Page 1

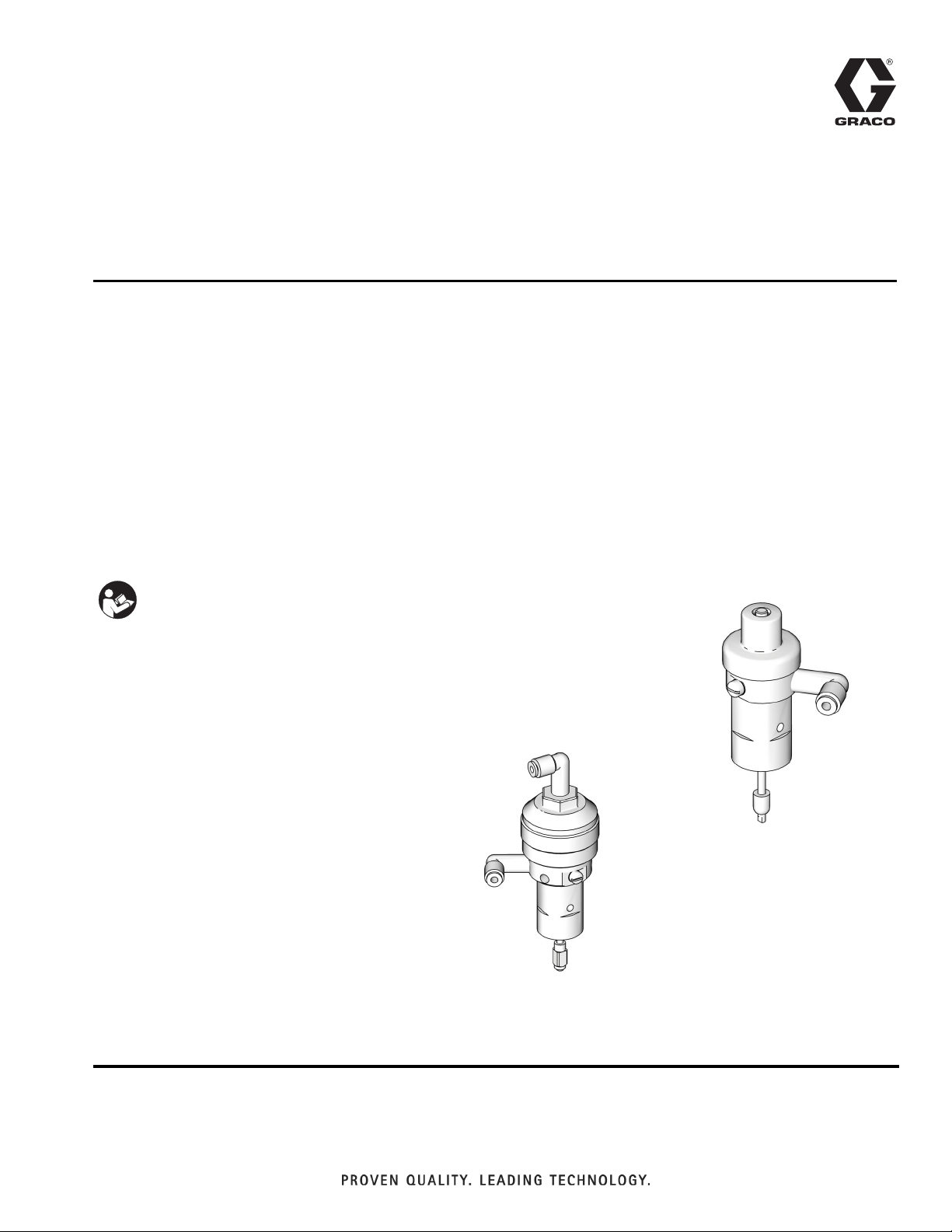

Instructions-Parts

Air Actuated

Dispense Valve

To dispense plural component fluids and solvents. For professional use only.

Part No. 15X303

High Pressure Dispense Valve

3000 psi (21 MPa, 207 bar) Maximum Fluid Working Pressure

100 psi (0.7 MPa, 7 bar) Maximum Air Working Pressure

Part No. 15X304

Low Pressure Dispense Valve

300 psi (2.1 MPa, 21.0 bar) Maximum Fluid Working Pressure

100 psi (0.7 MPa, 7 bar) Maximum Air Working Pressure

312782D

EN

Important Safety Instructions

Read all warnings and instructions in this manual. For complete

warnings and instructions see your proportioning system manual.

Hazard symbols refer to specific procedure risks. Save all instructions.

15X303 High Pressure Valve

15X304 Low Pressure Valve

TI11663A

TI11581A

Page 2

Related Manuals

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Connect the Air Lines . . . . . . . . . . . . . . . . . . . . . 3

Connect the Fluid Lines . . . . . . . . . . . . . . . . . . . 3

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

System Pneumatic Schematic (used with

ProMix 2KS) . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Settings and Adjustments . . . . . . . . . . . . . . . . . . 6

Pressure Relief Procedure . . . . . . . . . . . . . . . . . 6

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Clean the Dispense Valve Daily . . . . . . . . . . . . . 6

Flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

15X303 High Pressure Valve . . . . . . . . . . . . . . . 9

15X304 Low Pressure Valve . . . . . . . . . . . . . . . 10

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 12

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . 12

Related Manuals

See the following manuals for additional information on

the dispense valves.

Manual Description

312775 ProMix 2KS Manual System Installation

312776 ProMix 2KS Manual System Operation

312777 ProMix 2KS Manual System Repair-Parts

312778 ProMix 2KS Automatic System Installation

312779 ProMix 2KS Automatic System Operation

312780 ProMix 2KS Automatic System

Repair-Parts

312781 Fluid Mix Manifold

312782 Dispense Valve

312783 Color and Catalyst Change Valve Stacks

312787 Color Change Module Kit

2 312782D

Page 3

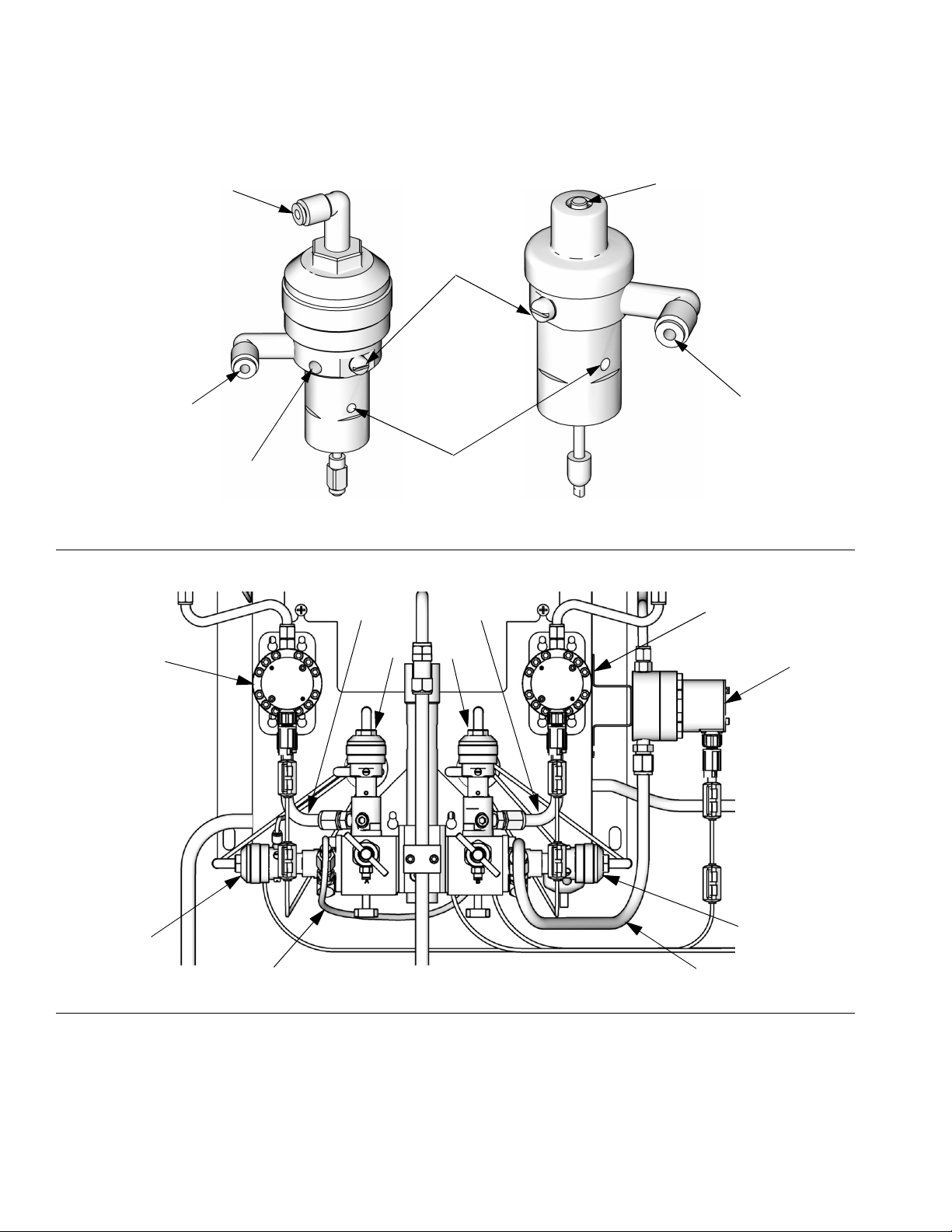

Installation

Installation

FIG. 2 shows the dispense valves installed in an electronic 2-component proportioning system. In this example, the dispense valves are used as dose valves for

components A and B (DVA, DVB), an air purge valve

(APV), and a solvent purge valve (SPV).

F

IG

. 3 shows a pneumatic schematic of a complete

2-component proportioning system, in which the dispense valves are also used as A and B dump valves,

and color change valves.

Connect the Air Lines

Clean all lines and connections of dirt, burrs, etc., and

blow them out with clean air before connecting them to

the system. The air supply line should contain an air filter to remove harmful dirt and moisture from the compressed air.

Use a normally closed 4-way air solenoid valve to control the dispense valve. Attach 5/32 in. (4 mm) OD air

supply lines from the 4-way valve to the air inlets of the

dispense valve.

Accessories

Two accessories are required in your system: a

bleed-type master air valve and a fluid drain valve.

These accessories help reduce the risk of serious injury

including fluid injection, splashing in the eyes or on the

skin, and injury from moving parts if you are adjusting or

repairing the pump.

The bleed-type master air valve is required only with

air-powered pumps. It relieves air trapped between this

valve and the pump after the air regulator is shut off.

Trapped air can cause the pump to cycle unexpectedly.

Locate the valve close to the pump.

The fluid drain valve helps relieve fluid pressure in the

displacement pump, hose, and dispense valve; triggering the valve to relieve pressure may not be sufficient.

Connect the Fluid Lines

Connect a grounded fluid line from the pump or meter to

the 1/4 npt fluid inlet of the dispense valve adapter.

If fluid is supplied by a pump, install a fluid pressure regulator upstream of the dispense valve. A fluid regulator

enables you to control fluid pressure more accurately

than by regulating air pressure to the pump.

Install a fluid filter to remove particles and sediment

which may clog the nozzle.

Grounding

To reduce the risk of static sparking, ground the pump

and all other components used or located in the dispensing area. Check your local electrical code for

detailed instructions for your area and type of equipment

and be sure to ground all of these components.

•

Fluid hoses:

with a maximum of 500 feet (150 m) combined hose

length to ensure grounding continuity.

•

Dispense valve:

tion to a properly grounded fluid hose and pump.

use only electrically conductive hoses

obtain grounding through connec-

312782D 3

Page 4

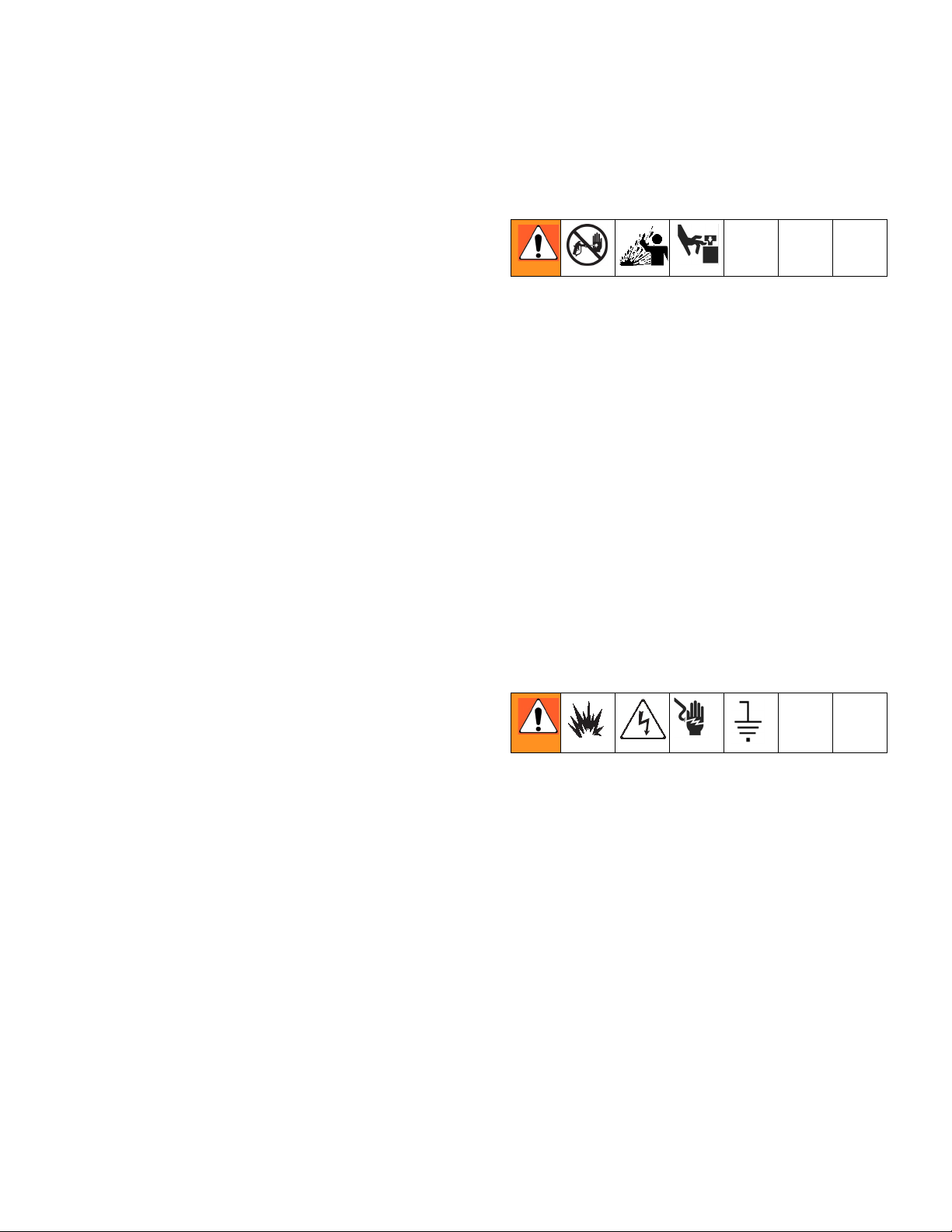

Installation

15X303 High Pressure Valve

5/32 in. (4 mm) OD air tube

fitting, to close

5/32 in. (4 mm) OD air tube

fitting, to open

Valve position

sight port

FIG. 1. Valve Air Ports

Seal weep port

and Lubrication

Cup connection

TI11581A

15X304 Low Pressure Valve

Actuation indicator

Optional air

open port

5/32 in. (4 mm) OD air tube

fitting, to open

TI11663A

MA

APV

APL SPL

IG

. 2: Typical Installation

F

Key:

MA Component A Meter

DVA Component A Dose Valve

MB Component B Meter

DVB Component B Dose Valve

MS Solvent Meter

SPV Solvent Purge Valve

DVA

BSLASL

DVB

APV Air Purge Valve

ASL Component A Supply Line

BSL Component B Supply Line

APL Air Purge Line

SPL Solvent Purge Line

MB

MS

SPV

TI12556a

4 312782D

Page 5

System Pneumatic Schematic (used with ProMix 2KS)

Installation

COLOR

CHANGE

AIR EXHAUST MUFFLER

12 VDC

4-WAY SOLENOID

12 VDC

TO MANIFOLD 1/4 TUBE

05

3/8 AIR FILTER

MANUAL DRAIN

5 MICRON

WALL MOUNT ONLY

PURGE AIR

MANIFOLD

CONTROL AIR

4-WAY SOLENOID

12 VDC

4-WAY SOLENOID

12 VDC

4-WAY SOLENOID

12 VDC

4-WAY SOLENOID

AIR EXHAUST MUFFLER

12 VDC

3-WAY SOLENOID

12 VDC

3-WAY SOLENOID

12 VDC

3-WAY SOLENOID

12 VDC

3-WAY SOLENOID

A

B

A

B

A

B

A

B

A

B

A

A

A

A

MANIFOLD

CLOSE

5/32 TUBE

OPEN

CLOSE

5/32 TUBE

OPEN

CLOSE

5/32 TUBE

OPEN

CLOSE

5/32 TUBE

OPEN

CLOSE

5/32 TUBE

OPEN

5/32 TUBE

OPEN

5/32 TUBE

OPEN

5/32 TUBE

OPEN

5/32 TUBE

OPEN

DOSE A

VALVE

DOSE B

VALVE

PURGE A

VALVE

PURGE B

VALVE

PURGE C

VALVE

(OPTIONAL)

DUMP A

VALVE

(OPTIONAL)

DUMP B

VALVE

(OPTIONAL)

GFB 1

VALVE

(OPTIONAL)

GFB 2

VALVE

(OPTIONAL)

FLUSH AIR TO FLUID INLET 1/4 TUBE

CONTROL

36 SERIES SOLENOID VALVES

COLOR

VALVE

STACKS

COLOR 1

COLOR 2

COLOR 3

COLOR 4

COLOR 5

COLOR 6

COLOR 7

COLOR 8

COLOR SOLVENT

COLOR 9

COLOR 10

COLOR 11

COLOR 12

CATALYST 1

CATALYST 2

CATALYST 3

CATALYST 4

CATALYST SOLVENT

COLOR 13

COLOR 14

COLOR 15

COLOR 16

COLOR 17

COLOR 18

COLOR 19

COLOR 20

COLOR 21

COLOR 22

COLOR 23

COLOR 24

COLOR 25

COLOR 26

COLOR 27

COLOR 28

COLOR 29

COLOR 30

MAC

FIG. 3. System Pneumatic Schematic

312782D 5

Page 6

Operation

Operation

Settings and Adjustments

Set the actuating air to at least 75 psi (0.52 MPa, 5.2

bar) and start the pump. Adjust the pump speed and

pressure to obtain the desired flow rate. Always use the

lowest pump speed necessary to get the results you

want.

To decrease needle travel, turn the cap (11, see pages

9 and 10) clockwise; to increase, turn counterclockwise.

The valve is factory set at one open turn. The maxi-

mum setting is four turns open.

Pressure Relief Procedure

1. Shut off the fluid supply to the dispense valve.

2. Actuate the dispense valve to relieve fluid pressure

in the valve.

NOTICE

Be sure the solvent used is compatible with the fluid

being dispensed, to avoid clogging the valve’s fluid

passages.

An important part of the care and maintenance of your

automatic dispense valve is proper flushing. Flush the

valve daily with a compatible solvent until all traces of

fluid are removed from the valve passages. Relieve the

pressure before flushing.

Clean the outside surfaces of the valve by wiping with a

soft cloth dampened with a compatible solvent.

NOTICE

Never immerse the entire dispense valve in solvent.

Immersing in solvent removes lubricants and may

damage the o-rings.

Flushing

3. Relieve fluid pressure upstream and downstream of

the dispense valve. See your system operation

manual.

4. If you suspect the spray tip or hose is clogged or

that pressure has not been fully relieved after following the steps above,

retaining nut or hose end coupling to relieve pressure gradually, then loosen completely. Clear hose

or tip obstruction.

very slowly

loosen tip guard

Maintenance

Clean the Dispense Valve Daily

Before flushing, be sure the entire system and flushing

pails are properly grounded. Refer to Grounding on

page 3. Relieve the pressure. Always use the lowest

possible fluid pressure, and maintain firm metal-to-metal

contact between the dispense valve and the pail during

flushing to reduce the risk of fluid injection injury, static

sparking, and splashing.

Start the pump and flush the system with a compatible

solvent as explained in the instructions for your pump.

Check the system under pressure for leaks; if any are

found, relieve the pressure and repair the leaks. Pressurize the system again and make sure the leaking has

stopped.

6 312782D

Page 7

Troubleshooting

Troubleshooting

Before servicing this equipment always make sure to

relieve the pressure.

NOTE: Check all possible causes and solutions before

disassembling.

Problem Cause Solution

Valve will not close. Fluid needle binding. Clean, repair.

Piston o-rings binding. Repair.

Obstructed or worn needle or seat. Clean or replace.

Valve will not open. Fluid needle binding. Clean or repair.

Piston o-rings binding. Repair.

No trigger or actuator pressure. Check, clean all lines.

Worn or dry piston o-rings. Replace.

Valve will not dispense. Fluid supply source is not operating. Check on fluid supply source.

Fluid line clogged. Clear.

Fluid valve closed. Open.

Clogged orifice or needle seat. Clean.

Repair

Disassembly

1. Relieve the pressure.

2. Flush the valve with a compatible solvent.

3. Relieve the pressure after flushing and disconnect

the fluid and air hoses.

4. Unscrew the cap (C) to remove spring pressure on

the valve.

NOTE: Another method of removing spring pressure is by applying air to the ON port, to lift the valve

needle off the seat.

5. Unscrew the dispense valve from the adapter (A).

Inspect the needle ball (B). Also inspect the seat (S)

in the adapter for damage. The seat is reversible.

See F

IG

. 4.

NOTE: See Fluid Mix Manifold Manual 312781 for seat

replacement instructions and part numbers.

ON Port

C

B

A

S

TI12822A

FIG. 4. Valve Adapter and Seat

312782D 7

Page 8

Repair

NOTE: See the parts drawings on pages 9 and 10.

6. Unscrew valve cap (11). Remove the spring (12).

7. Hold the needle flats with a wrench to keep it from

turning. Unscrew the piston (9, high pressure

valves) or retainer (10, low pressure valves) from

the needle.

8. Remove the o-rings (7, 8) from the piston (9).

9. Push the needle (22) from the top while pulling it

from the bottom of the fluid body (3).

NOTE: Needle may be hard to remove.

10. Unscrew the needle ball assembly (23) from the

needle (22).

11. Unscrew the fluid body (3) from the air body (6).

Remove the packing (19), bearing (5), and u-cup (4)

from the fluid body.

12. On high pressure valves, remove the o-ring (17)

from the air body (6).

13. Clean, inspect, and replace parts as needed.

Reassembly

NOTE: Seal Kits 15U933 (for high pressure dispense

valve 15X303) and 15W621 (for low pressure dispense

valve 15X304) are available to replace the seals. Parts

included in the kit are marked with an asterisk, for example (4*). For best results, use all the parts in the kit.

NOTE: Use the 262028 Seal Installation Tool (supplied

with the ProMix 2KS) to ensure proper installation of the

u-cup (4).

1. Using the 262028 Installation Tool, install the u-cup

(4*) into the fluid body (3) with the lips facing down.

Install the bearing (5*) and packing (19*).

5. On high pressure valves, install the o-ring (17*) on

the air body (6).

6. Install the o-rings (7*, 8*) on the piston (9). Lubricate

the o-rings.

7. Reinstall the piston (9):

a.

On high pressure valves,

to the top threads of the needle (22*). Holding

the needle (22) steady by its flats, screw the piston (9) onto the needle (22*).

b.

On low pressure valves,

the needle (22*). Apply thread sealant to the top

threads of the needle. Holding the needle (22)

steady by its flats, screw the retainer (10) onto

the needle.

8. Before performing step 9, screw the dispense valve

securely into the adapter (A, F

9. Install the spring (12) and valve cap (11).

NOTE:

(11) onto the air body (6) only until slight resistance is

felt as the cap contacts the o-ring (17*). Do not tighten

the valve cap (11) at this time.

10. Screw the valve cap (11) down onto the air body (6)

11. Unscrew the valve cap (11) one complete turn for

NOTE: To decrease needle travel, turn the cap (11)

clockwise; to increase, turn counterclockwise. The valve

is factory set at one open turn. The maximum setting

is four turns open.

On high pressure valves,

until additional resistance is felt and the cap is tight

with the body.

the factory needle setting, or unscrew cap to setting

prior to repair.

apply thread sealant

slide the piston (9) onto

IG

. 4).

screw the valve cap

2. Slide the needle (22*) into the fluid body (3)

the top,

and u-cup (4).

3. Apply thread sealant and screw the needle ball

assembly (23*) onto the needle (22*).

4. Apply thread sealant and screw the fluid body (3)

onto the air body (6).

8 312782D

down through the packing (19), bearing (5),

from

Page 9

Parts

15X303 High Pressure Valve

6

13

15

*17

15

11

12

8*

9

7*

14

22*

Parts

Ref.

No. Part No. Description Qty

3 --- BODY, fluid 1

4* --- SEAL, u-cup, spring applied;

uhmwpe

5* --- BEARING, needle 1

6 --- BODY, air 1

7* --- O-RING, shaft, piston; buna-N 1

8* --- O-RING, body, piston; buna-N 1

9 15T413 PISTON 1

11 --- CAP, valve 1

12 15T454 SPRING, compression 1

13 104640 GASKET; buna-N 2

14 104644 PLUG, screw 2

15 109193 ELBOW, tube fitting; 10-32 x 5/32

in. (4 mm) OD tube

17* --- O-RING, body, air; buna-N 1

19 --- PACKING; uhmwpe 1

20* --- O-RING; ptfe 1

22* --- SHAFT, needle 1

23* --- BALL ASSEMBLY, needle 1

24 15V818 VENT, breather; not shown; remove

(15) and install breather vent in (11)

when valve is used as dump valve

or color change valve

25‡ 17B969 SPRING, compression (not shown) 1

1

2

1

19*

5*

4*

3

23*

20*

TI11582A

*

Parts included in Seal Kit 15U933 (purchase separately).

---

These parts are not available separately.

‡ Remove (12) and replace with this spring (marked

with black stain) when valve is used as a dump valve

or color change valve.

15V737 Valve Lubricator Cup (Option)

Install in fluid body (3) to lubricate seal (4).

TI13019A

312782D 9

Page 10

Parts

15X304 Low Pressure Valve

13

14

11

12

10

9

6

15

22*

8*

7*

Ref.

No. Part No. Description Qty

3 --- BODY, fluid 1

4* --- SEAL, u-cup, spring applied;

uhmwpe

5* --- BEARING, needle 1

6 --- BODY, air 1

7* --- O-RING, shaft, piston; buna-N 1

8* --- O-RING, body, piston; buna-N 1

9 180538 PISTON 1

10 15T452 RETAINER, piston 1

11 180612 CAP, valve 1

12 108017 SPRING, compression 1

13 104640 GASKET; buna-N 2

14 104644 PLUG, screw 2

15 109193 ELBOW, tube fitting; 10-32 x 5/32

in. (4 mm) OD tube

19* --- PACKING; uhmwpe 1

20* --- O-RING; ptfe 1

22* --- SHAFT, needle 1

23* --- BALL ASSEMBLY, needle 1

1

1

*19

*5

*4

3

23*

20*

TI11664A

*

Parts included in Seal Kit 15W621 (purchase separately).

---

These parts are not available separately.

15V737 Valve Lubricator Cup (Option)

Install in fluid body (3) to lubricate seal (4).

TI13019A

10 312782D

Page 11

Technical Data

Air Specifications

Maximum Air Input Pressure . . . . . . . . . . . . . . . . . . . 100 psi (0.7 MPa, 7 bar)

Minimum Air Pressure . . . . . . . . . . . . . . . . . . . . . . . . 75 psi (0.52 MPa, 5.2 bar)

Air Inlet Fitting Size . . . . . . . . . . . . . . . . . . . . . . . . . . 5/32 in. (4 mm) OD tube

Fluid Specifications

Maximum Fluid Working Pressure . . . . . . . . . . . . . . . Model 15X303: 3000 psi (21 MPa, 207 bar)

Model 15X304: 300 psi (2.1 MPa, 21 bar)

Wetted Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303 SST, 17-4PH SST, Tungsten Carbide (with nickel

binder), UHMWPE

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Model 15X303: 0.5 lb (0.23 kg)

Model 15X304: 0.3 lb (0.14 kg)

Technical Data

312782D 11

Page 12

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2008, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM

312782

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revision D, August 2014

Loading...

Loading...