Page 1

Operation

H-VR

Hydraulic Variable Ratio, Heated, Plural Component Proportioner. For spraying

polyurethane foam and polyurea coatings. For professional use only.

Not for use in explosive atmospheres.

U.S. Patent Pending

Russian Patent No. 2359181

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

313539F

ENG

See page 2 for model information, including maximum working pressure.

r_256886_313359_1A

#ONFORMSTO!.3)5,

3TD#ERTIFIEDTO

#!.#3!3TD

#.O

Page 2

Models

Contents

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Supplied Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Isocyanate Conditions . . . . . . . . . . . . . . . . . . . . . . 6

Material Self-ignition . . . . . . . . . . . . . . . . . . . . . . . . 6

Keep Components A and B Separate . . . . . . . . . . 6

Moisture Sensitivity of Isocyanates . . . . . . . . . . . . 6

Foam Resins with 245 fa Blowing Agents . . . . . . . 6

Changing Materials . . . . . . . . . . . . . . . . . . . . . . . . . 7

Typical Installation, with circulation . . . . . . . . . . . 8

Typical Installation, without circulation . . . . . . . . 9

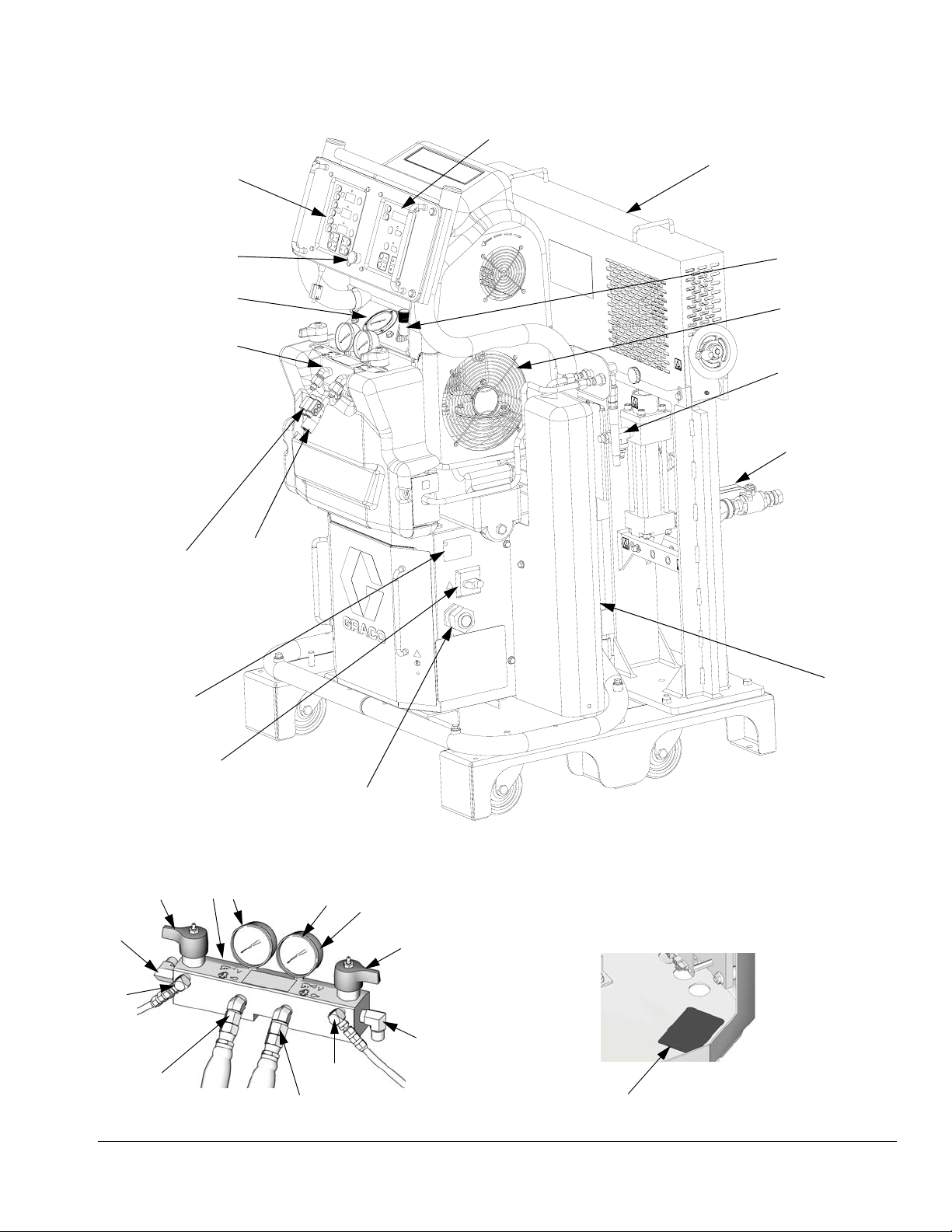

Component Identification . . . . . . . . . . . . . . . . . . . 10

Reactor H-VR . . . . . . . . . . . . . . . . . . . . . . . . . . 10

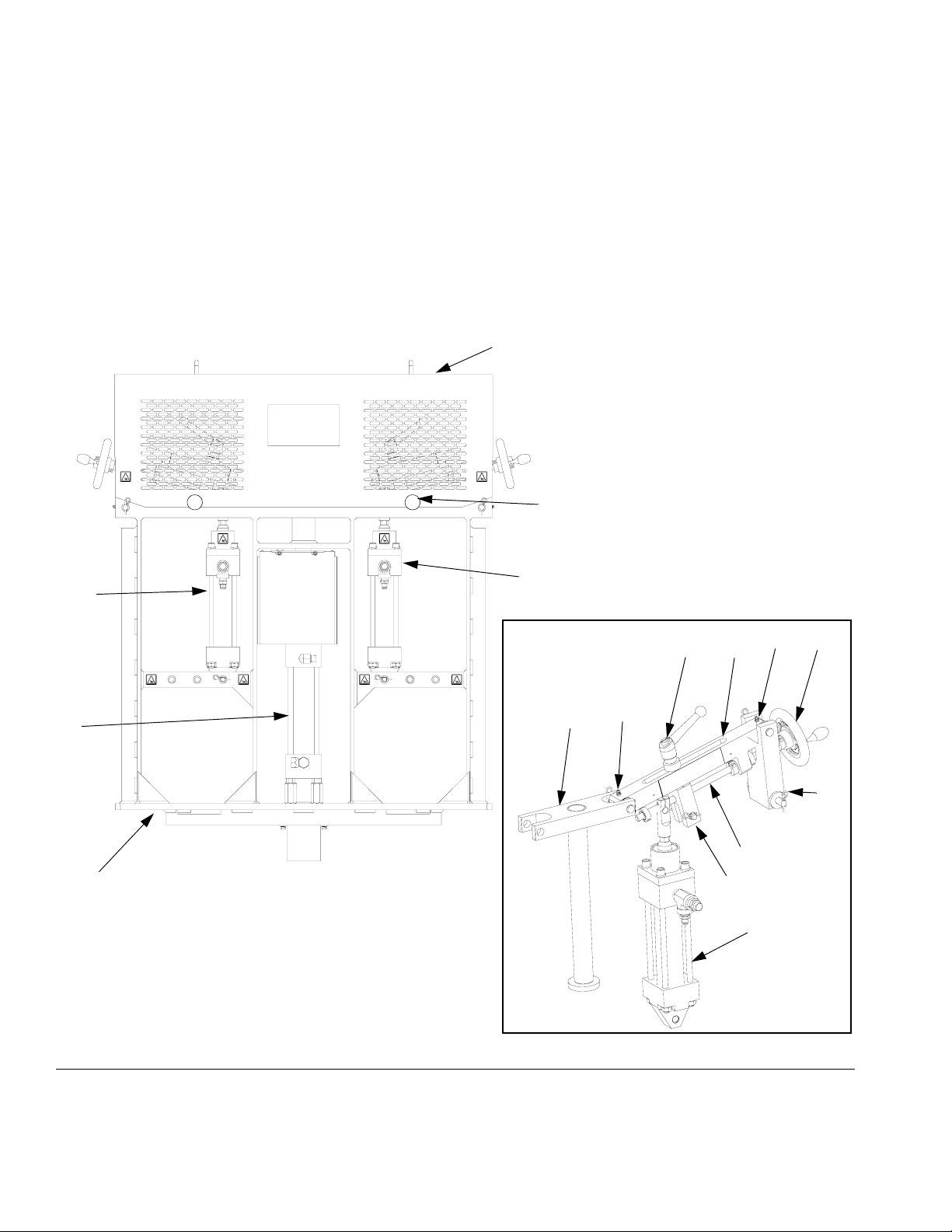

Pump Assembly . . . . . . . . . . . . . . . . . . . . . . . . 12

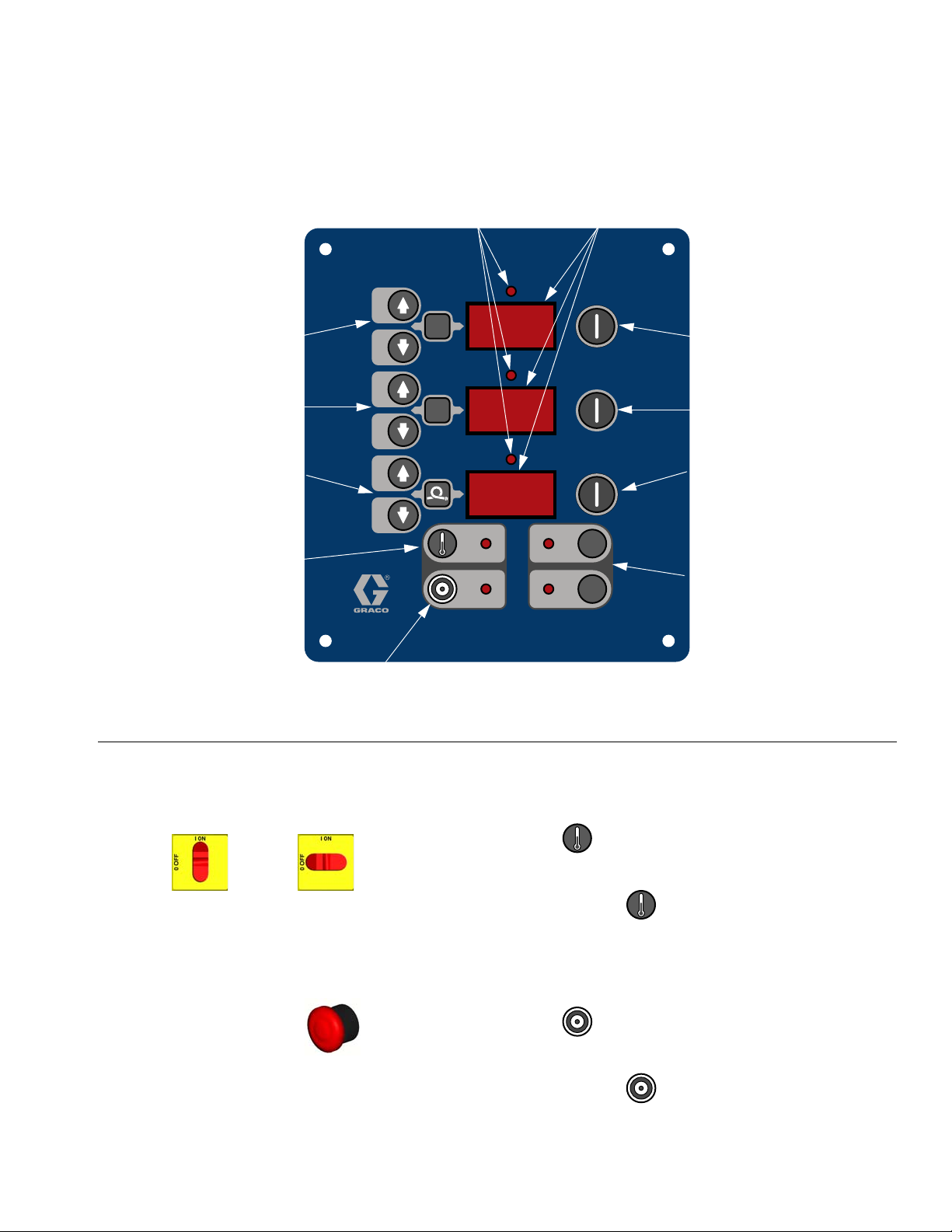

Temperature Controls and Indicators . . . . . . . . . 13

Main Power Switch . . . . . . . . . . . . . . . . . . . . . . 13

Red Stop Button . . . . . . . . . . . . . . . . . . . . . . . . 13

Actual Temperature Key/LED . . . . . . . . . . . . . . 13

Target Temperature Key/LED . . . . . . . . . . . . . . 13

Temperature Scale Keys/LEDs . . . . . . . . . . . . . 14

Heater Zone On/Off Keys/LEDs . . . . . . . . . . . . 14

Temperature Arrow Keys . . . . . . . . . . . . . . . . . . 14

Temperature Displays . . . . . . . . . . . . . . . . . . . . 14

Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . 14

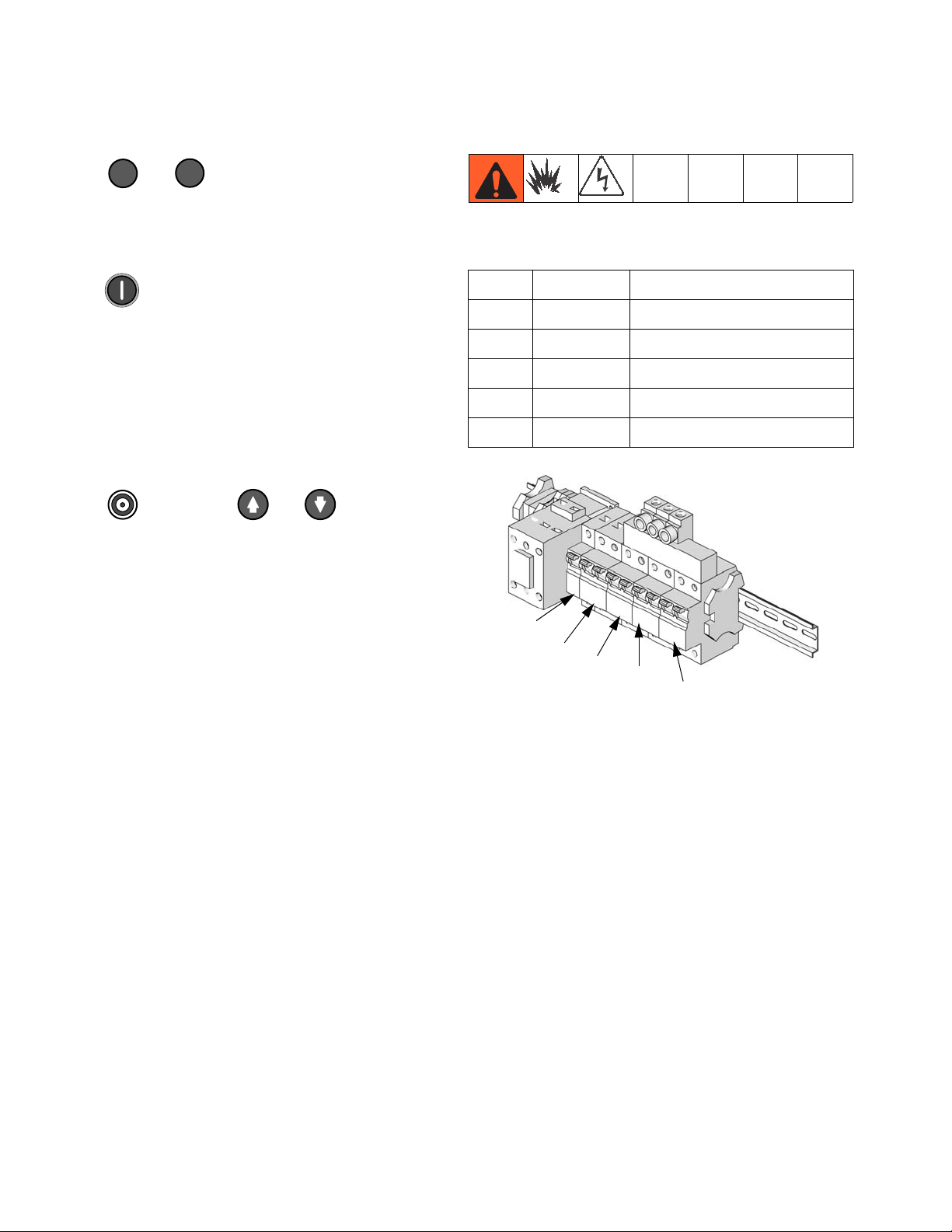

Motor Controls and Indicators . . . . . . . . . . . . . . . 15

Motor ON/OFF Key/LED . . . . . . . . . . . . . . . . . . 15

PARK Key/LED . . . . . . . . . . . . . . . . . . . . . . . . . 15

PSI/BAR Keys/LEDs . . . . . . . . . . . . . . . . . . . . . 15

Pressure Key/LED . . . . . . . . . . . . . . . . . . . . . . . 15

Cycle Count Key/LED . . . . . . . . . . . . . . . . . . . . 16

Hydraulic Pressure Control Knob . . . . . . . . . . . 16

Motor Control Arrow Keys . . . . . . . . . . . . . . . . . 16

Spray Adjustments . . . . . . . . . . . . . . . . . . . . . . . . 16

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Spraying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Standby . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 31

Fluid Circulation . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Circulation Through Reactor . . . . . . . . . . . . . . . 32

Circulation Through Gun Manifold . . . . . . . . . . . 33

Diagnostic Codes . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Temperature Control Diagnostic Codes . . . . . . . 34

Motor Control Diagnostic Codes . . . . . . . . . . . . 35

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Fluid Inlet Strainer Screen . . . . . . . . . . . . . . . . . . 37

Flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Performance Charts . . . . . . . . . . . . . . . . . . . . . . . . 41

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 44

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 44

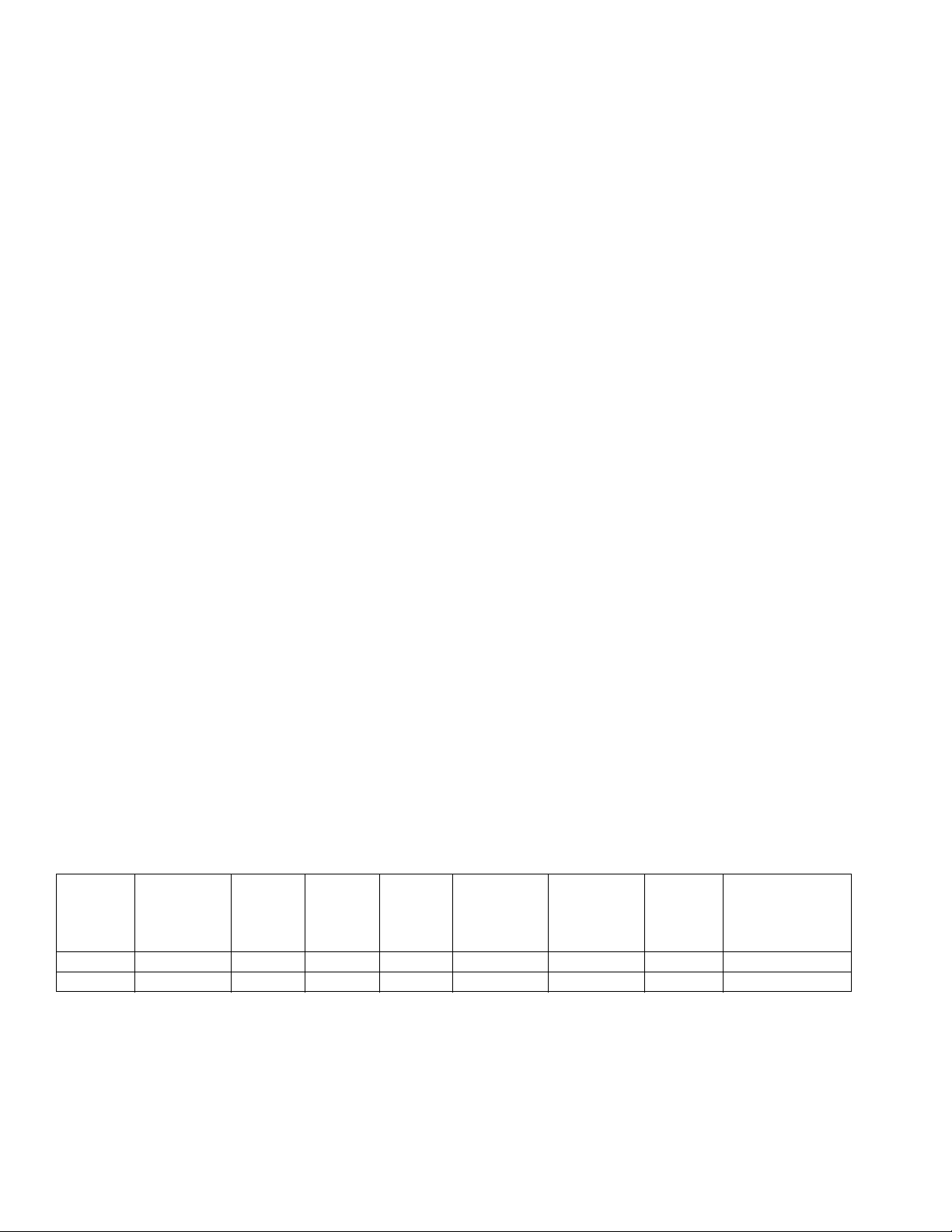

Models

Max Flow

Full Load

Part,

Series

256886 71 230V (3) 26,600 15,300 30 (13.6) Variable Variable 3500 (24.1, 241)

256887 41 400V (3) 26,600 15,300 30 (13.6) Variable Variable 3500 (24.1, 241)

* Full load amps with all devices operating at maximum capabilities. Fuse requirements at various flow rates and mix chamber

sizes may be less.

◆ Maximum flow rate given for 60 Hz operation. For 50 Hz operation, maximum flow rate is 5/6 of 60 Hz maximum flow.

2 313539F

Peak Amps*

Per Phase

Voltag e

(phase)

System

Watts†

Primary

Heater

Watts

Rate◆

lb/min

(kg/min)

Approximate

Output per

Cycle (A+B)

gal. (liter)

Hydraulic

Pressure

Ratio

Maximum Fluid

Working Pressure

psi (MPa, bar)

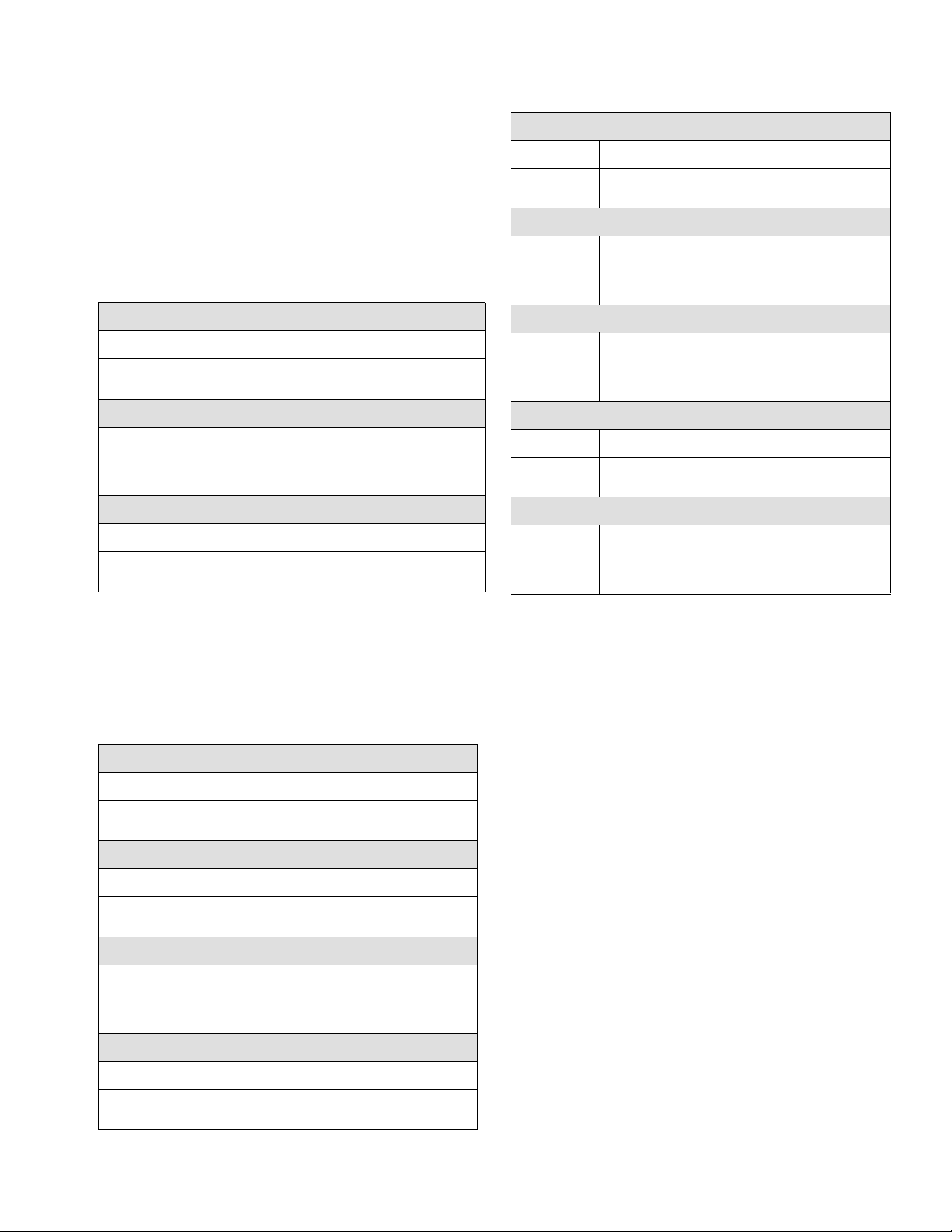

Page 3

Supplied Manuals

Supplied Manuals

The following manuals are shipped with the Reactor™

H-VR Proportioner. Refer to these manuals for detailed

equipment information.

Order Part 15M334 for a compact disk of Reactor manuals translated in several languages.

Reactor Hydraulic Proportioner

Part Description

313540 Reactor H-VR Proportioner,

Repair-Parts Manual (English)

Reactor Electrical Diagrams

Part Description

312064 Reactor Hydraulic Proportioner, Electri-

cal Diagrams (English)

Fluid Pump

Part Description

313485 H-VR Pump Instructions-Parts Manual

(English)

Circulation Kit

Part Description

309818 Instruction-Parts Manual

(English)

Circulation Valve Kit

Part Description

312070 Instruction-Parts Manual

(English)

Data Reporting Kit

Part Description

309867 Instruction-Parts Manual

(English)

Rupture Disk Assembly Kit

Part Description

309969 Instruction-Parts Manual

(English)

Proportioning Pump Repair Kits

Part Description

312071 Seal Kits Instruction-Parts Manual

(English)

Related Manuals

The following manuals are for accessories used with the

Reactor™.

Feed Pump Kits

Part Description

309815 Instruction-Parts Manual

(English)

Air Supply Kit

Part Description

309827 Instruction-Parts Manual

(English) for Feed Pump Air Supply Kit

Circulation and Return Tube Kits

Part Description

309852 Instruction-Parts Manual

(English)

Heated Hose

Part Description

309572 Instruction-Parts Manual

(English)

313539F 3

Page 4

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power cord before servicing equipment.

• Use only grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on power and extension cords.

• Do not expose to rain. Store indoors.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear impervious gloves when spraying or cleaning equipment.

• If this equipment is used with isocyanate material, see additional information on isocyanites in Isocyanate Conditions Section of this manual.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

4 313539F

Page 5

Warnings

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

PRESSURIZED ALUMINUM PARTS HAZARD

Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids

containing such solvents in pressurized aluminum equipment. Such use can cause serious chemical

reaction and equipment rupture, and result in death, serious injury, and property damage.

OR

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Do not leave the work area while equipment is energized or under pressure. Turn off all equipment

and follow the Pressure Relief Procedure in this manual when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe

burns:

• Do not touch hot fluid or equipment.

• Wait until equipment/fluid has cooled completely.

313539F 5

Page 6

Isocyanate Conditions

Isocyanate Conditions

Moisture Sensitivity of

Spraying materials containing isocyanates creates

potentially harmful mists, vapors, and atomized particulates.

Read material manufacturer’s warnings and material

MSDS to know specific hazards and precautions

related to isocyanates.

Prevent inhalation of isocyanate mists, vapors, and

atomized particulates by providing sufficient ventilation in the work area. If sufficient ventilation is not

available, a supplied-air respirator is required for

everyone in the work area.

To prevent contact with isocyanates, appropriate personal protective equipment, including chemically

impermeable gloves, boots, aprons, and goggles, is

also required for everyone in the work area.

Material Self-ignition

Isocyanates

Isocyanates (ISO) are catalysts used in two component

foam and polyurea coatings. ISO will react with moisture

(such as humidity) to form small, hard, abrasive crystals,

which become suspended in the fluid. Eventually a film

will form on the surface and the ISO will begin to gel,

increasing in viscosity. If used, this partially cured ISO

will reduce performance and the life of all wetted parts.

NOTE:

The amount of film formation and rate of crystallization

varies depending on the blend of ISO, the humidity, and

the temperature.

To prevent exposing ISO to moisture:

• Always use a sealed container with a desiccant

dryer in the vent, or a nitrogen atmosphere. Never

store ISO in an open container.

• Use moisture-proof hoses specifically designed for

ISO, such as those supplied with your system.

Some materials may become self-igniting if applied

too thickly. Read material manufacturer’s warnings

and material MSDS.

Keep Components A and B Separate

Cross-contamination can result in cured material in

fluid lines which could cause serious injury or damage

equipment. To prevent cross-contamination of the

equipment’s wetted parts, never interchange component A (isocyanate) and component B (resin) parts.

• Never use reclaimed solvents, which may contain

moisture. Always keep solvent containers closed

when not in use.

• Never use solvent on one side if it has been contaminated from the other side.

• Always park pumps when you shutdown, see page

30.

• Always lubricate threaded parts, except for GC1128,

GC0518, GC0697, and GC2150, with Part 217374

ISO pump oil or grease when reassembling.

Foam Resins with 245 fa Blowing Agents

Some foam blowing agents will froth at temperatures

above 90°F (33°C) when not under pressure, especially

if agitated. To reduce frothing, minimize preheating in a

circulation system.

6 313539F

Page 7

Changing Materials

• When changing materials, flush the equipment multiple times to ensure it is thoroughly clean.

• Always clean the fluid inlet strainers after flushing.

• Check with your material manufacturer for chemical

compatibility.

• Most materials use ISO on the A side, but some use

ISO on the B side.

• Epoxies often have amines on the B (hardener)

side. Polyureas often have amines on the B (resin)

side.

Changing Materials

313539F 7

Page 8

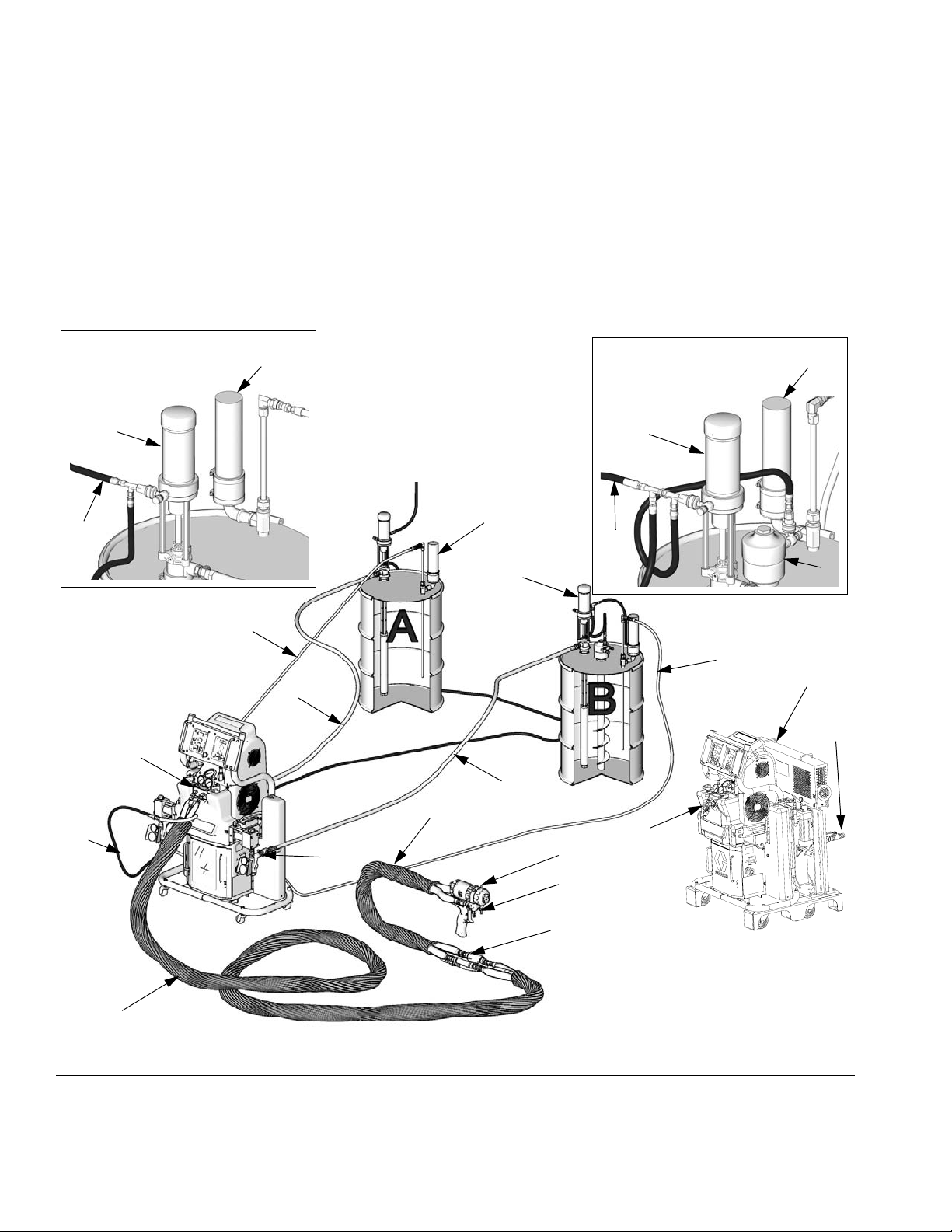

Typical Installation, with circulation

Typical Installation, with circulation

Key for FIG. 1

A Reactor H-VR Proportioner

BHeated Hose

C Fluid Temperature Sensor (FTS)

D Heated Whip Hose

E Fusion Spray Gun

F Gun Air Supply Hose

A Side Supply Detail

M

K

G

ti7820a 3

G Feed Pump Air Supply Lines

J Fluid Supply Lines

K Feed Pumps

L Agitator

M Desiccant Dryer

P Gun Fluid Manifold (part of gun)

R Circulation Lines

S Fluid Inlet

T Hose Manifold

B Side Supply Detail

K

K

G

K

M

L

ti7820a 2

R

J

T

F

S

B

FIG. 1: Typical Installation, with circulation

R

A

S

J

D

T

E

P

C*

r_256886_313359_1A

*Shown exposed for clarity.

Wrap with tape during operation.

ti10000a

8 313539F

Page 9

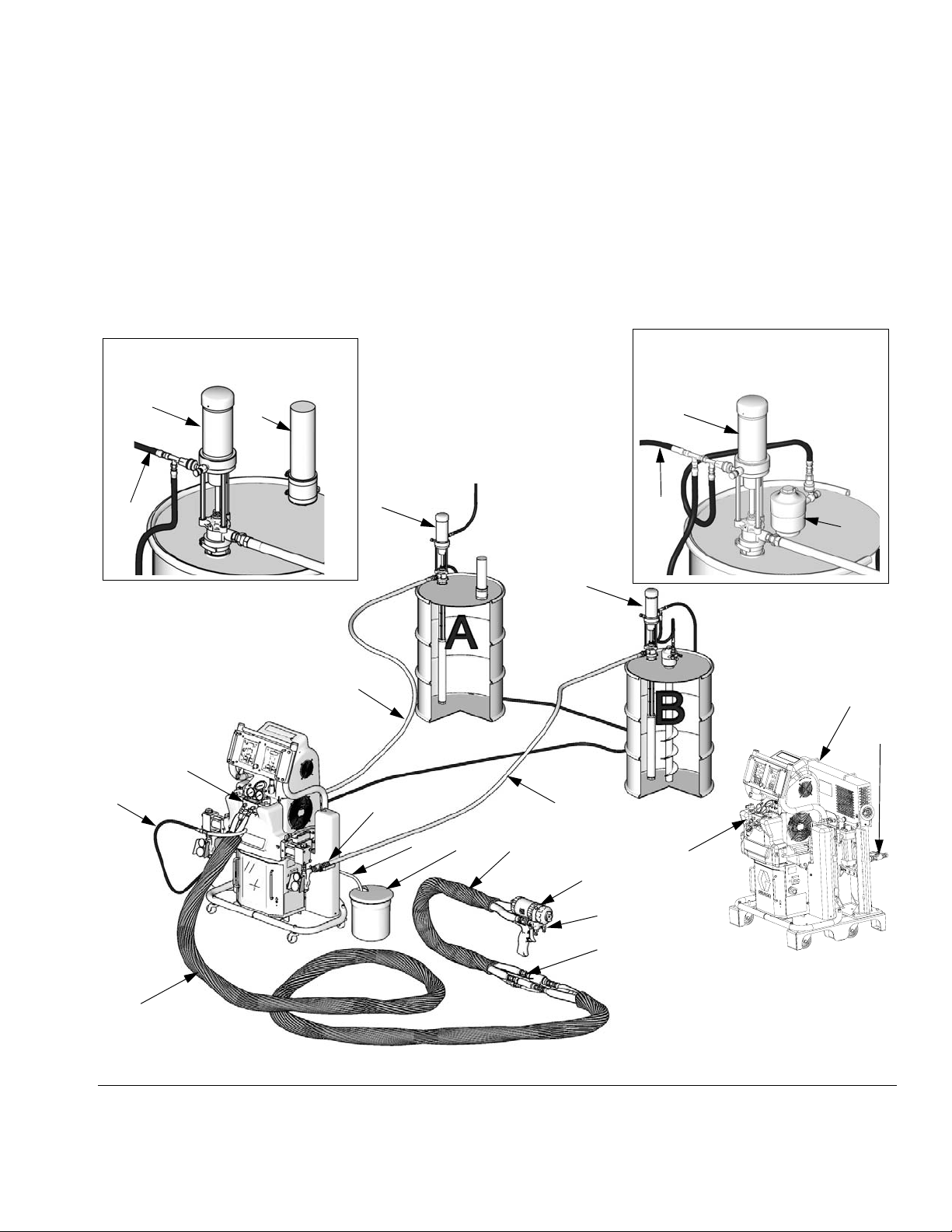

Typical Installation, without circulation

Typical Installation, without circulation

Key for FIG. 2

A Reactor H-VR Proportioner

BHeated Hose

C Fluid Temperature Sensor (FTS)

D Heated Whip Hose

E Fusion Spray Gun

F Gun Air Supply Hose

G Feed Pump Air Supply Lines

A Side Supply Detail

K

M

G

ti7821a 2

H Waste Containers

J Fluid Supply Lines

K Feed Pumps

L Agitator

M Desiccant Dryer

N Bleed Lines

P Gun Fluid Manifold (part of gun)

S Fluid Inlet

T Hose Manifold

B Side Supply Detail

K

K

G

L

K

ti7821a 3

J

T

F

S

N

B

FIG. 2: Typical Installation, without circulation

A

S

J

H

D

T

E

P

C*

r_256886_313359_1A

*Shown exposed for clarity.

Wrap with tape during operation.

ti10001a

313539F 9

Page 10

Component Identification

Component Identification

NOTICE

To prevent damage to soft key buttons, do not press

the buttons with sharp objects such as pens, plastic

cards, or fingernails.

Reactor H-VR

Key for FIG. 3

BA Component A Pressure Relief Outlet

BB Component B Pressure Relief Outlet

EC Heated Hose Electrical Connector

EM Electric Motor, Fan, and Belt Drive (behind shroud)

FA Component A Fluid Manifold Inlet (on left side of manifold

block)

FB Component B Fluid Manifold Inlet

FH Fluid Heater (behind shroud)

FM Reactor Fluid Manifold

FV Fluid Inlet Valve (B side shown)

GA Component A Outlet Pressure Gauge

GB Component B Outlet Pressure Gauge

HA Component A Hose Connection

HB Component B Hose Connection

HC Hydraulic Pressure Control

HP Hydraulic Pressure Gauge

LR ISO Lube Pump Reservoir

MC Motor Control Display

MP Main Power Switch

OP Overpressure Rupture Disk Assembly (on rear of A and B

pumps)

RS Red Stop Button

SA Component A PRESSURE RELIEF/SPRAY Valve

SB Component B PRESSURE RELIEF/SPRAY Valve

SC Fluid Temperature Sensor Cable

SN Serial Number Plate (one inside cabinet, one on right side

of cabinet)

SR Electrical Cord Strain Relief

TA Component A Pressure Transducer (behind gauge GA)

TB Component B Pressure Transducer (behind gauge GB)

TC Temperature Control Display

TD Oil Cooler

VR Pump Assembly (see page 12)

10 313539F

Page 11

TC

Component Identification

MC

VR

EC

SN

RS

HP

FM

HC

EM

OP

FV

SC

FH

MP

SR

r_256886_313359_1A

Detail of Reactor Fluid Manifold

(shroud removed for clarity)

TA

SA

FA

GA

GB

TB

Detail of Serial No. Plate

(inside cabinet)

SB

BA

FB

ti7823a

HA

HB

BB

ti9880a

SN

FIG. 3: Component Identification (15.3 kW Model Shown)

313539F 11

Page 12

Component Identification

Pump Assembly

Key for FIG. 4.

AA Component A Pump

AB Component B Pump

AC Hydraulic Proportioner Pump

AD Yoke and Rod Guide Assembly

AE Pump Drive Link

AF Pump Adapter

AG Pivot Bracket

AA

AH Guard

AJ Clamping Knob

AK Lube Fitting

AL Ratio Lock Handle

AM Ratio Adjustment Wheel

AN Frame

AP Ratio Adjustment Screw

AH

AJ

AB

Detail of Pump Assembly

(guard removed for clarity)

AL

AE

AG

AM

AC

AN

FIG. 4: Front View of Pump Assembly

AD

AK

AK

(behind

pivot bracket)

AP

AF

AB

12 313539F

Page 13

Temperature Controls and Indicators

Temperature Controls and Indicators

Zone A Arrow Keys

Zone B Arrow Keys

Hose Zone Arrow Keys

Actual Temperature Key

Heater Power Indicators

A

B

Heater Displays

°

F

°

C

Heater A On/Off Key

Heater B On/Off Key

Hose Heater On/Off Key

Temperature Scale Keys

Target Temperature Key

IG. 5. Temperature Controls and Indicators

F

Main Power Switch

Located on right side of unit, page 11. Turns Reactor

power ON and OFF . Does not turn

heater zones or pumps on.

Red Stop Button

Located between temperature control panel and motor

control panel, page 11. Press to shut off motor

and heater zones only. Use main power switch to shut

off all power to unit.

Actual Temperature Key/LED

Press to display actual temperature.

Press and hold to display electrical current.

Target Temperature Key/LED

Press to display target temperature.

Press and hold to display heater control circuit

board temperature.

313539F 13

Page 14

Temperature Controls and Indicators

Temperature Scale Keys/LEDs

Press or to change temperature scale.

°

F

°

C

Heater Zone On/Off Keys/LEDs

Press to turn heater zones on and off. Also clears

heater zone diagnostic codes, see page 34.

NOTE:

LEDs flash when heater zones are on. The duration of

each flash shows the extent that the heater is turned on.

Temperature Arrow Keys

Press , then press or to adjust tem-

perature settings in 1 degree increments.

Circuit Breakers

Located inside Reactor cabinet.

Ref. Size Component

CB1 50 A Hose/Transformer Secondary

CB2 40 A Transformer Primary

CB3 50 A Heater A

CB4 50 A Heater B

CB5 20 A Motor/Pumps

Temperature Displays

Show actual temperature or target temperature of

heater zones, depending on selected mode. Defaults to

actual at startup. Range is 32-190°F (0-88°C) for A and

B, 32-180°F (0-82°C) for hose.

CB1

CB2

CB3

For wiring and cabling, see repair manual 313540.

CB4

CB5

ti9884a

14 313539F

Page 15

Motor Controls and Indicators

Motor Controls and Indicators

Arrow Keys

Motor ON/OFF Key

PAR K Ke y

Pressure Key

Cycle Count Key

F

IG. 6. Motor Controls and Indicators

Pressure/Cycle Display

ON / OFF

PARK

PSI/BAR Keys

PSI

BAR

Motor ON/OFF Key/LED

Press to turn motor ON and OFF. Also clears

some motor control diagnostic codes, see page 35.

PARK Key/LED

Press at end of day to cycle component A pump

to home position, submerging displacement rod. Trigger

gun until pump stops. Once parked, motor will automatically shut off.

PSI/BAR Keys/LEDs

Press or to change pressure scale.

PSI

BAR

Pressure Key/LED

Press to display fluid pressure.

NOTE:

If pressures are imbalanced, display shows higher of

two pressures.

313539F 15

Page 16

Spray Adjustments

Cycle Count Key/LED

Press to display cycle count.

NOTE:

To clear counter, press and hold for 3 sec.

Hydraulic Pressure Control Knob

Use to adjust hydraulic pressure available to the hydraulic drive system. Turn knob (HC) clockwise to increase

pressure and counterclockwise to decrease pressure.

Use hydraulic pressure gauge (HP, page 11) to view

hydraulic pressure.

+-

ti7731a ti7732a

• Fluid pressure setting. Too little pressure results in

an uneven pattern, coarse droplet size, low flow,

and poor mixing. Too much pressure results in

excessive overspray, high flow rates, difficult control,

and excessive wear.

• Fluid temperature. Similar effects to fluid pressure

setting. The A and B temperatures can be offset to

help balance the fluid pressure.

• Mix chamber size. Choice of mix chamber is based

on desired flow rate, fluid viscosity, and selected

ratio.

• Clean-off air adjustment. Too little clean-off air

results in droplets building up on the front of the

nozzle, and no pattern containment to control overspray. Too much clean-off air results in air-assisted

atomization and excessive overspray.

NOTE:

Component A and B outlet pressures will be higher than

the hydraulic set pressure, depending on the model.

Component A and B pressure may be viewed on the

pressure gauges (GA, GB), or the higher of the two

pressures may be displayed on the motor control panel

(MC). See F

IG. 3, page 11.

Motor Control Arrow Keys

Use or to:

• Adjust pressure imbalance settings, page 26.

• Adjust standby settings, page 30.

Spray Adjustments

Flow rate, atomization, and amount of overspray are

affected by four variables.

16 313539F

Page 17

Setup

Setup

NOTICE

Proper system setup, startup, and shutdown procedures are critical to electrical equipment reliability. The following procedures ensure steady

voltage. Failure to follow these procedures will

cause voltage fluctuations that can damage electrical equipment and void the warranty.

1. Locate Reactor

a. Locate Reactor on a level surface. See Dimen-

sions, page 39, for clearance and mounting

hole dimensions.

b. Do not expose Reactor to rain.

NOTICE

Bolt Reactor to original shipping pallet before lifting.

c. Use the casters to move Reactor to a fixed loca-

tion, or bolt to shipping pallet and move with

forklift.

d. To mount on a truck bed or tailer, remove cast-

ers and bolt directly to truck or trailer bed. See

page 39.

2. General equipment guidelines

• Determine the correct size generator. Using the correct size generator and proper air compressor will

enable the proportioner to run at a nearly constant

RPM. Failure to do so will cause voltage fluctuations

that can damage electrical equipment. Ensure the

generator matches the voltage and phase of the

proportioner.

Use the following procedure to determine the correct size generator.

a. List system components that use peak load

requirements in watts.

b. Add the wattage required by the system compo-

nents.

c. Perform the following equation:

Total watts x 1.25 = kVA (kilovolt-amperes)

d. Select a generator size that is equal to or

greater than the determined kVA.

• Use proportioner power cords that meet or exceed

the requirements listed in Table 2. Failure to do so

will cause voltage fluctuations that can damage

electrical equipment.

• Use an air compressor with constant speed head

unloading devices. Direct online air compressors

that start and stop during a job will cause voltage

fluctuations that can damage electrical equipment.

• Maintain and inspect the generator, air compressor,

and other equipment per the manufacturer recommendations to avoid an unexpected shutdown.

Unexpected equipment shutdown will cause voltage

fluctuations that can damage electrical equipment.

• Use a wall power supply with enough current to

meet system requirements. Failure to do so will

cause voltage fluctuations that can damage electrical equipment.

313539F 17

Page 18

Setup

3. Electrical requirements

See table 1.

Installing this equipment requires access to parts

which may cause electric shock or other serious injury

if work is not performed properly. Have a qualified

electrician connect power and ground to main power

switch terminals, see step 3. Be sure your installation

complies with all National, State and Local safety and

fire codes.

Table 1: Electrical Requirements (kW/Full Load

Amps)

Full

Load

Peak

Amps*

Part Model

256886

256887

H-VR 230V (3) 71 26,600

H-VR 400V (3) 41 26,600

Volt age

(phase)

* Full load amps with all devices operating at maxi-

mum capabilities. Fuse requirements at various flow

rates, ratios, and mix chamber sizes may be less.

** Total system watts, based on maximum hose length

for each unit, 410 ft (125 m) including whip hose.

System

Watts**

4. Connect electrical cord

NOTE:

Power cord is not suppled. See table 2.

Table 2: Power Cord Requirements

Cord Specification

Part Model

256886

256887

H-VR 4 (21.2), 3 wire + ground

H-VR 8 (8.4), 4 wire + ground

AWG (mm

a. 230V, 3 phase: Using 5/32 or 4 mm hex allen

wrench, connect three power leads to L1, L2,

and L3. Connect green to ground (GND).

GND

L1

L2

b. 400V, 3 phase: Using 5/32 or 4 mm hex allen

wrench, connect three power leads to L1, L2,

and L3. Connect neutral to N. Connect green to

ground (GND).

2

)

ti2515b

GND

L1

L2

L3

ti3248b

NOTE:

The motor must rotate counter-clockwise when viewed

from shaft end. To reverse rotation, disconnect power

and reverse power leads L1 and L2.

18 313539F

Page 19

Setup

5. Connect feed pumps

a. Install feed pumps (K) in component A and B

supply drums. See F

and 9.

b. Seal component A drum and use desiccant

dryer (M) in vent.

c. Install agitator (L) in component B drum, if nec-

essary.

d. Ensure A and B inlet valves (FV) are closed.

NOTE:

Supply hoses from feed pumps should be 3/4 in. (19

mm) ID.

IG. 1 and FIG. 2, pages 8

FV

ti10971a

to component A and B drums. See F

IG. 1, page

8.

SB

SA

R

BA

R

BB

ti9880a

b. Alternatively: Secure supplied bleed tubes (N)

in grounded, sealed waste containers (H). See

F

IG. 2, page 9.

7. Install Fluid Temperature Sensor (FTS)

The Fluid Temperature Sensor (FTS) is supplied. Install

FTS between main hose and whip hose. See Heated

Hose manual 309572 for instructions.

e. Connect and tighten component A and B supply

hose to the 3/4 npt(f) swivel on the component A

and B inlet valve.

6. Connect pressure relief lines

Do not install shutoffs downstream of the PRESSURE

RELIEF/SPRAY valve outlets (BA, BB). The valves

function as overpressure relief valves when set to

SPRAY . Lines must be open so valves can

automatically relieve pressure when machine is operating.

If circulating fluid back to the supply drums, use high

pressure hose rated to withstand the maximum working pressure of this equipment.

a. Recommended: Connect high pressure hose

(R) to relief fittings (BA, BB) of both PRESSURE RELIEF/SPRAY valves, Route hose back

313539F 19

Page 20

Setup

8. Connect heated hose

NOTE:

See Heated Hose manual 309572 for detailed instructions on connecting heated hoses.

NOTE:

If spraying at a ratio other than 1:1, an E24 may occur.

Size hoses and mix chamber appropriately to avoid

pressure imbalance.

NOTICE

The fluid temperature sensor (C) and whip hose (D)

must be used with heated hose, see page 19. Hose

length, including whip hose, must be 60 ft (18.3 m)

minimum.

a. Turn main power OFF .

b. Assemble heated hose sections, FTS, and whip

hose.

bends. Wrap cable and electrical connections

with electrical tape.

Y

V

ti9881a

9. Close gun fluid manifold valves A and B

c. Connect A and B hoses to A and B outlets on

Reactor fluid manifold (FM). Hoses are color

coded: red for component A (ISO), blue for component B (RES). Fittings are sized to prevent

connection errors.

FM

N

A

P

B

ti9878a

NOTE:

Manifold hose adapters (N, P) allow use of 1/4 in. and

3/8 in. ID fluid hoses. To use 1/2 in. (13 mm) ID fluid

hoses, remove adapters from fluid manifold and install

as needed to connect whip hose.

ti2411a

10. Connect whip hose to gun fluid manifold

Do not connect manifold to gun.

ti2417a

11. Pressure check hose

See hose manual. Pressure check for leaks. If no leaks,

wrap hose and electrical connections to protect from

damage.

d. Connect cables (Y). Connect electrical connec-

tors (V). Be sure cables have slack when hose

20 313539F

Page 21

12. Ground system

a. Reactor: is grounded through power cord. See

page 18.

b. Spray gun: connect whip hose ground wire to

FTS, page 19. Do not disconnect wire or spray

without whip hose.

c. Fluid supply containers: follow your local code.

d. Object being sprayed: follow your local code.

e. Solvent pails used when flushing: follow your

local code. Use only metal pails, which are conductive, placed on a grounded surface. Do not

place pail on a nonconductive surface, such as

paper or cardboard, which interrupts grounding

continuity

Setup

f. To maintain grounding continuity when flushing

or relieving pressure, hold a metal part of spray

gun firmly to the side of a grounded metal pail,

then trigger gun.

13. Check hydraulic fluid level

a. Hydraulic reservoir is filled at the factory. Check

fluid level before operating the first time, and

weekly thereafter. See Maintenance, page 36.

313539F 21

Page 22

Startup

Startup

See table 3 for ratios with the one pump set at 1.0 and

available settings for the second pump.

Do not operate Reactor without all covers and shrouds

in place. Do not attempt to change ratio while machine

is pressurized or running. Do not loosen ratio lock

handle if A and B component pumps are pressurized

or while the pumps are operating.

1. Select ratio

The stroke lengths of the fluid pumps (AA and AB) can

be adjusted to select the ratio. The frame (AN) has three

pin positions for the bottom of the pump and a slider

mechanism at the top of the pump, which allows for

positioning of the pump at any required position. This

allows for a a range of ratio settings between the first

and last settings on the pump drive link.

a. Shutdown system, see page 30.

b. Relieve pressure, see page 31.

c. Loosen four clamping knobs (AJ) and remove

guard (AH).

Table 3: Ratio Range

Pump with higher

flow

1.0

1.0

POSN #1

1.0

1.0

1.0

1.0

POSN #1

POSN #1

1.0

1.0

1.0

1.0

1.0

1.0

Pump with lower

flow Ratio

1.0

0.95

POSN #1

POSN #2

POSN #3

0.90

0.85

0.80

0.75

0.70

0.66

0.60

0.55

0.50

0.45

1:1

1.05

1.11:1

1.2:1

1.25:1

1.33:1

1.42:1

1.51:1

1.66:1

1.88:1

2:1

2.22:1

AH

AL

AJ

AA

F

IG. 7: Front View

d. Use label on the pump drive link (AE) to identify

the correct position of the pump that needs to

be adjusted. See F

IG. 8.

AB

r_256886_313359_6

1.0

0.40

2.5:1

Pump A when viewed from rear of machine

Pump B when viewed from rear of machine

F

IG. 8: Pump Ratio Indicator Labels

22 313539F

Page 23

Startup

e. Remove base pin (BP) from frame (AN) if the

base of the pump needs to be moved. See F

8.

TP

BP

3

IG. 9

F

f. Loosen ratio lock handle (AL) over the pump

that needs adjustment. Use a soft mallet to

loosen ratio lock handle if necessary. Turn ratio

adjustment wheel (AM) until the mark on the

pump adapter block (AF) lines up with the correct position on the ratio indicator label on the

pump drive link (AE).

g. Reinstall base pin (BP) if it was removed.

Ensure bottom of pump is in correct position.

See F

12

IG. 8.

r_256886_313359_7

IG.

AL

1

23

FIG. 10

h. Ensure top of pump is in correct ratio position.

Tighten ratio lock handle (AL).

i. Install guard (AH) and tighten clamping knobs

(AJ). See F

IG. 7.

AF

AE

AP

r_256886_313359_5

AM

NOTICE

Move bottom position of pump once top of pump

enters a new position #. Failure to adjust bottom

position of pump will damage the machine.

NOTE:

For highest volume of material: Ensure pump has longest stroke length. Set the pump with more flow closest

to hydraulic pump (AC) or at 1.0 to achieve maximum

flowrates. See F

313539F 23

IG. 8.

Page 24

Startup

2. Load fluid with feed pumps

NOTE:

The Reactor is tested with oil at the factory. Flush out

the oil with a compatible solvent before spraying. See

page 38.

a. Check that all Setup steps are complete.

b. Turn on component B agitator, if used.

c. Turn both PRESSURE RELIEF/SPRAY valves

(SA, SB) to SPRAY .

SA

SB

ti9877a

Open fluid valves A and B until clean, air-free

fluid comes from valves. Close valves.

ti2484a

d. Start feed pumps.

e. Open fluid inlet valves (FV). Check for leaks.

FV

ti10972a

Do not mix components A and B during startup.

Always provide two grounded waste containers to

keep component A and component B fluids separate.

f. Use feed pumps to load system. Hold gun fluid

manifold over two grounded waste containers.

24 313539F

Page 25

3. Set temperatures

A

NOTE:

Startup

desired temperature. Repeat for and

zones.

B

B

°

F

°

C

Temperature Controls and Indicators, see page 13

This equipment is used with heated fluid, which can

cause equipment surfaces to become very hot. To

avoid severe burns:

• Do not touch hot fluid or equipment.

• Allow equipment to cool completely before touching it.

Wear gloves if fluid temperature exceeds 110°F

(43°C).

a. Turn main power ON .

For zone only, if FTS is disconnected at startup,

display will show hose current (0A). See step j, page 26.

e. Press to display actual temperatures.

Do not turn on hose heat without fluid in hoses.

f. Turn on heat zone by pressing .

Preheat hose (15-60 min). Indicator will flash

very slowly when fluid reaches target temperature. Display shows actual fluid temperature in

hose near FTS.

Thermal expansion can cause overpressurization,

resulting in equipment rupture and serious injury,

including fluid injection. Do not pressurize system

when preheating hose.

b. Press or to change temperature

scale.

c. Press .

d. To set heat zone target temperature,

press or until display shows

313539F 25

°

A

F

°

C

g. Turn on and heat zones by press-

ing for each zone.

h. Hold to view electrical currents for each

zone.

i. Hold to view heater control circuit board

temperature.

A

B

Page 26

Startup

j. Manual current control mode only:

When in manual current control mode, monitor hose

temperature with thermometer. Install per instructions

below. Thermometer reading must not exceed 160°F

(71°C). Never leave machine unattended when in

manual current control mode.

If FTS is disconnected or display shows diagnostic code E04, turn main power switch OFF

then ON to clear diagnostic

code and enter manual current control mode.

display will show current to hose. Current

is not limited by target temperature.

To prevent overheating, install hose thermometer close to gun end, within operator view. Insert

thermometer through foam cover of A component hose so stem is next to inner tube. Thermometer reading will be about 20°F less than

actual fluid temperature.

4. Set pressure

ON / OFF

PARK

PSI

BAR

Motor Controls and Indicators, see page 15

a. Press to display the pressure reading.

b. Press motor . Motor and pumps start.

If thermometer reading exceeds 160°F (71°C),

reduce current with key.

Display shows system pressure.

NOTE:

Motor must rotate counterclockwise when viewed from

shaft end. See Connect electrical cord, page 18.

c. Adjust hydraulic pressure control until display

shows desired fluid pressure.

+-

ti7731a ti7732a

NOTICE

Never adjust hydraulic pressure while spraying. This

will result in over pressure alarm E23.

NOTE:

If display pressure is greater than desired pressure,

reduce the hydraulic pressure and trigger gun to reduce

pressure.

26 313539F

Page 27

Startup

NOTE:

Check the pressure of each proportioning pump using

the component A and B gauges. The pressures should

be approximately equal and must remain fixed.

d. To display cycle count, press .

NOTE:

To clear counter, press and hold for 3 sec.

e. Press or to change pressure

PSI

BAR

scale.

5. Change pressure imbalance setting (optional)

The pressure imbalance function (status code 24, page

35) detects conditions that can cause off-ratio spray,

such as loss of feed pressure/supply, pump seal failure,

clogged fluid inlet filter, or a fluid leak.

Table 4: Available Pressure Imbalance Settings

PSI BAR PSI BAR

100 7 600 42

2001470049

3002180056

4002890063

*500 *35 999 69

* Factory default setting.

d. Turn main power switch OFF to save

changes.

NOTE:

Code 24 (pressure imbalance) is set to an alarm as the

default. To change to a warning, see H-VR Repair-Parts

manual 313540.

The pressure imbalance default is factory-set at 500 psi

(3.5 MPa, 35 bar). For tighter ratio error detection, select

a lower value. For looser detection or to avoid nuisance

alarms, select a higher value.

a. Turn main power switch OFF .

b. Press and hold or , then turn main

PSI

BAR

power switch ON . Display will read

dP500 for psi or dP_35 for bar.

c. Press or to select desired pres-

sure differential (100-999 in increments of 100

psi, or 7-70 in increments of 7 bar). See T

ABLE

4.

313539F 27

Page 28

Spraying

Spraying

4. Set PRESSURE RELIEF/SPRAY valves (SA, SB) to

SPRAY .

1. Engage gun piston safety lock.

ti2409a

2. Close gun fluid manifold valves A and B.

ti2728a

3. Attach gun fluid manifold. Connect gun air line.

Open air line valve.

SA

SB

ti9877a

5. Check that heat zones are on and temperatures are

on target, page 25.

6. Press motor to start motor and pumps.

7. Check fluid pressure display while the gun is detriggered and adjust as necessary, page 26.

8. Check fluid pressure gauges (GA, GB) to ensure

proper pressure balance. If imbalanced, reduce

pressure of higher component by slightly turning

PRESSURE RELIEF/SPRAY valve for that component toward PRESSURE RELIEF/CIRCULATION

, until gauges show balanced pressures.

GA

GB

In this example, B side

pressure is higher, so

use the B side valve to

balance pressures.

ti9877a

ti2543a

28 313539F

Page 29

9. Open gun fluid manifold valves A and B.

ti2414a

NOTE:

On impingement guns, never open fluid manifold valves

or trigger gun if pressures are imbalanced.

10. Disengage gun piston safety lock.

Spraying

ti2410a

11. Test spray onto cardboard. Adjust pressure and

temperature to get desired results.

12. Equipment is ready to spray.

NOTE:

If you stop spraying for a period of time, the unit will

enter standby (if enabled). See page 30.

313539F 29

Page 30

Standby

Standby

If you stop spraying for a period of time, the unit will

enter standby by shutting down the electric motor and

hydraulic pump, to reduce equipment wear and minimize heat buildup. The ON/OFF LED and the pressure/cycle display on the motor control panel will flash

when in standby.

NOTE:

The , , and heat zones will not be

A

shut off in standby.

To restart, spray off target for 2 sec. The system will

sense the pressure drop and the motor will ramp up to

full speed in a few seconds.

NOTE:

This feature is disabled from the factory.

To activate or disable standby, adjust DIP switch #3 on

the motor control board. See Reactor Repair-Parts manual 313540.

B

Shutdown

1. Shut off , , and heat zones.

2. Park pumps.

a. Press .

b. Trigger gun until pump A stops in the retracted

3. Turn main power OFF .

4. Close both fluid supply valves (FV).

A

position and the pressure of both pumps bleeds

down.

B

The idle time before entering standby is user-settable as

follows:

1. Turn main power switch OFF .

2. Press and hold , then turn main power switch

ON .

3. Press or to select desired timer set-

ting (5-20, in 5 minute increments). This sets the

length of inactive time before the unit will enter

standby.

4. Turn main power switch OFF to save

changes.

FV

ti10971a

5. Relieve pressure, page 31.

30 313539F

Page 31

Pressure Relief Procedure

1. Relieve pressure in gun and perform gun shutdown

procedure. See gun manual.

Pressure Relief Procedure

5. Engage gun piston safety lock.

2. Close gun fluid manifold valves A and B.

ti2421a

3. Shut off feed pumps and agitator, if used.

4. Turn PRESSURE RELIEF/SPRAY valves (SA, SB)

to PRESSURE RELIEF/CIRCULATION . Route

fluid to waste containers or supply tanks. Ensure

gauges drop to 0.

ti2409a

6. Disconnect gun air line and remove gun fluid manifold.

ti2554a

SA

SB

ti9879a

313539F 31

Page 32

Fluid Circulation

Fluid Circulation

Circulation Through Reactor

Do not circulate fluid containing a blowing agent without consulting with your material supplier regarding

fluid temperature limits.

To circulate through gun manifold and preheat hose, see

page 33.

1. Load fluid with feed pumps, page 24.

Do not install shutoffs downstream of the PRESSURE

RELIEF/SPRAY valve outlets (BA, BB). The valves

function as overpressure relief valves when set to

SPRAY . Lines must be open so valves can

automatically relieve pressure when machine is operating.

5. Set temperature targets, see page 25. Turn on

and heat zones by pressing .

A

Do not turn on heat zone unless hoses are

already loaded with fluid.

6. Press to display actual temperatures.

7. Before starting motor, reduce hydraulic pressure to

the minimum required to circulate fluid until

and temperatures reach targets.

B

B

A

-

ti7732a

2. See Typical Installation, with circulation, page 8.

Route circulation lines back to respective component A or B supply drum. Use hoses rated at the

maximum working pressure of this equipment. See

Technical Data, page 40.

3. Set PRESSURE RELIEF/SPRAY valves (SA, SB) to

PRESSURE RELIEF/CIRCULATION .

SA

SB

ti9879a

4. Turn main power ON .

8. Press motor to start motor and pumps. Cir-

culate fluid at lowest possible pressure until temperatures reach targets.

9. Turn on heat zone by pressing .

10. Set PRESSURE RELIEF/SPRAY valves (SA, SB) to

SPRAY .

SA

SB

ti9877a

32 313539F

Page 33

Fluid Circulation

Circulation Through Gun Manifold

Do not circulate fluid containing a blowing agent without consulting with your material supplier regarding

fluid temperature limits.

Circulating fluid through the gun manifold allows rapid

preheating of hose.

1. Install gun fluid manifold (P) on Part 246362 accessory circulation kit (CK). Connect high pressure circulation lines (R) to circulation manifold.

P

7. Before starting motor, reduce hydraulic pressure to

the minimum required to circulate fluid until

and temperatures reach targets.

B

A

-

ti7732a

8. Press motor to start motor and pumps. Cir-

culate fluid at lowest possible pressure until temperatures reach targets.

CK

2. Route circulation lines back to respective component A or B supply drum. Use hoses rated at the

maximum working pressure of this equipment. See

Typical Installation, without circulation, page 9.

3. Follow Select ratio, page 22.

4. Turn main power ON .

5. Set temperature targets, see page 25. Turn on

, , and heat zones by pressing

A

B

.

R

ti2767a

6. Press to display actual temperatures.

313539F 33

Page 34

Diagnostic Codes

Diagnostic Codes

Temperature Control Diagnostic Codes

Temperature control diagnostic codes appear on temperature display.

These alarms turn off heat. E99 clears automatically

when communication is regained. Codes E03 through

E06 can be cleared by pressing . For other codes,

turn main power OFF then ON to clear.

See repair manual for corrective action.

Code Code Name Alarm Zone

01 High fluid temperature Individual

02 High current Individual

03 No current Individual

04 FTS not connected Individual

05 Board overtemperature Individual

06 Loss of zone communication Individual

30 Momentary loss of communica-

tion

99 Loss of display communication All

NOTE:

For hose zone only, if FTS is disconnected at startup,

display will show hose current 0A.

All

34 313539F

Page 35

Motor Control Diagnostic Codes

Diagnostic Codes

Motor control diagnostic codes E21 through E27 appear

on pressure display.

There are two types of motor control codes: alarms and

warnings. Alarms take priority over warnings.

See repair manual for corrective action.

Alarms

Alarms turn off Reactor. Turn main power OFF

then ON to clear.

NOTE:

Alarms can also be cleared, except for code 23, by

pressing .

NOTE:

Code 24 (pressure imbalance) is set to an alarm default

of 500 psi (3.5 MPa, 35 bar). To change to a warning,

see Reactor Repair-Parts manual 313540. To change

the default pressure imbalance setting, see page 27.

Warnings

Reactor will continue to run. Press to clear. A

warning will not recur for a predetermined amount of

time (varies for different warnings), or until main power

is turned OFF then ON .

Code

No.

21 No transducer (component A) Alarm

22 No transducer (component B) Alarm

23 High pressure Alarm

24 Pressure imbalance Selectable;

27 High motor temperature Alarm

30 Momentary loss of communi-

cation

31 Pumpline switch failure/high

cycle rate

99 Loss of communication Alarm

Code Name

Alarm or

Warning

see repair

manual

Alarm

Alarm

313539F 35

Page 36

Maintenance

Maintenance

• Inspect hydraulic and fluid lines for leaks daily.

• Clean up all hydraulic leaks; identify and repair

cause of leak.

• Inspect fluid inlet strainer screens daily, see below.

• Grease circulation valves weekly with Fusion grease

(117773).

ti9879a

• Check hydraulic fluid level weekly. Check hydraulic

fluid level on dipstick (DS). Fluid level must be

between indent marks (IM) on dipstick. Refill as

required with approved hydraulic fluid; see Techni-

cal Data on page 40 and the Approved Anti-Wear

(AW) Hydraulic Oils table in the Reactor

Repair-Parts manual 313540. If fluid is dark in color,

change fluid and filter.

• Keep component A from exposure to moisture in

atmosphere, to prevent crystallization.

• Clean gun mix chamber ports regularly. See gun

manual.

• Clean gun check valve screens regularly. See gun

manual.

• Use compressed air to prevent dust buildup on control boards, fan, motor (under shield), and hydraulic

oil coolers.

• Keep vent holes on bottom of electrical cabinet

open.

DS

S

IM

ti10003a

ti7861a

• Change break-in oil in a new unit after first 250

hours of operation or within 3 months, whichever

comes first. See Table 4 for recommended frequency of oil changes

Table 5: Frequency of Oil Changes

Ambient

Temperature

0 to 90°F

(-17 to 32°C)

90°F and above

(32°C and above)

36 313539F

Recommended

Frequency

1000 hours or 12 months,

whichever comes first

500 hours or 6 months,

whichever comes first

Page 37

Fluid Inlet Strainer Screen

The inlet strainers filter out particles that can plug the

pump inlet check valves. Inspect the screens daily as

part of the startup routine, and clean as required.

Use clean chemicals and follow proper storage, transfer,

and operating procedures, to minimize contamination of

the A-side screen.

NOTE:

Clean the A-side screen only during daily startup. This

minimizes moisture contamination by immediately flushing out any isocyanate residue at the start of dispensing

operations.

1. Close the fluid inlet valve at the pump inlet and shut

off the appropriate feed pump. This prevents material from being pumped while cleaning the screen.

2. Place a container under the strainer manifold (59d)

to catch fluid. Remove the strainer plug (59j).

Fluid Inlet Strainer Screen

4. Ensure the pipe plug (59k) is screwed into the

strainer plug (59j). Install the strainer plug with the

screen (59g) and gasket (59h) in place and tighten.

Do not overtighten. Let the gasket make the seal.

5. Open the fluid inlet valve, ensure that there are no

leaks, and wipe the equipment clean. Proceed with

operation.

59d

FIG. 11: Fluid Inlet Strainer

* See Reactor Repair-Parts manual 313540 for fluid filter

screen replacements.

59g*

59h

59j

59k

ti9886a

3. Remove the screen (59g) from the strainer manifold.

Thoroughly flush the screen with compatible solvent

and shake it dry. Inspect the screen. If more than

25% of the mesh is blocked, replace the screen.

Inspect the gasket (59h) and replace as required.

313539F 37

Page 38

Flushing

Flushing

Flush equipment only in a well-ventilated area. Do not

spray flammable fluids. Do not turn on heaters while

flushing with flammable solvents.

• Flush out old fluid with new fluid, or flush out old

fluid with a compatible solvent before introducing

new fluid.

• Use the lowest possible pressure when flushing.

• All fluid components are compatible with common

solvents. Use only moisture-free solvents.

• To flush feed hoses, pumps, and heaters separately

from heated hoses, set PRESSURE

RELIEF/SPRAY valves (SA, SB) to PRESSURE

RELIEF/CIRCULATION . Flush through bleed

lines (N).

SA

SB

N

N

ti9880a

• To flush entire system, circulate through gun fluid

manifold (with manifold removed from gun).

• To prevent moisture from reacting with isocyanate,

always leave the system dry or filled with a moisture-free plasticizer or oil. Do not use water. See

page 6.

38 313539F

Page 39

Dimensions

Dimensions

Dimension in. (mm)

A (height) 57.31 (1455.42)

B (width) 37.86 (961.6)

C (depth) 33 (838.2)

A

Dimension in. (mm)

D (front and rear mounting holes) 32.5 (825.5)

F (side mounting holes) 30.375 (7715)

G (mounting post inner diameter) 0.44 (11)

Top View

D

Front of Machine

C

G

F

r_256886_313359_1A

Rear of Machine

D

B

313539F 39

Page 40

Technical Data

Technical Data

Category Data

Maximum Fluid Working Pressure 3500 psi (24.1 MPa, 241 bar)

Fluid Inlets 3/4 npsm union in 1 in. npt(f) ball valve

Fluid Outlets Component A (ISO): #8 (1/2 in.) JIC, with #5 (5/16 in.) JIC adapter

Component B (RES): #10 (5/8 in.) JIC, with #6 (3/8 in.) JIC adapter

Fluid Circulation Ports 1/4 npsm(m), with plastic tubing, 250 psi (1.75 MPa, 17.5 bar) maximum

Maximum Fluid Temperature 190°F (88°C)

Maximum Output (10 weight oil at

ambient temperature) 1:1

Output per Cycle Variable: 2 oz.- 5 oz. (60 cc - 150 cc) per pump*

Stroke Length Variable: 2 in. - 5 in. (5.08 cm - 12.7 cm)

Line Voltage Requirement 230V 3 phase units: 195-264 Vac, 50/60 Hz

Amperage Requirement See Models, page 2.

Heater Power

(A and B heaters total, no hose)

Hydraulic reservoir capacity 3.5 gal. (13.6 liters)

Recommended hydraulic fluid Citgo A/W Hydraulic Oil, ISO Grade 46

Sound power, per ISO 9614-2 90.9 dB(A)

Sound pressure,

1 m from equipment

Weight 955 lb (433 kg)

Wetted Parts Aluminum, stainless steel, zinc-plated carbon steel, brass, carbide, chrome,

Model H-VR: 3.0 gpm (11.4 liter/min) (60 Hz)

400V 3 phase units: 338-457 Vac, 50/60 Hz

See Models, page 2.

84.0 dB(A)

fluoroelastomer, PTFE, ultra-high molecular weight polyethylene, chemically

resistant o-rings

*Output example: 2.5:1 ratio = 150 cc (B side):60 cc (A side)

2.5:1 output = 150 cc (B side) + 60 cc (A side) = 210 cc per cycle

All other brand names or marks are used for identification purposes and are trademarks of their respective owners.

40 313539F

Page 41

Performance Charts

Foam Performance Chart

Performance Charts

2000

(13.8, 138)

KEY

A = H-25 at 50 Hz

B = H-25 at 60 Hz

1500

(10.3, 103)

1000

(6.9, 69)

A

B

G

C

C = H-40 at 50 Hz

D = H-40 at 60 Hz

E = H-50 at 50 Hz

❄F = H-50 at 60 Hz

G = H-VR at 60 Hz

E

Pressure in psi (MPa, bar)

500

(3.4, 34)

D

F

0

5

15

(2.3)

(6.8)

25

(11.4)

35

(15.9)

45

(20.5)

55

(25.0)

Flow Rate in lb/min (kg/min)

❄ Pressure flow curve for model 253725 (H-50 230V 1 phase) not shown.

Maximum pressure limited to 1700 psi (11.7 MPa, 11.7 bar)

Pressure in psi (MPa, bar)

3500

(24.1, 241)

3000

(20.7, 207)

2500

(17.2, 172)

2000

(13.8, 138)

1500

(10.3, 103)

1000

(6.9, 69)

500

(3.4, 34)

Coatings Performance Chart

H

J

0

0.5

(1.9) (3.8) (5.7)

1.0 1.5

Flow Rate in gal/min (liter/min)

2.0 2.5 3.0

(7.6) (9.5) (11.4)

KEY

H = H-XP2 at 50 Hz

J = H-XP2 at 60 Hz

K = H-XP3 at 50 Hz

L = H-XP3 at 60 Hz

M = H-VR at 60 Hz

K

M

L

313539F 41

Page 42

Performance Charts

140

(78)

130

(72)

120

(67)

110

(61)

100

(56)

90

(50)

80

(44)

70

(39)

60

(33)

50

(28)

Delta T in degrees F (degrees C)

40

(22)

30

(17)

20

(11)

10

(6)

Heater Performance Chart

KEY

H-VR = 15.3 kW

H-VR

0

0.5

(1.9)

1.0

(3.8)

1.5

(5.7)

2.0

(7.6)

2.5

(9.5)

3.0

(11.4)

3.5

(13.2)

4.0

(15.1)

4.5

(17.0)

Flow Rate in gpm (lpm)

★ Heater performance data is based on testing with 10 wt.

hydraulic oil and 230V across heater power wires.

42 313539F

Page 43

Performance Charts

313539F 43

Page 44

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 313539

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2009, Graco Inc. is registered to ISO 9001

www.graco.com

Revised 08/2010

Loading...

Loading...