Page 1

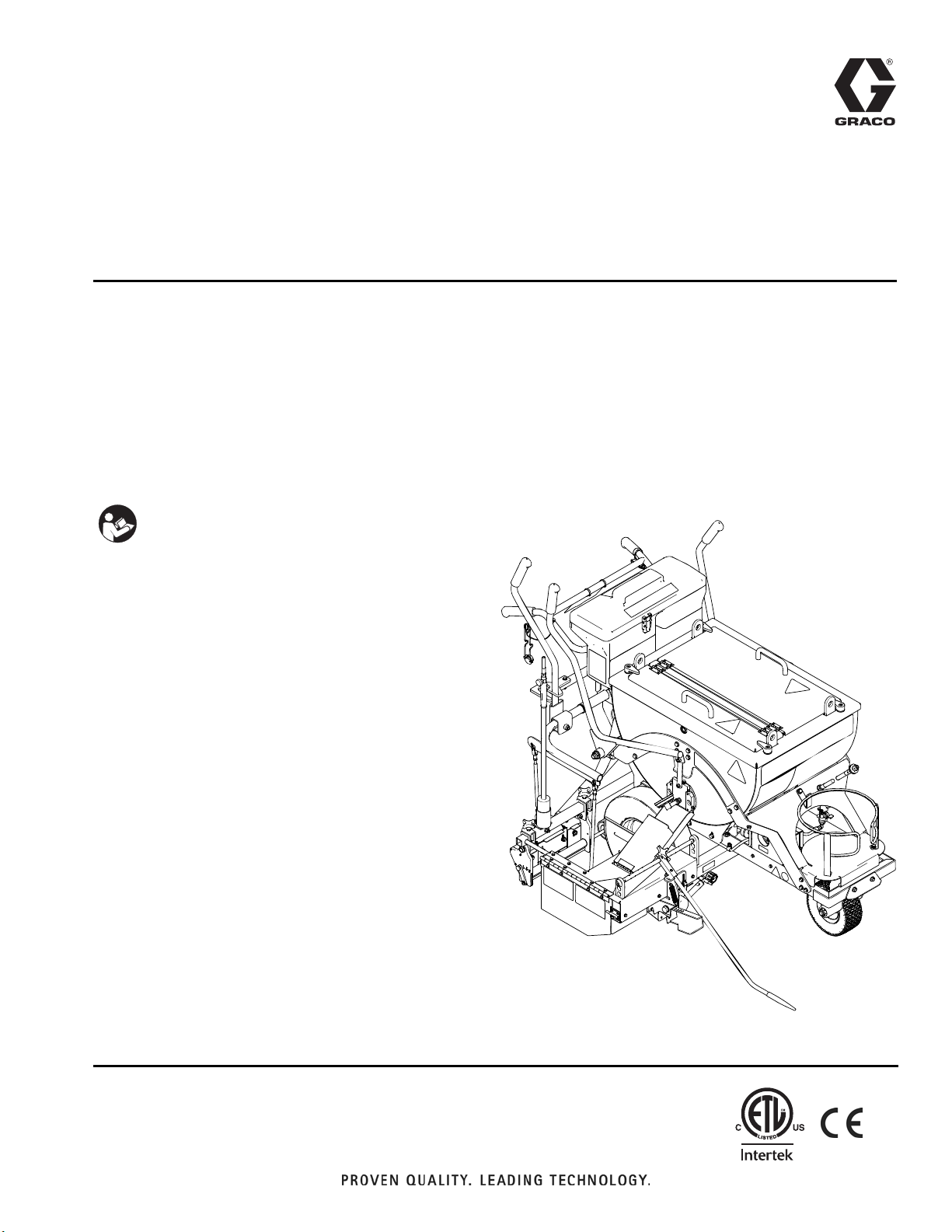

Operation

ThermoLazer™ Pavement Marking System

US Patent No. D619,625 S

- For professional application of thermoplastic traffic marking compound materials

(reflective beads applied simultaneously with screeding) -

- For outdoor use only (not to be operated in rain or damp conditions) -

Model No. 258699 North America - Includes 257500 and 4 in. (10 cm) SmartDie

™

Model No. 257500 International (SmartDie

Fuel: LP Gas (Propane Vapor)

Burner capacities (max total): 138,000 BTU/hr. (40.44 kW) [38,000 BTU/hr. (7.03 kW) without torch]

Material capacity (max): 300 lb (136 kg)

IMPORTANT SAFETY INSTRUCTIONS

Read all warnings and instructions in this

manual. Save these instructions.

Related Manuals

Repair 313879

Parts 313880

™

For use with the following SmartDie

Part Description

24F630 3 IN. (8 cm) Screed Box

256736 4 in. (10 cm) Screed Box

257469 5 in. (12 cm) Screed Box

256737 6 in. (15 cm) Screed Box

257470 7 in. (18 cm) Screed Box

256738 8 in. (20 cm) Screed Box

257471 9 in. (22.5 cm) Screed Box

257472 10 in. (26 cm) Screed Box

256739 12 in. (30 cm) Screed Box

256799 Double Line 4-4-4 in. (10-10-10 cm) Screed Box

24B729 Double Line 4-3-4 in. (10-8-10 cm) Screed Box

24F631 Double Line 3-3-3 in. (8-8-8 cm) Screed Box

Screed Box:

Screed Box not included)

™

Screed Box

257500

313787C

ENG

24C528 Double Bead Box Kit

ti14144a

Page 2

Table of Contents

Table of Contents

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Component Identification . . . . . . . . . . . . . . . . . . . . 5

Component ID (Continued) . . . . . . . . . . . . . . . . . . . 6

Important Safety Information . . . . . . . . . . . . . . . . . 7

Lighting Instructions . . . . . . . . . . . . . . . . . . . . . . . 10

SmartDie

Preparing ThermoLazer

Bead Dispenser Box . . . . . . . . . . . . . . . . . . . . . . . 17

™

Screed Box . . . . . . . . . . . . . . . . . . . . . 13

™

for Application . . . . . . 16

Adding Beads to SplitBead

Applying Material to a Surface . . . . . . . . . . . . . . . 17

Shutting Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Clean-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 24

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 24

™

Bead Hopper . . . . . 17

2 313787C

Page 3

Warnings

Warnings

The following are general warnings related to the safe setup, use, grounding, maintenance and repair of this equipment. In the text of this manual, the exclamation point symbol alerts you to a warning and the hazard symbol refers to

specific risks. Refer back to these General Warnings pages. Additional procedure-specific warnings will be included

where applicable.

Warnings

FIRE AND EXPLOSION HAZARD

Flammable fumes and liquids, such as propane gas, gasoline and combustible fuel, in work area can

ignite or explode. To help prevent fire and explosion:

• Do not use equipment unless fully trained and qualified.

• Do not allow open containers of flammables within 25 ft (7.6 m) of equipment. Do not operate equipment within 10 ft (3 m) of any structure, combustible material, or other gas cylinders.

• Shut off all burners when adding fuel to equipment.

• Close the tank shut-off valve immediately if you smell propane gas; extinguish all open flames. If gas

odor continues, keep away from equipment and immediately call the fire department.

• Follow lighting instructions for the burner and torch.

• Do not heat thermoplastic traffic marking compound material above 450° F (232° C)

• Fire extinguisher equipment shall be present and working.

• Keep work area free of debris, including solvent, rags and gasoline.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not leave equipment unattended.

• Keep children and animals away from work area.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Da ta in all equipment manuals.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your Graco distributor for information.

• Do not fill material beyond maximum capacity.

• Route gas lines, hoses, wires and cables away from traffic areas, sharp edges, moving parts, and hot

surfaces.

• Do not kink or overbend gas lines.

• Do not override or defeat safety devices.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

BURN HAZARD

Equipment surfaces and fluid that is heated can become very hot during operation. To avoid severe

burns:

• Do not touch hot fluid or equipment.

• Wait until equipment and material has cooled completely.

CARBON MONOXIDE HAZARD

Exhaust contains poisonous carbon monoxide, which is colorless and odorless. Breathing carbon

monoxide can cause death. Do not operate in an enclosed area.

313787C 3

Page 4

Warnings

Warnings

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed.

• Read MSDS to know the specific hazards of the materials you are using.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Clothing and respirator as recommended by the fluid, material, and solvent manufacturer.

• Gloves, shoes, overalls, face shield, hat, etc. rated for elevated temperatures of at least 500° F

(260° C).

4 313787C

Page 5

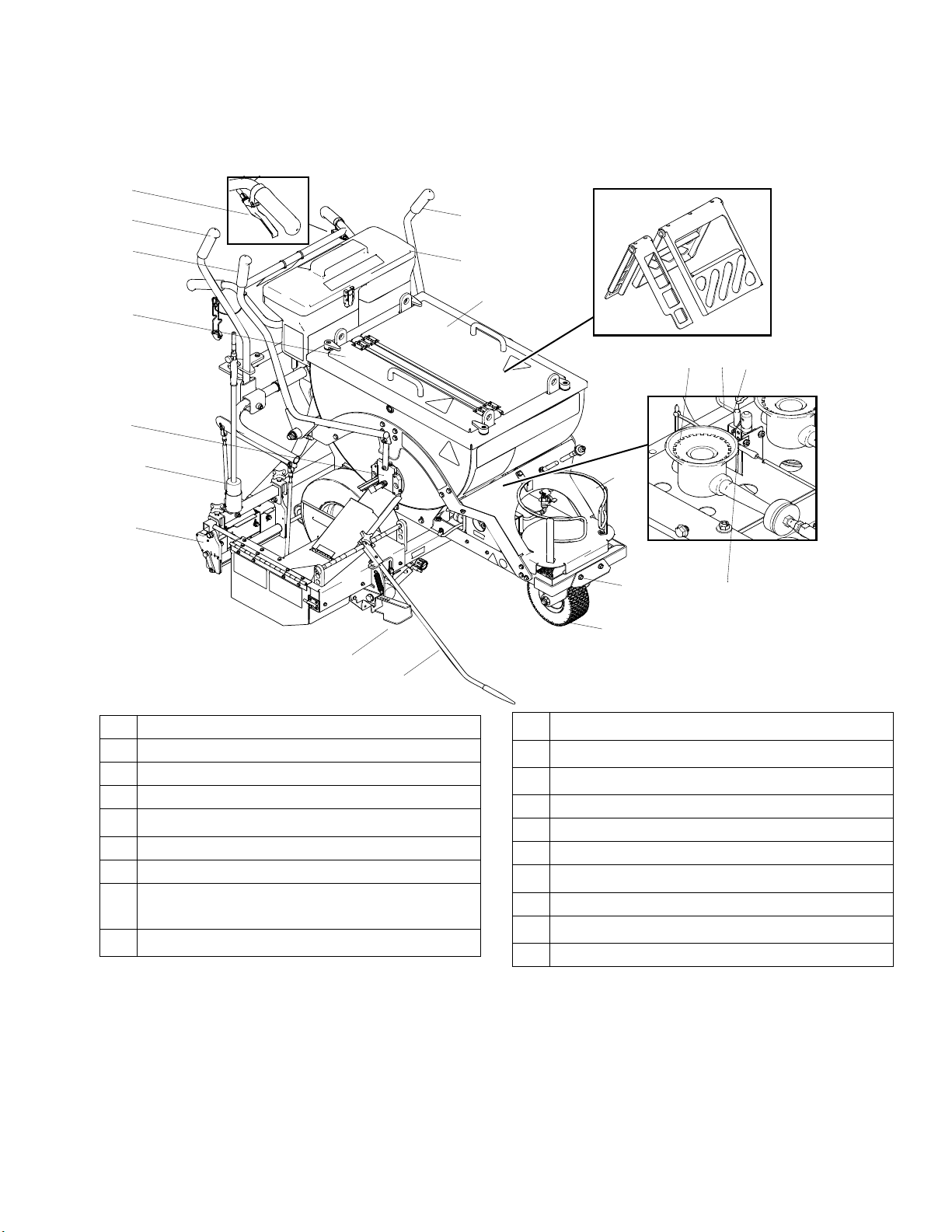

Component Identification

Component Identification

U

N

S

Y

R

AB

M

ti14145a

X

P

W

Z

A

L

C

J

U

V

T

K

H

A Kettle Main Burners

C Kettle Pilot Burner

H Line Guide

J LP Gas Cylinder Holder

K

SmartDie

L Kettle Thermopile

M Bead Dispenser Box

N

SmartDie

Actuator

P

SplitBead

*LP-Gas supply cylinder not supplied by Graco. LP-Gas supply cylinder must be designed, fabricated, and marked in

accordance with specifications and regulators for LP-Gas cylinders at The U.S. Department of Transportation (DOT),

The National Standard of Canada, CAN/CSA-B339, Cylinders, Spheres, and Tubes for Transportation of Dangerous

Goods, The Transportable Pressure Vessels Regulators 2001 (S1 2001/1426), The Gas Cylinders (Pattern Approval)

Regulations 1987 (SI 1987/116)(Pattern Approval Regulations) for EEC-type cylinders under European Directive

84/525/EEC, 84/526/EEC, and 84/527/EEC.

™

Lever

™

Screed Box/Bead Dispenser Box

™

Bead Hopper

R

ControlFlow

S

ControlFlow

T

SmoothRide

U Lock/Unlock for Swivel Wheel

V Kettle Pilot Ignitor Electrode

W Central Pour Access Cover with Latches

X

PaddleMax

Y Inspection Cover with Latches

Z

PaddleMax

AB Torch

™

Gate Valve

™

Gate Valve Actuator

™

Swivel Tire

™

Agitator Actuator

™

Agitator

313787C 5

Page 6

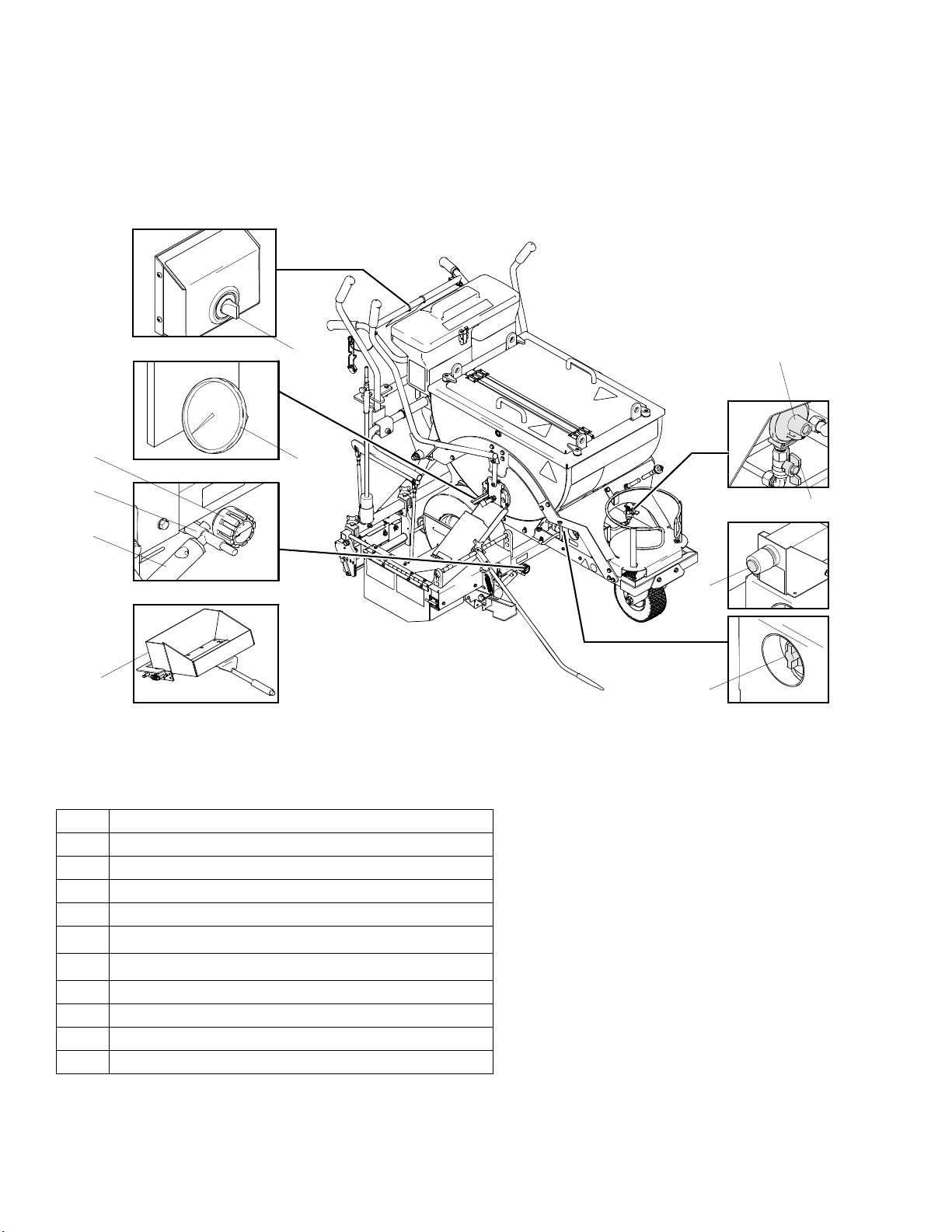

Component ID (Continued)

Component ID (Continued)

JJ

HH

GG

EE

AA

BB

LL

KK

DD

ti14146a

CC

Ref. Component

AA Kettle Temperature Control Knob

BB Kettle Temperature Indicator

CC Kettle Gas Safety Valve

DD Kettle Pilot Burner Ignitor

EE

GG

HH IR Burner Safety Shut-Off Valve with Thermocouple

JJ IR Burner Regulator/Flow Control Valve

KK Kettle Burners Manual Shut-Off Valve

LL Kettle Burner Regulator

6 313787C

SmartDie

SmartDie

™

Screed Box

™

Screed Box IR Burner

Page 7

Important Safety Information

If you do not follow these instructions exactly, a fire or

explosion may result causing property damage, personal injury or death.

Keep gas supply hose away from hot surfaces and

flames.

Use equipment in accordance with state and local ordinances with Storage, Handling and Transportation of

Liquid Petroleum Gases, ANSI/NFPA58 or CSA B149.1

If equipment has been in storage, check for insects and

insect nests on burners and Venturi tubes.

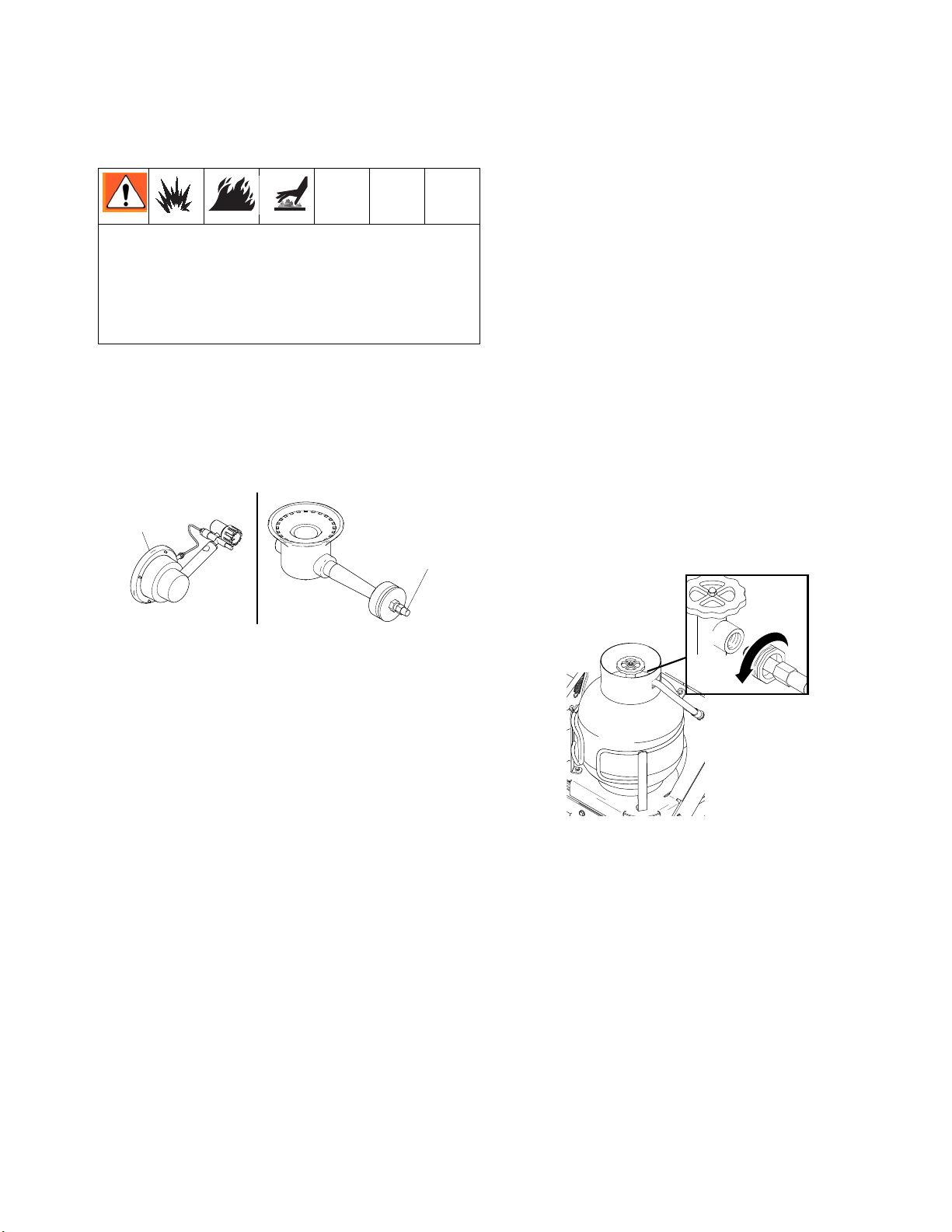

Burner

Venturi Opening

Important Safety Information

Use only vertical vapor-withdrawal LP gas cylinders

which have been designed, fabricated, tested and

marked in accordance with registration of the U.S.

Department of Transportation (DOT) or the Standard for

Cylinders, Spheres, and Tubes for the Transportation of

Dangerous Goods CAN/CSA-B337, The Transportable

Pressure Vessels Regulators 2001 (S1 2001/1426), The

Gas Cylinders (Pattern Approval) Regulations 1987 (SI

1987/116)(Pattern Approval Regulations) for EEC-type

cylinders (under European Directive 84/525/EEC,

84/526/EEC, and 84/527/EEC. Use only 20 lb to 30 lb

(9.07 kg to 13.6 kg) LP-Gas cylinders.

LP-Gas cylinder to be used only in vertical upright position as noted on agency approved LP-Gas cylinder for

proper vapor withdrawal.

Check gas supply hose connection to LP-Gas cylinder.

Make sure fitting is free of debris before connecting to

tank. Make sure gas connection is screwed completely

on and is free of leaks.

IR Burner

ti14156a

Kettle Burner

ti14411a

313787C 7

Page 8

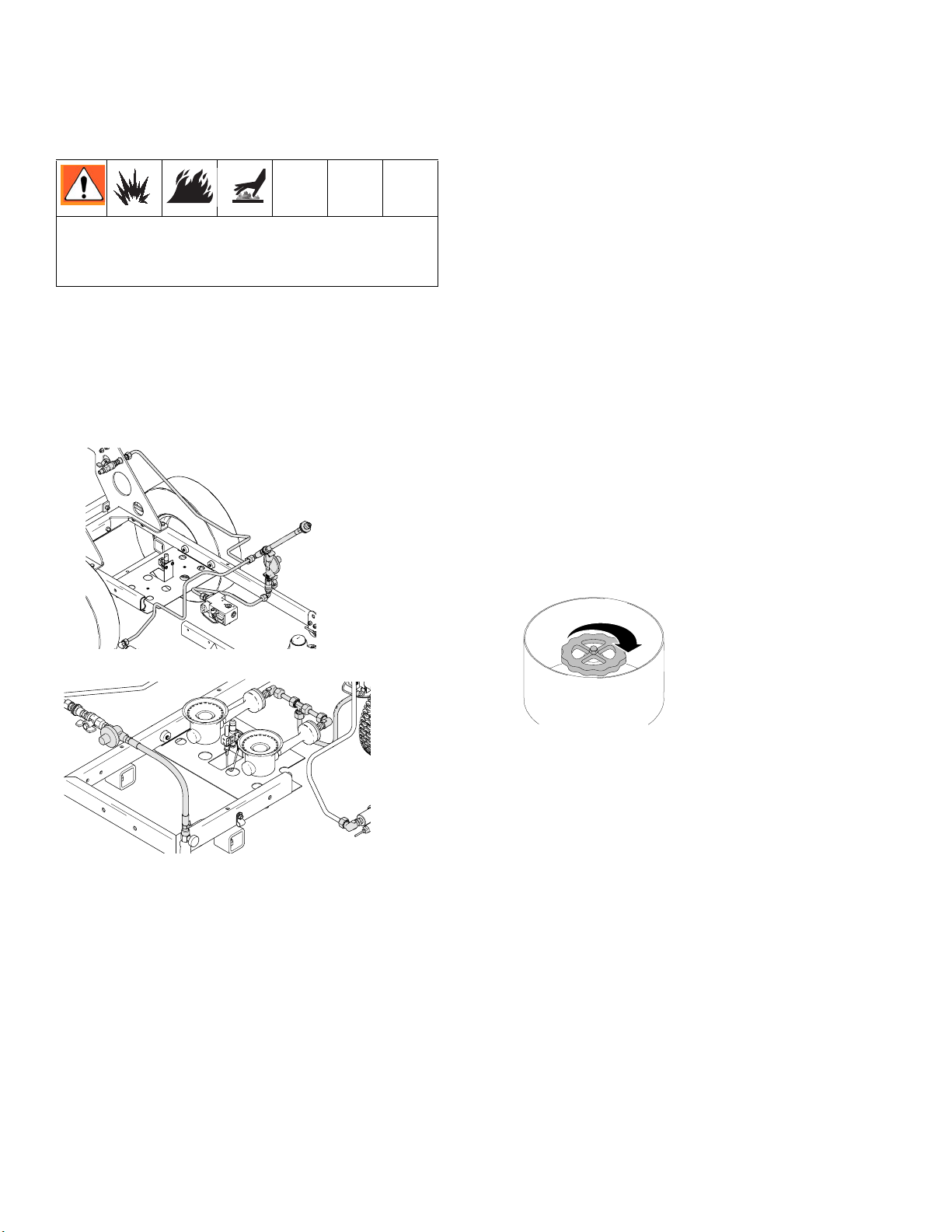

Important Safety Information

Important Safety Information

If you do not follow these instructions exactly, a fire or

explosion may result causing property damage, personal injury or death.

BEFORE LIGHTING: Smell all around the working area

for gas. Be sure to smell next to the ground because

propane is heavier than air and will settle on the ground.

DAILY: Check for gas leaks. Use mild soap and water

solution or other approved method. Apply solution to all

gas lines and fittings then watch for gas bubbles.

WHAT TO DO IF YOU SMELL GAS OR FIND GAS

BUBBLES:

• Evacuate all unqualified personnel from area

• Do not try to light any burner

• Do not strike a flame

• Do not use electric fans to remove gas from area

• Do not touch any electric switch and do not use

any phone

• If leak is from a gas fitting, tighten fitting until leak

stops

• If leak is from a gas line, shut off at LP-gas cylinder and replace gas line

• Immediately call your gas supplier from a remote

phone. Follow gas supplier’s instructions.

• If leak can not be stopped by shutting off LP-gas

cylinder shut-off valve, immediately call your gas

supplier from a remote phone. Follow gas supplier’s instructions.

• If you cannot reach your gas supplier call the fire

department

ti14560a

ti14561a

NOTE: Burners will need to be ignited to test gas lines

and fittings downstream of gas safety valves (CC and

HH). Ignite burners only after thoroughly checking gas

line and fitting upstream of gas safety valves.

ti14128a

Use only your hand to push in or turn the kettle gas

safety valve (CC). Never use tools. If the knob will not

push in or turn by hand, do not try to repair it; call a qualified service technician. Attempted repair or force may

result in a fire or explosion.

Do not use this equipment if any part has been under

water. Immediately call a qualified service technician to

inspect equipment and all components. Replace defective parts only with approved manufactured parts.

8 313787C

Page 9

Important Safety Information

Before attempting to start equipment:

If you do not follow these instructions exactly, a fire or

explosion may result causing property damage, personal injury or death.

All surfaces are capable of becoming extremely hot.

Be sure to always wear heat-resistant gloves and

other protective equipment rated for 500° F (260° C).

Material and unit are very hot 350° - 500° F

(177° C - 260° C). Never exceed 450° F (232° C)

material temperatures.

Hot molten plastic will burn skin. Do not attempt to

remove from skin. Cool under running water and

seek medical attention.

See MSDS for Thermoplastic Traffic Marking

Compound.

Important Safety Information

ti14409a

DAILY: Check all gas lines and fittings for gas leaks.

DAILY: Check gas supply hose for wear, abrasions, cuts

or leaks. Replace only with hoses recommended by

Graco.

Check gas supply hose connection to LP-gas cylinder.

Make sure fitting is free of debris before connecting to

tank. Make sure gas connection is screwed completely

on and is free of leaks.

Check to ensure that the following are closed:

• LP Gas Tank manual shut-off valve

• ControlFlow

™

gate valve

• Screed IR burner regulator/gas flow control valve

• Kettle gas burner manual shut-off valve

• Kettle gas safety valve

• Torch manual shut-off valve

• Kettle temperature control knob (turn to “OFF”)

• Torch gas flow control valve

If using Thermolazer™ in conjunction with Line-

™

Driver

, do not fill gasoline tank while burners are

ignited. Allow equipment to completely cool before

refueling.

Avoid prolonged inhalation of fumes.

Check to make sure exhaust openings on kettle are not

obstructed.

ti14412a

Check to make sure combustion air supply openings on

kettle are not obstructed.

ti14503a

Air Openings

313787C 9

Page 10

Lighting Instructions

Lighting Instructions

Lighting Kettle Burners

Read For Your Safety, page 7.

1. Turn temperature control knob (AA) to 0 (“OFF”).

AA

ti14124a

2. Turn kettle gas safety valve (CC) to “OFF”.

CC

ti14131a

6. Push in gas safety valve knob.

7. Push kettle pilot burner igniter (DD) until pilot

ignites.

8. Continue to push in gas safety valve (CC) in for

approximately 1 minute. If pilot goes out, repeat

steps 4-6 after 10 minutes.

If pilot ignites without depressing the gas safety valve

knob, replace gas safety valve. If gas safety valve

knob does not pop back after releasing in pilot position, STOP and replace gas safety valve. Shut off gas

at propane tank before replacing valve.

9. Turn gas safety valve knob to “ON”.

10. Turn temperature to 250° F (121° C) and observe

that main burners have ignited. Turn kettle temperature control back to “0” and observe that main burners shut off.

3. Open burner view port.

ti14130a

4. Open manual shut-off valve on propane tank

located at front of unit; open kettle manual shut-off

valve (KK) below kettle and behind propane tank.

ti14129a

ti14127a

5. Turn gas safety valve (CC) to “PILOT”.

DD

CC

ti14131a

KK

If main burners do not ignite or shut off when rotating

temperature control knob, STOP. Shut off gas at the

propane tank. Follow diagnostic procedure in Repair

manual.

11. Close burner view port.

12. Turn temperature control to desired setting.

Shutting Off Burner

1. Turn gas safety valve to “OFF”.

2. Close manual shut-off valve on propane tank. Close

kettle manual shut-off valve (KK) when finished

heating with kettle burners.

KK

ti14125a

ti14128a

NOTE: The kettle gas burner can be lit manually with a

small torch (for example: DOT 39 NRC 228/286 Cylinder

with #3 torch tip) if the battery powered pulse ignitor fails

to light the pilot.

10 313787C

Page 11

Torch Lighting Instructions

1. Open manual shut-off valve on propane tank

located at front of unit.

Lighting Instructions

Shutting Off Torch

1. Fully close torch flame adjusting valve.

ti14127a

2. Open torch manual shut-off valve next to torch regulator.

ti14137a

3. Remove external torch from holder.

ti14138a

ti14605a

2. Close torch manual shut-off valve when finished

heating with torch.

ti14602a

3. Close manual shut-off valve on propane tank when

finished heating with torch.

ti14128a

4. Slowly open torch flame adjusting valve and use

striker to ignite flame.

ti14141a

ti14139a

5. Adjust flame to desired length.

313787C 11

Page 12

Lighting Instructions

SmartDie™ Screed Box IR Burner

Lighting Instructions

Read Important Safety Information, page 7.

1. Open manual shut-off valve on propane tank

located at front of unit.

ti14127a

5. Place torch at end of IR burner next to stainless

steel mesh on burner.

ti14142a

6. Press in safety shut-off valve knob (HH).

2. Light torch (see Torch Lighting Instructions, page

11).

3. Turn gas flow control knob (JJ) to full-on (three

flames position).

JJ

ti14126b

4. Open screed box shroud access door.

HH

ti14143a

7. Hold in safety shut-off knob until burner ignites. The

burner will give off a bright glow once burner ignites.

Shutting Off Gas

1. Turn gas flow control knob to “OFF” (0 position).

2. Close manual shut-off valve on propane tank when

finished heating with screed box IR burner.

ti14128a

ti14140a

12 313787C

Page 13

SmartDie™ Screed Box

Installation

Use extreme caution when installing and removing

screed box. Expect all equipment components and

material to be extremely hot. See MSDS for Thermoplastic Traffic Marking Compound.

1. Shut off the SmartDie™ screed box IR burner.

SmartDie™ Screed Box

™

5. Engage SmartDie

screed box rod into SmartDie™

lever.

ti14268a

6. Align hole of rod clevis with connecting hole in

SmartDie

™

screed box yoke and install hairpin cot-

ter pin.

ti14126a

2. Open screed shroud door.

ti14140a

3. Move SmartDie

™

screed box actuator out of full

raised locked position.

ti14267a

4. Slide SmartDie

™

screed box under screed shroud

and press down on SmartDie

™

lever.

ti14155a

7. Close and lock screed shroud door.

8. Re-light SmartDie

™

screed box IR burner as

required.

Removal

1. Shut off SmartDie™ screed box IR burner.

ti14126a

2. Open screed shroud door.

ti14140a

ti14271a

313787C 13

Page 14

SmartDie™ Screed Box

3. Set SmartDie™ screed box on ground but not in

locked open position.

ti14267a

4. Remove hairpin cotter pin connecting SmartDie

screed box to rod clevis.

ti14155a

5. Press down SmartDie

™

lever.

™

1. Loosen two bolts on SmartDie

screed box mount-

ing bracket.

ti14504a

2. Slide mount down until leading box edge of Smart-

™

™

Die

screed box die runner is just off of the ground

surface. For best performance, raise leading edge

0 - 0.03 in. (0 - 0.076 cm) off ground surface.

ti14505a

SmartDie™ Screed Box Gate

SmartDie

™

Screed Box Trough

ti14270a

™

6. Disengage SmartDie

™

lever and carefully remove SmartDie™.

Die

screed box rod from Smart-

Adjustment

The height and angle of the SmartDie™ screed box can

be adjusted to ensure a solid line of material on any surface. For optimum delivery of thermoplastic material,

make sure the SmartDie

allel to road surface.

™

SmartDie

Screed Box Gate

™

screed box die runner is par-

SmartDie

™

Screed Box Trough

ti14414a

0 - 0.030 in.

™

SmartDie

Screed Box Die Runner

3. Tighten bolts on screed box mounting bracket.

ti14506a

ti14545a

SmartDie™ Screed Box Die Runner

14 313787C

Page 15

Replacing SmartDie™

Screed Box Spring

SmartDie™ Screed Box

1. Position replacement spring as shown below and

slide into spring guard.

ti14551a

2. Push spring up through guard and loop end around

guard pin until spring sits in groove.

ti14549a

3. Set SmartDie

™

screed box on its side.

4. Loop open end of spring and guard over first pin on

™

SmartDie

and over second pin on SmartDie

screed box. Then push spring guard up

™

screed box.

ti14550a

ti14552a

NOTE: Make sure spring end is fully engaged in groove

to prevent spring from coming loose.

Line Thickness Adjustment

To adjust the thickness of the line of material delivered

from the screed box, loosen all acorn nuts on the Smart-

™

Die

screed box gate and move the spacer until desired

line thickness is achieved.

ti14553a

ti14272a

ti14273a

Typical settings on pavement: 0.060 - 0.125 in.

(0.153 - 0.318 cm).

Typical settings on metal stencil: Flush - 0.0 in. (0.0 cm).

313787C 15

Page 16

Preparing ThermoLazer™ for Application

Preparing ThermoLazer™ for Application

Keep all access covers closed and latched when equipment is in use.

Always secure ThermoLazer

™

by chocking wheels

when adding thermoplastic.

1. Make sure kettle burners and SmartDie™ screed

box burner are lit.

2. Allow kettle to heat up before adding material. If kettle is completely empty, allow kettle to reach

300° - 350° F (149° - 177° C) before adding material. If kettle has material, allow material to reach

380° F (193° C) before adding material.

3. Secure ThermoLazer

™

by chocking wheels.

5. Move ControlFlow

™

Gate Valve Actuator (S) to

raised position and fill screed box with melted thermoplastic material.

S

ti14123a

0.5 in.

NOTE: The material gate is adjustable. The gate is

factory set at a 0.5 in. (1.3 cm) gap. You can

increase this gap for more material flow or decrease

the gap for less material flow.

6. Do not overfill material in kettle. Overfill would be

material higher than 5 in. (13 cm) below top of kettle.

5.0 in.

4. Add thermoplastic material to kettle.

ti14122a

ti14603a

Overfill

Line

ti14410a

7. Close and latch cover access doors when applying

thermoplastic.

8. Avoid bumping or impacting Thermolazer

™

to pre-

vent spillage or splashing of hot material.

16 313787C

Page 17

Bead Dispenser Box

Bead Dispenser Box

The Bead Dispenser Box has three doors which can be

opened and closed to allow beads to be dispensed at

desired width patterns.

ti14153a

ti14151a

ti14152a

Bead flow rate can be adjusted using the Bead Flow

Rate Lever on the outside of the Bead Dispenser Box.

ti14157a

Adding Beads to SplitBead™ Bead Hopper

Single Bead Application

1. Unlock and open SplitBead™ bead hopper door.

2. Fill both sides of hopper with beads.

3. Close and lock hopper door. Do not allow beads to

remain in hopper, hoses or bead dispenser for an

extended period of time. Beads will absorb moisture, bond to adjacent beads and harden.

Bead Dispenser Engagement Wheel

To properly dispense beads, drive wheel (27) must be in

direct contact with tire (89). If drive wheel (27) becomes

loose and/or starts to slip, use allen wrench to tighten

set screw (211).

Double Bead Application

(Requires Installation of Double Bead Kit 24C528)

1. Fill element beads on left side (smaller chamber).

2. Fill glass beads on right side (larger chamber).

3. Close and lock hopper door. Do not allow beads to

remain in hopper, hoses or bead dispenser for an

extended period of time. Beads will absorb moisture, bond to adjacent beads and harden.

Applying Material to a Surface

3. Pull thermoplastic ControlFlow

4. Open bead box gate and fill bead box dispenser to a

1. Position unit over target area and push Thermo-

™

Lazer

locks into centered position (a slight click will be

heard when wheel is engaged). Use Line Guide to

help orientate ThermoLazer

2. Pull unit back to start of target area and move

screed box into position.

forward in a straight line until front wheel

™

.

5. Push SmartDie

6. Push ThermoLazer

For examples of correct and incorrect material application, see Troubleshooting section in Repair manual.

211

89

27

™

Gate Valve Actua-

tor (S) and fill screed box with melted material.

level 1.5 in. (3.8 cm) from top.

™

screed box/bead dispenser box

actuator (N) lever forward to deploy screed box and

engage bead dispense wheel.

™

unit forward with screed box

deployed and bead dispenser wheel engaged to

apply material.

ti14564a

313787C 17

Page 18

Shutting Down

Shutting Down

1. Turn kettle gas safety valve (CC) to “OFF” position.

5. Turn torch gas flow valve to closed position.

ti14139a

ti14626a

2. Turn temperature control knob (AA) to 0 (“OFF”).

ti14124a

3. Turn screed burner regulator/flow control valve to “0”

(OFF).

ti14126a

6. Turn torch manual shut-off valve OFF.

7. Turn main gas valve on propane tank OFF.

ti14128a

Always store LP-Gas cylinder outside and in an

approved/secure storage locker.

4. Close kettle burner manual shut-off valve (KK)

below kettle and behind propane tank OFF.

ti14125a

18 313787C

Thermolazer

the LP-Gas cylinder has been removed.

™

can be stored inside a building ONLY IF

Page 19

Clean-Up

Never scoop out remaining melted thermoplastic from

kettle. Remaining thermoplastic can be left to harden

inside the kettle and can be remelted at a later date.

Always secure ThermoLazer

when adding thermoplastic.

1. Secure ThermoLazer™ by chocking wheels.

™

by chocking wheels

ti14603a

Clean-Up

NOTICE

Be sure to thoroughly clean all material on BlackMax

Screed Die bar of screed box and any open areas to

prevent material from freezing moving parts of screed

box. Always run all material out of each die before

removing. Scrape out all remaining material before it

sets within the die.

NOTICE

To prevent material from hardening and blocking flow,

scrape all excess material off of external surfaces after

each use, including the material trough.

NOTICE

When using hand torch to loosen material from screed

box, do not allow flames to come in contact with screed

box springs. Screed box springs will lose their temper

from flames and will not properly close screed box.

NOTICE

Remove any remaining beads in the bead hopper and

bead dispenser to prevent beads from clogging hopper

and dispenser.

™

2. Use scraper to clean out trough and screed box.

ti14529a

Transporting

Remove LP-Gas supply cylinder from ThermoLazer™

before transporting. Secure in an approved location and

method as authorized by local, state, federal, national,

and international agencies.

Always use the designated mounted lifting lugs when

lifting the Thermolazer

only use ANSI approved slings and equipment rated for

a minimum of 2000 lb. Always use ANSI approved

equipment for securing ThermoLazer to transporting

equipment.

™

. When lifting the Thermolazer™

313787C 19

Page 20

Maintenance

Maintenance

DAILY: Make sure kettle main burners (A) are burning

correctly. The flame should be 1 - 2 in. (2.5 - 5.0 cm)

high and blue/orange in color.

DAILY: Check gas lines and fittings for gas leaks. Use

soap and water mixture or LP-gas leak detector to

detect gas leaks.

DAILY: Check LP-gas supply hose for abrasions, cut or

wear. Make sure hose fitting and tank fitting are free of

debris before connecting.

DAILY: Make sure kettle gas safety valve (CC) rotates

freely. Make sure valve freely moves in and out at the

“PILOT” position.

DAILY: Make sure a good spark is being produced at

the kettle pilot burner by the kettle pilot igniter electrode.

Spark gap should be .17 - .20 in. (.43 - .50 cm).

.17 to .20 in.

1 to 2 in.

A

ti14520a

Venturi gap .20 in. (.50 cm)

DAILY: Make sure IR burner safety shut-off valve (HH)

moves freely in and out.

DAILY: Make sure LP-gas only flows to burner when

safety shut-off valve knob is pressed in.

DAILY: Make sure the IR burner face emits a bright

orange glow when at high fire; i.e. the “three flames”

position on the Regulator/Flow Control Valve (JJ).

DAILY: Grease SmartDie

™

screed box.

DAILY: Check screed box springs for foreign debris &

wear.

ti14519a

DAILY: Make sure kettle main burners (A) ignite when

heat is required and shut-off when heat is not required.

DAILY: Make sure kettle pilot burner (C) is burning correctly. The flame should be 2 - 3 in. (5.0 - 7.6 cm) high

and blue/orange in color.

2 to 3 in.

ti14413a

DAILY: Check bead box dispenser drive wheel (27) and

Thermolazer

™

tire (89) for foreign debris.

WEEKLY: Grease thermoplastic flow control gate valve

guides.

WEEKLY: Check tire pressures.

WEEKLY: Check screed box die bar carbide runners for

wear.

MONTHLY: Grease PaddleMax

™

agitator rod ball joint

ends.

20 313787C

Page 21

Maintenance

Fat Track™ Front Swivel Wheel

System

ANNUALLY: Tighten nut (86a) on screw under dust cap

(92) until spring washer bottoms out. Then back off the

nut 1/2 to 3/4 turns.

ANNUALLY: Tighten nut (82) on screw (90) until it

begins to compress spring washer (83). Then tighten an

additional 1/4 turn.

MONTHLY: Grease the wheel bearing.

PERIODICALLY: Check caster locking pin (86t) for

wear. If pin is worn out, there will be play in the caster

wheel. Reverse or replace the pin as needed.

PERIODICALLY: Check caster wheel alignment as necessary.

FatTrack™ Front Swivel Tire Alignment

Align front wheel as follows:

1. Loosen cap screw (86h).

86h

ti14527a

2. Rotate front wheel fork left or right, as necessary, to

straighten alignment.

3. Tighten cap screw (86h). Push striper and let striper

roll with hands off of striper.

NOTE: If striper rolls right or left, then repeat steps 1

and 3 until striper rolls straight.

313787C 21

Page 22

Technical Data

Technical Data

Fuel: Liquefied petroleum gas (LP-gas) (propane vapor)

Gas supply pressure (maximum): 250 psi (17.24 bar)

Kettle burner inlet pressure: 11 in. w.c. (2.7 kPa)

IR burner inlet pressure: 12 psi (.83 bar)

Torch inlet pressure: 18 psi (1.24 bar)

Kettle main burner heating capacity (maximum): Two (2) burners; each burner rated at 10,100 btu/hr (2.96 kW)

Kettle pilot burner heating capacity (maximum): 3800 btu/hr (1.11 kW)

IR burner heating capacity (maximum): 14,000 btu/hr (4.10 kW)

Torch heating capacity (maximum): 100,000 btu/hr (29.31 kW)

Kettle holding capacity (maximum): 300 lb (136 kg) (thermoplastic traffic marking compound materials)

Kettle Temperature (maximum): 450° F (232° C)

Kettle Temperature (operating): 380° - 420° F (193° - 216° C) 60 psi (4.14 bar)

Tire pressure (rear wheels): 60 psi (4.14 bar)

Tire pressure (swivel wheel): 45 psi (3.10 bar)

Battery (Kettle Pilot Burner Igniter): AA (1.5 V)

Bead Hopper Capacity (maximum): 80 lb (36.3 kg) Type II glass beads

Dimensions

Weight: 295 lb (134 kg)

Length: 72 in. (1.83 m)

Height: 51 in. (1.30 m)

Width: 48 in. (1.22 m)

22 313787C

Page 23

Notes

Notes

313787C 23

Page 24

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Toll Free: 1-800-690-2894.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 313787

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2008, Graco Inc. is registered to ISO 9001

www.graco.com

Revised 10/2010

Loading...

Loading...