Page 1

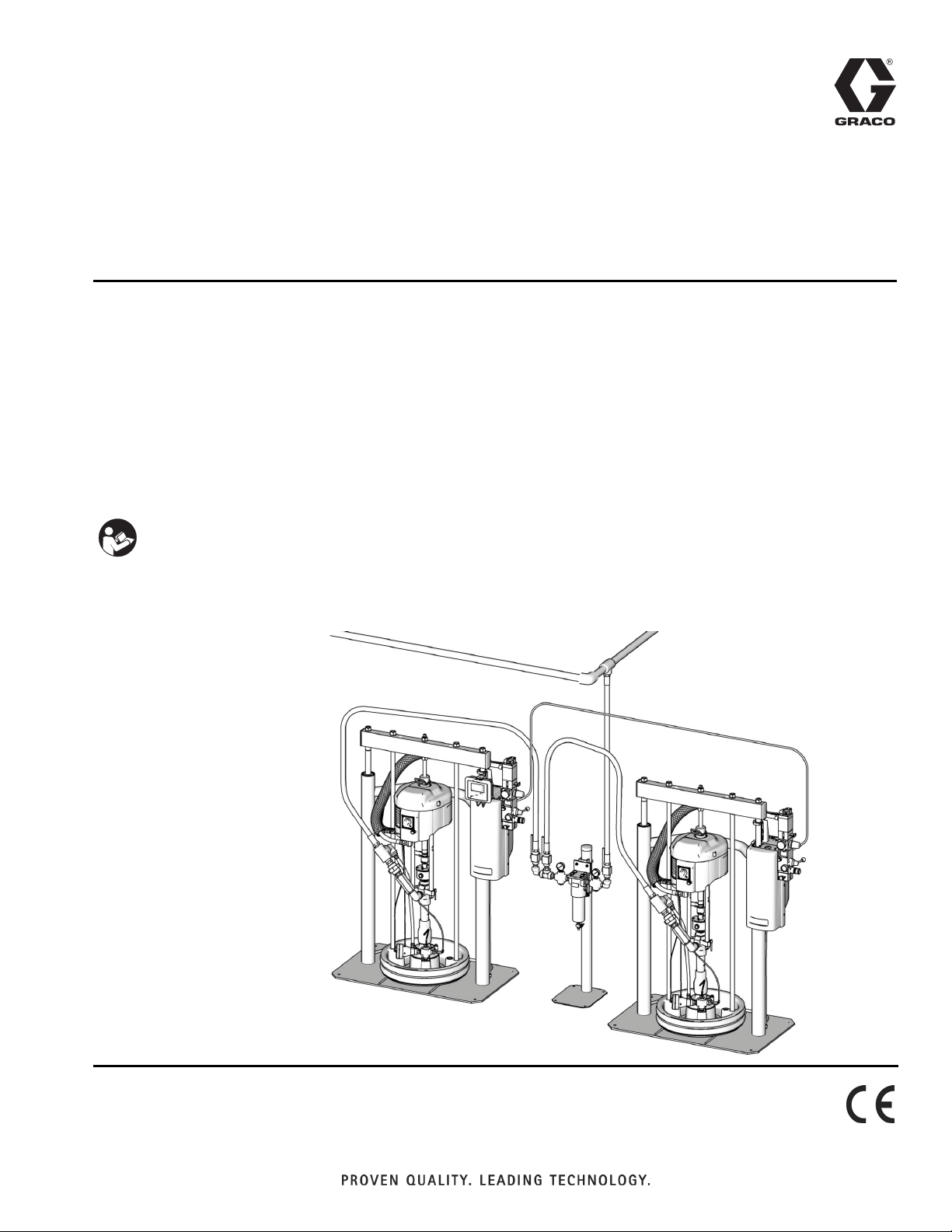

Operation

Tandem Supply

313528E

Systems

For use with non-heated bulk supply of medium to high viscosity sealants and adhesive

materials. For professional use only.

Not for use in explosive atmospheres.

125 psi (0.9 MPa, 9 bar) Maximum Air Inlet Pressure - S20 3 in. rams

150 psi (1.0 MPa, 10 bar) Maximum Air Inlet Pressure - D60 and D200 3 in. rams

125 psi (0.9 MPa, 9 bar) Maximum Air Inlet Pressure - D200S 6.5 in. rams

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

EN

US Patent Pending

The Graco Control Architecture Electric Components are Listed in Intertek’s Directory of Listed Products.

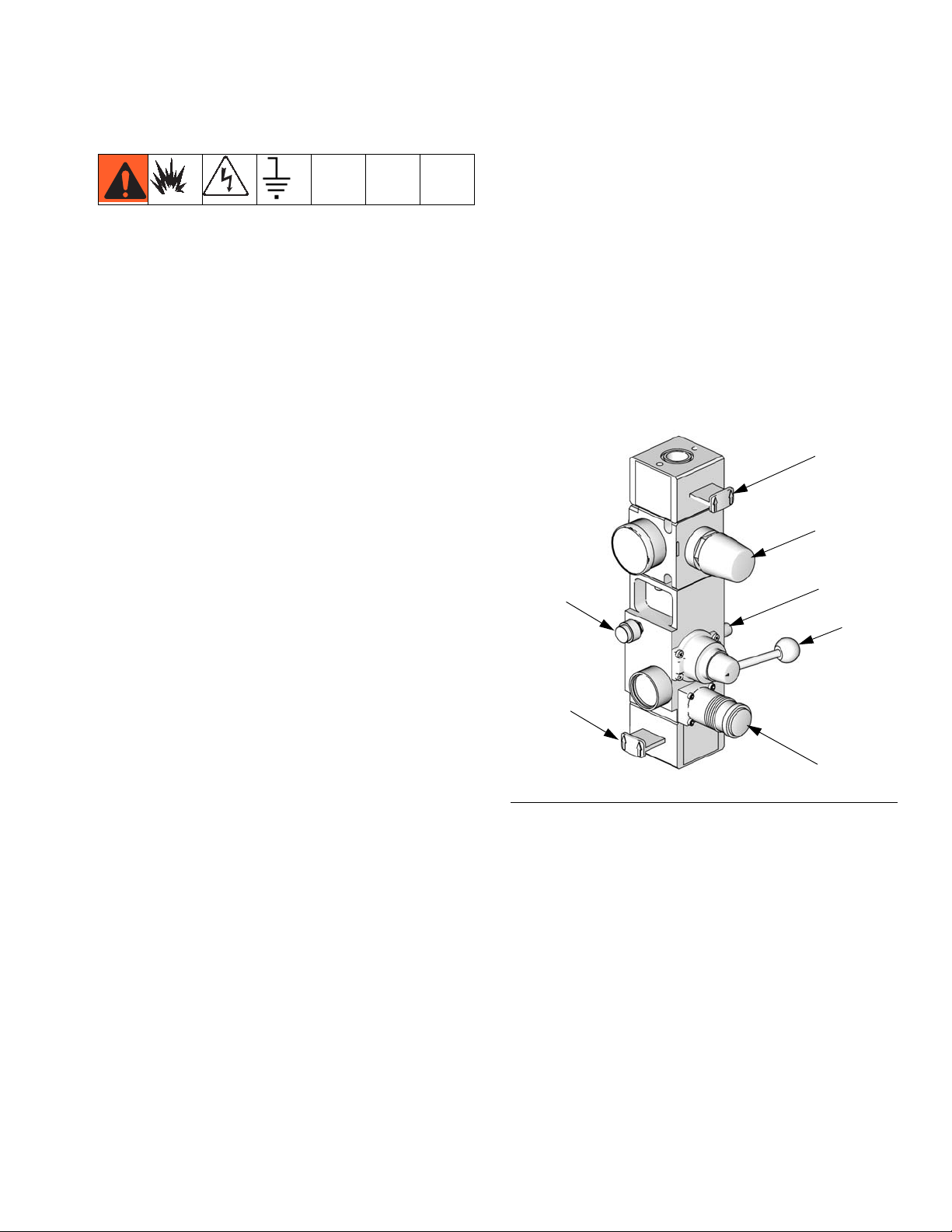

D200 Rams with Electronic

Crossover Shown

TI10865A

Page 2

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Translations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

System Description . . . . . . . . . . . . . . . . . . . . . . 10

Ram Installation and Setup . . . . . . . . . . . . . . . . 10

Fluid Filter Kit Installation . . . . . . . . . . . . . . . . . 10

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Integrated Air Controls . . . . . . . . . . . . . . . . . . . 11

Pneumatic Crossover System Components . . . 12

Electronic Crossover System Components . . . . 14

255468 Light Tower Accessory . . . . . . . . . . . . . 16

Communications Gateway Module . . . . . . . . . . 16

CGM Status LED Signals . . . . . . . . . . . . . . . . . 16

Display Module (Electronic Crossover Systems) 17

Fluid Control Module . . . . . . . . . . . . . . . . . . . . . 21

Electronic Crossover Operation . . . . . . . . . . . . . . 22

Pressure Relief Procedure . . . . . . . . . . . . . . . . 22

Flush Before Using Equipment . . . . . . . . . . . . . 22

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Prime . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Automatic Crossover . . . . . . . . . . . . . . . . . . . . . 25

Manual Crossover . . . . . . . . . . . . . . . . . . . . . . . 25

Recirculate Function . . . . . . . . . . . . . . . . . . . . . 26

Depressurize Function . . . . . . . . . . . . . . . . . . . 26

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Diagnose Alarms . . . . . . . . . . . . . . . . . . . . . . . . 28

Clear Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Alarm Codes and Troubleshooting . . . . . . . . . . 28

Appendix A - User Interface Display . . . . . . . . . . 31

Display Overview . . . . . . . . . . . . . . . . . . . . . . . . 31

Display Details . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Setup Mode Screens . . . . . . . . . . . . . . . . . . . . . 33

Run Mode Screens . . . . . . . . . . . . . . . . . . . . . . 38

Fluid Filter Kit Dimensions . . . . . . . . . . . . . . . . . . 44

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 46

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 46

2 313528E

Page 3

Related Manuals

Related Manuals

Component Manuals in U.S. English:

Manual Description

313529 Tandem Supply Systems Repair-Parts

313526 Supply Systems Operation

313527 Supply Systems Repair-Parts

Check-Mate

312375

Instructions-Parts

Check-Mate

312376

Instruction-Parts

Dura-Flo

311827

180cc, 220cc, 290cc) Instructions-Parts

Manual

311825

311717

Dura-Flo

580cc) Instructions-Parts Manual

Carbon Steel Displacement Pump

(1000cc) Instructions-Parts Manual

Dura-Flo

311828

180cc, 220cc, 290cc) Instructions-Parts

Manual

311826

311833

312889

312467

312468

312469

312470

311238

312796

Dura-Flo

580cc) Instructions-Parts Manual

Two-Ball NXT

Instructions-Parts Manual

60 cc Check-Mate Displacement Pump

Repair Parts Manual

100 cc Check-Mate Displacement Pump

Repair Parts Manual

200 cc Check-Mate Displacement Pump

Repair Parts Manual

250 cc Check-Mate Displacement Pump

Repair Parts Manual

500 cc Check-Mate Displacement Pump

Repair Parts Manual

™

NXT

Instructions-Parts

™

NXT

Instructions-Parts

308213 Premier

312374 Air Controls Instructions-Parts

312491 Pump Fluid Purge Kit

®

Displacement Pumps

®

Pump Packages

™

Displacement Pumps (145cc,

™

Displacement Pumps (430cc,

™

Pump Packages (145cc,

™

Pump Packages (430cc,

™

Pump Packages (1000cc)

Air Motor (Nxxxxx models)

Air Motor (Mxxxxx models)

®

Air Motor Instructions-Parts

Translations

This manual is available in the following languages. See

the following chart for specific languages and corresponding part numbers.

Manual Language

313926 Chinese

313923 French

313924 German

313929 Italian

313927 Japanese

313928 Korean

313925 Spanish

312492 Drum Roller Kit Instruction

312493 Light Tower Kit Instruction

312864

313138

Communications Gateway Module,

Instructions-Parts

Supply System Communications Gateway

Module Installation Kit, Instructions-Parts

406681 Platen Cover Kit

313528E 3

Page 4

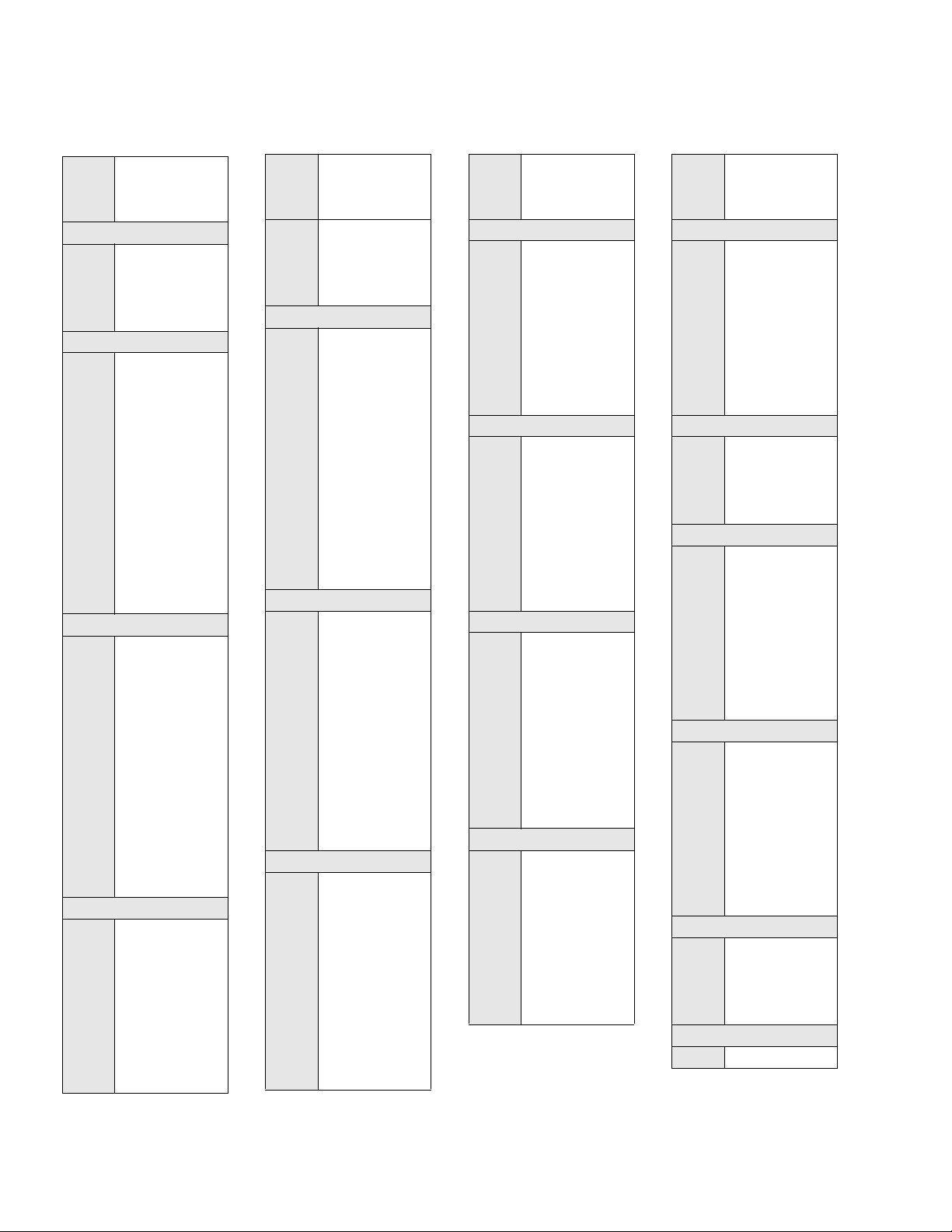

Models

Models

Check the identification plate (ID) for the 6-digit part number of your tandem system. Use the following matrix to define the construction of your system, based on

the six digits. For example, Tandem Part No. TC2414 represents a Check-Mate

tandem system (TC), pump (24), crossover option (1), and platen/ram option (4).

NOTE:

Systems with the TD as the first and second digits are Dura-Flo tandem systems.

Some configurations in the following matrix cannot be built. See the Product

Selection Guide for available systems.

ID

To order replacement parts, see Parts section in manual 313529. The digits in

the matrix do not correspond to the Ref. Nos. in the Parts drawings and lists.

TC 24 1 4

First and

Second Digit

TC

(Tandem

System with

Check-Mate

displacement

pump)

TD

(Tandem

System with

Dura-Flo dis-

placement

pump)

Third and

Fourth Digit Fifth Digit Sixth Digit

Crossover Options

Depressurize/

Recirculate Valve

Material

Carbon

Steel SST

Ram Size

n/a

n/a

n/a

n/a

n/a

n/a

S20, D60,

Pump Code

(See Table 2

for 2-digit

Check-Mate

pump code)

Electronic

Crossover

1

2

3

4

5

6

7

Pneumatic

Crossover

(Smart

Motors

only)

(Standard

Motors

only)

Fluid

Filter

✔✔✔

✔✔✔

✔✔

✔✔

✔✔

✔

✔

D200,

(See Table 3

for 2-digit

Dura-

8

✔

(3 in.)

D200S,

(6.5 in.)

Flo pump

code)

TI11157A

Platen/Ram

Options

See Table 1

for Selections

All supply systems with DataTrak and 24 Vdc or 100-240 Vac power supplies are ETL approved.

2ECOGNIZED#OMPONENT

#-

#ERTIFIEDTO#!.#3!#3!#.O

4 313528E

#ONFORMSTO5,

Page 5

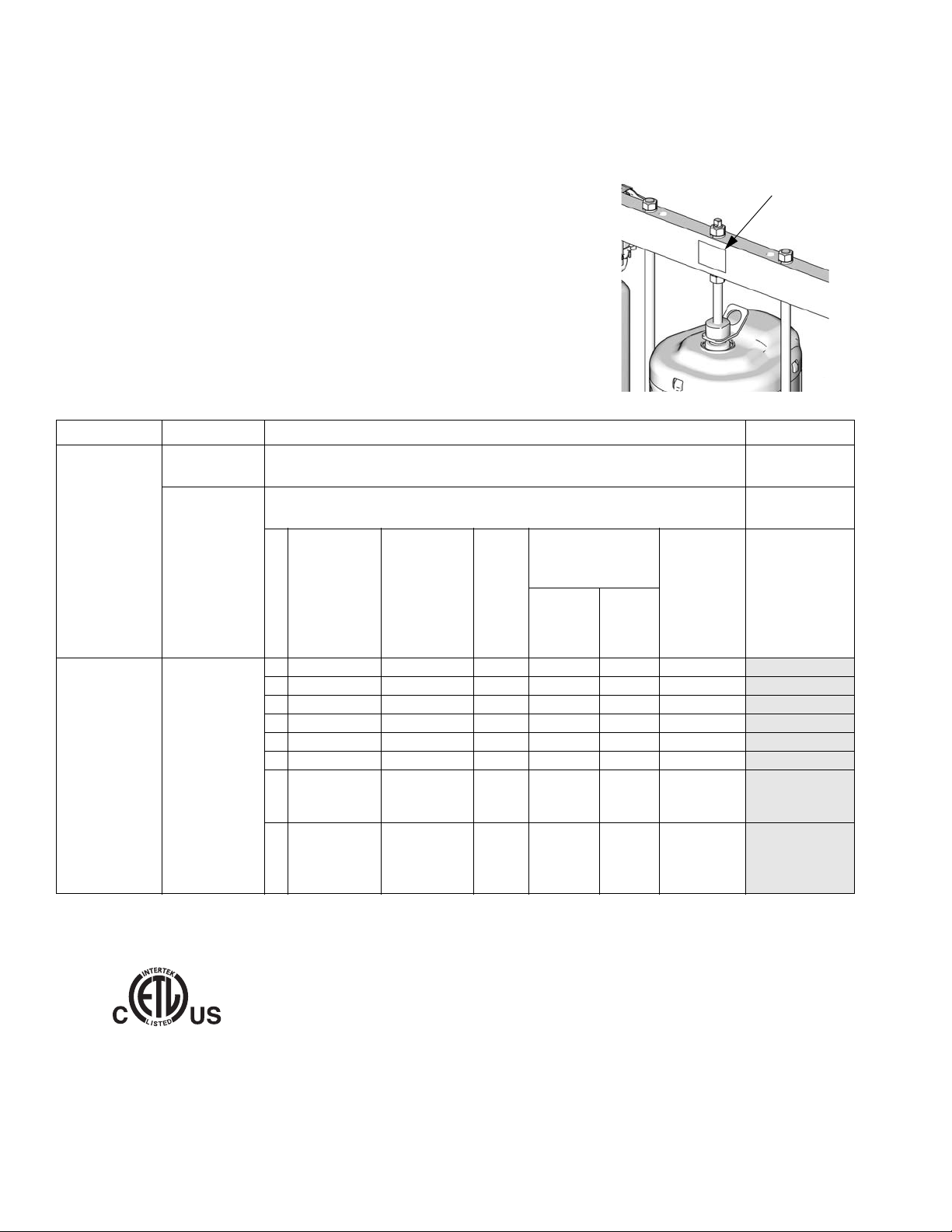

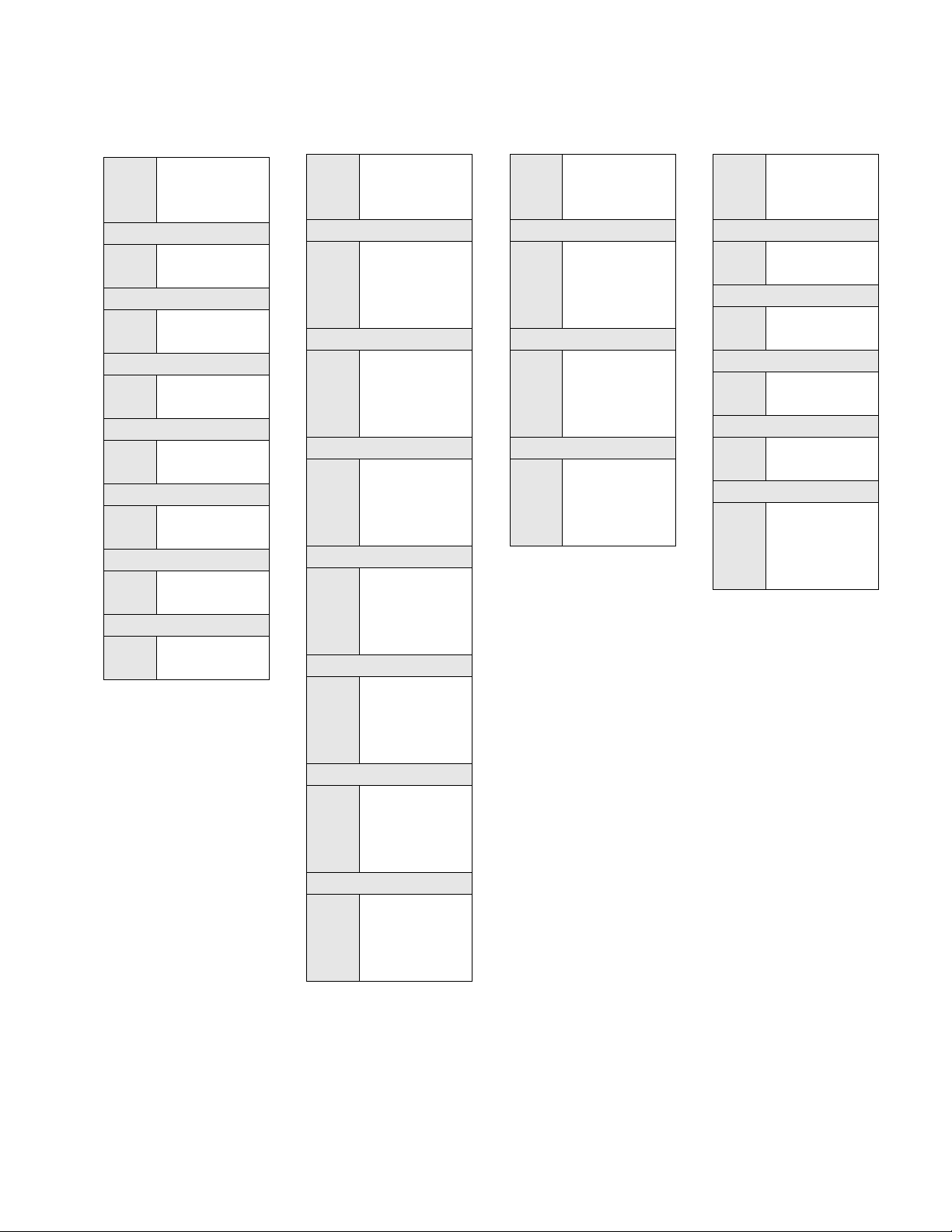

Table 1: Platen/Ram Options

Models

Sixth

Digit Platen Size Platen Style

Platen

Material

Seal Material Ram Size Voltage

2 20 L (5 Gal) Flat, Single Wiper CS Polyurethane S20, 3 in. none

3 20 L (5 Gal) Flat, Single Wiper SST PTFE-Coated Nitrile S20, 3 in none

7 20 L (5 Gal) Flat, Dual Wiper CS Polyurethane D60, 3 in. none

8 20 L (5 Gal) Flat, Dual Wiper CS Polyurethane D60, 3 in. 120 Vdc

9 20 L (5 Gal) Flat, Dual Wiper CS Polyurethane D60, 3 in. 24 Vdc

0 30 L (8 Gal) Flat, Single Wiper SST PTFE-Coated Nitrile D60, 3 in. none

D 30 L (8 Gal) Flat, Single Wiper SST PTFE-Coated Nitrile D60, 3 in. 120 Vdc

E 30 L (8 Gal) Flat, Single Wiper SST PTFE-Coated Nitrile D60, 3 in. 24 Vdc

K 30 L (8 Gal) Flat, Dual Wiper CS Polyurethane D60, 3 in. none

N 30 L (8 Gal) Flat, Dual Wiper CS Polyurethane D60, 3 in. 120 Vdc

P 30 L (8 Gal) Flat, Dual Wiper CS Polyurethane D60, 3 in. 24 Vdc

U 60 L (16 Gal) Flat, Single Wiper SST PTFE-Coated Nitrile D60, 3 in. none

V 60 L (16 Gal) Flat, Single Wiper SST PTFE-Coated Nitrile D60, 3 in. 120 Vdc

W 60 L (16 Gal) Flat, Single Wiper SST PTFE-Coated Nitrile D60, 3 in. 24 Vdc

X 60 L (16 Gal) Flat, Dual Wiper CS Polyurethane D60, 3 in. none

Y 60 L (16 Gal) Flat, Dual Wiper CS Polyurethane D60, 3 in. 120 Vdc

Z 60 L (16 Gal) Flat, Dual Wiper CS Polyurethane D60, 3 in. 24 Vdc

4 115L (30 Gal) D Style CS EPDM D200, 3 in. none

1 20 L (5 Gal) Flat, Single Wiper SST PTFE-Coated Nitrile D200, 3 in. none

6 20 L (5 Gal) Flat, Dual Wiper CS Polyurethane D200, 3 in none

A 200 L (55 Gal) Dual O-ring AL PTFE-Coated EPDM D200, 3 in. none

B 200 L (55 Gal) Dual O-ring AL PTFE-Coated EPDM D200, 3 in. 120 Vdc

C 200 L (55 Gal) Dual O-ring AL PTFE-Coated EPDM D200, 3 in. 24 Vdc

F 200 L (55 Gal) Dual O-ring AL PTFE-Coated EPDM D200S, 6.5 in. none

G 200 L (55 Gal) Dual O-ring AL PTFE-Coated EPDM D200S, 6.5 in. 120 Vdc

H 200 L (55 Gal) Dual O-ring AL PTFE-Coated EPDM D200S, 6.5 in. 24 Vdc

J 200 L (55 Gal) Dual O-ring AL EPDM D200, 3 in. none

L 200 L (55 Gal) Dual O-ring AL EPDM D200, 3 in. 120 Vdc

M 200 L (55 Gal) Dual O-ring AL EPDM D200, 3 in. 24 Vdc

R 200 L (55 Gal) Dual O-ring AL EPDM D200S, 6.5 in. none

S 200 L (55 Gal) Dual O-ring AL EPDM D200S, 6.5 in. 120 Vdc

T 200 L (55 Gal) Dual O-ring AL EPDM D200S, 6.5 in. 24 Vdc

313528E 5

Page 6

Models

Table 2: Check-Mate Pump Identification Code/Part No. Index

Pump Part No.

Pump

Code

(see manual

312376)

NXT 200/CM 60

4A P05LCS

4B P05LCM

4C P05LSS

4F P05LSM

NXT 400/CM 60

6A P11LCS

6B P11LCM

6C P11LSS

6F P11LSM

6G P11RCS

6H P11RCM

6J P11RSS

6K P11RSM

61 P11SCS

62 P11SCM

63 P11SSS

64 P11SSM

NXT 700/CM 60

7A P20LCS

7B P20LCM

7C P20LSS

7F P20LSM

7G P20RCS

7H P20RCM

7J P20RSS

7K P20RSM

71 P20SCS

72 P20SCM

73 P20SSS

74 P20SSM

NXT 1200/CM 60

8A P38LCS

8B P38LCM

8C P38LSS

8F P38LSM

8G P38RCS

8H P38RCM

8J P38RSS

8K P38RSM

Pump Part No.

Pump

Code

(see manual

312376)

81 P38SCS

82 P38SCM

83 P38SSS

84 P38SSM

NXT 1800/CM 60

9A P61LCS

9B P61LCM

9C P61LSS

9F P61LSM

9G P61RCS

9H P61RCM

9J P61RSS

9K P61RSM

91 P61SCS

92 P61SCM

93 P61SSS

94 P61SSM

NXT 2200/CM 100

11 P40LCS

12 P40LCM

1F P40LSS

1G P40LSM

13 P40RCS

14 P40RCM

1H P40RSS

1J P40RSM

10 P40SSS

1A P40SSM

19 P40SCS

NXT 3400/CM 100

15 P63LCS

16 P63LCM

1T P63LSS

1U P63LSM

17 P63RCS

18 P63RCM

1W P63RSS

1Y P63RSM

1B P63SSS

1C P63SSM

Pump Part No.

Pump

Code

(see manual

312376)

NXT 2200/CM 200

21 P23LCS

22 P23LCM

23 P23RCS

24 P23RCM

25 P23LSS

26 P23LSM

27 P23RSS

28 P23RSM

NXT 3400/CM 200

29 P36LCS

2A P36LCM

2B P36RCS

2C P36RCM

2F P36LSS

2G P36LSM

2H P36RSS

2J P36RSM

NXT 6500/CM 200

2L P68LCS

2M P68LCM

2R P68RCS

2S P68RCM

2T P68LSS

2U P68LSM

2W P68RSS

2Y P68RSM

20 P68SCS

NXT 3400/CM 250

31 P29LCS

32 P29LCM

33 P29RCS

34 P29RCM

35 P29LSS

36 P29LSM

37 P29RSS

38 P29RSM

Pump Part No.

Pump

Code

(see manual

312376)

NXT 6500/CM 250

39 P55LCS

3A P55LCM

3B P55RCS

3C P55RCM

3F P55LSS

3G P55LSM

3H P55RSS

3J P55RSM

Premier/CM 250

3L P82LCS

3M P82LCM

3R P82LSS

3S P82LSM

NXT 3400/CM 500

51 P14LCS

52 P14LCM

53 P14RCS

54 P14RCM

55 P14LSS

56 P14LSM

57 P14RSS

58 P14RSM

NXT 6500/CM 500

59 P26LCS

5A P26LCM

5B P26RCS

5C P26RCM

5F P26LSS

5G P26LSM

5H P26RSS

5J P26RSM

Premier/CM 500

5L P39LCS

5M P39LCM

5R P39LSS

5S P39LSM

No Pump

NN

6 313528E

Page 7

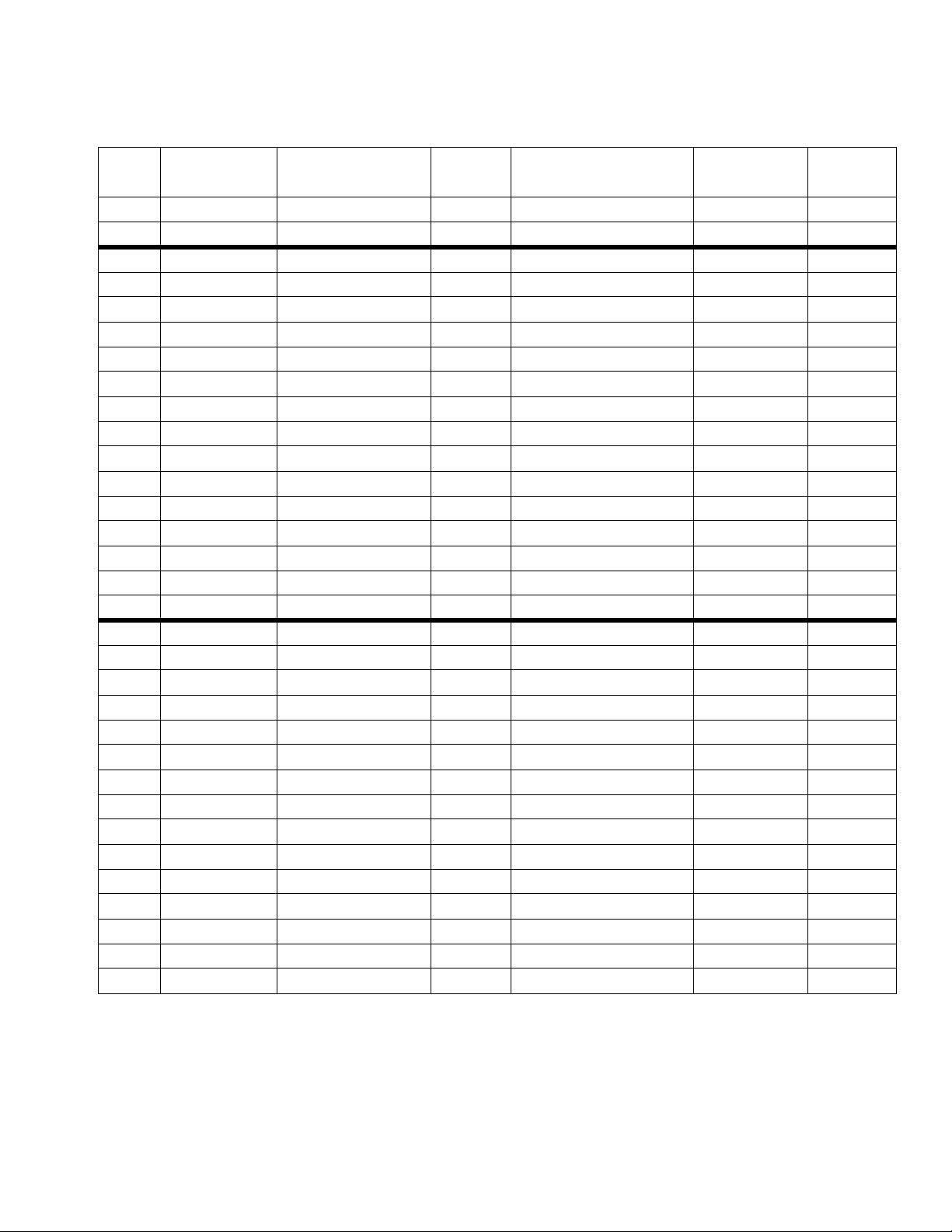

Table 3: Dura-Flo Pump Identification Code/Part No. Index

Models

Pump Part No.

Pump

Code

(see manual

311828)

NXT 2200/DF 145SS

A1 P31LSS

A3 P31HSS

NXT 3400/DF 145SS

B1 P46LSS

B3 P46HSS

NXT 3400/DF 180SS

B5 P41LSS

B7 P41HSS

NXT 3400/DF 220SS

C1 P30LSS

C3 P30HSS

NXT 6500/DF 220SS

CA P57LSS

CC P57HSS

NXT 6500/DF 290SS

D1 P45LSS

D3 P45HSS

Premier/DF 290SS

DL P67LSS

DR P67HSS

Pump Part No.

Pump

Code

(see manual

311826)

NXT 3400/DF 430CS

E1 P15LCS

E2 P15LCM

E3 P15HCS

E4 P15HCM

NXT 3400/DF 430SS

E5 P15LSS

E6 P15LSM

E7 P15HSS

E8 P15HSM

NXT 6500/DF 430CS

E9 P32LCS

EA P32LCM

EB P32HCS

EC P32HCM

NXT 6500/DF 430SS

EF P32LSS

EG P32LSM

EH P32HSS

EJ P32HSM

Premier/DF 430

EL P44LSS

EM P44LSM

ER P44LCS

ES P44LCM

NXT 3400/DF 580CS

F1 P12LCS

F2 P12LCM

F3 P12HCS

F4 P12HCM

NXT 3400/DF 580SS

F5 P12LSS

F6 P12LSM

F7 P12HSS

F8 P12HSM

Pump Part No.

Pump

Code

(see manual

311826)

NXT 6500/DF 580CS

F9 P22LCS

FA P22LCM

FB P22HCS

FC P22HCM

NXT 6500/DF 580SS

FF P22LSS

FG P22LSM

FH P22HSS

FJ P22HSM

Premier/DF 580CS

FL P34LSS

FM P34LSM

FR P34LCS

FS P34LCM

Pump Part No.

Pump

Code

(see manual

311833)

NXT 3400/DF 1000CS

G1 P06LCS

G3 P06HCS

NXT 3400/DF 1000SS

G5 P06LSS

G7 P06HSS

NXT 6500/DF 1000CS

G9 P10LCS

GB P10HCS

NXT 6500/DF 1000SS

GF P10LSS

GH P10HSS

Premier/DF 1000

GL NR

GM NR

GR NR

GS NR

NR = Not released

313528E 7

Page 8

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

8 313528E

Page 9

Warnings

WARNING

WARNINGWARNINGWARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

ELECTRIC SHOCK HAZARD

Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power cord before servicing equipment.

• Use only grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on sprayer and extension cords.

• Do not expose to rain. Store indoors.

SPLATTER HAZARD

During blowoff of platen splatter may occur.

• Use minimum drum removal air pressure.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear impervious gloves when spraying or cleaning equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

313528E 9

Page 10

Overview

Overview

System Description

Each tandem supply system consists of two air-powered

rams; both of which are always the same size. Each ram

drives a Check-Mate pump and a platen into a drum of

material. The pump removes material from the drum

and pushes it through a supply hose to a customer-supplied header. Material flows through the header to individual dispense drops.

When one drum is emptied the system performs an

automatic crossover, shutting off the air supply to the

pump on the empty ram and activating the pump on the

full ram.

Keep clear of the inactive ram, as automatic crossover

may occur unexpectedly. To repair or adjust the ram,

first follow all steps of the Pressure Relief Procedure

on page 22.

Ram Installation and Setup

Fluid Filter Kit Installation

Some systems include a fluid filter kit. See Appendix A

- User Interface Display on page 31. Ensure that the

fluid filter stand base is level in all directions. If necessary, level the base using metal shims. Secure the base

to the floor using anchors that are long enough to prevent the filter stand from tipping.

1. Connect pressure sensor cable from the fluid filter

kit to port 7 of the fluid control module.

2. Connect male side of the splitter to the other end of

the pressure sensor cable.

3. Connect end of splitter cable labeled #1 to the pressure sensor on the outlet side of the filter.

4. Connect end of splitter cable labeled #2 to the pressure sensor on the inlet side of the filter.

1. Install and set up individual rams as explained in

manual 313526 (supplied).

NOTE:

See F

IG. 2 on page 13 (for pneumatic crossover sys-

tems) and F

systems) for examples.

2. Connect pneumatic line (AC) or CAN cable (X)

between rams.

IG. 3 on page 15 (for electronic crossover

inlet

outlet

#1#2

#7

splitter

pressure sensor cable

10 313528E

Page 11

Overview

Grounding

The equipment must be grounded. Grounding reduces

the risk of static and electric shock by providing an

escape wire for the electrical current due to static build

up or in the event of a short circuit.

Pump: use ground wire and clamp (supplied). Loosen

grounding lug locknut and washer. Insert ground wire

end into lug slot and tighten locknut securely. Connect

ground clamp to a true earth ground.

Air and fluid hoses: use only electrically conductive

hoses with a maximum of 500 ft. (150 m) combined

hose length to ensure grounding continuity. Check electrical resistance of hoses. If total resistance to ground

exceeds 29 megohms, replace hose immediately.

Air compressor: follow manufacturer’s recommendations.

Dispense valve: ground through connection to a prop-

erly grounded fluid hose and pump.

• Exhaust port with muffler (BD)

• Air motor regulator (BE): Controls air pressure to

motor.

• Air motor slider valve (BF): turns air on and off to

the air motor. When closed, the valve relieves air

trapped between it and the air motor. Push the valve

in to shutoff. Remote DataTrak: The air solenoid

(Y, F

IG. 2), the air motor slider valve (BF), and the

main air slider valve (BA) must be open for air to

flow. (See Remote DataTrak Setup section in Supply

Systems operation manual 313526.)

• Blowoff button (BG): turns air on and off to push

the platen out of an empty drum.

BF

BE

BG

BD

BC

Fluid supply container: follow local code.

Solvent pails used when flushing: follow local code.

Use only conductive metal pails, placed on a grounded

surface. Do not place the pail on a nonconductive surface, such as paper or cardboard, which interrupts

grounding continuity.

To maintain grounding continuity when flushing or

relieving pressure: hold metal part of the dispense

valve firmly to the side of a grounded metal pail, then

trigger the valve.

Integrated Air Controls

The integrated air controls include:

• Main air slider valve (BA): turns air on and off to

the system. When closed, the valve relieves pressure downstream.

• Ram air regulator (BB): controls ram up and down

pressure and blowoff pressure.

• Ram director valve (BC): controls ram direction.

BA

TI10438A

FIG. 1. Integrated Air Controls

BB

Air Line Accessories

See FIG. 2.

• Air line drain valve (U)

• Air line filter (V): removes harmful dirt and moisture from compressed air supply.

• Second bleed-type air valve (W): isolates air line

accessories and supply system for servicing. Locate

upstream from all other air line accessories.

• Air relief valve (attached to ram air regulator, not

visible): automatically relieves excessive pressure.

313528E 11

Page 12

Overview

Pneumatic Crossover System Components

NOTE:

D200, D60, and S20 sizes are used in pneumatic

crossover systems.

F

IG. 2. shows a pneumatic crossover system. Refer to

manual 313526 (supplied) for ram installation and operating instructions. The pneumatic crossover operates as

follows:

During system operation, as the ram approaches the

drum bottom, the top of the ram contacts the limit switch

(E). The limit switch shuts off air to the air motor via a

solenoid valve (Y), which stops air flow to one motor and

starts air flow to the other air motor. This allows continuous material flow and changing of material drums.

The position of the limit switch (E) on the ram determines when the air motor is turned off. Start by positioning the limit switch to trip when the ram platen (D) is 1 in.

(25 mm) from the bottom of the drum. During operation

the position may be adjusted as desired.

The bypass valve (L) allows you to prime the inactive

pump after a drum change. Open the valve to prime the

pump. Close the valve when priming is complete, and

during normal operation.

12 313528E

Page 13

Overview

D200 Rams Shown

AA

E

A

S

V

W

AB

T

AC

V

W

U

E

U

T

Y

L

Y

H

L

H

S

C

D

Y

S20 Ram Shown

L

H

FIG. 2: Component Identification, Pneumatic Crossover

Key to FIG. 2:

ARam A

BRam B

C Pump (Ram A and B)

D Platen (Ram A and B)

E Limit Switch (Ram A and B)

H Integrated Air Controls (Ram A and B); see page 11

L Bypass Valve (Ram A and B)

S Fluid Line (not supplied)

C

D

E

T Main Air Line (not supplied)

U Air Line Drain Valve (not supplied)

V Air Filter (not supplied)

W Bleed-Type Air Shutoff Valve (not supplied)

Y Solenoid Valve (Ram A and B)

AA Cable from Ram A to Limit Switch A

AB Cable from Ram A to Limit Switch B

AC Main Crossover Cable; from Ram A to Solenoid B

B

TI11160A

313528E 13

Page 14

Overview

Electronic Crossover System Components

NOTE:

D200 and D60 sizes are used in electronic crossover

systems. See F

you should be familiar with the following components.

NOTE:

Reference numbers and letters in parentheses in the

text refer to the callouts in the figures.

Both rams (A and B) include a Check-Mate Pump (C),

platen (D), integrated air controls (H), drum empty sensor (E), and fluid control module (G).

Only Ram A includes the display module (F) and power

supply box (K).

Drum empty sensor (E). Signals drum empty condition.

Display module (F). Mounted on Ram A only. Provides

Run Mode status screens, Setup screens, and control

keys.

Fluid control module (G). See page 21.

IG. 3. Before you install the system,

Integrated air controls (H). See page 11.

Power supply box (K).

Air motor solenoid (Y). Solenoid is on when system is on

and in Run Mode, Recirculate Mode, or Prime Mode.

Solenoid is off when system is shut off or when in

Depressurize Mode, or the ram is in an Inactive Ready

Mode. Turns on in Recirculate Mode. The solenoid LED

will illuminate when the solenoid is on.

Depressurize/recirculate fluid valve (Z). Depressurizes

system when Depressurize Mode is active. Recirculates

fluid when Recirculate Mode is active.

To depressurize the system, press the Depressurize

key on the display module and select Yes when

asked if you want to depressurize the system. Follow

the Pressure Relief Procedure on page 22. Shutting

off power or removing power from the system will not

depressurize the system.

14 313528E

Page 15

D200 Rams Shown

Overview

A

F

E

Y

B

E

X

H

Y

H

G

G

K

C

Z

DZ

J

D

TI10865A

FIG. 3: Component Identification, Electronic Crossover

Key to FIG. 3:

ARam A

BRam B

C Pump (Ram A and B)

D Platen (Ram A and B)

E Drum Empty Sensor (partially hidden; Ram A and B)

F Display Module (Ram A only)

G Fluid Control Module (behind rear shroud, Ram A and B)

H Integrated Air Controls (Ram A and B); see page 11

J Fluid Filter and Stand

K Power Supply Box (behind shroud, Ram A only)

X CAN Communication Cable

Y Air Motor Solenoid (Ram A and B)

Z Depressurize/Recirculate Fluid Valve (Ram A and B)

C

313528E 15

Page 16

Overview

255468 Light Tower Accessory

Order the 255468 Light Tower Accessory as a diagnostic indicator for tandem supply systems. Refer to Light

Tower Kit manual for installation instructions. See Table

4 for a description of light tower signals.

Table 4: Light Tower Signals

Signal Description

Green on only System is powered up and there

are no error conditions present.

Yellow flashing A low priority error exists.

Yellow on A medium priority error exists.

Red flashing A high priority error exists.

Red on The system is shut down due to

error conditions.

Communications Gateway Module

The Communications Gateway Module (CGM) provides

a control link between Graco Control Architecture based

systems and a selected fieldbus. This provides the

means for remote monitoring and control by external

automation systems.

CGM Status LED Signals

Signal Description

Green on System is powered up

Yellow Internal communication in progress

Red

Solid

*Red

(7 flashes)

*The red LED (F) will flash a code, pause, then repeat.

See for diagnostic information in CGM manual 312864.

NOTE: Verify that you are using the correct token for

your system and reinstall token. If fails, order new

token.

CGM hardware failure

Data map load failure

Incorrect data map for fieldbus type

No data map loaded

Data provided by the CGM to the fieldbus depends on

which Graco Control Architecture based system and

fieldbus are connected. A data map supplied on a map

token is defined for this pairing. Once the data map has

been loaded into the CGM, it is stored internally, and the

map token is no longer required for operation.

16 313528E

Page 17

Display Module (Electronic Crossover Systems)

Overview

FIG. 4: Display Module

Key Function

System On/Off

Cancel

Setup

Enter

Powers air motor solenoid ON and OFF from Ram Operation screen (F

• When ON, the air motor solenoid is ON and the pump of the active ram is pressurized.

• When OFF, the air motor solenoids are OFF.

CAUTION: Turning the air motor solenoid OFF relieves pressure from the pump motor. It does

not depressurize the fluid pressure. Follow the Pressure Relief Procedure, page 22.

NOTE: The ram up/down and blowoff air is independent of the electronic controls and can be

operated anytime the main air slider valve is open and air pressure is available.

Cancel a selection or number entry while in the process of entering a number or making a

selection.

Toggle between run and setup screens.

• Setup changes can be made while system is operating.

• If setup screens are password protected, button toggles between run and password entry

screen.

Opens drop down menus on Setup fields.

Press to enter changes and make a selection.

Table 5: Display Module Button Functions

IG. 29, page 38).

Arrows Left/Right

Arrows Up/Down

313528E 17

Navigate left or right to a new screen.

Navigate left or right within a screen while in Jump In mode. See Appendix A - User Interface

Display, page 31, for more information.

Navigate up or down within a screen or to a new screen.

• Move between selections within a drop-down menu.

• Increment or decrement the selected numerical field within a selection menu.

Page 18

Overview

Table 5: Display Module Button Functions

Key Function

Soft Key

Soft keys activate the mode or action represented by the icon above each button in the LCD.

See Table 6 for soft key modes and actions.

Table 6: Display Soft Key Icons

Icon Function

Depressurize Depressurize relieves fluid pressure from the pump outlet to below the platen on the currently

active ram.

If system is pressurized, press button.

• When prompted to depressurize the system, select or . Depressurizing the

active ram will depressurize both rams.

NOTE: If additional user-supplied check valves have been added to the system, only the active

ram will be depressurized. You must perform manual crossover and select depressurize again

to depressurize both rams. See Crossover section of this table on page 19.

If system is depressurized, press button.

• When prompted to pressurize the system, select or .

Pump Prime

Pump Prime

• Tandem ram: if pump is off, activates the air solenoid on the active ram;

• Tandem ram: if pump is on, activates the air solenoid on the inactive ram which enables you

to purge air and prime the pump;

• Single ram: activates air solenoid whether or not pump is on;

• clears the Pump Not Primed deviation or alarm (depending on setup selection); and

• resets the drum volume remaining to the drum fill volume setpoint for pump being primed.

Press button.

• When prompted to prime the ram, select to prime.

Press button to exit Prime Mode or to reset counter to the prime time.

• When prompted to exit Prime Mode, select to exit or to reset prime counter.

Recirculate Recirculate Mode pumps fluid from the drum, through the pump, and back into the drum on the

currently active ram.

Set motor air regulator to 30 psi (0.2 MPa, 2.1 bar) before pressing Recirculate key.

If system is not in Recirculate Mode, press button.

• When prompted to turn recirculation on, select or . Adjust motor air regulator to

obtain desired flow rate.

If system is in Recirculate Mode, press button.

• When prompted to turn recirculation off, select or .

18 313528E

Page 19

Overview

Table 6: Display Soft Key Icons

Icon Function

Crossover Crossover key transitions the active ram to inactive, and inactive ram to active. Available on

Warm Melt Tandem Supply Systems only.

NOTE: If an alarm is present on the inactive ram, crossover will not be successful. Manual

crossover is disabled in single ram operation.

Press button.

• When prompted to initiate a crossover, select or .

Jump In

In screens that have editable fields, press to access the fields and make changes. See

Appendix A - User Interface Display, page 31, for more information.

313528E 19

Page 20

Overview

User Interface Display

NOTE: For details regarding the user interface display see Appendix A - User Interface Display, page

31.

Display Screen Components

The following figure calls out the navigational, status, and general informational components of each display screen.

Current Date and Time

Displays soft keys

that are active for

particular screen

Soft Keys

IG. 5: Display Screen Components (example of tandem system)

F

Navigation

Status

Mode

Function Display

20 313528E

Page 21

Overview

Fluid Control Module

Table 7: Fluid Control Module Sensor Connections

Connection Ram Sensor Description

1 Ram A and Ram B Air motor solenoid (white), light tower (green), drum low (yel-

low), drum empty (black)

2 Ram A Light tower

3 Ram A + B Fluid depressurize/recirculate solenoid

4 not used not used

5 Ram A and Ram B Air motor reed switch, sensors

6 not used not used

7 Ram A Filter pressure at inlet and outlet

CAN communication

cable 1

CAN communication

cable 2

Ram A From Ram A Fluid Control Module to Display Module.

Ram A and Ram B 49 ft (15 m) from Ram A Fluid Control Module to Ram B Fluid

Control Module.

CAN Cable 2

TI12337A

CAN Cable 1

FIG. 6: Fluid Control Module Sensor Connections

3

7

4

6

5

TI12336A

313528E 21

Page 22

Electronic Crossover Operation

Electronic Crossover Operation

NOTE:

These instructions are for the display module functions used on tandem systems. For basic ram and

pump operation, refer to the component manuals

supplied.

Pressure Relief Procedure

1. Lock the gun/valve trigger.

2. Press On/Off key . If system is On, display will

highlight . Select to turn off.

If you suspect that the spray tip/nozzle or hose is completely clogged, or that pressure has not been fully

relieved after following the steps above, very slowly

loosen the tip guard retaining nut or hose end coupling

and relieve pressure gradually, then loosen completely.

Now clear the tip/nozzle or hose.

Flush Before Using Equipment

The pump was tested with lightweight oil, which is left in

the fluid passages to protect parts. To avoid contaminating your fluid with oil, flush the pump with a compatible

solvent before use. See your pump manual for flushing

directions.

Startup

1. On both ram A and B, turn on the main air slider

valve (BA). Set the ram director valve (BC) to the

down position. The ram will slowly drop.

2. Turn on the air motor slider valve (BF) on both ram A

and B.

FIG. 7: System Function Screen

3. Turn off the air motor slider valve (BF) on both ram A

and B.

4. On both ram A and B, turn off the main air slider

valve (BA). Set the ram director valve (BC) to the

down position. The ram will slowly drop.

5. Unlock the gun/valve trigger.

6. Hold a metal part of the gun/valve firmly to the side

of a grounded metal pail, and trigger the gun/valve

to relieve pressure.

7. Lock the gun/valve trigger.

8. On both ram A and B, open the fluid line drain valve

and/or the pump bleed port. Have a container ready

to catch the drainage.

BF

BE

BC

BA

BB

TI10438A

FIG. 8. Integrated Air Controls

22 313528E

Page 23

3. Turn on the power on/off switch at the back of the

power supply box on ram A. The Power Up screen

will appear. See F

F

IG. 9: Power Up Screen

IG. 9.

4. Press On/Off key . If system is Off, press

to turn the system on.

Electronic Crossover Operation

5. See F

IG. 10. The Ram Operation screen displays

which ram (A or B) is active and how much volume

is remaining in each drum. The fluid line is shown

filled indicating the system is on.

6. The air motor solenoid LED will illuminate.

Active ram is

highlighted

Fluid line shown filled

when system is ON

Volume

Remaining

F

IG. 10: Ram Operation Screen

313528E 23

Page 24

Electronic Crossover Operation

Prime

1. Make sure the system is at required temperature.

2. To prime the active ram, ensure that the system is

on and not in Run Mode. To prime the inactive ram,

ensure that the system is on and in Run Mode.

FIG. 11: Ram Operation Screen - Tandem System

3. If using a manual dispense valve, unlock the dispense valve trigger and place dispense valve over a

waste container.

NOTE: To exit Prime Mode before the timer expires,

press the Pump Prime key . The display

prompts the operator to confirm. See F

IG. 13. Select

to exit prime.

FIG. 13: Exit Prime Mode Confirmation

NOTE: To extend the prime time counter, select

IG. 13. Display prompts operator to confirm. See

in F

F

IG. 14. Select to reset.

4. Press the Pump Prime key . The display

prompts the operator to confirm. See F

IG. 12. Select

to begin prime.

F

IG. 12: Prime Confirmation

5. When the timer expires the air motor solenoid LED

will turn off.

6. Prime the system until a smooth flow of material dispenses from the dispense valve.

IG. 14: Reset Prime Time Counter Confirmation

F

7. Lock the dispense valve trigger lock.

24 313528E

Page 25

Electronic Crossover Operation

Automatic Crossover

Keep clear of the inactive ram, as automatic crossover may occur unexpectedly. To repair or adjust the

ram, first follow all steps of the Pressure Relief Pro-

cedure on page 22.

The automatic crossover feature allows continuous flow

and prevents system shutdown. If the active ram

encounters a pump runaway, drum empty, or air solenoid disconnected alarm it will attempt an automatic

crossover to the inactive ram.

The system will generate a crossover error if the active

ram attempts an automatic crossover while the inactive

ram has a pump runaway, drum empty, air solenoid disconnected, or not primed alarm.

Manual Crossover

Manual crossover can only be initiated if the following

conditions are met:

• inactive ram is not in the drum empty error condition.

• pump runaway and not primed alarms do not exist.

To initiate a manual crossover to the inactive ram:

1. From the Ram Operation screen, press the Cross-

over key . The display prompts the operator to

confirm.

2. Select to confirm manual crossover operation

or select to cancel.

FIG. 15: Crossover Function Screen

NOTE: If the active ram has a pump runaway error or

drum empty error, the system will attempt an automatic crossover.

313528E 25

Page 26

Electronic Crossover Operation

Recirculate Function

Recirculate mode pumps fluid from the drum, through

the pump, and back into the drum on the currently active

ram.

To enter Recirculate mode:

1. Set the motor air regulator to 30 psi (0.2 MPa, 2.1

bar).

2. From the Ram Operation screen, press the Recircu-

late key . The display prompts the operator to

confirm.

3. Select to confirm recirculation or select to

cancel.

Depressurize Function

Follow the Pressure Relief Procedure on page 22.

Shutting off power or removing power from the system will not depressurize the system.

When the system is pressurized the depressurize function relieves fluid pressure from the pump outlet to below

the platen on the currently active ram. However, when

the system is depressurized pressing the depressurize

key will restore fluid pressure.

Depressurize System

From the Ram Operation screen, press the Depressur-

ize key . The display prompts the operator to con-

firm. Select to confirm depressurize or select

to cancel.

IG. 16: Enter Recirculate Mode

F

4. Adjust motor air regulator to obtain desired flow

rate.

NOTE:

While in Recirculate Mode, the manual crossover

function cannot be used and the inactive ram cannot be primed.

To exit Recirculate Mode, press the Recirculate key

. The display prompts the operator to confirm.

Select to confirm or select to cancel. See F

16.

NOTE:

You must exit Recirculate Mode before depressurizing or initiating a crossover.

IG.

F

IG. 17: Depressurize Function Screen

26 313528E

Page 27

Shutdown

Turning the system OFF relieves pressure from the

pump motor. It does not depressurize the fluid pressure. Follow the Pressure Relief Procedure, page

22.

Follow the procedure below for normal system shut

down, such as at the end of the work day.

NOTE:

The ram up/down and blowoff air is independent of

the electronic controls and can be operated anytime

the main air slider valve is open and air pressure is

available.

1. Press while in the Ram Operation screen to

Electronic Crossover Operation

turn off the air motor. Select to confirm.

2. Press while in the Heater Run screen to turn

off the heaters. Select to confirm.

3. Follow the Pressure Relief Procedure, page 22.

313528E 27

Page 28

Alarms

Alarms

Supply system alarms alert you to a problem and help

Diagnose Alarms

prevent system shutdown or application errors. If an

alarm occurs, operation may stop and the following

occurs.

See Alarm Codes and Troubleshooting, page 28, for

causes and solutions to each alarm code.

• Light tower indication changes (if equipped)

• Status bar on the display shows the alarm description

Clear Alarms

Alarms are cleared by the solution(s) listed in the following table or from the screen in which they appear. Refer

to Alarm Codes and Troubleshooting, page 28, for

details.

Alarm Codes and Troubleshooting

Alarm

Code Alarm Problem Cause Solution Clear Alarm

Fluid Control Module

CB1X A - Communication Error -

Ram A Not Found

CB2X B - Communication Error -

Ram B Not Found

B61X

B62X

Crossover Error (Ram A)

Crossover Error (Ram B)

Ram cannot communicate with

FCM A.

Ram cannot communicate with

FCM B.

Inactive ram has a Not Primed

alarm.

There is a Runaway alarm Correct runaway condition

There is a Drum Empty alarm. Replace empty drum with

Verify that power is supplied.

Check that CAN cables are

connected.

Verify that selector switch is

set correctly.

Replace FCM A.

Verify that power is supplied.

Check that CAN cables are

connected.

Verify that selector switch is

set correctly.

Replace FCM B

Set inactive ram to Prime

mode to automatically clear

alarm.

and clear alarm on Status

screen 1.

full drum to clear.

Alarm automatically

cleared by solution.

Alarm automatically

cleared by solution.

Cleared from Ram Alarm

screen. See Appendix A -

User Interface Display,

page 31.

28 313528E

Page 29

Alarm

Code Alarm Problem Cause Solution Clear Alarm

Fluid Control Module (continued)

DA1X

DA2X

L11X

L12X

DB1X

DB2X

WJ1X

WJ2X

DK1X

DK2X

L21X

L22X

WK1X

WK2X

ML1X

ML2X

MA1X

MA2X

Pump Runaway A

Pump Runaway B

A - Drum Empty

B - Drum Empty

A - Not Primed

B - Not Primed

A - Air Solenoid Disconnected

B - Air Solenoid Disconnected

A - Air Motor Sensor Error

B - Air Motor Sensor Error

A - Drum Low Deviation

B - Drum Low Deviation

A - Fluid Solenoid Disconnected Deviation

B - Fluid Solenoid Disconnected Deviation

A - Rebuild Platen Seals

B - Rebuild Platen Seals

A - Rebuild Pump

B - Rebuild Pump

Pump is running faster than

set runaway limit due to:

• Increased air pressure.

• Increased fluid output.

• Exhausted fluid supply.

• Open fitting, hose, drain,

or bleed valve.

Drum empty sensor has been

activated.

The pump is not primed. Set ram to Prime mode to

Solenoid unplugged. Check that solenoid cable

Damaged solenoid / wires. Inspect solenoid wires for

System has seen multiple up

strokes without a down stroke,

or multiple down strokes without an up stroke.

Damaged or disconnected air

motor sensors.

Drum low sensor has been

activated.

Solenoid unplugged. Check that solenoid cable

Damaged solenoid wires. Inspect solenoid cable for

Counter has reached programmed platen maintenance

interval.

Counter has reached programmed pump maintenance

interval.

Correct runaway condition

and clear alarm.

Replace empty drum with

full drum to clear.

automatically clear alarm,

or manually clear alarm

from Ram Alarm screen.

is connected.

damage.

See air motor manual. Cleared from Ram Alarm

Check that air motor sensors are connected.

Inspect air motor sensor

harness for damage.

Replace empty drum with

full drum to clear.

is connected.

damage.

Perform platen maintenance; see Supply Systems Repair-Parts manual.

Perform pump maintenance. See Check-Mate

Displacement Pump manual.

Cleared from Ram Alarm

screen. See Appendix A -

User Interface Display,

page 31.

Alarm automatically

cleared by solution.

Cleared from Ram Alarm

screen or Ram Operation

screen. See Appendix A -

User Interface Display,

page 31.

Alarm automatically

cleared by solution.

Alarm automatically

cleared by solution.

screen. See Appendix A -

User Interface Display,

page 31.

Deviation automatically

cleared by solution.

Deviation automatically

cleared by solution.

Cleared from Maintenance

screen. See Appendix A -

User Interface Display,

page 31.

Cleared from Maintenance

screen. See Appendix A -

User Interface Display,

page 31.

Alarms

313528E 29

Page 30

Alarms

Alarm

Code Alarm Problem Cause Solution Clear Alarm

Fluid Control Module (continued)

DD1X

DD2X

001X

A - Pump Diving

B - Pump Diving

A - Platen Seals Maintenance Reset

or

A- Pump Maintenance

Reset

Pump leak. Worn valve or packings.

See Check-Mate Displacement Pump manual.

Ram air pressure set too low. Increase air pressure to

ram until diving stops.

Material flow rate exceeds

ability of ram to feed pump.

Reminder when maintenance

counter was last reset.

Decrease pump air pressure to slow cycle rate.

Decrease pressure until

diving stops.

Reset on Maintenance

Screen 2.

Cleared from Ram Alarm

screen. See Appendix A -

User Interface Display,

page 31.

Cleared when reset from

Maintenance Screen 2.

002X

MGDX Filter Pressure Drop Low Pressure drop from filter inlet

B - Platen Seals Maintenance Reset

or

B- Pump Maintenance

Reset

to outlet is below minimum

drop setpoint for 10 consecutive cycles. Filter element has

collapsed or is not present.

Filter Pressure Drop High Pressure drop from filter inlet

to outlet is above maximum

drop setpoint for 10 consecutive cycles. Filter is clogged.

Replace filter element. Cleared when reset from

Status Screen 2.

Remove and clean filter. Cleared when reset from

Status Screen 2.

30 313528E

Page 31

Appendix A - User Interface Display

Appendix A - User Interface Display

Display Overview

The user interface display is divided into two main functions: Setup mode and Run mode.

Setup Mode Functions

The setup mode functions enable users to:

• set and change the password;

• configure system parameters;

• set heat zone parameters;

• schedule maintenance parameters;

• configure system hardware settings;

• set and change display units and format for all

other screens;

• set pump size and drum fill volume;

• and view software information for each system

component.

Run Mode Functions

The run mode functions enable users to:

• view current flow rate and drum volume;

• view temperature for heat zones;

• view system job totals and grand totals, and

reset totals;

• view current pressures;

• view and reset maintenance counters;

• view and clear individual alarms;

• and view the alarm log.

Display Details

Power Up Screen

The following screen appears when the display module

is powered up. It remains on while the display module

runs through initialization and establishes communication with other components in the system.

F

IG. 18: Power Up Screen

Menu Bar

The menu bar appears at the top of the screen, and

consists of the following components.

IG. 19: Menu Bar

F

Date and Time

The date and time are always displayed in one of the following formats. The time is always displayed as a

24-hour clock.

• DD/MM/YY HH:MM

• MM/DD/YY HH:MM

Navigation

The navigation section, which is to the right of the date

and time, indicates the active screen with the center,

highlighted icon. The left and right arrows indicate there

are more screens that can be accessed within a mode.

313528E 31

Page 32

Appendix A - User Interface Display

Status

The current system status is displayed on the right of the

menu bar. If there is an error, an event icon and either a

text description of the event or the standard error code

for the event is displayed. If there are no errors or deviations, nothing is displayed.

Mode

The mode section displays the current system mode.

The current mode is highlighted.

Error

The current system error is displayed in the menu bar.

There are four possibilities:

Icon Function

No Icon

No information or no error has occurred

Advisory

Deviation

Alarm

Navigation within Screens

Press to open drop-down menus on Setup

screens. Also, press to enter changes or make a

selection.

Press to navigate to new screens and to

navigate left and right within a screen. Also press

select digits within a field to change.

Press to navigate to new screens and to

navigate up and down within a screen. Also press

to move between fields within a drop-down

menu, and to increment or decrement numbers within a

field.

Soft Keys

Icons above the soft keys indicate which mode or action

is associated with each soft key. Soft keys that do not

have an icon above them are not active in the current

screen.

Jump In/Jump Out

In screens that have editable fields, press to

access the fields and make changes. When changes

are complete press to exit edit mode.

32 313528E

Page 33

Setup Mode Screens

Appendix A - User Interface Display

Setup mode screens are divided into six sections: password, system setup, heat zone setup, maintenance

setup, hardware setup, and advanced setup.

Password Screen

While in Run mode, press the Setup button. If the

password is not set to 0000, the Password screen will

appear. Enter the password to continue to Setup mode.

NOTE: Upon the first system startup, the System

Setup screen will display. Otherwise, the last setup

screen viewed will display.

Set Password

To set the password, press to enter the screen.

Press to select digit to change. Press

to set value for each digit. Press

again to enter the password.

System Setup

The System Setup screen enables users to configure

system settings for the ram(s). Press to access the

fields and make changes. Press to exit edit mode.

Icon Function

Select tandem operation, ram A only operation, or ram B only operation.

Select if a Not Primed event will issue an

alarm or deviation.

Set number of minutes (1-9) for priming.

Set pump cycles per minute that will issue

a pump runaway alarm. Set between 0 and

99; default setting is 60 cycles; 00 setting

disables this function.

F

IG. 21: System Setup

IG. 20: Password Screen

F

313528E 33

Page 34

Appendix A - User Interface Display

Maintenance Setup Screen

The Maintenance Setup screen enables users to set

maintenance intervals for rebuilding platen seals and

rebuilding the pump.

Icon Function

Set the number of drums (0-9999) between

platen seal maintenance. Setting the number of pump cycles to 0 disables this function. If using a tandem system, set for each

ram. A rebuild platen seals error is issued

when maintenance is required. See Alarm

Codes and Troubleshooting on page 28.

Set the number of pump cycles (0-9999)

between pump maintenance. Setting the

number of pump cycles to 0 disables this

function. If using a tandem system, set for

each pump. A rebuild pump error is issued

when maintenance is required. See Alarm

Codes and Troubleshooting on page 28.

F

IG. 22: Maintenance Setup

34 313528E

Page 35

Appendix A - User Interface Display

Hardware Setup Screens

The Hardware Setup screens enable users to specify if

specific hardware is installed on the system and to

adjust hardware settings. Press to scroll

through the Hardware Setup screens. Once in the

desired Hardware Setup screen, press to access

the fields to make changes. Press to exit edit

mode.

NOTE: Must exit edit mode to scroll through the

Hardware Setup screens.

Hardware Setup Screen 1

This screen enables users to specify if a fluid filter monitor is installed, and set the high and low limits for the

pressure drop across the filter.

Icon Function

Select what type of error will be issued if filter pressure drops below the low limit or

raises above the high limit. Select to

Monitor the filter pressure readings through the normal

range of flow with a clean filter to establish the initial limit

settings.

FIG. 23: Hardware Setup Screen 1 (Filter)

Hardware Setup Screen 2

This screen enables users to specify if a fluid solenoid is

installed, and if a drum low sensor is installed. The fluid

solenoid controls the depressurize/recirculate valve.

Icon Function

Select if fluid solenoid is installed on system. Set for A and B rams.

disable filter monitoring or if there is no filter installed on the system.

Set low limit (0-1000 psi) for pressure drop

that will issue an error. Set the low limit to

detect a filter element collapse or a missing

element.

Set high limit (0-5000 psi) for pressure drop

that will issue an error. Set the high limit to

detect a clogged filter.

Select if drum low sensor is installed on

system. Set for A and B rams.

IG. 24: Hardware Setup Screen 2

F

313528E 35

Page 36

Appendix A - User Interface Display

Advanced Setup Screens

The Advanced Setup screens enable users to set units,

adjust values, set formats, and view software informa-

tion for each component. Press to scroll

through the Advanced Setup screens. Once in the

desired Advanced Setup screen, press to access

the fields to make changes. Press to exit edit

mode.

NOTE: Must exit edit mode to scroll through the

Advanced Setup screens.

Advanced Setup Screen 1

This screen enables users to set units that display on

other screens.

NOTE: On two-zone and four-zone enclosure acces-

sory kit, only and settings are available.

Advanced Setup Screen 2

This screen enables users to set the pump size (in

cc/cycle) and the drum fill volume (in volume units). The

drum fill volume is the amount of material in a new drum,

which is used to calculate the volume of material

remaining during operation.

NOTE: These values must be entered accurately for

the volume remaining estimates on the Ram Operation screen to be accurate.

Icon Function

Set pump size (cc/cycle) for each ram.

Check-Mate: Select between 60, 100,

200, 250, and 500.

Dura-Flo: Select between 145, 180,

220, 290, 430, 580, and 1000.

Set fill volume for each drum. Use digits 1-9999.

Change between a Check-Mate or

Dura-Flo pump.

Icon Function

Select units of measurement for volume.

Select between cycles/gal. gal., oz., and

liters/cc.

Set units of measurement for maintenance

intervals. Select between 1000 cycles,

drums, gal., and liters.

Set units of measurement for pressure.

Select between psi and bar.

Set the password. Use digits 0-9999;

0000 = no password.

F

IG. 26: Advanced Setup Screen 2

F

IG. 25: Advanced Setup Screen 1

36 313528E

Page 37

Appendix A - User Interface Display

Advanced Setup Screen 3

This screen enables users to set the date, time, and

date format.

Icon Function

Set date format. Select between

MM-DD-YYYY and DD-MM-YYYY.

Set current date.

Set current time.

Advanced Setup Screens 4 and 5

These screens display the software part number and

version information for the system components. Only

system components that are detected via the system

data bus will be displayed on these screens.

Icon Function

Controller software part number and version.

Display software part number and version.

Fieldbus gateway software part number

and version.

Temperature controller software part number and version.

IG. 27: Advanced Setup Screen 3

F

F

IG. 28: Advanced Setup Screens 4 and 5

313528E 37

Page 38

Appendix A - User Interface Display

Run Mode Screens

Run mode screens are divided into six sections: ram

operation, heat zone operation, current system status,

preventative maintenance schedule, current alarms, and

error reports. The system starts in Run mode. If the sys-

tem is in Setup mode, press to enter Run mode.

Ram Operation Screen

The Ram Operation screen displays which ram (A or B)

is active, and how much volume remains in each drum.

This screen also displays the flow rate of the active ram.

When the fluid line is shown filled the system is on.

Depending on the current system status, users can perform the following procedures from the Ram Operation

screen:

• turn the air motor on and off;

• depressurize and pressurize the system;

• recirculate fluid within the active ram;

• prime the pump(s);

• and perform a manual crossover on tandem systems.

See Electronic Crossover Operation, page 22, for

instructions on all of these procedures.

Active ram is

highlighted

Volume

Remain

-ing

Current

mode

Flow

rate

Fluid line shown filled

when system is ON

FIG. 29: Ram Operation Screen - Tandem System

The Ram Operation screen will display the appropriate

icon and highlight the corresponding soft key if the system is:

• depressurized ,

• in Recirculate mode ,

• or if a ram is in Prime mode .

38 313528E

Page 39

Appendix A - User Interface Display

Status Screen

This screen displays the job totals and grand totals. If

there is a filter or an error issued, there will be additional

screens. Press to scroll to through the

Status screens.

NOTE: If an alarm is issued, the Alarm screen will be

the first status screen shown.

Icon Function

Job total column; indicates pump cycle

count total for a single job.

Grand total column; indicates pump cycle

count total for all jobs.

Displays pump cycle count for Ram A for

a single job and all jobs.

Displays pump cycle count for Ram B for

a single job and all jobs.

Displays pump cycle count for entire system for a single job and all jobs.

Alarm Screen

The alarm screens display the type of alarm currently

occurring on each ram. Once an alarm is resolved, use

this screen to clear the alarm.

NOTE: For more information regarding alarms. See

Alarms on page 28.

Alarm

Icon

Code Function

B61X

B62X

DA1X

DA2X

DB1X

DB2X

DK1X

KD2X

DD1X

DD2X

Crossover Error

A crossover to a pump with an

error was attempted.

Pump Runaway

Pump is running faster than the

runaway limit.

Pump Not Primed

A new drum has not been

primed.

Air Motor Sensor Error

Air motor sensor detects a fault

in the pump motion.

Pump Diving

Pump leak or ram air pressure is

too low.

F

IG. 30: Status Screen 1

To reset a job total for a single ram (A or B), press

to access the fields, navigate to the value, and press

. When prompted, press to confirm. If the job

total is reset, A and B totals will also be reset. Press

to exit edit mode.

NOTE: Grand totals cannot be reset.

L11X

L12X

F

IG. 31: Ram Alarm Screen

To clear an alarm, press to access the fields, navi-

gate to the alarm icon, and press . When

prompted, press to confirm. Press to exit edit

Drum Empty

Drum for ram A or ram B is

empty.

mode.

313528E 39

Page 40

Appendix A - User Interface Display

Maintenance Screen

The maintenance screen enables operators to establish

a preventive maintenance schedule based on the system application and repair history. This screen displays

the number of maintenance units remaining before preventive maintenance is due for the platen seals and

pump.

NOTE: If a maintenance interval is set to 0, the display will be a dash.

Icon Function

Current count remaining until platen

requires maintenance. Platen mainte-

FIG. 32: Maintenance Screen

nance is reported in drums .

Current count remaining until pump

requires maintenance. Pump maintenance is reported in units set by the main-

tenance unit control in the Advanced

Setup screen 1. The example shown in

IG. 32 is set to units of 1000 pump cycles

F

.

To reset a counter, press to access the fields, navi-

gate to the value, and press . When prompted,

press to confirm. Press to exit edit mode.

40 313528E

Page 41

Appendix A - User Interface Display

Filter Screen

NOTE: The filter screen is only available if the fluid

filter option is enabled. See Hardware Setup Screen

2, page 35.

This screen displays the fluid filter inlet pressure, outlet

pressure, and the differential pressure across the filter.

Icon Function

Fluid filter inlet pressure.

Fluid filter outlet pressure.

Differential pressure across the fluid filter.

Over or Under Pressure Alarm

If the differential pressure measured across the fluid filter for at least five strokes is greater than the high limit or

less than the low limit value set in the Hardware Setup

Screen 1, and alarm or deviation is indicated; see F

IG.

34. Whether an alarm or deviation is issued depends on

the error type set in the Hardware Setup Screen 1.

FIG. 34: Fluid Filter Screen with Alarm

To clear a filter alarm or deviation, press from the

IG. 33: Fluid Filter Screen

F

fluid filter screen. Then press on the confirmation

screen.

IG. 35: Fluid Filter Screen with Alarm

F

313528E 41

Page 42

Appendix A - User Interface Display

Report Screens

The five report screens display a chronological list of the

most recent 20 errors. See Alarm Codes and Trouble-

shooting, page 28, for details regarding each alarm

code.

Icon Function

Chronological order of errors as they

occur.

Date when error occurred.

Time when error occurred.

Error code.

Press to scroll to through the five report

screens.

F

IG. 36: Report Screen

42 313528E

Page 43

Appendix A - User Interface Display

313528E 43

Page 44

Fluid Filter Kit Dimensions

Fluid Filter Kit Dimensions

NOTE:

Refer to the Related Manuals list on page 3 to find

the correct manuals that list the dimensions of the

rams, pumps, and other components.

F

G

A

Key

A 52.25 in. (1327 mm)

B 11 in. (279 mm)

C 14 in. (356 mm)

D 17 in. (432 mm)

E 14. in. (356 mm)

F (fluid inlets) 1 in. npt(f)

G (fluid outlet) 1 in. npt(f)

Filter Element Mesh Sizes

Part No. Mesh

515219 60

515220 50

515221 40

515222 30 (standard)

B

C

44 313528E

E

D

TI11158A

Page 45

Technical Data

Max air input pressure (supply system) psi (MPa, bar) / Air inlet size

S20 - 3 in. single post, 5 gal. (20 L) . . . . . . . . . . . . . . 125 psi (0.9 MPa, 9 bar) / 1/2 npt(f)

D60 - 3 in. dual post, 16 gal. (60 L), 5 gal. (20 L), 30 gal.

(115 L) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150 psi (1.0 MPa, 10 bar) / 3/4 npt(f)

D200 - 3 in. dual post, 55 gal. (200 L), 30 gal. (115 L),

16 gal. (60 L), 8 gal. (30 L), 5 gal. (20 L) . . . . . . . . . . 150 psi (1.0 MPa, 10 bar) / 3/4 npt(f)

D200s - 6.5 in. dual post, 55 gal. (200 L), 30 gal. (115 L) 125 psi (0.9 MPa, 9 bar) / 3/4 npt(f)

Technical Data

Max fluid, air working pressure, and weight

(displacement pump) . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump Wetted parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . For Check-Mate displacement pumps, see manual

Platen/Ram Codes (page 5): Part number, size, platen;

Wetted parts

A, B, C, F, G, H: 255662, 55 gal. (200 L) . . . . . . . . .

J, L, M, R, S, T: 255663, 55 gal. (200 L) . . . . . . . . . . EPDM, aluminum, zinc plated carbon steel, 316 sst

4: 255661, 30 gal. (115 L) . . . . . . . . . . . . . . . . . . . . . zinc plated carbon steel, EPDM, sst, fluoroelastomer

2: 257728, 5 gal. (20 L) . . . . . . . . . . . . . . . . . . . . . . .

1, 3: 257729, 5 gal. (20 L)

D, E: 257734, 8 gal. (30 L)

U, V, W: 257738, 16 gal. (60 L) . . . . . . . . . . . . . . . . .

6, 7, 8, 9: 257731, 5 gal. (20 L)

K, N, P: 257736, 8 gal. (30 L)

X, Y, Z: 257741, 16 gal. (60 L) . . . . . . . . . . . . . . . . . .

For Check-Mate pump packages, see manual 312376.

For Dura-Flo pump packages, see manuals 311826,

311828, 311833.

312375.

For Dura-Flo displacement pumps, see manuals

311717, 311825, 311827.

PTFE, EPDM, PTFE coated aluminum, zinc plated

carbon steel, 316 sst

Electroless nickel, polyurethane, carbon steel, polyethylene, nitrile, zinc plated carbon steel, buna, 316 sst

17-4PH sst

Stainless steel, polyurethane, PTFE coated nitrile, polyethylene, nitrile, PTFE, 303 sst, 304 sst, 316 sst,

17-4PH sst

Electroless nickel, aramind reinforced elastomer, rubber-based PSA, polyurethane, polyethylene, nitrile, zinc

plated carbon steel, buna, 1018 carbon steel, 304 sst,

316 sst, 17-4PH sst

Ambient operating temperature range (supply system) 32-120 °F (0- 49°C)

Sound data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See separate air motor manual.

External power supply requirements (DatraTrak)

AC power units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100-240 Vac, 50/60 Hz, single phase, 1.2 amps max

draw

DC power units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 Vdc, 1.2 amps max draw

313528E 45

Page 46

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective par ts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,