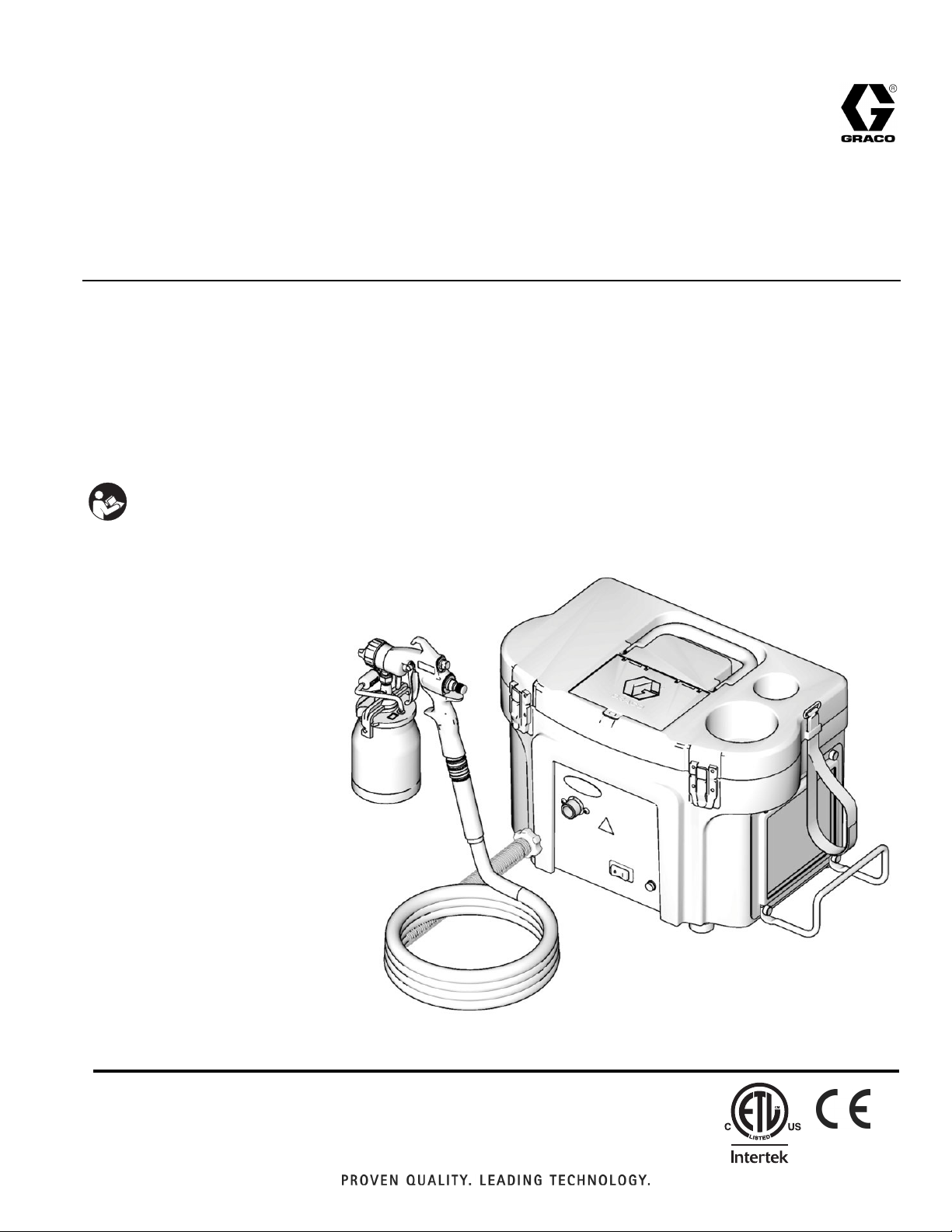

Page 1

Operation, Repair, Parts

FinishPro™ HVLP 7.0/9.0/9.5

313406L

For portable spray applications of fine finish coatings. For professional use only.

Not approved for use in European explosive atmosphere locations.

120 Vac Models: 256847, 256848, 256849

240 Vac Models: 256851, 256852, 256853

Maximum Working Pressure: 10 psi (0,07 MPa, 0.7 bar)

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

US Patent No.: 7,950,598, 7,971,806

EN

ti12834a

Page 2

Table of Contents

Table of Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Grounding and Electric Requirements . . . . . . . . 5

Component Identification . . . . . . . . . . . . . . . . . . . . 6

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Fluid Preparation . . . . . . . . . . . . . . . . . . . . . . . . . 7

Connect Fluid and Air Supply . . . . . . . . . . . . . . . 7

Pressure Relief Procedure . . . . . . . . . . . . . . . . . 7

Operation Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Sprayer Disassembly . . . . . . . . . . . . . . . . . . . . 10

Sprayer Assembly . . . . . . . . . . . . . . . . . . . . . . . 10

Turbine Replacement . . . . . . . . . . . . . . . . . . . . . . . 11

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Parts Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 18

2 313406L

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance and repair of this equipment. The exclamation

point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risks. Refer back to

these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

GROUNDING

This product must be grounded. In the event of an electrical short circuit, grounding reduces the risk of

electric shock by providing an escape wire for the electric current. This product is equipped with a cord having a grounding wire with an appropriate grounding plug. The plug must be plugged into an outlet that is

properly installed and grounded in accordance with all local codes and ordinances.

• Improper installation of the grounding plug is able to result in a risk of electric shock.

• When repair or replacement of the cord or plug is required, do not connect the grounding wire to either

flat blade terminal.

• The wire with insulation having an outer surface that is green with or without yellow stripes is the

grounding wire.

• Check with a qualified electrician or serviceman when the grounding instructions are not completely

understood, or when in doubt as to whether the product is properly grounded.

• Do not modify the plug provided; if it does not fit the outlet, have the proper outlet installed by a qualified electrician.

• This product is for use on a nominal 120V circuit and has a grounding plug similar to the plug illustrated

in the figure below.

• Only connect the product to an outlet having the same configuration as the plug.

• Do not use an adapter with this product.

Extension Cords:

• Use only a 3-wire extension cord that has a 3-blade grounding plug and a 3-slot receptacle that

accepts the plug on the product.

• Make sure your extension cord is not damaged. If an extension cord is necessary, use 12 AWG

(2.5 mm

• An undersized cord results in a drop in line voltage and loss of power and overheating.

313406L 3

2

) minimum to carry the current that the product draws.

Page 4

Warnings

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire and explosion:

• Do not spray flammable or combustible materials near an open flame or sources of ignition such as cigarettes,

motors, and electrical equipment.

• Paint or solvent flowing through the equipment is able to result in static electricity. Static electricity creates a risk of

fire or explosion in the presence of paint or solvent fumes. All parts of the spray system, including the pump, hose

assembly, spray gun, and objects in and around the spray area shall be properly grounded to protect against static

discharge and sparks. Use Graco conductive or grounded high-pressure airless paint sprayer hoses.

• Verify that all containers and collection systems are grounded to prevent static discharge.

• Connect to a grounded outlet and use grounded extensions cords. Do not use a 3-to-2 adapter.

• Do not use a paint or a solvent containing halogenated hydrocarbons.

• Keep spray area well-ventilated. Keep a good supply of fresh air moving through the area. Keep pump assembly in

a well ventilated area. Do not spray pump assembly.

• Do not smoke in the spray area.

• Do not operate light switches, engines, or similar spark producing products in the spray area.

• Keep area clean and free of paint or solvent containers, rags, and other flammable materials.

• Know the contents of the paints and solvents being sprayed. Read all Material Safety Data Sheets (MSDS) and

container labels provided with the paints and solvents. Follow the paint and solvents manufacturer’s safety instructions.

• Fire extinguisher equipment shall be present and working.

• Sprayer generates sparks. When flammable liquid is used in or near the sprayer or for flushing or cleaning, keep

sprayer at least 20 feet (6 m) away from explosive vapors.

ELECTRIC SHOCK HAZARD

Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power cord before servicing equipment.

• Use only grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on sprayer and extension cords.

• Do not expose to rain. Store indoors.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Always wear appropriate gloves, eye protection, and a respirator or mask when painting.

• Do not operate or spray near children. Keep children away from equipment at all times.

• Do not overreach or stand on an unstable support. Keep effective footing and balance at all times.

• Stay alert and watch what you are doing.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not kink or over-bend the hose.

• Do not expose the hose to temperatures or to pressures in excess of those specified by Graco.

• Do not use the hose as a strength member to pull or lift the equipment.

PRESSURIZED ALUMINUM PARTS HAZARD

Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids containing such

solvents in pressurized aluminum equipment. Such use can cause serious chemical reaction and equipment rupture,

and result in death, serious injury, and property damage.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic fumes, burns, and hearing loss. This

equipment includes but is not limited to:

• Protective eyewear and hearing protection

• Gloves, clothing and respirator as recommended by the fluid and solvent manufacturer

4 313406L

Page 5

WARNING

CALIFORNIA PROPOSITION 65

The engine exhaust from this product contains a chemical known to the State of California to cause

cancer, birth defects or other reproductive harm.

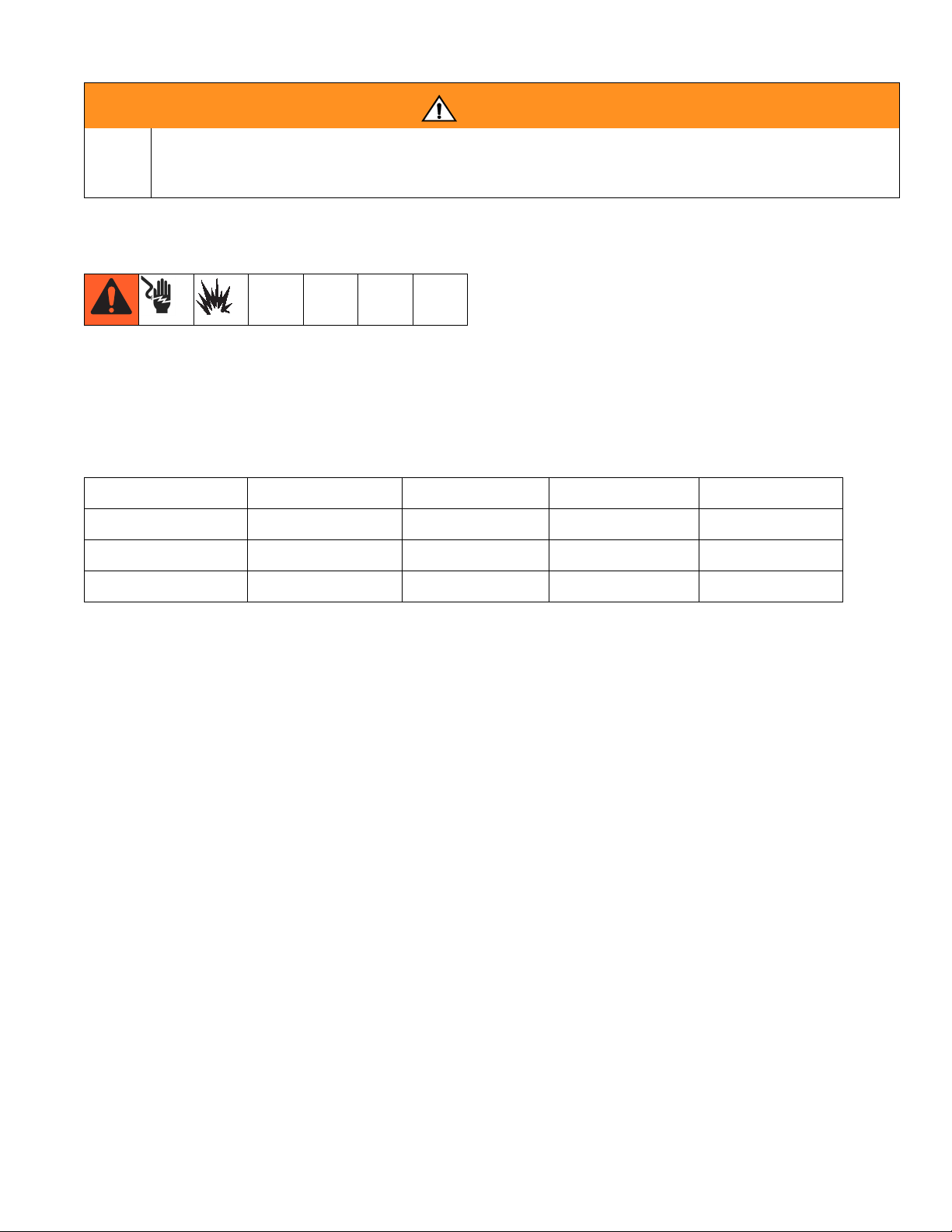

Grounding and Electric Requirements

Warnings

This equipment requires a 120 Vac, 60 Hz, 15A circuit,

with a grounding receptacle.

Do not alter the ground prong or use an adapter.

Sprayer Components Table

Sprayer Model Hose Gun Fluid Sets

FinishPro 7.0

FinishPro 9.0

FinishPro 9.5

256847, 256851 30-ft 256855 EDGE #3

256848, 256852 30-ft 256855 EDGE #3, #4

256849, 256853 30-ft and 4-ft 256855 EDGE #2, #3, #4

Use 3-wire, 12 awg, 50 ft (15 m) or shorter, extension

cords with ground prong.

313406L 5

Page 6

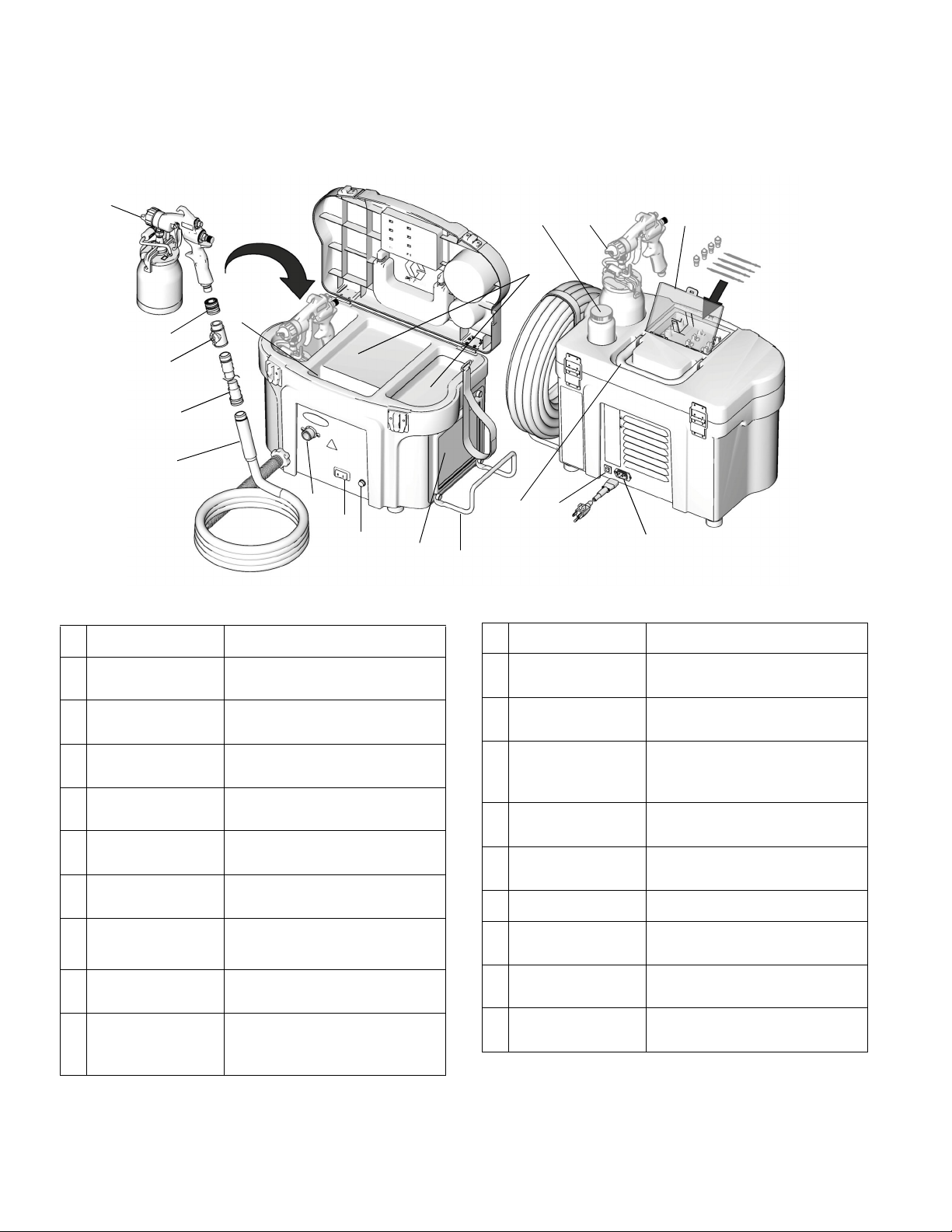

Component Identification

Component Identification

G

L

M

U

N

Item Description

A Sprayer air outlet

Sprayer power

B

switch

Fluid storage

C

compartment

D Sprayer handle

Power

E

cord storage

Air filters (pre-fil-

F

ter and main)

G Spray gun

H Air filter indicator

Connector and

J

power cord

E

A

B

H

F

HVLP connector for air supply to HVLP spray Gun

On/Off switch for sprayer

motor

Provides storage for up to

four fluid sets

Folds flat for minimum storage space

Provides storage for power

cord

Provides filtered air for spray

gun and motor

Graco EDGE

with EasyGlide

™

spray gun

™

trigger

Lights when air filter needs to

be cleaned or replaced

Provides power for sprayer

(power cord provided with

sprayer)

ST

R

D

K

P

C

J

Item Description

Resettable circuit

K

L

breaker

Quick

connect

Provides protection for motor

Enables quick connection to

spray gun

Provides FinishPro 9.0 and

M Air valve

9.5 sprayers ability to shut off

air to spray gun

N Air hose

P Hose wrap

Hose, 30 ft x 1 in., that connects spray gun and sprayer.

Provides storage for air hose

when air hose is not in use

R Storage tray Provides extra storage

Cleaning cup

S

holder

EDGE spray gun

T

holder

U Hose, 4-ft

Provides storage for cleaning

cup

Provides external storage for

spray gun

Allows increased flexibility for

the FinishPro 9.5

ti12858a

6 313406L

Page 7

Setup

Setup

Fluid Preparation

• Strain fluids before you spray. This includes color,

reducers and hardeners.

• Use a slower drying reducer or thinner to compensate for the faster drying time caused by the warm air

of the turbine. Do not over reduce

• Sprayer performance varies with the viscosity of the

material sprayed and the length of the hose. To prevent pressure drop, use hose supplied with sprayer.

• Most material manufacturers provide recommendations for their materials. Follow these recommendations.

Connect Fluid and Air Supply

Spray Gun with Siphon Cup

1. Connect air hose to sprayer.

Hand tighten.

ti13082a

2. Connect air hose from sprayer to

inlet fitting of gun.

Pressure Relief Procedure

The spray gun siphon cup is pressurized by the gun

air supply. To reduce the risk of serious injury from

pressurized fluid or accidental spray from gun, always

turn off the air supply to the spray gun before removing the siphon cup.

1. Turn off sprayer.

2. Unplug sprayer.

3. Unlatch cup cover; loosen or remove cup from cover

to relieve pressure.

Operation Tips

Sparks can be expected during normal operation of

motor. These sparks can ignite fumes from flammable

liquids, dust particles, and other flammable substances in the spray area.

• Use additional hose if necessary, and ensure the

sprayer is operated in clean, dry, well ventilated

area.

• Never use sprayer inside spray booth.

• Turn sprayer on a few minutes before spraying to

ti12797a

3. Fill cup 3/4 full. Install cover. Latch

the gun cup cover to secure it to

siphon cup. See HVLP EDGE Gun

manual 313317 for operation

instructions.

ti12872a

Connect to Electric Supply

Plug sprayer power cord into grounded outlet. Grounding

and Electric Requirements, page 5.

313406L 7

allow warm-up.

• Ensure sprayer filter is clean before operating. Clean

filter, page 8.

• To adjust spray gun pattern, see HVLP EDGE Gun

manual 313317.

• To get proper adhesion, ensure surface is completely

clean.

• Always spray with the least amount of pressure

required to provide the desired spray pattern and rate

of application. Spraying at pressures higher than necessary wastes paint and can result in an orange peel

finish.

Page 8

Maintenance

The sprayer system is lifetime lubricated. The only maintenance required is filter cleaning and replacement.

Maintenance

Filter Operation

The sprayer filter must be clean at all times to provide sufficient air flow to cool the motor and atomize the fluid.

The sprayer has an air filter indicator light on the front

panel. The indicator light illuminates if the filter is clogged

or has low airflow.

ti8049a

Cleaning Filter

1. Turn off and unplug sprayer.

To avoid electric shock, never install a damp filter in the

turbine. Installing a damp filter in sprayer can also

damage turbine.

21

20

17

18

ti13061a

2. Loosen four screws (18), remove filter retainer (17)

and pre-filter (20).

3. Remove main filter (21) and clean using one of the

following methods:

• Tap filter gently on flat surface, dirty side down.

• Direct, compressed air 100 psi (7 bar, 70 MPa)

(maximum) through filter panel in the opposite

direction of arrows on side of filter from the clean

side to the dirty side.

• Soak filter for 15 minutes in water and mild deter-

gent. Rinse filter until clean. Air dry.

8 313406L

Page 9

Troubleshooting

Problem Cause Solution

Troubleshooting

No fluid delivery No material, no remote cup pressur-

ization, hose or pickup tube clogged

Sprayer not starting No power Check outlet for power. Cycle red

Poor atomization Dirty filter Clean filter and replace as necessary.

Extension cord too long Extension cord must be 3-wire, 12

Hose too long Replace with shorter hose. See

Circuit breaker trips Filter clogged Clean filter and replace as necessary

High ambient temperature Move sprayer to cooler area.

Excessive current draw Return to authorized service center.

Check cup for material

Check for leaks at the container gasket (1-quart remote cup cover).

Tighten cover if loose.

Check air flow (approximately 1/4

CFM) from male quick-disconnect at

Compact outlet.

Turn pressure regulator clockwise.

Look for pressure on gauge. (If no

pressure on gauge, check air line fittings.)

Check hole in 1-quart remote cup

cover at needle valve for blockage or

dirt. Clean if necessary.

Check for obstructions.

Check if fluid pickup tube is loose.

Tighten.

Blow out and clear material hose.

Clean check valve. See manual

313317

rocker switch.

Check that correct IEC (modular)

cord is used and plugged in.

Check circuit breaker (38). Push to

reset.

AWG, 50 ft (15 m) or shorter.

Graco Fine Finish Solutions brochure

300564, for hose part numbers.

313406L 9

Page 10

Repair

Repair

Sprayer Disassembly

To avoid injury, including electric shock turn off sprayer

and unplug power cord before performing any repair

procedures on the turbine.

1. Remove four thumbscrews (18) and remove filter

retainer (17), prefilter (20) and main filter (16). Parts,

page 14.

18

16

20

17

ti13061a

3. Place sprayer upside down. Remove four screws (77)

from sprayer base plate (2).

77

2

ti12973a

4. Pull up sprayer base plate and attached parts.

Thread motor wires that connected to inlet plug

through access in HVLP box.

5. Repair or replace any required parts.

Sprayer Assembly

1. Replace duct gaskets (59, 60) and any other damaged or worn parts. Replace circuit breaker (32), if it

has cycled. Remove residual adhesive from previous

gaskets by wiping any sticky surfaces with mineral

spirits solvent (also called white spirit). Let solvent

evaporate thoroughly before installing replacement

gasket.

2. Remove two screws (101) and inlet plug (61) from

HVLP box (1). Remove three motor wire connectors

from inlet plug (61).

ti13063a

61

101

ti13062a

2. Use an adjustable square with blade running full

length of longest side of duct (22), to position duct

perpendicular to the base (2). Hold duct in place to

keep duct perpendicular to base edge and carefully

remove square.

3. Turn sprayer upside-down. Carefully slip base plate

and attached parts down into HVLP box (1).

NOTE: Be sure duct to maintain duct alignment.

4. Thread motor wires that connect with plug (61)

through access port in HVLP box.

5. Use four screws (77) to secure base plate to HVLP

box (1). Use an adjustable clamp over the outside of

HVLP box (1) to align screw holes if necessary.

6. Install three motor wire connectors onto plug (61).

Install plug (61) with two screws (101) into HVLP box

(1).

7. Install filter gaskets (19), main filter (16) with arrow

facing into HVLP box (1), pre-filter (20), filter retainer

(17), and hose rack (35) with four thumbscrews (18).

10 313406L

Page 11

Turbine Replacement

Turbine Replacement

Refer to Parts Drawing, page 14.

1. Follow Sprayer Disassembly procedure, page 10.

2. Remove gasket (21).

3. Remove three screws (14) from spacer (38).

4. Remove plate (21) and three spacers (83).

5. Remove motor wires from spade connectors.

6. Rotate motor (11) from outlet fitting (29) and lift up

from spacers (41).

7. Install new gaskets (21, 23, 24, 59 and 60). Use mineral spirits solvent (also called white spirit) to remove

any adhesive remaining from old gaskets.

8. Reassemble turbine. Use an adjustable square with

the blade running the full length of the longest side of

the duct (22) to position duct perpendicular to base

(2). Hold duct in place and carefully remove square to

keep duct perpendicular to edge of base. With

sprayer upside down, carefully slip base plate and

attached parts (see page 16) down into HVLP box

(1). NOTE: Be sure to maintain duct alignment.

9. Connect ground wire to motor housing.

10. Reconnect wires. Attach plug (61) to HVLP box with

two screws (101).

313406L 11

Page 12

Wiring Diagrams

y

Wiring Diagrams

USA

GROUND

12

7

3

4

N

L

G

1

Ref. Part Description Qt

1 244273 Conductor, BK 1

2 15W486 Conductor, BK 1

3 15W485 Conductor, G/Y 1

4 15W484 Conductor, W 1

8

G

BK

W

2

9

5 257333 Conductor, W, BK, G 1

6 240256 Conductor, W 1

7 114064 Plug, inlet 1

8 114403 Circuit Breaker, 15A 1

9 15V923 Plug, outlet, CompPack 1

L

G

N

10 114280 Light, indicator, 120V 1

11 120660 Switch, rocker 1

12 114279 Sensor, pressure 1

6

11

3

2

5

6

5

10

ti12765a

International

GROUND

15

8

6

7

10

3

4

N

L

G

1

Ref. Part Description Qty

1 244273 Conductor, BK 1

2 15W486 Conductor, BK 1

3 15W485 Conductor, G/Y 1

4 15W484 Conductor, W 1

11

BK

G

W

16

2

12

5 257333 Conductor, W, BK, G 1

6 15W488 Conductor, W 1

7 15W487 Conductor, BK 1

8 240558 Conductor, G/Y 1

9 240256 Conductor, W 1

L

G

10 114064 Plug, inlet 1

N

11 16A348 Circuit Breaker, 10A 1

LG

LINE

L2

L1

G

LOAD

L2

12 15V923 Plug, outlet, CompPack 1

13 114286 Light, Indicator, 240V 1

5

14 120660 Switch, rocker 1

15 114279 Sensor, pressure 1

16 116168 Filter, suppression 1

3

2

5

6

14

9

13

ti12770a

12 313406L

Page 13

Technical Data

120 Vac, 60 Hz

Ampere Watts

Maximum

Hose Length

ft (m)

Sprayer Weight

lb (kg)

Total Weight

lb (kg)

Sound

Power*

Technical Data

Sound

Pressure*

FinishPro 7.0

FinishPro 9.0

FinishPro 9.5

240 Vac, 50 Hz

FinishPro 7.0

FinishPro 9.0

FinishPro 9.5

* Sound Power and Sound Pressure are measured at

1 meter per ISO 3744

11.0 200 40 (12,2) 28 (12,7) 38 (17,2) 94.9 dBa 82 dBa

11.0 250 60 (18,3) 29 (13,2) 39 (17,7) 95.9 dBa 83 dBa

13.6 300 60 (18,3) 30 (13,6) 40 (18,1) 96.3 dBa 83.4 dBa

Maximum

Hose Length

Ampere Watts

5,40 200 40 (12,2) 28 (12,7) 38 (17,2) 94.9 dBa 82 dBa

5,93 250 60 (18,3) 29 (13,2) 39 (17,7) 95.9 dBa 83 dBa

7,07 300 60 (18,3) 30 (13,6) 40 (18,1) 96.3 dBa 83.4 dBa

ft (m)

Sprayer Weight

lb (kg)

Total Weight

lb (kg)

Sound

Power*

Sound

Pressure*

313406L 13

Page 14

Parts

Models 256847, 256848, 256849, 256851, 256852, 256853

Parts

4

103

3

6

30

8

1

102

34

100

30

63

62

33

104

105

49

89

13

87

25

77

88

61

101

77

19

16

18

20

17

18

35

ti12835a

14 313406L

Page 15

Parts List

Models 256847, 256848, 256849, 256851, 256852, 256853

Parts List

Ref. Part Description Qty.

1 277934 BOX, HVLP 1

3 24B055 COVER, HVLP (includes 6) 1

4 15V791 HANDLE 1

6 15V771 LID, accessory 1

8 15V926 LATCH 2

13 257159 HOSE, air, 30 ft, black 1

16 240273 FILTER, main 1

17 15W794 RETAINER, filter 1

18 15W897 SCREW, captive 4

19 15W217 GASKET, filter 2

20 15W909 FILTER, foam 1

25 113817 BUMPER 4

30 15W505 SCREW, mach, phillips pan hd 2

33 256855 GUN, HVLP, with cup 1

34 114271 STRAP, retaining 1

35 15V862 HOSE, rack 1

49 VALVE, air control

FinishPro 7.0 (not included)

240065 FinishPro 9.0 1

Ref. Part Description Qty.

240065 FinishPro 9.5 1

61 15V923 PLUG, inlet 1

62 ▲ 15W100 LABEL, safety 1

63 ▲ 15W223 LABEL, safety 1

77 15W359 SCREW, mach, hex, washer hd 8

87 15W635 LABEL, FinishPro, HVLP 1

88 LABEL, FinishPro, HVLP

15W636 LABEL, FinishPro, HVLP 7.0 1

15W637 LABEL, FinishPro, HVLP 9.0 1

15W638 LABEL, FinishPro, HVLP 9.5 1

89 257161 HOSE, 4 ft, FinishPro 9.5 1

100 15V927 HINGE 2

101 117317 SCREW, plastite, pan hd 2

102 15X227 SCREW, cap, hex hd 2

103 102040 NUT, lock, hex 2

104 116234 BOTTLE 1

105 M70402 QUICK DISCONNECT 1

▲ Extra Danger and Warning labels are available for free.

313406L 15

Page 16

Parts Drawing

Models 256847, 256848, 256849, 256851, 256852, 256853

Parts Drawing

29

14

38

9

48

24

41

5

59

31

90

21

15

11

109

107

108, 111

30

58

110

27

86

28

106

45

39

14

22

60

44

42

23

37

56

2

64

45

36

46

45

32

ti12836d

16 313406L

Page 17

Parts List

Models 256847, 256848, 256849, 256851, 256852, 256853

Parts List

Ref. Part Description Qty.

2 257066 PLATE, base, turbine, painted 1

5 114279 SENSOR, pressure 1

9 156698 O-RING 1

11+* TURBINE

15Y812 FinishPro 7.0, 3-stage, 120V 1

15Y813 FinishPro 9.0, 4-stage, 120V 1

15Y814 FinishPro 9.5, 5-stage, 120V 1

15Y815 FinishPro 7.0, 3-stage, 240V 1

15Y816 FinishPro 9.0, 4-stage, 240V 1

15Y817 FinishPro 9.5, 5-stage, 240V 1

14 114670 SCREW, cap, hex hd 6

15 194094 PLATE, turbine 1

21 GASKET, turbine

15W153 FinishPro 7.0 1

15W152 FinishPro 9.0 1

192788 FinishPro 9.5 1

22 15W274 DUCT, turbine 1

◆✓

23

16P954 GASKET, DUCT 1

24 192845 GASKET, DUCT 1

27 120660 SWITCH, rocker 1

28 LIGHT, indicator

114280 120V 1

114286 240V 1

29 16A180 FITTING, outlet 1

30 114669 SCREW, mach, phillips pan hd 2

31 193059 GASKET, sensor 1

32

◆✓

CIRCUIT Breaker

114403 120V, 15A 1

16A348 240V, 10A 1

36 114064 PLUG, INLET 1

37 192905 PLATE, deflector 1

38

◆✓

SPACER, turbine

15W148 FinishPro 7.0 3

15W149 FinishPro 9.0 3

15W150 FinishPro 9.5 3

39 192810 HOSE, air 1

Ref. Part Description Qty.

41 15X722 SPACER, turbine 3

42 111593 SCREW, grounding 1

44 102063 WASHER, lock, ext 1

45 SCREW, mach, torx pan hd

15W998 120V 4

15W998 240V 6

46 CORD, power

15W126 USA, 6 ft. 15A, 120V 1

116281 Euro, 2 m, 8A, 240V 1

48 15Y606 FITTING, barbed 1

56 186620 LABEL, ground 1

58▲ 15K616 LABEL, brand, hot surface 1

59◆✓16E351 GASKET, duct, left 1

60

◆✓

16E353 GASKET, duct, right 1

64▲ 15W224 LABEL, safety 1

86 15W640 LABEL, brand, TurboForce 1

90 114689 BUSHING, strain relief 1

106 116168 FILTER, suppression, EMI, 240V 1

107 242001 CORDSET, adapter, Europe 1

108 287121 CORDSET, adapter, 220V, global,

includes 108a through 108d

108a CORDSET, adapter, Italy 1

108b CORDSET, adapter, Denmark 1

108c CORDSET, adapter, Switzerland 1

109 195551 RETAINER, plug adapter 1

110 15X254 SWITCH INDICATOR 1

111 242005 CORDSET, adapter, Australia 1

* Cleaning Brush Kits 256953 and 256954 are also available.

▲

Extra Danger and Warning labels are available for free.

+

Turbine kit includes items 9, 15, 21, 23, 24, 59 and 60

◆ Gasket/Breaker Kit 15 Amp 24F670 includes items 23,

32, 59, 60

✓ Gasket/Breaker Kit 10 Amp 24F671 includes items 23,

32, 59, 60

1

313406L 17

Page 18

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in material

and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty published by

Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non-Graco

component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with structures,

accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or maintenance of structures,

accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of the

claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned to the

original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will be made

at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO

WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT MANUFACTURED BY

GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their

manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or the

furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the negligence of

Graco, or otherwise.

ADDITIONAL WARRANTY COVERAGE

Graco does provide extended warranty and wear warranty for products described in the “Graco Contractor Equipment Warranty Program”.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2008, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions.

International Offices:

This manual contains English. MM 313406

Graco Headquarters:

Minneapolis

Belgium, China, Japan, Korea

www.graco.com

Revised October 2013

Loading...

Loading...