Page 1

Instructions/Parts

®

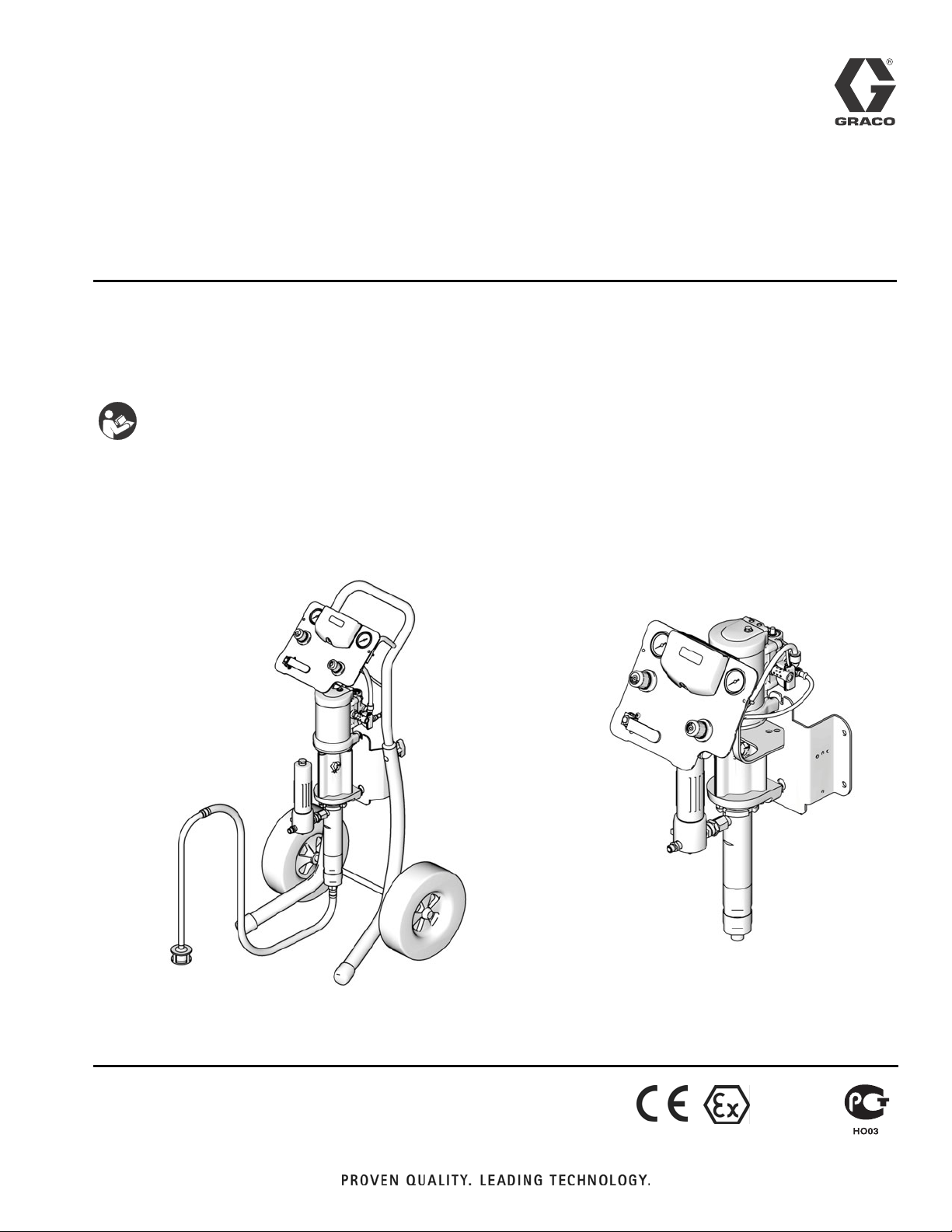

Merkur

Non-Heated

Spray Packages

For high-performance finishing and coating applications in hazardous or non-hazardous

locations. For professional use only.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

See the charts beginning on page 5 for model information, including maximum air inlet pressures and maximum fluid

working pressures.

For patent information, see www.graco.com/patents

Cart Mount Wall Mount

EN

312797P

ti11881a

ti11882a

ll 2 G c T3

Page 2

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Merkur 10:1 Packages

(G10Cxx and G10Wxx) . . . . . . . . . . . . . . . . 6

Merkur 15:1 Packages

(G15Wxx, G15Cxx, and G15Txx) . . . . . . . . . 7

Merkur 18:1 Packages

(G18Wxx and G18Cxx) . . . . . . . . . . . . . . . . 8

Merkur 23:1 Packages

(G23Wxx and G23Cxx) . . . . . . . . . . . . . . . . 8

Merkur 24:1 Packages

(G24Wxx and G24Cxx) . . . . . . . . . . . . . . . . 9

Merkur 28:1 Packages

(G28Wxx and G28Cxx) . . . . . . . . . . . . . . . . 9

Merkur 30:1 Packages

(G30Wxx, G30Cxx, and G30Txx) . . . . . . . . 10

Merkur 36:1 Packages

(G36Wxx and G36Cxx) . . . . . . . . . . . . . . . 12

Merkur 45:1 Packages

(G45Wxx and G45Cxx) . . . . . . . . . . . . . . . 13

Merkur 48:1 Packages

(G48Wxx and G48Cxx) . . . . . . . . . . . . . . . 14

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

General Information . . . . . . . . . . . . . . . . . . . . . 16

Prepare the Operator . . . . . . . . . . . . . . . . . . . . 16

Prepare the Site . . . . . . . . . . . . . . . . . . . . . . . . 16

Wall Mount Packages . . . . . . . . . . . . . . . . . . . . 16

Cart Mount Packages . . . . . . . . . . . . . . . . . . . . 16

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Air Line Accessories . . . . . . . . . . . . . . . . . . . . . 17

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Pressure Relief Procedure . . . . . . . . . . . . . . . . 18

Flush the Pump Before First Use . . . . . . . . . . . 19

Trigger Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Wet Cup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Prime the Pump . . . . . . . . . . . . . . . . . . . . . . . . 19

Install the Spray Tip . . . . . . . . . . . . . . . . . . . . . 20

Adjust the Atomization . . . . . . . . . . . . . . . . . . . 20

Adjust the Spray Pattern . . . . . . . . . . . . . . . . . . 21

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Preventive Maintenance Schedule . . . . . . . . . . 22

Tighten Threaded Connections . . . . . . . . . . . . . 22

Flush the Pump . . . . . . . . . . . . . . . . . . . . . . . . . 22

Wet Cup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

DataTrak Controls and Indicators . . . . . . . . . . . . . 24

DataTrak Operation . . . . . . . . . . . . . . . . . . . . . . . . 25

Setup Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Run Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Replace DataTrak Battery or Fuse . . . . . . . . . . 28

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Cart Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Wall Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Stand Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

G10xxx Models . . . . . . . . . . . . . . . . . . . . . . . . . 33

G15xxx Models . . . . . . . . . . . . . . . . . . . . . . . . . 34

G18xxx Models . . . . . . . . . . . . . . . . . . . . . . . . . 35

G23xxx Models . . . . . . . . . . . . . . . . . . . . . . . . . 36

G24xxx Models . . . . . . . . . . . . . . . . . . . . . . . . . 37

G28xxx Models . . . . . . . . . . . . . . . . . . . . . . . . . 38

G30xxx Models . . . . . . . . . . . . . . . . . . . . . . . . . 39

G36xxx Models . . . . . . . . . . . . . . . . . . . . . . . . . 40

G45xxx Models . . . . . . . . . . . . . . . . . . . . . . . . . 41

G48xxx Models . . . . . . . . . . . . . . . . . . . . . . . . . 42

Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Wall Mount Kit 24A578 . . . . . . . . . . . . . . . . . . . 43

Cart Mount Kit 289694 . . . . . . . . . . . . . . . . . . . 43

Stand Mount Kit 24A577 . . . . . . . . . . . . . . . . . . 43

Pump and Gun Control Panel Kits . . . . . . . . . . . 44

Pump Only Control Panel Kits . . . . . . . . . . . . . . 45

DataTrak . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Hopper Kit 256410 . . . . . . . . . . . . . . . . . . . . . . . 46

Air Control Mounting Kit 24E883,

Wall and Stand . . . . . . . . . . . . . . . . . . . . . . 46

5-Gallon Suction Hose Kits . . . . . . . . . . . . . . . . 46

55-Gallon Suction Hose Kits . . . . . . . . . . . . . . . 46

PTFE Suction Hose Kits . . . . . . . . . . . . . . . . . . 46

Drain Valve Kit 256425 . . . . . . . . . . . . . . . . . . . 46

Reinforced PTFE V-Packing Kits . . . . . . . . . . . . 46

Guns and Hoses . . . . . . . . . . . . . . . . . . . . . . . . 47

50-Foot Air/Fluid Hose Kit 24A955 . . . . . . . . . . 47

50-Foot Fluid Hose 24A413 . . . . . . . . . . . . . . . . 47

Wall Bracket Mounting Dimensions . . . . . . . . . . . 48

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Package Weights . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 50

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 50

2 312797P

Page 3

Related Manuals

Manual Description

Related Manuals

.

DataTrak™ includes agency approvals listed

below.

312792 Merkur Displacement Pump

312794 Merkur Pump Assembly

312796

312798 Merkur Electrostatic Packages

313255 Merkur Heated Packages

3A0149 AA Series Spray Gun (G15,

312145

307273 Fluid Outlet Filter

™

NXT

Air Motor

G40, and G40 with RAC)

™

XTR

5 and XTR™7 Airless

Spray Gun

#53

Conforms to

FM std 3600 & 3610

for use in Class I Div 1

Group D

T3C Hazardous locations

0359

Nemko 06ATEX1124

II 1 G

EEx ia IIA T3

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual, refer back to these Warnings. Additional, product-specific warnings

may be found throughout the body of this manual where applicable.

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

312797P 3

Page 4

Warnings

WARNING

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on skin and

cause serious injury.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine Graco

replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your Graco distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

4 312797P

Page 5

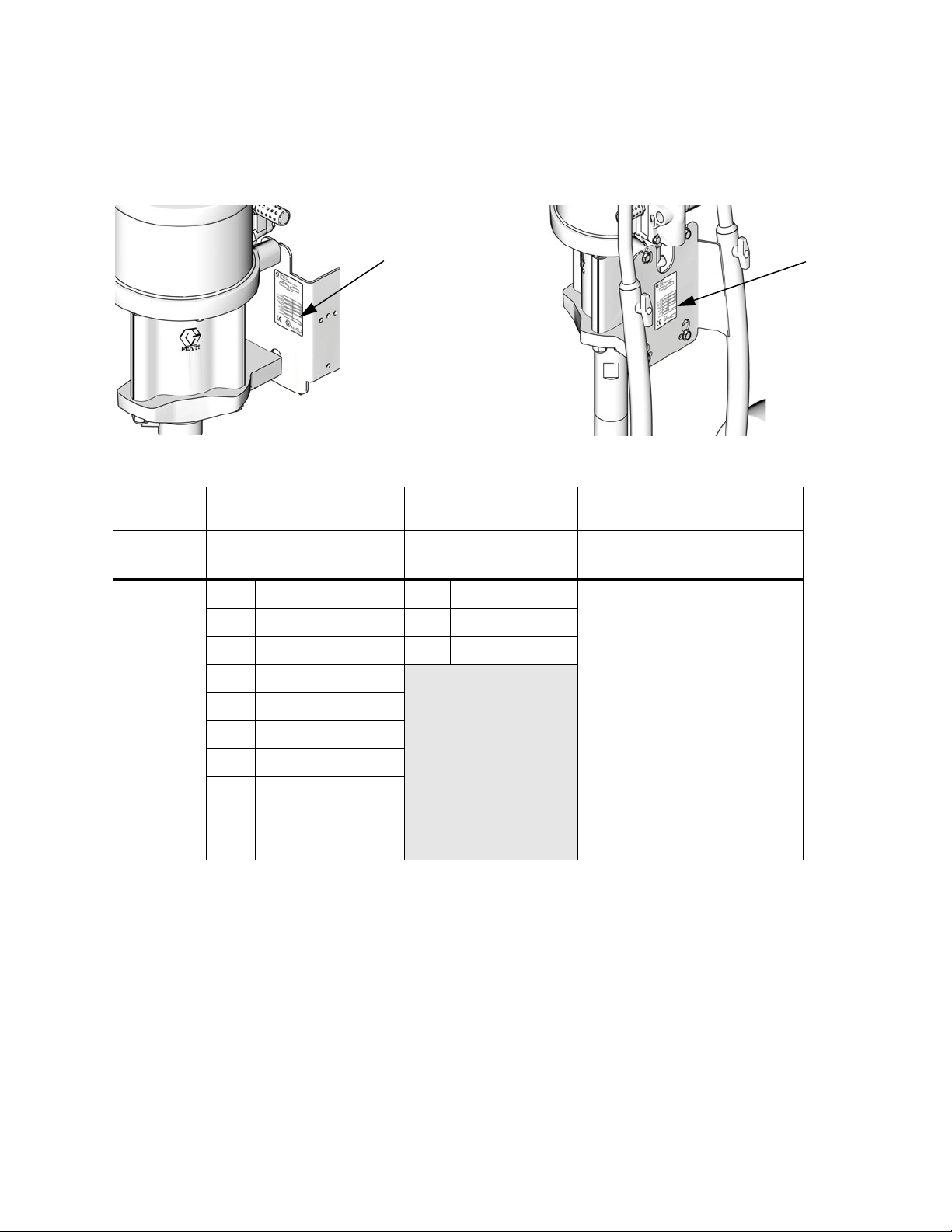

Models

Models

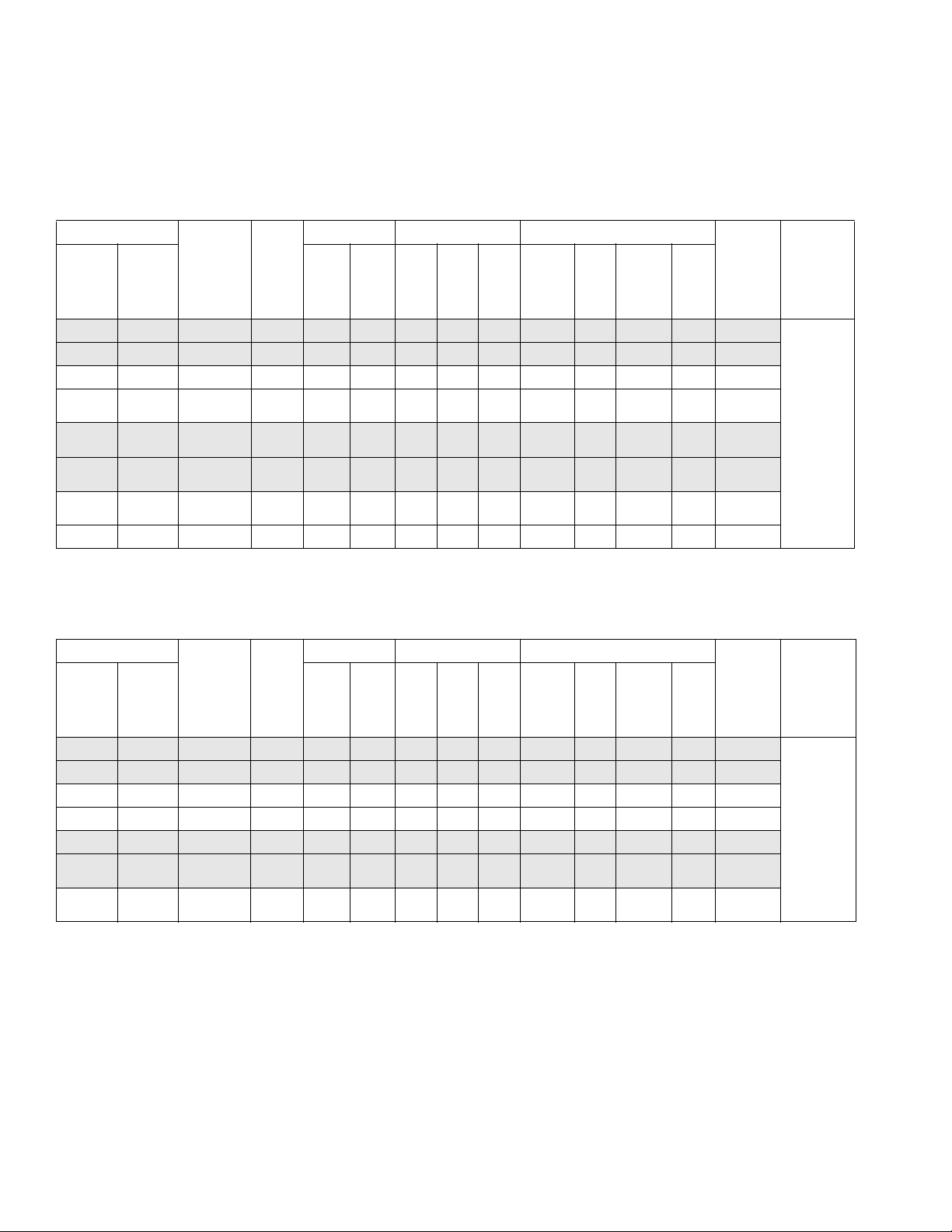

Check the identification plate (ID) for the 6-digit part number of your package. Use the following matrix and tables to

define the components of your package. For example, package number G30C26 represents a Merkur package (G),

with a 30:1 ratio pump (30), cart mounting (C), and the components shown for (26) in the table on page 10.

Wall Mount

ID

ti12326a ti12327a

G30 C 26

First Digit

G

(Merkur

Package)

Second and Third Digits

(Ratio)

10

15

18

23

24

28

30

36

45

48

10:1

15:1

18:1

23:1

24:1

28:1

30:1

36:1

45:1

48:1

Fourth Digit

(Mounting Type)

C

T

W

Cart See Tables, pages 6 to 14

Stand

Wall

Fifth and Sixth Digit

(Components Included)

Cart and

Stand Mount

ID

312797P 5

Page 6

Models

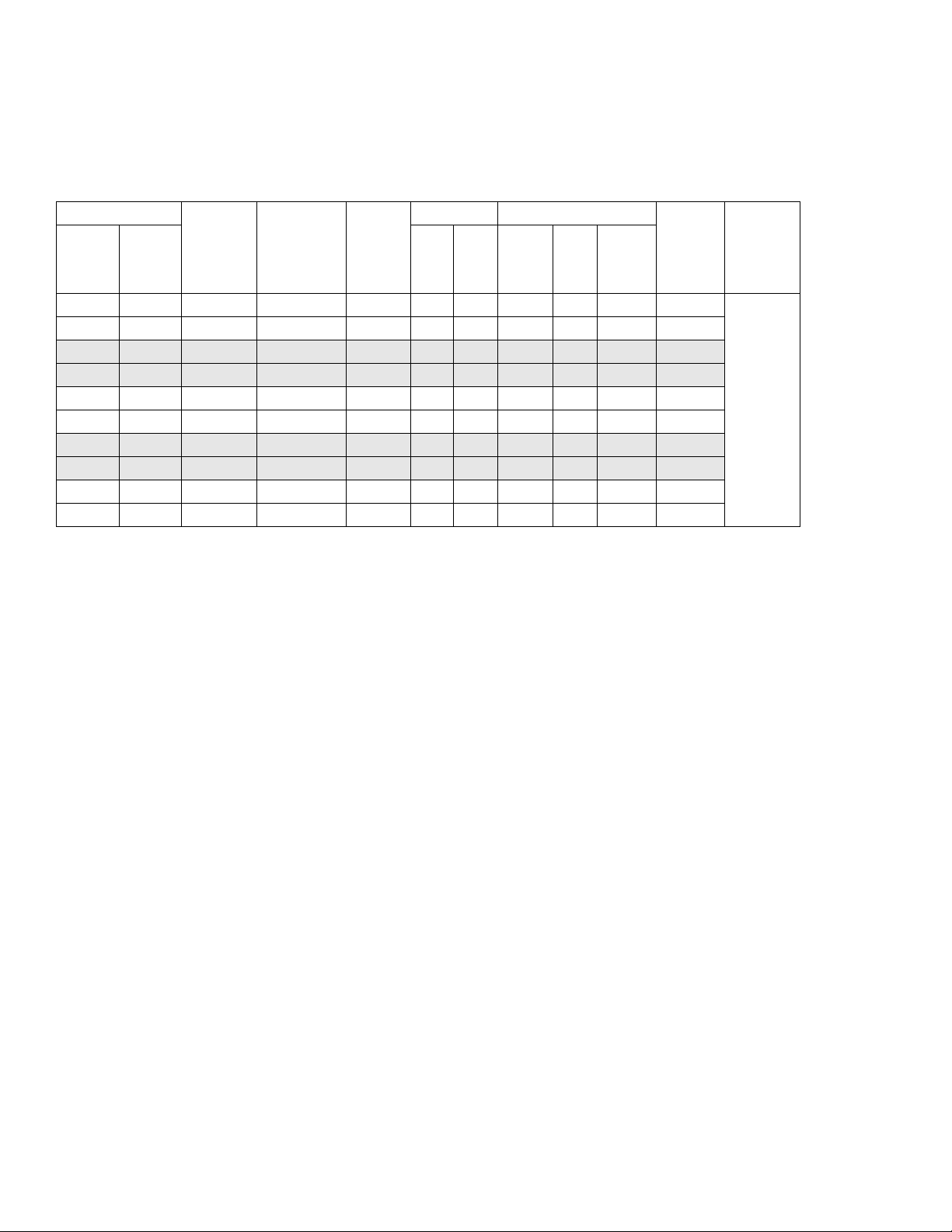

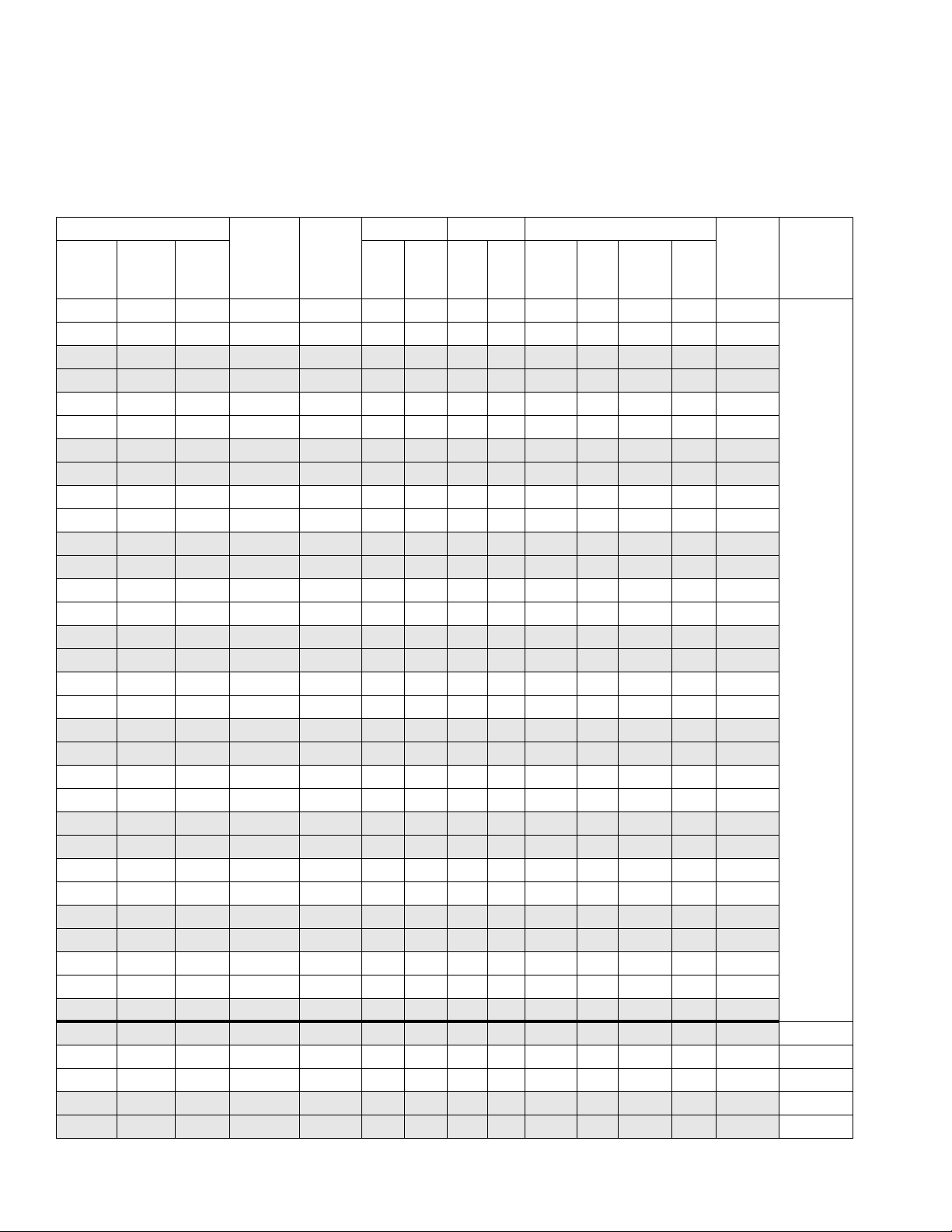

Merkur 10:1 Packages (G10Cxx and G10Wxx)

Maximum Inlet Air Pressure: 100 psi (0.7 MPa, 7 bar)

Maximum Fluid Working Pressure: 1000 psi (6.9 MPa, 69 bar)

Model

Wall

Mount

G10W09 ----- W10CAS None

G10W01 G10C01 W10CAS None

G10W03 G10C03 W10CAS None

----- G10C05 W10CAS None

G10W05 G10C07 W10CAS G15 Carbide

G10W06 G10C08 W10CBS G15 Carbide

G10W07 G10C09 W10CAS G15 Carbide

G10W08 G10C10 W10CBS G15 Carbide

----- G10C11 W10CAS G15 Carbide

----- G10C13 W10CAS G15 Carbide

Cart

Mount

Pump

Assembly Gun

Air

Controls

(pump

and

gun)

✔

✔ ✔

✔ ✔ ✔ ✔

✔✔✔✔

✔✔✔✔ ✔

✔ ✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔ ✔

✔✔✔ ✔

✔✔✔ ✔✔

Hoses Accessories

Gun

Gun

Fluid

Hose

Air

Hose

Siphon

Kit

Fluid

Filter Hopper

DataTrak

Maximum

Fluid Flow

Rate

gpm (lpm)

1.2 (4.5)

6 312797P

Page 7

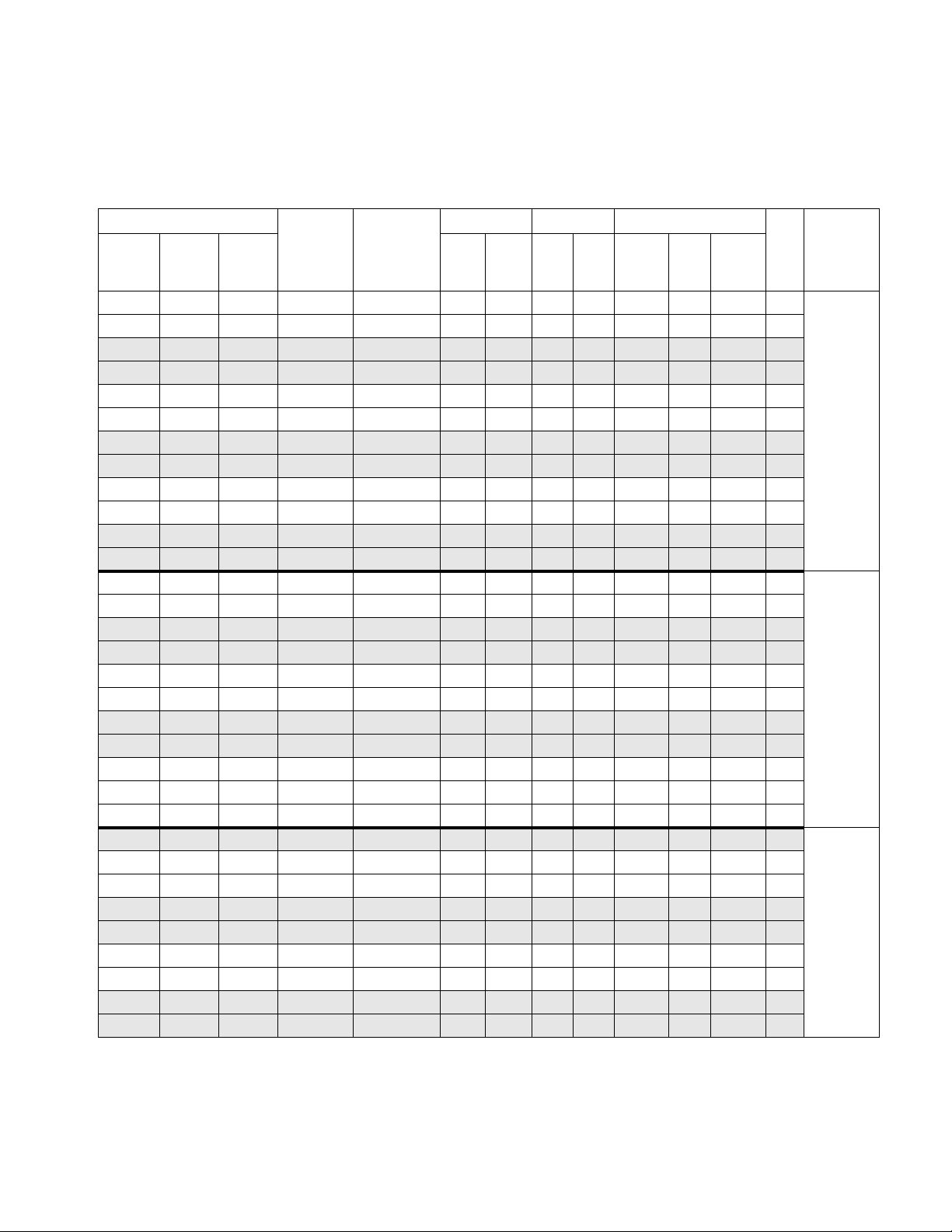

Merkur 15:1 Packages (G15Wxx, G15Cxx, and G15Txx)

Maximum Inlet Air Pressure 100 psi (0.7 MPa, 7 bar)

Maximum Fluid Working Pressure: 1500 psi (10.3 MPa, 103 bar)

Models

Model

Wall

Mount

G15W09 ----- ----- W15AAS None

G15W01 G15C01 G15T01 W15AAS None

G15W03 G15C03 ----- W15AAS None

----- G15C05 W15AAS None

G15W05 G15C07 G15T03 W15AAS G15 Carbide

G15W06 G15C08 G15T04 W15AAS G15 Carbide

G15W07 G15C09 ----- W15AAS G15 Carbide

G15W08 G15C10 ----- W15AAS G15 Carbide

----- G15C11 G15T05 W15AAS G15 Carbide

----- G15C12 ----- W15AAS G15 Carbide

----- G15C13 ----- W15AAS G15 Carbide

----- G15C14 ----- W15AAS G15 Carbide

G15W19 ----- ----- W15BAS None

G15W21 G15C21 ----- W15BAS None

G15W23 G15C23 ----- W15BAS None

----- G15C25 G15T11 W15BAS None

----- ----- G15T12 W15BBS None

G15W25 G15C27 G15T13 W15BAS G15 Carbide

G15W26 G15C28 G15T14 W15BBS G15 Carbide

G15W27 G15C29 ----- W15BAS G15 Carbide

G15W28 G15C30 ----- W15BBS G15 Carbide

----- G15C31 G15T15 W15BAS G15 Carbide

----- G15C33 ----- W15BAS G15 Carbide

G15W51 G15C75 ----- W15FAS None

G15W52 ----- ----- W15FBS None

----- G15C77 ----- W15FAS None

----- G15C78 ----- W15FBS None

G15W53 G15C79 ----- W15FAS None

G15W54 G15C80 ----- W15FBS None

----- G15C81 ----- W15FAS None

G15W55 G15C83 ----- W15FAS G15 Carbide

G15W56 G15C84 ----- W15FBS G15 Carbide

Cart

Mount

Stand

Mount

Pump

Assembly Gun

Air Controls Hoses

Pump

Pump

Only

Gun

and

Fluid

Gun

Hose

✔

✔ ✔

✔ ✔ ✔ ✔

✔✔✔ ✔

✔✔✔ ✔

✔ ✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔

✔✔✔

✔✔✔

✔ ✔ ✔ ✔

✔ ✔ ✔ ✔

✔

✔ ✔

✔

✔ ✔

✔

✔✔

✔✔✔ ✔

✔ ✔ ✔ ✔

✔ ✔ ✔ ✔

✔✔✔ ✔

✔✔✔

✔✔✔

Gun

Air

Hose

Accessories

Siphon

Kit

✔

✔

Fluid

Filter Hopper

✔

✔✔*

✔

✔ ✔*

✔

✔✔

✔

✔✔

✔

✔ ✔

✔

✔

✔

✔

✔

✔

✔✔

✔ ✔

✔ ✔

✔

✔

✔ ✔

✔ ✔

Data

Trak

✔*

✔*

✔

✔

✔

✔

✔

Maximum

Fluid Flow

Rate

gpm (lpm)

0.40 (1.5)

0.8 (3.0)

2.4 (9.0)

* DataTrak with cycle counter only, no runaway solenoid.

312797P 7

Page 8

Models

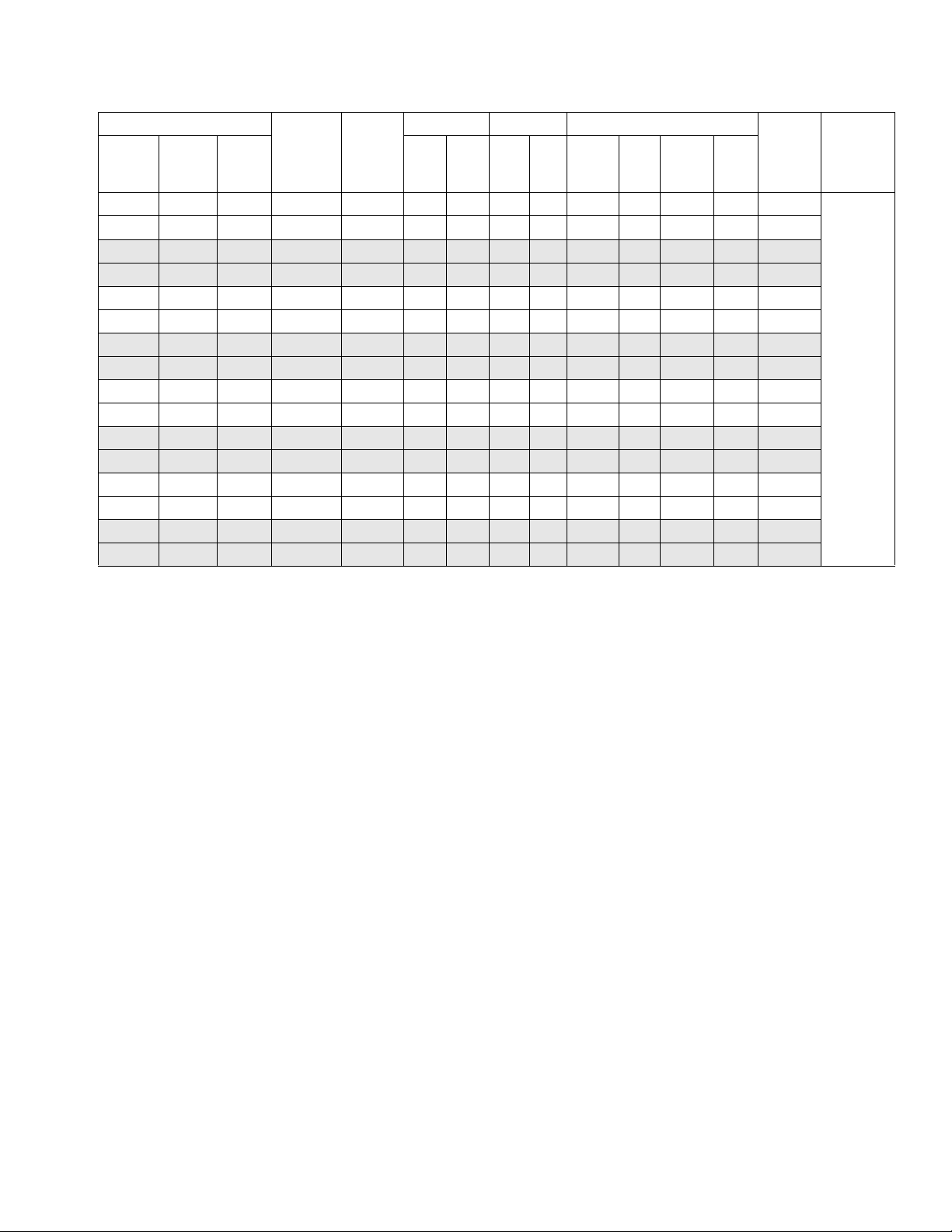

Merkur 18:1 Packages (G18Wxx and G18Cxx)

Maximum Inlet Air Pressure: 100 psi (0.7 MPa, 7 bar)

Maximum Fluid Working Pressure: 1800 psi (12.4 MPa, 124 bar)

Model

Wall

Mount

G18W01 ----- W18EAS None

G18W03 ----- W18EAS None

G18W04 ----- W18EBS None

G18W05 G18C01 W18EAS None

G18W06 G18C02 W18EBS None

----- G18C03 W18EAS None

G18W07 G18C05 W18EAS G40

G18W08 G18C06 W18EBS G40

G18W09 G18C07 W18EAS G40 RAC

G18W10 G18C08 W18EBS G40 RAC

Cart

Mount

Pump

Assembly Gun

Air Controls Hoses Accessories

Pump

Pump

only

and

Gun

Gun

Fluid

Hose

Gun

Air

Hose

Fluid

Whip

Hose

✔

✔ ✔

✔ ✔ ✔

✔✔✔✔

✔✔

✔ ✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔ ✔

✔✔✔ ✔ ✔

✔✔✔ ✔ ✔ ✔

Merkur 23:1 Packages (G23Wxx and G23Cxx)

Maximum Inlet Air Pressure: 100 psi (0.7 MPa, 7 bar)

Maximum Fluid Working Pressure: 2300 psi (15.9 MPa, 159 bar)

Gun

Siphon

Kit

Fluid

Filter

DataTrak

Maximum

Fluid Flow

Rate

gpm (lpm)

2.0 (7.5)

Model

Wall

Mount

G23W01 ----- W23DAS None

G23W03 ----- W23DAS None

G23W04 ----- W23DBS None

----- G23C01 W23DAS None

----- G23C02 W23DBS None

G23W05 ----- W23DAS None

G23W06 ----- W23DBS None

G23W07 G23C03 W23DAS XTR5

G23W08 G23C04 W23DBS XTR5

----- G23C05 W23DAS None

----- G23C07 W23DAS G40

G23W09 G23C09 W23DAS G40

----- G23C11 W23DAS G40

G23W10 G23C12 W23DBS G40

G23W11 G23C13 W23DAS G40 RAC

G23W12 G23C14 W23DBS G40 RAC

Cart

Mount

Pump

Assembly Gun

Air Controls Hoses Accessories

Pump

Pump

only

and

Gun

Gun

Fluid

Hose

Gun

Air

Hose

Siphon

Kit

Fluid

Filter

Hopper

DataTrak

Maximum

Fluid Flow

Rate

gpm (lpm)

✔

✔ ✔

✔ ✔

✔✔ ✔

✔✔✔

✔ ✔ ✔ ✔

✔ ✔ ✔ ✔

1.6 (6.0)

✔✔ ✔✔ ✔

✔✔

✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔

✔✔✔ ✔ ✔

✔✔✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔ ✔

8 312797P

Page 9

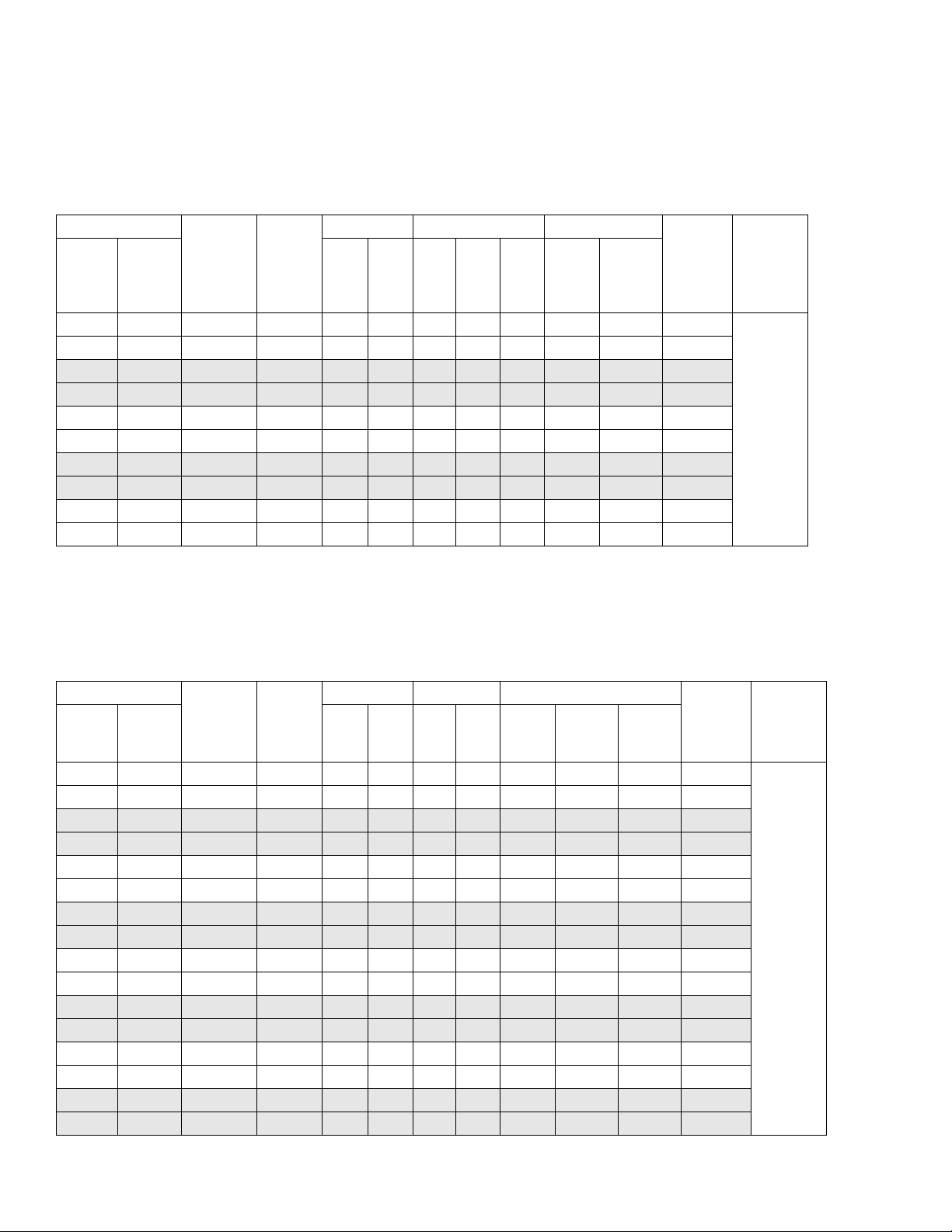

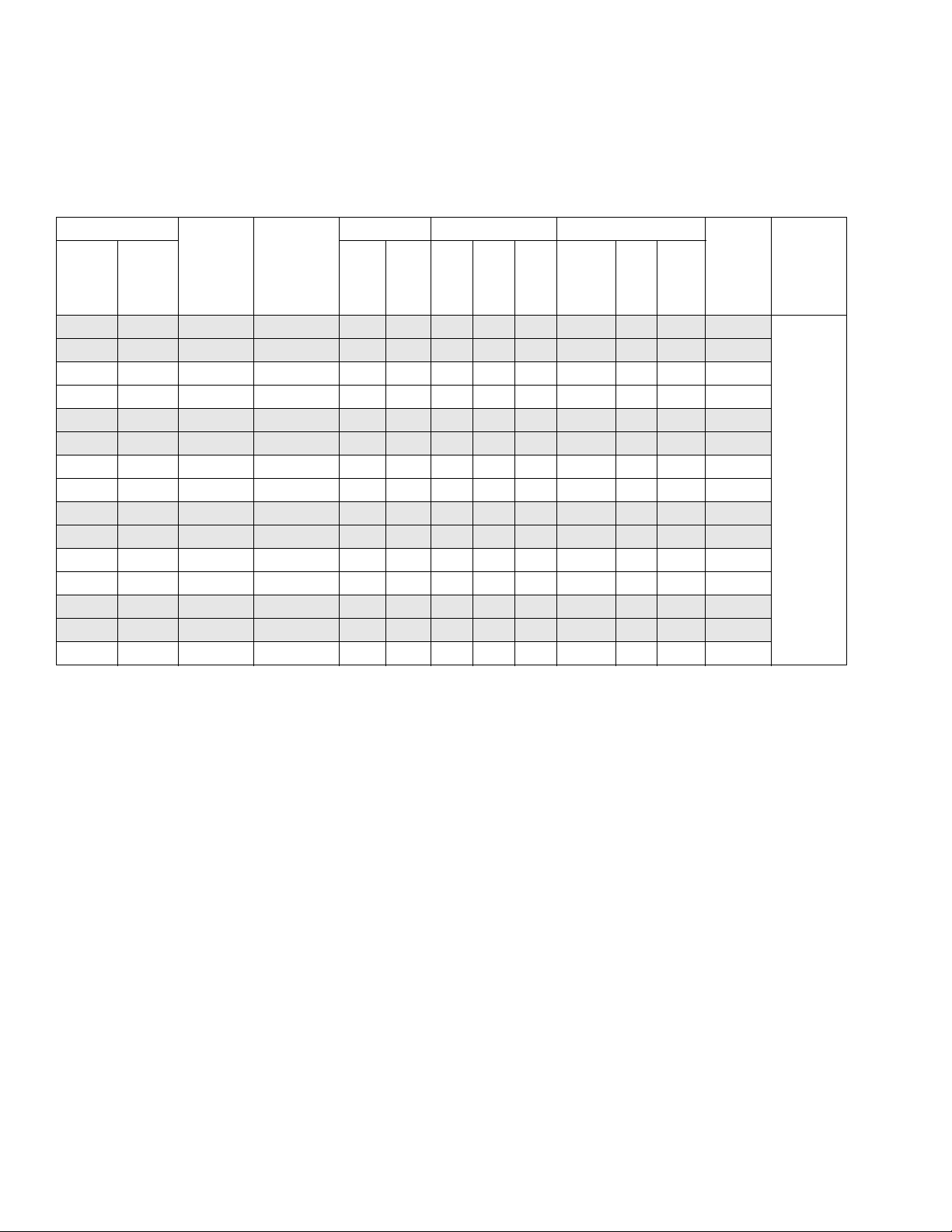

Merkur 24:1 Packages (G24Wxx and G24Cxx)

Maximum Inlet Air Pressure: 100 psi (0.7 MPa, 7 bar)

Maximum Fluid Working Pressure: 2400 psi (16.5 MPa, 165 bar)

Models

Model

Wall

Mount

G24W01 ----- W24FAS

G24W02 ----- W24FBS

G24W03 G24C01 W24FAS None

G24W04 G24C02 W24FBS None

G24W05 G24C03 W24FAS XTR5

G24W06 G24C04 W24FBS XTR5

G24W07 G24C09 W24FAS G40

G24W08 G24C10 W24FBS G40

G24W09 G24C11 W24FAS G40RAC

G24W10 G24C12 W24FBS G40RAC

Cart

Mount

Pump

Assembly Gun

Air Controls Hoses Options

Pump

Pump

Only

✔

✔✔✔

✔✔✔

✔ ✔ ✔ ✔

✔ ✔ ✔ ✔

Gun

Gun

and

Fluid

Gun

Hose

✔✔✔ ✔ ✔

✔✔✔ ✔ ✔

✔ ✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔

Air

Hose

Siphon

Merkur 28:1 Packages (G28Wxx and G28Cxx)

Maximum Inlet Air Pressure: 100 psi (0.7 MPa, 7 bar)

Maximum Fluid Working Pressure: 2800 psi (19.3 MPa, 193 bar)

Kit

Fluid

Filter

DataTrak

✔

✔

✔

✔

✔

Maximum

Fluid Flow

Rate

gpm (lpm)

2.4 (9.0)

Model

Wall

Mount

G28W01 ----- W28EAS None

G28W02 ----- W28EBS None

G28W03 G28C01 W28EAS None

G28W04 G28C02 W28EBS None

G28W05 G28C03 W28EAS XTR5

G28W06 G28C04 W28EBS XTR5

G28W11 G28C09 W28EAS G40

G28W12 G28C10 W28EBS G40

G28W13 G28C11 W28EAS G40RAC

G28W14 G28C12 W28EBS G40RAC

Cart

Mount

Pump

Assembly Gun

Air Controls Hoses Accessories

Pump

Pump

Only

✔

✔✔✔

✔✔✔

✔ ✔ ✔ ✔

✔ ✔ ✔ ✔

Gun

Gun

and

Fluid

Gun

Hose

✔✔✔ ✔ ✔

✔✔✔ ✔ ✔

✔ ✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔

Air

Hose

Siphon

Kit

Fluid

Filter

DataTrak

Maximum

Fluid Flow

Rate

gpm (lpm)

✔

✔

2.0 (7.5)

✔

✔

✔

312797P 9

Page 10

Models

Merkur 30:1 Packages (G30Wxx, G30Cxx, and G30Txx)

Maximum Inlet Air Pressure: 100 psi (0.7 MPa, 7 bar)

Maximum Fluid Working Pressure: 3000 psi (20.7 MPa, 207 bar

)

Model

Wall

Mount

G30W19 ----- W30AAS

G30W01 G30C01 ----- W30AAS None

G30W03 G30C03 ----- W30AAS None

G30W05 G30C05 ----- W30AAS None

----- G30C07 ----- W30AAS XTR5

----- G30C08 ----- W30ABS XTR5

G30W07 G30C09 ----- W30AAS XTR5

G30W08 G30C10 ----- W30ABS XTR5

----- G30C11 ----- W30AAS XTR5

----- G30C13 ----- W30AAS XTR5

----- G30C15 ----- W30AAS XTR5

G30W09 G30C17 ----- W30AAS None

----- ----- G30T01 W30AAS None

----- ----- G30T02 W30ABS None

G30W11 G30C19 ----- W30AAS None

G30W12 ----- ----- W30ABS None

G30W13 G30C21 G30T03 W30AAS G40

G30W14 G30C22 G30T04 W30ABS G40

----- G30C23 G30T09 W30AAS G40

G30W15 G30C25 G30T05 W30AAS G40

G30W16 G30C26 G30T06 W30ABS G40

----- G30C27 ----- W30AAS G40

----- G30C29 G30T07 W30AAS G40 RAC

----- G30C30 G30T08 W30ABS G40 RAC

----- G30C31 ----- W30AAS G40 RAC

G30W17 G30C33 G30T11 W30AAS G40 RAC

G30W18 G30C34 G30T12 W30ABS G40 RAC

----- G30C35 ----- W30AAS G40 RAC

----- G30C37 ----- W30AAS XTR5

----- G30C39 ----- W30AAS G40

----- G30C40 ----- W30ABS G40

G30W51 ----- W30CAS None 1.2 (4.5)

G30W53 ----- W30CAS None

----- G30C51 W30CAS None

G30W55 G30C53 W30CAS None

G30W56 G30C54 W30CBS None

Cart

Mount

Stand

Mount

Pump

Assembly Gun

Air Controls Hoses Accessories

Pump

Pump

Only

✔

✔ ✔

✔ ✔ ✔

✔✔✔

✔✔✔

✔ ✔ ✔ ✔

✔ ✔ ✔ ✔

✔✔

✔

✔ ✔ ✔

✔

✔

✔✔

✔ ✔ ✔

✔ ✔ ✔ ✔

Gun

Gun

and

Fluid

Air

Siphon

Gun

Hose

Hose

✔**

✔

✔

✔✔

✔

✔✔

✔ ✔

✔ ✔

✔✔✔ ✔

✔✔✔ ✔

✔ ✔

✔ ✔ ✔ ✔ ✔

✔✔✔ ✔ ✔

✔✔✔ ✔

✔ ✔ ✔ ✔

✔ ✔ ✔ ✔

✔✔✔

✔✔✔ ✔ ✔

✔ ✔ ✔ ✔ ✔

✔ ✔ ✔ ✔

✔✔✔

✔ ✔ ✔

✔ ✔

✔

Fluid

Kit

Filter Hopper

✔✔

✔

✔

✔

✔

✔

✔

✔

✔*

Drain

Valve

✔

✔

✔

✔

✔

✔

✔ ✔

DataTrak

✔

✔

✔

✔

✔

✔

✔

✔

Maximum

Fluid Flow

Rate

gpm (lpm)

0.4 (1.5)

10 312797P

Page 11

Models

Model

Wall

Mount

G30W57 ----- W30CAS XTR5

G30W58 ----- W30CBS XTR5

G30W59 G30C55 W30CAS XTR5

G30W60 G30C56 W30CBS XTR5

----- G30C57 W30CAS XTR5

G30W71 ----- W30CAS None

----- G30C63 W30CAS None

----- G30C65 W30CAS G40

G30W73 G30C67 W30CAS G40

G30W74 G30C68 W30CBS G40

----- G30C69 W30CAS G40

----- G30C71 W30CAS G40 RAC

G30W75 G30C73 W30CAS G40RAC

G30W76 G30C74 W30CBS G40RAC

----- G30C85 W30CAS XTR5

----- G30C86 W30CBS XTR5

Cart

Mount

Stand

Mount

Pump

Assembly Gun

Air Controls Hoses Accessories

Pump

Pump

Only

✔✔✔

✔✔✔ ✔

✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔

✔✔** ✔✔

Gun

Gun

and

Fluid

Air

Siphon

Gun

Hose

Hose

✔

✔ ✔

✔ ✔ ✔ ✔

✔✔✔ ✔ ✔

✔✔✔ ✔ ✔ ✔

✔ ✔** ✔ ✔ ✔

✔ ✔ ✔ ✔

✔✔✔ ✔ ✔

✔✔✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔ ✔ ✔

Kit

Fluid

Filter Hopper

Drain

Valve

DataTrak

Maximum

Fluid Flow

gpm (lpm)

Rate

1.2 (4.5)

* This package offers a short suction tube, rather than the standard suction hose.

** Fluid hose is 3/16 x 50 ft., rather than standard 3/16 x 25 ft.

312797P 11

Page 12

Models

Merkur 36:1 Packages (G36Wxx and G36Cxx)

Maximum Inlet Air Pressure: 100 psi (0.7 MPa, 7 bar)

Maximum Fluid Working Pressure: 3600 psi (24.8 MPa, 248 bar)

Model

Wall

Mount

G36W01 ----- W36DAS None

G36W03 ----- W36DAS None

G36W04 ----- W36DBS None

G36W05 G36C01 W36DAS None

G36W06 G36C02 W36DBS None

G36W07 G36C03 W36DAS XTR5RAC

G36W08 G36C04 W36DBS XTR5RAC

G36W13 G36C09 W36DAS G40

G36W14 G36C10 W36DBS G40

G36W15 G36C11 W36DAS G40RAC

G36W16 G36C12 W36DBS G40RAC

G36W17 G36C13 W36DAS G40

G36W18 G36C14 W36DBS G40

----- G36C15 W36DAS XTR5RAC

----- G36C16 W36DBS XTR5RAC

Cart

Mount

Pump

Assembly Gun

Air Controls Hoses Accessories

Gun

Pump

Pump

Only

✔

✔✔

✔✔✔

✔ ✔ ✔ ✔

✔ ✔ ✔ ✔

✔✔ ✔✔ ✔

✔

✔

Gun

Fluid

Gun

and

Fluid

Whip

Gun

Hose

Hose

✔ ✔✔✔ ✔ ✔

✔ ✔ ✔ ✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔ ✔

✔ ✔✔✔ ✔ ✔ ✔

✔ ✔✔✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔

✔ ✔ ✔ ✔

✔✔✔✔✔

Air

Hose

Suction

Hose

Fluid

Filter

Drain

Valve

DataTrak

Maximum

Fluid Flow

Rate

gpm (lpm)

1.6 (6.0)

12 312797P

Page 13

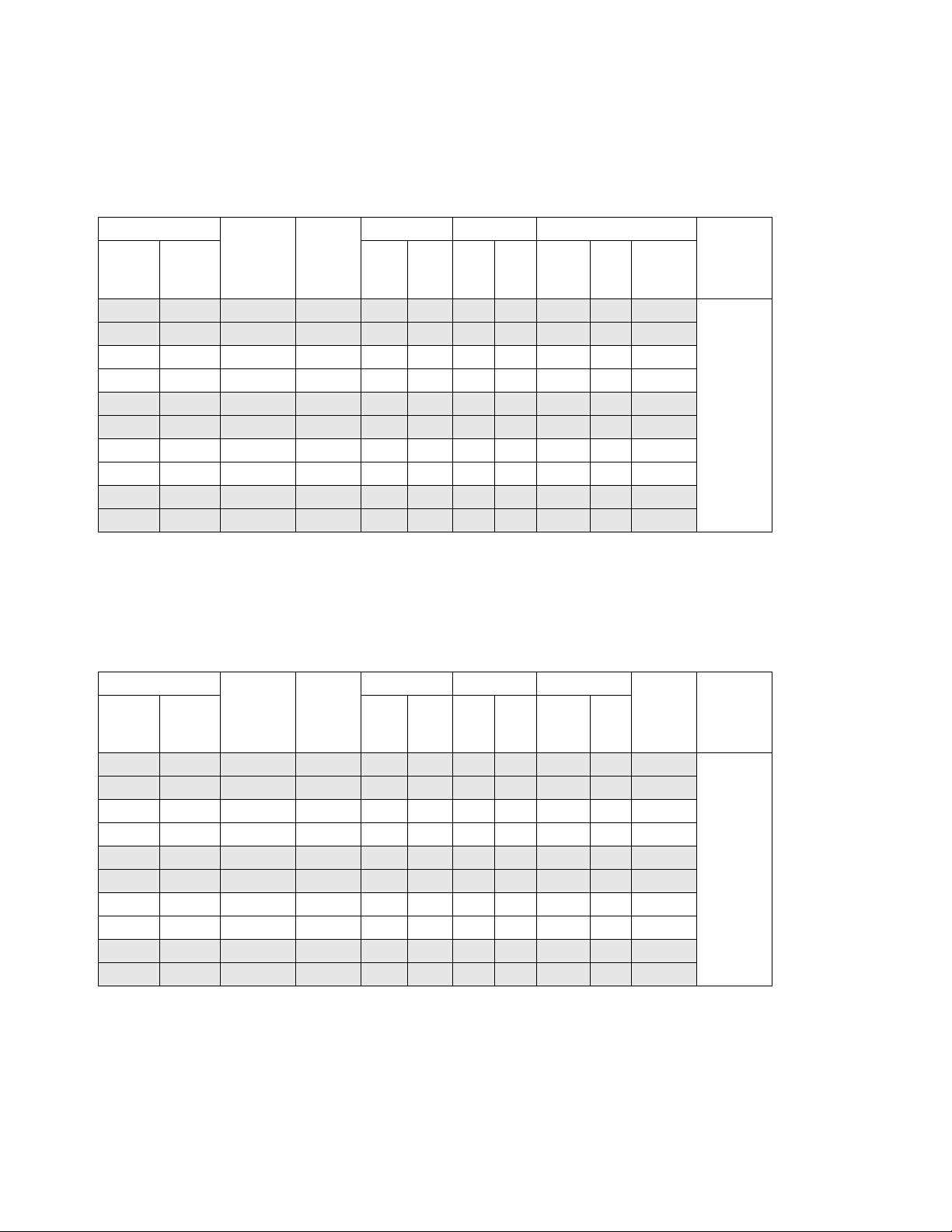

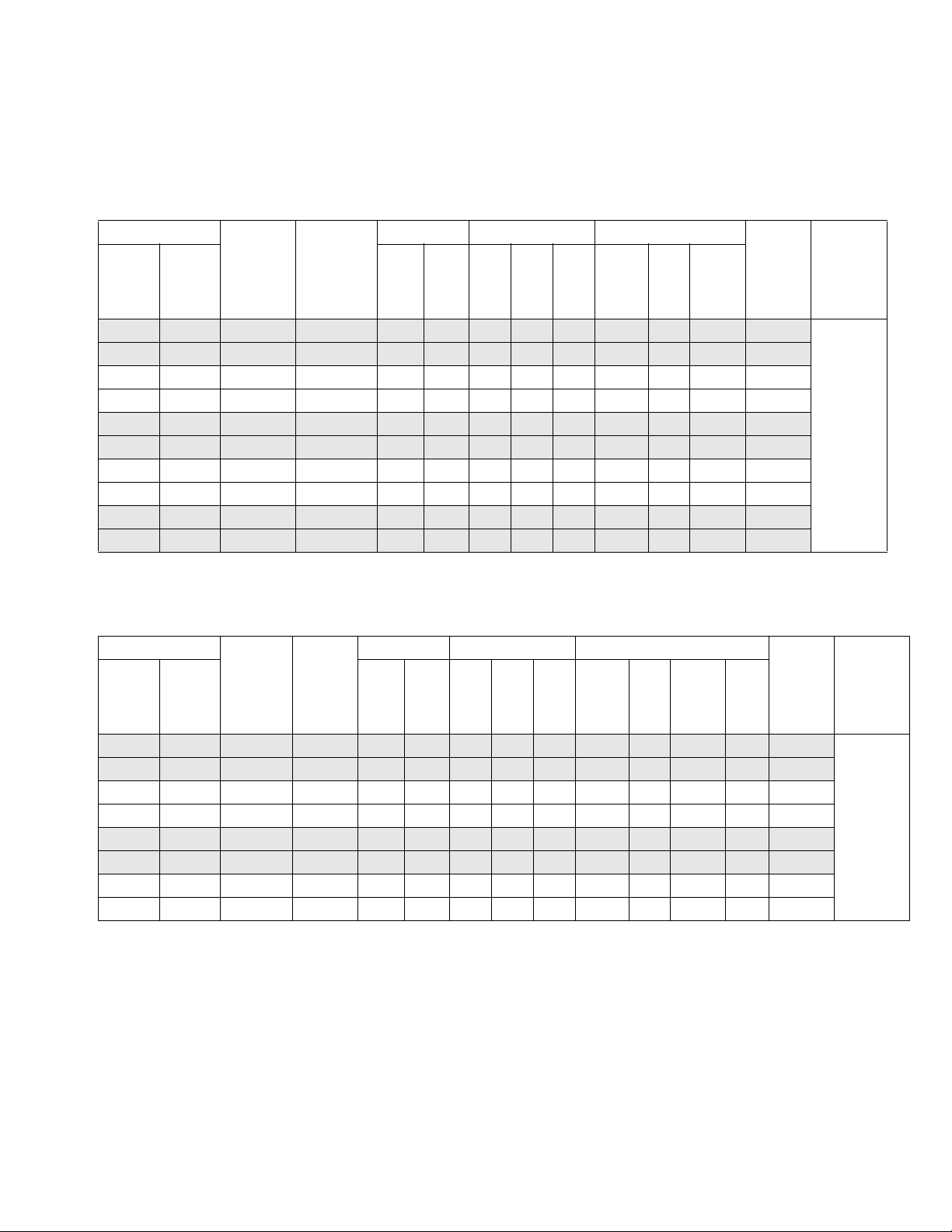

Merkur 45:1 Packages (G45Wxx and G45Cxx)

Table A: Maximum Inlet Air Pressure: 100 psi (0.7 MPa, 7 bar)

Maximum Fluid Working Pressure: 4500 psi (31.0 MPa, 310 bar)

Models

Model

Wall

Mount

G45W01 ----- W45BAS None

G45W03 ----- W45BAS None

G45W04 ----- W45BBS None

----- G45C01 W45BAS None

G45W05 G45C03 W45BAS XTR5RAC

G45W06 G45C04 W45BBS XTR5RAC

----- G45C05 W45BAS XTR5RAC

----- G45C06 W45BBS XTR5RAC

G45W11 ----- W45BAS None

----- G45C11 W45BAS None

Cart

Mount

Pump

Assembly Gun

Air Controls Hoses Accessories

Gun

Pump

Pump

Only

✔

✔

✔✔

✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔

✔✔ ✔✔

✔✔ ✔✔✔

Gun

Fluid

and

Fluid

Whip

Gun

Hose

Hose

✔✔✔✔

✔

✔ ✔

Table B: Maximum Inlet Air Pressure: 90 psi (0.6 MPa, 6 bar)

Maximum Fluid Working Pressure: 4000 psi (27.6 MPa, 276 bar)

Model

Wall

Mount

----- G45C13 W45BAS G40

G45W13 G45C15 W45BAS G40

G45W14 G45C16 W45BBS G40

G45W15 G45C17 W45BAS G40 RAC

G45W16 G45C18 W45BBS G40 RAC

G45W17 G45C19 W45BAS G40

G45W18 G45C20 W45BBS G40

----- G45C21 W45BAS G40

Cart

Mount

Pump

Assembly Gun

Air Controls Hoses Accessories

Gun

Pump

Pump

Only

Gun

Fluid

Gun

and

Fluid

Whip

Gun

Hose

Hose

✔ ✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔ ✔

✔ ✔✔✔ ✔ ✔ ✔

✔ ✔✔✔ ✔ ✔

✔ ✔ ✔ ✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔ ✔ ✔

✔ ✔✔✔ ✔ ✔ ✔ ✔

✔ ✔✔✔ ✔ ✔ ✔

Air

Hose

Gun

Air

Hose

Siphon

Kit

Siphon

Kit

Fluid

Filter Hopper

Fluid

Filter Hopper

DataTrak

Drain

Valve

Maximum

Fluid Flow

gpm (lpm)

DataTrak

Rate

0.8 (3.0)

Maximum

Fluid Flow

Rate

gpm (lpm)

0.8 (3.0)

312797P 13

Page 14

Models

Merkur 48:1 Packages (G48Wxx and G48Cxx)

Table A: Maximum Inlet Air Pressure: 100 psi (0.7 MPa, 7 bar)

Maximum Fluid Working Pressure: 4800 psi (33.1 MPa, 331 bar)

Model

Wall

Mount

G48W01 W48CAS None

G48W03 G48C01 W48CAS None

G48W04 G48C02 W48CBS None

G48W05 G48C03 W48CAS

G48W06 G48C04 W48CBS

----- G48C05 W48CAS

----- G48C06 W48CBS

G48W11 ----- W48CAS None

Cart

Mount

Pump

Assembly Gun

XTR5

XTR5

XTR5

XTR5

Air Controls Hoses Accessories

Gun

RAC

RAC

RAC

RAC

Pump

Pump

Only

✔ ✔ ✔

✔✔✔✔

✔✔ ✔✔

✔ ✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔

✔✔ ✔✔ ✔✔

and

Gun

✔

Gun

Fluid

Hose

Fluid

Whip

Hose

Gun

Air

Hose

Table B: Maximum Inlet Air Pressure: 85 psi (0.6 MPa, 6 bar)

Maximum Fluid Working Pressure: 4000 psi (27.6 MPa, 276 bar)

Model

Wall

Mount

G48W07 G48C07 W48CAS G40

G48W08 G48C08 W48CBS G40

----- G48C09 W48CAS G40

G48W13 G48C11 W48CAS G40

G48W14 G48C12 W48CBS G40

G48W15 G48C13 W48CAS

G48W16 G48C14 W48CBS

Cart

Mount

Pump

Assembly Gun

Air Controls Hoses Accessories

Gun

Pump

Pump

Only

G40

RAC

G40

RAC

Gun

Fluid

Gun

and

Fluid

Whip

Gun

Hose

Hose

✔ ✔ ✔ ✔ ✔ ✔* ✔

✔ ✔ ✔ ✔ ✔ ✔* ✔ ✔

✔✔✔✔ ✔

✔✔✔✔ ✔ ✔

✔ ✔ ✔ ✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔ ✔

✔✔✔✔ ✔ ✔ ✔

Air

Hose

Siphon

Kit

Siphon

Kit

Fluid

Filter Hopper

Fluid

Filter Hopper

Drain

Valve

Drain

Valve

DataTrak

DataTrak

Maximum

Fluid

Flow Rate

gpm (lpm)

1.2 (4.5)

Maximum

Fluid Flow

Rate

gpm (lpm)

1.2 (4.5)

14 312797P

Page 15

Installation

Installation

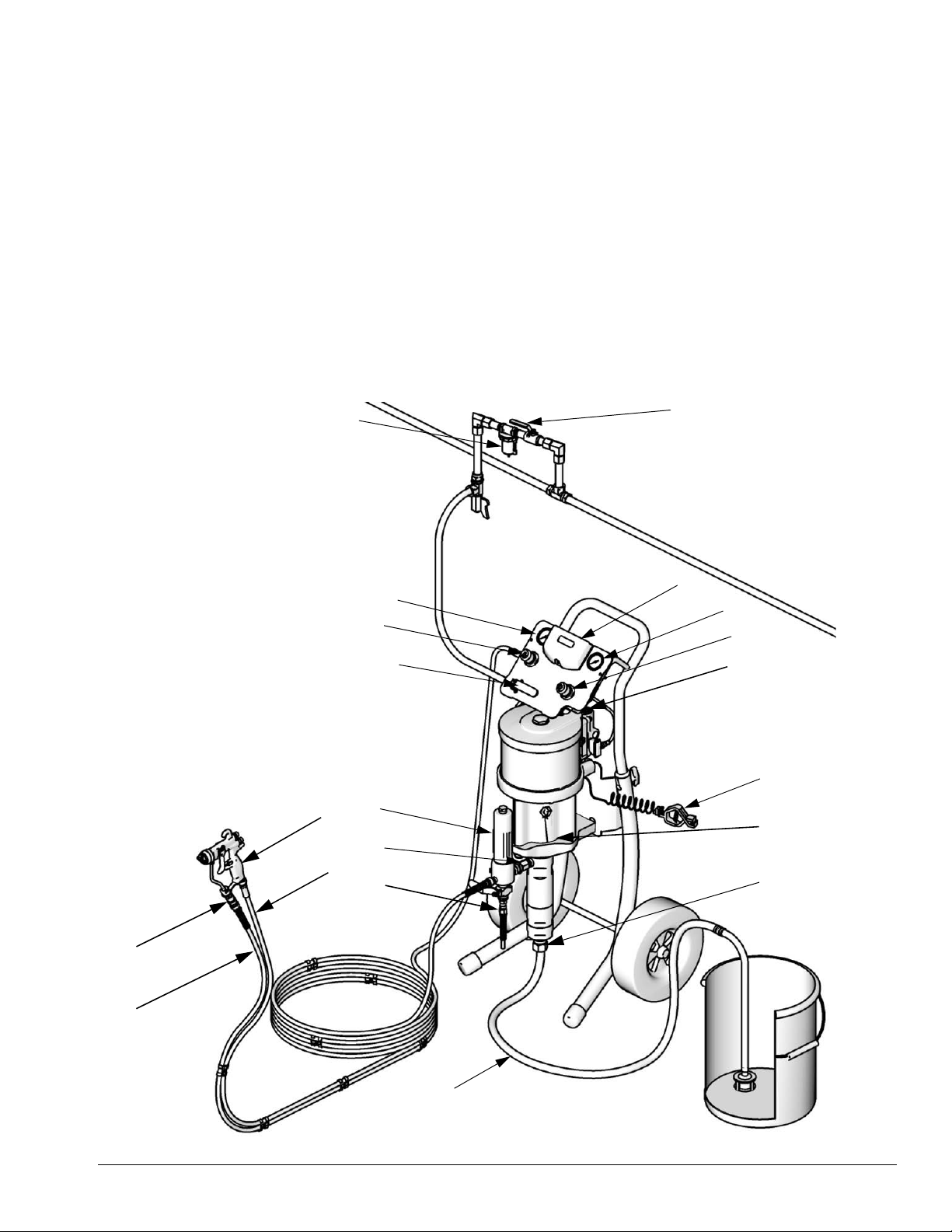

Package configurations vary widely. See pages 6-14 to determine the components included in your model. Items

designated as accessories are not included in the packages.

A Air Shutoff Valve (optional accessory)

B Air Filter (optional accessory)

C Gun Air Pressure Gauge

D Gun Air Pressure Regulator

E Bleed Type Master Air Valve

F DataTrak

G Pump Air Pressure Gauge

H Pump Air Pressure Regulator

J Solenoid Release Button (DataTrak equipped packages

only, not visible, see F

KGun Swivel

™

IG. 8, page 25)

B

C

D

E

L Air-Assisted Spray Gun

M Gun Fluid Supply Hose

N Gun Air Supply Hose

P Fluid Filter

R Pump Fluid Outlet

S Grounding Wire

T Wet-Cup (not visible, see F

U Pump Fluid Inlet

V Suction Hose

W Fluid Drain Valve

A

F

IG. 4, page 19)

G

H

J

G15 Spray Gun Shown

with Supply Hose

K

M

P

L

R

N

W

V

S

T

U

ti12800a

FIG. 1. Typical Installation (Your package may not include all items shown.)

312797P 15

Page 16

Installation

General Information

NOTE: Reference numbers and letters in parentheses in

the text refer to the callouts in the figures and the parts

drawing.

NOTE: Always use Genuine Graco Parts and Accessories, available from your Graco distributor. If you supply

your own accessories, be sure they are adequately

sized and pressure-rated for your system.

F

IG. 1 is only a guide for selecting and installing system

components and accessories. Contact your Graco distributor for assistance in designing a system to suit your

particular needs.

Prepare the Operator

All persons who operate the equipment must be trained

in the operation of all system components as well as the

proper handling of all fluids. All operators must thoroughly read all instruction manuals, tags, and labels

before operating the equipment.

Prepare the Site

Ensure that you have an adequate compressed air

supply.

Wall Mount Packages

1. Be sure the wall can support the weight of the

pump, bracket, hoses and accessories, as well as

the stress caused during operation.

2. Position the wall bracket about 1.2-1.5 m (4-5 ft)

above the floor. For ease of operation and service,

make sure the pump air inlet, fluid inlet, and fluid

outlet ports are easily accessible.

3. Using the wall bracket as a template, drill 10 mm

(0.4 in.) mounting holes in the wall. Wall mounting

dimensions are shown on page 48.

4. Attach the bracket to the wall. Use 3/8 in. (9 mm)

screws that are long enough to keep the pump from

vibrating during operation.

NOTE: Be sure the bracket is level.

Cart Mount Packages

In packages with M012xx and M018xx motors the muffler(s) are shipped loose. Ensure the muffler(s) are

installed before first use.

Bring a compressed air supply line from the air compressor to the pump location. Be sure all air hoses are

properly sized and pressure-rated for your system. Use

only electrically conductive hoses. The air hose should

have a 3/8 npt(m) thread. A quick disconnect coupling is

recommended.

Keep the site clear of any obstacles or debris that could

interfere with the operator's movement.

Have a grounded, metal pail available for use when

flushing the system.

16 312797P

Page 17

Installation

Components

See FIG. 1. Components vary by package ordered.

See tables on pages 6 to 14. Your package may include:

• The red-handled bleed-type master air valve (E) is

required in your system to relieve air trapped

between it and the air motor and gun when the valve

is closed. Do not block access to the valve.

• The pump air regulator (H) controls pump speed

and outlet pressure by adjusting the air pressure to

the pump.

• The air relief valve (not shown) opens automatically

to prevent overpressurization of the pump.

• The gun air regulator (D) adjusts the air pressure to

the air-assisted spray gun (L).

• The air-assisted or airless spray gun (L) dispenses

the fluid. The gun houses the spray tip (not shown),

which is available in a wide range of sizes for different spray patterns and rates of flow. Refer to gun

manual for tip installation.

Air Line Accessories

Install the following accessories in the order shown in

F

IG. 1, using adapters as necessary.

• An air-line filter (B) removes harmful dirt and moisture from the compressed air supply.

• A second bleed-type air shutoff valve (A) isolates

the air line accessories for servicing. Locate

upstream from all other air line accessories.

Grounding

1. Pump: See FIG. 2. Verify that the ground screw (GS)

is attached and tightened securely to the air motor.

Connect the other end of the ground wire (S) to a

true earth ground.

S

• The transparent hose (N, labeled “Air Hose Only”)

provides the gun air supply.

• The blue hose (M) provides the gun fluid supply.

• The gun swivel (K) allows for freer gun movement

and comes attached to the blue hose (AA packages). The airless gun has a built-in fluid swivel.

• The suction hose (V) with strainer allows the pump

to draw fluid from a 5 gallon (19 liter) pail. A fluid

hopper with screen also is available.

• A fluid filter (P) with a 60 mesh (250 micron) stainless steel element filters particles from fluid as it

leaves the pump.

• A fluid drain valve (W) relieves fluid pressure in the

hose and gun.

• DataTrak (F) provides pump diagnostics and material usage information. DataTrak equipped packages

with M02xxx air motors do not have a runaway solenoid; all other DataTrak equipped packages do. See

page 24.

GS

ti12914a

FIG. 2. Ground screw and wire

2. Pump fluid hoses: use only electrically conductive

fluid hoses Check electrical resistance of hoses. If

total resistance to ground exceeds 25 megohms,

replace hose immediately.

3. Air compressor: follow manufacturer's recommendations.

4. Spray gun: ground through connection to a properly

grounded fluid hose and pump.

5. Fluid supply container: follow your local code.

6. Object being sprayed: follow your local code.

7. Solvent pails used when flushing: follow your local

code. Use only metal pails, which are conductive,

placed on a grounded surface. Do not place the pail

on a nonconductive surface, such as paper or cardboard, which interrupts the grounding continuity.

8. To maintain grounding continuity when flushing or

relieving pressure, hold a metal part of the spray

gun firmly to the side of a grounded metal pail, then

trigger the gun.

312797P 17

Page 18

Operation

Setup

1. See FIG. 1. Attach end of blue fluid hose (M) to

pump outlet (R) or filter (P) outlet.

2. Attach one end of the air hose (N) to gun air regulator (D).

3. Attach remaining end of the air hose (N) to air inlet

at base of gun (L).

4. Attach gun swivel (K) to gun fluid inlet.

5. Attach other end of blue fluid hose (M) to gun

swivel (K).

6. Clip fluid and air hoses together with the supplied

hose clips (qty. of 7). Space clips as needed.

7. Apply lens cover to both regulator gauge lenses.

8. Verify that suction hose fittings are tight.

Operation

Pressure Relief Procedure

1. Engage the trigger lock.

2. See F

3. Disengage the trigger lock.

4. Hold a metal part of the gun firmly to a grounded

5. Engage the trigger lock.

6. Open all fluid drain valves in the system, having a

IG. 1. Turn off the bleed-type master air valve

(D).

metal waste container. Trigger the gun to relieve

fluid pressure.

waste container ready to catch the drainage. Leave

the drain valve(s) open until you are ready to spray

again.

7. If you suspect that pressure has not been fully

relieved after following the steps above, check the

following:

a. The spray tip may be completely clogged. Very

slowly loosen the air cap retaining ring to relieve

pressure in the cavity between the ball/seat

shutoff and the plugged tip. Clear the tip orifice.

b. The gun fluid filter or the fluid hose may be com-

pletely clogged. Very slowly loosen the hose

end coupling at the gun and relieve pressure

gradually. Then loosen completely to clear the

obstruction.

c. After following the steps above, if the spray tip

or hose still seems completely clogged, very

slowly loosen the tip guard retaining nut or hose

end coupling and relieve pressure gradually,

then loosen completely. With tip removed, trigger gun into waste container.

18 312797P

Page 19

Operation

Flush the Pump Before First Use

The pump is tested with lightweight oil, which is left in to

protect the pump parts. If the fluid you are using may be

contaminated by the oil, flush it out with a compatible

solvent. See Flush the Pump on page 22.

Trigger Lock

See FIG. 3. Always engage gun trigger lock when you

stop spraying to prevent gun from being triggered accidentally by hand or if dropped or bumped.

Gun Trigger

Safety Locked

TI6581A

Wet Cup

Before starting, fill wet cup (T) 1/3 full with Graco Throat

Seal Liquid (TSL) or compatible solvent.

T

ti11927a

FIG. 4. Wet Cup

Gun Trigger

Safety Unlocked

FIG. 3. Trigger Lock

TI6582A

Prime the Pump

1. See FIG. 1. Lock gun trigger. Remove tip guard and

spray tip from gun (L). Refer to gun manual.

2. Close gun air regulator (D) and pump air regulator

(H) by turning knobs counterclockwise reducing

pressure to zero. Close bleed-type air valve (E).

Also verify that all drain valves are closed.

3. Connect air line to bleed type air valve (D).

4. Check that all fittings throughout system are tightened securely.

5. Position pail close to pump. Suction hose is 4 ft

(1.2 m) long. Do not stretch hose tight; let it hang to

assist fluid flow into pump.

6. Hold metal part of gun (L) firmly to side of grounded

metal pail, unlock trigger, and hold trigger open.

7. Units with runaway protection only: enable the

prime/flush function by pushing the prime/flush button on the DataTrak.

312797P 19

Page 20

Operation

8. Open bleed-type air valve (E). Slowly turn clockwise

pump air regulator (H) increasing pressure until

pump starts.

9. Cycle pump slowly until all air is pushed out and

pump and hoses are fully primed.

10. Units with runaway protection only: disable the

prime/flush function by pushing the prime/flush button on the DataTrak.

11. Release gun trigger and lock trigger safety. Pump

should stall against pressure.

Install the Spray Tip

Follow Pressure Relief Procedure, page 18. Install the

spray tip and tip guard as explained in your separate

gun manual, supplied.

Adjust the Atomization

1. Do not turn on atomizing air supply. Fluid pressure

is controlled by the air pressure supplied to the

pump (pump air regulator). Set fluid pressure at low

starting pressure. For low viscosity fluids (less than

25 sec, #2 Zahn cup) with lower percent solids (typically less than 40%), start at 300 psi (2.1 MPa, 21

bar) at pump outlet. For fluids with higher viscosity

or higher solids content, start at 600 psi (4.2 MPa,

42 bar). Refer to the following example.

Example:

Pump Air

Pump

Ratio

15:1 x 20 (0.14, 1.4) = 300 (2.1, 21)

30:1 x 20 (0.14, 1.4) = 600 (4.2, 42)

Regulator Setting

psi (MPa, bar)

Approximate

Fluid Pressure

psig (MPa, bar)

The fluid output and pattern width depend on the size of

the spray tip, the fluid viscosity, and the fluid pressure.

Use the Spray Tip Selection Chart in your gun instruction manual as a guide for selecting an appropriate

spray tip for your application.

2. Hold gun perpendicular and approximately 12

inches (304 mm) from surface.

3. Move gun first, then pull gun trigger to spray onto

test paper.

4. Increase fluid pressure in 100 psi (0.7 MPa, 7 bar)

increments, just to the point where a further

increase in fluid pressure does not significantly

improve fluid atomization. Refer to the following

example.

Example:

Pump Air Regulator

Pump

Ratio

15:1 x 7 (.05, 0.5) = 100 (0.7, 7.0)

30:1 x 3.3 (0.02, 0.2) = 100 (0.7, 7.0)

Increment

psi (MPa, bar)

Incremental

Fluid Pressure

psi (MPa, bar)

20 312797P

Page 21

Operation

Adjust the Spray Pattern

Packages with Airless Guns

The spray tip orifice and spray angle determine pattern

coverage and size. When you need more coverage, use

a larger spray tip rather than increasing fluid pressure.

Align guard horizontally to spray a horizontal pattern.

Align guard vertically to spray a vertical pattern.

Packages with AA Guns

1. See FIG. 5. Close off pattern adjustment air by turning knob (AA) clockwise (in) all the way. This sets

gun for its widest pattern.

AA

OUT (narrower

pattern)

AA

IN (wider

pattern)

3. See F

IG. 5. For narrower pattern, turn pattern

adjustment valve knob (AA) counterclockwise (out).

If pattern is still not narrow enough, increase air

pressure to gun slightly or use different size tip.

no air

too little air correct

amount of

air

FIG. 6. Spray Pattern Problems

Shutdown

TI0792A

F

IG. 5. Pattern Air Knob

2. See F

IG. 6. Set atomizing air pressure at about 5 psi

(0.35 bar, 35 kPa) when triggered. Check spray pattern, then slowly increase air pressure until tails are

completely atomized and pulled into spray pattern.

Do not exceed 100 psi (0.7 MPa, 7 bar) air pressure

to gun.

Follow Pressure Relief Procedure, page 18.

Always flush the pump before the fluid dries on the displacement rod. See Flush the Pump on page 22.

TI6559A

312797P 21

Page 22

Maintenance

Maintenance

Preventive Maintenance Schedule

The operating conditions of your particular system

determine how often maintenance is required. Establish

a preventive maintenance schedule by recording when

and what kind of maintenance is needed, and then

determine a regular schedule for checking your system.

Replace lens covers on regulator gauge lenses when

dirt makes gauges difficult to read.

Tighten Threaded Connections

Before each use, check all hoses for wear or damage.

Replace as necessary. Check that all threaded connections are tight and leak-free.

Flush the Pump

Read all Warnings. Follow all Grounding instructions.

See page 17.

1. Follow Pressure Relief Procedure, page 18.

2. Remove tip guard and spray tip from gun. Refer to

separate gun manual.

3. Place siphon tube in grounded metal pail containing

cleaning fluid.

4. Set pump to lowest possible fluid pressure, and start

pump.

5. Hold a metal part of the gun firmly to a grounded

metal pail.

6. Units with runaway protection only: enable the

prime/flush function by pushing the prime/flush button on the DataTrak.

7. Trigger gun. Flush system until clear solvent flows

from gun.

8. Units with runaway protection only: disable the

prime/flush function by pushing the prime/flush button on the DataTrak.

9. Follow Pressure Relief Procedure, page 18.

10. Clean the tip guard, spray tip, and fluid filter element

separately, then reinstall them.

Flush the pump:

• Before first use

• When changing colors or fluids

• Before repairing equipment

• Before fluid dries or settles out in a dormant pump

(check the pot life of catalyzed fluids)

• At the end of the day

• Before storing the pump.

Flush at the lowest pressure possible. Flush with a fluid

that is compatible with the fluid you are pumping and

with the wetted parts in your system. Check with your

fluid manufacturer or supplier for recommended flushing

fluids and flushing frequency.

11. Clean inside and outside of suction tube.

Wet Cup

Fill the wet cup one-half full with Graco Throat Seal Liquid (TSL). Maintain level daily.

22 312797P

Page 23

Troubleshooting

NOTE: Check all possible problems and causes before

disassembling the pump.

Relieve the pressure before checking or servicing

the equipment.

Problem Cause Solution

Pump fails to operate. Restricted line or inadequate air sup-

ply; closed or clogged valves.

Obstructed fluid hose or gun; fluid

hose ID is too small.

Fluid dried on the displacement rod. Clean; always stop the pump at the bottom

Dirty, worn, or damaged air motor

parts.

DataTrak models only: Air valve

cannot cycle because solenoid pin is

extended.

Pump operates, but output is

low on both strokes.

Pump operates, but output is

low on downstroke.

Erratic or accelerated pump

speed.

Fluid being pumped is visible

in the TSL reservoir.

Restricted line or inadequate air supply; closed or clogged valves.

Obstructed fluid hose or gun; fluid

hose ID is too small.

Worn packings in displacement

pump.

Held open or worn ball check valves

or piston packings.

Exhausted fluid supply. Refill and prime.

Held open or worn ball check valves

or packings.

Worn throat packings. Replace throat packings. See manual

Troubleshooting

Clear line or increase air supply. Check that

the valves are open.

Open, clear*; use hose with larger ID.

of its stroke; keep the wet-cup 1/3 filled with

Graco throat seal liquid (TSL).

Clean or repair air motor. See manual

312796.

Enable runaway protection (See DataTrak

Operation, Setup Mode, page 25). Bleed

air from motor. Press on the DataTrak

display to retract solenoid pin.

Clear line or increase air supply. Check that

the valves are open.

Open, clear*; use hose with larger ID.

Replace packings. See manual 312792.

Clear valve; replace packings. See manual

312792.

Clear valve, replace packings; see manual

312792.

312792.

* To determine if the fluid hose or gun is obstructed, relieve the pressure. Disconnect the fluid hose and place a container at the pump fluid outlet to catch any fluid. Turn on the air just enough to start the pump. It the pump starts when

the air is turned on, the obstruction is in the hose or gun.

312797P 23

Page 24

DataTrak Controls and Indicators

DataTrak Controls and Indicators

Key for FIG. 7

AA Runaway Limit, in cycles per minute (user settable;

00=OFF)

AB Lower Displacement (user settable)

AC Flow Rate Units (user settable to gpm [US], gpm

[Imperial], oz/min [US], oz/min [Imperial], l/min, or cc/min)

AD LED (fault indicator when lit)

AE Display

PF Prime/Flush Key (Enables Prime/Flush mode. While in

Prime/Flush mode, runaway protection is disabled and the

batch totalizer [BT] will not count.) LED will flash while in

Prime/Flush mode.

/min,

AE, see details at right

RK

RK Reset Key (Resets faults. Press and hold for 3 seconds to

clear the batch totalizer.) Push to toggle between flow rate

and cycle rate. With runaway protection enabled, push to

extend and retract the solenoid pin.

CF Cycle/Flow Rate

BT Batch Totalizer

GT Grand Totalizer

RT Runaway Toggle (enable/disable)

UT E1 Toggle

DT E2 Toggle

ST E5 Toggle

GT

Run Mode

PF

AD

TI11883a

FIG. 7. DataTrak Controls and Indicators

AC

AB

RK

AA

CF BT

Setup Mode

ti8622b

RT

UT

DT

PF

ti8623b

ST

24 312797P

Page 25

DataTrak Operation

DataTrak Operation

NOTE: The display (AE) will turn off after 1 minute to

save battery life. Press any key to wake up the display.

NOTICE

To prevent damage to the soft key buttons, do not

press the buttons with sharp objects such as pens,

plastic cards, or fingernails.

Setup Mode

1. See FIG. 7. Press and hold for 5 seconds until

Setup menu appears.

2. To enter settings for runaway (if equipped), lower

size, and flow rate units, and to enable runaway, E1,

E2, and E5 error options, press to change the

value, then to save the value and move the cursor to the next data field. See page 27 for a descrip-

tion of E1, E2, and E5 error codes.

NOTE: Graco recommends setting runaway (if

equipped) to 60 . All DataTrak modules are

shipped with runaway protection not enabled.

2. Runaway Screens 1 and 2: To reset the runaway

solenoid, close the master air valve (E). Wait for air

to completely bleed off the air motor.

3. Runaway Screens 3 and 4: After the air is bled off,

push the solenoid release button (J) down to reset

the air valve. The button will pop back up when the

air valve is repressurized.

J

NOTE: When runaway, E1, E2, and E5 error options are

enabled, a ✓ will appear on the setup screen. See F

7.

3. Move the cursor to the E5 error enable option field,

then press once more to exit Setup mode.

IG.

Run Mode

Runaway

NOTE: DataTrak is available with and without runaway

protection. Packages with M02xxx air motors ship without a runaway solenoid. All other packages are

equipped with a runaway solenoid.

1. See F

IG. 7. If pump runaway occurs, the runaway

solenoid will actuate, stopping the pump. The LED

(AD) will flash and the display (AE) will indicate a

runaway condition (see Table 1). The display will

cycle through six instruction screens.

ti11902a

FIG. 8. Solenoid Release Button

4. Runaway Screens 5 and 6: Press to clear the

diagnostic code and reset the runaway solenoid.

5. Open master air valve (E) to restart pump.

NOTE: To disable runaway monitoring, go to setup

mode and set runaway value to 0 (zero) or toggle (RT)

off (see F

IG. 7).

312797P 25

Page 26

DataTrak Operation

Prime/Flush

1. See FIG. 7. To enter Prime/Flush mode, press any

key to wake up the display, then press . The

Prime/Flush symbol will appear in the display and

the LED will flash .

2. While in Prime/Flush mode, runaway protection is

disabled and the batch totalizer (BT) will not count.

The grand totalizer (GT) continues to count.

3. To exit Prime/Flush mode, press any key to wake up

the display, then press . The Prime/Flush sym-

bol will disappear from the display and the LED will

stop flashing.

Counter/Totalizer

See FIG. 7. The last digit of the batch totalizer (BT) represents tenths of gallons or liters. To reset the totalizer,

press any key to wake up the display, then press and

hold for 3 seconds.

Display

See FIG. 7. The display (AE) will turn off after 1 minute

of inactivity in Run mode or 3 minutes in Setup mode.

Press any key to wake up the display.

NOTE: DataTrak will continue to count cycles when display is off.

NOTE: The display (AE) may turn off if a high-level static

discharge is applied to the DataTrak. Press any key to

wake up the display.

Diagnostics

DataTrak can diagnose several problems with the pump.

When the monitor detects a problem, the LED (AD, F

7) will flash and a diagnostic code will appear on the display. See Table 1.

To acknowledge the diagnosis and return to the normal

operating screen, press once to wake up the display,

and once more to clear the diagnostic code screen

IG.

• If AC is set to gallons or ounces, BT and GT dis-

play gallons.

• If AC is set to liters or cc, BT and GT display

liters.

• If AC is set to cycles, BT and GT display cycles.

Press to toggle between flow rate units and cycles.

A letter under the BT display indicates that both BT and

GT are displaying gallons (g) or liters (l). No letter

means both BT and GT are displaying cycles.

26 312797P

Page 27

DataTrak Operation

.

Table 1: Diagnostic Codes

Symbol Code Code Name Diagnosis Cause

Runaway

(DataTrak only)

Pump running faster than set

runaway limit.

• Increased air pressure.

• Increased fluid output.

• Exhausted fluid supply.

E-1 Diving Up Leak during upstroke. Worn piston valve or packings.

E-2 Diving Down Leak during downstroke. Worn intake valve.

E-3 Low Battery Battery voltage too low to stop

runaway.

E-4 Service

Problem with stopping runaway. • Damaged solenoid.

Component 1

(units with

runaway

protection only)

E-4 Disconnected

Solenoid is disconnected. • Solenoid unplugged.

Solenoid

(units with

runaway

protection only)

E-5 Service

Component 2

Solenoid is not engaging piston

cup (112).

Problem with sensing valve

movement.

E-6 Blown Fuse Fuse is blown. Replace fuse;

see page 28.

Low battery. Replace battery;

see page 28.

• Damaged valve carriage.

• Runaway (RT, FIG. 7) protection may be enabled with

pump that is not equipped

with a runaway solenoid

valve. Enter setup screen and

disable runaway protection.

• Damaged solenoid wires.

• Bracket and solenoid not tight

against air valve housing.

• Sensors unplugged.

• Sensors mounted incorrectly.

• Damaged sensors.

• Damaged valve carriage.

• Faulty solenoid or solenoid

wiring.

• Extreme temperatures

(above 140°F [60°C]).

• Runaway (RT, F

IG. 7) protec-

tion may be enabled with

pump that is not equipped

with a runaway solenoid

valve. Enter setup screen and

disable runaway protection.

312797P 27

Page 28

DataTrak Operation

Replace DataTrak Battery or Fuse

4. Remove two screws on back of module to access

battery.

The battery and fuse must be replaced in a

non-hazardous location.

Use only the following approved replacement batteries. Use of an unapproved battery will void Graco’s

warranty and FM and Ex approvals.

• Ultralife lithium # U9VL

• Duracell alkaline # MN1604

• Energizer alkaline # 522

• Varta alkaline # 4922

Use only a Graco-approved replacement fuse. Order

Part 24C580.

Replace Battery

1. Unscrew cable from the back of the reed switch

assembly. See F

2. Remove the cable from the two cable clips.

IG. 9.

5. Disconnect the used battery and replace with an

approved battery. See F

IG. 11.

Replace Fuse

1. Remove the screw, metal strap, and plastic holder.

2. Pull the fuse away from the board.

3. Replace with a new fuse.

Solenoid Cable

Connection

Fuse

Sensor Cable

Connection

ti11992a

F

IG. 9. Disconnect DataTrak

3. Remove DataTrak module from bracket. See F

10. Take module and attached cable to a non-hazardous location.

ti11884a

F

IG. 10. Remove DataTrak

IG.

Battery

ti11994a

FIG. 11. DataTrak Battery and Fuse Location

28 312797P

Page 29

DataTrak Operation

312797P 29

Page 30

Parts

Parts

Cart Mount

3a

3b

2

48

1

13

6

41

44

45

4

7

16

23

53

15

21

17

5

30 312797P

20

19

ti12632a

Page 31

Wall Mount

Parts

3a

3b

16

2

49

23

6

41

1

48

13

23

54

7

4

5

44

45

ti12920a

312797P 31

Page 32

Parts

Stand Mount

3a

3b

1

2

4

23

6

41

44

4816

13

7

23

55

45

15

21

20

17

5

19

ti12919a

32 312797P

Page 33

Parts

NOTE:

• See page 43 for mounting kits for all packages.

• See page 44 for repair parts and accessories.

Package

Parts List

Page

G10xxx 33

G15xxx 34

G18xxx 35

G23xxx 36

G24xxx 37

G28xxx 38

G30xxx 39

G36xxx 40

G45xxx 41

G48xxx 42

G10xxx Models

This list includes all possible parts for G10xxx packages. See page 6 to check whether a part is included in your

particular package.

Ref Part Description Qty

1 Pump Assembly; see Manual 312794 1

W10CAS M04LN0 x LW075A

W10CBS M04LT0 x LW075A

2 24A585 PANEL, air control; see page 44 1

3a 24A575 DATATRAK, assembly; see manual

313541

3b ----- INSERT, panel (included with Part 2) 1

4 256420 HOSE, suction (includes Part 5) 1

5 ----- STRAINER (included with Part 4, or

see page 46 for packages of 10)

6 24A587 FILTER, fluid 1

7 ----- FITTING, union, 3/8-18 npsm x

3/8-18 npt, (included with Part 6)

8 189018 SWIVEL, fluid hose (packages with

gun)

9 241812 HOSE, fluid (packages with gun) 1

10 24C853 GUN, G15, carbide 1

11 AAM413 TIP (packages with gun) 1

12 AAMxxx TIP OPTION, (packages with gun) 1

13 512351 ADAPTER, outlet, 1/4 nptm x 3/8 nptf 1

14 256390 AIR HOSE, gun, (packages with gun) 1

15 256410 HOPPER (includes 17, 19, 20) 1

16 105332 NUT, lock, M5 x 0.08 (included with

Parts 2 and 49)

Ref Part Description Qty

17 ----- TUBE, inlet, hopper (included with

Part 15)

18 ----- CLIP, hose (packages with gun), see

page 46 for packages of 10

19 ----- O-RING, hopper (included with

1

20 ----- SCREEN, hopper (included with

21 24B299 ADAPTER, inlet, 3/4 nptf to 1/2 nptm,

1

23 111799 SCREW, M8 x 16 (included with

1

1

48 238909 WIRE, grounding assembly 1

49 24E883 BRACKET, air control, wall mount only

53 See p. 43 CART MOUNTING KIT; see page 43

54 See p. 43 WALL MOUNTING KIT; see page 43

----- Not sold separately.

2

NOTE: Replacement Warning labels, signs, tags, and cards

are available at no cost.

Part 15)

Part 15)

for suction hose

Parts 49, 53, and 54)

Wall mount 6

Cart mount 4

(includes Parts 16 and 23)

(G10Cxx models only)

(G10Wxx models only)

1

7

1

1

1

1

1

1

312797P 33

Page 34

Parts

G15xxx Models

This list includes all possible parts for G15xxx packages. See page 7 to check whether a part is included in your

particular package.

Ref. Part Description Qty.

1 Pump Assembly; see Manual 312794 1

W15AAS M02LN0 x LW025A

W15BAS M04LN0 x LW050A

W15BBS M04LT0 x LW050A

W15FAS M12LN0 x LW150A

W15FBS M12LT0 x LW150A

2 PANEL, air controls (includes Part 3b) 1

24A585 M02xxx or M04xxx motor, pump

and gun; see page 44

24A583 M12xxx motor, pump only; see

page 45

24A581 M12xxx motor, pump and gun; see

page 44

3a DATATRAK, assembly; see manual

313541

24A575 M02xxx and M04xxx motor

24A576 M12xxx motor

3b ----- INSERT, panel (included with Part 2) 1

4 HOSE, suction (includes Part 5)) 1

256420 LW025A or LW050A displacement

pump

256422 LW150A displacement pump, cart

mount

256424 LW150A displacement pump, wall

mount

5 STRAINER (included with Part 4) 1

----- LW025A or LW050A displacement

pump, see page 46 for packages of

10

187190 LW150A displacement pump

6 24A587 FILTER, fluid 1

7 ----- FITTING, union (included with Part 6) 1

8 189018 SWIVEL, fluid hose (packages with AA

gun)

9 241812 HOSE, fluid (packages with gun) 1

10 24C853 GUN, G15 Carbide 1

11 AAM413 TIP (packages with AA gun) 1

12 AAMxxx TIP OPTION (packages with AA gun) 1

13 ADAPTER, outlet 1

512351 LW025A or LW050A displacement

pump,1/4 nptm x 3/8 nptf

121238 LW150A displacement pump,

3/8 nptm x 3/4 nptf

14 256390 AIR HOSE, gun (all AA packages) 1

15 256410 HOPPER (includes 17, 19, 20, and 21) 1

Ref. Part Description Qty.

16 105332 NUT, lock, M5 x 0.08 (included with

Parts 2 and 49)

17 ----- TUBE, inlet, hopper (included with Part

15)

18 ----- CLIP, hose (all AA packages), see page

46 for packages of 10

19 ----- O-RING, hopper (included with Part 15) 1

20 ----- SCREEN, hopper (included with Part

15)

21 ADAPTER, 3/4 in. to 1/2 in. 1

----- LW025A displacement pump with

hopper (included with Part 15)

24B299 LW050A or LW075A displacement

1

22 239069 HOSE, whip 1

23 111799 SCREW, M8 x 16 (included with

26 105335 SCREW (stand mount only) 1

37 166846 ADAPTER, for whip hose 1

48 238909 GROUNDING WIRE assembly 1

49 24E883 BRACKET, air control, wall and stand

53 289694 CART MOUNTING KIT; see page 43

54 24A578 WALL MOUNTING KIT; see page 43

55 24A577 STAND MOUNTING KIT; see page 43

----- Not sold separately.

NOTE: Replacement Warning labels, signs, tags, and cards

1

are available at no cost.

pump with suction hose

Parts 49, 53, and 54)

Wall and stand mount 6

Cart mount 4

mount only (includes Parts 16 and 23)

(G15Cxx models only)

(G15Wxx models only)

(G15Txx models only)

2

1

7

1

1

1

1

1

34 312797P

Page 35

G18xxx Models

This list includes all possible parts for G18xxx packages. See page 8 to check whether a part is included in your

particular package.

Parts

Ref. Part Description Qty.

1 Pump Assembly, see Manual 312794 1

W18EAS M12LN0 x LW125A

W18EBS M12LT0 x LW125A

2 PANEL, air controls (includes 3b) 1

24A583 pump only; see page 45

24A581 pump and gun; see page 44

3a 24A576 DATATRAK, assembly; see manual

313541

3b ----- INSERT, panel (included with Part 2) 1

4 HOSE, suction (includes Part 5) 1

256422 cart mount packages

256424 wall mount packages

5 187190 STRAINER (included with Part 4) 1

6 24A587 FILTER, fluid 1

7 ----- FITTING, union (included with Part 6) 1

8 189018 SWIVEL, fluid hose (packages with AA

gun)

9 241812 HOSE, fluid (packages with gun) 1

10 GUN 1

24C855 G40

24C857 G40 with RAC tip

11 AAM413 TIP, (packages with gun) 1

12 AAMxxx TIP OPTION (packages with gun) 1

13 121237 ADAPTER, 3/8 nptm x

1/2 nptf

Ref. Part Description Qty.

14 256390 AIR HOSE, gun (all AA packages) 1

16 105332 NUT, lock, M5 x 0.08 (included with

Parts 2 and 49)

18 ----- CLIP, hose (all AA packages), see

page 46 for packages of 10

22 239069 HOSE, whip 1

23 111799 SCREW, M8 x 16 (included with

1

37 166846 ADAPTER, for whip hose 1

48 238909 WIRE, grounding assembly 1

49 24E883 BRACKET, air control, wall mount only

53 289694 CART MOUNTING KIT; see page 43

1

54 24A578 WALL MOUNTING KIT; see page 43

----- Not sold separately.

NOTE: Replacement Warning labels, signs, tags, and cards

are available at no cost.

1

Parts 49, 53, and 54)

Wall mount 6

Cart mount 4

(includes Parts 16 and 23)

(G18Cxx models only)

(G18Wxx models only)

2

7

1

1

1

312797P 35

Page 36

Parts

G23xxx Models

This list includes all possible parts for G23xxx packages. See page 8 to check whether a part is included in your

particular package.

Ref. Part Description Qty.

1 Pump Assembly, see Manual 312794 1

W23DAS M12LN0 x LW100A

W23DBS M23LT0 x LW100A

2 PANEL, air controls (includes 3b) 1

24A583 pump only; see page 45

24A581 pump and gun; see page 44

3a 24A576 DATATRAK, assembly; see manual

313541

3b ----- INSERT, panel (included with Part 2) 1

4 HOSE, suction (includes Part 5) 1

256421 cart mount packages

256423 wall mount packages

5 187146 STRAINER (included with Part 4) 1

6 24A587 FILTER, fluid 1

7 ----- FITTING, union (included with Part 6) 1

8 189018 SWIVEL, fluid hose (packages with AA

gun)

9 241812 HOSE, fluid (packages with gun) 1

10 GUN 1

XTR501 XTR 5

24C855 G40

24C857 G40 with RAC tip

11 AAM413 TIP (packages with G40 gun) 1

12 AAMxxx TIP OPTION (packages with G40 gun) 1

13 512351 ADAPTER, 1/4 nptm x 3/8 nptf 1

14 256390 AIR HOSE, gun (all AA packages) 1

15 256410 HOPPER (includes Parts 17, 19, and

20)

16 105332 NUT, lock, M5 x 0.08 (included with

Parts 2 and 49)

Ref. Part Description Qty.

17 ----- TUBE, inlet, hopper (included with

Part 15)

18 ----- CLIP, hose (all AA packages), see

page 46 for packages of 10

19 ----- O-RING, hopper (included with Part

15)

20 ----- SCREEN, hopper (included with Part

1

22 239069 HOSE, whip 1

23 111799 SCREW, M8 x 16 (included with

37 166846 ADAPTER, for whip hose 1

48 238909 WIRE, grounding assembly 1

49 24E883 BRACKET, air control, wall mount only

1

53 289694 CART MOUNTING KIT; see page 43

54 24A578 WALL MOUNTING KIT; see page 43

----- Not sold separately.

NOTE: Replacement Warning labels, signs, tags, and cards

are available at no cost.

1

2

15)

Parts 49, 53, and 54)

Wall mount 6

Cart mount 4

(includes Parts 16 and 23)

(G23Cxx models only)

(G23Wxx models only)

1

7

1

1

1

1

1

36 312797P

Page 37

G24xxx Models

This list includes all possible parts for G24xxx packages. See page 9 to check whether a part is included in your

particular package.

Parts

Ref. Part Description Qty.

1 Pump Assembly, see Manual 312794 1

W24FAS M18LN0 x LW150A

W24FBS M18LT0 x LW150A

2 PANEL, air controls (includes Part 3b) 1

24A583 pump only; see page 45

24A581 pump and gun; see page 44

3a 24A576 DATATRAK, assembly; see manual

313541

3b ----- INSERT, panel (included with Part 2) 1

4 HOSE, suction (includes Part 5) 1

256422 cart mount packages

256424 wall mount packages

5 187190 STRAINER (included with Part 4) 1

6 24A587 FILTER, fluid 1

7 ----- FITTING, union (included with Part 6) 1

8 189018 SWIVEL, fluid hose (packages with AA

gun)

9 241812 HOSE, fluid (packages with gun) 1

10 GUN 1

XTR501 XTR 5

24C855 G40

24C857 G40 with RAC tip

11 AAM413 TIP (Packages with G40 gun) 1

12 AAMxxx TIP OPTION (Packages with G40 gun) 1

13 121238 ADAPTER, 3/8 nptf x 3/4 nptm 1

Ref. Part Description Qty.

14 256390 AIR HOSE, gun (all AA packages) 1

16 105332 NUT, lock, M5 x 0.08 (included with

Parts 2 and 49)

18 ----- CLIP, hose (all AA packages), see

page 46 for packages of 10

22 239069 HOSE, whip 1

23 111799 SCREW, M8 x 16 (included with

1

37 166846 ADAPTER, for whip hose 1

48 238909 WIRE, grounding assembly 1

49 24E883 BRACKET, air control, wall mount only

53 289694 CART MOUNTING KIT; see page 43

1

54 24A578 WALL MOUNTING KIT; see page 43

----- Not sold separately.

NOTE: Replacement Warning labels, signs, tags, and cards

are available at no cost.

Parts 49, 53, and 54)

Wall mount 6

Cart mount 4

(includes Parts 16 and 23)

(G24Cxx models only)

(G24Wxx models only)

2

7

1

1

1

312797P 37

Page 38

Parts

G28xxx Models

This list includes all possible parts for G28xxx packages. See page 9 to check whether a part is included in your

particular package.

Ref. Part Description Qty.

1 Pump Assembly, see Manual 312794 1

W28EAS M18LN0 x LW125A

W28EBS M18LT0 x LW125A

2 PANEL, air controls (includes Part 3b) 1

24A583 pump only; see page 45

24A581 pump and gun; see page 44

3a 24A576 DATATRAK, assembly; see manual

313541

3b ----- INSERT, panel (included with Part 2) 1

4 HOSE, suction (includes Part 5) 1

256422 cart mount packages

256424 wall mount packages

5 187190 STRAINER (included with Part 4) 1

6 24A587 FILTER, fluid 1

7 ----- FITTING, union (included with Part 6) 1

8 189018 SWIVEL, fluid hose (packages with AA

gun)

9 241812 HOSE, fluid (packages with gun) 1

10 GUN 1

XTR501 XTR 5

24C855 G40

24C857 G40 with RAC tip

11 AAM413 TIP (Packages with AA gun) 1

12 AAMxxx TIP OPTION (Packages with AA gun) 1

13 121237 ADAPTER, 3/8 nptm x 1/2 nptf 1

Ref. Part Description Qty.

14 256390 AIR HOSE, gun (all AA packages 1

16 105332 NUT, lock, M5 x 0.08 (included with

Parts 2 and 49)

18 ----- CLIP, hose (all AA packages), see

page 46 for packages of 10

22 239069 HOSE, whip 1

23 111799 SCREW, M8 x 16 (included with

1

37 166846 ADAPTER, for whip hose 1

48 238909 WIRE, grounding assembly 1

49 24E883 BRACKET, air control, wall mount only

53 289694 CART MOUNTING KIT; see page 43

1

54 24A578 WALL MOUNTING KIT; see page 43

----- Not sold separately.

NOTE: Replacement Warning labels, signs, tags, and cards

are available at no cost.

Parts 49, 53, and 54)

Wall mount 6

Cart mount 4

(includes Parts 16 and 23)

(G28Cxx models only)

(G28Wxx models only)

2

7

1

1

1

38 312797P

Page 39

Parts

G30xxx Models

This list includes all possible parts for G30xxx packages. See page 10 to check whether a part is included in your

particular package.

Ref. Part Description Qty.

1 Pump Assembly, see Manual 312794 1

W30AAS M04LN0 x LW025A

W30ABS M04LT0 x LW025A

W30CAS M12LN0 x LW075A

W30CBS M12LT0 x LW075A

2 PANEL, air controls (includes Part 3b) 1

24A586 M04xxx motor, pump only, see

page 45

24A585 M04xxx motor, pump and gun; see

page 44

24A583 M12xxx motor, pump only; see

page 45

24A581 M12xxx motor, pump and gun; see

page 44

3a DATATRAK, assembly; see manual

313541

24A575 M04xxx motors

24A576 M12xxx motors

3b ----- INSERT, panel (included with Part 2) 1

4 HOSE, suction (includes Part 5) 1

256420 LW025A displacement pump

24C581 G30C37 Model

256421 LW075A displacement pump, cart

mount

256423 LW075A displacement pump, wall

mount

5 STRAINER (included with Part 4) 1

----- LW025A displacement pump, see

page 46 for packages of 10

187146 LW075A displacement pump

6 24A587 FILTER, fluid, assembly (if included,

uses parts 6a and 6b)

6a 24A587 FILTER, fluid, see Manual 307273 1

6b ----- FITTING, union 1

8 189018 SWIVEL, fluid hose (packages with AA

gun)

9 HOSE, fluid (packages with gun) 1

H52525 G30W57–G30W60

24B562 G30C13, G30C57, G30C69

241812 All other packages

10 GUN 1

XTR501 XTR 5

24C855 G40

24C857 G40 with RAC tip

11 AAM413 TIP (Packages with AA guns 1

12 AAMxxx TIP OPTION (Packages with AA guns) 1

13 512351 ADAPTER, 1/4 nptm x

3/8 nptf

Ref. Part Description Qty.

14 256390 AIR HOSE, gun, 25 ft (7.6 m); used on

most AA packages

256389 AIR HOSE, gun, 50 ft (15.2 m); Model

G30C69 only

15 256410 HOPPER (includes Parts 17, 19, and

20)

16 105332 NUT, lock, M5 x 0.08 (included with

Parts 2 and 49)

17 ----- TUBE, inlet, hopper (included with Part

15)

18 ----- CLIP, hose (all AA packages), see page

46 for packages of 10

19 ----- O-RING, hopper (included with Part 15) 1

20 ----- SCREEN, hopper (included with Part

1

21 ----- ADAPTER, 3/4 in. to 1/2 in.,

22 239069 HOSE, whip 1

23 111799 SCREW, M8 x 16 (included with

26 105335 SCREW (stand mount only) 1

37 166846 ADAPTER, for whip hose 1

41 256425 VALVE, drain, stainless steel (if

44 ----- COUPLING, hose, drain (included with

45 ----- HOSE, drain (included with Part 41) 1

48 238909 GROUNDING WIRE assembly 1

49 24E883 BRACKET, air control, wall and stand

1

53 289694 CART MOUNTING KIT; see page 43

54 24A578 WALL MOUNTING KIT; see page 43

1

55 24A577 STAND MOUNTING KIT; see page 43

----- Not sold separately.

NOTE: Replacement Warning labels, signs, tags, and cards

are available at no cost.

1

15)

(LW025A only, included with Part 15)

Parts 49, 53, and 54)

Wall and stand mount 6

Cart mount 4

equipped, includes Parts 44 and 45)

Part 41)

mount only (includes Parts 16 and 23)

(G30Cxx models only)

(G30Wxx models only)

(G30Txx models only)

1

1