Page 1

Instructions

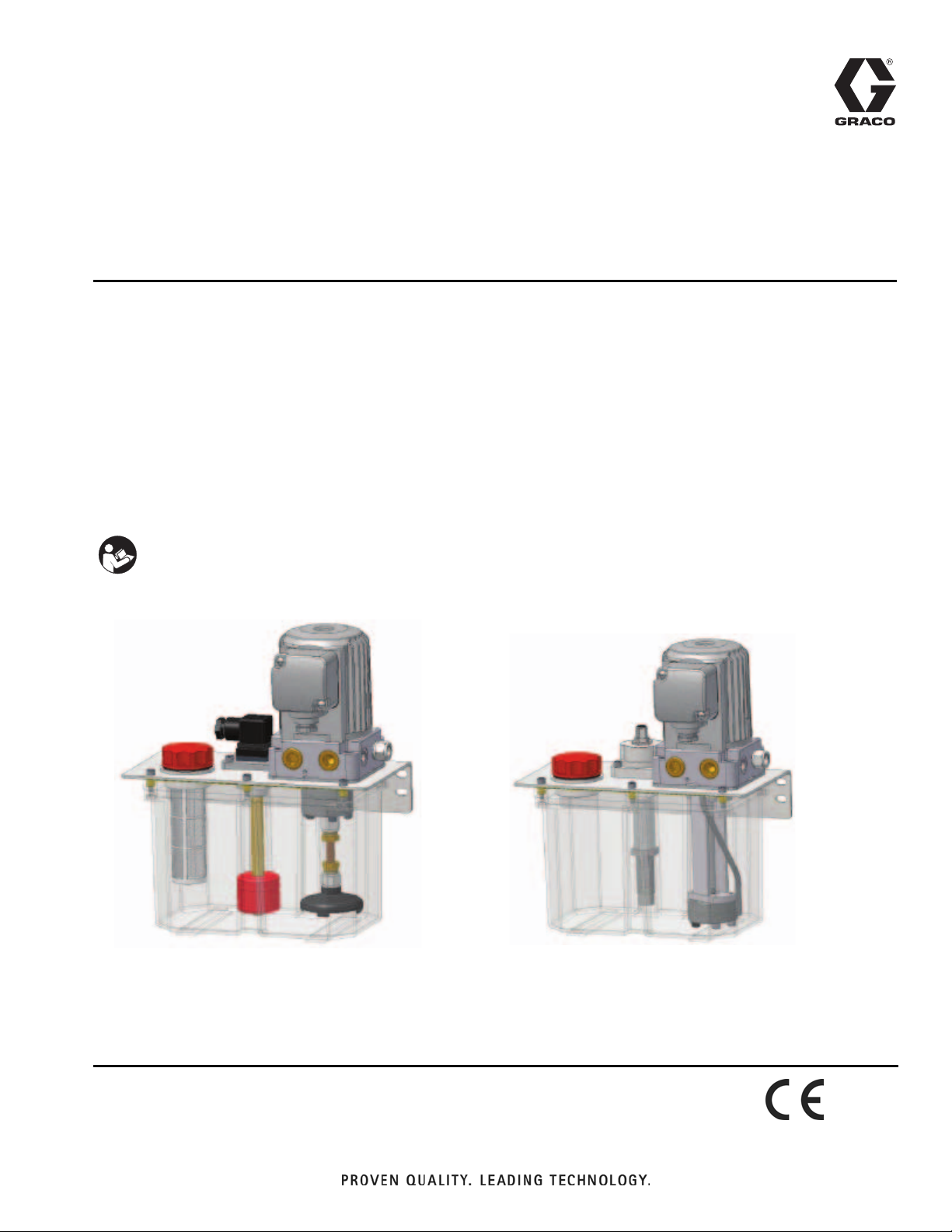

Injecto-Flo II Single Line

Pumps with No Control

- For feeding volumetric dosing meters in a single-line system -

- Not for use in hazardous locations -

Part No.: See page 2

OIL: 435 psi (3.0 MPa, 30 bar) Maximum Working Pressure

GREASE: 580 psi (4.0 MPa, 40 bar) Maximum Working Pressure

313839C

EN

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

Oil Model Grease Model

Page 2

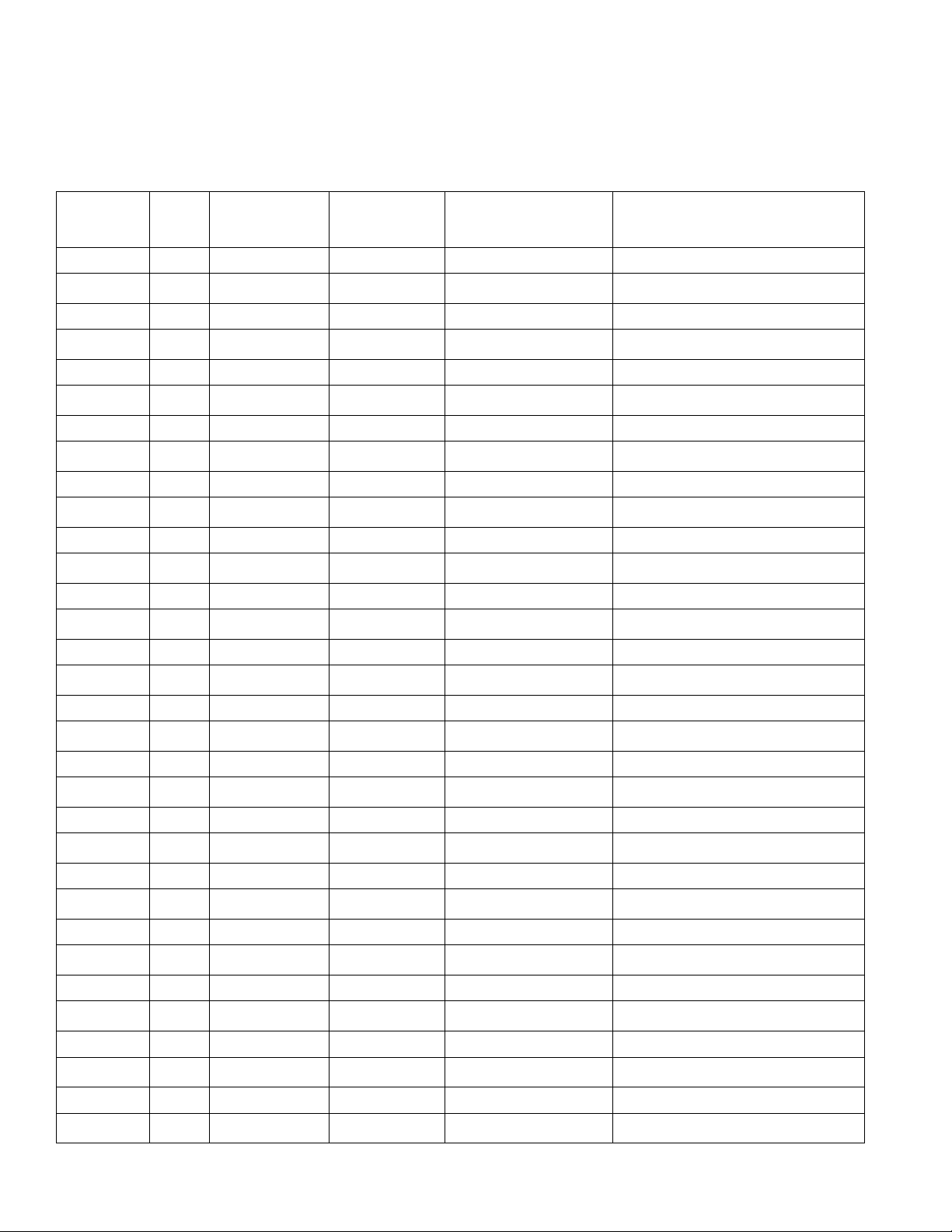

Models

Models

Oil Systems

Reservoir

Model CE

122545 ✓ 0.8 (3.0) 0.05 (0.2) None Screw Cap

122546 ✓ 0.8 (3.0) 0.05 (0.2) None

122547 ✓ 0.8 (3.0) 0.13 (0.5) None Screw Cap

122548 ✓ 0.8 (3.0) 0.13 (0.5) None

122549 ✓ 0.8 (3.0) 0.05 (0.2) Single w/DIN Screw Cap

122550 ✓ 0.8 (3.0) 0.05 (0.2) Single w/DIN

122551 ✓ 0.8 (3.0) 0.13 (0.5) Single w/DIN Screw Cap

122552 ✓ 0.8 (3.0) 0.13 (0.5) Single w/DIN

122553 ✓ 0.8 (3.0) 0.05 (0.2) Single w/M12 Top Screw Cap

15U859 0.8 (3.0) 0.05 (0.2) Single w/M12 Top

122554 ✓ 0.8 (3.0) 0.13 (0.5) Single w/M12 Top Screw Cap

122555 ✓ 0.8 (3.0) 0.13 (0.5) Single w/M12 Top

122556 ✓ 0.8 (3.0) 0.05 (0.2) Dual w/DIN Screw Cap

122557 ✓ 0.8 (3.0) 0.05 (0.2) Dual w/DIN

122558 ✓ 0.8 (3.0) 0.13 (0.5) Dual w/DIN Screw Cap

122559 ✓ 0.8 (3.0) 0.13 (0.5) Dual w/DIN

Gal (liters)

Flow

GPM (lpm) Level Switch Refill System

Straight Connector (

Straight Connector (

Straight Connector (

Straight Connector (

Straight Connector (

Straight Connector (

Straight Connector (

Straight Connector (

∅ 10 pipe)

∅ 10 pipe)

∅ 10 pipe)

∅ 10 pipe)

∅ 10 pipe)

∅ 10 pipe)

∅ 10 pipe)

∅ 10 pipe)

122560 ✓ 0.8 (3.0) 0.05 (0.2) Dual w/M12 Top Screw Cap

122561 ✓ 0.8 (3.0) 0.05 (0.2) Dual w/M12 Top

122562 ✓ 0.8 (3.0) 0.13 (0.5) Dual w/M12 Top Screw Cap

122840 ✓ 0.8 (3.0) 0.13 (0.5) Dual w/M12 Top

122563 ✓ 1.6 (6.0) 0.05 (0.2) None Screw Cap

122564 ✓ 1.6 (6.0) 0.05 (0.2) None

122565 ✓ 1.6 (6.0) 0.13 (0.5) None Screw Cap

122566 ✓ 1.6 (6.0) 0.13 (0.5) None

122567 ✓ 1.6 (6.0) 0.05 (0.2) Single w/DIN Screw Cap

122568 ✓ 1.6 (6.0) 0.05 (0.2) Single w/DIN

564138 1.6 (6.0) 0.05 (0.2) Single w/DIN Screw Cap

122569 ✓ 1.6 (6.0) 0.05 (0.2) Single w/DIN

122570 ✓ 1.6 (6.0) 0.05 (0.2) Single w/M12 Top Screw Cap

122571 ✓ 1.6 (6.0) 0.05 (0.2) Single w/M12 Top

122572 ✓ 1.6 (6.0) 0.13 (0.5) Single w/M12 Top Screw Cap

122573 ✓ 1.6 (6.0) 0.13 (0.5) Single w/M12 Top

Straight Connector (

Straight Connector (

Straight Connector (

Straight Connector (

Straight Connector (

Straight Connector (

Straight Connector (

Straight Connector (

∅ 10 pipe)

∅ 10 pipe)

∅ 10 pipe)

∅ 10 pipe)

∅ 10 pipe)

∅ 10 pipe)

∅ 10 pipe)

∅ 10 pipe)

2 313839C

Page 3

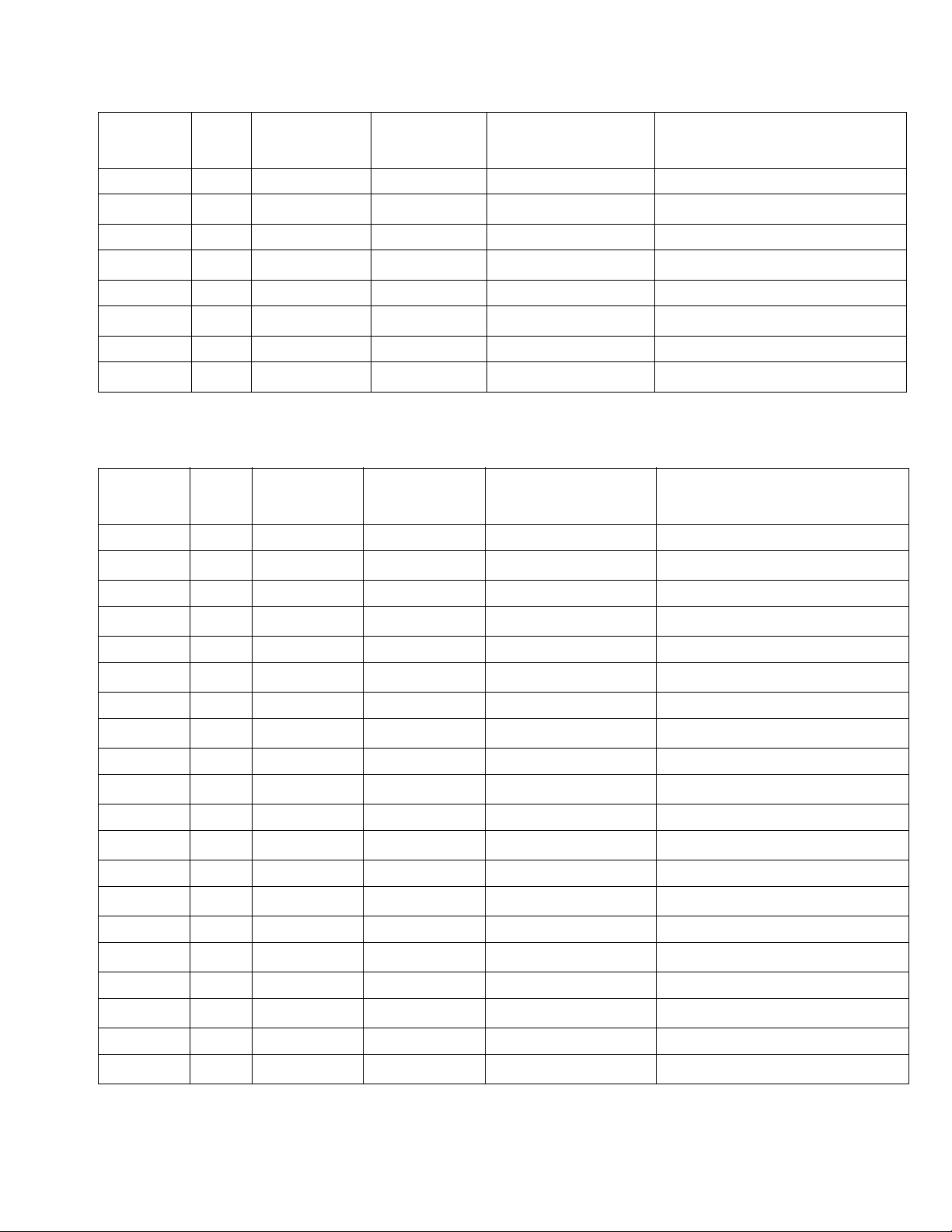

Models

Reservoir

Model CE

122574 ✓ 1.6 (6.0) 0.05 (0.2) Dual w/DIN Screw Cap

122575 ✓ 1.6 (6.0) 0.05 (0.2) Dual w/DIN

122576 ✓ 1.6 (6.0) 0.13 (0.5) Dual w/DIN Screw Cap

122577 ✓ 1.6 (6.0) 0.13 (0.5) Dual w/DIN

122578 ✓ 1.6 (6.0) 0.05 (0.2) Dual w/M12 Top Screw Cap

122579 ✓ 1.6 (6.0) 0.05 (0.2) Dual w/M12 Top

122580 ✓ 1.6 (6.0) 0.13 (0.5) Dual w/M12 Top Screw Cap

15U860 1.6 (6.0) 0.05 (0.2 Dual w/M12 Top

Gal (liters)

Flow

GPM (lpm) Level Switch Refill System

Straight Connector (

Straight Connector (

Straight Connector (

Straight Connector (

Grease Systems

Reservoir

Model CE

122581 ✓ 0.8 (3.0) 0.05 (0.2) None Screw Cap

563301 0.8 (3.0) 0.05 (0.2) None

Gal (liters)

Flow

GPM (LPM) Level Switch Refill System

Straight Connector (

∅ 10 pipe)

∅ 10 pipe)

∅ 10 pipe)

∅ 10 pipe)

∅ 10 pipe)

122582 ✓ 0.8 (3.0) 0.13 (0.2) Single w/DIN Screw Cap

122583 ✓ 0.8 (3.0) 0.13 (0.2) Single w/DIN

122584 ✓ 0.8 (3.0) 0.13 (0.2) Single w/M12 Top Screw Cap

122585 ✓ 0.8 (3.0) 0.13 (0.2) Single w/M12 Top

122586 ✓ 0.8 (3.0) 0.13 (0.2) Dual w/DIN Screw Cap

122587 ✓ 0.8 (3.0) 0.13 (0.2) Dual w/DIN

122588 ✓ 0.8 (3.0) 0.13 (0.2) Dual w/M12 Top Screw Cap

557547 0.8 (3.0) 0.13 (0.2) Dual w/M12 Top

122589 ✓ 1.6 (6.0) 0.13 (0.2) None Screw Cap

122590 ✓ 1.6 (6.0) 0.13 (0.2) None

122591 ✓ 1.6 (6.0) 0.13 (0.2) Single w/DIN Screw Cap

122592 ✓ 1.6 (6.0) 0.13 (0.2) Single w/DIN

122593 ✓ 1.6 (6.0) 0.13 (0.2) Single w/M12 Top Screw Cap

122594 ✓ 1.6 (6.0) 0.13 (0.2) Single w/M12 Top

122595 ✓ 1.6 (6.0) 0.13 (0.2) Dual w/DIN Screw Cap

122596 ✓ 1.6 (6.0) 0.13 (0.2) Dual w/DIN

122597 ✓ 1.6 (6.0) 0.13 (0.2) Dual w/M12 Top Screw Cap

122598 ✓ 1.6 (6.0) 0.13 (0.2) Dual w/M12 Top

Straight Connector (

Straight Connector (

Straight Connector (

Straight Connector (

Straight Connector (

Straight Connector (

Straight Connector (

Straight Connector (

Straight Connector (

∅ 10 pipe)

∅ 10 pipe)

∅ 10 pipe)

∅ 10 pipe)

∅ 10 pipe)

∅ 10 pipe)

∅ 10 pipe)

∅ 10 pipe)

∅ 10 pipe)

313839C 3

Page 4

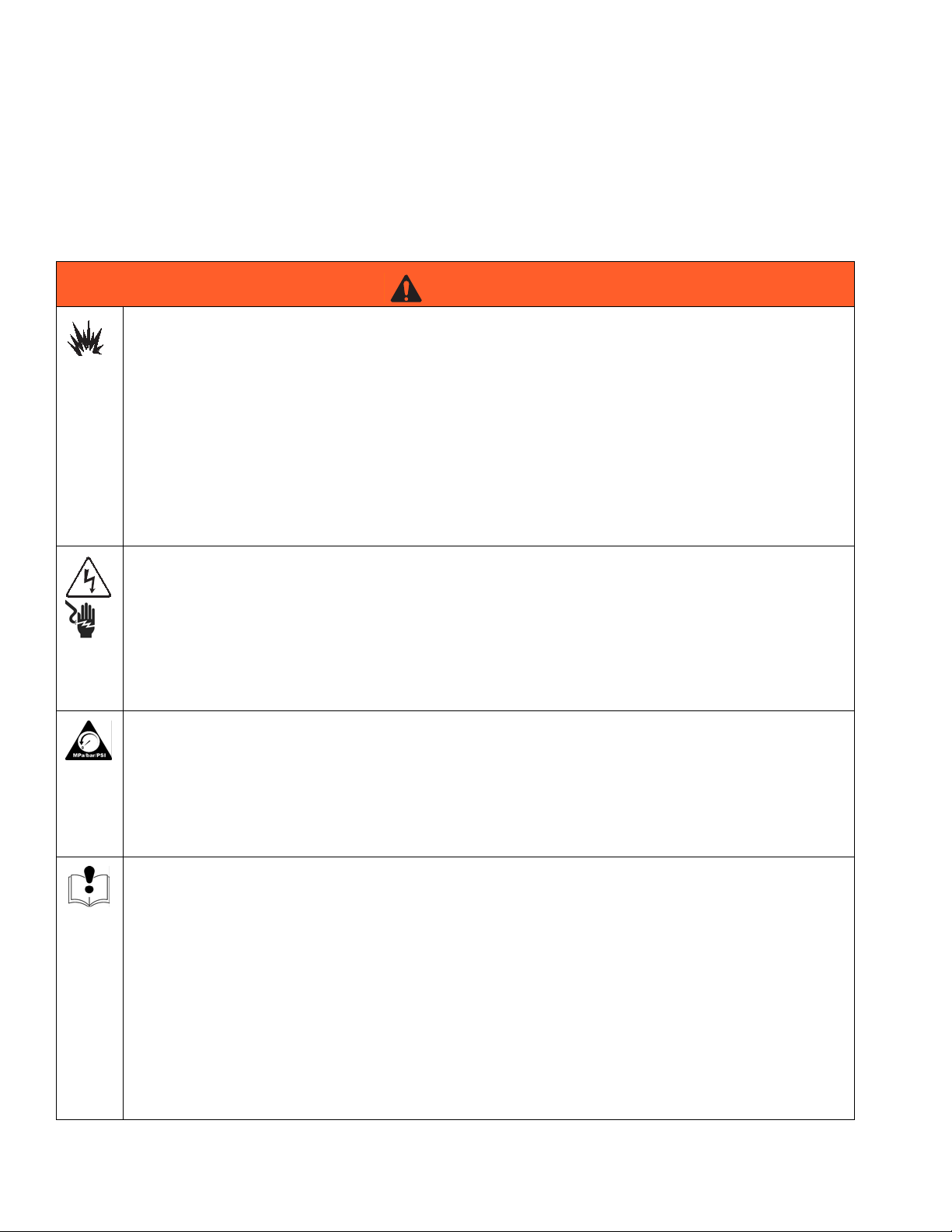

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

FIRE AND EXPLOSION HAZARD

When flammable fluids are present in the work area, such as gasoline and windshield wiper fluid, be

aware that flammable fumes can ignite or explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources, such as cigarettes and portable electric lamps.

• Keep work area free of debris, including rags and spilled or open containers of solvent and gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Ground all equipment in the work area.

• Use only grounded hoses.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause

electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on skin and

cause serious injury.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

4 313839C

Page 5

Grounding

The equipment must be grounded. Grounding reduces

the risk of static and electric shock by providing an

escape wire for the electrical current due to static build

up or in the event of a short circuit.

Pressure Relief Procedure

To relieve pressure, loosen outlet fitting connection to

bleed air and relieve pressure.

Warnings

NOTE: Pumps have a built-in decompression valve that

relieves pressure when cycle is complete.

313839C 5

Page 6

Installation

Installation

Component Identification

Doser

B

G

D

Doser

C

J

G

A

A

D

Hydraulic Diagram

H

F

E

B

C

FIG. 1

Key: Grease Models

ATank

B Electric Motor

CGear Pump

D Electric Level Switch

E Pressure Limiting Valve

FRelief Valve

G Filling Cap-Filter

H Pressure Outlet

6 313839C

Oil Models*

(includes all items A - H and also the following)

J Suction Filter

Page 7

Refilling Options

Oil Systems (FIG. 2) Grease Systems (FIG. 3)

Installation

A

C

D

C

F

IG. 2

A Screw Cap Option

B Elbow Connector Option

C Screw Cap

D Strainer Basket (Oil Models Only)

E Down Tube (Oil Models Only)

F Vent (additional information)

G Elbow Connector

E

F

G

A

B

C

F

C

G

B

D

H

FIG. 3

Vent (FIG. 4)

NOTE: A vent is included with all units with refilling systems using a connector (G).

F

IG. 4

F

313839C 7

Page 8

Installation

Level Switch Connector Options

Oil Systems

A

F

IG. 5

A Standard Connector Option: Minimal level with standard DIN connector; Minimum + Prealarm level with standard DIN

connector.

B M12 Connector Top Entry Option: Minimum level with M12 connector top entry; Minimum + Premalarm level with M12

connector top entry.

B

A

Grease Systems

B

Instructions

The control of these units is external (without control) programming by the machine automatism or external control

(CNC, Automatic device, etc.).

It can be equipped with an electrical level (minimum level) control in the tank.

8 313839C

Page 9

Electrical Diagram

Electrical Diagram

W2U2V

U1V1W

L1 L2

1

L3

231

Oil

MIN.

PRE.

3

2

1

2

W

2U2V2

1V1W1

U

L1 L2

L3

W2U2V

U1V1W

L1 N

2

1

MIN.

Grease

PNP

BN

BK

BU

+

-

313839C 9

Page 10

Replacement Parts Available from Graco

Replacement Parts Available from Graco

Part No. Description

122901 PUMP, electric motor, oil, 0.2L/min

122902 PUMP, electric motor, oil, 0.5L/min

122903 SWITCH, min level w/din, 3L

122904 SWTICH, min level w/din, 6L

122905 SWITCH, min, prealarm level, w/din, 3L

122906 SWITCH, min, prealarm level, w/din, 6L

122907 SWITCH, min level w/M12, 3L

122908 SWITCH, min level w/M12, 6L

122909 SWITCH, min prealarm level w/M12, 3L

122910 SWITCH, min prealarm level w/M12, 3L

122911 RESERVOIR, 3 Liter, no cover

122912 CAP, screw

122913 FILTER, refilling

122914 FILTER, suction, 3L, reservoir

122915 FILTER, suction, 6L, reservoir

122916 PUMP, electric motor, grease, 3L

122917 PUMP, electric motor, grease, 6L

122918 SWITCH, min level w/din, 3L

122919 SWTICH, min level w/din, 6L

122920 SWITCH, min, prealarm level, w/din, 3L

Part No. Description

122921 SWITCH, min, prealarm level, w/din, 6L

122922 SWITCH, min level w/M12, 3L

122923 SWITCH, min level w/M12, 6L

122924 SWITCH, min prealarm level w/M12, 3L

122925 SWITCH, min prealarm level w/M12, 3L

15X624 MANIFOLD, tee, M8

15X625 MANIFOLD, tee, M10

15X626 MANIFOLD, tee, M14

15X667 MANIFOLD, M10/M8 2 station

15X668 MANIFOLD, M10/M8 3 station

15X669 MANIFOLD, M10/M8 4 station

15X670 MANIFOLD, M10/M8 5 station

15X671 MANIFOLD, M10/M8 6 station

15X672 MANIFOLD, M10/M8 7 station

15X673 MANIFOLD, M10/M8 8 station

189930 LABEL, warning, electric shock ▲

▲ Replacement Danger and Warning labels, tags, and

cards are available at no cost.

10 313839C

Page 11

Technical Data

Tank Capacity

Models: Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.8 - 1.6 gallons (3 - 6 liters)

Models: Grease . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.6 gallons (6 liters)

Tank Material. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Transparent Polymide

Output Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . M14 x 1.5

Pump

Lubricant

Models: Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Mineral or synthetic oil

Models: Grease . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fluid grease NLGI00-000

Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.05 - 0.13 gal/min (0.2 - 0.5 L/min)

Maximum Pressure

Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 435 psi (3.0 MPa, 30 bar)

Grease . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 580 psi (4.0 MPa, 40 bar)

Working Temperature

Lubricant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140°F (60°C)

Ambient (Oil models only) . . . . . . . . . . . . . . . . . . . . . 104°F (40°C)

A/C Motor

Voltage / Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230/400 VAC, 50/60 Hz, 0.5 - 0.3A

Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70W

Technical Data

313839C 11

Page 12

Technical Data

Dimensions

11.3 in.

(289 mm)

5.37 in.

(136.5 mm)

_

6 in.

(152.5 mm)

5.59 in

(142 mm)

8.6 & 9.0 in.

(220 & 230 mm)

9.65 in.

(245 mm)

_

12 313839C

Page 13

Notes

Notes

313839C 13

Page 14

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 313389

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2009, Graco Inc. is registered to ISO 9001

www.graco.com

5/2009, revised 1/2012

Loading...

Loading...