Page 1

Repair-Parts

Tandem Supply

313529J

Systems

For use with non-heated bulk supply of medium to high viscosity sealants and adhesive

materials. For professional use only.

Not approved for use in European explosive atmosphere locations.

125 psi (0.9 MPa, 9 bar) Maximum Air Inlet Pressure - S20 3 in. rams

150 psi (1.0 MPa, 10 bar) Maximum Air Inlet Pressure - D60 and D200 3 in. rams

125 psi (0.9 MPa, 9 bar) Maximum Air Inlet Pressure - D200S 6.5 in. rams

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

EN

The Graco Control Architecture Electric Components are Listed in Intertek’s Directory of Listed Products.

D200 Rams with Electronic

Crossover Shown

TI10865A

Page 2

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Selector Switch . . . . . . . . . . . . . . . . . . . . . . . . . 12

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Pressure Relief Procedure . . . . . . . . . . . . . . . . 13

Ram Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Pump Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Crossover Schematics . . . . . . . . . . . . . . . . . . . 13

Electronic Crossover Schematic . . . . . . . . . . . . . 14

Pneumatic Crossover Schematic . . . . . . . . . . . . . 15

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Electronic Crossover Kits, with display . . . . . . . 19

Power Supply Detail . . . . . . . . . . . . . . . . . . . . . 22

Electronic Crossover Kits, without display . . . . . 23

Pneumatic Crossover Kits . . . . . . . . . . . . . . . . . 25

Pneumatic Crossover Kits (continued) . . . . . . . 26

Fluid Filter Kit . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Pump Outlet Check Valve Kits . . . . . . . . . . . . . 29

Depressurization Kits . . . . . . . . . . . . . . . . . . . . 30

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Communications Gateway Module . . . . . . . . . . 32

Pressure Sensor Accessories . . . . . . . . . . . . . . 32

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 34

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . 34

2 313529J

Page 3

Related Manuals

Component Manuals in U.S. English:

Manual Description

313528 Tandem Supply Systems Operation

313526 Supply Systems Operation

313527 Supply Systems Repair-Parts

Check-Mate

312375

Instructions-Parts

Check-Mate

312376

Instruction-Parts

Dura-Flo

311827

180cc, 220cc, 290cc) Instructions-Parts

Manual

311825

311717

Dura-Flo

580cc) Instructions-Parts Manual

Carbon Steel Displacement Pump

(1000cc) Instructions-Parts Manual

Dura-Flo

311828

180cc, 220cc, 290cc) Instructions-Parts

Manual

311826

311833

312889

312467

312468

312469

312470

311238

312796

Dura-Flo

580cc) Instructions-Parts Manual

Two-Ball NXT

Instructions-Parts Manual

60 cc Check-Mate Displacement Pump

Repair Parts Manual

100 cc Check-Mate Displacement Pump

Repair Parts Manual

200 cc Check-Mate Displacement Pump

Repair Parts Manual

250 cc Check-Mate Displacement Pump

Repair Parts Manual

500 cc Check-Mate Displacement Pump

Repair Parts Manual

™

NXT

Instructions-Parts

™

NXT

Instructions-Parts

308213 Premier

312374 Air Controls Instructions-Parts

312491 Pump Fluid Purge Kit

®

Displacement Pumps

®

Pump Packages

™

Displacement Pumps (145cc,

™

Displacement Pumps (430cc,

™

Pump Packages (145cc,

™

Pump Packages (430cc,

™

Pump Packages (1000cc)

Air Motor (Nxxxxx models)

Air Motor (Mxxxxx models)

®

Air Motor Instructions-Parts

Related Manuals

312492 Drum Roller Kit Instruction

312493 Light Tower Kit Instruction

312864

313138

Communications Gateway Module,

Instructions-Parts

Supply System Communications Gateway

Module Installation Kit, Instructions-Parts

406681 Platen Cover Kit

313529J 3

Page 4

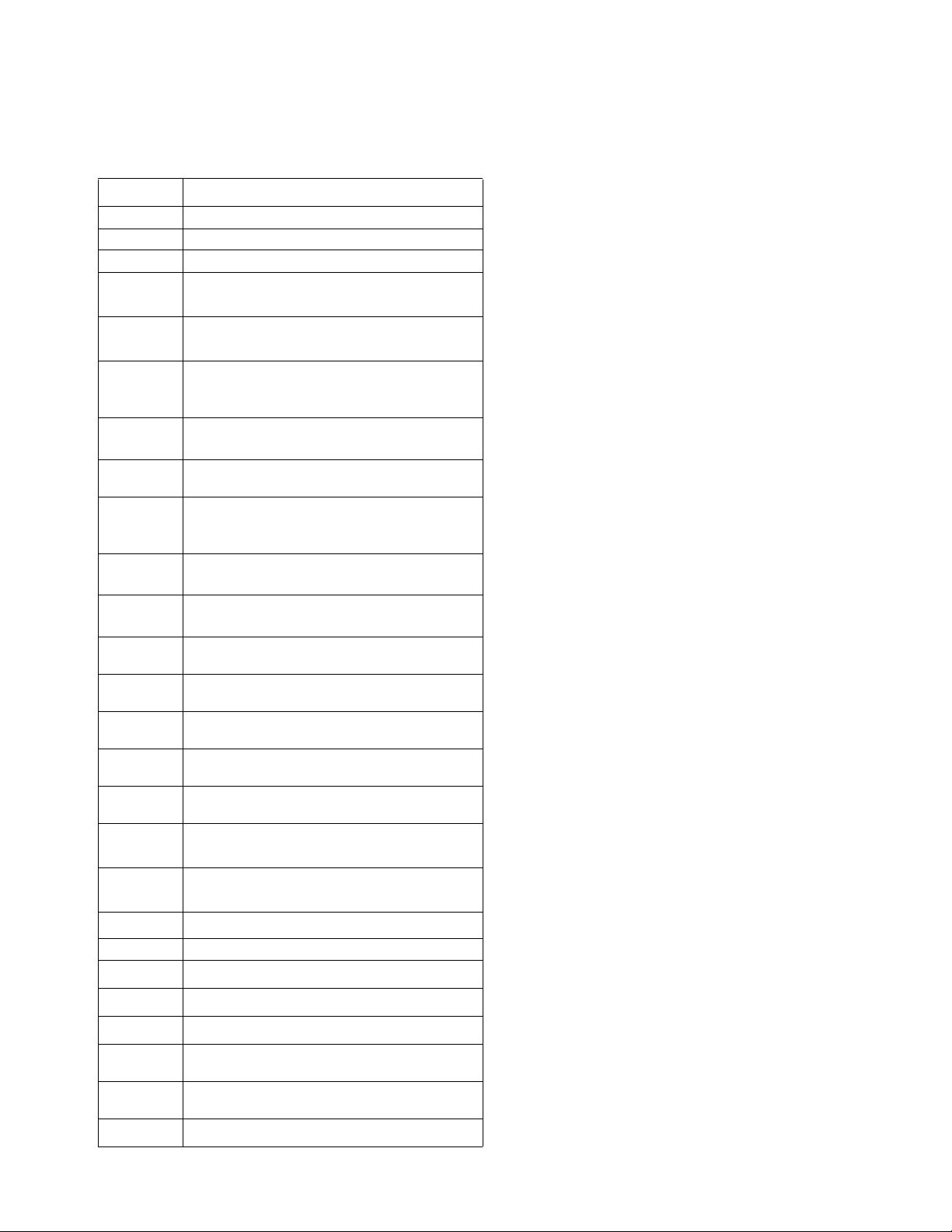

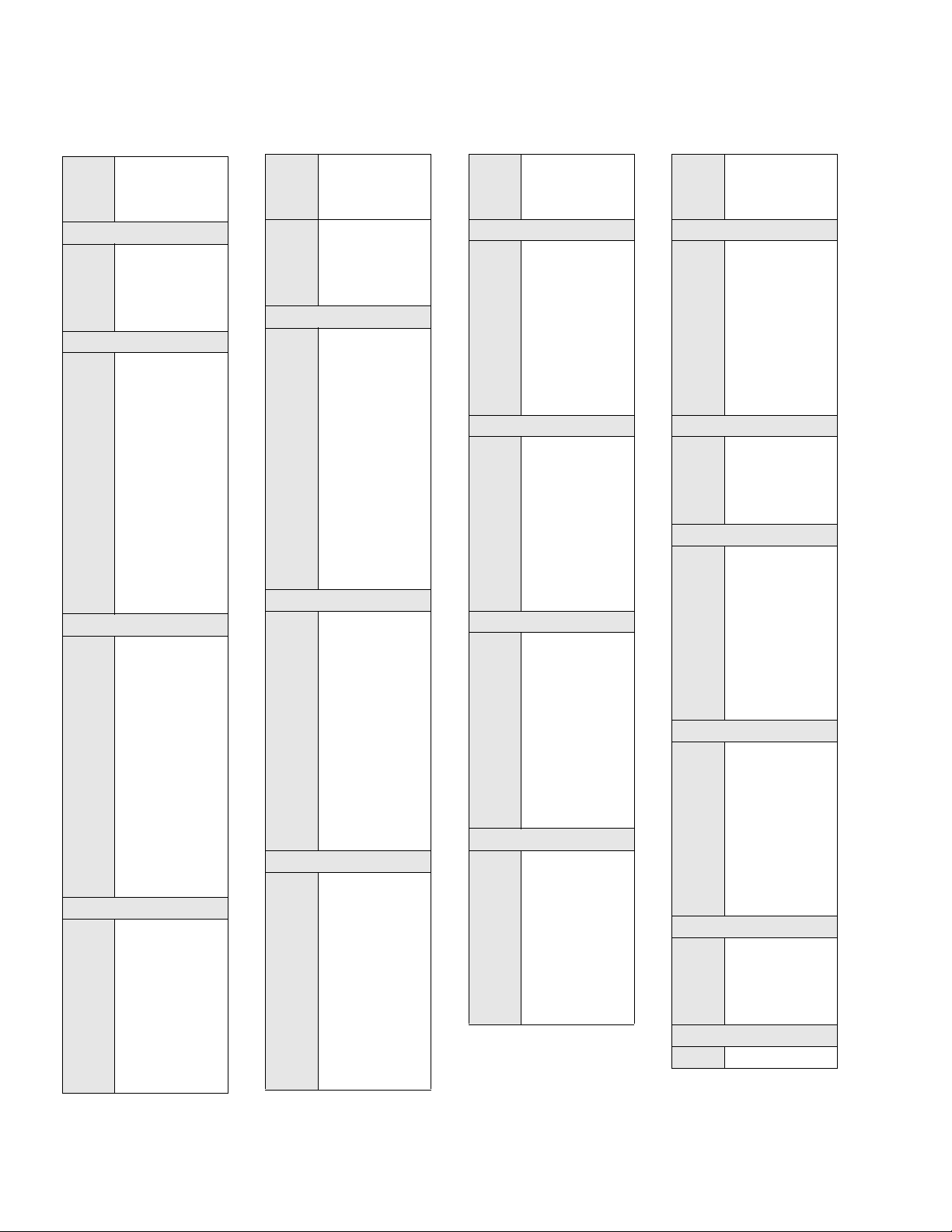

Models

Models

Check the identification plate (ID) for the 6-digit part number of your tandem system. Use the following matrix to define the construction of your system, based on

the six digits. For example, Tandem Part No. TC2414 represents a Check-Mate

tandem system (TC), pump (24), crossover option (1), and platen/ram option (4).

NOTE:

Systems with the TD as the first and second digits are Dura-Flo tandem systems.

Some configurations in the following matrix cannot be built. See the Product

Selection Guide for available systems.

To order replacement parts, see on page 16. The digits in the matrix do not correspond to the Ref. Nos. in the Parts drawings and lists.

TC 24 1 4

First and

Second Digit

TC

(Tandem

System with

Check-Mate

displacement

pump)

TD

(Tandem

System with

Dura-Flo dis-

placement

pump)

Third and

Fourth Digit Fifth Digit Sixth Digit

Crossover Options

Depressurize/

Recirculate Valve

Material

Carbon

Steel SST

Ram Size

n/a

n/a

n/a

n/a

n/a

n/a

S20, D60,

Pump Code

(See Table 2

for 2-digit

Check-Mate

pump code)

Electronic

Crossover

1

2

3

4

5

6

7

Pneumatic

Crossover

(Smart

Motors

only)

✔

(Standard

Motors

only)

Fluid

Filter

✔✔

✔✔✔

✔✔

✔✔

✔✔

✔

✔

D200,

(See Table 3

for 2-digit

Dura-

8

✔

(3 in.)

D200S,

(6.5 in.)

Flo pump

code)

ID

TI11157A

Platen/Ram

Options

See Table 1

for Selections

All supply systems with DataTrak and 24 Vdc or 100-240 Vac power supplies are ETL approved.

2ECOGNIZED#OMPONENT

#-

#ERTIFIEDTO#!.#3!#3!#.O

4 313529J

#ONFORMSTO5,

Page 5

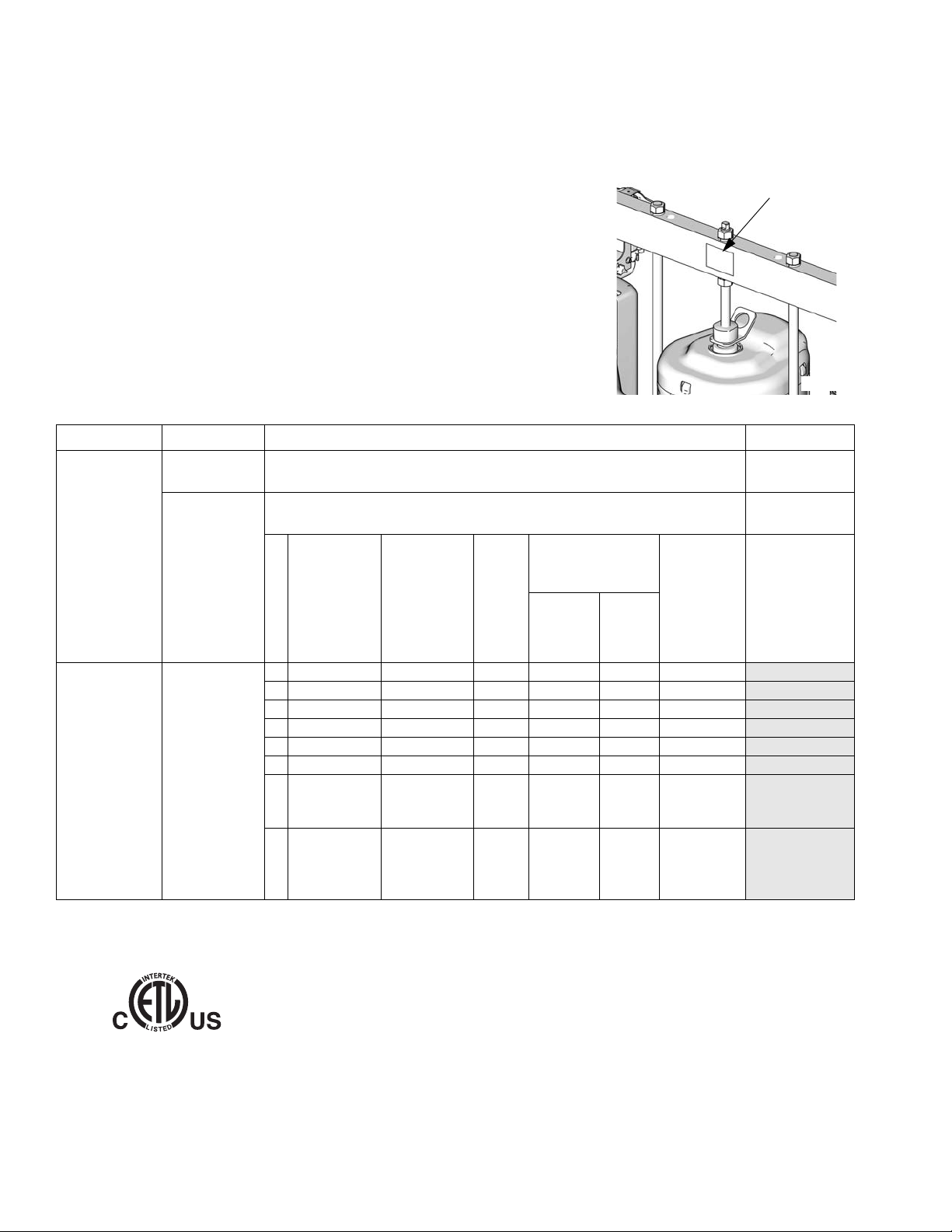

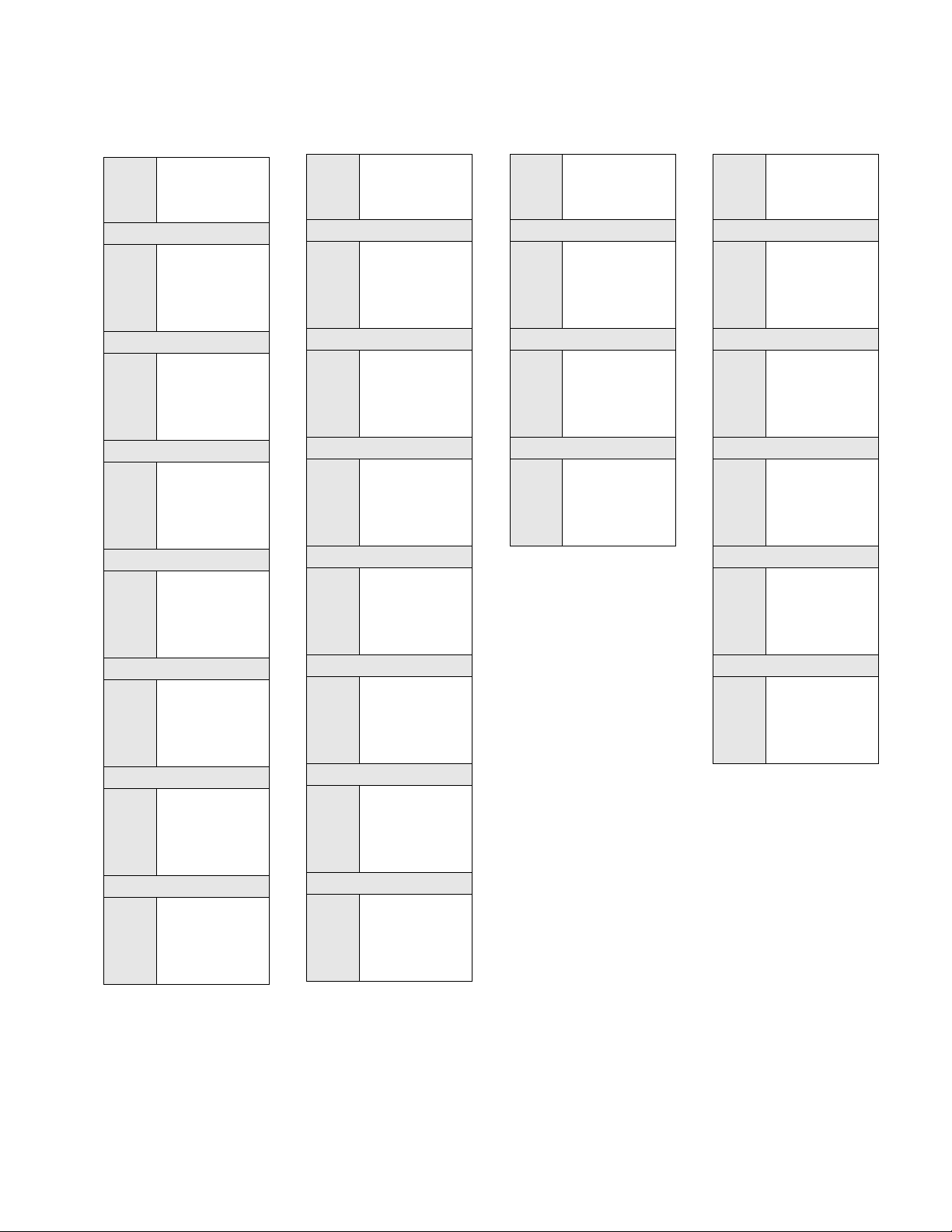

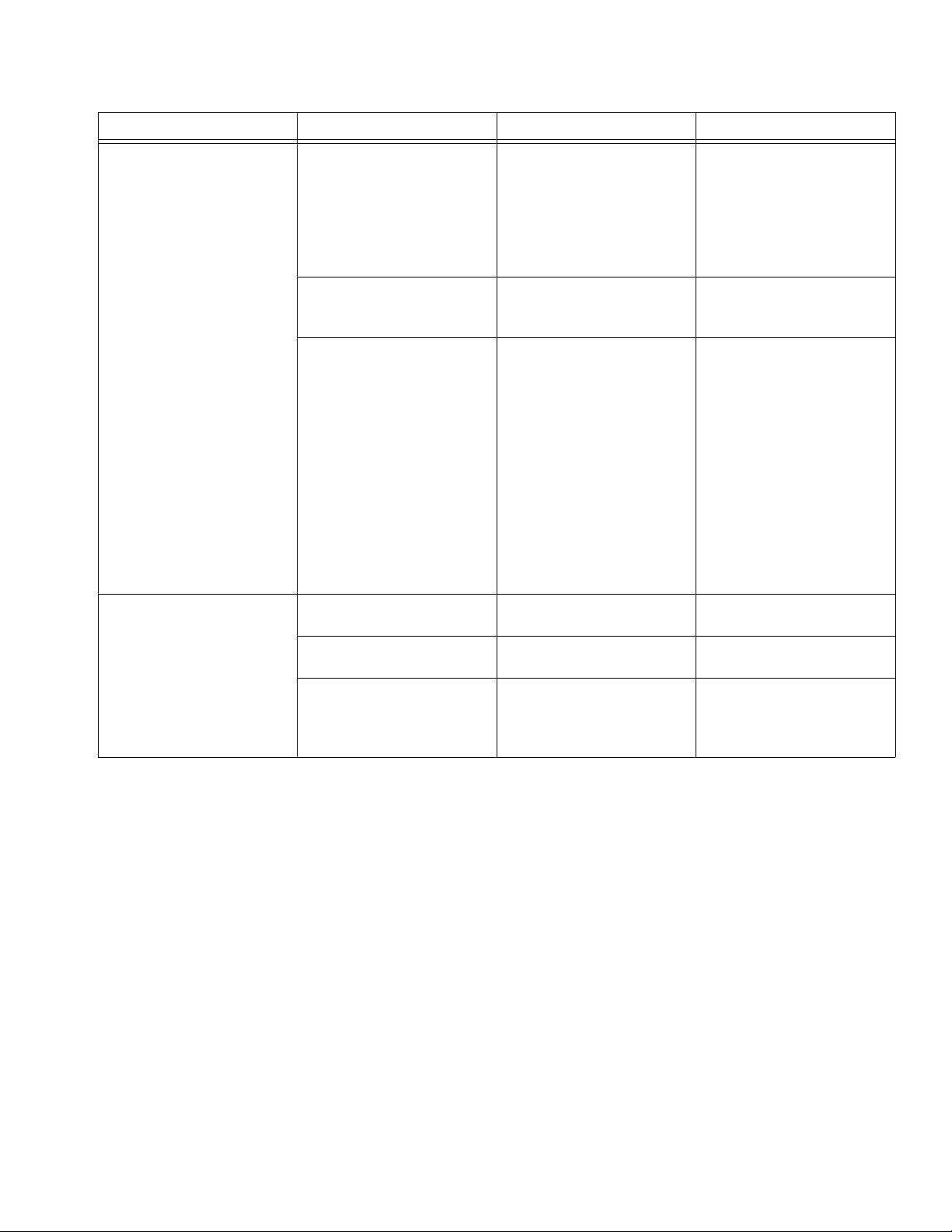

Table 1: Platen/Ram Options

Models

Sixth

Digit Platen Size Platen Style

Platen

Material

Seal Material Ram Size Voltage

2 20 L (5 Gal) Flat, Single Wiper CS Polyurethane S20, 3 in. none

3 20 L (5 Gal) Flat, Single Wiper SST PTFE-Coated Nitrile S20, 3 in none

7 20 L (5 Gal) Flat, Dual Wiper CS Polyurethane D60, 3 in. none

8 20 L (5 Gal) Flat, Dual Wiper CS Polyurethane D60, 3 in. 120 Vdc

9 20 L (5 Gal) Flat, Dual Wiper CS Polyurethane D60, 3 in. 24 Vdc

0 30 L (8 Gal) Flat, Single Wiper SST PTFE-Coated Nitrile D60, 3 in. none

D 30 L (8 Gal) Flat, Single Wiper SST PTFE-Coated Nitrile D60, 3 in. 120 Vdc

E 30 L (8 Gal) Flat, Single Wiper SST PTFE-Coated Nitrile D60, 3 in. 24 Vdc

K 30 L (8 Gal) Flat, Dual Wiper CS Polyurethane D60, 3 in. none

N 30 L (8 Gal) Flat, Dual Wiper CS Polyurethane D60, 3 in. 120 Vdc

P 30 L (8 Gal) Flat, Dual Wiper CS Polyurethane D60, 3 in. 24 Vdc

U 60 L (16 Gal) Flat, Single Wiper SST PTFE-Coated Nitrile D60, 3 in. none

V 60 L (16 Gal) Flat, Single Wiper SST PTFE-Coated Nitrile D60, 3 in. 120 Vdc

W 60 L (16 Gal) Flat, Single Wiper SST PTFE-Coated Nitrile D60, 3 in. 24 Vdc

X 60 L (16 Gal) Flat, Dual Wiper CS Polyurethane D60, 3 in. none

Y 60 L (16 Gal) Flat, Dual Wiper CS Polyurethane D60, 3 in. 120 Vdc

Z 60 L (16 Gal) Flat, Dual Wiper CS Polyurethane D60, 3 in. 24 Vdc

4 115L (30 Gal) D Style CS EPDM D200, 3 in. none

1 20 L (5 Gal) Flat, Single Wiper SST PTFE-Coated Nitrile D200, 3 in. none

6 20 L (5 Gal) Flat, Dual Wiper CS Polyurethane D200, 3 in none

A 200 L (55 Gal) Dual O-ring AL PTFE-Coated EPDM D200, 3 in. none

B 200 L (55 Gal) Dual O-ring AL PTFE-Coated EPDM D200, 3 in. 120 Vdc

C 200 L (55 Gal) Dual O-ring AL PTFE-Coated EPDM D200, 3 in. 24 Vdc

F 200 L (55 Gal) Dual O-ring AL PTFE-Coated EPDM D200S, 6.5 in. none

G 200 L (55 Gal) Dual O-ring AL PTFE-Coated EPDM D200S, 6.5 in. 120 Vdc

H 200 L (55 Gal) Dual O-ring AL PTFE-Coated EPDM D200S, 6.5 in. 24 Vdc

J 200 L (55 Gal) Dual O-ring AL EPDM D200, 3 in. none

L 200 L (55 Gal) Dual O-ring AL EPDM D200, 3 in. 120 Vdc

M 200 L (55 Gal) Dual O-ring AL EPDM D200, 3 in. 24 Vdc

R 200 L (55 Gal) Dual O-ring AL EPDM D200S, 6.5 in. none

S 200 L (55 Gal) Dual O-ring AL EPDM D200S, 6.5 in. 120 Vdc

T 200 L (55 Gal) Dual O-ring AL EPDM D200S, 6.5 in. 24 Vdc

313529J 5

Page 6

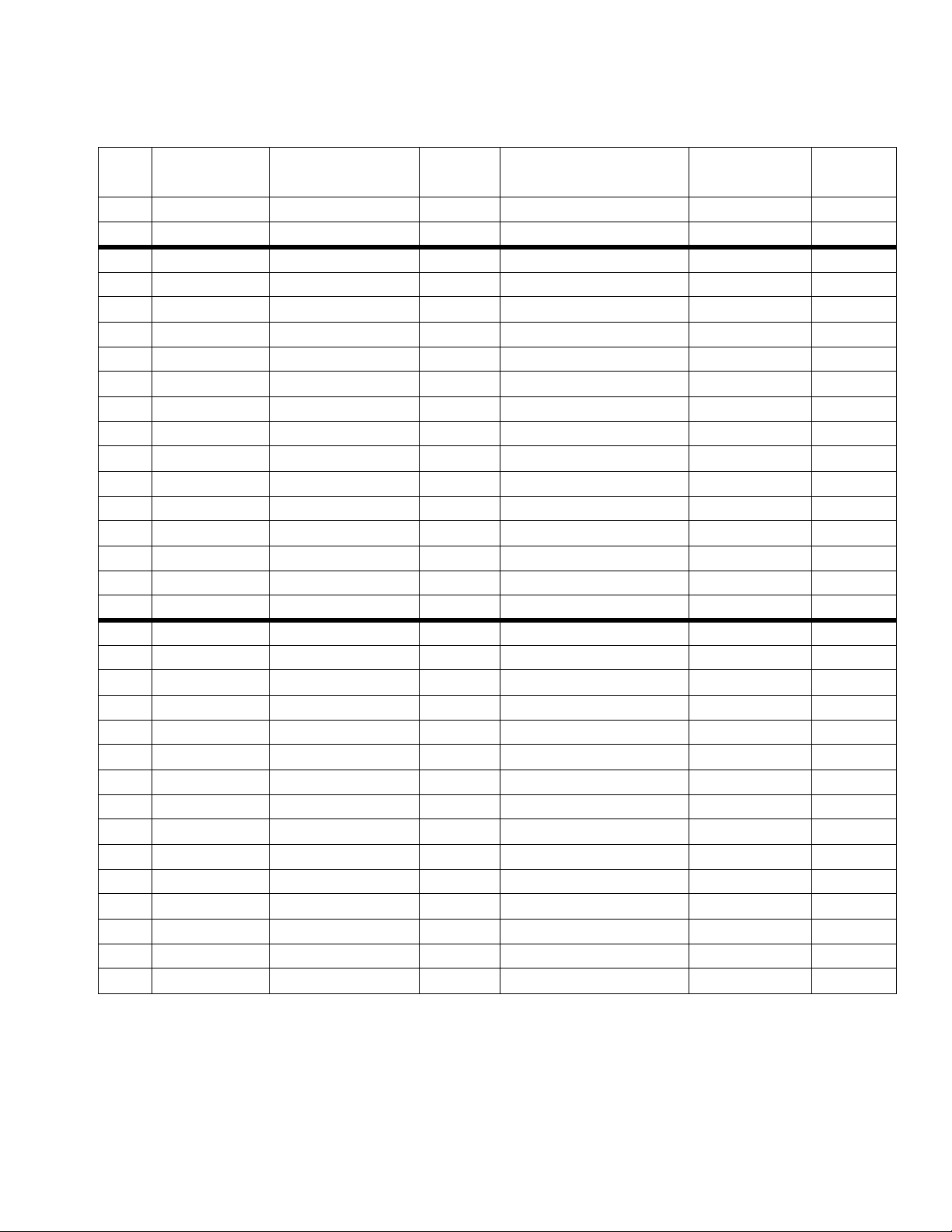

Models

Table 2: Check-Mate Pump Identification Code/Part No. Index

Pump Part No.

Pump

Code

(see manual

312376)

NXT 200/CM 60

4A P05LCS

4B P05LCM

4C P05LSS

4F P05LSM

NXT 400/CM 60

6A P11LCS

6B P11LCM

6C P11LSS

6F P11LSM

6G P11RCS

6H P11RCM

6J P11RSS

6K P11RSM

61 P11SCS

62 P11SCM

63 P11SSS

64 P11SSM

NXT 700/CM 60

7A P20LCS

7B P20LCM

7C P20LSS

7F P20LSM

7G P20RCS

7H P20RCM

7J P20RSS

7K P20RSM

71 P20SCS

72 P20SCM

73 P20SSS

74 P20SSM

NXT 1200/CM 60

8A P38LCS

8B P38LCM

8C P38LSS

8F P38LSM

8G P38RCS

8H P38RCM

8J P38RSS

8K P38RSM

Pump Part No.

Pump

Code

(see manual

312376)

81 P38SCS

82 P38SCM

83 P38SSS

84 P38SSM

NXT 1800/CM 60

9A P61LCS

9B P61LCM

9C P61LSS

9F P61LSM

9G P61RCS

9H P61RCM

9J P61RSS

9K P61RSM

91 P61SCS

92 P61SCM

93 P61SSS

94 P61SSM

NXT 2200/CM 100

11 P40LCS

12 P40LCM

1F P40LSS

1G P40LSM

13 P40RCS

14 P40RCM

1H P40RSS

1J P40RSM

10 P40SSS

1A P40SSM

19 P40SCS

NXT 3400/CM 100

15 P63LCS

16 P63LCM

1T P63LSS

1U P63LSM

17 P63RCS

18 P63RCM

1W P63RSS

1Y P63RSM

1B P63SSS

1C P63SSM

Pump Part No.

Pump

Code

(see manual

312376)

NXT 2200/CM 200

21 P23LCS

22 P23LCM

23 P23RCS

24 P23RCM

25 P23LSS

26 P23LSM

27 P23RSS

28 P23RSM

NXT 3400/CM 200

29 P36LCS

2A P36LCM

2B P36RCS

2C P36RCM

2F P36LSS

2G P36LSM

2H P36RSS

2J P36RSM

NXT 6500/CM 200

2L P68LCS

2M P68LCM

2R P68RCS

2S P68RCM

2T P68LSS

2U P68LSM

2W P68RSS

2Y P68RSM

20 P68SCS

NXT 3400/CM 250

31 P29LCS

32 P29LCM

33 P29RCS

34 P29RCM

35 P29LSS

36 P29LSM

37 P29RSS

38 P29RSM

Pump Part No.

Pump

Code

(see manual

312376)

NXT 6500/CM 250

39 P55LCS

3A P55LCM

3B P55RCS

3C P55RCM

3F P55LSS

3G P55LSM

3H P55RSS

3J P55RSM

Premier/CM 250

3L P82LCS

3M P82LCM

3R P82LSS

3S P82LSM

NXT 3400/CM 500

51 P14LCS

52 P14LCM

53 P14RCS

54 P14RCM

55 P14LSS

56 P14LSM

57 P14RSS

58 P14RSM

NXT 6500/CM 500

59 P26LCS

5A P26LCM

5B P26RCS

5C P26RCM

5F P26LSS

5G P26LSM

5H P26RSS

5J P26RSM

Premier/CM 500

5L P39LCS

5M P39LCM

5R P39LSS

5S P39LSM

No Pump

NN

6 313529J

Page 7

Table 3: Dura-Flo Pump Identification Code/Part No. Index

Models

Pump Part No.

Pump

Code

(see manual

311828)

NXT 2200/DF 145SS

A1 P31LSS

A2 P31LSM

A3 P31HSS

A4 P31HSM

NXT 3400/DF 145SS

B1 P46LSS

B2 P46LSM

B3 P46HSS

B4 P46HSM

NXT 3400/DF 180SS

B5 P41LSS

B6 P41LSM

B7 P41HSS

B8 P41HSM

NXT 3400/DF 220SS

C1 P30LSS

C2 P30LSM

C3 P30HSS

C4 P30HSM

NXT 6500/DF 220SS

CA P57LSS

CB P57LSM

CC P57HSS

CD P57HSM

NXT 6500/DF 290SS

D1 P45LSS

D2 P45LSM

D3 P45HSS

D4 P45HSM

Premier/DF 290SS

DL P67LSS

DM P67LSM

DR P67HSS

DS P67HSM

Pump Part No.

Pump

Code

(see manual

311826)

NXT 3400/DF 430CS

E1 P15LCS

E2 P15LCM

E3 P15HCS

E4 P15HCM

NXT 3400/DF 430SS

E5 P15LSS

E6 P15LSM

E7 P15HSS

E8 P15HSM

NXT 6500/DF 430CS

E9 P32LCS

EA P32LCM

EB P32HCS

EC P32HCM

NXT 6500/DF 430SS

EF P32LSS

EG P32LSM

EH P32HSS

EJ P32HSM

Premier/DF 430

EL P44LSS

EM P44LSM

ER P44LCS

ES P44LCM

NXT 3400/DF 580CS

F1 P12LCS

F2 P12LCM

F3 P12HCS

F4 P12HCM

NXT 3400/DF 580SS

F5 P12LSS

F6 P12LSM

F7 P12HSS

F8 P12HSM

Pump Part No.

Pump

Code

(see manual

311826)

NXT 6500/DF 580CS

F9 P22LCS

FA P22LCM

FB P22HCS

FC P22HCM

NXT 6500/DF 580SS

FF P22LSS

FG P22LSM

FH P22HSS

FJ P22HSM

Premier/DF 580CS

FL P34LSS

FM P34LSM

FR P34LCS

FS P34LCM

Pump Part No.

Pump

Code

(see manual

311833)

NXT 3400/DF 1000CS

G1 P06LCS

G2 P06LCM

G3 P06HCS

G4 P06HCM

NXT 3400/DF 1000SS

G5 P06LSS

G6 P06LSM

G7 P06HSS

G8 P06HSM

NXT 6500/DF 1000CS

G9 P10LCS

GA P10LCM

GB P10HCS

0C P10HCM

NXT 6500/DF 1000SS

GF P10LSS

GG P10LSM

GH P10HSS

GJ P10HSM

Premier/DF 1000

GL NR

GM NR

GR NR

GS NR

NR = Not released

313529J 7

Page 8

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

8 313529J

Page 9

Warnings

WARNING

WARNINGWARNINGWARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

ELECTRIC SHOCK HAZARD

Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power cord before servicing equipment.

• Use only grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on sprayer and extension cords.

• Do not expose to rain. Store indoors.

SPLATTER HAZARD

During blowoff of platen splatter may occur.

• Use minimum drum removal air pressure.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear impervious gloves when spraying or cleaning equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

313529J 9

Page 10

Troubleshooting

Troubleshooting

NOTE: Refer to the Supply System Repair-Parts

manual for specific ram troubleshooting. Refer to

the Check-Mate Pump Packages manual for pump

troubleshooting.

Problem Cause Verification Solution

No power. Customer supplied main

circuit breaker tripped.

No graphics on screen. No graphics are shown on

display screen.

1. Follow Pressure Relief Procedure, page 13, before

disassembling any part of the supply system.

2. Disconnect power before repairing the supply system.

3. Check all possible problems and causes before disassembling the supply system.

Measure voltage across

disconnect switch; voltage

should measure between

190 and 250 Vac.

Verify green LED on bottom

of display is illuminated.

Determine cause of the

tripped circuit breaker.

Then repair fault and reset

main circuit breaker.

If green LED is not illuminated:

Backlight does not power

up.

Can see display, but backlight is not illuminated when

a button is pressed.

1. Check for DC power at

display. Replace faulty

cable/component.

2. Replace faulty display

module.

If green LED is illuminated,

check red LED. If red LED

is illuminated, replace display module.

Replace display module.

10 313529J

Page 11

Problem Cause Verification Solution

Missing module. Modules not on network. Verify attached modules

through Advanced Setup

screens 4 and 5.

Cable disconnected. Verify all green LEDs are

illuminated and yellow

LEDs are flashing.

Module with wrong selector switch setting.

Verify selector switch is set

correctly.

Troubleshooting

Enter Setup screen and

scroll to Advanced Setup

screens 4 and 5. These

screens lists all components corresponding software revision number on

network.

Reconnect/replace faulty

cable.

1. Remove power from

unit.

2. Remove access cover

and visually check

rotary switch setting.

3. If incorrect, set to correct setting. See Selec-

tor Switch, page 12,

for selector switch locations.

Does not crossover. Alternate ram has an empty

sensor activated.

Alternate pump is not

primed.

Alternate pump has an

active alarm.

4. Replace access cover.

Verify ram has material. Replace empty drum.

Verify alternate ram is

Prime pump.

ready to run.

See Alarm Codes and

Troubleshooting in the

Tandem Supply Systems

Operation manual.

See Alarm Codes and

Troubleshooting in the

Tandem Supply Systems

Operation manual.

313529J 11

Page 12

Troubleshooting

Selector Switch

Ensure the selector switch (inside the fluid control module) is set correctly for each ram.

1. Turn power off.

2. Remove access cover (D).

D

TI12334a

F

IG. 1:

3. For ram A, ensure the selector switch (S) is set to

“A”. If it is not, use a flat head screwdriver to adjust

the switch to “A”.

4. For ram B, ensure the selector switch (S) is set to

“B”. If it is not, use a flat head screwdriver to adjust

the switch to “B”.

S

F

IG. 2:

5. Replace access cover.

6. Turn power on.

12 313529J

Page 13

Repair

Pressure Relief Procedure

1. Lock the gun/valve trigger.

Repair

BF

2. Press On/Off key . If system is On, display will

highlight . Select to turn off.

FIG. 3: System Function Screen

3. Turn off the air motor slider valve (BF) on both ram A

and B.

4. On both ram A and B, turn off the main air slider

valve (BA). Set the ram director valve (BC) to the

down position. The ram will slowly drop.

5. Unlock the gun/valve trigger.

BE

BG

BC

BB

BA

TI10438A

FIG. 4. Integrated Air Controls

Ram Repair

See manual 313527 for ram and platen repair procedures and replacement parts.

6. Hold a metal part of the gun/valve firmly to the side

of a grounded metal pail, and trigger the gun/valve

to relieve pressure.

7. Lock the gun/valve trigger.

8. On both ram A and B, open the drain valve and/or

the pump bleed port. Have a container ready to

catch the drainage.

If you suspect that the spray tip/nozzle or hose is completely clogged, or that pressure has not been fully

relieved after following the steps above, very slowly

loosen the tip guard retaining nut or hose end coupling

and relieve pressure gradually, then loosen completely.

Now clear the tip/nozzle or hose.

313529J 13

Pump Repair

See pump manuals for pump repair procedures and

replacement parts.

See manual 311238 (Nxxxxx NXT models), 312796

(Mxxxxx NXT models), or 308213 (Premier) for air motor

repair procedures and replacement parts.

Crossover Schematics

See page 14 for a schematic of electronic crossover

systems and page 15 for a schematic of pneumatic

crossover systems.

Page 14

Electronic Crossover Schematic

Electronic Crossover Schematic

Fluid Solenoid

(1) Signal

(2) Common

(GND) Unused

Graco P/N 15M574

F

(1)

(2)

(3)

Wire Harness

Graco P/N 15Y047

M

(1)

(2)

(3)

(4)

3

Drain (2)

Signal (4)

Unused (1)

Common (3)

FLUID

RAM B

MODULE

CONTROL

5

(2) N/C

(3) Motor Reed Up

(5) Motor Reed Com

(7) Linear Com

(1) Linear Input

(4) Motor Reed Down

(6) Linear Power

M

(8) Drain

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

DRUM LOW

Graco P/N 122716

Cable Splitter

Graco P/N 15X968

DRUM EMPTY

(2) Unused

(1) Power

(1)

(3)

(2)

M

1

(3) COM

(2) Unused

(1) Power

(4) SIGNAL

(3) COM

Graco P/N 122716

F

(1)

(3)

(4)

(2)

(4) SIGNAL

(4)

(5)

(1)

(2)

(3)

(4)

Power (1)

Common (3)

Air Solenoid (5)

Low Sensor (2)

Empty Sensor (4)

(1) Solenoid signal

(2) Solenoid RTN

F

(1)

(2)

AIR SOLENOID

Graco P/N 121235

SHLD (1)

SHLD (1)

-24Vdc (3)

+24Vdc (2)

-24Vdc (3)

+24Vdc (2)

CAN_L (5)

CAN_H (4)

CAN_H (4)

CAN_L (5)

Motor Pigtail

Graco P/N 15X619

M

(1)

FLUID

CONTROL

Motor Pigtail

Graco P/N 15X619

M

(1)

(2)

(2)

(3)

(4)

RAM A

MODULE

(3)

(4)

(5)

Cable 8 Pin

Graco P/N 15Y051

FM

(5)

5

(1) Linear Input

M

(1)

Cable 8 Pin

Graco P/N 15Y051

F

M

Sensor Reed Switch

(1)

(2)

(3)

(4)

(1)

(2)

(3)

(4)

MF

(1)

(2)

(3)

(1)

(2)

(3)

Top Switch (1)

Top Switch (2)

Graco P/N 119700

Bottom Switch (1)

Sensor Reed Switch

(4) Motor Reed Down

(6) Linear Power

(2) N/C

(3) Motor Reed Up

(5) Motor Reed Com

(2)

(3)

(4)

(5)

(6)

(1)

(2)

(3)

(4)

(5)

(6)

(1)

(2)

(3)

(4)

(5)

(6)

(1)

(2)

(3)

(4)

MF

(1)

(2)

(3)

(4)

Top Switch 1

Top Switch 2

Bottom Switch 1

Bottom Switch 2

Graco P/N 119700

(5)

(6)

(7)

(8)

(5)

(6)

(7)

(8)

(4)

(4)

Bottom Switch (2)

(8) Drain

(7) Linear Com

(7)

(8)

(7)

(8)

(7)

(8)

Cable Splitter

Graco P/N 15Y037

(1)

(2)

(3)

7

M

Cable 15 Meter

MF

(4)

(4) Filter Outlet Press.

(5) Drain

(1) Power

(2) Filter Inlet Press.

(3) Common

(5)

(1)

(2)

(3)

(4)

Graco P/N 15Y048

(1)

(2)

(3)

(4)

(1)

(2)

(3)

(4)

(5) (5)

(1)

Ferrite Bead

Graco P/N 121901

Depressurization

Accessory Kit

DRUM EMPTY

(1) Power

(4) SIGNAL

(3) COM

(2) Unused

Graco P/N 122716

F

(1)

(3)

(4)

(2)

Light Tower

(1) Unused

(2) Amber

(3) Common

(4) Green

(1) Signal

(2) Common

(GND) Unused

Fluid Solenoid

Graco P/N 15M574

F

(1)

(2)

(3)

Ferrite Bead

Wire Harness

Graco P/N 121901

Graco P/N 15Y047

M

(1)

(2)

(3)

(4)

3

Drain (2)

Signal (4)

Unused (1)

Common (3)

DISPLAY

MODULE

(2)

(3)

(4)

Graco P/N 15X472

M

(1)

(2)

(3)

2

Amber (2)

Unused (1)

Common (3)

(5) Red

(5)

(4)

Red (5)

Green (4)

E

M

B

M

DRUM LOW

Graco P/N 122716

Cable Splitter

Graco P/N 15X968

E

N

A

R

P

S

I

D

W

S

A

L

(2) Unused

(1) Power

(1)

(2)

I

C

T

Y

(3) COM

(3)

M

1

H

(4)

(4) SIGNAL

(1)

(2)

Power (1)

Low Sensor (2)

F

(3)

(4)

(5)

Common (3)

Air Solenoid (5)

Empty Sensor (4)

AIR SOLENOID

(1) Solenoid signal

(2) Solenoid RTN

Graco P/N 121235

(1)

(2)

Cable, CAN 0.4m

Graco P/N 121226

SHLD (1)

+24Vdc (2)

+24Vdc (2)

SHLD (1)

SHLD (1)

+24Vdc (2)

+24Vdc (2)

SHLD (1)

-24Vdc (3)

CAN_H (4)

-24Vdc (3)

CAN_H (4)

-24Vdc (3)

CAN_H (4)

-24Vdc (3)

CAN_H (4)

Cable, CAN 15m

Graco P/N 121228

CAN_L (5)

CAN_L (5)

Cable, CAN 0.6m

Graco P/N 121227

CAN_L (5)

CAN_L (5)

Ferrite Bead

Graco P/N 121901

Ferrite Bead

Graco P/N 121901

Ferrite Bead

Graco P/N 121901

Press Signal (4)

Power (1)

Unused (2)

Common (3)

Press Signal (4)

Graco P/N 121175

Fluid Pressure Sensor

SHLD

-24Vdc

+24Vdc

Gracp P/N 15M293

+24Vdc POWER SUPPLY

L

N

Power (1)

Unused (2)

Common (3)

Graco P/N 121175

Fluid Pressure Sensor

Filter Accessory Kit

14 313529J

Page 15

Pneumatic Crossover Schematic

Pneumatic Crossover Schematic

313529J 15

Page 16

Pneumatic Crossover Schematic

16 313529J

Page 17

Parts

Tandem Supply System; Electronic Crossover Model Shown

D200 Rams Shown

Supply System A Supply System B

5

5

10

Parts

11

12

10

2

7

3

6

4

9

11

12

4

8

2

3

6

TI10865A

313529J 17

Page 18

Parts

NOTE:

See on page 4 to identify the components included in

your Tandem Supply System.

Ref. Part Description Qty.

2 255648❄ RAM ASSEMBLY, D200, 3 in. 2

255688❄ RAM ASSEMBLY, D200s, 6.5 in. 2

257620❄ RAM ASSEMBLY, S20, 3 in. 2

257621❄ RAM ASSEMBLY, D60, 3 in. 2

3 see Table

2, page 6

4 255662❄ PLATEN, 55 gal., o-ring, PTFE 2

255663❄ PLATEN, 55 gal., o-ring, EPDM 2

255661❄ PLATEN, 30 gal., D-style, EPDM 2

257728❄ PLATEN, 20 liter, single wiper, polyure-

257729❄ PLATEN, 20 liter, single wiper, PTFE 2

257731❄ PLATEN, 20 liter, double wiper, polyure-

257734❄ PLATEN, 30 liter, single wiper, PTFE 2

257736❄ PLATEN, 30 liter, double wiper, polyure-

257738❄ PLATEN, 60 liter, single wiper, PTFE 2

257741❄ PLATEN, 60 liter, double wiper, polyure-

5 255305❄ KIT, mounting, pump; 3 in.; 55 gal. 2

255308❄ KIT, mounting, pump; 3 in.; 20 liter and 30

255309❄ KIT, mounting, pump; 3 in.; 20 liter and 30

255315❄ KIT, mounting, pump; 6.5 in.; 55 gal. 2

255316❄ KIT, mounting, pump; 6.5 in.; 20 liter and

255317❄ KIT, mounting, pump; 6.5 in.; 20 liter and

256235❄ KIT, mounting, pump; 3 in.; 55 gal.; for

257666❄ KIT, mounting, pump; S20, 3 in.; 5 gal.; for

257664❄ KIT, mounting, pump; S20, 3 in.; 5 gal.; for

257623❄ KIT, mounting, pump; D60, 3 in.; 5 gal.; for

257624❄ KIT, mounting, pump; D60, 3 in.; 5 gal.; for

6 255392❄ KIT, mounting; for all 55 gal. and 30 gal.

257630❄ KIT, mounting; for DuraFlo pumps to 20,

7 255706✠ KIT, electronic crossover, with display,

255759✠ KIT, electronic crossover, with display,

255707✠ KIT, electronic crossover, with display,

255760✠ KIT, electronic crossover, with display,

8 255708† KIT, electronic crossover, no display; for 3

255709† KIT, electronic crossover, no display; for

PUMP, Check-Mate; see manual 312375

for parts

thane

thane

thane

thane

gal.; for NXT 3400 and 6500 air motors

gal.; for NXT 2200 air motors

30 gal.; for NXT 3400 and 6500 air motors

30 gal.; for NXT 2200 air motors

Dura-Flo pumps

NXT 2200 and 3400 air motors

NXT 200, 400, 700, 1200, and 1800 air

motors

NXT 2200 air motors

NXT 3400 and 6500 air motors

platens

30, 60 liter platens

Vac; for 3 in. D200 and D60 Ram A

Vdc; for 3 in. D200 and D60 Ram A

Vac; for 6.5 in. D200s Ram A

Vdc; for 6.5 in. D200s Ram A

in. D200 and D60 Ram B

6.5 in. D200s Ram B

Ref. Part Description Qty.

9 247504 KIT, fluid filter; included with electronic

crossover models only; see page 28

10 VALVE, safety relief; located out of view,

on back side of air controls

116643 For systems with pumps: P55xxx and

P57xxx

103347 For systems with pumps: P05xxx, P06xxx,

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

1

1

1

1

1

1

120306 For systems with pumps: P61xxx, P63xxx,

108124 For systems with pumps: P68xxx

110065 For systems with pumps: P82xxx

11 255452◆ KIT, pump outlet check valve; used on cst

257377◆ KIT, pump outlet check valve; used on sst

255453◆ KIT, pump outlet check valve; used on cst

255454◆ KIT, pump outlet check valve; used on sst

255455◆ KIT, pump outlet check valve; used on cst

255456◆ KIT, pump outlet check valve; used on sst

256882◆ KIT, pump outlet check valve; used on cst

12 255457❖ KIT, depressurization; cst; included with

255458❖ KIT, depressurization; sst; included with

13★ 255675✓ KIT, pneumatic crossover; for 3 in. D200

255676✓ KIT, pneumatic crossover; for 6.5 in.

257633✓ KIT, pneumatic crossover; for S20 rams 1

257632✓ KIT, pneumatic crossover; for 3 in. D60

★ Not shown.

❄ See Supply Systems Repair-Parts manual 313527 for

parts.

✠ See page 19 for parts.

† See page 23 for parts.

◆ See page 29 for parts.

❖ See page 30 for parts.

✓ See page 25 for parts.

P10xxx, P11xxx, P12xxx, P14xxx,

P15xxx, P20xxx, P22xxx, P23xxx,

P26xxx, P29xxx, P30xxx, P31xxx,

P32xxx, P34xxx, P36xxx, P38xxx,

P39xxx, P40xxx, P41xxx, P44xxx,

P45xxx, P46xxx

and P67xxx

Check-Mate 60 and 100 displacement

pumps

Check-Mate 60 and 100 displacement

pumps

Check-Mate 200 and 250 displacement

pumps

Check-Mate 200 and 250 displacement

pumps

Check-Mate 500 displacement pumps

Check-Mate 500 displacement pumps

Dura-Flo 430 and 580 displacement

pumps

electronic crossover models only

electronic crossover models only

rams

D200s rams

rams

2

2

2

2

2

2

2

2

2

1

1

1

18 313529J

Page 19

Electronic Crossover Kits, with display

255706, with display, Vac, for 3 in. D200 and D60 Ram A

255759, with display, Vdc, for 3 in. D200 and D60 Ram A

255707, with display, Vac, for 6.5 in. D200s Ram A

255760, with display, Vdc, for 6.5 in. D200s Ram A

110

109

114

111

121

116

101

102

112

116

124

113

117

115 (Ref)

102

Parts

101

125

115 (Ref)

108

106

122

126

146

148

115 (Ref)

5

129

140

127

147

128

See page 22 for

power supply detail

4

102

107

101

r_257374_313529_4a

Harness (115) Detail

2

1

To connection 1 on fluid control module (126).

2

To air motor solenoid (129).

4

To drum empty sensor (124).

5

To accessory drum low sensor (if present).

1

TI10909A_1

313529J 19

Page 20

Parts

Electronic Crossover Kits, with display

255706

(Vac, for D200

and D60 Rams;

see pages 18

Ref. Description

101 WASHER, lock; 1/4 100016 100016 100016 100016 15

102 SCREW, cap, socket-hd; 1/4-20 x

5/8 in. (16 mm)

106 COVER, shroud front, 3 in. n/a n/a 1

COVER, shroud front, 6.5 in.

107 COVER, shroud rear, 3 in. n/a n/a 1

COVER, shroud rear, 6.5 in. n/a n/a 1

108 BRACKET, light tower, 3 in. n/a n/a 1

BRACKET, light tower, 6.5 in.

109 CABLE, CAN, display/power sup-

ply; m x f; 0.4 m

110* MODULE, display 24F493 24F493 24F493 24F493 1

111 BRACKET, pivot n/a n/a n/a n/a 1

112 BRACKET, mounting, display mod-

ule

113 SCREW, cap, socket-hd, 1/4-20 x

4.25 in. (108 mm)

114 NUT, lock, hex; 1/4-20 102040 102040 102040 102040 1

115 HARNESS, fluid control module 15X968 15X968 15X968 15X968 1

116 WASHER, plain 110755 110755 110755 110755 1

117 KNOB, display adjustment 121253 121253 121253 121253 1

121 CABLE, CAN, display/fluid control

module; fbe; 0.6 m

122 CABLE, M12, 8 pin, air motor reed

switch

124 SENSOR, inductive, low/empty 122716 122716 122716 122716 1

125 BRACKET, sensor, low/empty n/a n/a n/a n/a 1

126* MODULE, fluid control 289696 289696 289696 289696 1

127‡

128 MODULE, base, fluid control n/a n/a n/a n/a 1

129 SOLENOID, air motor 121235 121235 121235 121235 1

130★ LABEL, shutoff valve 15V954 15V954 15V954 15V954 1

ACTUATOR, sensor, low/empty;

3 in.

ACTUATOR, sensor, low/empty; 6.5

in.

and 22)

101682 101682 101682 101682 15

121226 121226 121226 121226 1

n/a n/a n/a n/a 1

121250 121250 121250 121250 1

121227 121227 121227 121227 1

15Y051 15Y051 15Y051 15Y051 1

n/a n/a 1

255759

(Vdc, for D200

and D60 Rams;

see pages 18

and 22)

255707

(Vac, for

D200s Ram; see

pages 18 and 22)

n/a n/a 1

n/a n/a 1

n/a n/a 1

255760

(Vdc, for

D200s Ram; see

pages 18 and 22) Qty.

Parts designated n/a are not available separately.

★ Not shown.

‡ D60 ram only: Position collar of actuator sensor

D60 Ram

Actuator sensor position

down, near ram weldment, with bracket pointing up.

* Requires Ref. 149 for programming.

20 313529J

127

Page 21

Parts

255706

(Vac, for D200

and D60 Rams;

see pages 18

Ref. Description

131 SCREW; 6-32 x 3/8 in. (10 mm) 121255 121255 121255 121255 6

132 ENCLOSURE, power supply n/a n/a n/a n/a 1

133 BRACKET, power supply, 3 in. n/a n/a

BRACKET, power supply, 6.5 in. n/a n/a 1

134 POWER SUPPLY, 100-240 Vac 15M293

POWER MODULE, 24 Vdc, with

switch

135a SWITCH, power, 100-240 Vac 121254

135b COVER, switch mount, Vdc n/a n/a 1

136 SCREW, self-tapping 101845

137 COVER, power supply n/a n/a 1

138 FUSE, 250V, 1.2A 121261 121261 2

139 CABLE, power, female, 0.8 m 255673 255673 1

140▲ LABEL, warning; hot surface 189285 189285 189285 189285 1

141▲ LABEL, warning; electric 15J074 15J074 15J074 15J074 1

143▲ LABEL, warning; crush and pinch 196548 196548 196548 196548 1

144 GROMMET 112738 112738 112738 112738 1

145 WASHER, lock 100272 100272 100272 100272 2

146 SCREW 114417 114417 114417 114417 4

147 ENCLOSURE, door 277674

148 SCREW, mach, pan hd, ground 121070 121070 121070 121070 1

149 TOKEN, upgrade

and 22)

16C027 16C027 16C027 16C027 1

255759

(Vdc, for D200

and D60 Rams;

see pages 18

and 22)

255649 255649 1

277674 277674 277674 1

255707

(Vac, for

D200s Ram; see

pages 18 and 22)

15M293 1

121254 1

101845 6

255760

(Vdc, for

D200s Ram; see

pages 18 and 22) Qty.

1

Parts designated n/a are not available separately.

★ Not shown.

▲ Replacement Danger and Warning labels, tags and cards are available at no cost.

313529J 21

Page 22

Parts

Power Supply Detail

(Both 24 Vdc and 100-240 Vac Power Supplies Shown)

See Supply Units Repair-Parts manual 313527 for power supply repair procedures. Part numbers listed on page 22.

Power Supplies on D200 and D60

132

101

102

131

144

137

145

141

136

135a, 135b, 138

134✿

146

120

139

136

134✖

136

131

143

Fuse Detail

138

135a

TI10852A

133

101

102

r_255648_313527_24a2

✿ 24 Vdc Power Supply

✖ 120-240 Vac Power Supply

22 313529J

Page 23

Electronic Crossover Kits, without display

255708, without display, for 3 in. D200 and D60 Ram B

255709, without display, for 6.5 in. D200s Ram B

115 (Ref)

129

Parts

102

101

125

143

115 (Ref)

106

147

148

126

128

115 (Ref)

124

140

108

101

127

102

102

101

107

102

101

133

r_2573734_313259_5a

146

120

132

151

131

Harness (115) Detail

5

4

2

1

To connection 1 on fluid control module (126).

2

To air motor solenoid (129).

4

To drum empty sensor (124).

5

To accessory drum low sensor (if present).

1

TI10909A_1

313529J 23

Page 24

Parts

Electronic Crossover Kits, without display

255708

(without display, for

D200 and D60 Rams;

Ref. Description

101 WASHER, lock; 1/4 100016 100016 11

102 SCREW, cap, socket-hd; 1/4-20 x 5/8 in. (16 mm) 101682 101682 11

106 COVER, shroud front, 3 in. n/a 1

COVER, shroud front, 6.5 in.

107 COVER, shroud rear, 3 in. n/a 1

COVER, shroud rear, 6.5 in.

108 BRACKET, light tower, 3 in. n/a 1

BRACKET, light tower, 6.5 in.

115 HARNESS, fluid control module 15X968 15X968 1

120 SCREW, machine, pan-head; 10-24 x 3/8 in. (10 mm) 110637 110637 4

122★ CABLE, M12, 8 pin 15Y051 15Y051 1

124 SENSOR, inductive, low/empty 122716 122716 1

125 BRACKET, sensor, low/empty n/a n/a 1

126 MODULE, fluid control

127‡ ACTUATOR, sensor, low/empty; 3 in. n/a 1

ACTUATOR, sensor, low/empty; 6.5 in.

128* MODULE, base, fluid control n/a n/a 1

129 SOLENOID, air motor 121235 121235 1

130★ LABEL, shutoff valve 15V954 15V954 1

131 SCREW; 6-32 x 3/8 in. (10 mm) 121255 121255 6

132 ENCLOSURE, power supply n/a n/a 1

133 BRACKET, power supply, 3 in. n/a

BRACKET, power supply, 6.5 in. n/a 1

140▲ LABEL, warning; hot surface 189285 189285 1

143▲ LABEL, warning; crush and pinch 196548 196548 1

146 SCREW 114417 114417 4

147 ENCLOSURE, door 277674 277674 1

148 SCREW, mach, pan hd, grounding 121070 121070 1

150★ CABLE, CAN, unit A/unit B; fbe; 15 m 121228 121228 1

151 COVER, blank n/a n/a 1

152 TOKEN, upgrade 16C027 16C027 1

see page 23)

289696 289696

(without display, for

255709

D200s Ram;

see page 23) Qty.

n/a 1

n/a 1

n/a 1

n/a 1

1

1

Parts designated n/a are not available separately.

★ Not shown.

▲ Replacement Danger and Warning labels, tags and

cards are available at no cost.

‡ D60 ram only: Position collar of actuator sensor

down, near ram weldment, with bracket pointing up.

* Requires Ref. 152 for programming.

24 313529J

D60 Ram

Actuator sensor position

127

Page 25

Pneumatic Crossover Kits

255675, for 3 in. D200 Rams

255676, for 6.5 in. D200s Rams

257633, for S20 Rams

257632, for 3 in. D60 Rams

Parts

D60 and D200 Rams

202

201

229

203

206

207

205

204

206

208

209

235

203

233

229

202

201

S20 Rams

206

207

205

206

208

204

209

TI10932A

r_257373_313529_2a

229

224

214

225

229

223

221

222

230

226

229 229

313529J 25

225

TI10941A

Page 26

Parts

Pneumatic Crossover Kits (continued)

218

217

228

216

226

229

226

211

D200 Rams

215 214

210

219

229

220

213

212

222

221

TI10942A

214

215

211

219

226

229

217

220

218

228

229

D60 Rams

213

212

216

226

222

221

210

234

219

216

220

228

226

229

229

S20 Rams

222

r_257374_313529_2a

211

213

218

217

212

221

226

210

214

215

r_257373_313529_1a

26 313529J

Page 27

Pneumatic Crossover Kits

Parts

Ref. Part Description Qty

201 111337 TEE, street; 3/4 npt(m) x 3/4 npt(f)

x 3/4 npt(f)

202 C20487 NIPPLE, hex; 3/4 npt 2

203 C59752 VALVE, pneumatic, 3-way. 2

204 113218 VALVE, ball, vented; 3/4 npt (m x f) 2

205 buy

locally

206 C19683 BUSHING, reducing; 3/4 npt(m) x

207 115240 FITTING, tube; 3/8 npt(m) x 3/8 in.

208 115436 ELBOW, tube, 90°; 3/8 npt(m) x 3/8

209 116658 FITTING, tube; 1/4 npt(m) x 1/4 in.

210 n/a BRACKET, crossover 2

211 n/a BRACKET, limit valve; for D200

n/a BRACKET, limit valve; for D60 rams 2

n/a BRACKET, limit valve; for S20 rams 2

212 104116 WASHER, plain; #10 4

213 111820 SCREW, cap, socket hd; 10-24 x

214 C19204 WASHER, lock; #10 6

215 100179 NUT, hex mscr; 10-24 4

HOSE, nylon; 3/8 in. (10 mm) OD;

6 in. (153 mm); black

3/8 npt(f)

(10 mm) OD tube

in. (10 mm) OD tube

(6 mm) OD tube

rams

3/4 in. (19 mm)

Ref. Part Description Qty

216 C06182 VALVE, limit, air 2

2

217 100813 WASHER, flat 4

218 C19965 SCREW, cap, socket-hd; 6-32 x

1-1/4 in. (31 mm)

219 100068 WASHER, lock, spring; #6 4

220 100072 NUT, hex mscr; 6-32 4

1

221 100016 WASHER, lock; 1/4 6

222 101682 SCREW, cap, socket-hd; 1/4-20 x

4

223 n/a PLATE, mounting, 4-way valve 1

2

224 113338 VALVE, air, remote, 4-way 1

225 123366 SCREW, cap, socket-hd; 10-24 x

2

226 C06061 MUFFLER 5

2

228 100139 PLUG, pipe; 1/8 npt 2

229 597151 ELBOW, tube; 1/8 npt(m) x 1/4 in.

2

230 110475 TEE, street; 1/8 npt(m) x 1/8 npt(f)

231 buy

locally

232★ 114958 STRAP, tie 4

4

233 104969 BUSHING, reducing; for S20 rams 2

234 158223 WASHER 4

235 100896 BUSING, reducing 2

5/8 in. (16 mm)

1-1/8 in. (29 mm)

OD tube

x 1/8 npt(f)

TUBE, nylon; 1/4 in. (6 mm) OD; 52

ft (15.9 m); black

4

6

2

12

1

1

Parts designated n/a are not available separately.

★ Not shown.

313529J 27

Page 28

Parts

Fluid Filter Kit

NOTE:

Fluid filter is rated for 5000 psi (35 MPa, 9 bar)

maximum working pressure.

247504 Fluid Filter and Stand, used with electronic crossover models only

Ref. Part Description Qty

301 n/a BASE, mounting 1

302 C30021 BOLT, U; 3/8-16 2

303 210658 VALVE, ball; 3/8 npt (mbe); see

manual 306861

304 515216 HOUSING, filter 1

305 C19652 BUSHING, reducing; 1 in. npt(m) x

1/4 npt(f)

306 121189 ELBOW, street, 90°; 1 in. npt (m x f) 2

307 521477 VALVE, ball; 1 in. npt (fbe) 3

308 121182 ADAPTER, pipe 2

309 102814 GAUGE, pressure, fluid 2

310 C19488 TEE; 1 in. npt (f) 1

311 121163 CROSS; 1 in. npt(f) 2

312 158585 NIPPLE; 1 in. npt 6

313 101044 WASHER, plain; 1/2 4

314 100018 WASHER, lock, spring; 1/2 4

315 C19853 SCREW, cap, socket-hd; 1/2-13 x

1-1/4 in. (31 mm)

316 100023 WASHER, flat; 3/8 4

317

318

307

312

306

309

315

314

313

Ref. Part Description Qty

317 100133 WASHER, lock; 3/8 4

318 100131 NUT, full hex; 3/8-16 4

319 n/a STAND 1

1

320 121190 CAP, plug 1

321 515222 ELEMENT, filter, 30 mesh; sst (see

4

322 121175 TRANSDUCER, pressure 2

323 15Y048 CABLE, filter, pressure sensor; 49

324 15Y037 CABLE, splitter, pressure sensor 1

Parts designated n/a are not available separately.

Replacement filter elements are available in the following sizes:

4

316

Part No. 515219, 60 mesh

Part No. 515220, 50 mesh

Part No. 515221, 40 mesh

Part No. 515222, 30 mesh (standard)

list below for other sizes)

ft (15 m)

320

302

301

1

1

305

308

309

312

323

307

312

306

311

305

322

324

TI10889A_1

305

310

312

311

305

322

319

28 313529J

312

308

304

321

303

Page 29

Parts

Pump Outlet Check Valve Kits

255452, used on carbon steel Check-Mate 60 and 100 Displacement Pumps (shown)

257377, used on stainless steel Check-Mate 60 and 100 Displacement Pumps

255453, used on carbon steel Check-Mate 200 and 250 Displacement Pumps

255454, used on stainless steel Check-Mate 200 and 250 Displacement Pumps

255455, used on carbon steel Check-Mate 500 Displacement Pumps

255456, used on stainless steel Check-Mate 500 Displacement Pumps

256882, used on carbon steel Dura-Flo 430 and 580 Displacement Pumps

Ref. Description 255452 257377 255453 255454 255455 255456 256882 Qty.

401 UNION, pipe; 1-1/4 in. npt(f) 521975 521975 521975 521975 1

CONNECTOR; 3/4 npt(m) x

1-1/16 in. unf

402 NIPPLE, hex; 1-1/4 in. npt C20490 C20490 C20490 1

NIPPLE, hex; 1-1/4 in. npt

NIPPLE, reducing; 1 in. npt x

3/4 npt

403 VALVE, check; 1-1/4 in. npt

(fbe)

VALVE, check; 3/4 npt (fbe) C59546 C59546 C59546 1

404 ELBOW, street, 90°; 1-1/4 in.

npt (m x f)

ELBOW; 3/4 npt (m x f) 15M864 15M864 15M864 1

ELBOW; 1-1/2 in. npt (f x f)

405 BUSHING, reducing; 1 in.

npt(m) x 3/4 npt(f)

NIPPLE, reducing; 1-1/4 in. npt

x 1 in. npt

NIPPLE, reducing; 1 in. npt x

3/4 npt

BUSHING, reducing; 1-1/2 npt

x 1-1/4 npt (fbe)

COUPLING, reducing; 1-1/2 in.

npt x 1 in. npt (fbe)

521850

C38324

C19661 1

15M863 15M863 15M863 1

C20490 2

15M805 1

521850 521850 521850 1

C38324 C38324 1

115129 1

C38306 1

15M805 1

16A999 1

15M865 1

255455 Shown

401

401

405

402

403

404

313529J 29

405

TI10888A

402

403

402

404

r_255455_313529_1f

Page 30

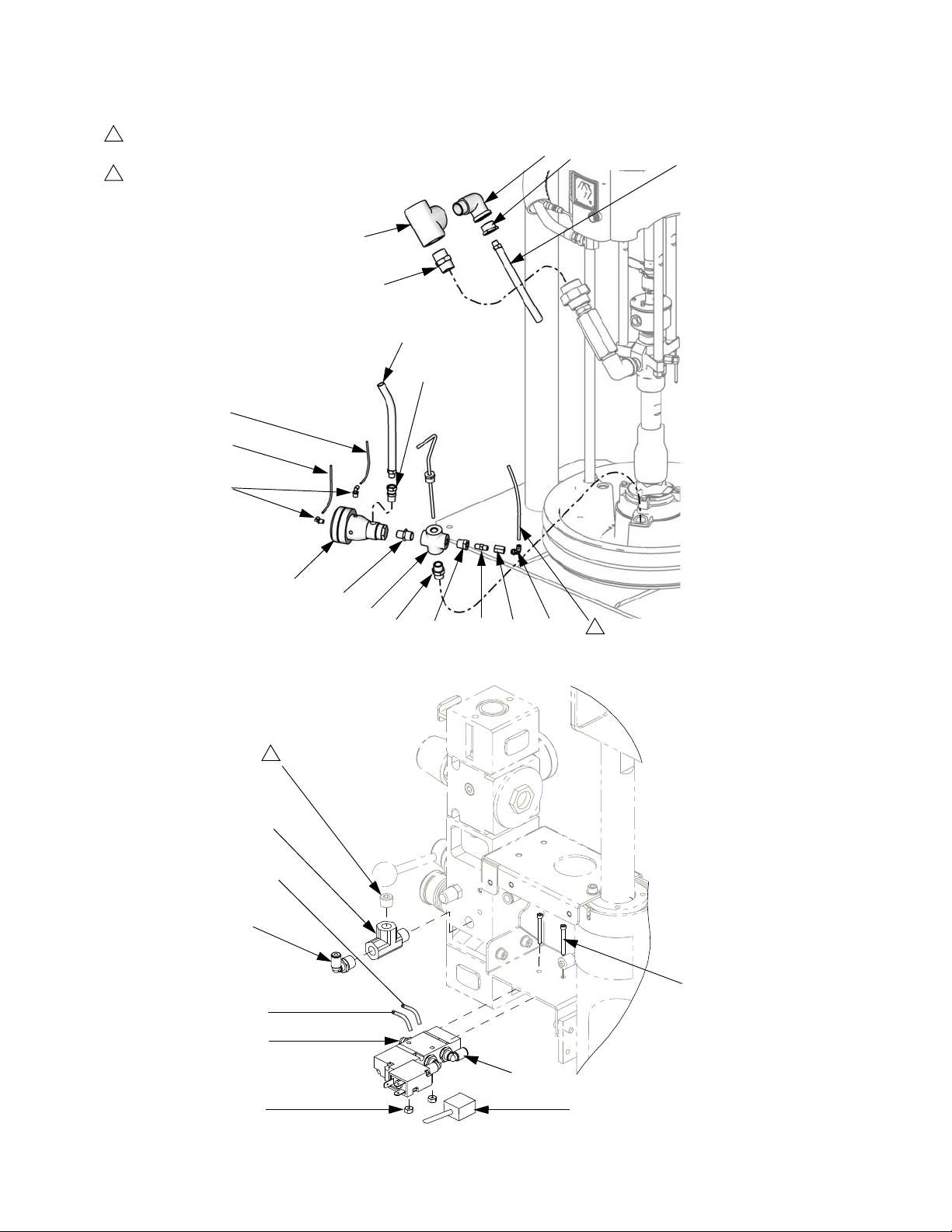

Parts

Depressurization Kits

255457, carbon steel

255458, stainless steel

5

255457

Ref. Description

501 TEE; 1-1/4 npt(f) C19491 1

TEE; 3/4 npt(f)

502 ELBOW, street; 1-1/4

npt (m x f)

ELBOW; 3/4 npt (m x f)

503 BUSHING, reducing;

1-1/4 in. npt(m) x 3/4

npt(f)

BUSHING, reducing;

3/4 npt(m) x 1/2 npt(f)

504 HOSE; 1/2 npt (mbe)

cst; 28 in. (712 mm);

buna-N

HOSE; 1/2 npt (mbe)

sst; 28 in. (712 mm);

ptfe

505 NIPPLE, hex; 1-1/4 npt C20490 1

NIPPLE, hex; 3/4 npt

506 TUBE; nylon; 5/32 in. (4

mm) OD; 10 ft (3.05 m);

black

507 VALVE, depressuriza-

tion/recirculation, 1/2

npt port; see manual

310550 for parts

508 UNION, adapter, swivel;

1/2 npt (m x f)

510 CROSS; 3/4 npt(f) 15M834 15M866 1

(cst)

C38324 1

C19660 1

n/a 1

buy

locally

918537 918537 1

156684 15M859 1

255458

(sst) Qty.

15M862 1

15M864 1

502033 1

n/a 1

190724 1

buy

locally

255457

Ref. Description

511 VALVE, check; 1/4

npt(m)

512 CONNECTOR, pipe; 1/4

npt (fbe)

513 ELBOW, tube; 1/4

npt(m) x 1/4 in. (6 mm)

OD tube

514 REDUCER, pipe; 3/4

npt(m) x 1/4 npt(f)

515 NIPPLE, hex; 3/4 npt C20487 190724 1

517 ADAPTER; 1/2 npt(m) x

3/4 npt(m)

520 VALVE, solenoid, 4-way 15M574 15M574 1

521 SCREW, cap,

socket-hd; 6-32 x 1-1/4

in. (31 mm)

522 NUT, lock, hex; M4 C19862 C19862 2

523 TEE; 1/4 npt(m) x 1/4

2

npt(f) x 1/4 npt(f)

524 ELBOW, tube; 1/4

npt(m) x 5/32 in. (4 mm)

OD tube

525 WIRE, harness 15Y047 15Y047 1

Parts designated n/a are not available separately.

(cst)

15M867 15M867 1

113093 113093 1

114109 114109 1

C19681 15M861 1

157191 15R232 1

C19965 C19965 2

116504 116504 1

198178 198178 3

255458

(sst) Qty.

30 313529J

Page 31

1

Remove plug from integrated air controls. Install tee fitting (523).

Assemble plug into top of tee fitting.

2

Platen blow off air line.

501

505

(Ref. 504)

508

506c

506b

524

502

503

Parts

504

523

506c (Ref)

524

506a

506b (Ref)

506a (Ref)

507

1

517

510

515 514 513

511

512

2

Solenoid Valve Detail

521

TI10886A

520

522

313529J 31

525

r_257374_313259_6a

Page 32

Accessories

Accessories

Communications Gateway Module

Communications Gateway Module CGMxx0 requires

CGK010 Mounting Kit. Use reference kit noted below

for mounting a CGM on electric tandem supply system.

See manual 313138 for installation and repair parts.

Communications

Gateway Module

Mounting Kit

CGK010

Communications Gateway

Module Part No. Fieldbus

CGMDN0 DeviceNet

CGMEP0 EtherNet/IP

CGMPB0 PROFIBUS

CGMPN0 PROFINET

See manual 312864 for CGM setup instructions.

Pressure Sensor Accessories

Sensors

Part No. Description

121175 Pressure sensor filter

Cables

Part No. Description

15Y049 M12 male/female reverse key cable

15Y037 Pressure sensor splitter cable

32 313529J

Page 33

Technical Data

Max air input pressure (supply system) psi (MPa, bar) / Air inlet size

S20 - 3 in. single post, 5 gal. (20 L) . . . . . . . . . . . . . . 125 psi (0.9 MPa, 9 bar) / 1/2 npt(f)

D60 - 3 in. dual post, 16 gal. (60 L), 8 gal. (30 L), 5 gal.

(20 L), . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150 psi (1.0 MPa, 10 bar) / 3/4 npt(f)

D200 - 3 in. dual post, 55 gal. (200 L), 30 gal. (115 L),

16 gal. (60 L), 8 gal. (30 L), 5 gal. (20 L) . . . . . . . . . . 150 psi (1.0 MPa, 10 bar) / 3/4 npt(f)

D200s - 6.5 in. dual post, 55 gal. (200 L), 30 gal. (115 L) 125 psi (0.9 MPa, 9 bar) / 3/4 npt(f)

Technical Data

Max fluid, air working pressure, and weight

(displacement pump) . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump Wetted parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . For Check-Mate displacement pumps, see manual

Platen/Ram Codes (page 5): Part number, size, platen;

Wetted parts

A, B, C, F, G, H: 255662, 55 gal. (200 L) . . . . . . . . .

J, L, M, R, S, T: 255663, 55 gal. (200 L) . . . . . . . . . . EPDM, aluminum, zinc plated carbon steel, 316 sst

4: 255661, 30 gal. (115 L) . . . . . . . . . . . . . . . . . . . . . zinc plated carbon steel, EPDM, sst, fluoroelastomer

2: 257728, 5 gal. (20 L) . . . . . . . . . . . . . . . . . . . . . . .

1, 3: 257729, 5 gal. (20 L)

0, D, E: 257734, 8 gal. (30 L)

U, V, W: 257738, 16 gal. (60 L) . . . . . . . . . . . . . . . . .

6, 7, 8, 9: 257731, 5 gal. (20 L)

K, N, P: 257736, 8 gal. (30 L)

X, Y, Z: 257741, 16 gal. (60 L) . . . . . . . . . . . . . . . . . .

For Check-Mate pump packages, see manual 312376.

For Dura-Flo pump packages, see manuals 311826,

311828, 311833.

312375.

For Dura-Flo displacement pumps, see manuals

311717, 311825, 311827.

PTFE, EPDM, PTFE coated aluminum, zinc plated

carbon steel, 316 sst

Electroless nickel, polyurethane, carbon steel, polyethylene, nitrile, zinc plated carbon steel, buna, 316 sst

17-4PH sst

Stainless steel, polyurethane, PTFE coated nitrile, polyethylene, nitrile, PTFE, 303 sst, 304 sst, 316 sst,

17-4PH sst

Electroless nickel, aramind reinforced elastomer, rubber-based PSA, polyurethane, polyethylene, nitrile, zinc

plated carbon steel, buna, 1018 carbon steel, 304 sst,

316 sst, 17-4PH sst

Ambient operating temperature range (supply system) 32-120 °F (0- 49°C)

Sound data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See separate air motor manual.

External power supply requirements (DatraTrak)

AC power units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100-240 Vac, 50/60 Hz, single phase, 1.2 amps max

draw

DC power units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 Vdc, 1.2 amps max draw

313529J 33

Page 34

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective par ts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2009, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 313529

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised July 2013

Loading...

Loading...