Page 1

Instructions

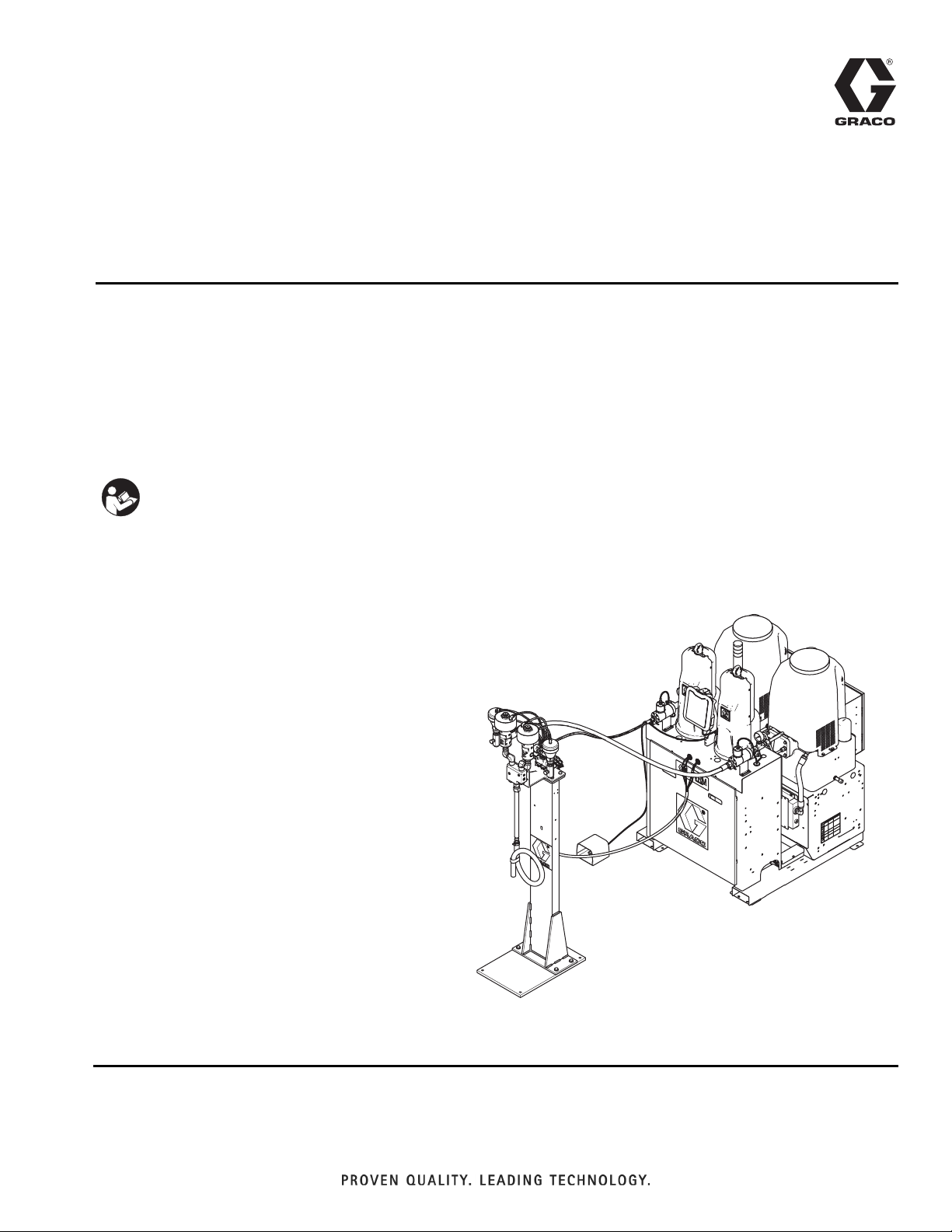

™

313873H

VRM

Hydraulic, Plural-Component, Variable-Ratio Proportioner.

For pouring and dispensing sealants and adhesives. For professional use only.

Not approved for use in European explosive atmosphere locations.

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

See page 4 for model information, including maximum working pressure and approvals.

EN

ti17663a

Page 2

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Important Two-Component Material Information . 8

Isocyanate Conditions . . . . . . . . . . . . . . . . . . . . . 8

Material Self-ignition . . . . . . . . . . . . . . . . . . . . . . 8

Keep Components A (Red) and B (Blue) Separate 8

Moisture Sensitivity of Isocyanates . . . . . . . . . . . 8

Changing Materials . . . . . . . . . . . . . . . . . . . . . . . 9

A (Red) and B (Blue) Components . . . . . . . . . . . . . 9

Component Identification . . . . . . . . . . . . . . . . . . . 10

Hydraulic Power Pack . . . . . . . . . . . . . . . . . . . . 13

Motor Control Module (MCM) . . . . . . . . . . . . . . 14

Advanced Display Module (ADM) . . . . . . . . . . . 16

Fluid Control Module (FCM) . . . . . . . . . . . . . . . 19

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Initial Machine Setup . . . . . . . . . . . . . . . . . . . . . 20

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Priming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

ADM Operation Overview . . . . . . . . . . . . . . . . . 26

Machine Operation Overview . . . . . . . . . . . . . . 28

System Setup and Calibration . . . . . . . . . . . . . . 29

Dispensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Short-term . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

End of Shift . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 42

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Install Upgrade Tokens . . . . . . . . . . . . . . . . . . . 44

Advanced Display Module (ADM) . . . . . . . . . . . 44

Motor Control Module (MCM) . . . . . . . . . . . . . . 45

Fluid Control Module (FCM) . . . . . . . . . . . . . . . 45

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Light Tower (Optional) . . . . . . . . . . . . . . . . . . . . 47

Common Problems . . . . . . . . . . . . . . . . . . . . . . 47

ADM Troubleshooting . . . . . . . . . . . . . . . . . . . . 49

Motor Control Module . . . . . . . . . . . . . . . . . . . . 50

Fluid Control Module . . . . . . . . . . . . . . . . . . . . . 52

Appendix A - ADM Icons Overview . . . . . . . . . . . 54

Setup Screen Icons . . . . . . . . . . . . . . . . . . . . . . 54

Home Screen Icons . . . . . . . . . . . . . . . . . . . . . 55

Appendix B - ADM Setup Screens Overview . . . 56

Appendix C - ADM Run Screens Overview . . . . . 62

Optional Screens . . . . . . . . . . . . . . . . . . . . . . . . 65

Appendix D - ADM Event and Error Codes Overview

66

Event Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

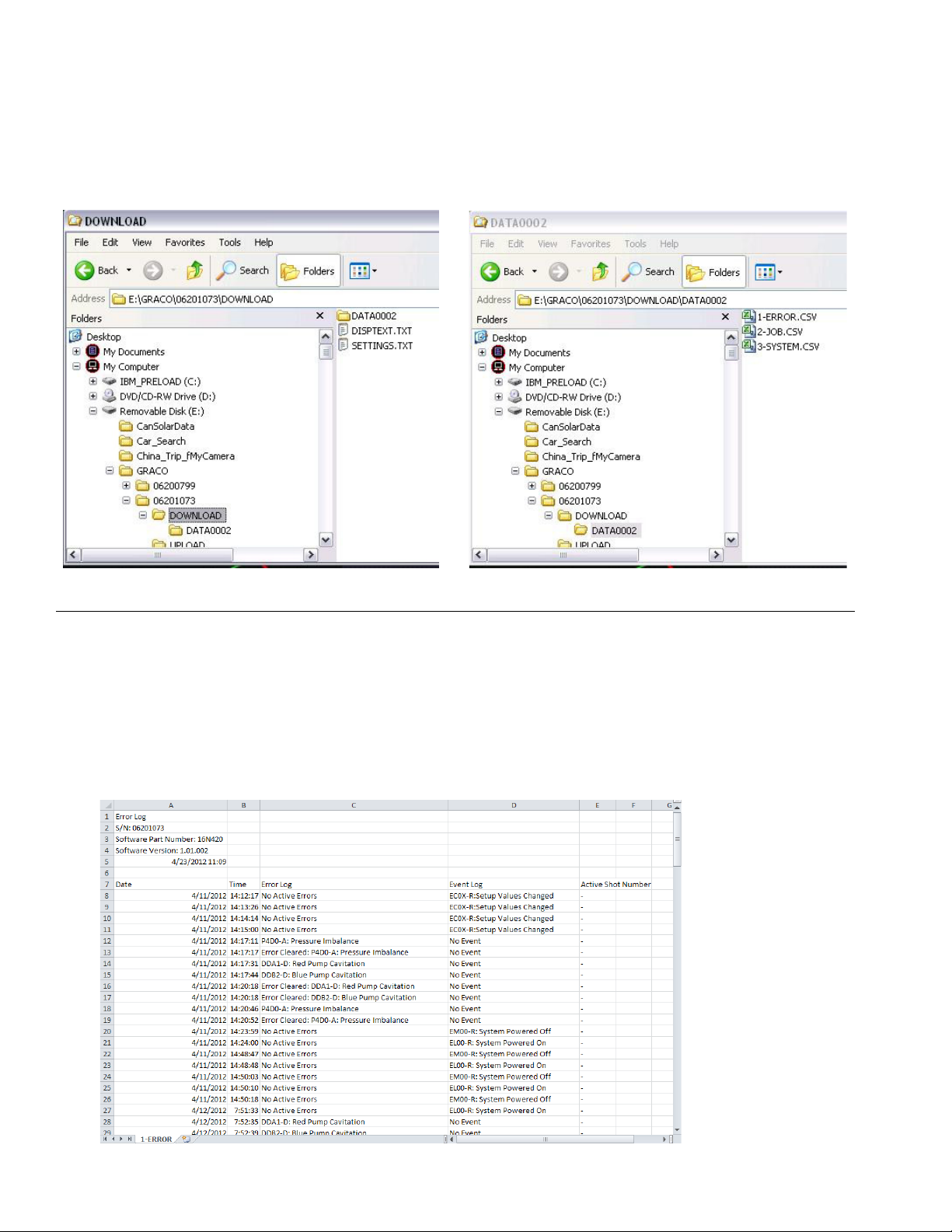

Appendix E - USB Operation . . . . . . . . . . . . . . . . 77

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

USB Options . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Download Log Files . . . . . . . . . . . . . . . . . . . . . . 77

Log Files, Folder Structure . . . . . . . . . . . . . . . . 78

Transfer System Settings . . . . . . . . . . . . . . . . . . 80

Update Custom Language . . . . . . . . . . . . . . . . . 81

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

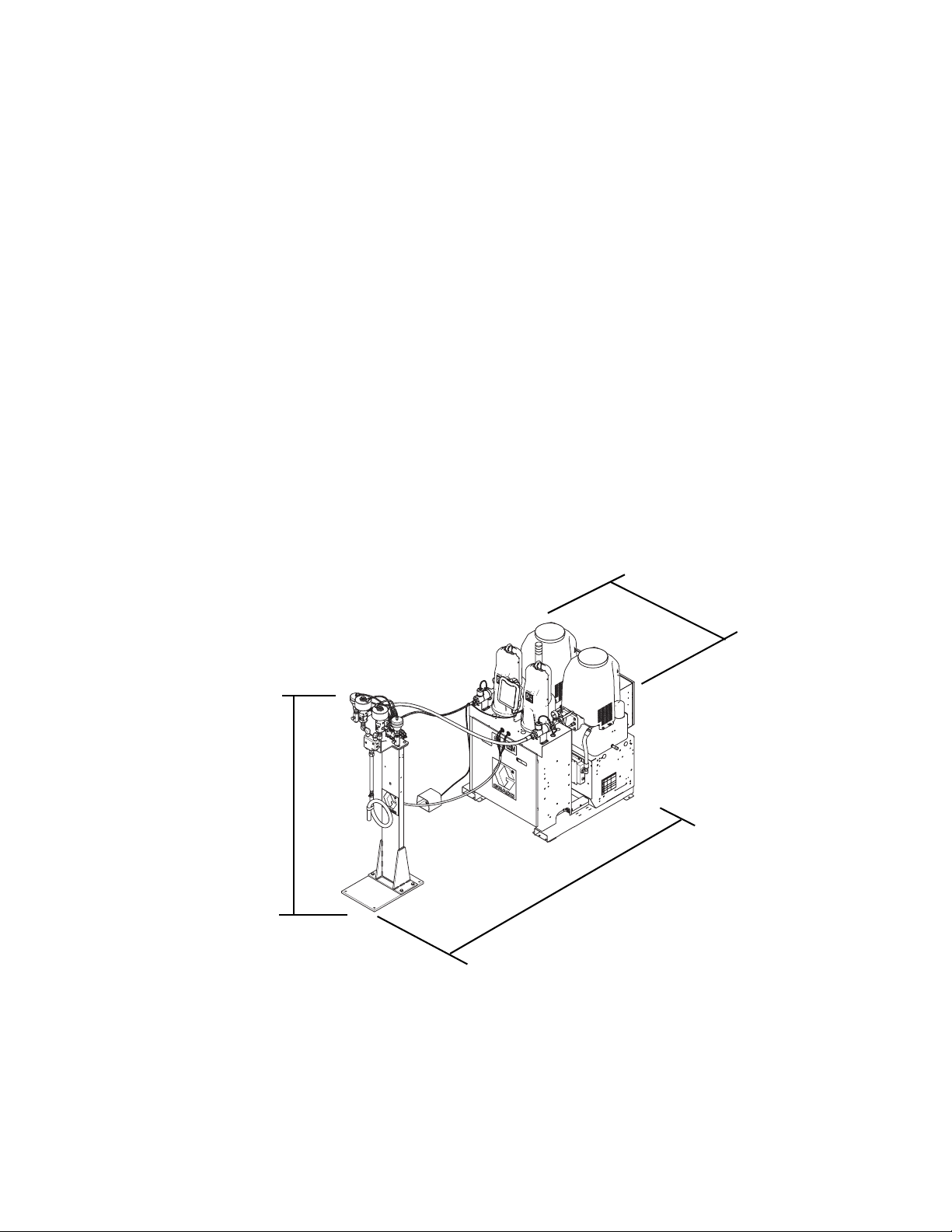

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 84

2

313873H

Page 3

Related Manuals

Manuals are available at www.graco.com.

Component manuals in English:

System Manuals

313874 VRM Repair-Parts

Power Distribution Box Manual

3A0239 Power Distribution Boxes Instruc-

tions-Parts

Pumpline Manuals

3A0022

3A0021 Vertical Hydraulic Driver

Feed System Manuals

U-Cup Dura-Flo

Repair-Parts

™

Lowers

Related Manuals

3A1159 VRM Feed Systems

Val ve Manuals

310550 1/2 in. NPT Fluid Port Ball Seat

Applicator

310551 3/4 in. NPT Fluid Port Ball Seat

Applicator

3A1792 DV Series Dispense Valves

Flow Meter Manual

309834 Helical Gear Fluid Flow Meter

313873H 3

Page 4

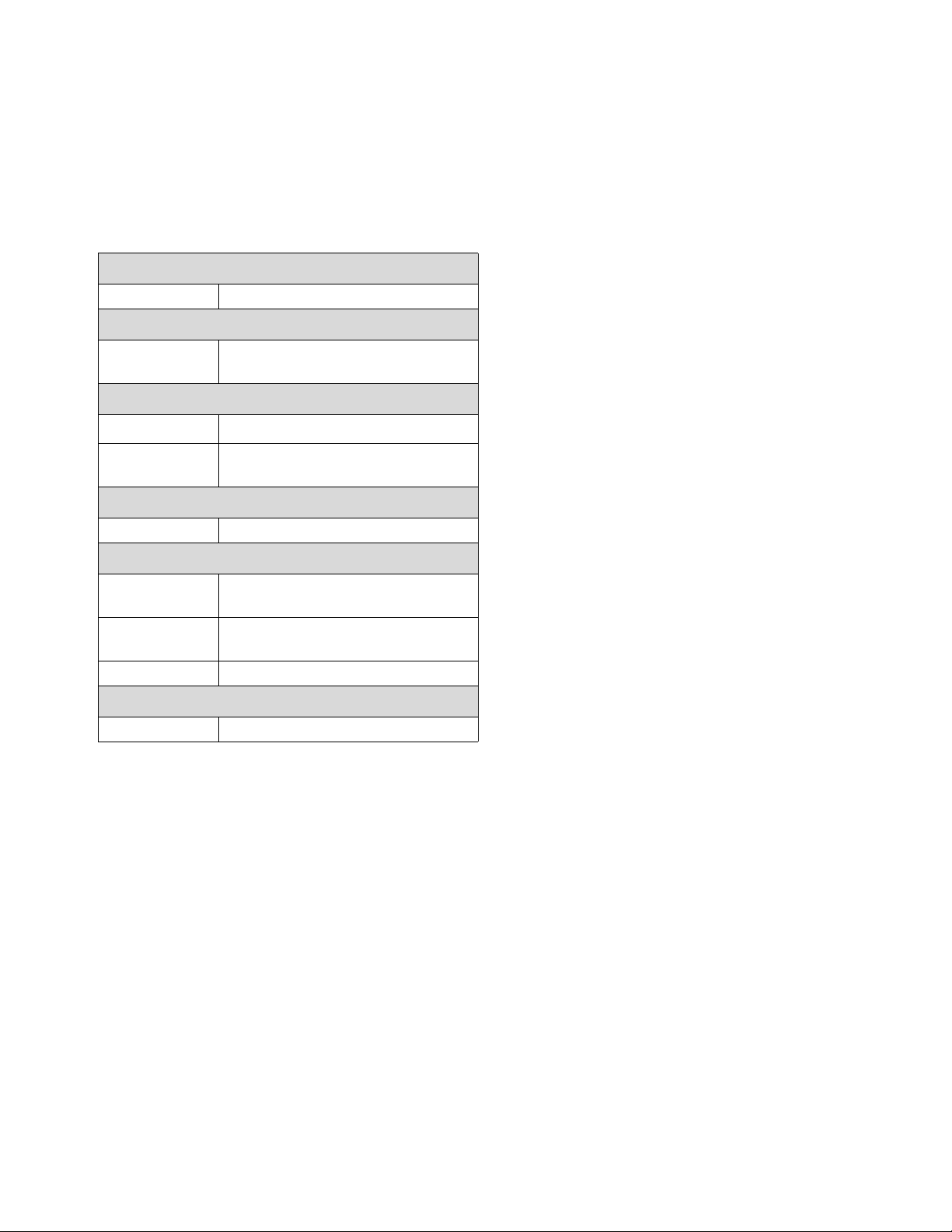

Models

Models

Approximate

Full Load

System

approved

Peak Amps

Per Phase*

Voltage

(phase)

System

Watts†

24F872 60 A 230 (3)

24F391

24F873

✔

55 A 400 (3)

55 A 400 (3)

24,000 66 (30) 1.0 (3.8) 1.63 2000 (14, 138)

* Full load amps with all devices operating at maximum capabilities. Fuse requirements at various flow rates and

mix chamber sizes may be less.

** Values are dependent on installed pump size. Values shown are for largest available pump size.

◆ Flow rate is independent of frequency 50/60 Hz.

‡ If a motor control module is replaced, see the Adjust Motor Control Module Selector Switch section in the

VRM repair manual to set the machine to the proper maximum fluid working pressure.

Max Flow

Rate◆**

lb/min (kg/min)

Output per

Cycle (A+B)**

gal. (liter)

Hydraulic

Pressure

Ratio**

Maximum Fluid

Working Pressure ‡

psi (MPa, bar)

4 313873H

Page 5

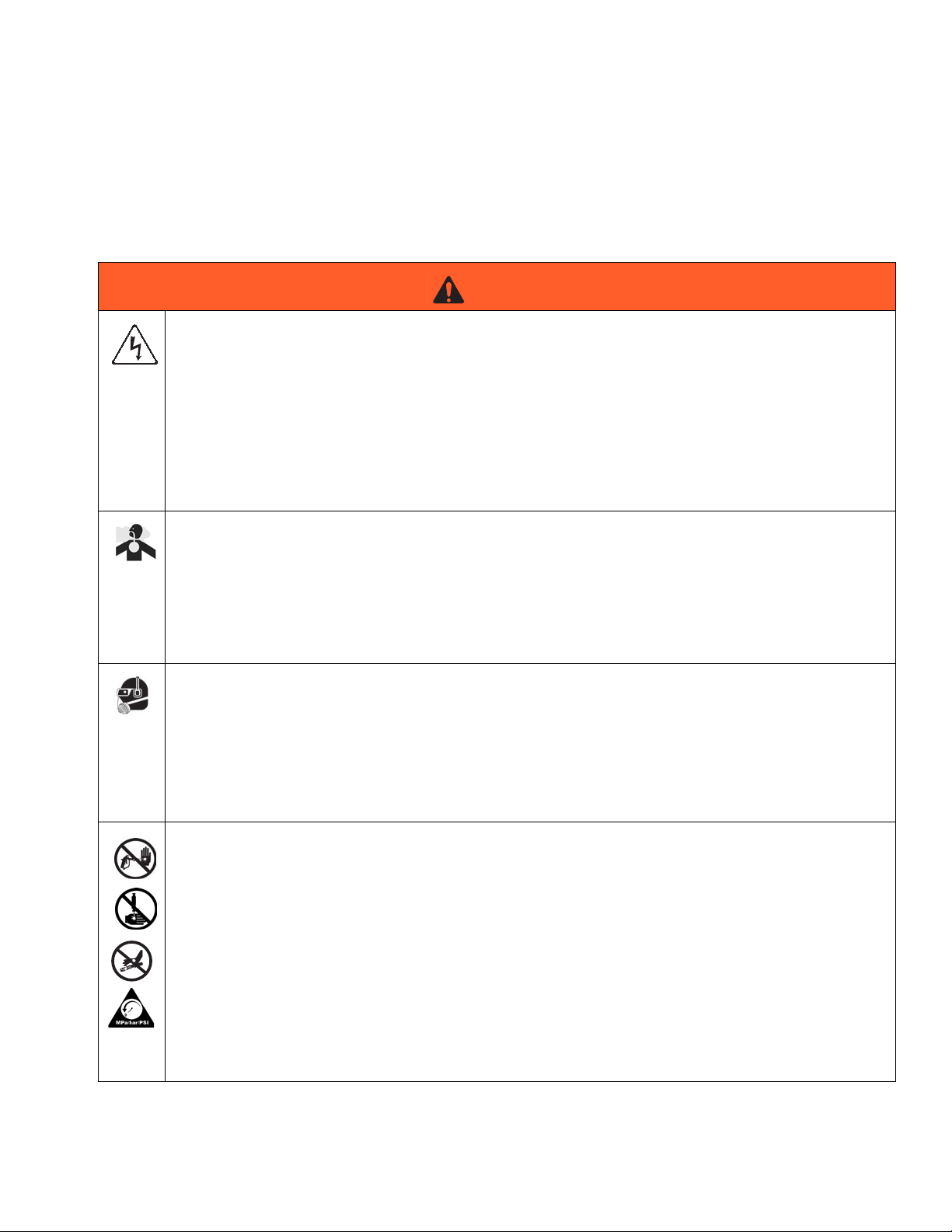

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and regulations.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear chemically impermeable gloves when spraying, dispensing, or cleaning equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, hearing loss, inhalation of toxic fumes, and burns. This equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This

may look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispensing device at anyone or at any part of the body.

• Do not put your hand over the fluid outlet.

+

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking,

or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

313873H 5

Page 6

Warnings

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic

drop cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technica l Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure. Turn off all equipment

and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

6 313873H

Page 7

Warnings

WARNING

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment, follow the Pressure Relief Procedure and disconnect all power sources.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe

burns:

• Do not touch hot fluid or equipment.

313873H 7

Page 8

Important Two-Component Material Information

Important Two-Component Material Information

Isocyanate Conditions

Spraying or dispensing materials containing isocyanates creates potentially harmful mists, vapors, and

atomized particulates.

Read material manufacturer’s warnings and material

MSDS to know specific hazards and precautions

related to isocyanates.

Prevent inhalation of isocyanate mists, vapors, and

atomized particulates by providing sufficient ventilation in the work area. If sufficient ventilation is not

available, a supplied-air respirator is required for

everyone in the work area.

To prevent contact with isocyanates, appropriate personal protective equipment, including chemically

impermeable gloves, boots, aprons, and goggles, is

also required for everyone in the work area.

Material Self-ignition

Some materials may become self-igniting if applied

too thickly. Read material manufacturer’s warnings

and material MSDS.

Moisture Sensitivity of Isocyanates

Isocyanates (ISO) are catalysts used in two component

foam and polyurea coatings. ISO will react with moisture

(such as humidity) to form small, hard, abrasive crystals,

which become suspended in the fluid. Eventually a film

will form on the surface and the ISO will begin to gel,

increasing in viscosity. If used, this partially cured ISO

will reduce performance and the life of all wetted parts.

NOTE: The amount of film formation and rate of crystallization varies depending on the blend of ISO, the

humidity, and the temperature.

To prevent exposing ISO to moisture:

• Always use a sealed container with a desiccant

dryer in the vent, or a nitrogen atmosphere. Never

store ISO in an open container.

• Keep the pump wet cups filled with IsoGuard

®

Select

rier between the ISO and the atmosphere.

• Use moisture-proof hoses specifically designed for

ISO, such as those supplied with your system.

• Never use reclaimed solvents, which may contain

moisture. Always keep solvent containers closed

when not in use.

• Never use solvent on one side if it has been contaminated from the other side.

• Always lubricate threaded parts with ISO pump oil

or grease when reassembling.

, part 24F516. The lubricant creates a bar-

Keep Components A (Red) and B(Blue) Separate

Cross-contamination can result in cured material in

fluid lines which could cause serious injury or damage equipment. To prevent cross-contamination of

the equipment’s wetted parts, never interchange

component A (Red) and component B (Blue) parts.

8 313873H

Page 9

Changing Materials

• When changing materials, flush the equipment multiple times to ensure it is thoroughly clean.

• Always clean the fluid inlet strainers after flushing.

• Check with your material manufacturer for chemical

compatibility.

• Most materials use ISO on the A (Red) side, but

some use ISO on the B (Blue) side. See the following section.

A (Red) and B (Blue) Components

A (Red) and B (Blue) Components

IMPORTANT!

Material suppliers can vary in how they refer to plural

component materials.

Be aware that when standing in front of the manifold on

proportioner:

• Component A (Red) is on the left side.

• Component B (Blue) is on the right side.

NOTE: On the VRM system, A (Red) is on the left side

of the base unit and B (Blue) is on the right side of the

base unit. The sides switch when going to the dispense

valve stand so that A (Red) is on the right side of the dispense valve stand and B (Blue) is on the left side of the

dispense valve stand.

A (Red)

B (Blue)

For all machines:

• The A (Red) side is intended for ISO, hardeners,

and catalysts.

• The B (Blue) side is intended for polyols, resins, and

bases.

NOTE: For machines with material volume ratios other

than 1:1, the higher volume side is typically the B (Blue)

side.

B (Blue)

A (Red)

ti17663a

313873H 9

Page 10

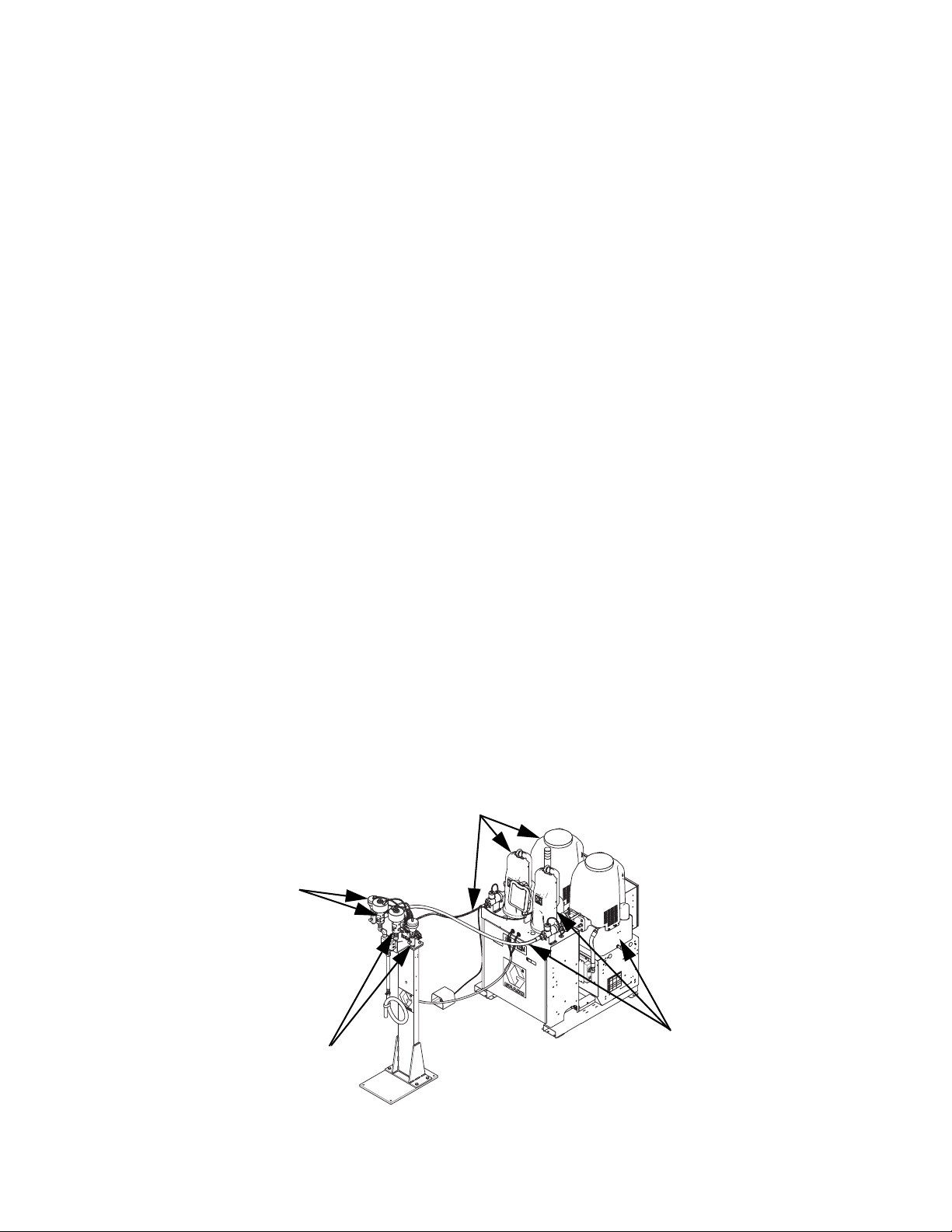

Component Identification

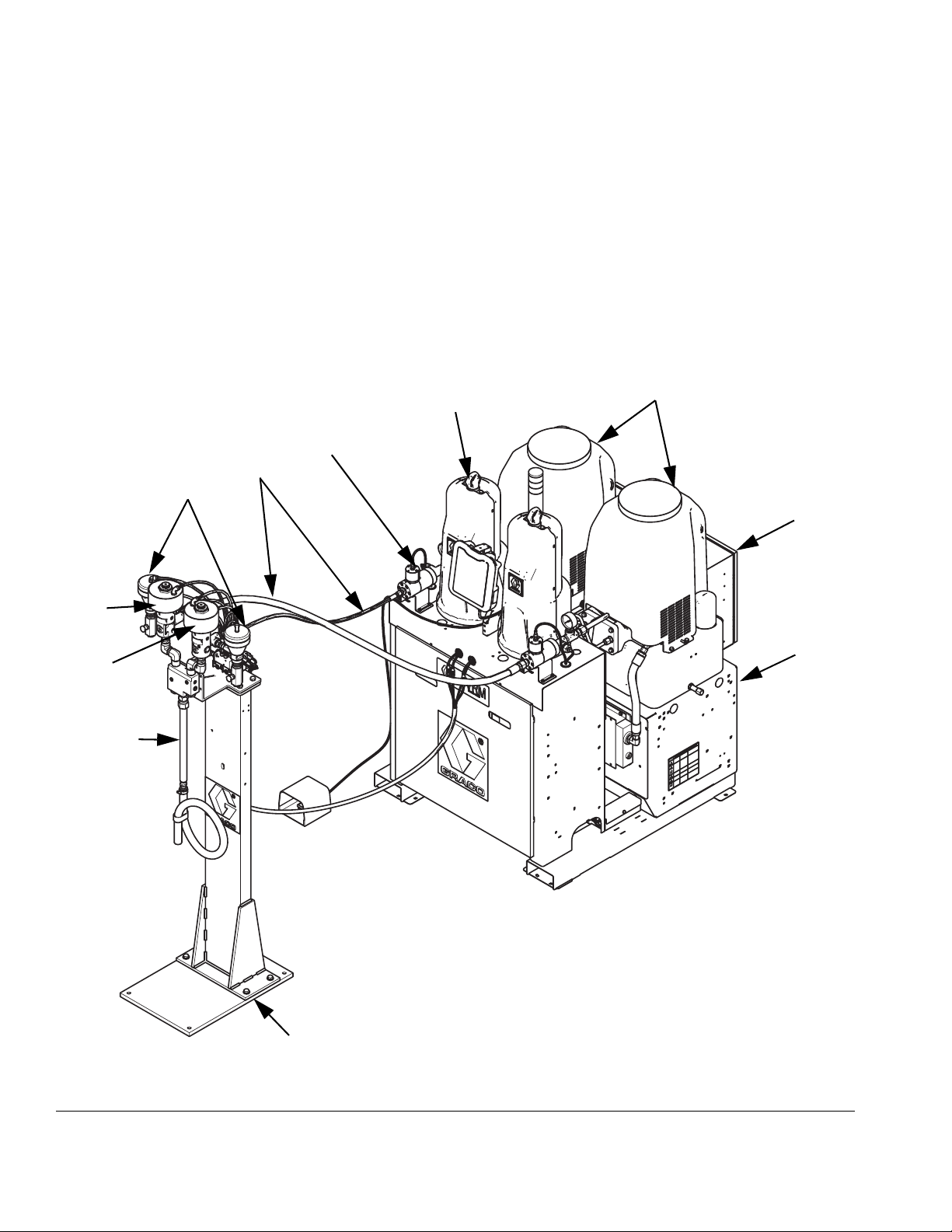

Component Identification

AA Advanced Display Module (see page 16)

AB Hydraulic Power Pack

AC Vertical Hydraulic Driver

AD Pump Lower

AE Flow Meter

AF Power Distribution Box

AG Dispense Stand

AH Mixer

AE

AP

AN

AS

AA

AJ Pump Wet Cup

AK Main Power Switch

AL Air Supply Inlet

AM Electrical Enclosure

AN Ratio Check Dispense Valves/Ports

AP Material Line

AR A (Red) Dispense Valve

AS B (Blue) Dispense Valve

AC

AB

AF

AR

AM

AH

ti17663a

AG

FIG. 1: Component Identification

10 313873H

Page 11

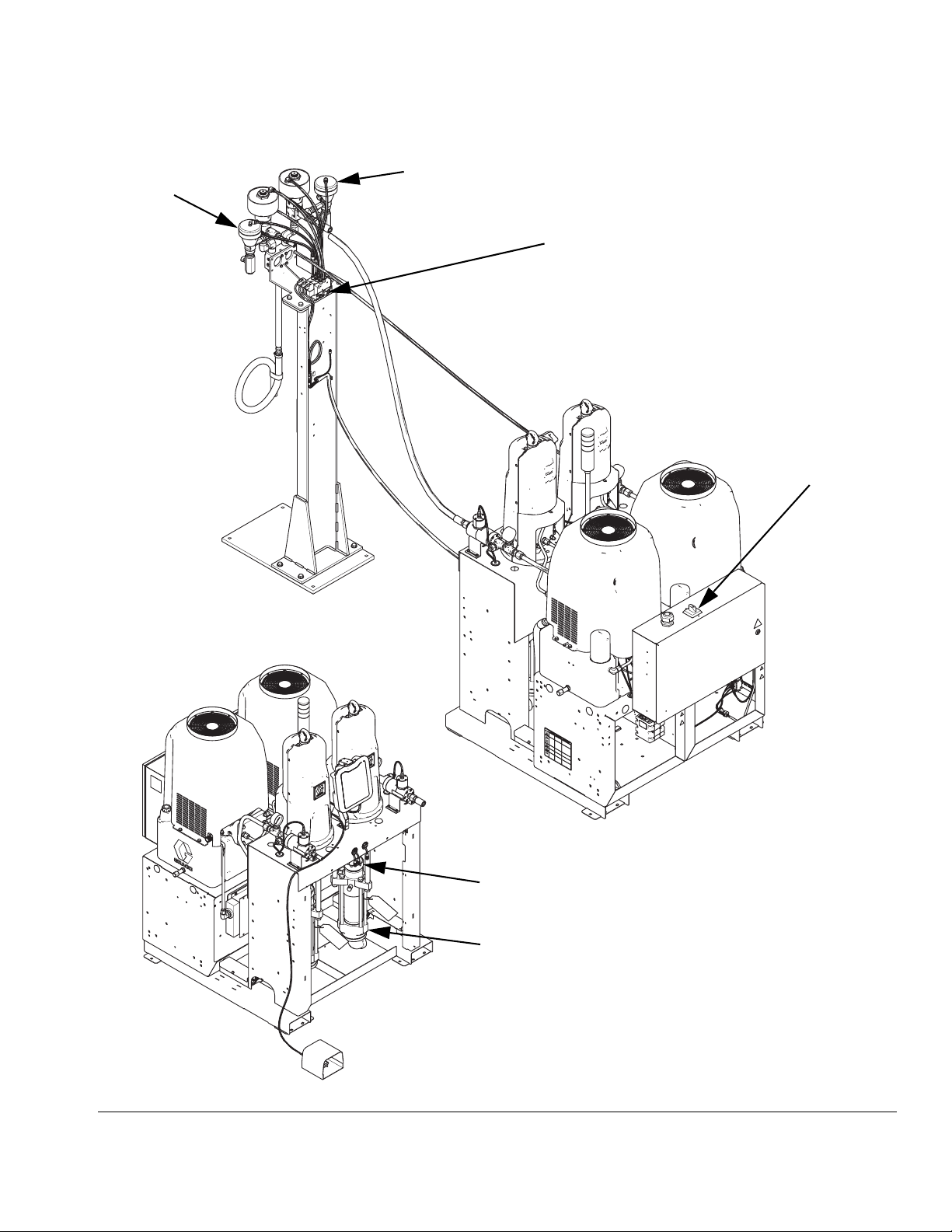

AN

Component Identification

AN

AL

AK

AJ

AD

ti17664a

FIG. 2: Component Identification

313873H 11

Page 12

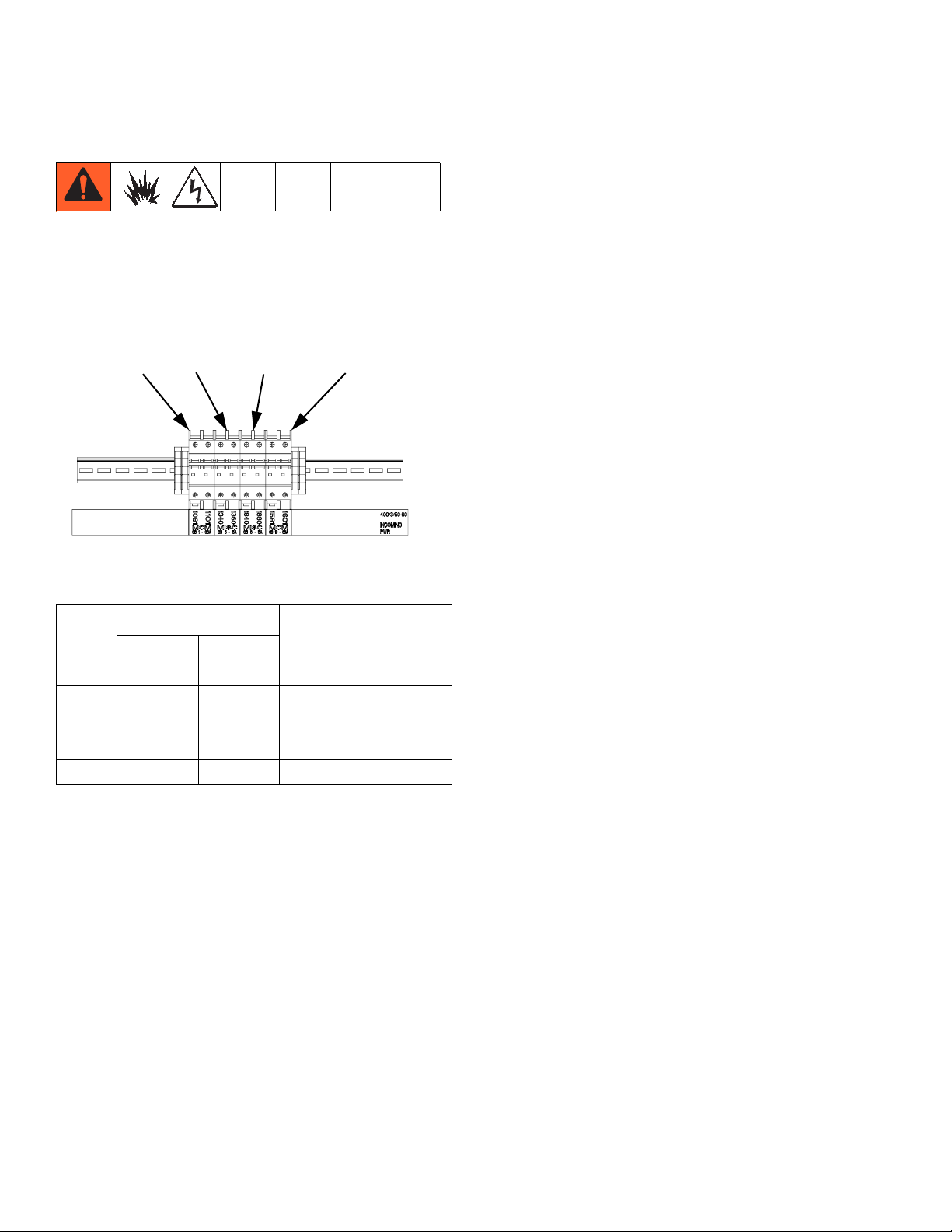

Component Identification

Circuit Breakers

Most circuit breakers are located inside the power distribution box. The main block of circuit breakers in the

power distribution box is shown below, with detailed

information in the following table. See the power distribution box manual for more information.

CB1 CB5 CB10CB6

24C687_313873-5_1c

Size

Ref.

230V/

3 phase

400V/

3 phase

Component

CB1 30A 63A Motor Control Module

CB5 5A 5A Miscellaneous

CB6 5A 5A Miscellaneous

CB10 30A 63A Motor Control Module

12 313873H

Page 13

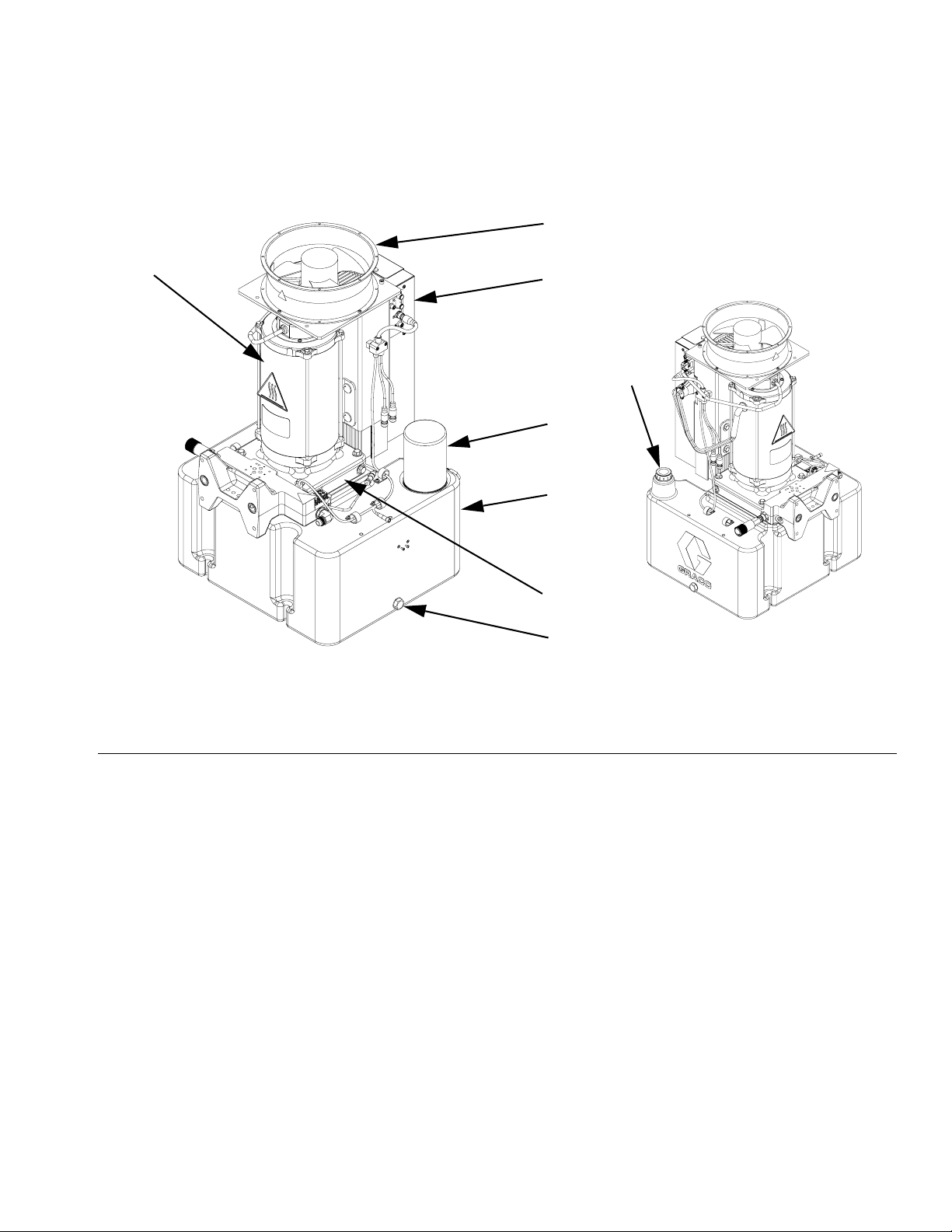

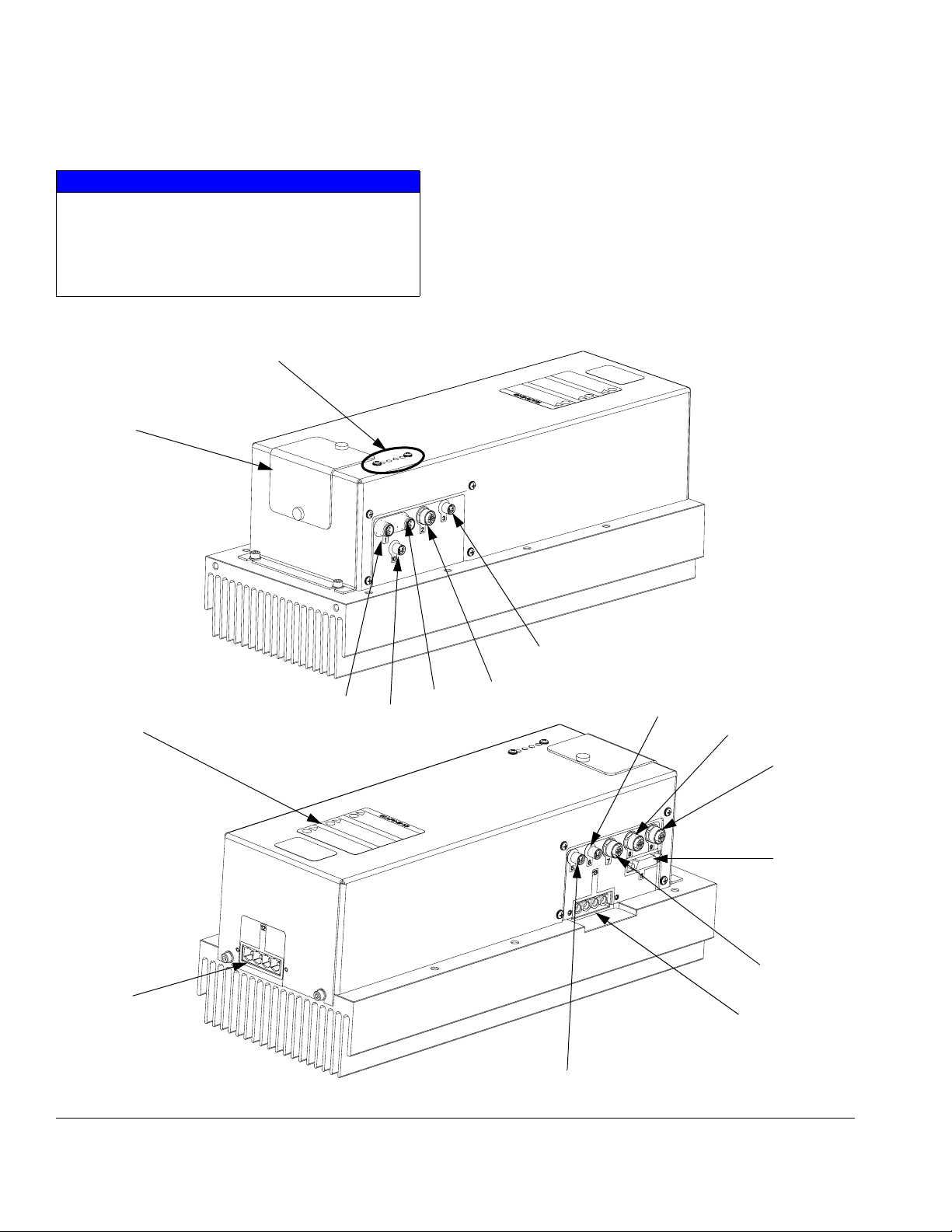

Hydraulic Power Pack

Component Identification

F

B

257442_313873-5_1t

Shown with shroud removed

E

C

G

A

D

H

257442_313873-5_2t

FIG. 3

Key:

A 8 Gallon Hydraulic Oil Reservoir (see Technical Data on

page 83 for specifications)

B Electric Motor

C Dipstick

D Hydraulic Housing

313873H 13

E Motor Control Module (see page 14)

FFan

G Hydraulic Oil Filter

H Hydraulic Fluid Drain Port

Page 14

Component Identification

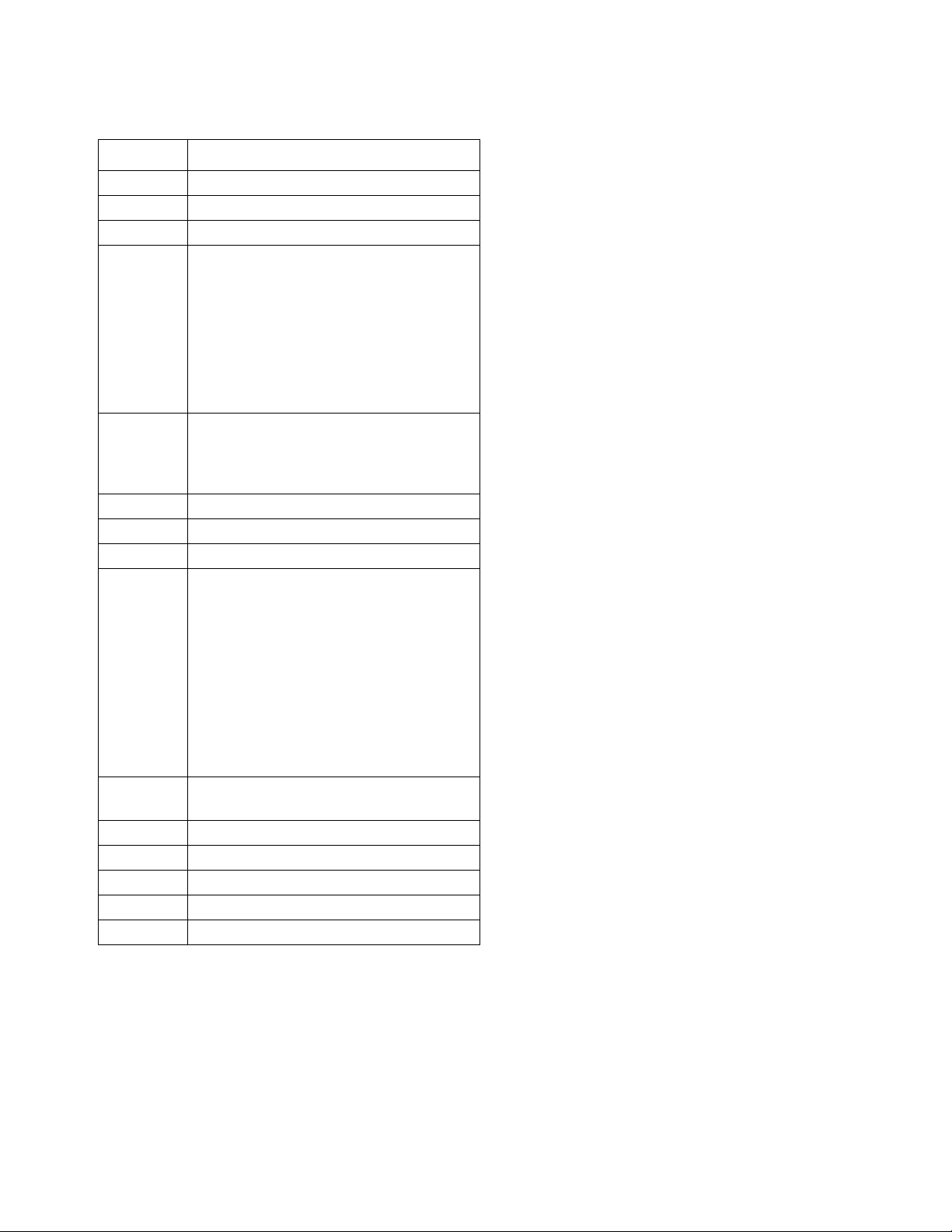

Motor Control Module (MCM)

NOTICE

If the Motor Control Module is replaced, the selector switch must be set prior to initial startup of the

Motor Control Module or damage may occur. See

system repair manual for MCM replacement procedure.

B

A

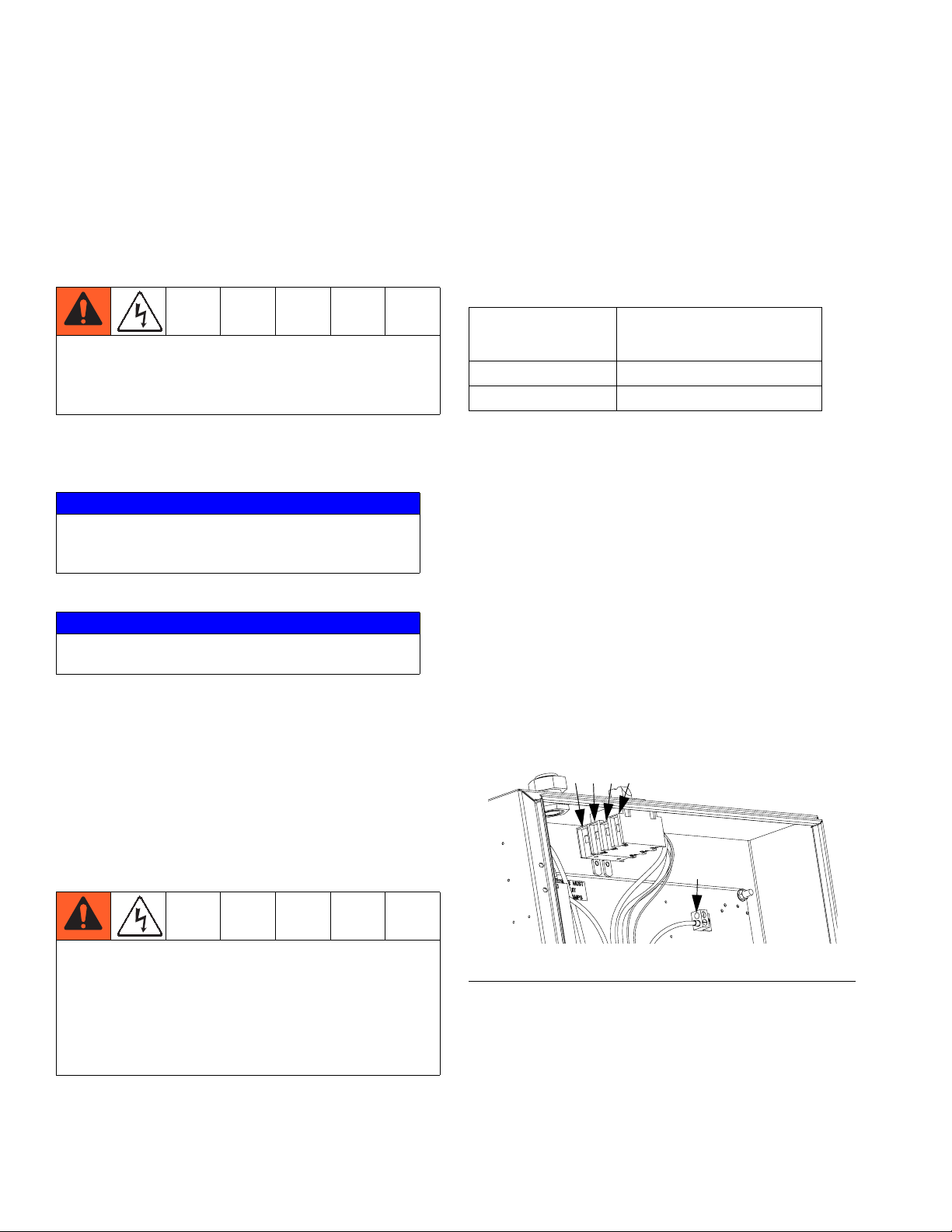

The MCM is located in the Hydraulic Power Pack.

When installed, the end of the MCM with the power

input connection (12) faces down and the end with the

access cover (A) faces up.

The Motor Control Module uses an 8-position selector

switch to set the system maximum working pressure.

C

12

FIG. 4: MCM Component Identification

1A

10

1B

3

2

5

r_257396_3b9905_01b

6

8

9

11

7

13

r_257396_3b9905_03b

14 313873H

Page 15

Ref Description

A Access Cover

B Module Status LEDs

C Warning Label

A (Red) MCM only:

ADM,

Power Distribution Box

Component Identification

1A, 1B

B (Blue) MCM only:

FCM,

Power Distribution Box

NOTE: 1A and 1B are interchangeable.

2 Three-way Splitter to:

Oil Low Level Sensor,

Dispense Valve Solenoid,

Footswitch

3 Oil Temperature Sensor

5 Electric Motor Temperature Sensor

6LVDT

7 A (Red) MCM only:

Three-way Splitter to:

Hydraulic Directional Valve,

Oil Overtemperature Switch,

Ratio Check Solenoid Valve

B (Blue) MCM only:

Three-way Splitter to:

Hydraulic Directional Valve,

Oil Overtemperature Switch

(Third connection is not used)

8 Pressure Transducer (for material side

controlled by the MCM)

9 Not used

10 MCM to MCM Analog Connection

11 Motor Position Sensor

12 MCM Power Input Connection

13 Motor Power Connection

313873H 15

Page 16

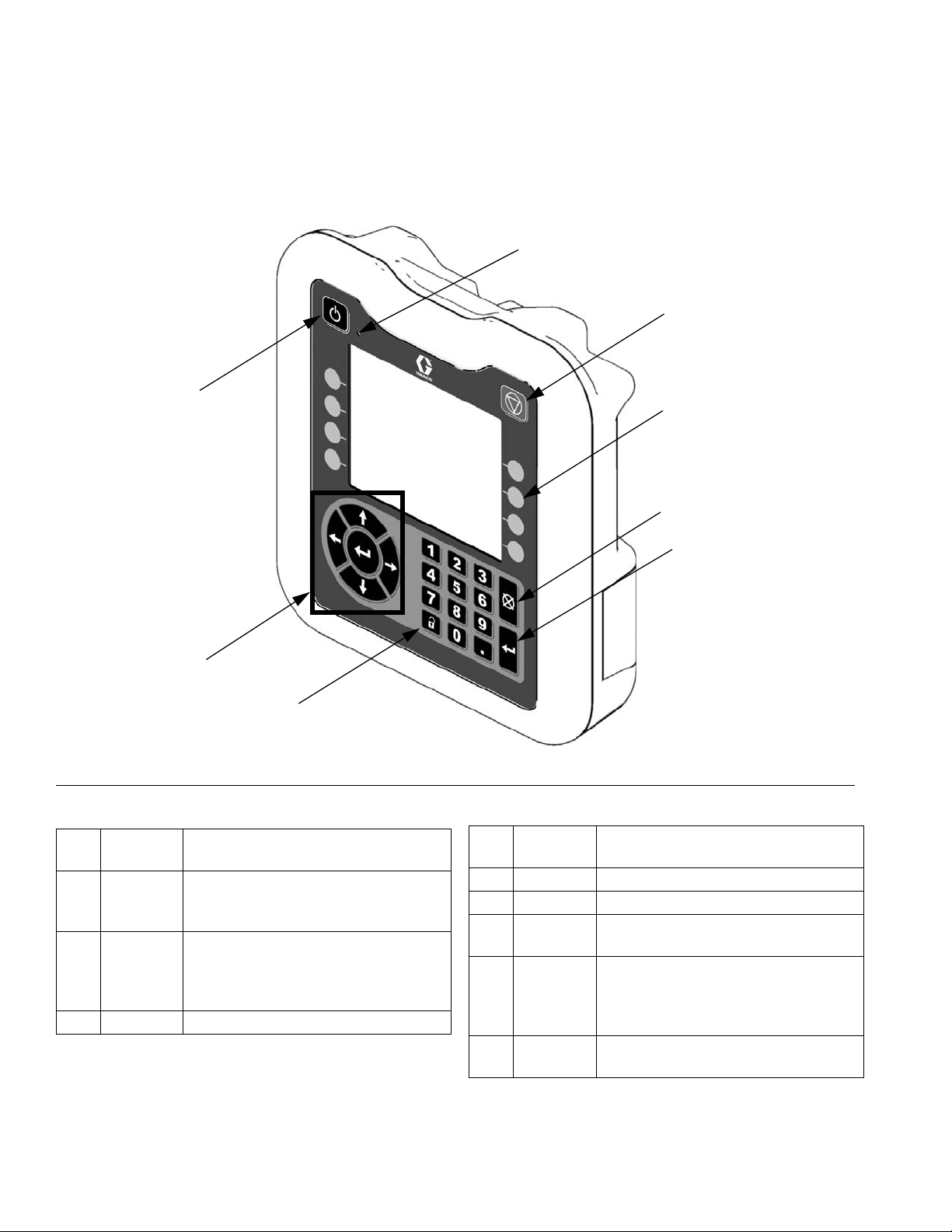

Component Identification

Advanced Display Module (ADM)

User Interface

A

B

C

D

E

H

G

FIG. 5: ADM Component Identification - Front

Buttons

Call

out Button Function

AADM

Enable/

Disable

B System

Status

Indicator

LED

C Stop Stop all system processes

Enable/disable ADM

Displays system status

F

TI12362a1

Call

out Button Function

D Softkeys Defined by icon next to softkey

E Abort Abort current operation

F Enter Accept change, acknowledge error,

select item, toggle selected item

GRun/

Setup

Toggle between Run and Setup

screens

Screens

Toggle

HArrow

Keys

Navigate within a screen or to a new

screen

16 313873H

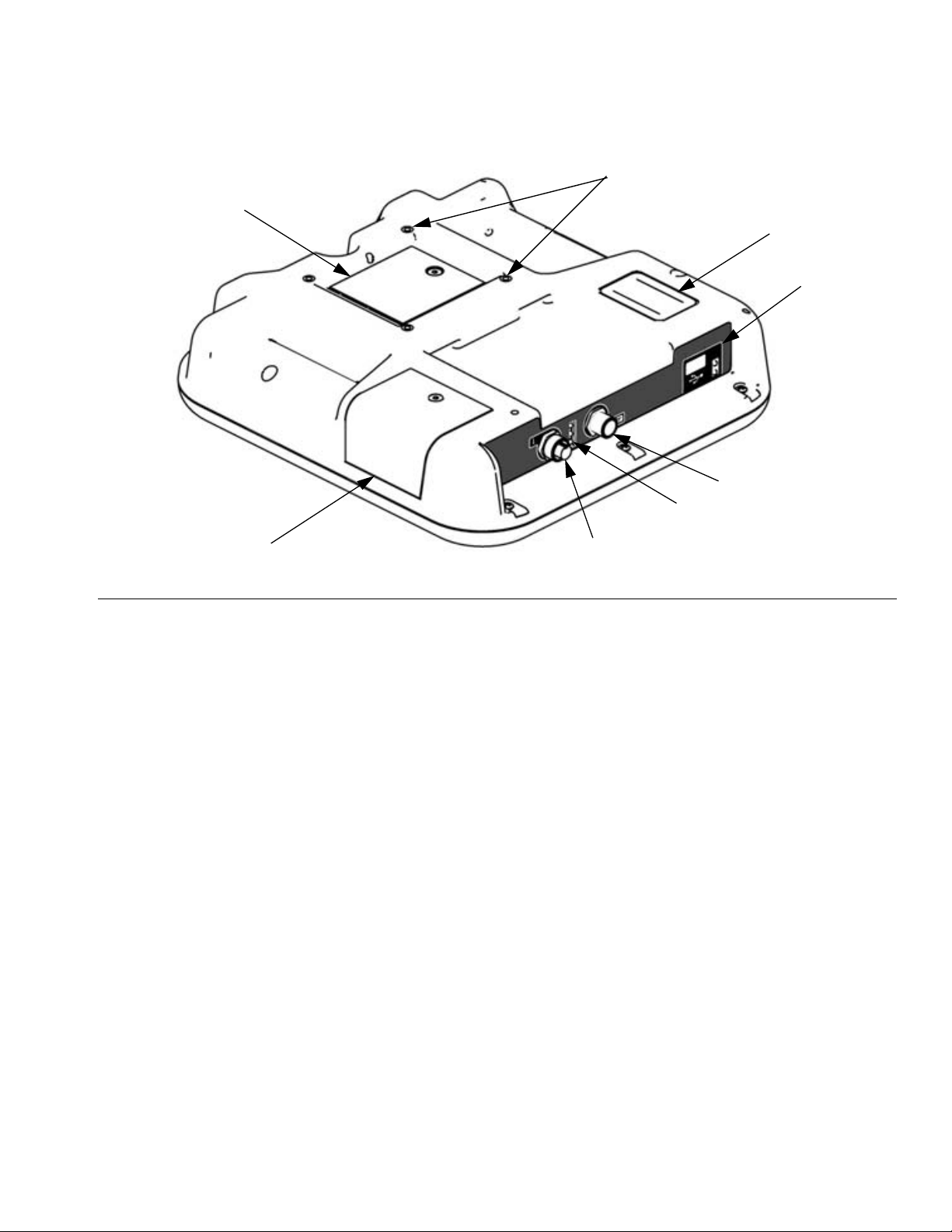

Page 17

Component Identification

J

S

K

L

M

N

R

F

IG. 6: ADM Component Identification - Rear

P

ti12902a

Key:

J Flat Panel Mount

K Model Number Identification Label

L USB Interface (see Appendix E - USB Operation

beginning on page 77)

M CAN Cable Connection to MCM

N Module Status LEDs

P Accessory Cable Connection

R Software Token Access Cover

S Battery Access Cover

See ADM Troubleshooting on page 49 for LED status information.

See Maintenance section beginning on page 43 for battery replacement and software update procedures.

313873H 17

Page 18

Component Identification

ADM Screen Components

See the ADM appendix sections beginning with Appendix A - ADM Icons Overview on page 54 for more informa-

tion.

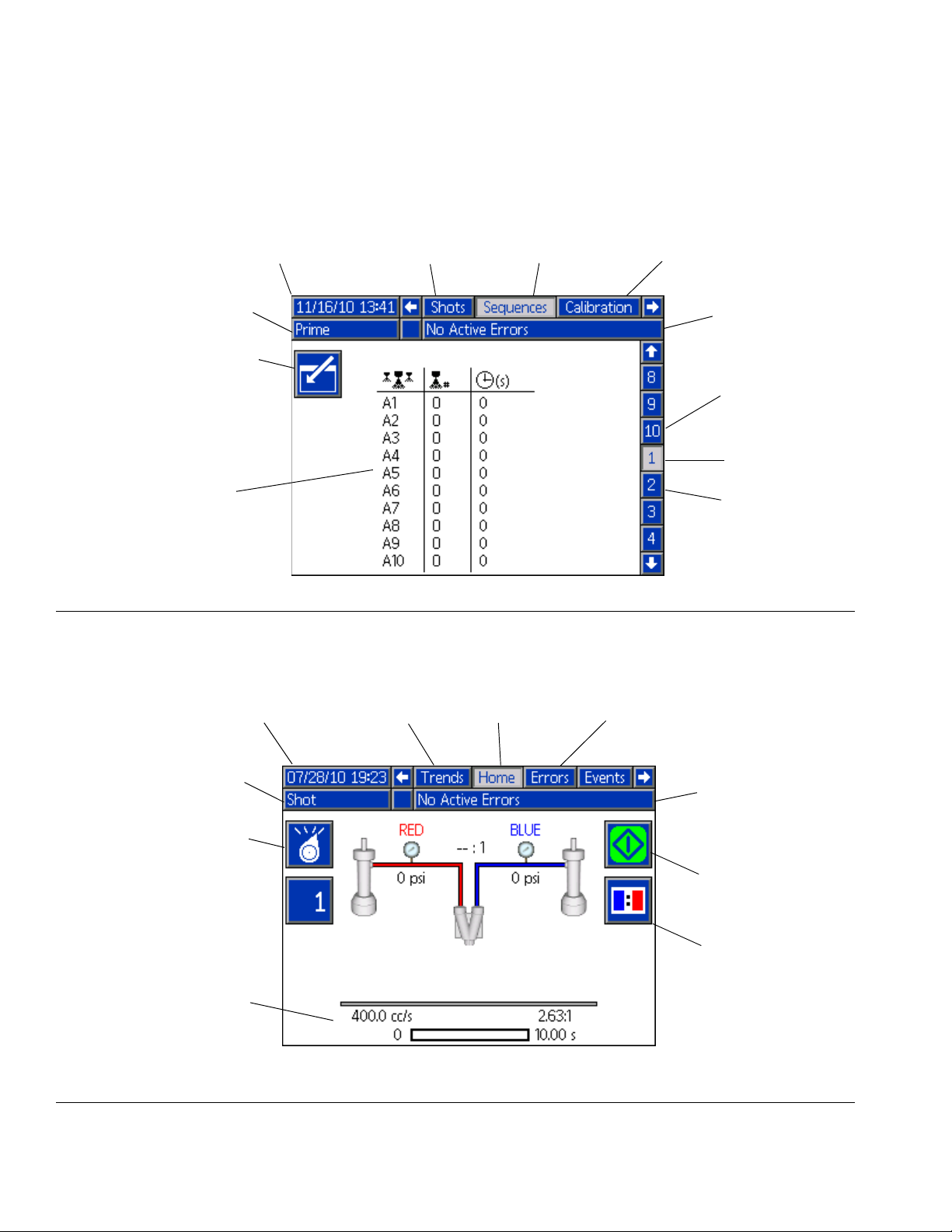

Current date and time Current screen

Previous screen Next screen

Operating Mode

Enter/Exit screen

Settings Detail

F

IG. 7: Main Display Components - Typical Setup Screen

Faults, Status

Previous

screen no.

Current

screen no.

Next

screen no.

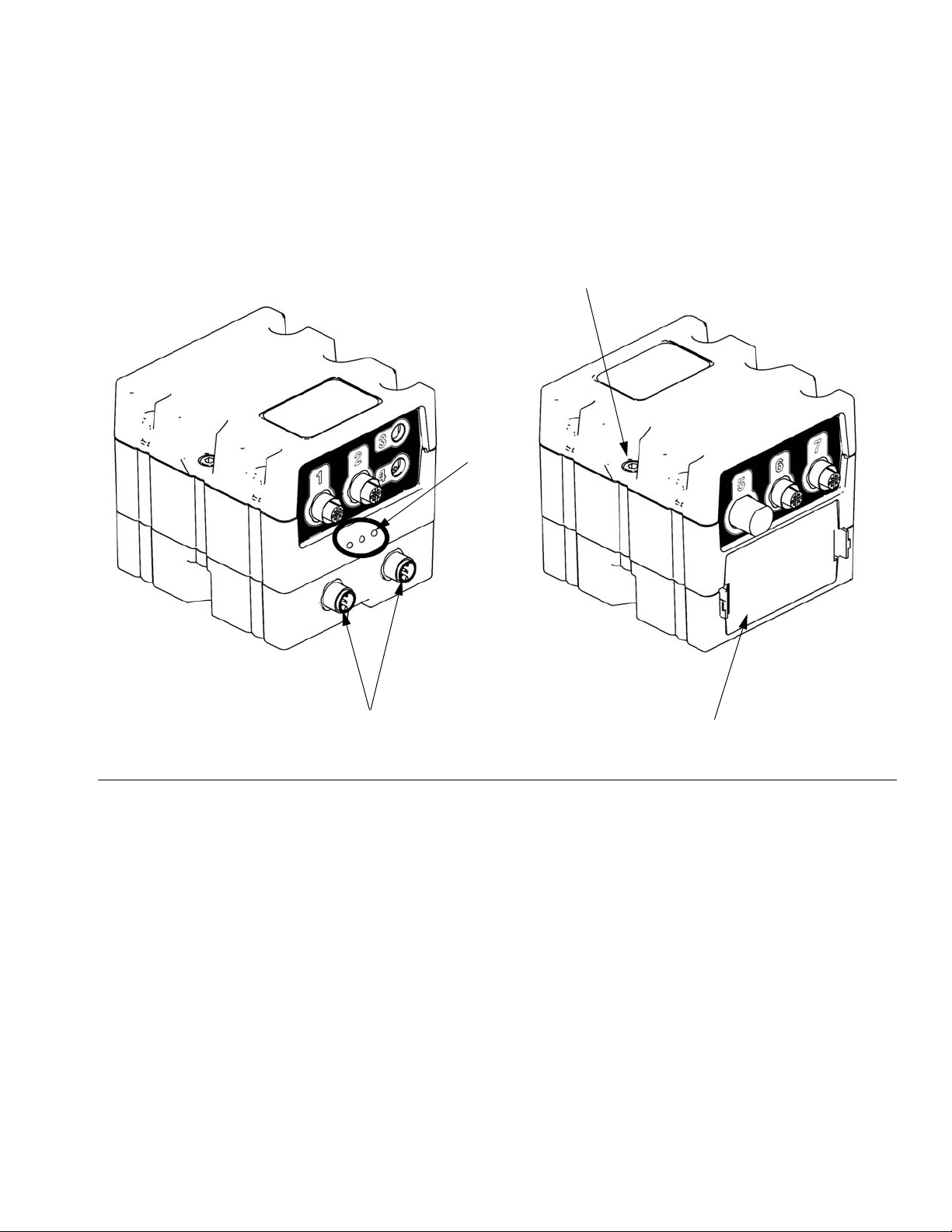

Current date and time Current screen

Previous screen Next screen

Operating Mode

Change Operating

Mode

Dispense Details

F

IG. 8: Main Display Components - Home Screen (Shot mode shown)

Faults, Status

Initiate Dispense

Initiate Ratio

Check Dispense

18 313873H

Page 19

Fluid Control Module (FCM)

The fluid control module is located inside the electrical

enclosure.

Component Identification

A

C

ti12337a1

D

FIG. 9:

Key:

A Module Connection Screws

B Access Cover

C Module Status LEDs

D CAN Connectors (one is connected to MCM, other is

unused)

ti12336a1

B

313873H 19

Page 20

Setup

Setup

Initial Machine Setup

Perform this setup procedure to prepare the machine for

initial operation.

The machine is not properly grounded until this setup

procedure is performed. To prevent risk of electric

shock, do not start the machine until this setup procedure is completed.

1. Locate the machine.

NOTICE

Be careful not to hit hydraulic power pack drain port

while moving machine. Applying significant force to

drain port may damage the hydraulic tank.

NOTICE

To prevent machine damage, do not expose system

to rain.

a. Bolt machine to original shipping pallet before

lifting.

Electrical Cord Requirements

NOTE: Power cord is not supplied. See the following

table.

Table 1: Power Cord Requirements

Cord Requirements

Model

230V, 3 phase 8 (8.4), 3 wire + ground

400V, 3 phase 6 (13.3), 4 wire + ground †

† Residual Current Device (RCD) must be rated at

300 mA if installed.

Electrical Cord Wires by Model

230V, 3 phase: L1, L2, L3, GND

400V, 3 phase: L1, L2, L3, N, GND

Electrical Requirements

See Models on page 4 for detailed electrical requirements information.

a. Use 5/32 in. or 4 mm hex allen wrench to con-

nect the power leads to L1, L2, L3, and N as

applicable.

b. Connect green wire to ground (GND).

AWG (mm

2

)

b. Locate the machine on a level surface. See

Dimensions on page 83 for space requirements.

L1L2L3N

2. Connect electrical cord.

GND

Installing this equipment requires access to parts

F

which may cause electric shock or other serious injury

if work is not performed properly. Have a qualified

electrician connect power and ground to main power

switch terminals. All electrical wiring must be done by

a qualified electrician and comply with all local codes

and regulations.

20 313873H

IG. 10: 400V, 3 phase shown

r_24C686_313998_1a

Page 21

Setup

Power Line Voltage Surges

Power conversion equipment can be sensitive to voltage

fluctuations on incoming power. The Motor Control Module falls under the category of power conversion equipment because energy is stored on a capacitive bus and

then modulated to control a brushless motor. Engineered design takes this into account and withstands a

wide range of conditions, but it is possible for supplied

power to occasionally fall outside the tolerable range in

industrial plants with high-amperage reactive pulsed

loads such as welding equipment. If the tolerable range

is exceeded, an overvoltage condition is flagged and the

system will shut down in an alarm state to protect itself

and alert the user of unstable power. Excessive or

repeated overvoltage may permanently damage hardware.

The MAX-HOLD feature on a multimeter can be used to

determine peak DC voltage on the line. DC is the proper

setting, as opposed to AC, because peak voltage is the

critical parameter that affects the DC voltage level

stored on the capacitive bus in power conversion equipment. Reading should not regularly exceed approximately 400VDC to avoid tripping the 420VDC alarm

level in the Motor Control Module. If power quality is suspect, power conditioning or isolation of the device(s)

causing poor power quality is recommended. Consult a

qualified electrician if there are any concerns about the

available power supply.

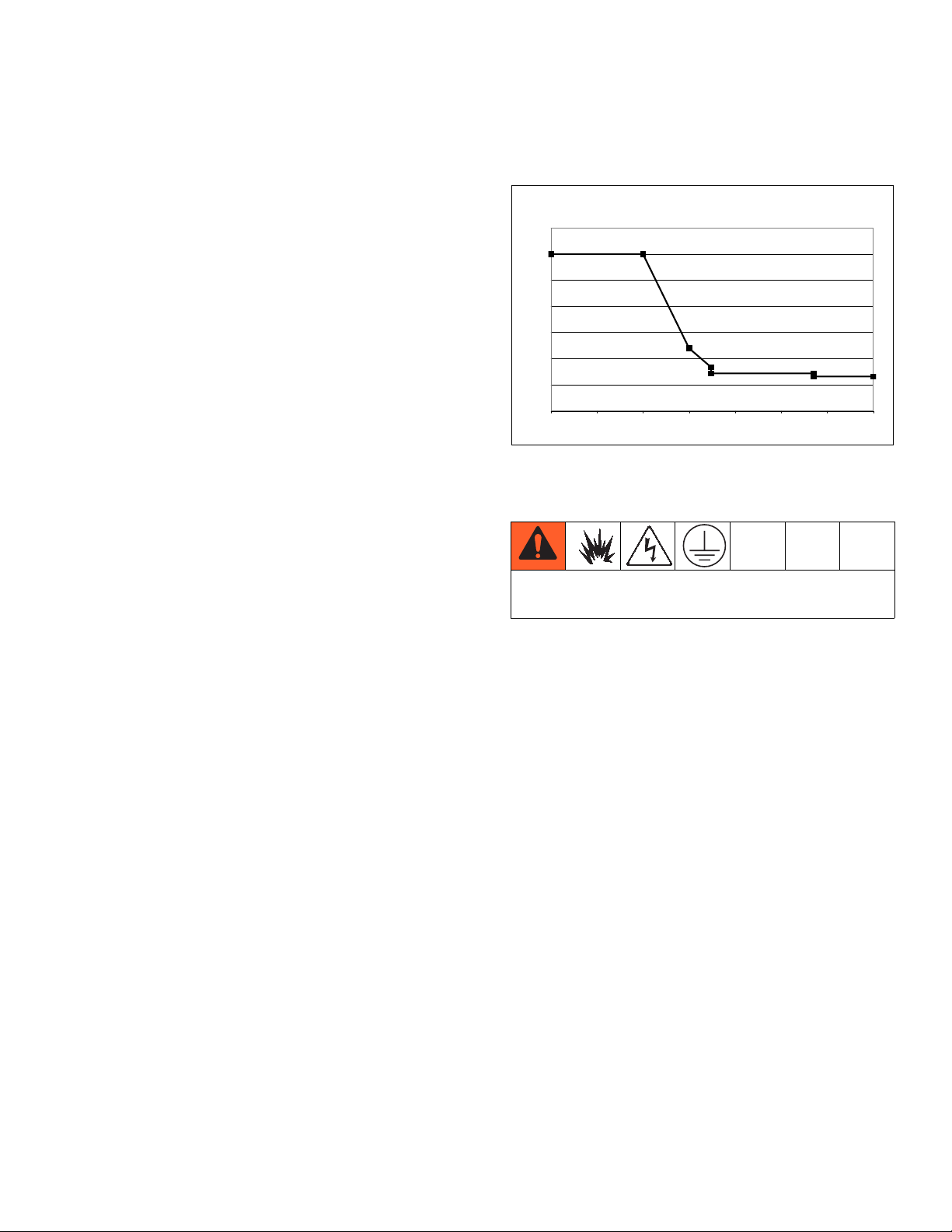

The chart below shows the permissible magnitude and

duration of temporary over-voltage events:

Maximum Permissible Transient Voltage Surges

* Constructed from ITIC 1996 curve, referenced by IEC 61000-2-4

1400

1200

1200Vac, 1697Vdc

1000

800

600

400

Voltage (Volts RMS)

200

0

0.000001 0.00001 0.0001 0.001 0.01 0.1 1 10

<--1 MW Max Surge Power

480Vac, 679Vdc

<--150 KW Max Surge Power

336Vac, 475Vdc

Time (seconds)

<--50 KW Max Surge Power

288Vac, 407Vdc

<--No Power Limit

264Vac, 373Vdc

3. Ground the system.

This equipment must be grounded.

a. VRM: grounded through power cord. See Con-

nect Electrical Cord, step #2 on page 20.

Power Line Test Steps with Multimeter

i. Set multimeter to “DC voltage”.

ii. Connect multimeter probes to supplied power line.

iii. Press “Min Max” successively to show the peak

positive and negative DC voltages.

iv. Confirm readings do not exceed 400VDC (Motor

Control Module alarm issued at 420VDC).

b. Dispense Valve: follow your local code.

c. Fluid supply containers: follow your local code.

d. Dispensing target/container: follow your local

code.

e. Solvent pails used when flushing: follow your

local code. Use only metal pails, which are conductive, placed on a grounded surface. Do not

place pail on a nonconductive surface, such as

paper or cardboard, which interrupts grounding

continuity.

f. To maintain grounding continuity when flushing

or relieving pressure, hold grounded metal pail

firmly to a metal part of dispense valve then initiate a dispense.

313873H 21

Page 22

Setup

4. Install feed system.

NOTE: This step only connects the feed system. Do not

allow fluid to flow into the system in this step.

Supply hoses from feed tank should be 2 in. (51 mm) ID

minimum.

Use at least 10 layers of PTFE tape and use pipe

dope on the fluid inlet fitting to prevent galling.

NOTICE

a. Close inlet ball valve.

b. Connect and tighten component B (Blue) supply

hose to the 2 in. npt(f) fitting on the component

B (Blue) fluid inlet at the base of the pump

lower.

c. Repeat previous steps for A (Red) material side.

5. Connect system base to dispense

stand.

a. Connect fluid hoses.

7. Check hydraulic fluid levels.

The hydraulic reservoirs are filled at the factory. See

Technical Data on page 83 for hydraulic fluid specifications.

8. Fill pump wet cups 2/3 full with

IsoGuard Select Fluid.

ti14725a

b. Connect electrical wires.

c. Connect ground wire.

6. Connect 1/2 in. air supply to dispense stand air inlet.

NOTICE

To prevent machine damage, air supply must be filtered and dried.

ti17664a1

9. Perform Startup, page 24.

10.Perform ADM setup.

NOTE: All ADM setup items are located in the Setup

screens. See Appendix B - ADM Setup Screens Overview beginning on page 56 for more information.

See ADM Operation Overview on page 26 for help with

operating the ADM including how to modify settings.

a. Navigate to Advanced #1 screen then set gen-

eral system settings. See page 60.

b. Navigate to Advanced #2 screen then set units

of measure. See page 60.

c. Navigate to Advanced #3 screen then

enable/disable system features. See page 61.

22 313873H

Page 23

d. Navigate to System #1 screen then define con-

trol mode, dispense mode, and pump information. See page 58.

e. Navigate to System #2 screen then define dis-

pense valve details and other system settings.

See page 58.

f. Navigate to System #3 screen then define

labels, pressure imbalance, and flow meter

details. See page 59.

g. Navigate to Shots screen then define shots.

See page 56.

h. Navigate to Sequences screen then define

sequences. See page 57.

i. If desired, navigate to Maintenance screen

then reset counters. See page 59.

Setup

11.Perform Flushing procedure,

page 40.

NOTICE

The machine is tested with oil at the factory. Flush

out the oil with a compatible solvent before loading

the machine with material. See Flushing on

page 40.

12.If not already open, open the fluid

inlet ball valves to load the system

with material.

13.Perform System Setup and Calibration procedure, page 29.

313873H 23

Page 24

Startup

Startup

1. Perform all required maintenance tasks. See Maintenance on page 43.

2. Check for leaks.

3. Check hydraulic fluid levels.

4. Check pump wet cup fluid levels.

5. Check feed system fluid levels.

6. Turn Main Power Switch to the ON position. The

splash screen will be displayed on the ADM until it is

finished loading.

7. When the ADM is finished loading, press to

enable the ADM. The System Status Indicator Light

next to will illuminate green.

8. Press repeatedly to select a different operating

mode then press to accept.

NOTE: The Setup screens cannot be accessed when

Disabled mode is the active operating mode. Also, certain machine functions and setup changes are disabled

when Standby mode is selected.

24 313873H

Page 25

Priming

Priming

1. Place waste containers below both ratio check dispense valves.

NOTE: Both ratio check dispense valves will be open

when dispensing in Prime Mode. Only one pump moves

but material may drip from the other ratio check dispense valve when opened.

2. Press repeatedly to select Prime Mode then

press to accept.

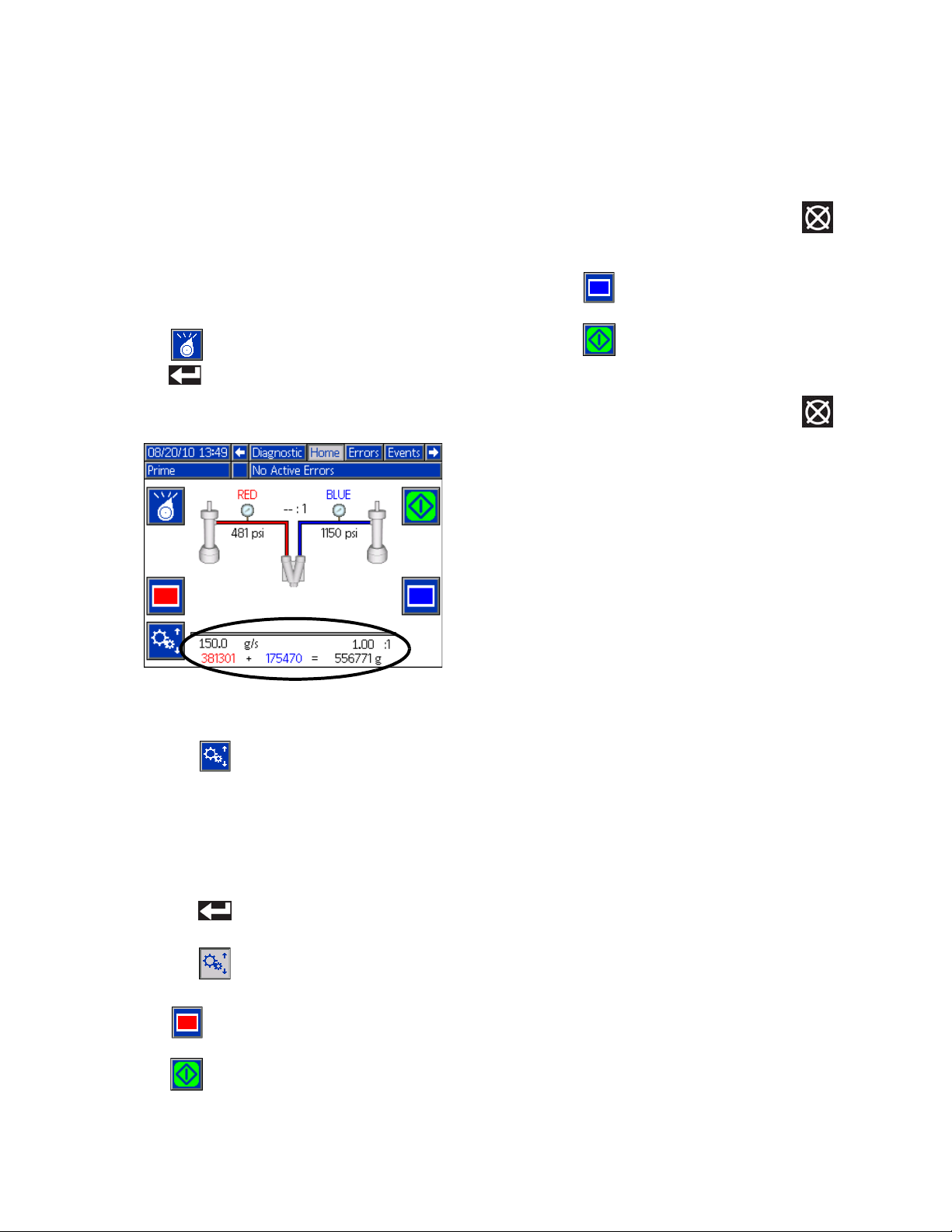

3. Check the dispense settings shown at the bottom of

the screen.

7. Continue dispensing until clean, air-free material is

dispensed from both sides then press to stop

dispensing.

8. Press to select the B (Blue) side.

9. Press to begin dispensing B (Blue) material.

10. Continue dispensing until clean, air-free material is

dispensed from both sides then press to stop

dispensing.

4. If desired, change the dispense settings.

a. Press to enter editing mode.

b. Use the left and right arrow keys to select the

item to change.

c. Use the numeric keypad to type the new value.

d. Press to accept the new value.

e. Press to exit editing mode.

5. Press to select the A (Red) side.

6. Press to begin dispensing A (Red) material.

313873H 25

Page 26

Operation

Operation

ADM Operation Overview

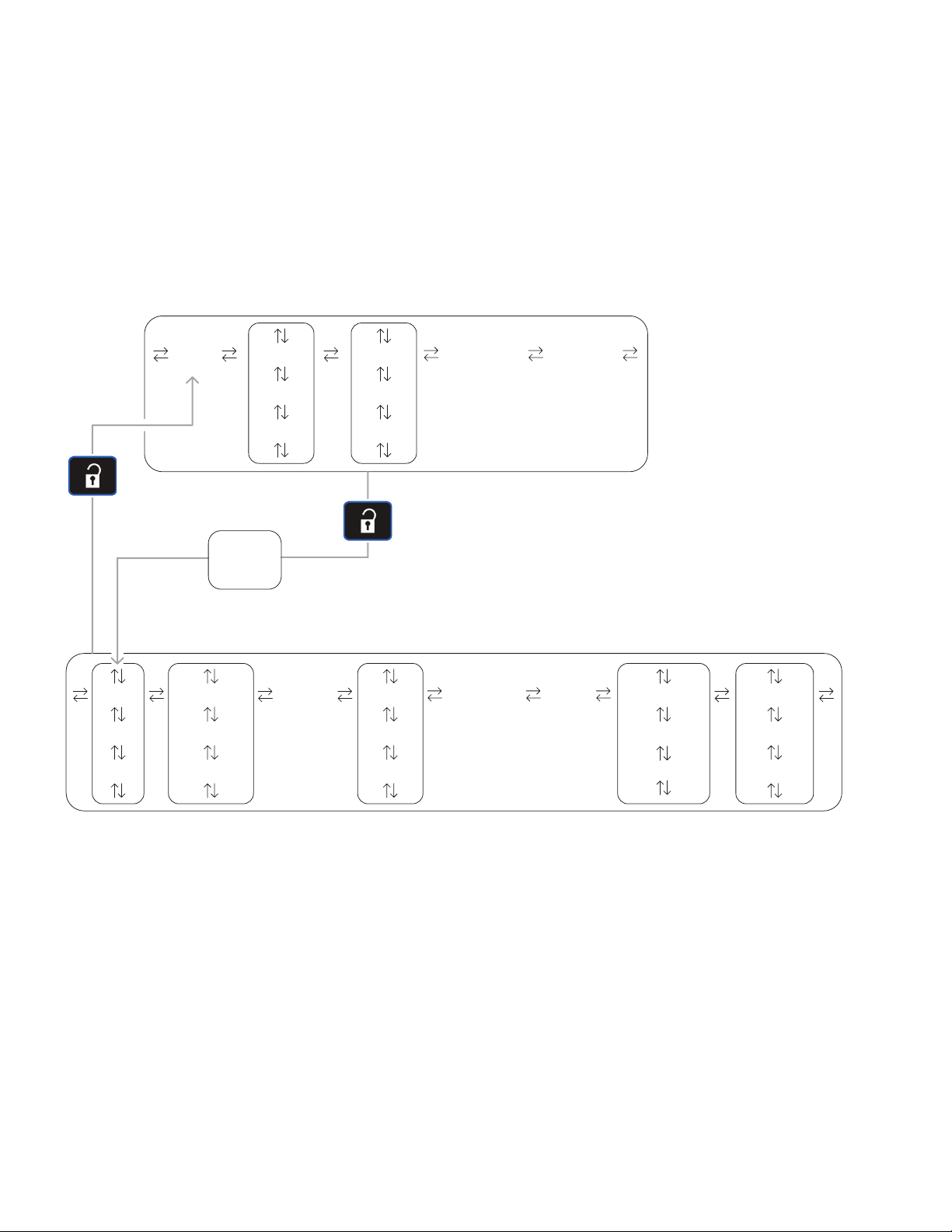

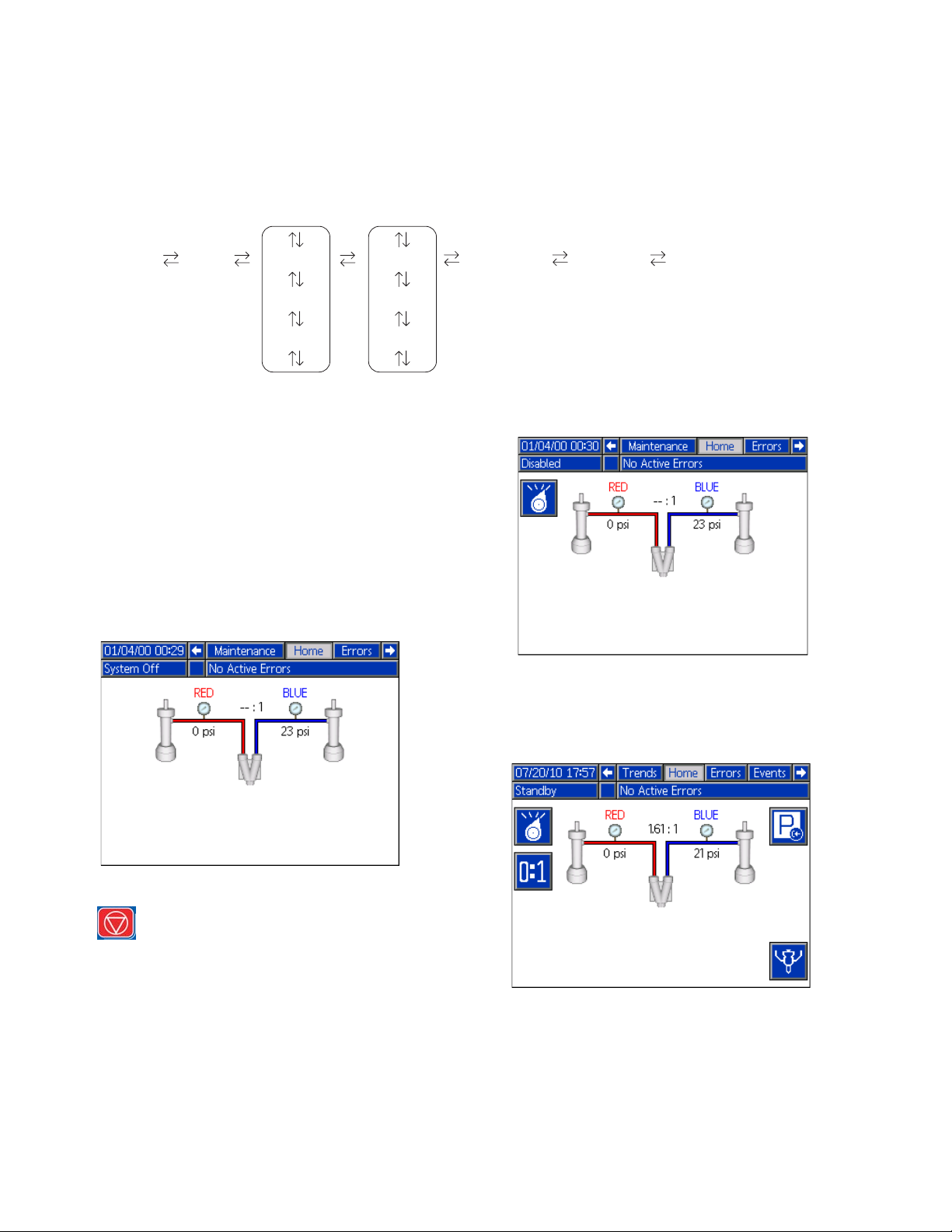

ADM Navigation Diagram

Run Screens

Shot #1

Shot #2

Shot #...

Home

Password

(if enabled)

Setup Screens

Sequences #1

Sequences #2

Sequences #...

Entry

Errors #1

Errors #2

Errors #...

Calibration

Events #1

Events #2

Events #...

System #1

System #2

System #3

Maintenance

Maintenance

Optional:

Diagnostic

Supply

Conditioning #1

Conditioning #2

Conditioning #3

Advanced #1

Advanced #2

Advanced #...

26 313873H

Page 27

Operation

Navigation Overview

For all ADM screens to be accessible and functional, the

ADM must be enabled and an operating mode other

than Standby or Disabled must be selected.

NOTE: The optional Diagnostic screen can be enabled

from Advanced #3 screen, see page 61.

To navigate between screens use the arrow keys on the

ADM keypad. To access the Setup screens,

press . If the Setup screens password is turned

on, use the ADM keypad to enter the password then

press . For Setup screens information, see Appen-

dix B - ADM Setup Screens Overview on page 56. For

Run screens information, see Appendix C - ADM Run

Screens Overview on page 62.

Change ADM Values

To edit information in a screen, such as a shot definition

or a system setting like time or date format, follow this

general process:

1. Press .

NOTE: Operator mode flow settings are edited using a

slightly different process. To edit dispensing settings

when in Operator mode, see Dispense in Operator

Mode section on page 39.

2. Once in the screen, use the arrow keys to navigate

to the desired item.

3. Edit the value:

• If the item has a drop-down list to select

from, press to display the dropdown list.

Use the up and down arrow keys to highlight the

desired item then press to select the item.

• If the item is a numeric value, use the numeric

keypad on the ADM to type the new value then

press to accept the value.

• If the item is a select/deselect or enable/dis-

able checkbox option, press to toggle

the value.

If a screen has been entered by pressing or if the

system is in editing mode then navigating to a different

screen will be disabled. As applicable, exit the screen

and editing mode to re-enable screen navigation.

• If necessary, press to cancel editing.

4. Press .

313873H 27

Page 28

Operation

Machine Operation Overview

Ramp Up Feature

The purpose of the ramp up feature is to enable dispensing at the correct ratio but at a reduced flow rate

when materials are too thick to dispense at the correct

flow rate. As the fluid warms up due to the friction of

moving through the system, the Ramp Up feature will

slowly increase the flow rate until the desired flow rate is

achieved. After a period of idle time the system will cool

down and the fluids will not be as warm while dispensing, which may result in the Ramp Up feature being activated.

While the system is dispensing, the ramp up feature

monitors the torque supplied to the B (Blue) pump to

verify it does not apply more torque than the pump can

handle. If it does, it will reduce the flow rate in both

pumps to maintain the required dispense ratio. As the

system warms up and material thickness decreases, the

ramp up feature will increase the flow rate until the

desired flow rate is achieved.

NOTE: Because the B (Blue) side is the high volume

side, it is closer to its maximum flow rate capacity than

the A (Red) side pump.

Learning Mode

When a flow rate or dispense ratio is requested that the

machine has not learned, the system will use the pump

volume of each pump to estimate the pump velocities

needed then Learn mode will be used to adjust them to

the correct flow rates. The system will begin dispensing

at the estimated pump velocity and each stroke performed will be used to gather information and adjust the

velocity. After a number of strokes, the system will have

sufficient data to accurately dispense at the desired setpoint and Learning mode will be exited.

When Learn mode is active, a “Learning New Set Point”

advisory is generated and the yellow light on the light

tower is illuminated. After Learn mode is complete, the

advisory is cleared.

When the ramp up feature reduces the flow rate, a “System Dispensing Below Requested Set Point” advisory is

generated and the yellow advisory lamp on the light

tower is illuminated. If the system is able to achieve the

desired flow rate the advisory is cleared.

28 313873H

Page 29

Operation

System Setup and Calibration

Perform this entire procedure if any of the following conditions are met:

• The machine is new

• One or both materials in the system have changed

since last performing this procedure

• Flow rate, ratio, or ambient temperature has

changed

If the software has been updated, verify all software settings in the first section of this procedure are still correct.

If any incorrect software setting is found, perform this

entire setup and calibration procedure.

Software Settings

1. With the machine on, press to enable the

ADM. The LED next to the button should be green.

2. Press repeatedly to select Standby mode then

press to accept.

7. Navigate to the System 2 screen.

8. Select a base purge flow rate. A value of approximately 100 g/s or 100 cc/s is recommended.

9. If installed, check the “Supply Low Level Sensor”

option.

10. Verify the correct Dispense Valve type is selected.

11. Navigate to the System 3 screen.

3. Press to enter the Setup screens.

4. Navigate to the System 1 screen.

5. Verify the correct pumps and pump sizes are

selected. Most systems use Dura-Flo 580 or 430

pumps.

6. Select volume or weight for the dispense mode.

Weight mode is recommended because it is easier

to calibrate.

313873H 29

Page 30

Operation

12. Select the flow meter types installed on your system. Most systems use “HG6000” flow meters for

both sides. If no flow meters are installed, select the

“Disable” option as indicated below and proceed to

step 14.

16. Press .

17. Enter the specific gravities for the two materials in

the system.

13. Set the Ratio “Alarm %” to 0 to turn off ratio alarms

and set the Ratio “Deviation %” to any number

greater than or equal to 5%.

NOTE: The “Alarm %” can be turned back on after this

setup and calibration procedure is completed.

14. Set the “Pressure Imbalance Alarm” to 2000 psi

(137.9 bar, 13.8 MPa).

15. Navigate to the main Calibration screen.

NOTE: The specific gravities do not need to be exact but

should be close.

18. Press to exit the Setup screens.

Prime the Machine

Refer to Priming section on page 25.

Piston Position Learning

19. Navigate to the Calibration screen.

20. Perform Learn Mode.

NOTE: Learn Mode will teach the system the mechanical limits of piston travel. It must be performed whenever

the pump line is rebuilt or if any other maintenance is

performed that may affect the mechanical tolerances in

the pump line. If the machine does not appear to be utilizing the full extent of the pump stroke, or if the machine

appears to be contacting the end of the hydraulic cylinder, perform the Learn Mode procedure.

a. From the Calibration screen, press to

access the Learn Mode screen.

30 313873H

Page 31

Operation

b. Place a waste container below the ratio check

valves. The next steps will cause the machine to

dispense material.

c. Press then . The pump will travel to

bottom-most position.

d. After the pump stops moving, press then

press . The pump will travel to the top-most

position.

NOTE: During this process, the system learned the

mechanical limits of piston travel. If the pump did not

reach either piston mechanical travel limit for any reason, repeat the procedure.

Flow Rate and Ratio Learning

25. At the main Calibration screen, press to erase

all learned data.

NOTE: This will not affect the weight calibration that was

just completed.

26. Press to exit the Setup screens.

21. Press to exit the Setup screens.

22. Press repeatedly to select Operator mode

then press to accept.

23. Press to enter the Setup screens then press

left or right to navigate to the main Calibration

screen.

Flow Meter / No Flow Meter Calibration

24. If flow meters are installed, refer to Flow Meter or

Flow/Ratio Calibration starting on page 34. If flow

meters are not installed, refer to No Flow Meter

Machine Calibration starting on page 35.

27. Press repeatedly to select Shot mode then

press to accept.

28. Select a defined shot that will provide a 10 second

or longer dispense at the flow rate and ratio

intended to be used during normal system operation.

NOTE: Changes to the ambient temperature will affect

the maximum flow rate for the system. If the ambient

temperature decreases, the flow rate should be

decreased.

313873H 31

Page 32

Operation

29. On the main run screen, verify the ratio check valve

button is not active.

NOTE: This verifies material dispenses through the

static mixer.

30. Place bucket under the end of the static mixer.

31. Press to begin dispensing then write down the

A (Red) and B (Blue) dispense pressures shown on

the ADM.

NOTE: During the dispense an off-ratio deviation may

be generated and that is ok.

32. Repeat the previous step until the “System Learning

New Setpoint” advisory turns off and the light tower

yellow lights turns from yellow to green.

NOTE: Continue base purge until clean material comes

out of the end of the mixer.

d. When all mixed material is pushed out of the

mixer, press to stop dispensing.

34. Press repeatedly to select Shot Mode then

press to accept.

35. Press to activate the ratio check valves.

NOTE: Be ready to adjust ratio check valves immediately after performing the following step.

36. With buckets below the ratio check valves,

press to begin dispensing.

37. While dispensing, adjust the ratio check opening

adjustment screws until both material line pressures

are approximately equal to the pressures recorded

in step 31.

NOTE: If adjusting the ratio check opening screws after

a ratio check dispense, the pressure difference due to

the adjustment will not be shown until the next dispense.

NOTE: After the ratio check dispense pressures are

properly adjusted a ratio check dispense can be performed. The ratio check dispense should be at least 10

seconds.

33. Base purge the mixer to clear mixer of mixed mate-

38. If the pressures are correctly adjusted prior to com-

rial:

pleting the shot, press to stop dispensing.

NOTE: A base purge will dispense only the B (Blue)

material to push all mixed material out of the mixer.

Base purge settings are defined on the System #2

39. If the pressures were not correctly adjusted prior to

the shot finishing, go to step 36 to repeat.

screen, see page 58.

Ratio Check

a. Press repeatedly to select Standby Mode

NOTE: In the following steps, the weight of the dispensed materials is used to calibrate the flow meters.

then press to accept.

This works regardless of whether the selected dispense

mode is weight or volume.

b. Press .

40. With active and with pre-weighed buckets

c. Press to begin dispensing.

below the ratio check valves, press to begin

dispensing a ratio check dispense.

32 313873H

Page 33

41. Weigh the two buckets and use the net weight of

each dispensed material to calculate the actual ratio

of the dispensed material.

42. If the calculated ratio of the weighed materials does

not match the ratios displayed on the ADM, go to

step 1 to re-calibrate the flow meters.

43. If the calculated ratio of the weighed materials

matches the ratio displayed on the ADM, then navigate to the System 3 screen and change the ratio

alarm percentage to the desired percentage.

44. If at any point in the future the ratio, flow rate, or

ambient temperature changes from what was used

while performing this procedure, go to step 1.

NOTE: If the ratio or flow rate is changed to a ratio or

flow rate that has not been calibrated by performing this

procedure, the system will generate a “Learning New

Setpoint” advisory. The system usually produces a good

dispense ratio during the learning process however the

advisory is generated to inform the user of the condition.

The system can store calibration data in its memory for

up to five different flow rates and ratios.

Operation

NOTE: If the ambient temperature changes significantly

from the ambient temperature seen while performing

this calibration procedure, the system will need to

“learn” the new temperature and the flow rate may need

to be decreased. The machine will not automatically be

aware of the temperature change but it will try to find the

correct dispensing properties to compensate for the new

temperature. If the ambient temperature changes significantly, go to step 1.

313873H 33

Page 34

Operation

Flow Meter or Flow/Ratio Calibration

1. At the main Calibration screen, press to erase

any previously learned flow meter calibration data.

NOTE: At this point, the “Learning New Set Point” advisory will be generated.

2. Select to enter the flow meter calibration

screen.

NOTE: After the weights are entered the K-factor will be

shown to the right of the weights. The previous K-factor

is shown to the left of the weight entry fields.

9. Repeat steps 5-8 until the new K-factor shown is

within 1% of the previous K-factor.

10. Select to exit the flow meter calibration screen.

3. On the flow meter calibration screen, enter the flow

rate and ratio that will be used during normal operation.

4. If either K-Factor value is 0, enter 3000 if an

HG6000 flow meter is installed in that side.

NOTE: In the following steps, the weight of the dispensed materials is used to calibrate the flow meters.

This works regardless of whether the selected dispense

mode is weight or volume.

5. Weigh two buckets and record the weight of each

then place below the ratio check valves.

6. With two buckets in place to catch material dis-

pensed from the ratio check valves, press to

begin dispensing.

7. After dispensing for at least 10 seconds, press

to stop dispensing.

NOTE: If available, a footswitch can also be used.

8. Weigh both buckets and enter the net weight of

each material dispensed in the last two fields provided on the screen.

34 313873H

Page 35

Operation

No Flow Meter Machine Calibration

It is highly recommended that the user operate the

machine in weight mode when flow meters are not

installed or have been disabled.

NOTE: In weight mode, the ratio displayed is a weight

ratio and should not be considered as volumetric ratio.

1. Press to enter the Setup screens then press

left or right to navigate to Advanced #3 screen. Turn

off the “Enable Ratio Check Weight Mode Entry”

option.

3. Press to exit the setup screen and verify the

ratio check option is not selected.

4. Place a waste container under the mixer.

Press to begin dispensing and record the average A (Red) and B (Blue) pressures shown on the

ADM.

NOTE: The dispense can be aborted early after record-

2. Press and navigate to the shot definition

screen. Define a shot which is 10 times larger than

the desired flow rate selected. This will set approximately a 10 second dispense time.

Example: If the dispense rate is 300 grams/second,

set the amount to 3000 grams.

ing by pressing .

5. Select Standby mode and perform a base purge.

NOTE: A base purge will dispense only the B (Blue)

material to push all mixed material out of the mixer.

Base purge settings are defined on the System #2

screen, see page 58.

a. Press .

b. Press to begin dispensing.

c. When all mixed material is pushed out of the

mixer, press to stop dispensing.

NOTE: Approximately 1 to 2 liters of base material will

need to be dispensed.

6. Select Shot mode and select the ratio check option

by pressing .

313873H 35

Page 36

Operation

7. Place waste containers below the ratio check nozzles and start a ratio check dispense. Adjust the

ratio check opening screws until the pressures displayed are near the values previously recorded

when dispensing through the mixer (step 4).

8. Press to enter the Setup screens then press

left or right to navigate to Advanced #3 screen. Turn

on the “Enable Ratio Check Weight Mode Entry”

option.

NOTE: After entering the net weight of B (Blue) material,

the ADM will inform the user how close the respective

flow of the pump was to the desire rate.

11. Press to accept the information.

NOTE: The ADM will respond by generating a “System

Learning Setpoint” advisory and the corresponding advisory light will be illuminated on the machine light tower

(if installed).

9. Press to exit the setup screen and verify the

ratio check option is selected.

10. With new waste containers below the ratio check

nozzles, start the dispense by pressing the foot-

switch or . At the end of the dispense, enter the

A (Red) and B (Blue) material weights into the

prompt boxes. Enter the weight of each bucket for

both materials.

12. Press to accept the advisory. Repeat steps 10

through 11 until the percentages approach zero and

the advisory is removed.

NOTE: The machine will be calibrated for the flow and

ratio selected once the advisory is removed.

13. If the user needs to operate at a second flow or

ratio, repeat the calibration process for the second

desired flow or ratio.

NOTE: The machine will store the necessary control

data for both calibration points.

36 313873H

Page 37

NOTE: It is recommended that the user calibrate the

machine at the extreme rates where it will be used.

Example: If the machine is to be used at mixed flows

between 300 & 500 grams/second (at 3:1 ratio), calibrate the machine at the two 300 and 500 grams/ second extremes, then stop the calibration process. The

machine will be very close to all requested flows and

ratios in between.

14. Turn off the “Enable Ratio Check Weight Mode

Entry” option in the Advanced #3 screen. The user

can verify the machine calibration by performing a

ratio check dispense and weighing the A (Red) and

B (Blue) materials.

Operation

313873H 37

Page 38

Operation

Dispensing

Dispense in Shot Mode

To dispense in Shot mode, at least one shot number

must be defined. Shots are defined on the Shots

screen, see page 56.

1. Navigate to the Home screen.

2. Press repeatedly to select Shot Mode then

press to accept.

3. If desired, change the selected shot.

a. Press .

b. Use numeric keypad to type the desired shot

number.

c. Press to accept. The shot number defini-

tion details will be shown on the bottom of the

screen.

NOTE: Only defined shot numbers can be entered. If an

undefined shot number is entered, it will be ignored.

Dispense in Sequence Mode

Sequences can be defined on the Sequences screen.

Sequences are defined on the Sequences screen, see

page 57.

1. Navigate to the Home screen.

2. Press repeatedly to select Sequence Mode

then press to accept.

3. If desired, changed the selected sequence.

a. Press once.

b. Press the right arrow key on the ADM keypad

once.

c. Use the up and down arrow keys to select a

sequence.

d. Press to accept.

4. If desired, press to skip to the next defined

shot position in the sequence. Repeat as desired.

To go to the first defined position in the sequence,

4. Press to begin dispensing the active shot. To

abort the shot at any time, press or . The

shot will continue until the predefined amount has

been dispensed.

5. Check the ADM for errors and pop-up notifications

that could indicate a faulty dispense. Press to

acknowledge any displayed errors.

press .

5. Press to begin dispensing the active shot.

NOTE: To abort the shot at any time, press or

. If the shot is not aborted, material will continue to

dispense until the predefined amount has been dispensed. The next position in the Sequence will automatically be selected upon completion of the shot.

6. Check the ADM for errors and pop-up notifications

that could indicate a faulty dispense. Press to

acknowledge any displayed errors.

38 313873H

Page 39

Operation

Dispense in Operator Mode

Operator Mode begins dispensing when is pressed

and stops when it is pressed again.

NOTE: If a footswitch is used, press and hold to dispense. Release to stop dispensing.

1. Navigate to the Home screen.

2. Press repeatedly to select Operator Mode

then press to accept.

3. Check the dispense settings shown at the bottom of

the screen.

7. Check the ADM for errors and pop-up notifications

that could indicate a faulty dispense. Press to

acknowledge any displayed errors.

4. If desired, change the dispense settings.

a. Press to enter editing mode.

b. Use the left and right arrow keys to select the

item to change.

c. Use the numeric keypad to type the new value.

d. Press to accept the new value.

e. Press to exit editing mode.

NOTE: The user can disable changing the flow, ratio, or

both on the Advanced #3 setup screen.

5. Press to begin dispensing.

6. Press to stop dispensing.

313873H 39

Page 40

Flushing

Flushing

Flush equipment only in a well-ventilated area. Do not

dispense flammable fluids. Do not turn on heaters

while flushing with flammable solvents.

Flush out old fluid with new fluid, or flush out old fluid

with a compatible solvent before introducing new fluid.

All fluid components are compatible with common solvents. Use only moisture-free solvents. See Technica l

Data on page 83 for list of wetted components to verify

compatibility of solvent with wetted materials. See solvent manufacturers information for material compatibility. To prevent moisture from reacting with isocyanate,

always leave the system dry or filled with a moisture-free

plasticizer or oil. Do not use water. See Important

Two-Component Material Information on page 8.

Grounding the solvent pails used when flushing: follow

your local code. Use only metal pails, which are conductive, placed on a grounded surface. Do not place pail on

a nonconductive surface, such as paper or cardboard,

which interrupts grounding continuity.

9. To maintain grounding continuity when flushing or

relieving pressure, hold a metal part of dispense

valve firmly to the side of a grounded metal pail,

then press . Continue to dispense until the sys-

tem is thoroughly flushed then press to stop

dispensing.

10. Close the solvent flush ball valve.

11. Disconnect solvent flush feed system.

12. Open the feed system ball valve.

13. Perform Priming procedure, page 25.

If flushing with a compatible solvent, perform the following procedure.

1. Perform Shutdown procedure, page 41.

2. Close the feed system ball valve at inlet near the

pump lower.

3. Connect solvent flush feed system to unused inlet

port near the pump lower.

4. Open solvent flush ball valve.

5. Perform Startup procedure, page 24.

6. Press repeatedly to select Operator Mode

then press to accept.

7. Press to enter editing mode.

8. Navigate to the flow rate value, change the value to

50-75% of the maximum flow rate, then press

to accept.

40 313873H

Page 41

Shutdown

Shutdown

Short-term

1. Place container under mixer.

2. If using a moisture-sensitive material, park pumps.

a. Navigate to the Home screen.

b. Press repeatedly to select Standby Mode

then press to accept.

c. Press to park pump. Material will dis-

pense. when the pumps are in the parked position, they will stop moving.

3. Allow material to drain completely from the mixer

prior to base purge.

4. Perform base purge.

NOTE: A base purge will dispense only the B (Blue)

material to push all mixed material out of the mixer.

Base purge settings are defined on the System #2

screen, see page 58.

7. Place container under the mixer and allow mixer to

drain completely.

NOTICE

Preventing material from draining from the mixer

may cause material in the mixer to harden and damage the dispense block.

8. Turn Main Power Switch to the OFF position.

End of Shift

1. Perform Short-term Shutdown procedure.

2. Remove, disassemble, and flush mixer.

a. Press .

b. Press to begin dispensing.

c. When all mixed material is pushed out of the

mixer, press to stop dispensing.

NOTE: Approximately 1 to 2 liters of base material will

need to be dispensed.

5. Press to park pumps again.

6. Press .

313873H 41

Page 42

Pressure Relief Procedure

Pressure Relief

Procedure

1. Perform Shutdown procedure.

2. Place a waste container below each ratio check

valve.

In the following step, any pressure in the lines will be

instantly relieved which may lead to material spraying

out of the valve and splashing in the bucket. Use

appropriate protective wear to prevent contact with

materials.

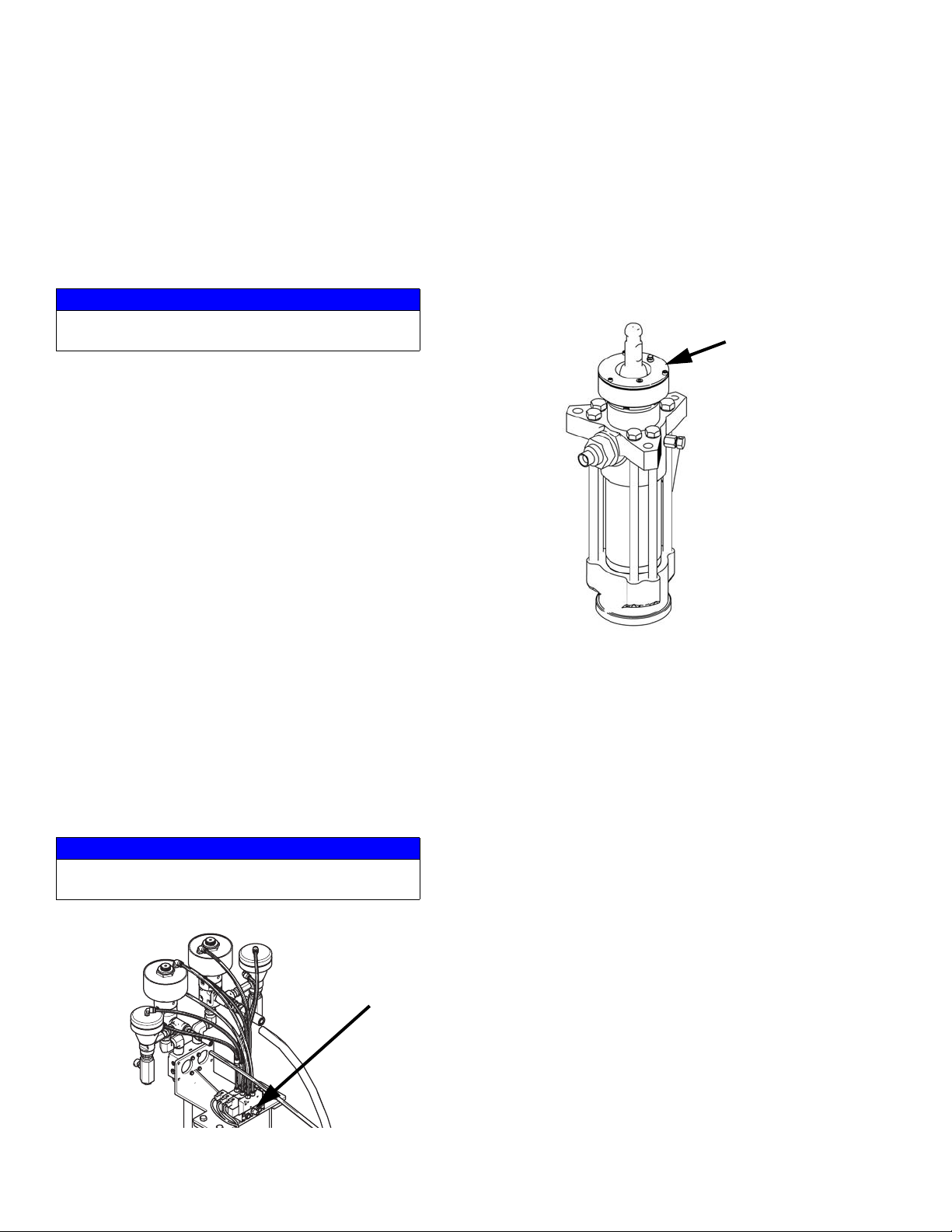

3. Press the red override button on top of the pneumatic valve nearest the mixer. This will open the

ratio check valves and relieve any residual pressure

in the fluid lines.

ti17666a

42 313873H

Page 43

Maintenance

Check all sub-component manuals for maintenance

schedule and procedures.

Task Schedule

Replace hydraulic oil and filter See table

Inspect fluid lines for leaks and

signs of wear

Check wet cup fluid level, add

IsoGuard Select fluid as necessary

Check hydraulic fluid level Weekly

Verify operation of tank air drying

system to prevent isocyanate

crystallization

Verify vent holes on bottom of

hydraulic power pack shroud are

clear and unobstructed

Daily

Weekly

Weekly

Weekly

(more often in

dusty environ-

ments)

Maintenance

Change Hydraulic Oil and Filter

Change break-in oil in a new unit after the first 250

hours of operation or within 3 months, whichever comes

first. After initial break-in, see the following table for recommended oil and filter change schedule.

Table 2: Frequency of Oil Changes

Ambient

Tem perature

0 to 90°F

(-17 to 32°C)

90°F and above

(32°C and above)

Recommended

Frequency

1000 hours or 12 months,

whichever comes first

500 hours or 6 months,

whichever comes first

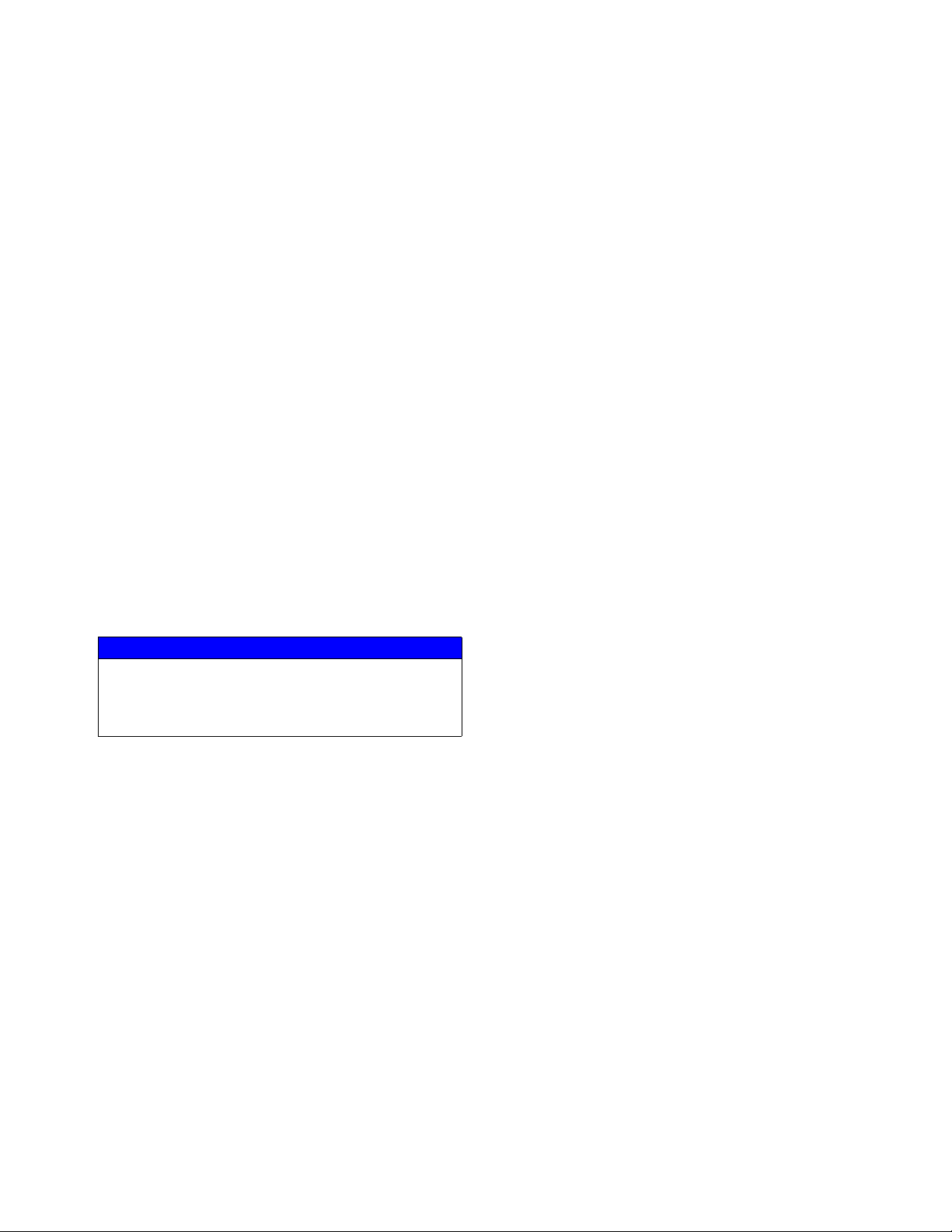

Check Hydraulic Fluid Level

Check hydraulic fluid level on dipstick (A). Fluid level

must be between indent marks (B) on dipstick. Refill as

required with approved hydraulic fluid; see Technical

Data on page 83. If fluid is dark in color, change fluid

and filter.

Check all fittings and connections, tighten as necessary

Use compressed air to remove

dust buildup on control boards,

fan, motor (under shield), hydraulic oil coolers, and component

heat sink fins

As necessary

Monthly

A

S

B

ti7861a1

257442_313873-5_2t

313873H 43

Page 44

Maintenance

Install Upgrade Tokens

NOTE: The Motor Control Module, Fluid Control Mod-

ule, and Temperature Control Module connection to the

system is temporarily disabled during the installation of

upgrade tokens.

To install software upgrades:

1. Use correct software token stated in the table. See

Graco Control Architecture

manual for instructions.

NOTE: Upgrade all modules in the system to the

software version on the token, even if you are

replacing only one or two modules. Different software versions may not be compatible.

All data in the module (System Settings, USB Logs,

Recipes, Maintenance Counters) may be reset to

factory default settings. Download all settings and

user preferences to a USB before the upgrade, for

ease of restoring them following the upgrade.

See manuals for locations of specific GCA components.

™

Module Programming

Advanced Display Module (ADM)

Replace Battery

A lithium battery maintains the ADM clock when power

is not connected.

To replace the battery:

1. Disconnect power to the ADM.

2. Remove rear access panel.

The software version history for each system can be

viewed in the technical support section at

www.graco.com.

Token Application

16G407 Ratio Monitoring (Flow Meters):

- Fluid Control Module

16G365 VRM:

- Advanced Display Module

- Motor Control Module

- Communication Gateway Module

r_257396_3b9905_04b

F

IG. 11: Remove Access Cover

ti12334a1

ti12903a

3. Remove the old battery and replace with a new

CR2032 battery.

4. Replace rear access panel.

Install Upgrade Token

See Install Upgrade Tokens on page 44.

Cleaning

Use any alcohol-based household cleaner, such as

glass cleaner, to clean the ADM. Spray on the rag then

wipe ADM. Do not directly spray the ADM.

44 313873H

Page 45

Motor Control Module (MCM)

Keep heat sink fins clean at all times. Clean them using

compressed air.

NOTE: Do not use conductive cleaning solvents on the

module.

Heat

Sink Fins

Maintenance

r_257396_3b9905_02b

FIG. 12: Clean Heat Sink Fins

Install Upgrade Token

See Install Upgrade Tokens on page 44.

Fluid Control Module (FCM)

Install Upgrade and Key Tokens

See Install Upgrade Tokens on page 44.

313873H 45

Page 46

Maintenance

46 313873H

Page 47

Troubleshooting

For information about ADM error and event codes see

Appendix D - ADM Event and Error Codes Overview,

page 66.

Before performing any troubleshooting procedure:

1. Perform Pressure Relief Procedure on page 42.

2. Turn Main Power Switch to the OFF position.

3. Allow equipment to cool.

Try the recommended solutions in the order given for

each problem to avoid unnecessary repairs. Also, determine that all circuit breakers, switches, and controls are

properly set and wiring is correct before assuming there

is a problem.

Troubleshooting

Light Tower (Optional)

Signal Description

Green on only System is powered up and there are

no error conditions present

Yellow on An advisory exists

Red flashing A deviation exists

Red on The system is shut down due to an

alarm occurring.

Errors include advisories, deviations, or alarms, so

green will only be on when none of these occur. A yellow

light can be on at the same time as red (flashing or solid

on) when an advisory exists at the same time as a deviation or alarm.

Common Problems

Problem Cause Solution

General

Display Module completely

dark

No or incorrect amount of

material dispensed from

either side

Significant material leaking

from pump seal

Material dispensed not correct weight

Proportioning System

Proportioning pump does not

hold pressure when stalled

No power Verify main power switch is ON

Thrown circuit breaker Check machine breakers and reset

Loose connection Tighten 5-pin cable on Advanced Display Module

Bad display module Replace Advanced Display Module

Ball valve closed (if installed) Open tank ball valve

Tank empty Add fluid

Tank clogged Clean tank

Air in material Prime the machine

Pump shaft worn and/or shaft seal

worn

Specific gravity of one or more of the

two materials has changed since calibration

Check valve malfunction Remove check valve; clean or replace as necessary

Piston worn or broken Replace piston

Pump piston or intake valve leaking 1. Observe gauges to determine which pump is los-

Remove pump shaft assembly and reinstall, see

pump manual for instructions and rebuild kit

Perform calibration procedure

ing pressure.

2. Determine in which direction the pump has

stalled by observing which directional valve indicator light is on.

3. Repair the valve.

313873H 47

Page 48

Troubleshooting

Problem Cause Solution

Material imbalance Inadequate flow from pump; cavitation Clean inlet strainer screen

Worn pump inlet valve ball/seat or gasket, repair as

necessary

Erratic pump movement Pump cavitation Feed pump pressure is too low, adjust pressure to

within required range

Pump output low Obstructed fluid hose or mixer; fluid

hose ID too small

Worn piston valve or intake valve in

displacement pump

Inadequate feed pump pressure Check feed pump pressure and adjust to within

Open, clear; use hose with larger ID

See pump manual for appropriate repair procedure

required range

48 313873H

Page 49

ADM Troubleshooting

B

Troubleshooting

C

A

H

G

FIG. 13: ADM Component Identification - Rear

D

E

F

ti12362a1

ADM System Status LEDs (B) Conditions

Module Status

LED Signal Description

Green on Run mode, System on

Green flashing Setup mode, System on

Yellow on Run Mode, System off

J

S

K

L

M

N

R

ti12902a

P

ADM Module Status LEDs (N) Conditions

Module Status

LED Signal Description

Green on System is powered up

Yellow on Communication in progress

Red solid ADM hardware failure

Red flashing Uploading software

USB Module Status LEDs (L) Conditions

Module Status

LED Signal Description

Green flashing System is powered up

Yellow on Downloading information to USB

Green/Yellow

Flashing

313873H 49

ADM is busy, USB cannot transfer

information when in this mode

Page 50

Troubleshooting

Motor Control Module

Diagnostic Information

Table 3: LED Status Signal

Module Status LED Signal Description

Green on System is powered up

Yellow on Internal communication in progress

Red solid MCM hardware failure. Replace MCM

Red flashing fast Uploading software

Red flashing slow Token error, remove token and upload

software token again

LED

Signals

FIG. 14: LED Signals

50 313873H

r_257396_3b9905_07b

Page 51

Acceptable Size and Duration of Power Line Voltage Fluctuations

The Motor Control Module is designed to withstand voltage fluctuations from the incoming power supply. If the

incoming power supply goes outside of the tolerable

range, an over-voltage condition is flagged and the system shuts down in an alarm state. Excessive or

repeated over-voltage may permanently damage hardware. The chart below shows the permissible magnitude

and duration of temporary over-voltage events. Consult

a qualified electrician if there are any concerns about

the available power supply.

Maximum Permissible Transient Voltage Surges

* Constructed from ITIC 1996 curve, referenced by IEC 61000-2-4

1400

Troubleshooting

1200

1000

800

600

400

Voltage (Volts RMS)

200

0

0.000001 0.00001 0.0001 0.001 0.01 0.1 1 10

1200Vac, 1697Vdc

<--1 MW Max Surge Power

480Vac, 679Vdc

336Vac, 475Vdc

<--150 KW Max Surge Power

<--50 KW Max Surge Power

288Vac, 407Vdc

<--No Power Limit

264Vac, 373Vdc

Time (seconds)

313873H 51

Page 52

Troubleshooting

Fluid Control Module

Diagnostic Information

Module Status LED Signal Diagnosis

Green on System is powered up

Yellow Internal communication in progress

Red solid FCM hardware failure. Replace FCM.

Red flashing fast Uploading software

Red flashing slow Token error. Remove token and

upload software token again.

FIG. 15:

Module Status LEDs

ti12337a1

52 313873H

Page 53

Troubleshooting

313873H 53

Page 54

Appendix A - ADM Icons Overview

Appendix A - ADM Icons Overview

Setup Screen Icons

Icon Description

Enter Screen

Exit Screen

Erase Selected Item

Erase All Items Shown

Change Multiple Values

(see Using the button on

page 56)

Ratio Calculator

(see Using the button on

page 56)

Icon Description

Learn Top-Most Piston Position

Go to Next Calibration Screen

Begin Weight Calibration Shot

Dispense Valve Details

Shot Number

Sequence

Flow

Weight

Volume

Return to Previous/Main Screen

Calibrate Piston Position

On Main Calibration screen:

Calibrate Weight Dispense

On Flow Meter Calibration screen:

Use Dispensed Material Weight to

Calibrate Flow Meters

Use Dispensed Material Volume to

Calibrate Flow Meters

Calibrate Flow Meters

Learn Bottom-Most Piston Position

Duration

Ratio

Calculated Ratio

Tank/Tank Heater

Primary Heater

Heated Hose

Chiller

54 313873H

Page 55

Appendix A - ADM Icons Overview

Home Screen Icons

Icon Description

Select Operating Mode

Initiate Dispense

Dispense Disabled

Ratio Check

Park Piston

Park Piston Disabled

Close Dispense Valve

Icon Description

Prime A (Red) Side

Prime B (Blue) Side

Enter Screen

Exit Screen

Erase Selected Item

Erase All Items Shown

Weight

Perform Base Purge

Selected Shot Number

No Shot Number Selected

Selected Sequence and Sequence

Position

No Sequence Selected

Skip to Next Shot in Sequence

Abort Sequence

Volume

Duration

Piston Cycles

Edit Operator Mode Flow Properties

313873H 55

Page 56

Appendix B - ADM Setup Screens Overview

Appendix B - ADM Setup Screens Overview

Setup Screens Navigation Diagram

Shot #1

Shot #2

Shot #...

Sequences #1

Sequences #2

Sequences #...

Calibration

System #1

System #2

System #3

Shots

This screen allows the user to edit shot definitions. The

contents of this screen change based on the Dispense

Mode. Shots may be defined by flow rate and by

time (duration), volume, or weight depending on the Dispense Mode selection. See System #1 on page 58 for

Dispense Mode options.

Maintenance

Supply

Conditioning #1

Conditioning #2

Conditioning #3

Advanced #1

Advanced #2

Advanced #...

4. Type the new value then press enter. All values

below the selected shot will change to the new

value.

5. Repeat the previous two steps as desired.

6. Press to deactivate.

Using the button

The button can be used to calculate an x:1 ratio

from a non x:1 ratio. For example, if the desired ratio is

5:2, the button can be used to convert 5:2 to 2.5:1.

1. From the Shots screen, press .

2. Navigate to the column.

Using the button

The button can be used to change multiple shot

definitions at once.

3. Press .

4. Enter the non x:1 ratio in the column. The calculated x:1 ratio will automatically be displayed in

the column and in the shot definition.

1. From the Shots screen, press .

5. Press .

2. Press .

3. Navigate to a shot definition value.

56 313873H

Page 57

Appendix B - ADM Setup Screens Overview

Sequences

This screen allows the user to edit sequence definitions.

The contents of this screen change based on the Dispense mode.

Dispense detail is shown as volume, time, or weight

depending on which Dispense Mode is selected. See

System #1 on page 58 for Dispense Mode options.

NOTE: 5 sequences with 20 positions each are avail-

able across 10 pages.

Calibration - Learn Mode

This screen is for learning the mechanical limits for piston travel.

Calibration - Weight

Calibration - Main

This screen shows calibration data for the system and

provides access to the individual calibration screens.

See System Setup and Calibration on page 29 for

how to use the calibration screens.

The date next to each key represents the last time that

function was performed.

The “Cal. Min” and “Cal. Max” values are the system

recognized extreme ends of piston travel.

This screen is for calibrating weight.

Calibration - Flow Meters

This screen is for calibrating the flow meters.

313873H 57

Page 58

Appendix B - ADM Setup Screens Overview

System #1

This screen allows the user to set mechanical system

settings and the Dispense Mode setting.

Dispense mode can be set to time, volume, or weight.

Dispense mode controls how dispense quantities are

measured. Dispensing must be calibrated, see System

Setup and Calibration on page 29 for more information.

Pump sizes and inlet pressures must be entered on this

screen. The inlet pressure is the minimum allowable

fluid inlet pressure. If the inlet pressure is below this

value, dispensing is disabled. If pump sizes and inlet

pressures are not entered properly, system performance

will be affected.

System #2

This screen allows the user to set the Gel Timer properties and set which items are installed on the machine.

NOTICE

The correct dispense valve option must be selected.

Selecting an incorrect dispense valve option will

lead to erratic machine performance.

When enabling the Gel Timer, the user must select one

of the 100 available shot definitions to use as the Gel

Shot. This shot will be dispensed when the Idle Period

expires. The Idle Period will begin after a dispense is