Page 1

Instruction Manual

Full Line Software with

Reynolds & Reynolds Certified

Interface

For use with Graco Matrix Electronic Meter and Tank Level Monitor Components.

312353B

EN

Graco Inc. P.O. Box 1441 Minneapolis, MN 55440-1441

Copyright 2007, Graco Inc. is registered to I.S. EN ISO 9001

Page 2

Contents

System Requirements . . . . . . . . . . . . . . . . . . . . . . . 3

General Matrix System Specifications . . . . . . . . 3

PC Hardware Requirements . . . . . . . . . . . . . . 3

PC Software Requirements . . . . . . . . . . . . . . . 4

Pop-Up Blocker . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Software Firewalls . . . . . . . . . . . . . . . . . . . . . . . . 6

Windows XP Security . . . . . . . . . . . . . . . . . . . . . 7

Installation Instructions . . . . . . . . . . . . . . . . . . . . . 8

Stand Alone Configuration . . . . . . . . . . . . . . . . . 8

Networked Configurations . . . . . . . . . . . . . . . . . . 8

Browser Configuration . . . . . . . . . . . . . . . . . . . . . 9

Setup Path 1- Typical (Matrix Server and Client) 9

HASP Key Driver Setup Program . . . . . . . . . 12

Matrix Server and Client Shortcuts . . . . . . . . 13

Setup Path 2 - Matrix Client Only. . . . . . . . . . . . 13

Matrix Client Only Shortcuts . . . . . . . . . . . . . 16

Sun Java Runtime . . . . . . . . . . . . . . . . . . . . . . . 17

Clock and Time Zone Settings . . . . . . . . . . . 18

MatrixLogs Folder . . . . . . . . . . . . . . . . . . . . . . . 18

How to Turn Off Hibernation

Mode in Windows XP . . . . . . . . . . . . . . . . . . 19

Software Installation Troubleshooting . . . . . . . . 21

Uninstalling Matrix on Windows XP . . . . . . . . . 24

Operator Screens . . . . . . . . . . . . . . . . . . . . . . . . . 25

Meter Dispense Information . . . . . . . . . . . . . . . 25

Tank Level Information . . . . . . . . . . . . . . . . . . . 26

Battery Level Information . . . . . . . . . . . . . . . . . 27

Entering Work Orders . . . . . . . . . . . . . . . . . . . . 27

Work Orders and the Matrix/R & R Interface . 28

Work Order Pop-up Windows . . . . . . . . . . . . 30

System Administrator Screens . . . . . . . . . . . . . . 32

Matrix System Setup . . . . . . . . . . . . . . . . . . . . . 32

System Configuration . . . . . . . . . . . . . . . . . . . . 33

Security Level (Global Setting) . . . . . . . . . . . 33

System Emergency Code . . . . . . . . . . . . . . . 33

Unit of Measure (English or Metric) . . . . . . . . 34

Edit Contact Information. . . . . . . . . . . . . . . . . 34

Transceiver Setup . . . . . . . . . . . . . . . . . . . . . . . 35

Transceiver Power-up . . . . . . . . . . . . . . . . . . 35

Confirm PC/Transceiver Communication. . . . 35

Matrix Client PC Setup . . . . . . . . . . . . . . . . . . . 36

Add a Client PC to the Matrix System . . . . . . 37

System User Setup . . . . . . . . . . . . . . . . . . . . . . 38

Adding a New User . . . . . . . . . . . . . . . . . . . . . . 38

Modify User Profile. . . . . . . . . . . . . . . . . . . . . 38

Changing User Information. . . . . . . . . . . . . . . 39

Removing a User . . . . . . . . . . . . . . . . . . . . . 39

Tank Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Customized Fluid Setup . . . . . . . . . . . . . . . . 39

Adding a New Tank using a TLM . . . . . . . . . 40

2 312353B

Tank Shape Screen . . . . . . . . . . . . . . . . . . . . 41

Manual Tank Adjustment . . . . . . . . . . . . . . . . . . 42

Removing a Tank . . . . . . . . . . . . . . . . . . . . . . . . 42

Programming the Tank Level Monitor . . . . . . . . 43

Meter Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Adding a Meter . . . . . . . . . . . . . . . . . . . . . . . 45

Modifying Meter Information . . . . . . . . . . . . . 45

Removing a Meter . . . . . . . . . . . . . . . . . . . . . 47

Meter Programming . . . . . . . . . . . . . . . . . . . . 47

E-Mail Setup . . . . . . . . . . . . . . . . . . . . . . . . . . 49

E-mail Configuration . . . . . . . . . . . . . . . . . . . 49

Adding an E-Mail Event . . . . . . . . . . . . . . . . . 50

Removing an E-Mail Event . . . . . . . . . . . . . . 50

R&R Interface . . . . . . . . . . . . . . . . . . . . . . . . . 51

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Dealer Management System (DMS) . . . . . . . 53

Fluids Configuration . . . . . . . . . . . . . . . . . . . . 55

Unit and Menu Pricing - Parts . . . . . . . . . . . . 55

Unit and Menu Pricing - Gas, Oil,

Grease (GOG) . . . . . . . . . . . . . . . . . . . . . . . . 60

Menu Pricing . . . . . . . . . . . . . . . . . . . . . . . . . 61

Non-Fluid Parts . . . . . . . . . . . . . . . . . . . . . . . . . 64

Return to Operating Screens . . . . . . . . . . . . . . 65

Matrix Reporter . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Production Data . . . . . . . . . . . . . . . . . . . . . . . . . 66

Starting Matrix Reporter . . . . . . . . . . . . . . . . 66

Creating a Report . . . . . . . . . . . . . . . . . . . . . 66

Saving Report Data to File . . . . . . . . . . . . . . 67

Printing Report Data . . . . . . . . . . . . . . . . . . . 67

Filtering Report Data . . . . . . . . . . . . . . . . . . . 67

Matrix Database Import and Export . . . . . . . . 67

Exporting the Matrix Database . . . . . . . . . . . 67

Importing a Matrix Database File . . . . . . . . . . 68

Database File Import Instructions . . . . . . . . . 68

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Appendix A - Matrix Network and Port Settings . 71

Edit Matrix Server Network Settings. . . . . . . . . . 71

Edit Matrix Client Network Settings . . . . . . . . . 72

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 74

Graco Phone Numbers . . . . . . . . . . . . . . . . . . . . . 74

Page 3

System Requirements

System Requirements

Matrix PC hardware requirements differ somewhat,

depending on how the system is configured. The system

might consist of a single PC, as previous versions of

Matrix were limited to, or it might consist of multiple PCs.

In the multiple-PC configuration, one PC is designated

to be the Matrix Server; all the rest are Matrix Clients.

The Matrix Server must support the Matrix-related activities of all the clients, and thus has a higher threshold of

minimum hardware requirements.

Graco strongly recommends that the end user’s IT

(Information Technology) representative be involved

in the following Matrix installation activities:

• Assist with the selection and/or purchase of the

Matrix PC. The PC must meet the performance

specifications listed under PC Hardware Require-

ments. If the Matrix PC will be connected to a Network with other PCs, the IT representative should

be contacted to properly configure the PC before

loading Matrix software.

• The IT representative should be present during

Matrix software loading on the day of Matrix installation.

This version of Matrix will support a network of up

to 25 Matrix Client PCs; more than 25 are not supported. Please call Graco if you require more than

25 client PCs.

PC Hardware Requirements

Standalone Matrix PC:

• 2 MHz Pentium 4 (or equivalent) processor

• 512 MB RAM, 1024x768 screen resolution

• 1 GB free hard disk space

•CD-ROM drive

• one available RS232 port

• one available USB port

•network card

• uninterruptible power supply (UPS).

• Some means of archiving Matrix production data

and backup database files over time is recommended--examples of hardware that can help with

this are a CD/RW or DVD-R/W drive, a USB flash

drive, or an accessible network drive.

General Matrix System Specifications

Matrix PC software supports systems using a single PC

(also referred to as a standalone PC) as well as multiple-PC systems.

Single PC (Standalone) Systems: Intended primarily

for applications that do not require interaction with

Matrix screens from multiple locations and have few

meters and tank level monitors, this type of system provides complete Matrix system functionality at one PC.

Multiple-PC (Networked) Systems: Using an existing

network, Matrix deployed in this fashion consists of a

single (dedicated) PC functioning as the Matrix Server

and one or more PCs functioning as Matrix Clients. The

Matrix system’s transceiver(s) are always connected to

the Matrix Server. This configuration is recommended

for applications where Matrix screen access from multiple physical locations is desired or there are large numbers of meters and tank level monitors.

Graco recommends that this PC be dedicated to

Matrix--i.e. it is not used for other purposes, like

running spreadsheet programs, sending e-mail,

etc.

Matrix Server PC in a multiple-PC system:

The same requirements as for the standalone PC,

except:

• 3.8 MHz Pentium 4 (or equivalent) processor

•1 GB RAM

Graco requires that this PC be dedicated to

Matrix--i.e. it is not used for other purposes, like

running spreadsheet programs, sending e-mail,

etc.

Matrix Client PC in a multiple-PC system:

2 MHz Pentium 4 (or equivalent) processor, 512 MB

RAM, 1024x768 screen resolution, 500 MB free hard

disk space, CD-ROM drive, network card.

312353B 3

Page 4

System Requirements

Serial Port

If the standalone Matrix PC or Matrix Server does not

have a physical serial port, a USB-to-serial port converter will be required. The converter selected is based

on the number of transceivers used in the system.

Graco recommends Edgeport converters, which are

available in 1, 4, or 8 port models (Edgeport/1, Edgeport/4, and Edgeport/8, respectively) and can be purchased from B & B Electronics Manufacturing Company

(www.bb-elec.com). Each model comes with a 3.3 foot

(1 meter) cable.

Uninterruptible Power Supply

An Uninterruptible Power Supply (UPS) is required in all

Matrix systems and is available from Graco (part no.

119425 for North American applications or part no.

120104 in Australia). This power supply provides continuous battery power to the PC during power interruption

and safely shuts down the PC, securing your Matrix software and preventing data corruption. Be sure the PC

and monitor are plugged into the battery back-up side of

the UPS during installation.

E-Mail

Matrix can send e-mail to responsible parties based on

certain bulk fluid tank conditions. If this feature is to be

used, an “always on” Internet connection or network

access to an outgoing mail server is required.

Sound Card

If the Parts Room Authorization feature of Matrix is

used, Matrix will generate an audible alert whenever

parts room authorization is received. A sound card in

the standalone Matrix PC or Matrix Server will allow this

to be heard by authorizing personnel.

PC Software Requirements

• Microsoft XP Professional or Home Edition (no other

operating system will work).

• Microsoft Internet Explorer (IE) version 6.0 or

higher.

• Java Runtime Environment (JRE) 1.4 or later. Version 1.4.2_04 is included in the Matrix setup; if

Matrix finds no JRE installed on the machine or it

finds an installed JRE older than 1.4, the user is

prompted to install this version. This check occurs

when the Matrix Client is started.

• If the installation is a multiple-PC system, the PCs

must be configured for the network they’re connected to.

• If the installation will use the e-mail feature of

Matrix, the standalone Matrix PC or Matrix Server

must have network access to an outgoing mail

server.

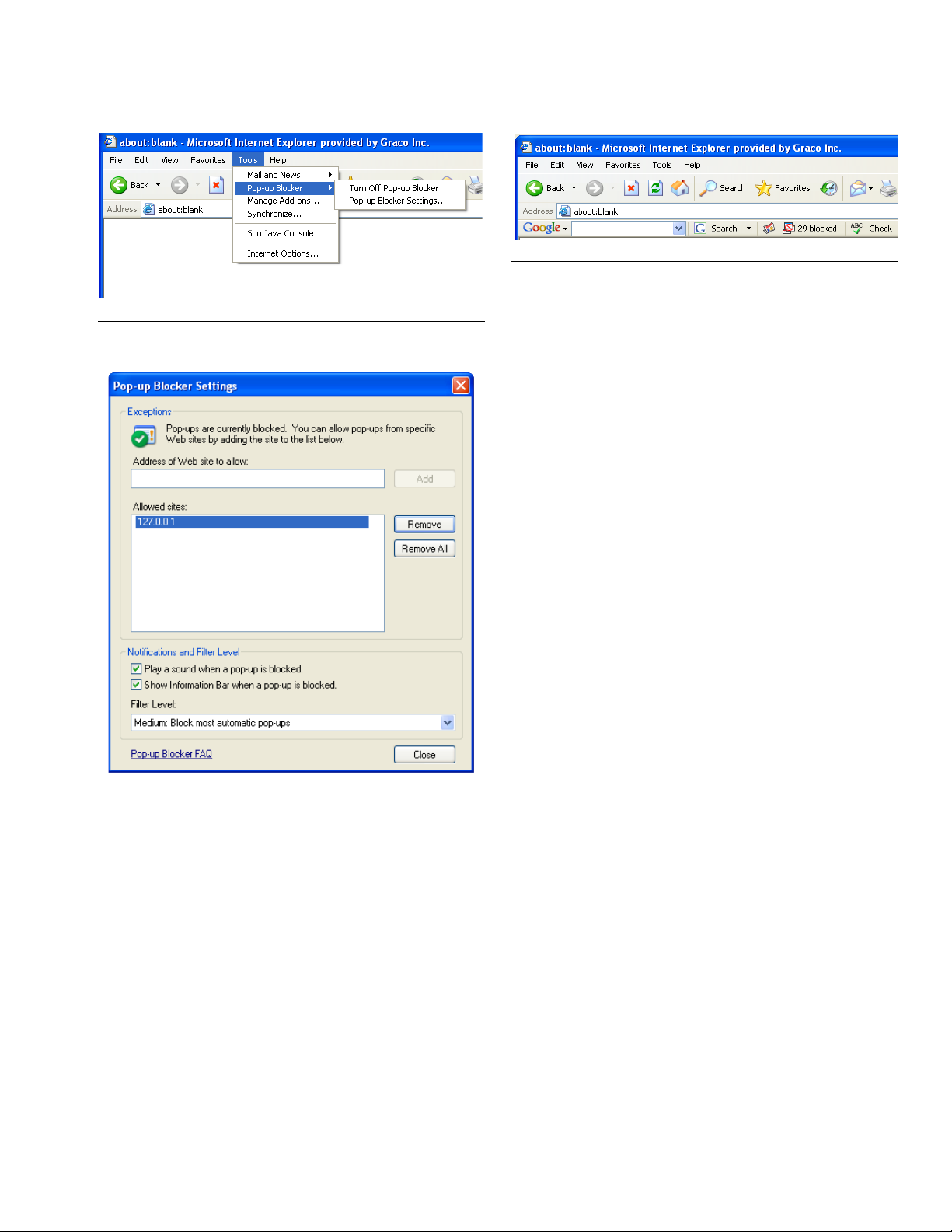

Pop-Up Blocker

Special Considerations for pop-up blockers

Summary: If a browser pop-up blocker is installed, it

must either be disabled or configured to allow pop-ups.

If it’s a single-PC system, the pop-up blocker must allow

pop-ups from http://127.0.0.1:8080. If it’s a multiple-PC

system, a pop-up blocker on the Matrix Server must

allow pop-ups from http://127.0.0.1:8080, while a

pop-up blocker on a Matrix Client must allow pop-ups

from http://MatrixServer:8080, where “Matrix Server” is

the computer name or IP address of the Matrix Server

PC. Recent versions of Internet Explorer have a built-in

pop-up blocker. You may have one or more browser toolbars that have pop-up blocker functionality, such as

those from Google and Yahoo. Security software programs, such as those provided by Symantec and

McAfee can contain pop-up blockers. It is fairly common

for PCs to have multiple pop-up blockers.

Matrix relies on the IE browser for its user interface. In

particular, Matrix uses browser pop-up windows extensively. The Matrix server includes a web server that generates the screens viewed within the browser. If the PC

has a pop-up blocker present, it can stop Matrix browser

windows from appearing. For Matrix windows to appear

properly, any pop-up blockers installed on the PC must

be configured to allow pop-ups from the Matrix server

(or be turned off).

Pop-up blockers come in many forms. The version of IE

that comes with Windows XP Service Pack 2, for example, contains a built-in pop-up blocker.

The IE browser’s pop-up blocker can either be turned off

or configured to allow pop-ups by adding allowed sites in

the pop-up blocker settings of IE. In F

“Pop-up Blocker Settings”, the window shown in F

appears. This example is taken from a “default” installation of the Matrix software on a standalone PC (the

allowed site shown in F

Matrix).

IG. 2 was added manually, not by

IG. 1, if you select

IG. 2

4 312353B

Page 5

F

IG. 1

System Requirements

FIG. 3

Typically, when a PC has an active pop-up blocker and

the Matrix client is launched, a progress bar appears

briefly and disappears without any further visible indication of anything happening. This is usually an indication

that the PC has a pop-up blocker that is stopping the

Matrix window from appearing.

There are some general guidelines to follow to track

down the responsible pop-up blocker (there can easily

be multiple pop-up blockers present in any system). The

goal is to configure each pop-up blocker by either turning it off or telling it to allow pop-ups generated by the

Matrix server (while still blocking pop-ups from all other

sites). On a single-PC Matrix system, you should configure the pop-up blocker to allow pop-ups from server

address http://127.0.0.1. On multiple-PC systems, the

address to allow is that of the Matrix server, either its

host name or IP address.

F

IG. 2

Many toolbars that integrate with IE also contain pop-up

blockers, such as those available from Google and

Ya h o o. F

IG. 3 shows an example of the Google toolbar;

others are very similar.

Many pop-up blockers recognize the Control key on the

keyboard, if pressed while clicking on a Link, as a command to temporarily allow pop-ups originating from that

link’s source. To try this method, hold down the Control

key on the keyboard while double-clicking on the Matrix

Client Icon on the desktop. This works only for that particular pop-up instance, so it’s not a good long-term

solution.

General guidelines to find and configure pop-up

blockers:

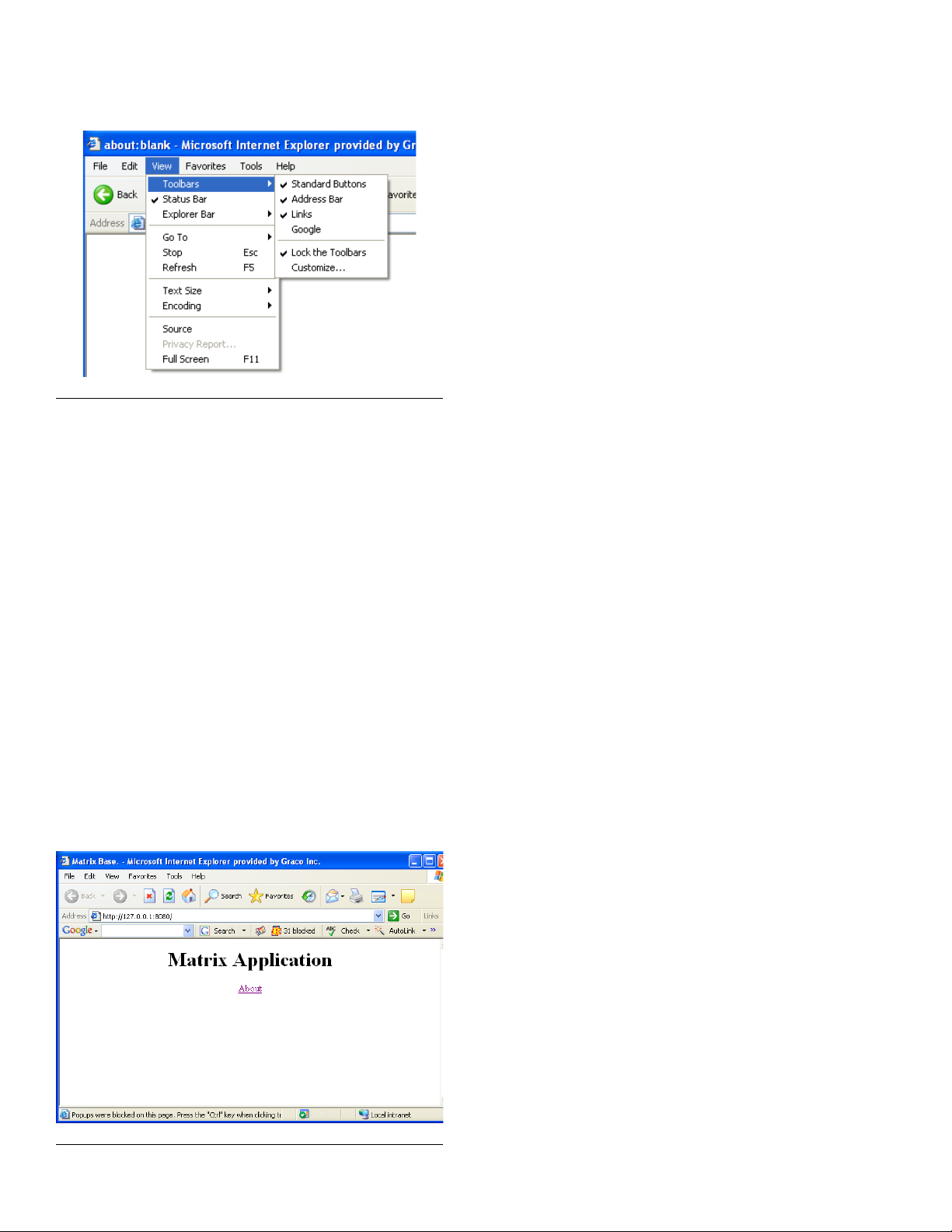

First, open a blank IE browser window. Click on Tools in

the menu bar (F

IG. 1). Choose Turn O f f Po p-up

Blocker or configure the pop-up blocker to allow

pop-ups from the Matrix server.

If IE has been properly configured and the Matrix windows still do not appear, it’s time to look for pop-up

blockers from other vendors, starting with toolbars integrated with IE. In IE, click on View in the menu bar and

choose Toolbars (F

IG. 4).

312353B 5

Page 6

F

IG. 4

Toolbars integrated with IE usually show up in the list

here. Look for entries like Google, Yahoo, MSN, etc.

Make sure each of these is checked (which will cause

them to appear, usually underneath the address bar in

the browser window) and then confirm with each one

that it’s allowing pop-ups from the Matrix server.

The following example illustrates the Google toolbar, but

the others generally function in a very similar fashion.

Example: Assuming a Google toolbar is installed and

the system is a single PC Matrix system. The system

has been rebooted since the application was installed.

While the Matrix Client is in the Windows Startup folder,

no browser window appeared when Windows started.

Open a blank IE window. With the Google toolbar visible, enter http://127.0.0.1:8080 in the address bar and

press Enter. If a window like the one shown in F

appears, the Matrix server is running, but you have a

pop-up blocker.

IG. 5

System Requirements

Note the button in the middle of the Google toolbar that

shows 31 blocked; this is a count of how many pop-ups

the Google toolbar has stopped from appearing. Click

Button to make the toolbar allow pop-ups from the

address currently in the address bar. Close the browser

window and try launching Matrix via the Matrix client

desktop icon again.

The same series of steps is performed for multiple-PC

systems, only the address used is different--the address

of the Matrix server is used instead of 127.0.0.1.

Pop-up blockers are not limited to those included with

browser toolbars. Security products such as Norton

Internet Security also block pop-ups; refer to the vendor’s instructions on how to configure these software

programs.

Software Firewalls

Special Considerations for Firewalls

Summary: Any firewalls in use must allow TCP traffic on

ports 8080, 8083, 8084 and 3306 at the Matrix Server

and port 8082 at each Matrix Client. Matrix will not function properly if any of these ports are blocked. Windows

XP has a built-in firewall, which is turned on by default

(meaning that these ports are blocked) in Service Pack

2.

Any firewalls on the Matrix PC must allow network traffic

over several ports. PCs communicate with each other

via IP addresses and port numbers. An IP address can

be compared to the street address of an apartment

building, with a port number as a specific apartment

number in the building. The Matrix server and Matrix clients require certain ports be available/open in order to

communicate properly. These are the default TCP ports

required by the server and each client:

Matrix server:

Port 3306 - Matrix Database

Port 8080 - Matrix Web Server

Port 8083 - Matrix/R & R link

Port 8084 - Matrix Server

Matrix Client:

Port 8082 - Matrix Client

Communication to these ports can be blocked by firewall

software installed on your computer. Windows XP contains the Windows Firewall, but there are numerous

products provided by third parties such as Symantec

and McAfee that also provide firewall functionality. What

this means for Matrix is that any Firewalls) on the Matrix

F

IG. 5

6 312353B

PC must be either configured to allow traffic over these

ports or turned off altogether.

Page 7

System Requirements

The Matrix setup program offers to open these ports for

you in the Windows Firewall. It does not do this for other

firewall products.

Network traffic over these ports can also be blocked by

what is called a proxy server. Whether or not a network

has a proxy server that stops traffic on these ports, port

8080 in particular, is a question for the facility IT personnel.

The ports listed above are the defaults. If they are

changed for any reason, corresponding changes must

be made in the firewall settings to allow traffic over the

new port numbers. Changing the port numbers may be

necessary if, for example, another application is already

using these port numbers. Graco strongly recommends

that IT personnel familiar with the network are involved

with this configuration change.

Windows XP Security

The following security-related configuration settings are

not required but are recommended for all Matrix PCs:

1. Be sure a user name and password are required to

access the operating system.

2. Ensure the password-protected screensaver is

enabled and set to automatically activate after 15-30

minutes of system inactivity.

3. Change user passwords on a regular basis and

choose passwords that are difficult to guess.

4. Use anti-virus software to protect against viruses.

Some anti-virus programs are bundled with other

security software, including other security tools such

as pop-up blockers and firewalls. Take note of the

recommendations in the sections titled Special

Considerations for Pop-up Blockers on page 4

and Special Considerations for Firewalls on page

6.

5. Be sure the system is kept up to date with Microsoft

XP updates and service packs.

6. Use a firewall. As mentioned in the section titled

Special Considerations for Firewalls, take care to

allow for continued operation of Matrix by not blocking the network ports Matrix needs to use.

312353B 7

Page 8

Installation Instructions

p

p

Installation Instructions

IMPORTANT!

The user must be logged into Windows XP with

administrator privileges.

If an older version of Matrix is already installed, the older

version must be uninstalled before this one can be

installed. See the Matrix Software Instruction Manual

that accompanied your current Matrix installation for

instructions on how to uninstall Matrix.

Software Installation & Networking

This version of Matrix has two types of installations to

choose from in its setup program. One is the Matrix

Server & Client and the other is the Matrix Client. Select

Matrix Server & Client for single-PC installations and for

the one PC in a multiple-PC installation that will perform

the role of Matrix Server.

Stand Alone Configuration

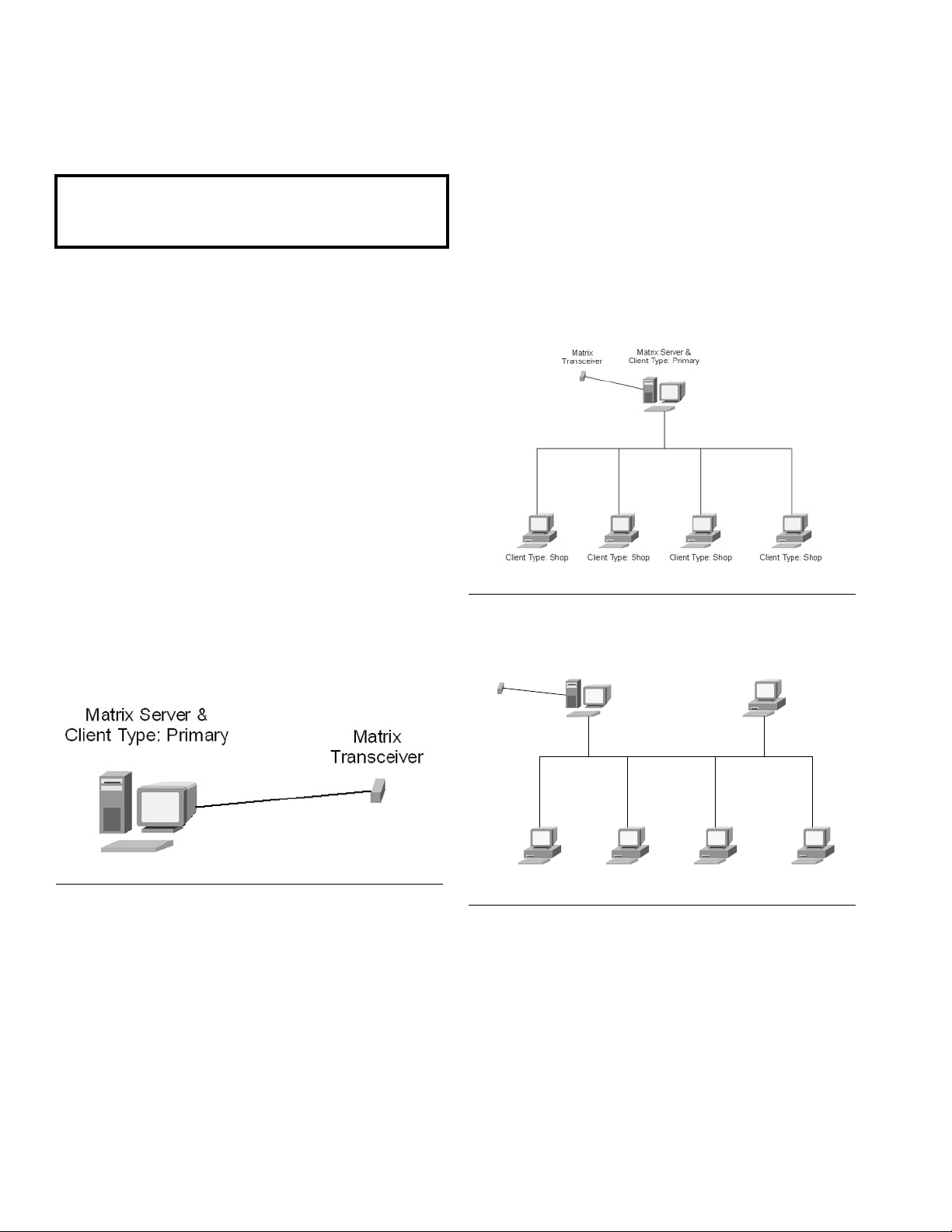

This configuration (FIG. 6) has one PC dedicated to

Matrix system operation. The Matrix Server and Client

version of the software should be loaded to the PC.

Networked Configurations

Matrix Full Line Software with R & R Approved Interface

can be networked in the two configurations shown in

F

IG. 7 and FIG. 8. In FIG. 7, the server and primary client

are shown as one PC. In F

client are shown as separate pieces of hardware.

FIG. 7 Server and Primary Client as One PC

Matrix Server &

Matrix

Transceiver

Client Type: Shop

IG. 8, the server and primary

Client Type: Primary

F

IG. 6 Stand Alone Configuration

Follow setup path 1 beginning on page 9.

Client Type: ShopClient Type: ShopClient Type: Sho

IG. 8 Server and Primary Client Separate

F

Client Type: Sho

Follow setup path 1, beginning on page 9, on the PC

designated as the Matrix Server and setup path 2,

beginning on page 13, for all other PCs in the system.

8 312353B

Page 9

Installation Instructions

Browser Configuration

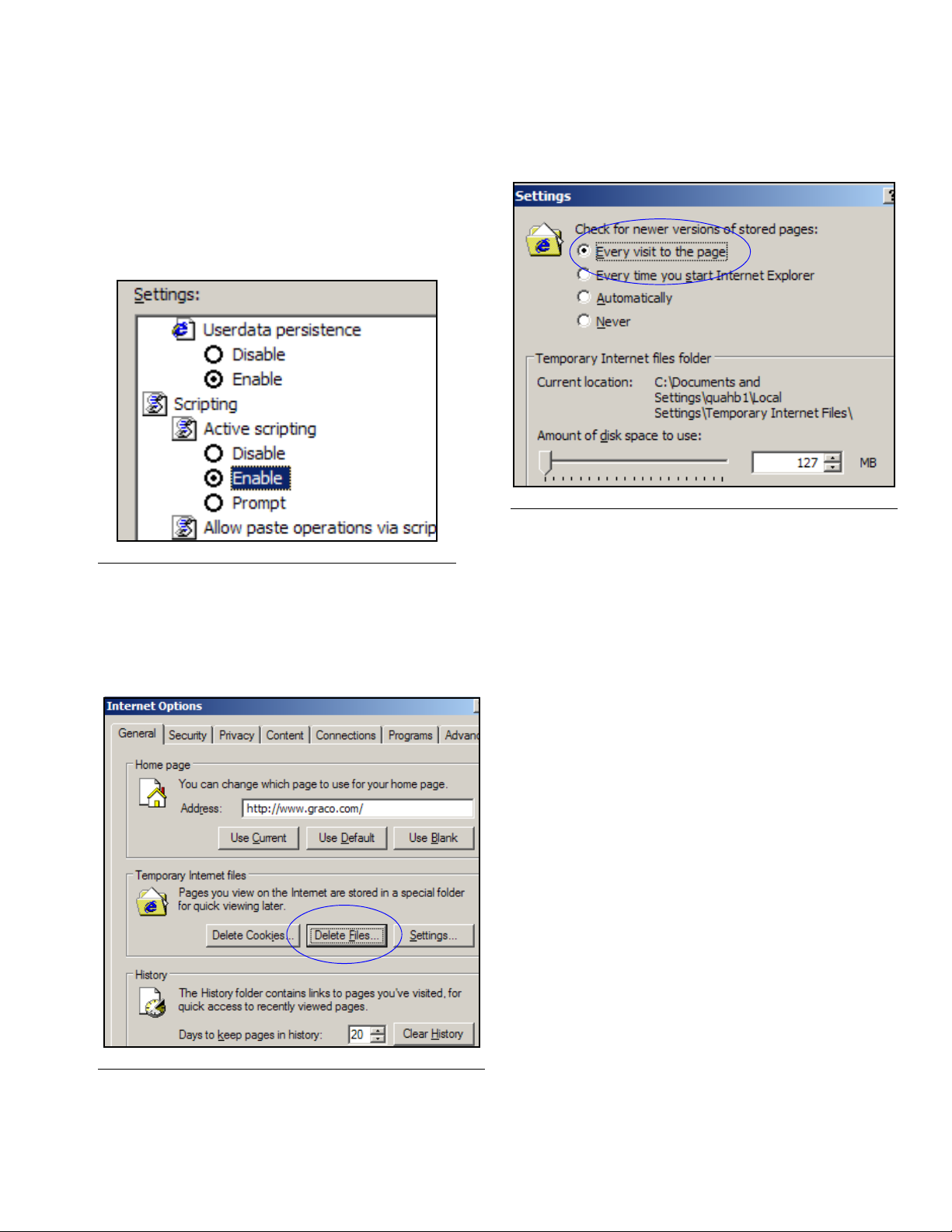

Prior to running the setup program, ensure that IE is

configured properly.

Open IE and verify that active scripting is enabled. This

setting is typically found in Tools / Internet Options /

Security Settings / Custom selection (F

F

IG. 9 Internet Java Script Security Settings

1. In the Temporary Internet Files section of the Internet Options box, click Delete Files. Select the

Delete All Offline Content check box.

Click OK (F

IG. 10).

IG. 9).

2. Click Settings. Select Every visit to the page.

Click OK (F

FIG. 11 Internet Page Settings

3. Select the Content tab and click the AutoComplete

Button. Clear the check marks from all the boxes.

Click the Clear Forms Button and select Yes to

any pop-up screens. Click the Clear Passwords

Button and select Yes to any pop-up screens. Click

OK.

Click OK to close the Internet Options dialog box.

IG. 11).

IG. 10 Internet Options General

F

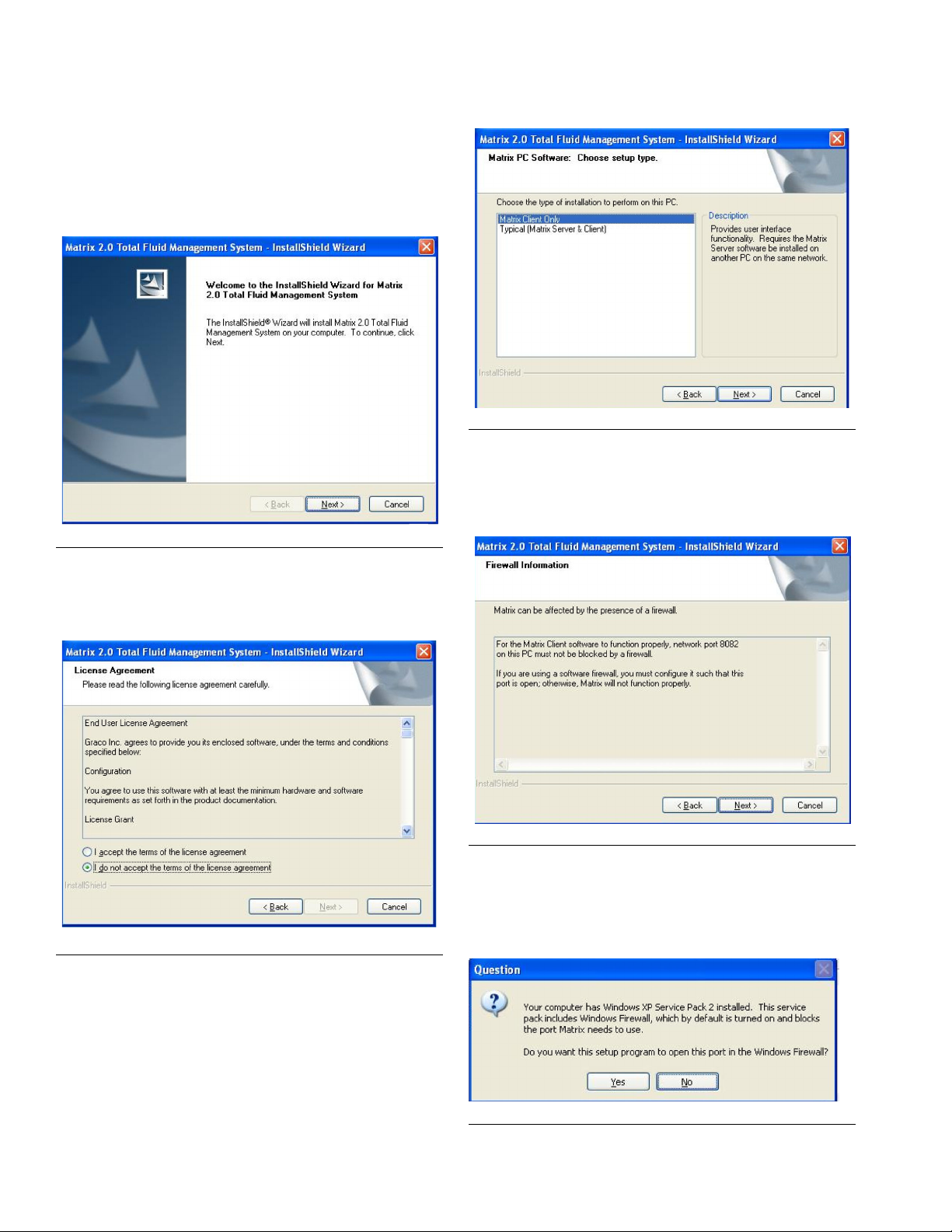

Setup Path 1- Typical (Matrix Server and Client)

FIG. 12 through FIG. 25.

1. Log into Windows XP as administrator.

2. Configure IE according to the Browser Configuration

section.

3. Insert the Matrix CD in the CD-ROM drive.

312353B 9

Page 10

Installation Instructions

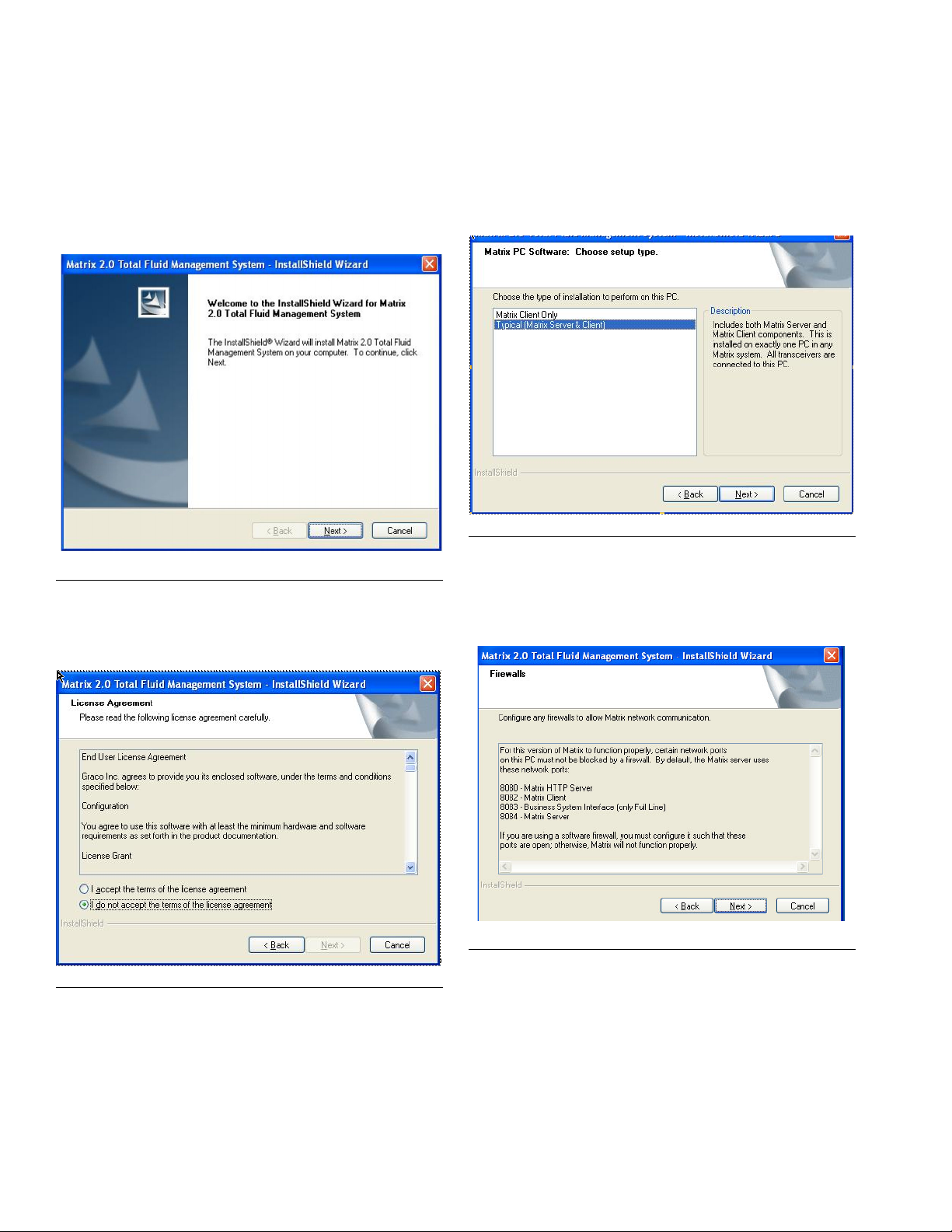

4. The setup program should start automatically. If it

doesn’t, open Windows Explorer (Start / All Pro-

grams / Accessories). Locate the CD-ROM drive

letter under My Computer and double-click the

Setup Executable File to see the screen shown in

F

IG. 12. Click Next.

IG. 12 Setup Path 1 - InstallShield Wizard

F

5. Review the End User License Agreement (FIG. 13).

If acceptable, select “I accept…” and click Next.

6. The default setup type is shown selected: Typical

(Matrix Server & Client) (F

IG. 14). Chose this setup

type for either standalone Matrix PCs or for the

Matrix Server in multiple-PC applications. Click

Next.

FIG. 14 Setup Path 1 - Choose Setup Type

7. Note firewall configuration settings that may need to

be changed for Matrix to function (F

IG. 15). Click

Next.

F

IG. 15 Setup Path 1 - Firewalls

F

IG. 13 Setup Path 1 - License Agreement

10 312353B

Page 11

Installation Instructions

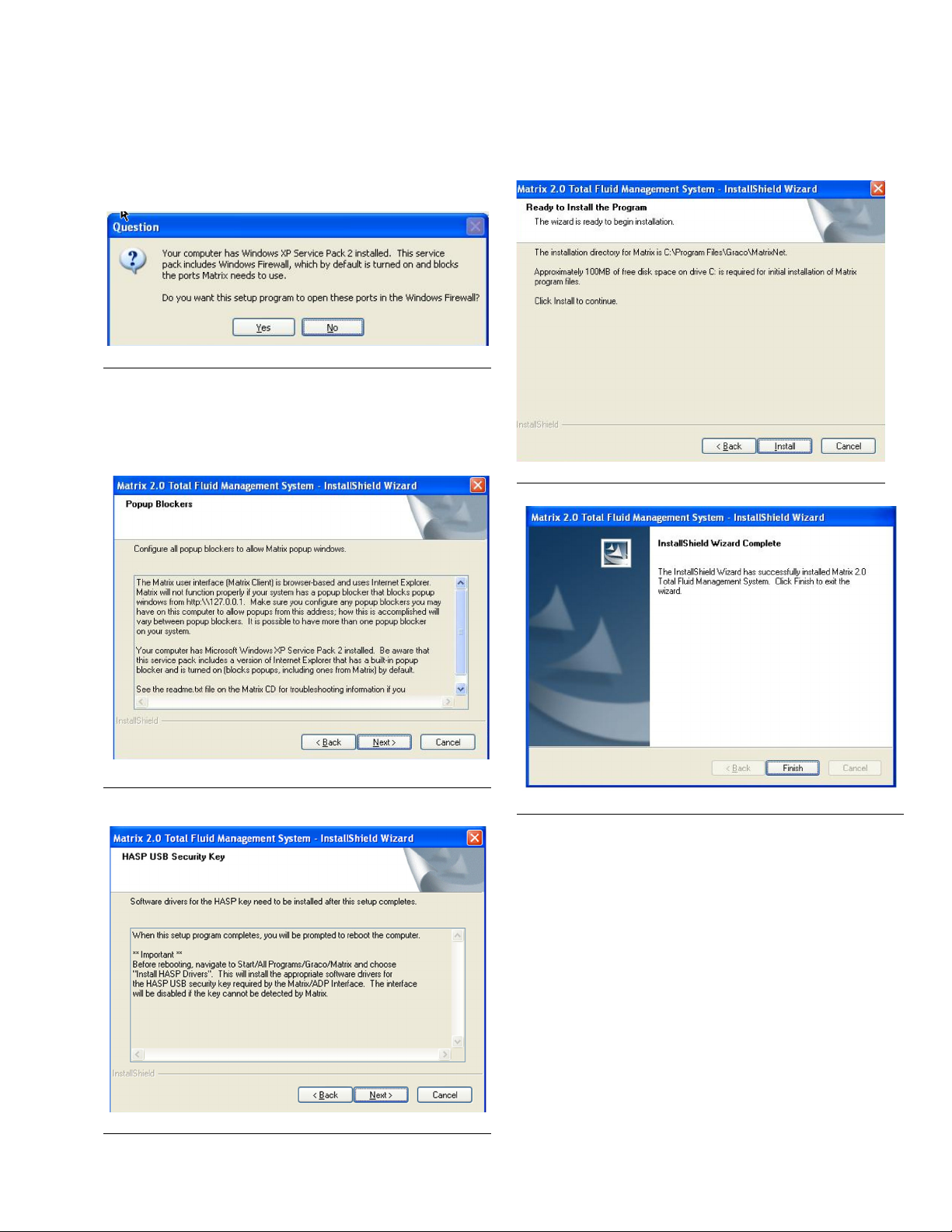

8. Setup checks for Windows XP Service Pack 2

installation. If Service Pack 2 is present, the pop-up

shown in F

IG. 16 appears. Choose Yes or No to

continue.

F

IG. 16 Setup Path 1 - Firewall Question

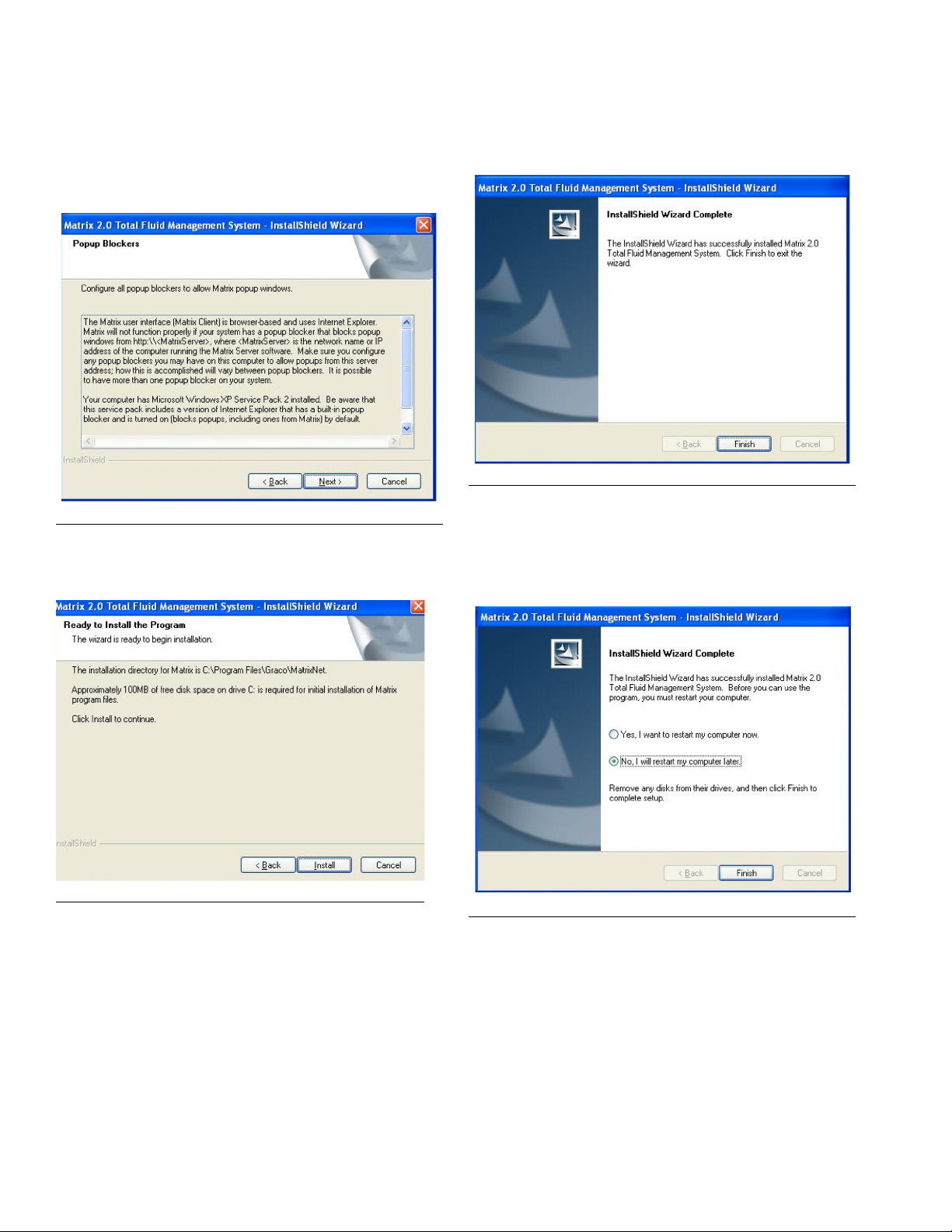

9. You may need to make changes to pop-up blockers

installed on the PC for Matrix to function properly.

Read this information carefully for guidance

(F

IG. 17). Click Next.

10. Setup is ready to install Matrix application files (F

19). Click Install.

FIG. 19 Setup Path 1 - Ready to Install

IG.

IG. 17 Setup Path 1 - Pop-up Blockers

F

F

IG. 20 Setup Path 1 - Install Complete

IG. 18 HASP USP Security Key Install Screen

F

312353B 11

Page 12

Installation Instructions

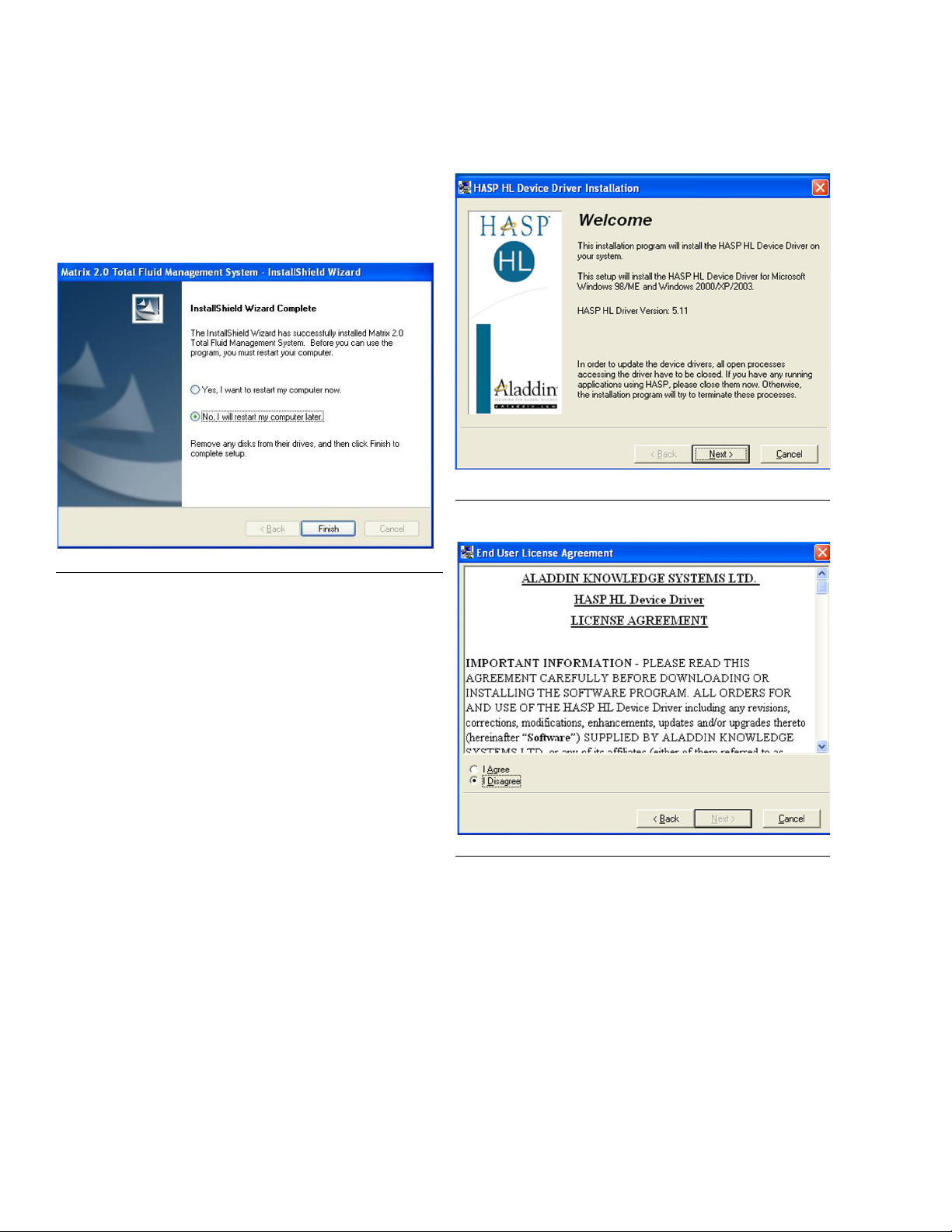

11. Matrix software installation is almost complete.

Before restarting your computer, the software drivers for the HASP key need to be installed and several configuration settings need to be checked

and/or set. Select “No, I will restart my computer

later”. Click Finish.

FIG. 21

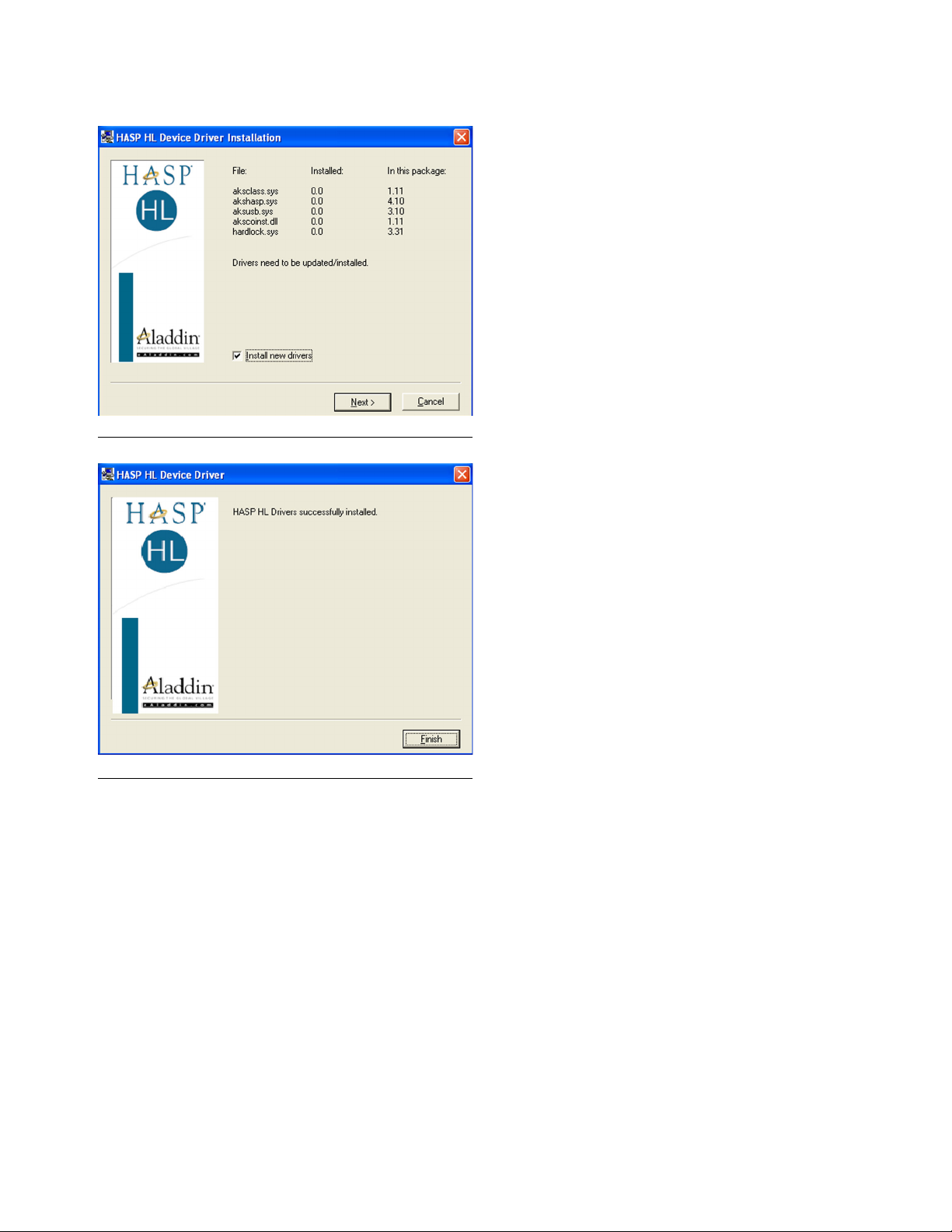

HASP Key Driver Setup Program

FIG. 22 HASP Setup Welcome Screen

12. Install the HASP key driver (see HASP Key Driver

Setup Program section (below).

13. Review the Sun Java Runtime section on page 17.

14. Confirm that Windows on the Matrix Server PC is

not configured to hibernate after a period of inactivity (page 19).

15. Shut down the PC.

16. Plug the HASP key into an available USB port.

Since the key must be plugged in at all times for

Matrix to function properly, it is recommended that

a port out of the way (such as on the back of the

machine) be selected.

17. Restart the computer.

F

IG. 23 HASP License Agreement

12 312353B

Page 13

F

IG. 24 HASP Driver Files

Installation Instructions

• Matrix Reporter - accessible to Matrix system

administrators, Matrix Reporter generates system

reports on production and configuration data. Matrix

Reporter is used any time a Matrix report needs to

be generated, as well as to generate a database

backup file.

• Edit Matrix Server Network Settings - a graphical

editing tool used to configure network settings used

by the Matrix Server. Typically used only once when commissioning the Matrix system. In most

cases the default server settings will not need to be

edited.See Appendix A, page 71 and Matrix Client

PC Setup, page 36 for details.

• Edit Matrix Client Network Settings - a graphical

editing tool used to configure network settings used

by the Matrix Client. Typically used only once - when

commissioning the Matrix system. See Appendix A,

page 71 and Matrix Client PC Setup, page 36 for

details.

• End user license agreement (EULA).

F

IG. 25 HASP Setup Complete

Matrix Server and Client Shortcuts

The Typical (Matrix Server and Client) setup creates

the following shortcuts.

In Start / All Programs / Graco / Matrix:

• Matrix Server - launches the Matrix Server which

handles all RF communication to meters, tank level

monitors, database storage of dispense data and

system configuration and generates system warnings and e-mails. Matrix Server must be running at

all times.

• Install HASP Drivers - this is a shortcut to the

setup program for the software drivers required for

Matrix and Windows XP to communicate with the

HASP key. This needs to be run one time only,

immediately after installing Matrix software.

In Start / All Programs / Startup:

• Matrix Server

• Matrix Client

On the Windows Desktop:

• Matrix Client

Setup Path 2 - Matrix Client Only

FIG. 26 through FIG. 34.

1. Log into Windows XP as administrator.

2. Configure IE according to the Browser Configuration

section.

3. Insert the Matrix CD in the CD-ROM drive.

• Matrix Client - provides the IE browser-based

graphical user interface and accompanying screens.

Matrix Client must be running to access Matrix

Screens.

312353B 13

Page 14

4. The setup program should start automatically. If it

doesn’t, open Windows Explorer (Start / All Pro-

grams / Accessories). Locate the CD-ROM drive

letter under My Computer and double-click the

Setup Executable File. Click Next (F

IG. 26).

Installation Instructions

FIG. 28 Setup Path 2 - Choose Setup Type

7. Note firewall configuration settings that may need to

be changed for Matrix to function (F

IG. 29). Click

Next.

F

IG. 26 Setup Path 1 - InstallShield Wizard

5. Review the End User License Agreement (F

IG. 27).

If acceptable, select “I accept…” and click Next.

F

IG. 27 Setup Path 2 - License Agreement

6. The setup type shown selected is Matrix Client

Only (F

IG. 28), used for all machines except the

Matrix Server in multiple-PC Matrix systems. Click

Next.

F

IG. 29 Setup Path 2 - Firewall Information

8. Setup checks for Windows XP Service Pack 2

installation. If Service Pack 2 is present, the pop-up

shown in F

IG. 30 appears. Choose Yes or No to

continue.

F

IG. 30 Setup Path 2 - Firewall Question

14 312353B

Page 15

Installation Instructions

9. You may need to make changes to pop-up blockers

installed on the PC for Matrix to function properly.

Read this information carefully for guidance (F

IG.

31). Click Next.

F

IG. 31 Setup Path 2 - Pop-up Blockers

10. .Setup is ready to install Matrix application files (F

IG.

32). Click Install.

11. Transfer of application files from the setup program

to the hard disk is complete (F

IG. 33). Click Finish.

FIG. 33 Setup Path 2 - Install Complete

12. Matrix software installation is complete, however,

there are several configuration settings to check

and/or set. Select “No, I will restart my computer

later” (F

IG. 34). Click Finish.

IG. 32 Setup Path 2 - Ready to Install

F

F

IG. 34 Setup Path 2 - Setup Complete

13. Review the Sun Java Runtime section on page 17.

Confirm the settings related to the Java Plugin are

OK on this machine.

14. Follow the instructions for configuring the client PC

to communicate with the Matrix Server in the Matrix

Client PC Setup beginning on page 36.

15. Reboot the PC when complete.

312353B 15

Page 16

Installation Instructions

Matrix Client Only Shortcuts

The Matrix Client Only setup creates the following

shortcuts.

In Start / All Programs / Graco / Matrix:

• Matrix Client - provides the IE browser-based

graphical user interface and accompanying screens.

Matrix Client must be running to access Matrix

Screens.

• Matrix Reporter - accessible to Matrix system

administrators, Matrix Reporter generates system

reports on production and configuration data. Matrix

Reporter is used any time a Matrix report needs to

be generated, as well as to generate a database

backup file.

• Edit Matrix Client Network Settings - a graphical

editing tool used to configure network settings used

by the Matrix Client. Typically used only once - when

commissioning the Matrix system. See Appendix A,

page 71 and Matrix Client PC Setup, page 36 for

details.

• End user license agreement (EULA).

In Start / All Programs / Startup:

• Matrix Server

• Matrix Client

On the Windows Desktop:

• Matrix Client

16 312353B

Page 17

Installation Instructions

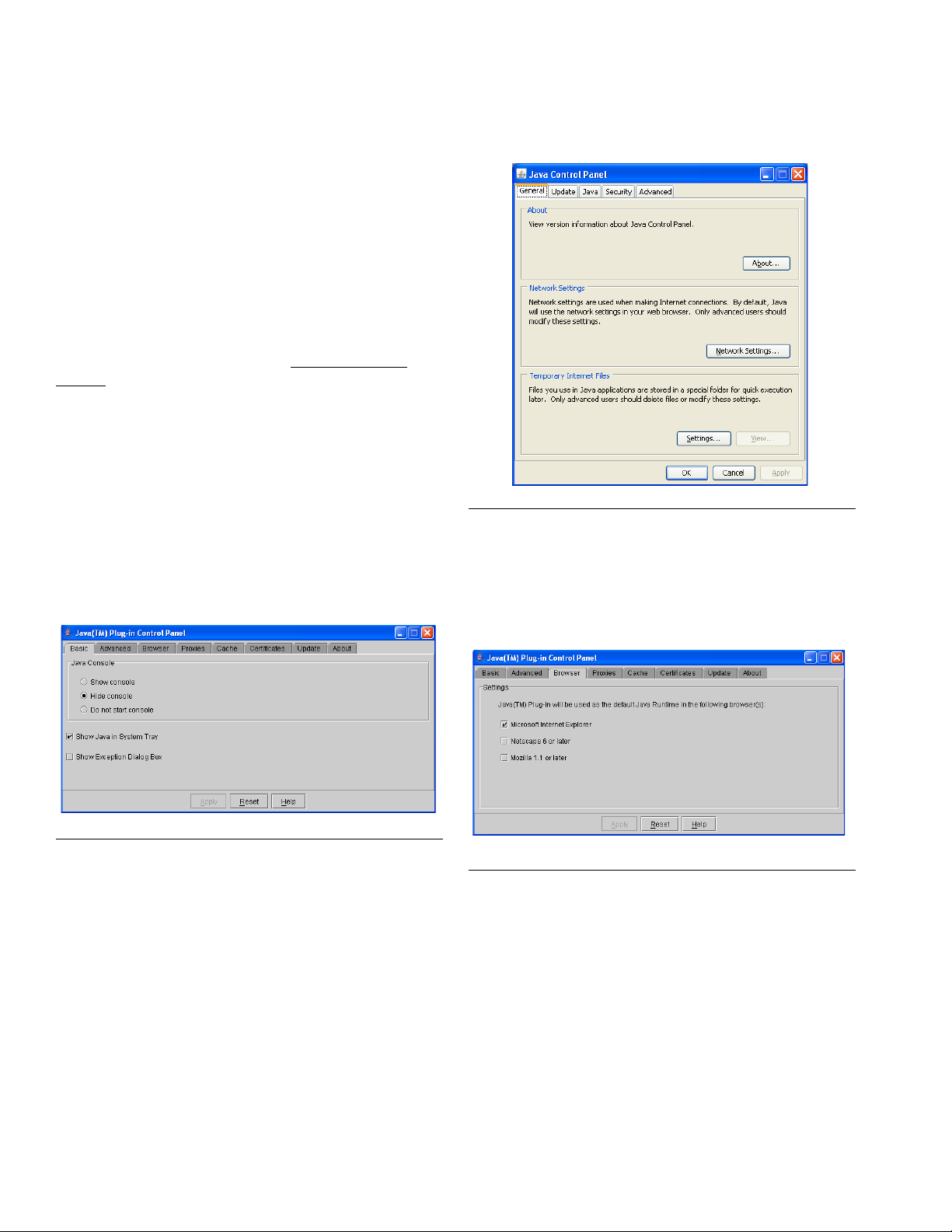

Sun Java Runtime

Because the startup program places shortcuts to Matrix

in the Windows Startup folder, Matrix will launch automatically when the you log into Windows. Each time

Matrix is launched, it checks for the presence of the Sun

Java Runtime Environment (JRE) on the PC. If it is not

found, Matrix will launch the setup program for it (JRE

version 1.4.2_04 is bundled with the Matrix setup) and

then exit. You must be logged into Windows XP with

administrator privileges for the JRE installation to succeed. Proceed through the JRE installation. When

installation is complete, reboot your computer. When

logged back into Windows, Graco strongly recom-

mends the following Java Plug-in configuration

changes:

The Sun Java Plug-in must be configured to function

with the Internet Explorer browser. Graco recommends

that the Plug-in be configured to not cache Java applets.

Depending on what version of the Java Plug-in is

installed on the PC, the configuration pages for it will differ. In any case, to access the Java Plug-in Control

Panel, navigate to the Windows Control Panel and double-click the Java (Coffee Cup) Icon.

The older Plug-in looks like F

IG. 35.

The newer Plug-in looks like F

IG. 36.

FIG. 36

• Configure the Plug-in for use with Internet Explorer.

Ensure that the checkbox next to “Microsoft Internet

Explorer” is checked.

The older Java Plug-in looks like F

IG. 37.

IG. 35

F

IG. 37

F

312353B 17

Page 18

Installation Instructions

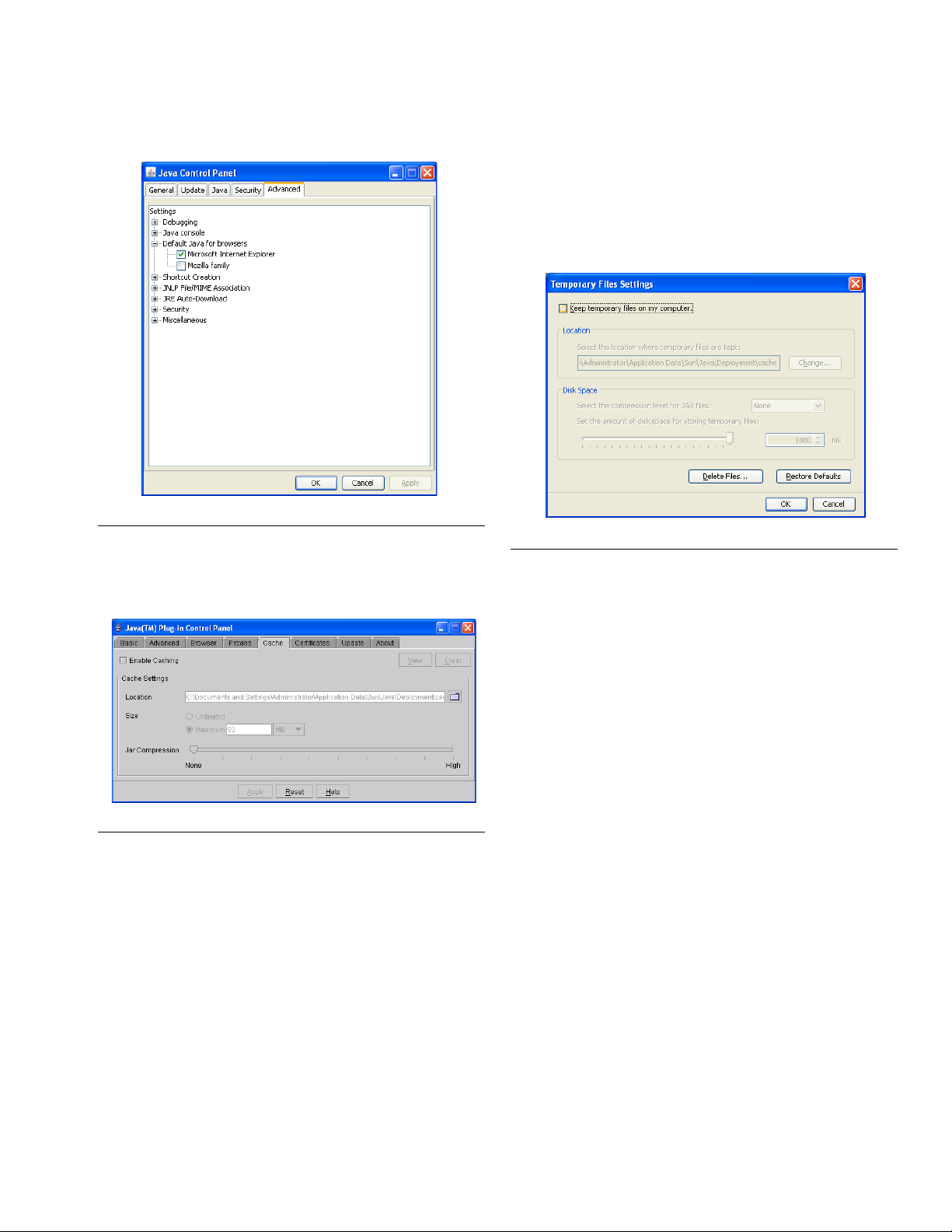

The newer Java Plug-in looks like F

F

IG. 38

• Configure the Plug-in to not cache Java applets.

The older Plug-in looks like F

IG. 38.

IG. 39.

The newer Plug-in looks like F

On the General tab, click the Settings Button in the

Temporary Internet Files section. In the corresponding popup, ensure that the checkbox is labeled

“Keep temporary files on my computer” is NOT

checked.

FIG. 40

See Software Installation Troubleshooting on page if the Java applets do not display properly.

IG. 40.

F

IG. 39

Clock and Time Zone Settings

Verify that the Microsoft XP clock and time zone settings

are correct. When the time is changed by either the PC

operator or automatically by Microsoft XP (i.e. daylight

savings time automated change), the PC must be

restarted.

MatrixLogs Folder

The Matrix setup program creates a folder named

c:\MatrixLogs. Various log files generated during Matrix

operation stored in this folder, do not delete it.

18 312353B

Page 19

Installation Instructions

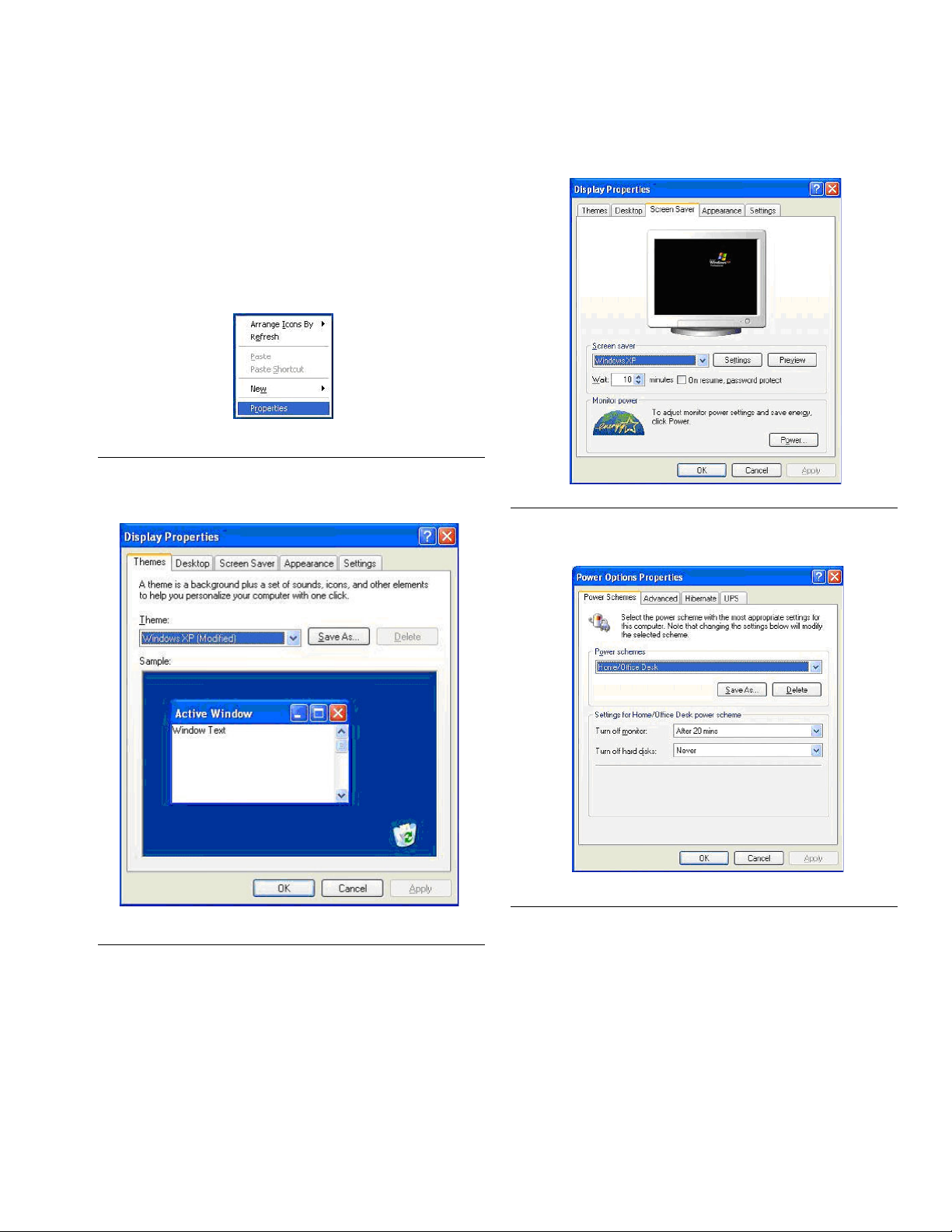

How to Turn Off Hibernation Mode in Windows XP

Ensure that Windows XP is not configured to hibernate

after a period of inactivity. If it hibernates, all meters and

tank level monitors in the system will expire a loss of RF

signal.

1. Right-click on the Desktop and choose Properties.

F

IG. 41

2. You should see a Properties window.

3. Choose the Screen Saver tab.

FIG. 43

4. Click on the Power Button.

F

IG. 44

IG. 42

F

312353B 19

Page 20

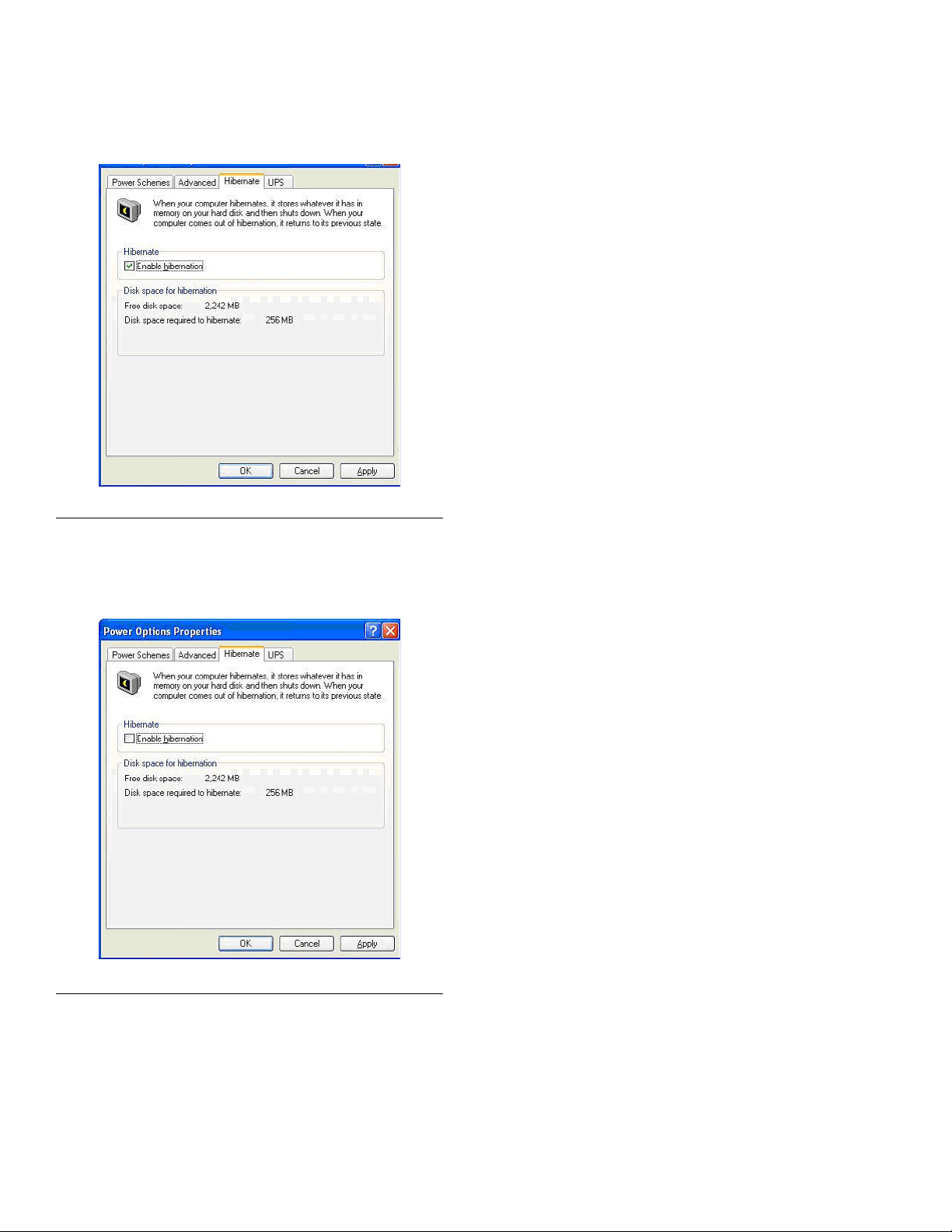

5. Click Hibernate Tab.

F

IG. 45

Installation Instructions

6. Turn off hibernation by clearing (unchecking) the

Enable hibernation check box. Click Apply and OK

to close all windows.

IG. 46

F

20 312353B

Page 21

Software Installation Troubleshooting

Problem Cause/Solution

Software Installation Troubleshooting

When Matrix is launched, I see

a progress bar for a short

period of time, but the browser

window showing the Matrix

application never appears.

At a client PC, when the Matrix

Client is launched a progress

bar appears for a long time,

finally disappears, but not

Matrix screens appear.

There may be a pop-up blocker program running on your PC and preventing

the Matrix window from opening. Verify that you do not have a pop-up blocker

integrated with your IE browser. Programs such as the Google, Yahoo, and

AOL Toolbars—among many others, including IE itself if Service Pack 2 for

Windows XP is installed—contain such features. You must configure your

pop-up blocker to not block pop-ups from the Matrix Server software. If this is

happening at the server PC, the address the pop-up blocker must allow

pop-ups from is http://127.0.0.1

pop-up blocker must allow pop-ups from http://<MatrixServer>, where

<MatrixServer> is the host name or IP address of the Matrix Server PC. How

the pop-up blocker is configured varies depending on the program, so check

that program’s documentation for instructions on how to do this. Usually, the

easiest solution is to disable the pop-up blocker entirely.

If a pop-up blocker causes the browser-based user interface to not show, the

underlying program that handles system communication, warning pop-ups,

sending e-mails, etc., should still function as normal.

A client PC cannot make a network connection to the Matrix Server. There are

numerous possible reasons for this, but the most common are:

• the host name or address of the Matrix Server as configured at the client

PC, is not correct.

• the Matrix Server has a firewall blocking port 8080.

• the client isn’t connected properly to the network.

• the network is down.

. If this is happening at a Matrix Client, the

At a client PC, when the Matrix

Client is launched, the Matrix

screens appear but the dispense history screen (or tank

level, battery level or work

order screen) shows a large

red rectangle that says something about the database not

being available.

At a client PC, the dispense

history and tank level screens

appear OK but I cannot access

the setup screens.

When Matrix is launched, I get

an error that says a connection

could not be made to the Matrix

server.

This is usually a firewall on the Matrix Server blocking port 3306. Matrix client

PCs need access to two ports on the Matrix Server, 8080 and 3306.

If the PC is designed as a Matrix shop client, this is by design. If the PC is a

primary client, make sure the name or address used in the PC client table on

the System Configuration page in the Matrix setup screens (check this on the

Matrix Server) matches exactly with the name/address given for the client in

Start / All Programs / Graco / Matrix / Edit Matrix Client Network Settings.

Make sure you do not have a software firewall blocking ports 8080-8083 or

3306 at the Matrix Server and port 8082 at each Matrix Client. Matrix must be

able to use these ports for normal operation. By default, Service Pack 2 for

Windows XP turns the built-in Windows Firewall on; ensure that these ports

are open. The system may have a firewall from another vendor, such Symantec’s Norton Internet Security, installed; this type of security software packages can contain firewalls and pop-up blockers, among other tools.

312353B 21

Page 22

Software Installation Troubleshooting

I’m sure I have no pop-up

blockers or firewalls on my

Matrix Client, but I still can’t

access the Matrix screens.

The meter dispense information screen has a white/gray

rectangle where the dispense

information should be.

After installing the JRE as

described in the installation

instructions, There is a coffee

cup icon in the system tray and

frequent pop-up windows.

What is this for, and is there a

way to turn off the pop-ups?

With Matrix installed on single

PC in a standalone system

configuration, when I launch

Matrix while my computer is not

attached to my network, the

Matrix browser-based screens

do not appear. However, if I

attach my computer to the network and launch Matrix, they

do appear.

Verify with your IT network administrator that the network has no proxy servers

that block traffic on port 8080, the default port used by Matrix for http traffic.

The meter dispense information is displayed in a table in a Java applet. Verify

that you have the Java Plugin (version 1.4.2_04 or later) installed and that it is

not disabled in IE (Tools->Internet Options->Advanced tab, the section

marked Java (Sun)).

Also, in the Windows Control Panel, you should find a Java Plug-in icon. Double-click the Icon and verify that IE is set up to use the Sun JRE for viewing

applets.

This is the Java Update mechanism that is part of the JRE, which, if enabled,

allows the JRE to make periodic automatic checks over the Internet for new

versions of the JRE. For the purpose of running Matrix this isn’t necessary. To

turn this off, go to Control Panel, double-click on the Java Plugin Icon and

choose the Update tab. Clear the Check for Updates Automatically check-

box

This happens most often with laptops that frequently connect to multiple networks using different configurations.

First, verify the proxy settings configured in your IE browser. Open a blank IE

window, click on Tools->Internet Options, and select the Connections tab.

Ensure that 1) Never dial a connection is selected, and 2) Click on LAN Set-

tings and disable automatic proxy configuration.

Also, be aware that IE, will always check for an Internet connection before

serving local web pages (see article ID 290766 on Microsoft’s online support

site, support.microsoft.com, for details).

I clicked on a Button to get to a

different page at a Matrix Client

and I got a gray screen that

says “Direct access to this

Matrix page not allowed.”

I keep getting a popup window

that says “USB security key not

found on Matrix server!

Matrix/R & R interface is disabled.” What’s going on?

Usually this means that the Matrix Server was restarted. In the Matrix system,

if the Matrix Server is restarted for any reason, all Matrix Clients must also be

restarted to reconnect to the screens. This is one reason why it’s important

that the Matrix Server be dedicated to the Matrix system.

The HASP security key shipped with this version of Matrix must be plugged

into a USB port on the Matrix Server at all times, even if the Matrix/R & R interface is disabled. This message will appear when the Matrix Server software

cannot detect the presence of the key. The key could be unplugged. The software drivers for the key may not have been installed; if this is the case, while

logged in with Windows administrative rights, navigate to Start/All Programs/Graco/Matrix and choose Install HASP Drivers. Graco recommends the

key be plugged into a USB port on the Matrix Server itself, as opposed to

being plugged into a USB hub that is in turn plugged into the Server

Make sure you reboot the Matrix Server after installing the HASP driver software.

22 312353B

Page 23

Software Installation Troubleshooting

When I enter a work order at a

meter, I get a “WO

REJECTED” message, even

though I know the work order

exists in the DMS and is open.

Why?

When a work order is sent to the PC from a meter, the PC must validate the

work order with the R & R DMS. If, for any reason, the work order cannot be

validated (the work order is closed, it has a status that doesn’t allow the addition of charges, the network between Matrix and the DMS is down, etc.), the

PC returns this message to the meter. You could try adding the work order at

the PC for better detail on why the work order isn’t being validated.

312353B 23

Page 24

Software Installation Troubleshooting

Uninstalling Matrix on Windows XP

Follow this procedure to remove Matrix software and

data files stored on your computer. You will lose all

Matrix system parameters and all Matrix dispense history using these procedures unless you first use Matrix

Reporter to make a back-up of the database by exporting it to a *.sql file.

• You must have Windows XP administrator privileges

in order to add or remove Matrix from the computer.

• Any files you have created with Matrix since it was

originally installed, such as database export files,

reports, and log files will not be removed by the

uninstall program. If you wish to also remove these

from your hard drive, you will have to do so manually

using Windows Explorer after the uninstall program

completes.

1. Choose Start / Control Panel from the Windows

Start menu.

2. In Control Panel, double-click Add or Remove Pro-

grams.

3. Scroll to Matrix in the program listing and click it

once to highlight it.

4. Click the Remove box.

5. In the dialog box that appears, choose Remove.

from the list of options and click Next.

6. Click Yes in the window that asks you to confirm

your selection.

7. The uninstall program runs.

8. Click Finish.

You may be prompted to reboot as the final step of the

uninstall process. Graco recommends that you always

reboot when you have uninstalled Matrix software.

Matrix log files found in c:\MatrixLogs, will not be

removed by the automated uninstall process. They

must be deleted manually.

24 312353B

Page 25

Operator Screens

Operator Screens

F

IG. 47 Operating Screens

Meter Dispense Information _________________________________

Position the cursor over the Meter Dispense Status box causing the text to turn yellow. Left click the Box to go to the

Meter Dispense Information screen (F

IG. 48 Meter Dispense Information Screen

F

This screen displays the complete dispense history of all

meters in the system through two tables of information.

The top table lists all the active dispenses in the system

and the bottom table displays all completed dispenses.

Active Work Orders

Date & Time - the date and time of the dispense.

Meter Name - the meter and fluid names.

Work Order - the tracking number the facility uses for

work orders (if the meter is in work order mode).

Status - the current status of the dispense.

Dispense History

IG. 48).

Meter Name - the meter and fluid names.

Amount - the exact fluid amount dispensed, with units.

Work Order - the tracking number the facility uses for

work orders (if the meter is in work order mode).

Posting Status - displays the status of the Matrix R & R

interface’s attempt to add this fluid charge to the RO on

the R & R DMS.

User Data - allows the user to add information to the

screen

Status - the final status of the dispense.

Date & Time - the date and time of the dispense.

312353B 25

Page 26

Operator Screens

Tank Level Information _____________________________________

Place the cursor over the Tank Level Information box, causing the text to turn yellow. Left click the Box to go to the

Tank Setup screen (F

F

IG. 49 Tank Level Information Screen

IG. 49).

This screen provides tank level status activity for all

tanks in the system:

Date & Time - displays the day, month, date, time, and

year that the dispense took place.

Tan k N a m e - displays each fluid storage tank in use with

the Matrix system and the numbers or labels that are

assigned to them.

Fluid Type - displays the type of fluid stored in the tank.

Tan k C a p a c i t y - displays the total gallons of fluid that the

tank is capable of holding when full.

Current Volume - displays the tank volume in gallons.

Battery - displays the amount of battery life remaining.

Tank volume, as shown in F

of several different events:

1. Tank Level Monitor reading – The current tank volume is updated by readings sent by a tank level

monitor mounted on the tank. These readings can

be both scheduled (programmed) to happen a specific times during the day; they also happen each

time the blue button on the tank level monitor is

pressed. The tank level readings sent from the tank

level monitor always overwrite whatever Matrix currently has as the current tank volume.

2. Meter dispenses – When a meter dispenses from

the tank, Matrix calculates the new current tank volume by subtracting the amount dispensed. For

every dispense from the tank, this is repeated.

3. Manual tank level adjustments – On the tank setup

screen, the adjust link there allows the user to manually increase or decrease the current tank volume.

This is commonly done for fresh oil deliveries and

waste oil removal.

IG. 49, changes as a result

26 312353B

Page 27

Operator Screens

Battery Level Information ___________________________________

Place the cursor over the Battery Level Information box, causing the text to turn yellow. Left click the Box to go to the

Battery Level Information screen (F

F

IG. 50 Battery Level Information Screen

IG. 50).

This screen provides battery charge level for all meters

and tank level monitor batteries in the system. Each row

corresponds to a meter or tank.

Date & Time - the date and time of the last battery status update

Meter Or Tank Name - the name of the meter or tank,

including the fluid name associated with it.

Warning Level - the user-configurable point at which the

battery should be replaced for the meter or tank,

expressed as a percentage of a fully charged battery

and set in the meter or tank’s setup configuration.

Battery Level Status - the actual battery status,

expressed as a percentage of a fully charged battery.

Entering Work Orders ______________________________________

Place the cursor over the Entering Work Orders box, causing the text to turn yellow. Left click the Box to go to the

Entering Work Orders Status screen (F

To access this screen, you first need to type in your user name and password when the authenticate user

screen appears. User Names and Passwords are initially set up by the System Administrator.

IG. 51).

F

IG. 51 Work Order Information Screen

This screen displays all the meters that are programmed

to be in work order mode and their respective work

orders. It is a password protected screen that allows

users to assign work orders to specific meters.

Meter Name - the meter and fluid names.

312353B 27

Status - indicates meter status when assigning work

orders.

Slot 1 through Slot 5 - displays the meter’s work order

list. Each meter has its own work order list that can contain up to 5 work orders, one per “slot” in the list.

Page 28

Operator Screens

Work Orders and the Matrix/R & R Interface

For meters configured to use the Matrix R & R Interface,

dispenses are tracked by work order. This version of

Matrix requires that work orders entered at a Matrix PC

or at a meter, be validated before fluid can be dispensed. Once the dispense is complete, the appropriate

charge for the fluid will be automatically posted (added)

to the work order (RO) in R & R.

Adding Work Order From PC

1. To add a work order, left click Add Work Order,

located in the upper left corner of the screen (F

52).

IG.

For more information on what validation and posting means, see Work Order Validation and Work

Order Posting below and on page 29.

To override validation, check the Don’t validate

RO checkbox. To override posting of charges,

check the Don’t post charges to RO checkbox.

Enter a Matrix administrator’s user name and

password. If posting charges is overridden, the

Add Parts button is disabled.

6. At this point you may click, Send To Meter or Add

Parts.

Clicking Send To Meter will submit this work order

for validation. If successfully validated, the work

order will be sent to the meter and appear in the

meter’s work order list. If the work order is not validated, a popup window similar to F

IG. 53 will

appear; you can either retry or cancel. Until the

work order is successfully validated, the work order

will not appear in the meter’s work order list.

IG. 52 Add Work Order

F

2. Select the desired meter from the drop-down box.

This is the meter that will dispense the fluid on the

work order being entered.

3. Enter a work order number, up to 12 characters.

This must exactly match the RO number in R & R.

4. Enter a numeric job code. The number entered into

this field corresponds to the job (line) on the R & R

RO to which the oil should be charged. It cannot be

left blank or not be a number. This field is where the

user tells Matrix where on the R & R RO the fluid

part must be added.

5. Matrix administrators have the ability to override

work order validation and/or posting of Matrix-generated charges to the work order.

F

IG. 53 Validation Failed

Clicking Add Parts will allow you to “attach” one or

more non-fluid parts to this work order on a screen

that looks like F

IG. 54 Add Parts

F

IG. 54.

28 312353B

Page 29

Add Parts To Work Order

In the drop down list at the top left, select the category of

parts you wish to choose from; the parts loaded into

Matrix in that category (appear in the list box on the left.

Click Add>> to select the part. Selected parts appear in

the list box on the right. Clicking the Clear All button

removes the entire list of selected parts. Individual parts

can be removed from the selected list by selecting the

part and pressing Remove Part.

When finished adding parts, click Send To Meter, which

submits this work order for validation. If successfully validated, the work order is then sent to the meter and will

appear in the meter’s work order list. The list of selected

parts are not physically sent anywhere; Matrix “remembers” the selected parts list for this work order until the

fluid has been dispensed and successfully posted to the

RO in R & R; once this has happened, the selected

parts list is also posted to the RO.

Work Order Validation

Operator Screens

F

IG. 55

Work Order Posting

Matrix does not add any parts or other charges to a

work order (RO) on the R & R DMS until the Matrix system has dispensed fluid against that work order. Upon

completing a fluid dispense, Matrix will do the following:

A work order is considered “validated” if within the R & R

DMS it meets these criteria:

1. The work order exists, including the user-entered

job number on that work order.

2. The work order is open and is not currently being

edited. Matrix cannot post charges to work orders

that have been closed.

3. The status of the work order must be such that additional parts/charges can be added to the work order.

Depending on the activity level of the network and the R

& R DMS, the time it takes to validate a work order can

range from a few seconds to 30 seconds.

If the work order is not validated, a message similar to

F

IG. 55 will appear, stating the reason why it could not

be validated. Right click on the work order to try validating it again or correct the core problem (e.g., if someone

has the work order open and is editing it, retry again

when they are out of it).

1. Record the amount dispensed in the meter dispense history.

2. Based on the unit and measure pricing configuration

for the fluid dispensed, the appropriate part or GOG

charge is determined.

3. The part of GOG charge is sent to the DMS for that

work order. See “Interface Behavior, Parts and

GOG” on page 52 and Table 1 on page 53 for more

details

If a posting is successful, the Dispense History will

appear similar to the one shown in F

IG. 56. To view

more detailed posting status, right-click on the Work

Order Record and select View Posting Details

(F

IG. 56). Additional posting details will appear in a

popup screen (F

IG. 57). This information is also

available in report format using Matrix Reporter.

312353B 29

Page 30

Operator Screens

Sending a Work Order to a Meter

If the PC cannot send a work order to the chosen meter

for any reason, a Retry/Cancel pop-up box, as shown in

F

IG. 61, will be displayed. Clicking Retry will make the

PC attempt to send the work order again. Clicking Can-

cel will do just that, effectively deleting the work order at

the PC; no more retries will be attempted.

There are several system conditions that can cause this

to happen:

1. The battery in the meter is very low or dead. With a

dead battery, the meter cannot communicate to the

PC. Replace the battery with a fully charged battery.

2. The meter is already in the process of accepting a

work order (possibly from another Matrix PC). Wait

ten seconds and try sending it again.

F

IG. 56

F

IG. 57

If you are editing the RO while Matrix is attempting to

add parts to it, the Matrix posting attempt will fail, since

an R & R RO can only be edited by one person at any

time.

In Matrix, when any posting error occurs, the record

associated with this work order will turn red in the meter

dispense history and Matrix will generate a popup windows explaining the problem. You can manually retry the

posting or cancel by right-clicking on the Work Order in

the Meter Dispense History and selecting Retry Posting Charges.

3. A poor RF signal between transceiver and meter

can cause the work order to not be successfully

delivered to the meter. You may need to move the

transceiver closer to the meter.

4. A meter cannot accept work orders while it is dispensing fluid. It is unlikely that the meter and PC will

get out of synch for this to happen. At the meter, end

the dispense; the meter’s end-of-dispense message

to the PC will cause the two to get back in synch.

Work Order Pop-up Windows

The system is not always able to send new work

orders from the PC. If this is the case, one of the following pop-up windows will appear to inform you

that the work order was not received by the meter.

1. Work Order Limit (F

when the PC has five open work orders associated

with the meter being addressed. No RF communication is attempted when this message appears. At

least one work order will need to be processed or

removed before a new one can be loaded.

IG. 58). This message appears

If no fluid was dispensed (dispense volume is 0), Matrix

will not attempt to post charges of any kind to an R & R

RO.

FIG. 58 Work Order Limit

2. Work Order Already In Process (F

IG. 59). This

message appears when the PC is attempting to

send another work order. No RF communication is

30 312353B

Page 31

attempted when this screen appears. Attempt to

send the work order again.

F

IG. 59 Work Order Already in Process

Operator Screens

3. Meter is Busy (F

IG. 60). This message appears

when the PC has received an Activate message

from the meter being addressed. No RF communication is attempted when this screen appears.

Attempt to send the work order again when the

meter has completed processing the active work

order.

F

IG. 60 Meter Is Busy

4. Couldn’t Send Work Order (F

IG. 61). This mes-

sage appears when the PC tries to communicate

with the meter and receives no response. RF communication is attempted when this screen appears.

This message indicates the battery in the meter is

removed or needs to be recharged, the transceiver

is unplugged, or the RF environment has changed.

Correct these conditions and attempt to send the

work order again.

F

IG. 61 Couldn’t Send Work Order

312353B 31

Page 32

System Administrator Screens

System Administrator Screens

Matrix System Setup

Once the Matrix PC software is installed, it’s necessary

to synchronize the software with the other hardware

components of the Matrix system. This is done through

the system administrator portion of the software. This

section is password protected and provides access to all

Matrix setup screens. Only individuals with system

administrator rights have access to this portion of the

program.

Move the mouse pointer to the box labeled Matrix System Setup. The text will turn yellow. Left click to bring up

the Authenticate User Dialogue Box.

1. Key in your user information and click Submit. For

initial log on only, type in matrix (lowercase) for user

name and graco (lowercase) for the password.

Click Submit. Once the initial log on information is

authenticated, the System Administration screen

appears (F

Personalized passwords for System Administration, Entering Work Orders, and for Adjusting Tank

Levels are entered at the System User Setup

screen, see page 38. Once a new admin user

account is created, the default matrix/graco

account is disabled.

IG. 62).

The system administrator has access to:

• System Configuration - setting global security, measurement system, Transceiver configuration and

Matrix PC client information.

• System User Setup - add, modify, and remove

users, set security level and PIN information.

• Ta n k S e t u p - add, modify, adjust, remove, and program tank level monitors.

• Meter Setup - add, remove, modify, and program

meters.

• E-mail Setup - configure email to be sent to responsible parties based on various tank conditions.

• R & R Interface Setup - Configure the Matrix/R&R

interface.

• Return to Operating Screens- returns the user to the

operating screens.

F

IG. 62 System Administration Screen

32 312353B

Page 33

System Administrator Screens

System Configuration ______________________________________

There are three sections of the System Configuration screen: General system-wide default settings, transceiver settings, and PC client settings (F

The System Configuration setup must be performed prior to defining all other Matrix system setup parame-

ters.

IG. 63).

F

IG. 63 System Configuration Screen

To change any of the settings listed for system configuration, click Modify.

Security Level (Global Setting)

The security level is the global security setting for all

meters in the system, The default is System Monitoring.

PIN code and Parts Room Authorization Security are

other options on the pull down menu. This security

choice can be changed on a meter-to-meter basis if

desired (F

1. Click Security Level Drop Down Box and select

• System Monitoring - anyone can dispense oil, but

• PIN Code Required - the operator must enter a

IG. 64).

from the list.

the dispense information will be communicated to

the PC.

user-specific 4-digit numeric code into the meter to

have authorization to dispense.

System Emergency Code (FIG. 64)

The System Emergency Code is used to bypass PIN

Code or Parts Room Authorization security features

should the communication link to the Matrix PC stop (i.e.

computer failure, power outage).

2. Type in a four digit system emergency code number.

This number is used at the meter to override all meter

programming should there be a loss of RF signal.

This allows the operator to continue dispensing fluids

even though the meter is not receiving an RF signal.

If the system emergency code is used to override the meter program, the meter must be programmed again using the Matrix PC software

once the RF signal has been restored.

• Parts Room Authorization - the operator selects

authorization to dispense at the meter. This requires

someone in the Parts Room to authorize the dispense at the Matrix PC.

312353B 33

Page 34

System Administrator Screens

Unit of Measure (English or Metric) (FIG. 64)

Measurement System is the global units of measurement setting. English and Metric are the two options in

the pull down menu. This setting can be changed on a

tank-to-tank and meter-to-meter basis.

1. In the Measurement System box, select English or

Metric.

2. Click Apply.

Edit Contact Information (FIG. 64)

The Edit Contact Information dialog box appears once

apply is selected. Fill in the appropriate fields. This information will be placed automatically on all outgoing

Matrix e-mail (F

IG. 65).

IG. 64 Select Settings Below

F

FIG. 65 Edit Contact Information

Click Apply to update contact information and return to

the System Configuration screen.

34 312353B

Page 35

System Administrator Screens

Transceiver Setup

Click Add Transceiver Button, then click Modify.

1. Enter the area of the shop where the transceiver is

located (i.e., Main Shop, Fast Lube Shop, Engine

Department) in the Transceiver Name field.

2. The Network ID is a letter designation for the Transceiver network identification. The default is (A).

There are eight network ID’s available designated

with the letters A through H. Type in the selected

Network ID.

The Network ID letter for a given Transceiver

must match that Transceiver’s dipswitch settings.

3. Transceiver ID is a letter designation for the Transceiver Identification. The default is (A). There are

eight Transceiver ID’s available designated with the

letters A through H.

The Transceiver ID letter for a given Transceiver

must match that Transceivers equivalent dipswitch settings.

Confirm PC/Transceiver Communication

Each time a transceiver is powered up, it reads its dip

switch settings for Network ID and Transceiver ID and

sends this information to the PC. It also sends the transceiver’s firmware revision level. These settings are displayed as “Last Power-up Settings” and “Firmware

Revision” on this screen. If these fields are “N/A”, it

means that the transceiver has never (successfully)

communicated with the PC.

One way to confirm that the serial connection between

PC and transceiver is functioning properly is to change

the transceiver dip switch settings and verify that the PC

software reflects the new settings. Refer to the transceiver manual on how to set transceiver dip switches.

Example:

A Matrix system has a single transceiver, the desired

settings on the transceiver setup screen (F

Network ID = A, Transceiver ID = A, and Serial Port =

COM1 (factory defaults).

IG. 66) are

4. Serial Port is a pull down menu of all available communication ports on the Matrix PC. COM 1 is the

default setting. If COM 1 is not available, select an

open port from the pull down list.

Some computers may not have any serial ports.

In this case a USB converter will be required to

obtain serial ports. Graco recommends Edgeport models from B & B Electronics.

If you attempt to add a Transceiver and the PC

has no COM ports available, an error message

appears. Contact your IT professional or add

serial ports using the USB convertors recommended by Graco. See page 4 for additional

information.

Firmware Revision is the Transceiver firmware

revision level.

Transceiver Power-up

Graco recommends that when you plug in the power

cord to the transceiver, do it with the PC serial cable

already plugged in.

FIG. 66

1. If it’s open, close the transceiver setup screen (F

66).

2. Power off the transceiver.

3. Set the transceiver dipswitch settings to:

Network ID = H

Transceiver ID = H

Refer to transceiver manual 309498 for instructions.

4. With one end of the serial cable already plugged

into the PC and the other end in the transceiver,

power up the transceiver.

IG.

312353B 35

Page 36

System Administrator Screens

5. As the transceiver initializes itself on power-up,

watch the LED lights on the side of the transceiver.

You should see the lights flicker briefly with a burst

of activity. You may see occasional flickering of the

lights after this initial burst.

6. After the brief burst of LED activity, open the transceiver setup screen in the PC software and check

the “Last Power-up Settings”. If they show the Network ID = H and Transceiver ID = H settings as

described above, the serial connection between the

PC and the transceiver is functioning properly.

7. Close the transceiver setup screen.

8. Power down the transceiver and restore the dip

switch settings to their Network ID = A, Transceiver

ID = A settings.

9. Power up the transceiver.

10. After the initialization activity reflected by the lights

on the transceiver, open the transceiver setup

screen and confirm that the “Last Power-up Settings” read Network ID = A and Transceiver ID = A.

If the “Last Power-up Settings” do not update, one or

more things may be happening.

First, the serial port selected on the transceiver setup

screen may not be the one the serial cable is plugged

into. Many newer computers have only one serial port

on the back of the computer; the port may or may not be

COM1. It could easily be another COM number, so if

other COM ports show up in the transceiver setup

screen’s drop down list for Serial Port selection, try

using each of those in turn and repeat the above steps.

Many new computers have no serial ports at all, in which

case a USB to RS232 converter is required to supply at

least one serial port. Graco recommends the purchase

of Edgeport brand USB to RS232 converters, available

from www.bb-elec.com

tions for the converter carefully and make sure you

reboot the computer when complete. Again, don’t

assume the COM port number—the documentation with

the converter should help explain what COM port number the converter will provide.

When the Matrix PC software starts up, one of the first

things it does is check with Windows to find out what

serial ports (COM ports) exist in the system. These

ports are the ones listed in the Serial Port drop down list

on the transceiver setup screen. If a port you expect is

not listed there, it is because it is not registered as a

valid port with Windows.

. Follow the installation instruc-

Second, the selected COM port may be in use by

another program on the PC. In this case, even if the

Serial Port selection on the transceiver setup screen

matches the port the cable is plugged into, no Matrix

communication will happen because a different software

program “owns” the port. The only way to get it to work

is to either shut down the other program or configure

either the other program or Matrix to use a different

COM port. Software programs that use serial ports

include fax software and PDA software.

Third, the cable between the PC and the transceiver

could be either bad or wired improperly. The latter is

most likely to occur when an RS422 connection is used;

the former could happen with either serial cable choice.

Make sure the cables are firmly connected, so that there

isn’t a chance the plug or wire is falling out on either

end.

Repeat this setup for each Transceiver ensuring that no

two Transceivers use the same Network and Transceiver

IDs. If you have only one transceiver, Graco recommends using the default Network ID and Transceiver ID

settings.

Matrix Client PC Setup

The lower portion of the System Configuration page is

used to register a networked PC client in the Matrix system. Without registration here, a client PC will have limited functionality (such as not being able to submit work

orders to meters or viewing system-wide alerts/errors)

even though many of the screens will still be viewable

from the client.

Note that by default, the PC client table on this page has

one entry; this entry corresponds to the Matrix Server

and always must be present. Graco recommends you

not change this entry’s name/address field from

127.0.0.1, nor the port number from 8082 unless there

are known port conflicts.

Every PC client in the Matrix system is either a “shop client” or a “primary client”. Exactly one PC in the system

can be the primary client. Both types can view the

Matrix screens and run reports, but only primary clients

can access the Matrix setup screens and display system-wide alerts/error messages. The Matrix Server can

always access the setup screens, regardless of the client type it is set to.

36 312353B

Page 37

System Administrator Screens

Add a Client PC to the Matrix System

At the Matrix Server PC (FIG. 67):

1. Click Add Pc Client Button; this adds a new row to

the bottom of the table.

2. Click New Row’s Modify Link.

3. In the PC Client field, enter the host name or IP

address of the client PC (remember this name or

address; it will be needed when configuring the

Matrix software at the client PC).

4. Enter an appropriate description for this PC in the

Description field and select its Client Type. Click

Apply.

2. When the installation is complete, the installation

program prompts you to reboot the PC. Before

doing so, navigate in Windows to Start / All Pro-

grams / Graco / Matrix / Edit Matrix Client Network Settings.

3. Set the Matrix Client Host Name to the client PC’s

actual host name or IP address.

• Do not set this to 127.0.0.1.

• This entry must match exactly with the

name/address give for this PC in the PC client

table on the System Configuration page in the

Matrix setup screens (F

IG. 68).