Page 1

Operation - Maintenance

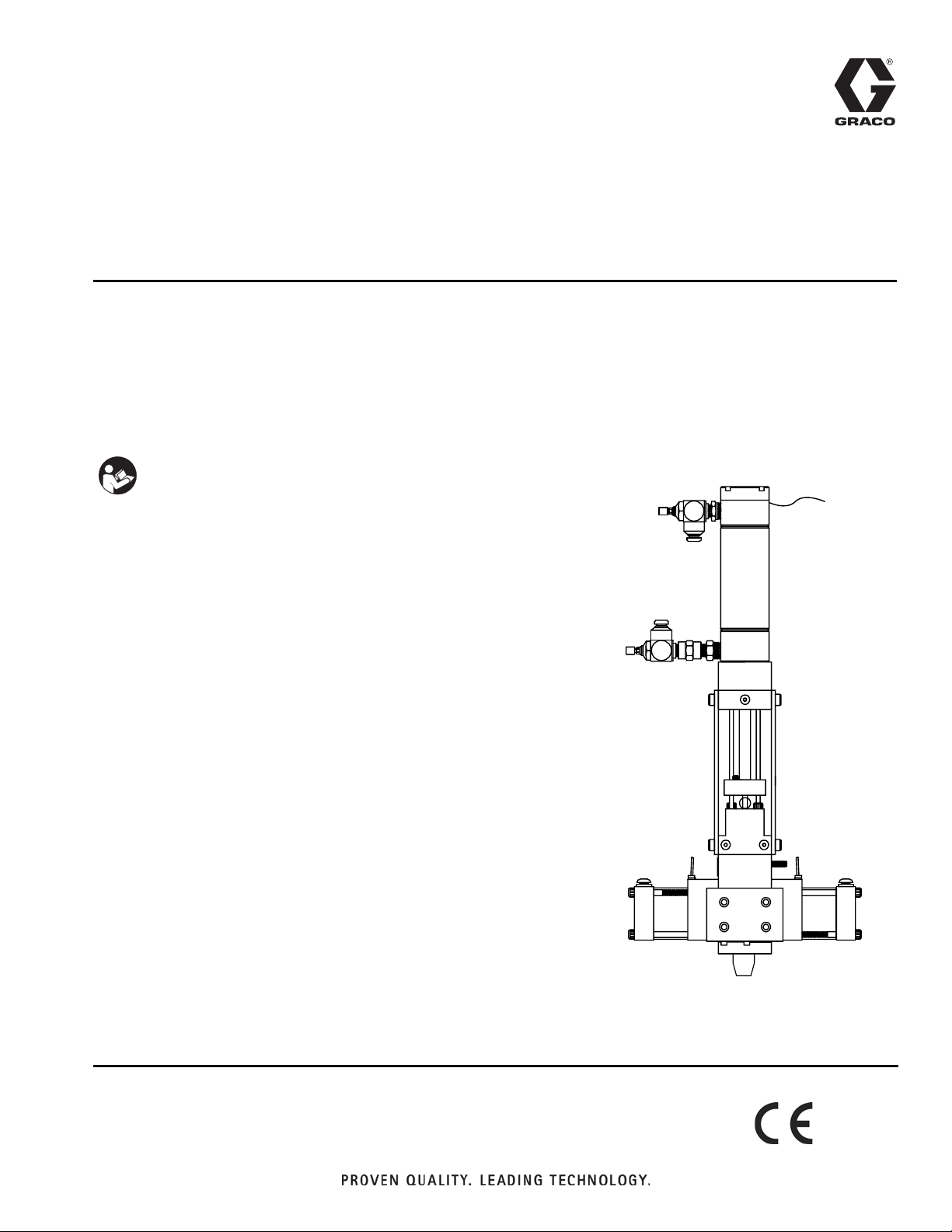

PD44

Metering Valves and Feed Systems

Meter, mix, and dispense system for precise two-component micro-dispensing of sealants

and adhesives.

Not approved for use in European explosive atmosphere locations.

Important Safety Instructions

Read all warnings and instructions in this manual. Save these instructions.

See page 3 for model information, including maximum

working pressure and approvals. See page 6 for product configuration information.

313876F

ENG

Linear Resistive Transducer PD44 Meter-

ing Valve shown, Feed Systems not shown

Page 2

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Product Configurator . . . . . . . . . . . . . . . . . . . . . . . 6

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Isocyanate Conditions . . . . . . . . . . . . . . . . . . . . . 13

Material Self-ignition . . . . . . . . . . . . . . . . . . . . . . 13

Moisture Sensitivity of Isocyanates . . . . . . . . . . . 13

Keep Components A and B Separate . . . . . . . . . 13

Foam Resins with 245 fa Blowing Agents . . . . . . 13

Changing Materials . . . . . . . . . . . . . . . . . . . . . . . . 13

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Component Identification . . . . . . . . . . . . . . . . . . . 15

Typical System Configurations . . . . . . . . . . . . . 15

Typical Feed System Components . . . . . . . . . . 16

Micrometer PD44 Metering Valve . . . . . . . . . . . 18

LRT PD44 Metering Valve . . . . . . . . . . . . . . . . . 19

Motor Driven PD44 Metering Valve . . . . . . . . . . 20

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Typical Installation . . . . . . . . . . . . . . . . . . . . . . . 21

Tank Level Sensor Wiring Schematic . . . . . . . . 22

Valve Mounting Diagram . . . . . . . . . . . . . . . . . . 22

Motor Mounting Diagram . . . . . . . . . . . . . . . . . . 23

Custom Drive Mounting Diagram . . . . . . . . . . . 23

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Adjusting the Shot Size . . . . . . . . . . . . . . . . . . . . 25

Micrometer PD44 Only . . . . . . . . . . . . . . . . . . . 25

LRT and Motor Driven PD44 . . . . . . . . . . . . . . . 25

Ratio Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Sequence of Operation . . . . . . . . . . . . . . . . . . . 27

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 28

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Rebuild . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Wetted Section Disassembly . . . . . . . . . . . . . . 30

Wetted Section Reassembly . . . . . . . . . . . . . . . 32

Spool Valve Rebuild . . . . . . . . . . . . . . . . . . . . . 33

Wetted Section Rebuild . . . . . . . . . . . . . . . . . . . 34

Micrometer Drive Rebuild

(Micrometer PD44 Only) . . . . . . . . . . . . . . . 37

Electrical Requirements . . . . . . . . . . . . . . . . . . . . 39

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Graco Ohio Standard Warranty . . . . . . . . . . . . . . 44

Graco Ohio Information . . . . . . . . . . . . . . . . . . . . . 44

2 313876F

Page 3

Related Manuals

Manuals are available at www.graco.com

Component manuals in U.S. English.

PD44 Manuals

Part Description

313877 PD44 Control Box Setup - Operation

3A0987 PD44 Parts

Feed System Manuals

306565 Air-Driven, Stainless Steel Agitators

307043 Monark Air Motor

308116 Severe-Duty, UHMWPE/PTFE or PTFE

Packed Stainless Steel Pumps

308167 Low Volume Air Regulators

308168 High Volume Air Regulators

Related Manuals

308169 Air Filters, Lubricators and Kits

309306 Air-Operated Husky Diaphragm Pumps

312376 Stainless Steel Agitator Kit

313526

3A1452 20 oz Cartridge

Check-Mate

®

Pump Packages

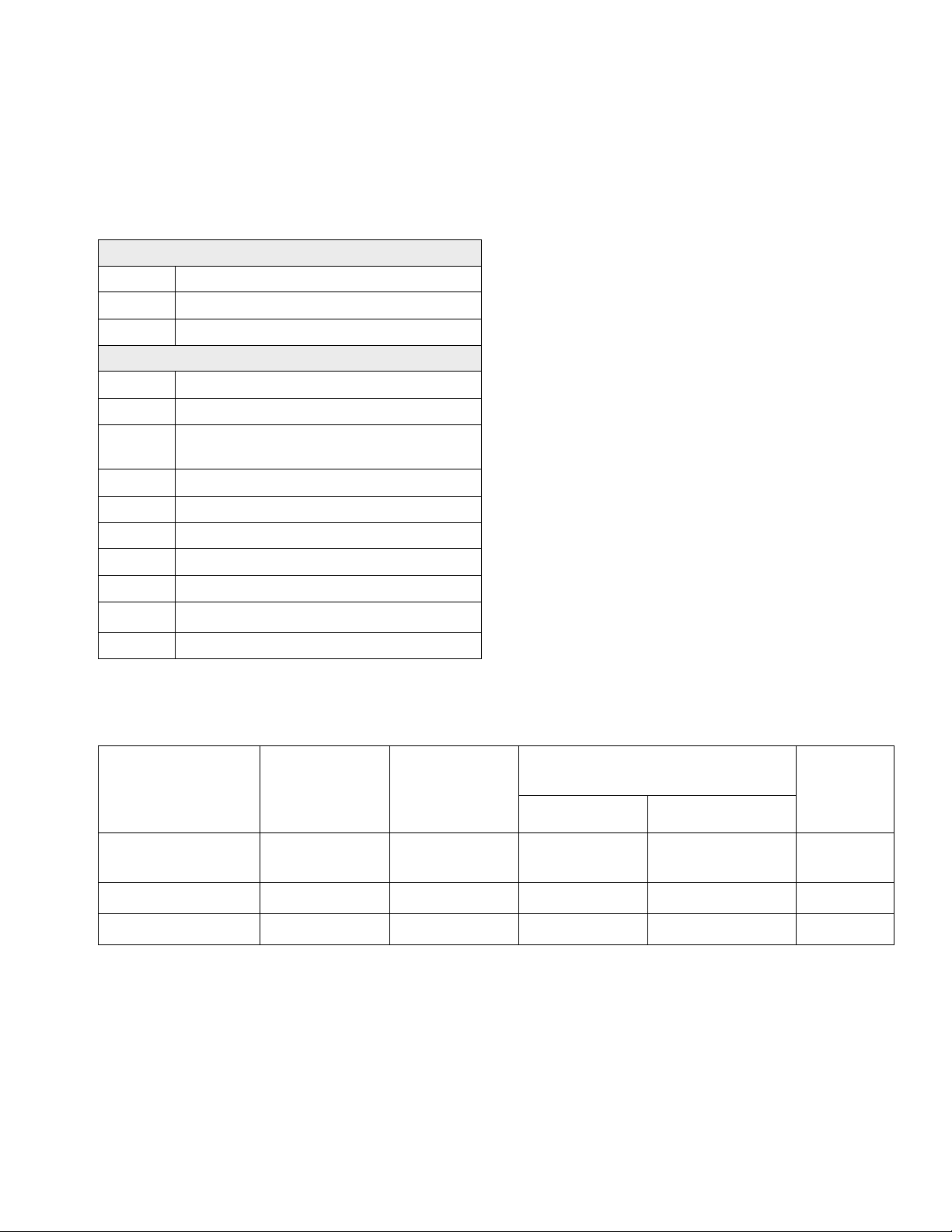

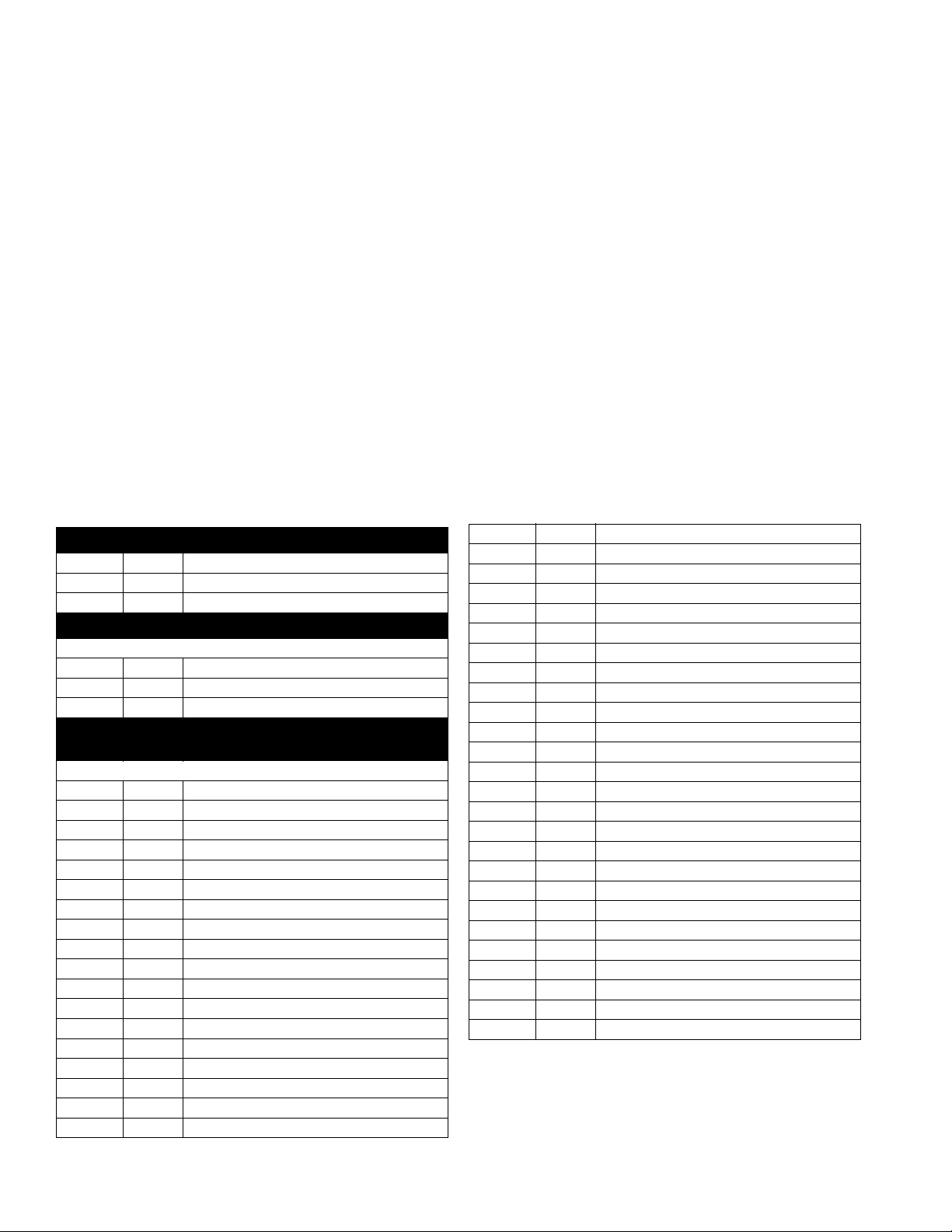

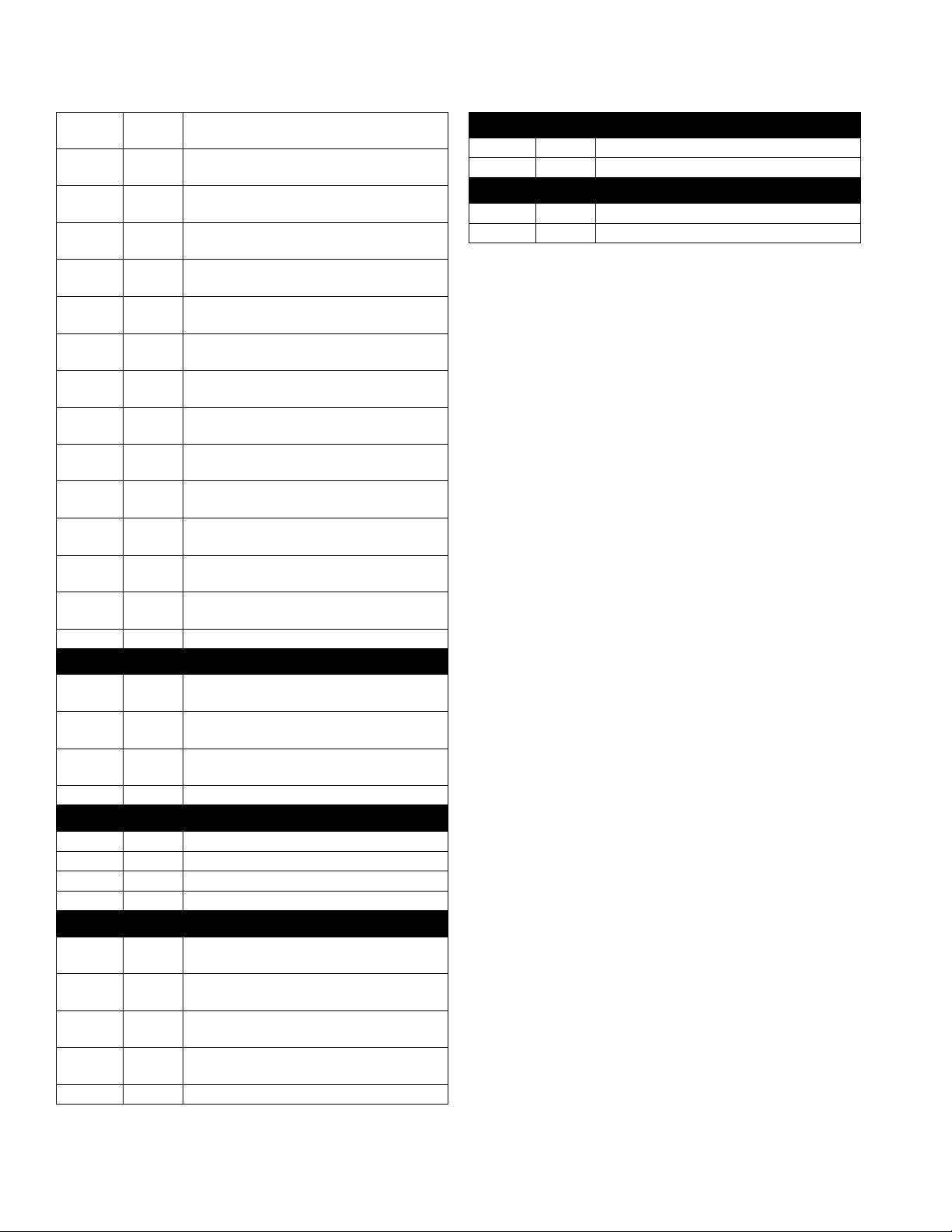

Models

Max Outlet

Fluid Working

Metering Valve

Model

Linear Resistive

Transducer (LRT)

Micrometer

Motor Driven

* If a custom PD44 is ordered, it will not be CE

approved unless otherwise noted.

Pressure

psi (MPa, bar)

2000 (14, 138) 100 (0.7, 7) 1200 (8, 83) 400 (2.8, 28)

2000 (14, 138) 100 (0.7, 7) 1200 (8, 83) 400 (2.8, 28)

2000 (14, 138) 100 (0.7, 7) 1200 (8, 83) 400 (2.8, 28)

Max Air

Working

Pressure

psi (MPa, bar)

Max Inlet Working Pressure

psi (MPa, bar)

CE

Approved*Metal Sleeves Plastic Sleeves

✔

✔

✔

313876F 3

Page 4

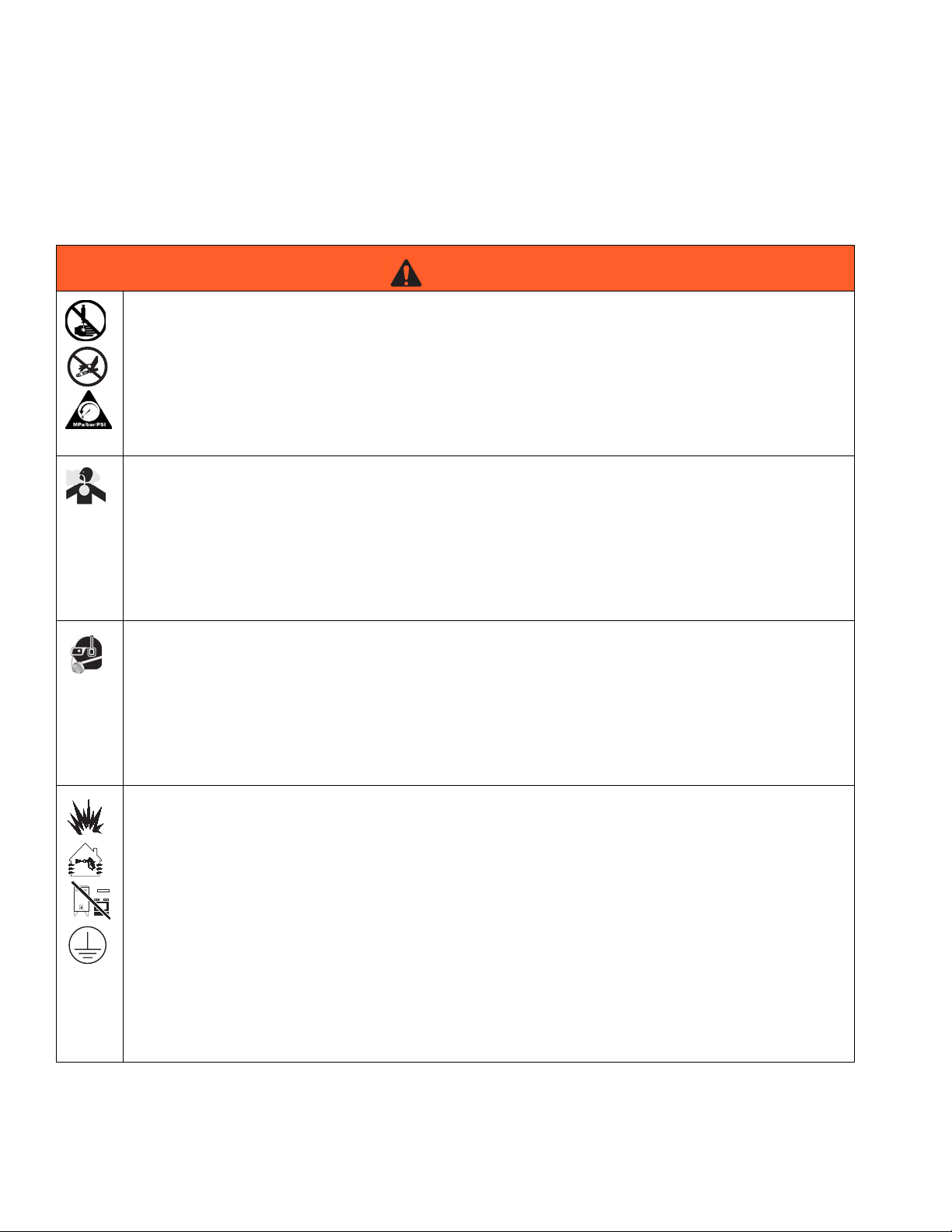

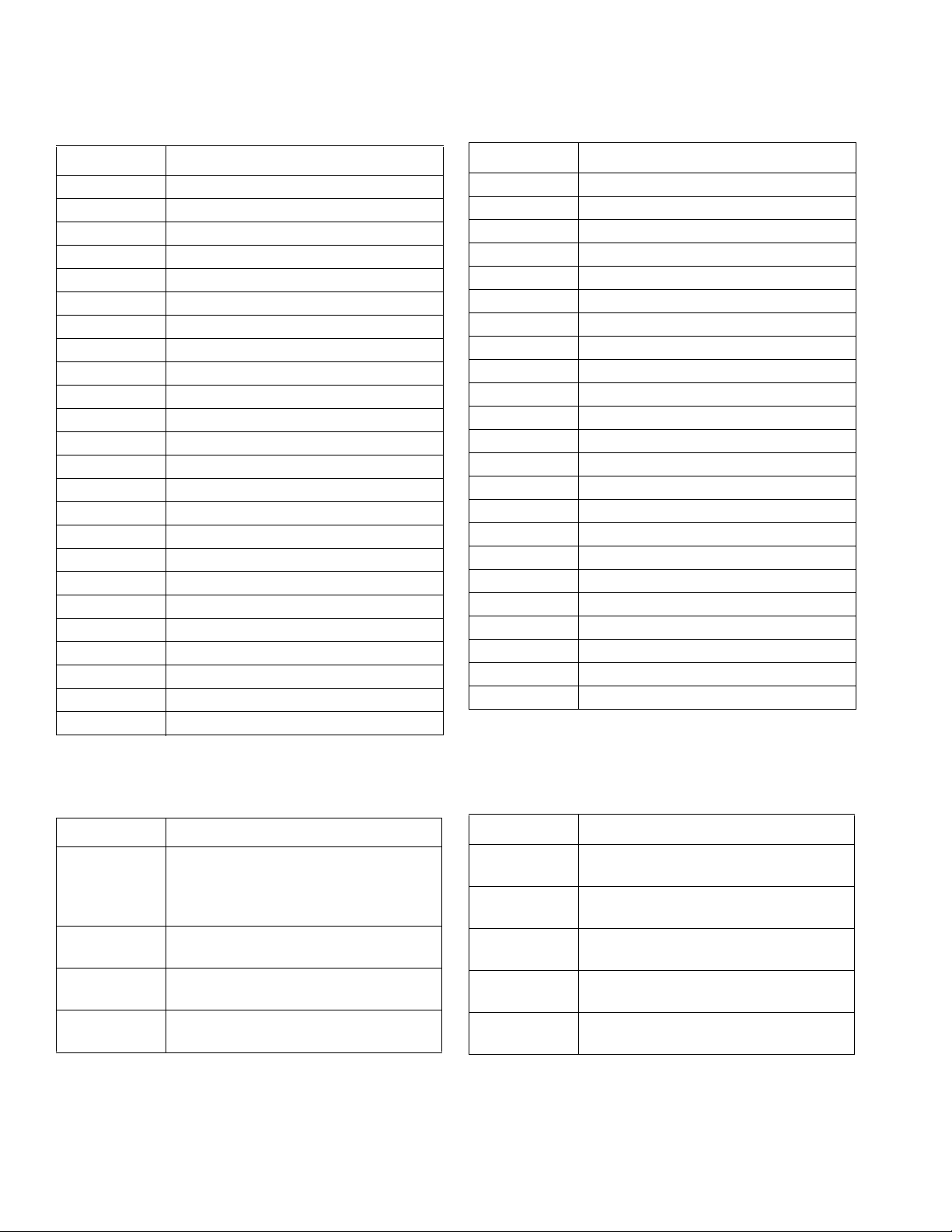

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the dispense outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow Pressure Relief Procedure in this manual, when you stop dispensing and before cleaning,

checking, or servicing equipment.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear impervious gloves when spraying or cleaning equipment.

• If this equipment is used with isocyanate material, see additional information on isocyanates in Isocyanate Conditions Section of this manual.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

4 313876F

Page 5

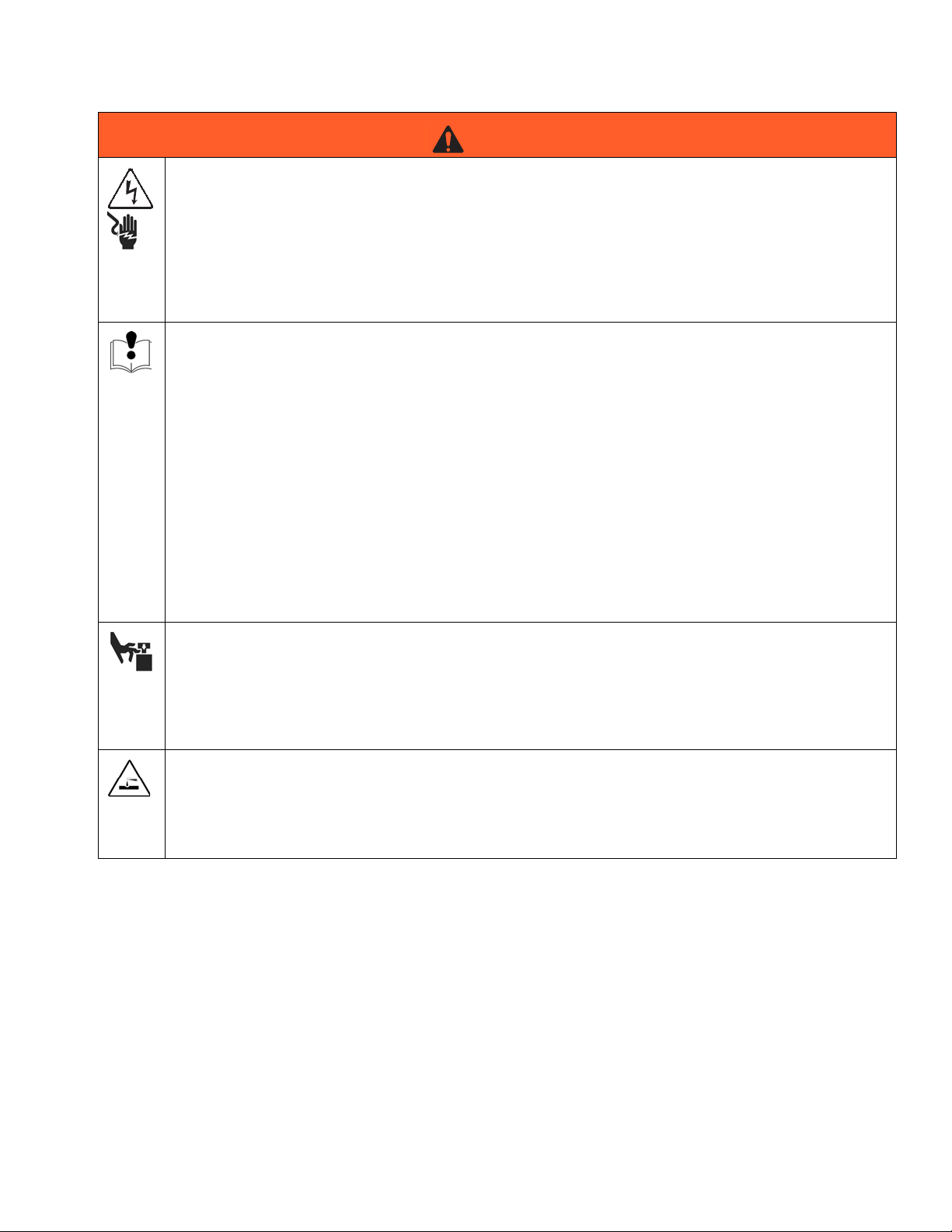

Warnings

WARNING

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power cord before servicing equipment.

• Use only grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on power and extension cords.

• Do not expose to rain. Store indoors.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Do not leave the work area while equipment is energized or under pressure. Turn off all equipment

and follow the Pressure Relief Procedure in this manual when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

PLASTIC PARTS CLEANING SOLVENT HAZARD

Use only compatible water-based solvents to clean plastic structural or pressure-containing parts. Many

solvents can degrade plastic parts and cause them to fail, which could cause serious injury or property

damage. See Technica l Data in this and all other equipment instruction manuals. Read fluid and solvent

manufacturer’s warnings.

313876F 5

Page 6

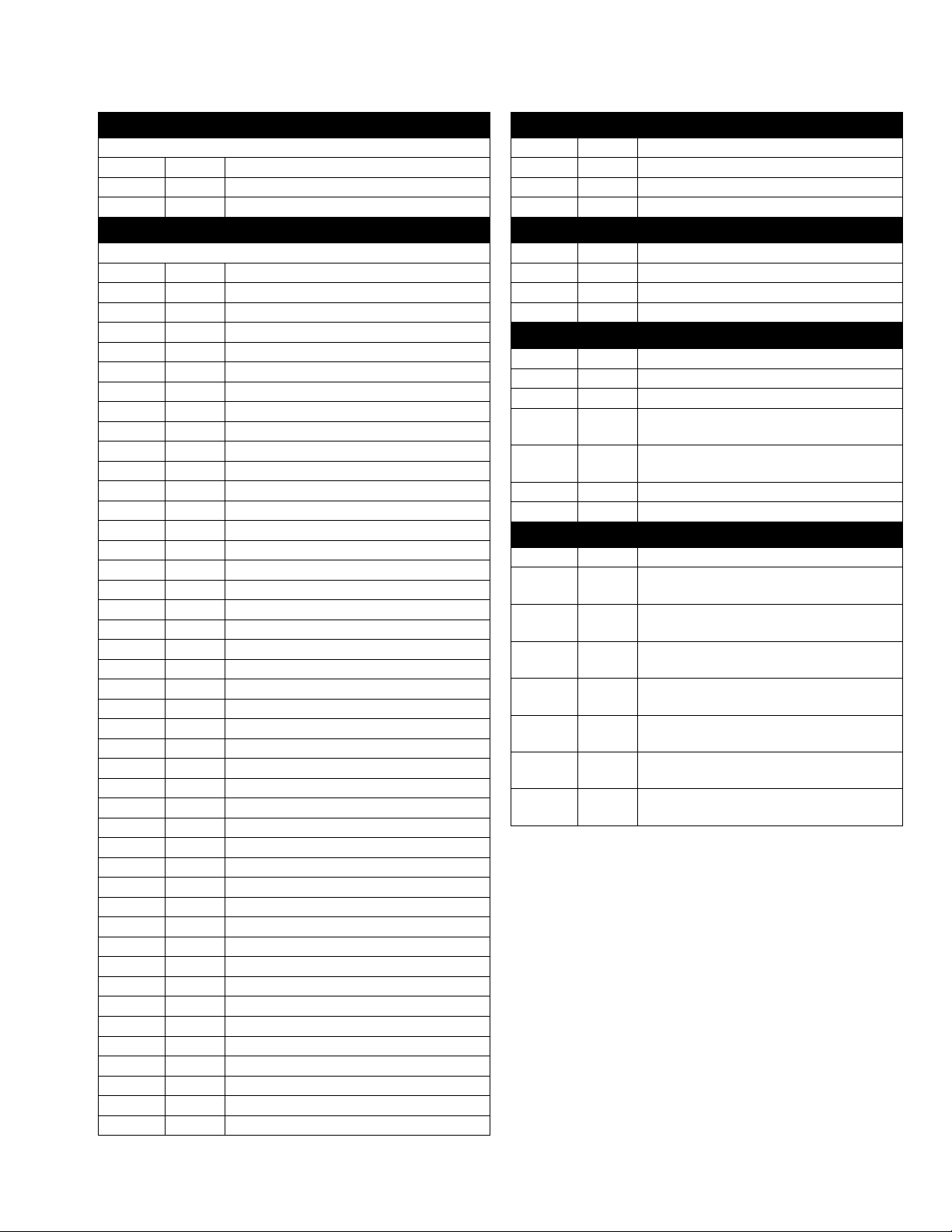

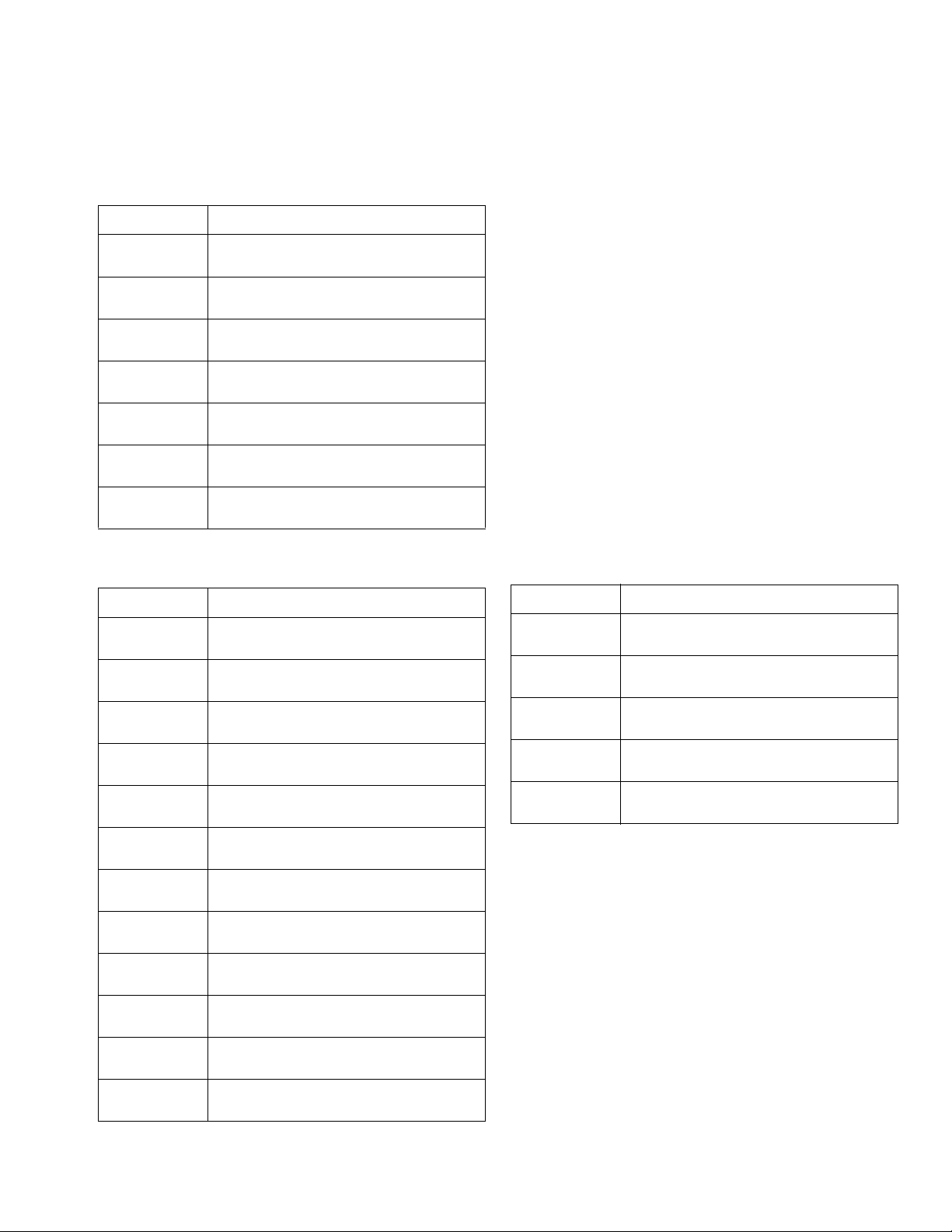

Product Configurator

Product Configurator

This system can be ordered with many different options as shown in the configurator below.

PD44 C-A-BCD-EFG- H - I -J -K-L-M-NO-P-Q-RS-T-U-V-W- X

Configurator Series Level

Base Unit

High Volume Rod Material, Size

Low Volume Rod Material, Size

High Volume Spool

Low Volume Spool

Outlet Nose

Mixer

Controls

Power Cord

High Volume Feed

High Volume Feed Hose

High Volume Feed Options

Low Volume Feed

Low Volume Feed Hose

Low Volume Feed Options

Vacuum Pump(s)

Bench Stand

Seal Lubricant

The following table applies to the PD44 configurations and indicates all of the options available for each letter shown

above.

Code A Part Base Unit

A 964000 Micrometer PD44

B 964001 Linear Resistive Transducer PD44

C 964002 Motor Driven PD44

Code B Part High Volume Rod Material

NOTE: See code CD for last two digits of part number

A 9641__ Hardened Steel

B 9642__ Stainless Steel, UHMW

C 9643__ Tungsten Carbide, UHMW

Code

CD Part High Volume Rod Size

NOTE: See code B for first four digits of part number

01 ____01 1.25 mm rod diameter

02 ____02 1.38 mm rod diameter

03 ____03 1.50 mm rod diameter

04 ____04 1.63 mm rod diameter

05 ____05 1.75 mm rod diameter

06 ____06 2.00 mm rod diameter

07 ____07 2.13 mm rod diameter

08 ____08 2.25 mm rod diameter

09 ____09 2.38 mm rod diameter

10 ____10 2.50 mm rod diameter

11 ____11 2.63 mm rod diameter

12 ____12 2.75 mm rod diameter

13 ____13 3.00 mm rod diameter

14 ____14 3.13 mm rod diameter

15 ____15 3.25 mm rod diameter

16 ____16 3.38 mm rod diameter

17 ____17 3.50 mm rod diameter

18 ____18 3.63 mm rod diameter

19 ____19 3.75 mm rod diameter

20 ____20 4.00 mm rod diameter

21 ____21 4.25 mm rod diameter

22 ____22 4.50 mm rod diameter

23 ____23 4.63 mm rod diameter

24 ____24 4.75 mm rod diameter

25 ____25 4.88 mm rod diameter

26 ____26 5.00 mm rod diameter

27 ____27 5.13 mm rod diameter

28 ____28 5.25 mm rod diameter

29 ____29 5.50 mm rod diameter

30 ____30 5.75 mm rod diameter

31 ____31 6.00 mm rod diameter

32 ____32 6.13 mm rod diameter

33 ____33 6.25 mm rod diameter

34 ____34 6.38 mm rod diameter

35 ____35 6.50 mm rod diameter

36 ____36 6.63 mm rod diameter

37 ____37 6.75 mm rod diameter

38 ____38 7.00 mm rod diameter

39 ____39 7.25 mm rod diameter

40 ____40 7.50 mm rod diameter

41 ____41 7.63 mm rod diameter

42 ____42 7.75 mm rod diameter

43 ____43 7.88 mm rod diameter

44 ____44 8.00 mm rod diameter

6 313876F

Page 7

Product Configurator

Code E Part Low Volume Rod Material

NOTE: See code FG for last two digits of part number

A 9641__ Hardened Steel

B 9642__ Stainless Steel, UHMW

C 9643__ Tungsten Carbide, UHMW

Code FG Part Low Volume Rod Size

NOTE: See code E for first four digits of part number

01 ____01 1.25 mm rod diameter

02 ____02 1.38 mm rod diameter

03 ____03 1.50 mm rod diameter

04 ____04 1.63 mm rod diameter

05 ____05 1.75 mm rod diameter

06 ____06 2.00 mm rod diameter

07 ____07 2.13 mm rod diameter

08 ____08 2.25 mm rod diameter

09 ____09 2.38 mm rod diameter

10 ____10 2.50 mm rod diameter

11 ____11 2.63 mm rod diameter

12 ____12 2.75 mm rod diameter

13 ____13 3.00 mm rod diameter

14 ____14 3.13 mm rod diameter

15 ____15 3.25 mm rod diameter

16 ____16 3.38 mm rod diameter

17 ____17 3.50 mm rod diameter

18 ____18 3.63 mm rod diameter

19 ____19 3.75 mm rod diameter

20 ____20 4.00 mm rod diameter

21 ____21 4.25 mm rod diameter

22 ____22 4.50 mm rod diameter

23 ____23 4.63 mm rod diameter

24 ____24 4.75 mm rod diameter

25 ____25 4.88 mm rod diameter

26 ____26 5.00 mm rod diameter

27 ____27 5.13 mm rod diameter

28 ____28 5.25 mm rod diameter

29 ____29 5.50 mm rod diameter

30 ____30 5.75 mm rod diameter

31 ____31 6.00 mm rod diameter

32 ____32 6.13 mm rod diameter

33 ____33 6.25 mm rod diameter

34 ____34 6.38 mm rod diameter

35 ____35 6.50 mm rod diameter

36 ____36 6.63 mm rod diameter

37 ____37 6.75 mm rod diameter

38 ____38 7.00 mm rod diameter

39 ____39 7.25 mm rod diameter

40 ____40 7.50 mm rod diameter

41 ____41 7.63 mm rod diameter

42 ____42 7.75 mm rod diameter

43 ____43 7.88 mm rod diameter

44 ____44 8.00 mm rod diameter

Code H Part High Volume Spool

1 964003 High viscosity, HS

2 964004 High viscosity, Stainless Steel/UHMWPE

3 964005 High viscosity, TC/UHMWPE

4 964006 Low viscosity, Stainless Steel

Code I Part Low Volume Spool

1 964011 High viscosity, HS

2 964012 High viscosity, Stainless Steel/UHMWPE

3 964013 High viscosity, TC/UHMWPE

4 964014 Low viscosity, Stainless Steel

Code J Par t Outlet Nose

1 964020 Luer lock, equal ports, no check valves

2 964021 Luer lock, equal ports, dual check valves

3 964022 Equal ports, 7/8-9, no check valves

4 964023 Large and small ports, 7/8-9, no check

valves

5 964024 Large and small ports, 7/8-9, single

check valve

6 964025 Dual small ports, 7/8-9, no check valves

7 964026 Dual small ports, 7/8-9 dual check valves

Code K Part Mixer

1 964027 1/8-24 Luer Lock inlet and outlet, 0.5 cc

2 964028 3/16-32 bell mouth inlet, luer lock outlet,

2.0 cc

3 964029 1/4-24 bell mouth inlet, luer lock outlet,

4.0 cc

4 964030 1/4-32 bell mouth inlet, luer lock outlet,

5.5 cc

5 964031 1/4-48 bell mouth inlet, luer lock outlet,

8.0 cc

6 964032 3/16-32 bell mouth inlet, tapered outlet,

1.5 cc

7 964033 1/4-24 bell mouth inlet, tapered outlet,

3.5 cc

8 964034 3/16-24 bell mouth inlet, tapered outlet,

1.0 cc

313876F 7

Page 8

Product Configurator

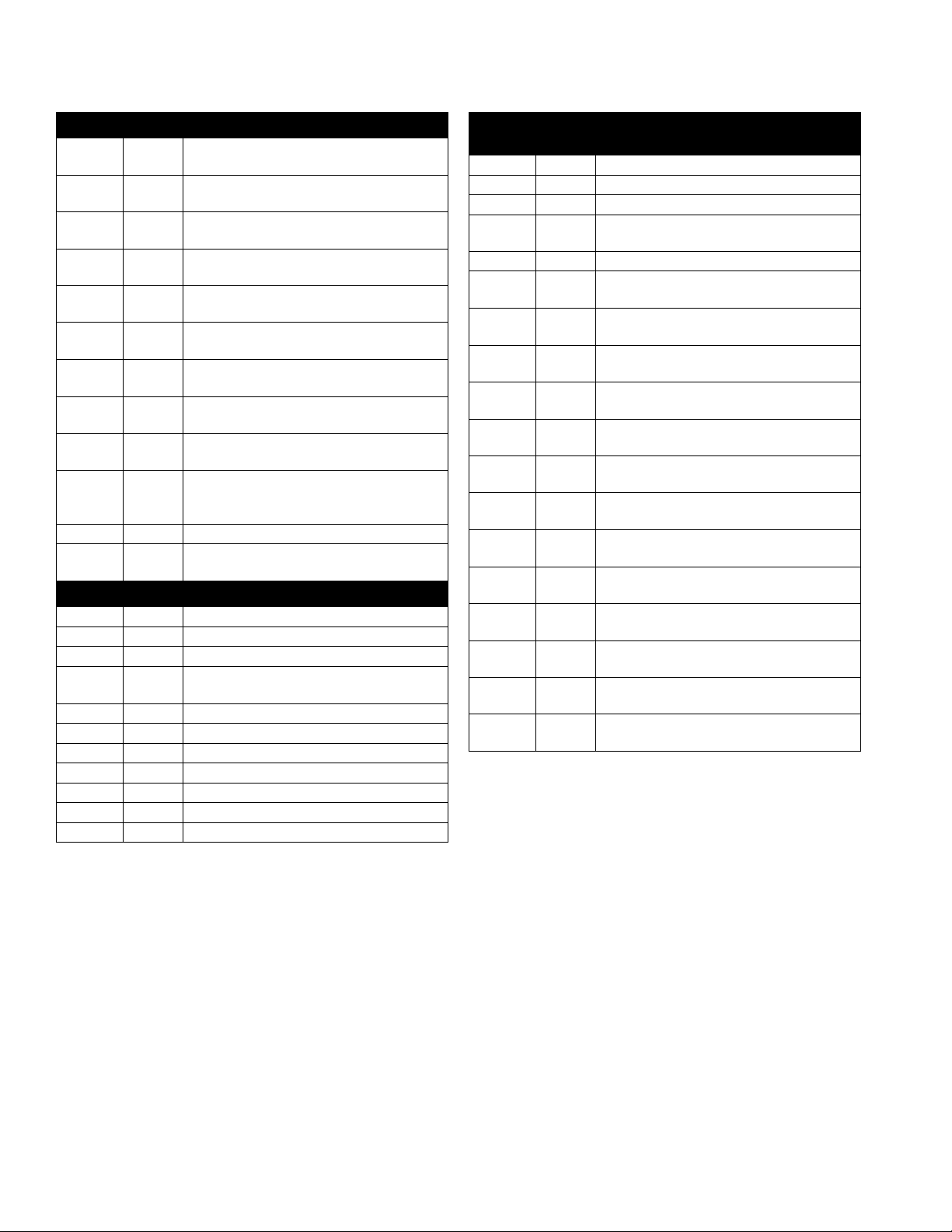

Code L Part Controls

1 964035 Pneumatic, micrometer, wire harness

only

2 964036 Pneumatic, micrometer, HMI controls, low

level

3 964037 Pneumatic, micrometer, HMI controls, low

level, I/O package

4 964038 Pneumatic, micrometer, HMI controls, low

level, high level

5 964039 Pneumatic, micrometer, HMI controls, low

level, high level, I/O package

6 964040 Pneumatic, linear resistive transducer,

wire harness only

7 964041 Pneumatic, linear resistive transducer,

HMI controls, low level

8 964042 Pneumatic, linear resistive transducer,

HMI controls, low level, I/O package

9 964043 Pneumatic, linear resistive transducer,

HMI controls, low level, high level

A 964044 Pneumatic, linear resistive transducer,

HMI controls, low level, high level, I/O

package

B 964045 Motor driven, I/O, wire harness only

C 964046 Stepper motor, HMI control, low level,

high level, I/O package

Code M Part Power Cord

1 121055 120 VAC, North American cord set

2 121054 250 VAC, 1 phase, no plug

3 121056 10 amp, 250 volt, continental Europe

4 121057 10 amp, 250 volt, United Kingdom and

Ireland

5 121058 10 amp, 250 volt, Israel

6 124864 10 amp, 250 volt, Australia

7 124861 10 amp, 250 volt, Italy

8 124863 10 amp, 250 volt, Switzerland

9 124862 10 amp, 250 volt, Denmark

A 121060 10 amp, 250 volt, India

N -- None

Code

NO Part High Volume Feed

01 964050 20 oz cartridge feed with mounting post

02 964051 1 gallon pail Ram and transfer pump

03 964052

04 964053

05 964054

06 964055

07 964056 5 gallon single post Ram with 11:1 pump,

08 964057 5 gallon single post Ram with 11:1 pump,

09 964058 5 gallon tank, support and diaphragm

10 964059

11 964060 5 gallon tank, support, diaphragm pump,

12 964061 5 gallon tank, support, diaphragm pump,

13 964062 5 gallon tank, support, diaphragm pump,

14 964063 5 gallon tank, support, diaphragm pump,

15 964064 5 gallon tank, support and 5:1 pump, mild

16 964065 5 gallon tank, support, 5:1 pump, agitator,

17 964066

18 964067 5 gallon tank, support, 5:1 pump, stain-

5 gallon pail cover with diaphragm pump

5 gallon pail cover diaphragm pump and

agitator

5 gallon pail cover and 5:1 transfer pump

5 gallon pail cover, 1:1 pump with dip

tube for moisture sensitive materials

mild steel

stainless steel

pump, mild steel

5 gallon tank, support, diaphragm pump

and agitator, mild steel

agitator and vacuum fill, mild steel

stainless steel

agitator, stainless steel

agitator, vacuum fill, stainless steel

steel

mild steel

5 gallon tank, support, 5:1 pump, agitator,

vacuum fill, mild steel

less steel

8 313876F

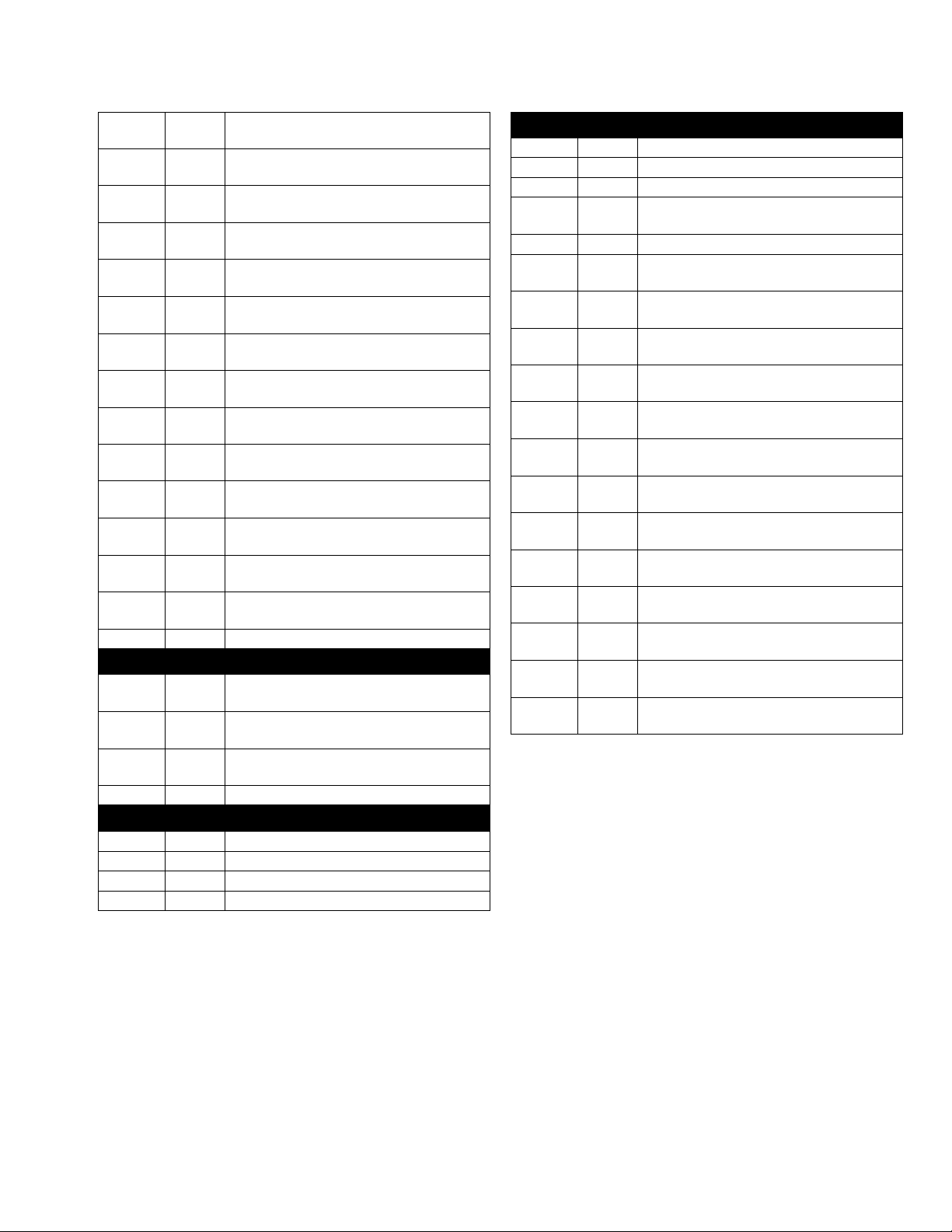

Page 9

Product Configurator

19 964068

20 964069

21 964070 10 gallon tank, support, diaphragm

22 964071 10 gallon tank, support, diaphragm

23 964072 10 gallon tank, support, diaphragm

24 964073 10 gallon tank, support, diaphragm

25 964074 10 gallon tank, support, diaphragm

26 964075 10 gallon tank, support, diaphragm

27 964076

28 964077 10 gallon tank, support, 5:1 pump, agita-

29 964078 10 gallon tank, support, 5:1 pump, agita-

30 964079 10 gallon tank, support, 5:1 pump, stain-

31 964080 10 gallon, tank, support, 4:1 pump, agita-

32 964081 10 gallon tank, support, 5:1 pump, agita-

NN -- None

Code P Part High Volume Feed Hose

1 964082 1/2 in. x 8 ft PTFE and stainless steel

3 964084 1/2 in. x 10 ft PTFE and stainless steel

5 964086 1/2 in. x 15 ft PTFE and stainless steel

N -- None

Code Q Part High Volume Feed

A 964088 Dessicant dryers for tank lids

B 964089 Nitrogen harness assembly for tank lids

C 964090 Low level sensor 11:1 Ram only

N -- None

5 gallon tank, support, 5:1 pump, agitator,

stainless steel

5 gallon tank, support, 5:1 pump, agitator,

vacuum fill, stainless steel

pump, mild steel

pump, agitator, mild steel

pump, agitator, vacuum fill, mild steel

pump, stainless steel

pump, agitator, stainless steel

pump, agitator, vacuum fill, stainless steel

10 gallon tank, support, 5:1 pump, mild

steel

tor, mild steel

tor, vacuum fill, mild steel

less steel

tor, stainless steel

tor, vacuum fill, stainless steel

hose, stainless steel fittings

hose, stainless steel fittings

hose, stainless steel fittings

Code RS Par t Low Volume Feed

01 964050 20 oz cartridge feed with mounting post

02 964051

03 964052 5 gallon pail cover with diaphragm pump

04 964053

05 964054 5 gallon pail cover and 5:1 transfer pump

06 964055 5 gallon pail cover, 1:1 pump with dip

07 964056 5 gallon single post Ram with 11:1 pump,

08 964057

09 964058 5 gallon tank, support and diaphragm

10 964059 5 gallon tank, support, diaphragm pump

11 964060 5 gallon tank, support, diaphragm pump,

12 964061

13 964062

14 964063

15 964064 5 gallon tank, support and 5:1 pump, mild

16 964065 5 gallon tank, support, 5:1 pump, agitator,

17 964066 5 gallon tank, support, 5:1 pump, agitator,

18 964067 5 gallon tank, support, 5:1 pump, stain-

1 gallon pail Ram and transfer pump

5 gallon pail cover diaphragm pump and

agitator

tube for moisture sensitive materials

mild steel

5 gallon single post Ram with 11:1 pump,

stainless steel

pump, mild steel

and agitator, mild steel

agitator and vacuum fill, mild steel

5 gallon tank, support, diaphragm pump,

stainless steel

5 gallon tank, support, diaphragm pump,

agitator, stainless steel

5 gallon tank, support, diaphragm pump,

agitator, vacuum fill, stainless steel

steel

mild steel

vacuum fill, mild steel

less steel

313876F 9

Page 10

Product Configurator

19 964068

20 964069

21 964070 10 gallon tank, support, diaphragm

22 964071 10 gallon tank, support, diaphragm

23 964072 10 gallon tank, support, diaphragm

24 964073 10 gallon tank, support, diaphragm

25 964074 10 gallon tank, support, diaphragm

26 964075 10 gallon tank, support, diaphragm

27 964076

28 964077 10 gallon tank, support, 5:1 pump, agita-

29 964078 10 gallon tank, support, 5:1 pump, agita-

30 964079 10 gallon tank, support, 5:1 pump, stain-

31 964080 10 gallon, tank, support, 4:1 pump, agita-

32 964081 10 gallon tank, support, 5:1 pump, agita-

NN -- None

Code T Part Low Volume Feed Hose

1 964082 1/2 in. x 8 ft PTFE and stainless steel

3 964084 1/2 in. x 10 ft PTFE and stainless steel

5 964086 1/2 in. x 15 ft PTFE and stainless steel

7 -- None

Code U Part Low Volume Feed

A 964088 Dessicant dryers for tank lids

B 964089 Nitrogen harness assembly for tank lids

C 964090 Low level sensor 11:1 Ram only

N -- None

Code V Part Vacuum Pump(s)

1 964091 1-115V, 1 phase, 6.9 cfm, inlet and outlet

2 964092 1-115V, 1 phase, 6.9 cfm, inlet and outlet

3 964093 1-230V, 1 phase, 6.9 cfm, inlet and outlet

4 964094 1-230V, 1 phase, 6.9 cfm, inlet and outlet

N -- None

5 gallon tank, support, 5:11 pump, agita-

tor, stainless steel

5 gallon tank, support, 5:1 pump, agitator,

vacuum fill, stainless steel

pump, mild steel

pump, agitator, mild steel

pump, agitator, vacuum fill, mild steel

pump, stainless steel

pump, agitator, stainless steel

pump, agitator, vacuum fill, stainless steel

10 gallon tank, support, 5:1 pump, mild

steel

tor, mild steel

tor, vacuum fill, mild steel

less steel

tor, stainless steel

tor, vacuum fill, stainless steel

hose, stainless steel fittings

hose, stainless steel fittings

hose, stainless steel fittings

filter, 1 in. hose to single tank

filter, 1 in. hose to two tanks

filter, 1 in. hose to single tank

filter, 1 in. hose to two tanks

Code W Part Bench Stand

A 964095 Adjustable height bench stand

N -- None

Code X Part Seal Lubricant

A 964096 Non-silicone seal lubricant

B 964097 Silicone seal lubricant

10 313876F

Page 11

Accessories

Mixer Kits with Shroud

Part Description

964034 Mixer, Kit, 3/16 in. (4.8mm) x 24, 10

taper tip mixers with shroud

964032 Mixer, Kit, 3/16 in. (4.8mm) x 32, 10

taper tip mixers with shroud

964028 Mixer, Kit, 3/16 in. (4.8mm) x 32, 10

Luer Lock tip mixers with shroud/sleeve

964033 Mixer, Kit, 1/4 in. (6.5mm) x 24, 10

taper tip mixers with shroud

964029 Mixer, Kit, 1/4 in. (6.5mm) x 24, 10 Luer

Lock tip mixers with shroud/sleeve

964030 Mixer, Kit, 1/4 in. (6.5mm) x 32, 10 Luer

Lock tip mixers with shroud/sleeve

964031 Mixer, Kit, 1/4 in. (6.5mm) x 48, 10 Luer

Lock tip mixers with shroud/sleeve

Accessories

Mixer Packs

Part Description

964027 Mixer, 1/8 in. (3.2mm) x 24 Luer Lock

inlet/tip, 10 Pack

16D962 Mixer, 1/8 in. (3.2mm) x 24 Luer Lock

inlet/tip, 50 Pack

16D963 Mixer, 1/8 in. (3.2mm) x 24 Luer Lock

inlet/tip, 250 Pack

16D978 Mixer, 3/16 in. (4.8mm) x 24 taper tip,

50 Pack

16D979 Mixer, 3/16 in. (4.8mm) x 24 taper tip,

250 Pack

LC0077 Mixer, 3/16 in. (4.8mm) x 32 taper tip,

50 Pack

LC0084 Mixer, 3/16 in. (4.8mm) x 32 taper tip,

250 Pack

LC0082 Mixer, 3/16 in. (4.8mm) x 32 Luer Lock

tip, 50 Pack

LC0090 Mixer, 3/16 in. (4.8mm) x 32 Luer Lock

tip, 250 Pack

LC0078 Mixer, 1/4 in. (6.5mm) x 24 taper tip

mixer, 50 Pack

LC0085 Mixer, 1/4 in. (6.5mm) x 24 taper tip

mixer, 250 Pack

LC0083 Mixer, 1/4 in. (6.5mm) x 24 Luer Lock

tip, 50 Pack

Part Description

LC0089 Mixer, 1/4 in. (6.5mm) x 24 Luer Lock

tip, 250 Pack

16D968 Mixer, 1/4 in. (6.5mm) x 32 Luer Lock

tip, 50 Pack

16D969 Mixer, 1/4 in. (6.5mm) x 32 Luer Lock

tip, 250 Pack

16D970 Mixer, 1/4 in. (6.5mm) x 48 Luer Lock

tip, 50 Pack

16D973 Mixer, 1/4 in. (6.5mm) x 48 Luer Lock

tip, 250 Pack

313876F 11

Page 12

Accessories

O-Rings and Seals

Part Description

24E247 Kit, O-ring, chemical resistant, PD44

24E248 Kit, Seal, Spool, H.V., PD44

24E249 Kit, Seal, Spool, L.V., PD44

16B265 Seal, Posipack, 1.25, ZAP

16B266 Seal, Posipack, 1.38, ZAP

16B267 Seal, Posipack, 1.50, ZAP

16B268 Seal, Posipack, 1.63, ZAP

16B269 Seal, Posipack, 1.75, ZAP

16B270 Seal, Posipack, 2.00, ZAP

16B271 Seal, Posipack, 2.13, ZAP

16B272 Seal, Posipack, 2.25, ZAP

16B273 Seal, Posipack, 2.38, ZAP

16B274 Seal, Posipack, 2.50, ZAP

16B275 Seal, Posipack, 2.63, ZAP

16B276 Seal, Posipack, 2.75, ZAP

16B277 Seal, Posipack, 3.00, ZAP

16B278 Seal, Posipack, 3.13, ZAP

16B279 Seal, Posipack, 3.25, ZAP

16B280 Seal, Posipack, 3.38, ZAP

16B281 Seal, Posipack, 3.50, ZAP

16B282 Seal, Posipack, 3.63, ZAP

16B283 Seal, Posipack, 3.75, ZAP

16B284 Seal, Posipack, 4.00, ZAP

16B285 Seal, Posipack, 4.25, ZAP

Part Description

16B286 Seal, Posipack, 4.50, ZAP

16B287 Seal, Posipack, 4.63, ZAP

16B288 Seal, Posipack, 4.75, ZAP

16B289 Seal, Posipack, 4.88, ZAP

16B290 Seal, Posipack, 5.00, ZAP

16B291 Seal, Posipack, 5.13, ZAP

16B292 Seal, Posipack, 5.25, ZAP

16B293 Seal, Posipack, 5.50, ZAP

16B294 Seal, Posipack, 5.75, ZAP

16B295 Seal, Posipack, 6.00, ZAP

16B296 Seal, Posipack, 6.13, ZAP

16B297 Seal, Posipack, 6.25, ZAP

16B298 Seal, Posipack, 6.38, ZAP

16B299 Seal, Posipack, 6.50, ZAP

16B300 Seal, Posipack, 6.63, ZAP

16B301 Seal, Posipack, 6.75, ZAP

16B302 Seal, Posipack, 7.00, ZAP

16B303 Seal, Posipack, 7.25, ZAP

16B304 Seal, Posipack, 7.50, ZAP

16B305 Seal, Posipack, 7.63, ZAP

16B306 Seal, Posipack, 7.75, ZAP

16B307 Seal, Posipack, 7.88, ZAP

16B450 Seal, Posipack, 8.00, ZAP

Needles

Part Description

E4000025-50 Needle, Luer Lock, Sampler Package

(10 each 14 ga x 1/2 in., 16 ga x

1/2 in., 18 ga x 1/2 in., 20 ga x 1/2 in.,

22 ga x 1/2 in.)

E4000001-50 Needle, Luer Lock, 14 Gauge x 1/2 in.,

50 Pack

E4000004-50 Needle, Luer Lock, 15 Gauge x 1/2 in.,

50 Pack

E4000005-50 Needle, Luer Lock, 16 Gauge x 1 in.,

50 Pack

12 313876F

Part Description

E4000006-50 Needle, Luer Lock, 18 Gauge x 1 in.,

50 Pack

E4000011-50 Needle, Luer Lock, 22 Gauge x 1/2 in.,

50 Pack

E4000014-50 Needle, Luer Lock, 14 Gauge x 1 in.,

50 Pack

E4000024-50 Needle, Luer Lock, 23 Gauge x 1/2 in.,

50 Pack

E4000088-50 Needle, Luer Lock, 16 Gauge x 1/2 in.,

50 Pack

Page 13

Isocyanate Conditions

Isocyanate Conditions

Spraying or dispensing materials containing isocyanates creates potentially harmful mists, vapors, and

atomized particulates.

Read material manufacturer’s warnings and material

MSDS to know specific hazards and precautions

related to isocyanates.

Prevent inhalation of isocyanate mists, vapors, and

atomized particulates by providing sufficient ventilation in the work area. If sufficient ventilation is not

available, a supplied-air respirator is required for

everyone in the work area.

To prevent contact with isocyanates, appropriate personal protective equipment, including chemically

impermeable gloves, boots, aprons, and goggles, is

also required for everyone in the work area.

Material Self-ignition

Some materials may become self-igniting if applied

too thickly. Read material manufacturer’s warnings

and material MSDS.

To prevent exposing ISO to moisture:

• Always use a sealed container with a desiccant

dryer in the vent, or a nitrogen atmosphere. Never

store ISO in an open container.

• Keep the ISO lube pump reservoir (if installed) filled

with Graco Throat Seal Liquid (TSL), Part 206995.

The lubricant creates a barrier between the ISO and

the atmosphere.

• Use moisture-proof hoses specifically designed for

ISO, such as those supplied with your system.

• Never use reclaimed solvents, which may contain

moisture. Always keep solvent containers closed

when not in use.

• Never use solvent on one side if it has been contaminated from the other side.

• Always lubricate threaded parts with ISO pump oil

or grease when reassembling.

Keep Components A and B Separate

NOTICE

To prevent cross-contamination of the equipment’s

wetted parts, never interchange component A (isocyanate) and component B (resin) parts.

Foam Resins with 245 fa

Moisture Sensitivity of

Blowing Agents

Some foam blowing agents will froth at temperatures

Isocyanates

Isocyanates (ISO) are catalysts used in two component

foam and polyurea coatings. ISO will react with moisture

(such as humidity) to form small, hard, abrasive crystals,

which become suspended in the fluid. Eventually a film

will form on the surface and the ISO will begin to gel,

increasing in viscosity. If used, this partially cured ISO

will reduce performance and the life of all wetted parts.

NOTE: The amount of film formation and rate of crystallization varies depending on the blend of ISO, the

humidity, and the temperature.

313876F 13

above 90°F (33°C) when not under pressure, especially

if agitated. To reduce frothing, minimize preheating in a

circulation system.

Changing Materials

• When changing materials, flush the equipment multiple times to ensure it is thoroughly clean.

• Always clean the fluid inlet strainers after flushing.

• Check with your material manufacturer for chemical

compatibility.

• Most materials use ISO on the A side, but some use

ISO on the B side.

• Epoxies often have amines on the B (hardener)

side. Polyureas often have amines on the B (resin)

side.

Page 14

Grounding

Grounding

This product must be grounded. In the event of an electrical short circuit, grounding reduces the risk of electric

shock by providing an escape wire for the electric current.

Metering valve: attach ground wire from grounding lug

to true earth ground. See Component Identification

starting on page 15.

Fluid hoses: use only electrically conductive hoses.

Feed system components: attach ground wire from

grounding lug to true earth ground. See feed system

manual for grounding points. See Related Manuals on

page 3.

Fluid supply container: follow local code.

Solvent pails used when flushing: follow local code.

Use only conductive metal pails, placed on a grounded

surface. Do not place the pail on a nonconductive surface, such as paper or cardboard, which interrupts

grounding continuity.

Overview

This plural component meter, mix, and dispense device

accurately meters liquid and semi-paste materials.

The machine is ideal for a two-component application

requiring very small and precisely mixed shots.

The ratio of the pneumatic cylinder area to pump shaft

area provides the adjustable pressure intensification

needed to move the separate liquids through the mixer

with a flow rate suitable for production requirements.

The complete system is enclosed. Mixing of the two

materials takes place only in the mixer at the final stage

of metering valve operation. See Sequence of Opera-

tion on page 27.

14 313876F

Page 15

Component Identification

Typical System Configurations

Base Unit

Component Identification

A Side Feed

A Side Feed

1

Liquid Control Corp.

8400 PORT JACKSON AVE. N.W.

NORTH CANTON, OH 44720 USA

SERIAL

NUMBER

10 56 9078234

MODEL

NUMBER

B Side Feed

WARNING

Do Not service without

removing air pressure and

waring saftey glasses.

Controls

PUSH TO

LOCK

PULL TO

RELEASE

B Side Feed

Base Unit

Controls

CONTROL POWER

Liquid Control Corp.

8400 PORT JACKSON AVE. N.W.

NORTH CANTON, OH 44720 USA

MODEL

SERIAL

NUMBER

NUMBER

FIG. 1

313876F 15

Page 16

Component Identification

Typical Feed System Components

5 Gallon Pail Cover

with Diaphragm Pump

20 oz Cartridge Feed

with Mounting Post

1 Gallon Ram

and Pump

WARNING

DO NOT SERVICE WITHOUT

REMOVING AIR PRESSURE AND

WEARING SAFETY GLASSES.

0

psi

200

5 Gallon Pail Cover

with Diaphragm

Pump and Agitator

F

FIG. 2

5 Gallon Pail Cover

with 5:1 Transfer

Pump

5 Gallon Pail Cover

with Diaphragm

Pump

5 Gallon Ram and

11:1 Transfer Pump

16 313876F

Page 17

Typical Feed System Components (continued)

Component Identification

R

5 Gallon Tank with Diaphragm Pump and Stand 5 Gallon Tank with 5:1 Pump and Stand

15

19

12

15

19

12

22

8

26

4

0

30

psi

22

8

26

4

0

30

psi

R

10 Gallon Tank with Diaphragm Pump, Agitator,

Vacuum, and Stand

10 Gallon Tank with 5:1 Pump, Agitator, Vacuum,

and Stand

FIG. 3

313876F 17

Page 18

Component Identification

Micrometer PD44 Metering Valve

T

G

S

L

H

P

N

C

R

M

E

F

R

A B

K

J

D

D

Side View Front View

Key:

A A Material Inlet

B B Material Inlet

C Grounding Lug

D Spool Assemblies

E Metering Rods

F Oil Cup Retaining Block

G Extend Air Inlet

H Retract Air Inlet

J Dispense Air Inlet

K Reload Air Inlet

L Extend Air Flow Adjustment

Knob

M Retract Air Flow Adjustment

Knob

N Retract Proximity Switch

P Extend Proximity Switch

R Spool Valve Proximity Switch

S Shot Size Locking Ring

T Shot Size Adjuster

FIG. 4

18 313876F

Page 19

LRT PD44 Metering Valve

Component Identification

U

L

G

H

M

E

C

R

K

F

R

J

A

B

D

Side View

D

Front View

Key:

A A Material Inlet

B B Material Inlet

C Grounding Lug

D Spool Assemblies

E Metering Rods

F Oil Cup Retaining Block

G Extend Air Inlet

H Retract Air Inlet

J Dispense Air Inlet

K Reload Air Inlet

L Extend Air Flow Adjustment

Knob

M Retract Air Flow Adjustment

Knob

R Spool Valve Proximity Switch

U Transducer Connection

FIG. 5

313876F 19

Page 20

Component Identification

Motor Driven PD44 Metering Valve

W

V

X

E

C

R

K

D

D

F

R

J

W

N

A

P

B

Side View Front View

Key:

A A Material Inlet

B B Material Inlet

C Grounding Lug

D Spool Assemblies

E Metering Rods

F Oil Cup Retaining Block

J Dispense Air Inlet

K Reload Air Inlet

L Extend Air Flow Adjustment

Knob

M Retract Air Flow Adjustment

Knob

N Over-travel Proximity Switch

P Home Proximity Switch

R Spool Valve Proximity Switch

V Optional Motor (provided with

configured controls)

W Over-travel Proximity Switch

X Main Air Inlet (on far side of

valve as shown)

FIG. 6

20 313876F

Page 21

Setup

Setup

NOTE: See Typical Installation diagram.

2.

1. Perform Setup procedure for feed system components. See feed system manuals. See Related

Manuals on page 3.

2. Place an in-line air pressure regulator, air-water

separator/filter, and shut-off/bleed valve between

the air supply and the control solenoids.

3. Connect each 1/4 in. outside diameter supplied air

line to the corresponding control solenoid. See

Component Identification starting on page 15.

Typical Installation

Air Supply

4. On the Motor Driven PD44, if a non-Graco motor is

used, install the motor onto the metering valve. See

Motor Mounting Diagram, page 23.

5. On the Motor Driven PD44, connect the required

electrical power to the metering valve. See Motor

Specifications, page 43.

6. Connect chemical lines from feed system to metering valve material inlets. See Component Identifi-

cation starting on page 15.

User Supplied

Air Shut-off and Bleed Valve

Air-Water Separator/Filter

Air Pressure Regulator

A Side Material Tank (optional)

A Side Pump

B Side Pump

B Side Material Tank

FIG. 7

313876F 21

A Side Fluid Shut-Off Valve

B Side Fluid Shut-Off Valve

Control Solenoids

Metering Valve

Page 22

Setup

Tank Level Sensor Wiring Schematic

TANK LEVEL

12

345

67

PIN

1

2

3

4

5

6

7

PIN USAGE

BROWN

BLACK

BLUE

BROWN

BLACK

BLUE

BLUE

NUMBER

JUMPER PIN 6 AND 7

24 VDC+

BRN

TYPICAL LEVEL SENSOR WIRING

BLK

BLU

USAGE

HIGH

HIGH

HIGH

LOW

LOW

LOW

LOW

SIGNAL

COM

Valve Mounting Diagram

As desired, use the following diagram to mount the

metering valve.

Front of Metering Valve

1.75

0.563

4X 10-24 X 0.5 DP

0.38

4X Ø 0.188

0.862

0.75

1.50

1.06

C

L

DOWEL PINS

1.63

0.190

3.25

3.75

Bottom View

(Spool Assembly Not Shown)

FIG. 8

22 313876F

Page 23

Motor Mounting Diagram

If using a non-Graco motor with the Motor Driven PD44,

use the following diagram to install the non-Graco motor

onto the Motor Driven PD44 metering valve. See Motor

Specifications, page 43.

0.182

Setup

2.22

2.039

0.182

Ø 0.251

STANDARD

2.039

Top View of Drive Assembly

F

2.22

IG. 9

Custom Drive Mounting Diagram

If using a non-Graco lead screw or housing, use the following diagram to ensure that the guide rods will align

properly with the custom housing.

2X #30 (0.129Ø)

FLAT BTTM DRILL X .25 DP

1.31

4X 10-32

1.56

1.75

.44

.19

1.75

Bottom View of Lead Screw Housing

IG. 10

F

313876F 23

Page 24

Startup

Startup

1. Lubricate the metering rod ports in the oil cup

retaining block and fill the spool valve ports with

compatible lubricant. Consult with your material

supplier to select an acceptable lubricant. Regularly

verify that lubricant is present.

NOTICE

Testing has shown that failure to lubricate the valve

will significantly reduce seal life.

Metering Rod Ports

Spool Valve Ports

F

IG. 11: Top View of Metering Valve with Top Section

Removed

5. Dispense several full stroke shots until material is

air-free and has good shut-off at the nose.

NOTE: Very viscous, compressible materials may continue to droll after system is primed. Reduce flow rate as

required to produce air-free dispense.

NOTE: Very thin materials may require tilting the valve

greater than 45 degrees and dispensing shots until

material is air-free. Remove oil from cups before proceeding.

2. Perform Ratio Check, page 26.

3. Install mixer and shroud.

4. Pressurize the A and B material feed systems connected to the metering valve to prime the system.

See page 3 for maximum inlet feed pressures.

24 313876F

Page 25

Adjusting the Shot Size

Adjusting the Shot Size

Micrometer PD44 Only

1. Rotate the shot size locking ring counterclockwise to

loosen.

2. Rotate the shot size adjuster to adjust shot size.

6. If LED on the extend proximity switch is not illu-

minated, slide the proximity switch until the LED on

the proximity switch is illuminated.

Extend

Proximity

Switch

Retract

Proximity

Switch

NOTE: The retract proximity switch (PX-RET) is factory

preset and does not need to be adjusted. If the lower

proximity switch is changed from the factory setting, see

the assembly drawings for more information on readjustment. This switch is marked with a RET tag on the wire.

LRT and Motor Driven PD44

3. Rotate the shot size locking ring clockwise to

tighten.

4. Dispense into waste container to test shot size.

5. Repeat until desired shot size is achieved.

On LRT and Motor Driven PD44s, shot size is controlled

by the PD44 Control Box. See the PD44 Control Box

manual. See Related Manuals on page 3.

313876F 25

Page 26

Ratio Check

Ratio Check

Perform ratio check procedure at startup and after

rebuild.

1. Weigh six small cups and label as indicated. Record

weights.

2. Remove mixer.

3. Install the ratio check nozzle.

4. Dispense into a waste container to prime the ratio

check nozzle.

8. Subtract weight of empty cups from weight of filled

cups to get material weights.

9. Complete ratio calculations.

5. Place cups as indicated under ratio check nozzle

and cycle machine once.

6. Repeat until all three sets of cups have been used.

7. Re-weigh all six cups and record weights.

26 313876F

Page 27

Operation

Operation

The operation of the PD44 metering valve is controlled

by an external source. If a PD44 Control Box was purchased, see the PD44 Control Box manual for operation

instructions. See Related Manuals on page 3.

Sequence of Operation

Step 1: Reload

• Spools shift to the right

• Material feed inlets are opened

• Materials are transferred into the metering chambers by a pressurized feed system

• Outlet ports are blocked

• Metering rods are retracted to a precise position

determining the volume of each material

Step 3: Dispense

• Metering rods extend

• A and B materials are simultaneously dispensed

from the metering chamber into the disposable

mixer

• A and B materials are dispensed at the predetermined volume ratio.

Upon completion of the dispense stroke, the metering

rod and spool assemblies shift back to the reload position.

Step 2: Shift

• The balanced spool assemblies shift to the dispense position

• Material path to the mixer inlet is opened

• Material feed inlet ports are blocked

• Metering rods remain in the retracted position

313876F 27

Page 28

Pressure Relief Procedure

Pressure Relief

Procedure

1. Retract the metering rods. See the PD44 Control

Box manual. See Related Manuals on page 3.

2. Close both the A side and B side fluid shut-off

valves.

3. Remove static mixer.

4. Dispense 5 shots. Shots should be at least 75% of

the full stroke.

5. Extend the metering rods into the tubes. If Graco

controls are provided with the system, see the PD44

Controls manual. See Related Manuals on page 3.

6. Close the incoming air shut-off/bleed valve that supplies air to the metering valve.

Maintenance

Perform the following procedures once a shift.

NOTE: If material is leaking, see Troubleshooting on

page 29.

Material Reservoirs

Check material levels and refill as necessary. Ensure

that the material reservoirs are properly vented.

Air Dryer

Check the condition of the desiccant air dryer. Replace

as necessary.

Metering Rod Ports

Lubricate with compatible lubricant such as mesamoll or

silicone oil. See F

IG. 11 on page 24.

7. Close the incoming air shut-off/bleed valve that supplies the A feed system. Repeat for the B side feed

system. Refer to feed system manual for pressure

relief procedure. See Related Manuals on page 3.

Shutdown

1. Perform Pressure Relief Procedure.

2. Inspect the metering rods for material buildup.

Clean as necessary.

3. Lubricate the metering rods with compatible lubricant such as mesamoll or silicone oil.

4. Install storage cap on outlet nose.

Spool Valve Ports

Fill with compatible lubricant such as mesamoll or silicone oil. See F

IG. 11 on page 24.

Ratio Check

See Ratio Check on page 26.

28 313876F

Page 29

Troubleshooting

Troubleshooting

Perform Pressure Relief Procedure before performing any troubleshooting procedure.

Problem Cause Solution

Metering valve stalling and no material being dispensed despite adequate input pressure

Metering valve not discharging normal or full volume

Material leaks past spool valves Spool valve worn or damaged Replace the spool valve and sleeve

Improper material mixing Mixer not clean or free Remove and replace the mixer

Material leaks around mixer while

dispensing

Blocked mixer Check mixer for cured material,

replace mixer as required

Flow control valve closed Open

Low material level in reservoirs Fill material reservoirs and prime the

machine

Air in material tanks Fill reservoirs and prime machine

Cured material in mixer Check mixer for cured material,

replace mixer

Schematics

For standard machines, the schematics will be

included in the PD44 Parts manual. See Related Manuals on page 3.

For custom machines, the schematics will be included

in the assembly drawings manual.

313876F 29

Page 30

Rebuild

Rebuild

Wetted Section Disassembly

1. Perform Pressure Relief Procedure, page 28.

2. On Motor Driven PD44s, remove electrical power.

3. Mark and disconnect all material feed lines, pneumatic lines, and proximity switch wiring. Remove the

metering valve from mounts.

NOTE: On Micrometer and Motor Driven PD44s, the

rear tie plate is the tie plate with the proximity switches.

NOTE: On LRT PD44s, the rear tie plate is the tie plate

on the same side of the metering valve as the main air

inlets.

4. Remove the four cap screws to remove the rear tie

plate.

6. Loosen set screws on top of the connecting block.

7. Slide the metering rod retaining plate until the larger

hole position is in-line with the metering rod. See

F

IG. 12 in the following step.

8. Once the metering rod plate is in position, manually

move connecting block up. Rods will remain in position and connecting block is separated from rods.

Connecting Block

Metering Rod Retaining Plate

Cap Screws

5. Manually move the connecting block down so that

rods are in the extended position.

Metering Rod

FIG. 12

9. Once the metering rods are disconnected from the

retaining plate, remove the four cap screws from the

front tie plate.

Cap Screws

10. Separate the drive cylinder and the valve guides

from the oil cup retaining block.

30 313876F

Page 31

Rebuild

11. Remove the four cap screws located at the top of

the oil cup retaining block.

Oil Cup Retaining Block

Cap Screws

12. Remove the metering rods and oil cup retaining

block.

Oil Cup Retaining Block

14. Remove the two metering rods and tubes. Always

keep rods and tubes together as they are a matched

set.

Tu be

15. Remove the protruding cap screws on the each

spool block.

Spool Block

Cap Screws

Metering Rod

13. Remove the eight cap screws attaching the material

inlet blocks. Remove the material inlet blocks.

Material Inlet Blocks

16. Remove the two pneumatic spools.

313876F 31

Page 32

Rebuild

Wetted Section Reassembly

1. Install the pneumatic spool rod drive. Torque fasteners to 67-70 in-lb (7.5-7.9 N•m).

2. Repeat for other side.

4. Install drive assembly to the guides.

Micrometer PD44 shown

5. Attach the front plate to the serial number side of the

metering body.

6. On Micrometer and LRT PD44s, ensure the air

inlet ports are pointed towards the front plate.

7. Install the cap head screws to the back plate.

3. Install guide rods. Refer to Wetted Section Rebuild

on page 34 for details on spool valve and metering

rod assembly.

Guide Rods

Cap Screws

8. Slide connecting block down until rod heads are

inserted into retaining plate keyway.

9. Slide the metering rod retaining plate to the locked

position.

Retaining Plate

10. Tighten set screw located on top of connecting block

until it contacts the top of the metering rod head.

Evenly torque the A and B set screws to 4-8 in-lb

(0.45-0.9 N•m).

32 313876F

Page 33

Rebuild

11. Manually move connecting block up and down to

insure rods are properly installed.

12. Install the back plate and cap screws.

Back Plate

Cap Screws

13. Install material inlet blocks with new o-rings.

Material Inlet Block

O-Ring

Spool Valve Rebuild

1. Perform Wetted Section Disassembly, page 30.

2. Remove the two cap screws.

Cap Screws

3. Disassemble the spool cylinder.

14. Install material nose assembly with new o-rings.

4. Remove the piston from the cylinder.

O-Rings

Nose

15. Attach material line, pneumatic line, and electrical

harness.

16. Perform Startup procedure, page 24.

313876F 33

5. Install new u-cup seal on piston.

Page 34

Rebuild

6. Insert new o-ring into spool air cylinder end cap.

7. Install proximity switch.

8. Apply Krytox or compatible lubricant to cylinder.

9. Insert piston into cylinder with the u-cup lip pointed

in the direction of the tapered end of the cylinder.

The “U” points toward the air inlet.

Air Inlet O-ring

10. Careful not to cut the o-ring, install pneumatic spool

blocks.

11. Install the two cap screws.

2. Remove spool rods and sleeves from the metering

block.

NOTE: The spool sleeve can be removed by sliding the

sleeve in the direction of the identification marking.

3. Remove the pneumatic drive spool bearing, seals,

and seal retainer for both spools.

4. Inspect the metering rod and sleeve assemblies and

the spool rod and sleeve assemblies for excessive

wear. If there are any scratches on the rod that can

be felt by a fingernail, replace the rod and sleeve

assembly.

Cap Screws

12. Repeat for opposite side pneumatic spool rod drive.

Wetted Section Rebuild

1. Perform Wetted Section Disassembly, page 30.

5. Clean all wetted components thoroughly with compatible solvent.

34 313876F

Page 35

Rebuild

6. For each pneumatic drive spool block, install new

zap seals and o-rings onto o-ring retainer.

Low Viscosity Spool

High Viscosity Spool

NOTE: Correct orientation of seals shown.

Low Viscosity Spool Sleeve Seals

High Viscosity Spool Sleeve Cutout View

11. Carefully install the spool sleeves into the metering

block. Make sure the notched edge will align with

the pin in the metering block and not cut the spool

sleeve o-rings.

7. Lubricate o-rings and bearing surfaces with Krytox

or compatible lubricant.

8. Re-install the rod bearings, zap seals, and o-rings

retainers into each spool block.

NOTE: Typically, the spring in the zap seal and the

o-rings in the retainers point toward the metering block

which is in the direction of the material.

9. On each spool sleeve, install new zap seal (on low

viscosity spool), and o-rings on the outside of the

sleeves.

10. Lubricate o-rings and bearing surfaces with Krytox

or compatible lubricant.

Metering Block

Spool Sleeve

Spool Sleeve Notch

313876F 35

Page 36

Rebuild

12. Apply Krytox to spool rod then carefully install the

spool rod into the spool sleeve (inside the metering

block). Make sure not to cut the spool sleeve zap

seals (on low viscosity spools).

13. Torque bolts 67-70 in-lb (7.6-7.9 N•m)

14. Install new zap seal in the metering tube sleeve with

the spring facing down or toward the material pressure side of the sleeve.

17. Install the wetcup sleeve onto the metering sleeve.

Wetcup Sleeve

18. Install the oil cup retaining block. Torque to 77 in-lb

(8.7 N•m).

Oil Cup Retaining Block

19. Apply Krytox grease to chamfer of metering rod.

NOTE: Seals are individually packaged with part number and size. Verify rod nominal size matches seal prior

to installation.

Metering Sleeve PTFE Seal

15. Install the metering sleeve PTFE seal in the metering block. Replace the metering sleeve PTFE seal

with a new one every rebuild.

16. Install metering tube sleeve into the metering block.

Metering Block

20. Carefully insert metering rod through bearing, seal,

and metering tube. Make sure not to cut the metering sleeve zap seals.

21. Move connecting block to extended position.

22. Move slide plate to capture the metering rods.

23. Install the set screw until it contacts the top of the

metering rod. Torque set screw to 4-8 in-lb

(0.45-0.90 N•m).

Set Screw

"A" Side

Front

Metering Tube Sleeve

36 313876F

Page 37

Rebuild

Micrometer Drive Rebuild

(Micrometer PD44 Only)

1. Perform Wetted Section Disassembly, page 30.

2. Remove the four cap screws located at the top of

the pneumatic drive assembly.

Cap Screws

3. Remove the drive top cap.

5. Slide the pneumatic drive piston off the drive rod.

6. Slide the air cylinder mounting block off the drive

rod.

Drive Top Cap

4. Slide the drive rod into the open slot.

7. Install new seals on the drive piston. Make sure the

lip of the seal points toward the pressure side of the

drive. See the following illustration and the assembly

drawings for more information.

8. Remove retaining ring, washer, and posipak seal

from the air cylinder mounting block.

Retaining Ring

Washer

Posipak Seal

313876F 37

Page 38

Rebuild

9. Install new posipak seal with the o-ring pointed

towards the drive piston, then install washer and

retaining ring.

Retaining Ring

Washer

Posipak Seal

10. Apply Krytox or compatible lubricant to drive rod.

11. Careful not to cut the posipak seal, install drive rod

into the block.

13. Slide the drive rod into the closed slot in the piston.

14. Install the cylinder o-ring then, careful not to cut the

piston seal, install the drive rod into the block.

15. Install the upper cylinder o-ring.

12. Install the drive rod into the piston.

16. Install top cap block to cylinder.

17. Install drive housing bolts to the cylinder mounting

block.

38 313876F

Page 39

Electrical Requirements

Electrical Requirements

Electrical requirements for pneumatically driven and

stepper driven control boxes can be found in the PD44

Control Box manual. See Related Manuals, page 3.

PX-RET

USE SENSOR

HARDWARE

PX-EXT

3-7/8

1-7/16

VIEW A-A

RED

(48")

PD44 metering valve only: Wiring harness sensors are

24 VDC normally open PNP. See F

F

IG. 15 as appropriate.

BLUE

SOL-RET

(45")

SOL-EXT

METERING

RODS

A

SERIAL

FRONT

WIRE

LEGEND

LABEL

IG. 13, FIG. 14, or

SOL-OSV

YELLOW

(44")

PX-OSV

(42.5")

TYP

A

RELOAD POSITION (ADJUSTABLE).

DISPENSE STROKE (FIXED MOUNT).

PX-EXT METERING RODS AT HOME OR

PX-RET METERING RODS COMPLETED

I/O DEFINITION:

PX-CSV SPOOL VALVE IN THE RELOAD

POSITION ALWAYS ON WHEN VALVE

IS NOT DISPENSING.

POSITION ON ONLY DURING

PX-OSV SPOOL VALVE IN THE DISPENSE

DISPENSE STROKE.

RODS DOWN (DISPENSE) RED TUBE.

RODS (RELOAD) BLUE TUBE.

SOL-RET AIR SIGNAL TO RETRACT METERING

SOL-CSV AIR SIGNAL TO CLOSE SPOOL VALVE

(RELOAD POSITION) GREEN TUBE.

SOL-OSV AIR SIGNAL TO OPEN SPOOL VALVE

SOL-EXT AIR SIGNAL TO DRIVE METERING

(DISPENSE READY POSITION) YELLOW TUBE.

SEE DETAIL 1

DETAIL 1

(42")

PX-EXT

22

25

PX-RET

(41.5")

PX-CSV

BRN (24VDC+)

BLK (SIG)

LABEL PX-EXT

(39.5")

BLU (DC COM)

LABEL PX-RET

GREEN

(39")

BLU (DC COM)

BLK (SIG)

BRN (24VDC+)

BRN (24VDC+)

LABEL PX-CSV

SOL-CSV

2

BLK (SIG)

BLU (DC COM)

LABEL PX-OSV

BRN (24VDC+)

BLK (SIG)

BLU (DC COM)

GND

230

(SOL-CSV 'ON', PX-CSV 'ON')

POSITION (SOL-RET 'ON', PX-EXT 'ON')

(SOL-CSV 'OFF', SOL-OSV 'ON',

PX-OSV 'ON', PX-CSV 'OFF')

(SOL-RET 'OFF', SOL-EXT 'ON')

(SOL-OSV 'OFF', SOL-CSV 'ON',

PX-OSV 'OFF', PX-CSV 'ON')

(SOL-EXT 'OFF', SOL-RET 'ON'

PX-OSV 'OFF', PX-CSV 'ON',

SEQUENCE OF OPERATION:

1. SPOOLS IN RELOAD POSITION

2. METERING RODS IN HOME/RELOAD

3. START SIGNAL INITIATED

4. SPOOL SHIFT DISPENSE

5. METERING RODS DISPENSE

7. SPOOLS SHIFT RELOAD POSITION

6. METERING ROD REACH PX-RET SWITCH.

PX-EXT 'ON', PX-RET 'OFF')

8. METERING RODS RETRACT

RED EXTEND6BLUE RETRACT

YELLOW DISPENSE

GREEN RELOAD

FIG. 13: Micrometer PD44 Metering Valve Electrical Requirements

313876F 39

Page 40

Electrical Requirements

FRONT

WIRE

TYP

LABEL

PX-OSV

(44")

YELLOW

(42.5")

2) FOR PX-UP AND PX-DOWN, USE SCREW PROVIDED WITH SENSORS

1) SENSORS ARE PNP NORMALLY OPEN

NOTES:

PX-HOME

(47")

USE SENSOR

3) PX-UP AND DOWN TO BE USED FOR OVER TRAVELS

HARDWARE

A

A

STUD

GROUND

(39.5")

PX-CSV

GREEN

(39")

TYP

3 7/8

25"

30" 2"

VIEW A-A

PX-UP

(47")

HARDWARE

USE SENSOR

(45")

PX-DOWN

HARDWARE

USE SENSOR

3 15/16

1 5/16

2" 2"

2"

6"

YELLOW DISPENSE

GREEN RELOAD

BLK (SIG)

BRN (24VDC+)

LABEL PX-UP

BLU (DC COM)

BRN (24VDC+)

BLK (SIG)

LABEL PX-DOWN

BLU (DC COM)

BRN (24VDC+)

LABEL PX-CSV

BLU (DC COM)

BLK (SIG)

BRN (24VDC+)

LABEL PX-OSV

BLK (SIG)

BLU (DC COM)

BRN (24VDC+)

LABEL PX-HOME

BLU (DC COM)

BLK (SIG)

GND

FIG. 14: Motor Driven PD44 Metering Valve Electrical Requirements

40 313876F

Page 41

SEE

Electrical Requirements

(44")

FRONT

BLUE

(45")

PX-OSV

(48")

RED

TYP

WIRE

LABEL

PG-7

M

F

(48")

YELLOW

(42.5")

1 BLK

PG-7

LOOKING FROM SOLDER SIDE

3 WHT

MALE

2 RED

3 WHT

1 BLK

DETAIL 1

SEE 02/2980-4/25

FEMALE

DETAIL 1

2 RED

1 MOhm

>0 TO SLIGHTLY LESS

25 INCHES/SECOND

THAN FS SIGNAL INPUT

25

(39.5")

PX-CSV

GREEN

(39")

230

22

2

NOTES:

RED EXTEND6BLUE RETRACT

YELLOW DISPENSE

LRT SIGNAL INPUT: 10 VDC TYPICAL

INPUT IMPEDANCE REQ:

SIGNAL OUTPUT:

SPEED:

GREEN DISPENSE

RED (OUTPUT)

BLK (-10VDC)

LABEL LRT

WHT (+10VDC)

BRN (24VDC+)

BLK (SIG)

LABEL PX-CSV

BLU (DC COM)

LABEL PX-OSV

BRN (24VDC+)

BLK (SIG)

BLU (DC COM)

GND

FIG. 15: LRT PD44 Metering Valve Electrical Requirements

313876F 41

Page 42

Technical Data

Technical Data

NOTE: See feed system manuals for dimensions, weights, and wetted parts lists for those components. Dimensions,

weights, and wetted parts for components not covered in component feed system manuals and for combined assemblies are listed below.

Maximum Ambient Temperature . . . . . . . . . . . . . . . . . . . 110°F (43°C)

Maximum Operating Temp . . . . . . . . . . . . . . . . . . . . . . . . 150°F (65°C)

Maximum Outlet Fluid Working Pressure . . . . . . . . . . . . . 2000 psi (14 MPa, 138 bar)

Maximum Air Working Pressure. . . . . . . . . . . . . . . . . . . . 100 psi (0.7 MPa, 7 bar)

Maximum Material Inlet Pressure. . . . . . . . . . . . . . . . . . . Metal Sleeves: 1200 psi (8 MPa, 83 bar)

Plastic Sleeves: 400 psi (2.8 MPa, 28 bar)

Supplied Air Requirements . . . . . . . . . . . . . . . . . . . . . . . 1 to 3 cfm at 80 psi to 100 psi

Ratio Range (depending on metering rods selected). . . . 1:1 to 25:1

Shot Size Range (depending on metering rods selected) 0.005 cc to 5.0 cc

Maximum Cycle Rate (application dependent) . . . . . . . . Micrometer PD44: Up to 60 cycles per minute

LRT PD44: Up to 60 cycles per minute

Motor Driven PD44: Up to 15 cycles per minute (with

standard Graco motor)

Dimensions (H x L x W), height to end of material inlet

block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Micrometer PD44: 17.5 x 4.13 x 7.57 in.

(445x105x192mm)

LRT PD44: 14.5 x 4.13 x 7.57 in. (368 x 105 x 192 mm)

Motor Driven PD44 (with Graco motor):

17.5 x 4.13 x 7.57 in. (445 x 105 x 192 mm)

Mixer: 4 - 14.75 in. (102 - 375 mm)

Graco-supplied Feed System Assemblies

(depends on selected options):

Smallest: 22.5 x 10 x 4 in. (572 x 254 x 102 mm)

Largest: 60 x 28 x 19 in. (1524 x 711 x 483 mm)

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PD44 Metering Valve: 14 - 15 lb (6.35 - 6.80 kg)

Valve stand only: 8 lb (3.6 kg)

Feed Systems: 4 - 175 lb (1.8 - 79.4 kg)

Sound Data*. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PD44 Metering Valve:

76.5 dBA Sound Power Level

92.8 dB Max Sound Pressure

Graco-supplied Feed Systems:

See Related Manuals, page 3.

Wetted Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PD44 Metering Valve: Hardened steel, 303/304, 404,

UHMWPE, Tungsten, carbide, fluoroelastomer,

EPDM, PTFE

Graco-supplied Feed System Hoses and Fittings: Mild

steel, 303/304, PTFE, buna, polyethylene, polypropyl-

ene

Graco-supplied Tanks: Polyethylene, 303/304, mild steel

* Sound data measured per standard ISO 11202 (1993) & ISO3746 (1995).

42 313876F

Page 43

Motor Specifications

If a non-Graco motor is used with the Motor Driven

PD44 Metering Valve, it must meet the following specifications.

Frame: NEMA 23

Torque at Typical Dispense Speed: 180 oz-in.

(11.25 in-lb) at 10 revolutions per second (1/2 in. rod

travel per second) or less. Above 10 revolutions per second, the power declines.

Torque at Maximum Speed: 117 oz-in (7.3 in-lb) at 20

revolutions per second (1 in. of rod travel per second).

Motor Face Pilot Boss: 1.5 in. diameter by 0.0625 in.

projection from motor face flange.

Shaft Size: 0.25 diameter by 0.75 in. projection from

motor face pilot boss to end of shaft.

Technical Data

313876F 43

Page 44

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Toll Free: 1-800-746-1334 or Fax: 330-966-3006

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO OHIO INC. 8400 PORT JACKSON AVE NW, NORTH CANTON, OH 44720

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 313876

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

Copyright 2009, Graco Ohio Inc. is registered to ISO 9001

www.graco.com

Revised 07/2011

Loading...

Loading...