregates up to 2.5 mm (.100

in.) in longest dimension

When Base Coat Pump is Installed

Pump will only run when on/off switch is in ON position

AND:

• Pump control is rotated clockwise away from OFF

position, and either of the following switches are

also switched ON:

Prime Switch on pressure control box AND/OR

Applicator Switch near end of material hose

The pressure control will limit the sprayer to 1,000 psi

(69 bar), stopping the pump whenever pressure limit is

reached.

ti13758a

4. OFF (fully counterclockwise) - stops pump completely:

ti13755a

5. Adjust engine speed to control flow rate of sprayer.

Start with the slowest speed possible for maximum

spray control. Different spray tip nozzle sizes can

also be tried.

ti5251a

313888E 5

Page 6

Product Overview

Top Coat Pump (Kit 24B140)

ti13653a

The pump on the HTX 2030 Sprayer can also be

switched out with a Top Coat Kit 24B140 (purchased

separately). This pump is used for less viscous

materials such as:

• Oil-based coatings

• Enamels

• Latex

When Top Coat Pump is Installed

• Pump will only run when on/off switch is in ON posi-

tion and pump control is rotated clockwise away

from OFF position

• Pump control setting adjusts sprayer pressure

a. Rotating knob fully clockwise allows sprayer to

reach maximum working pressure of 3300 psi

(228 bar, 22.8 MPa)

b. Settings below maximum will lower system

pressure

• Pump will run whenever system pressure is below

the setting of the pump control

• Sprayer will not respond to Prime switch or Applicator switch when Top Coat pump is installed

• Block fillers

• Elastomerics

• Epoxies

• Drywall mud

• Other high-build materials

For instructions on installing the Top Coat Pump, see

manual 313889.

ti13653a

6 313888E

Page 7

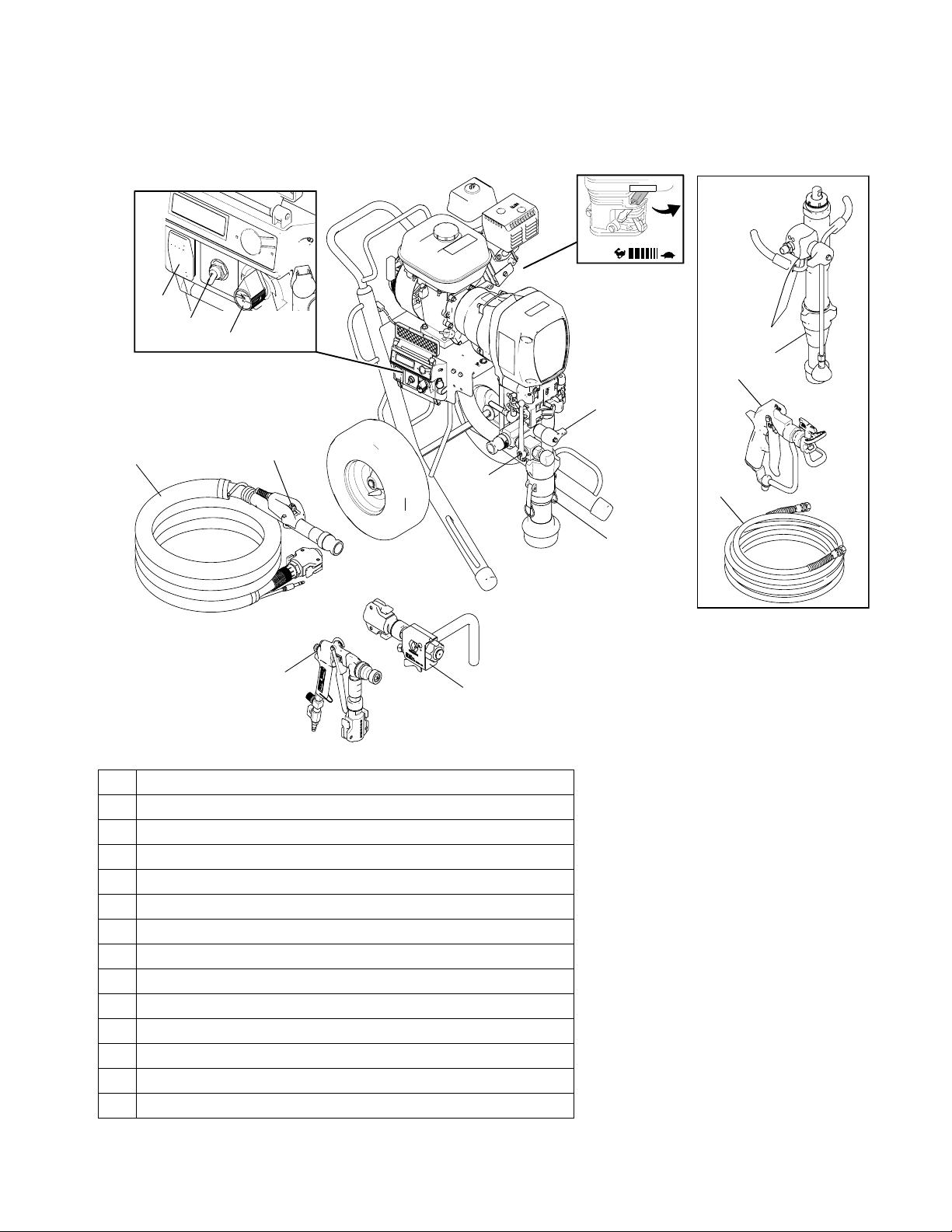

Component Identification - Sprayer

14

1

2

3

8

Component Identification - Sprayer

Top Coat Kit

9

10

4

1 ON/OFF Switch

2 Prime Switch (used with Base Coat Pump)

3 Pump Control Knob

4 Heavy Texture Material Hose (used with Base Coat Pump)

5 Applicator Switch (used with Base Coat Pump--on Hose)

6 Applicator (Base Coat) (Model 257369)

7 Pump (Base Coat)

8 Over Pressure Relief Valve

9 Pump (Top Coat)

10 Spray Gun (Top Coat)

11 Paint/Texture Material Hose (used with Top Coat Pump)

12 Prime/Drain Valve

13 Air Spray Gun (24R054)

14 Engine Throttle Lever/Material Flow

5

12

13

6

11

7

ti14415b

313888E 7

Page 8

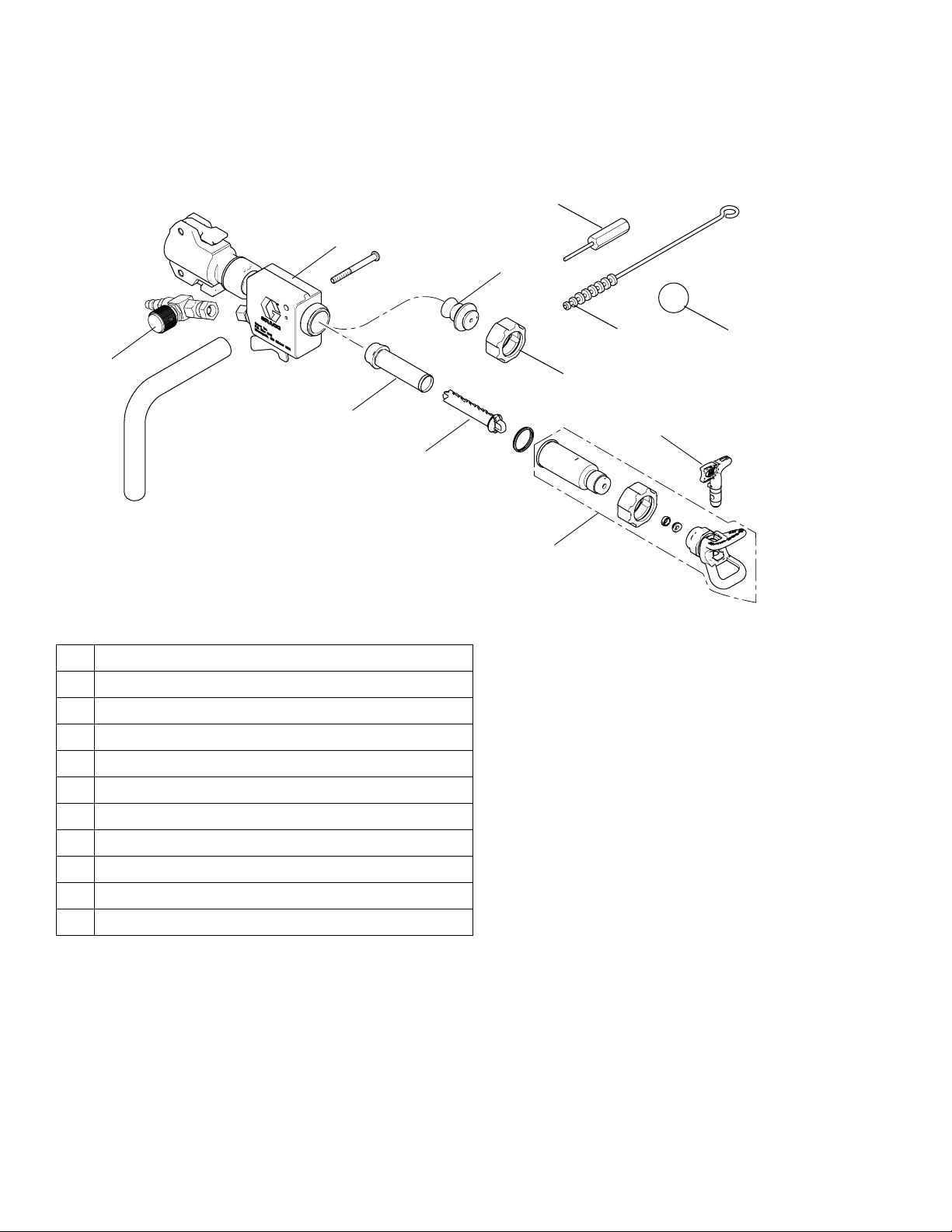

Component Identification - Base Coat Applicator

Component Identification - Base Coat Applicator

8

1

7

2

3

1 Applicator

2 Air Hose Adapter and Air Adjustment Valve

3 Airless Filter or Air Passage Plug

4 Filter Support

5 Airless Spray Assembly

6 Airless Spray Tip Nozzle

9

11

6

4

5

10

ti14357a

7 Air Nozzle (4 mm, 6mm, 8mm, 10mm)

8 Air Nozzle Cleaner

9 Cleaning Brush

10 Cleaning Ball

11 Retaining Nut

8 313888E

Page 9

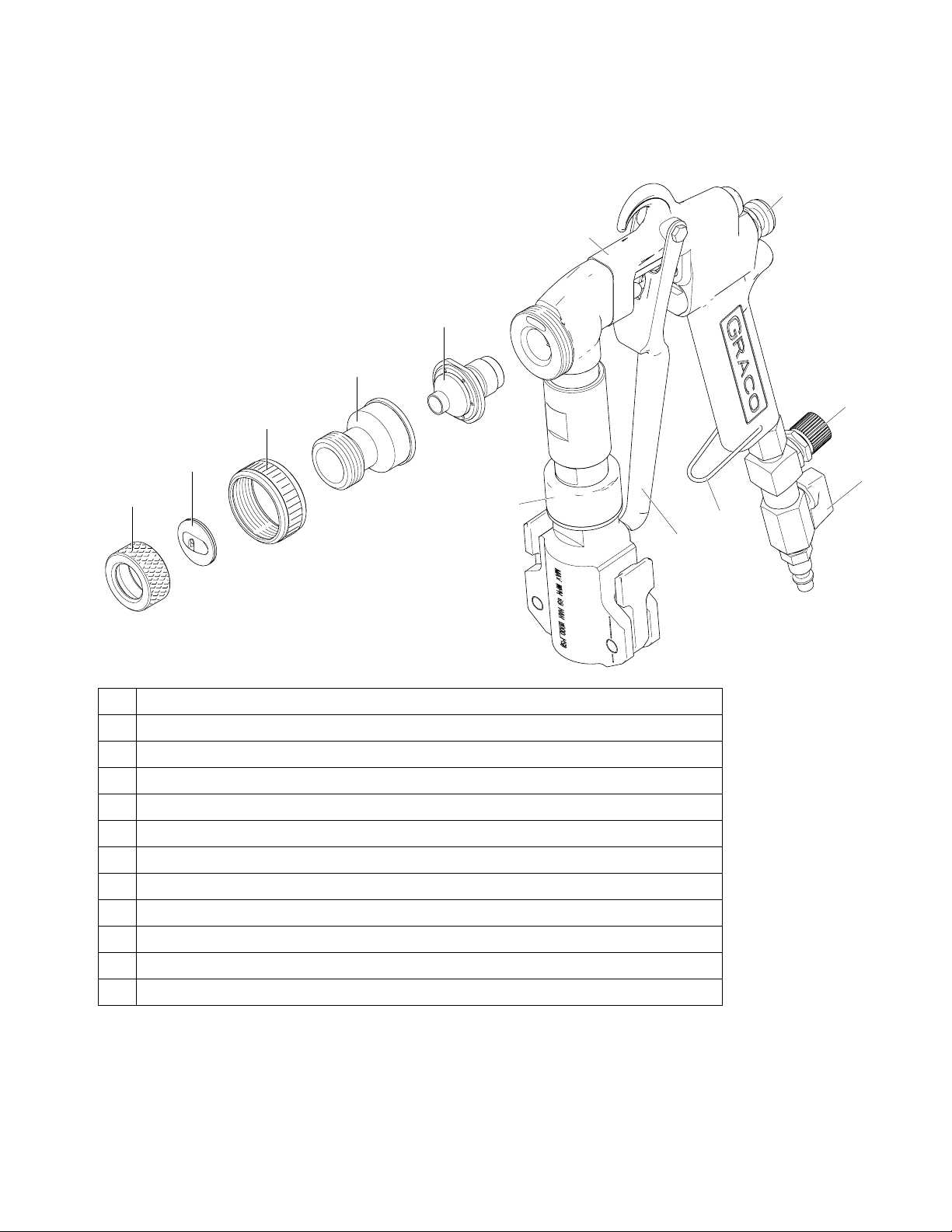

Component Identification - HTX2030 Air Spray Trigger Gun

Component Identification - HTX2030 Air Spray Trigger Gun

11

1

2

3

7

4

5

6

9

12

1 HTX2030 Air Spray Trigger Gun

2 Nozzle, Size #1, Size #2, Size #3

3 Adapter, Housing

4 Ring, Retaining Nozzles

5 Tip, Disc, Spray, 1/8 in. (3 mm), 1/4 in. (6.3 mm), 5/16 in. (8 mm), 3/8 in. (9.5 mm)

6 Ring, Retaining, Spray Discs

7 Air Adjustment Valve

8 Trigger, Latch On

9 HTX Swivel Assembly

10 Air, Control Ball Valve

10

8

ti21036a

11 Flow, Adjust Knob

12 Trigger

313888E 9

Page 10

Grounding

Grounding

The equipment must be grounded to reduce the risk of

static sparking. Static sparking can cause fumes to

ignite or explode. Grounding provides an escape wire

for the electric current.

Ground sprayer with grounding clamp to earth ground

when flushing sprayer.

ti3058a

Pressure Relief Procedure

Applicator and Air Spray Trigger Gun

(Base Coat Pump)

Follow the Pressure Relief Procedure whenever

you see this symbol.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid, such as skin injection, splashing

fluid and moving parts, follow the Pressure Relief

Procedure when you stop spraying and before cleaning, checking, or servicing the equipment.

1. Turn engine OFF.

To maintain grounding continuity when flushing or

relieving pressure: Hold metal part of the spray gun

firmly to the side of a grounded metal pail, then trigger

the gun/valve.

ti6208b

2. Turn on/off switch OFF and turn pressure control

knob fully counterclockwise.

3. HTX2030 Air Spray Trigger Gun only: Pull gun

trigger to release pressure.

4. Turn prime/drain valve down to DRAIN position.

Fluid from drain valve can splash in eyes or skin and

cause serious injury. Keep hands clear of pressure

relief valve and always wear safety glasses.

NOTE: If you suspect spray tip nozzle or hose is completely clogged or that pressure has not been fully

relieved after following the previous steps, cover the

connection at end of hose with a heavy rag and very

slowly loosen connection.

ti13050a

ti14632a

10 313888E

Page 11

Pressure Relief Procedure

Spray Gun (Top Coat Pump)

1. Lock gun trigger safety and turn engine OFF.

ti13131a

2. Turn on/off switch to OFF and turn pressure control

knob fully counterclockwise.

ti13050a

3. Unlock trigger safety. Hold metal part of gun firmly

to side of grounded metal pail and trigger gun to

relieve pressure.

ti10796b

4. Lock gun trigger safety. Open pressure prime/drain

valve. Leave valve open until ready to spray again.

ti13131a

ti14632a

NOTE: If you suspect that the spray tip nozzle or hose is

completely clogged, or that pressure has not been fully

relieved after following the previous steps, VERY

SLOWLY loosen the tip guard retaining nut or hose end

coupling to relieve pressure gradually, then loosen completely. Then clear tip or hose.

ti13130a

ti13128a

313888E 11

Page 12

Start Engine

Start Engine

1. Move fuel valve to OPEN.

ti5248a

2. Move choke to CLOSED.

5. Pull starter rope.

ti5263a

6. After engine starts, move choke to OPEN.

ti5264a

ti5249a

3. Set throttle to FAST.

ti5250a

4. Set engine switch to ON.

ti3315a

7. Set throttle to desired setting.

ti5251a

12 313888E

Page 13

Setup

Setup

NOTICE

DO NOT USE MATERIALS THAT CURE RAPIDLY!

Materials with a fast curing time could plug the pump,

hose, gun, or applicator.

1. Fill mixing pail with pre-mixed texture material. Mix

per material manufacturer instructions.

ti4118a

Add approximately 10% water to texture m ix or per material manufacturer instructio ns. Mix thoroughly.

2. Connect material hose to pump outlet.

ti14416a

ti13638a

Prime Pump

1. Start gasoline engine and adjust speed to half throttle. Turn prime/drain valve to DRAIN.

ti14632a

2. Place material hose outlet over supply pail.

ti13640a

3. Turn on/off switch ON.

Material and Sprayer Preparation

NOTE: To minimize material pack-out in hose when

priming, completely empty hose of all water. In hot conditions, it may be necessary to wet the hose with water

to lower internal hose temperature, slowing material

setup. In this case, water removal is still recommended.

If using hose lubricant/wetting solutions, refer to manufacturer instructions for proper priming techniques.

Cementicious and other curing materials can harden

within the drain valve while spraying. At least once per

hour stop spraying and open the drain valve to flush out

the older material.

3. Pour mixed material into supply pail under sprayer.

4. Place pump suction tube into mixed material.

NOTE: For best results with aggregate, remove strainer.

ti10795b

Base Coat Pump:

Also turn Prime switch ON, or activate applicator

switch on material hose.

4. Rotate pump control knob 1/4 turn. Run pump until

a steady stream of material flows from drain valve.

ti11930a

ti13652a

313888E 13

Page 14

Setup

5. Turn on/off switch OFF and turn drain valve knob to

SPRAY.

ti10796b

6. Turn on/off switch ON, and run pump until a steady

stream of material flows from material hose. Turn

on/off switch to OFF and turn drain valve knob to

DRAIN.

ti13649a

7. Connect applicator to material hose.

Spray With Airless Tip

1. Install filter and tip extension.

ti13648a

2. Insert metal seat and OneSeal. Insert Switch Tip.

Screw assembly onto applicator.

ti13650a

3. Turn drain valve to SPRAY, and turn on/off switch to

ON. Turn pump control knob clockwise and/or

adjust engine speed until desired material delivery

rate is achieved.

ti21038a

ti8794a

4. Spray test pattern. Aim applicator at floor. Turn

applicator switch ON and move applicator to spray

surface.

ti21042a

ti13651a

14 313888E

Page 15

Setup

Spray Without Air - Clear Clog

1. Relieve Pressure, page 10.

2. Rotate SwitchTip to Clear position. Aim applicator at

floor and turn pump ON. When clog clears, turn

pump OFF.

ti11714a

3. Rotate SwitchTip to Spray position. Turn pump ON.

Spray test pattern.

ti11715a

4. Turn air valve OFF. Connect applicator to material

hose and air hose. Air supply minimum requirements vary with material thickness and desired

thickness.

ti21037a

NOTICE

DO NOT USE MATERIALS THAT CURE RAPIDLY!

Materials with a fast curing time could plug the pump

hose, gun, or applicator.

5. Turn on/off switch ON.

Air Assisted Spray

(Base Coat Applicator)

1. Prepare material, page 13. Place material hose in

supply pail.

2. Turn on/off switch OFF.

ti10796b

3. Remove cap and install air valve assembly.

ti10795b

6. Hold applicator over material pail and turn pump ON

using applicator switch on hose.

ti13641a

7. Turn pump control clockwise until desired material

delivery rate is achieved.

ti13647a

313888E 15

ti8794a

ti5251a

Page 16

Setup

8. Spray test pattern. Aim applicator at floor. Turn air

valve ON. Move applicator to spray surface.

ti13646a

9. Adjust air valve and/or select alternative nozzle size

(4 - 10mm) for desired finish.

4 mm

6 mm

8 mm

10 mm

ti11798a

NOTICE

IF PUMP IS STOPPED LONGER THAN 3 MINUTES, TO AVOID PUMP PLUGGING:

• Relieve pressure in the pump (See Pressure

Relief procedure - page 10).

• Recirculate the material by pumping back into

original material container.

Air Assisted Spray

(Air Spray Trigger Gun)

3. Turn air valve OFF. Connect applicator to material

hose and air hose. Air supply minimum requirements vary with material thickness and desired

thickness.

ti21263a

NOTICE

DO NOT USE MATERIALS THAT CURE RAPIDLY!

Materials with a fast curing time could plug the pump

hose, gun, or applicator.

4. Turn on/off switch ON.

ti10795b

5. Hold applicator over material pail, trigger on, and

turn pump ON using applicator switch on hose.

NOTE: Remove spray disk then set material flow to

prevent material from back-flowing into air passages

of gun.

Due to the high pressure fluid emitted, a strong recoil

action may occur when you trigger this gun. If you are

unprepared, your hand could be forced back toward

your body or you could lose your balance and fall,

resulting in serious injury.

1. Prepare material, page 13. Place material hose in

supply pail.

6. Turn pump control clockwise and adjust engine

throttle to lowest setting until desired material deliv-

ti21243a

ery rate is achieved.

2. Turn on/off switch OFF.

ti10796b

ti8794a

16 313888E

Page 17

Setup

7. Turn air valve on and adjust air valve and/or select

alternative nozzles or spray discs to achieve desired

pattern.

1/8 in.

1/4 in.

3/8 in.

ti21034a

5/16 in.

8. Spray test pattern. Move applicator to spray surface. NOTE: See Air Spray Trigger Gun manual for

helpful hints on spray patterns.

NOTICE

• Keep gun triggered as much as possible to

prevent pack-out.

• If gun has not been triggered for longer than 3

minutes, perform Pressure Relief (page 10) in

the pump and hose to prevent packout.

• Turn off applicator switch on hose before detriggering to minimize retained pressure.

2. Screw assembly onto gun. Hand tighten.

ti5801a

3. Trigger gun and spray test pattern. Slowly adjust

pressure to eliminate heavy edges. Use smaller tip

size if pressure adjustment can not eliminate heavy

edges.

heavy

ti5823a

edges

4. Hold gun perpendicular, 10-12 in. (25-30 cm) from

surface. Spray back and forth. Use strokes overlapped by 50%. Start gun movement before triggering gun and release trigger before stopping gun

movement.

• Make sure air is flowing before triggering gun.

Spray Gun (Top Coat Pump)

1. Lock gun trigger safety. Insert seat and OneSeal™.

Insert SwitchTip.

ti13131a

SwitchTip

ti5800a

Seat

One seal

ti5824a

313888E 17

Page 18

Cleanup

Cleanup

1. Turn on/off switch OFF.

ti10796b

2. Perform Pressure Relief procedure, page 10.

3. Place pump in pail of clean water.

5. Base Coat Pump: Disconnect material hose from

pump outlet.

ti13639a

6. Insert wet cleaning ball into hose (Base Coat Only).

Connect material hose to pump outlet.

ti13644a

4. Shut OFF air if spraying with air. Remove applicator

from material and air hoses.

ti14284a

ti21040a

ti13643a

ti13638a

7. Hold material hose over waste pail.

ti13640a

8. Turn on/off switch ON and prime switch ON, or

applicator switch on material hose.

ti10795b

18 313888E

Page 19

Cleanup

9. Run pump until cleaning ball exits material hose.

Save cleaning ball (Base Coat Only).

ti4551c

10. Turn on/off switch OFF and turn prime/drain valve to

DRAIN. Clean outside of pump and suction tube

with brush and water.

ti10796b

ti14632a

11. Connect applicator to material hose. Close

prime/drain valve.

14. Add additional water and repeat steps 12 - 13 if necessary.

ti13839a

15. Open prime/drain valve and turn prime switch ON to

flush valve.

ti14632a

ti21038a

12. Turn on/off switch ON.

Base Coat Pump: Turn prime switch ON, or applicator switch on material hose.

ti10795b

13. Run pump until clean water flows from applicator.

16. Turn on/off switch OFF when valve is thoroughly

flushed.

ti10796b

17. Open over pressure relief valve and turn prime

switch ON to flush valve.

ti13633a

ti13641a ti21039a

313888E 19

Page 20

Cleanup

18. Remove and thoroughly clean applicator, spray tip

nozzle and guard with brush.

19. Turn on/off switch OFF when valve is thoroughly

flushed.

NOTICE

Do not use air nozzle cleaner to clean applicator

check valve or airless spray tip nozzle. Damage will

occur.

20. Clean hardened material from applicator nozzles

with air nozzle cleaner.

ti11810a

ti11811a

Remove air check valve from applicator to clean

hardened material from interior of applicator.

ti13642a

ti21035a

20 313888E

Page 21

Digital Tracking System (DTS)

Digital Tracking System (DTS)

Main Menu

Close cover when spraying to protect display.

ti5802a

1. Perform Startup steps 1 - 2.

• Open drain valve

• Turn pump control counterclockwise to lowest set-

ting

• Set applicator switch to OFF

2. Start Engine, page 12. Display will momentarily

show which pump is installed (Base or Top) and

then Flow 1, 2, or 3 (if Base Coat pump is installed).

Pressure display appears, then dashes appear

when pressure is less than 60 psi (4 bar, 0.4 MPa).

ti5804a

4. Short press DTS button to move to Engine RPM.

ti13761a

5. Short press DTS button to return to Pressure.

ti13762a

To Change Pressure Units:

Press and hold (8 seconds) DTS button to change pressure unit (psi, bar, MPa).

Continue to press DTS button to cycle from psi to bar to

MPa. Release DTS button to select units.

psi

NOTE: Information other than pressure cannot be

accessed if applicator switch is ON. And, if system pressure is greater than 200 psi (14 bar, 1.4 MPa), the display will revert back to pressure after 3 seconds.

3. Short press DTS button to display installed pump.

ti13760a

bar

MPa

psi

ti6225a

313888E 21

Page 22

Digital Tracking System (DTS)

Secondary Menu - Stored Data

Mode

• Open drain valve

• Turn pump control counterclockwise to lowest set-

ting

• Set applicator switch to OFF

1. Start Engine, page 12. Pressure display appears.

ti5812a

2. Press and hold DTS button and turn applicator

switch ON.

ti13764a

6. Short press DTS button and Base Coat hours displays.

Short press DTS button and Top Coat hours display.

Short press DTS button and Engine hours display.

ti13787a

7. Short press DTS button and LAST ERROR scrolls

through display followed by stored error message

and error code. This information cycles repeatedly

until cleared.

See page 23 for error code explanations.

3. SERIAL NUM scrolls through display and a 3 to

5-digit serial number displays.

ti6213a

4. Short press DTS button and date code displays.

ti6215a

5. Short press DTS button and part number displays.

ti6220a

8. Press and hold DTS button until CLEAR ERROR

NO ERROR CODE scrolls through the display and

error code E=00 displays.

ti6218a

9. Short press DTS button again and SOFTWARE

REV scrolls through display followed by revision

level (for example 10102).

ti13788a

10. Short press to return to step 3. Turn on/off switch

OFF at any time to exit stored data mode.

ti13786a

ti5822a

22 313888E

Page 23

Digital Display Messages

DISPLAY* SPRAYER OPERATION INDICATION ACTION

No Display Sprayer may be

pressurized

Sprayer may be

ti6314a

BASE

or

pressurized

Displays installed pump

when engine is started

TOP

OFF

FLOW 1

FLOW 2

or

Displays flow control

setting in Base Coat mode

when pump control setting

is changed

FLOW 3

psi

bar

MPa

ti6315a

Sprayer is pressurized.

Power is applied. (Pressure

varies with tip size and

pressure control setting.)

Top Coat Only:

stops. Engine is running.

ti6316a

Sprayer stops. Engine is

running.

ti6317a

Sprayer stops. Engine is

running.

ti6318a

Sprayer

Loss of power or

display not connected

Pressure less than

Check power source. Relieve pressure before repair

or disassembly. Verify display is connected.

Increase pressure as needed

60 psi (4 bar, 0.4 MPa)

Normal operation Spray

Normal operation

Spray

(with Base Coat pump)

Normal operation Spray

Pressure greater than

4500 psi (310 bar, 31

MPa)

1 Check fluid path for clogs.

2 Use Graco paint hose, 3/8 in. x 50 ft minimum.

Smaller hose or metal braid hose may result in

pressure spikes.

3 Replace transducer if fluid path is not clogged and

proper hose is used.

Pressure transducer

faulty, bad connection

or broken wire

1 Check transducer connection.

2 Disconnect and reconnect transducer plug to

ensure good connection with control board

socket.

3 Open prime valve. Replace sprayer transducer

with known good transducer and run sprayer.

Replace transducer if sprayer runs or control

board if sprayer does not run.

High clutch current 1 Check wiring connections.

2

Measure:

1.7 + 0.2Ω across clutch field at 70°F.

3 Replace clutch field assembly.

Digital Display Messages

Base Coat Only:

stops. Engine is running.

Sprayer

Pressure greater than

1000 psi (69 bar, 6.9

MPa)

1 Open prime valve and gun.

2 Verify no flow obstructions. Use Graco texture

hoses 3/4 in. x 50 ft minimum.

3 Replace transducer if fluid path is not clogged and

proper hose is used.

* Error codes also appear on control board as a blinking red

LED. LED is an alternate to digital messages.

1 Remove two screws (71) and swing down cover (130).

2 Start engine. Blink count is the same as error code(E=0X).

After a fault, follow these steps to restart sprayer:

1 Correct fault condition.

2 Turn sprayer OFF.

3 Turn sprayer ON.

(E02 and E06 errors will self-correct when system is reduced)

313888E 23

Page 24

Maintenance

Maintenance

NOTICE

For detailed engine maintenance and specifications,

refer to separate Honda Engines Owner’s Manual

(supplied).

DAILY

AFTER EACH 100 HOURS OF OPERATION

• Change engine oil. Reference Honda Engines

Owner’s Manual for correct oil viscosity.

SPARK PLUG

Use only BPR6ES (NGK) or W20EPR-U (NIPPONDENSO) plug. Gap plug to 0.028 to 0.031 in. (0.7 to 0.8

mm). Use spark plug wrench when installing and removing plug.

• Check engine oil level and fill as necessary

• Check hose for wear and damage

• Check that all hose fittings are secure

• Check gun safety for proper operation

• Check and fill the gas tank

• Check level of TSL in displacement pump packing

nut. Fill nut, if necessary. Keep TSL in nut to help

prevent fluid buildup on piston rod and premature

wear of packings and pump corrosion.

AFTER FIRST 20 HOURS OF OPERATION

• Drain engine oil and refill with clean oil. Reference

Honda Engines Owner’s Manual for correct oil viscosity.

WEEKLY

• Remove engine air filter cover and clean element.

Replace element if necessary. If operating in an

unusually dusty environment, check filter daily and

replace (if necessary).

ENGINE OIL FUNNEL

• Use the supplied engine oil funnel when draining oil.

ti6200a

Replacement elements can be purchased from your

local Honda dealer.

24 313888E

Page 25

Technical Data

Technical Data

Honda GX 200 Engine:

ANSI Power Rating @ 3600 rpm 6.5 Horsepower (4.8 kW)

Maximum Working Pressure:

Base Coat Pump 1000 psi (69 bar, 6.9 MPa)

Top Coat Pump 3300 psi (228 bar, 22.8 MPa)

Noise Level:

Sound Power 105 dBa per ISO 3744

Sound Pressure 96 dBa measured at 3.1 ft (1 m)

Maximum Delivery Rating:

Base Coat Pump 3.0 gpm (11.36 liter/min)

Top Coat Pump 2.20 gpm (8.33 liter/min)

Maximum Tip Size:

Base Coat Pump 1 applicator with .071 in. tip or 10 mm Nozzle

Top Coat Pump 1 gun with 0.048 in. tip

2 guns with 0.035 in. tip

3 guns with 0.027 in. tip

4 guns with 0.023 in. tip

Inlet Paint Strainer:

Base Coat Pump 2 in. npsm, #5 mesh sst

Top Coat Pump 1 in. npsm, #8 mesh sst

Pump Inlet Size:

Base Coat Pump 2 in. QD Camlock male coupler

Top Coat Pump 1 in. - 11.5 npsm

Fluid Outlet Size:

Base Coat Pump 1 in. QD Camlock male coupler

Top Coat Pump 3/8 npsm

Wetted Parts:

zinc-plated carbon steel, PTFE, nylon, polyurethane, UHMW, polyethyl-

ene, fluoroelastomer, acetal, leather, aluminum, tungsten carbide,

nickel- and zinc-plated carbon steel, stainless steel, chrome plating

Dimensions

Part Weight lb (kg) Height in. (cm) Width in. (cm) Length in. (cm)

HTX 2030 Sprayer 155 (70.5) 34.25 (87.0) 24.5 (62.2) 33.0 (83.8)

3/4 in. Hose 29 (13.2) — — —

Applicator/Swivel 3 (1.3) — — —

HTX2030 Air Spray Trigger Gun 3.65 (1.7) 12 (30.5) 1.7 (2.5) 10.4 (26.4)

313888E 25

Page 26

Notes

Notes

26 313888E

Page 27

Notes

Notes

313888E 27

Page 28

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 313888

International Offices:

Graco Headquarters:

Belgium, China, Japan, Korea

Minneapolis

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2008, Graco Inc. is registered to I.S. EN ISO 9001

www.graco.com

Revision E - March 2013

Loading...

Loading...