Page 1

Instructions

DSL/SVK Pumps

- For pumping exact amounts of lubrication fluids from a reservoir

to specific lubrication points -

DSL Models: 256907, 256908, 256929

3000 psi ( 20.7 MPa, 206.8 bar) Maximum Working Pressure

SVK Models: 256904, 256905

Maximum Working Pressure*: 5000 PSI (9.7 MPa/96.5 bar - 34.7 MPa/344.7 bar)

Pressure above 1400 PSI (9.7 MPa/96.5 bar) requires use of a high pressure sight glass

*

313261D

ENG

SVK Model: 256906

Maximum Working Pressure 1400 (9.7 MPa/96.5 bar)

7

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

Piston

Size

Part No.

256907

256908

256929 9/32

256906 7/32

256904

256905 9/32

(Inches)

Max Pressure

PSI (MPa/bar)

Max. Min. Max. Min. Max. Min. Max. Min.

3000 psi

(20.7 MPA / 206.8 bar) 6.25 2.0 0.15 0.0048 0.0245 0.079 25 3

1400 psi

(9.6 MPa / 96.5 bar) 3.4 0.5 0.008 0.0012 0.131 0.020 25 1

1400 psi / 5000 psi

(9.6 MPa / 96.5 bar) /

(34.4 MPa / 344.7 bar) 6.25 0.5 0.15 0.0012 0.245 0.020 25 1

Drops /

Stroke

Cubic Inches /

Stroke

Cubic

Centimeters /

Stroke

Strokes /

Minute

Page 2

WARNING

FIRE AND EXPLOSION HAZARD

When flammable fluids are present in the work area, such as gasoline and windshield wiper fluid, be aware that

flammable fumes can ignite or explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources, such as cigarettes and portable electric lamps.

• Keep work area free of debris, including rags and spilled or open containers of solvent and gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Ground all equipment in the work area.

• Use only grounded hoses.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment until you

identify and correct the problem.

• Keep a working fire extinguisher in the work area.

SKIN INJECTION HAZARD

High-pressure fluid from dispense valve, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point dispense valve at anyone or at any part of the body.

• Do not put your hand over the end of the dispense nozzle.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning, checking, or

servicing equipment.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on skin and cause serious injury.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system component.

See Techni cal Dat a in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technica l Da ta in all equipment

manuals. Read fluid and solvent manufacturer’s warnings. For complete information about your material,

request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s

replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area of the

equipment to help protect you from serious injury, including eye injury, inhalation of toxic fumes, burns, and hearing

loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

2 313261D

Page 3

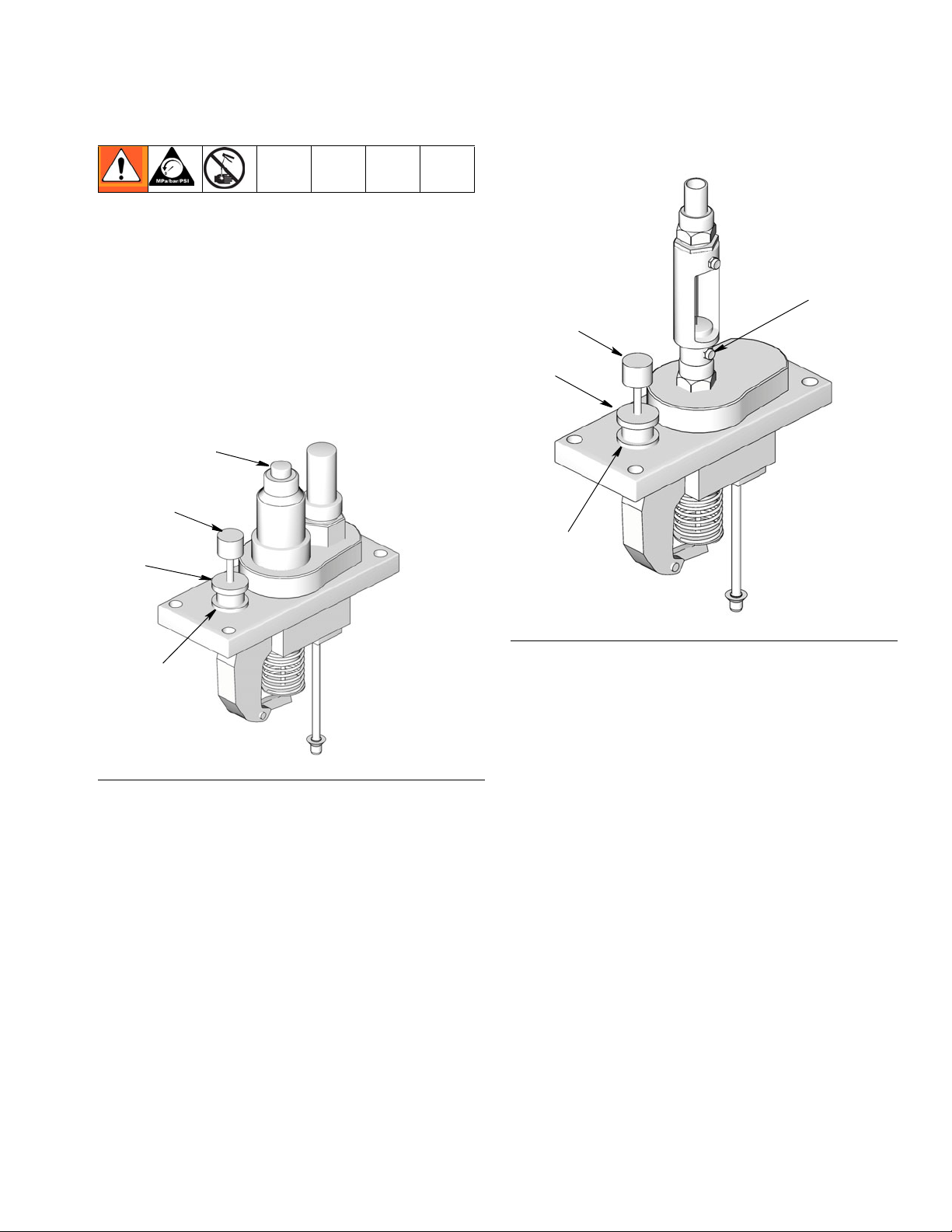

Pressure Relief Instructions

Follow this pressure relief procedure whenever you are

instructed to relieve pressure or need to check or service equipment.

SVK Models

Starting Lubricator

To relieve pressure, loosen vent screw DSL Models: (a)

in F

IG. 1; SVK Models: (e) in FIG. 2, allowing pressure to

vent.

DSL Models

Starting Lubricator

a

b

d

c

e

b

d

c

FIG. 2

To start lubricator for the first time, or to prime lubricator

if it stops feeding due to lack of oil in the reservoir:

1. Verify reservoir is filled with oil.

2. Loosen or remove small hexagonal screw (e) in

FIG. 1

1. Verify reservoir is filled with oil.

2. Remove vent screw (a) on sight dome.

3. Fill dome to upper line with oil.

4. Replace and tighten vent screw (a) (hand tight only

is recommended).

5. Remove hex coupling nut on outlet fitting.

6. Prime by manually pumping spindle (b) in front of

sight dome until air bubbles are purged.

7. Retighten outlet nut.

313261D 3

sight feed body.

3. Prime by manually pumping spindle (b) unit until

clear oil is delivered.

NOTE: For quicker results adjustment should be made

for full amount.

Adjusting Rate of Flow

DSL and SVK Models

1. Loosen lock nut (c) on adjustment gland.

2. To increase flow, turn adjustment gland (d) counter-clockwise, to decrease flow turn adjustment

gland clockwise.

3. Tighten lock nut (c).

NOTE: Pump unit manually each week to purge air

which might be trapped in oil supply.

Page 4

Maintenance

Sight Feed

SVK Models Only

When lubricating with mineral oils, synthetic oils or

detergent oils, keep the sight feed full of 3-M

oroinert FC-77.

™

brand flu-

Maintenance

• Use clean oil only.

• Keep lubricator reservoir full of oil.

• Verify that all connections are tight.

• Support oil leads where excessive vibration occurs.

• Check driving device to make sure studs and links

are tight and belt is in good condition.

• Flush reservoir regularly.

• Clean all pump units.

• Inspect all ball check valves for rust, carbon or

gummy, dirty deposits. Replace if necessary.

F

IG. 3

4 313261D

Page 5

Parts DSL Models

1 560104 UNION, nut 1

2 562600 OUTLET, tailpiece assembly 1

3 555875 DOME, single 1

4 555947 GASKET 1

5 555948 GASKET 1

6 555906 GASKET 1

7 555915 GASKET 1

8 560049 TUBE, drip (model 256907 only) 1

9 560017 ARM, rocker 1

10 560047 SCREW, vent (model 256907 only) 1

11 560051 SCREW 1

12 564243 TUBE, suction, assembly (model

246907 only)

13 562605 VALVE, outlet assembly 1

14 562606 VALVE, cage assembly 1

15 555893 SPRING, compression 1

16 555953 RETAINER, spring 1

Parts DSL Models

DSL Models: 256907FN Part No. Description Qty

10

2

3

1

11

1

13

6

8

7

14

5

12

4

9

313261D 5

Page 6

Parts DSL Models

DSL Models: 256908

2

11

1

13

6

7

14

5

15

3

4

16

9

6 313261D

Page 7

Parts SVK Models

Parts SVK Models

FN Part No. Description Qty

1 555321 GASKET 1

2 555322 GASKET 1

3 RETAINER, ball 1

4 VALVE, outlet body 1

5

3

4

FN Part No. Description Qty

5 562604 VALVE, outlet, complete 1

6 562607 TUBE, suction assembly 1

7 555947 GASKET 1

8 560017 ARM, rocker 1

9 562630 PUMP, assembly 1

7

9

6

8

313261D 7

Page 8

Parts SVK Models

SVK-Liquid Sight Feed Assemblies

SF1 - Part No. 562592

1400 psi (9.6 MPa, 96 bar)

Medium pressure liquid sight feed assembly. 1/2” NPTF

outlet with 100% 3M

all types of mineral and synthetic oils.

™

brand fluorinert FC-77. Use with

SF3 - Part No. 562610

1400 psi (9.6 MPa, 96 bar)

Same as SF1, but with a 1/4” NPTF tube connector outlet.

SF5 - Part No. 562593

1400 psi (9.6 MPa, 96 bar)

Same as SF1 with a white background on the sight

glass.

SF7 - Part No. 562595

5000 psi (34.4 MPa, 344 bar)

High pressure liquid sight feed assembly. 1/8” NPTF out-

let with 100% 3M

types of mineral and synthetic oils.

™

brand fluorinert FC-77. Use with all

8 313261D

Page 9

Dimensions

DSL Pump SVK Pump

Dimensions

Dim Inches Millimeter.

A

B

C

D

E

F

G

H

J

K

2.06

3.50

4.00

0.31

1.44

8.80

8.67

3.41

5.39

3.27

52.4

88.9

101.6

7.9

36.5

223.7

220.1

86.7

137.0

83.2

Dim Inches Millimeter.

A

B

C

D

E

F

G

H

2.00

3.50

4.00

0.31

1.44

13.52

8.13

5.39

50.8

88.9

101.6

7.9

36.5

343.4

206.5

137.0

313261D 9

Page 10

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 313261

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2008, Graco Inc. is registered to ISO 9001

www.graco.com

8/2008, revised 11/2010

Loading...

Loading...