Graco 312877C User Manual

Operation

®

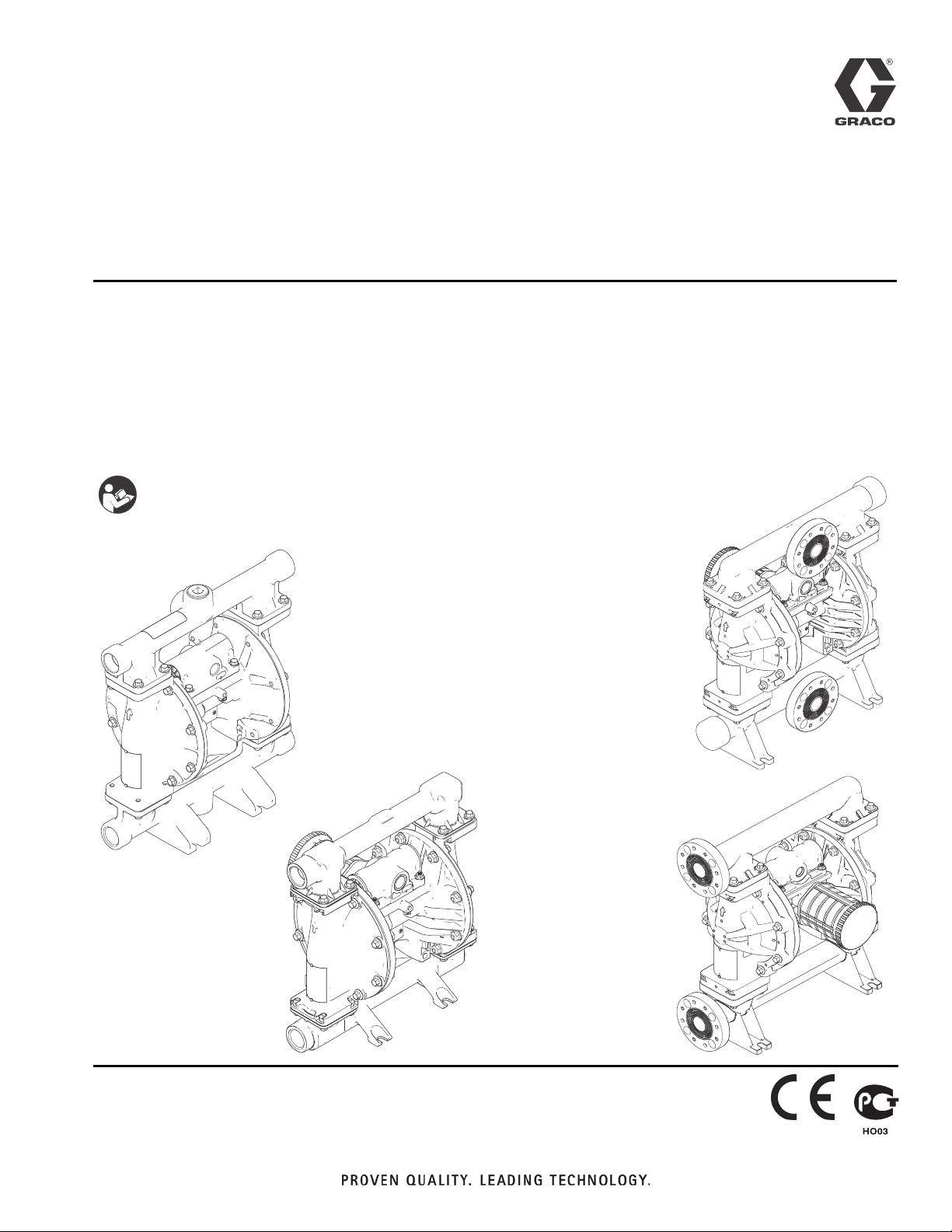

Husky

1050 Air-Operated

Diaphragm Pump

1-inch pump with modular air valve for fluid transfer applications.

For professional use only.

See page 3 for model information, including approvals.

125 psi (0.86 MPa, 8.6 bar) Maximum Fluid Working Pressure

125 psi (0.86 MPa, 8.6 bar) Maximum Air Input Pressure

312877G

ENG

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

1050A Aluminum

ti13946a

1050P Polypropylene

1050C Conductive

Polypropylene

1050F PVDF

Patents Pending

End

Flange

Center

Flange

ti13843a

1050S Stainless Steel

1050H Hastelloy

ti13844a

ti14342a

0359

Related Manuals

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Pump Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ATEX Certifications . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Tighten Fasteners Before Setup . . . . . . . . . . . . . 6

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Air Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Reed Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Air Exhaust Ventilation . . . . . . . . . . . . . . . . . . . . 8

Fluid Supply Line . . . . . . . . . . . . . . . . . . . . . . . . 9

Fluid Outlet Line . . . . . . . . . . . . . . . . . . . . . . . . . 9

Fluid Inlet and Outlet Ports . . . . . . . . . . . . . . . . 12

Fluid Pressure Relief Valve . . . . . . . . . . . . . . . . 13

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Pressure Relief Procedure . . . . . . . . . . . . . . . . 14

Flush the Pump Before First Use . . . . . . . . . . . 14

Tighten Fasteners Before Setup . . . . . . . . . . . . 14

Starting and Adjusting the Pump . . . . . . . . . . . 14

DataTrak Operation . . . . . . . . . . . . . . . . . . . . . . 15

Pump Shutdown . . . . . . . . . . . . . . . . . . . . . . . . 15

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Maintenance Schedule . . . . . . . . . . . . . . . . . . . 15

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Tighten Threaded Connections . . . . . . . . . . . . . 15

Flushing and Storage . . . . . . . . . . . . . . . . . . . . 15

Torque Instructions . . . . . . . . . . . . . . . . . . . . . . 16

Dimensions and Mounting . . . . . . . . . . . . . . . . . . 18

Aluminum (1050A) . . . . . . . . . . . . . . . . . . . . . . . 18

Polypropylene (1050P),

Conductive Polypropylene (1050C) and

PVDF (1050F) . . . . . . . . . . . . . . . . . . . . . . . 19

Hastelloy (1050H) and

Stainless Steel (1050S) . . . . . . . . . . . . . . . 20

Performance Charts . . . . . . . . . . . . . . . . . . . . . . . . 21

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Graco Standard Husky Pump Warranty . . . . . . . . 24

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 24

Related Manuals

Manual Description

313435 Husky 1050 Air-Operated Diaphragm Pump, Repair/Parts

313597 Husky 1050A UL-Listed Diaphragm Pump, Operation

313598 Husky 1050A CSA-Certified Diaphragm Pump, Operation

313840 DataTrak, Instructions/Parts

406824 Pulse Count Kits, Instructions

2 312877G

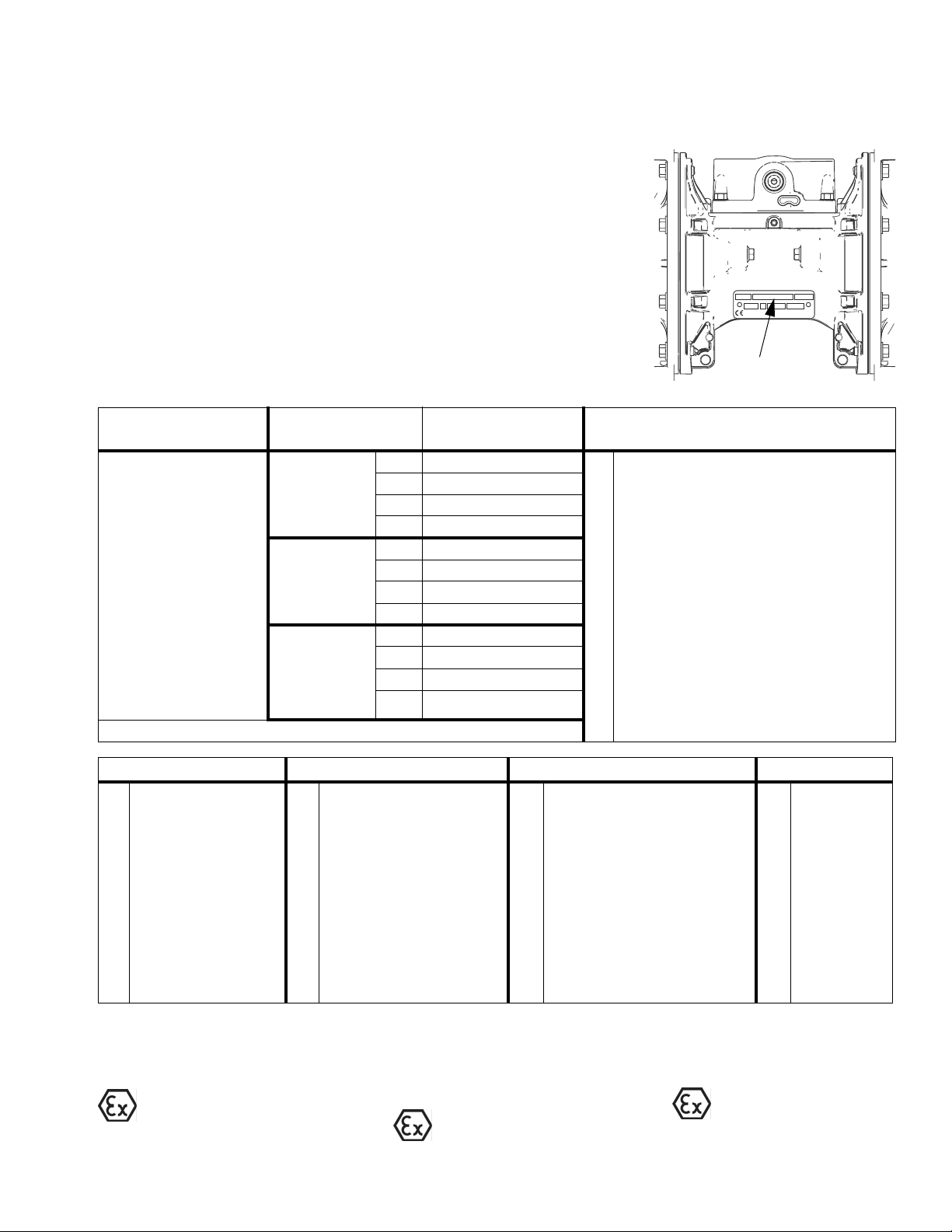

Pump Matrix

★

p

Check the identification plate (ID) for the 20-digit part number of your

pump. Use the following matrix to define the components of your pump.

For example, pump number 1050A-A01AA1SSBNBNPT represents a

Husky 1 inch, 50 gpm aluminum pump (1050A), with aluminum center

section (A01), a standard air valve (A), aluminum fluid covers (A) and

manifolds with standard ports in inches (1). The pump has stainless steel

seats (SS), buna-N check balls (BN), buna-N diaphragms (BN), and

PTFE manifold o-rings (PT).

NOTE: Available options for seats, check balls, diaphragms, and seals

vary based on pump model (1050A-1050S). To build a pump, use the

selector tool at www.graco.com or talk to your distributor.

CONFIGURATION NO.PART NO. SERIAL NO.

SERIESDATE CODE

MAX WPR PSI-bar

Pump ID

Pump Matrix

MADE IN

ti14103a

Pump

(1 inch ports, 50 gpm)

1050A★

Aluminum

1050C★

Conductive

Polypropylene

1050F

PVDF

1050H‡

Hastelloy

1050P

Polypropylene

1050S‡

Stainless Steel

Center Section and

Air Valve Material Air Valve/Monitoring Fluid Covers and Manifolds

Aluminum

Conductive

Polypropylene

Polypropylene

A01A Standard A1

A01B Pulse Count✖

A01C DataTrak✖

A01D Remote

C01A Standard

C01B Pulse Count✖

C01C DataTrak✖

C01D Remote

P01A Standard

P01B Pulse Count✖

P01C DataTrak✖

P01D Remote

Aluminum, standard ports, inch

A2

Aluminum, standard ports, metric

C1

Conductive polypropylene, center flange

C2

Conductive polypropylene, end flange

F1

PVDF, center flange

F2

PVDF, end flange

H1

Hastelloy, standard ports, inch

H2

Hastelloy, standard ports, metric

P1

Polypropylene, center flange

P2

Polypropylene, end flange

S1

Stainless steel, standard ports, inch

S2

Stainless steel, standard ports, metric

★, ‡, or ✖: See ATEX Certifications below.

Check Valve Seats Check Valve Balls Diaphragm Manifold O-Rings

AC

AC

Acetal

AL

Aluminum

BN

Buna-N

FK

FKM Fluoroelastomer

Geolast

GE

Polypropylene

PP

PVDF

PV

Santoprene

SP

316 Stainless Steel

SS

TPE

TP

®

®

Acetal

BN

Buna-N

CR

Polychloroprene Standard

CW

Polychloroprene Weighted

FK

FKM Fluoroelastomer

GE

Geolast

PT

PTFE

SP

Santoprene

SS

316 Stainless Steel

TP

TPE

BN

Buna-N

CO

Polychloroprene Overmolded

FK

FKM Fluoroelastomer

GE

Geolast

PO

PTFE/EPDM Overmolded

PT

PTFE/EPDM Two-Piece

SP

Santoprene

TP

TPE

—PTNone

PTFE

ATEX Certifications

All 1050A (Aluminum) and

1050C (Conductive Polypropylene)

umps are certified:

‡ 1050S (Stainless Steel) and 1050H

(Hastelloy) pumps with aluminum or

conductive polypropylene centers are

certified:

II 2 GD c IIC T4

II 2 GD c IIC T4

312877G 3

✖ DataTrak and Pulse Count

are certified:

EEx ia IIA T3

Nemko

II 1 G

06ATEX1124

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers

to procedure-specific risk. When these symbols appear in the body of this manual, refer back to

these warnings. Additional, product-specific warnings may be found throughout the body of this

manual where applicable.

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or

explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric

lamps, and plastic drop cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when

flammable fumes are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not

use equipment until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

Static charge may build up on plastic parts during cleaning and could discharge and

ignite flammable materials and gases. To help prevent fire and explosion:

• Clean plastic parts in a well ventilated area.

• Do not clean with a dry cloth.

• Do not operate electrostatic guns in equipment work area.

4 312877G

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest

rated system component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Tech-

nical Data in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about your material, request MSDS from distributor

or retailer.

• Do not leave the work area while equipment is energized or under pressure. Turn

off all equipment and follow the Pressure Relief Procedure in this manual when

equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with

genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and

hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the

eyes or on skin and cause serious injury.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and

before cleaning, checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immedi-

ately.

THERMAL EXPANSION HAZARD

Fluids subjected to heat in confined spaces, including hoses, can create a rapid rise

in pressure due to the thermal expansion. Over-pressurization can result in

equipment rupture and serious injury.

• Open a valve to relieve the fluid expansion during heating.

• Replace hoses proactively at regular intervals based on your operating conditions.

312877G 5

Installation

WARNING

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause

serious chemical reaction and equipment rupture. Failure to follow this warning can

result in death, serious injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated

hydrocarbon solvents or fluids containing such solvents.

• Many other fluids may contain chemicals that can react with aluminum. Contact

your material supplier for compatibility.

PLASTIC PARTS CLEANING SOLVENT HAZARD

Use only compatible water-based solvents to clean plastic structural or pressure-containing parts. Many solvents can degrade plastic parts and cause them to fail, which

could cause serious injury or property damage. See Technical Data in this and all

other equipment instruction manuals. Read fluid and solvent manufacturer’s warnings.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on

skin, inhaled, or swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Route exhaust away from work area. If diaphragm ruptures, fluid may be exhausted

with air.

• Store hazardous fluid in approved containers, and dispose of it according to appli-

cable guidelines.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To

avoid severe burns:

• Do not touch hot fluid or equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in

the operating area of the equipment to help protect you from serious injury, including

eye injury, inhalation of toxic fumes, burns, and hearing loss. This equipment includes

but is not limited to:

• Clothing and respirator as recommended by the fluid and solvent manufacturer

• Protective eyewear, gloves, and hearing protection

Installation

The Typical Installations shown in FIG. 3 and

F

IG. 4 are only guides for selecting and install-

ing system components. Contact your Graco

distributor for assistance in planning a system

to suit your needs.

Tighten Fasteners Before Setup

Before using the pump for the first time, check

and retorque all external fasteners. Follow

Torque Instructions, page 16.

6 312877G

Installation

Mounting

• The pump exhaust air may contain contam-

inants. Ventilate to a remote area. See Air

Exhaust Ventilation on page 8.

• Never move or lift a pump under pressure.

If dropped, the fluid section may rupture.

Always follow the Pressure Relief Proce-

dure on page 14 before moving or lifting

the pump.

1. For wall mounting, order Graco Kit 24C637.

2. Be sure the mounting surface can support

the weight of the pump, hoses, and accessories, as well as the stress caused during

operation.

3. For all mountings, be sure the pump is

bolted directly to the mounting surface.

wire to a true earth ground. A ground wire and

clamp, Part 238909, is available from Graco.

Polypropylene and PVDF: Only aluminum,

conductive polypropylene, hastelloy, and

stainless steel pumps have a ground screw.

Standard polypropylene and PVDF pumps

are not conductive. Never use a non-conductive polypropylene or PVDF pump with

non-conductive flammable fluids. Follow your

local fire codes. When pumping conductive

flammable fluids, always ground the entire

fluid system as described.

4. For ease of operation and service, mount

the pump so air valve, air inlet, fluid inlet

and fluid outlet ports are easily accessible.

5. Rubber Foot Mounting Kit 236452 is available to reduce noise and vibration during

operation.

Grounding

The equipment must be grounded.

Grounding reduces the risk of static and

electric shock by providing an escape wire

for the electrical current due to static build up

or in the event of a short circuit.

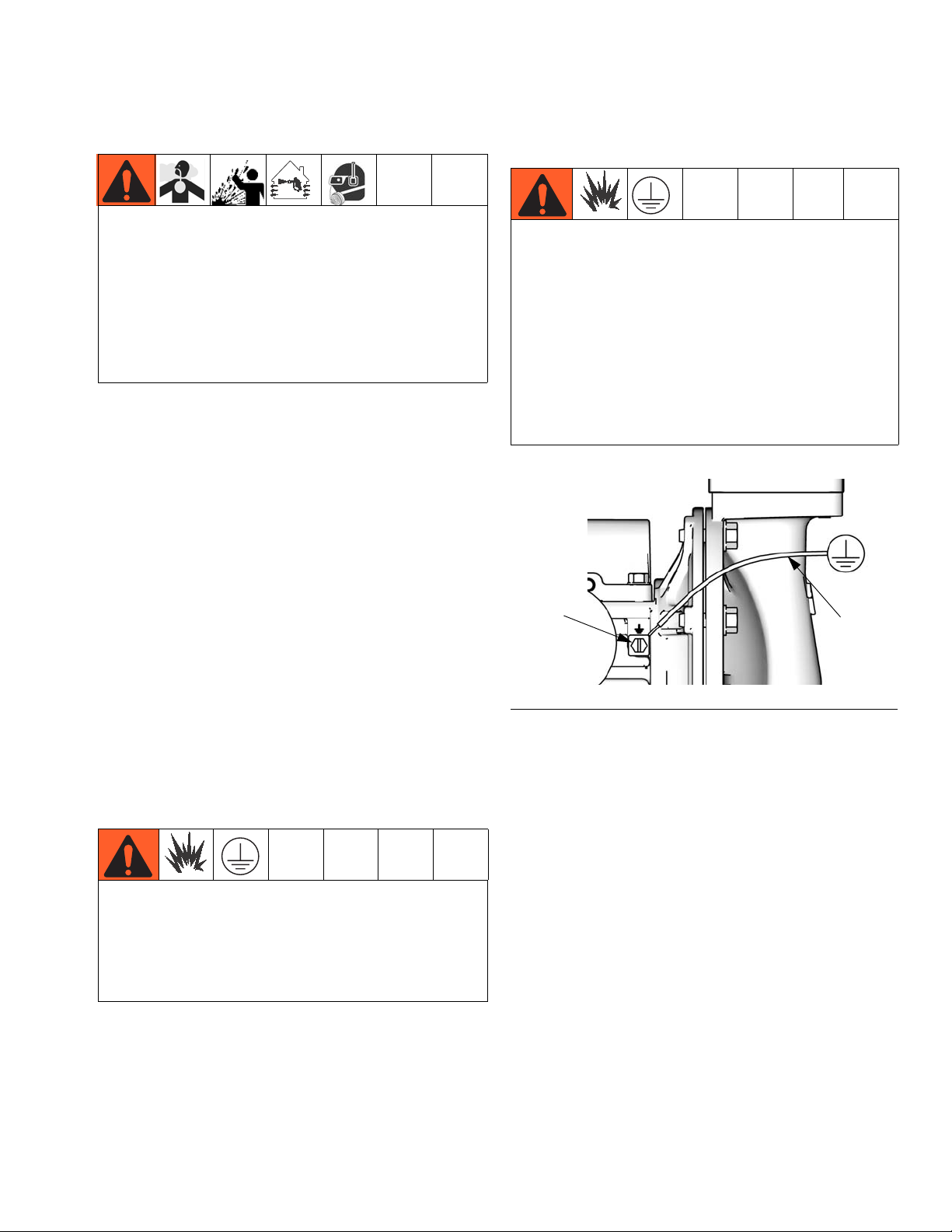

Pump: See FIG. 1. Loosen the grounding

screw (GS). Insert one end of a 12 ga.

minimum ground wire (R) behind the

grounding screw and tighten the screw

securely. Connect the clamp end of the ground

GS

R

ti12214a

FIG. 1. Grounding screw and wire

Air and fluid hoses: Use only grounded

hoses with a maximum of 500 ft (150 m) combined hose length to ensure grounding continuity.

Air compressor: Follow manufacturer’s

recommendations.

Fluid supply container: Follow local code.

Solvent pails used when flushing: Follow

local code. Use only conductive metal pails,

placed on a grounded surface. Do not place

the pail on a nonconductive surface, such as

paper or cardboard, which interrupts grounding continuity.

312877G 7

Installation

Check your system electrical continuity after

the initial installation, and then set up a regular

schedule for checking continuity to be sure

proper grounding is maintained.

Air Line

See FIG. 3 and FIG. 4, pages 10 and 11.

1. Install an air regulator (C) and gauge to

control the fluid pressure. The fluid stall

pressure will be the same as the setting of

the air regulator.

2. Locate a bleed-type master air valve (B)

close to the pump and use it to relieve

trapped air. Be sure the valve is easily

accessible from the pump and located

downstream from the regulator.

Remote option: Insert 5/32 OD tubing into the

push-to-connect fitting at each pilot and route

to your control.

NOTICE

Pilot supply pressure should not exceed

main air supply pressure. If pilot supply

pressure is too high, the pump could leak

air or exhaust excessive air at stall.

Reed Switch

Pulse Count models are intended for use with

customer-supplied fluid management or inventory tracking systems. Attach an M12, 5-pin

female cable to connect the reed switch to your

data monitoring system. See Manual 406824.

Air Exhaust Ventilation

Trapped air can cause the pump to cycle

unexpectedly, which could result in serious

injury from splashing.

3. Locate another master air valve (E)

upstream from all air line accessories and

use it to isolate them during cleaning and

repair.

4. An air line filter (F) removes harmful dirt

and moisture from the compressed air

supply.

5. Install a grounded, flexible air hose (A)

between the accessories and the 1/2 npt(f)

pump air inlet (D). Use a minimum 3/8 in.

(10 mm) ID air hose.

The air exhaust port is 3/4 npt(f). Do not

restrict the air exhaust port. Excessive exhaust

restriction can cause erratic pump operation.

To provide a remote exhaust:

1. Remove the muffler (T) from the pump air

exhaust port.

2. Install a grounded air exhaust hose (U) and

connect the muffler (T) to the other end of

the hose. The minimum size for the air

exhaust hose is 3/4 in. (19 mm) ID. If a

hose longer than 15 ft (4.57 m) is required,

use a larger diameter hose. Avoid sharp

bends or kinks in the hose.

3. Place a container at the end of the air

exhaust line to catch fluid in case a diaphragm ruptures. If the diaphragm ruptures, the fluid being pumped will exhaust

with the air.

8 312877G

Loading...

Loading...