Page 1

Operation

®

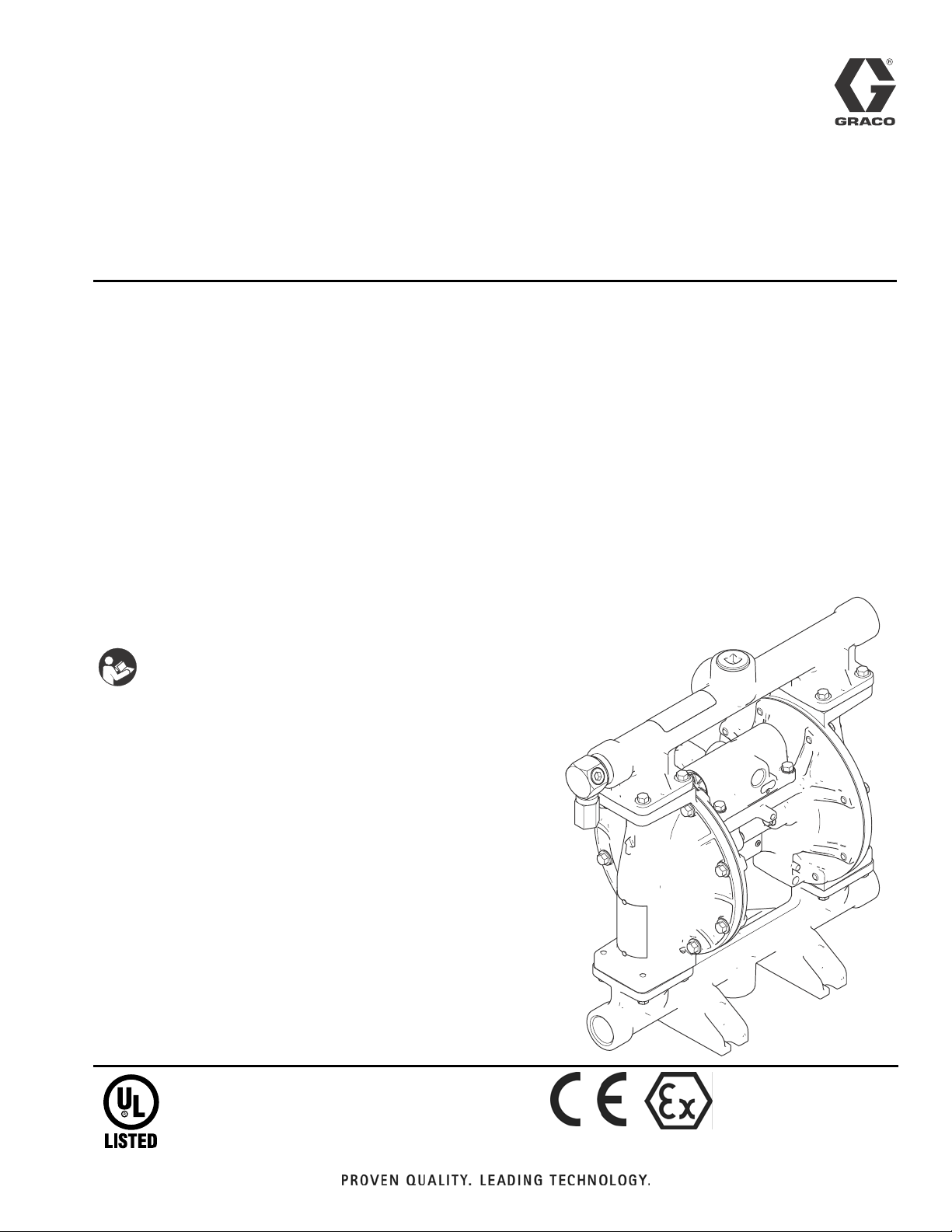

Husky

1050A UL-Listed

313597E

Diaphragm Pumps

Model 647016, Evacuation and Transfer Pump

For use in general fuel transfer applications.

100 psi (0.7 MPa, 7.0 bar) Maximum Fluid Working Pressure

100 psi (0.7 MPa, 7.0 bar) Maximum Air Input Pressure

Model 647648, Fuel Dispense Pump

For use in petroleum product dispense systems in accordance with the United States

Flammable and Combustible Liquids Code (NFPA 30) and the Automotive and Marine

Service Station Code (NFPA 30a). See page 4 for details.

50 psi (0.35 MPa, 3.5 bar) Maximum Fluid Working Pressure

50 psi (0.35 MPa, 3.5 bar) Maximum Air Input Pressure

EN

For professional use only.

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

Model 647648

ti14218a

714N

This symbol on the nameplate means the product is listed by Underwriters Laboratories Inc.

(UL Standard No. 79 for Power-Operated Pumps

for Petroleum Product Dispensing systems).

II 2 GD c IIC T4

Page 2

Related Manual

Contents

Related Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

To Order a New Pump: . . . . . . . . . . . . . . . . . . . . . . 3

To Order Parts for Your Existing Pump . . . . . . . . . 3

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

UL Listing Details . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

General Information . . . . . . . . . . . . . . . . . . . . . . 8

Tighten Fasteners Before Setup . . . . . . . . . . . . . 8

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Air Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Air Exhaust Ventilation . . . . . . . . . . . . . . . . . . . 10

Fluid Supply Line . . . . . . . . . . . . . . . . . . . . . . . 11

Fluid Outlet Line . . . . . . . . . . . . . . . . . . . . . . . . 12

Fluid Inlet and Outlet Ports . . . . . . . . . . . . . . . . 12

Fluid Pressure Relief Valve . . . . . . . . . . . . . . . . 14

Related Manual

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pressure Relief Procedure . . . . . . . . . . . . . . . . 15

Flush the Pump Before First Use . . . . . . . . . . . 15

Tighten Fasteners Before Setup . . . . . . . . . . . . 15

Starting and Adjusting the Pump . . . . . . . . . . . . 15

Pump Shutdown . . . . . . . . . . . . . . . . . . . . . . . . 16

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Maintenance Schedule . . . . . . . . . . . . . . . . . . . 17

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Tighten Threaded Connections . . . . . . . . . . . . . 17

Flushing and Storage . . . . . . . . . . . . . . . . . . . . 17

Torque Instructions . . . . . . . . . . . . . . . . . . . . . . 18

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Performance Chart . . . . . . . . . . . . . . . . . . . . . . . . . 20

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Graco Standard Husky Pump Warranty . . . . . . . . 22

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 22

Manual Description

313435 Husky 1050 Air-Operated

Diaphragm Pump, Repair/Parts

2 313597E

Page 3

To Order a New Pump:

To Order a New Pump:

NOTE: Do not configure and order a pump using only

this manual. Work with your Graco distributor or follow

the steps below.

1. Go to www.gracohusky.com.

2. Click on Toolbox in the gray banner near the top.

3. Click on the Husky 1050 Pump Selector, your

choice of either the download version or the online

version.

4. Click on Pump Selector in the blue banner. Use the

Selector Tool to configure your new pump.

To Order Parts for Your Existing Pump

1. Check the identification plate (ID) for the 20-digit

Configuration Number of your pump.

2. Use the Configuration Number Matrix on the next

page to understand which parts are described by

each digit.

3. Refer to Parts Manual 313435 for the necessary

part numbers.

313597E 3

Page 4

Models

Models

Maximum

Graco

Part

Graco Configuration

Number

Working Pressure

psi (MPa, bar)

647016 1050A-AU1AA1TPACTP-- 100 (0.7, 7.0)

647648 1050A-AU3AA1TPACTP-- 50 (0.35, 3.5)

Pump size

and material

1050A

1 inch ports,

50 gpm,

Aluminum

Aluminum

Center Section

and Air Valve

Configuration Fluid Covers

and Manifolds

UL-Listed

Fuel Transfer No Data

1

Fuel Dispense

3

(with pressure

relief valve)

Monitoring

Aluminum, npt TPE Acetal TPE None

A1

Seats

TP

Check

Balls

AC

Diaphragm

TP

Manifold

O-rings

--AU1 or 3A

UL Listing Details

Models 647016 and 647648 are certified per UL 79 for use in pumping gasoline and

gasoline/alcohol blends up to 10% ethanol, diesel fuel, fuel oil, and lubricating oil. This

certification does not cover oil burner pumps; pumps for engine-powered automotive equipment;

or pumps for use in mobile applications, chemical plants, utility plants, petroleum production

facilities, and pipeline pump stations, nor does it cover the complete end user installation.

4 313597E

Page 5

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers

to procedure-specific risk. When these symbols appear in the body of this manual, refer back to

these warnings. Additional, product-specific warnings may be found throughout the body of this

manual where applicable.

WARNING

FIRE AND EXPLOSION HAZARD

When flammable fluids are present in the work area, such as gasoline and windshield

wiper fluid, be aware that flammable fumes can ignite or explode. To help prevent fire

and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as cigarettes and portable electric lamps.

• Keep work area free of debris, including rags and spilled or open containers of solvent and gasoline.

• Route exhaust away from all sources of ignition. If diaphragm ruptures, fluid may be

exhausted with air. See Air Exhaust Ventilation, page 10.

• Do not plug or unplug power cords, or turn lights on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not

use equipment until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

313597E 5

Page 6

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest

rated system component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Tech-

nical Data in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about your material, request MSDS from distributor

or retailer.

• Do not leave the work area while equipment is energized or under pressure. Turn

off all equipment and follow the Pressure Relief Procedure in this manual when

equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with

genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and

hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the

eyes or on skin and cause serious injury.

•Follow Pressure Relief Procedure in this manual, when you stop spraying and

before cleaning, checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause

serious chemical reaction and equipment rupture. Failure to follow this warning can

result in death, serious injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated

hydrocarbon solvents or fluids containing such solvents.

• Many other fluids may contain chemicals that can react with aluminum. Contact

your material supplier for compatibility.

PLASTIC PARTS CLEANING SOLVENT HAZARD

Use only compatible water-based solvents to clean plastic structural or pressure-containing parts. Many solvents can degrade plastic parts and cause them to fail, which

could cause serious injury or property damage. See Technical Data in this and all

other equipment instruction manuals. Read fluid and solvent manufacturer’s warnings.

6 313597E

Page 7

Warnings

WARNING

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on

skin, inhaled, or swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Route exhaust away from work area. If diaphragm ruptures, fluid may be exhausted

with air.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To

avoid severe burns:

• Do not touch hot fluid or equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in

the operating area of the equipment to help protect you from serious injury, including

eye injury, inhalation of toxic fumes, burns, and hearing loss. This equipment includes

but is not limited to:

• Clothing and respirator as recommended by the fluid and solvent manufacturer

• Protective eyewear, gloves, and hearing protection

313597E 7

Page 8

Installation

Installation

General Information

• The Typical Installations shown in FIG. 3

through FIG. 5 are only guides for selecting

and installing system components. Contact

your Graco distributor for assistance in

planning a system to suit your needs.

• Installation and use must be in accordance

with the Flammable and Combustible Liquids Code (NFPA 30) and Automotive and

Marine Service Station Code (NFPA 30a)

and must comply with all local, state, and

federal codes.

• All pipe joints must be made tight with UL

listed gasoline-resistant pipe compound.

Tighten Fasteners Before Setup

Before using the pump for the first time, check

and retorque all external fasteners. Follow

Torque Instructions, page 18.

Mounting

2. For all mountings, be sure the pump is

bolted directly to the mounting surface.

3. For ease of operation and service, mount

the pump so the air valve, air inlet, fluid

inlet and fluid outlet ports are easily

accessible.

4. Rubber Foot Mounting Kit 236452 is available to reduce noise and vibration during

operation.

Grounding

This pump must be electrically grounded

using the grounding conductor provided.

Improper grounding can cause hazardous

operation.

The equipment must be grounded. Grounding

reduces the risk of static and electric shock by

providing an escape wire for the electrical current due to static build up or in the event of a

short circuit.

Pump: See F

• The pump exhaust air may contain contaminants. Ventilate to a remote area. See

Air Exhaust Ventilation on page 10.

• Never move or lift a pump under pressure.

If dropped, the fluid section may rupture.

Always follow the Pressure Relief Proce-

dure on page 15 before moving or lifting

the pump.

1. Be sure the mounting surface can support

the weight of the pump, hoses, and accessories, as well as the stress caused during

operation.

8 313597E

screw (GS). Insert one end of a 12 ga. minimum ground wire (R) behind the grounding

screw and tighten the screw securely. Connect

the clamp end of the ground wire to a true

earth ground. A ground wire and clamp,

Part 238909, is available from Graco.

IG. 1. Loosen the grounding

Page 9

Installation

Air Line

Install the air line accessories as shown in

FIG. 3 through FIG. 5. Mount these accessories

on the wall or on a bracket. Be sure the air line

supplying the accessories is grounded.

GS R

ti12214a

IG. 1. Ground screw and wire

F

Air and fluid hoses: Use only grounded

hoses with a maximum of 500 ft (150 m) com-

bined hose length to ensure grounding

continuity.

Air compressor: Follow manufacturer’s

recommendations.

Fluid supply container: Follow local code.

Solvent pails used when flushing: Follow

local code. Use only conductive metal pails,

placed on a grounded surface. Do not place

the pail on a nonconductive surface, such as

paper or cardboard, which interrupts grounding continuity.

1. Install an air regulator (C) and gauge to

control the fluid pressure. Locate it close to

the pump.

2. Locate a bleed-type master air valve (B)

close to the pump and use it to relieve

trapped air. Be sure the valve is easily

accessible from the pump and located

downstream from the regulator.

Trapped air can cause the pump to cycle

unexpectedly, which could result in serious

injury from splashing.

3. Locate another master air valve (E)

upstream from all air line accessories and

use it to isolate them during cleaning and

repair.

4. An air line filter (F) removes harmful dirt

and moisture from the compressed air

supply.

Suction device nozzle: Bond to metal container from which it is suctioning by firm

metal-to-metal contact to a properly grounded

supply hose and pump.

5. Install a grounded, flexible air hose (A)

between the accessories and the 1/2 npt(f)

pump air inlet (D). Use a minimum 3/8 in.

(10 mm) ID air hose.

Piping, valves, and fittings: Use only electrically conductive materials. Bond and ground

per code.

Check your system electrical continuity after

the initial installation, and then set up a regular

schedule for checking continuity to be sure

proper grounding is maintained.

313597E 9

Page 10

Installation

Air Exhaust Ventilation

Be sure to read and follow the TOXIC FLUID

OR FUMES HAZARD warnings, page 7, and

FIRE AND EXPLOSION HAZARD warnings,

page 5, before operating this pump. You must

vent the exhaust away from people, animals,

food handling areas, and all sources of ignition when pumping flammable or hazardous

fluids. Vent in accordance with local codes, or

in the absence of local codes, an industry or

nationally recognized code having jurisdiction

over the specific installation.

The air exhaust port is 3/4 npt(f). Do not

restrict the air exhaust port. Excessive exhaust

restriction can cause erratic pump operation.

1. Remove the muffler (T) from the pump air

exhaust port.

2. Install a grounded air exhaust hose (U) and

connect the muffler (T) to the other end of

the hose. The minimum size for the air

exhaust hose is 3/4 in. (19 mm) ID. If a

hose longer than 15 ft (4.57 m) is required,

use a larger diameter hose. Avoid sharp

bends or kinks in the hose.

3. Place a container at the end of the air

exhaust line to catch fluid in case a diaphragm ruptures. Locate the container

away from all sources of ignition, including

pilot lights and waste materials. If the diaphragm ruptures, the fluid being pumped

will exhaust with the air.

C

E

B

FIG. 2. Vent exhaust air

D

A

U

Key:

A Air supply line

B Bleed-type master air valve

(required for pump)

C Air filter/regulator assembly

D Air inlet

E Master air valve (for accessories)

TMuffler

U Grounded air exhaust hose

V Container for remote air exhaust

V

T

ti14219b

10 313597E

Page 11

E

C

G

W

B

A

D

H

R

J

K

Key:

A Air supply line

B Bleed-type master air valve

(required for pump)

C Air filter/regulator assembly

D Air inlet

E Master air valve (for accessories)

G Grounded, flexible fluid supply line

H Fluid drain valve (required)

J Fluid shutoff valve

K Grounded, flexible fluid outlet line

R Ground wire (required, see page 8

for installation instructions)

W Waste oil receiver

Installation

ti14221b

FIG. 3. Waste oil or general fluid transfer, typical installation

Fluid Supply Line

always install the pump as close as possible to the material source.

See FIG. 3 through FIG. 5, pages 11 through

13.

4. For a Waste Oil Receiver Evacuation System, connect an appropriate suction hose

1. Use grounded, flexible fluid supply lines

(G). See Grounding, page 8.

2. If the inlet fluid pressure to the pump is

more than 25% of the outlet working pressure, the ball check valves will not close

fast enough, resulting in inefficient pump

operation. Excessive inlet fluid pressure

(G) between the pump fluid inlet and the

waste oil receiver. See F

5. For a Gear Oil Evacuation System, install a

control valve (M), flexible hose (L), and an

appropriate wand (N) in each service bay

and connect to the fluid suction line (G).

See FIG. 4, page 12.

also will shorten diaphragm life. Approximately 3 - 5 psi (0.02- 0.03 MPa, 0.21-0.34

bar) should be adequate for most materials.

6. For a Fuel Dispense System, connect a

fluid supply line (G) to the fluid inlet. See

FIG. 5, page 13.

IG. 3.

3. For maximum suction lift (wet and dry), see

Technical Data, page 21. For best results,

313597E 11

Page 12

Installation

M

L

N

E

B

A

Key:

A Air supply line

B Bleed-type master air

valve (required for pump)

C Air filter/regulator

assembly

D Air inlet

E Master air valve (for

accessories)

G Fluid suction line, flexible

hose

H Fluid drain valve

(required)

J Fluid shutoff valve

K Waste oil line (to storage

tank)

L Fluid line, flexible hose

M Control valve

N Suction wand

R Ground wire (required, see

page 8 for installation in-

structions)

C

K

H

J

D

FIG. 4. Gear oil evacuation, typical installation

Fluid Outlet Line

See FIG. 3 through FIG. 5, pages 11 through

13.

1. Use grounded fluid hoses (G, K). See

Grounding, page 8.

2. The pump fluid outlet is 1 in. npt(f). Screw

the fluid fitting into the pump outlet

securely.

3. A fluid drain valve (H) is required in your

system to relieve pressure in the hose and

dispense valve. Install the valve close to

the pump fluid outlet.

G

R

ti14222b

4. Install a shutoff valve (J) in the fluid outlet

line.

Fluid Inlet and Outlet Ports

NOTE: Remove and reverse the manifold(s) to

change the orientation of inlet or outlet port(s).

Follow Torque Instructions, page 18.

The fluid inlet and outlet manifolds each have

four 1 in. npt(f) threaded ports. Close off the

unused ports, using the supplied plugs.

12 313597E

Page 13

Installation

P

X

Pipe to

supply

tank

Key:

A Air supply line

B Bleed-type master air valve

(required for pump)

C Air filter/regulator assembly

D Air inlet

E Master air valve (for accessories)

G Grounded, flexible fluid supply line

H Fluid drain valve (required)

J Fluid shutoff valve

E

C

B

A

K

J

D

S

H

K Grounded, flexible fluid outlet line

P Hose reel

R Ground wire (required, see page 8

for installation instructions)

S Pressure relief valve (required to

limit fluid outlet pressure to 50 psi

[350 kPa, 3.5 bar])

X Fuel dispense valve

1

G

Fluid from the relief valve must be

1

piped back to the supply tank.

R

ti14220b

FIG. 5. Fuel dispense, typical installation

313597E 13

Page 14

Installation

Fluid Pressure Relief Valve

Fuel Dispense Systems (Model 647648)

Fuel dispense model 647648 requires a pressure relief valve (S), Graco part 24B910,

which is supplied with the pump, to prevent

fluid pressure from exceeding 50 psi (350 kPa,

3.5 bar). See FIG. 5, page 13.

Recommended air operating pressure is 40

psi (280 kPa, 2.8 bar) or less. As the air inlet

pressure approaches 50 psi (350 kPa,

3.5 bar), the relief valve will open and vent

fluid. Vented fluid must be routed to a container in a non-hazardous location.

Evacuation and Transfer Systems (Model 647016)

Some evacuation and transfer systems may

require installation of a pressure relief valve at

the pump outlet to prevent overpressurization

and rupture of the pump or hose. Graco Kit

238428 is available. See FIG. 6. Relief pressure is between 150 and 180 psi (1.03

Thermal expansion of fluid in the outlet line

can cause overpressurization. Thermal

expansion can occur when using long fluid

lines exposed to sunlight or ambient heat, or

when pumping from a cool to a warm area (for

example, from an underground tank).

MPa-1.24 MPa, 10.3-12.4 bar).

Overpressurization also can occur if the

This kit is not for use in fuel dispense applications, which require pressure relief at 50 psi

(350 kPa, 3.5 bar). Order a fuel dispense pump

(Model 647648), which is equipped with pres-

Husky pump is used to feed fluid to a piston

pump, and the intake valve of the piston pump

does not close, causing fluid to back up in the

outlet line.

sure relief valve 24B910. See Warning above.

1

Apply thread sealant on threaded con-

Pressure

Relief Kit

ti14214b

nections and install kit between fluid

inlet and outlet manifolds.

2

Connect fluid inlet line in one of the

optional ports.

3

Connect fluid outlet line in one of the

optional ports.

FIG. 6. Optional Fluid Pressure Relief Kit 238428, for Model 647016

(not acceptable for fuel dispense application)

14 313597E

Page 15

Operation

Operation

Pressure Relief Procedure

Trapped air can cause the pump to cycle

unexpectedly, which could result in serious

injury from splashing.

1. Shut off the air supply to the pump.

2. Open the dispensing valve (if used).

3. Open the fluid drain valve to relieve fluid

pressure, having a waste container ready

to catch the drainage.

Flush the Pump Before First Use

The pump was tested in water. If water could

contaminate the fluid you are pumping, flush

the pump thoroughly with a compatible solvent.

See Flushing and Storage, page 17.

Waste Oil Receiver Evacuation Systems or

General Fluid Transfer Applications

See F

1. Close the pump air regulator (C) and the

2. Connect the pump suction hose (G) to the

3. Place the end of the fluid hose into an

4. Close the fluid drain valve (H). Open the

5. Connect the air supply line to the pump air

6. Open the bleed-type master air valves

IG. 3.

bleed-type master air valves (B, E).

pump fluid inlet. Attach a fluid quick coupler

to the other end of the hose, then connect

the coupler to the outlet fitting of the waste

oil receiver.

appropriate container.

fluid shutoff valve (J).

inlet (D).

(B, E).

Tighten Fasteners Before Setup

Before using the pump for the first time, check

and retorque all external fasteners. Follow

Torque Instructions, page 18. After the first

day of operation, retorque the fasteners.

Starting and Adjusting the Pump

1. Be sure the pump is properly grounded.

Refer to Grounding on page 8.

2. Check fittings to be sure they are tight. Use

a compatible liquid thread sealant on male

threads. Tighten the fluid inlet and outlet fittings securely.

NOTE: If fluid inlet pressure to the pump is

more than 25% of outlet working pressure, the

ball check valves will not close fast enough,

resulting in inefficient pump operation.

7. Slowly increase air pressure with the air

regulator (C) until the pump starts to cycle.

Allow the pump to cycle slowly until all air is

pushed out of the lines and the pump is

primed.

NOTE: Use lowest possible air pressure to

prime, just enough to cycle the pump. If the

pump does not prime as expected, turn air

pressure DOWN.

NOTICE

When replacing Husky 1040s: The Husky

1050 operates more efficiently than did the

1040. Reduce air inlet pressure by approximately 20 percent to maintain an equivalent

fluid output.

313597E 15

Page 16

Operation

Gear Oil Evacuation Systems

See FIG. 4.

1. Close the pump air regulator (C) and the

bleed-type master air valves (B, E).

2. Attach an appropriate wand to the suction

hose. Place the wand in the differential or

fluid to be pumped.

3. Place the end of the fluid hose into an

appropriate container.

4. Close the fluid drain valve (H). Open the

fluid shutoff valve (J).

5. Connect the air supply line to the pump air

inlet (D).

6. Open the bleed-type master air valves

(B, E).

7. Set the air regulator (C) to about 50 psi

(350 kPa, 3.5 bar).

8. Pull the control valve handle (M) down to

start the pump.

NOTE: Adjust the air regulator (C). Allow the

pump to cycle slowly until all air is pushed out

of the lines and the pump is primed. Use lowest possible air pressure to prime, just enough

to cycle the pump. If the pump does not prime

as expected, turn air pressure DOWN.

NOTE: Be sure the control valve handle is

closed when evacuation is completed. Failure

to close it may prevent other service bays from

developing full suction.

Fuel Dispense Systems

See FIG. 5.

1. Close the pump air regulator (C) and the

bleed-type master air valves (B, E).

2. Close the fluid drain valve (H). Open the

fluid shutoff valve (J).

3. Hold the dispense valve (X) firmly to a

grounded metal container, and open the

valve.

4. Connect the air supply line to the pump air

inlet (D).

5. Open the bleed-type master air valves

(B, E).

6. Slowly open the air regulator (C) until the

pump starts to cycle. Allow the pump to

cycle slowly until all air is pushed out of the

lines and pump is primed.

7. Adjust the air regulator. Always use the

lowest air pressure necessary to get the

desired results.

Pump Shutdown

NOTICE

When replacing Husky 1040s: The Husky

1050 operates more efficiently than did the

1040. Reduce air inlet pressure by approximately 20 percent to maintain an equivalent

fluid output.

At the end of the work shift and before you

check, adjust, clean or repair the system, follow Pressure Relief Procedure, page 15.

9. Push the control valve handle (M) up when

finished. Place the wand in the holder on

the control valve.

16 313597E

Page 17

Maintenance

Maintenance

Maintenance Schedule

Establish a preventive maintenance schedule,

based on the pump’s service history. Scheduled maintenance is especially important to

prevent spills or leakage due to diaphragm

failure.

Lubrication

The pump is lubricated at the factory. It is

designed to require no further lubrication for

the life of the pump. There is no need to add

an in-line lubricator under normal operating

conditions.

Tighten Threaded Connections

Before each use, check all hoses for wear or

damage and replace as necessary. Check to

be sure all threaded connections are tight and

leak-free. Check fasteners. Tighten or retorque

as necessary. Although pump use varies, a

general guideline is to retorque fasteners every

two months. See Torque Instructions,

page 18.

Flushing and Storage

• Flush before fluid can dry in the equipment,

at the end of the day, before storing, and

before repairing equipment.

• Flush at the lowest pressure possible.

Check connectors for leaks and tighten as

necessary.

• Flush with a fluid that is compatible with the

fluid being dispensed and the equipment

wetted parts.

Flush the pump often enough to prevent the

fluid you are pumping from drying or freezing

in the pump and damaging it. Use a compatible solvent.

Always flush the pump and relieve the pressure before storing it for any length of time.

313597E 17

Page 18

Maintenance

Torque Instructions

NOTE: Fluid cover and manifold fasteners

have a thread-locking adhesive patch applied

to the threads. If this patch is excessively worn,

the fasteners may loosen during operation.

Replace screws with new ones or apply

medium-strength (blue) Loctite or equivalent to

the threads.

If fluid cover or manifold fasteners have been

loosened, it is important to torque them using

the following procedure to improve sealing.

NOTE: Always completely torque fluid covers

before torquing manifolds.

Start all fluid cover screws a few turns. Then

turn down each screw just until head contacts

cover. Then turn each screw by 1/2 turn or less

working in a crisscross pattern until each

screw is torqued to 100 in-lb (11.3 N•m).

Repeat for manifolds. See FIG. 7.

Retorque the air valve fasteners (V) in a

crisscross pattern, to 80 in-lb (9.0 N•m).

ti18537a

9

ti18538a

FIG. 7. Torque sequence

18 313597E

Page 19

Dimensions

Dimensions

G

1

3

A

%

&

D

F

/

E

0

ti12212b ti12211b

A ..... 12.7 in. (323 mm)

B ..... 14.4 in. (366 mm)

C ..... 15.9 in. (404 mm)

D ..... 10.9 in. (277 mm)

E .....1.8 in. (46 mm)

F...... 7.3 in. (185 mm)

G..... 14.7 in. (373 mm)

H ..... 6.2 in. (158 mm)

J...... 3.9 in. (99 mm)

H

J

ti12213b

K

5.5 in.

(140 mm)

5.0 in.

(127 mm)

ti14540a

K .....10.2 in. (258 mm)

L......1/2 npt(f) air inlet

M .....1 in. npt(f) fluid inlet ports (4)

N .....1 in. npt(f) fluid outlet ports (4)

P......3/4 npt(f) air exhaust port

313597E 19

Page 20

Performance Chart

)

Performance Chart

Test Conditions: Pump tested in water with inlet submerged.

56 84 112 140 168 196 224 252 28028

120

(0.83. 8.3)

Cycle Rate

Operating Air Pressure

A

100 psi (0.7 MPa, 7.0 bar)

B

70 psi (0.48 MPa, 4.8 bar)

C

40 psi (0.28 MPa, 2.8 bar)

How to Read the Charts

1. Locate fluid flow rate along

bottom of chart.

2. Follow vertical line up to

intersection with selected

operating air pressure

curve.

3. Follow left to scale to read

fluid outlet pressure

(top chart) or

air consumption

(bottom chart).

100

(0.7, 7.0)

(0.55, 5.5)

(0.41, 4.1)

(0.28, 2.8)

(0.14, 1.4)

Fluid Outlet Pressure — psi (MPa, bar)

(2.24)

(1.68)

(1.12)

80

60

40

20

80

60

40

A

Fluid Pressure

B

C

0

0

510

(19) (38)

56 84 112 140 168 196 224 252 28028

15

(57)

20 25

(76) (95)

Fluid Flow — gpm (lpm)

Cycle Rate

30 35

(114) (133)

40 45

(152)

(170)

50

(189)

Air Consumption

A

B

20

(0.56)

0

Air Consumption — scfm (cubic meters/min)

20 313597E

0 5 10 15 20 25 30 35 40 45 50

(19) (38)

(57) (76) (95)

Fluid Flow — gpm (lpm)

(114) (133) (152)

C

(170) (189

Page 21

Technical Data

Technical Data

Maximum fluid working pressure

Transfer Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Dispense Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air pressure operating range

Transfer Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Dispense Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air consumption at 70 psi (0.48 MPa, 4.8 bar), 20 gpm (76 lpm). . . . . . . .

Air consumption at 50 psi (0.35 MPa, 3.5 bar), full flow. . . . . . . . . . . . . . .

Fluid displacement per cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.17 gal. (0.64 liters)

Maximum values with water as media under submerged inlet conditions at

ambient temperature:

Maximum air consumption. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum free-flow delivery

Transfer Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Dispense Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum pump speed

Transfer Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Dispense Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum suction lift (varies widely based on ball/seat selection and

wear, operating speed, material properties, and other variables) .

Maximum size pumpable solids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/8 in. (3.2 mm)

Recommended cycle rate for continuous use . . . . . . . . . . . . . . . . . . . . . . . 93 - 140 cpm

Recommended cycle rate for circulation systems . . . . . . . . . . . . . . . . . . . . 20 cpm

Sound Power*

at 70 psi (0.48 MPa, 4.8 bar) and 50 cpm . . . . . . . . . . . . . . . . . . . . . . .

at 100 psi (0.7 MPa, 7.0 bar) and full flow . . . . . . . . . . . . . . . . . . . . . . .

Sound Pressure**

at 70 psi (0.48 MPa, 4.8 bar) and 50 cpm . . . . . . . . . . . . . . . . . . . . . . .

at 100 psi (0.7 MPa, 7.0 bar) and full flow . . . . . . . . . . . . . . . . . . . . . . .

Operating temperature range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10°F-150°F (-12°C-65°C)

Air inlet size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/2 npt(f)

Fluid inlet size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 in. npt(f)

Fluid outlet size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 in. npt(f)

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 lb. (10.5 kg)

Wetted parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . aluminum, TPC-ET, Acetal, PTFE

Non-wetted external parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . aluminum, coated carbon steel

100 psi (0.7 MPa, 7.0 bar)

50 psi (0.35 MPa, 3.5 bar)

20-100 psi (0.14-0.7 MPa, 1.4-7.0 bar)

20-50 psi (0.14-0.35 MPa, 1.4-3.5 bar)

25 scfm

25 scfm

64 scfm

50 gpm (189 lpm)

38 gpm (144 lpm)

275 cpm

210 cpm

16 ft (4.9 m) dry, 29 ft (8.8 m) wet

78 dBa

90 dBa

84 dBa

96 dBa

* Sound power measured per ISO-9614-2.

** Sound pressure was tested 3.28 ft (1 m) from equipment.

All trademarks mentioned in this manual are the property of their respective owners.

313597E 21

Page 22

Graco Standard Husky Pump Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of five years from the date of sale, repair or replace any part of the equipment determined by Graco to

be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within six (6) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2010, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 313597

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised 01/2012

Loading...

Loading...