Page 1

Instructions

Oil and Grease

Piston Distributors

- For injecting lubricant from an intermittent pump system.

Suitable for use in centralized, single-line, lubrication systems. -

Models: Page 2 (includes working pressure)

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

WARNING

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on skin and

cause serious injury.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

313759A

Page 2

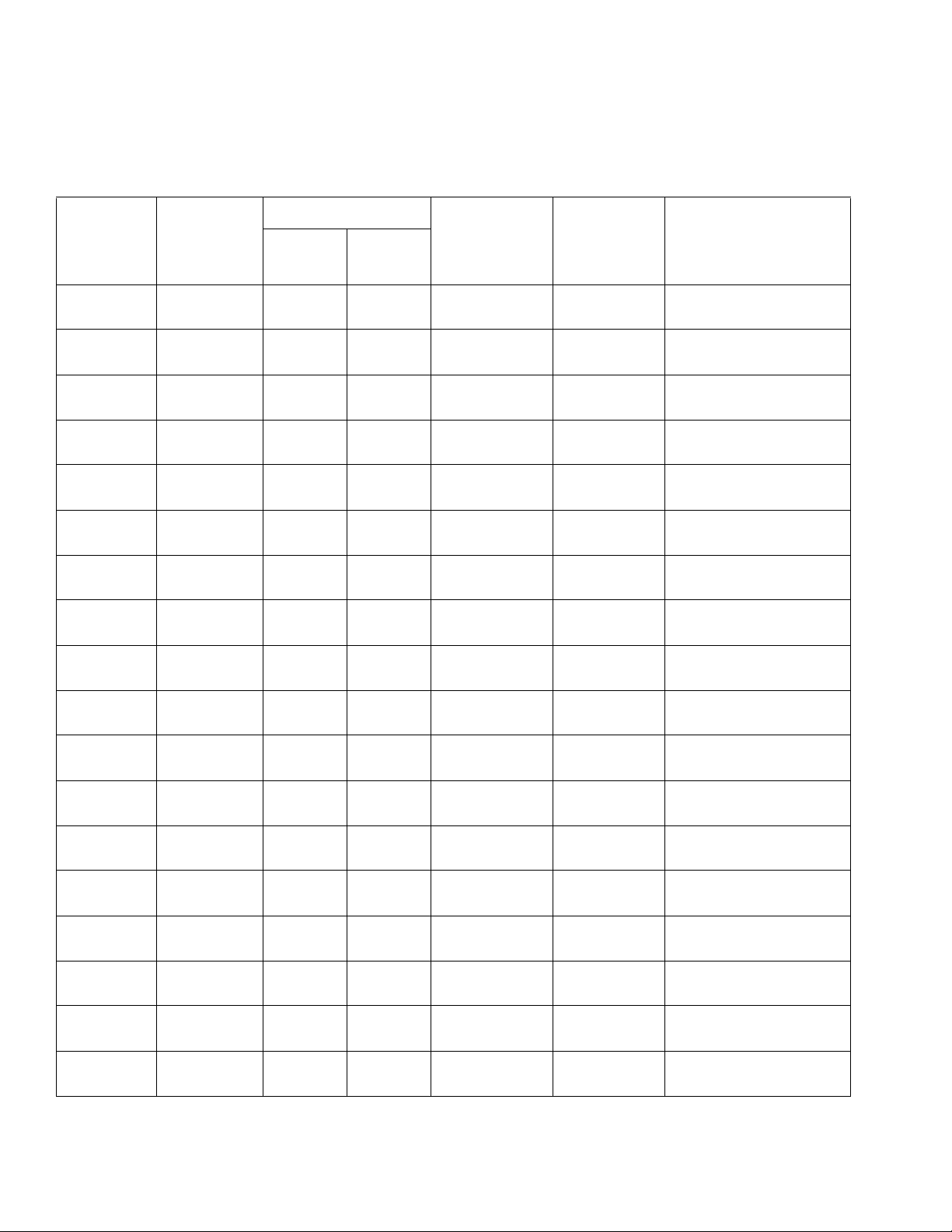

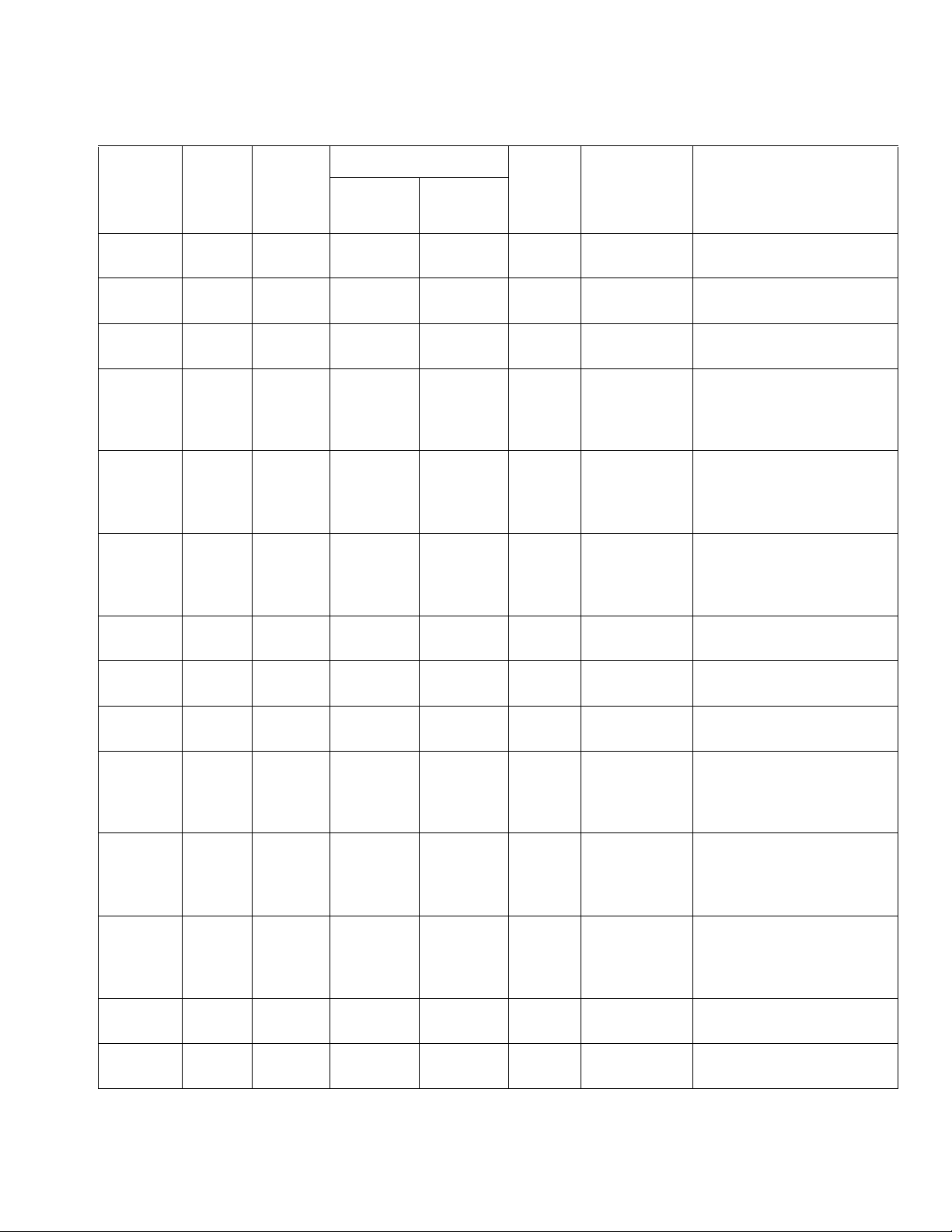

Models

3400 (Oil) / 3410 (Grease) Single Point Series

Fitting &

Part No.

121654 M8 x 1

121655 M8 x 1

121656 M8 x 1

121657 M8 x 1

122804 M10 x 1

122805 M10 x 1

122806 M10 x 1

122807 M10 x 1

122808 M10 x 1

122809 M10 x 1

122810 M10 x 1

122811 M10 x 1

122812 M10 x 1

558306 M8 x 1

558307 M8 x 1

558308 M8 x 1

558309 M8 x 1

558310 M8 x 1

Sleeve Oil Grease

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

Fluid

✔

✔

✔

✔

✔

✔

✔

✔

Dispense

Volume (cm3)

.01

.03

.06

.10

.01

.03

.06

.10

.16

.01

.03

.06

.10

.01

.03

.06

.10

.16

Operating

Pressure

Range

psi (bar) Viscosity

188 - 653

(13 - 45)

188 - 653

(13-45)

188 - 653

(13 - 45)

188 - 653

(13-45)

145 - 653

(10 - 45)

145 - 653

(10 - 45)

145 - 653

(10 - 45)

145 - 653

(10 - 45)

145 - 653

(10 - 45)

188 - 653

(13 - 45)

188 - 653

(13 - 45)

188 - 653

(13 - 45)

188 - 653

(13 - 45)

145 - 653

(10 - 45)

145 - 653

(10 - 45)

145 - 653

(10 - 45)

145 - 653

(10 - 45)

145 - 653

(10 - 45)

NLGI 000-00

NLGI 000-00

NLGI 000-00

NLGI 000-00

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

NLGI 000-00

NLGI 000-00

NLGI 000-00

NLGI 000-00

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

2 313759A

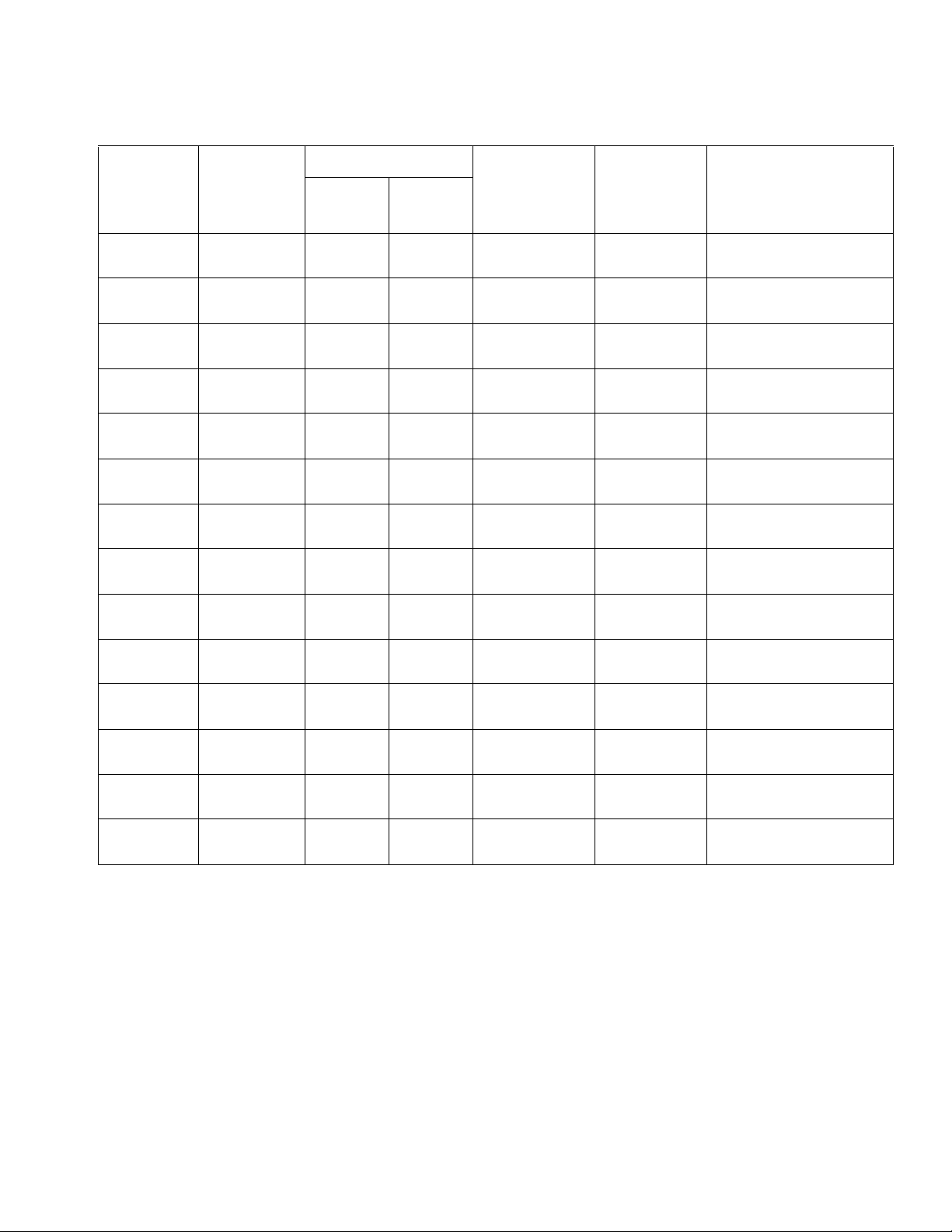

Page 3

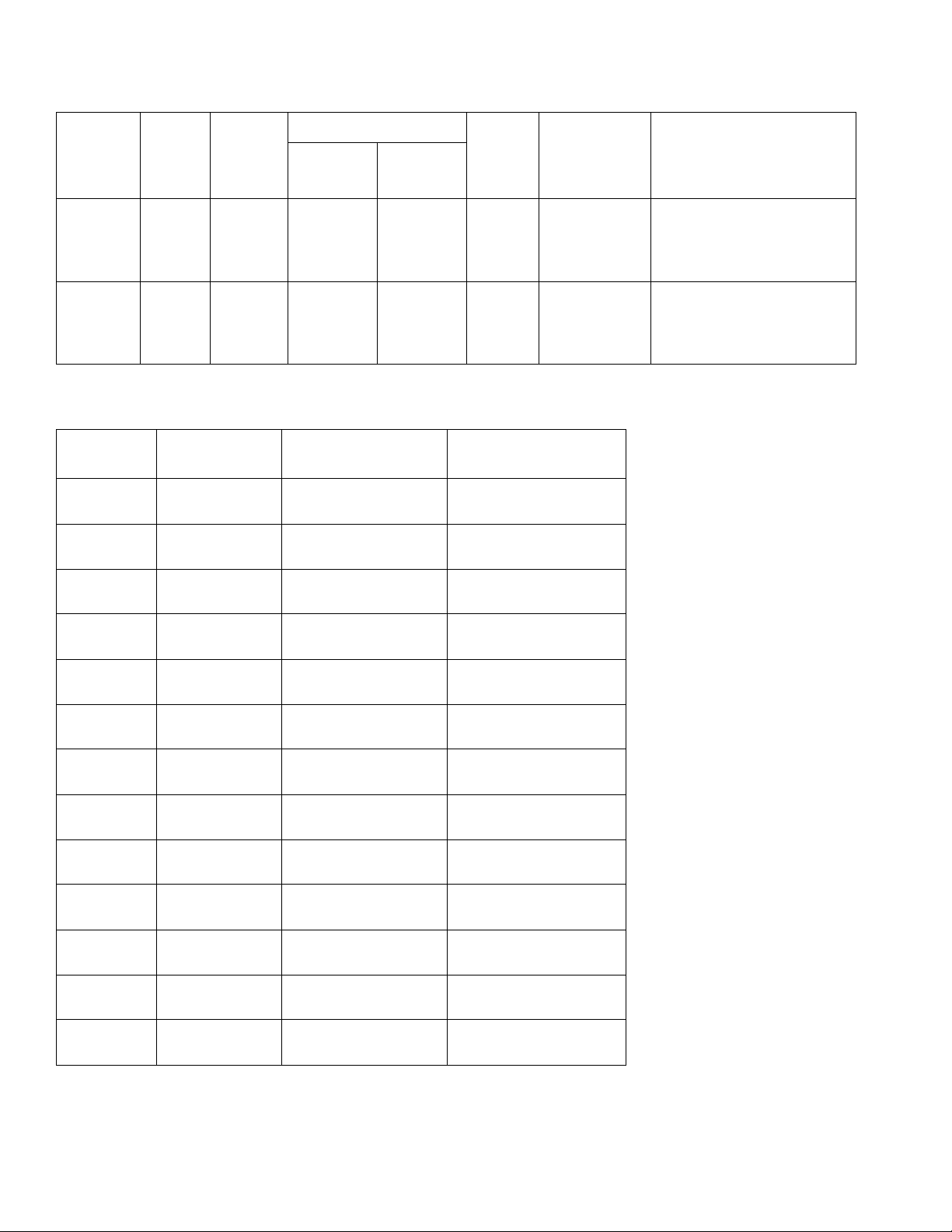

3500 (Oil) / 3510 (Grease) Single Point Series

Fitting &

Part No.

112817 M12 x 1

121658 M10 x 1

121659 M10 x 1

121660 M10 x 1

121661 M10 x 1

121662 M10 x 1

121663 M10 x 1

121664 M10 x 1

122813 M12 x 1

122814 M12 x 1

122815 M12 x 1

122816 M12 x 1

122818 M12 x 1

122819 M12 x 1

Sleeve Oil Grease

✔

✔

✔

✔

✔

✔

✔

✔

Fluid

✔

✔

✔

✔

✔

✔

Dispense

Volume (cm3)

.1

.1

.2

.4

.6

.1

.2

.3

.1

.2

.4

.6

.2

.3

Operating

Pressure

Range

psi (bar) Viscosity

188 - 653

(13 - 45)

145 - 653

(10 - 45)

145 - 653

(10 - 45)

145 - 653

(10 - 45)

145 - 653

(10 - 45)

188 - 653

(13 - 45)

188 - 653

(13 - 45)

188 - 653

(13-45)

145 - 653

(10 - 45)

145 - 653

(10 - 45)

145 - 653

(10 - 45)

145 - 653

(10 - 45)

188 - 653

(13 - 45)

188 - 653

(13 - 45)

NLGI 000-00

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

NLGI 000-00

NLGI 000-00

NLGI 000-00

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

NLGI 000-00

NLGI 000-00

313759A 3

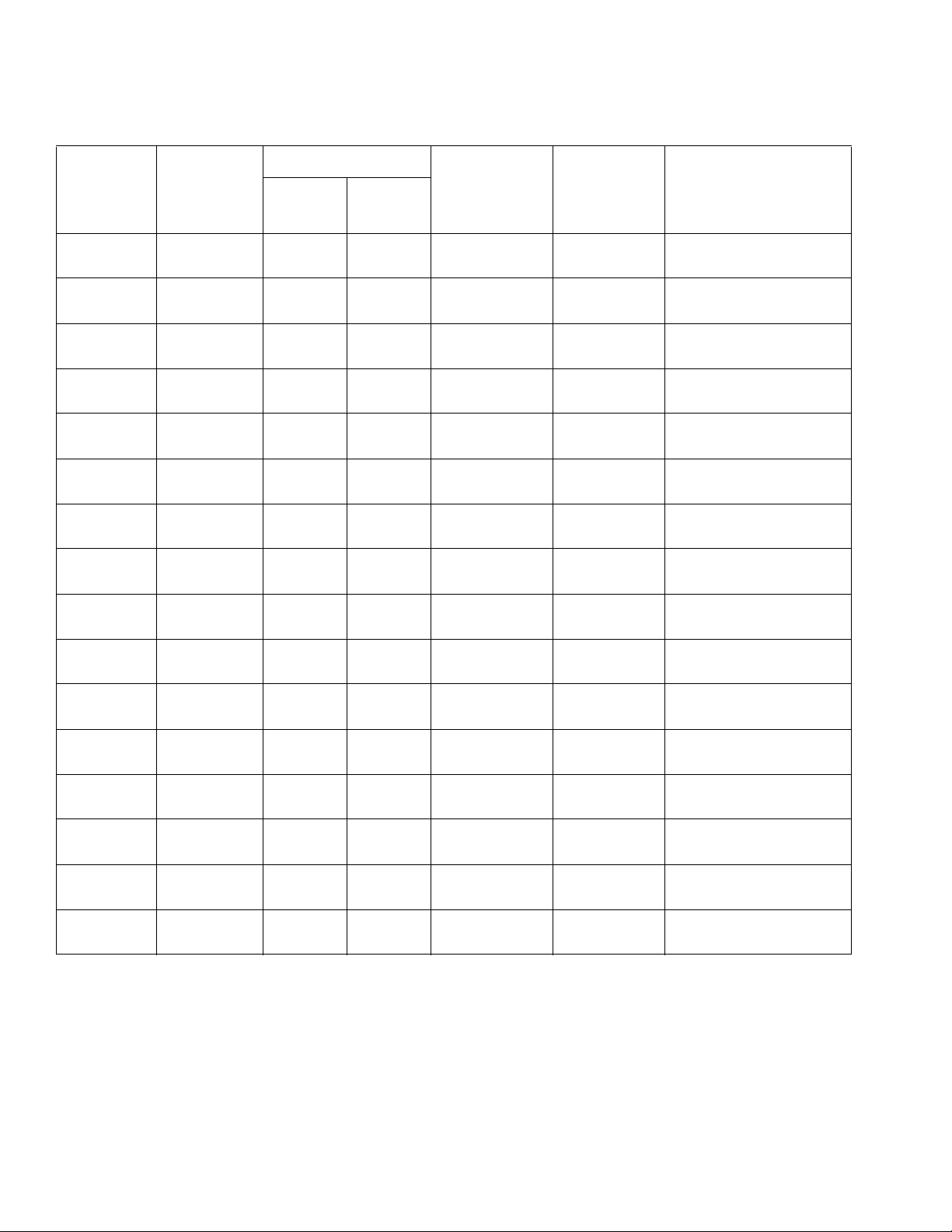

Page 4

3900 (Oil) / 3910 (Grease) Single Point Series

Fitting &

Part No.

121665 M14 x 1’5

121666 M14 x 1’5

121667 M14 x 1’5

121668 M14 x 1’5

121669 M14 x 1’5

121670 M14 x 1,5

121671 M14 x 1’5

121672 M14 x 1’5

122820 M12 x 1

122821 M12 x 1

122822 M12 x 1

122823 M12 x 1

122824 M12 x 1

122825 M12 x 1

122826 M12 x 1

122827 M12 x 1

Sleeve Oil Grease

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

Fluid

✔

✔

✔

✔

✔

✔

Dispense

Volume (cm3)

.2

.4

.6

1.0

1.5

.1

.2

.3

.2

.4

.6

1.0

1.5

.1

.2

.3

Operating

Pressure

Range

psi (bar) Viscosity

145 - 653

(10 - 45)

145 - 653

(10 - 45)

145 - 653

(10 - 45)

145 - 653

(10 - 45)

145 - 653

(10 - 45)

348 - 653

(24 - 45)

348 - 653

(24-45)

348 - 653

(24-45)

145 - 653

(10 - 45)

145 - 653

(10 - 45)

145 - 653

(10 - 45)

145 - 653

(10 - 45)

145 - 653

(10 - 45)

348 - 653

(24 - 45)

348 - 653

(24 - 45)

348 - 653

(24 - 45)

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

NLGI 000-00

NLGI 000-00

NLGI 000-00

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

NLGI 000-00

NLGI 000-00

NLGI 000-00

4 313759A

Page 5

Complete Castings

Part No.

122841 3400 2

122861 3400 3

122862 3400 5

122863 3410 2

122864 3410 3

122865 3410 5

Outlets Oil Grease

No.

✔

✔

✔

Fluid

✔

✔

✔

Operating

Pressure

Plug

Color

Red 145 - 653

Red 145 - 653

Red 145 - 653

White 145 - 653

White 145 - 653

White 145 - 653

Range

psi (bar) ViscositySeries

(10 - 45)

(10 - 45)

(10 - 45)

(10 - 45)

(10 - 45)

(10 - 45)

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

(Oil) 32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

(Grease) NLGI 000-00

(Oil) 32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

(Grease) NLGI 000-00

(Oil) 32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

(Grease) NLGI 000-00

122866 3500 2

122868 3500 3

122869 3500 5

122885 3510 2

122886 3510 3

122887 3510 5

122888 3900 2

122889 3900 3

✔

✔

✔

✔

✔

✔

✔

✔

Red 145 - 653

(10 - 45)

Red 145 - 653

(10 - 45)

Red 145 - 653

(10 - 45)

White 145 - 653

(10 - 45)

White 145 - 653

(10 - 45)

White 145 - 653

(10 - 45)

Red 145 - 653

(10 - 45)

Red 145 - 653

(10 - 45)

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

(Oil) 32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

(Grease) NLGI 000-00

(Oil) 32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

(Grease) NLGI 000-00

(Oil) 32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

(Grease) NLGI 000-00

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

313759A 5

Page 6

Fluid

Plug

Color

White 145 - 653

Part No.

Outlets Oil Grease

122890 3910 2

No.

✔

122891 3910 3

White 145 - 653

✔

Direct to Bearing Piston Distributors (Lubricant - Oil)

Operating Pressure

Part No. Flow

122789

122790

122791

122792

122793

122794

122795

122796

122797

122798

122799

122800

122801

0’03 cm

0’06 cm

0’1 cm

0’03 cm

0’06 cm

0’1 cm

0’03 cm

0’06 cm

0’1 cm

0’1 cm

0’2 cm

0’3 cm

0’4 cm

3

3

3

3

3

3

3

3

3

3

3

3

3

Range psi (bar) Viscosity

261 - 725 psi

(18 - 50 bar)

261 - 725 psi

(18 - 50 bar)

261 - 725 psi

(18 - 50 bar)

261 - 725 psi

(18 - 50 bar)

261 - 725 psi

(18 - 50 bar)

261 - 725 psi

(18 - 50 bar)

261 - 725 psi

(18 - 50 bar)

261 - 725 psi

(18 - 50 bar)

261 - 725 psi

(18 - 50 bar)

261 - 725 psi

(18 - 50 bar)

261 - 725 psi

(18 - 50 bar)

261 - 725 psi

(18 - 50 bar)

261 - 725 psi

(18 - 50 bar)

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

Operating

Pressure

Range

psi (bar) ViscositySeries

(10 - 45)

(10 - 45)

(Oil) 32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

(Grease) NLGI 000-00

(Oil) 32 to 2000 MM^2/S

.047 to 3.1 in. 2/S

(Grease) NLGI 000-00

6 313759A

Page 7

Metering Nipples

Part No. For Use on

Series

Nipple Index Dispense

Volume (cm3)

Corresponding

Casting plug Color

558311 3400 2 .03 Red

558312 3400 3 .06 Red

558313 3400 4 .10 Red

558314 3400 5 .16 Red

558324 3410 2 .03 White

558325 3410 3 .06 White

558326 3410 4 .10 White

558315 3500 4 .10 Red

558316 3500 5 .20 Red

558317 3500 6 .40 Red

558318 3500 7 .60 Red

558327 3510 4 .1 White

558328 3510 5 .2 White

558329 3510 6 .3 White

558319 3900 5 .2 Red

558320 3900 6 .4 Red

558321 3900 7 .6 Red

558322 3900 8 1.0 Red

558323 3900 9 1.5 Red

558330 3910 4 .1 White

558331 3910 5 .2 White

558332 3910 6 .3 White

122989

122990

1

Part No. 122989 is a kit consisting of a nipple and corresponding piston for oil. Must remove existing piston and

casting when replacing with 3400 Series, Index 1 nipple.

2

Part No. 122990 is a kit consisting of a nipple and corresponding piston for grease. Must remove existing piston

when replacing with 3410 Series, Index 1 nipple.

1

2

3400 1 .01 Red

3410 1 .01 White

313759A 7

Page 8

Pressure Relief Procedure

The equipment may be pressurized or may become

pressurized by an automatic lubrication cycle initiated by

a lubrication controller such as a timer.

1. Disconnect power to the timer.

2. Consult your pump manual for any additional pressure relief instructions related to your pump modulal.

Single Line Circuit (FIG. 1)

Single Point to Manifold Assembly

Instructions

1. Install gasket washer between piston distributor and

manifold.

2. Thread in manifold. Torque to 17 in.-lbs (2 N.m).

Direct to Bearing Option (FIG. 2)

Used in centralized, single line lubrication systems,

injecting lubricant from an intermittent pump system.

The piston distributor is mounted directly on the grease

point.

A

A

A

FIG. 1

A Doser

B Pressure Filter

C Lubrication Unit

AA

IG. 2

F

ADoser

B Pressure Filter

C Lubrication Unit

Assembly Options

B

C

Insert into the previously machined housing.

IG. 3

F

B

C

8 313759A

Page 9

Nipple Installation Instructions

BC

A

FIG. 4

A M8x1 connection for fitting + sleeve

B Copper Washer

C M10 x 1 or M12 x 1 straight fitting for dosers

1. (If adding nipple to casting with red or white plug, or

replacing an existing nipple) Relieve pressure,

page 7.

2. Carefully remove cap.

NOTE: Due to spring located under cap, cap will be

under pressure.

3. Thread nipple into fitting. Torque to 13 to 17. 7 in-lbs

(1.46 to 1.99 N.m).

NOTE: For a #1 nipple only, piston must also be

removed. Then install piston from #1 nipple followed by

nipple. Torque to specification in step 3.

313759A 9

Page 10

Technical Data

Technical Data

Oil

Lubricant Synthetic and mineral oils

Working pressure 145 to 652 psi (10 to 45 bar, 1.0 to 4.5 MPa)

Pressure relief < 21.7 psi(1.5 bar, 0.15 MPa)

Working temperature 32° to 158°F (0° to 70°C)

Gasket material FPM

Viscosity

1.25 to 78.3 inches

Grease

Lubricant Synthetic and mineral oils; fluid grease NLGI 00-000

Working pressure 145 to 652 psi (10 to 45 bar, 1.0 to 4.5 MPa)

Pressure relief < 21.7 psi (1.5 bar, 0.15 MPa)

Working temperature 32° to 158°F (0° to 70°C)

Gasket material FPM

2

/sec (32 to 2000 mm2 /sec)

Piston Distributor Mounted Directly to Greasing Point - Oil

Lubricant Synthetic and mineral oils

Working pressure 261 to 725 psi (18 to 50 bar, 1.8 to 5.0 MPa)

Pressure relief < 43.5 psi (3 bar, 0.3 MPa)

Working temperature 32° to 158°F (0° to 70°C)

Gasket material FPM

Viscosity

1.25 to 78.3 inches

2

/sec (32 to 2000 mm2 /sec)

10 313759A

Page 11

Single Point Manifold Dimensions

NOTE: All dimensions are provided in Metric (mm) only.

HH

Technical Data

IG. 5

F

Fitting and

M14 x 1’5 8

A

Pipe A Outlets

Sleeve

M10 x 1 6

M10 x 1

A

B

D

C

B

8 130 52

10 156 78

6 113 39

8 139 65

6

6 126 68 20 18 11 17 2.8 7.4 4’3 4 Aluminum

H

C D E F G H K L M N Material

17 13 10’5 13 2.8 7.4 4’3 4 Aluminum

20 18 11 13 2.8 7.4 4’3 4 Aluminum

B

M

G

N

F

L

F

E

K

G

E

K

D

J

C

FIG. 6

Part No.

15X624 M8 X 1 20 40 28 25.4 15 18 16 7.5 4

15X625 M10 X 1 20

15X626 M14 X 1.5 24.5

15X667 M10 / M8 18 2 524025.41518167.5 6

15X668 M10 / M8 18 3 685625.41518167.5 6

15X669 M10 / M8 18 4 847225.41518167.5 6

Fitting and

Sleeve

313759A 11

A

Outlets

B

CDEFGHJK

40 28 25.4 15 18 16 7.5 6

49 37 30 20 18 16 10 8

Page 12

Technical Data

15X670 M10 / M8 18 5 100 88 25.4 15 18 16 7.5 6

15X671 M10 / M8 18 6 116 104 25.4 15 18 16 7.5 6

15X672 M10 / M8 18 7 132 120 25.4 15 18 18 7.5 6

15X673 M10 / M8 18 8 148 136 25.4 15 18 18 7.5 6

15X674 M10 / M8 18 10 180 168 25.4 15 18 18 7.5 6

15X675 M10 / M10 18 2 544225.41518187.56

15X676 M10 / M10 18 3 726025.41518187.56

15X677 M10 / M10 18 4 907825.41518187.56

15X678 M10 / M10 18 5 108 96 25.4 15 18 18 7.5 6

15X679 M10 / M10 18 6 126 114 25.4 15 18 18 7.5 6

15X680 M10 / M10 18 7 144 132 25.4 15 18 18 7.5 6

15X681 M10 / M10 18 8 162 150 25.4 15 18 18 7.5 6

15X682 M10 / M10 18 10 198 186 25.4 15 18 18 7.5 6

15X683 M14 / M8 19 2 5440302021.51610 8

15X684 M14 / M8 19 3 7056302021.51610 8

15X685 M14 / M8 19 4 8672302021.51610 8

15X686 M14 / M8 19 5 102 88 30 20 21.5 16 10 8

15X687 M14 / M8 19 6 118 104 30 20 21.5 16 10 8

15X688 M14 / M8 19 7 134 120 30 20 21.5 16 10 8

15X689 M14 / M8 19 8 150 136 30 20 21.5 16 10 8

15X690 M14 / M8 19 10 182 168 30 20 21.5 16 10 8

15X691 M14 / M10 19 2 5642302021.51810 8

15X692 M14 / M10 19 3 7460302021.51810 8

15X693 M14 / M10 19 4 9278302021.51810 8

15X694 M14 / M10 19 5 110 96 30 20 21.5 18 10 8

15X695 M14 / M10 19 6 128 114 30 20 21.5 18 10 8

15X696 M14 / M10 19 7 146 132 30 20 21.5 18 10 8

15X697 M14 / M10 19 8 164 150 30 20 21.5 18 10 8

15X698 M14 / M10 19 10 200 186 30 20 21.5 18 10 8

15X699 M14 / M14 24.5 2 69 55 30 16 21.5 16 10 8

15X700 M14 / M14 24.5 3 89 75 30 16 21.5 16 10 8

15X701 M14 / M14 24.5 4 109 95 30 16 21.5 16 10 8

15X702 M14 / M14 24.5 5 129 115 30 16 21.5 16 10 8

15X703 M14 / M14

15X704 M14 / M14 24.5 7 169 155 30 16 21.5 16 10 8

15X705 M14 / M14 24.5 8 189 175 30 16 21.5 16 10 8

15X706 M14 / M14 24.5 10 229 215 30 16 21.5 16 10 8

24.5 6 149 135 30 16 21.5 16 10 8

12 313759A

Page 13

Dimensions

Technical Data

cc

2 Outlets 3 Outlets 5 Outlets

A

5

J

H

G

5

5

5

4

K

5

5

5

4

F

E

C

M

N

B

D

B

FIG. 7

Model 3500/3510 Mounting Hole Locations (see note with dd).

6

5

6

5

6 5

5

dd

3

5

5

5 5

5

4

3

2 1

5

aa

bb

D

B

5 6

7

5 5

5

F

4

dd

IG. 8

5

4 3

5

3

12

dd

aa Flow Index

bb Outlet Number

cc Pipe = Ø4

dd Mounting Hole Location: NOTE: 3400, 3410, 3900 and 3910 Models. For Model 3500 and 3510 mounting hole locations see

IG. 8,.

F

313759A 13

Page 14

Technical Data

Dimensions (All models)*

Ref. 3400 / 3410 3500 / 3510 3900 / 3910

Outlets

A

B

C

D

E

F

G

H

J

K

M

N

2 3 5 2 3 5 2 3

.67 in.

(17 mm)

1.9 in.

(48 mm)

.94 in.

(24 mm)

.27 in.

(7 mm)

.59 in.

(15 mm)

2.05 in.

(52 mm)

1.02 in.

(26 mm)

5 mm 5 mm 5 mm 6.5 mm 6.5 mm 6.5 mm 11 mm 11 mm

M10 x 1 M10 x 1 M10 x 1 M12 x 1 M12 x1 M12 x 1 M12 x 1 M12 x 1

.11 in.

(3 mm)

.35 in.

(9 mm)

.67 in.

(17 mm)

2.55 in

(65 mm)

.94 in.

(24 mm)

.67 in.

(17 mm)

.27 in.

(7 mm)

.59 in.

(15 mm)

2.05 in.

(52 mm)

1.02 in.

(26 mm)

.11 in.

(3 mm)

.35 in.

(9 mm)

.67 in.

(17 mm)

3.9 in.

(99 mm)

.94 in.

(24 mm)

2 in.

(51 mm)

.27 in.

(7 mm)

.59 in.

(15 mm)

2.05 in.

(52 mm)

1.02 in.

(26 mm)

.11 in.

(3 mm)

.35 in.

(9 mm)

.67 in.

(17 mm)

1.81 in.

(46 mm)

.90 in.

(23 mm)

.35 in.

(9 mm)

.67 in.

(17 mm)

3.09 in.

(78.5 mm)

2.52 in.

(64 mm)

.43 in.

(11 mm)

.59 in.

(15 mm)

.67 in.

(17 mm)

2.48 in.

(63 mm)

1.24 in.

(31.5 mm)

.35 in.

(9 mm)

.67 in.

(17 mm)

3.09 in.

(78.5 mm)

2.52 in.

(64 mm)

.43 in.

(11 mm)

.59 in.

(15 mm)

.67 in.

(17 mm)

3.8 in.

(97 mm)

1.9 in.

(48.5 mm)

.35 in.

(9 mm)

.67 in.

(17 mm)

3.09 in.

(78.5 mm)

2.52 in.

(64 mm)

.43 in.

(11 mm)

.59 in.

(15 mm)

.82 in.

(21 mm)

1.96 in.

(50 mm)

.98 in.

(25 mm)

.35 in.

(9 mm)

.67 in.

(17 mm)

3.1 in.

(76.5 mm)

2.32 in.

(59 mm)

.47 in.

(12 mm)

.63 in.

(16 mm)

.82 in.

(21 mm)

2.8 in.

(71 mm)

.98 in.

(25 mm)

.82 in.

(21 mm)

.35 in.

(9 mm)

.67 in.

(17 mm)

3.1 in.

(76.5 mm)

2.32 in.

(59 mm)

.47 in.

(12 mm)

.63 in.

(16 mm)

* Casting dimensions are the same for both oil and grease manifolds. However the nipple height is taller for grease.

14 313759A

Page 15

Single Point Oil

Technical Data

3400 3500 3900

A

D

B

D

B

C

C

C

D

B

FIG. 9

Single Point Grease (NLGI 00-000)

REF Description 3400 3500 3900

Outlet Pipe

A

B

C

D

Connection

Height

Connection

depth

Width

4 mm 4mm 4mm

1.7 in.

(43.5 mm).

.236 in.

(6 mm)

.472 in.

(12 mm)

2.7 in.

(67.5 mm)

.256 in.

(6.5 mm)

.630 in.

16 mm)

(66.5 mm)

2.6 in.

.315 in.

(8 mm)

.827 in.

(21 mm)

B

FIG. 10

3410

3510

A

3910

Models

Ref Description

3410 3510 3910

Outlet Pipe

A

4

6

D

B

C

D

C

C

6

B

Connection

Height

B

Connection

depth

C

Width

D

4 mm 4 mm 4 mm

1.81 in.

(46 mm)

.236 in.

(6 mm)

.472 in.

(12 mm)

2.402 in.

(61 mm)

.256 in.

(6.5 mm)

.590 in.

(15 mm)

3.032 in.

(77 mm)

.335 in.

(8.5 mm)

.827 in.

(21 mm)

313759A 15

Page 16

Technical Data

Piston Distributors

Type F

A

FIG. 11

Type GC

A

C

FIG. 12

C

B

3

B

D

G

F

E

D

E

H

G

3

J

K

L

H

F

A10

BFlow Index

C M14 x 1.5

D40.6

E32.5

F23.5

G Ø11.7

Housing

H17

J M14 x 1.5

K15

L35

A13.5

B10

CM3

D50

EFlow Index

Housing

F13.5

G 15° Angle

H1

16 313759A

Page 17

Notes

Notes

313759A 17

Page 18

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 313759A

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2009, Graco Inc. is registered to ISO 9001

www.graco.com

05/2009

Loading...

Loading...