Page 1

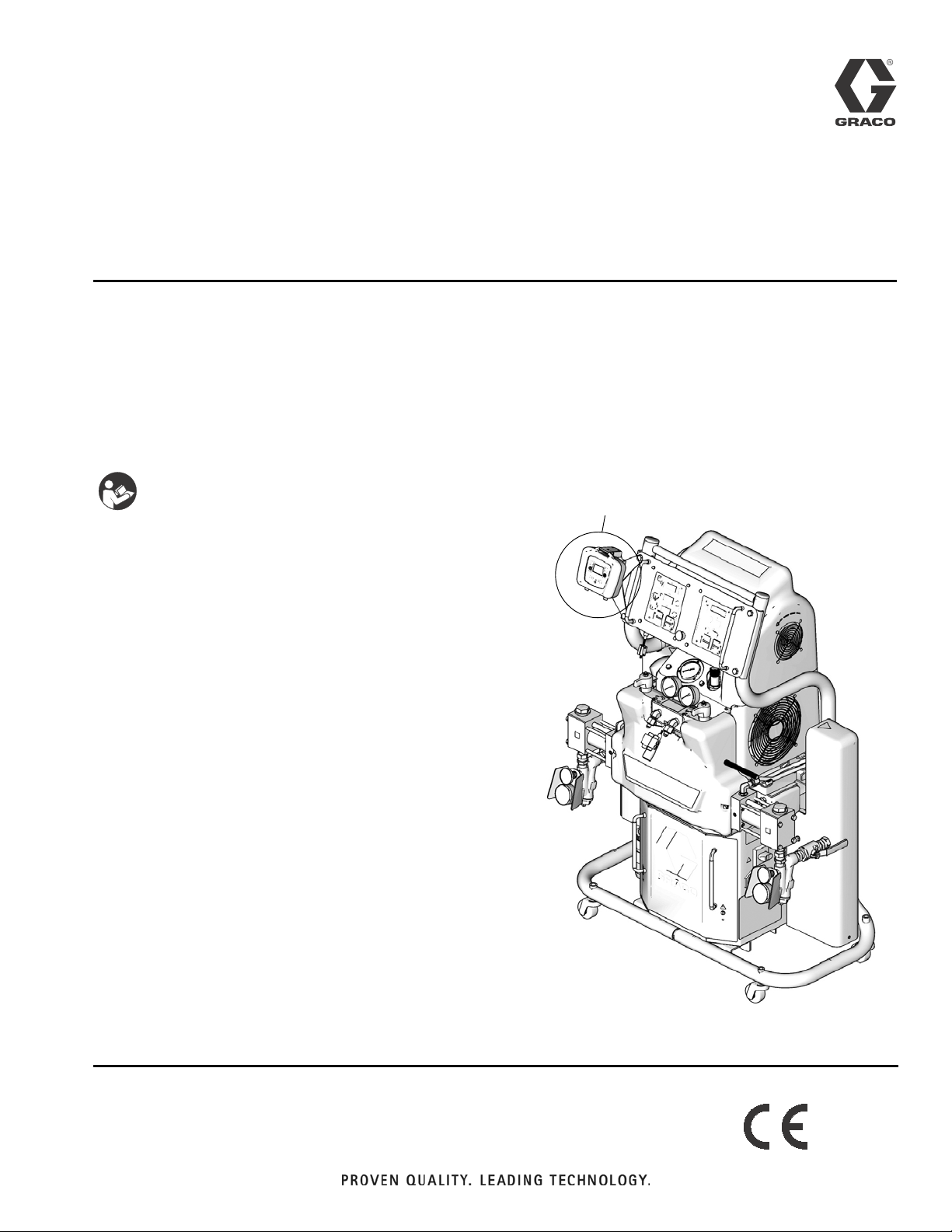

Installation - Operation

Shot Controller

For use with non-flammable polyurethane foams. For professional use only.

Not approved for use in European explosive atmosphere locations.

2000 psi (13.8 MPa, 138 bar) Maximum Working Pressure

312878J

ENG

Important Safety Instructions

Read all warnings and instructions in this

manual and the Hydraulic Reactor

Operation manual. Save all instructions.

See page 3 for model information.

Proportioner shown includes Shot Controller,

™

proportioner also available without Shot Controller

ti11756a

Page 2

Related Manuals

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Isocyanate Hazard . . . . . . . . . . . . . . . . . . . . . . . . . 6

Material Self-ignition . . . . . . . . . . . . . . . . . . . . . . . 6

Moisture Sensitivity of Isocyanates . . . . . . . . . . . . 6

Keep Components A and B Separate . . . . . . . . . . 6

Foam Resins with 245 fa Blowing Agents . . . . . . . 6

Changing Materials . . . . . . . . . . . . . . . . . . . . . . . . . 6

Component Identification . . . . . . . . . . . . . . . . . . . . 7

IPH System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Human Machine Interface (HMI) . . . . . . . . . . . . 8

Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Run Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Conversion Kit Installation . . . . . . . . . . . . . . . . . . 13

Disable Motor Standby Operation . . . . . . . . . . . 17

Simplified Schematic, Shot Controller Wiring . . 18

Simplified Schematic, Shot Controller Electrical 19

Simplified Schematic, Alternate Gun Connection 20

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Hydraulic Proportioner Setup . . . . . . . . . . . . . . 21

Controller Setup . . . . . . . . . . . . . . . . . . . . . . . . 21

Password Protection . . . . . . . . . . . . . . . . . . . . . 23

Learn Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Piston Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Optional External Machine Control . . . . . . . . . . 26

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Change Operating Mode . . . . . . . . . . . . . . . . . . 29

Change Shot Number . . . . . . . . . . . . . . . . . . . . 29

Change Shot Volume/Weight . . . . . . . . . . . . . . 29

Sequence Mode Options . . . . . . . . . . . . . . . . . 30

Dispense Material . . . . . . . . . . . . . . . . . . . . . . 31

Maintenance Mode . . . . . . . . . . . . . . . . . . . . . 31

Demo Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Hibernate Mode . . . . . . . . . . . . . . . . . . . . . . . . 31

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 32

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Hydraulic Proportioner . . . . . . . . . . . . . . . . . . . . 34

Conversion Kit 24A024 . . . . . . . . . . . . . . . . . . . 34

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Performance Charts . . . . . . . . . . . . . . . . . . . . . . . . 37

Graco Ohio Standard Warranty . . . . . . . . . . . . . . 38

Graco Ohio Information . . . . . . . . . . . . . . . . . . . . . 38

Related Manuals

These manuals can be found at www.graco.com.

Reactor Hydraulic Proportioner

Part Description

312062

312063

Reactor Electric Diagrams

Part Description

312064

AR Pour Gun

Part Description

312888 AR Pour Gun, Operation-Parts Manual

Proportioning Pump

312068 Proportioning Pump Repair-Parts Manual

Reactor Hydraulic Proportioner, Operation

Manual

Reactor Hydraulic Proportioner,

Repair-Parts Manual

Reactor Hydraulic Proportioner, Electrical

Diagrams

2 312878J

Page 3

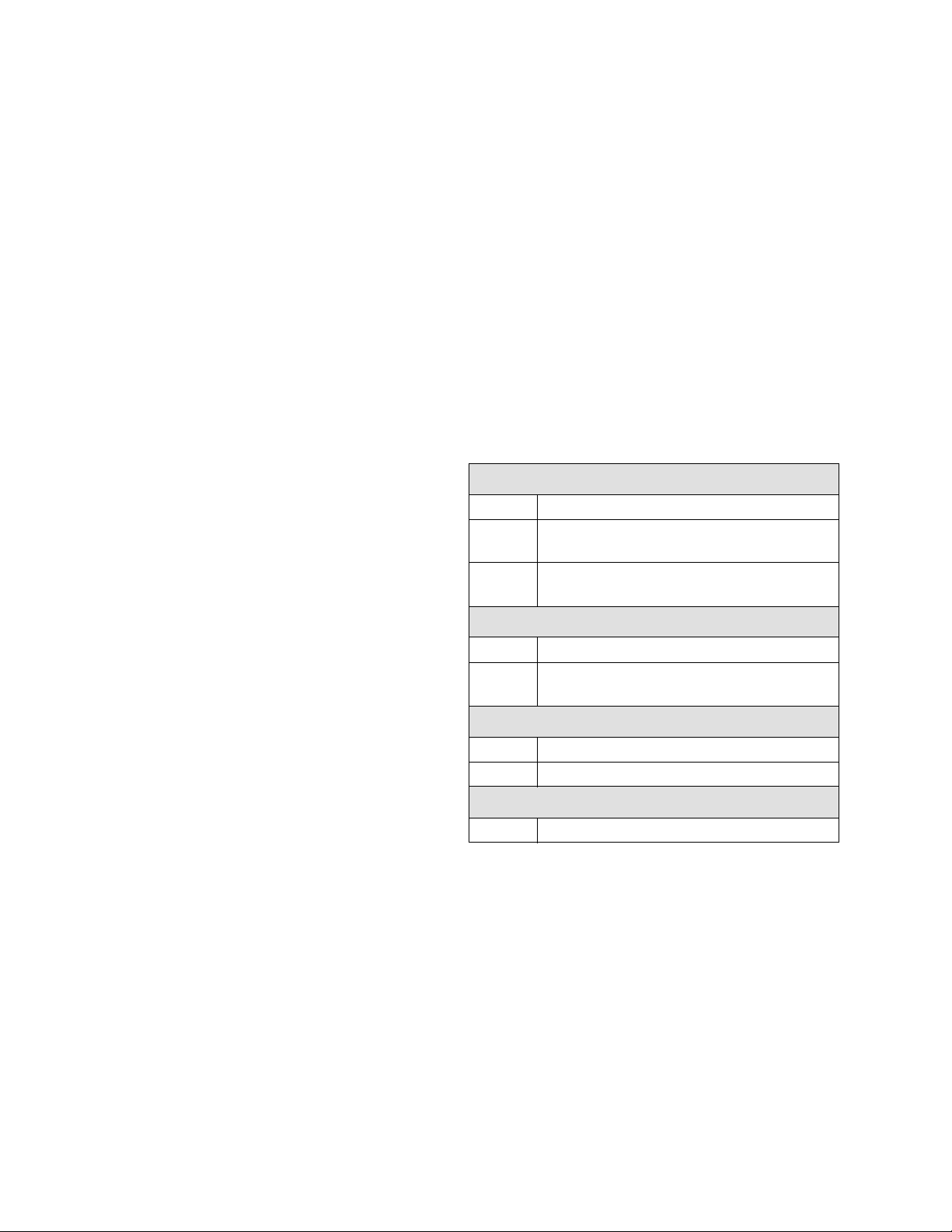

Models

Models

IPH-25 SERIES

Max Flow

Full Load

Part,

Series

255814, B 69 230V (1) 15960 8000 22 (10) 0.063 (0.24) 1.91:1 2000 (13.8, 138)

255815, B 46 230V (3) 15960 8000 22 (10) 0.063 (0.24) 1.91:1 2000 (13.8, 138)

255816, B 35 400V (3) 15960 8000 22 (10) 0.063 (0.24) 1.91:1 2000 (13.8, 138)

255819, A 100 230V (1) 23260 15300 22 (10) 0.063 (0.24) 1.91:1 2000 (13.8, 138)

255820, A 89 230V (1) 23260 15300 22 (10) 0.063 (0.24) 1.91:1 2000 (13.8, 138)

255824, B 69 230V (1) 15960 8000 22 (10) 0.063 (0.24) 1.91:1 2000 (13.8, 138)

255825, B 46 230V (3) 15960 8000 22 (10) 0.063 (0.24) 1.91:1 2000 (13.8, 138)

255826, B 35 400V (3) 15960 8000 22 (10) 0.063 (0.24) 1.91:1 2000 (13.8, 138)

Peak Amps*

Per Phase

Volt ag e

(phase)

System

Watts

Primary

Heater

Watts

Rate◆

lb/min

(kg/min)

IPH-40 SERIES

Max Flow

Full Load

Part,

Series

255811, B 100 230V (1) 23100 12000 50 (23) 0.076 (0.29) 1.64:1 2000 (13.8, 138)

255812, B 71 230V (3) 26600 15300 50 (23) 0.076 (0.29) 1.64:1 2000 (13.8, 138)

255813, B 41 400V (3) 26600 15300 50 (23) 0.076 (0.29) 1.64:1 2000 (13.8, 138)

255821, B 100 230V (1) 23100 12000 50 (23) 0.076 (0.29) 1.64:1 2000 (13.8, 138)

255822, B 71 230V (3) 26600 15300 50 (23) 0.076 (0.29) 1.64:1 2000 (13.8, 138)

255823, B 41 400V (3) 26600 15300 50 (23) 0.076 (0.29) 1.64:1 2000 (13.8, 138)

Peak Amps*

Per Phase

Voltage

(phase)

System

Watts

Primary

Heater

Watts

Rate◆

lb/min

(kg/min)

Approximate

Output per

Cycle (A+B)

gal. (liter)

Approximate

Output per

Cycle (A+B)

gal. (liter)

Hydraulic

Pressure

Ratio

Hydraulic

Pressure

Ratio

Maximum Fluid

Working

Pressure

psi (MPa, bar)

Maximum Fluid

Working

Pressure

psi (MPa, bar)

CONVERSION KIT

Part, Series Description

24A024, A Conversion kit for existing H-25 and H-40 hydraulic proportioners

* Full load amps with all devices operating at maximum capabilities. Fuse requirements at various flow rates and mix

chamber sizes may be less.

◆ Maximum flow rate given for 60 Hz operation. For 50 Hz operation, maximum flow rate is 5/6 of 60 Hz maximum

flow.

312878J 3

Page 4

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear impervious gloves when spraying or cleaning equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

• Gloves

• Hearing protection

SKIN INJECTION HAZARD

High-pressure fluid from dispense valve, hose leaks, or ruptured components will pierce skin. This may

look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispense valve at anyone or at any part of the body.

• Do not put your hand over the end of the dispense nozzle.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes and couplings daily. Replace worn or damaged parts immediately.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use and clean equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Ground equipment, personnel, object being sprayed, and conductive objects in work area. See

Grounding instructions.

• Use only Graco grounded hoses.

• Check gun resistance daily.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Do not flush with gun electrostatics on. Do not turn on electrostatics until all solvent is removed from

system.

• Keep a working fire extinguisher in the work area.

4 312878J

Page 5

Warnings

WARNING

ELECTRIC SHOCK HAZARD

Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

PRESSURIZED ALUMINUM PARTS HAZARD

Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids

containing such solvents in pressurized aluminum equipment. Such use can cause serious chemical

reaction and equipment rupture, and result in death, serious injury, and property damage.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated

system component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical

Data in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For com-

plete information about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot sur-

faces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe

burns, do not touch hot fluid or equipment. Wait until equipment/fluid has cooled completely.

312878J 5

Page 6

Isocyanate Hazard

Isocyanate Hazard

Spraying materials containing isocyanates creates

potentially harmful mists, vapors, and atomized particulates.

Read material manufacturer’s warnings and material

MSDS to know specific hazards and precautions

related to isocyanates.

Prevent inhalation of isocyanate mists, vapors, and

atomized particulates by providing sufficient ventilation in the work area. If sufficient ventilation is not

available, a supplied-air respirator is required for

everyone in the work area.

To prevent contact with isocyanates, appropriate personal protective equipment, including chemically

impermeable gloves, boots, aprons, and goggles, is

also required for everyone in the work area.

Material Self-ignition

• Keep the ISO lube pump reservoir (if installed) filled

with Graco Throat Seal Liquid (TSL), Part 206995.

The lubricant creates a barrier between the ISO and

the atmosphere.

• Use moisture-proof hoses specifically designed for

ISO, such as those supplied with your system.

• Never use reclaimed solvents, which may contain

moisture. Always keep solvent containers closed

when not in use.

• Never use solvent on one side if it has been contaminated from the other side.

• Always lubricate threaded parts with ISO pump oil

or grease when reassembling.

Keep Components A and B Separate

CAUTION

To prevent cross-contamination of the equipment’s

wetted parts, never interchange component A (isocyanate) and component B (resin) parts.

Some materials may become self-igniting if applied

too thickly. Read material manufacturer’s warnings

and material MSDS.

Moisture Sensitivity of Isocyanates

Isocyanates (ISO) are catalysts used in two component

foam and polyurea coatings. ISO will react with moisture

(such as humidity) to form small, hard, abrasive crystals,

which become suspended in the fluid. Eventually a film

will form on the surface and the ISO will begin to gel,

increasing in viscosity. If used, this partially cured ISO

will reduce performance and the life of all wetted parts.

The amount of film formation and rate of crystallization varies depending on the blend of ISO, the

humidity, and the temperature.

To prevent exposing ISO to moisture:

• Always use a sealed container with a desiccant

dryer in the vent, or a nitrogen atmosphere. Never

store ISO in an open container.

Foam Resins with 245 fa Blowing Agents

New foam blowing agents will froth at temperatures

above 90°F (33°C) when not under pressure, especially

if agitated. To reduce frothing, minimize preheating in a

circulation system.

Changing Materials

• When changing materials, flush the equipment multiple times to ensure it is thoroughly clean.

• Always clean the fluid inlet strainers after flushing.

• Check with your material manufacturer for chemical

compatibility.

• Most materials use ISO on the A side, but some use

ISO on the B side.

• Epoxies often have amines on the B (hardener)

side. Polyureas often have amines on the B (resin)

side.

6 312878J

Page 7

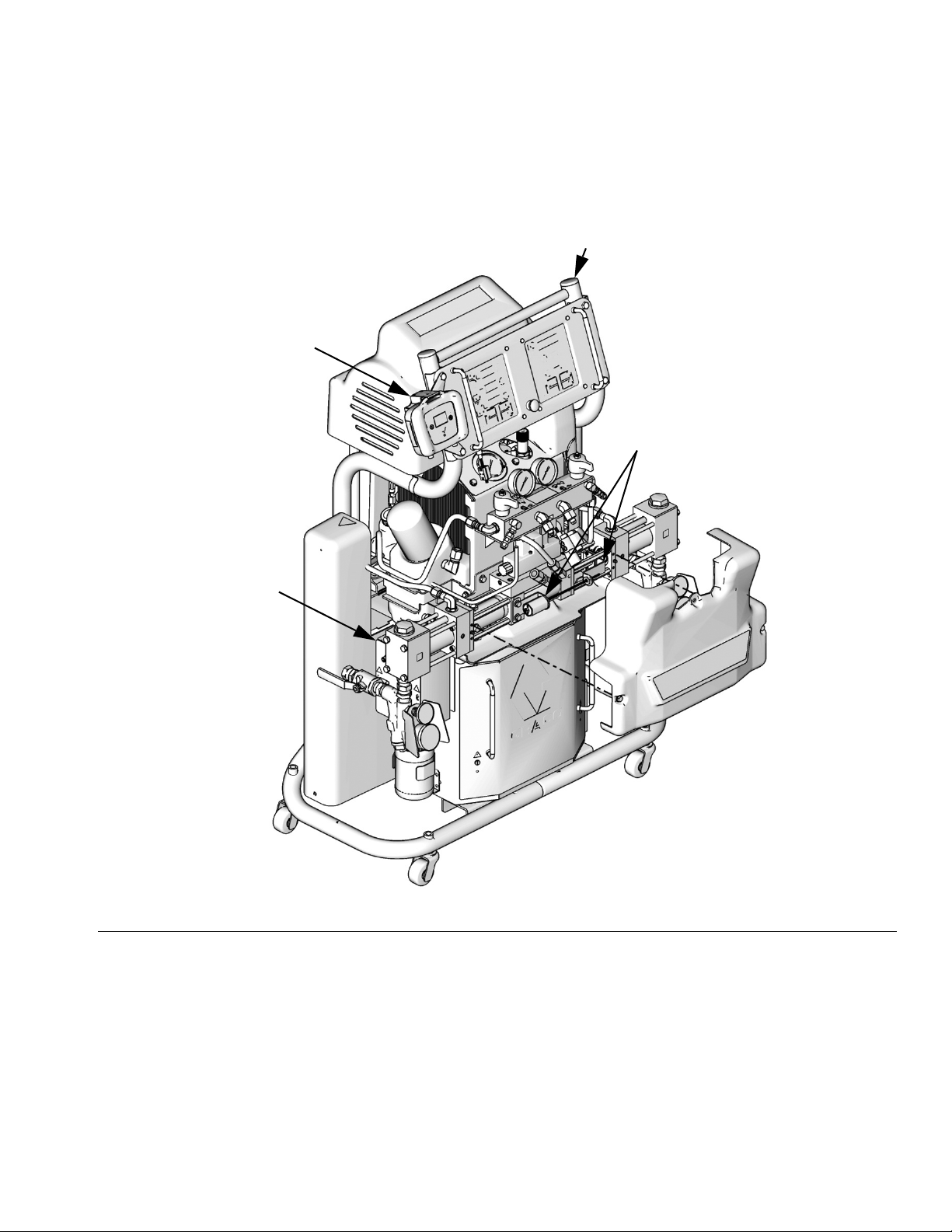

Component Identification

IPH System

B

Component Identification

A

D

C

Model 255811 shown

FIG. 1: IPH System with Front Cover Removed

Key:

A Hydraulic Proportioner

B Shot Controller, HMI, and Bracket

C Electrical Enclosure

D Linear Sensor Assembly

ti11820a

312878J 7

Page 8

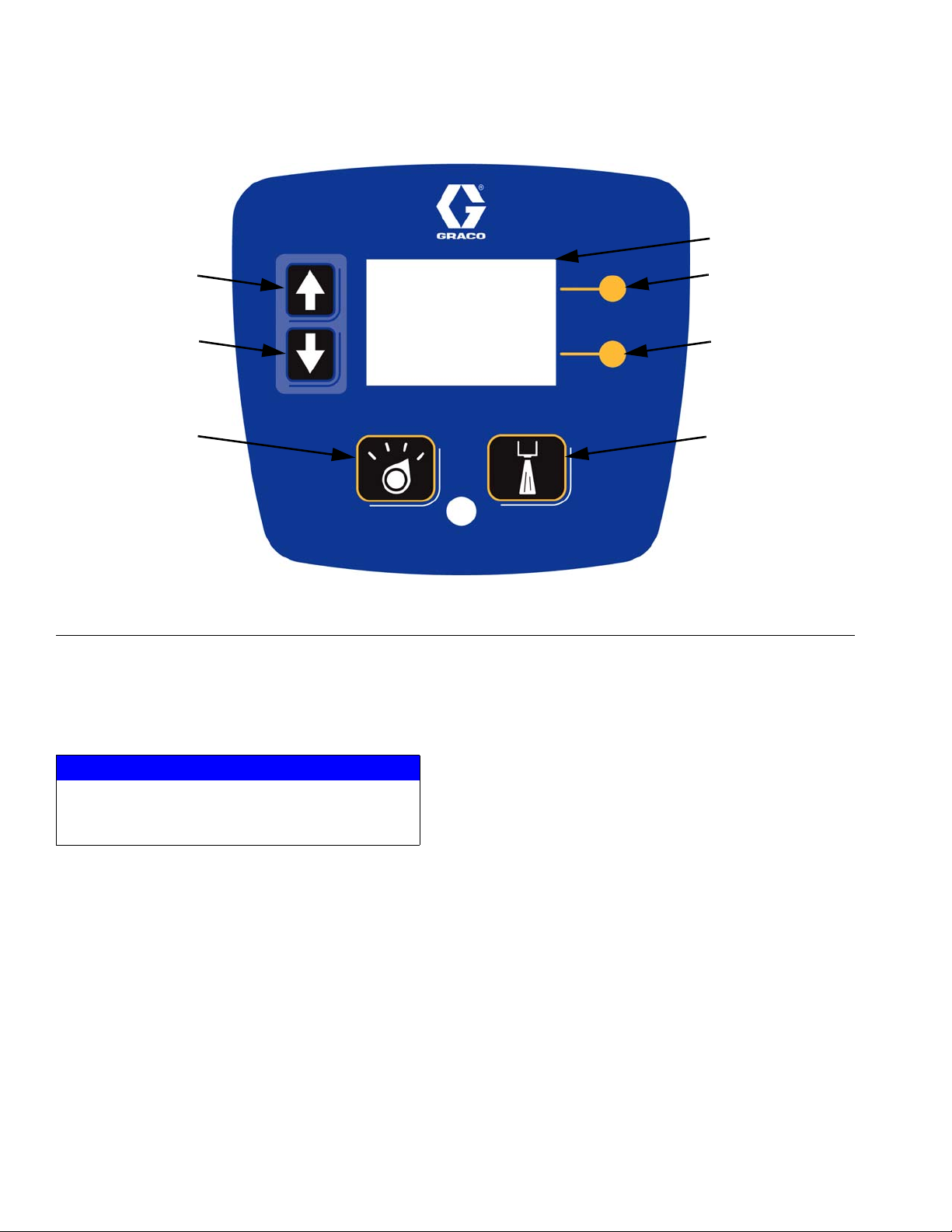

Component Identification

Human Machine Interface (HMI)

AG

AA

AB

AC

F

IG. 2

Key:

AA Up arrow key

AB Down arrow key

AC Mode select button

AD Top soft key

AD

AE

AF

AE Bottom soft key

AF Initiate shot button

AG LCD screen

NOTICE

To prevent damage to soft key buttons, do not press

the buttons with sharp objects such as pens, plastic

cards, or fingernails.

Initiate Shot button

Pressing this button will start a shot for either the

selected shot number, the next shot number in the

selected sequence, or when in manual mode will dis-

Mode Select button

Pressing this button will allow selection of an operating

mode. The available choices will always include Shot,

“Sh,” and Manual, “Mn”.

pense until the user releases the button.

If one or more sequences have been programmed, the

This button is initially set as disabled and can be

enabled or disabled from setup screen #7. See Setup

Sequence modes available will show up as the name of

each sequence (“Sq-A,” “Sq-B,” etc.).

Screen #7: Enable/Disable Run Screen Shot Editing

or “Initiate Shot” button on page 23.

8 312878J

Page 9

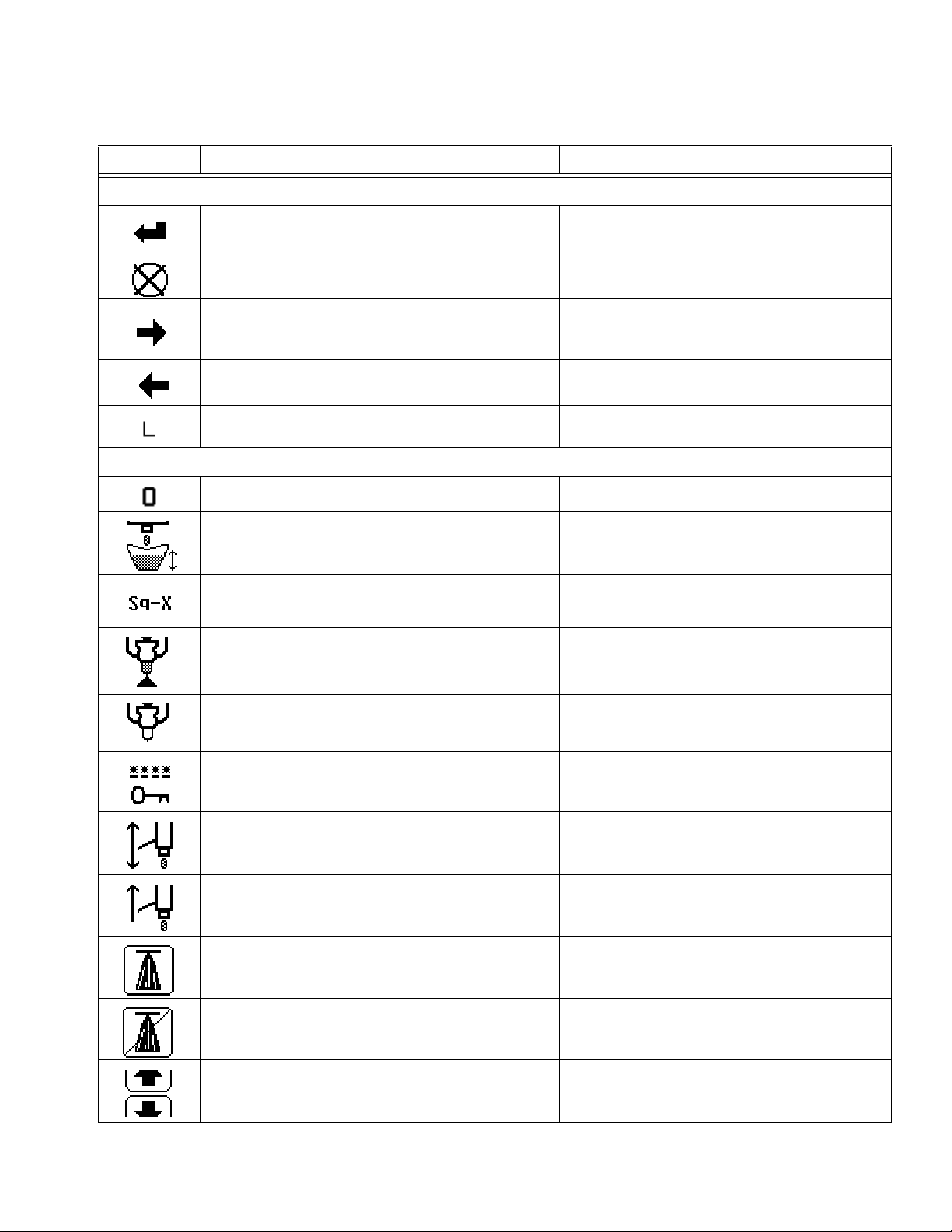

Icons

Icon Function Shown on Screen(s)

General Icons

Confirm changes • All

Exit without saving changes • All

• Setup screen #1

Next

Previous

Learn Mode Active Indicator (shown in lower-left

corner)

Setup Icons - see Controller Setup section on page 21

Reset Piston Counter to Zero • Setup screen #1

• Setup screen #3

• Run screen when Learn Mode is enabled

• Setup screen #1

• Run screen when Learn Mode is enabled

• Run screen when Learn Mode is enabled

Component Identification

Define Shot Amount • Setup screen #2

Define Sequence Modes • Setup screen #3

Open Gun Dispense Valve • Setup screen #4

Close Gun Dispense Valve • Setup screen #4

Change Password • Setup screen #5

Enable “Tap” mode • Setup screen #6

Enable “Hold” mode • Setup screen #6

Enable “Initiate Shot” button on HMI • Setup screen #7

Disable “Initiate Shot” button on HMI • Setup screen #7

Enable Run Screen Shot Editing • Setup screen #7

312878J 9

Page 10

Component Identification

Icon Function Shown on Screen(s)

Disable Run Screen Shot Editing • Setup screen #7

Enter Learn Mode • Setup screen #8

Exit Learn Mode • Setup screen #8

10 312878J

Page 11

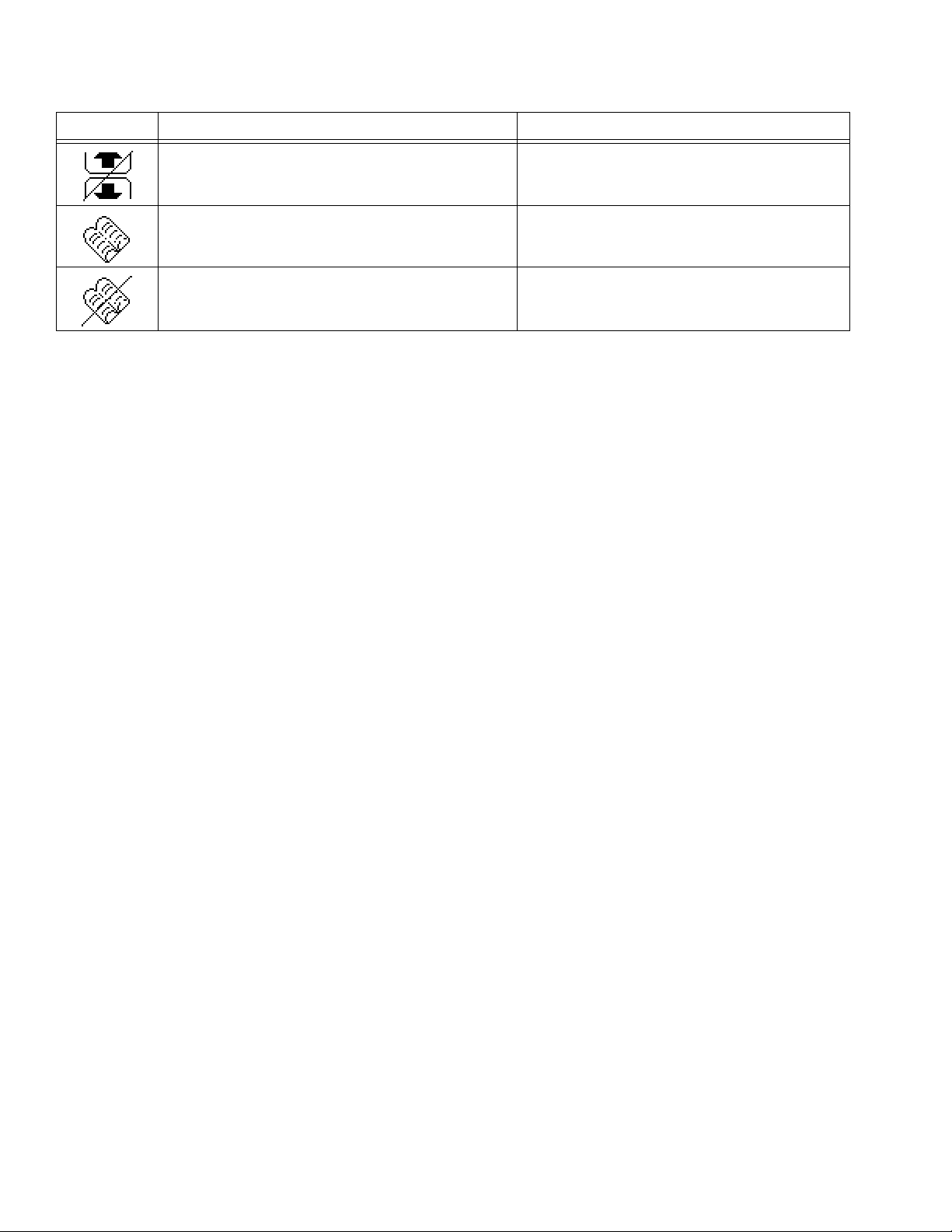

Run Screen

Component Identification

BA

BB

3

BC

BD

BE

BF

BM

BL

BK

1

1

When no errors are active, “E” will be displayed.

2

Shown only during shot dispensing in Shot or Sequence mode

3

Displayed only in Sequence mode

BJ

2

BH

BG

Key:

BA Current operating mode

BB nth shot in sequence

BC Number of shots executed for selected shot number

BD Quantity of selected shot (Shot or Sequence modes) or previous shot

(Manual mode)

BE Quantity unit of measure (cubic centimeters or grams)

BF Top soft key icon

BG Bottom soft key icon

BH Duration of selected shot (Shot or Sequence modes) or previous shot

(Manual mode)

BJ Progress bar for current shot

BK Error status

BL Piston position

BM Shot number currently selected

F

IG. 3: Run Screen

Run Screen Variables

Available operating modes vary by setup but will include

“Sh” for predefined shot mode and “Mn” for manual shot

mode. If sequences have been defined, operating mode

options will include “Sq-A”, “Sq-B”, etc. to select any of

the defined sequences. See Change Operating Mode

on page 29.

Shot quantity can be displayed either in cubic centimeters or grams depending on whether specific gravity is

entered. See Setup Screen #6: Quantity Units and

Gun Configuration on page 22.

312878J 11

The top and bottom soft key icons indicate the function

of the respective soft key. See Icons section on page 9

for icon descriptions.

Page 12

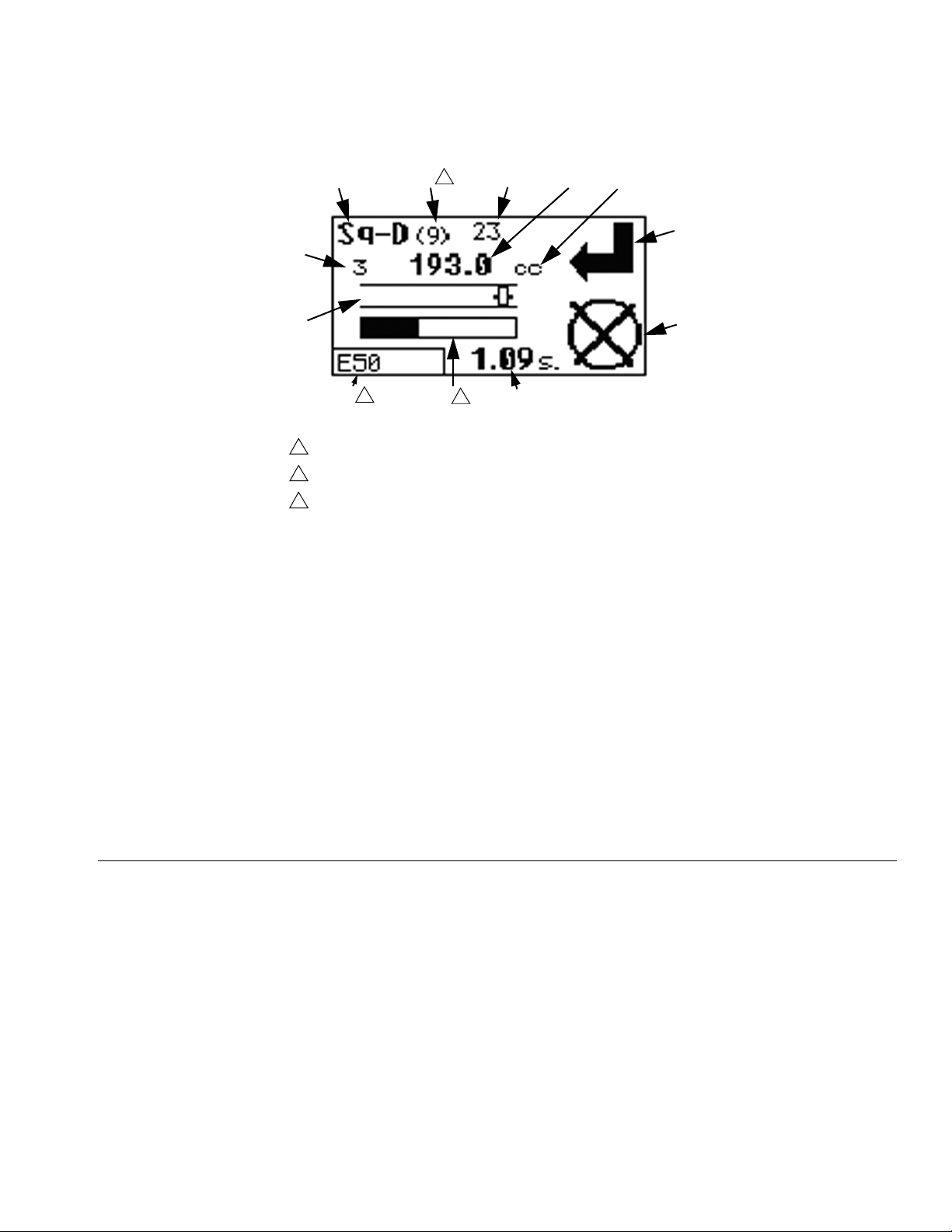

Component Identification

Maintenance Mode

Press and hold bottom

soft key for 2 sec

Idle Run Screen

After 15 sec

for 3 se

key

ft

Press and hold top

so

Initiate shot

Pr

e

ar

ss a

r

ow ke

n

d h

ys

o

for 3 s

c

ld b

e

Press up arrow key to

access Setup Screen 8

Enter and confirm

correct password

Password Entry

This screen is skipped

when password is disabled

Dispensing

Run Screen

o

th

c

Setup Screen 1

Press down

arrow key

Setup Screen 2

Press down

arrow key

Setup Screen 3

Press down

arrow key

Press up

arrow key

Press up

arrow key

Press up

arrow key

Splash Screen

Tur n on HM I

START

Run Screen

Shot Editing

Exit setup screens and return to Idle Run Screen by

pressing and holding both soft keys for 3 sec

Setup Screen 4

Press down

arrow key

Setup Screen 5

Press down

arrow key

Setup Screen 6

Press down

arrow key

Setup Screen 7

Press down

arrow key

Press up

arrow key

Press up

arrow key

Press up

arrow key

Press up

arrow key

Setup Screen 8

Press down arrow key to

access Setup Screen 1

FIG. 4: Screen Navigation Diagram

12 312878J

Page 13

Conversion Kit Installation

The IPH-25 and IPH-40 systems include a hydraulic proportioner and conversion kit 24A024 and are

assembled at the factory.

These instructions are for installing Conversion Kit

24A024 onto an existing H-25 or H-40 hydraulic

proportioner.

See Parts on page 34 for Conversion Kit 24A024

parts.

Install New Reversing Switch Activator Plate

CA

Conversion Kit Installation

ti11756a

F

IG. 5

1. Remove front cover (CA).

For steps 2 through 4, refer to Proportioning Pump

manual 312068 for detailed instructions.

2. Remove right clevis 261503 and reversing switch

activator plate.

3. Install new reversing switching activator plate (21).

4. Replace right clevis 261503.

312878J 13

Page 14

Conversion Kit Installation

Install Linear Sensor

4

6

14

13

12

15

F

IG. 6

12

14

13

5

5. Place the magnet bracket plate (9) on the left side of

the activator plate (21).

6. Pass two socket head cap screws (10) through the

bottom two holes of magnet bracket plate (9) and

activator plate (21).

7. Place the magnet bracket spacer (8) on top of the

activator plate (21).

10

15

9

21

8

7

11

ti11759a

The holes in the magnet bracket spacer (8) are

off-center. Make sure the side with more space

between the edge and holes faces down.

8. Pass the remaining two socket head cap screws

(10) through the top two holes of magnet bracket

plate (9) and the two holes in magnet bracket

spacer (8).

9. Place the magnet mounting bracket (7) on the right

side of the activator plate (21), guiding the four

socket head cap screws (10) through the four holes

in the bracket.

10. Spin the four lock nuts (11) onto the ends of the four

socket head cap screws (10) and tighten.

11. Apply thread sealant to threads of magnet

holder (5).

12. Attach magnet holder (5) to the end of the magnet

mounting bracket (7) using nut (15).

Linear Sensor

Assembly

ti11796a

F

IG. 7: Assembled View with Front Cover Removed

13. Attach linear sensor bracket (6) to the left hydraulic

cylinder port block using two hex head cap

screws (12), flat washers (14), and split lock

washers (13).

14. Apply thread sealant to remaining nut (15)

15. Install linear sensor (4) in the linear sensor bracket

(6) using remaining nut (15).

16. Pass wiring harness from linear sensor (4) through

opening in top of electrical cabinet (DE).

17. Replace front cover (CA).

14 312878J

Page 15

Install Electrical Enclosure

DC

DD

DB

DA

Conversion Kit Installation

DE

Key:

DA Screw

DB Electrical enclosure cover

DC Electrical enclosure

DD Wire access cover screws

DE Electrical cabinet

F

IG. 8

18. Remove three screws (DD) holding wire access

cover to the electrical cabinet.

19. Remove wire access cover from the left side of the

electrical cabinet (DF). The wire access cover will

not be re-used.

20. Remove electrical enclosure cover (DB) from the

electrical enclosure (DC) by removing two

screws (DA).

21. Pass wire harness from electrical enclosure

cover (DB) through back of electrical

enclosure (DC) and into electrical cabinet (DE).

22. Install electrical enclosure (DC) to side of electrical

cabinet (DE) using three screws (DD).

ti11757a

23. Install electrical enclosure cover (DB) to electrical

enclosure using two screws (DA).

312878J 15

Page 16

Conversion Kit Installation

Install Shot Controller

2

EA

1

EA

F

IG. 9

24. Remove the two left side crown nuts (EA) from the

display (EC).

25. Apply thread sealant to threads of crown nuts (EA).

26. Install shot controller bracket (2) to display (EC)

using crown nuts (EA).

EC

ti11758a

29. Connect the “pump” plug to J12 on the motor control

board.

30. Connect the “temp” plug to the “data” connector on

the temperature control board.

31. Connect wire harness to the linear sensor.

32. Connect 3-pin plug to J5 on the motor control board.

33. Connect 5-pin plug to J6 on the motor control board.

34. Connect the two power leads to the fan fuse block.

35. Replace electrical cabinet front cover (CB).

Connect Shot Controller Cables

See Simplified Schematic, Shot Controller Wiring on page 18.

36. Plug DB25 data cable 15T859 into the receptacles

on the electrical enclosure cover (DB) and the shot

controller (1).

37. Plug power cable 121003 into the electrical enclosure cover (DB) and the left receptacle on the shot

controller (1).

27. Snap shot controller (1) into shot controller

bracket (2).

Connect the Wire Harnesses

See Simplified Schematic, Shot Controller Wiring on page 18.

CB

IG. 10

F

28. Remove electrical cabinet front cover (CB).

ti11756a

16 312878J

Page 17

Disable Motor Standby Operation

A shot delivered while the Reactor™ electric motor and

hydraulic pump are ramping up to full speed may be

inaccurate. Because of this, it is recommended that

Motor Standby mode be disabled when the Shot Controller is installed. See the Standby section in the Reactor operation manual 312062 for information about

disabling Standby mode.

If the Reactor Standby mode has not been disabled and

the motor has entered Standby mode the machine can

be brought back to full pressure in one of two ways:

• Not recommended: Trigger a shot. The system will

sense the pressure drop and the motor will ramp up

to full speed. Shot may be inaccurate.

• Recommended: Press on the Motor Controls to

turn the motor circuit OFF, then press it again to turn

it back ON. This will cancel Standby mode and

restart the motor. Wait for the Reactor to regain full

pressure before triggering a shot.

Conversion Kit Installation

312878J 17

Page 18

Conversion Kit Installation

Simplified Schematic, Shot Controller Wiring

FA

FK

FL

FJ

FC

FG

FH

FB

1

FF

FE

FD

1

See FIG. 18 on page 34 for detailed view.

Key:

FA Shot Controller

FB Hydraulic Proportioner Fan Fuse Block

FC Electrical Enclosure

FD Hydraulic Proportioner Temperature

Control Board

(view from front of hydraulic proportioner)

FE Linear Sensor

FF Hydraulic Proportioner Motor Control

Board

FG Shot Controller Power Cable

FH Port for Optional Data Reporting Kit

248848 (purchase separately)

FJ Port for External Machine Control

FK Shot Controller Data Cable

FL Port for Gun Cable

FIG. 11: H25, H40 Conversion Kit Wiring Diagram

18 312878J

Page 19

Simplified Schematic, Shot Controller Electrical

,).%!2

3%.3/2

0/3)4)/.

Conversion Kit Installation

0/7%23500,9

0/7%2#!",%4/

3(/4#/.42/,,%2

$!4!#!",%4/

3(/4#/.42/,,%2

#/--/.

7)2%(!2.%33

#/..%#4/2"/!2$

3500,9

60/7%2

6

*

6

#/--/.

0)34/.0/3)4)/.

*

7)2%(!2.%33

,).%!23%.3/2

'2/5.$

*

*

-/4/2

#/.42/,

#/--/.

,%&4).$)#!4)/.

2)'(4).$)#!4)/.

(!2.%33

37)4#(

05-0,).%

-%#(!.)#!,

1

37)4#((!2.%33

-%#(!.)#!,2%6%23).'

Connect harness to J5 on Motor Control

1

Board to return to spray operation.

3(/4#/.42/,,%2%,%#42)#!,%.#,/352%

*

'5.#!",%

#/.42/,#!",%

%84%2.!,-!#().%

*

*

*

*

*

*

312878J 19

*

-/4/2#/.42/,"/!2$

*

*

*

*

/04)/.!,$!4!

2%0/24).'+)4

ti12349a

Page 20

Conversion Kit Installation

Simplified Schematic, Alternate Gun Connection

3/,%./)$6!,6%

./2-!,,9/0%.

37)4#('5.42)''%2

#/),2%452.

$)30%.3%#/--!.$

$)30%.3%2%15%34!#4)6%

37)4#(2%452.

3(/4#/.42/,,%2

%,%#42)#!,%.#,/352%

-!,%$"

#/..%#4/2

ti12350a

20 312878J

Page 21

Setup

Setup

Hydraulic Proportioner Setup

See hydraulic proportioner manual 312062.

Controller Setup

When in any of the setup screens, pouring is disabled.

To enter the setup screens, press and hold the top soft

key for three seconds. To exit the setup screens, press

and hold both soft keys for three seconds. See F

page 8 for HMI button identification.

To navigate between the setup screens, for example

from setup screen #1 to setup screen #2, use the up

and down arrow keys. To navigate within a setup screen,

for example from the first page of setup screen #6 to the

second page of setup screen #6, use the soft keys.

See F

IG. 4 on page 12 for illustration of the setup

screens and navigation.

Setup Screen #1: System Data

IG. 2 on

Setup Screen #2: Shot Number Definitions

The shot quantity units, cubic centimeters or grams,

for which each shot number quantity is defined is

dependent on whether the material specific gravity

has been entered. See Setup Screen #6: Quantity

Units and Gun Configuration on page 22.

From setup screen #2, any of the twenty-five available

shot numbers can be edited. Each shot number can be

defined so that the machine will dispense the input

quantity of material when the shot number is selected

and a shot is initiated.

To edit a shot, navigate to setup screen #2. Press the

top soft key, and then use the arrow keys to highlight the

number of the shot to edit. Press the top soft key to

select and change the quantity for the selected shot

using the up and down arrow keys. Press the top soft

key to highlight the calibration factor. If required, use the

up and down arrow keys to adjust the calibration factor,

Refer to Calibration, page 30, for more information.

Press the top soft key to enter the change, and then

confirm the change when prompted.

This screen is a collection of system data that includes

the shot counter for each programmed shot, total piston

stroke counter, and a separate resettable piston stroke

counter. The piston stroke counters are displayed on the

last screen of setup screen #1.

To restart the counter for the resettable piston stroke

counter navigate to setup screen number one. Press the

top soft key to navigate to the next data page. Press the

top soft key repeatedly until the icon for the bottom soft

key is “0.” Press the bottom soft key to zero the counter

and confirm the selection when prompted.

312878J 21

Setup Screen #3: Shot Sequences

Setup screen #3 shows the five customizable shot

sequences, each with a sequence of ten shots. Each of

the ten shots in each sequence can be changed to any

of the shot numbers defined using setup screen #2. If

any sequence contains either an undefined shot or one

of the positions in the sequence is undefined, that shot

will be skipped when operating with that sequence.

Page 22

Setup

To edit a shot sequence, navigate to setup screen #3.

Hit the top soft key to move to the next screen then use

the up and down arrows to highlight a shot sequence.

Press the top soft key to select the highlighted sequence

then use the arrow keys to navigate to the n

th

shot in

that sequence and hit the top soft key to select. Once

selected, use the arrow keys to change the n

th

shot in

the sequence to a different shot number. See Setup

Screen #2: Shot Number Definitions.

Setup Screen #4: Adjusting E52 Error Delay

Smaller piston sizes and longer hoses will require a

longer delay.

When finished dispensing, the piston will continue to

travel slightly before being stopped and if the piston travels longer than expected the E52 error will occur. If the

E52 error code is triggered often, the likelihood of the

alarm triggering can be lowered by extending the time

the machine waits before triggering the alarm.

To edit the E52 error delay, navigate to Setup Screen #4

then press the top soft key to enter editing mode. Use

the up and down arrow keys to edit the time then press

the top soft key to enter the change.

Quantity Units

To configure the machine to display shot quantity in

grams, when it is currently displaying cubic centimeters,

navigate to setup screen #6. Press the top soft key then

enter the specific gravity of the dispensed and mixed

material using the arrow keys. Press the top soft key

when finished to confirm.

To configure the machine to display shot sizes in cubic

centimeters, when it is currently displaying in grams,

navigate to setup screen #6. Press the top soft key then

confirm the selection when prompted.

“Tap” and “Hold” Gun Modes

“Tap” mode and “Hold” mode define how the machine

responds to pulling/releasing the gun trigger and, if

enabled, pressing/releasing the “Initiate Shot” button on

the HMI.

When in manual mode, the machine will only shoot

when the gun trigger or “Initiate Shot” button is

held, regardless of which mode, “Tap” or “Hold,” is

selected.

In “Tap” mode, signified by the icon , a shot is first

initiated by tapping and releasing the gun trigger or “Initiate Shot” button. Once a shot is started, the shot can

only be stopped or started again by tapping the trigger

or the bottom soft key. The shot will continue until the

predefined time elapses or the trigger or bottom soft key

is tapped.

Setup Screen #5: Password Protection

See Password Protection section on page 23.

In “Hold” mode, signified by the icon , shots are initiated by pulling the gun trigger or pushing the “Initiate

Shot” button. Unlike “Tap” mode, the shot will only continue as long as the trigger or button is held. If the trigger

Setup Screen #6: Quantity Units and Gun

Configuration

or button is held longer than the predefined duration of

the selected shot, the shot will end when the predefined

duration elapses.

To toggle between “Tap” and “Hold” mode, navigate to setup screen #6 and press the top soft key

which will have next to it either the “Tap” or “Hold” icon.

Setup screen #6 serves two functions: toggling between

measuring shot quantity in cubic centimeters or grams,

and toggling between gun modes “Tap” and “Hold.”

22 312878J

Page 23

Setup

Setup Screen #7: Enable/Disable Run

Screen Shot Editing or “Initiate Shot”

button

Enabling the “Initiate Shot” button allows starting and

stopping shots from both the gun and the “Initiate

Shot” button. When operating with the “Initiate Shot”

button enabled, the gun must be locked in a pouring

enclosure so that all dispensed material will be dispensed in a direction away from people.

The system is shipped with the “Initiate Shot” button disabled.

To enable or disable Run Screen Shot Editing of the “Initiate Shot” button on the HMI, navigate to setup

screen #7 and push the top soft key. Confirm the selection when prompted. See Icons section on page 9.

Setup Screen #8: “Learn” Mode

To access the setup screens when the password is

enabled, press the top soft key for three second and the

password entry screen will appear. Enter the password

and confirm to access the setup screens.

Entering a Password

Use the up and down arrow keys to change the selected

digit in the password. To move to the next digit, press the

top soft key. If a mistake is made, hit the bottom soft key

to exit password entry and then re-enter setup mode to

enter the password.

FIG. 12: Password Entry Screen

Resetting Password

If the password is forgotten, the password can be reset

without losing the current machine settings or shot data.

1. Remove power from the shot controller for 10 seconds.

See Learn Mode section on page 24.

Setup Screen #10: Define Piston Size

See Piston Size section on page 25.

2. Reapply power to the shot controller.

3. When the idle run screen appears, immediately

press and hold both the top soft key and up arrow

key for six seconds. The password will then automatically be reset to “00000.”

Password Protection

The setup screens can be protected by a password to

restrict their accessibility. When the password is

“00000,” the setup screens can be accessed without

entering a password.

To create a password to protect the setup screens or to

change the existing password, navigate to setup screen

#5 and hit the top soft key to enter the password entry

screen. Enter the new password twice and then hit the

top soft key to confirm.

To disable the password, change the password to

“00000” as described in the previous paragraph.

312878J 23

Page 24

Setup

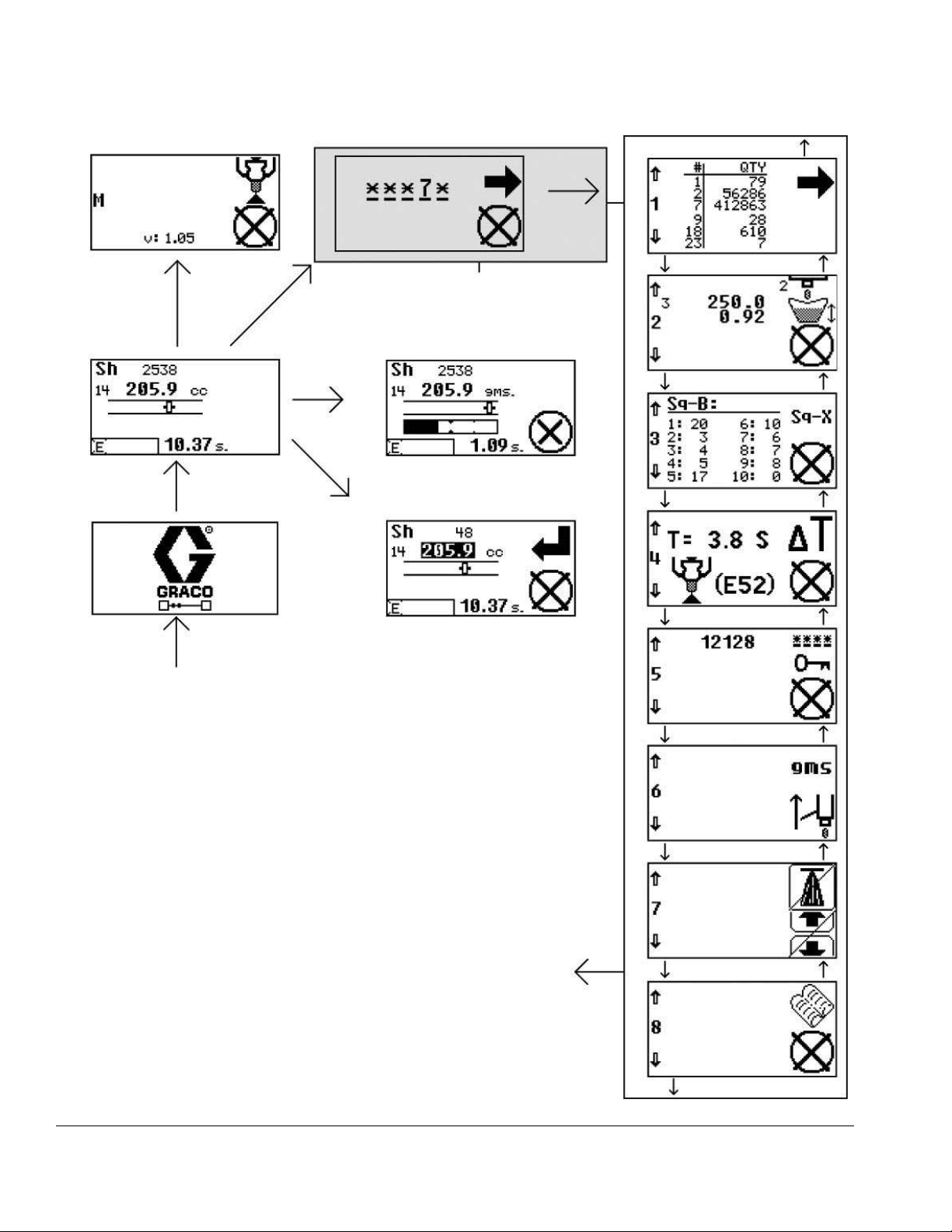

Learn Mode

Learn mode will need to be used following the

installation of the conversion kit, the linear sensor

or its mounting bracket, or the shot controller.

The IPH units are programmed at the factory so

Learn mode will not need to used prior to pouring.

Obtain Piston Range Information

To view the physical piston movement, remove the

front cover (CA) from the machine. Replace the

cover when finished using Learn mode.

5. Using a bucket to catch the dispensed material, trigger the gun until the piston reaches the left-most or

right-most position.

6. Manually reverse piston direction by pressing the

top soft key.

Learn mode enables the shot controller to learn the

left-most and right-most piston positions. To do this, the

standard piston controls are disabled and the piston is

moved left and right using the top soft key. With Learn

mode enabled the top soft key icon will be a left or right

arrow to signify the direction the piston will move when

pressed. In the usual bottom soft key icon location, the

left-most and right-most piston positions obtained from

using Learn mode will be shown.

F

IG. 13: Run Screen with Learn Mode Enabled

Learn Piston Left-most and Right-most

Positions

7. Repeat steps 5 and 6 until the piston range displayed in the bottom right corner of the screen

remains constant.

If the piston range displayed in the bottom right corner of the screen contains a number outside the

range of 200 to 4650, error code E50 will be generated. A number outside this range means that

either the linear position sensor is not properly

installed or there is a problem with the shot controller electronics. Error code E50 will be generated

until the problem is corrected.

Disable Learn Mode

8. Navigate to setup screen #8.

9. Press the soft key adjacent to the “Disable Learn

Mode” icon. Confirm the selection when prompted.

10. Exit setup mode by pressing and holding both soft

keys for three seconds.

Enable Learn Mode

1. Change the operating mode to Manual, see

Change Operating Mode section on page 29.

2. Navigate to setup screen #8. See F

IG. 4 on page 12.

3. Select the top soft key with the “Enter Learn Mode”

icon and confirm the selection when prompted. See

Icons section on page 9.

4. Press and hold both the top and bottom soft keys for

three seconds to exit the setup screens.

24 312878J

Page 25

Piston Size

If the system is off-ratio with a B side piston size different from the A side piston, the impingers in the

gun may need to be adjusted to achieve equal

pressures in the A and B side chemical lines. For

impinger adjustment procedure for the AR Pour

Gun, see manual 312888 available at

www.graco.com.

Setup

Define Piston Size

If piston diameter editing is aborted prior to confirming the entry of both piston diameters, no

changes will be saved.

1. Remove then re-supply power to the shot controller.

2. Within 20 seconds of the Idle Run Screen appearing, press and hold both the top soft key and the

down arrow key for six seconds.

3. When prompted, enter password “88888.” See

Password Protection section on page 23.

4. Edit the “A” side piston diameter using the up and

down arrow keys and the information provided in the

preceding table.

Size Pump Diameter (mm)

30 247371 22.225

40 247372 25.629

48 247373 28.092

60 247374 31.496

80 247375 36.297

88 247577 38.024

96 247376 39.802

120 247377 44.552

140 247576 47.955

5. Press the top soft key to edit the “B” side piston

diameter.

6. Edit the “B” side piston diameter using the up and

down keys and the information provided in the preceding table.

7. Press the top soft key to confirm the piston entries.

The shot controller will then return to the idle run

screen.

312878J 25

Page 26

Setup

Optional External Machine Control

GA

GF

GB

GG

GC

GH

GD

GJ

GE

F

IG. 14: DB9 Male Connector on Electrical Enclosure

Key:

GA Pin #1: External Machine Return Ground

GB Pin #2: Not used

GC Pin #3: Not used

GD Pin #4: Not Used

GE Pin #5: Ground for Cable Shields

GF Pin #6: Not used

GG Pin #7: Shot Number or Sequence n

GH Pin #8: Dispense Request

GJ Pin #9: Ready Status

th

Shot Selection

All electrical work must be done by a technician

knowledgeable in electronics.

CAUTION

The external machine must use a semi-conductor

based output, such as an NPN transistor.

An optional external machine control interface can be

installed if desired. The external machine will be able to

select specific shots and to initiate shots.

CAUTION

The external machine will not supply any voltage

through any of the DB9 lines. It will only ground the

received signals from Pins #7 and #8 to Pin #1 as

needed.

Ready Status Line

See FIG. 15 on page 28.

The Ready Status line tells the external machine when

the shot controller is ready to receive signals. This line

has two states: “High” and “Low.” When it is “High” there

is 24V and when it is “Low” there is less than 5V.

The machine will send a 24V, or “High,” signal specifying

it is ready to receive inputs when it is at the idle run

screen.

The machine will send a less than 5V, or “Low,” signal

specifying it is not ready to receive signals when it is dispensing, in one of the setup screens, or when an error

code has been generated and has not yet been

acknowledged on the shot controller.

26 312878J

Page 27

Setup

Dispense Request Line

See FIG. 15 on page 28.

The gun must be configured to “Tap” mode to use

the dispense request line.

For the external machine to request a shot Pin #8: Dispense Request should be momentarily connected to

Pin #1: External Machine Return Ground. This connection should last 150 milliseconds (mS) to 200 mS before

being released.

If a Dispense Request signal is received when the

Ready Status “High” signal is not being sent, the request

is ignored.

Shot Number or Sequence nth Shot

Selection Line

See FIG. 15 on page 28.

The operating mode can only be changed using the

HMI. When an external machine tries to select a

shot, the machine will select a specific shot number

if in Shot mode and will select a specific shot position within the selected sequence if in Sequence

mode.

After Pin #7 has been grounded n+1 times, there must

be a delay of four times the period Pin #7 was grounded

for each of the n+1 repetitions. For example, if Pin #7

was grounded for 15 milliseconds then ungrounded for

15 milliseconds and so on, there must be a delay of 60

milliseconds before activating the Dispense Request

line.

Selecting a shot is done in a manner similar to the Dispense Request line, where Pin #7 should be momentarily connected to Pin #1 using a semi-conductor based

output.

Unlike the Dispense Request line where the line is

grounded only once, Pin #7 is grounded to Pin #1

repeatedly. The period of time between Pin #7 being

grounded should equal the period of time it is grounded,

meaning the pattern followed should be x mS grounded,

x mS ungrounded, x mS grounded, x mS ungrounded,

etc. The allowable range for the period of time Pin #7 is

ground/ungrounded is 10 to 100 milliseconds.

To request shot n or the n

sequence, Pin #7 must be connected to and then disconnected from Pin #1 n+1 times. For example, to

request shot 3, Pin #7 must be grounded four times.

th

shot within the selected

312878J 27

Page 28

Setup

Pin #7: Shot Number or Sequence n

th

Shot Request

Not Grounded

1234

15 mS 15 mS 15 mS 15 mS 15 mS 15 mS 15 mS

4 X 15 mS

100 mS

Pin #8: Dispense Request

Pin #9: Ready Status

15 12045 75 10560 90 180 280 330

300

50 mS

TIME (milliseconds)

Grounded

Not Grounded

Grounded

Dispensing begins

24V signal

< 5V signal

FIG. 15: Timing Diagram Example - Request and Dispense Shot #3

28 312878J

Page 29

Operation

The AR Pour Gun and shot controller modify the

hydraulic proportioner to pour instead of spray but

all operation procedures from hydraulic proportioner

operation manual 312062 are applicable.

Operation

Change Shot Number

Only shots with non-zero volumes/weights can be

selected.

Startup

See hydraulic proportioner operation manual 312062.

Change Operating Mode

Operating modes Shot (“Sh”) and Manual (“Mn”) will

always be available and Sequence mode (“Sq-X”) will be

available when one or more sequences are created by

the user. See Setup Screen #3: Shot Sequences on

page 21. To change the operating mode, hit the Mode

Select key on the HMI until the desired operating mode

is shown in the top left corner of the screen. Hit the top

soft key to confirm the mode selection.

1

2

1

To change the selected shot from the idle run screen, hit

the up or down arrow keys. When the desired shot is

selected, hit the top soft key to confirm the selection.

Change Shot Volume/Weight

To change the defined shot volume or weight for the

selected shot, first enter Run Screen Shot Editing mode

by pressing and holding both the up and down arrow

keys for three seconds. Use the up and down arrow keys

to change the shot volume/weight then confirm the

change when prompted.

2 3

4

1

changing the operating mode or shot number, the item being changed will be

highlighted

2

During Run Screen Shot Editing, the shot quantity will be highlighted

3

A password may be required to edit this item

4

All changes must be confirmed or cancelled

IG. 16: Run Screen Shot Editing, Changing Operating Mode

F

312878J 29

When

Page 30

Operation

Sequence Mode Options

Calibration

The Shot Meter dispenses a programmed shot amount

based on the measured motion of the pump during the

shot delivery. This provides a precise and repeatable

shot volume. However, the accuracy of the shot amount

may not be sufficient for the application due to many factors that are dependent on the specific options and

installation. Factors such as the dispense valve, length

of hoses, pressure, and material temperature may affect

the accuracy of the volume dispensed.

To account for these variables, you can calibrate the

delivered volume of each programmed shot. When a

new shot is defined in setup screen #2 the default value

of the calibration factor is 1.00. Decrease this value to

decrease the shot amount. Increase this value to

increase the shot amount. Use the following procedure

to calculate calibration factors. You can set the calibration factor to any value between 0.20 and 2.00.

Calculate Calibration Factors

To calculate the calibration factor for a shot:

1. Dispense and measure a shot with the calibration

factor set to 1.00 (default).

Example

Assume a programmed shot size of 250cc. In this example, the dispensed shot size as measured is 271cc. Calculate: 250 / 271 = 0.9225. Enter the amount 0.92 into

the Calibration Factor for the programmed shot.

Restart Shot Sequence

In sequence mode, to restart a shot sequence from the

first defined shot, press and hold the down arrow key for

three seconds. When prompted, hit the top soft key to

confirm restarting the sequence.

Repeat/Skip Shot in Sequence

To repeat a shot, while at the idle run screen press the

down arrow key and confirm when prompted. To skip a

shot, while at the idle run screen press the up arrow key

and confirm when prompted.

2. Divide the programmed shot size by the measured

shot size.

If the measured shot is larger than the programmed

amount, the calibration factor is less than 1.00.

If the measured shot is smaller than the programmed amount, the calibration factor is greater

than 1.00.

3. Enter the result of step 2 into the scale factor setting

in setup screen #2 for the specific shot.

4. Dispense and measure another shot to verify the

calibration. You can adjust the value entered in step

3 up or down fractionally to improve the accuracy of

the shot delivery.

30 312878J

Page 31

Operation

Dispense Material

A shot can be initiated using either the gun trigger or the

“Initiate Shot” button. See “Tap” and “Hold” Gun

Modes on page 22.

Maintenance Mode

When using Maintenance mode for anything other

than shutting down the machine, close the material

valves on the coupling block to avoid accidentally dispensing material. See AR Pour Gun manual 312888

for more information.

To perform cleaning, maintenance, or other work on the

AR Pour Gun without error codes being generated, use

Maintenance Mode. To enter Maintenance Mode, press

and hold the bottom soft key for two seconds from the

idle run screen.

Demo Mode

Demo mode is an alternate operating mode that is identical to standard operation but with a few exceptions.

When in Demo mode, pouring, control of the gun and

hydraulic proportioner, and Learn mode are all disabled.

Also, settings and passwords saved in Demo mode are

separate from settings saved in normal operation.

Enter/Exit Demo mode

1. Remove then resupply power to the shot controller.

2. Within five seconds of the idle run screen appearing, press and hold both the bottom soft key and the

down arrow key for six seconds.

A “D” in the bottom, left corner of the HMI screen

will be shown when in Demo mode.

Hibernate Mode

The HMI will enter hibernate mode when idle for six minutes. To exit hibernate mode, press the up or down

arrow key or trigger the gun.

If hibernate mode is exited by triggering the gun, the

HMI will light to half brightness. To have the HMI display

light to full brightness, press any key.

When in Maintenance mode, the gun dispense valve

can be opened and closed by pressing the top soft key

twice or by pressing the gun trigger. Once the top soft

key has been used to open or close the gun dispense

valve, the gun trigger will be disabled. To regain the ability to open and close the gun using the trigger after

using the top soft key, exit and re-enter Maintenance

mode.

Shutdown

When shutting down the hydraulic proportioner, a

small amount of material will be dispensed. Have a

sheet of cardboard or other item ready to catch the

dispensed material.

Enter Maintenance mode by pressing and holding the

bottom soft key for two seconds then park the hydraulic

proportioner by selecting the “PARK” button on the proportioner display. See hydraulic proportioner operation

manual 312062 for more information.

312878J 31

Page 32

Pressure Relief Procedure

Pressure Relief Procedure

1. Relieve pressure in gun and perform gun shutdown

procedure. See gun manual 312888.

2. Close gun fluid manifold valves A and B. See gun

manual 312888.

3. Shut off feed pumps and agitator, if used.

4. Turn PRESSURE RELIEF/SPRAY valves (SA, SB)

to PRESSURE RELIEF/CIRCULATION . Route

fluid to waste containers or supply tanks. Ensure

gauges drop to 0.

SA

SB

ti9879a

5. Engage gun safety lock. See gun manual 312888.

6. Disconnect gun air line and remove gun fluid manifold. See gun manual 312888.

32 312878J

Page 33

Troubleshooting

Troubleshooting

A

B

Key:

AError Code

BError Icon

FIG. 17: Error Alert Screen

Error Codes

Error Code Error Icon Cause Possible Solutions

E11

E50

E52

E53

E54

E55

E56

A key has been pressed for more than 30

seconds

Linear sensor fault, often caused if in Learn

mode and piston position measured is outside the expected range

Dispense valve is stuck open or one of the

material tanks is empty, leading to higher

dispensed quantity than requested

A piston stroke has taken more than 10 seconds

This error code warns of the possibility of

inconsistent shots but will allow the

requested shot to occur. Shots requiring

less than 1/8 of a full piston stroke will trigger this error code.

A shot has been requested that is above the

maximum allowable amount.

Learn mode failed to learn piston travel

range because:

1) Piston did not move during Learn mode

2) Linear sensor failure

• Check shot controller for stuck key

• Replace shot controller

• Check wiring and replace as necessary

• Check linear sensor and replace as necessary

• Learn mode will need to be used if linear

sensor is replaced

• If dispense valve is stuck, the machine will automatically attempt to release it

• The amount dispensed will be more than

requested when this error occurs

• Fill tank

• Adjust E52 alarm delay time from setup

screen #4

• Verify that the gun safety is off

• Verify that the gun dispense valve is not stuck

closed

• Verify adequate hydraulic or pneumatic pressure

to machine

• Inspect for mechanical interference with the piston

• Verify correct power to the proportioner piston

• Request a larger shot

• Verify that shot volume variation is ok

• Request a smaller shot

• Repeat Learn mode

• Inspect the linear sensor and replace as neces-

sary

312878J 33

Page 34

Parts

Parts

Model, Series Hydraulic Proportioner Conversion Kit

255811, B 253725 24A024

255812, B 253726 24A024

255813, B 253727 24A024

255814, B 255400 24A024

255815, B 255401 24A024

255816, B 255402 24A024

255819, A 255406 24A024

255820, A 255407 24A024

255821, B 253725 24A024

255822, B 253726 24A024

255823, B 253727 24A024

255824, B 255400 24A024

255825, B 255401 24A024

255826, B 255402 24A024

Hydraulic Proportioner

Refer to hydraulic proportioner repair manual 312063 for

parts lists for each hydraulic proportioner.

Conversion Kit 24A024

1

4

14

13

12

ti11787a

6

2

10

3

ti11786a

9

21

8

7

14

13

12

F

IG. 18

34 312878J

15

5

15

11

ti11759a

Page 35

Ref Part Description Qty

1* 262416 PENDANT, shot meter 1

2 256217 KIT, bracket, pendant 1

3 256230 ENCLOSURE, electrical, assy 1

4 287839 SENSOR, assembly 1

5◆ KIT, holder, magnet 1

6◆ BRACKET, mounting, linear sensor 1

7◆ BRACKET, mounting, magnet 1

8◆ SPACER, bracket, magnet 1

9◆ PLATE, clamp, bracket, magnet 1

10◆ SCREW, cap, sch 4

11◆ NUT, lock, hex 4

12◆ SCREW, cap, hex hd 2

13◆ WASHER, lock, spring 2

14◆ WASHER, plain 2

15◆ NUT, head 2

16† 15T859 CABLE, shot controller data, DB25,

10 ft

17† 121002 CABLE, shot controller power,

female / female 3.0 m

18† 15T852 CABLE, gun, DB9, 25 ft 1

19† 15T602 CABLE, gun, DB9, 10 ft 1

20†◆ ADHESIVE, anaerobic 1

21◆ PLATE, activator, asm 1

22▲ 189930 LABEL, caution 2

Parts

1

1

* Software token 24F322 is required to install software

before use

◆ Parts included in Kit 24A071 which can be pur-

chased separately.

† Parts not shown.

▲ Replacement Danger and Warning labels, tags, and

cards are available at no cost.

312878J 35

Page 36

Technical Data

Technical Data

Category Data

Maximum Fluid Working Pressure Models IPH-25 and IPH-40: 2000 psi (13.8 MPa, 138 bar)

Fluid:Oil Pressure Ratio Model IPH-25: 1.91:1

Model IPH-40: 1.64:1

Fluid Inlets Component A (ISO): 1/2 npt(f), 250 psi (1.75 MPa, 17.5 bar) maximum

Component B (RES): 3/4 npt(f), 250 psi (1.75 MPa, 17.5 bar) maximum

Fluid Outlets Component A (ISO): #8 JIC (3/4-16 unf), with #5 JIC adapter

Component B (RES): #10 JIC (7/8-14 unf), with #6 JIC adapter

Fluid Circulation Ports 1/4 npsm(m), with plastic tubing, 250 psi (1.75 MPa, 17.5 bar) maximum

Maximum Fluid Temperature 190°F (88°C)

Maximum Output (10 weight oil at

ambient temperature)

Output per Cycle (A and B) Model IPH-25: 0.063 gal. (0.23 liter)

Line Voltage Requirement 230V 1 phase and 230V 3 phase units: 195-264 Vac, 50/60 Hz

Amperage Requirement See Models, page 3.

Heater Power

(A and B heaters total, no hose)

Hydraulic reservoir capacity 3.5 gal. (13.6 liters)

Recommended hydraulic fluid Citgo A/W Hydraulic Oil, ISO Grade 46

Sound power, per ISO 9614-2 90.2 dB(A)

Sound pressure, 1 m from equipment 82.6 dB(A)

Weight IPH-25 Models with 8.0 kW Heaters: 535 lb (243 kg)

Model IPH-25: 22 lb/min (10 kg/min) (60 Hz)

Model IPH-40: 50 lb/min (23 kg/min) (60 Hz)

Model IPH-40: 0.076 gal. (0.29 liter)

400V 3 phase units: 338-457 Vac, 50/60 Hz

See Models, page 3.

IPH-25 Models with 15.3 kW Heaters: 562 lb (255 kg)

IPH-40 Models with 12.0 kW Heaters: 597 lb (271 kg)

IPH-40 Models with 15.3 kW Heaters: 597 lb (271 kg)

Wetted Parts Aluminum, stainless steel, zinc-plated carbon steel, brass, carbide, chrome,

fluoroelastomer, PTFE, ultra-high molecular weight polyethylene, chemically

resistant o-rings

All other brand names or marks are used for identification purposes and are trademarks of their respective owners.

36 312878J

Page 37

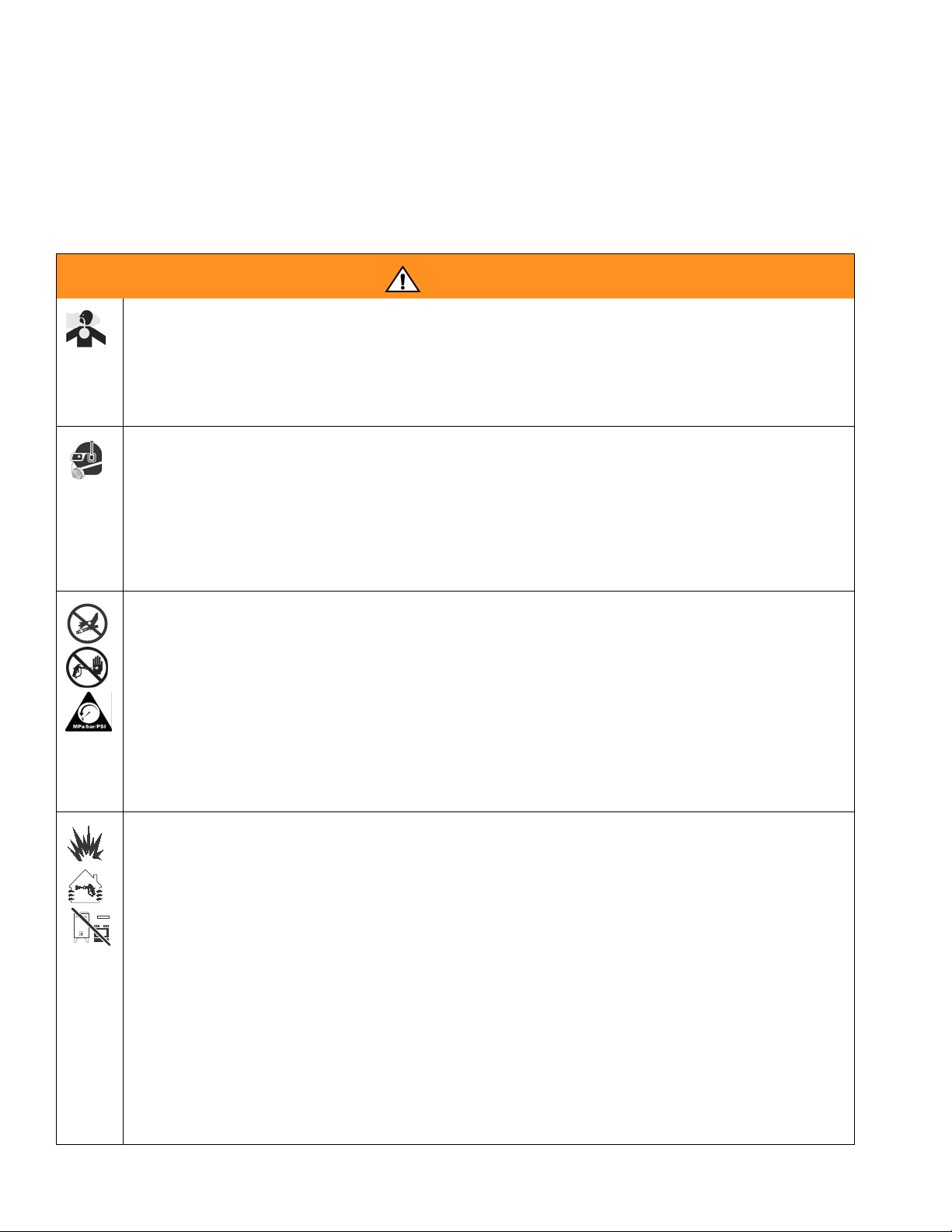

Performance Charts

AR Pour Gun Impingers and

Reactor Foam Performance Chart

Performance Charts

2000

(13.8, 138)

KEY

A = IPH-25 at 50 Hz

B = IPH-25 at 60 Hz

1500

(10.3, 103)

1000

(6.9, 69)

A

B

C

D

E

C = IPH-40 at 50 Hz

❄D = IPH-40 at 60 Hz

E = AR-C 23-B-1 impingers

F = AR-C 36-C-1 Impingers

G = AR-C 58-C-1 impingers

◆H = AR-D 59-D-1 front

impinger and AR-D 58-C-1

rear impinger

25

(11.4)

F

G

H

35

(15.9)

45

(20.5)

55

(25.0)

Pressure in psi (MPa, bar)

500

(3.4, 34)

0

5

15

(2.3)

(6.8)

Flow Rate in lb/min (kg/min)

❄ Pressure flow curve for model 255811 (IPH-40 230V 1 phase) not shown.

Maximum pressure limited to 1700 psi (11.7 MPa, 11.7 bar)

◆ Impingers tested with 100-150 centipoise Mesamoll with a specific gravity of

1.055.

312878J 37

Page 38

Graco Ohio Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Ohio Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Toll Free: 1-800-746-1334 or Fax: 330-966-3006

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO OHIO INC. 8400 PORT JACKSON AVE NW, NORTH CANTON, OH

Graco reserves the right to make changes at any time without notice.

Original Instructions. This manual contains English. MM 312878

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

Copyright 2009, Graco Ohio Inc. is registered to ISO 9001

www.graco.com

Revised 06/2011

Loading...

Loading...