Page 1

Operation - Parts

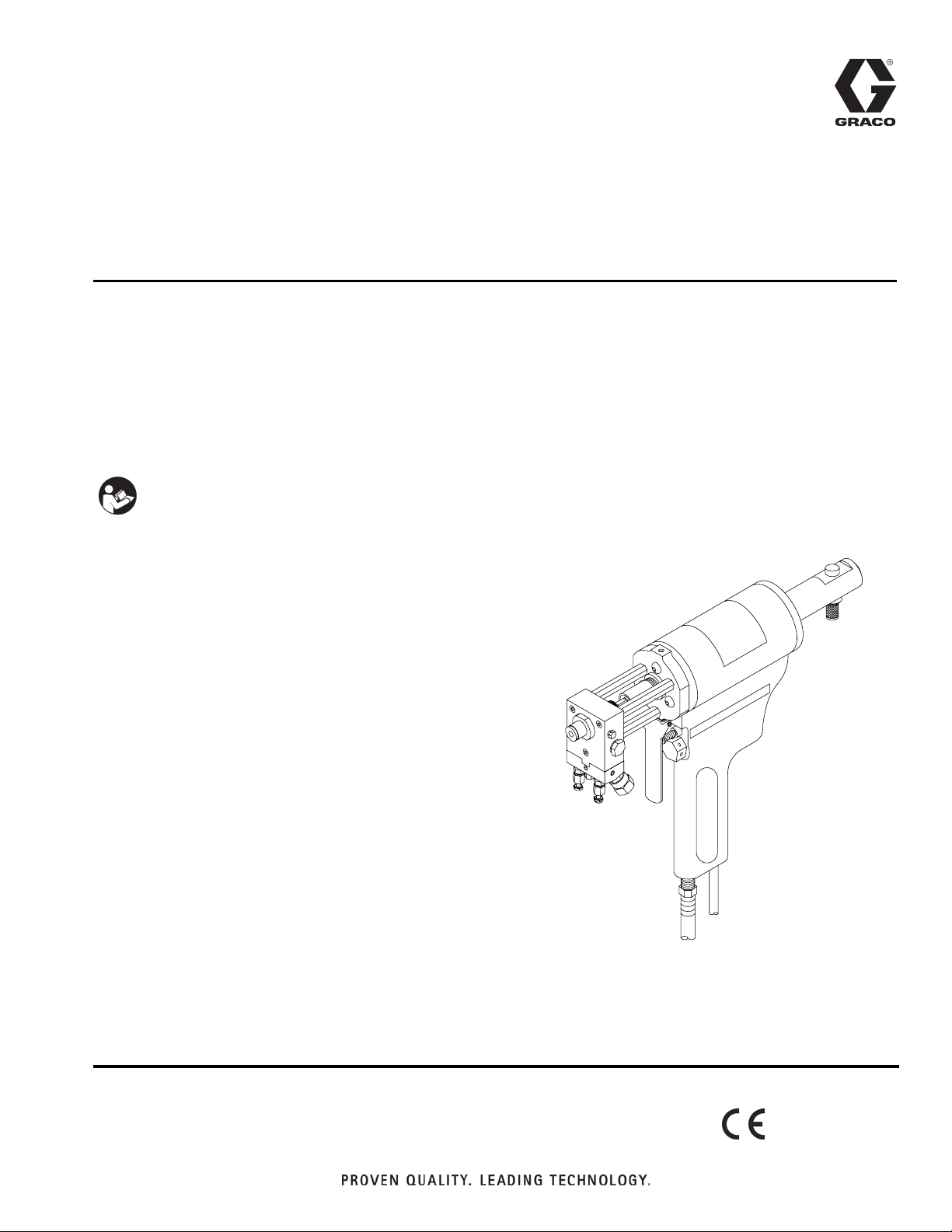

AR Pour Gun

For use with non-flammable polyurethane foams.

Not for use in explosive atmospheres.

Part No. 255828

2000 psi (13.8 MPa, 138 bar) Maximum Working Pressure

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

312888D

Page 2

Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Isocyanate Hazard . . . . . . . . . . . . . . . . . . . . . . . . . 5

Material Self-ignition . . . . . . . . . . . . . . . . . . . . . . . 5

Moisture Sensitivity of Isocyanates . . . . . . . . . . . . 5

Keep Components A and B Separate . . . . . . . . . . 5

Foam Resins with 245 fa Blowing Agents . . . . . . . 5

Changing Materials . . . . . . . . . . . . . . . . . . . . . . . . . 5

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operation Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Air Hose Connection . . . . . . . . . . . . . . . . . . . . . . 8

Coupling Block . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Initial Set Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Daily Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Daily Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 12

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Gun Service Kits . . . . . . . . . . . . . . . . . . . . . . . . 13

Daily Cleaning Procedure,

with Gun Service Kit . . . . . . . . . . . . . . . . . 13

Daily Cleaning Procedure,

without Gun Service Kit . . . . . . . . . . . . . . . 14

Flush Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Trigger Gun While Disconnected . . . . . . . . . . . 14

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Pattern Control Tip . . . . . . . . . . . . . . . . . . . . . . 16

Screen Screw and Port Closure Plugs . . . . . . . 16

Valving Rod and Resilient Sleeve . . . . . . . . . . . 17

Coupling Block and Check Valves . . . . . . . . . . . 18

Impingers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Gun Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Pressure Check Valving Rod Resilient Sleeve . 21

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

AR Pour Gun 255828 . . . . . . . . . . . . . . . . . . . . 23

AR-D Conversion Kit 24A023 . . . . . . . . . . . . . . 29

Electrical Diagram . . . . . . . . . . . . . . . . . . . . . . . . 30

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Performance Charts . . . . . . . . . . . . . . . . . . . . . . . 31

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 32

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 32

2 312888D

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

•

Read MSDS’s to know the specific hazards of the fluids you are using.

•

Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

•

Always wear impervious gloves when spraying or cleaning equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

•

Protective eyewear

•

Clothing and respirator as recommended by the fluid and solvent manufacturer

•

Gloves

•

Hearing protection

SKIN INJECTION HAZARD

High-pressure fluid from dispense valve, hose leaks, or ruptured components will pierce skin. This may

look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

•

Do not point dispense valve at anyone or at any part of the body.

•

Do not put your hand over the end of the dispense nozzle.

•

Do not stop or deflect leaks with your hand, body, glove, or rag.

•

Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

•

Tighten all fluid connections before operating the equipment.

•

Check hoses tubes and couplings daily. Replace worn or damaged parts immediately.

312888D 3

Page 4

Warnings

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

•

Use and clean equipment only in well ventilated area.

•

Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

•

Keep work area free of debris, including solvent, rags and gasoline.

•

Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

•

Ground equipment, personnel, object being sprayed, and conductive objects in work area. See

Grounding instructions.

•

Use only Graco grounded hoses.

•

Check gun resistance daily.

•

If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

•

Do not flush with gun electrostatics on. Do not turn on electrostatics until all solvent is removed from

system.

•

Keep a working fire extinguisher in the work area.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

•

Do not operate the unit when fatigued or under the influence of drugs or alcohol.

•

Do not exceed the maximum working pressure or temperature rating of the lowest rated

system component. See Technical Data in all equipment manuals.

•

Use fluids and solvents that are compatible with equipment wetted parts. See Technical

Data in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For com-

plete information about your material, request MSDS forms from distributor or retailer.

•

Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

•

Do not alter or modify equipment.

•

Use equipment only for its intended purpose. Call your distributor for information.

•

Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

•

Do not kink or over bend hoses or use hoses to pull equipment.

•

Keep children and animals away from work area.

•

Comply with all applicable safety regulations.

4 312888D

Page 5

Isocyanate Hazard

Spraying materials containing isocyanates creates

potentially harmful mists, vapors, and atomized particulates.

Read material manufacturer’s warnings and material

MSDS to know specific hazards and precautions

related to isocyanates.

Prevent inhalation of isocyanate mists, vapors, and

atomized particulates by providing sufficient ventilation in the work area. If sufficient ventilation is not

available, a supplied-air respirator is required for

everyone in the work area.

Isocyanate Hazard

•

Keep the ISO lube pump reservoir (if installed) filled

with Graco Throat Seal Liquid (TSL), Part 206995.

The lubricant creates a barrier between the ISO and

the atmosphere.

•

Use moisture-proof hoses specifically designed for

ISO, such as those supplied with your system.

•

Never use reclaimed solvents, which may contain

moisture. Always keep solvent containers closed

when not in use.

•

Never use solvent on one side if it has been contaminated from the other side.

•

Always lubricate threaded parts with ISO pump oil

or grease when reassembling.

To prevent contact with isocyanates, appropriate personal protective equipment, including chemically

impermeable gloves, boots, aprons, and goggles, is

also required for everyone in the work area.

Material Self-ignition

Some materials may become self-igniting if applied

too thickly. Read material manufacturer’s warnings

and material MSDS.

Moisture Sensitivity of Isocyanates

Isocyanates (ISO) are catalysts used in two component

foam and polyurea coatings. ISO will react with moisture

(such as humidity) to form small, hard, abrasive crystals,

which become suspended in the fluid. Eventually a film

will form on the surface and the ISO will begin to gel,

increasing in viscosity. If used, this partially cured ISO

will reduce performance and the life of all wetted parts.

The amount of film formation and rate of crystallization varies depending on the blend of ISO, the

humidity, and the temperature.

To prevent exposing ISO to moisture:

•

Always use a sealed container with a desiccant

dryer in the vent, or a nitrogen atmosphere. Never

store ISO in an open container.

Keep Components A and B Separate

CAUTION

To prevent cross-contamination of the equipment’s

wetted parts, never interchange component A (isocyanate) and component B (resin) parts.

Foam Resins with 245 fa Blowing Agents

New foam blowing agents will froth at temperatures

above 90°F (33°C) when not under pressure, especially

if agitated. To reduce frothing, minimize preheating in a

circulation system.

Changing Materials

•

When changing materials, flush the equipment multiple times to ensure it is thoroughly clean.

•

Always clean the fluid inlet strainers after flushing.

•

Check with your material manufacturer for chemical

compatibility.

•

Most materials use ISO on the A side, but some use

ISO on the B side.

•

Epoxies often have amines on the B (hardener)

side. Polyureas often have amines on the B (resin)

side.

312888D 5

Page 6

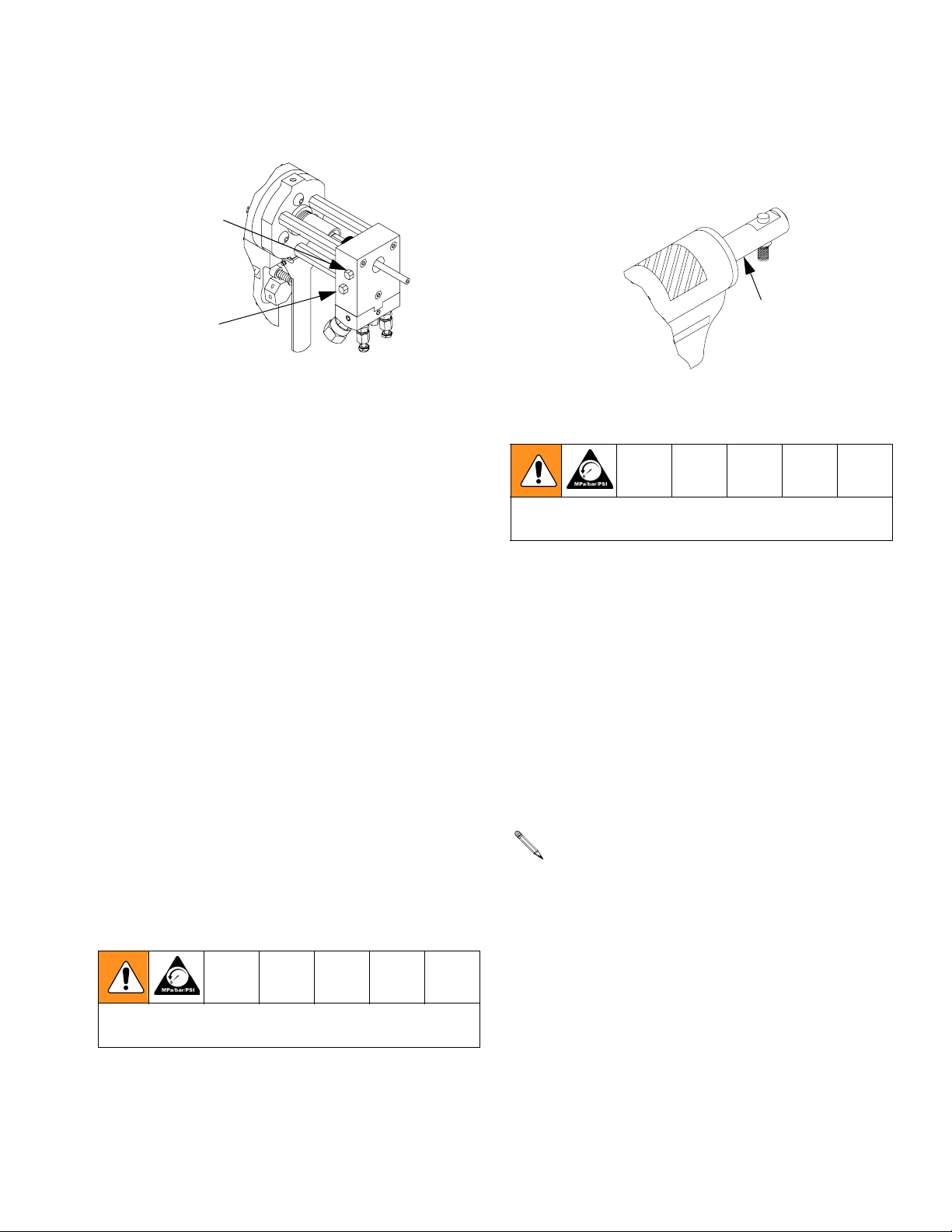

Components

Components

F

Overall View

Gun Block

E

B

C

D

A

Q

P

N

M

L

R

S

T

W

X

G

U

V

AA

K

H

Key:

A Manual Valves

B Gun Block

C Coupling Block

D Trigger

E Valving Rod

F Piston Rod

G Safety Stop

H Pattern Control Tip

J Front Packing

KO-ring

L Front Impinger

M Throat

N Rear Impinger

P Screen Screw Mounting Screw

Q R-Port Closure Screw

Z

AB

AE

AC

J

AD

R Gun Block

S Resin Seal Retainer

TSpacer

U Resin Seal Screw

VO-ring

WResin Packing

X A-Port Closure Screw

Y Gun Block Screen

Z Gun Block Screen Screw

AA Screen Screw Seal

AB Snap Ring

AC A-Check Valve

AD Coupling Block Gaskets

AE R-Check Valve

Y

6 312888D

Page 7

Operation Basics

To prevent accidental gun operation, always disconnect air supply before servicing gun or anytime gun is

not in use.

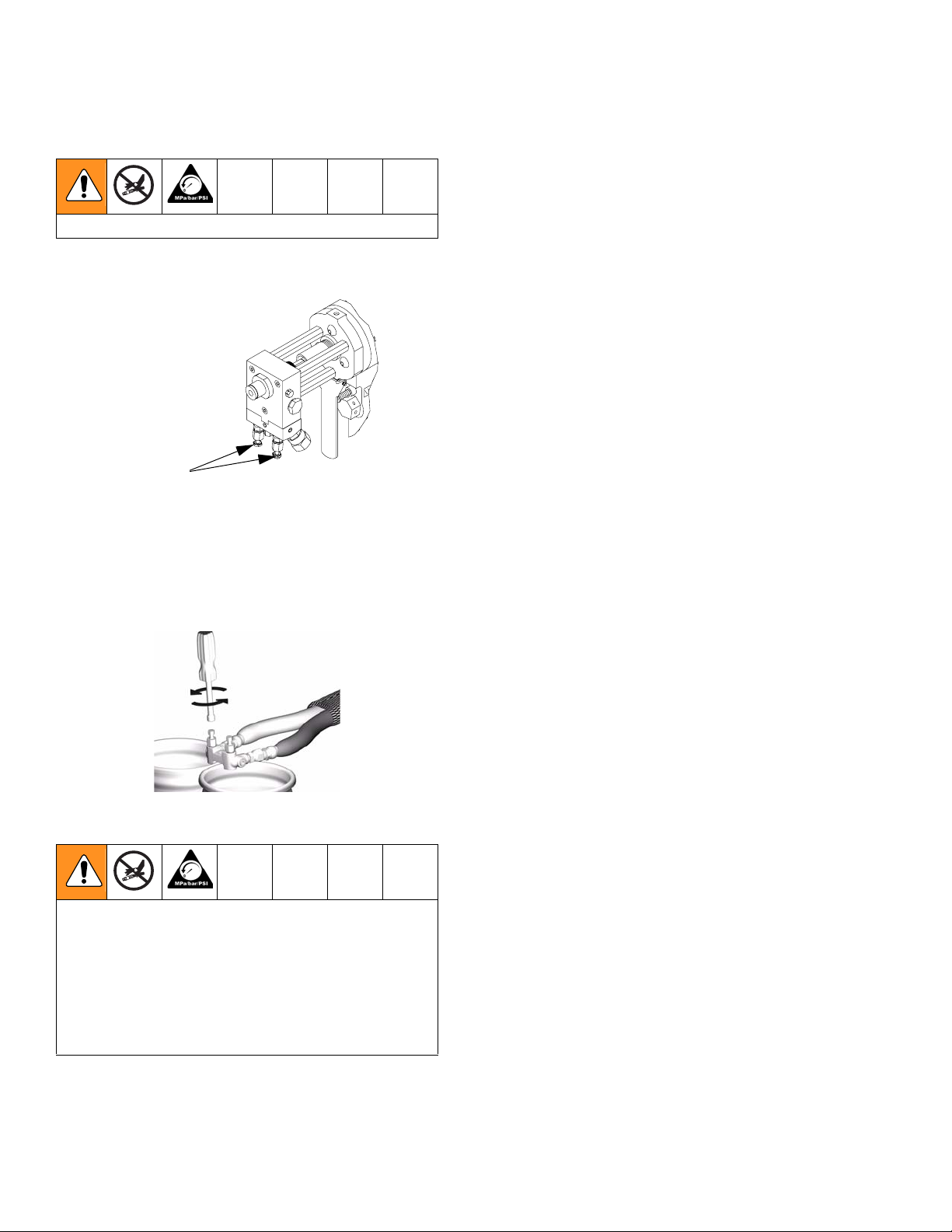

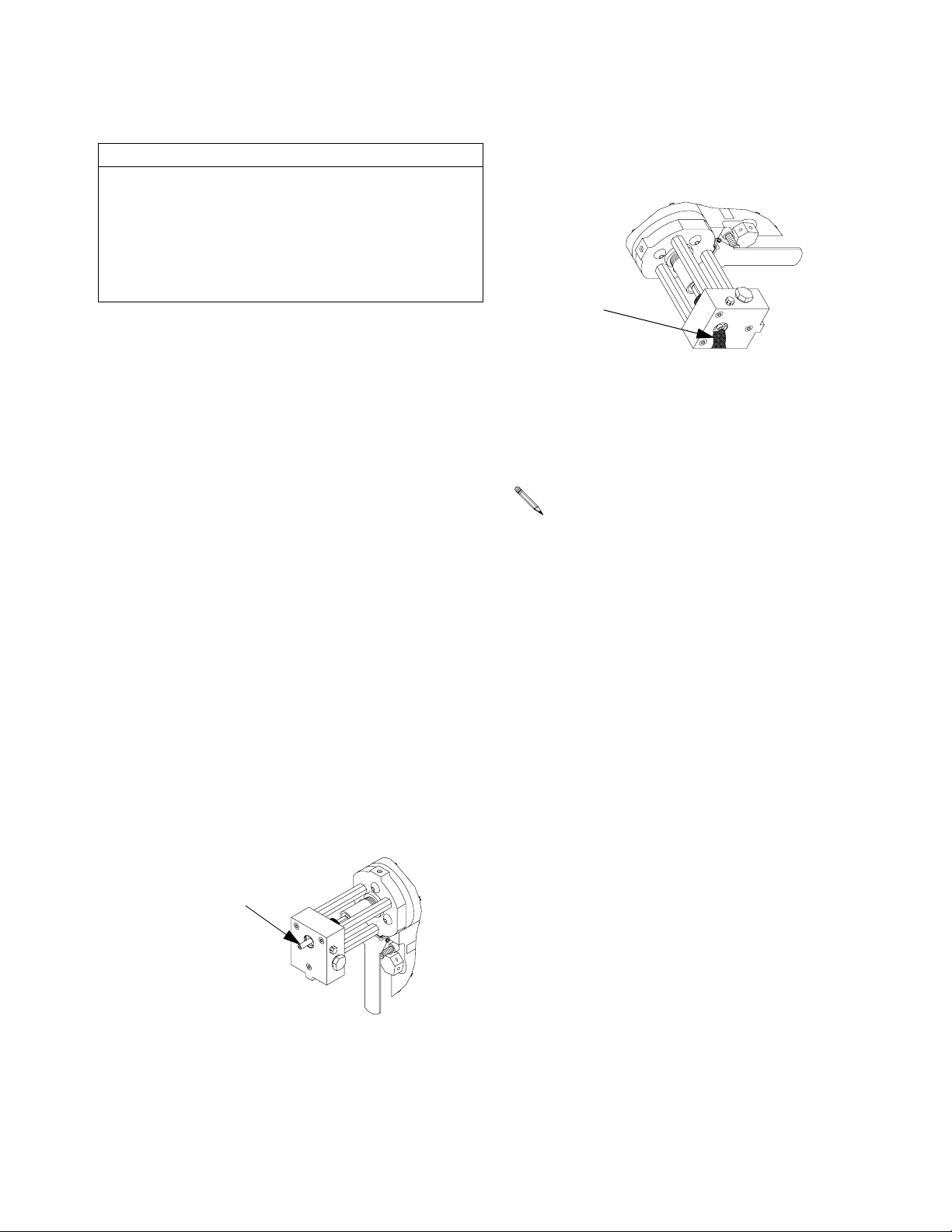

Grounding

Operation Basics

Safety Stop

The gun has a two-position safety stop. The SERVICE

(CLOSED) position permits both material inlet ports to

remain closed when gun is triggered.

Safety Stop

Check your local electrical code and your proportioner

manual for detailed grounding instructions.

Ground the spray gun through connection to a

Graco-approved grounded fluid supply hose.

Engage Safety Stop

To engage safety stop, push in and turn clockwise to

CLOSED (rear detent) position, then release.

Disengage Safety Stop

To disengage safety stop, push in and turn counterclockwise to place in OPEN (forward detent) position, then

release.

312888D 7

Page 8

Operation Basics

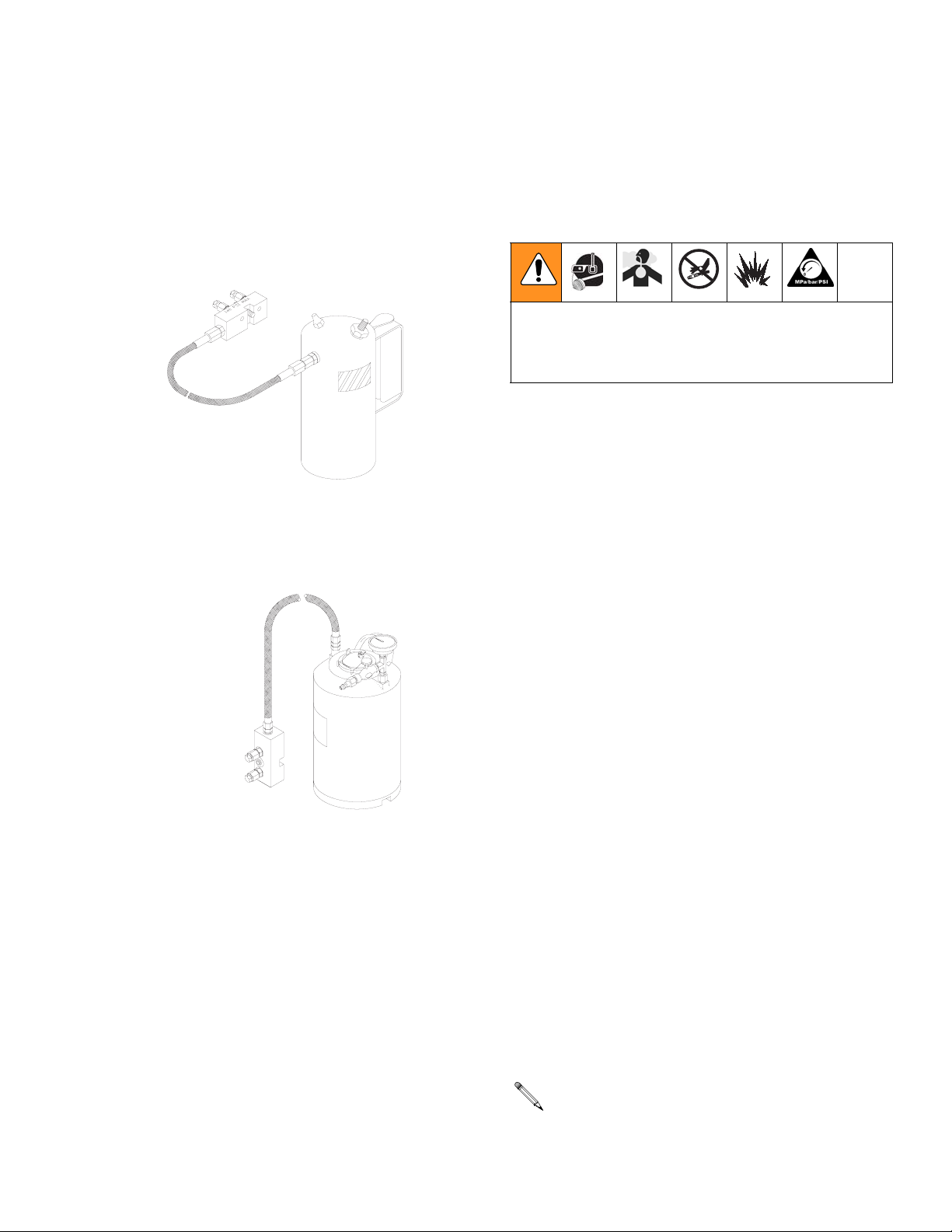

Air Hose Connection

Connect Air Hoses

Pull back sleeve of female fitting, insert male fitting and

slide sleeve forward to secure connection.

Disconnect Air Hoses

Pull back sleeve of female fitting and pull out male fitting.

Pull Sleeve

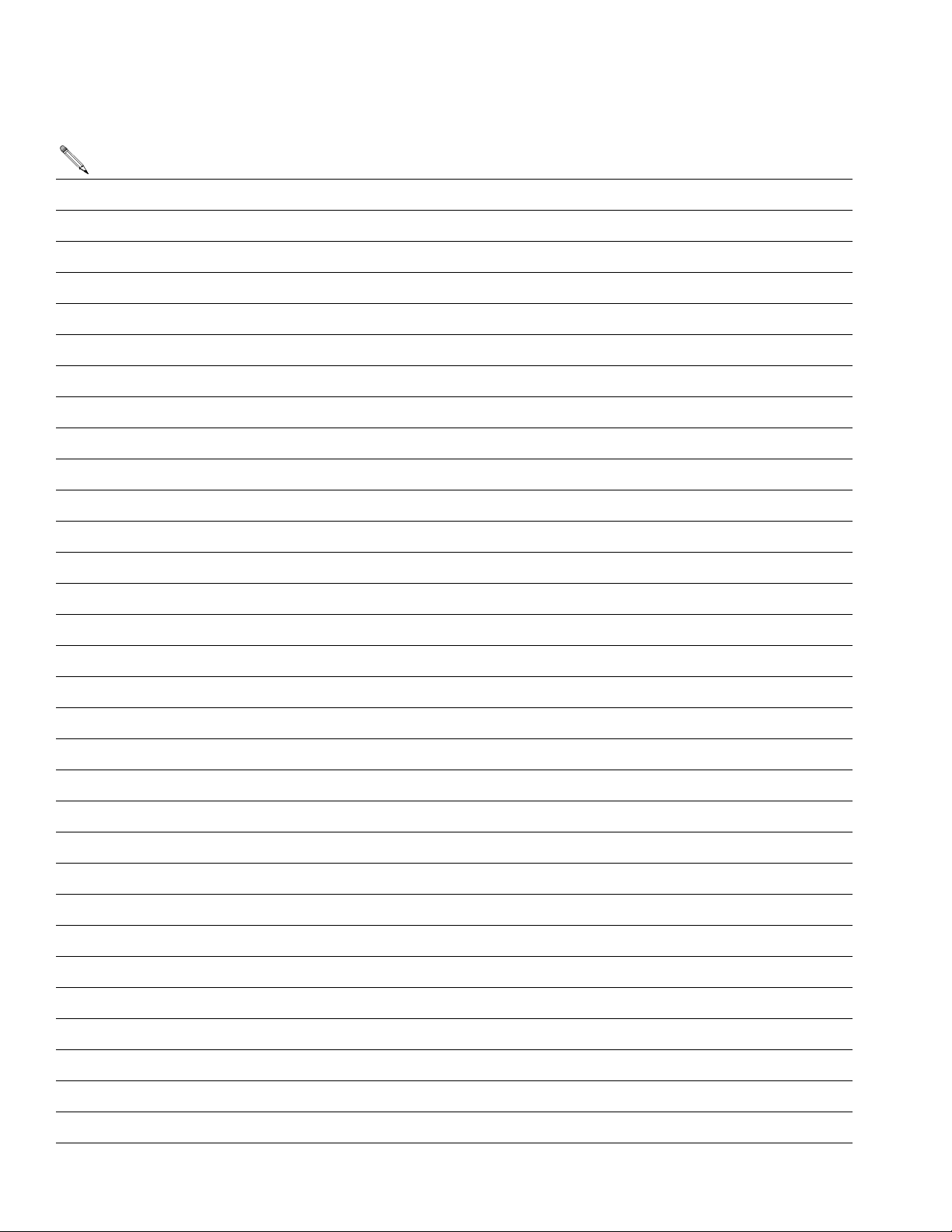

Coupling Block

Chemical hoses are joined to gun block by coupling

block to ease installation and removal of gun.

1. Open manual valves using 5/16 in. nut driver; turn

manual valves counterclockwise approximately

three full turns. Do not open until it bottoms out.

2. Close manual valves by turning fully clockwise.

Manual Valves

Removal and Installation

Manual Valves

Triggering gun with manual valves closed may

cause crossover if gun ports contain residual chemical.

To prevent release of pressurized chemicals, never

open manual valves unless coupling block is secured

to gun or exit port is directed into flush pail.

To prevent release of pressurized chemicals, close

both manual valves before removing coupling block.

Remove Coupling Block

1. Set safety stop to SERVICE (CLOSED).

2. Disconnect air hose.

3. Close both manual valves.

4. Remove coupling block mounting screw.

5. Separate coupling block from gun.

6. Wipe mating surfaces of gun block and coupling

block to remove residual chemical.

8 312888D

Page 9

7. Cover exposed openings with grease.

Coupling

Block

Install Coupling Block

Replace nicked, damaged, or worn coupling block gaskets.

1. With gaskets in place, fit coupling block to gun

block.

Operation Basics

2. Insert coupling block mounting screw and use

5/16 in. nut driver to tighten to gun block.

312888D 9

Page 10

Initial Set Up

Initial Set Up

1. Remove coupling block from gun.

2. Check valving rod clearance in closed position. Rod

should extend approximately 1/32 in. (1 mm)

beyond tip of mixing chamber.

3. Adjust valving rod travel to initial setting. See Valv-

ing Rod and Resilient Sleeve, page 17.

4. Connect air supply hose to gun.

5. Connect A-isocyanate hose (red-taped) to notched

fitting on coupling block. Then connect R-resin hose

(blue-taped) to fitting without notches on coupling

block.

6. Close both manual valves.

7. Pressurize the A and R chemical hoses and check

for leaks. (See Proportioning Unit manual.)

8. Bleed air from chemical hoses:

a. Hold coupling block with exit ports pointed into

disposable container.

b. Open each manual valve to allow trapped air to

escape. Bleed each side until chemical is free of

air.

c. Close both manual valves.

9. Use clean cloth soaked in gun cleaner to wipe clean

coupling block and its mating surfaces.

CAUTION

To avoid accumulation of dirt and other contaminants,

do not apply grease to mating surfaces of coupling

block.

10. Install coupling block to gun block.

11. Proceed with Daily Start-up procedure or Shutdown

procedure as required.

10 312888D

Page 11

Daily Start-Up

Daily Start-Up

Ensure gun is attached to coupling block and air hose,

and the proportioning unit is at desired temperature

and pressure.

1. Ensure gun is mounted onto gun block.

2. Connect air supply to gun; see Air Hose Connec-

tion, page 8.

3. Connect electrical harness to gun.

4. Trigger gun multiple times to ensure valving rod

moves through its full travel quickly and freely.

CAUTION

Sluggish valving rod action may result in valving rod

sticking in open position when fluid pressure is

applied. Always have a 5/16 in. nut driver available to

quickly close manual valves on coupling block.

5. Open both manual valves; see Manual Valves,

page 8.

Daily Shutdown

Follow daily shutdown when gun is out of service

for any length of time. Daily disassembly of gun for

cleaning is not recommended if it has been operating properly. However, if you remove the gun from

the coupling block, flush and clean thoroughly.

1. Set safety stop to OPEN.

2. Close both manual valves.

3. Disconnect air supply from gun.

4. Shutdown proportioning unit as required. See Proportioner manual.

5. Clean as required.

Do not disassemble gun daily for cleaning if it is

operating properly. However, if gun is removed from

coupling block, it must be flushed and cleaned thoroughly.

6. Test spray on disposable surface and adjust spray

pattern as needed.

Do not exceed 2000 psi (13.8 MPa, 138 bar) maximum fluid working pressure even in static de-triggered conditions, or check valve damage may

result.

312888D 11

Page 12

Pressure Relief Procedure

Pressure Relief Procedure

Relieve pressure before cleaning or repairing gun.

1. Close both manual valves.

Manual Valves

2. Set safety stop to OPEN.

3. Trigger gun onto cardboard or into waste container

to relieve pressure.

4. Release gun trigger, set safety stop to SERVICE

(CLOSED), and close manual valves.

If fluid in hose and proportioner is still under pressure,

follow Pressure Relief Procedure in your Proportioner

manual.

To relieve pressure in hose after gun is removed, place

fluid manifold over containers, facing away from you.

Very carefully open fluid valves. Under high pressure,

fluid will spray sideways from fluid ports.

12 312888D

Page 13

Maintenance

Maintenance

Gun Service Kits

Use either the 1-Quart Gun Service Kit (296980) or

3-Gallon Gun Service Kit (296981) to perform daily

flushing of spray gun without disassembly.

1-Quart Kit

For more information about the 1-Quart Gun Service Kit,

see Manual 311340.

Daily Cleaning Procedure, with Gun Service Kit

To avoid static sparking that may result in fire or explosion, ensure all equipment in cleaning procedure is

grounded. Do not clean on or near foamed or coated

surfaces or any other flammable surfaces or objects.

1. Set safety stop to SERVICE (CLOSED).

2. Close both manual valves.

3. Remove gun from coupling block.

4. Disconnect air and electric.

5. Attach service block of gun service kit to gun, and

then tighten using 5/16 in. nut driver.

6. Pressurize Service Kit container up to 100 psi. Do

not exceed 100 psi (0.7 MPa, 7 bar).

3-Gallon Kit

For more information about the 3-Gallon Gun Service

Kit, see Manual 311340.

7. Open one manual valve on service block.

8. Connect air to gun. Set safety stop to OPEN.

9. Hold gun against grounded waste container.

10. Trigger gun and 1-Quart Gun Service Kit. Spray into

waste container until there is a fine, unobstructed

mist of gun cleaner.

11. Release trigger and close manual valve on service

block.

12. Repeat steps 7-11 for other side of gun.

13. Remove service block of gun service kit from spray

gun.

14. Set safety to SERVICE (CLOSED).

15. Disconnect air supply.

16. Clean removed component parts.

Do not use metal cleaning devices to clean plastic

components.

312888D 13

Page 14

Maintenance

Daily Cleaning Procedure, without Gun Service Kit

If the Gun Service Kit is not available, the iso side components must be cleaned daily.

See AR Gun Tool Kit 253728 on page 28.

1. Place safety stop in SERVICE (CLOSED) position.

2. Remove pattern control tip.

3. Remove front impinger, packing, and o-ring from

pattern control tip.

4. Using pattern control tip/impinger cleanout tool

(607), clean the inside bore of the pattern control tip

by inserting and spinning.

5. Using cleanout spade (609), clean the front

impinger by sliding through slots. Clean inside bore

of the impinger as necessary.

Flush Gun

To avoid static sparking that may result in fire or explosion, ensure all equipment in flushing procedure is

grounded. Do not flush on or near foamed or coated

surfaces.

1. Set safety stop to SERVICE (CLOSED).

2. Close both manual valves.

3. Loosen screen screw and then remove by hand.

4. Use flush can to thoroughly flush screen screw and

screen screw cavity.

5. Service gun by following Troubleshooting proce-

dures, page 15.

Trigger Gun While Disconnected

6. Inspect packing for built-up iso and deformities and

replace as necessary.

7. Inspect o-ring for flat areas and replace as necessary.

8. Remove screen screw then remove screen from

screen screw. Inspect gasket and replace as necessary.

9. Clean screen screw and screen with solvent. If iso

build-up exists on screen screw, clean with brass

wire brush as necessary.

10. Clean gun block with solvent.

11. Remove iso check valve gasket using gasket

removal tool (611).

12. Using check valve removal tool (612), remove iso

check valve.

13. Clean all parts with solvent then blow dry with compressed air and reassemble.

During gun maintenance, it may be helpful to trigger the

gun while the electrical harness is disconnected. To do

so, perform the following steps.

1. Connect gun to air supply.

2. Using a small allen key, insert the small end into the

center hole of the exhaust valve cap (217) located

behind the trigger.

217

3. Pull trigger to depress allen key into muffler and

activate the valving mechanism. The gun should

trigger and the valving rod should pull back.

14 312888D

Page 15

Troubleshooting

Troubleshooting

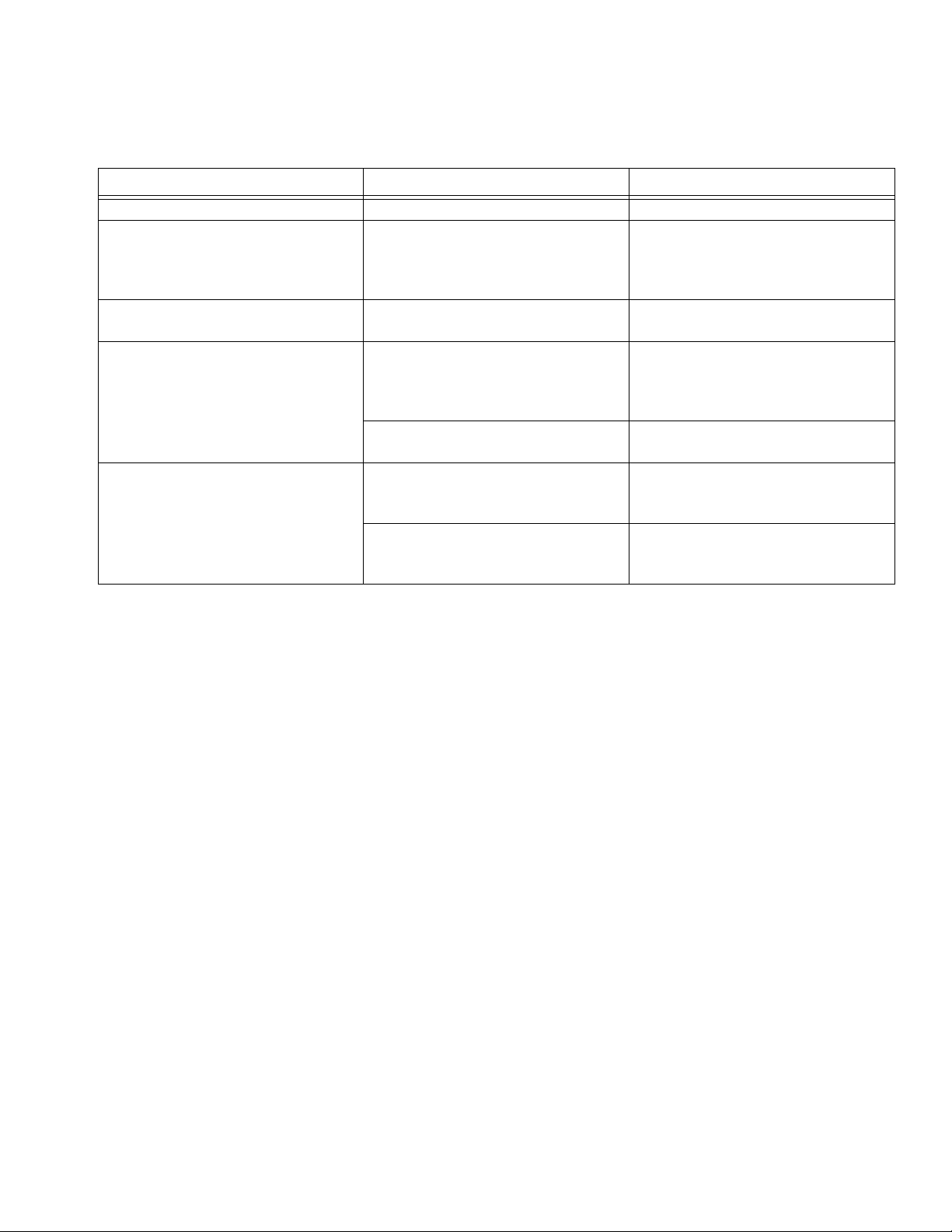

Problem Cause Solution

Interruption of flow of one material Running out of material Supply more material to proportioner

Change of color in mixed product

Only one component coming out of

gun

Poor spray pattern

Minor weepage around throat in gun

block

Materials in proportioner are too viscous

Filter screens are clogged Flush gun. See Flush Gun, page 14.

Materials in proportioner are too viscous

Impinger slots are clogged See Impingers, page 19, for service

Valving rod is worn Perform Pressure Check Valving

Valving rod or throat is

damaged

Check with material supplier for recommended temperature range that

should be maintained to control viscosity.

Check with material supplier for recommended temperature range that

should be maintained to control viscosity.

instructions.

Rod Resilient Sleeve procedure;

see page 21.

Perform Pressure Check Valving

Rod Resilient Sleeve procedure;

see page 21.

312888D 15

Page 16

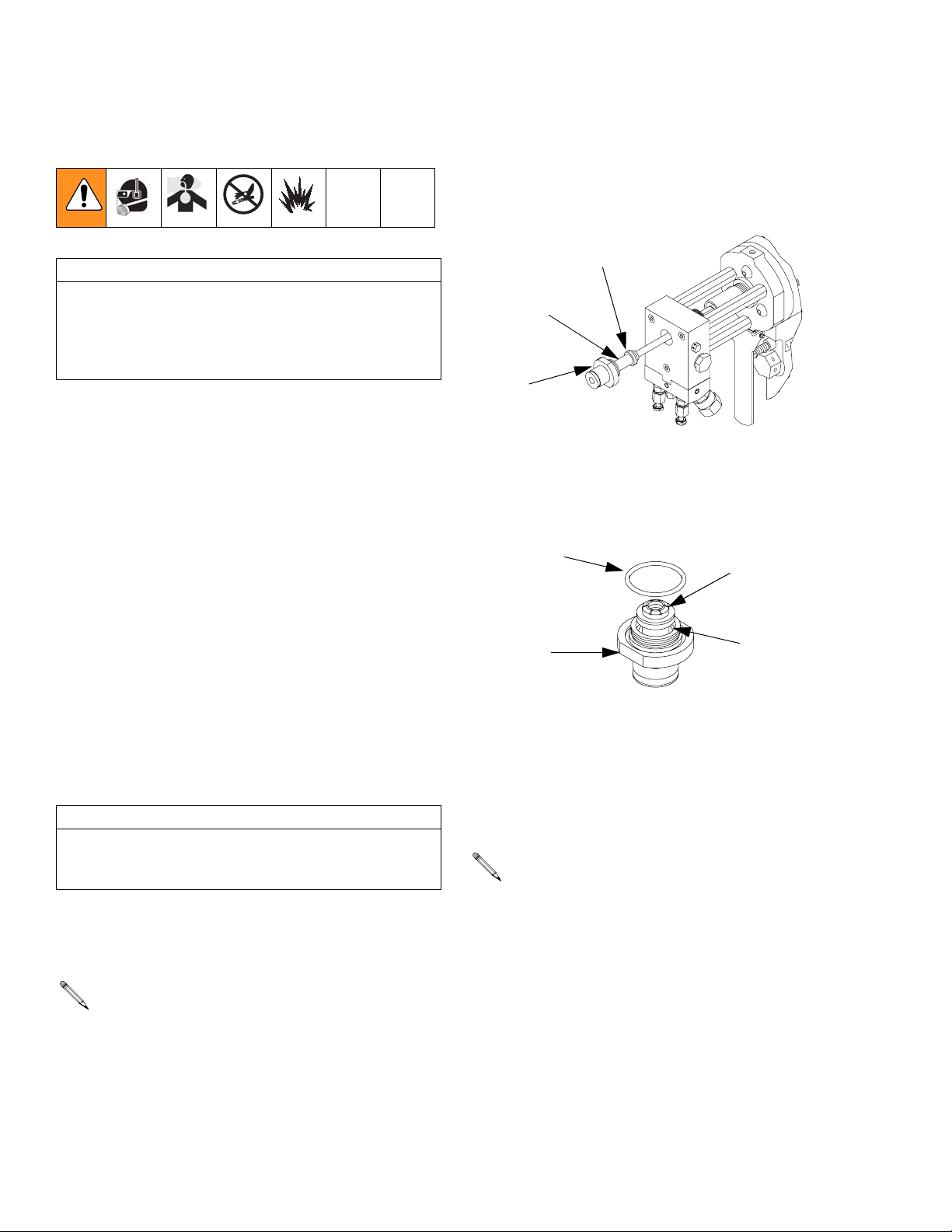

Repair

Repair

CAUTION

Shutdown proportioner and allow chemicals to cool

before servicing gun.

Clean A and R components in separate containers to

avoid cross contamination.

Tools Required

•

flush can

•

impinger cleanout brush

•

5/16 in. nut driver

•

utility knife

•

pin vise without cleanout spade

•

gun block component hole cleanout brush

•

check valve removal tool

•

throat wrench

•

pattern control tip front impinger packing seal

cleanout tool

•

gasket removal tool

•

wooden stick

•

pry tool/rear impinger wrench

•

pressure flush kit (optional)

3. Remove front impinger from front packing. It is not

necessary to remove front packing if no damage to

packing is evident or suspected.

Front Impinger

Front Packing

Pattern Control Tip

4. Remove pattern control tip o-ring and front packing

from pattern control tip. If packing cannot be

removed by hand, use pliers. However, this will

require replacement of packings.

O-ring

Front Impinger

Pattern

Control

Tip

Front Packing

Pattern Control Tip

1. Set safety stop to SERVICE (CLOSED).

CAUTION

Ensure safety stop is set to SERVICE (CLOSED)

while removing pattern control tip. If it is not, the resilient sleeve of the valving rod may be damaged.

2. Loosen pattern control tip with a 10 in. adjustable

wrench. Once loosened, unthread tip by hand.

If front packing and/or front impinger remain on

valving rod when pattern control tip is removed,

release trigger and carefully slide these parts off

valving rod.

5. Use pattern control tip cleanout tool to clean inside

walls of tip. Flush tip and clean surrounding external

surface.

6. Set pattern control tip and front impinger and packing aside.

Reassembly instructions are included in

Impingers, page 19.

Screen Screw and Port Closure Plugs

1. Perform Pattern Control Tip steps; see page 16.

2. Use a 5/16 in. nut driver to remove screen screw

mounting screw while holding large hex head of

screen screw with finger or against solid surface.

16 312888D

Page 17

Repair

3. Slide screen screw assembly out of gun block. Allow

excess Isocyanate material to drain.

Port Closure Plug

Screen Screw

Mounting Screw

4. Flush assembly and place it in gun cleaner.

5. Remove port closure plugs with nut driver. These

are installed using high-strength sealant, apply heat

to help break free when removing.

6. Clean port closure plugs with gun cleaner and

inspect for damage. Replace if necessary. Apply

sealant (49) to plugs before reinstalling.

2. Remove spring retainer case by grasping handle

firmly and pushing in on retainer case with palm of

hand. Simultaneously rotate case a quarter turn

counterclockwise to remove case from locking collar.

Spring Retainer Case

3. Cover open end of air cylinder with hand protected

by a cloth and depress gun trigger.

The following two steps must be accomplished next to

prevent accidental operation of gun.

7. Remove screen from screen screw. Soak in gun

cleaner or replace if clogged or dirty.

8. Clean screen screw cavity. Clean with clean out

drills and flush with gun cleaner. If more than 20% of

screen is blocked, replace screen.

9. Inspect screen screw seal and closure screw gasket

for damage. Replace if necessary.

10. Reinstall screen screw assembly and tighten mounting screw.

11. Insert port closure plugs.

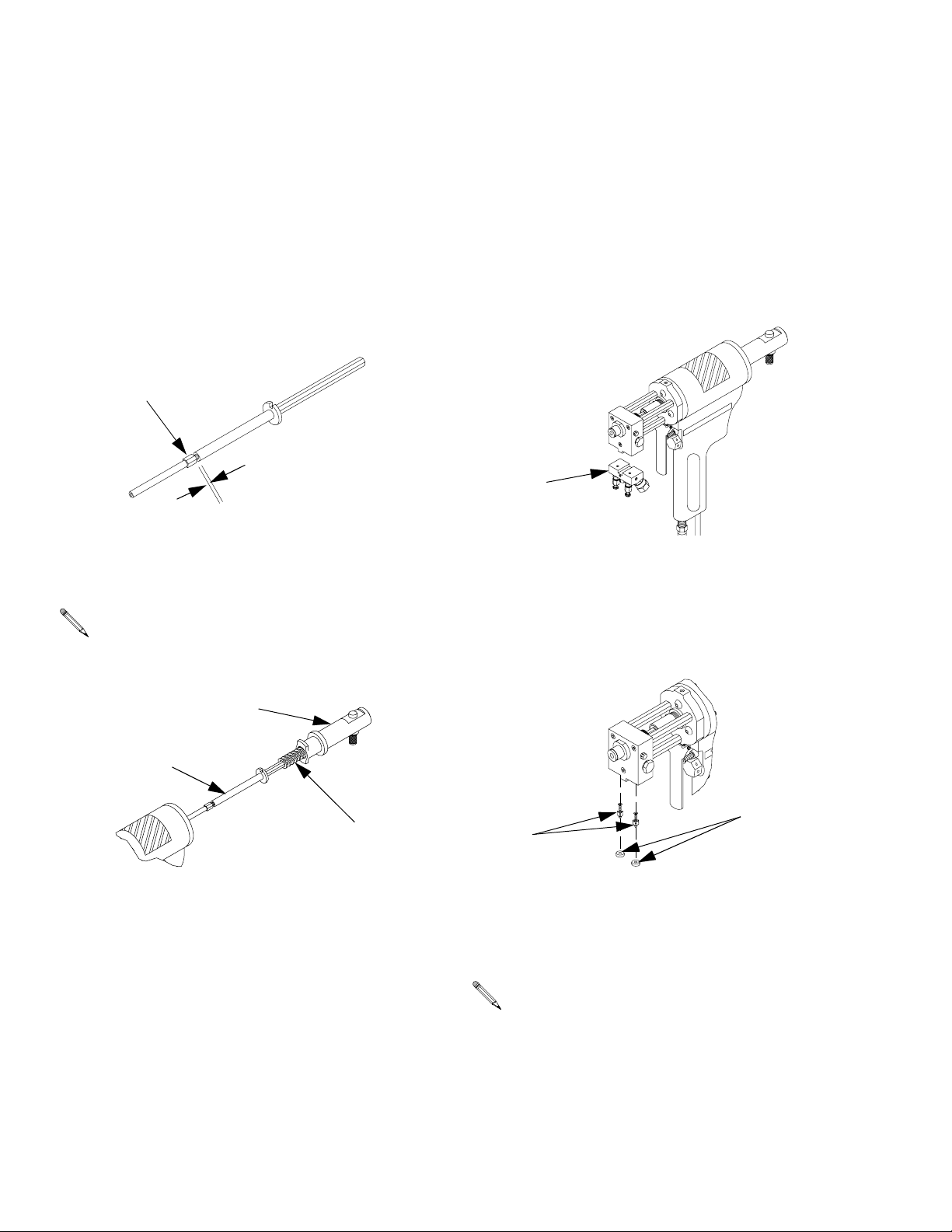

Valving Rod and Resilient Sleeve

Disassembly and Cleaning

Inadvertent actuation of trigger with spring retainer

case removed could cause serious injury.

1. Follow Pressure Relief Procedure, page 12.

4. Disconnect airline to gun. Pull back on outer ring of

quick disconnect coupling to disconnect air from

gun.

5. Disconnect electrical harness from gun.

6. Examine resilient sleeve assembly for damage.

Structural damage or wear will show as:

•

scratches or chaffing of outside wall of sleeve;

•

movement or extrusion of sleeve in either

threaded mandrils;

•

reduction in sleeve diameter.

A uniform depression of equal depth around diameter of sealing point of throat is normal.

7. If any damage or wear exists, replace both valving

rod resilient sleeve and front packing.

8. Remove valving rod resilient sleeve assembly if it

needs to be replaced.

a. Use a 6 in. adjustable wrench to unthread cou-

pler toward resilient sleeve. If necessary, use a

5/16 in. nut driver to hold valving rod.

b. Once coupler is loose, unthread resilient sleeve

assembly.

312888D 17

Page 18

Repair

Reassembly

1. If valving rod resilient sleeve assembly was removed

or is being replaced, use the following steps:

a. Thread coupler onto resilient sleeve assembly

by hand as far as it will go toward sleeve. There

should be approximately 1/16 in. (1.5 mm)

clearance between coupler and valving rod.

b. Use a 6 in. adjustable wrench and a 5/16 in. nut

driver to securely tighten coupler.

Coupler

1/16 in.

2. Align slot on valving rod with pin in cylinder and

push valving rod assembly all the way forward then

rotate 180 degrees.

Coupling Block and Check Valves

Disassembly

1. Follow Pressure Relief Procedure, page 12.

2. Use 5/16 in. nut driver to remove coupling block

mounting screw, and separate gun from coupling

block.

Coupling

Block

3. Flush both material ports on face of coupling block

to prevent material buildup.

There should be some resistance when pushing

valving rod assembly through throat.

Valving Rod Retainer Case

Valving Rod Assembly

Valving Rod

Closure Spring

3. Insert valving rod closure spring into cylinder and

over end of valving rod.

4. Push valving rod retainer case over spring into cylinder and rotate clockwise (approximately a quarter

rotation) until retainer case snaps into position.

4. Remove check valve gasket. Place end of coupling

block gasket removal tool into notches next to gaskets and pry them out.

Coupling

Check

Valves

5. Flush open ports and check valves with gun cleaner.

6. Remove check valves by pressing them inward and

popping them out, or by using the magnet.

Iso check valve is notched for identification purposes.

Block Gaskets

18 312888D

Page 19

Repair

7. If material buildup prevents easy removal, use

three-pronged end of check valve removal tool to

grasp check valve and turn free.

Opposite end of check valve removal tool is

designed to clean check valve cavity.

8. Place all parts in gun cleaner and flush exposed

ports.

Reassembly

1. Inspect seats on gaskets for nicks. Replace seats if

damaged.

2. Insert check valves (notched valve on left side) and

gaskets into gun block pressing gaskets in place.

Gaskets are designed for use on either side. Carefully check angular seat to ensure sealing point of

check valve.

3. Place coupling block to gun and use 5/16 in. nut

driver to install coupling block mounting screw.

Impingers

Disassembly and Cleaning

1. Follow Pressure Relief Procedure, page 12.

2. Perform Pattern Control Tip steps; see page 16.

3. Remove rear impinger from throat. Hold throat in

place with throat wrench (604) and use rear

impinger wrench 28576 to loosen impinger from

throat. Continue un-threading by hand.

Rear Impinger

Throat

4. Flush gun block with gun cleaner.

5. Inspect seating surface (area around center hole)

within throat for damage. Use a soft object, such as

a wooden stick or soft brush, to clean surface.

CAUTION

Never use a sharp or hard metal object for cleaning

impingers or throat. Seating surface of throat is highly

polished to ensure sealing of resilient sleeve.

6. Use impinger cleaning brush (608) to clean both

external and internal threads of throat.

7. Use impinger cleaning brush to clean rear and front

impingers. Use cleanout spade to clean each injection slot of both impingers.

Injection Slots

Rear Impinger

Front Impinger

Reassembly

1. Assemble rear impinger into throat. Thread slotted

end of rear impinger into female thread of throat.

Hold throat in place with throat wrench and use rear

impinger wrench to tighten impinger into throat.

312888D 19

Page 20

Repair

2. Thread throat assembly by hand into gun block. Use

throat wrench to tighten.

Front impinger should contact throat surface about

1/2 to 3/4 turns from actual seating of throat to gun

block surface. This compression creates the internal seal within front portion of chamber.

3. Assemble front impinger and pattern control tip.

Insert front packing into pattern control tip. Place

front impinger over end of front packing. Place pattern control tip o-ring into groove on pattern control

tip.

4. Engage safety stop, see Safety Stop on page 7.

Press and hold trigger then hand-tighten pattern

control tip into gun block.

5. Release trigger to align components then press and

hold trigger. Use 10 in. adjustable wrench to tighten

pattern control tip about 1/8-turn. Release trigger.

Repeat until the pattern control tip is snug on the

gun block.

If after finishing step 5 the valving rod is not protruding at least 1/64 in. from the end of the pattern

control tip, the pattern control tip will need to be

removed then steps 4 and 5 repeated. The pattern

control tip will need to be tightened in 1/16- or

1/32-turn increments.

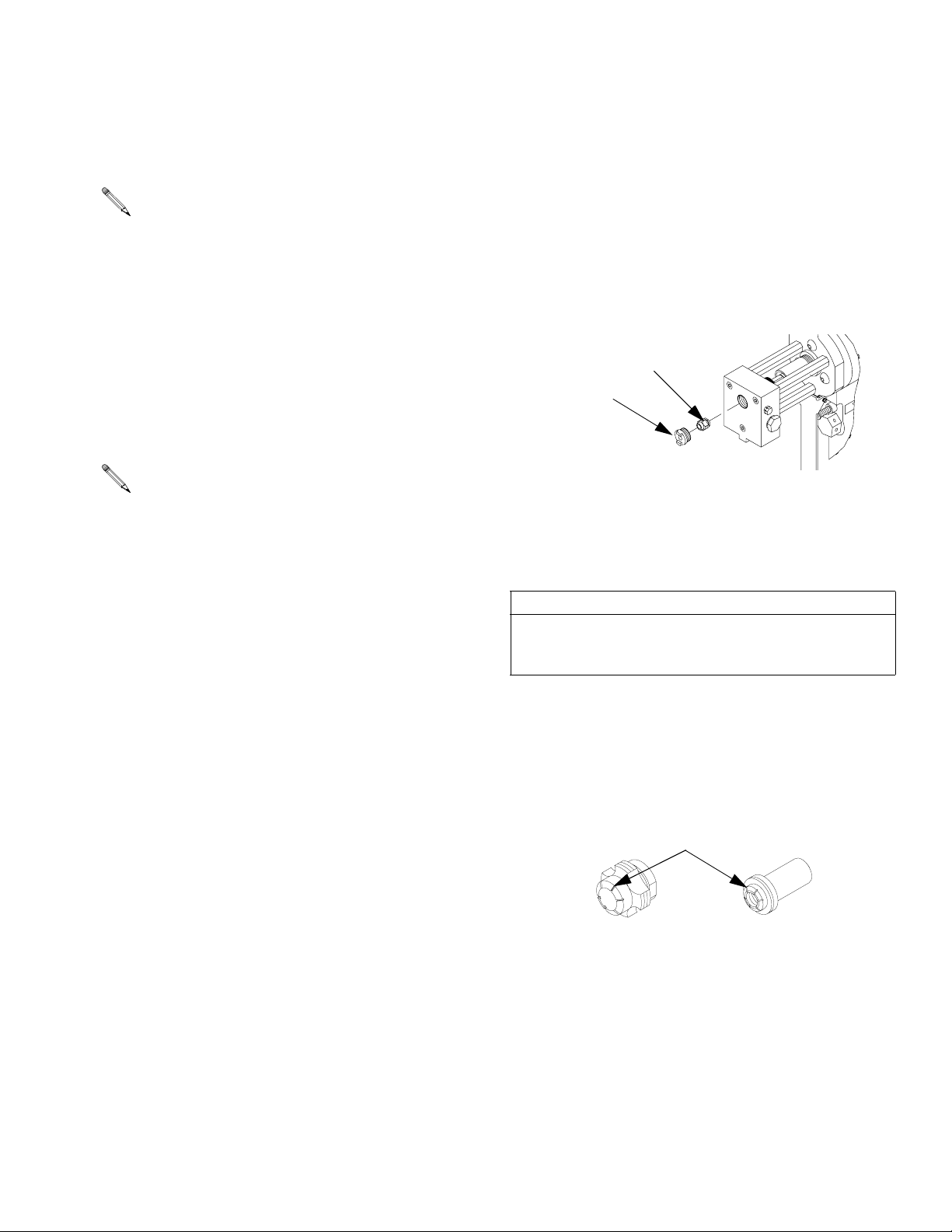

Gun Block

In severe cases of material buildup, it may be necessary

to remove the gun block and soak it in gun cleaner.

1. Follow Pressure Relief Procedure, page 12.

2. Remove the pattern control tip and front impinger;

see Pattern Control Tip, page 16.

3. Remove coupling block and check valves; see Cou-

pling Block and Check Valves, page 18.

4. Remove rear impinger and throat; Impingers, page

19.

5. Remove gun block mounting screws.

Mounting Screws

6. Remove resin (rear) seal screw and resin seal

o-rings.

Pattern

Control Tip

20 312888D

Page 21

Repair

7. Soak gun block in gun cleaner.

CAUTION

Do not allow gun block or component parts to soak in

gun cleaner for extended periods of time, such as

overnight, as certain solvents may cause corrosion or

pitting.

Do not soak gun block o-rings in gun cleaner. To clean

o-rings, dip in gun cleaner and immediately wipe dry.

8. Reassemble resin (rear) seal screw and resin seal

o-rings into gun block.

9. Reinstall gun block using gun block mounting

screws.

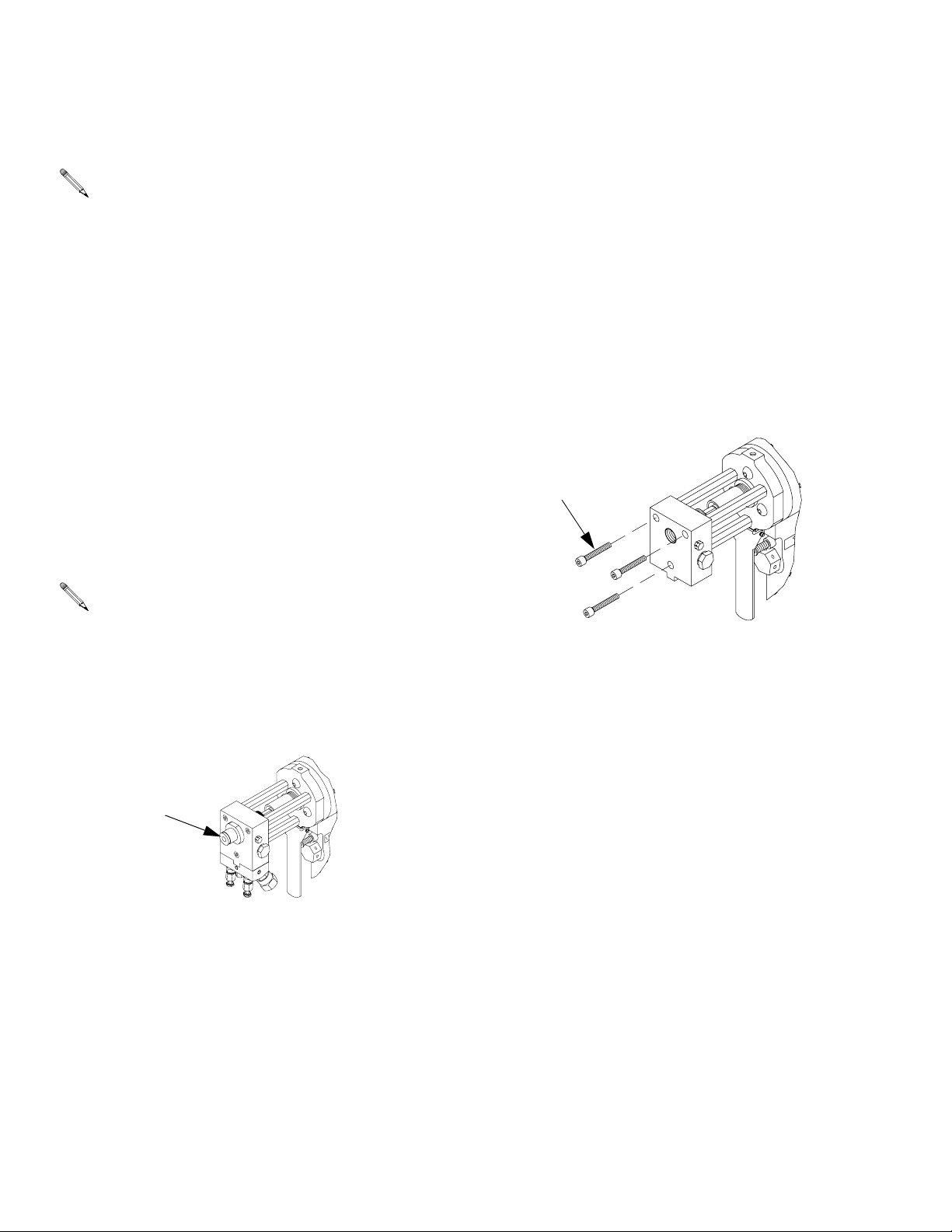

Pressure Check Valving Rod Resilient Sleeve

Perform this test to check seal created by interference fit

between resilient sleeve and opening in throat.

6. Set safety stop to SERVICE (CLOSED), and then

pull trigger to determine if weepage occurs in this

position.

Weepage

7. If weepage is observed in either step, replace valving rod and/or throat. See Valving Rod and Resil-

ient Sleeve, page 17, to replace valving rod. See

Impingers, page 19, to replace throat.

If throat is not properly seated in gun block, material leakage will occur around outer area of throat. If

this occurs, insert throat wrench over resilient

sleeve and tighten throat.

1. Follow Pressure Relief Procedure, page 12.

2. Remove the pattern control tip and front impinger;

see Pattern Control Tip, page 16.

3. Remove coupling block and check valves; see Cou-

pling Block and Check Valves, page 18.

4. Remove rear impinger and throat; Impingers, page

19.

5. Turn on proportioner, and with only the resin manual

valve open, determine if there are resin leaks at

front (Iso) surface of throat.

Should be protruding

8. Close resin manual valve.

312888D 21

Page 22

Repair

22 312888D

Page 23

Parts

Parts

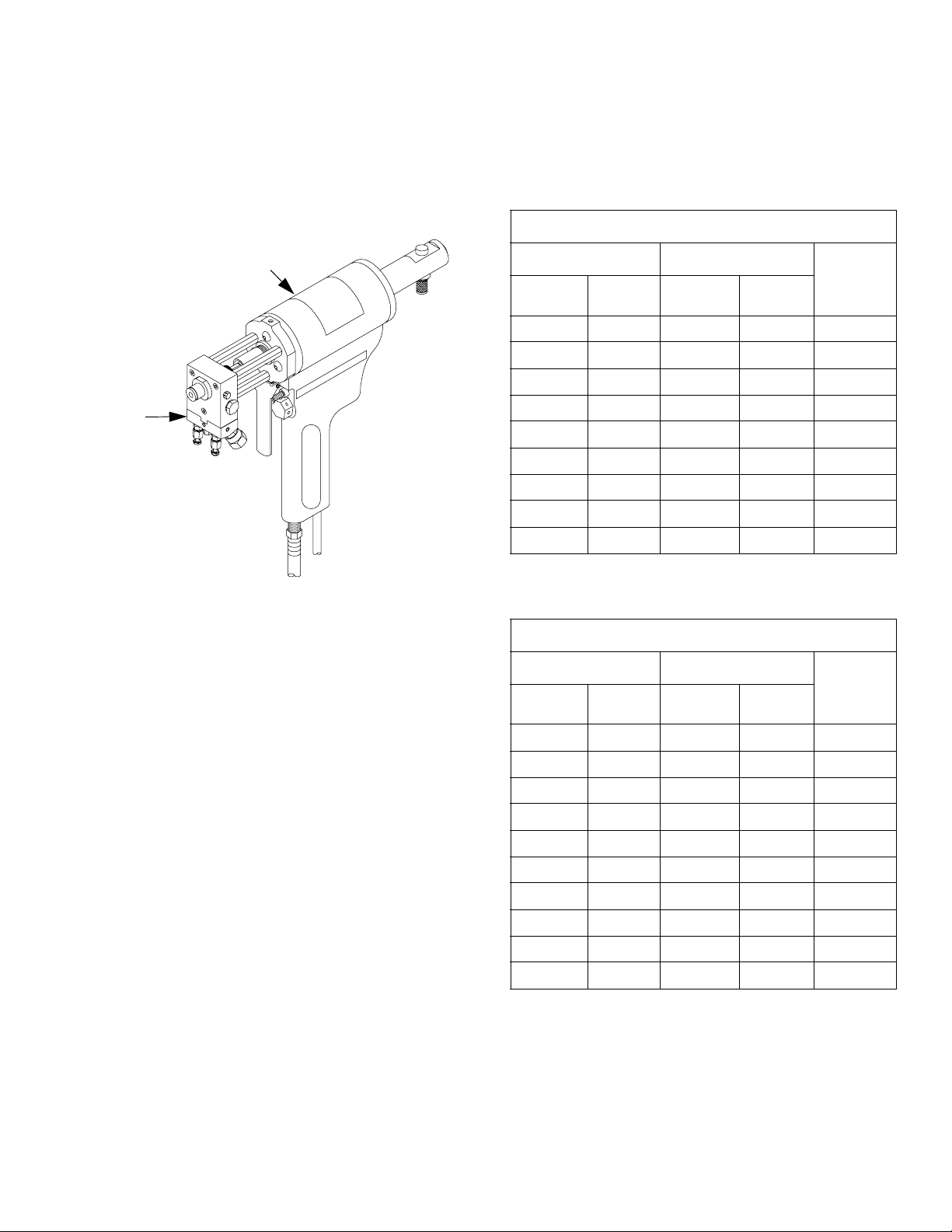

AR Pour Gun 255828

BA

BC

Ref Part Description Qty

BA 255827 GUN, auto AR-C 1

BB 253728 KIT, AR gun tool (not shown) 1

BC 285771 BLOCK, AR coupling 1

Impinger Options

Impinger (C Size)

Front Rear Orifice

Area

FactorPart Style Part Style

299974 23-B-1 299990 23-B-1 900

299975 33-B-1 None 33-B-1 1200

299976 33-C-1 299991 33-C-1 1800

299977 34-C-1 299992 34-C-1 2400

299980 46-B-1 299995 46-B-1 3000

299978 36-C-1 299993 36-C-1 3600

None 46-C-1 299996 46-C-1 4500

299982 48-C-1 299997 48-C-1 6000

299983 58-C-1 299999 58-C-1 7200

Table 1: Impinger Options - C Size

Impinger (D Size)

Front Rear Orifice

Area

FactorPart Style Part Style

299979 33-C-1 None 33-C-1 1800

None 36-C-1 299994 36-C-1 3600

None 48-C-1 299998 48-C-1 6000

None 58-C-1 261789 58-C-1 7200

299984 59-D-1 None 59-D-1 10800

299985 66-D-1 285750 66-D-1 8400

None 78-D-1 285751 78-D-1 12800

261790 79-D-1 None 79-D-1 14400

299987 90-D-1 285752 90-D-1 18000

299988 94-D-1 None 94-D-1 25200

Table 2: Impinger Options - D Size

312888D 23

Page 24

Parts

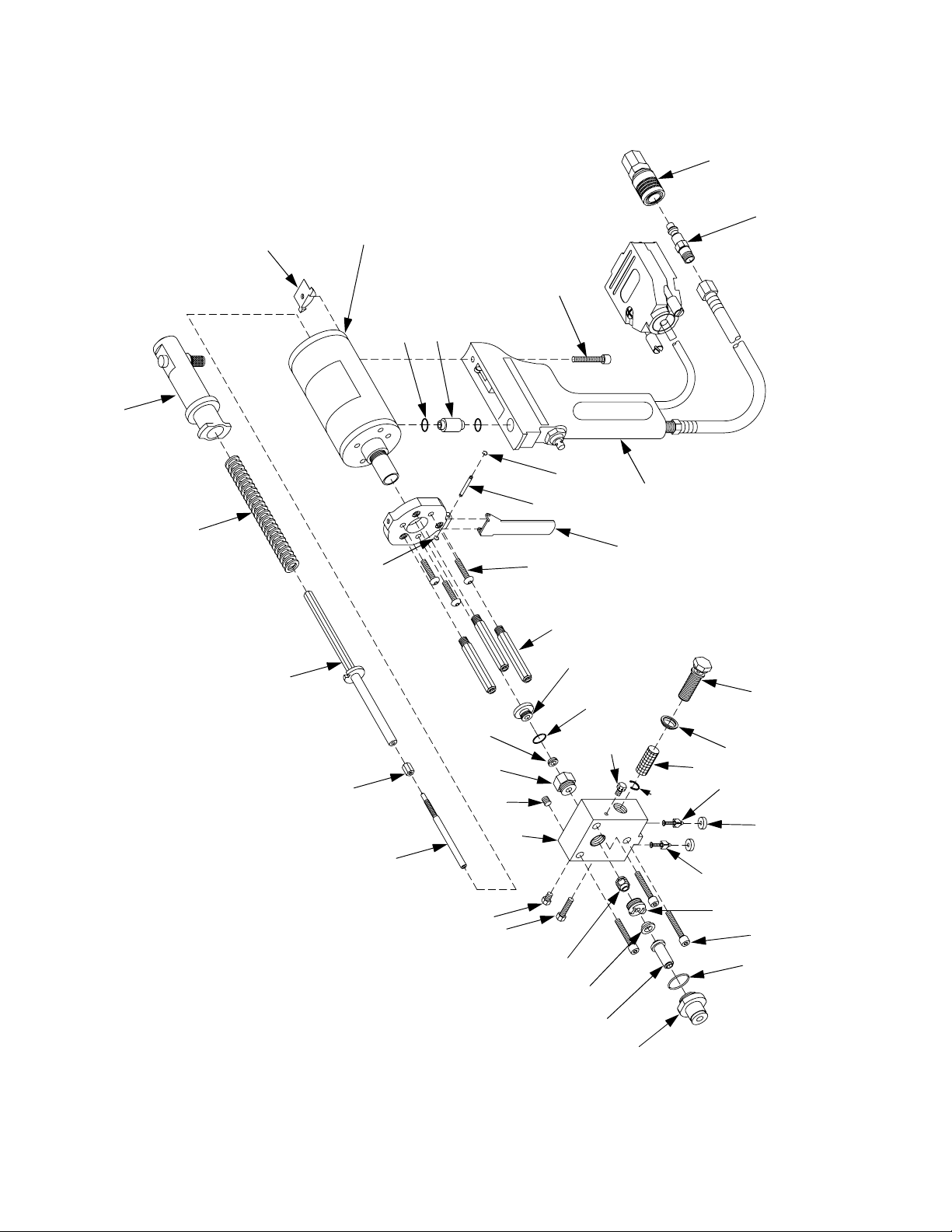

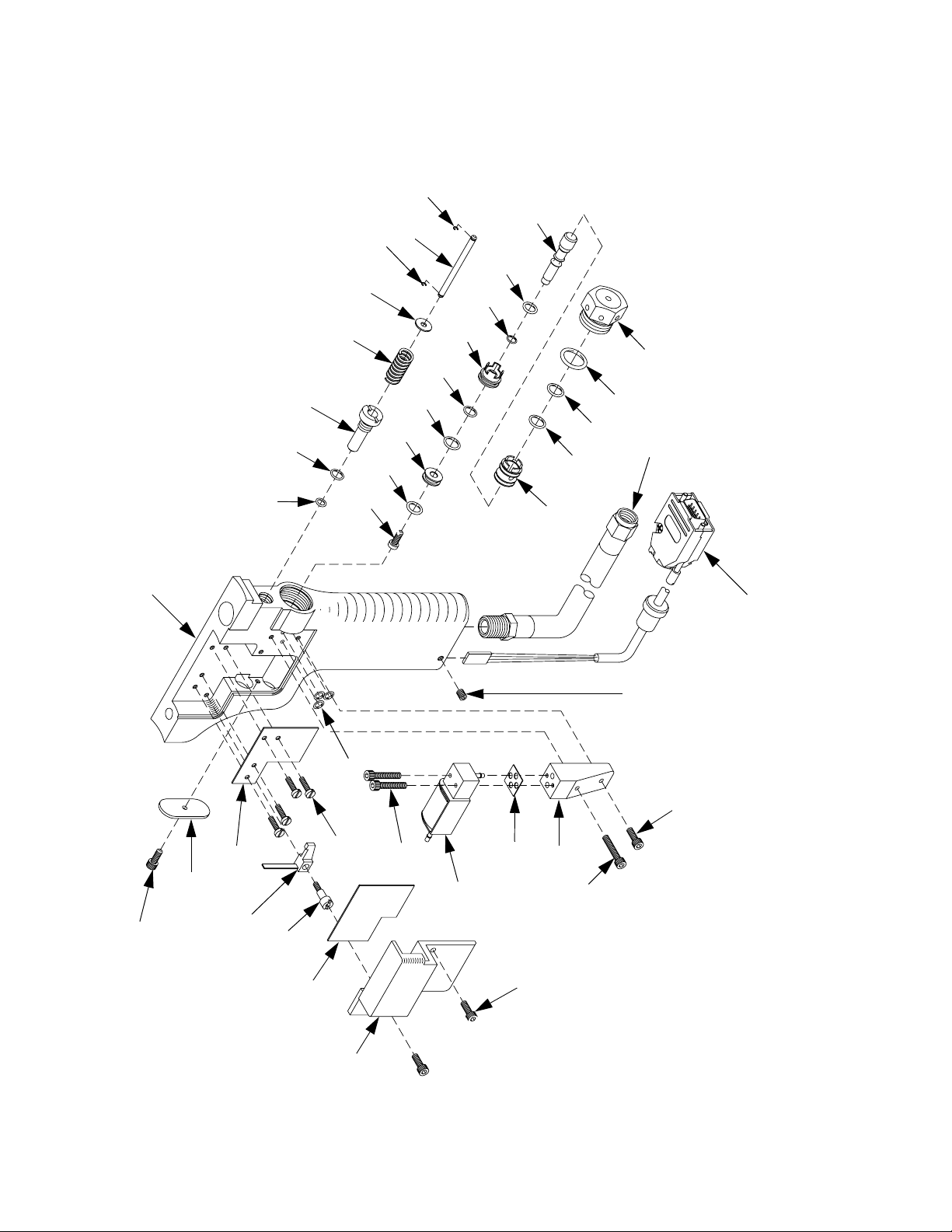

Auto AR-C Gun 255827

11

24

25

28

21

20

19

27

26

18

37

10

38

19

39

17

14

36◆

4†

33◆

35

22

23

24 312888D

34

9

40

13

8

44

43

31

12

1†

2†

6

3†

5

7

32

15

29

41

Page 25

Parts

Ref Part Description Qty

1† 296621 SEAL, screw, screen 1

2† 296622 SCREEN, block, gun 1

3† 295595 RING, retaining 1

4† 295175 SCREW, screen, gun block 1

5 296128 GASKET, block, gasket 2

6 295623 VALVE, check, A 1

7 295624 VALVE, check, R 1

8 297307 SCREW, mounting, 1 in. 1

9 295693 PLUG, pipe 1

10 295596 PLUG, coupler 1

11 208536 COUPLER, line, air 1

12 297308 SCREW, closure, A-port 1

13 296129 SCREW, closure, R-port 1

14 299923 BLOCK, gun spacer w/stud 3

15 297150 SCREW, cap, socket head 3

16 299925 HANDLE, gun mounting plate 1

17 299951 TRIGGER, lever 1

18 298354 PIN, mounting 1

19 299475 RETAINER 1

20 299960 CYLINDER, air assy 1

21 299962 ROD, valving 1

22 297312 COLLAR, lock 1

23 296136 SLEEVE 1

24 299966 RETAINER, spring case assy 1

25 297313 SPRING, die, heavy duty 1

Ref Part Description Qty

26 299969 COUPLING, connecting 1

27 297314 O-RING, fluoroelastomer 2

28 299970 STOP, notched 1

29 111603 PACKING, o-ring 1

31 296137 PACKING, front 1

32 296138 PACKING, throat 1

33 103648 PACKING, o-ring 1

34 298355 SEAL, retainer, 250 1

35 296140 PACKING, R 1

36 298356 SEAL, screw, 250 1

37 298117 SCREW, 1/4-28 x 1 bhcs-nyloc 2

38 299908 SCREW, 1/4-28 x 1 1/4

shcs-nyloc

39 256213 HANDLE, auto ar gun 1

40 285795 BLOCK, gun assy 1

41 299973 TIP, 250 pattern control, also

shown on page 24

42 IMPINGER, front; see

Impinger Options on page 23

for part numbers

43 IMPINGER, rear; see

Impinger Options on page 23

for part numbers

49 102969 ADHESIVE, anaerobic 1

1

1

1

1

†

Parts included in Kit 296624, available separately.

◆

Parts included in Kit 298357, available separately.

312888D 25

Page 26

Parts

Gun Handle Assembly 256213

230

214

230

213

207

232

212

205

211

216

210

206

208

209

210

234

215

217

202

205

231

205

233

235

219

228

204

203

223

225

221

201

224

220

229

201

226

203

227

218

203

222

26 312888D

Page 27

Parts

Ref Part Description Qty

201 298116 SCREW, 4-40 x 3/4 shcs 3

202 108195 PACKING, o-ring 1

203 C19950 SCREW, cap, sch 4

204 296066 O-RING, piston, pump 3

205 106555 PACKING, o-ring 3

206 106560 PACKING, o ring 1

207 C20988 PACKING, o-ring 1

208 112085 PACKING, o-ring 1

209 299917 SCREW, 5-40 x 3/8

button-hd cap

210 295685 O-RING 2

211 299926 TRIGGER, bushing 1

212 299927 SPRING, 1

213 299928 TRIGGER, actuator pin 1

214 299929 SPOOL 1

215 299930 RING, seal 1

216 299931 ROD, piston 1

217 299932 VALVE, exhaust cap 1

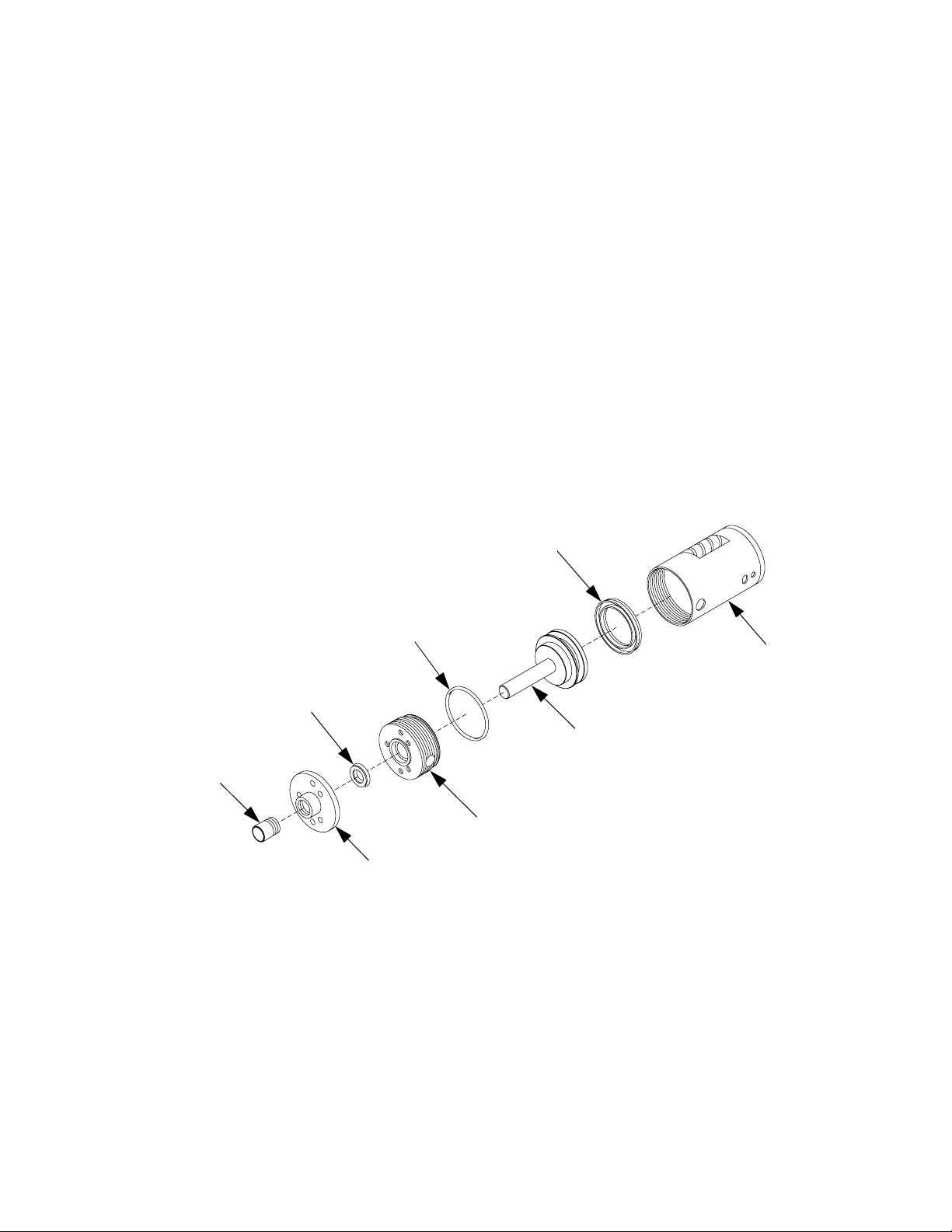

Air Cylinder Assembly 299960

Ref Part Description Qty

218 299933 INSULATOR, circuit board 1

219 256214 WIRE, gun harness assy 1

220 299936 MANIFOLD, air 1

221 299937 SCREW, 2-56 x 7/16 phms 4

222 299938 COVER 1

223 299939 PLATE, rear cover 1

224 299940 GASKET, pilot valve 1

225 15M966 BOARD, assy 1

226 299135 SWITCH, arm lever 1

1

227 299020 SCREW, shoulder 1

228 102279 SCREW, set, socket 1

229 299948 VALVE, solenoid valve assy 1

230 299475 RETAINER 2

231 299971 HOSE, 1/4 x 2 in. (mxf) air 1

232 285776 WASHER, packing washer 1

233 295439 LINER, valve, spool 1

234 114375 PACKING, o-ring 1

235 HANDLE 1

407

406

402

401

405

Ref Part Description Qty

401 299954 COVER, dust 1

402 297309 SEAL, u-cup, fluoroelastomer 1

403 299956 CYLINDER, air 1

404 299957 PISTON, assy 1

405 299959 CYLINDER, flange assy. 1

406 297310 O-RING, fluoroelastomer 1

407 297311 SEAL, u-cup, fluoroelastomer 1

403

404

403

312888D 27

Page 28

Parts

Coupling Block Assembly 285771

503

506

501

505

Ref Part Description Qty

501 295619 SCREW, mounting 1

502 295693 PLUG, pipe (285771 only) 2

503 VALVE, manual 2

504 BLOCK, coupling 1

505 117506 FITTING, swivel, 1/4 npt x #6

JIC

506 117595 FITTING, swivel, 1/4 npt x #5

JIC

1

1

504

AR Gun Tool Kit 253728

604

606

609

611

607

612

502

Ref Part Description Qty

601 117642 TOOL, nut driver 1

602 117661 PIN, vise 1

603 118665 TUBE, grease, 4 oz 1

604 285763 TOOL, throat wrench 1

605 KIT, cleanout drills 1

606 285765 TOOL, 250 rear impinger wrench 1

607 285767 TOOL, 250 pct/imp cleanout 1

608 295898 BRUSH, cleanout, impinger 1

609 295935 KIT, spade, cleanout 1

610 296187 BRUSH, bore, cleanout, gun block 1

611 296191 TOOL, removal, gasket 1

612 297973 TOOL, removal, valve 1

28 312888D

Page 29

AR-D Conversion Kit 24A023

See Repair section on page 16 for conversion kit

parts installation.

Ref Part Description Qty

701 299961 CYLINDER, air assy (AR-D) 1

702 297141 SLEEVE, AR-D (375) 1

703 299968 SPRING, die, heavy duty, medium 1

704 285755 SEAL, 375 resin retainer 1

705 285756 SEAL, 375 resin screw 1

706 297143 PACKING 1

707 299989 NOZZLE, 375 throat 1

708 297142 PACKING, front 1

709 299972 TIP, 375 pattern control 1

Parts

312888D 29

Page 30

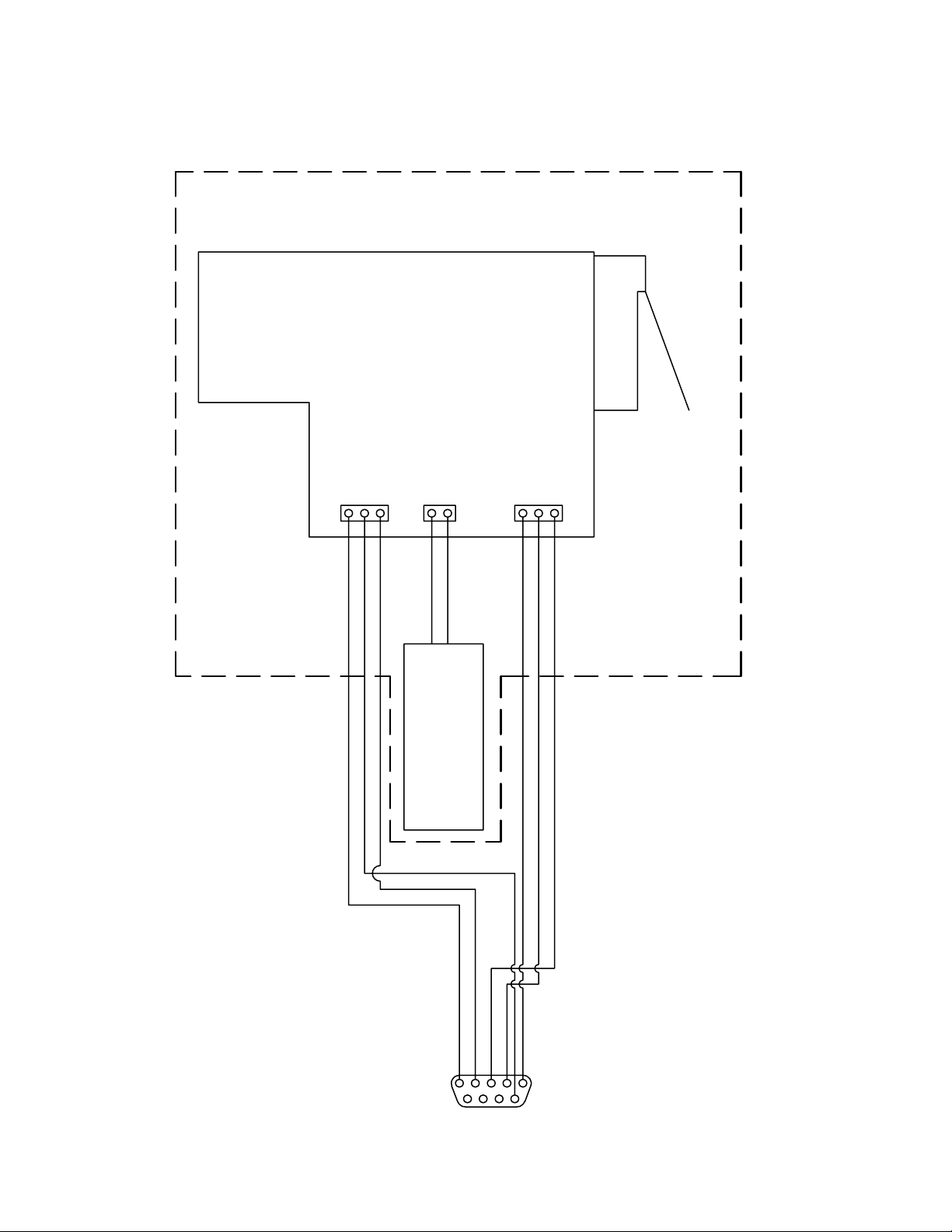

Electrical Diagram

Electrical Diagram

'5.#)2#5)4"/!2$

*

#/),2%452.

#!3%

$)30%.3%#/--!.$

*

*

!2'5.(!.$,%

3/,%./)$6!,6%

37)4#(2%452.

$)30%.3%!#4)6%

$)30%.3%2%15%34!#4)6%

30 312888D

ti12351a

Page 31

Technical Data

Technical Data

Category Data

Maximum Fluid Working Pressure 2000 psi (13.8 MPa, 138 bar)

Minimum Air Inlet Pressure 90 psi (0.62 MPa, 6.2 bar)

Maximum Air Inlet Pressure 120 psi (0.84 MPa, 8.4 bar)

Maximum Output (flow rate) † 40 lb/min (18.1 kg/min)

Air Inlet Size 1/4 npt, quick disconnect nipple

A Component (ISO) Inlet Size #5 JIC

R Component (Resin) Inlet Size #6 JIC

Length 12.5 in. (318 mm)

Height 9.5 in. (241 mm)

Width 2.8 in. (71 mm)

Weight 6.7 lbs (3.0 kg)

Wetted Parts Stainless Steel, Zinc Plated Carbon Steel, Black Oxide

Coated Carbon Steel, Tool Steel, 6/6 Nylon, Acetal

† Flow rate depends on pump sizes, hose diameter, hose length, and impingers

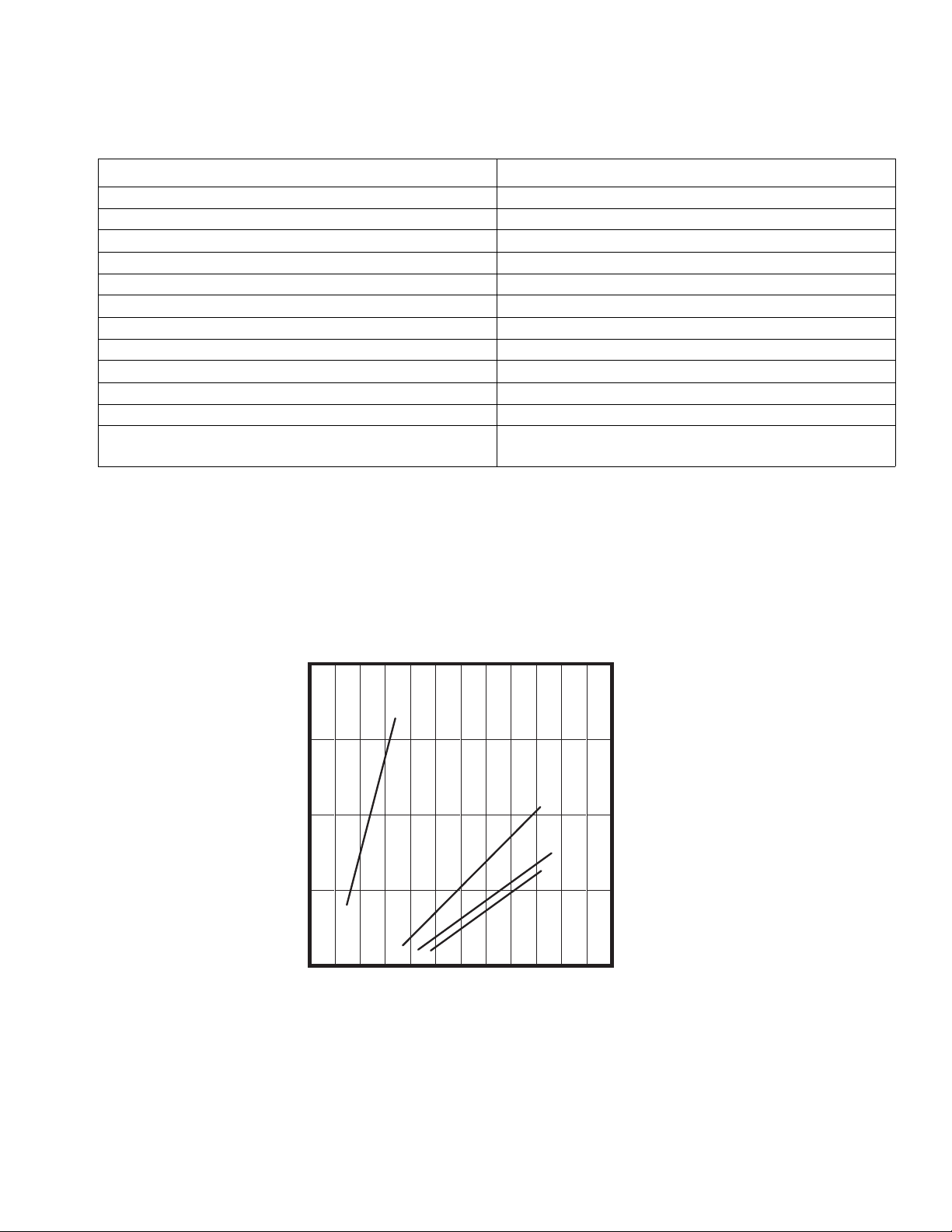

Performance Charts

Impingers Performance Chart

2000

(13.8, 138)

1500

(10.3, 103)

1000

(6.9, 69)

Pressure in psi (MPa, bar)

500

(3.4, 34)

0

5

(2.3)

A

15

(6.8)

25

(11.4)

KEY

A = AR-C 23-B-1 impingers

B = AR-C 36-C-1 Impingers

C = AR-C 58-C-1 impingers

D = AR-D 59-D-1 front

impinger and AR-D 58-C-1

rear impinger

B

C

D

35

(15.9)

45

(20.5)

55

(25.0)

Flow Rate in lb/min (kg/min)

Impingers tested with 100-150 centipoise Mesamoll with a specific gravity of

1.055.

312888D 31

Page 32

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

TO PLACE AN ORDER,

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

contact your Graco distributor or call to identify the nearest distributor.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 312888

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2008, Graco Inc. is registered to I.S. EN ISO 9001

www.graco.com

Revised 11/2008

Loading...

Loading...