Page 1

Operation

313526J

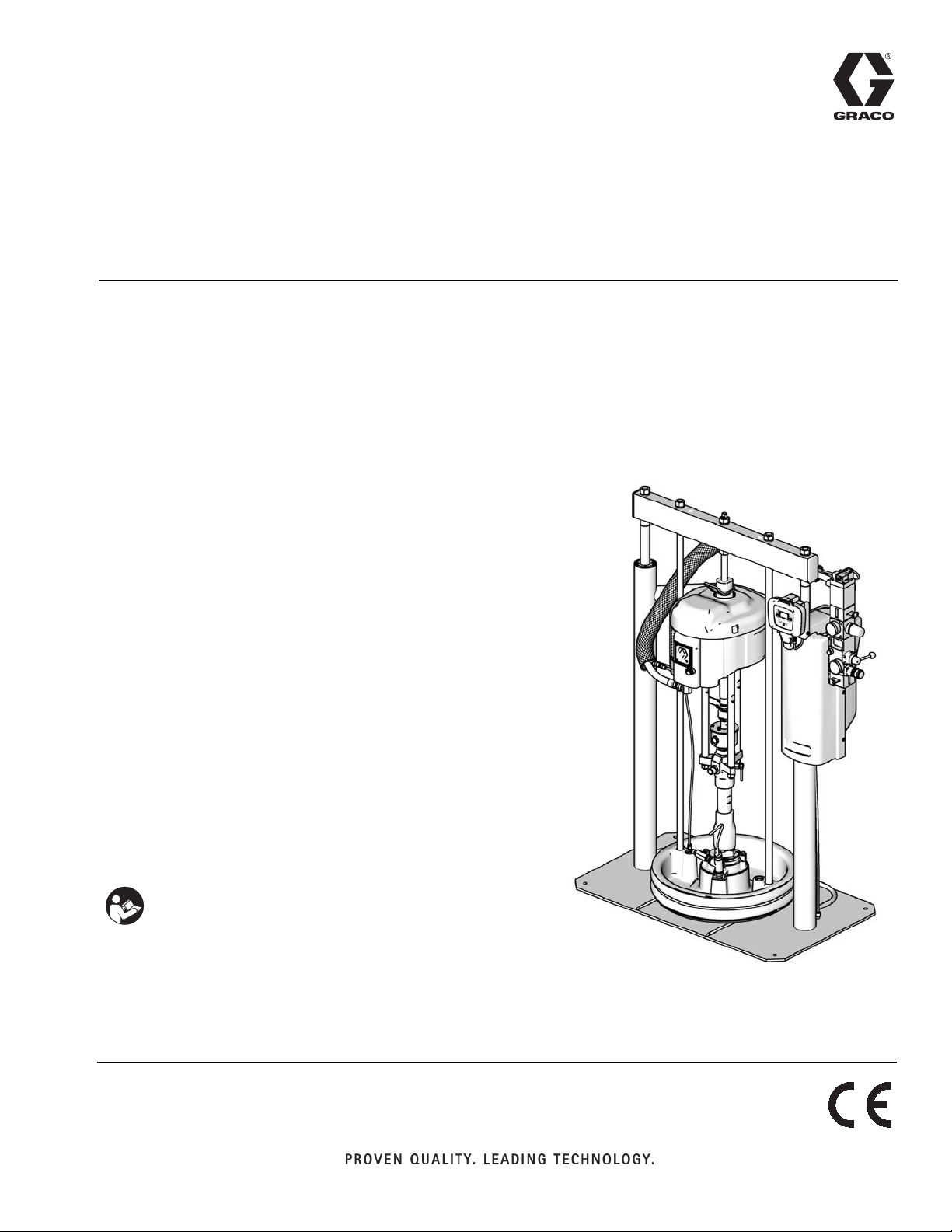

Supply Systems

For use with non-heated bulk supply of medium to high viscosity sealants and adhesive

materials. For professional use only.

Not for use in European explosive atmosphere locations.

L20c 2 inch single post elevator

20 liter (5 gallon) size

100 psi (0.7 MPa, 7 bar) Maximum Air Inlet Pressure

S20 3 inch single post

20 liter (5 gallon) size

125 psi (0.9 MPa, 9 bar) Maximum Air Inlet Pressure

EN

D60 3 inch dual post

60 liter (16 gallon) size, 30 liter (8 gallon),

20 liter (5 gallon) sizes

150 psi (1.0 MPa, 10bar) Maximum Air Inlet Pressure

D200 3 inch dual post

200 liter (55 gallon), 115 liter (30 gallon),

60 liter (16 gallon) size, 30 liter (8 gallon),

20 liter (5 gallon) sizes

150 psi (1.0 MPa, 10 bar) Maximum Air Inlet Pressure

D200S 6.5 inch dual post

55 gallon (200 liter), 30 gallon (115 liter) sizes

125 psi (0.9 MPa, 9 bar) Maximum Air Inlet Pressure

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

See page 6 for model information and approvals.

The Graco Control Architecture Electric Components are Listed in Intertek’s Directory of Listed Products.

Model CM14BA

D200

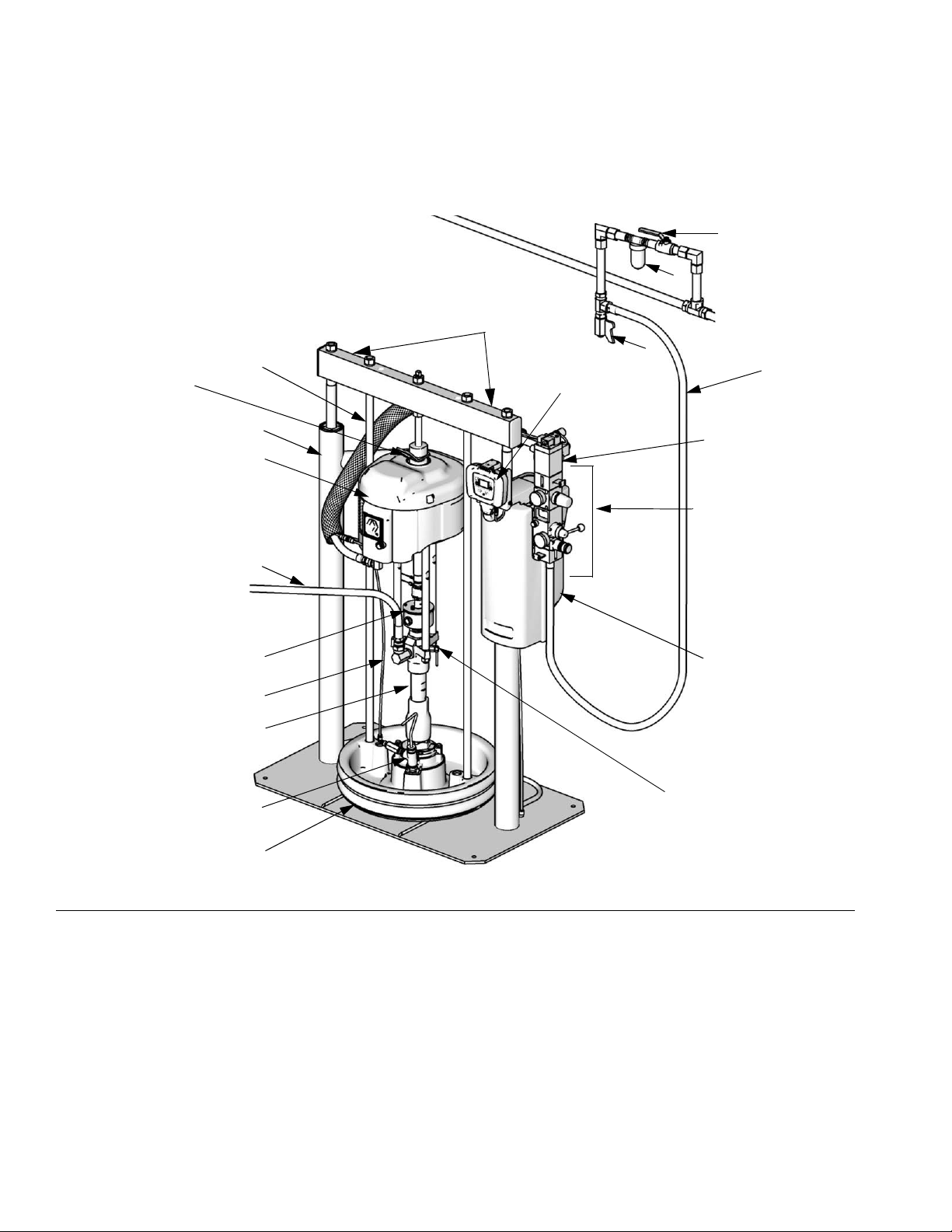

ti10429a

Page 2

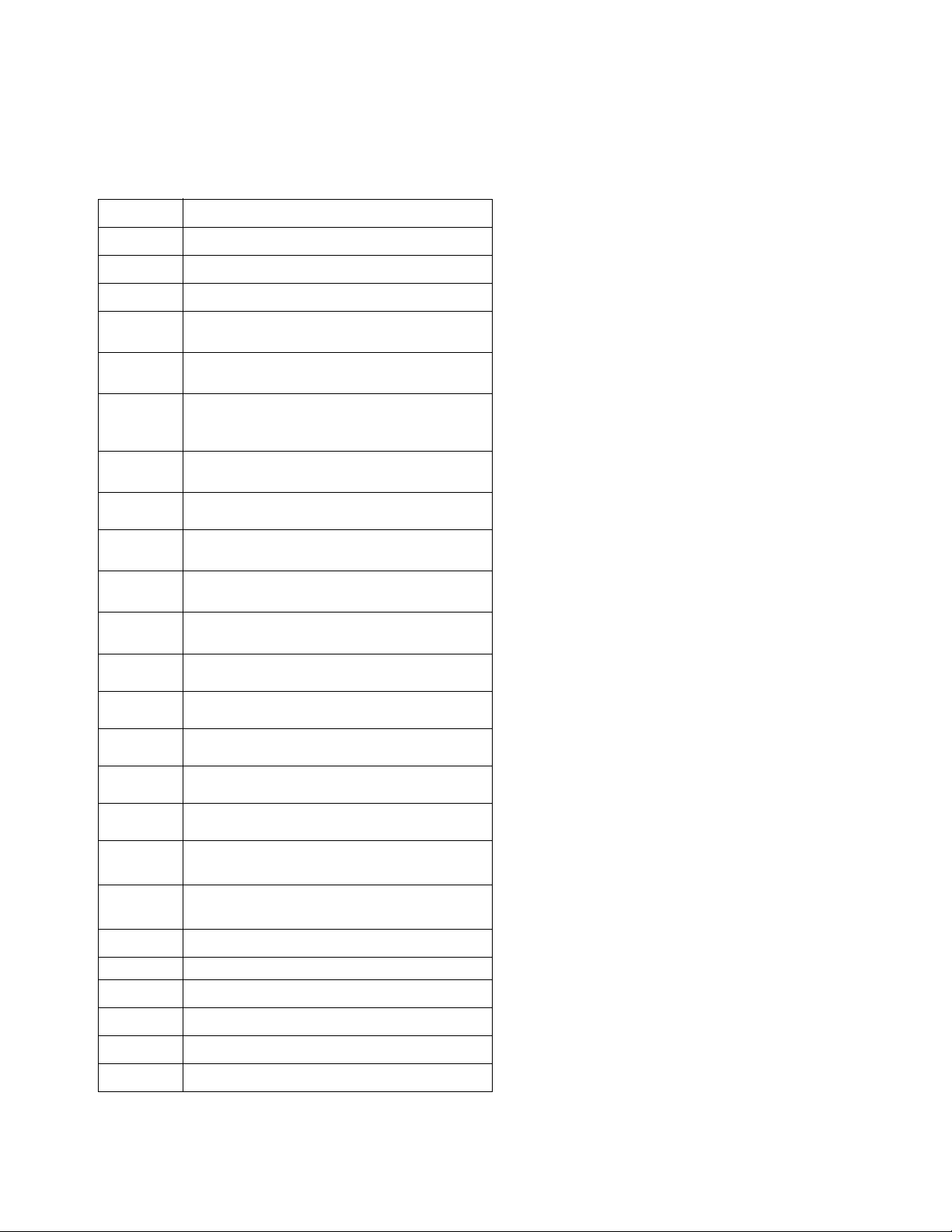

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Component Identification . . . . . . . . . . . . . . . . . . . 10

D200 3 in. and D200s 6.5 in. Dual Post . . . . . . 10

S20 3 in. Single Post and D60 3 in. Dual Post . 11

L20c 2in. Elevator . . . . . . . . . . . . . . . . . . . . . . . 13

L20c 2 in. Air Controls . . . . . . . . . . . . . . . . . . . . 14

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

General Information . . . . . . . . . . . . . . . . . . . . . 15

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Mechanical Setup . . . . . . . . . . . . . . . . . . . . . . . 16

Connect Remote DataTrak to Power . . . . . . . . 16

Attach and Adjust Drum Low/Empty Sensor . . . 17

Light Tower Accessory . . . . . . . . . . . . . . . . . . . 17

Attach Drum Stops . . . . . . . . . . . . . . . . . . . . . . 18

Supply System Operation . . . . . . . . . . . . . . . . . . . 19

Pressure Relief Procedure . . . . . . . . . . . . . . . . 19

Flush Before Using Equipment . . . . . . . . . . . . . 19

Start and Adjust Ram . . . . . . . . . . . . . . . . . . . . 19

Start and Adjust Pump . . . . . . . . . . . . . . . . . . . 21

Change Drums . . . . . . . . . . . . . . . . . . . . . . . . . 21

Shutdown and Care of the Pump . . . . . . . . . . . 22

Replace Throat Seals . . . . . . . . . . . . . . . . . . . . 22

Remote DataTrak Setup . . . . . . . . . . . . . . . . . . 23

Remote DataTrak Controls and Indicators . . . . . 24

Remote DataTrak Operation . . . . . . . . . . . . . . . . . 25

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Run Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Prime Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Setup Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Diagnostic Mode . . . . . . . . . . . . . . . . . . . . . . . . 29

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Remote DataTrak, Light Tower, Drum Low/Empty

Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

D200S, D200, S20, and D60 Supply Systems

Point of Operation Instructions . . . . . . . . . . . 37

Start and Adjust Ram . . . . . . . . . . . . . . . . . . . . 37

Start and Adjust Pump . . . . . . . . . . . . . . . . . . . 38

Change Drums . . . . . . . . . . . . . . . . . . . . . . . . . 38

Remote DataTrak Operation . . . . . . . . . . . . . . . 38

L20c Supply Systems

Point of Operation Instructions . . . . . . . . . . . 39

Start and Adjust Ram . . . . . . . . . . . . . . . . . . . . 39

Start and Adjust Pump . . . . . . . . . . . . . . . . . . . . 40

Change Drums . . . . . . . . . . . . . . . . . . . . . . . . . 40

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 42

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 42

Note: The D200s, D200, D60, S20, and L20c Operation

Quick Guides on page 37- 40 can be removed.

2 313526J

Page 3

Related Manuals

The following manuals are available at www.graco.com.

Component Manuals in English:

Manual Description

313527 Supply Systems Repair-Parts

313528 Tandem Supply Systems Operation

313529 Tandem Supply Systems Repair-Parts

312375

312376

Check-Mate

Instructions-Parts

Check-Mate

Instruction-Parts

Dura-Flo

311827

180cc, 220cc, 290cc) Instructions-Parts

Manual

311825

311717

311828

311826

311833

312889

312467

312468

312469

312470

311238

312796

308213

Dura-Flo

580cc) Instructions-Parts Manual

Carbon Steel Displacement Pump (1000cc)

Instructions-Parts Manual

Dura-Flo

220cc, 290cc) Instructions-Parts Manual

Dura-Flo

Instructions-Parts Manual

Two-Ball NXT

Instructions-Parts Manual

60 cc Check-Mate Displacement Pump

Repair Parts Manual

100 cc Check-Mate Displacement Pump

Repair Parts Manual

200 cc Check-Mate Displacement Pump

Repair Parts Manual

250 cc Check-Mate Displacement Pump

Repair Parts Manual

500 cc Check-Mate Displacement Pump

Repair Parts Manual

™

NXT

Instructions-Parts

™

NXT

Instructions-Parts

Premier

312374 Air Controls Instructions-Parts

312491 Pump Fluid Purge Kit

®

Displacement Pumps

®

Pump Packages

™

Displacement Pumps (145cc,

™

Displacement Pumps (430cc,

™

Pump Packages (145cc, 180cc,

™

Pump Packages (430cc, 580cc)

™

Pump Packages (1000cc)

Air Motor (Nxxxxx models)

Air Motor (Mxxxxx models)

®

Air Motor Instructions-Parts

Related Manuals

312492 Drum Roller Kit Instruction

312493 Light Tower Kit Instruction

406681 Platen Cover Kit

313526J 3

Page 4

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the dispense outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

•Follow Pressure Relief Procedure in this manual, when you stop dispensing and before cleaning,

checking, or servicing equipment.

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

4 313526J

Page 5

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Do not leave the work area while equipment is energized or under pressure. Turn off all equipment

and follow the Pressure Relief Procedure in this manual when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power cord before servicing equipment.

• Use only grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on power and extension cords.

• Do not expose to rain. Store indoors.

SPLATTER HAZARD

Hot or toxic fluid can cause serious injury if splashed in the eyes or on skin. During blow off of platen,

splatter may occur.

• Use minimum air pressure when removing platen from drum.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear impervious gloves when spraying or cleaning equipment.

• If this equipment is used with isocyanate material, see additional information on isocyanites in Isocyanate Conditions Section of this manual.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

313526J 5

Page 6

Models

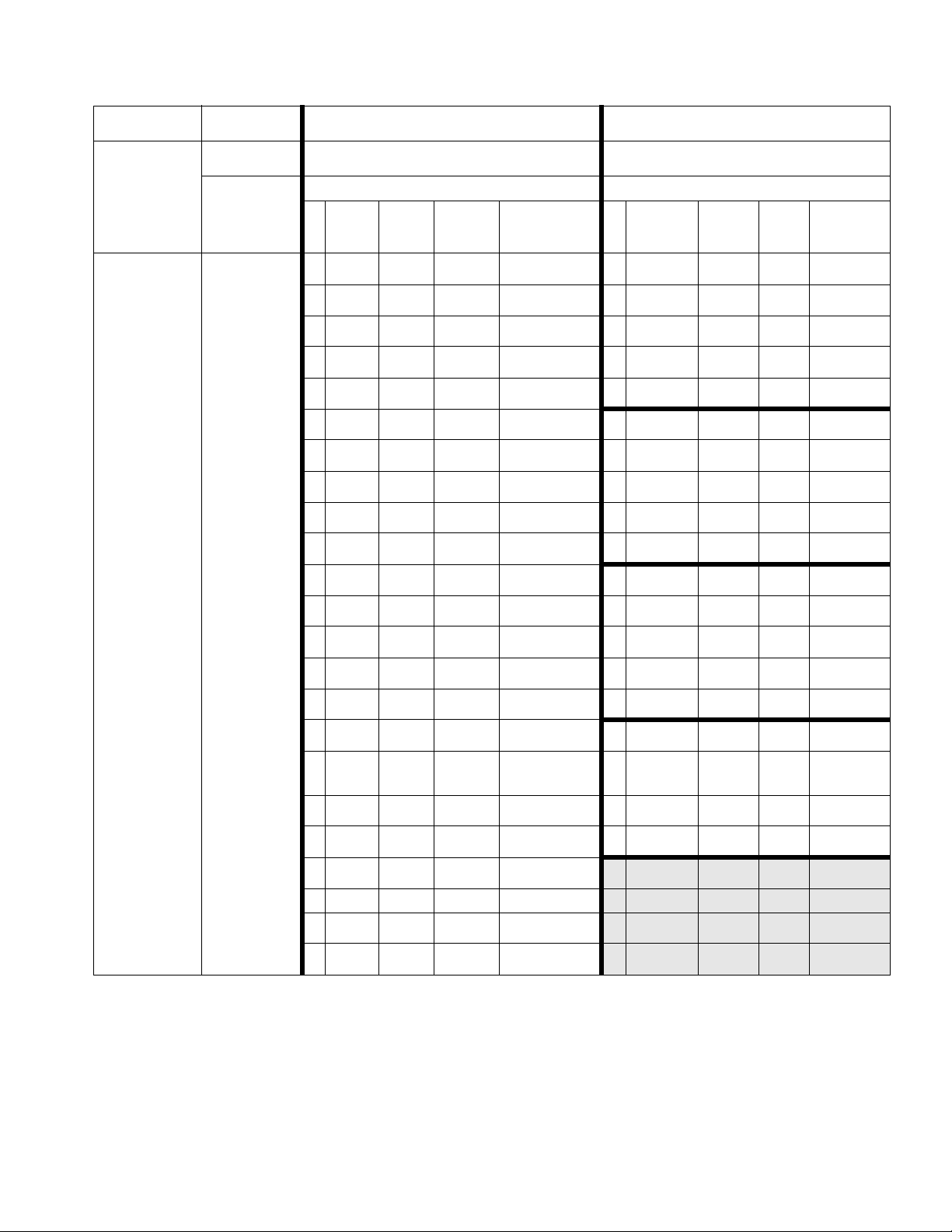

Models

Check the identification plate (ID) for the 6-digit part number of the supply system. Use the following matrix to define the construction of the supply system,

based on the six digits. For example, Part No. CM14BA represents a

®

Check-Mate supply system (CM), a carbon steel Check-Mate 100 MaxLife

displacement pump with an NXT 2200 air motor with remote DataTrak (pump

code 14), a 3 in. dual post ram with integrated air controls (B) and a 55-gallon,

uncoated platen with a neoprene seal (A).

Systems with the GD as the first and second digits are Dura-Flo supply

systems.

Some configurations in the following matrix cannot be built. See the

Product Selection guide for available systems.

To order replacement parts, see Parts section in manual 313527. The digits in the matrix on the next page do not

correspond to the Ref. Nos. in the Parts drawings and lists.

All supply systems with DataTrak and 24 Vdc or 100-240 Vac power supplies are ETL approved.

2ECOGNIZED#OMPONENT

#-

ID

ti11157a

#ERTIFIEDTO#!.#3!#3!#.O

#ONFORMSTO5,

6 313526J

Page 7

Models

CM 14 B

First and

Second Digit

CM

(Supply

System with

Check-Mate

displacement

pump)

GD

(Supply

System with

Dura-Flo

displacement

pump)

Third and

Fourth Digit Fifth Digit

Pump Code

(See Table 1

for 2-digit

Check-Mate

Pump Code)

(See Table 2

for 2-digit

Dura-Flo

Pump Code)

Size Style

1 2 in. L20c no volt

2 3 in. S20c no volt INT C

3 3 in. S20 no volt INT F

4 3 in. D60 no volt INT G

5 3 in. D200 no volt INT H

6 3 in D200i no volt

7 6.5 in. D200s no volt INT K

8 6.5 in. D200si no volt

9 3 in. D200 24 Vdc INT M

A 3 in. D200i 24 Vdc

B 3 in. D200

C 3 in. D200i

F 6.5 in. D200s 24 Vdc INT U

G 6.5 in. D200si 24 Vdc

H 6.5 in. D200s

J 6.5 in. D200si

L 3 in. S20

M 3 in. S20 24 Vdc INT 9

R 3 in. D60

T 3 in. D60i

U 3 in. D60 24 Vdc INT

W 3 in. D60i 24 Vdc

Y 3 in. D60i no volt

Ram Options

DataTra

k

Voltage Air Controls

2-Button Inter-

2-Button Inter-

2-Button Inter-

100-240

Vac INT S

100-240

Vac

100-240

Vac INT Y

100-240

Vac

100-240

Vac INT 8

100-240

Vac INT A

100-240

Vac

2-Button Inter-

2-Button Inter-

2-Button Inter-

2-Button Inter-

2-Button Inter-

2-Button Inter-

Air Control

Panel B

lock J

lock L

lock R

lock T

lock W

lock 7

lock

lock

lock

A

Sixth Digit

Platen and Seal Options

Platen

Size

20 L

(5 Gal) F, SW CS Nitrile

20 L

(5 Gal) F, SW CS

20 L

(5 Gal) F, SW SST

20 L

(5 Gal) F, DW CS Nitrile

20 L

(5 Gal) F, DW CS

30 L

(8 Gal) F, SW CS Nitrile

30 L

(8 Gal) F, SW CS

30 L

(8 Gal) F, SW SST

30 L

(8 Gal) F, DW CS Nitrile

30 L

(8 Gal) F, DW CS

60 L

(16 Gal) F, SW CS Nitrile

60 L

(16 Gal) F, SW CS

60 L

(16 Gal) F, SW SST

60 L

(16 Gal) F, DW CS Nitrile

60 L

(16 Gal) F, DW CS

115 L

30 Gal D CS EPDM

200 L

(55 Gal) DR

200 L

(55 Gal) DR AL EPDM

200 L

(55 Gal) DR AL Neoprene

Platen

Style

Platen

MaterialSeal

Material

Polyure-

thane

PTFE

coated

Polyure-

thane

Polyure-

thane

PTFE

coated

Polyure-

thane

Polyure-

thane

PTFE

coated

Polyure-

thane

PTFE

coated

AL EPDM

KEY:

S = Single post ram i = 2-Button Interlock F = Flat SW = Single wiper

c = Cart mounted s = 6.5 inch D = D Style DW = Double wiper

D = Dual post ram INT = Integrated air controls DR = Dual o-ring

* Other Available Models: 262868. This model is the same as CM-_ _-3-B models, such as CM-11-3-B, but uses Check-Mate

Pump P40DCS (NXT2200/CM 100) instead of the other pumps listed on page 8.

313526J 7

Page 8

Models

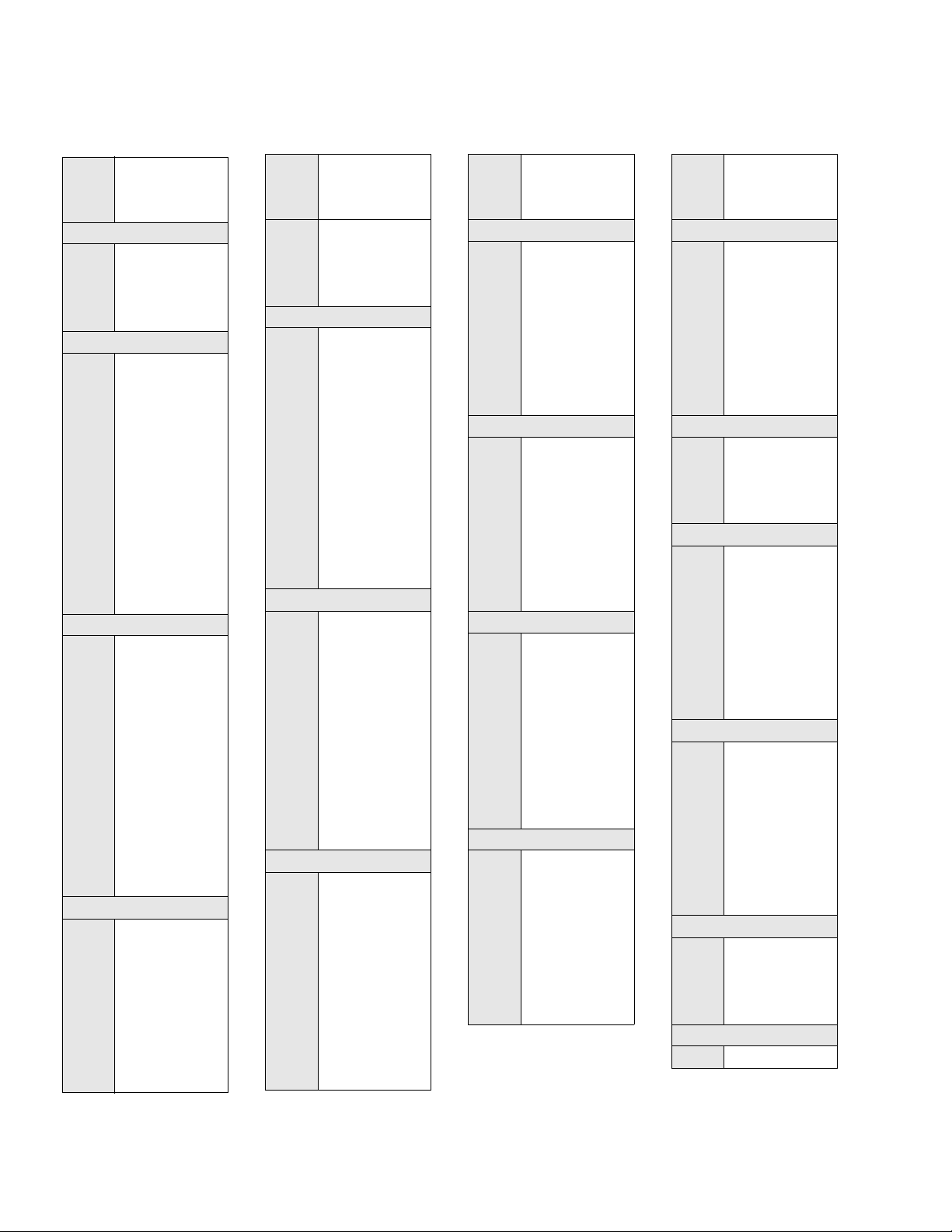

Table 1: Check-Mate Pump Identification Code/Part No. Index

Pump Part No.

Pump

Code

(see manual

312376)

NXT 200/CM 60

4A P05LCS

4B P05LCM

4C P05LSS

4F P05LSM

NXT 400/CM 60

6A P11LCS

6B P11LCM

6C P11LSS

6F P11LSM

6G P11RCS

6H P11RCM

6J P11RSS

6K P11RSM

61 P11SCS

62 P11SCM

63 P11SSS

64 P11SSM

NXT 700/CM 60

7A P20LCS

7B P20LCM

7C P20LSS

7F P20LSM

7G P20RCS

7H P20RCM

7J P20RSS

7K P20RSM

71 P20SCS

72 P20SCM

73 P20SSS

74 P20SSM

NXT 1200/CM 60

8A P38LCS

8B P38LCM

8C P38LSS

8F P38LSM

8G P38RCS

8H P38RCM

8J P38RSS

8K P38RSM

Pump Part No.

Pump

Code

(see manual

312376)

81 P38SCS

82 P38SCM

83 P38SSS

84 P38SSM

NXT 1800/CM 60

9A P61LCS

9B P61LCM

9C P61LSS

9F P61LSM

9G P61RCS

9H P61RCM

9J P61RSS

9K P61RSM

91 P61SCS

92 P61SCM

93 P61SSS

94 P61SSM

NXT 2200/CM 100

11 P40LCS

12 P40LCM

1F P40LSS

1G P40LSM

13 P40RCS

14 P40RCM

1H P40RSS

1J P40RSM

10 P40SSS

1A P40SSM

19 P40SCS

NXT 3400/CM 100

15 P63LCS

16 P63LCM

1T P63LSS

1U P63LSM

17 P63RCS

18 P63RCM

1W P63RSS

1Y P63RSM

1B P63SSS

1C P63SSM

Pump Part No.

Pump

Code

(see manual

312376)

NXT 2200/CM 200

21 P23LCS

22 P23LCM

23 P23RCS

24 P23RCM

25 P23LSS

26 P23LSM

27 P23RSS

28 P23RSM

NXT 3400/CM 200

29 P36LCS

2A P36LCM

2B P36RCS

2C P36RCM

2F P36LSS

2G P36LSM

2H P36RSS

2J P36RSM

NXT 6500/CM 200

2L P68LCS

2M P68LCM

2R P68RCS

2S P68RCM

2T P68LSS

2U P68LSM

2W P68RSS

2Y P68RSM

20 P68SCS

NXT 3400/CM 250

31 P29LCS

32 P29LCM

33 P29RCS

34 P29RCM

35 P29LSS

36 P29LSM

37 P29RSS

38 P29RSM

Pump Part No.

Pump

Code

(see manual

312376)

NXT 6500/CM 250

39 P55LCS

3A P55LCM

3B P55RCS

3C P55RCM

3F P55LSS

3G P55LSM

3H P55RSS

3J P55RSM

Premier/CM 250

3L P82LCS

3M P82LCM

3R P82LSS

3S P82LSM

NXT 3400/CM 500

51 P14LCS

52 P14LCM

53 P14RCS

54 P14RCM

55 P14LSS

56 P14LSM

57 P14RSS

58 P14RSM

NXT 6500/CM 500

59 P26LCS

5A P26LCM

5B P26RCS

5C P26RCM

5F P26LSS

5G P26LSM

5H P26RSS

5J P26RSM

Premier/CM 500

5L P39LCS

5M P39LCM

5R P39LSS

5S P39LSM

No Pump

NN

See manual 312376 or the ID plate on the pump to determine pump part number.

8 313526J

Page 9

Table 2: Dura-Flo Pump Identification Code/Part No. Index

Models

Pump Part No.

Pump

Code

(see manual

311828)

NXT 2200/DF 145SS

A1 P31LSS

A3 P31HSS

NXT 3400/DF 145SS

B1 P46LSS

B3 NR

NXT 3400/DF 180SS

B5 P41LSS

B7 P41HSS

NXT 3400/DF 220SS

C1 P30LSS

C3 P30HSS

NXT 6500/DF 220SS

CA P57LSS

CC NR

NXT 6500/DF 290SS

D1 P45LSS

D3 NR

Premier/DF 290SS

DL P67LSS

DR NR

Pump Part No.

Pump

Code

(see manual

311826)

NXT 3400/DF 430CS

E1 NR

E2 NR

E3 NR

E4 NR

NXT 3400/DF 430SS

E5 P15LSS

E6 P15LSM

E7 P15HSS

E8 P15HSM

NXT 6500/DF 430CS

E9 NR

EA NR

EB NR

EC NR

NXT 6500/DF 430SS

EF P32LSS

EG P32LSM

EH P32HSS

EJ P32HSM

Premier/DF 430

EL P44LSS

EM NR

ER NR

ES NR

ET P44LCS

NXT 3400/DF 580CS

F1 NR

F2 NR

F3 NR

F4 NR

NXT 3400/DF 580SS

F5 P12LSS

F6 P12LSM

F7 P12HSS

F8 P12HSM

Pump Part No.

Pump

Code

(see manual

311826)

NXT 6500/DF 580CS

F9 P22LCS

FA NR

FB NR

FC NR

NXT 6500/DF 580SS

FF P22LSS

FG P22LSM

FH P22HSS

FJ P22HSM

Premier/DF 580CS

FL P34LSS

FM NR

FR NR

FS NR

FT P34LCS

Pump Part No.

Pump

Code

(see manual

311833)

NXT 3400/DF 1000CS

G1 P06LCS

G3 NR

NXT 3400/DF 1000SS

G5 NR

G7 NR

NXT 6500/DF 1000CS

G9 P10LCS

GB NR

NXT 6500/DF 1000SS

GF NR

GH NR

Premier/DF 1000

GL NR

GM NR

GR NR

GS NR

NR = Not released

313526J 9

Page 10

Component Identification

Component Identification

D200 3 in. and D200s 6.5 in. Dual Post

W

H

(Note: Do not use motor

lift ring to lift entire

system.)

CM14BA Model

Shown

N

A

B

S

R

M

V

Lift Locations

U

T

E

X

G

K

C

J

D

FIG. 1

Key:

ARam Assembly

B Air Motor

C Displacement Pump

DPlaten

E Remote DataTrak (single ram systems) or

Display Module (tandem systems)

IG

G Integrated Air Controls (see F

H Air Motor Lift Ring

J Platen Bleed Port

K Power Supply Box

M Blowoff Air Supply Line

. 3)

P

TI10430a

N Platen Lift Rod

P Pump Bleeder Valve

R Enclosed Wet Cup

S Fluid Line (not supplied)

T Main Air Line (not supplied)

U Air Line Drain Valve (not supplied)

V Air Filter (not supplied)

W Bleed Type Air Shutoff Valve (not supplied)

X Air Motor Solenoid

10 313526J

Page 11

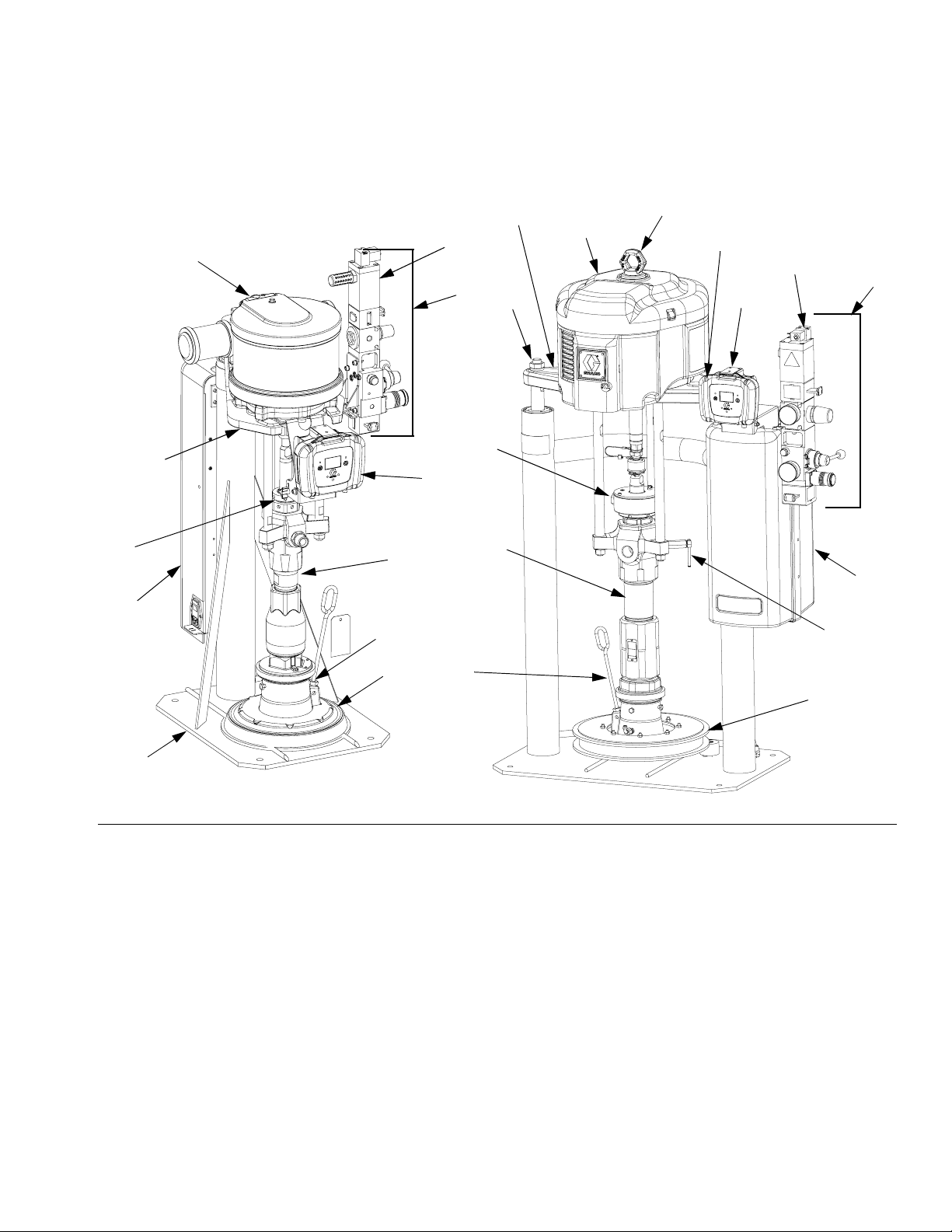

S20 3 in. Single Post and D60 3 in. Dual Post

Model CM9HLB Shown Model CM2MRY Shown

Lift Location

B

X

G

A

B

H

Component Identification

(Note: Do not use motor

lift ring to lift entire

system.)

Lift Location

X

G

F

Lift

Location

R

K

A

r_255648_313527_5a

FIG. 2

Key:

ARam Assembly

B Air Motor

C Displacement Pump

DPlaten

F Remote DataTrak (single ram systems) or

Display Module (tandem systems)

IG

G Integrated Air Controls (see F

H Lift Ring

J Platen Bleed Port

K Power Supply Box (under shrouding)

P Pump Bleed Valve

R Enclosed Wet Cup

S Fluid Line (not supplied, see F

T Air Line (not supplied, see F

U Air Line Drain Valve (not supplied, see F

V Air Filter (not supplied, see F

. 3)

IG

. 1)

IG

. 1)

IG

. 1)

R

F

C

C

K

J

D

J

P

D

r_255648_313527_6a

IG

W Bleed Type Air Shutoff Valve (not supplied, see F

X Air Motor Solenoid

IG

. 1)

. 1)

313526J 11

Page 12

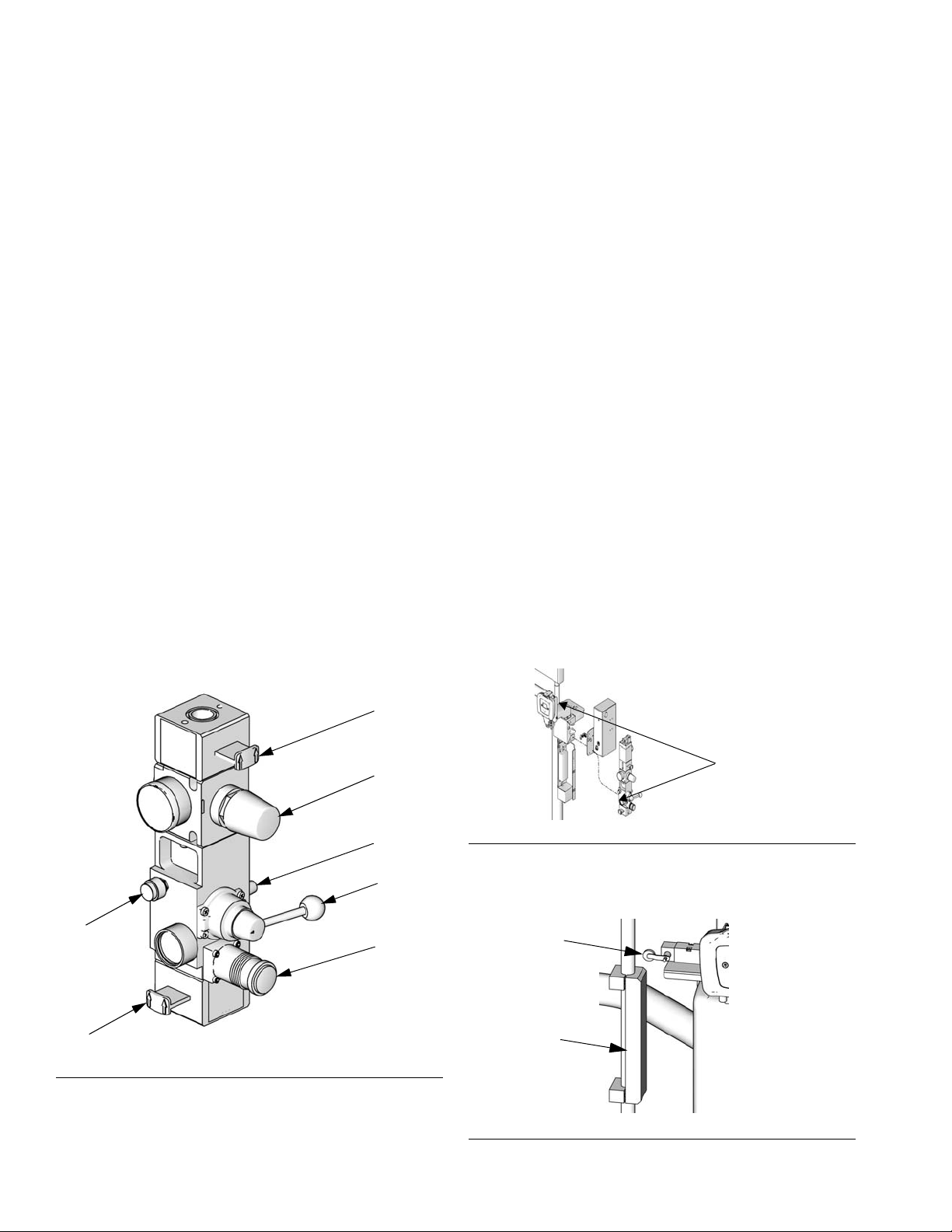

Component Identification

Integrated Air Controls

D200, D200s, D60, and S20 Models

The integrated air controls include:

• Main air slider valve (BA): turns air on and off to

the system. When closed, the valve relieves pressure downstream.

• Ram air regulator (BB): controls ram up and down

pressure and blowoff pressure.

• Ram director valve (BC): controls ram direction.

• Exhaust port with muffler (BD)

• Air motor regulator (BE): Controls air pressure to

motor.

• Air motor slider valve (BF): turns air on and off to

the air motor. When closed, the valve relieves air

trapped between it and the air motor. Push the valve

in to shutoff. Remote DataTrak: The air solenoid

(X, F

IG

. 1), the air motor slider valve (BF), and the

main air slider valve (BA) must be open for air to

flow. (See Remote DataTrak Setup, page 23.)

• Blowoff button (BG): turns air on and off to push

the platen out of an empty drum.

Air Line Accessories

See FIG. 1.

• Air line drain valve (U)

• Air line filter (V): removes harmful dirt and mois-

ture from compressed air supply.

• Second bleed-type air valve (W): isolates air line

accessories and supply system for servicing. Locate

upstream from all other air line accessories.

• Air relief valve (attached to ram air regulator, not

visible): automatically relieves excessive pressure.

2-Button Interlock Air Controls

D60i, D200i, and D200si Models

Units that have 2-Button Interlock controls have the following additional components:

• 2-Button Module: See manual 312374 for

information.

• Roller switch (CA): shuts off air supply when it

contacts the bracket actuator. Operator must push

and hold the activation buttons simultaneously to

resume ram movement.

BG

BA

F

IG

. 3. Integrated Air Controls

ti10438a

BF

BE

BD

BC

BB

Activation

Buttons

ti10843a1

FIG. 4

• Bracket actuator (CB): attaches to the platen lift

rod. When platen is outside of drum, actuator makes

contact with the roller switch.

CA

CB

ti10846a

F

IG

. 5

12 313526J

Page 13

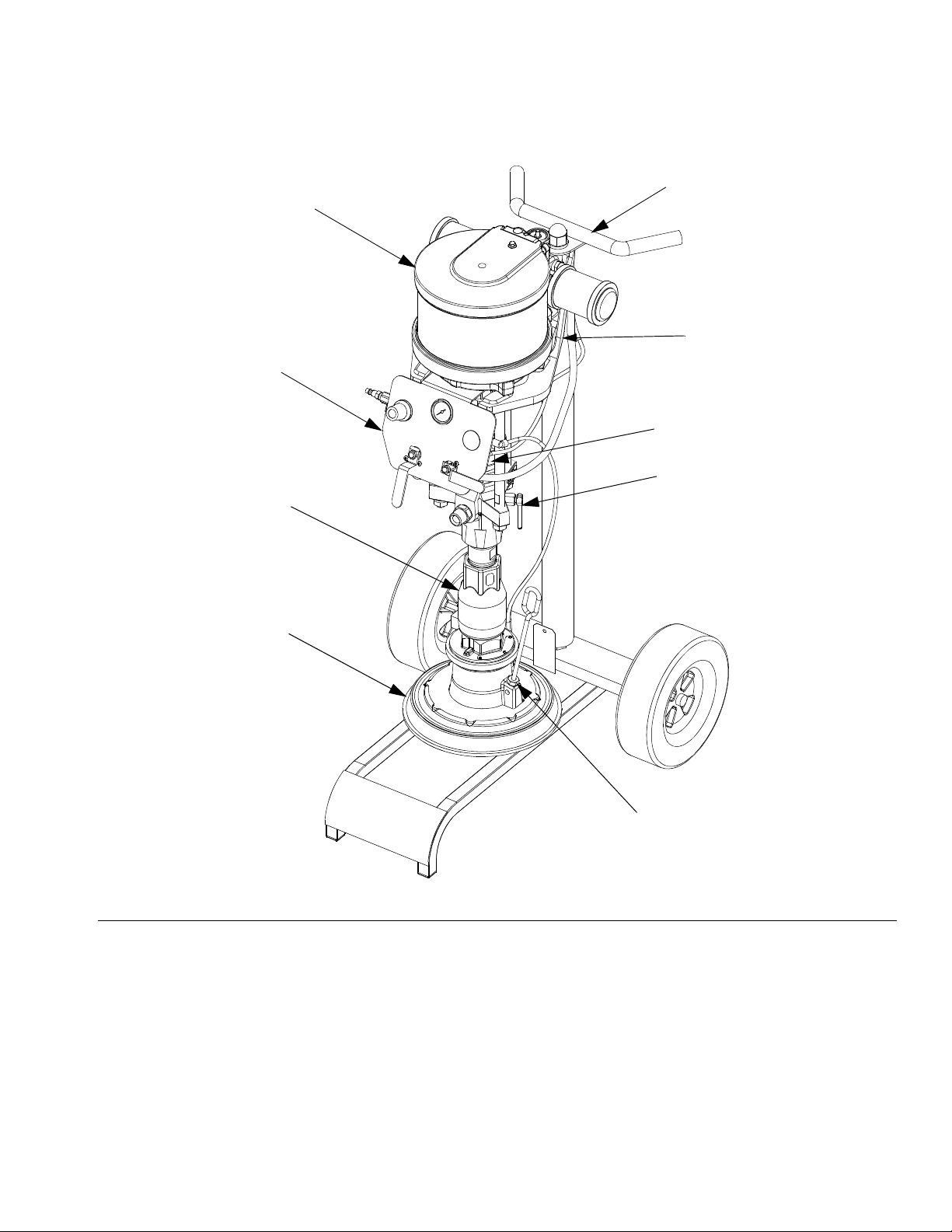

L20c 2in. Elevator

Component Identification

CM7B1G Model Shown

CF

CC

CD

CA

CB

Lift Location

CE

P

J

r_257032_312376_1e

FIG. 6

Key:

CA Elevator Cart

CB Air Motor

CC Displacement Pump

CD Platen

CE Enclosed Wet Cup (behind air controls)

CF Elevator and Pump Air Controls

J Platen Bleed Port

P Pump Bleed Valve

313526J 13

Page 14

Component Identification

L20c 2 in. Air Controls

• Air motor regulator (DA): Controls air pressure to

motor.

• Blowoff button (DB): turns air on and off to push

the platen out of an empty drum.

• Air motor shutoff valve (DC): turns air on and off

to the air motor.

• Elevator director valve (DD): controls elevator

direction.

DB

DA

DC

F

IG

. 7: Elevator Air Controls

DD

r_257302_312376_2e

Air and Fluid Hoses

Be sure all air hoses (T) and fluid hoses (S) are properly

sized and pressure-rated for your system. Use only

electrically conductive hoses. Fluid hoses must have

spring guards on both ends. Use of a short whip hose

and a swivel between the main fluid hose and the

gun/valve allows freer gun/valve movement.

14 313526J

Page 15

Installation

Installation

General Information

Reference numbers and letters in parentheses in

the text refer to the callouts in the figures.

Accessories are available from Graco. Make certain all

accessories are adequately sized and pressure-rated to

meet the system’s requirements.

F

IG

. 1, FIG. 2, and FIG. 6 are only guides for selecting

and installing system components and accessories.

Contact your Graco distributor for assistance in designing a system to suit your particular needs.

Location

NOTICE

Always lift supply system at proper lift locations (see

F

IG

. 1, FIG. 2, and FIG. 6). Do not lift in any other way.

Attach a lifting sling at the proper lift spots. Lift off the

pallet using a crane or a forklift.

Position the ram so the air controls are easily accessible. Ensure that there is enough space overhead for the

ram to raise fully. (See Dimensions, page 34.)

Pump: use a ground wire and clamp. Loosen grounding

lug locknut and washer. Insert one end of supplied

ground wire into slot in lug and tighten locknut securely.

Connect other end of wire to a true earth ground. See

F

IG

. 8.

ti8250a

FIG. 8

Air and fluid hoses: use only electrically conductive

hoses with a maximum of 500 ft. (150 m) combined

hose length to ensure grounding continuity. Check electrical resistance of hoses. If total resistance to ground

exceeds 29 megohms, replace hose immediately.

Air compressor: follow manufacturer’s recommendations.

Spray gun/dispense valve: ground through connection

to a properly grounded fluid hose and pump.

Fluid supply container: follow local code.

Using the holes in the ram base as a guide, drill holes

for 1/2 in. (13 mm) anchors.

Ensure that the ram base is level in all directions. If necessary, level the base using metal shims. Secure the

base to the floor using 1/2 in. (13 mm) anchors that are

long enough to prevent the ram from tipping.

Grounding

NOTICE

The equipment must be grounded. Grounding

reduces the risk of static and electric shock by providing an escape wire for the electrical current due to

static build up or in the event of a short circuit.

313526J 15

Object being sprayed: follow local code.

Solvent pails used when flushing: follow local code.

Use only conductive metal pails, placed on a grounded

surface. Do not place the pail on a nonconductive surface, such as paper or cardboard, which interrupts

grounding continuity.

To maintain grounding continuity when flushing or

relieving pressure: hold metal part of the dispense

valve firmly to the side of a grounded metal pail, then

trigger the valve.

Page 16

Installation

Mechanical Setup

1. Fill displacement pump wet cup 2/3 full with Graco

Throat Seal Liquid (TSL).

2. Back-off air regulators to their full counterclockwise

position and close all shutoff valves.

3. Connect air line from an air source to the system air

inlet. See F

mance curves in manual 312376 to determine your

air supply flow requirements. Use a supply hose

capable of meeting the required flow.

Quick disconnects restrict flow for large air motors.

Connect Remote DataTrak to Power

100-240 Vac

The system has an IEC-C14 power input connection

located on the back of the power supply box. The user

must supply an appropriate adapter. The 100-240 Vac

supply must be capable of sourcing at least 1.2 Amps

and have supply current protection rated in accordance

with the supply wire gauge provided.

Frequency Voltage Max. Current Phase

50-60 Hz 100-240 Vac 1.2 Amps 1

IG

. 1 or FIG. 2. Refer to the pump perfor-

24 Vdc

Attach 24V Class 2 power supply to terminals on the

24V assembly: +24 Vdc to terminal 2 (+) and -24 Vdc to

terminal 5 (-). Attach protective earthing (PE) conductor

to terminal marked .

5 (-)

PE

ti10853a

The 24 Vdc supply must be capable of supplying at least

1.2 Amps and have supply current protection rated at no

more than 2.5 Amps.

Voltage Max. Current

24 Vdc 1.2 Amps

2 (+)

ti10985a

Have a trained electrician install and inspect power connection per local code. Plug power supply cord into the

outlet on the back of the power supply box and into a

properly grounded electrical outlet. Use a zip tie, if

needed, to secure power cord in place.

ti10433a

Have a trained electrician install and inspect power connection per local code.

16 313526J

Page 17

Installation

Attach and Adjust Drum Low/Empty Sensor

For supply systems with remote DataTrak, an optional

kit can be purchased to indicate either when the drum is

low or when it is empty. Order kit 255469 for a D60 or

D200 3 in. ram, 255689 for a D200s 6.5 in. ram, or

257634 for a S20 3 in. ram.

1. Position ram at desired level (low or empty).

2. Attach low/empty sensor bracket (EA) to mounting

bracket (EB).

EA

EE

ED

4. For D60, D200, and D200s supply systems: Attach

the actuator (ED) to the ram piston rod, near the top,

so it passes in front of the sensor (EE) at the correct

level for drum low or drum empty. See F

For D60 supply systems: Flip actuator bracket (ED)

so that it points upwards instead of downwards to

allow it to pass the sensor (EE).

5. For S20 supply systems: Attach the actuator (ED) to

the ram cylinder endcap, so the sensor (EE) passes

in front of the bracket (ED) at the correct level for

drum low or drum empty. See F

6. Make precise adjustments by moving the sensor

within the slot on the sensor bracket.

7. Attach the sensor to the corresponding connector

on the D-Sub harness of the remote DataTrak.

IG

. 10.

IG

. 9.

Light Tower Accessory

Order the 255467 Light Tower Accessory as a diagnostic indicator for D200s, D200, D60, and S20 supply systems. See T

signals.

ABLE

3 for a description of light tower

EB

F

IG

. 9: D200 and D200s supply systems

EB

EA

ED

EE

r_cm9hlb_313526_3a

F

IG

. 10: S20 supply systems

3. To measure either drum low or drum empty, attach

one sensor (EE) to the sensor bracket (EA).

Table 3: Light Tower Signals

Signal Description

Yellow flashing A low priority error exists.

Yellow on A medium priority error exists.

Red flashing A high priority error exists.

Red on The system is shut down due to

error conditions.

313526J 17

Page 18

Installation

Attach Drum Stops

Only D200s, D200, and D60 Supply systems are

shipped with drum stops in place to help position the

drum on the ram. For replacement parts, order Kit

255477. The kit includes 2 each of capscrews (FA), lock

washers (not shown), and drum stops (FB).

FB

F

IG

. 11

FA

ti10917a

1. Locate the correct set of mounting holes on the ram

base.

2. Using the capscrews (FA) and lock washers (not

shown), attach the drum stops (FB) to the ram base.

55 gal (200 L)

8 gal (30 L)

FIG. 12: Ram Base

D200 and D200s Base D60 Base

30 gal (115 L)

8 gal (30 L)

16 gal (60 L)

5 gal (20 L)

5 gal (20 L)

60 gal (16 L)

18 313526J

Page 19

Supply System Operation

Pressure Relief Procedure

1. Lock the gun/valve trigger.

Supply System Operation

Flush Before Using Equipment

The pump was tested with lightweight oil, which is left in

the fluid passages to protect parts. To avoid contaminating fluid with oil, flush the pump with a compatible solvent before use. See pump manual for flushing

directions.

2. For D200s, D200, S20, and D60 Air Controls: See

F

IG

. 3, page 12.

a. Close the air motor slider valve (BF) and the

main air slider valve (BA).

b. Set the ram director valve (BC) to DOWN. The

ram will slowly drop.

c. Jog the director valve up and down to bleed air

from ram cylinders.

IG

3. For L20c Air Controls: See F

a. Close the air motor valve (DC) and the elevator

director valve (DD). The ram will slowly drop.

4. Unlock the gun/valve trigger.

5. Hold a metal part of the gun/valve firmly to the side

of a grounded metal pail, and trigger the gun/valve

to relieve pressure.

6. Lock the gun/valve trigger.

7. Open the fluid line drain valve and the pump bleeder

valve (P). Have a container ready to catch the drainage.

8. Leave the pump bleeder valve (P) open until ready

to spray again.

If you suspect that the spray tip/nozzle or hose is completely clogged, or that pressure has not been fully

relieved after following the steps above, very slowly

loosen the tip guard retaining nut or hose end coupling

and relieve pressure gradually, then loosen completely.

Now clear the tip/nozzle or hose.

. 7, page 14.

Start and Adjust Ram

D200 3 in. and D200s 6.5 in. Dual Post

Moving parts can pinch or amputate fingers. When the

pump is operating and when raising or lowering the

ram, keep fingers and hands away from the pump

intake, platen, and lip of the drum.

1. Refer to FIG. 1 and FIG. 3. Close all air regulators

and air valves.

2. Open main air slider valve (BA) and set ram air regulator (BB) to 40 psi (0.28 MPa, 2.8 bar). Set director valve handle (BC) to UP and let the ram rise to

its full height. 2-Button Interlock: If the system has

this feature, ram will stop as it nears the top. Press

and hold both buttons to raise ram completely. See

F

IG

. 3 on page 12.

3. Lubricate the platen seals (D) with grease or other

lubricant compatible with the fluid you will pump.

4. Remove the drum cover and smooth the surface of

the fluid with a straightedge.

5. Put a full drum of fluid on the ram base, slide it back

against the drum stops, and center it under the

platen (D). An optional drum roller kit is available for

D200 and D200s supply systems to make it easier

to load the drum on the base. Order Kit 255627.

To avoid damage to the platen seals, do not use a

drum that is dented or damaged.

313526J 19

Page 20

Supply System Operation

6. Remove bleed stick from platen bleed port (J).

7. If drum has a plastic liner, pull it over edge of drum.

Secure liner with tape wrapped around circumference of drum.

J

D

F

IG

. 13

ti10543a

8. Set the director valve (BC) to DOWN and lower the

ram until fluid appears at the top of the platen bleed

port (J). Adjust ram air regulator (BB) as needed.

Set the director valve (BC) to neutral and close the

platen bleed port (J). 2-Button Interlock: If system

has this feature, press and hold both buttons to start

lowering the ram. See F

IG

. 3, page 12.

L20c 2 in. Elevator, S20 3 in. Single Post,

and D60 3 in. Single Post

1. Raise ram:

a. For S20 and D60: Open the main air slider

valve (BA) and set the ram air regulator (BB) to

40 psi (0.28 MPa, 2.8 bar). Set director valve

handle (BC) to UP and let the ram rise to its full

height. 2-Button Interlock: If the system has

this feature, ram will stop as it nears the top.

Press and hold both buttons to raise ram completely. See F

IG

. 3 on page 12.

being trapped under the platen, scoop fluid from the

center of the pail to the sides, to make the surface

concave.

5. Adjust the pail to be sure it is aligned with the

platen, and remove the bleed stick to open the

platen bleed port (J).

6. With hands away from the pail and the platen, push

down on the director valve (BC) handle, and lower

the ram until the platen rests on the lip of the pail.

For S20 and D60 only: Move the director valve

handle to the horizontal position (neutral).

J

D

r_255648_313527_7a

7. Lower ram:

a. For S20 and D60: Set the director valve (BC) to

DOWN and continue to lower the ram until fluid

appears at the platen bleed port (J) and close

the platen bleed port. Set the director valve to

neutral, reinstall the vent handle, and tighten

securely.

b. For L20c: Turn elevator director valve (DD) to

DOWN and continue to lower the ram until fluid

appears at the platen bleed port (J). Close the

platen bleed port (J).

b. For L20c: Set elevator director valve (DD) to

UP and let the ram rise to its full height.

2. Lubricate the platen seals (D) with grease or other

lubricant compatible with the fluid you will pump.

3. Put a full drum on the ram base and center it under

the platen (D).

4. Remove the drum cover and smooth the surface of

the fluid with a straightedge. To prevent air from

20 313526J

Page 21

Supply System Operation

Start and Adjust Pump

1. Connect pump outlet fittings and hose (not supplied).

Be sure all components are adequately sized and

pressure rated to meet the system’s requirements.

2. Be sure the pump air valve is closed. Then set the

ram air regulator (BB) to about 50 psi (0.35 MPa,

3.5 bar). Set the director valve (BC) or elevator

director valve (DD) to DOWN. Remote DataTrak: If

system has this feature, press the prime/flush key

(see page 26).

3. Start the pump as explained in the separate pump

instruction manual.

4. Keep the director valve (BC) or elevator director

valve (DD) set to DOWN while pump is operating.

Increase air pressure to the ram if the pump does

not prime properly with heavier fluids. Decrease air

pressure if fluid is forced out around the top seal or

platen.

Change Drums

2. Raise the platen out of the drum.

a. For D200s, D200, S20, and D60: Set ram

director valve (BC) to UP to raise the platen (D)

and immediately press and hold the blowoff air

button (BG) until the platen (D) is completely out

of drum. Use minimum amount of air pressure

necessary to push the platen out of the drum.

b. For L20c: Set elevator director valve (DD) to

UP to raise the platen (D) and immediately

press and hold the blowoff air button (DB) until

the platen (D) is completely out of drum.

3. Follow steps 4-8.

Excessive air pressure in the material drum could

cause the drum to rupture, causing serious injury.

The platen must be free to move out of the drum.

Never use drum blowoff air with a damaged drum.

4. Release the blowoff air button and allow the ram to

rise to its full height. 2-Button Interlock: If system

has this feature, the ram will stop as it nears the top.

Press and hold both buttons to raise ram completely. See F

IG

. 4, page 12.

1. Stop the pump.

a. For D200s, D200, S20, and D60: Push in the

air motor slider valve (BF) to stop the pump.

b. For L20c: Turn air motor valve (DC) off to stop

the pump.

5. Remove empty drum.

6. Inspect platen and, if necessary, remove any

remaining material or material build–up.

7. Place full drum on ram base.

8. Lower the ram and adjust the position of the drum

relative to the platen. See Start and Adjust Ram on

page 19.

313526J 21

Page 22

Supply System Operation

Shutdown and Care of the Pump

1. Set the ram director valve (BC) or elevator director

valve (DD) to DOWN.

2. Follow the Pressure Relief Procedure on page 19.

3. Follow the pump shutdown instructions in separate

pump manual.

Replace Throat Seals

Quick Coupler

Remove wet cup from displacement pump while

attached to the ram to replace throat seals.

1. Ensure displacement pump is at bottom of stroke.

2. Follow the Pressure Relief Procedure on page 19.

3. Remove Quick Coupler:

Remove clip (GC), and slide coupling cover (GB) up

to remove coupling (GA).

GB

GC

4. Remove Threaded Coupler: (not shown)

Loosen and remove coupling nut as described in

pump packages manual 312376.

5. Lift air motor rod to bring rod to top of stroke.

GA

ti10508a

6. Remove wet cup and packing cartridge according to

instructions in displacement pump manual(s).

22 313526J

Page 23

Remote DataTrak Setup

Supply System Operation

The remote DataTrak display unit comes fully assembled. Use the following instructions and figure to connect remote DataTrak to the supply system.

The system requires either 100-240 Vac, 50/60 Hz

input, or 24 Vdc to the power supply. Ensure that the

main disconnect rocker switch is set to OFF (O). Connect power to the DataTrak unit as detailed in Connect

Remote DataTrak Units to Power, page 16.

1. Feed CAN cable (HB) and D-Sub cable (HA) under

the remote DataTrak bracket and attach to corresponding connectors on remote DataTrak display.

The CAN cable (HB) can connect to either of the

two CAN style connectors on the remote DataTrak.

2. Snap remote DataTrak unit to mount on ram supply

system.

X

BF

HA

connector

HB connector

r_cm9hlb_313526_6a

FIG. 15: S20 supply systems

3. Drum Low/Empty Sensor: If system has this fea-

ture, attach sensor cable to the corresponding connector on the D-Sub harness. See Drum

Low/Empty Sensor, page 15.

HA

HB

IG

. 14: D200, D200s, and D60 supply systems

F

ti10431a

BF

4. Light Tower: If system has this feature, attach the

X

connector on the light tower cable to the corresponding connector on the D-Sub harness. See

manual 312493.

5. Solenoid: Attach the connector on the D-Sub har-

ness to the corresponding connector on the solenoid (X).

313526J 23

Page 24

Remote DataTrak Controls and Indicators

Remote DataTrak Controls and Indicators

Key for FIG. 16

SC Display Screen

LE LED (diagnostic indicator when lit)

FR Flow Rate Units, user settable to:

/min,

= cycles per minute

gpm [US] = gallons per minute, United States

gpm [UK] = gallons per minute, United Kingdom

oz/min [US] = ounces per minute United States

oz/min [UK] = ounces per minute United Kingdom

l/min = liters per minute

cc/min = cubic centimeters per minute

VU Volume Units

PF Prime/Flush Key

RK Reset/Cancel Key (also used to scroll)

CF Cycle/Flow Rate

JT Job Total Counter, resettable

MC Maintenance Counter

MS Maintenance Counter Setpoint

DV Drum Volume Remaining

DS Drum Size

DF Drum Fill Volume

RT Runaway Protection (enable/disable)

RS Runaway Cycle Rate

PV Displacement Pump Volume

Run Mode

DV

RK

JT

MC

PF

LE

ti10249A

SC; See Details at right.

FIG. 16. Remote DataTrak Controls and Indicators

RS

RK

PV

CF

RT

VU

FR

Setup Mode

VU

DS

PF

DF

24 313526J

Page 25

Remote DataTrak Operation

Remote DataTrak Operation

NOTICE

To prevent damage to soft key buttons, do not press

the buttons with sharp objects such as pens, plastic

cards, or fingernails.

Startup

1. Turn the air motor slider valve (BF) off before turning the remote DataTrak power on.

NOTICE

If the motor air valve is not turned off, the air supply to

the motor will automatically turn on via activation of

the air solenoid (X) when the display changes from

the Splash screen to Run mode.

2. Turn on the remote DataTrak system using the

rocker switch on the ram power supply.

Run Mode

See FIG. 16 and FIG. 19.

The Run Mode screen displays the resettable job total

counter (JT), maintenance counter (MC), cycle/flow rate

(CF), and the remaining volume in the drum (DV) in both

numeric and icon versions.

All items are displayed using the defined volume

units (VU).

DV

JT

MC

ti10433a

ti10433a

F

IG

. 17

3. The Splash screen (F

progress bar fills from left to right. It will then go

directly to Run mode (F

4. Follow the Start and Adjust Pump procedure in the

pump manual.

IG

. 18) will flash on while the

IG

. 19).

CF

F

IG

. 19: Run Mode Screen

Key Functions When in Run Mode

1. To enter Prime Mode, press and release .

2. To enter Setup Mode (page 26), press and hold

for 3 seconds.

3. To enter Diagnostic Mode (page 29), press and

release . The system will enter Diagnostic Mode

only if there are active warnings/alarms.

4. To reset the job total counter, press and hold

from Run Mode for 3 seconds.

F

IG

. 18: Splash Screen

313526J 25

Page 26

Remote DataTrak Operation

Prime Mode

See FIG. 20.

1. Press to enter Prime Mode screen. The Prime

symbol (PS) will appear in the display and the LED

(B, F

IG

. 16) will flash.

JT

MC

PS

IG

. 20: Prime Mode Screen

F

2. While in Prime Mode, the job total counter (JT) is

blank and will not count. However, the maintenance

counter (MC) will continue to decrement.

3. When a new drum is installed, press and hold

while in Prime Mode to reset the drum volume

remaining (DV) to the drum fill volume (DF).

Password Screen

If a password has been assigned (not set to ‘0000’), the

Password screen will appear (F

word to access the Setup screens.

FIG. 21: Password Screen

1. To enter a password, press to enter edit mode.

2. Once in edit mode, press to scroll through digits.

3. Press to select the correct digit and move on to

the next.

4. When password is correct, press on the rightmost digit to submit the password.

IG

. 21). Enter the pass-

4. To exit Prime Mode, press . The Prime symbol

will disappear and the LED will stop flashing; the

screen will return to Run Mode (F

5. To enter Setup Mode, press and hold for 3 seconds.

IG

. 19).

Setup Mode

If a key is not pressed within one minute of entering

a setup screen, the system will return to Run Mode

(F

IG

. 19).

See FIG. 16. Press and hold for 3 seconds.

• If a password has not been assigned (set to ‘0000’),

the system will go directly to Setup screen 1.

Setup Screen 1

Use Setup screen 1 to set runaway cycle rate (RS),

enable/disable runaway protection (RT), select pump

volume per cycle (PV), select flow rate units (FR), enter

drum size (DS), and enter drum fill volume (DF). See

F

IG

. 22.

1. Press to toggle from field to field through the

screen.

If you go past a field you want to edit, toggle

through the remaining fields, exit the Setup mode,

and reenter Setup. It is impossible to back up in the

Setup screens.

2. Press to scroll through available values for each

field.

3. Press again to set the value and move the cursor to the next data field.

26 313526J

Page 27

Remote DataTrak Operation

C

Runaway Cycle Rate/Enable Runaway

Protection

Graco recommends setting runaway

cycle rate (RS) to 60 or less. Choose

a value that is just above the maximum cycle rate of the application.

When runaway protection is enabled (RT), a ✓ will

appear on the setup screen. See F

Displacement Pump Volume

Press to scroll through the available displacement pump volumes (PV) in cc per cycle. set the

values to the pump size installed. Refer to manual

312375 or the marking on the displacement pump

cylinder.

Flow Rate Units

Press to scroll through the available flow rate

units. See Key on page 24. The selected units will

be used to display flow rate and volume on the main

Run screen and most of the setup values.

IG

. 22.

RT

RS

PV

FIG. 22: Setup Screen 1

FR

DS

DF

Setup Screen 2

Use Setup screen 2 to set the maintenance counter setpoint (MC), reset the maintenance counter, enable/disable diagnostic codes (EC), and choose whether the E7

drum icon (DL) will indicate when the drum is low or

when the drum is completely empty.

M

Initially, choose units that will allow easy definition

of the setup values (e.g. drum volume in gallons).

Then, return and select the flow rate unit to display

on the Run screen. The defined setup values will

convert automatically.

Drum Size

Use DS to enter the size of the container.

Drum Fill Volume

Use the Drum Fill Volume field (DF) to enter the

exact volume of material in the drum. Contact supplier for exact volume. This value is used to determine the remaining volume in the drum.

4. To move to Setup screen 2, move the cursor to the

Drum Fill Volume field (DF), then press once

more.

EC

{

DL

F

IG

. 23: Setup Screen 2

1. Press to toggle from field to field through the

screen.

2. Press to scroll through available values for each

field.

3. Press again to set the value and move the cursor to the next data field.

Maintenance Counter

Use the maintenance counter setpoint (MS) to set

the maintenance schedule based on the units dis-

played. Press and hold for 3 seconds when the

entire MS field is highlighted to reset the MC value.

313526J 27

Page 28

Remote DataTrak Operation

4. See page 30 for a description of E1, E2, and E4

diagnostic codes.

When E1, E2, and E4 diagnostic options are

enabled, a ✓ will appear on the setup screen. See

F

IG

. 23.

Drum Low/Empty Diagnostic Code

The E7 drum icon can represent either a drum low

or a drum empty.

Drum Low: A drum low setting will result in a warning condition. The icon will show as an almost

empty drum. The light tower and diagnostic LED will

signal a warning. The pump will continue to cycle.

Drum Empty: A drum empty setting will result in an

alarm condition. The icon will show as a completely

empty drum. The light tower and diagnostic LED will

signal an alarm. The pump will stop cycling.

Press while E7 is selected to toggle between

these options.

2. Press to scroll through available values for each

field.

3. Press again to set the value and move the cursor to the next data field.

The screensaver turns off the backlight of the LCD

after the specified time has elapsed. A setting of 0

minutes is not recommended because it turns off

the screensaver, leaving the backlight on constantly.

When in the contrast setting field press to

adjust the contrast + (up) or - (down) respectively.

4. To return to the Run screen, move the cursor to the

contrast setting, then press once more. If you

entered Setup Mode from Prime Mode, you will be

returned to that screen.

5. To enter Setup screen 3, move the cursor to the E7

drum setting, then press once more.

Setup Screen 3

Setup screen 3 displays a non-resettable grand total

counter (GT) at the top. Use Setup screen 3 to set the

password (PW), assign a time limit for the screensaver

(SS), and adjust the LCD contrast (CS).

GT

PW

F

IG

. 24

CS

SS

1. Press to toggle from field to field through the

screen.

28 313526J

Page 29

Remote DataTrak Operation

Diagnostic Mode

Diagnostics

Remote DataTrak can diagnose several problems with

the supply system. When the monitor detects a problem,

the LED (B, F

appear on the display. See Table 4, page 33.

If the accessory light tower kit is installed a light will illuminate or flash on the tower. See T

Diagnostic screens will become the active screen

as soon as the diagnostic code condition is

detected. See T

To acknowledge the diagnosis and return to the normal

operating screen, press once. To clear a diagnostic

code, see the section specific to the code.

IG

See F

nostic screens. The system will enter Diagnostic Mode

only if active warnings/alarms are present.

IG

. 16) will flash and a diagnostic code will

ABLE

4.

ABLE

4.

. 16. Press and release to access the Diag-

3. To clear the Runaway diagnostic code:

a. Press and release to enter Diagnostic Mode

IG

from Run Mode (F

. 19).

b. Press and release to scroll to the Runaway

Diagnostic screen, or return to the previous Run

screen if no other Diagnostic screens are active.

c. Press and hold for 3 seconds while on the

runaway Diagnostic screen to clear the diagnostic code and scroll to the next available

Diagnostic screen, or return to the previous Run

screen if no other Diagnostic screens are active.

NOTICE

Clearing this diagnostic code will immediately cause

the air solenoid to activate, applying air to the motor.

To disable runaway monitoring, go to setup mode

and set runaway value to 0 (zero) or toggle (RT)

off. See F

IG

. 22.

Runaway Diagnostic Code Screen

See FIG. 25. If pump runaway occurs, the Runaway

screen becomes active, stopping the pump.

RS

F

IG

. 25: Runaway Diagnostic Code Screen

1. Correct the condition causing the diagnostic code.

See T

ABLE

4, page 33.

2. Press and release to acknowledge the diagnostic code and return to the previous screen.

313526J 29

Page 30

Remote DataTrak Operation

Diving Up Diagnostic Code Screen

See FIG. 26. If the pump shows diving up symptoms and

the E1 Diagnostic Code is enabled, the Diving Up

screen becomes active.

F

IG

. 26: Diving Up Diagnostic Code Screen

1. Press and release to exit the Diving Up screen.

This will set the diagnostic code as a standing diag-

nostic code. A standing diagnostic code has not

been cleared, simply acknowledged.

2. Correct the condition causing the diagnostic code.

See T

ABLE

4, page 33.

3. To clear the diagnostic code, navigate to the Diving

Up diagnostic screen.

a. Press and release to enter Diagnostic Mode

from Run Mode.

b. Press and release to scroll to the Diving Up

Diagnostic screen, or return to the previous Run

screen if no other Diagnostic screens are active.

Diving Down Diagnostic Code Screen

See FIG. 27. If the pump shows diving down symptoms

and the E2 Diagnostic Code is enabled, the Diving

Down screen becomes active.

FIG. 27: Diving Down Diagnostic Code Screen

1. Press and release to exit the Diving Down

screen.

2. Correct the condition causing the diagnostic code.

See T

ABLE

4, page 33.

3. To clear the diagnostic code, navigate to the Diving

Down diagnostic screen.

a. Press and release to enter Diagnostic Mode

from Run Mode.

b. Press and release to scroll to the Diving

Down Diagnostic screen, or return to the previous Run screen if no other Diagnostic screens

are active.

c. Press and hold for 3 seconds while on the

Diving Up Diagnostic screen to clear the diagnostic code and scroll to the next available

Diagnostic screen, or return to the previous Run

Diving Down Diagnostic Screen to clear the

diagnostic code and scroll to the next available

Diagnostic screen, or return to the previous Run

screen if no other Diagnostic screens are active.

screen if no other Diagnostic screens are active.

30 313526J

c. Press and hold for 3 seconds while on the

Page 31

Remote DataTrak Operation

Disconnected Solenoid Diagnostic Code

Screen

See FIG. 28. If the system detects a disconnected air

motor solenoid and the E4 Diagnostic Code is enabled,

the Disconnected Solenoid screen becomes active.

F

IG

. 28: Disconnected Solenoid Diagnostic Code

Screen

1. Press and release to exit the Disconnected

Solenoid screen.

2. Correct the condition causing the diagnostic code;

ABLE

see T

4, page 33.

Drum Low/Empty Diagnostic Code Screen

See FIG. 29 and FIG. 30. If the drum low/empty sensor

trips, the Drum Low or Drum Empty screen becomes

active, depending on which sensor setting is chosen,

see page 28.

FIG. 29: Drum Empty Diagnostic Code Screen

3. This diagnostic code will automatically clear when

the system detects that the solenoid is connected.

F

IG

. 30. Drum Low Diagnostic Code Screen

1. Press and release to exit the Drum Low/Empty

screen. This will set the diagnostic code as a stand-

ing diagnostic code. A standing diagnostic code has

not been cleared, simply acknowledged.

2. Replace the low or empty drum with a full drum.

When the sensor no longer detects a low or empty

drum the diagnostic code will clear automatically.

313526J 31

Page 32

Remote DataTrak Operation

Reed Switch Diagnostic Code Screen

See FIG. 31.

If the system detects an air motor reed switch error, the

Reed Switch Diagnostic screen becomes active.

F

IG

. 31. Reed Switch Diagnostic Code Screen

1. Press and release to exit the Reed Switch Diagnostic screen.

2. Correct the condition causing the diagnostic code.

See T

ABLE

4, page 33.

3. To clear the diagnostic code, navigate to the Reed

Switch diagnostic screen.

Maintenance Counter Expired Screen

See FIG. 32.

If the system has counted down to 0 from the setpoint

for number of cycles/gallons/liters, the Maintenance

Counter Expired Screen becomes active.

FIG. 32. Maintenance Counter Expired Screen

1. Press and release to exit the Maintenance

Counter Expired screen.

2. Perform necessary maintenance.

3. Reset the Maintenance Counter. See Setup Screen

2, page 27.

a. Press and release to enter Diagnostic Mode

from Run Mode.

b. Press and release to scroll to the Reed

Switch Diagnostic screen, or return to the previous Run screen if no other Diagnostic screens

are active.

c. Press and hold for 3 seconds while on the

Reed Switch Diagnostic Screen to clear the

diagnostic code and scroll to the next available

Diagnostic screen, or return to the previous Run

screen if no other Diagnostic screens are active.

32 313526J

Page 33

Symbol

Table 4: Diagnostic Codes

Code

No. Code Name Diagnosis Cause

Runaway Pump running faster than set

runaway limit.

• Increased air pressure.

• Increased fluid output.

• Exhausted fluid supply.

Remote DataTrak Operation

Accessory

LED

Flash

Code*

Light

Tower

Code

2Red Solid

E1 Diving Up Leak during upstroke. Worn piston valve or

packings.

E2 Diving Down Leak during downstroke. Worn intake valve or

priming rod seal.

E4 Disconnected

Solenoid

E7 Drum Empty Drum empty sensor has

E7 Drum Low Drum low sensor has tripped. Replace empty drum with

Solenoid is disconnected. • Solenoid unplugged.

• Damaged solenoid

wires.

Replace empty drum with

tripped.

full drum to clear.

full drum to clear.

7Yellow

Solid

6Yellow

Solid

3Red Solid

4Red Solid

4 Red

Flashing

E5 Reed Switch The air motor has seen

multiple up strokes without a

down stroke, or vice versa.

Maintenance

Counter

Expired

Maintenance Counter has

counted down to 0 from

setpoint.

Damaged or disconnected

reed switches.

Number of

cycles/gallons/liters

specified by setpoint have

passed since last reset.

8Yellow

Solid

5Yellow

Flashing

*LED (B, page 24) will flash a code, pause, then repeat.

313526J 33

Page 34

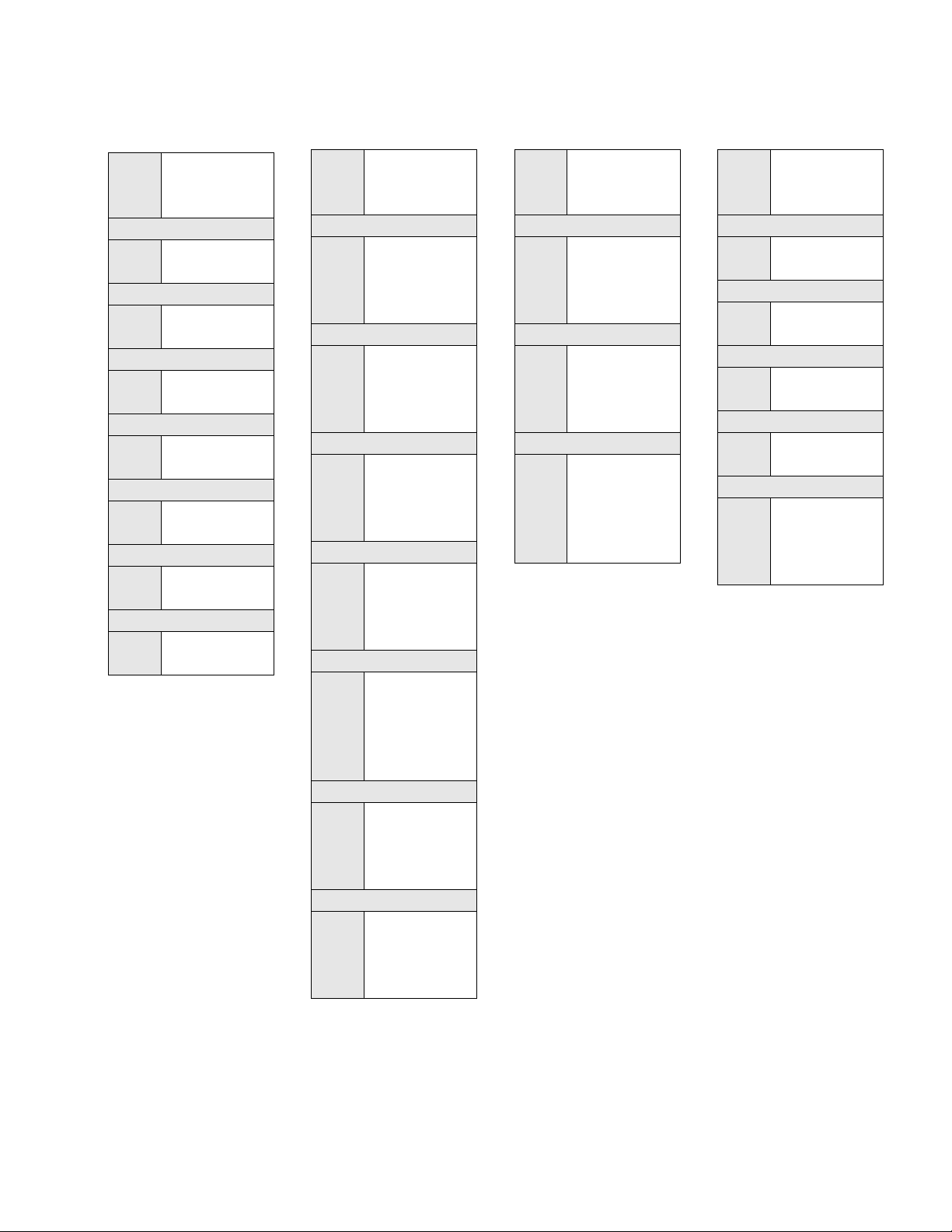

Dimensions

Dimensions

A

(ram up)

D200

S20

B

(ram down)

F

A

(ram up)

B

(ram down)

ti10429a

C

E

C

D

D60

(ram up)

D

E

F

r_255648_313527_5a

L20c

A

A

(ram up)

B

(ram down)

C

D

E

F

34 313526J

r_255648_313527_6a

B

(ram down)

F

r_257032_312376_1e

D

Page 35

Dimensions

S20

(NXT)

S30

WLD

A

(ram up)

B

(ram down)

C

E

D

F

Dimensions

Ram Model

L20c

S20 (NXT)

S20

S20c

D60

D200

D200s

A

in. (mm)

69 (1752.6) 44 (1117.6) 21 (533.4) 22 (558.8)

84 (2133.6) 59 (1498.6) 16 (406.4) 19 (482.6) 11 (279.4) 17 (431.8)

59.3 (1506) 35.8 (909) 16 (406.4) 19 (482.6) 11 (279.4) 17 (431.8)

90 (2286) 65 (1651) 26.0 (661) 22.1 (562)

89 (2260.6) 59 (1498.6) 14 (355.6) 18 (457.2) 24 (609.6) 28 (711.2)

102.3 (2599) 64.8 (1646) 21.0 (533) 25.0 (635) 38.0 (965) 42.0 (1067)

109 (2769) 68.2 (1732) 23.0 (584) 25.0 (635) 45.0 (1143) 48.0 (1219)

B

in. (mm)

in. (mm)

Weight

Use the table below to identify the maximum weight for

each available platen size.

Platen Size

Gallons (Liters)

55 (200)

30 (115)

16 (60)

8 (30)

5 (20)

Maximum Weight

lbs (kg)

51 (23)

44 (20)

25 (11.3)

21 (9.5)

19 (8.7)

C

D

in. (mm)

E

in. (mm)

in. (mm)

See the identification plate (ID) for the weight of your

supply system.

ID

ti11157a

F

313526J 35

Page 36

Schematic

Schematic

Remote DataTrak, Light Tower, Drum Low/Empty Sensor

(4) Signal

(1) Power

(2) Unused

(3) COM

DRUM LOW

Graco P/N 122716

(1)

(2)

(3)

(4)

Ambient Ram

Harness, DataTrak

Graco P/N 15X728

3

Red (15)

Drain (1)

Amber (2)

Common (14)

Graco P/N 255415

REMOTE DATATRAK

LOCAL CONTROL MONITOR,

(3) COM

(2) RED

(1) UNUSED

LIGHT TOWER

Graco P/N 15X471

M

(1)

(2)

(3)

F

(3)

(1)

(2)

N/C (3)

Power (5)

Common (16)

Drum Low (17)

Air Solenoid (4)

AIR SOLENOID

Graco P/N 121235

(4) AMBER

(5) UNUSED

(4)

(5)

(4)

(5)

Common (18)

Top Motor Reed (6)

(1) Solenoid Signal

N/C (7)

N/C (8)

N/C (20)

Bottom Motor Reed (19)

(GND) UNUSED

(2) Solenoid RTN

(1)

(2)

(3)

N/C (23)

N/C (10)

N/C (22)

Drain (9)

Drain (21)

REED SWITCH

(1) N/C

(2) N/C

Graco P/N 24A032

(1)

(2)

(1)

(2)

(3)

FM

(1)

(2)

(3)

N/C (25)

N/C (11)

N/C (12)

N/C (24)

(3) Motor Down

(4) Motor Up

(3)

(4)

(5) (5) Reed Switch Com

Graco P/N 16A758

ADAPTER CABLE

(4)

(5)

(7)

(8)

(6)

(7)

(8)

(4)

(5)

(6)

N/C (13)

SHLD (1)

-24Vdc (3)

+24Vdc (2)

CAN_L (5)

CAN_H (4)

12

-24Vdc (3)

+24Vdc (2)

CAN_H (4)

CAN_L (5)

SHLD (1)

Device Net Cable

Graco P/N 121226

SHLD

SUPPLY

+24VDC POWER

-24Vdc

+24Vdc

Graco P/N 15M293

L

N

36 313526J

Page 37

D200S, D200, S20, and D60 Supply Systems Point of Operation Instructions

For use with non-heated bulk supply of medium to high viscosity sealants and adhesive materials.

Not for use in hazardous locations.

Safety Practices: The instruction on this sheet are abbreviated and are provided only as a customer service. They

are not meant to replace the Operation Manual. If you are unsure of the equipment’s safe and proper operation,

request Graco Operation Manual 313526. It is important that you read and understand all instructions and hazards

before operating this equipment.

WARNINGS

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or

look like just a cut, but it is a serious injury that can

result in amputation. Get immediate surgical treat-

ment.

Point of Operation Instructions

ruptured components will pierce skin. This may

• Do not point gun at anyone or at any part of the

body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body,

glove, or rag.

• Do not spray without tip guard and trigger guard

installed.

• Engage trigger lock when not spraying.

•Follow Pressure Relief Procedure in this manual,

when you stop spraying and before cleaning,

checking, or servicing equipment.

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and

other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or

covers removed.

Start and Adjust Ram

Moving parts can pinch or amputate fingers. When

the pump is operating and when raising or lowering

the ram, keep fingers and hands away from the pump

intake, platen, and lip of the drum.

1. Close all air regulators and air valves.

2. Open main air slider valve and set ram air regulator

to 40 psi (0.28 MPa, 2.8 bar). Set director valve

handle to UP and let the ram rise to its full height.

2-Button Interlock: If the system has this feature,

ram will stop as it nears the top. Press and hold

both buttons to raise ram completely.

3. Lubricate the platen seals with grease or other

lubricant compatible with the fluid you will pump.

4. Remove the drum cover and smooth the surface of

the fluid with a straightedge.

5. Put a full drum of fluid on the ram base, slide it back

against the drum stops, and center it under the

platen.

SPLATTER HAZARD

During blowoff of platen splatter may occur.

• Use minimum drum removal air pressure.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or in the operating area of the equipment to help protect you

from serious injury. This equipment includes

but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the

fluid and solvent manufacturer

•Gloves

• Hearing protection

313526J 37

To avoid damage to the platen seals, do not use a

drum that is dented or damaged.

6. Remove bleed stick from platen bleed port.

7. Set the director valve to DOWN and lower the ram

until fluid appears at the top of the platen bleed

port. Adjust ram air regulator as needed. Set the

director valve to neutral and close the platen bleed

port. 2-Button Interlock: If system has this feature,

press and hold both buttons to start lowering the

ram.

Page 38

D200S, D200, S20, and D60 Supply Systems Point of Operation Instructions

Start and Adjust Pump

Keep hands and fingers away from the priming piston

during operation and whenever the pump is charged

with air. Follow Pressure Relief Procedure before

checking, clearing, or cleaning the priming piston.

1. Supply fluid to the pump, per the requirements of

your system.

2. Close the air motor slider valve. Set the ram air

regulator to about 50 psi (0.35 MPA, 3.5 bar). Set

the director valve to DOWN.

3. Reduce the air motor regulator pressure and open

the air motor slider valve.

4. Adjust air motor regulator until the pump starts.

5. Cycle the pump slowly until all air is pushed out and

the pump and hoses are fully primed.

6. Release the gun/valve trigger and lock the trigger

safety. The pump should stall against pressure.

Change Drums

1. Close the air motor slider valve to stop the pump.

2. Set ram director valve to UP to raise the platen and

immediately press and hold the blowoff air button

until the platen is completely out of drum. Use minimum amount of air pressure necessary to push the

platen out of the drum.

Excessive air pressure in the material drum could

cause the drum to rupture, causing serious injury.

The platen must be free to move out of the drum.

Never use drum blowoff air with a damaged drum.

3. Release the blowoff air button and allow the ram to

rise to its full height. 2-Button Interlock: If system

has this feature, the ram will stop as it nears the top.

Press and hold both buttons to raise ram completely.

4. Remove empty drum.

To reduce the risk of fluid injection, do not use your

hand or fingers to cover the bleed hole on the underside of the bleed valve body when priming the pump.

Use the handle or a crescent wrench to open and close

the bleed plug.

7. If the pump fails to prime properly, open the pump

bleed valve slightly. Use the bleed hole, on the

underside of the valve, as a priming valve until the

fluid appears at the hole. Close the plug.

Always use lowest possible fluid pressure to bleed

air out of pump.

8. With the pump and lines primed, and with adequate

air pressure and volume supplied, the pump will

start and stop as you open and close the gun/valve.

In a circulating system, the pump will speed up or

slow down on demand, until the air supply is shut

off.

9. Use the air motor regulator to control the pump

speed and the fluid pressure. Always use the lowest

air pressure necessary to get the desired results.

Higher pressures cause premature tip/nozzle and

pump wear.

5. Inspect platen and, if necessary, remove any

remaining material or material build–up.

6. Go to Step 4 of Start and Adjust Ram.

Remote DataTrak Operation

Key Functions When in Run Mode

1. To enter Prime Mode, press and release .

a. When a new drum is installed, press and hold

while in Prime Mode to reset the drum vol-

ume remaining to the drum fill volume.

b. To exit Prime Mode, press . The Prime sym-

bol will disappear and the LED will stop flashing;

the screen will return to Run Mode.

2. To reset the job total counter, press and hold

from Run Mode for 3 seconds.

3. To enter Setup Mode, press and hold for 3 seconds.

4. To enter Diagnostic Mode, press and release .

The system will enter Diagnostic Mode only if there

are active warnings/alarms.

38 313526J

Page 39

L20c Supply Systems Point of Operation Instructions

For use with non-heated bulk supply of medium to high viscosity sealants and adhesive materials.

Not for use in hazardous locations.

Safety Practices: The instruction on this sheet are abbreviated and are provided only as a customer service. They

are not meant to replace the Operation Manual. If you are unsure of the equipment’s safe and proper operation,

request Graco Operation Manual 313526. It is important that you read and understand all instructions and hazards

before operating this equipment.

•Gloves

WARNINGS

• Hearing protection

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or

look like just a cut, but it is a serious injury that can

result in amputation. Get immediate surgical treat-

ment.

Point of Operation Instructions

ruptured components will pierce skin. This may

• Do not point gun at anyone or at any part of the

body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body,

glove, or rag.

• Do not spray without tip guard and trigger guard

installed.

• Engage trigger lock when not spraying.

•Follow Pressure Relief Procedure in this manual,

when you stop spraying and before cleaning,

checking, or servicing equipment.

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and

other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or

covers removed.

SPLATTER HAZARD