Page 1

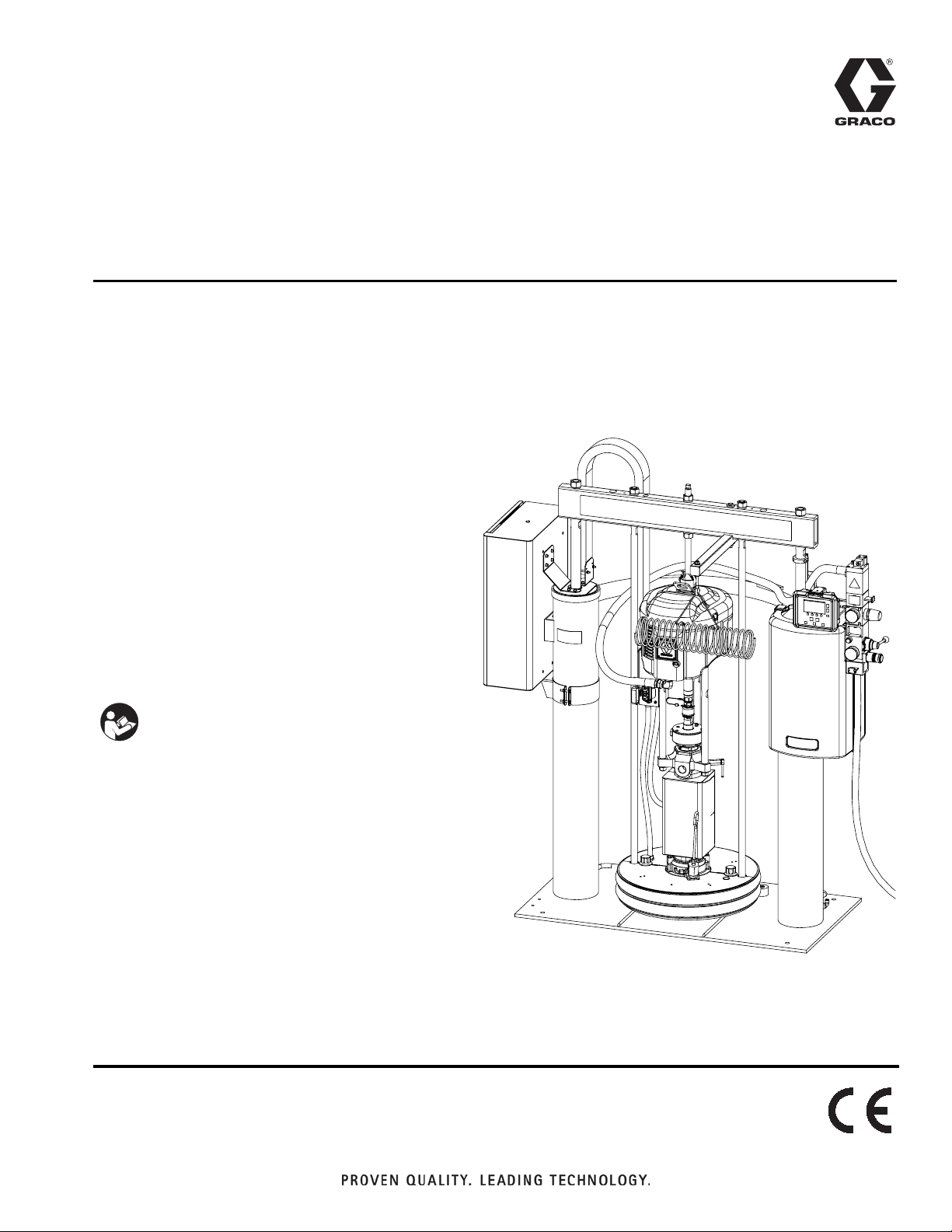

Instructions - Parts

Warm Melt Supply

313296J

Systems

For use with heated bulk supply of medium to high viscosity sealant and adhesive

materials. Not for use in hazardous locations. Intended for indoor use only.

D60 3 inch dual post

60 liter (16 gallon), 30 liter (8 gallon), and

20 liter (5 gallon) sizes

150 psi (1.0 MPa, 10 bar) Maximum Air Inlet Pressure

D200 3 inch dual post

200 liter (55 gallon)

150 psi (1.0 MPa, 10 bar) Maximum Air Inlet Pressure

EN

D200S 6.5 inch dual post

200 liter (55 gallon)

125 psi (0.9 MPa, 9 bar) Maximum Air Inlet Pressure

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

See page 4 for model information.

The Graco Control Architecture Electric Components

are listed in Intertek’s Directory of Listed Products.

D200s (WM2179) Shown

Page 2

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Heat Control Zone Selection . . . . . . . . . . . . . . . . . . . . . 7

Component Identification . . . . . . . . . . . . . . . . . . . . . . . . . 8

Single Supply Systems . . . . . . . . . . . . . . . . . . . . . . . . . 8

Tandem Supply Systems . . . . . . . . . . . . . . . . . . . . . . .9

Integrated Air Controls . . . . . . . . . . . . . . . . . . . . . . . . 10

Air Line Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-Button Interlock Air Controls . . . . . . . . . . . . . . . . . . 11

Communications Gateway Module . . . . . . . . . . . . . . . 11

Fluid Control Module . . . . . . . . . . . . . . . . . . . . . . . . . . 12

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Location Requirements . . . . . . . . . . . . . . . . . . . . . . . . 17

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Connect Power Source . . . . . . . . . . . . . . . . . . . . . . . . 18

Install/Adjust Drum Low or Empty Sensor . . . . . . . . . 19

Light Tower Accessory . . . . . . . . . . . . . . . . . . . . . . . . 19

Attach Drum Stops . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Check Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Hose Installation and Care . . . . . . . . . . . . . . . . . . . . . 23

Overview of Temperature Control Settings . . . . . . . . . 23

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Purge System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Set Values on Display Module . . . . . . . . . . . . . . . . . . 24

Load Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

System Heat Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Prime . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . . . 28

Trigger Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Start and Adjust Ram . . . . . . . . . . . . . . . . . . . . . . . . . 28

Start and Adjust Pump . . . . . . . . . . . . . . . . . . . . . . . . 28

Automatic Crossover . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Manual Crossover . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Recirculate Function . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Depressurize Function . . . . . . . . . . . . . . . . . . . . . . . . 30

Change Drums . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Replace Throat Seals . . . . . . . . . . . . . . . . . . . . . . . . . 32

Platen Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Electrical Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Pump Heaters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Diagnose Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Clear Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Alarm Codes and Troubleshooting . . . . . . . . . . . . . . . 36

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Air Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Displacement Pump . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Disconnect Pump from Platen . . . . . . . . . . . . . . . . . . 50

Connect Pump to Platen . . . . . . . . . . . . . . . . . . . . . . . 51

Replace Pump Heaters . . . . . . . . . . . . . . . . . . . . . . . 51

Replace Platen Heaters and Sensor . . . . . . . . . . . . . 52

Replace Platen Wipers . . . . . . . . . . . . . . . . . . . . . . . . 54

Replace Ram Piston Rod Seals . . . . . . . . . . . . . . . . . 54

Electrical Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Display/User Interface . . . . . . . . . . . . . . . . . . . . . . . . 58

Replace Fluid Control Module . . . . . . . . . . . . . . . . . . 59

Replace Cable Track . . . . . . . . . . . . . . . . . . . . . . . . . 60

Electrical Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Ram A Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

D200 Single Ram Schematic . . . . . . . . . . . . . . . . . . . 61

D200 Ram A Schematic . . . . . . . . . . . . . . . . . . . . . . . 62

D200 Ram B Schematic . . . . . . . . . . . . . . . . . . . . . . . 63

D200 Displacement Pump and Platen Schematics . . 64

D200 Junction Box Schematic . . . . . . . . . . . . . . . . . . 65

D200 Cable Track Schematic . . . . . . . . . . . . . . . . . . . 66

D60 Single Ram Schematic . . . . . . . . . . . . . . . . . . . . 67

D60 Ram A Schematic . . . . . . . . . . . . . . . . . . . . . . . . 68

D60 Ram B Schematic . . . . . . . . . . . . . . . . . . . . . . . . 69

D60 Pump and Platen Schematic . . . . . . . . . . . . . . . . 70

D60 Junction Box Schematic . . . . . . . . . . . . . . . . . . . 71

D60 Cable Harness Schematic . . . . . . . . . . . . . . . . . 72

Electrical Enclosure Schematic . . . . . . . . . . . . . . . . . 73

Electrical Enclosure Schematic . . . . . . . . . . . . . . . . . 74

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Warm Melt Kits for D200 Systems . . . . . . . . . . . . . . . 78

Warm Melt Kits for D60 Systems . . . . . . . . . . . . . . . . 83

Electrical Enclosure Parts . . . . . . . . . . . . . . . . . . . . . . 90

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Appendix A - User Interface Display . . . . . . . . . . . . . . . 93

Display Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Display Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Setup Mode Screens . . . . . . . . . . . . . . . . . . . . . . . . . 95

Run Mode Screens . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

D200 Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

D60 Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . . . . . 108

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

2 313296J

Page 3

Related Manuals

Manuals are available at www.graco.com.

Component Manuals in U.S. English:

Manual Description

313528 Tandem Supply Systems Operation

313529 Tandem Supply Systems Repair-Parts

313526 Supply Systems Operation

313527 Supply Systems Repair-Parts

Check-Mate

312375

Instructions-Parts

Check-Mate

312376

312468

311238 NXT

Instruction-Parts

200 cc Check-Mate Displacement Pump

Repair Parts

™

312374 Air Controls Instructions-Parts

3A0099

3A0100

Two-Zone Enclosure Expansion Kit

Instructions-Parts

Two-Zone and Four-Zone Enclosure

Accessory Kits Instructions-Parts

3A0135 Bracket Mounting Kits Parts

®

Displacement Pumps

®

Pump Packages

Air Motor Instructions-Parts

Related Manuals

312491 Pump Fluid Purge Kit Instructions

312492 Drum Roller Kit Instructions

312493 Light Tower Kit Instructions

309160 Heated Hose Instructions-Parts

312396

Hotmelt/Warm Melt Heated Fluid Regulator Instructions-Parts

307517 Mastic Fluid Regulator Instructions-Parts

309133

309181

311209

310538

309376

312864

Pressure Compensating Valve

Instructions-Parts

Heated Header and Manifold

Instructions-Parts

Hot Melt Dispense Guns

Instructions-Parts

Therm-O-Flow

®

Automatic Dispense

Valves Instructions-Parts

™

EnDure

Automatic Dispense Valves

Instructions-Parts

Communications Gateway Module

Instructions-Parts

Supply System Communications Gate-

313138

way Module Installation Kit Instructions-Parts

406681 Platen Cover Kit Instructions

313296J 3

Page 4

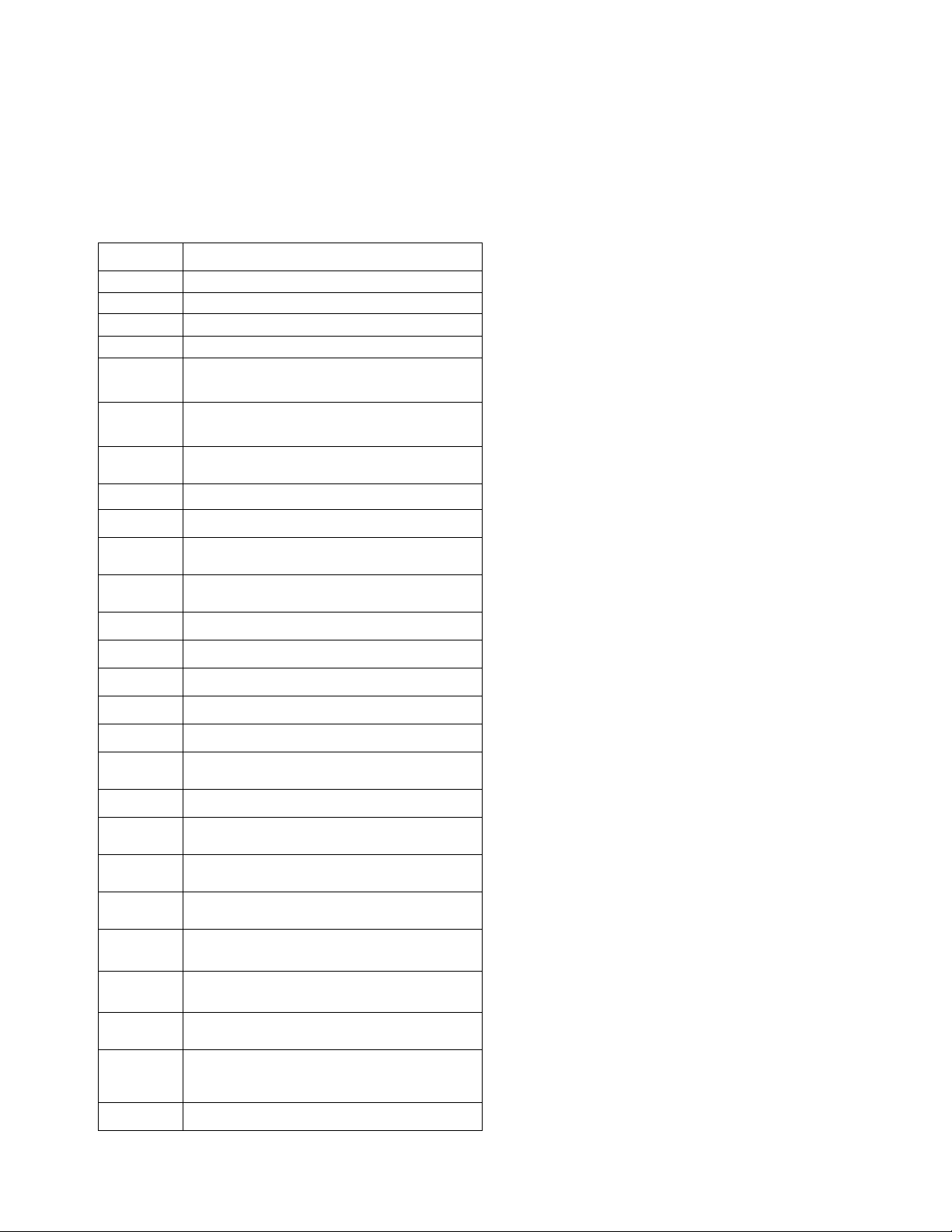

Models

Models

Check the identification plate (ID) for the 6-digit part number of your warm melt

supply system. Use the following matrix to define the construction of your system,

based on the six digits. For example, Part No. WM2979 represents a Warm Melt

supply system (WM), a carbon steel Check-Mate 200 Severe Duty

pump with an NXT 3400 air motor (pump code 29), a 6.5 in. dual post ram with

integrated air controls (7) and a 55-gallon, uncoated platen with an EPDM seal

(9).

NOTE: Some configurations in the following matrix cannot be built. See the

Product Selection guide for available systems.

®

displacement

ID

To order replacement parts, see Parts section in this manual and in manual

313527. The digits in the matrix do not correspond to the Ref. Nos. in the Parts

drawings and lists.

WM 29 7

First and

Second Digit

WM

(Warm Melt

Single Supply

System)

TW

(Warm Melt

Tandem

Supply

System)

Third and

Fourth Digit Fifth Digit

Ram Options

DataTra

Pump Code

Size Style

k

Voltage Air Controls

4 3 in. D60 no volt INT

5 3 in. D200 no volt INT

6 3 in D200i no volt

(See Table 1

for 2-digit

Pump Code)

7 6.5 in. D200s no volt INT

8 6.5 in. D200si no volt

Y 3 in. D60i no volt

2-Button

Interlock

2-Button

Interlock

2-Button

Interlock

F

H

L

R

U

Y

8

9

TI11157A

9

Sixth Digit

Platen and Seal Options

Platen

Size

20 L

(5 Gal) F, SW SST

20 L

(5 Gal) F, DW CS

30 L

(8 Gal) F, SW SST

30 L

(8 Gal) F, DW CS

60 L

(16 Gal) F, SW SST

60 L

(16 Gal) F, DW CS

200 L

(55 Gal) DR

200 L

(55 Gal) DR AL EPDM

Platen

Style

Platen

Material

PTFE

coated

AL EPDM

Seal

Material

PTFE

coated

Polyure-

thane

PTFE

coated

Polyure-

thane

PTFE

coated

Polyure-

thane

Key:

D = Dual post ram

i = 2-Button interlock

s = 6.5 in. ram

INT = Integrated air controls

F = Flat

SW = Single wiper

DW = Dual wiper

DR = Dual o-ring

4 313296J

Table 1: Check-Mate Pump Identification Code/Part

Pump

Code

NXT 2200/CM 200 NXT 6500/CM 200

NXT 3400/CM 200

Pump Part No. (see

manual 312376)

21 P23LCS 2L P68LCS

22 P23LCM 2M P68LCM

26 P23LSM 2U P68LSM

29 P36LCS

2A P36LCM

2G P36LSM

Pump

Code

Pump Part No. (see

manual 312376)

Page 5

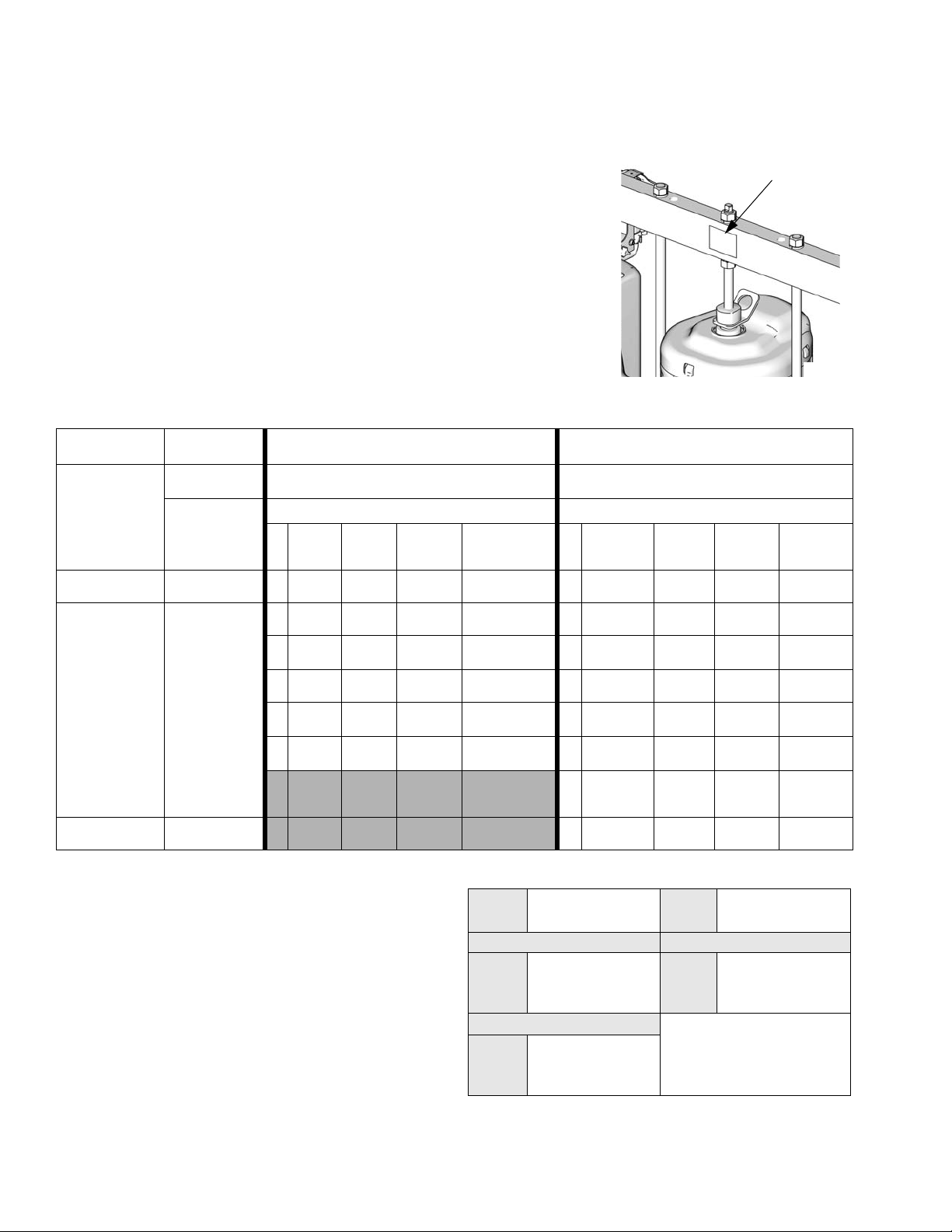

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause

electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe

burns:

• Do not touch hot fluid or equipment.

• Wait until equipment/fluid has cooled completely.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the dispense outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

•Follow Pressure Relief Procedure in this manual, when you stop dispensing and before cleaning,

checking, or servicing equipment.

313296J 5

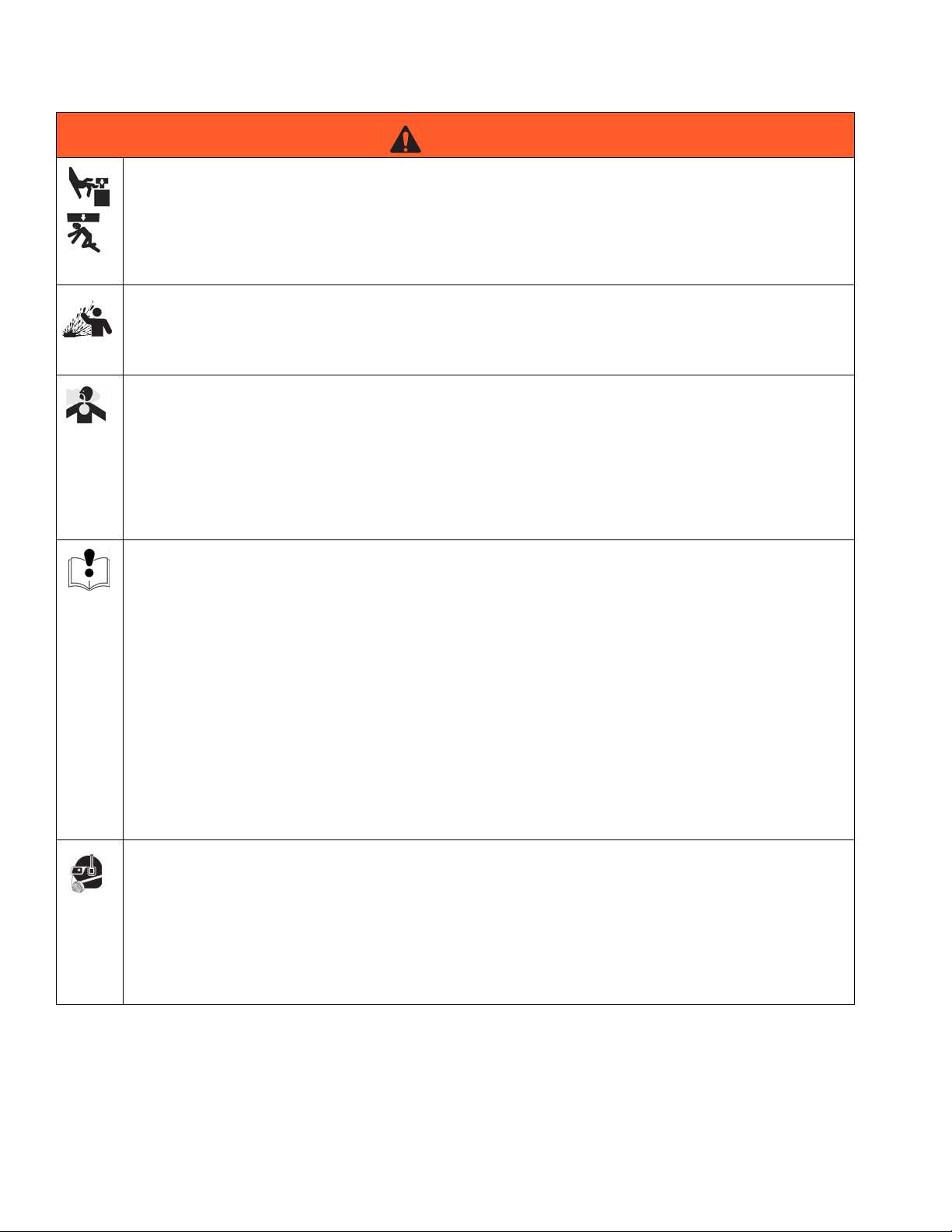

Page 6

Warnings

WARNING

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

SPLATTER HAZARD

Hot or toxic fluid can cause serious injury if splashed in the eyes or on skin. During blow off of platen,

splatter may occur.

• Use minimum air pressure when removing platen from drum.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear impervious gloves when spraying or cleaning equipment.

• If this equipment is used with isocyanate material, see additional information on isocyanates in Isocyanate Conditions Section of this manual.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Do not leave the work area while equipment is energized or under pressure. Turn off all equipment

and follow the Pressure Relief Procedure in this manual when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

6 313296J

Page 7

Overview

Overview

System Description

Warm melt supply systems are used for melting and

pumping warm melt adhesives and high viscosity sealants.

The system consists of an air-powered ram that drives a

Check-Mate pump and a heated platen into a drum of

material. The heated platen heats the material and the

pump removes it from the drum. The material is then

pushed through a supply hose to the applicator.

All features of the warm melt supply system are controlled by Graco Control Architecture components: Fluid

Control Module (FCM), Temperature Control Modules

(TCM), and the display module. The FCM controls the

motor and pump, and the TCMs control the heaters. The

display module provides the user interface for the entire

warm melt supply system.

Power Requirements

A 30A (minimum) - 60A (maximum) circuit breaker (not

provided) must be installed on the incoming power supply. See Table 1, and Technical Data, page 106, for

more information regarding electrical requirements.

Table 1: Electrical Requirements

AC Panel

Voltage HZ Phase

240 50/60 1 57.0

Full Load

Amps

Heat Control Zone Selection

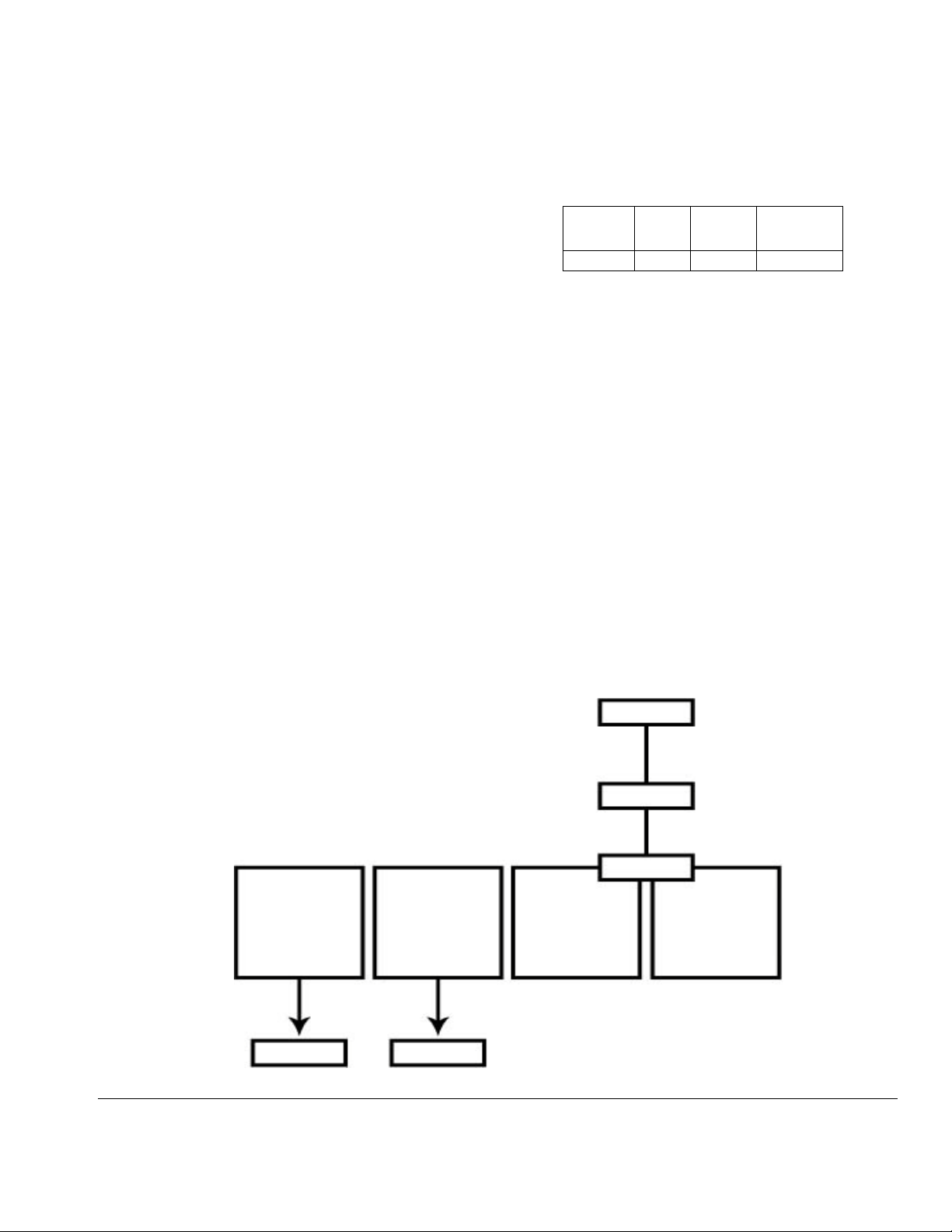

Warm melt supply systems have four heat zones (see

F

IG

. 1).

• Zones 1 and 2 are always used for the heated

platen and the heated pump respectively.

• Zones 3 and 4 are used for the heated hose and

valve. These zones are rated for 1920 watts at 240

volts.

Heated hoses have a 16-pin connector on the inlet end

cable, and an 8-pin connector on the outlet end cable.

All heated valves, manifolds, and heaters are equipped

with an 8-pin matching connector. Accessory cables are

available for other possible combinations.

ZONE 1

Control

Platen

FIG. 1: Heat Control Zone Selection

ZONE 2

Control

Pump

Valve 1

ZONE 3

Control

1920 Watts max

Hose 1

ZONE 4

Control

1920 Watts max

313296J 7

Page 8

Component Identification

Component Identification

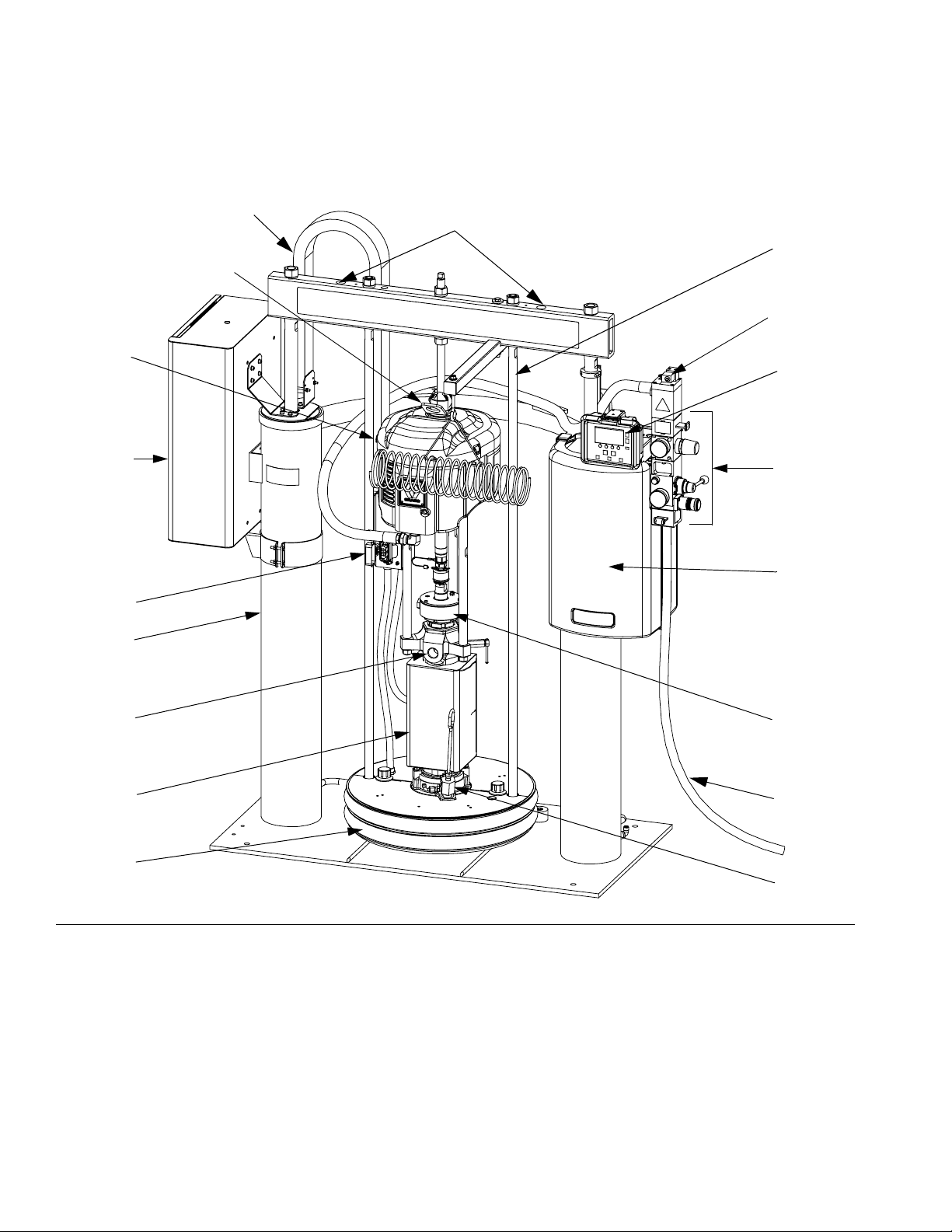

Single Supply Systems

D200s Ram Shown

AF

S

Lift Locations

NOTE: Do not

use air motor lift

ring (S) to lift

entire system.

V

AD

C

H

AE

G

J

K

A

U

D

X

Z

E

T

FIG. 2: Single Supply System

Key:

ARam Assembly

C Air Motor

D Heated Check-Mate Displacement Pump

E Heated Platen

G Display Module

H Electrical Enclosure

IG

J Integrated Air Controls (see F

K Fluid Control Module (inside shroud)

S Lift Ring (air motor)

T Platen Bleed Port

U Pump Outlet

8 313296J

. 4)

V Platen Lift Rod

XWet Cup

Z Main Air Line (not supplied)

AD Air Motor Solenoid

AE Junction Box

AF Cable Track

Page 9

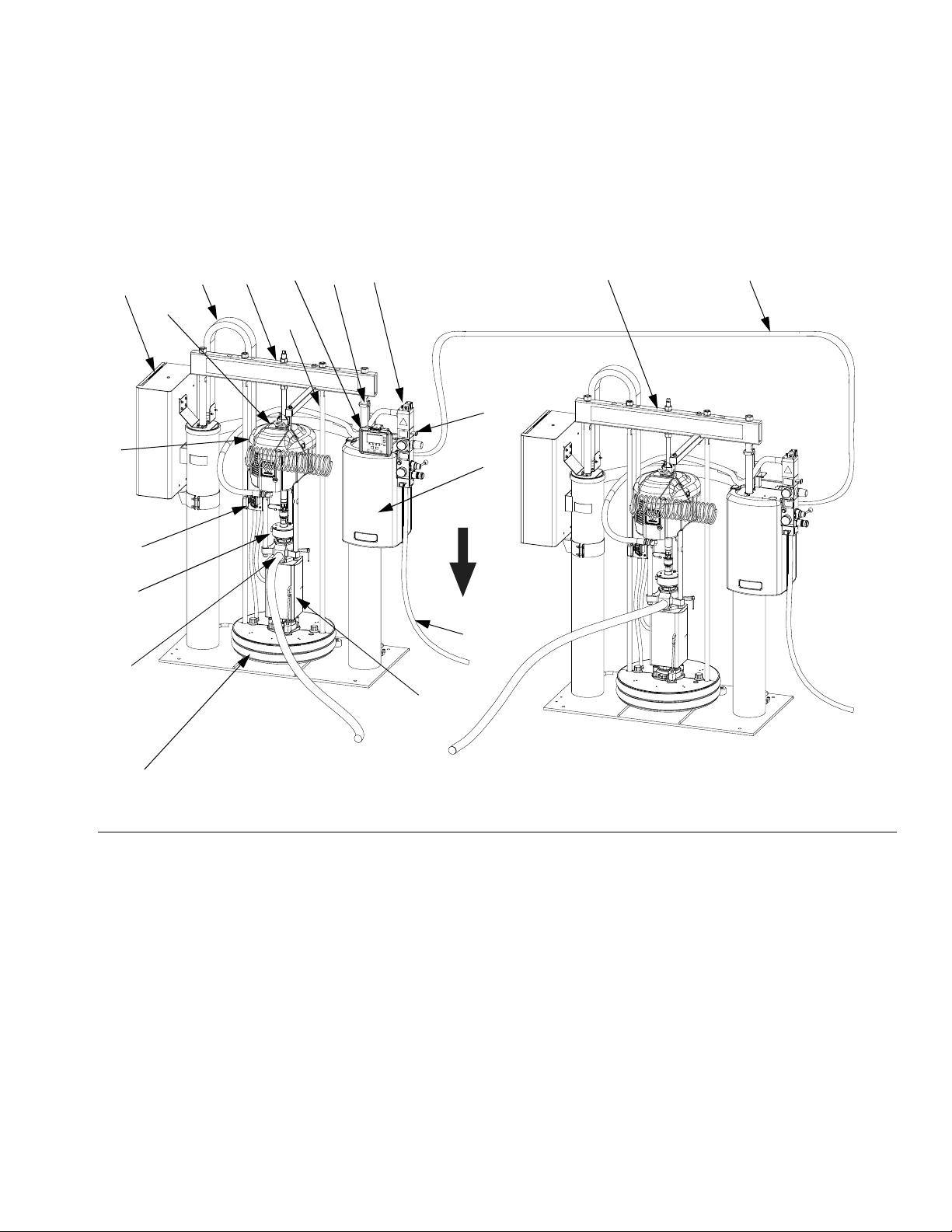

Tandem Supply Systems

D200s Rams Shown

Component Identification

Supply System A

A

H

AF

G

AD

F

Supply System B

B

N

S

V

J

C

K

AE

To heated

X

manifold

(243697)

Z

U

D

E

FIG. 3: Tandem Supply System

Key:

ARam A

BRam B

C Air Motor

D Heated Check-Mate Displacement Pump (Ram A and B)

E Heated Platen (Ram A and B)

F Drum Empty Sensor (partially hidden; Ram A and B)

G Display Module (Ram A only)

H Electrical Enclosure (Ram A and B)

J Integrated Air Controls (Ram A and B); see page 10

K Fluid Control Module (inside shroud, Ram A and B)

N CAN Communication Cable

S Lift Ring (Air Motor)

T Platen Bleed Port

U Pump Outlet

V Platen Lift Rod

r_wm2179_313269_4a

XWet Cup

Z Main Air Line (not supplied)

AD Air Motor Solenoid (Ram A and B)

AE Junction Box (Ram A and B)

AF Cable Track (Ram A and B)

313296J 9

Page 10

Component Identification

NOTE:

See F

IG

. 2 and FIG. 3. Before you install the system,

you should be familiar with the following components.

Reference numbers and letters in parentheses in the

text refer to the callouts in the figures.

Both rams (A and B) include a Check-Mate Pump (D),

platen (E), integrated air controls (J), drum empty sensor (F), and fluid control module (K).

Only Ram A includes the display module (G).

• Drum empty sensor (F). Signals drum empty condi-

tion. See F

IG

. 11, page 19.

• Display module (G). Mounted on Ram A only. Pro-

vides Run Mode status screens, Setup screens, and

control keys. See F

• Fluid control module (K). See F

• Integrated air controls (J). See F

IG

. 8, page 13.

IG

. 7, page 12.

IG

. 4.

• Air motor solenoid (AD). Solenoid is on when the

selected ram is on and in Run Mode, Recirculate

Mode, or Prime Mode. Solenoid is off when system

is shut off or when in Depressurize Mode, or the ram

is in an Inactive Ready Mode. The solenoid LED will

illuminate when the solenoid is on.

• Depressurize/recirculate fluid valve. Depressurizes

system when Depressurize Mode is active. Recirculates fluid when Recirculate Mode is active.

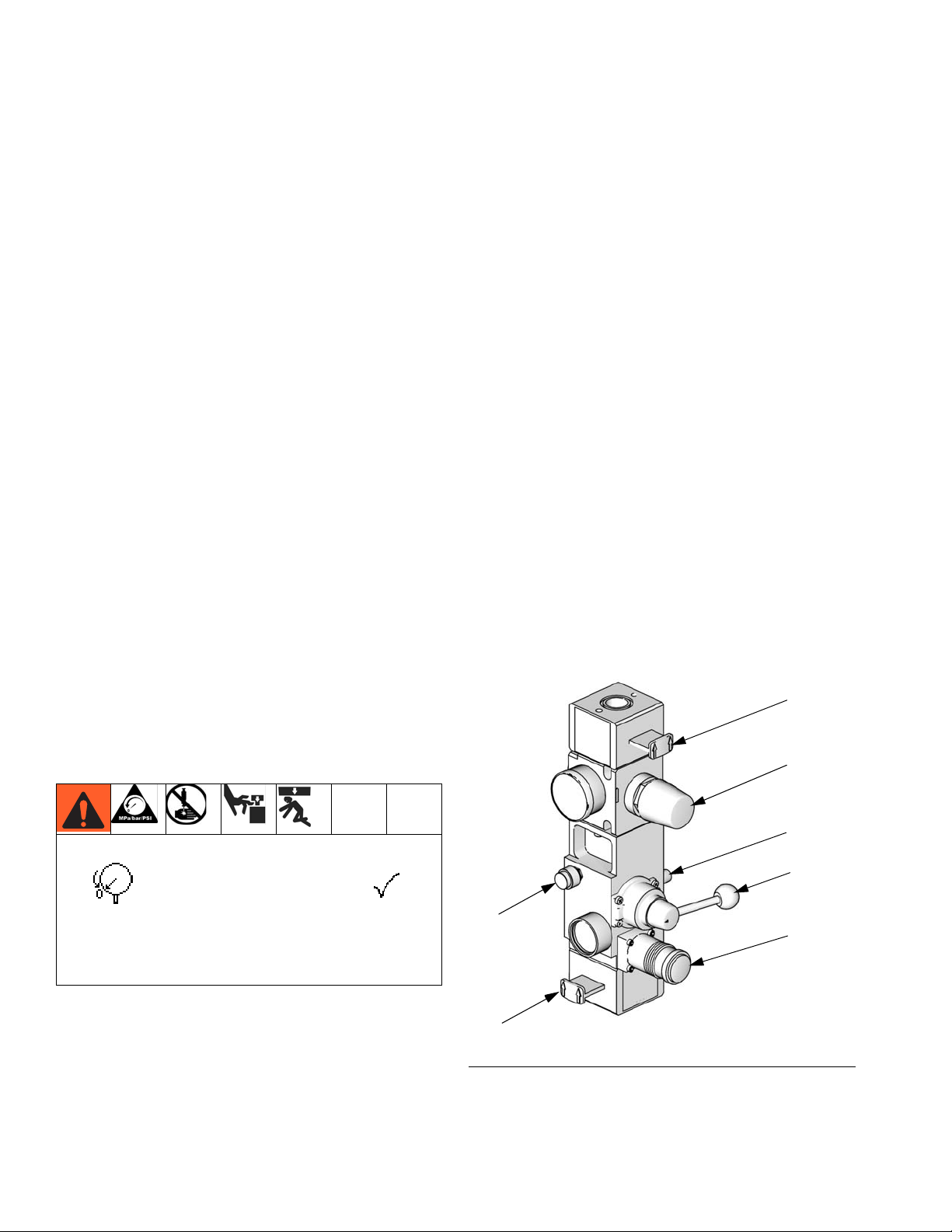

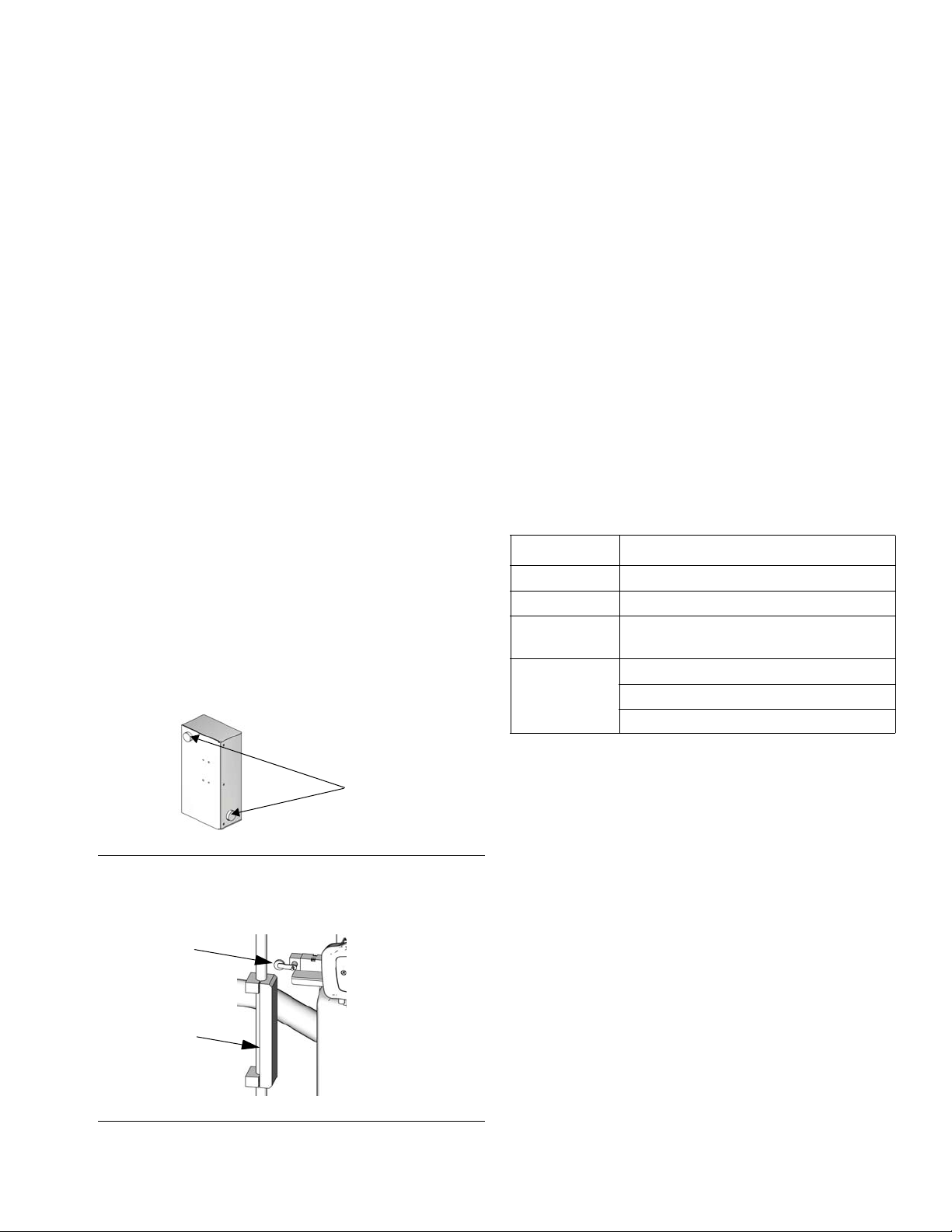

Integrated Air Controls

D60, D200, and D200s Models

The integrated air controls include:

• Main air slider valve (BA): turns air on and off to

the system. When closed, the valve relieves pressure downstream.

• Ram air regulator (BB): controls ram up and down

pressure and blowoff pressure.

• Ram director valve (BC): controls ram direction.

• Exhaust port with muffler (BD)

• Air motor regulator (BE): Controls air pressure to

motor.

• Air motor slider valve (BF): turns air on and off to

the air motor. When closed, the valve relieves air

trapped between it and the air motor. Push the valve

in to shutoff. The air solenoid (AD), the air motor

valve (BF), and the main air slider valve (BA) must

be open for air to flow.

• Blowoff button (BG): turns air on and off to push

the platen out of an empty drum.

BF

BE

To depressurize the system, press the Depressurize

BD

key on the display module and select

when asked if you want to depressurize the system.

Follow the Pressure Relief Procedure on page 28.

BG

BC

BB

Shutting off power or removing power from the system will not depressurize the system.

BA

ti10438a

FIG. 4. Integrated Air Controls

10 313296J

Page 11

Component Identification

Air Line Accessories

See Supply Systems Operation manual.

• Air line drain valve. Not included.

• Air line filter: removes harmful dirt and moisture

from compressed air supply. Not included.

• Second bleed-type air valve isolates air line

accessories and supply system for servicing. Locate

upstream from all other air line accessories. Not

included.

• Air relief valve: automatically relieves excessive

pressure. Not included.

2-Button Interlock Air Controls

D60i, D200i, and D200si Models

Systems that have 2-Button Interlock controls have the

following additional components:

Communications Gateway Module

The Communications Gateway Module (CGM) provides

a control link between Graco Control Architecture based

systems and a selected fieldbus. This provides the

means for remote monitoring and control by external

automation systems.

Data provided by the CGM to the fieldbus depends on

which Graco Control Architecture based system and

fieldbus are connected. A data map supplied on a map

token is defined for this pairing. Once the data map has

been loaded into the CGM, it is stored internally, and the

map token is no longer required for operation.

See the Supply System Communications Gateway Module Installation Kit manual for fieldbus parameter setup

instructions and screen descriptions.

CGM Module Status LED Signals

Signal Description

• 2-Button Module: See the Air Controls manual for

information.

• Roller switch (CA): shuts off air supply when it

contacts the bracket actuator. Operator must push

and hold the activation buttons simultaneously to

resume ram movement.

Activation

Buttons

ti10843a1

F

IG

. 5: 2-Button Module

• Bracket actuator (CB): attaches to the platen lift

rod. When platen is outside of drum, actuator makes

contact with the roller switch.

CA

Green on System is powered up

Yellow Internal communication in progress

Red

Solid

*Red

(7 flashes)

* The red LED will flash a code, pause, then repeat.

See Communications Gateway Module manual

312864 for diagnostic information. Verify that you are

using the correct token for your system and reinstall

token. If fails, order new token.

CGM hardware failure

Data map load failure

Incorrect data map for fieldbus type

No data map loaded

CB

ti10846a

IG

. 6: Roller Switch and Bracket Actuator

F

313296J 11

Page 12

Component Identification

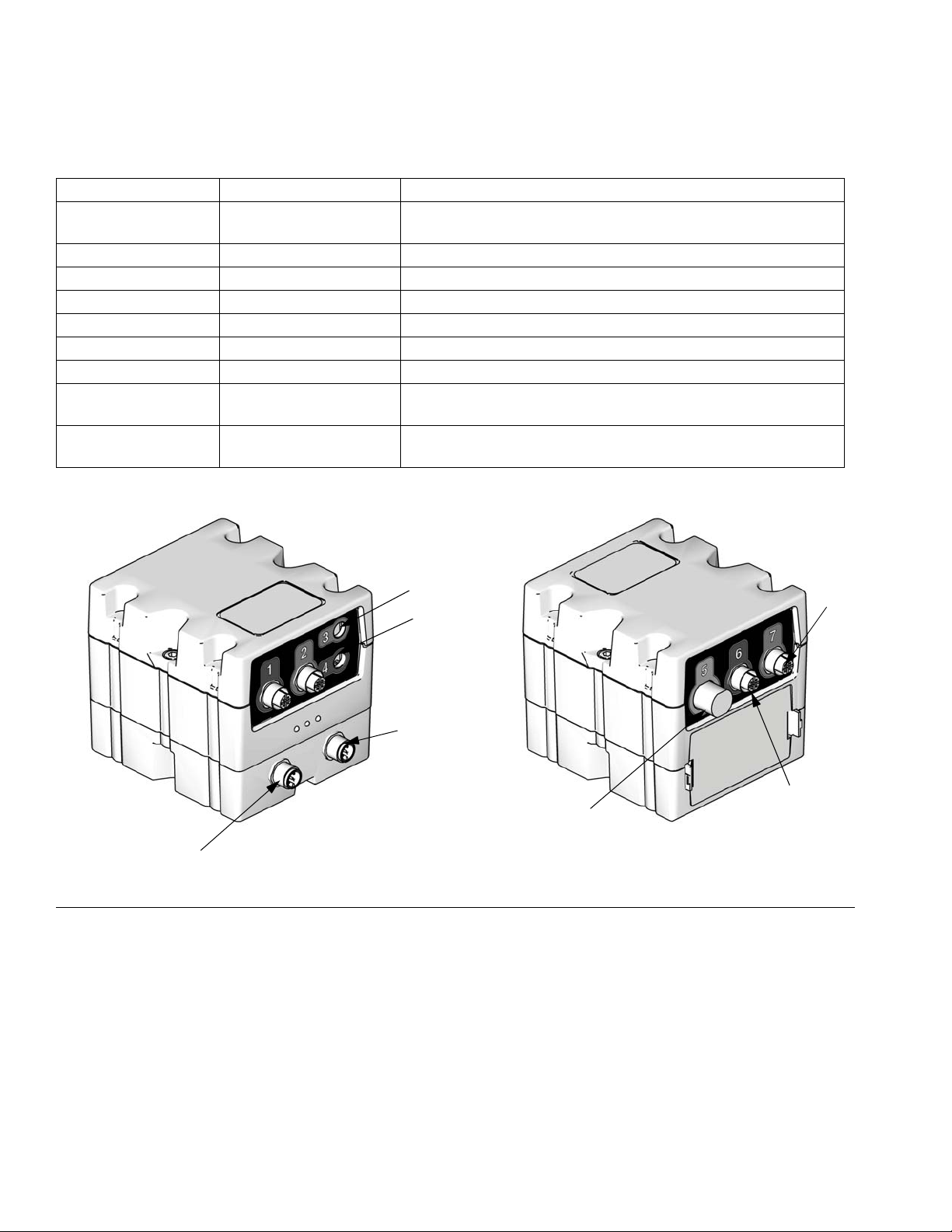

Fluid Control Module

Table 2: FCM Sensor Connections

Connection Ram Sensor Description

1 Ram A and Ram B Air motor solenoid (wire labeled 3), drum low (wire labeled 1),

drum empty (wire labeled 2)

2 Ram A Light tower

3 Ram A + B Fluid depressurize/recirculate solenoid

4 not used not used

5 Ram A and Ram B Air motor reed switch, sensors

6 not used not used

7 Ram A Filter pressure at inlet and outlet

CAN communication

cable 1

CAN communication

cable 2

Ram A From Ram A FCM to display module.

Ram A and Ram B 15 ft (4.57 m) from Ram A FCM to Ram B FCM.

CAN Cable 1

FIG. 7: FCM Sensor Connections

3

4

CAN Cable 2

TI12337A

7

6

5

TI12336A

12 313296J

Page 13

User Interface

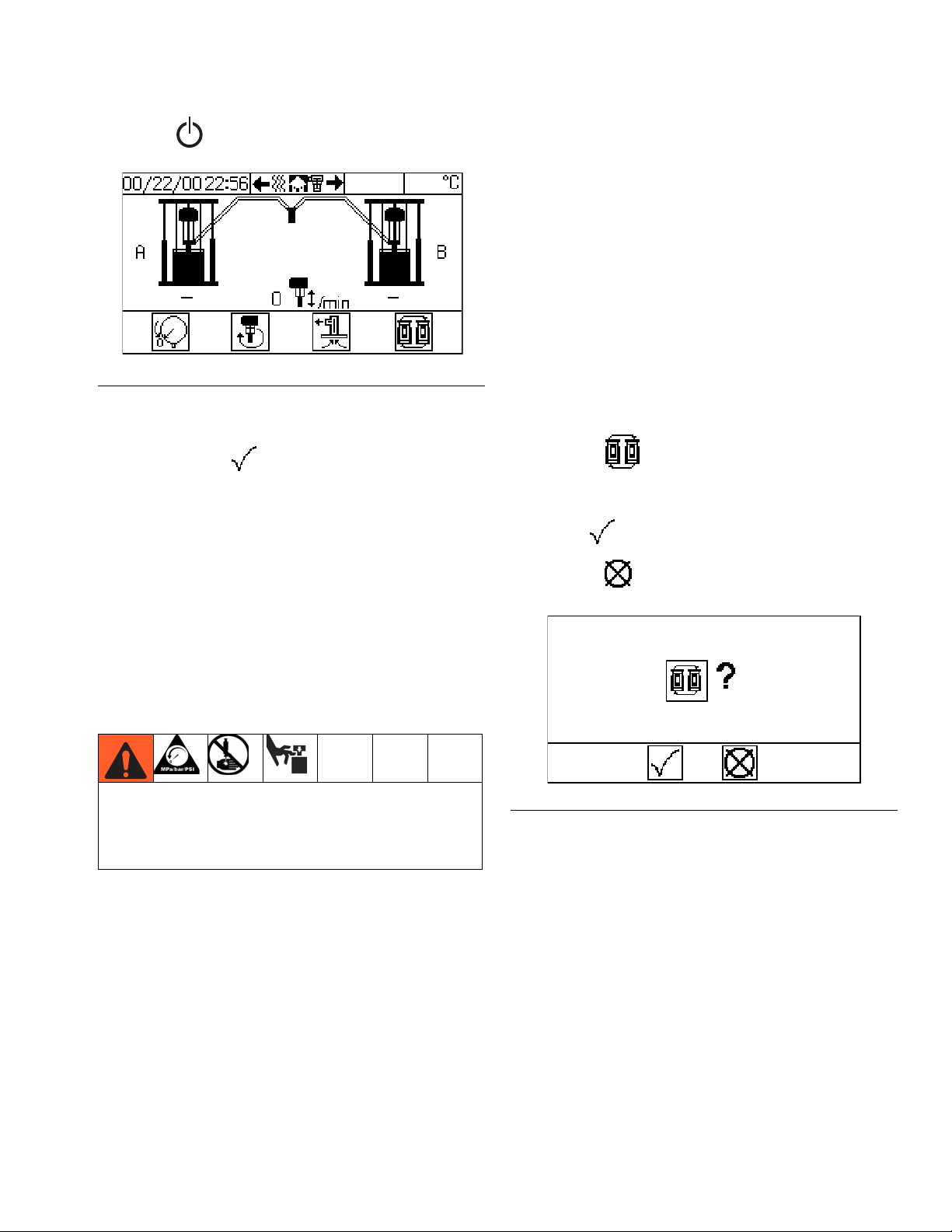

FIG. 8: Display Module

Button Function

On/Off

Powers air motor solenoid ON and OFF from Ram Operation screen (F

• When ON, the air motor solenoid is ON and the pump of the active ram is pressurized.

Table 3: Display Module Button Functions

Component Identification

IG

. 71, page 100).

Cancel

Setup

Enter

Arrows Left/Right

• When OFF, the air motor solenoids are OFF.

CAUTION: Turning the air motor solenoid OFF relieves pressure from the pump motor. It does

not depressurize the fluid pressure. Follow the Pressure Relief Procedure, page 28.

NOTE: The ram up/down and blowoff air is independent of the electronic controls and can be

operated anytime the main air slider valve is open and air pressure is available.

Powers heat ON and OFF from Heat Run screen (F

• When ON, the enabled heat zones are ON.

• When OFF, all heat zones are OFF.

Cancel a selection or number entry while in the process of entering a number or making a

selection.

Toggle between run and setup screens.

• Setup changes can be made while system is operating.

• If setup screens are password protected, button toggles between run and password entry

screen.

Opens drop down menus on Setup fields.

Press to enter changes and make a selection.

Navigate left or right to a new screen.

Navigate left or right within a screen while in Jump In mode. See Appendix A - User Interface

Display, page 93, for more information.

IG

. 72, page 101).

Arrows Up/Down

313296J 13

Navigate up or down within a screen or to a new screen.

• Move between selections within a drop-down menu.

• Increment or decrement the selected numerical field within a selection menu.

Page 14

Component Identification

Table 3: Display Module Button Functions

Button Function

Soft Key

Soft keys activate the mode or action represented by the icon above each button in the LCD.

See Table 4 for soft key modes and actions.

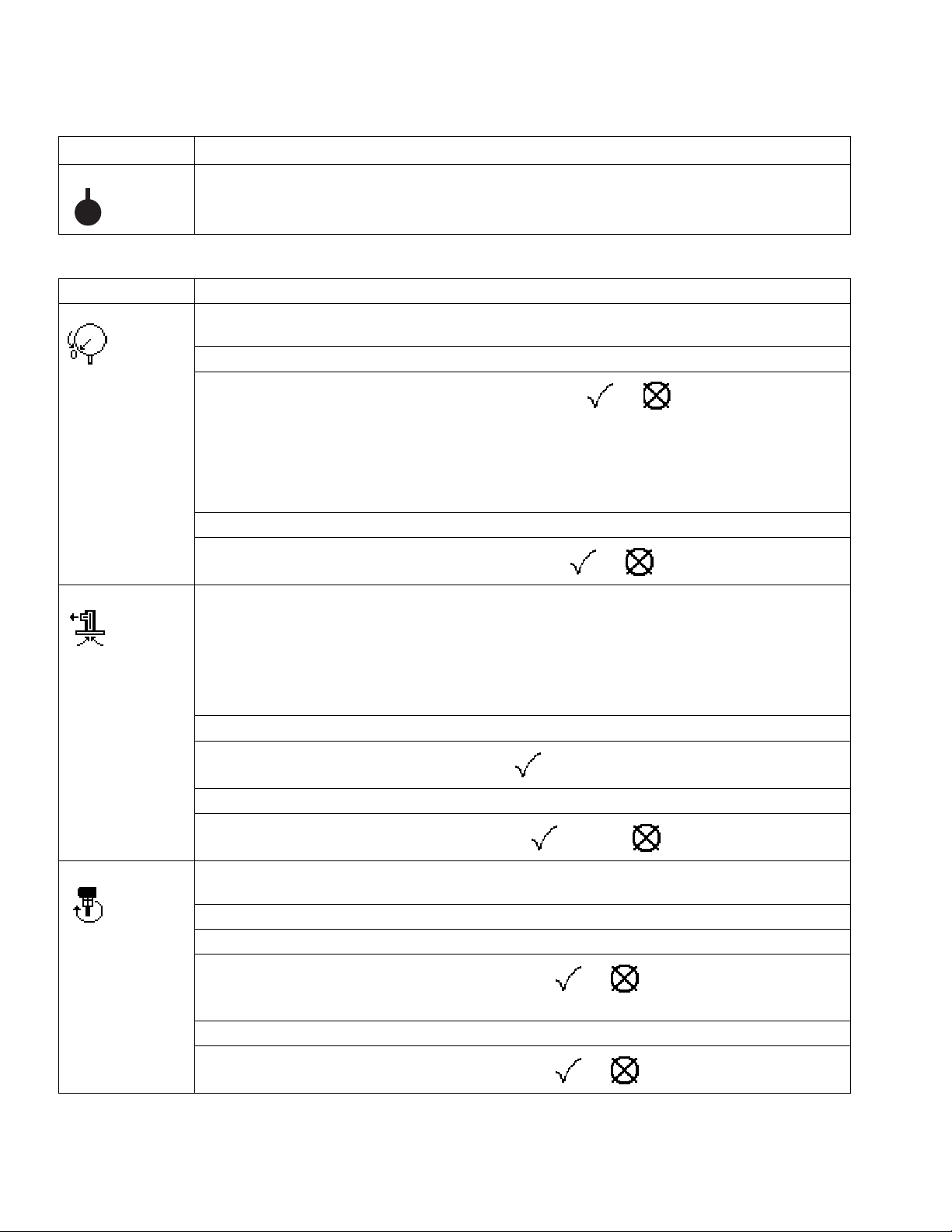

Table 4: Display Soft Key Icons

Icon Function

Depressurize Depressurize relieves fluid pressure from the pump outlet to below the platen on the currently

active ram.

If system is pressurized, press button.

Pump Prime

• When prompted to depressurize the system, select or .

active ram will depressurize both rams.

Depressurizing the

NOTE: If additional user-supplied check valves have been added to the system, only the

active ram will be depressurized. You must perform manual crossover and select depressurize

again to depressurize both rams. See Crossover section of this table on page 15.

If system is depressurized, press button.

• When prompted to pressurize the system, select or .

Pump Prime

•

Tandem ram:

•

Tandem ram:

if pump is off, activates the air solenoid on the active ram;

if pump is on, activates the air solenoid on the inactive ram which enables you

to purge air and prime the pump;

•

Single ram:

activates air solenoid whether or not pump is on;

• clears the Pump Not Primed deviation or alarm (depending on setup selection); and

• resets the drum volume remaining to the drum fill volume setpoint for pump being primed.

Press button.

• When prompted to prime the ram, select to prime.

Press button to exit Prime Mode or to reset counter to the prime time.

• When prompted to exit Prime Mode, select to exit or to reset prime counter.

Recirculate Recirculate Mode pumps fluid from the drum, through the pump, and back into the drum on the

currently active ram.

Set motor air regulator to 30 psi (0.2 MPa, 2.1 bar) before pressing Recirculate key.

If system is not in Recirculate Mode, press button.

• When prompted to turn recirculation on, select or . Adjust motor air regulator to

obtain desired flow rate.

If system is in Recirculate Mode, press button.

• When prompted to turn recirculation off, select or .

14 313296J

Page 15

Component Identification

Table 4: Display Soft Key Icons

Icon Function

Crossover Crossover key transitions the active ram to inactive, and inactive ram to active. Available on

Warm Melt Tandem Supply Systems only.

NOTE: If an alarm is present on the inactive ram, crossover will not be successful. Manual

crossover is disabled in single ram operation.

Press button.

• When prompted to initiate a crossover, select or .

Setback

Setback transitions the heaters into setback mode. The setpoint for each zone will be

decreased by the setback amount. See Heater System Setup Screen, page 95, and Heat

Run Screen, page 101.

Jump In

In screens that have editable fields, press to access the fields and make changes. See

Appendix A - User Interface Display, page 93, for more information.

NOTICE

To prevent damage to soft key buttons, do not

press the buttons with sharp objects such as pens,

plastic cards, or fingernails.

313296J 15

Page 16

Component Identification

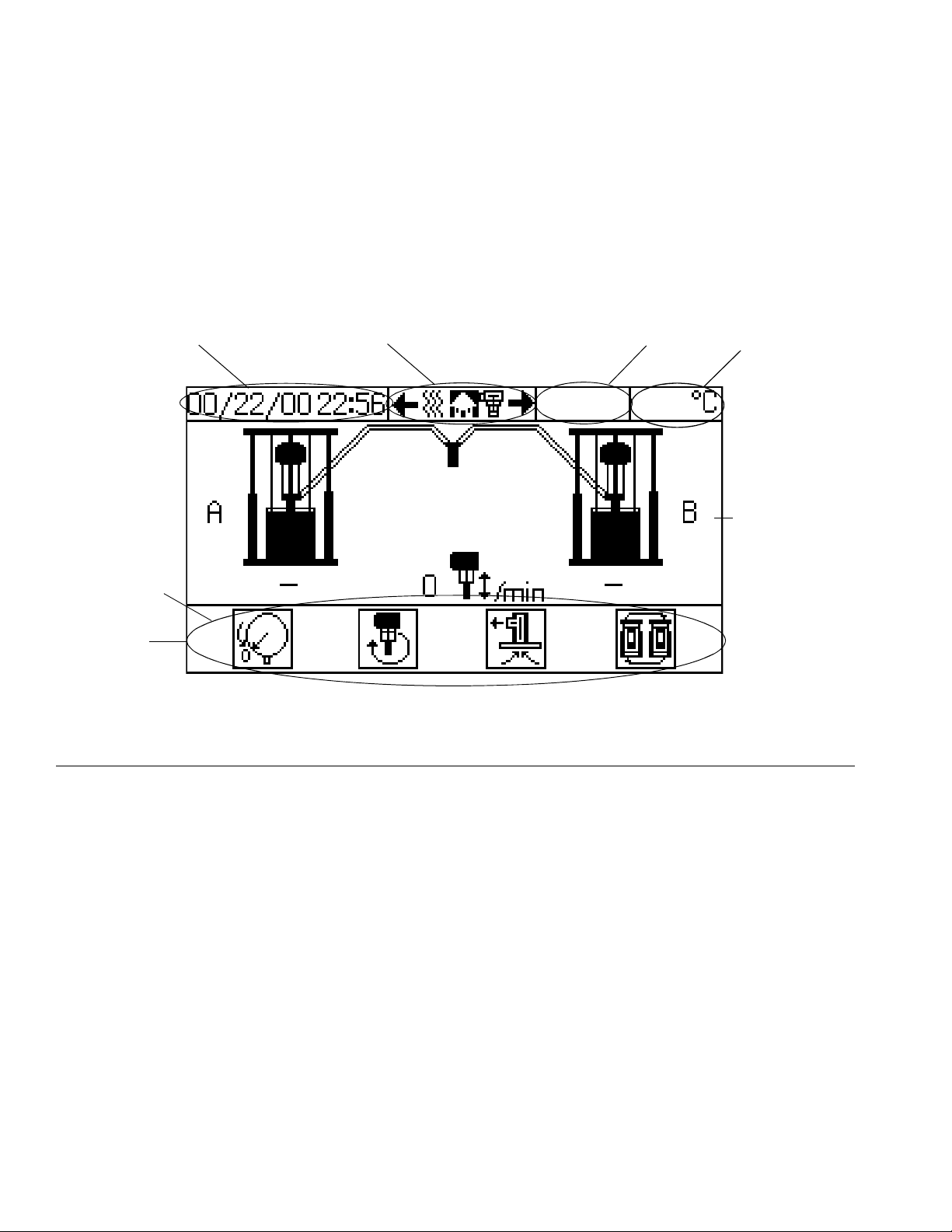

User Interface Display

NOTE: For details regarding the user interface display see Appendix A - User Interface Display, page

93.

Display Screen Components

The following figure calls out the navigational, status, and general informational components of each display screen.

Current Date and Time

Displays soft keys

that are active for

particular screen

Soft Keys

F

IG

. 9: Display Screen Components

Navigation

Status

Mode

Function Display

16 313296J

Page 17

Installation

Installation

Accessories are available from Graco. Make certain all

accessories are adequately sized and pressure-rated to

meet the system’s requirements.

Component Identification illustrations are only a guide

for selecting and installing system components and

accessories. Contact your Graco distributor for assistance in designing a system to suit your particular

needs.

Location Requirements

•Refer to Dimensions, page 104, for ram mounting

and clearance dimensions.

• Install indoors only, and not near water or any other

liquid that is sprayed.

Location

NOTICE

Always lift supply system at proper lift locations (see

F

IG

. 2) to avoid equipment damage. Do not lift in any

other way.

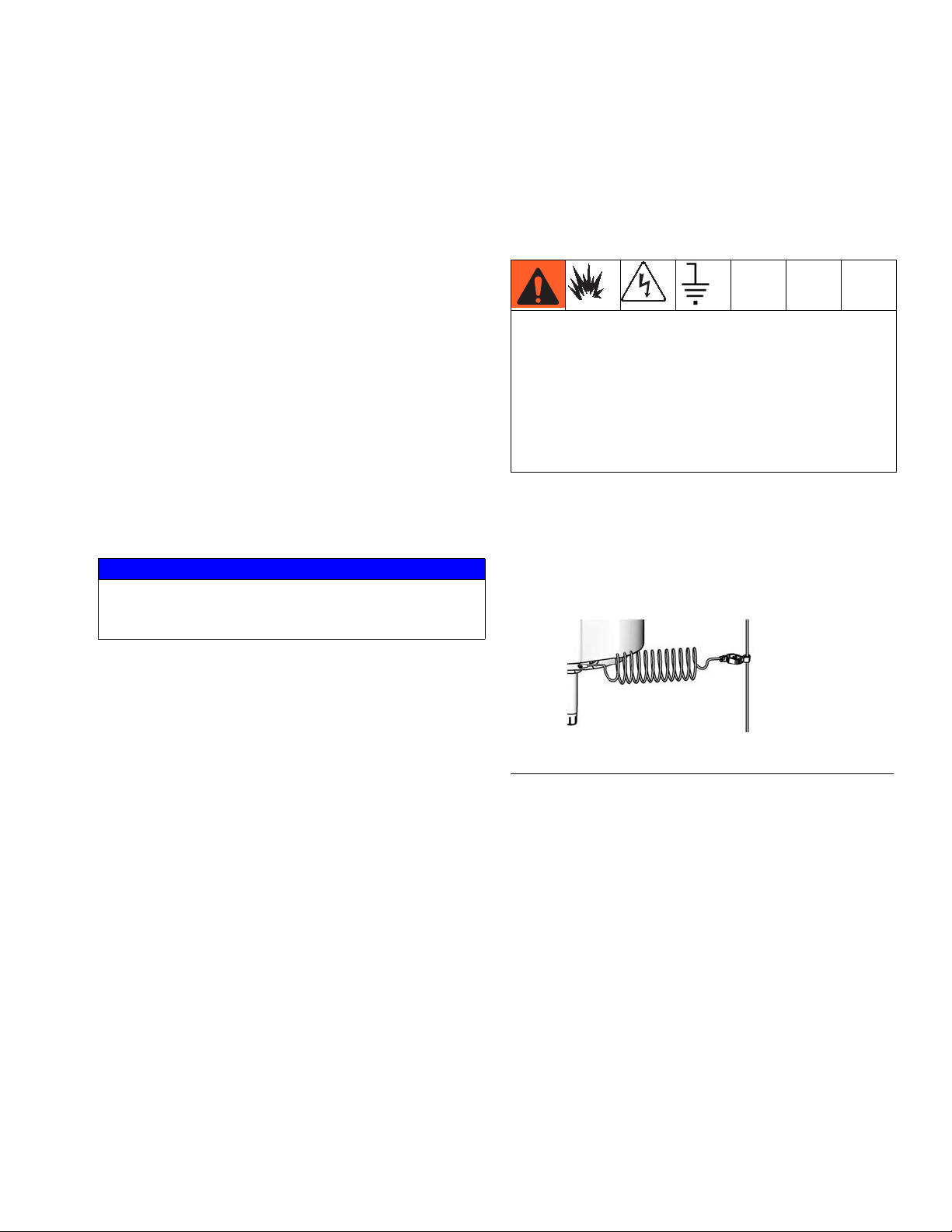

Grounding

Ground the supply system as instructed here and in the

individual component manuals.

The power source conduit is not an adequate ground

for the system. The unit must be bonded to either the

building ground or a true earth ground. To reduce the

risk of static sparking, ground the pump, the object

being dispensed to, and all other dispensing equipment used or located in the dispensing area. All electrical wiring must be done by a qualified electrician

and comply with local codes and regulations.

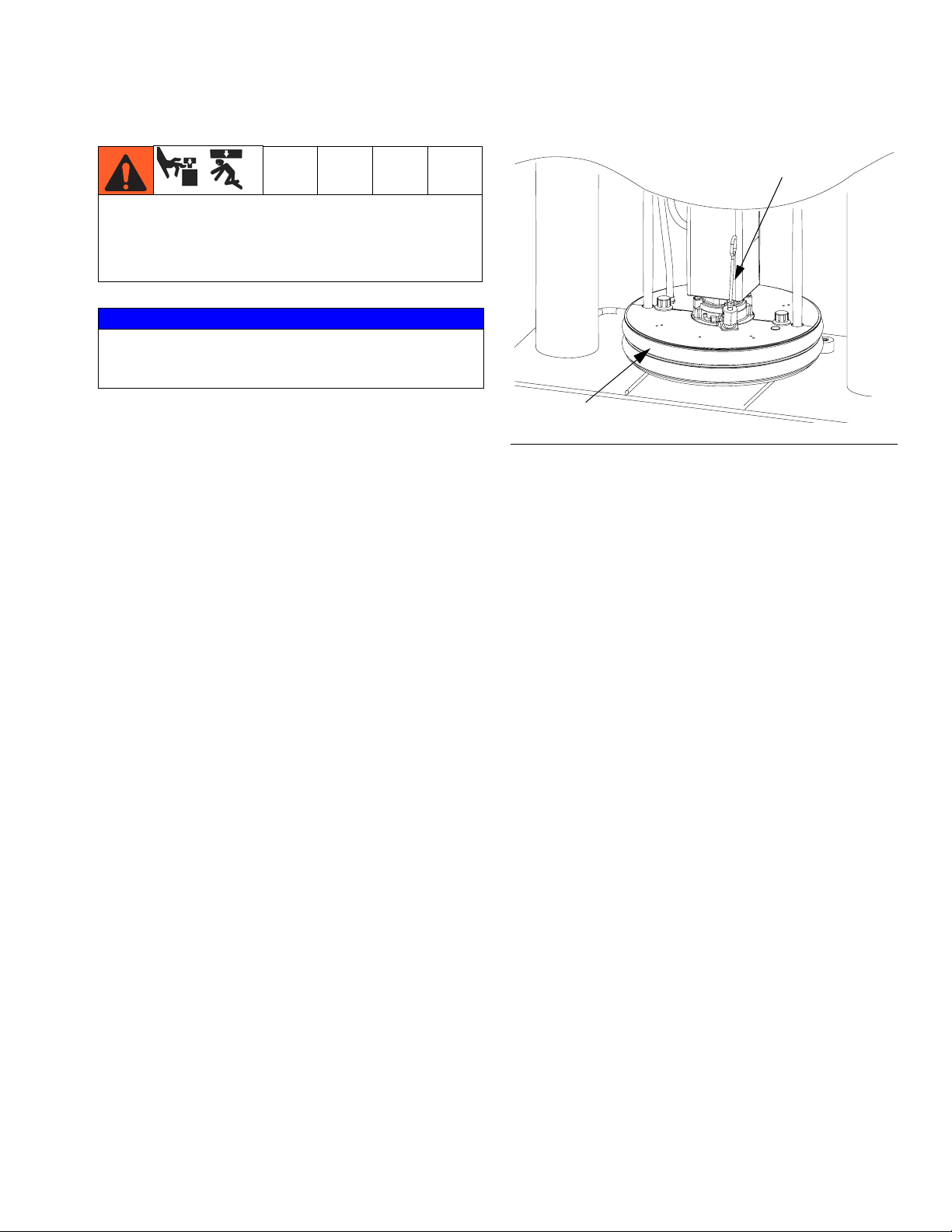

Pump: use a ground wire and clamp. Loosen grounding

lug locknut and washer. Insert one end of supplied

ground wire into slot in lug and tighten locknut securely.

Connect other end of wire to a true earth ground. See

F

IG

. 10.

1. Attach a lifting sling at the proper lift spots. Lift off

the pallet using a crane or a forklift. See F

proper lift locations.

2. Position the ram so the air controls and electrical

enclosure are easily accessible. Ensure that there is

enough space overhead for the ram to raise fully.

3. Using the holes in the ram base as a guide, drill

holes for 1/2 in. (13 mm) anchors.

4. Ensure that the ram base is level in all directions. If

necessary, level the base using metal shims.

Secure the base to the floor using 1/2 in. (13 mm)

anchors that are long enough to prevent the ram

from tipping.

IG

. 2 for

ti8250a

F

IG

. 10: Ground Pump

Air and fluid hoses: use only electrically conductive

hoses.

Air compressor: follow manufacturer’s recommendations.

Dispense valve: ground through connection to a prop-

erly grounded fluid hose and pump.

313296J 17

Page 18

Installation

Fluid supply container: follow local code.

Object being sprayed: follow local code.

Solvent pails used when flushing: follow local code.

Use only conductive metal pails, placed on a grounded

surface. Do not place the pail on a nonconductive surface, such as paper or cardboard, which interrupts

grounding continuity.

To maintain grounding continuity when flushing or

relieving pressure: hold metal part of the dispense

valve firmly to the side of a grounded metal pail, then

trigger the valve.

Connect Power Source

The electrical enclosure comes already attached and

wired to the ram; however, before the supply system

becomes functional you must connect the electrical

enclosure to a power source.

NOTE: See Power Requirements, page 7, for circuit

protection requirements.

1. Open electrical enclosure door and locate power

line filter.

2. Have a qualified electrician perform the following

steps:

a. Connect your plant power to the electrical

enclosure power line filter according to local

codes. A 1-3/8 in. (35 mm) diameter opening is

provided on the side of the enclosure adjacent

to the label. This opening is suitable for a 1 in.

npt conduit or strain relief fitting (supplied).

b. Connect a power protective ground to the cen-

ter post on the line end of the power line filter.

NOTE: Install safety insulation boots (supplied) on

the power line. Install 1/4 in. ring lugs (user supplied) on the power line and power protective

ground line prior to connecting to the power line filter posts.

Have a qualified electrician connect power according

to national, state, and local safety and fire codes.

NOTE: Required voltage and amperage is noted on

the electrical enclosure label. Also see Table 1.

Before running power to the unit, make sure the

plant electrical service meets the supply system’s

electrical requirements.

18 313296J

Page 19

Installation

Install/Adjust Drum Low or Empty Sensor

1. Position ram at desired level (low or empty).

NOTE: Follow Steps 2 through 4 only if installing the

low sensor.

2. Attach the low sensor to the existing sensor bracket

(EA), above the existing empty sensor (EE).

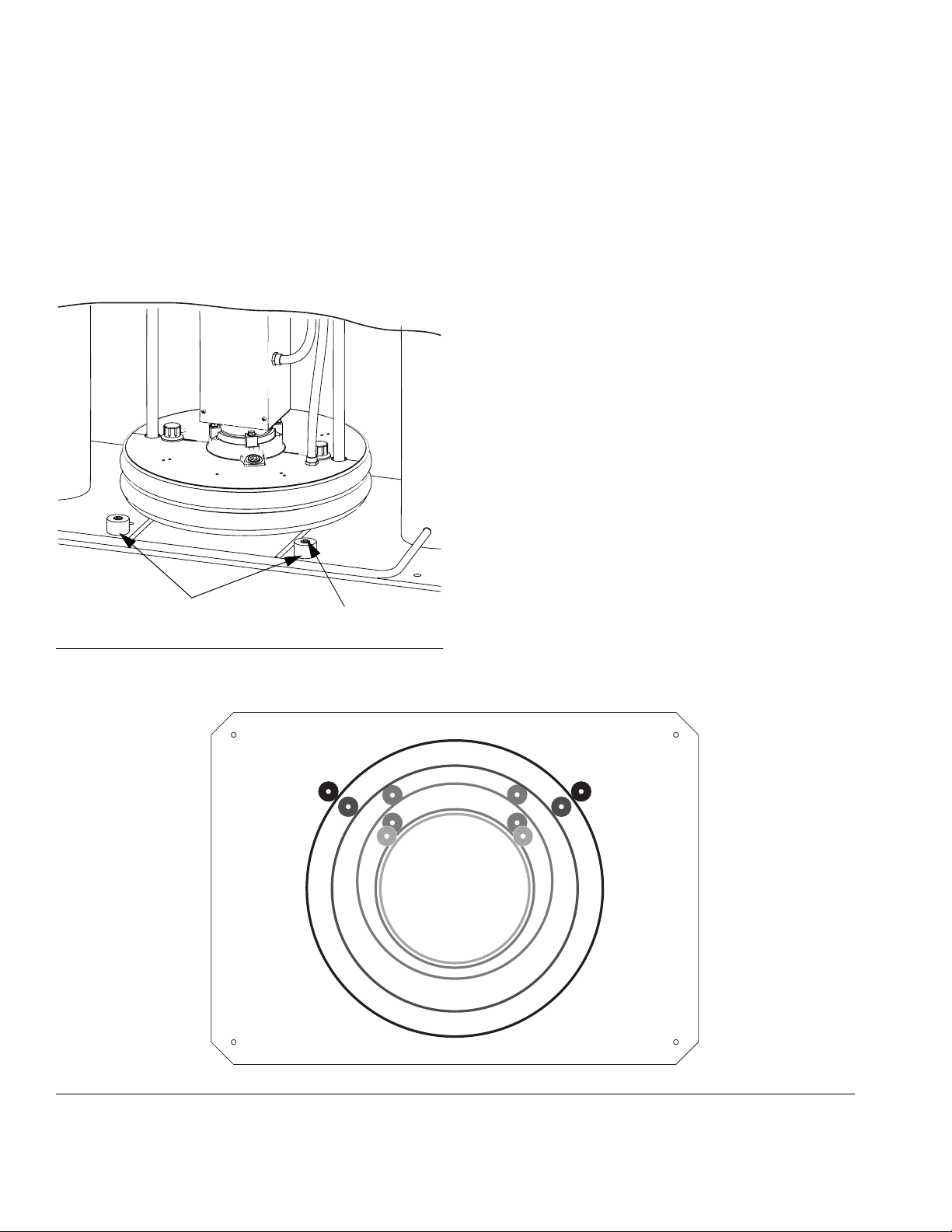

D200 Shown

EA

EE

ED

EB

F

IG

. 11: Low or Empty Sensor Kit

4. Attach the sensor to the corresponding connector

on the splitter cable. For drum low, attach the sensor to connector 1. For drum empty, attach the sensor to connector 2.

5. Power system on.

6. Make precise adjustments by moving the sensor

within the slot on the sensor bracket. Use the yellow

indicator on the sensor cable to indicate a drum low

or empty condition.

Light Tower Accessory

Order the 255468 Light Tower Accessory as a diagnostic indicator for supply systems. See T

description of light tower signals.

Table 5: Light Tower Signals

Signal Description

Yellow flashing A low priority error exists.

Yellow on A medium priority error exists.

Red flashing A high priority error exists.

Red on The system is shut down due to

error conditions.

ABLE

5 for a

3. Replace the existing cable between the empty sensor (EE) and FCM connector (see F

with the empty/low sensor splitter cable.

IG

. 7, page 12)

313296J 19

Page 20

Installation

Attach Drum Stops

Supply systems are shipped with drum stops in place to

help position the drum on the ram. For replacement

parts, order Kit 255477. The kit includes two each of

capscrews (FA), lock washers (not shown), and drum

stops (FB).

D200 Shown

1. Locate the correct set of mounting holes on the ram

base.

2. Using the capscrews (FA) and lock washers (not

shown), attach the drum stops (FB) to the ram base.

FB

F

IG

. 12: Attach Drum Stops

FA

55 gal (200 L)

30 gal (115 L)

8 gal (30 L)

5 gal (20 L)

IG

. 13: Drum Stop Location

F

20 313296J

Page 21

Installation

Check Resistance

Check the Resistance Between the Supply

System and the True Earth Ground

The resistance between the supply system components and true earth ground must be less than 0.25

ohms.

Have a qualified electrician check the resistance

between each supply system component and the true

earth ground. The resistance must be less than 0.25

ohms. If the resistance is greater than 0.25 ohms a different ground site may be required. Do not operate the

system until the problem is corrected.

NOTE: Use a meter that is capable of measuring

resistance at this level.

Sensor Resistance Checks

Conduct these electrical checks with the main disconnect OFF.

NOTE: For dispense valve and hose sensor resistance checks, refer to your dispense valve manual

or hose manual.

The supply system includes a heat sensor and controller

for each of the four heated zones. To check sensor

resistance:

1. Make sure the power is off and that the disconnect

switch is in the OFF position.

2. Make electrical resistance checks for the components.

3. Replace any parts that have resistance readings

that do not comply with the ranges listed in Table 6.

NOTE: Check resistance at ambient room temperature (63°– 77°F [17°– 25°C]

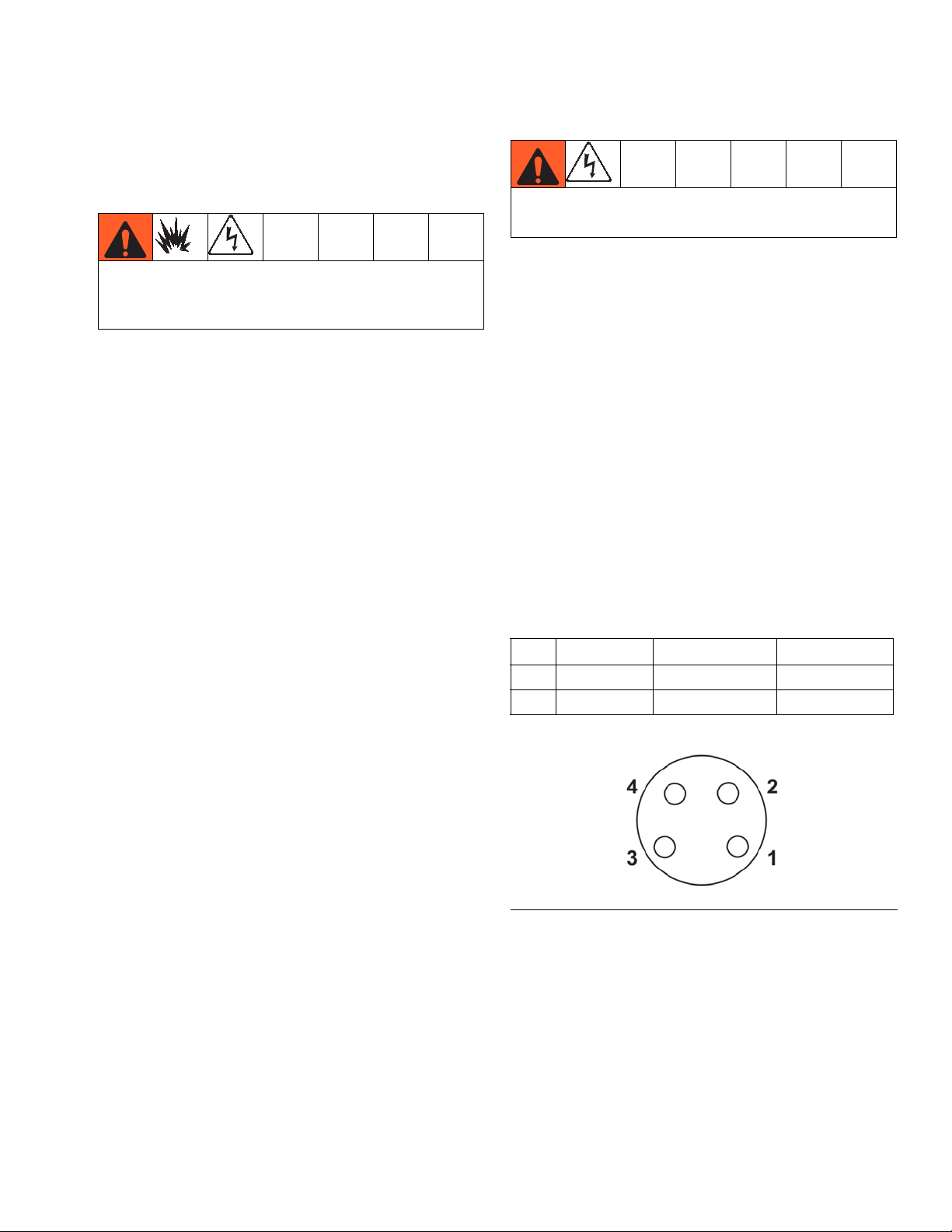

Table 6: RTD Sensor Resistance

Zone Component Connector Pin Range (ohms)

1 Platen Pin 1 to 3

2 Fluid Pump Pin 1 to 3

FIG. 14: RTD Connector Pins

).

1050-1100

1050-1100

Ω

Ω

313296J 21

Page 22

Installation

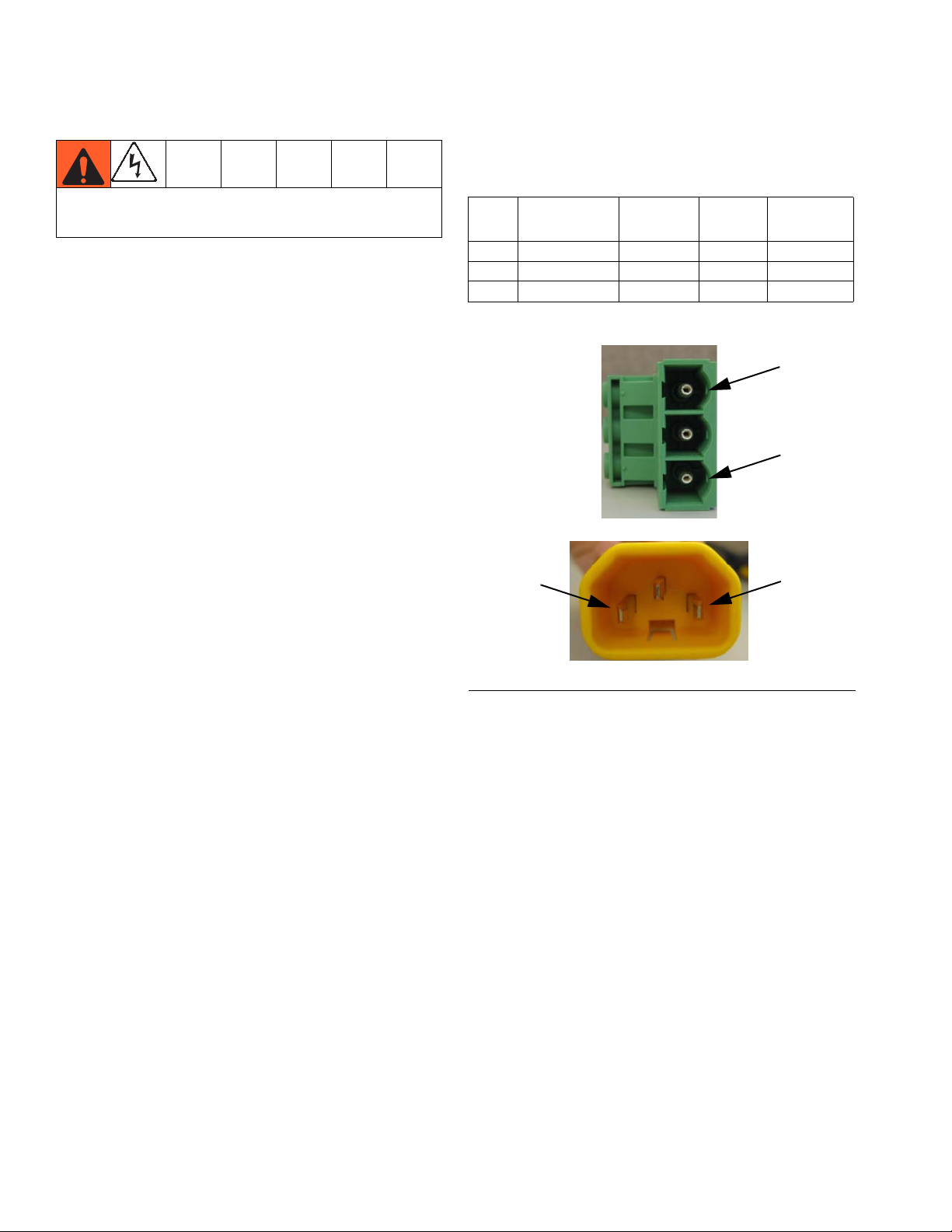

Heater Resistance Checks

Conduct these electrical checks with the main power

disconnect OFF.

NOTE: For dispense valve and hose sensor resistance checks, refer to your dispense valve manual

or hose manual.

To check heater resistance:

1. Make sure the power is off and that the disconnect

switch is in the OFF position.

2. Make electrical resistance checks for the components. Refer to Table 7. Heater terminal pins are

located on the back of the enclosure (H). See F

page 8.

3. Replace any parts whose resistance readings do

not comply with the ranges listed in Table 7.

IG

. 2,

NOTE: Check resistance at ambient room temperature (63°– 77°F [17°– 25°C]

).

Table 7: Resistance Chart of All Heaters

Between

Zone Component

1 Platen - D200 1 and 3 240 15 +5/-5

2 Platen - D60 1 and 3 240 80 +10/-10

3 Pump L and N 240 37 +5/-5

Terminals

Unit

Voltage

Range

(ohms)

1

3

L

FIG. 15: Heater Terminal Pins

N

22 313296J

Page 23

Installation

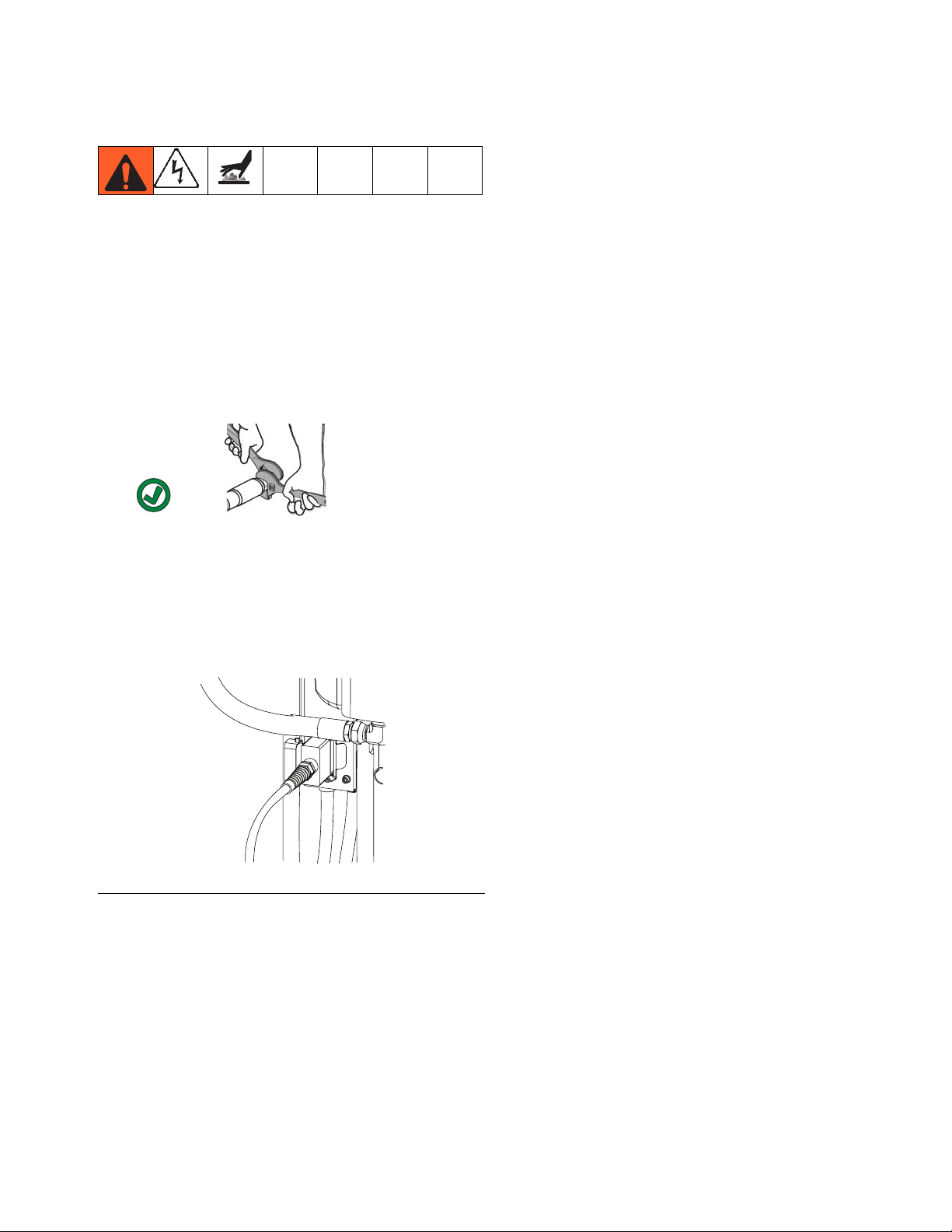

Hose Installation and Care

NOTE: The warm melt supply system requires

Graco single-circuit material hoses rated at a maximum of 1920 Watts.

Hose Installation

1. Connect heated hose to the pump outlet.

2. Use two wrenches to tighten. Torque to 470-550

in-lbs (53.1-62.1 N•m).

3. Wrap exposed fittings on the pump outlet with

Nomex insulation and secure insulation using fiberglass tape.

Mechanical Setup

1. Fill displacement pump wet cup 2/3 full with Graco

Throat Seal Liquid (TSL).

2. Turn all air regulators to their full counterclockwise

position.

3. Connect a 3/4 in. (19 mm) air line from an air source

to the system air inlet. Refer to the pump performance curves in the Check-Mate Pump Packages

manual to determine your air supply flow requirements.

NOTE: Quick disconnects restrict flow for large air

motors.

Overview of Temperature Control Settings

Temperature controls are set in Setup mode. See Setup

Mode Screens on page 95 for information about setting

temperature controls.

See Run Mode Screens on page 100 for information on

controlling temperatures for each zone.

4. Connect hose adapter to green receptacle on junction box.

FIG. 16: Connect Hose to Junction Box

5. Securely tighten the 16-pin electrical connectors on

long heated hose leads into 16-socket receptacles

on the end of the hose adapter.

6. Securely tighten the 8-socket electrical connectors

on short heated hose leads into 8-pin receptacle

located on the dispense valves.

Hose Care Guidelines

Refer to the Hotmelt/Warm Melt Heated Hose manual

for details regarding hose care guidelines.

313296J 23

Page 24

Setup

Setup

The pump was tested with lightweight oil, which is left in

the fluid passages to protect parts. To avoid contaminating fluid with oil, flush the pump with a compatible solvent before use. See Purge System, step 2.

Purge System

Purging the system before the initial use can prevent

material contamination, which may cause the material to

fail or perform poorly.

NOTICE

Purge the system before performing the initial material

loading procedure. The system was factory-tested

using a light soluble oil, a soybean oil, or some other oil

as tagged. Flush the system to avoid contaminating the

material that has been designated for initial material

loading.

To purge the system perform the following procedure:

This equipment should not be used with more than

one type of fluid due to potential compatibility issues

that could result in an unpredictable reaction. Graco

recommends using new hoses when chemicals are

changed or care must be taken to assure that all

traces of one chemical are removed before introducing a second chemical.

3. Select a container of material that can eliminate the

factory-test oil from the system. If necessary, check

with Graco or the material supplier for a recommended solvent.

4. Before purging ensure the entire system and waste

container are properly grounded.

NOTE: Remove any dispense valve orifices before

purging. Reinstall after purging has been completed.

1. Select the material for the initial material load.

2. Verify whether the factory-test oil and the initial

material load are compatible:

a. If the two substances are compatible, omit the

remaining steps in this procedure and refer to

the start up and operation instructions.

b. If the two substances are incompatible, perform

the remaining steps in this procedure to flush

the system at ambient temperature.

Use fluids that are chemically compatible with the

equipment wetted parts. See the Technical Data sections in the equipment manuals.

5. Purge the material through the system for approximately 1 to 2 minutes.

6. Remove the container if purge material was used.

Set Values on Display Module

Set desired values on display module Setup menus.

See Setup Mode Screens, page 95.

24 313296J

Page 25

Setup

Load Material

Moving parts can pinch or amputate fingers. When

the pump is operating and when raising or lowering

the ram, keep fingers and hands away from the

pump intake, platen, and lip of the drum.

NOTICE

Do not use a drum of material that has been dented or

otherwise damaged; damage to the platen wiper can

result.

NOTE: Before loading material, ensure that there is

a minimum overhead clearance of 105 in. (267 cm)

and all air regulators are backed off to their full

counterclockwise position.

NOTE: Follow steps below for both rams if using a

tandem warm melt supply system.

1. Refer to F

lators and air valves.

IG

. 2, FIG. 3, and FIG. 4. Close all air regu-

D200 Shown

J

D

FIG. 17: Heated Platen

8. Set the director valve (BC) to DOWN and lower the

ram until fluid appears at the top of the platen bleed

port (J). Adjust ram air regulator (BB) as needed.

Set the director valve (BC) to neutral and close the

platen bleed port (J). 2-Button Interlock: If system

has this feature, press and hold both buttons to start

lowering the ram. See F

IG

. 5, page 11.

2. Open main air slider valve (BA) and set ram air regulator (BB) to 40 psi (0.28 MPa, 2.8 bar). Set director valve handle (BC) to UP and let the ram rise to

its full height. 2-Button Interlock: If the system has

this feature, ram will stop as it nears the top. Press

and hold both buttons to raise ram completely. See

F

IG

. 5 on page 11.

3. Lubricate the platen seals (D) with grease or other

lubricant compatible with the fluid you will pump.

4. Remove the drum cover and smooth the surface of

the fluid with a straightedge.

5. Put a full drum of fluid on the ram base, slide it back

against the drum stops, and center it under the

platen (D). An optional drum roller kit is available to

make it easier to load the drum on the base. Order

Kit 255627.

6. Remove bleed stick from platen bleed port (J). See

F

IG

. 17.

7. If drum has a plastic liner, pull it over edge of drum.

Secure liner with tape wrapped around circumference of drum.

313296J 25

Page 26

Setup

System Heat Up

Never pressurize warm melt supply system while

using warm melt materials before turning on heat.

Many warm melt materials tend to expand when heating and may cause a heated hose to burst. Avoid the

potential of bursting a hose by opening the dispense

valve during system heat up and lock the dispense

valve trigger open every time you shut the system

down.

NOTE: Operate at the lowest temperature and pressure necessary for your application.

1. Turn the main disconnect on the electrical control

panel door to the ON position.

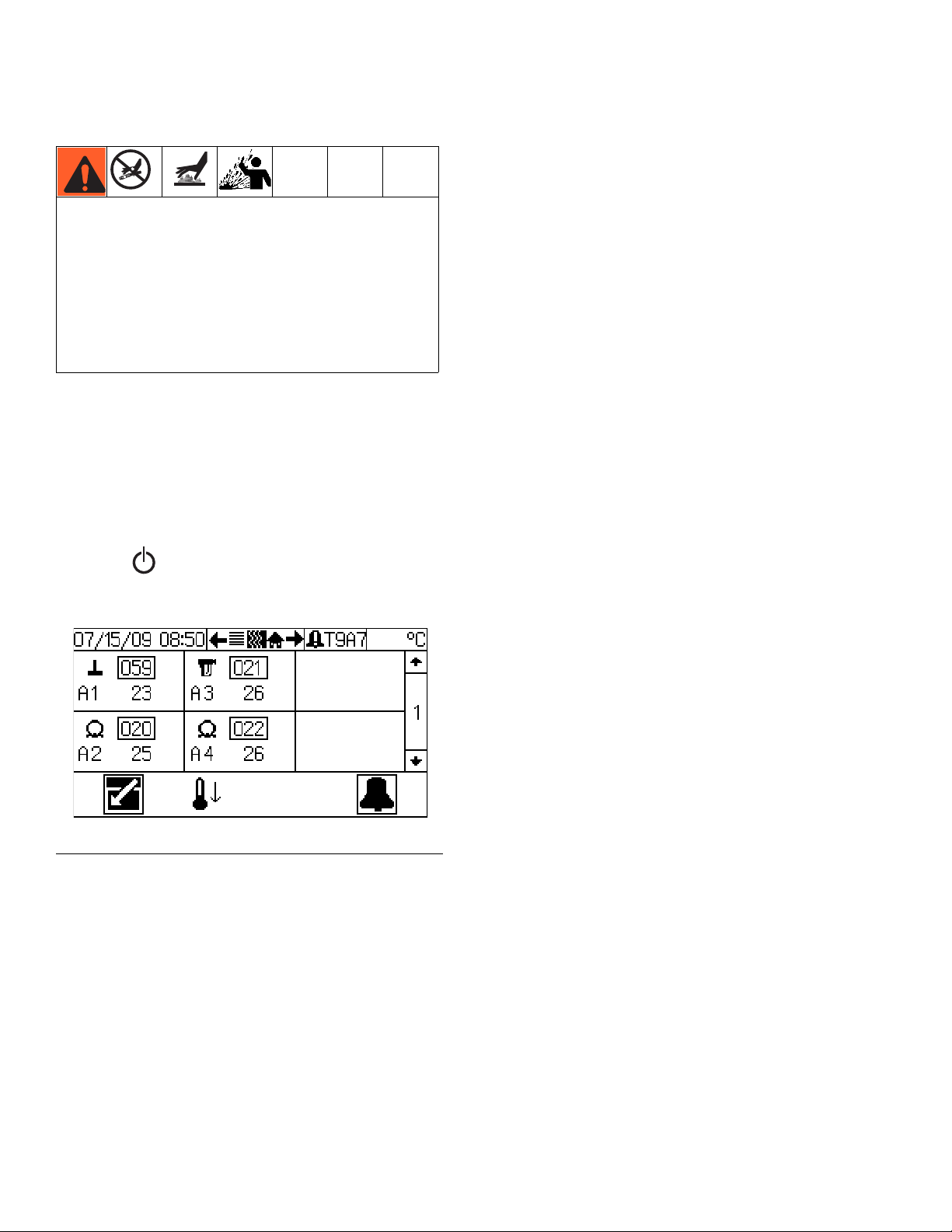

2. Press while in the Heat Run screen to turn the

heaters on for enabled heat zones.

F

IG

. 18: Heat Run Screen - Ram A

26 313296J

Page 27

Setup

Prime

1. Make sure the system is at required temperature.

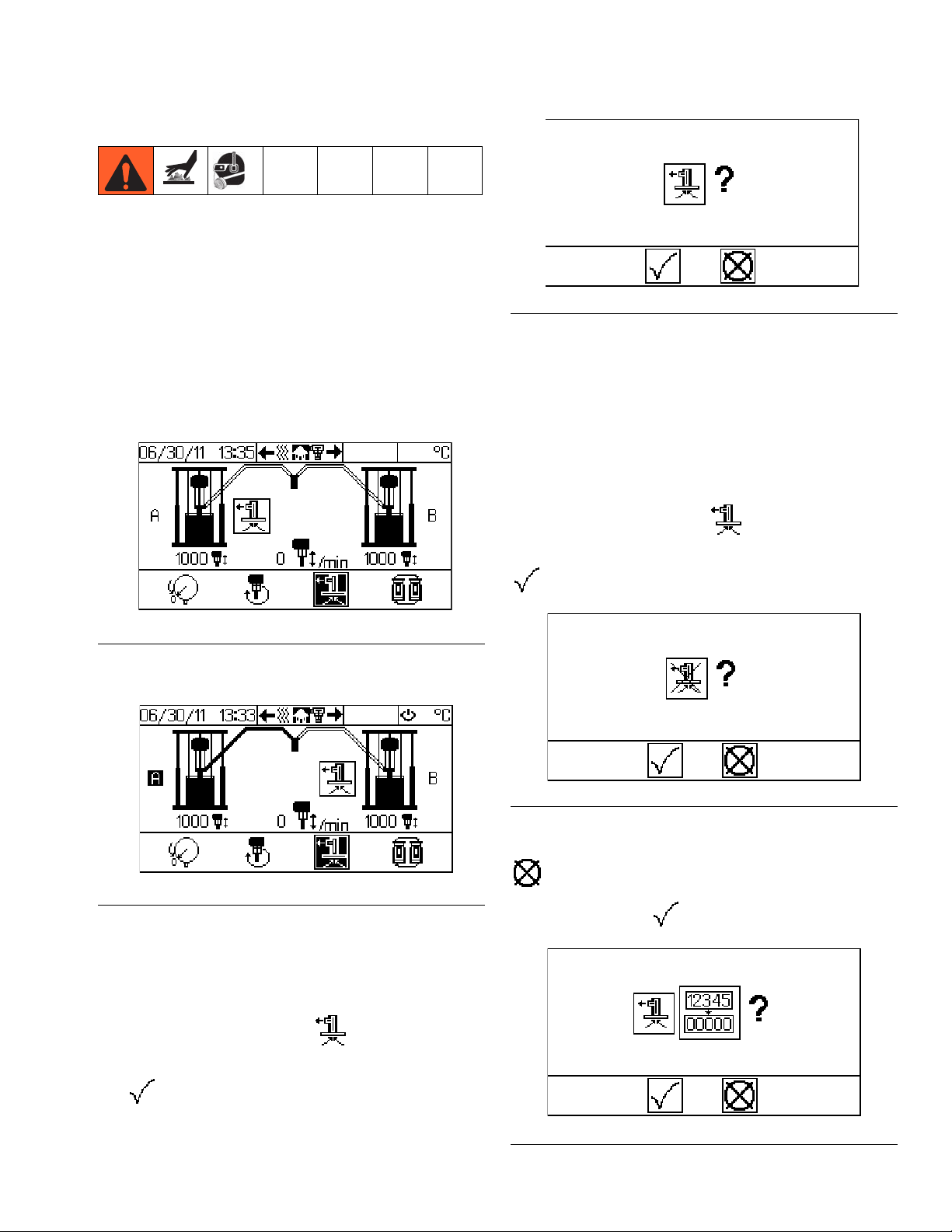

2. Tandem Systems Only: To prime the active ram,

ensure that the system is not in Run Mode. To prime

the inactive ram, ensure that the system is on and in

Run Mode.

3. Single Systems Only: To prime the ram, ensure

that the system is on. The system may or may not

be in Run Mode.

(Prime active ram - not Run Mode)

FIG. 21: Prime Confirmation

6. When the timer expires the air motor solenoid LED

will turn off.

7. Prime the system until a smooth flow of material dispenses from the dispense valve.

8. Lock the dispense valve trigger lock.

NOTE: To exit Prime Mode before the timer expires,

press the Pump Prime key . The display

prompts the operator to confirm. See F

IG

. 22. Select

to exit prime.

FIG. 19: Ram Operation Screen - Tandem System

(Prime inactive ram - in Run Mode)

IG

. 20: Ram Operation Screen - Tandem System

F

4. If using a manual dispense valve, unlock the dispense valve trigger and place dispense valve over a

waste container.

5. Press the Pump Prime key . The display

prompts the operator to confirm. See F

IG

. 21. Select

IG

. 22: Exit Prime Mode Confirmation

F

NOTE: To extend the prime time counter, select

in F

IG

. 22. Display prompts operator to confirm.

IG

See F

. 23. Select to reset.

to begin prime.

IG

. 23: Reset Prime Time Counter Confirmation

F

313296J 27

Page 28

Operation

Operation

Pressure Relief Procedure

This procedure describes how to relieve pressure for the

supply system. Use this procedure whenever you shut

off the system and before checking or adjusting any part

of the system.

1. Lock the dispense valve trigger.

2. Press On/Off key . If system is On, display will

highlight . Select to turn off.

If you suspect that the dispense tip/nozzle or hose is

completely clogged, or that pressure has not been fully

relieved after following the steps above, very slowly

loosen the tip guard retaining nut or hose end coupling

and relieve pressure gradually, then loosen completely.

Now clear the tip/nozzle or hose.

Trigger Lock

Always engage the trigger lock when you stop dispensing to prevent the gun from being triggered accidentally

by hand or if dropped or bumped.

Start and Adjust Ram

Moving parts can pinch or amputate fingers. When

the pump is operating and when raising or lowering

the ram, keep fingers and hands away from the

pump intake, platen, and lip of the drum.

FIG. 24: System Function Screen

3. See F

4. Set the ram director valve to DOWN. The ram will

5. Jog the director valve up and down to bleed air from

6. Unlock the dispense valve trigger.

7. Hold a metal part of the dispense valve firmly to the

8. Lock the dispense valve trigger.

9. Open all fluid drain valves on ram(s). Have a con-

IG

. 4, page 10. Close the air motor slider valve

(BF) and the main air slider valve (BA) on ram(s).

slowly drop.

ram cylinders.

side of a grounded metal pail, and trigger the dispense valve to relieve pressure.

tainer ready to catch the drainage. Leave fluid drain

valves open until ready to dispense again.

To start and adjust the ram(s), follow the Load Material

procedure on page 25.

Start and Adjust Pump

NOTE: Follow steps below for both pumps if using a

tandem warm melt supply system.

1. Connect pump outlet fittings and hose (not supplied).

NOTE: Be sure all components are adequately sized

and pressure rated to meet the system’s requirements.

2. Be sure the pump air valve is closed. Then set the

ram air regulator (BB) to 50 psi (0.35 MPa, 3.5 bar).

Set the director valve (BC) to DOWN. See F

page 10.

IG

. 4,

28 313296J

Page 29

Operation

3. Press while in the Ram Operation screen.

F

IG

. 25: Ram Operation Screen - Tandem System

4. When the confirmation screen appears with a

prompt, select to start the pump.

5. Open the pump air valve (BF) and keep the director

valve (BC) set to DOWN while pump is operating.

NOTE: Increase air pressure to the ram if the pump

does not prime properly with heavier fluids.

Decrease air pressure if fluid is forced out around

the top seal or platen.

Manual Crossover

(Tandem Warm Melt Supply System Only)

Manual crossover can only be initiated if the following

conditions are met:

• inactive ram is not in the drum empty error condition.

• pump runaway and not primed alarms do not exist.

To initiate a manual crossover to the inactive ram:

1. From the Ram Operation screen, press the Cross-

over key . The display prompts the operator

to confirm.

2. Select to confirm manual crossover operation

or select to cancel.

Automatic Crossover

(Tandem Supply System Only)

Keep clear of the inactive ram, as automatic crossover may occur unexpectedly. To repair or adjust the

ram, first follow all steps of the Pressure Relief Pro-

cedure on page 28.

The automatic crossover feature allows continuous flow

and prevents system shutdown. If the active ram

encounters a pump runaway or drum empty alarm, it will

attempt an automatic crossover to the inactive ram.

The system will generate a crossover error if the active

ram attempts an automatic crossover while the inactive

ram has a pump runaway, drum empty, or not primed

alarm. If this occurs, correct the error and clear the

alarm from the Alarm screen. See Alarm Screen, page

103, for details.

FIG. 26: Crossover Function Screen

NOTE: If the active ram has a pump runaway error

or drum empty error, the system will attempt an

automatic crossover.

313296J 29

Page 30

Operation

Recirculate Function

Recirculate mode pumps fluid from the drum, through

the pump, and back into the drum on the currently active

ram.

To enter Recirculate mode:

1. Set the motor air regulator to 30 psi (0.2 MPa, 2.1

bar).

2. From the Ram Operation screen, press the Recircu-

late key . The display prompts the operator to

confirm.

3. Select to confirm recirculation or select to

cancel.

Depressurize Function

Follow the Pressure Relief Procedure on page 28.

Shutting off power or removing power from the system will not depressurize the system.

When the system is pressurized the depressurize function relieves fluid pressure from the pump outlet to

below the platen on the currently active ram. However,

when the system is depressurized pressing the depressurize key will restore fluid pressure.

Depressurize System

From the Ram Operation screen, press the Depressur-

ize key . The display prompts the operator to con-

firm. Select to confirm depressurize or select

to cancel.

F

IG

. 27: Enter Recirculate Mode

4. Adjust motor air regulator to obtain desired flow

rate.

NOTE:

While in Recirculate Mode, the manual crossover

function cannot be used and the inactive ram cannot be primed.

To exit Recirculate Mode, press the Recirculate key

. The display prompts the operator to confirm.

Select to confirm or select to cancel. See F

27.

NOTE:

You must exit Recirculate Mode before depressurizing or initiating a crossover.

IG

F

IG

. 28: Depressurize Function Screen

.

30 313296J

Page 31

Operation

NOTE:

Depressurizing the active ram will depressurize

both rams. However, if additional user-supplied

check valves have been added to the system, only

the active ram will be depressurized.

To depressurize both rams perform manual crossover (see Manual Crossover, page 29), and then

press the Depressurize key again.

Pressurize System

From the Ram Operation screen, press the Depressur-

ize key . The display prompts the operator to con-

firm. Select to confirm pressurize or select to

cancel. See F

IG

. 28.

Change Drums

drum. Use minimum amount of air pressure necessary to push the platen out of the drum.

Excessive air pressure in the material drum could

cause the drum to rupture, causing serious injury.

The platen must be free to move out of the drum.

Never use drum blowoff air with a damaged drum.

3. Once the platen clears the drum, release the

blow-off air button (BG) and allow the ram to rise to

its full height. 2-Button Interlock: If system has this

feature, the ram will stop as it nears the top. Press

and hold both buttons to raise ram completely. See

F

IG

. 5.

4. Remove empty drum.

5. Inspect platen and, if necessary, remove any

remaining material or material build–up.

6. Place full drum on ram base.

NOTE: Follow this procedure to change the drum on

a fully heated warm melt supply system.

NOTE: Follow this procedure for either ram if using

a tandem warm melt supply system.

NOTICE

Do not use a drum of material that has been

dented or otherwise damaged; damage to the

platen wiper can result.

1. Push in the air motor slider valve (BF) to stop the

pump. See F

2. Set ram director valve (BC) to UP to raise the platen

(D) and immediately press and hold the blowoff air

button (BG) until the platen (D) is completely out of

IG

. 4.

7. Lower the ram and adjust the position of the drum

relative to the platen. See Load Material on page

25.

313296J 31

Page 32

Maintenance

Shutdown

Follow the procedure below for normal system shut

down, such as at the end of the work day.

NOTICE

Turning the system OFF relieves pressure from the

pump motor; however, it does not depressurize the fluid

pressure. Follow the Pressure Relief Procedure, page

28.

NOTE: The ram up/down and blowoff air is independent of the electronic controls and can be operated

anytime the main air slider valve is open and air

pressure is available.

1. Press while in the Ram Operation screen to

turn off the air motor. Select to confirm.

2. Press while in the Heater Run screen to turn

Maintenance

To reduce the risk of serious injury whenever you are

instructed to relieve pressure, always follow the Pres-

sure Relief procedure.

Replace Throat Seals

Quick Coupler

Remove wet cup from displacement pump while

attached to the ram to replace throat seals.

1. Ensure displacement pump is at bottom of stroke.

2. Follow the Pressure Relief Procedure on page 28.

3. Remove Quick Coupler:

Remove clip (GC), and slide coupling cover (GB) up

to remove coupling (GA).

off the heaters. Select to confirm.

3. Follow the Pressure Relief Procedure, page 28.

Many warm melt materials tend to expand when heating and may cause a heated hose to burst. Avoid the

potential of bursting a hose by opening the dispense

valve during system heat up and lock the dispense

valve trigger open every time you shut the system

down.

GB

GC

F

IG

. 29: Remove Quick Coupler

4. Lift air motor rod to bring rod to top of stroke.

5. Remove wet cup and packing cartridge according to

instructions in displacement pump manual(s).

GA

ti10508a

32 313296J

Page 33

Maintenance

Platen Maintenance

If the platen does not come out of the pail easily when

the pump is being raised, the air assist tube or check

valve may be plugged. A plugged valve prevents air

from reaching the underside of the plate to assist in raising it from the pail.

1. Turn off main disconnect.

2. Relieve pressure and disassemble air assist valve.

Refer to Supply Systems Repair-Parts manual.

3. Clear air assist tube in platen. Clean all parts of

valve and reassemble. Refer to Supply Systems

Repair-Parts manual.

4. Remove bleed stick from platen. Push bleed stick

through bleed relieve port (T) to remove material

residue. See F

5. Remove platen covers. See F

IG

. 30.

IG

. 30.

Remove and Reinstall Platen Wipers

Refer to Supply Units Repair-Parts manual for instructions.

70

49

Bleed

Stick

T

r_wm2179_313296_6a

43

48

a. Remove platen cover fasteners (70) or nuts

(309).

For 55 gallon platen (D200 3 in. and D200s 6.5

b.

in. supply systems):

Remove both platen covers

(49) and ground wire from platen.

For smaller platens (D60 3 in. supply systems):

Disconnect pump for the platen; see Discon-

nect Pump from Platen, page 50. Remove

screws (323) from upper heater plate (320).

Remove upper heater plate.

6. Remove any excess fluid. Use a soft wire brush on

heater coils (48) or heater (319). See F

IG

. 30.

7. Inspect platen heater blocks (43 or 320) or heater

(48 or 319) for burn or melt spots. Replace platen

heater blocks or heater if necessary. See F

IG

. 30.

8. Check for loose connections and damaged wires.

9. Follow steps in reverse order to reassemble platen.

309

Bleed

Stick

T

FIG. 30: Remove Platen Covers and Heaters

309

323

320

319

NOTE: Torque platen cover fasteners (70) to 60 +/10 in-lbs (6.8 +/- 1.1 N•m) for 55 gallon platen.

Torque nuts (309) to 45 +/- 5 in-lbs (5.1 +/- 0.6 N•m)

for smaller platens.

313296J 33

Page 34

Maintenance

Electrical Enclosure

1. Turn the main disconnect on the electrical control

panel door to the OFF position to disconnect power.

Power is still connected to the power line filter (459)

even after the main disconnect is open. Avoid contact with the power line filter.

2. Open door of electrical enclosure.

459

419

Check Ground Fault Circuit Interrupter

1. With electrical enclosure door still open, switch main

disconnect (421) back on.

Have a qualified electrician restore power to main

disconnect while electrical enclosure door is open.

2. Press Test button on ground fault circuit interrupter

(419). The blue switch should flip to the middle or

opposite side.

NOTE: Do not perform this test while the system is

in operation.

3. Press blue switch back into place to reset breaker.

419

421

F

IG

. 31: Inside View of Electrical Enclosure

3. Check for damaged or loose wires. Check connections from cable track.

F

IG

. 32: Ground Fault Circuit Interrupter

4. Switch main disconnect off.

34 313296J

Page 35

Maintenance

Pump Heaters

1. Turn the main disconnect on the electrical control

panel door to the OFF position to disconnect power.

2. Remove four screws (80 or 257) from back pump

shroud (52 or 234).

D200 Shown

80 or 257

4. Check for damaged wires and connections.

5. Ensure heaters (44 or 227) are secure so they cannot rotate on pump.

D200 Shown

44 or 227

F

IG

. 34: Pump Heaters

F

IG

. 33: Remove Pump Shroud

3. Remove pump heater front shroud (51 or 233).

313296J 35

Page 36

Alarms

Alarms

Warm Melt alarms alert you to a problem and help pre-

Diagnose Alarms

vent system shutdown or application errors. If an alarm

occurs, operation may stop and the following occurs.

See Alarm Codes and Troubleshooting, page 36, for

causes and solutions to each alarm code.

• Light tower indication changes (if equipped)

• Status bar on the display shows the alarm description

Clear Alarms

Alarms are cleared by the solution(s) listed in the following table or from the screen in which they appear. Refer

to Alarm Codes and Troubleshooting, page 36, for

details.

Alarm Codes and Troubleshooting

Alarm

Code Alarm Problem Cause Solution Clear Alarm

Fluid Control Module

CB1X A - Communication Error -

Ram A Not Found

CB2X B - Communication Error -

Ram B Not Found

B61X

B62X

Crossover Error (Ram A)

Crossover Error (Ram B)

Ram cannot communicate with

FCM A.

Ram cannot communicate with

FCM B.

Inactive ram has a Not Primed

alarm.

There is a Runaway alarm Correct runaway condition

There is a Drum Empty alarm. Replace empty drum with

Verify that power is supplied.

Check that CAN cables are

connected.

Verify that selector switch

is set correctly.

Replace FCM A.

Verify that power is supplied.

Check that CAN cables are

connected.

Verify that selector switch

is set correctly.

Replace FCM B

Set inactive ram to Prime

mode to automatically clear

alarm.

and clear alarm on Status

screen 1.

full drum to clear.

Alarm automatically

cleared by solution.

Alarm automatically

cleared by solution.

Cleared from Ram Alarm

screen. See Appendix A -

User Interface Display,

page 93.

36 313296J

Page 37

Alarm

Code Alarm Problem Cause Solution Clear Alarm

Fluid Control Module (continued)

DA1X

DA2X

L11X

L12X

DB1X

DB2X

WJ1X

WJ2X

DK1X

DK2X

L21X

L22X

WK1X

WK2X

ML1X

ML2X

MA1X

MA2X

Pump Runaway A

Pump Runaway B

A - Drum Empty

B - Drum Empty

A - Not Primed

B - Not Primed

A - Air Solenoid Disconnected

B - Air Solenoid Disconnected

A - Air Motor Sensor Error

B - Air Motor Sensor Error

A - Drum Low Deviation

B - Drum Low Deviation

A - Fluid Solenoid Disconnected Deviation

B - Fluid Solenoid Disconnected Deviation

A - Rebuild Platen Seals

B - Rebuild Platen Seals

A - Rebuild Pump

B - Rebuild Pump

Pump is running faster than

set runaway limit due to:

•

Increased air pressure.

•

Increased fluid output.

•

Exhausted fluid supply.

•

Open fitting, hose, drain,

or bleed valve.

Drum empty sensor has been

activated.

The pump is not primed. Set ram to Prime mode to

Solenoid unplugged. Check that solenoid cable

Damaged solenoid / wires. Inspect solenoid wires for

System has seen multiple up

strokes without a down stroke,

or multiple down strokes without an up stroke.

Damaged or disconnected air

motor sensors.

Drum low sensor has been

activated.

Solenoid unplugged. Check that solenoid cable

Damaged solenoid wires. Inspect solenoid cable for

Counter has reached programmed platen maintenance

interval.

Counter has reached programmed pump maintenance

interval.

Correct runaway condition

and clear alarm.

Replace empty drum with

full drum to clear.

automatically clear alarm,

or manually clear alarm

from Ram Alarm screen.

is connected.

damage.

See air motor manual. Cleared from Ram Alarm

Check that air motor sensors are connected.

Inspect air motor sensor

harness for damage.

Replace empty drum with

full drum to clear.

is connected.

damage.

Perform platen maintenance; see Supply Systems Repair-Parts manual.

Perform pump maintenance. See Check-Mate

Displacement Pump manual.

Cleared from Ram Alarm

screen. See Appendix A -

User Interface Display,

page 93.

Alarm automatically

cleared by solution.

Cleared from Ram Alarm

screen or Ram Operation

screen. See Appendix A -

User Interface Display,

page 93.

Alarm automatically

cleared by solution.

Alarm automatically

cleared by solution.

screen. See Appendix A -

User Interface Display,

page 93.

Deviation automatically

cleared by solution.

Deviation automatically

cleared by solution.

Cleared from Maintenance

screen. See Appendix A -

User Interface Display,

page 93.

Cleared from Maintenance

screen. See Appendix A -

User Interface Display,

page 93.

Alarms

313296J 37

Page 38

Alarms

Alarm

Code Alarm Problem Cause Solution Clear Alarm

Fluid Control Module (continued)

DA1X

DA2X

L11X

L12X

DB1X

DB2X

WJ1X

WJ2X

DK1X

DK2X

L21X

L22X

WK1X

WK2X

ML1X

ML2X

MA1X

MA2X

Pump Runaway A

Pump Runaway B

A - Drum Empty

B - Drum Empty

A - Not Primed

B - Not Primed

A - Air Solenoid Disconnected

B - Air Solenoid Disconnected

A - Air Motor Sensor Error

B - Air Motor Sensor Error

A - Drum Low Deviation

B - Drum Low Deviation

A - Fluid Solenoid Disconnected Deviation

B - Fluid Solenoid Disconnected Deviation

A - Rebuild Platen Seals

B - Rebuild Platen Seals

A - Rebuild Pump

B - Rebuild Pump

Pump is running faster than

set runaway limit due to:

•

Increased air pressure.

•

Increased fluid output.

•

Exhausted fluid supply.

•

Open fitting, hose, drain,

or bleed valve.

Drum empty sensor has been

activated.

The pump is not primed. Set ram to Prime mode to

Solenoid unplugged. Check that solenoid cable

Damaged solenoid / wires. Inspect solenoid wires for

System has seen multiple up

strokes without a down stroke,

or multiple down strokes without an up stroke.

Damaged or disconnected air

motor sensors.

Drum low sensor has been

activated.

Solenoid unplugged. Check that solenoid cable

Damaged solenoid wires. Inspect solenoid cable for

Counter has reached programmed platen maintenance

interval.

Counter has reached programmed pump maintenance

interval.

Correct runaway condition

and clear alarm.

Replace empty drum with

full drum to clear.

automatically clear alarm,

or manually clear alarm

from Ram Alarm screen.

is connected.

damage.

See air motor manual. Cleared from Ram Alarm

Check that air motor sensors are connected.

Inspect air motor sensor

harness for damage.

Replace empty drum with

full drum to clear.

is connected.

damage.

Perform platen maintenance; see Supply Systems Repair-Parts manual.

Perform pump maintenance. See Check-Mate

Displacement Pump manual.

Cleared from Ram Alarm

screen. See Appendix A -

User Interface Display,

page 93.

Alarm automatically

cleared by solution.

Cleared from Ram Alarm

screen or Ram Operation

screen. See Appendix A -

User Interface Display,

page 93.

Alarm automatically

cleared by solution.

Alarm automatically

cleared by solution.

screen. See Appendix A -

User Interface Display,

page 93.

Deviation automatically

cleared by solution.

Deviation automatically

cleared by solution.

Cleared from Maintenance

screen. See Appendix A -

User Interface Display,

page 93.

Cleared from Maintenance

screen. See Appendix A -

User Interface Display,

page 93.

38 313296J

Page 39

Alarm

Code Alarm Problem Cause Solution Clear Alarm

Fluid Control Module (continued)

DD1X

DD2X

A - Pump Diving

B - Pump Diving

Pump leak. Worn valve or packings.

See Check-Mate Displacement Pump manual.

Ram air pressure set too low. Increase air pressure to

ram until diving stops.

Material flow rate exceeds

ability of ram to feed pump.

Temperature Control Modules

Decrease pump air pressure to slow cycle rate.

Decrease pressure until

diving stops.

Cleared from Ram Alarm

screen. See Appendix A -

User Interface Display,

page 93.

The last digit in the temperature control module alarm codes identify the heat zone.

T3A1

T3A2

T3A3

T3A4

T3A5

T3A6

T3A7

T3A8

T3A9

T3A10

T3A11

T3A12

T2A1

T2A2

T2A3

T2A4

T2A5

T2A6

T2A7

T2A8

T2A9

T2A10

T2A11

T2A12

Alarm Above Setpoint

Deviation Above Setpoint

Deviation Below Setpoint Tripped circuit breaker. Visually check circuit

RTD on wrong module. Verify RTD wire and heater

power cord is attached to

correct heat module.

Shorted module. Replace module.

breaker for a tripped condition.

Low power. Measure voltage across