Page 1

Software Instructions

ProMix® 2KS/3KS Web

313386D

Interfaces

Installation and program setup instructions to allow communication between a PC and the

ProMix® 2KS/3KS Electronic Proportioner, via an Ethernet. For professional use only.

Not for use in explosive atmospheres.

Basic Web Interface (supplied with ProMix 2KS/3KS EasyKey software)

Advanced Web Interface Kit 15V337 (Accessory)

EN

Important Safety Instructions

Read all warnings and instructions in this manual

and in your proportioning system manual. Save

these instructions.

Advanced Web Interface Module Shown

TI12933b

Page 2

Related Manuals

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ProMix 2KS/3KS Basic Web Interface (BWI) . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Web Navigation Screens . . . . . . . . . . . . . . . . . . . 8

Install the Advanced Web Interface (AWI) Module 12

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Connect Module to EasyKey and PC . . . . . . . . 13

Computer Configuration . . . . . . . . . . . . . . . . . . . . 16

Set up an Automatic IP Address . . . . . . . . . . . . 16

System Initialization . . . . . . . . . . . . . . . . . . . . . 16

Password Recovery . . . . . . . . . . . . . . . . . . . . . 18

Related Manuals

Component Manuals in English

Set the Network Configuration . . . . . . . . . . . . . . 19

AWI Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Network Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Materials Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Settings Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

System Setup Screens . . . . . . . . . . . . . . . . . . . 26

Replace AWI Board . . . . . . . . . . . . . . . . . . . . . . . . 36

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

15V337 Advanced Web Interface Module . . . . . 38

15V336 Advanced Web Interface Server Hub . . 39

Electrical Schematic . . . . . . . . . . . . . . . . . . . . . . . 40

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 42

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 42

Manual Description

312775 ProMix 2KS Manual System Installation

312776 ProMix 2KS Manual System Operation

312777 ProMix 2KS Manual System Repair-Parts

312778 ProMix 2KS Automatic System Installation

312779 ProMix 2KS Automatic System Operation

312780 ProMix 2KS Automatic System Repair-Parts

313881 ProMix 3KS Installation (All Systems)

313882 ProMix 3KS Manual System Operation

313883 ProMix 3KS Repair-Parts (All Systems)

313885 ProMix 3KS Automatic System Operation

312781 Fluid Mix Manifold

312782 Dispense Valve

312783 Color Change Valve Stacks

312787 Color Change Module Kit

312784 Gun Flush Box Kits

310745 Gun Air Shutoff Kit

312786 Dump Valve and Third Purge Valve Kits

312785 Network Communication Kits

308778 G3000/G3000HR/G250/G250HR Flow Meter

310696 Coriolis Flow Meter

313212 Gun Flush Box Integration Kit

313290 Floor Stand Kit

2 313386D

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

ELECTRIC SHOCK HAZARD

Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

313386D 3

Page 4

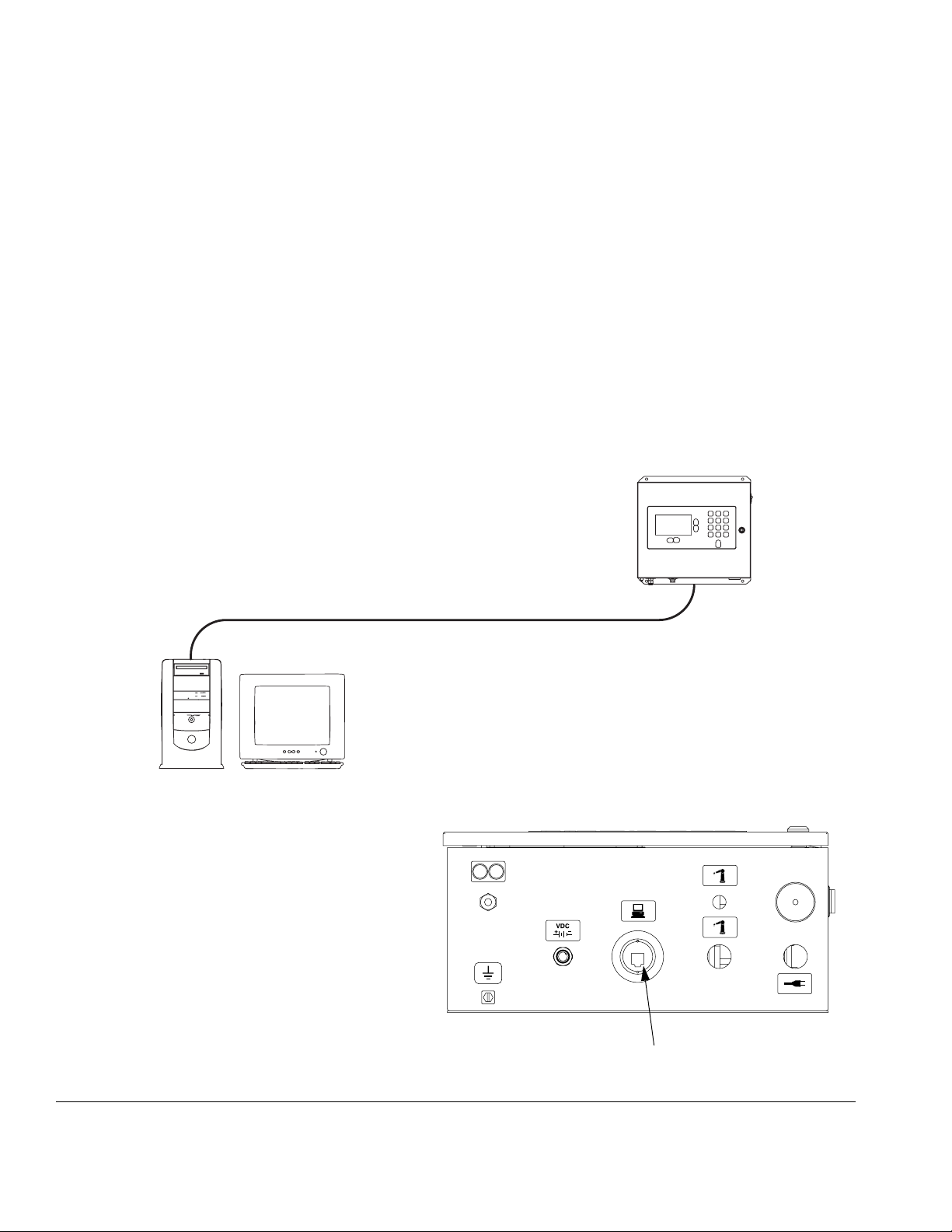

ProMix 2KS/3KS Basic Web Interface (BWI)

ProMix 2KS/3KS Basic Web Interface (BWI)

NOTE: Screen views in this manual are shown using

Microsoft Windows XP.

NOTE: The ProMix 2KS/3KS Basic Web Interface (BWI)

is supplied with all EasyKeys. To run the program, Java

Version 6 Update 10 (or later) must be loaded on your

computer. This is a free download.

15G869 CAT5 Ethernet Crossover Cable

Installation

1. Before connecting your computer to the EasyKey,

verify that Java Version 6 Update 10 (or later) is

loaded on your computer. To verify, go to Java.com

using your Internet browser and click on “Do I Have

Java?” for further information.

2. After verifying that Java is loaded on the computer,

connect the computer directly to the EasyKey, using

the 15G869 CAT5 ethernet crossover cable sup-

plied with the EasyKey. See F

IG. 1.

EasyKey

Computer

TI13102a

EasyKey (Bottom View)

TI12638a

CAT5 Cable Connector

IG. 1. ProMix 2KS/3KS Basic Web Interface Connection

F

4 313386D

Page 5

ProMix 2KS/3KS Basic Web Interface (BWI)

3. Before running the BWI software you must manually

assign an IP address to your computer:

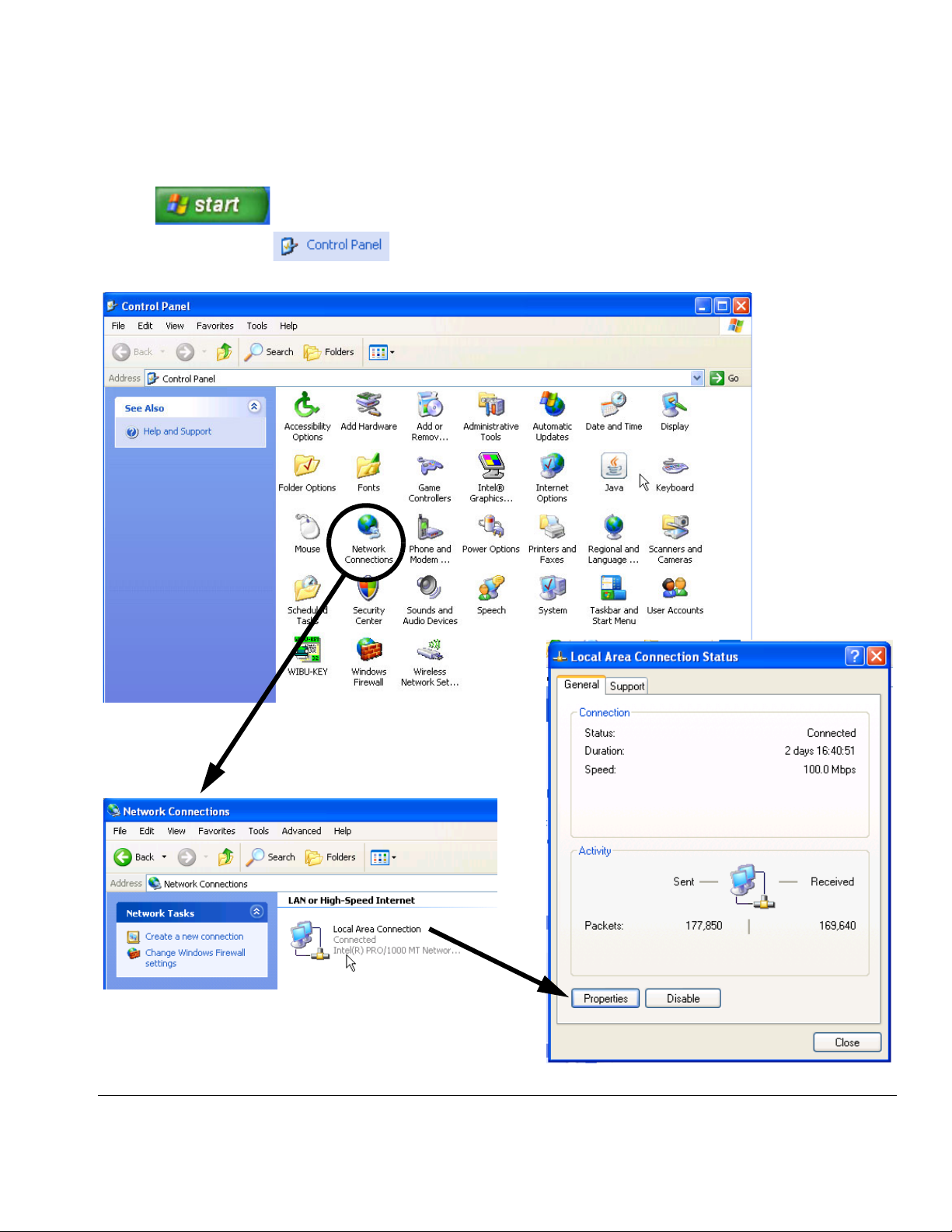

a. On your computer, click on the Start button

to open the menu, then click

on Control Panel .

b. See F

IG. 2. Double click on Network Connec-

tions. Double click on Local Area Connection to

open the Local Area Connection Status window.

Click on Properties to open the Local Area Con-

nection Properties window. See F

IG. 3.

FIG. 2. Assign IP Address on Computer

313386D 5

Page 6

ProMix 2KS/3KS Basic Web Interface (BWI)

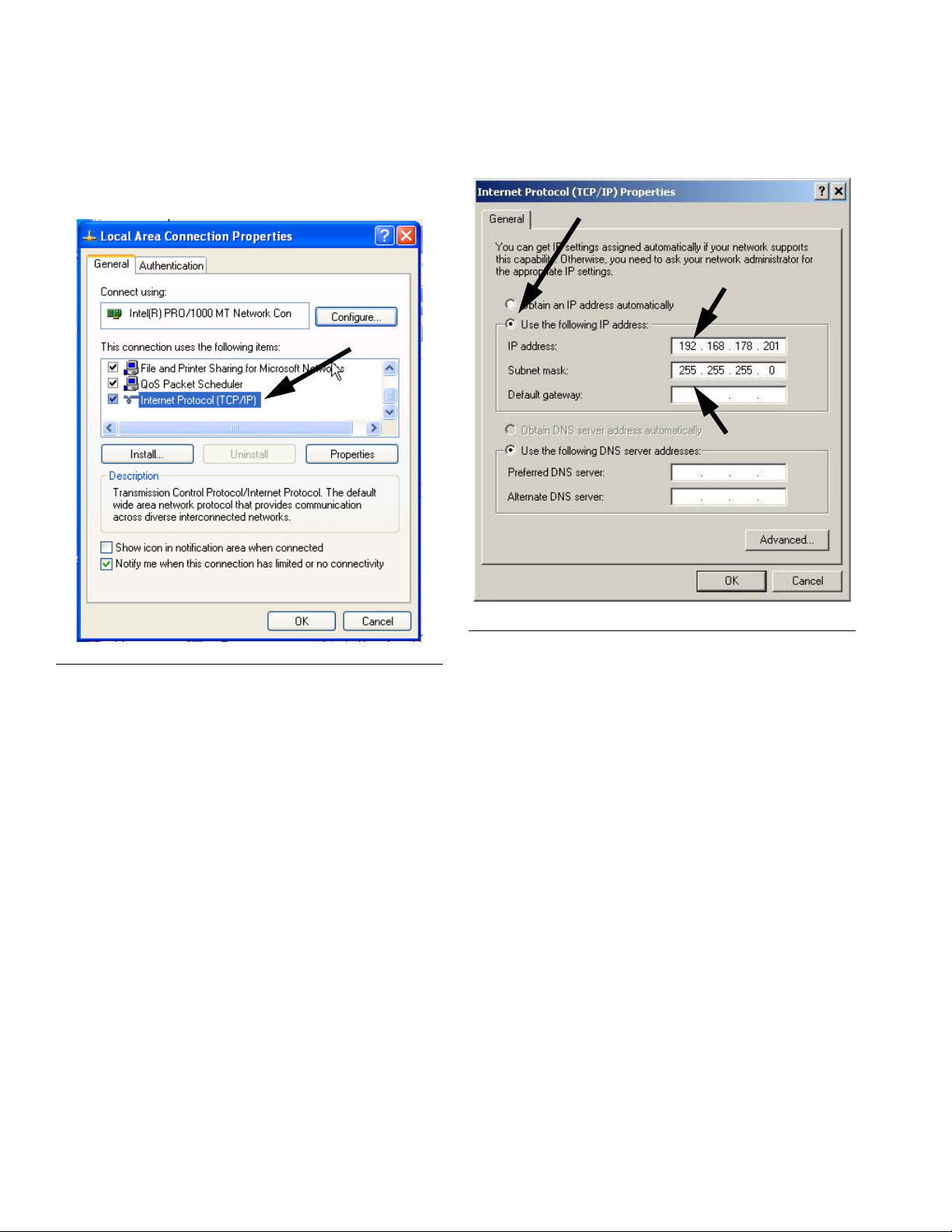

c. In the Local Area Connection Properties win-

dow, scroll to Internet Protocol (TCP/IP) and

double click, to open the Internet Protocol

(TCP/IP) Properties window. See F

IG. 4.

f. Type in the following Subnet mask:

255.255.255.0

F

IG. 3: Local Area Connection Properties Window

d. See F

IG. 4. Set to “Use the following IP

address:”

e. Type in the following IP address:

192.168.178.201

FIG. 4: Internet Protocol (TCP/IP) Window

NOTE: To reconnect to the user network, change the

setting back to “Obtain an IP Address Automatically.”

g. Click on OK to accept the changes and close

the Internet Protocol (TCP/IP) Properties window.

h. Click on OK to close the Local Area Connection

Properties window.

i. Close the Local Area Connection Status window

and Network Connections window.

6 313386D

Page 7

ProMix 2KS/3KS Basic Web Interface (BWI)

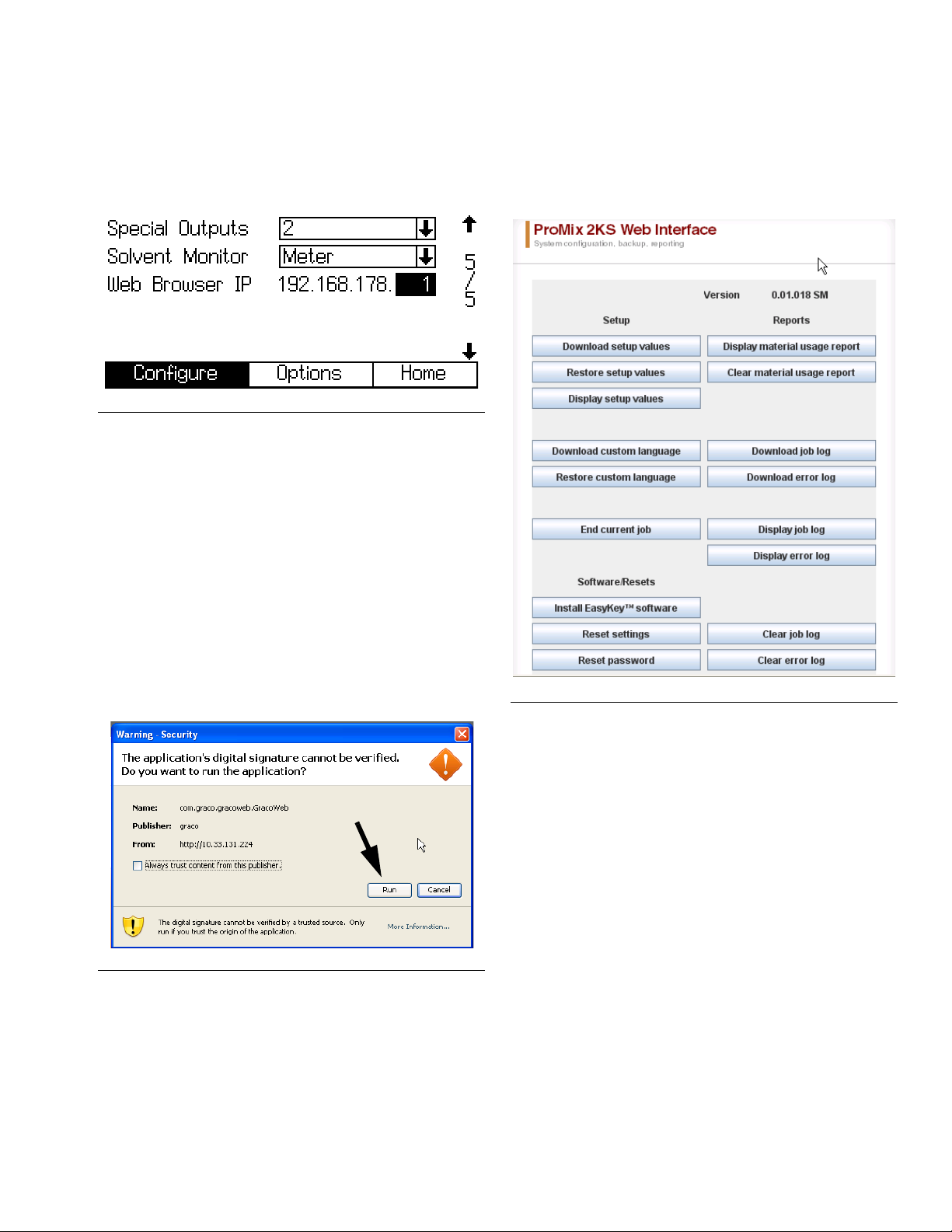

4. On the EasyKey, go to System Configuration

Screen 5 and write down the IP number assigned to

that EasyKey (1-99). See F

F

IG. 5: System Configuration Screen 5

IG. 5.

NOTE: Verify that the wireless connection is turned off

(disabled) before performing step 5.

5. Open Microsoft Internet Explorer (Start>All Programs>Internet Explorer).

6. In the address area type http://192.168.178.__ (fill in

the last digit with the EasyKey IP number recorded

in step 4).

• If “ProMix web interface requires Java to run”

appears, verify that Java Version 6 Update 10

(or later) is loaded on your computer. See page

4.

7. Press Enter.

8. Select Run when security screen appears. See F

6.

IG. 6: BWI Security Screen

F

9. Main software screen appears. See F

IG. 7.

• If “Cannot Read Firmware” appears check for

loose hardware connections.

IG.

FIG. 7. Main BWI Screen

313386D 7

Page 8

ProMix 2KS/3KS Basic Web Interface (BWI)

Web Navigation Screens

From the main BWI screen (see FIG. 7) the operator can

select Setup, Software/Resets, or Reports.

NOTE: Before running the BWI program, check the

EasyKey Status screen to ensure that the system is in

Standby.

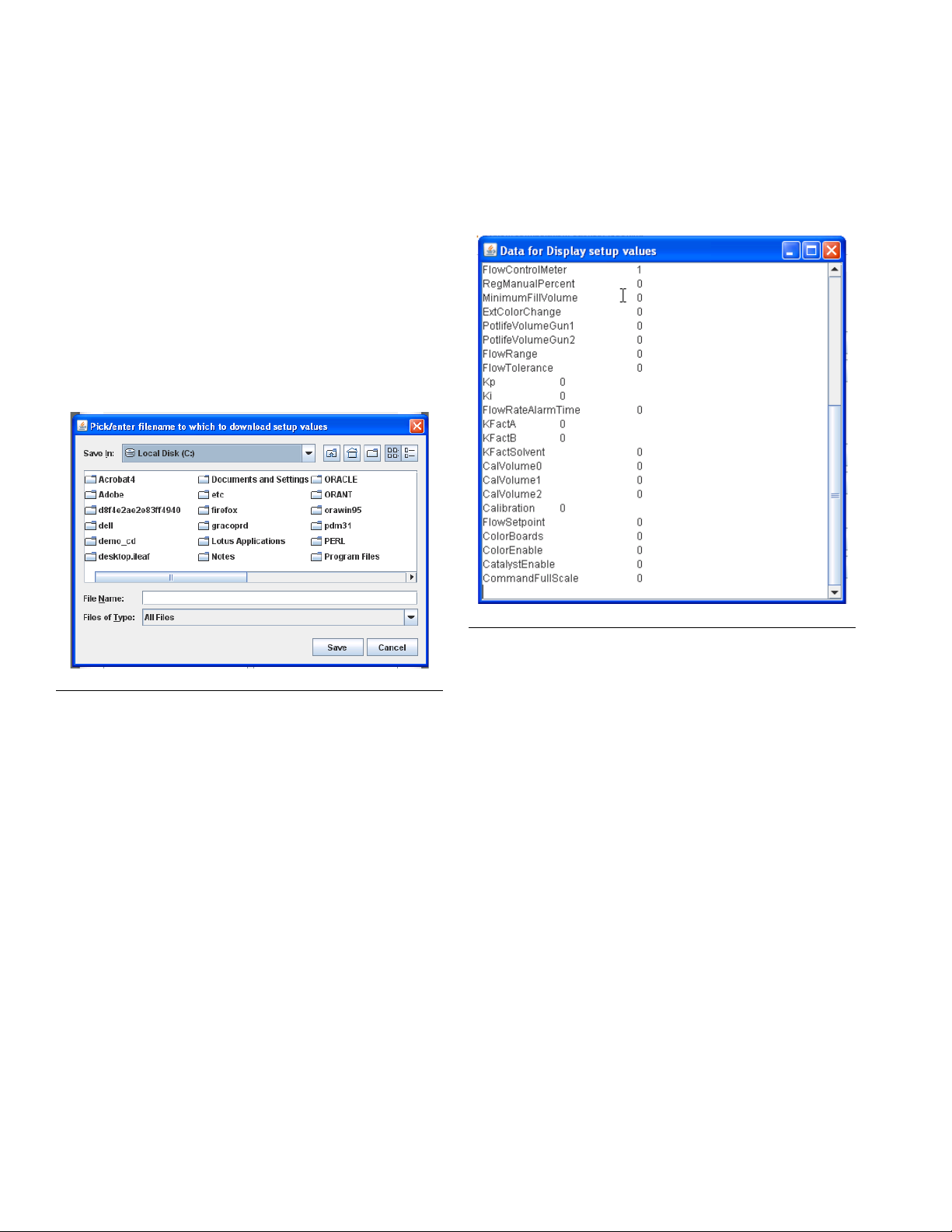

Setup

Download setup values - saves the ProMix 2KS/3KS

configuration to the PC. This file can be opened and

edited using Microsoft Excel, or used to set up multiple

systems.

Restore setup values - allows files to be uploaded and

restored to the ProMix 2KS/3KS.

Display setup values - indicates what values are

currently being used for the system. Allows the operator

to verify that the right values are being used. See F

IG. 9.

IG. 8: Download Setup Values

F

FIG. 9: Display Set Up

8 313386D

Page 9

ProMix 2KS/3KS Basic Web Interface (BWI)

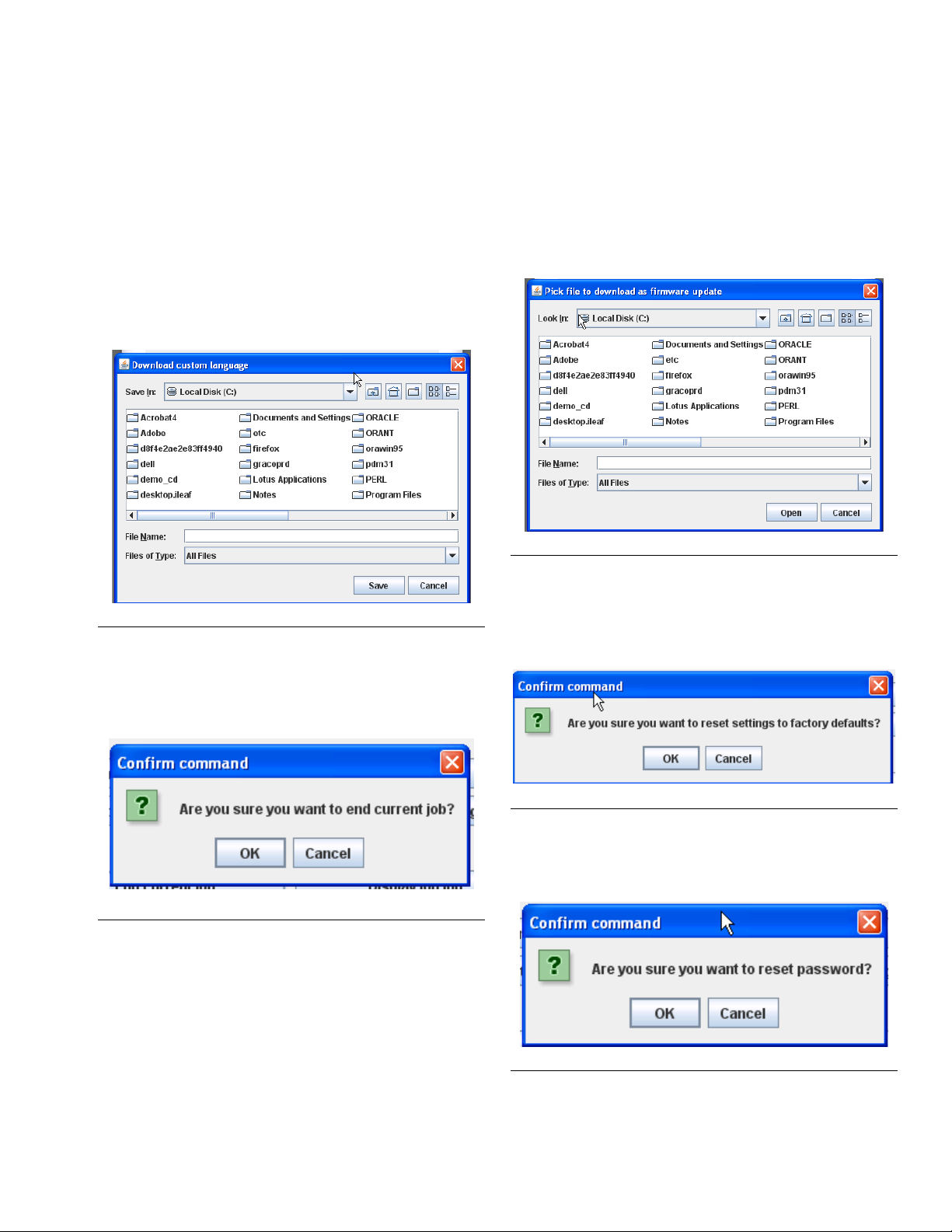

Download custom language - saves the current

system language to the PC. See F

IG. 10. This file is

opened and a custom language added to the B column

of the Excel file.

NOTE: Custom languages are limited to Ascii and Ascii

extended characters and a maximum of 32 characters.

Save the Excel file as a tab delineated file for uploading

purposes.

Restore custom language - allows the custom language file to be uploaded to the ProMix 2KS/3KS.

Software/Resets

Install EasyKey software - installs firmware for the cur-

rent device (approximately 6 minutes). See F

NOTE: If using the Graco Gateway in your system, disconnect its cable from the EasyKey before updating the

ProMix 2KS/3KS software.

FIG. 12: Install EasyKey Software

IG. 12.

F

IG. 10: Download Custom Language

End current job - ends a job and adds material to

usage report. The screen will prompt for confirmation.

See F

IG. 11.

IG. 11: End Current Job

F

Reset settings - places system back to factory default

mode. The screen will prompt for confirmation. See F

IG.

13.

IG. 13: Reset Settings

F

Reset password - clears password if lost or forgotten.

The screen will prompt for confirmation. See F

IG. 13.

IG. 14: Reset Password

F

313386D 9

Page 10

ProMix 2KS/3KS Basic Web Interface (BWI)

Reports

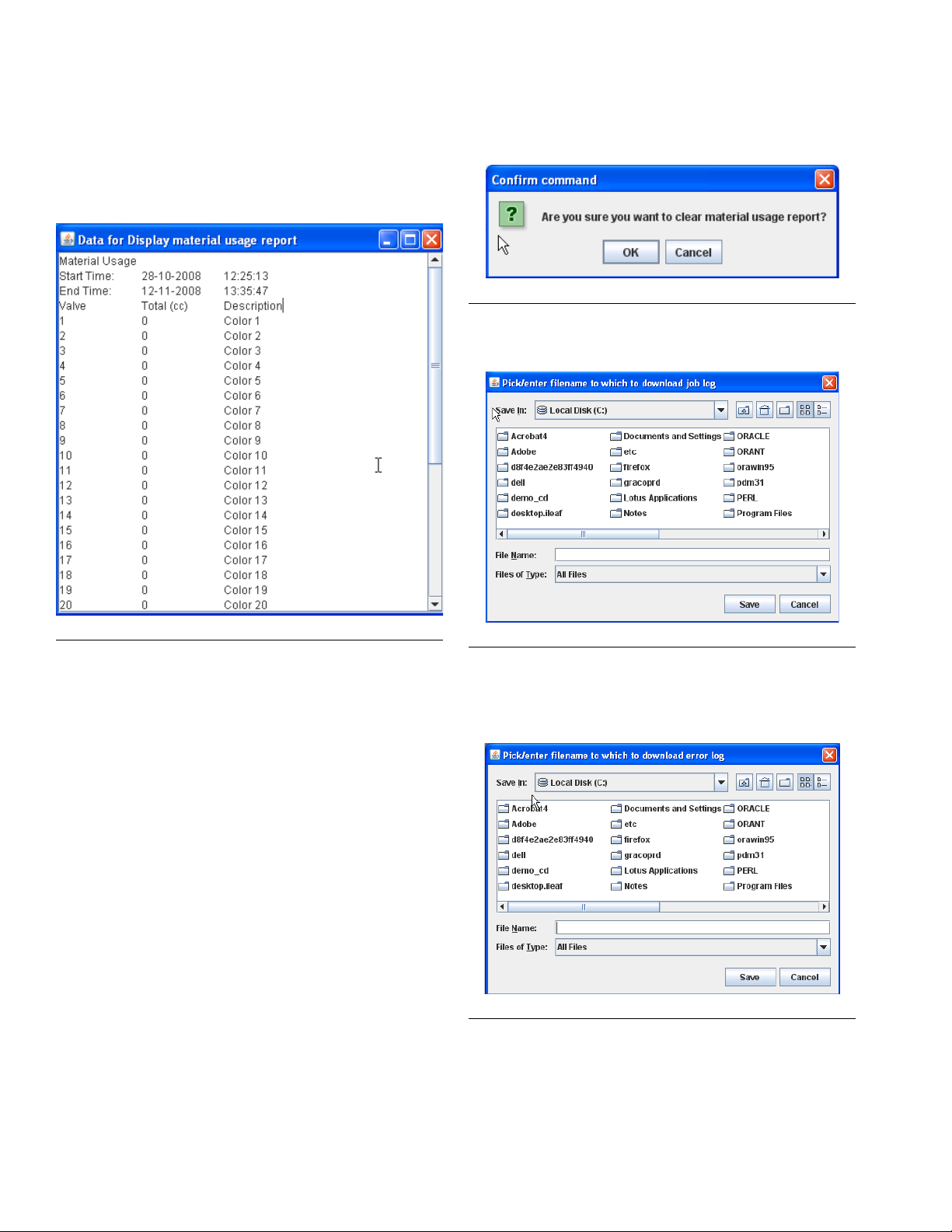

NOTE: Display material usage report - shows the

material sprayed from the ProMix 2KS/3KS. See F

15.

Clear material usage report - deletes the material

usage from the display.

IG.

FIG. 16: Clear Material Usage Report

Download job log - downloads the job log to the PC.

IG. 15: Display Material Usage Report

F

IG. 17: Download Job Log

F

Download error log - downloads the error log to the

PC.

IG. 18: Download Error Log

F

10 313386D

Page 11

ProMix 2KS/3KS Basic Web Interface (BWI)

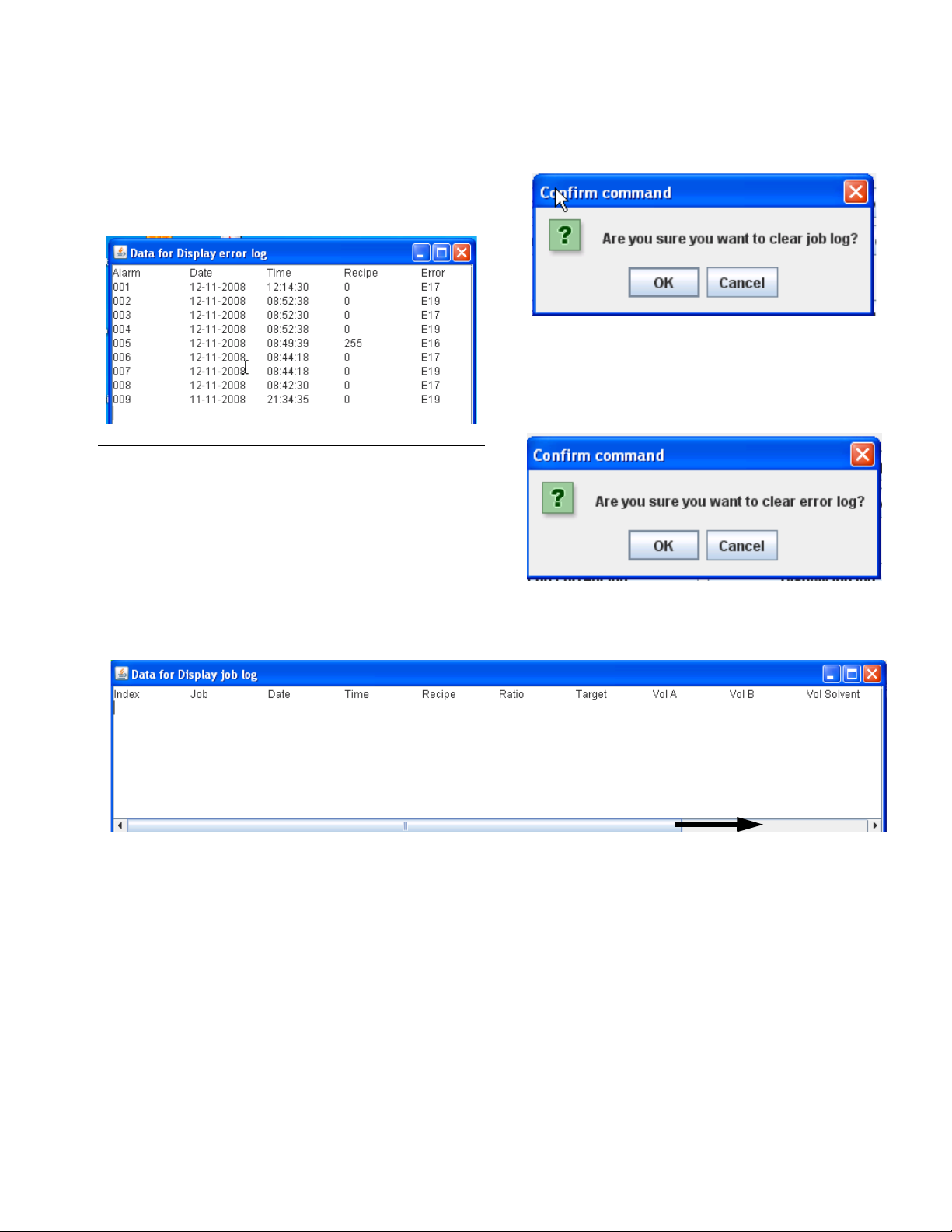

Display job log - displays the job number, date, time,

recipe, ratio, target, volumes, grand totals, and any

errors that occurred during the job. See F

IG. 22.

Display error log - displays the number of alarms, date,

time, recipe and what the error was. See F

IG. 19: Display Error Log

F

IG. 19.

Clear job log - deletes the jobs from the display. The

screen will prompt for confirmation. See F

IG. 20.

FIG. 20: Clear Job Log

Clear error log - deletes the errors from the display. The

screen will prompt for confirmation. See F

IG. 21.

FIG. 22: Display Job Log

IG. 21: Clear Error Log

F

NOTE: For ProMix 3KS, a column

will appear for Vol C.

Scroll to right to view Grand Totals and Errors

313386D 11

Page 12

Install the Advanced Web Interface (AWI) Module

Install the Advanced Web Interface (AWI) Module

Overview

The Graco Advanced Web Interface (AWI) Accessory

allows communication between multiple ProMix

2KS/3KS and a PC over an Ethernet, enabling users to

monitor the ProMix 2KS/3KS, view and change system

setup parameters, and create reports.

NOTE: Screen views in this manual are shown using

Microsoft Windows XP.

Location

The AWI module may be installed in a local ProMix network (see F

Do not install equipment approved only for non-hazardous location in a hazardous area.

Install the module near the EasyKey, in a non-hazardous area.

IG. 25) or in a LAN network (see FIG. 26).

Mounting

1. See Dimensions, page 41.

2. Ensure that the wall and mounting hardware are

strong enough to support the weight of the equipment, fluid, hoses, and stress caused during operation.

3. Using the equipment as a template, mark the

mounting holes on the wall at a convenient height

for the operator and so equipment is easily accessible for maintenance.

4. Drill mounting holes in the wall. Install anchors as

needed.

5. Bolt equipment securely.

12 313386D

Page 13

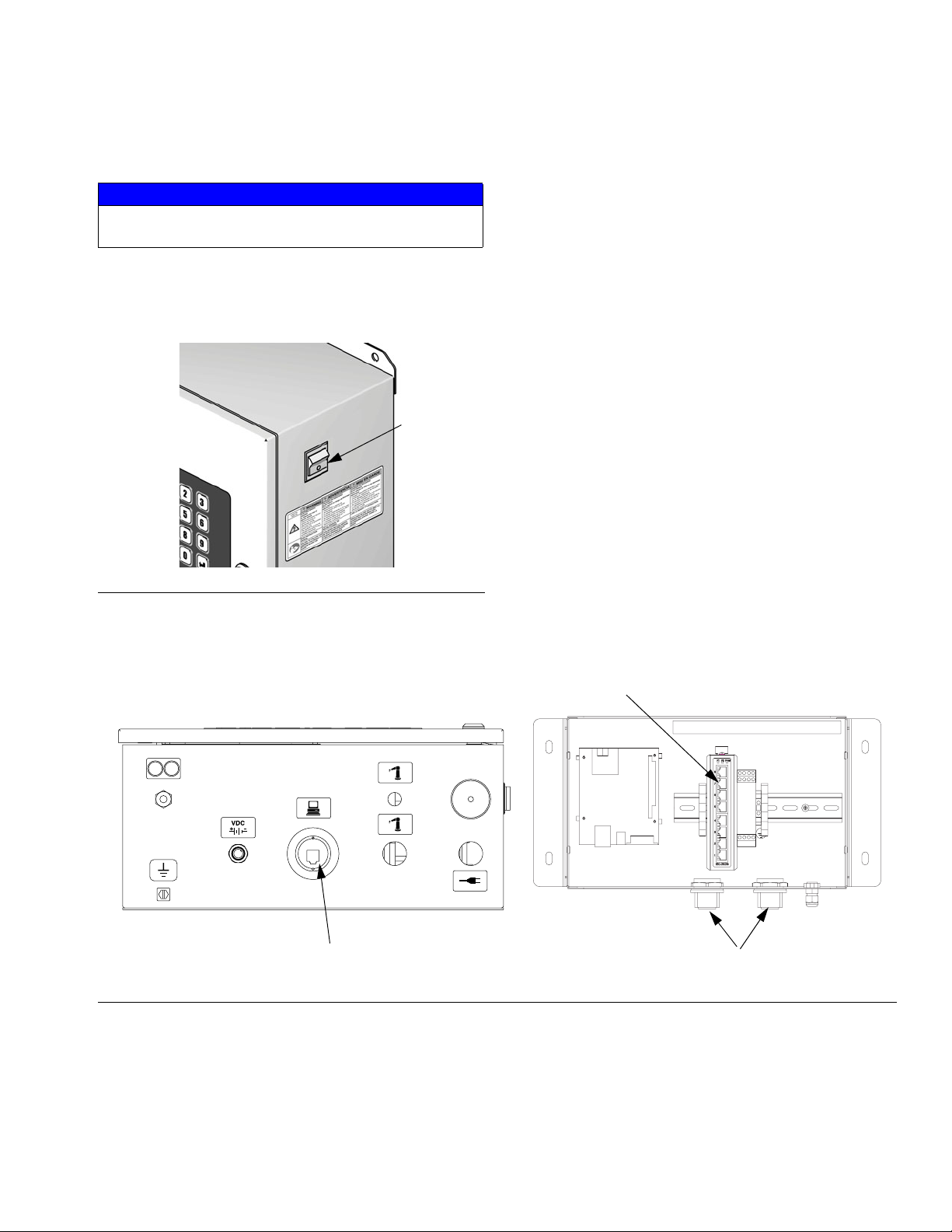

Install the Advanced Web Interface (AWI) Module

Connect Module to EasyKey and PC

NOTICE

To avoid damaging circuit board when servicing, wear

grounding strap on wrist and ground appropriately.

1. Shut off ProMix 2KS/3KS power (0 position). FIG.

23. Also shut off power at main circuit breaker.

0 = OFF

TI12657a

F

IG. 23: Power Off

2. Run a CAT5 cable from the EasyKey connector

through the grommet and connect it to any port in

the AWI module. Connect another CAT5 cable from

the AWI module to the PC. See F

IG. 24.

3. Plug in the module power cord.

NOTE: Multiple AWI server hubs can be connected to

the AWI master module in series. See F

IG. 25. Order

Part No. 15V336 Hub, see page 39.

EasyKey (Bottom View) Advanced Web Interface Module

TI12638a

CAT5 Cable Connector CAT5 Cable Grommets

FIG. 24: EasyKey and Module Cable Connection Points

Connect CAT5 Cables to any ports on module

TI12926a

313386D 13

Page 14

Install the Advanced Web Interface (AWI) Module

Computer

AWI Master Module

EasyKeys

Use CAT5 cables for connections.

FIG. 25: ProMix Network Typical Installation

AWI Hub

TI13065a

14 313386D

Page 15

EasyKey EasyKey

NOTE: LAN Network (Manual)

Installation requires completion of

the procedures on pages 16-20

before connecting to the network.

Install the Advanced Web Interface (AWI) Module

LAN Network

Computer

AWI Module

Use CAT5 cables for connections.

Internet

(via VPN)

Computer

TI13064b

FIG. 26: LAN Network (Manual) Typical Installation

313386D 15

Page 16

Computer Configuration

Computer Configuration

Set up an Automatic IP Address

See FIG. 27. On your computer, go to Control

Panel>Network Connections>Local Area Connection>Properties>Internet Protocol (TCP/IP). Verify that

“Obtain an IP address automatically” is selected in the

TCP/IP Properties window. If not, set it as shown. Click

OK and close out of the Control Panel.

Set to automatic IP address

System Initialization

NOTE: System initialization must be done by an admin-

istrator. This process is only required when the system

is first started.

NOTE: Verify that the wireless connection is turned off

(disabled) before performing step 1.

1. Open a browser. Firefox 3.0 or above is preferred.

Microsoft Internet Explorer 6.0 or above is also

acceptable.

2. Applies to Firefox only: To operate in a ProMix

2KS/3KS network with Firefox, you must turn off the

Proxy setting on your browser. In your Firefox

browser, go to Tools>Options>Advanced>Network

tab>Connection Settings. Click “No proxy.” See F

28.

IG.

IG. 27. Set Automatic IP Address

F

F

IG. 28. Turn Off Proxy Setting (Firefox only)

3. Type http://gracoawi: in the browser address bar,

and press Enter.

16 313386D

Page 17

Computer Configuration

4. The Welcome screen will appear. See FIG. 29. Click

Next.

IG. 29. System Initialization Step 1

F

5. The Security screen will appear. See F

IG. 30. The

administrator must fill in all fields. Click Next.

6. Initialization is complete. See F

IG. 31. Click Finish.

FIG. 31. System Initialization Step 3

7. The Login screen will appear. See F

IG. 32. Type in

the login name and password you entered in step 5.

Click Sign in. The Network screen will appear. See

page 21.

IG. 30. System Initialization Step 2

F

IG. 32. Login Screen

F

313386D 17

Page 18

Computer Configuration

Password Recovery

1. If you type in the wrong password, sign in will be

blocked. See F

IG. 33. Click on the block icon to

initiate the password recovery sequence.

Click on block icon

IG. 33. Sign in Blocked

F

2. See F

IG. 34. The system will prompt you for your

login name. Type in the name you entered in step 5

on page 17, then click Next.

3. The system will then ask the secret question you

entered in step 5. Type in the answer, then click

Next.

FIG. 35. Password Recovery Step 2

4. If the answer matches the one entered in step 5, the

system will prompt you for a new password. Enter

the new password twice, then click Next. The sys-

tem will return to the Login screen, F

IG. 32.

IG. 36. Password Recovery Step 3

IG. 34. Password Recovery Step 1

F

18 313386D

F

Page 19

Set the Network Configuration

Computer Configuration

ProMix 2KS/3KS Network Configuration

In a ProMix 2KS/3KS network, the AWI module is connected to an EasyKey and a personal computer. Up to

100 EasyKeys may be connected in the network. See

F

IG. 25.

To select a ProMix 2KS/3KS network, go to the Settings

tab and select ProMix network. See F

Click Save.

Turn off the Proxy setting (Firefox only). See page 16.

IG. 37.

IG. 37. ProMix 2KS/3KS Network Setting

F

313386D 19

Page 20

Computer Configuration

LAN Network (Manual) Configuration

See FIG. 26. A LAN network (manual) configuration

enables you to work through a local network. Up to 100

EasyKeys may be connected in the network. The

EasyKeys and AWI Module must be on the same subnetwork. The EasyKeys can be connected to any LAN

drop.

NOTE: To change to a LAN (manual) configuration, you

must first connect to the AWI via the ProMix 2KS/3KS

network. See pages 16-17 for instructions and F

for cable connections.

IG. 25

To select a LAN (manual) configuration, go to the Settings tab and select Manual configuration. You will be

required to enter IP, gateway, and Netmask addresses.

Contact your IS system administrator for assistance.

See F

IG. 38.

NOTE: Use a new IP address to access the AWI; this

replaces gracoawi (for LAN network systems only).

NOTE: Once Save is clicked, the AWI will disconnect the

user computer. Reconnect the AWI and computer as

shown in F

IG. 26. Reconfigure the user computer to

match the new LAN configuration. You can then login to

the AWI using the newly assigned IP address.

Click Save to apply the change.

IG. 38. LAN Network Setting

F

20 313386D

Page 21

AWI Screens

AWI Screens

This section describes how to use the AWI screens to

access and make changes to system settings and recipes. For complete information about these settings and

their effects, see the Setup section in the system operation manual.

Network Tab

Use the Network tab to select the desired EasyKey. See

F

IG. 39.

Each EasyKey must have a unique name and IP

address. See the Configuration Screen in F

the Station name (1-99).

Click on the desired EasyKey to access the setup

screens for that device.

IG. 46 to set

F

IG. 39. Network Tab

Click on desired EasyKey

313386D 21

Page 22

AWI Screens

Materials Tab

Use the Materials tab to enter information on Volatile

Components (VOC) and Hazardous Air Pollutants (HAP)

for each material being used in your system, for material

reporting. This information, and the manufacturer’s part

no., are available on the MSDS sheet provided by the

material manufacturer. See F

VOC values may be set at Lbs/Gal or Gram/Liter as

desired, using the pulldown menu.

Plus

Button

IG. 40.

To add a new material, click the Plus

the values in the new data fields.

To delete a material, click the Minus

To save your changes, click . A

checkmark (✓)will appear when the save is complete.

button. Enter

button.

Minus

Button

FIG. 40. Materials Tab

VOC Pulldown Menus

(Lb/Gal or Gram/Liter)

Save

Button

22 313386D

Page 23

AWI Screens

313386D 23

Page 24

AWI Screens

Settings Tab

Use the Settings tab to configure the main system settings (Time, Language, Upgrade AWI, and Edit

Accounts).

NOTE: F

in as a user. F

you log in as a system administrator.

IG. 41 shows the Settings screen when you log

IG. 42 shows the Settings screen when

Set Time

To synchronize the time settings on all networked ProMix 2KS/3KS devices, click the Sync

The change will take place in approximately one minute.

button.

Set Language

Set the desired language of the screen text, using the

pulldown menu. Select English (default), Spanish,

French, German, Italian, Dutch, Japanese (Kanji),

Korean, and Chinese (Simplified).

Upgrade AWI Software

To upgrade AWI, first download the latest version of AWI

software to your computer. Contact your Graco distributor for information.

Use the Browse button to locate the file

on your computer. Highlight the filename.

Click on the Upgrade

upgrade.

Sync ButtonLatest Software Version

button to start the

UpgradeBrowse

FIG. 41. System Settings Tab (User Screen Shown)

24 313386D

Page 25

AWI Screens

Edit Account Information

NOTE: Account information can only be entered by a

system administrator. See F

• To add a new account, click the Add User

ton. Enter the information in the data fields. Click

. A checkmark (✓)will appear in the top

right corner when the save is complete.

Latest Software Version

IG. 42.

but-

• To edit an existing account, click the Edit User

button. Enter the information in the data fields. Click

. A checkmark (✓)will appear the top

right corner when the save is complete.

• To delete an existing account, click the Delete User

button.

Sync Button

UpgradeBrowse

FIG. 42. System Settings Tab (Admin Screen Shown)

313386D 25

Page 26

AWI Screens

System Setup Screens

To view the system setup screens, go to the Network tab

and click on the desired EasyKey to access the setup

screens for that device. See F

Click on desired EasyKey

IG. 43.

Monitor Tab

Select the Monitor tab to view data from the EasyKey

Status screen, in real time. See F

IG. 44.

F

IG. 43. Open Device

IG. 44. Monitor Tab

F

26 313386D

Page 27

AWI Screens

Material Setup Tab

Go to the Material Setup tab to assign a catalyst, color,

reducer (on 3KS) and flush material for the valves of the

active device, using the pulldown menus. For 2KS, each

device may include up to 30 color valves, 4 catalyst

valves, and solvent flush valves. For 3KS, each device

may include up to 25 color valves, 4 catalyst valves, 4

reducer valves, and solvent flush valves. The materials

listed in each pulldown menu were established under

the Materials Tab on page 22. See F

IG. 45.

To save your changes, click . A

checkmark (✓)will appear when the save is complete.

FIG. 45. Material Setup Tab

313386D 27

Page 28

AWI Screens

System Setup Tab

The Setup tab has three editable screens:

•The Configuration screen corresponds to the Sys-

tem Configuration screens of the EasyKey. See F

46. For complete information about these settings

and their effects, see the Setup section in the system operation manual.

•The Advanced screen corresponds to the

Advanced Setup screens of the EasyKey. See F

47. For complete information about these settings

and their effects, see the Setup section in the system operation manual.

•The Recipe screen corresponds to the Recipe

Setup screens of the EasyKey. See F

IG. 48. For

complete information about these settings and their

effects, see the Setup section in the system operation manual.

IG.

IG.

Use the arrow buttons

to view the pre-

vious or the next recipe, or enter the recipe number

and press Enter.

Click on the Chart button

timing chart of the active recipe. See F

to create a

IG. 49.

To save your changes, click . A

checkmark (✓)will appear when the save is complete.

NOTE: Changes made on the EasyKey screen before

clicking will be overwritten by the

AWI data.

FIG. 46. System Setup Tab, Configuration Screen

50 cc

28 313386D

Page 29

AWI Screens

FIG. 47. System Setup Tab, Advanced Screen

1.0

2.0

Click to create a

recipe timing chart.

See F

IG. 49.

FIG. 48. System Setup Tab, Recipe Screen

313386D 29

Page 30

AWI Screens

FIG. 49. Sample Recipe Timing Chart

30 313386D

Page 31

AWI Screens

Reports Tab

The Reports tab enables you to produce three reports:

• Material Report

•Job Report

• Alarm Report

Select which of the three reports you want to create.

Click the desired output format

for the report:

• CSV (can be imported into Microsoft Excel).

• TXT (straight text).

Click the Create button

ate the report.

Material Report

See F

IG. 50. The Material Report compiles VOC and

HAP data for all recipes and jobs using a material, and

the total amount of material used. The material must be

assigned to a valve to be included in the report (see

page 27).

Click the Reset button

cycle (usually monthly).

to begin a new report

to gener-

FIG. 50. Material Report Screen

313386D 31

Page 32

AWI Screens

Job Report

See F

IG. 51. The Job Report provides detailed informa-

tion on all completed jobs within a designated time

period.

Select the information desired by clicking on the box to

the left of each parameter.

Set the time frame by using the Calendar buttons

the right of each date box.

NOTE: The dates use the day/month/year format.

to

FIG. 51. Job Report Screen

32 313386D

Page 33

AWI Screens

Alarm Report

See F

IG. 52. The Alarm Report lists all alarms triggered

within a designated time period.

Set the time frame by using the Calendar buttons

the right of each date box.

NOTE: The dates use the day/month/year format.

to

FIG. 52. Alarm Report Screen

313386D 33

Page 34

AWI Screens

Level Control Tab

See FIG. 53. The Level Control Tab allows you to input

the supply tank volume of the materials and the level at

which an alarm should be triggered.

The alarm function may be turned on or off for each

material valve.

F

IG. 53. Level Control Tab

34 313386D

Page 35

AWI Screens

Sidebar

See FIG. 54. The Sidebar relates to the EasyKey being

monitored. It has four links to related screens:

• Save - saves the current device configuration into a

file.

• Restore - restores configurations of the device from

a file.

• Copy (Sync Settings)- copies the configuration of

this device into other devices.

• Install Firmware - install firmware for the current

device (approximately 5 minutes).

F

IG. 54. Sidebar and Related Screens

313386D 35

Page 36

Replace AWI Board

Replace AWI Board

• To avoid electric shock, turn off EasyKey power

before servicing.

• Shut off power at main circuit breaker.

• All electrical wiring must be done by a qualified

electrician and comply with all local codes and regulations.

• Read Warnings, page 3.

NOTICE

To avoid damaging circuit board when servicing, wear

Part No. 112190 grounding strap on wrist and ground

appropriately.

1. Shut off ProMix 2KS/3KS power (0 position).

2. Shut off power at main circuit breaker.

3. Open the AWI module.

4. Disconnect the cable (15) and wires (17, 18) from

the board (22). F

5. Remove the screws (21) and board (22).

6. Install the new board. Reconnect the cable (15) and

wires (17, 18).

4

IG. 55.

10 15

1718

22

F

IG. 55. Replace AWI Board

36 313386D

TI12928a

Page 37

Replace AWI Board

313386D 37

Page 38

Parts

Parts

15V337 Advanced Web Interface Module

Screw Location

(item 28)

1, 2

To 4

+24

COM

+24

COM

17

18

21

To 1 0

10

22

Wiring Diagrams

V1+

V1-

+24

COM

13

7, 9, 12

3

8

12

TI12926a

11

5

4

4

56

181718

10

1517

To 4

Ref.

No. Part No. Description Qty

1 15V339 PANEL, back 1

2 15T752 COVER 1

3 n/a DIN RAIL 1

4 120369 POWER SUPPLY, 24 Vdc 1

5 15V345 GROMMET, cable entry 2

6 111987 CONNECTOR, strain relief 1

7n/a WIREWAY 1

8 186620 LABEL, ground 1

9 n/a COVER, wireway 1

10 15V342 SWITCH, ethernet 1

11 120838 BLOCK, clamp end 2

17

18

TI12927a

To 2 2

22

TI12928a

Power Supply Wiring Detail

L1+

NC

NC

N -

Ref.

No. Part No. Description Qty

12 103833 SCREW, machine 4

13 112443 BLOCK, terminal, ground 1

15 121994 CABLE, CAT5 1

17 n/a WIRE, copper, 16 ga.; 9 in. (230 mm) 1

18 n/a WIRE, copper, 16 ga; 9 in. (230 mm) 1

21 15V340 STANDOFF, board 4

22 258355 BOARD, server 1

28 n/a SCREW, machine, serrated

hex-head

Parts labeled n/a are not available separately.

OUT - -

DC - -

24V + +

1A + DC OK

4

38 313386D

Page 39

15V336 Advanced Web Interface Server Hub

Parts

Screw Location

(item 28)

1, 2

To 4

+24

COM

17

10

54

Wiring Diagrams

V1+

V1-

To 1 0

13

8

56

4

17

7, 9, 12

3

12

11

TI13204a

10

18

TI13206a

Ref.

No. Part No. Description Qty

1 15V339 PANEL, back 1

2 15T752 COVER 1

3 n/a DIN RAIL 1

4 120369 POWER SUPPLY, 24 Vdc 1

5 15V345 GROMMET, cable entry 2

6 111987 CONNECTOR, strain relief 1

7n/aWIREWAY 1

8 186620 LABEL, ground 1

9 n/a COVER, wireway 1

Parts labeled n/a are not available separately.

TI13205a

18

Ref.

No. Part No. Description Qty

10 15V342 SWITCH, ethernet 1

11 120838 BLOCK, clamp end 2

12 103833 SCREW, machine 4

13 112443 BLOCK, terminal, ground 1

17 n/a WIRE, copper, 16 ga.; 9 in.

(230 mm)

18 n/a WIRE, copper, 16 ga; 9 in.

(230 mm)

28 n/a SCREW, machine, serrated

hex-head

1

1

4

313386D 39

Page 40

Electrical Schematic

Electrical Schematic

Non-Hazardous Area

J4

MEMBRANE

SWITCH

WITH

RIBBON

CABLE

DISPLAY

DISPLAY

1

BOARD

2

3

4

5

6

7

8

9

10

11

J2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

2

J9

3

4

RJ45

J6

RJ45

1

2

3

4

5

J5

6

7

8

9

10

1

2

3

J10

4

5

6

J7

J8

RJ45

RJ45

P1

3'

RJ45

BULKHEAD

3'

(25'-200' OPTIONS)

RJ45

WEB SERVER

RJ45

MODULE

100-240 Vac Input

24 Vdc

COM

40 313386D

Page 41

Dimensions

Dimensions

16.57 in. (420.9 mm)

6.45 in.

(163.8 mm)

15.07 in. (382.8 mm)

5.31in.

(134.9 mm)

TI12926a

8.71in.

(221.2 mm)

TI12825b

313386D 41

Page 42

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS, MN 55440-1441 • USA

Copyright 2008, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 313386

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised 09/2011

Loading...

Loading...