Page 1

Parts

DSL/SVK

Lubricators*

313375B

Bulletin 51050

- For delivering small flows of mineral or synthetic oil

to machinery lubrication points -

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

End Rotary Drive

1:1 Model: 24A455, 24A456, 24A457, 24A458, 24A459, 24A460

37.5:1 / 75:1 Model: 24A461,24A462, 24A463, 24A464, 24A465, 24A466, 24A467, 24A468, 24A469, 24A470,

24A471, 24A472, 24A473, 24A474, 24A475, 24A476

283:1 Model: 24A453, 24A454

Side Rotary Drive

40:1 / 60:1 Model: 24A477, 24A478, 24A479, 24A480, 24A481, 24A482, 24A483, 24A484, 24A485, 24A486,

24A487, 24A488, 24A489, 24A490, 24A491, 24A492, 24A493, 24A494, 24A495, 24A496, 24A497, 24A498, 24A499,

24A501, 24A502, 24A503, 24A504, 24A505

Bottom Rotary Drive

1:1 / 2.5:1 Model: 24A506, 24A507, 24A508, 24A509

Maximum Working Pressure (with DSL Pump): 3000 psi (20.6 MPA, 206 bar)

Maximum Working Pressure (with SVK Pump): 5000 psi (34.7 MPA, 345 bar)†

*Does not include Pumps and Accessory Kits.

†Sight glass required.

Page 2

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNINGS

FIRE AND EXPLOSION HAZARD

When flammable fluids are present in the work area, such as gasoline and windshield wiper fluid, be

aware that flammable fumes can ignite or explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources, such as cigarettes and portable electric lamps.

• Keep work area free of debris, including rags and spilled or open containers of solvent and gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Ground all equipment in the work area.

• Use only grounded hoses.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the dispense outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow Pressure Relief Procedure in this manual, when you stop dispensing and before cleaning,

checking, or servicing equipment.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system component. See Technical Data in all equipment manuals.

• Do not leave the work area while equipment is energized or under pressure. Turn off all equipment

and follow the Pressure Relief Procedure in this manual when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

2 313375B

Page 3

Repair

Repair

NOTE: Graco recommends using the Graco DSL/SVK

Pumps with these lubricators. The following repair

instructions are for lubricators using those pumps. If you

use any other pump, these instructions may not apply

exactly as written.

Pressure Relief Instructions

Follow this pressure relief procedure whenever you are

instructed to relieve pressure or need to check or service equipment.

To relieve pressure, loosen vent screw on pump sight

glass, allowing pressure to vent. Also refer to DSL/SVK

Pump instruction manual 313261.

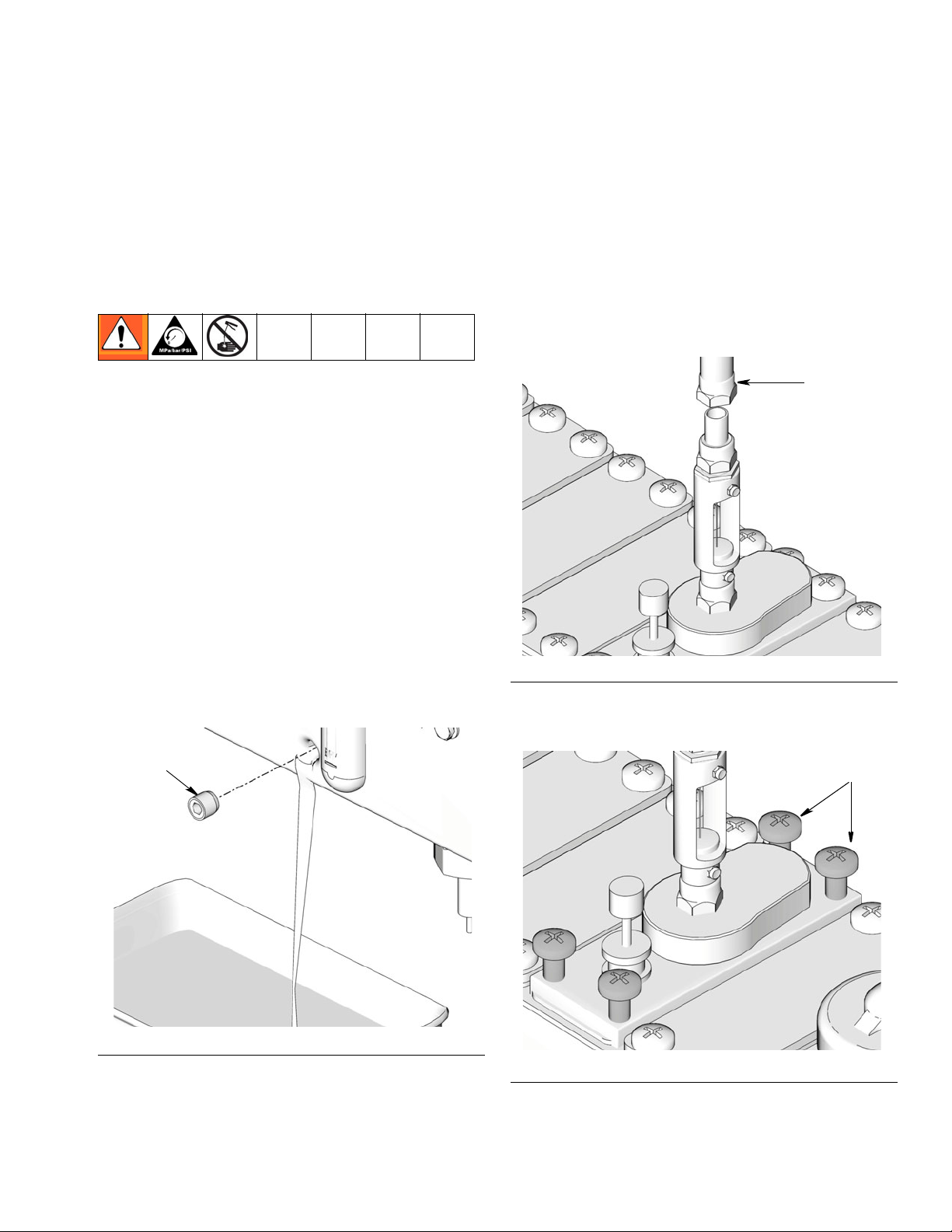

Draining Reservoir (FIG. 1)

To drain reservoir:

1. Position a waste container below drain plug to catch

fluid as it drains from reservoir.

2. Remove drain plug (17) and allow reservoir to drain

into a waste container.

Removing and Replacing Pump

Removal

1. Relieve Pressure.

2. Drain reservoir. See Draining Reservoir instructions.

3. Disconnect fluid lines (a) from pump (F

FIG. 2

4. Remove fasteners (9) from pump (F

IG. 2).

(a)

ti14184

IG. 3).

17

ti14183

FIG. 1

IG. 3

F

5. Remove pump from top of reservoir. Mak sure gasket (8) was removed with pump. If it is still in place in

313375B 3

ti14185

9

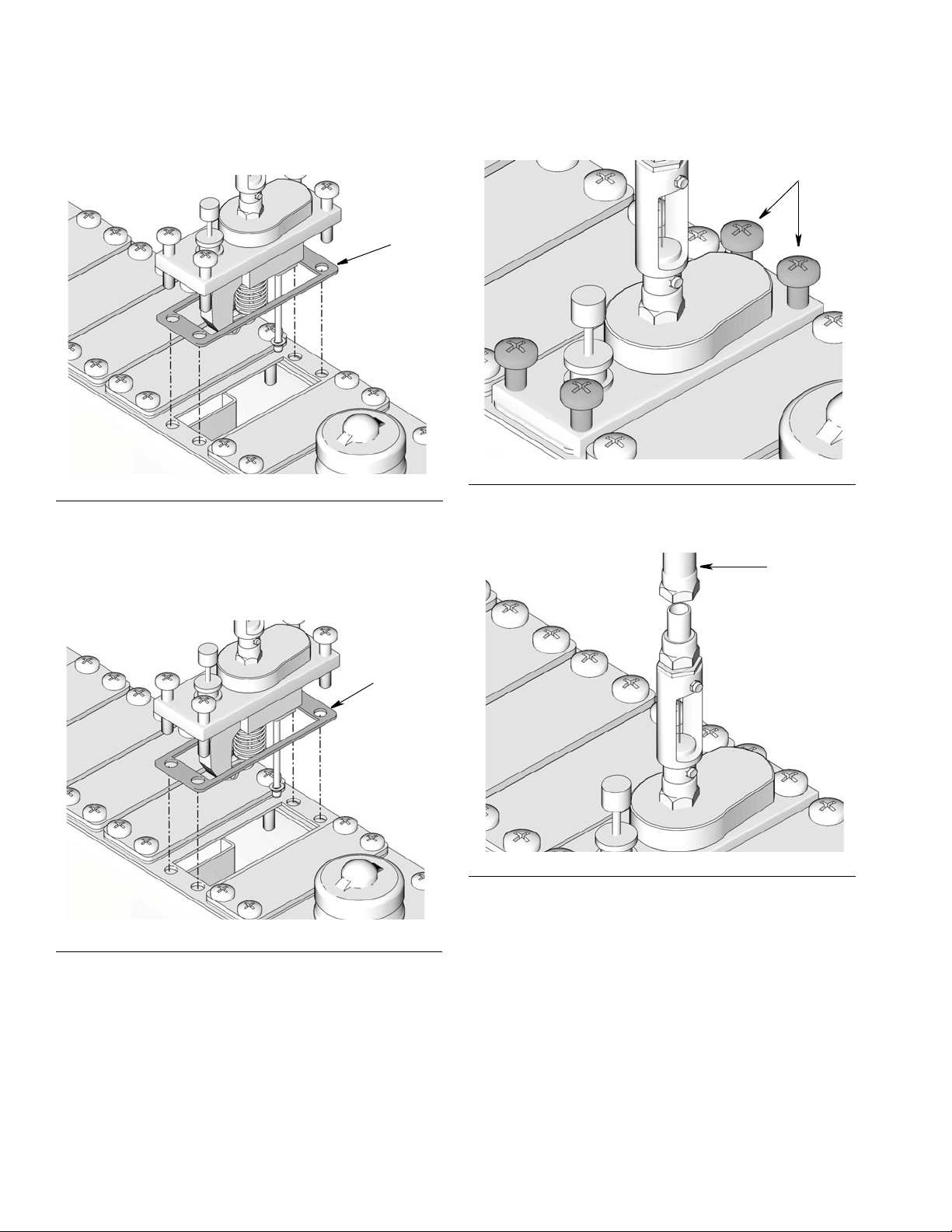

Page 4

Repair

top of reservoir, remove it. Discard gasket and use a

new gasket for installation.

8

ti14186

F

IG. 4

Installation

1. Install new gasket (8) and pump in top of reservoir

(F

IG. 4).

2. Install fasteners (9). Hand tighten securely (F

ti14185

FIG. 6

3. Connect fluid lines (a) to pump (F

IG. 7).

(a)

IG. 6).

9

IG. 5

F

ti14186

8

ti14184

F

IG. 7

4. Make sure reservoir drain plug (17) is installed. Fill

reservoir with fluid.

4 313375B

Page 5

Parts

End Rotary Drive Models

1:1 Models: 24A455, 24A456, 24A457, 24A458, 24A459, 24A460

Parts

Ref Part No. Description Qty

1 RESERVOIR 1

2 COVER 1

3 15V913 SHAFT, 3 feed, direct rotary, (mod-

els 24A455 and 24A456)

15V914 SHAFT, 6 feed, direct rotary, (mod-

els 24A457 and 24A458)

15V915 SHAFT, 9 feed, direct rotary, (mod-

els 24A459 and 24A460)

4 560288 CAM, pump actuating (models

24A455 and 24A456)

CAM, pump actuating (models

24A457 and 24A458)

CAM, pump actuating (models

24A459 and 24A460)

5 555377 KEY, #3 USA 404 woodruff (models

24A455 and 24A456)

KEY, #3 USA 404 woodruff (models

24A457 and 24A458)

KEY, #3 USA 404 woodruff (models

24A459 and 24A460)

6 555326 SCREW, set cp 1/4-20 x .25 (mod-

els 24A455 and 24A456)

SCREW, set cp 1/4-20 x .25 (mod-

els 24A457 and 24A458)

SCREW, set cp 1/4-20 x .25 (mod-

els 24A459 and 24A460)

7 555899 PLATE, blank unit, (models 24A455

and 24A456)

PLATE, blank unit, (models 24A457

and 24A458)

PLATE, blank unit, (models 24A459

and 24A460)

8 555947 GASKET, pumping unit (models

24A455 and 24A456)

GASKET, pumping unit (models

24A457 and 24A458)

GASKET, pumping unit (models

24A459 and 24A460)

9 555304 SCREW, 1/4-20 x 1.25 ZN (models

24A455 and 24A456)

SCREW, 1/4-20 x 1.25 ZN (models

24A457 and 24A458)

SCREW, 1/4-20 x 1.25 ZN (models

24A459 and 24A460)

10 556376 NUT, lock (models 24A455 and

24A456)

NUT, lock (models 24A457 and

24A458)

12

24

36

Ref Part No. Description Qty

NUT, lock (models 24A459 and

24A460)

11 555355 SCREW,thf hh st 10-32 x .50 zn 4

1

12 15U116 CAP, filler 1

14 556872 LABEL, name serial 1

1

15 555318 SCREW, thf ph st 1/4-20 x .75 2

16 15R634 LABEL, logo, "G" 3" x 3" 1

1

17 556000 PLUG,pipe 1/4""nptf hex drive 1

18 563923 KIT, sightglass, gauge 1

3

18a SIGHTGLASS, level 1

18b GASKET, level sight glass 1

6

18c NUT, pal self thd 3

22 556929 LABEL, cw ccw rotn 1

9

23 562586 BEARING, 5/8” ID

3

25 555905 BEARING, thr race 2

6

26 556578 SEAL, lip .50 id 1.12 od .25 w 1

28 556782 COLLAR, lock 1

9

29 562977 BEARING, end 5/8 id 1

30 562983 BEARING, oil seal assy 1/2 id lg 1

3

6

9

3

6

9

3

6

9

2

3

(model 24A457 and 24A458 1

(model 24A459 and 24A460 2

4

313375B 5

Page 6

Parts

1:1 End Rotary Drive Models

Model 24A457 Shown

9

11

15

12

7

8

29

28

23

14

10

4, 5, 6

1

2

18c

16

18a

17

18b

1

3

22

25

30

26

1

Apply Loctite® 515 to cover

Loctite® is a registered trademark of the Loctite Corporation.

6 313375B

ti12844a

Page 7

37.5:1 Models:

24A461, 24A462, 24A465, 24A466, 24A469, 24A470, 24A473, 24A474

75:1 Models:

24A463, 24A464, 24A467, 24A468, 24A471, 24A472, 24A475, 24A476

Parts

Ref Part No. Description Qty

1 RESERVOIR 1

2 COVER 1

3 560376 SHAFT, 3 feed, (models 24A461,

24A462), 75:1 (models 24A463,

24A464)

560377 SHAFT, 6 feed, 37.5:1 (models

24A465, 24A466), 75:1 (models

24A467, 24A468)

560378 SHAFT, 9 feed, 37.5:1 (models

24A469, 24A470), 75:1 (models

24A471, 24A472)

561321 SHAFT, 12 feed, 37.5:1 (models

24A473, 24A474), 75:1 (models:

24A475, 24A476)

4 560288 CAM, pump actuating SVK, 37.5:1

(models 24A461, 24A462), 75:1

(models 24A463, 24A464)

37.5:1 (models 24A465, 24A466),

75:1 (models 24A467, 24A468)

37.5:1 (models 24A469, 24A470),

75:1 (models 24A471, 24A472)

37.5:1 (models 24A473, 24A474),

75:1 (models: 24A475, 24A476)

5 555377 KEY, #3 USA 404 woodruff, 37.5:1

(models 24A461, 24A462), 75:1

(models 24A463, 24A464)

37.5:1 (models 24A465, 24A466),

75:1 (models 24A467, 24A468)

37.5:1 (models 24A469, 24A470),

75:1 (models 24A471, 24A472)

37.5:1 (models 24A473, 24A474),

75:1 (models: 24A475, 24A476)

6 555326 SCREW, set cp 1/4-20 x .25, 37.5:1

(models 24A461, 24A462), 75:1

(models 24A463, 24A464)

37.5:1 (models 24A465, 24A466),

75:1 (models 24A467, 24A468)

37.5:1 (models 24A469, 24A470),

75:1 (models 24A471, 24A472)

37.5:1 (models 24A473, 24A474),

75:1 (models: 24A475, 24A476)

7 555899 PLATE, blank unit, 37.5:1 (models

24A461, 24A462), 75:1 (models

24A463, 24A464)

37.5:1 (models 24A465, 24A466),

75:1 (models 24A467, 24A468)

37.5:1 (models 24A469, 24A470),

75:1 (models 24A471, 24A472)

12

11

14

12

Ref Part No. Description Qty

37.5:1 (models 24A473, 24A474),

75:1 (models: 24A475, 24A476)

8 555947 GASKET, pumping unit, 37.5:1

1

(models 24A461, 24A462), 75:1

(models 24A463, 24A464)

1

1

9 555304 SCREW, 1/4-20 x 1.25 zn, 37.5:1

1

3

6

9

10 556376 NUT, lock, 37.5:1 (models 24A461,

5

8

11 555355 SCREW, thf hh st 10-32 x .50 zn 4

12 15U116 CAP, filler 1

14 556872 LABEL, name serial 1

15 555318 SCREW, thf ph st 1/4-20 x .75 2

3

16 15R634 LABEL, logo, "G" 3" X 3" 1

17 556000 PLUG, pipe 1/4 nptf hex drive 1

18 563923 KIT, sightglass, gauge 1

6

18a SIGHTGLASS, level 1

18b GASKET, level sight glass 1

9

18c NUT, pal self thd 3

22 556929 LABEL, cw ccw rotn 1

23 562586 BEARING, 5/8” ID, 37.5:1 (models

3

6

9

24 560366 SHAFT, drv end rot 1

25 555430 PIN, roll .156 dia 1.50 lg 2

37.5:1 (models 24A465, 24A466),

75:1 (models 24A467, 24A468)

37.5:1 (models 24A469, 24A470),

75:1 (models 24A471, 24A472)

37.5:1 (models 24A473, 24A474),

75:1 (models: 24A475, 24A476)

(models 24A461, 24A462), 75:1

(models 24A463, 24A464)

37.5:1 (models 24A465, 24A466),

75:1 (models 24A467, 24A468)

37.5:1 (models 24A469, 24A470),

75:1 (models 24A471, 24A472)

37.5:1 (models 24A473, 24A474),

75:1 (models: 24A475, 24A476)

24A462), 75:1 (models 24A463,

24A464)

37.5:1 (models 24A465, 24A466),

75:1 (models 24A467, 24A468)

37.5:1 (models 24A469, 24A470),

75:1 (models 24A471, 24A472)

37.5:1 (models 24A473, 24A474),

75:1 (models: 24A475, 24A476)

24A465, 24A466), 75:1 (models

24A467, 24A468)

37.5:1 (models 24A469, 24A470),

75:1 (models 24A471, 24A472)

37.5:1 (models 24A473, 24A474),

75:1 (models: 24A475, 24A476)

12

3

6

9

12

12

24

36

48

2

3

4

5

1

2

3

313375B 7

Page 8

Parts

Ref Part No. Description Qty

26 555549 RING, retainer -50 basic ext 2

27 555873 BEARING, thr race 6

28 555905 BEARING, thr race 5

29 556578 SEAL, lip .50 id 1.12 od .25 w 1

31 556782 COLLAR, lock 2

32 556787 ARM, drv 1

33 557008 SPRING, rat drv model 76 2

34 557023 GEAR, rat 75 tooth 1

35 PAWL 1

36 560187 SCREW, shldr 1

37 560191 SCREW, shldr 1

38 560207 SPACER 1

39 560276 BRAKE 1

40 560291 ARM, ecc drv, 37.5:1 (models

24A461, 24A462, 24A465, 24A466,

24A469, 24A470, 24A473, 24A474)

560292 ARM, ecc drv, 75:1 (models

24A463, 24A464, 24A467, 24A468,

24A471, 24A472, 24A475, 24A476)

41 PAWL, drv 1

42 562977 BEARING, end 5/8 id 2

43 562983 BEARING, oil seal assy 1/2 id lg 1

1

1

8 313375B

Page 9

37.5:1 / 75:1 End Rotary Drive Models

Model 24A469 Shown

Parts

9

11

15

42

16

10

14

3

31

17

23

1

18a

18b

22

18c

7

8

12

4, 5, 6

2

1

page 10

24

26

42

43

28

29

1

Apply Loctite® 515 to cover

Loctite® is a registered trademark of the Loctite Corporation.

313375B 9

ti12838a

Page 10

Parts

37:5:1 / 75:1 End Rotary Drive Models

Exploded View (page 9)

31

37

33

36

33

41

34

5

35

25

26

38

28

25

27

39

32

27

40

28

10

10 313375B

Page 11

283:1 End Rotary Drive Models 24A453, 24A454

Parts

Ref Part No. Description Qty

1 RESERVOIR 1

2 COVER 1

3 560376 SHAFT, 3 feed (model 24A453) 1

560378 SHAFT, 9 feed (model 24A454) 1

4 560288 CAM, pump actuating (model

24A453)

CAM, pump actuating (model

24A454)

5 555377 KEY, #3 USA 404 woodruff (model

24A453)

KEY, #3 USA 404 woodruff (model

24A454)

6 555326 SCREW, set cp 1/4-20 x .25 (model

24A453)

SCREW, set cp 1/4-20 x .25 (model

24A454)

7 555899 PLATE, blank unit (model 24A453) 3

PLATE, blank unit (model 24A454) 9

8 555947 GASKET, pumping unit (model

24A453)

GASKET, pumping unit (model

24A454)

9 555304 SCREW, 1/4-20 x 1.25 zn (models

24A453)

SCREW, 1/4-20 x 1.25 zn (models

24A454)

10 556376 NUT, lock (models 24A453) 3

NUT, lock (models 24A454) 5

11 555355 SCREW, thf hh st 10-32 x .50 zn 6

12 15U116 CAP, filler 2

14 556872 LABEL, name serial 1

15 555318 SCREW, thf ph st 1/4-20 x .75 4

16 15R634 LABEL, logo, "G" 3" X 3" 1

17 556000 PLUG, pipe 1/4 nptf hex drive 2

18 563923 KIT, sightglass, gauge 1

18a SIGHTGLASS, level 1

18b GASKET, level sight glass 1

18c NUT, pal self thd 3

21 555958 SIGHTGLASS, gauge scr type 1

23 562586 BEARING, 5/8” ID, (model 24A454) 2

25 555308 WASHER, flat sst 1

26 555325 KEY, woodruff #2 1

27 555349 PIN, roll st .12 x .62 1

28 555352 SCREW, set cp st 10-24 x .38 1

29 555430 PIN, roll .156 dia 1.50 lg 2

30 555549 RING, retainer -50 basic ext 2

31 555873 BEARING, thr race 6

32 555891 BEARING, rad roller 2

33 555894 COLLAR, lock .50idx1.0odx.44w 1

34 555905 BEARING, thr race 4

35 555907 SEAL, lip lth .50 x 1.00 x .38 1

36 555924 WASHER, fl nob 1

37 556578 SEAL, lip .50 id 1.12 od .25 w 1

39 556782 COLLAR, lock 2

40 556787 ARM, drv 1

41 557008 SPRING, rat drv model 76 2

11

12

36

Ref Part No. Description Qty

42 557023 GEAR, rat 75 tooth 1

43 PAWL 1

44 560041 NUT, bearing lock 1

45 560083 SHAFT, input 1

46 560084 WASHER, race thr .875odx.51x.12 2

3

47 560085 GEAR 1

48 560086 HOUSING, bearing 1

9

49 560087 GEAR, 3.00 pitch dia 1

50 560095 SHAFT, interm dbl redu 1

5

51 560187 SCREW, shldr 1

52 560191 SCREW, shldr 1

53 560207 SPACER 1

54 BRAKE 1

3

55 560292 ARM, ecc drv 1

56 PAWL, drv 1

9

57 562976 BEARING, end 1/2 id 1

58 562977 BEARING, end 5/8 id 2

59 562983 BEARING, oil seal assy 1/2 id lg 1

3

9

313375B 11

Page 12

Parts

283:1 End Rotary Drive Models

Model 24A454 Shown

7

9

16

8

12

15

2

1

11

39

10

23

14

18c

4, 5, 6

page 13

44

1

18b

18a

21

58

17

3

ti12842a

1

Apply Loctite® 515 to cover

Loctite® is a registered trademark of the Loctite Corporation.

12 313375B

Page 13

283:1 End Rotary Drive Models

Exploded View (page 12)

51

42

30

34

39

31

55

29

56

40

34

Parts

31

59

50

47

52

43

36

46

32

41

53

29

48

54

45

37

33

25

58

26, 28, 49

57

30

35

46

313375B 13

Page 14

Side Rotary Drive

Side Rotary Drive

40:1 Models:

24A477, 24A478, 24A481, 24A482, 24A485, 24A486, 24A489, 24A490, 24A493, 24A494,

24A497, 24A498

60:1 Models:

24A479, 24A480, 24A483, 24A484, 24A487, 24A488, 24A491, 24A492, 24A495, 24A496,

24A499, 24A501, 24A502, 24A503, 24A504, 24A505

Ref Part No. Description Qty

1 RESERVOIR 1

2 COVER 1

3 560376 SHAFT, 3 feed, 40:1 (models

24A477, 24A478, 24A481,

24A482), 60:1 (models 24A479,

24A480, 24A483, 24A484)

560377 SHAFT, 6 feed, 40:1 (models

24A485, 24A486, 24A489,

24A490,) 60:1 (models 24A487,

24A488, 24A491, 24A492)

560378 SHAFT, 9 feed, 40:1 (models

24A493, 24A494, 24A497,

24A498,) 60:1 (models 24A495,

24A496, 24A499, 24A501)

560098 SHAFT, 15 feed, 60:1 (models

24A502, 24A503, 24A504, 24A505)

4 560288 CAM, pump, 40:1 (models 24A477,

24A478, 24A481, 24A482), 60:1

(models 24A479, 24A480, 24A483,

24A484)

40:1 (models 24A485, 24A486,

24A489, 24A490,) 60:1 (models

24A487, 24A488, 24A491, 24A492)

40:1 (models 24A493, 24A494,

24A497, 24A498,) 60:1 (models

24A495, 24A496, 24A499, 24A501)

60:1 (models 24A502, 24A503,

24A504, 24A505)

5 555377 KEY, #3 USA 404 woodruff, 40:1

(models 24A477, 24A478, 24A481,

24A482), 60:1 (models 24A479,

24A480, 24A483, 24A484)

40:1 (models 24A485, 24A486,

24A489, 24A490,) 60:1 (models

24A487, 24A488, 24A491, 24A492)

40:1 (models 24A493, 24A494,

24A497, 24A498,) 60:1 (models

24A495, 24A496, 24A499, 24A501)

60:1 (models 24A502, 24A503,

24A504, 24A505)

15

11

17

Ref Part No. Description Qty

6 555326 SCREW, set cp 1/4-20 x .25, 40:1

(models 24A477, 24A478, 24A481,

1

1

1

7 555899 PLATE, blank unit, 40:1 (models

1

3

6

9

8 555947 GASKET, pumping unit, 40:1 (mod-

5

8

9 555304 SCREW, 1/4-20 x 1.25 zn, 40:1

24A482), 60:1 (models 24A479,

24A480, 24A483, 24A484)

40:1 (models 24A485, 24A486,

24A489, 24A490,) 60:1 (models

24A487, 24A488, 24A491, 24A492)

40:1 (models 24A493, 24A494,

24A497, 24A498,) 60:1 (models

24A495, 24A496, 24A499, 24A501)

60:1 (models 24A502, 24A503,

24A504, 24A505)

24A477, 24A478, 24A481,

24A482), 60:1 (models 24A479,

24A480, 24A483, 24A484)

40:1 (models 24A485, 24A486,

24A489, 24A490,) 60:1 (models

24A487, 24A488, 24A491, 24A492)

40:1 (models 24A493, 24A494,

24A497, 24A498,) 60:1 (models

24A495, 24A496, 24A499, 24A501)

60:1 (models 24A502, 24A503,

24A504, 24A505)

els 24A477, 24A478, 24A481,

24A482), 60:1 (models 24A479,

24A480, 24A483, 24A484)

40:1 (models 24A485, 24A486,

24A489, 24A490,) 60:1 (models

24A487, 24A488, 24A491, 24A492)

40:1 (models 24A493, 24A494,

24A497, 24A498,) 60:1 (models

24A495, 24A496, 24A499, 24A501)

60:1 (models 24A502, 24A503,

24A504, 24A505)

(models 24A477, 24A478, 24A481,

24A482), 60:1 (models 24A479,

24A480, 24A483, 24A484)

3

6

9

15

3

6

9

15

3

6

9

15

12

14 313375B

Page 15

Side Rotary Drive

Ref Part No. Description Qty

40:1 (models 24A485, 24A486,

24

24A489, 24A490,) 60:1 (models

24A487, 24A488, 24A491, 24A492)

40:1 (models 24A493, 24A494,

36

24A497, 24A498,) 60:1 (models

24A495, 24A496, 24A499, 24A501)

60:1 (models 24A502, 24A503,

60

24A504, 24A505)

10 556376 NUT, lock, 40:1 (models 24A477,

24A478, 24A481, 24A482), 60:1

(models 24A479, 24A480, 24A483,

24A484)

40:1 (models 24A485, 24A486,

24A489, 24A490,) 60:1 (models

24A487, 24A488, 24A491, 24A492)

40:1 (models 24A493, 24A494,

24A497, 24A498,) 60:1 (models

24A495, 24A496, 24A499, 24A501)

60:1 (models 24A502, 24A503,

24A504, 24A505)

11 555355 SCREW, thf hh st 10-32 x .50 zn 4

12 15U116 CAP, filler 1

14 556872 LABEL, name serial 1

15 555318 SCREW, thf ph st 1/4-20 x .75 2

16 15R634 LABEL, logo, "G" 3" x 3" 1

17 556000 PLUG, pipe 1/4 nptf hex drive 1

18 563923 KIT, sightglass, gauge 1

18a SIGHTGLASS, level 1

18b GASKET, level sight glass 1

18c NUT, pal self thd 3

22 556929 LABEL, cw ccw rotn 1

23 562586 BEARING, 5/8” ID 40:1 (models

24A485, 24A486, 24A489,

24A490,) 60:1 (models 24A487,

24A488, 24A491, 24A492)

40:1 (models 24A493, 24A494,

24A497, 24A498,) 60:1 (models

24A495, 24A496, 24A499, 24A501)

60:1 (models 24A502, 24A503,

24A504, 24A505)

24 560364 SHAFT, drv f/r rot 1

25 555328 SCREW, set cp 5/16-18 x .25 1

26 555530 SCREW, set 1/4-20 x.187 soc cup 1

27 555877 GEAR, worm whl 40:1 (models

24A477, 24A478, 24A481, 24A482,

24A485, 24A486, 24A489, 24A490,

24A493, 24A494, 24A497, 24A498

555880 GEAR, worm whl 60:1 (models

24A479, 24A480, 24A483, 24A484,

24A4887, 24A488, 24A491,

24A492, 24A495, 24A496, 24A499,

24A501, 24A502, 24A503, 24A504,

24A505

Ref Part No. Description Qty

28 555879 GEAR, worm 40:1 (models

24A477, 24A478, 24A481, 24A482,

24A485, 24A486, 24A489, 24A490,

24A493, 24A494, 24A497, 24A498

555883 GEAR, worm 60:1 (models

24A479, 24A480, 24A483, 24A484,

24A4887, 24A488, 24A491,

24A492, 24A495, 24A496, 24A499,

4

24A501, 24A502, 24A503, 24A504,

24A505

29 555904 BEARING, thr roller 2

30 555905 BEARING, thr race 8

31 556578 SEAL, lip .50 id 1.12 od .25 w 1

5

32 556751 GASKET, end brg 1

33 556782 COLLAR, lock 2

34 560210 SPACER,. 510 id x .75 od x .25 lg 1

6

35 560211 SPACER,. 510 id x .75 od 1

36 562590 BEARING, assy 1 / id short 1

37 562976 BEARING, end 1/2 id 1

8

38 562977 BEARING, end 5/8 id 2

1

2

4

1

1

1

1

313375B 15

Page 16

Side Rotary Drive

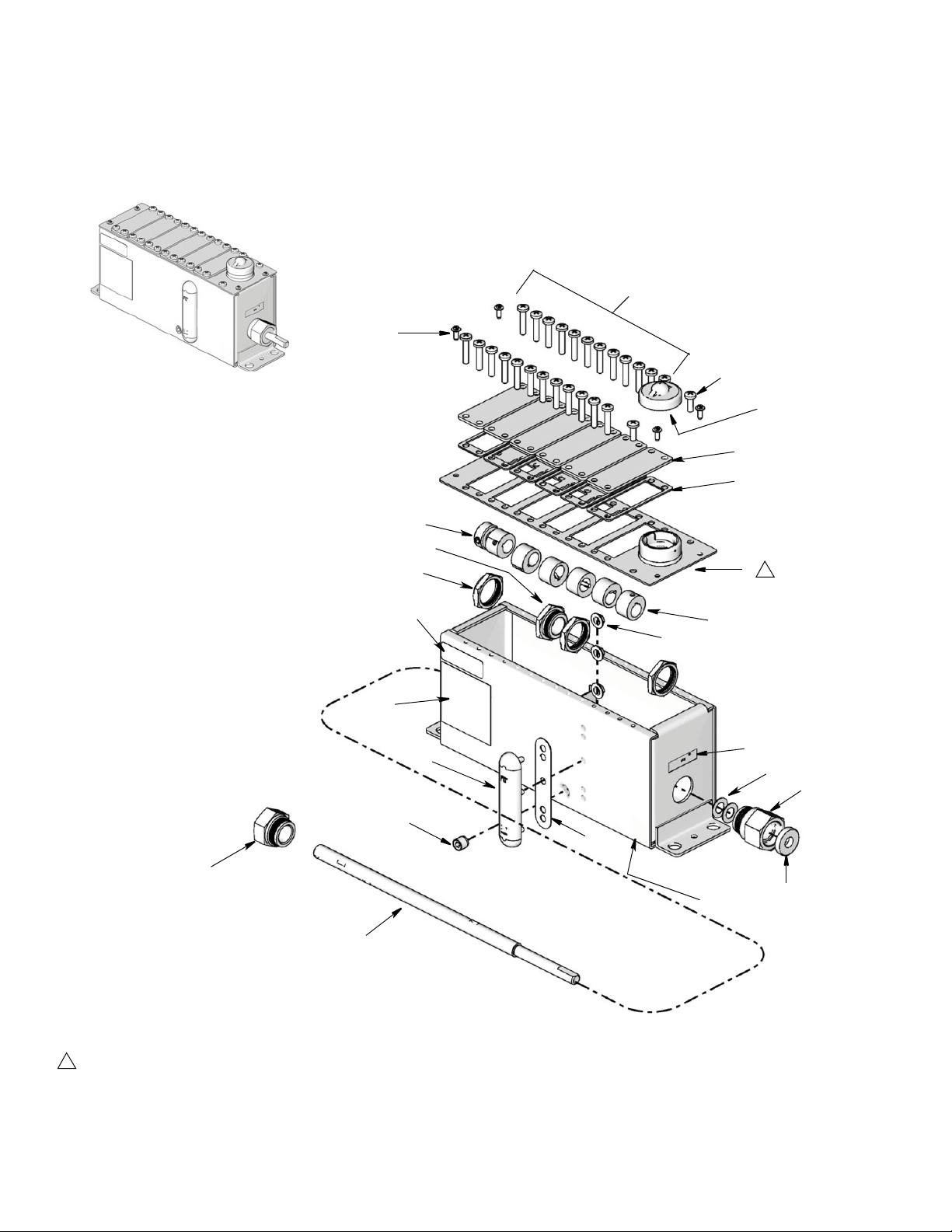

40:1 / 60:1 Side Rotary Drive Models

Model 24A488 Shown

33

4, 5, 6

10

23

18c

9

15

11

12

7

8

1

2

27

14

16

18b

18a

38

3

1

Apply Loctite® 515 to cover

Loctite® is a registered trademark of the Loctite Corporation.

24

17

31

36

32

37

30

29

30

35

28

34

30

29

30

22

38

1

ti12846a

16 313375B

Page 17

Bottom Rotary Drive

1:1 Model 24A506, 24A508

2.5:1 Models: 24A507, 24A509

Bottom Rotary Drive

Ref Part No. Description Qty

1 RESERVOIR 1

2 COVER 1

3 560374 SHAFT, 3 feed, cam (models

24A506, 24A507)

560375 SHAFT, 6 feed, cam (models

24A508, 24A509)

4 560288 CAM, pump (models 24A506,

24A507)

(models 24A508, 24A509) 6

5 555377 KEY, #3 USA 404 woodruff (models

24A506, 24A507)

(models 24A508, 24A509) 7

6 555326 SCREW, set cp 1/4-20 x .25 (mod-

els 24A506, 24A507)

(models 24A508, 24A509) 6

7 555899 PLATE, blank unit (models 24A506,

24A507)

(models 24A508, 24A509) 6

8 555947 GASKET, pumping unit (models

24A506, 24A507)

(models 24A508, 24A509) 6

9 555304 SCREW, 1/4-20 x 1.25 zn (models

24A506, 24A507)

(models 24A508, 24A509) 24

10 556376 NUT, lock (model 24A506, 24A507) 3

(model 24A508, 24A509) 4

11 555355 SCREW, thf hh st 10-32 x .50 zn 4

12 15U116 CAP, filler 1

14 556872 LABEL, name serial 1

15 555318 SCREW, thf ph st 1/4-20 x .75 2

16 15R634 LABEL, logo, "G" 3" x 3" 1

17 556000 PLUG, pipe 1/4 nptf hex drive 1

18 563923 KIT, sightglass, gauge 1

18a SIGHTGLASS, level 1

18b GASKET, level sight glass 1

18c NUT, pal self thd 3

22 556927 LABEL, cw rotn 1

23 562586 BEARING, 5/8” ID (model 24A508,

24A509)

24 560362 SHAFT, drv bot rot 2.50 ext 1

25 555357 SCREW, hh st 1/4-20x.500 zn 4

26 555549 RING, retainer -50 basic ext 2

27 555735 SEAL, wshr 4-20 thd 4

28 555904 BEARING, thr roller 2

29 555905 BEARING, thr race 14

30 556355 BEARING, flng 1

31 556578 SEAL, lip .50 id 1.12 od .25 w 2

32 556751 GASKET, end brg 2

33 556782 COLLAR, lock 1

34 556794 ROLLER, clutch 1

35 558839 GEAR, helical drv shaft 1:1

(models 24A506, 24A508)

12

Ref Part No. Description Qty

557013 GEAR, helical drv shaft 2.5:1 (mod-

els 24A507, 24A509)

36 560077 SPACER, .75od x .51id x .187 lg 1

1

37 560078 SPACER, .75od x .51id x 1.06lg 1

38 560147 SUPPORT, drive 1

1

39 560212 SPACER, .510 id x .75 od 1

40 561347 GEAR, helical camshaft 1:1 (mod-

3

560300 GEAR, helical camshaft 2.5:1

4

41 562590 BEARING, assy 1 / id short 2

42 562977 BEARING, end 5/8 id 1

3

3

3

1

1

els 24A506, 24A508)

(models 24A507, 24A509)

1

1

1

313375B 17

Page 18

Bottom Rotary Drive

1:1 / 2.5:1 Bottom Rotary Drive Models

Model 24A509 Shown

9

15

11

12

7

18a

33

4, 5, 6

10

14

16

18b

23

17

25

27

8

29

18c

34

35

37

29

1

32

29

1

2

31

26

30

28

41

27

36

38

40

29

39

28

25

41

42

3

1

Apply Loctite® 515 to cover

Loctite® is a registered trademark of the Loctite Corporation.

18 313375B

26

29

31

24

ti12848a

Page 19

Notes

Notes

313375B 19

Page 20

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective par ts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 313375

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2009, Graco Inc. is registered to ISO 9001

www.graco.com

6/2009

Loading...

Loading...