Page 1

Repair/Parts

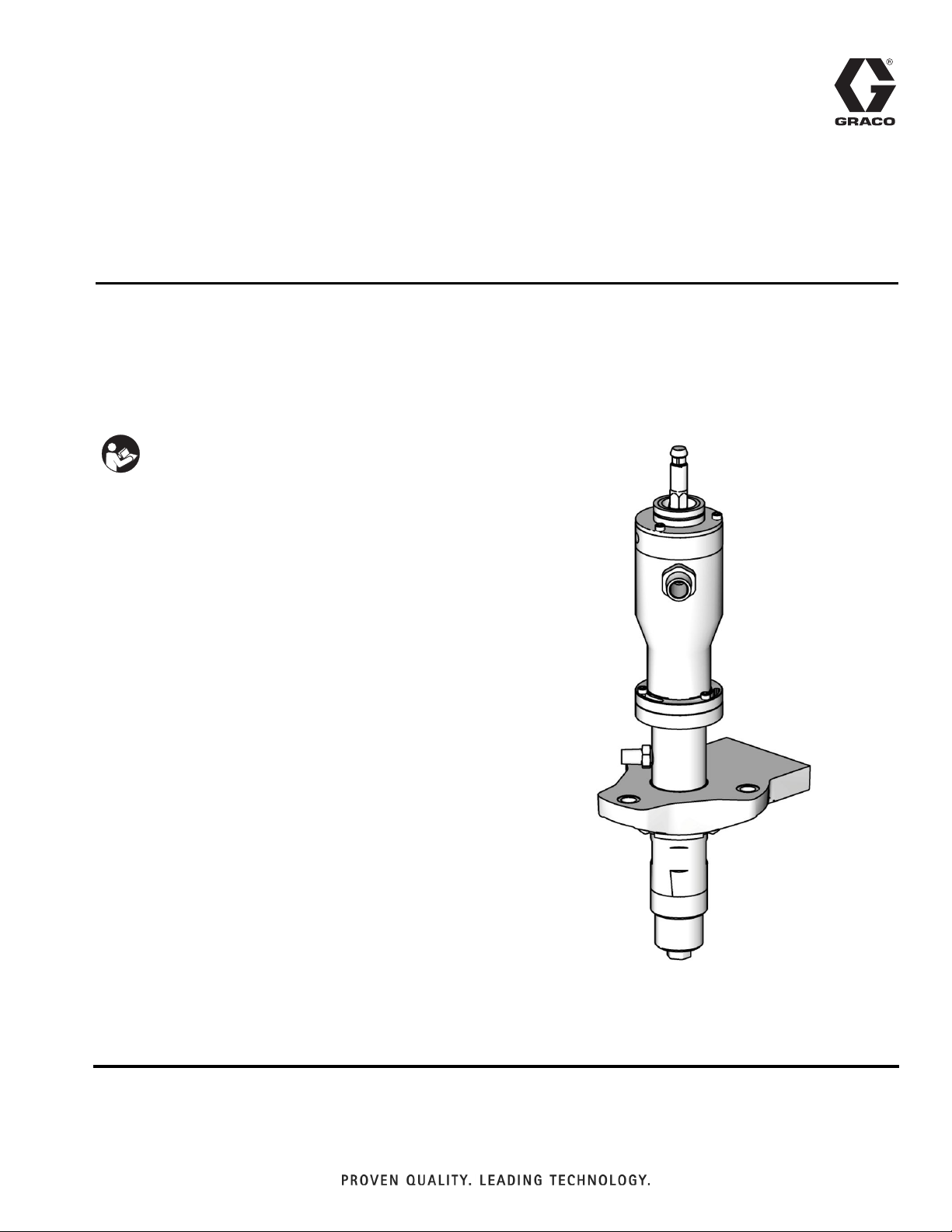

Merkur

™

Bellows

312793H

Displacement Pump

For pumping isocyanates, UV coatings, and other moisture-sensitive materials. For

professional use only.

See page 6 for model information, including maximum working pressures.

Important Safety Instructions

Read all warnings and instructions in this manual.

For complete warnings and instructions see your

pump or package manual. Hazard symbols refer to

specific procedure risks. Save these instructions.

EN

ti14532a

Page 2

Related Manuals

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Important Two-Component Material Information . 5

Isocyanate Conditions . . . . . . . . . . . . . . . . . . . . . 5

Material Self-ignition . . . . . . . . . . . . . . . . . . . . . . 5

Keep Components A and B Separate . . . . . . . . . 5

Moisture Sensitivity of Isocyanates . . . . . . . . . . . 5

Changing Materials . . . . . . . . . . . . . . . . . . . . . . . 5

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Component Identification . . . . . . . . . . . . . . . . . . . . 7

Related Manuals

Manual Description

312795 Merkur Bellows Pump Assembly

312796

312799 Merkur Bellows Spray Packages, AA and

312798 Merkur Electrostatic Spray Packages

™

NXT

Airless

Air Motor

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

General Information . . . . . . . . . . . . . . . . . . . . . . . 8

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Replace the Bellows . . . . . . . . . . . . . . . . . . . . . . 9

Complete Pump Repair . . . . . . . . . . . . . . . . . . . 11

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Repair Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Optional Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 24

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 24

2 312793H

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual, refer back to these Warnings. Product-specific hazard symbols and

warnings not covered in this section may appear throughout the body of this manual where applicable.

WARNING

WARNINGWARNINGWARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

312793H 3

Page 4

Warnings

WARNING

WARNINGWARNINGWARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about

your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure. Turn off all equipment

and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure and disconnect all power sources.

SUCTION HAZARD

Powerful suction could cause serious injury.

• Never place hands near the pump fluid inlet when pump is operating or pressurized.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear chemically impermeable gloves when spraying, dispensing, or cleaning equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area

of the equipment to help protect you from serious injury, including eye injury, hearing loss, inhalation of

toxic fumes, and burns. This equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

4 312793H

Page 5

Important Two-Component Material Information

Important Two-Component Material Information

Isocyanate Conditions

Spraying or dispensing materials containing isocyanates creates potentially harmful mists, vapors, and

atomized particulates.

Read material manufacturer’s warnings and material

MSDS to know specific hazards and precautions

related to isocyanates.

Prevent inhalation of isocyanate mists, vapors, and

atomized particulates by providing sufficient ventilation in the work area. If sufficient ventilation is not

available, a supplied-air respirator is required for

everyone in the work area.

To prevent contact with isocyanates, appropriate personal protective equipment, including chemically

impermeable gloves, boots, aprons, and goggles, is

also required for everyone in the work area.

Material Self-ignition

Some materials may become self-igniting if applied

too thickly. Read material manufacturer’s warnings

and material MSDS.

Moisture Sensitivity of Isocyanates

Isocyanates (ISO) are catalysts used in two component

coatings. ISO will react with moisture (such as humidity)

to form small, hard, abrasive crystals, which become

suspended in the fluid. Eventually a film will form on the

surface and the ISO will begin to gel, increasing in viscosity. If used, this partially cured ISO will reduce performance and the life of all wetted parts.

NOTE: The amount of film formation and rate of crystallization varies depending on the blend of ISO, the

humidity, and the temperature.

To prevent exposing ISO to moisture:

• Always use a sealed container with a desiccant

dryer in the vent, or a nitrogen atmosphere. Never

store ISO in an open container.

• Use moisture-proof hoses specifically designed for

ISO, such as those supplied with your system.

• Never use reclaimed solvents, which may contain

moisture. Always keep solvent containers closed

when not in use.

• Never use solvent on one side if it has been contaminated from the other side.

• Always lubricate threaded parts with ISO pump oil

or grease when reassembling.

Changing Materials

Keep Components A and B Separate

Cross-contamination can result in cured material in

fluid lines which could cause serious injury or damage equipment. To prevent cross-contamination of

the equipment’s wetted parts, never interchange

component A (isocyanate) and component B (resin)

parts.

312793H 5

• When changing materials, flush the equipment multiple times to ensure it is thoroughly clean.

• Always clean the fluid inlet strainers after flushing.

• Check with your material manufacturer for chemical

compatibility.

Most materials use ISO on the A side, but some use ISO

on the B side.

Page 6

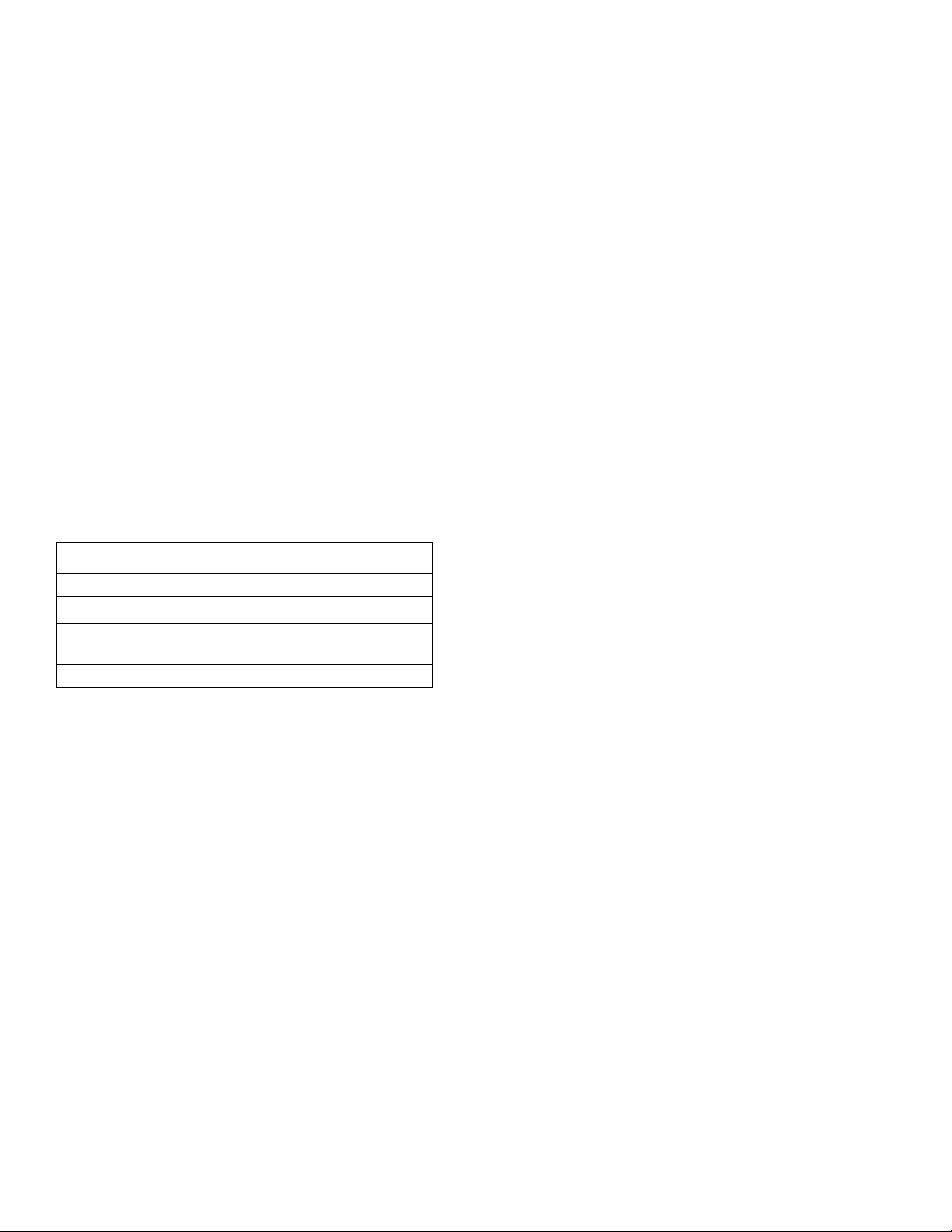

Models

Models

Check your displacement pump’s identification marking (ID) for the 6-digit part

number. Use the following matrix to define the construction of your displacement pump, based on the six digits. For example, displacement pump Part No.

LB100A represents a 303 stainless steel bellows style displacement pump,

100 cc, with 3 UHMWPE and 2 PTFE v-packings.

To order replacement parts, see Parts section starting on page 16. The digits

in the matrix do not correspond to the reference numbers in the Parts drawings

and lists.

L B 100 A

Third, Fourth, and Fifth

Digits

(Displacement Pump

First

Digit

Second Digit

(Material)

Volume Per Cycle in

cc)

ID

ti15221a

Sixth Digit

(Packings/Seals)

L

(Lower)

Part Number Series

LB050A

LB050B

LB100A

LB100B

LB150A

LB150B

B

Bellows Style

A 4500 (33.1, 310 3/4 in. npt 3/8 in. npt

A 3600 (24.8, 248) 3/4 in. npt 3/8 in. npt

A 2400 (16.5, 165) 1 in. npt 3/4 in. npt

050 A

100 B

150

Maximum Working

Pressure

psi (MPa, bar)

V-Packings (3 UHMWPE, 2 PTFE)

U-Cup Seal

Fluid Inlet Fluid Outlet

6 312793H

Page 7

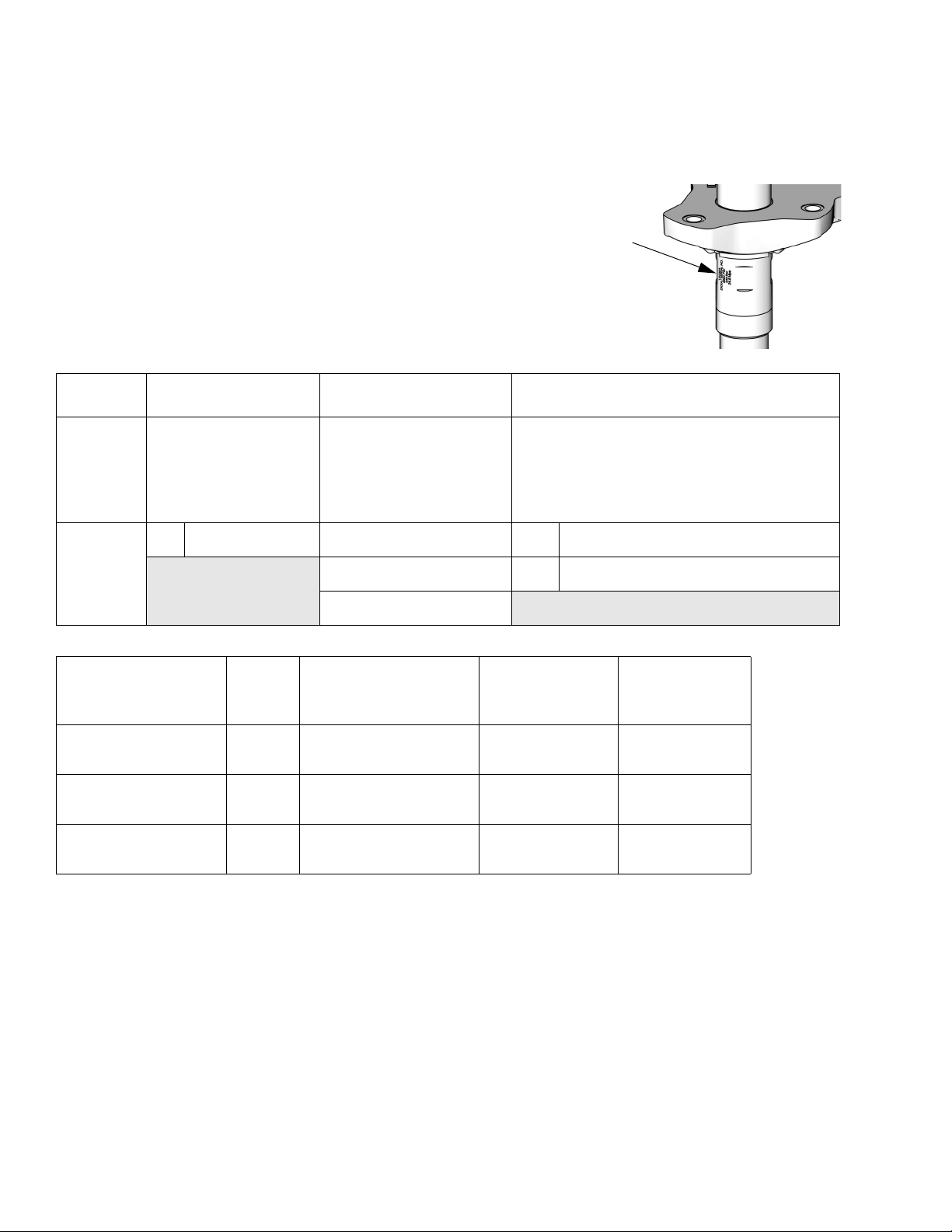

Component Identification

A

D

G

H

Component Identification

B

C

E

F

FIG. 1. Component Identification

Key:

A Connecting Rod

B Top Cap

C Pump Fluid Inlet

D Bellows Chamber

E Packing Nut

F Cylinder

G Pump Fluid Outlet

H Pump Adapter

J Foot Cap

J

ti14532a

312793H 7

Page 8

Repair

Repair

General Information

NOTE: Reference numbers and letters in parentheses

in the text refer to the callouts in the figures.

Always use Genuine Graco Parts and Accessories,

available from your Graco distributor. If you supply your

own accessories, be sure they are adequately sized and

pressure rated for your system.

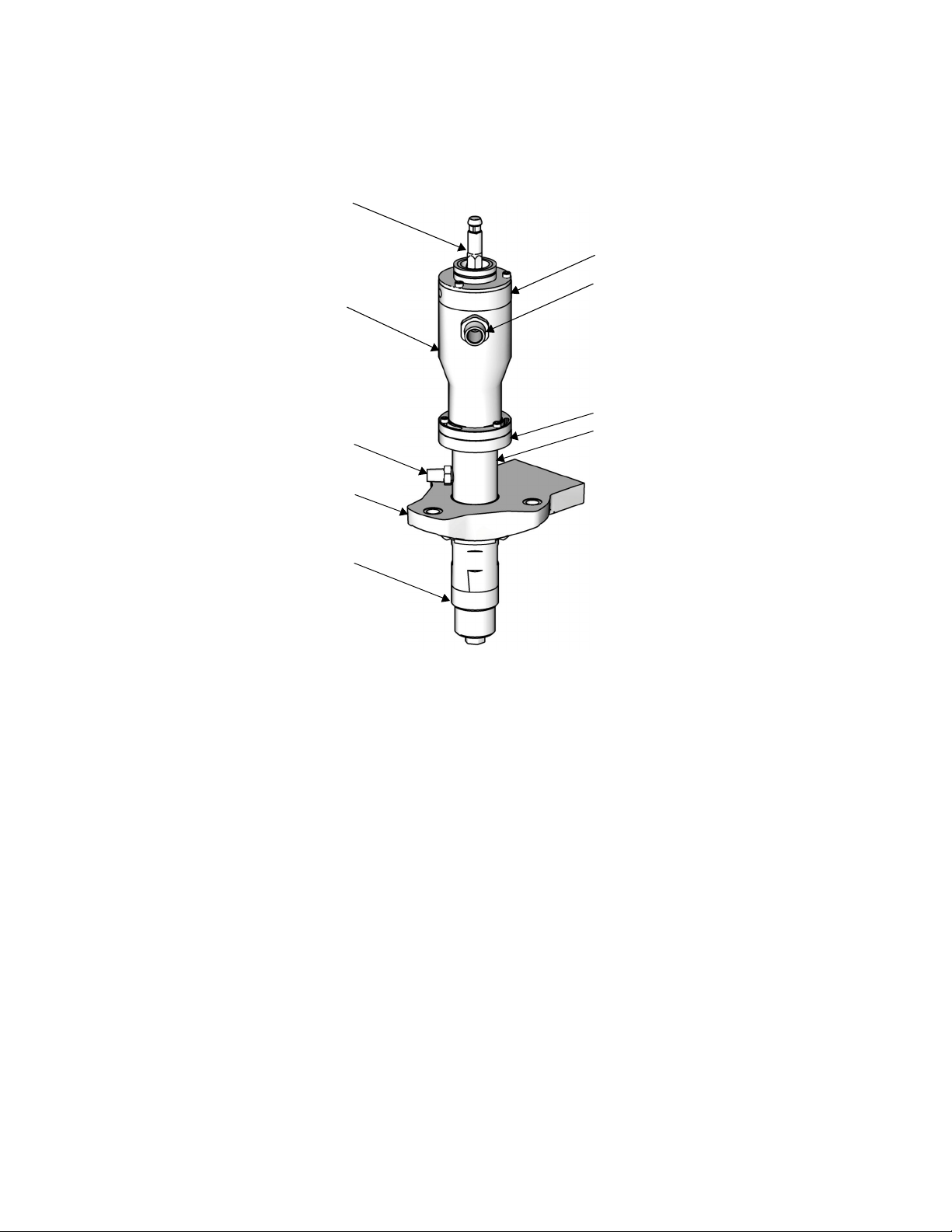

Preparation

Follow all warnings and instructions in your pump manual for the following preliminary steps:

1. Flush the equipment.

2. Stop the pump close to the middle of the stroke.

3. Relieve the pressure.

4. Disconnect the air and fluid hoses and the ground

wire.

6. Use a 5 mm hex wrench to loosen the screws (10)

on the top cap.

7. Hold the coupling nut

with a wrench. Use

another wrench to turn

the motor shaft. To

avoid damage to the

top cap and the

D-shaped seal, do not

turn the coupling nut.

8. Lower the coupling nut

and remove the coupling collars.

FIG. 2. Remove coupling collars.

9. Push up the motor shaft. Remove the coupling nut.

hold

ti12815a

ti14531a

ti15365a

turn

10

5. Remove the shield.

NOTE: If the overflow chamber (optional accessory)

contains fluid, unscrew the bottle (103) and discard. See

F

IG

. 4. If it has not been used, the bottle can remain

attached to the cap.

To avoid the buildup of electrostatic charge, do not

rub the plastic bottle with a dry cloth while it is

attached to the pump. Remove the bottle to clean, if

needed.

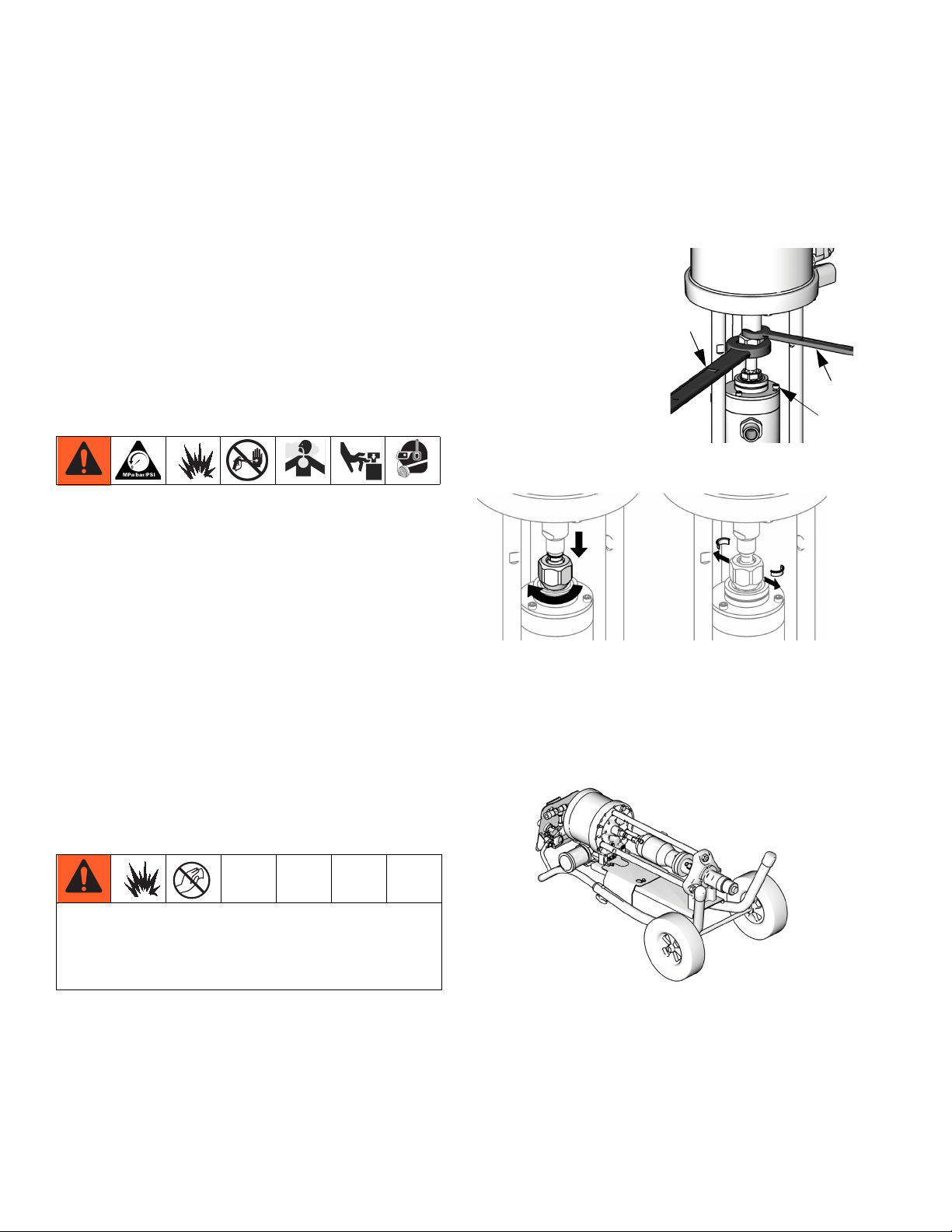

10. Cart Mount: Tilt the cart onto its back to service the

displacement pump.

ti15253a

FIG. 3. Tilt pump for repair.

8 312793H

Page 9

Repair

Replace the Bellows

Disassemble Bellows and Chamber

NOTICE

To avoid damage to the top cap and D-shaped seal,

never apply torque to the connecting rod.

1. Follow all steps under Preparation, page 8.

2. Use a 5 mm hex wrench to remove the three screws

(10), then remove the shield mount spacer (9) and

the top cap (8). Remove and discard the bellows

chamber o-ring (12).

3. Leave the overflow chamber attached to the top cap

unless it needs to be replaced.

4. If replacing overflow chamber: Unscrew the bottle

(103) if not already removed, then remove the lid

(101) from the fitting (104). Discard the cup and lid.

Use a socket to remove the retaining nut (105) in

the top cap (8). Remove and discard the D-shaped

seal (106). Leave the fitting (104) attached to the

top cap (8) unless it needs to be replaced.

5. Use a socket to remove the foot cap (42). Remove

and discard the o-ring (41).

6. Hold the hex on the connecting rod (14) with a

19 mm (3/4 in.) wrench. Brace against tie rod or

bench so it cannot turn. Use a socket to loosen the

piston/rod assembly.

turn

hold

ti15252a

FIG. 5. Hold connecting rod steady.

7. See F

IG

. 6. Pull the connecting rod (14) and bellows

(7) out of the top of the bellows chamber (1). Leave

the bellows chamber (1) attached to the packing

nut.

8. Remove the bellows bushing (6) and the damaged

bellows (7).

105

106

8

FIG. 4. Overflow chamber

104

9. Remove the snap bushing (3). Remove and discard

the o-rings (4, 5).

101

102

103

ti15254a

312793H 9

Page 10

Repair

Reassemble Bellows and Chamber

1. Slide the bellows bushing (6) and new bellows (7)

on the connecting rod (14).

2. Install new o-rings (4 and 5) into snap bushing.

Grease and install snap bushing (3) on end of bellows and snap into place.

3. Put the bellows o-ring (12) loosely around the bellows (7). Push the connecting rod (14), with fully

assembled bellows (7) into the bellows chamber (1).

Hand tighten the connecting rod.

4. Hold the hex on the connecting rod (14) and use a

torque wrench to turn the piston (45). Torque to

74-86 ft-lb (100-117 N•m).

5. Make sure the o-ring (12) is against the top of the

bellows. Push the connecting rod (14) and bellows

(7) snugly into the bellows chamber (1).

6. Set top cap (8) on the connecting rod (14). Do not

tighten.

7. If Replacing Overflow Chamber: Order Kit

24E298. (See page 21.) Install the new D-shaped

seal (106) on the connecting rod (14). Hold connecting rod with 19 mm (3/4 in.) wrench. Install and

tighten the retaining nut (105). Torque to 100-120

in-lb (11-14 N•m). Do not overtighten.

8. Install a new foot cap o-ring (41). Grease and install

the foot cap (42). Torque to 54-66 ft-lb (73-89 N•m).

9. Push up on the motor shaft. Slide on the coupling

nut (55). Install the coupling collars (56).

10. Hold connecting rod with 19 mm (3/4 in.) wrench.

Install and tighten the coupling nut. Torque to 75-80

ft-lb (138-146 N•m).

11. If Replacing Overflow Chamber: Insert the o-ring

(102) into the lid (101). Tighten the new bottle (103)

with lid (101) attached, to the fitting (104).

12. Turn connecting rod (14) to align holes in top cap (8)

with holes on bellows chamber (1) so the D-flat in

the top cap faces the front of the pump. Reattach

the top cap (8) and shield mount spacer (9). Torque

screws (10) to 100-120 in-lb (11-14 N•m).

1

Apply grease.

2

Apply thread lubricant.

3

Torque to 100-120 in-lb (11-14 N•m).

4

Torque to 54-66 ft-lb (73-89 N•m).

5

Torque to 74-86 ft-lb (100-117 N•m).

10

3

9

FIG. 6. Replace bellows.

2 4

1

42

7

14

2 5

1

41

45

3

1

4

12

1

1

5

6

8

ti14533a

10 312793H

Page 11

Repair

Complete Pump Repair

Disassembly

1. Follow all steps under Preparation, page 8.

2. Use a socket to remove the foot cap (42). Remove

and discard the o-ring (41).

3. Use a 5 mm hex wrench to loosen the three screws

(10) on the top cap. Lift the air motor shaft to

remove the top cap (8) and the shield mount spacer

(9) from the bellows chamber.

4. Hold the hex on the connecting rod (14) with a 19

mm (3/4 in.) wrench so it cannot turn. Use a socket

to loosen the piston/rod assembly. See F

5. Pull the piston/rod assembly out of the bottom of the

cylinder (27).

6. V-Packing Models: Remove the piston packings

(37, 39), glands (38, 40), and spring (35). See F

14, page 14.

7. U-Cup Models: Remove the bearing (52), u-cup

(53), and washer (54). See F

IG

. 13, page 13.

8. Models with overflow chamber: If overflow chamber needs to be replaced, see Replace the Bel-

lows, page 9. If overflow chamber is fine, leave it

attached to the top cap.

IG

. 5.

IG

.

12. V-Packing Models: Remove the glands (23, 26),

throat packings (24, 25), and spring (22). See F

IG

.

10, page 12.

13. U-Cup Models: Use an o-ring pick or pliers to

remove the spring clip (51), the u-cup (50), and the

bearing (49). F

IG

. 11, page 13.

14. Remove and discard the packing nut top o-ring (2)

and bottom o-ring (21).

15. Put the hex of the piston rod (31) in a vise. Use a

1/2 in. hex wrench to remove the flow-through nut

(44) from the bottom of the piston (45).

16. Remove the o-ring (32) and seat (46). Remove from

vise and tip out the check ball (47).

1/2 in. hex

44

2

1

1

32

46

47

1

Apply lubricant.

2

Torque to 74-86 ft-lb

(100-117 N•m).

45

31

9. Remove the connecting rod (14) and bellows (7).

10. Use a 5 mm allen wrench to remove the three

screws (17) and washers (18), then remove the bellows chamber (1). Remove and discard the bellows

FIG. 7. Outlet check.

ti15410a

chamber o-ring (12).

11. Use a 54 mm (2 1/8 in.) socket wrench to remove

the packing nut (20).

312793H 11

Page 12

Repair

17. Put the hex of the piston (45) in a vise, then use a

23 mm socket to remove the piston rod (31).

18. Remove the piston o-ring (32) and seat (33).

Remove from vise and tip out the check ball (34)

and spring (36).

1

Apply grease.

2

Apply thread lubricant.

3

Torque to 91-109 ft-lb

(123-148 N•m).

31

2 3

32

1

33

34

36

45

ti14536a

FIG. 8. Piston check.

19. If the bellows is damaged, see Replace the Bellows, page 9. If not, leave the bellows attached to

the connecting rod.

2. Install check ball (34) and seat (33) in the top of the

piston. Grease and install new o-ring (32).

3. With hex of piston (45) still in vise, apply thread

lubricant and then use a socket to reattach the displacement rod (31). Torque to 91-109 ft-lb

(123-148 N•m).

4. Clamp the hex of piston rod in vise. Install new

check ball (47) and seat (46) in the bottom of the

piston. Grease and install new o-ring (32).

5. Grease and reinstall the flow-through nut (44).

Torque to 74-86 ft-lb (100-117 N•m).

6. Place the packing nut (20) upside down on the

bench so packings will align properly.

V-Packing Models: Lubricate and install the female

gland (26), new v-packings, 24, 25) and the male

gland (23) in the packing nut. Lips must face up,

so they will face toward the cylinder when the

packing nut is installed. Push packings all the way

in.

.

1

23

1

2

25

1

2

24

Reassembly

1. Clamp the hex of the piston (45) in a vise. Install

new spring (36) on the ball stop.

ti15496a

FIG. 9. Ball stop spring

1

Apply lubricant.

2

Lips face up

(toward cylinder

when installed).

ti15255a

FIG. 10. Throat v-packings

U-Cup Models: Lubricate and install the bearing

(49), the u-cup packing (50), and the spring clip

(51). U-cup must face up, so it will face toward

the cylinder when the packing nut is installed.

26

20

1

12 312793H

Page 13

1

Apply grease.

2

U-cup faces up

(toward cylinder

when installed).

Repair

11. V-Packing Models: Install new piston spring (35).

Lubricate and install male gland (40), new piston

packings (37, 39), and female gland (38) on the dis-

1

51

1

2

50

placement rod (31). Lips must face toward the

cylinder.

1

49

20

ti15259a

FIG. 11. U-Cup throat seal

7. Install the top o-ring (2) and the bottom o-ring (21)

on the packing nut (20).

8. V-Packing Models: Install the spring (22) in the top

of the cylinder (27).

9. Grease and reattach the packing nut (20). Torque to

54-66 ft-lb (73-89 N•m).

10. Use screws (17) and washers (18) to reattach the

bellows chamber (1). Align the screws so the inlet

fitting does not interfere with the tie rods. Torque

screws (17) to 100-120 in-lb (11-14 N•m).

1

Apply grease.

12. U-Cup Models: Lubricate and install the washer

(54), u-cup (53), and bearing (52). U-cup must face

toward the cylinder.

1

Apply lubricant.

2

Lips face toward

cylinder.

53

54

1

52

1

ti15260a

FIG. 13. U-Cup piston seal

1

2

Apply thread lubricant.

3

Torque to 100-120 in-lb (11-14 N•m).

4

Torque to 54-66 ft-lb (73-89 N•m).

2 4

20

1

1

2

22

1

1

21

18 (x 3)

17 (x 3)

3

FIG. 12. Bellows chamber and packing nut.

ti14534a

312793H 13

Page 14

Repair

1

Apply grease.

2

Apply thread lubricant.

3

Torque to 100-120 in-lb (11-14 N•m).

4

Torque to 91-109 ft-lb (123-148 N•m).

5

Lips face toward cylinder.

FIG. 14. Piston v-packings

31

2 4

45

1

5

39

35

1

1

40

37

1

5

38

1

41

1

23

42

ti14535a

13. Grease the outside of the displacement rod shaft

and the piston, near the hexes. Push the rod and

the piston into the cylinder (27).

14. If Replacing Bellows: Follow steps 1 and 2 under

Reassemble Bellows and Chamber, page 10, to

put new bellows on connecting rod.

15. See F

IG

. 6, page 10. Put the bellows o-ring (12)

loosely around the bellows (7). Push the connecting

rod (14), with fully assembled bellows (7) into the

bellows chamber (1). Hand tighten the connecting

rod.

16. Hold the hex on the connecting rod (14) and use a

torque wrench to turn the piston (45). Torque to

74-86 ft-lb (100-117 N•m).

17. Set top cap (8) on the connecting rod (14). Do not

tighten.

18. If Replacing Overflow Chamber: Order Kit

24E298. (See page 21.) Install the new D-shaped

seal (106) on the connecting rod (14). Hold connecting rod with 19 mm (3/4 in.) wrench. Install and

tighten the retaining nut (105). Torque to 100-120

in-lb (11-14 N•m). Do not overtighten.

20. Push up on the motor shaft. Slide on the coupling

nut (55). Install the coupling collars (56).

21. Hold air motor shaft. Install and tighten the coupling

nut. Torque to 75-80 ft-lb (138-146 N•m).

22. If Replacing Overflow Chamber: Insert the o-ring

(102) into the lid (101). Tighten the new bottle (103)

with lid (101) attached, to the fitting (104).

23. Turn connecting rod (14) to align holes in top cap (8)

with holes on bellows chamber (1). Reattach the top

cap (8) and shield mount spacer (9). Torque screws

(10) to 100-120 in-lb (11-14 N•m).

NOTE: The overflow chamber fits best if the D flat is

aligned to the front of the pump.

Inlet or Outlet Fitting Repair

Remove and replace the inlet or outlet fitting only if damaged. Replace one or both o-rings if a leak or seepage

is present and every time a fitting is removed. To reassemble, grease the o-ring and apply high-strength

thread locker to the fitting. Torque to 54-66 ft-lb

(73-89 N•m).

19. Install a new foot cap o-ring (41). Grease and install

the foot cap (42). Torque to 54-66 ft-lb (73-89 N•m).

14 312793H

Page 15

Repair

312793H 15

Page 16

Parts

Parts

Models with V-Packings

3

10

9

8

7

1

12

14

2

Lips face

down.

1

1

2

31

6

2

4

20

32

1

33

21

1

26

34

36

24

25

45

24

25

24

23

22

47

46

32

44

1

1

2

5

5

2

6

1

5

3

1

4

1

15

3

17

18

1

Apply grease.

27

1

35

19

40

37

Lips

28

6

29

39

37

face

up.

39

37

38

41

2

4

42

ti15222a

2

Apply thread lubricant.

3

Torque to 100-120 in-lb (11-14 N•m).

4

Torque to 54-66 ft-lb (73-89 N•m).

5

Torque to 74-86 ft-lb (100-117 N•m).

6

Torque to 91-109 ft-lb (123-148 N•m).

16 312793H

Page 17

Models with V-Packings

NOTE: Many parts are available in one or more Service/Repair kits. See page 20.

4

Ref Description Part Qty

1 BELLOWS CHAMBER KIT (includes 2,

12, 15, 17, 18, 21, 32, and 41)

LBO50A 24E758

LB100A and LB150A 24E759

2 O-RING, packing nut, top 113082 1

3 BUSHING, snap ----- 1

4 O-RING, snap bushing 110135 1

5 O-RING, snap bushing C20182 1

6 BUSHING, bellows ----- 1

7 BELLOWS KIT (includes 2, 4, 5, 12, 21,

32, and 41)

LB050A 24A267

LB100A and LB150A 24E764

8 TOP CAP KIT (includes 9, 10, and 12) 24A271 1

9 SPACER, shield mount ----- 1

10 SCREW, M6 x 40;

see Hardware Kit,

117030 3

page 20

12 O-RING, bellows chamber 116377 1

14 CONNECTING ROD KIT (includes 4, 5,

12, 32, and 41)

15 INLET FITTING KIT 1

LB050A and LB100A,

3/4-14 npt x 1 3/16-16 un

LB150A

1-11.5 npt x 1 3/16-16 un

17 SCREW, bellows chamber, M6 x 25,

24E762 1

24A842

24E711

117029 3

see Hardware Kit, page 20

18 WASHER, bellows chamber;

117018 3

see Hardware Kit, page 20

19 OUTLET FITTING KIT (includes 48) 1

LB050A and LB100A,

3/8-18 npt x 3/4-16 un

LB150A, 3/4-14 npt x 1 3/16-16 un 24A842

20 PACKING NUT KIT (includes 2, 12, 21,

32, and 41)

LB050A 24F837

LB100A 24F223

LB150A 24F224

21 O-RING, packing nut, bottom 1

LB050A 107078

LB100A 104537

LB150A 110492

22 SPRING ----- 1

23 GLAND, male ----- 1

24 V-PACKING, UHMWPE ----- 3

25 V-PACKING, PTFE ----- 2

26 GLAND, female ----- 1

24A840

Ref Description Part Qty

1

1

1

27 CYLINDER KIT (includes 2, 12, 19, 21,

32, 41, and 48)

LB050A 24A828

LB100A 24A829

LB150A 24A830

28 ADAPTER, pump ----- 1

29 JAM NUT 1

LB050A 24A635

LB100A 24A637

LB150A 24A639

31 DISPLACEMENT ROD KIT (includes 2,

12, 21, 32, and 41)

LB050A 24F492

LB100A 24F296

LB150A 24F295

32 O-RING, piston ----- 2

33 SEAT, tungsten carbide ----- 1

34 CHECK BALL, stainless steel 1

LB050A 101947

LB100A and LB150A 107203

35 SPRING ----- 1

36 SPRING, ball stop ----- 1

37 V-PACKING, UHMWPE ----- 3

38 GLAND, female ----- 1

39 V-PACKING, PTFE ----- 2

40 GLAND, male ----- 1

41 O-RING, foot cap ----- 1

42 FOOT CAP KIT (includes 41) 1

LB050A 24A831

LB100A 24A832

LB150A 24A833

44 FLOW-THROUGH NUT ----- 1

45 PISTON KIT (includes 2, 12, 21, 32, and

41)

LB050A 24F488

LB100A 24F489

LB150A 24F490

46 SEAT, tungsten carbide ----- 1

47 CHECK BALL, stainless steel 1

LB050A 101947

LB100A and LB150A 101859

48 O-RING, outlet fitting, not shown ----- 1

55 NUT, coupling 15T311 1

56 COLLARS, coupling;

pack of 10

NOTE: Replacement Danger and Warning labels, tags,

and cards are available at no cost.

see page 20 for

Parts

1

1

1

184128 2

--- Parts not sold separately. See pages 20-21for

available kits.

312793H 17

Page 18

Parts

Models with U-Cup Packings

3

10

9

8

1

2

1

31

7

1

12

U-cup

faces

down.

4

2

20

21

1

49

50

51

27

19

32

33

34

36

45

2

6

1

1

47

46

1

52

14

28

6

6

1

5

29

3

1

4

1

15

32

44

54

53

52

41

2

5

1

U-cup

faces

up.

3

17

18

1

Apply grease.

2

Apply thread lubricant.

3

Torque to 100-120 in-lb (11-14 N•m).

4

Torque to 54-66 ft-lb (73-89 N•m).

5

Torque to 74-86 ft-lb (100-117 N•m).

6

Torque to 91-109 ft-lb (123-148 N•m).

42

4

2

ti15261a

18 312793H

Page 19

Models with U-Cup Packings

NOTE: Many parts are available in one or more Service/Repair kits. See page 20.

Parts

Part

Ref. Description

1 BELLOWS CHAMBER KIT (includes 2,

12, 15, 17, 18, 21, 32, and 41)

LBO50B 24E758

LB100B and LB150B 24E759

2 O-RING, packing nut, top 113082 1

3 BUSHING, snap ----- 1

4 O-RING, snap bushing 110135 1

5 O-RING, snap bushing C20182 1

6 BUSHING, bellows ----- 1

7 BELLOWS KIT (includes 2, 4, 5, 12, 21,

32, and 41)

LB050B 24A267

LB100B and LB150B 24E764

8 TOP CAP KIT (includes 9, 10, and 12) 24A271 1

9 SPACER, shield mount ----- 1

10 SCREW, M6 x 40;

see Hardware Kit,

Number Qty

117030 3

page 20

12 O-RING, bellows chamber 116377 1

14 CONNECTING ROD KIT (includes 4, 5,

12, 32, and 41)

15 INLET FITTING KIT 1

LB050B and LB100B,

3/4-14 npt x 1 3/16-16 un

LB150B, 1-11.5 npt x 1 3/16-16 un 24E711

17 SCREW, bellows chamber, M6 x 25,

24E762 1

24A842

117029 3

see Hardware Kit, page 20

18 WASHER, bellows chamber;

see Hard-

117018 3

ware Kit, page 20

19 OUTLET FITTING KIT (includes 48) 1

LB050B and LB100B,

3/8-18 npt x 3/4-16 un

LB150B, 3/4-14 npt x 1 3/16-16 un 24A842

20 PACKING NUT KIT (includes 2, 12, 21,

32, and 41)

LB050B 24F837

LB100B 24F223

LB150B 24F224

21 O-RING, packing nut, bottom 1

LB050B 107078

LB100B 104537

LB150B 110492

27 CYLINDER KIT (includes 2, 12, 19, 21,

32, 41, and 48)

LB050B 24A828

LB100B 24A829

LB150B 24A830

28 ADAPTER, pump ----- 1

24A840

Part

Ref. Description

1

1

1

29 JAM NUT 1

31 DISPLACEMENT ROD KIT (includes 2,

32 O-RING, piston ----- 2

33 SEAT, tungsten carbide ----- 1

34 CHECK BALL, stainless steel 107203 1

36 SPRING, ball stop ----- 1

41 O-RING, foot cap 106259 1

42 FOOT CAP KIT (includes 41) 1

44 FLOW-THROUGH NUT ----- 1

45 PISTON KIT (includes 2, 12, 21, 32,

46 SEAT, tungsten carbide ----- 1

47 CHECK BALL, stainless steel 101859 1

48 O-RING, outlet fitting, not shown ----- 1

49 BEARING, throat ----- 1

50 U-CUP Packing, throat ----- 1

51 SPRING CLIP, throat ----- 1

52 BEARING, piston ----- 1

53 U-CUP Packing, piston ----- 1

54 WASHER, piston ----- 1

55 NUT, coupling 15T311 1

56 COLLARS, coupling;

LB050B 24A635

LB100B 24A637

LB150B 24A639

12, 21, 32, and 41)

LB050B 24F492

LB100B 24F296

LB150B 24F295

LB050B 24A831

LB100B 24A832

LB150B 24A833

and 41)

LB050B 24F488

LB100B 24F489

LB150B 24F490

see page 20 for

Number Qty

pack of 10

NOTE: Replacement Danger and Warning labels, tags,

and cards are available at no cost.

--- Parts not sold separately. See pages 20-21 for avail-

1

able kits.

1

1

184128 2

312793H 19

Page 20

Repair Kits

Repair Kits

Kit Description

O-Ring Kit - Includes o-rings (2, 4, 5, 12, 16, 21, 32, 41, and 48)

V-Packing Seal Kit

Includes: springs (22, 35), glands (23, 26, 38, 40), v-packings (24, 25,

37, 39), and o-rings (2, 12, 21, 32, and 41)

U-Cup Seal Kit

Includes: throat u-cup (50), bearing (49), and spring clip (51); piston

u-cup (53), bearing (52), and washer (54). Also includes o-rings (2, 12,

21, 32, and 41)

Bushing Kit

Includes: bellows bushing (6), snap bushing (3), and o-rings (2, 4, 5,

12, 16, 21, 32, and 41)

440 Stainless Steel Check Ball Kit

Includes: Check balls (34, 47), ball stop spring (36), and o-rings (2, 12,

21, 32, and 41).

Tungsten Carbide Seats and 440 Stainless Steel Balls Repair Kit

Includes seats (33, 46), check balls (34, 47), flow-through nut (44), and

o-rings (2, 12, 21, 32, and 41)

Displacement Rod/Connecting Rod/Piston Kit

Includes: displacement rod (31), piston (45), nylon extrusions (not in

parts list), connecting rod (14), bellows (7), snap bushing (3), bellows

bushing (6), seats (33, 46), check balls (34, 47), spring (36);

flow-through nut (44); coupling nut (55), coupling collars (56), and

o-rings (2, 4, 5, 12, 21, 32, and 41)

Piston Kits

Includes: piston (45), nylon extrusions (not in parts list), and o-rings (2,

12, 21, 32, and 41)

Hardware Kit

Includes: three top cap screws (10); three bellows chamber screws

(17) and three washers (18)

Coupling Collars Kit - Includes: 10-pack of coupling collars

LB050A

LB050B

24E713 24E714 24E715

24A655 24A656 24A657

24E716 24E631 24E632

24A268 24E766 24E766

24A661 24A662 24A662

24A787 24A788 24A788

24A649 24A650 24A651

24F488 24F489 24F490

24E712 24E712 24E712

24A619 24A619 24A619

LB100A

LB100B

LB150A

LB150B

20 312793H

Page 21

Optional Kits

Optional Kits

Kit Description

Reinforced PTFE V-Packing Kit*

Reinforced PTFE throat packings and glands, reinforced PTFE

piston packings and glands, o-rings, and springs

PTFE Bellows Kit*

Includes PTFE bellows and o-rings

316 Stainless Steel Check Ball Kit**

Includes: Check balls (34, 47), ball stop spring (36), and o-rings (2,

12, 21, 32 and 41).

316 Stainless Steel Seat and Ball Kit**

Includes: Seats (33, 46), check balls (34, 47), flow-through nut (44)

and o-rings (2, 12, 21, 32, and 41).

* Use with materials that cause chemical compatibility concerns with UHMWPE, such as acid catalyst materials.

** Replaces standard kits for high corrosive applications.

LB050A

LB050B

24J858 24J859 24J860

24J850 24J851 24J851

24T257 24T258 24T258

24A800 24A801 24A801

LB100A

LB100B

LB150A

LB150B

Accessories

Overflow Chamber Kit 24E298

Ref. Description Qty.

101 LID 1

102 O-RING 1

103 BOTTLE 1

104 FITTING, 2 x 1/4-18 npt 1

105 NUT, retaining 1

106 D-SHAPED SEAL, bellows 1

312793H 21

Page 22

Dimensions

Dimensions

Displacement Pump Dimensions

A

Displacement

Pump

LB050A, LB050B

LB100A, LB100B

LB150A, LB150B

* Height measured at midstroke.

(Height*)

in. (mm)

23.6 (599) 3/4 in. 3/8 in. 26 (11)

23.6 (599) 3/4 in. 3/8 in. 30 (13)

23.6 (599) 1 in. 3/4 in. 34 (15)

B

(Inlet Size)

in. npt

C

(Outlet Size)

in. npt

Weight

lbs (kg)

B

A

C

ti14532a

22 312793H

Page 23

Technical Data

Technical Data

Maximum fluid working pressure

LB050A and LB050B

LB100A and LB100B . . . . . . . . . . . . . . . . . . . . . . . . .

LB150A and LB150B . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum fluid inlet pressure . . . . . . . . . . . . . . . . . . . . . . 15 psi (0.1 MPa, 1.0 bar)

Maximum fluid temperature . . . . . . . . . . . . . . . . . . . . . . . 160°F (71°C)

Ambient temperature range . . . . . . . . . . . . . . . . . . . . . . . 35°–120°F (2°–49°C)

Stroke length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5 in.

Wetted parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PEEK, PTFE, stainless steel, tungsten carbide,

4500 psi (33.1 MPa, 310 bar)

3600 psi (24.8 MPa, 248 bar)

2400 psi (16.5 MPa, 165 bar)

UHMWPE

312793H 23

Page 24

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER,

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2010, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

contact your Graco distributor or call to identify the nearest distributor.

Graco reserves the right to make changes at any time without notice.

Original instructions.

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

This manual contains English. MM 312793

www.graco.com

Revision H- April 2014

Loading...

Loading...